TO-SYN-FUEL Project to Convert Sewage Sludge in Value-Added Products: A Comparative Life Cycle Assessment †

Abstract

1. Introduction

2. Materials and Methods

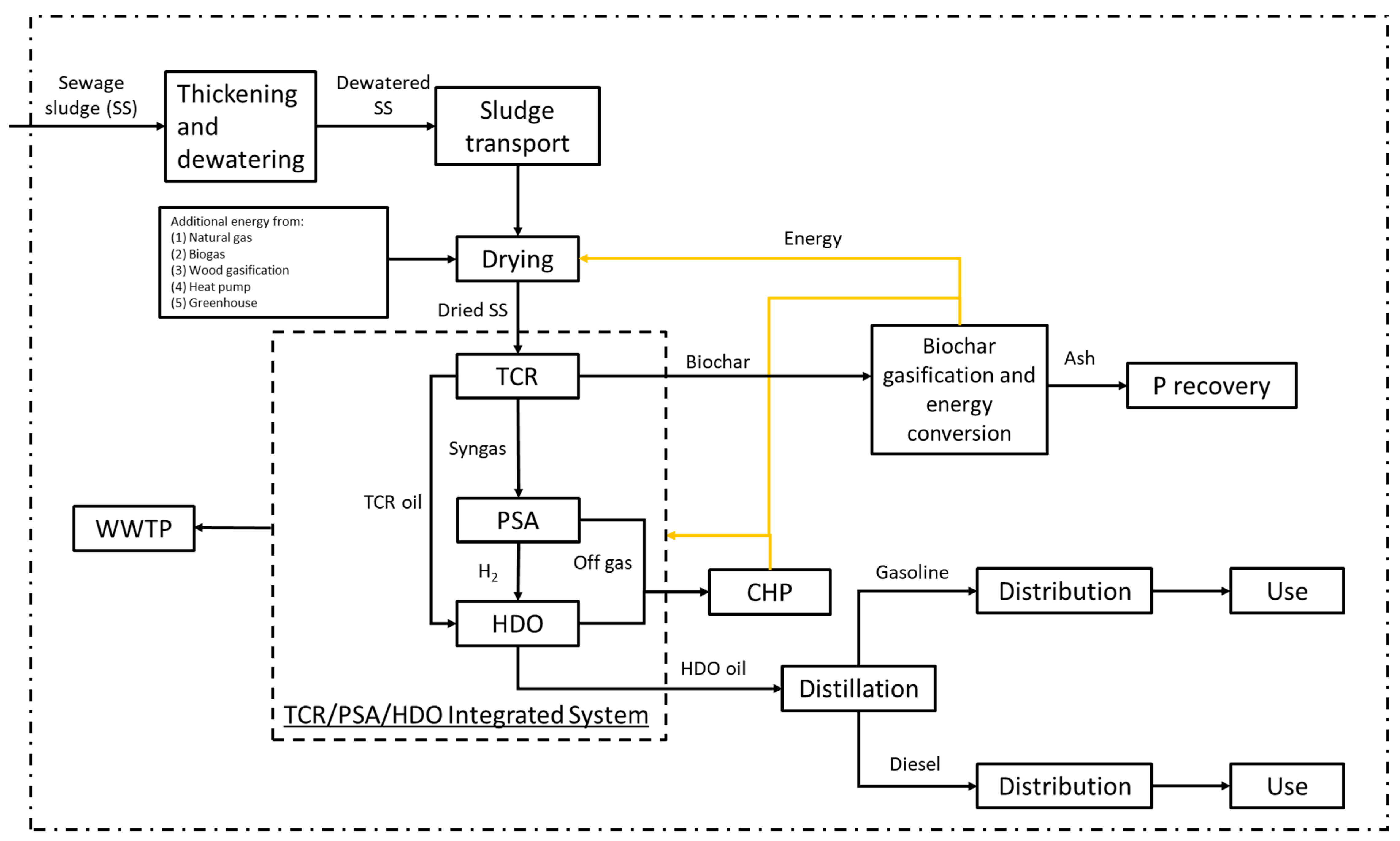

2.1. Production Process Description

2.2. Application of the Environmental Life Cycle Assessment

2.2.1. Scenarios Description

2.2.2. Life Cycle Inventory

2.2.3. Life Cycle Impact Assessment

3. Results

3.1. Climate Change Potential

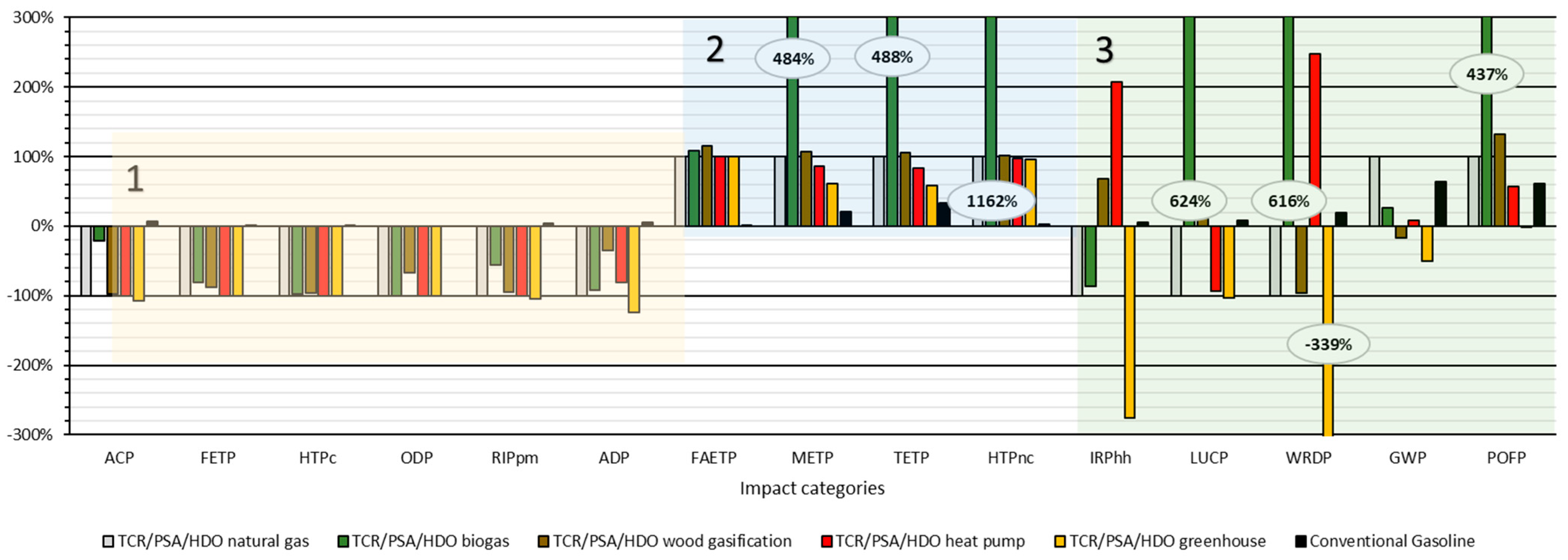

3.2. Comprehensive Environmental Profile

3.3. Contribution Analysis

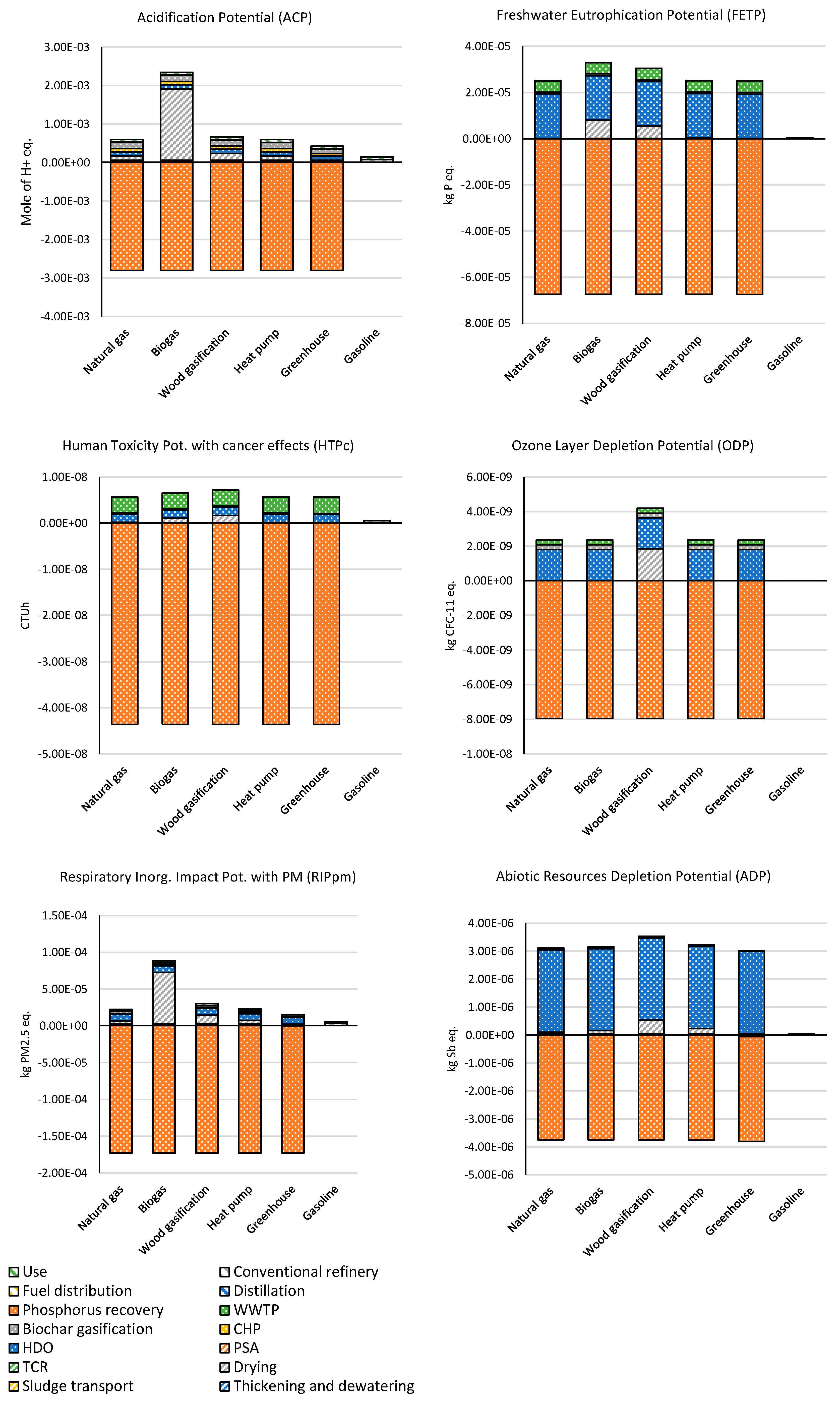

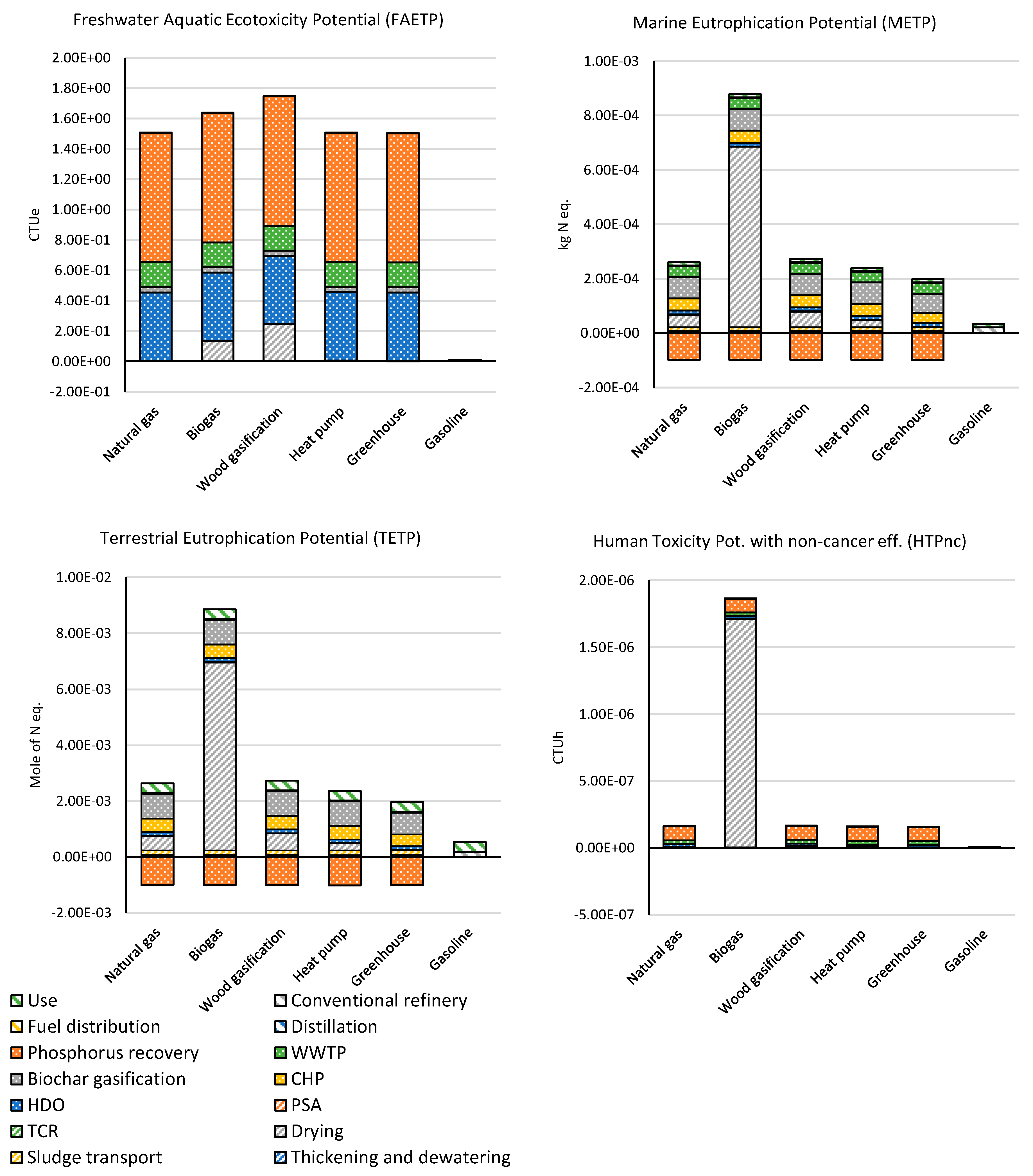

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ACP | Acidification Potential |

| ADP | Abiotic Resources Depletion Potential |

| CHP | Combined Heat-Power |

| ETP | Terrestrial Eutrophication Potential |

| EU | European Union |

| FAETP | Freshwater Aquatic Ecotoxicity Potential |

| FETP | Freshwater Eutrophication Potential |

| GHG | Greenhouse gas |

| GWPebc | Global Warming Potential excluded biogenic carbon |

| HDO | Hydrodeoxygenation |

| HHV | Higher Heating Value |

| HTPc | Human Toxicity Potential with cancer effects |

| HTPnc | Human Toxicity Potential with non-cancer effects |

| IRPhh | Ionizing Radiation Potential with human health impacts |

| LCA | Life Cycle Assessment |

| LCIA | Life Cycle Impact Assessment |

| LUCP | Land Use Change Potential |

| METP | Marine Eutrophication Potential |

| ODP | Ozone Layer Depletion Potential |

| POFP | Photochemical Ozone Formation Potential |

| PSA | Pressure Swing Adsorption |

| RED | Renewable Energy Directive |

| RES | Renewable Energy Sources |

| RIPpm | Respiratory Inorganics Impact Potential with particulate matter |

| TCR | Thermo-Catalytic Reforming |

| TRL | Technology Readiness Level |

| WRDP | Water Resource Depletion Potential |

| WTW | Well-To-Wheel |

| WWTP | Wastewater Treatment Plant |

References

- Chiaramonti, D.; Talluri, G.; Scarlat, N.; Prussi, M. The challenge of forecasting the role of biofuel in EU transport decarbonisation at 2050: A meta-analysis review of published scenarios. Renew. Sustain. Energy Rev. 2021, 139, 110715. [Google Scholar] [CrossRef]

- European Union. Directive (EU) 2023/2413 of the European Parliament and of the Council of 18 October 2023 on the Promotion of the Use of Energy from Renewable Sources, Amending and Subsequently Repealing Directives (EU) 2018/2001 and (EU) 2015/652, and Regulation (EU) 2018/1999. Off. J. Eur. Union 2023, L, 2023/2413. Available online: https://eur-lex.europa.eu/eli/dir/2023/2413/oj (accessed on 15 July 2025).

- Eurostat. Renewable Energy Statistics; European Commission: Luxembourg, 2024; Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Renewable_energy_statistics (accessed on 24 August 2025).

- Eurostat. Share of Energy from Renewable Sources; European Commission: Luxembourg, 2025; Available online: https://ec.europa.eu/eurostat/databrowser/product/page/NRG_IND_REN (accessed on 15 July 2025).

- European Union. Regulation (EU) 2019/631 of the European Parliament and of the Council of 17 April 2019 setting CO2 emission performance standards for new passenger cars and for new light commercial vehicles, and repealing Regulations (EC) No 443/2009 and (EU) No 510/2011. Off. J. Eur. Union 2019, L 111, 13–53. Available online: https://eur-lex.europa.eu/eli/reg/2019/631/oj (accessed on 16 July 2025).

- International Council on Clean Transportation (ICCT). EU CO2 Standards for Cars and Vans: Overview and Implications of Regulation (EU) 2023/851; ICCT: Washington, DC, USA, 2023; Available online: https://theicct.org/wp-content/uploads/2023/05/eu-co2-standards-cars-vans-may23.pdf (accessed on 13 September 2025).

- International Council on Clean Transportation (ICCT). EU CO2 Standards for Heavy-Duty Vehicles: Policy Update; ICCT: Washington, DC, USA, 2024; Available online: https://theicct.org/wp-content/uploads/2024/05/ID-130-%E2%80%93-EU-CO2_policy_update_final.pdf (accessed on 13 September 2025).

- AssoDistil. Relazione Annuale AssoDistil 2024; AssoDistil: Rome, Italy, 2024; Available online: https://assodistil.it/wp-content/uploads/2024/07/Relazione-Annuale-AssoDistil-2024.pdf (accessed on 24 August 2025).

- U.S. Environmental Protection Agency (EPA). Renewable Fuel Standard (RFS); EPA: Washington, DC, USA, 2025. Available online: https://www.epa.gov/renewable-fuel-standard (accessed on 24 August 2025).

- U.S. Department of Energy. Alternative Fuels Data Center: Renewable Fuel Standard; DOE: Washington, DC, USA, 2025. Available online: http://afdc.energy.gov/laws/RFS (accessed on 24 August 2025).

- IEA Bioenergy. Brazil Country Report 2024; IEA Bioenergy: Paris, France, 2024; Available online: https://www.ieabioenergy.com/wp-content/uploads/2024/12/CountryReport2024_Brazil_final.pdf (accessed on 24 August 2025).

- Ritchie, H.; Rosado, P.; Roser, M. Data page: Biofuels production. In Energy; Our World in Data: Oxford, UK, 2023; Available online: https://archive.ourworldindata.org/20250624-125417/grapher/biofuel-production.html (accessed on 24 August 2025).

- Jeswani, H.K.; Chilvers, A.; Azapagic, A. Environmental sustainability of biofuels: A review. Proc. R. Soc. A 2020, 476, 20200351. [Google Scholar] [CrossRef]

- Mat Aron, N.S.; Khoo, K.S.; Chew, K.W.; Show, P.L.; Chen, W.-H.; Nguyen, T.H.P. Sustainability of the four generations of biofuels—A review. Int. J. Energy Res. 2020, 44, 9266–9282. [Google Scholar] [CrossRef]

- Padder, S.A.; Khan, R.; Rather, R.A. Biofuel generations: New insights into challenges and opportunities in their microbe-derived industrial production. Biomass Bioenergy 2024, 185, 107220. [Google Scholar] [CrossRef]

- Kant, G.; Hasan, A.; Yadav, P.; Pandey, A.; Srivastava, S. The generational shift in biofuels: A path toward sustainable energy solutions. Biomass Bioenergy 2025, 196, 107757. [Google Scholar] [CrossRef]

- Ambaye, T.G.; Vaccari, M.; Bonilla-Petriciolet, A.; Prasad, S.; van Hullebusch, E.D.; Rtimi, S. Emerging technologies for biofuel production: A critical review on recent progress, challenges and perspectives. J. Environ. Manag. 2021, 290, 112627. [Google Scholar] [CrossRef]

- Nisar, A.; Khan, S.; Hameed, M.; Nisar, A.; Ahmad, H.; Mehmood, S.A. Bio-conversion of CO2 into biofuels and other value-added chemicals via metabolic engineering. Microbiol. Res. 2021, 251, 126813. [Google Scholar] [CrossRef] [PubMed]

- Khoo, K.S.; Ahmad, I.; Chew, K.W.; Iwamoto, K.; Bhatnagar, A.; Show, P.L. Enhanced microalgal lipid production for biofuel using different strategies including genetic modification of microalgae: A review. Prog. Energy Combust. Sci. 2023, 96, 101071. [Google Scholar] [CrossRef]

- Cieślik, B.M.; Świerczek, L.; Konieczka, P. Analytical and legislative challenges of sewage sludge processing and management. Monatsh. Chem. 2018, 149, 1635–1645. [Google Scholar] [CrossRef] [PubMed]

- Fini, E.H.; Kazemi, M.; Poulikakos, L.; Lazorenko, G.; Akbarzade, V.; Lamanna, A.; Lammers, P. Perspectives on innovative non-fertilizer applications of sewage sludge for mitigating environmental and health hazards. Commun. Eng. 2024, 3, 178. [Google Scholar] [CrossRef]

- European Union. Directive 2000/60/EC of the European Parliament and of the Council of 23 October 2000 Establishing a Framework for Community Action in the Field of Water Policy. Off. J. Eur. Union 2000, L 327, 1–73. Available online: https://eur-lex.europa.eu/eli/dir/2000/60/oj (accessed on 13 September 2025).

- European Union. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives (Consolidated version as of 5 July 2018). Off. J. Eur. Union 2018, L 312, 3–30. Available online: https://eur-lex.europa.eu/eli/dir/2008/98/2018-07-05/eng (accessed on 13 September 2025).

- Egle, L.; Marschinski, R.; Jones, A.; Yunta Mezquita, F.; Schillaci, C.; Huygens, D. Feasibility Study in Support of Future Policy Developments of the Sewage Sludge Directive (86/278/EEC); Publications Office of the European Union: Luxembourg, 2023; JRC134591. [Google Scholar] [CrossRef]

- European Commission. TO-SYN-FUEL: The Demonstration of Waste Biomass to Synthetic Fuels and Green Hydrogen. CORDIS EU Research Results. 2017. Available online: https://cordis.europa.eu/project/id/745749 (accessed on 23 August 2025).

- EN 590:2024; Automotive fuels — Diesel — Requirements and test methods. European Committee for Standardization (CEN): Brussels, Belgium, 2024.

- EN 228:2025; Automotive fuels — Unleaded petrol — Requirements and test methods. European Committee for Standardization (CEN): Brussels, Belgium, 2025.

- European Commission. Communication from the Commission to the Council and the European Parliament: Integrated Product Policy—Building on Environmental Life-Cycle Thinking (COM(2003) 302 Final); European Commission: Brussels, Belgium, 2003; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52003DC0302 (accessed on 24 August 2025).

- European Commission. Determining the Environmental Impacts of Conventional and Alternatively Fuelled Vehicles Through LCA (Final Report); Directorate-General for Climate Action, Publications Office of the European Union: Luxembourg, 2020; Available online: https://climate.ec.europa.eu/system/files/2020-09/2020_study_main_report_en.pdf (accessed on 24 August 2025).

- Hornung, A.; Daschner, R.; Ouadi, M.; Claret, A.; Bastos, J. To-syn-fuel project to convert sewage sludge in value-added products. In Proceedings of the European Biomass Conference and Exhibition, Virtual, 6–9 July 2020; pp. 537–541. [Google Scholar]

- Prussi, M.; Yugo, M.; De Prada, L.; Padella, M.; Edwards, R. JEC Well-to-Wheels Report v5. EUR 30284 EN; Publications Office of the European Union: Luxembourg, 2020. [Google Scholar] [CrossRef]

- Spizzirri, M. Le difficoltà nella gestione e le possibili soluzioni. In La Gestione dei Fanghi di Depurazione Acque Reflue; ACEA: Rome, Italy, 2019. [Google Scholar]

- Sphera. LCA for Experts; Sphera: Leinfelden-Echterdingen, Germany, 2024; Available online: https://sphera.com/product-stewardship/life-cycle-assessment-software-and-data/lca-for-experts/ (accessed on 24 August 2025).

- Sphera. Search Life Cycle Assessment Datasets; Sphera: Leinfelden-Echterdingen, Germany, 2024; Available online: https://lcadatabase.sphera.com/ (accessed on 24 August 2025).

- Ecoinvent. Releases Overview; Ecoinvent Association: Zürich, Switzerland, 2024; Available online: https://support.ecoinvent.org/releases-overview (accessed on 24 August 2025).

- Remy, C. Life Cycle Assessment of Selected Processes for P Recovery from Sewage Sludge, Sludge Liquor, or Ash (Deliverable D 9.2). Project: Sustainable Sewage Sludge Management Fostering Phosphorus Recovery and Energy Efficiency (FP7, Grant Agreement No. 308645). Kompetenzzentrum Wasser Berlin: Berlin, Germany. 2015. Available online: https://kompetenz-wasser.de/media/pages/forschung/publikationen/893/7464c6a205-1702634140/Remy-2015-893.pdf (accessed on 24 August 2025).

- Bianchini, A.; Bonfiglioli, L.; Pellegrini, M.; Saccani, C. Sewage sludge drying process integration with a waste-to-energy power plant. Waste Manag. 2015, 42, 159–165. [Google Scholar] [CrossRef] [PubMed]

- Marazza, D.; Macrelli, S.; D’Angeli, M.; Righi, S.; Hornung, A.; Contin, A. Greenhouse gas savings and energy balance of sewage sludge treated through an enhanced intermediate pyrolysis screw reactor combined with a reforming process. Waste Manag. 2019, 91, 42–53. [Google Scholar] [CrossRef]

- Iribarren, D.; Peters, J.F.; Dufour, J. Life cycle assessment of transportation fuels from biomass pyrolysis. Fuel 2012, 97, 812–821. [Google Scholar] [CrossRef]

- Geisler, G.; Hofstetter, T.B.; Hungerbühler, K. Production of fine and speciality chemicals: Procedure for the estimation of LCIs. Int. J. Life Cycle Assess. 2004, 9, 101–113. [Google Scholar] [CrossRef]

- Hischier, R.; Hellweg, S.; Capello, C.; Primas, A. Establishing life cycle inventories of chemicals based on differing data availability. Int. J. Life Cycle Assess. 2005, 10, 59–67. [Google Scholar] [CrossRef]

- Lopes, T.A.S.; Queiroz, L.M.; Kiperstok, A. Environmental performance of a full-scale wastewater treatment plant applying life cycle assessment. Rev. Ambiente Água 2018, 13, 1–15. [Google Scholar] [CrossRef][Green Version]

- EC-JRC. International Reference Life Cycle Data System (ILCD) Handbook: Recommendations for Life Cycle Impact Assessment in the European Context, 1st ed.; European Commission, Joint Research Centre: Ispra, Italy, 2011; Available online: http://eplca.jrc.ec.europa.eu/ (accessed on 10 July 2025).[Green Version]

- EC-JRC. Characterisation Factors of the ILCD Recommended Life Cycle Impact Assessment Methods: Database and Supporting Information, 1st ed.; European Commission, Joint Research Centre, Institute for Environment and Sustainability: Ispra, Italy, 2012. [Google Scholar][Green Version]

- Zhou, Y.; Zheng, G.; Long, Y.; Liu, Z.; Tao, C.; Liu, R. Advanced oxidation processes for wet-process phosphoric acid: Enhanced phosphorus recovery and removal of organic matters. Hydrometallurgy 2022, 210, 105842. [Google Scholar] [CrossRef]

- Oueriemi, S.; Ben Amor, H.; Hassen, W.; Hadrich, B.; Maatki, C.; Kriaa, K.; Kolsi, L. Removal of organic matter from Tunisian industrial phosphoric acid by adsorption onto purified natural illite/kaolinite clay: Kinetics, isothermal and thermodynamic studies. Materials 2023, 16, 6228. [Google Scholar] [CrossRef]

- El-Sofany, E.A.; Zaher, W.F.; Aly, H.F. Sorption potential of impregnated charcoal for removal of heavy metals from phosphoric acid. J. Hazard. Mater. 2009, 165, 623–629. [Google Scholar] [CrossRef]

- Bahsaine, K.; Mekhzoum, M.E.M.; Benzeid, H.; Qaiss, A.E.K.; Bouhfid, R. Recent progress in heavy metals extraction from phosphoric acid: A short review. J. Ind. Eng. Chem. 2022, 115, 120–134. [Google Scholar] [CrossRef]

- EHPA. Industrial Heat Pumps to Decarbonise Europe’s Industry. Position Paper; European Heat Pump Association: Brussels, Belgium, 2025; Available online: https://www.ehpa.org/news-and-resources/position-papers/industrial-heat-pumps-to-decarbonise-europes-industry/ (accessed on 24 August 2025).

- Eurostat. Final Energy Consumption in Industry—Detailed Statistics; Data Extracted in May 2024; European Commission: Luxembourg, 2024; Available online: https://ec.europa.eu/eurostat/statistics-explained/SEPDF/cache/110026.pdf (accessed on 24 August 2025).

- Eurostat. Electricity and Heat Statistics; Data Extracted in August 2024; European Commission: Luxembourg, 2024; Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Electricity_and_heat_statistics (accessed on 24 August 2025).

- IEA Bioenergy. Decarbonizing Industrial Process Heat: The Role of Biomass. A Report for the IEA Bioenergy Inter-Task Project on Industrial Process Heat; Olsson, O., Schipfer, F., Eds.; IEA Bioenergy: Paris, France, 2021; Available online: https://www.ieabioenergy.com/blog/publications/decarbonizing-industrial-process-heat-the-role-of-biomass/ (accessed on 24 August 2025).

- EHPA. Financial Barriers to the Widespread Adoption of Heat Pumps. Position Paper; European Heat Pump Association: Brussels, Belgium, 2024; Available online: https://www.ehpa.org/wp-content/uploads/2024/04/Financial-barriers-to-the-widespread-adoption-of-heat-pumps_Final-version_April-2024.pdf (accessed on 24 August 2025).

- EurObservER. Biogas Barometer. October 2023; EurObservER: Paris, France, 2023; Available online: https://www.eurobserv-er.org/biogas-barometer-2023/ (accessed on 24 August 2025).

- IEA. Outlook for Biogas and Biomethane: A Global Geospatial Assessment; International Energy Agency: Paris, France, 2025; Available online: https://www.iea.org/reports/outlook-for-biogas-and-biomethane/biogas-and-biomethane-outlook-to-2050 (accessed on 24 August 2025).

- Sorrenti, A.; Corsino, S.F.; Traina, F.; Viviani, G.; Torregrossa, M. Enhanced sewage sludge drying with a modified solar greenhouse. Clean Technol. 2022, 4, 407–419. [Google Scholar] [CrossRef]

- Berroug, F.; Bellaziz, Y.; Tagnamas, Z.; Bahammou, Y.; Faraji, H.; Bougayr, E.H.; Ouazzani, N. Drying performance of a combined solar greenhouse dryer of sewage sludge. Sustainability 2024, 16, 9925. [Google Scholar] [CrossRef]

- Wasserman, M.; Moretti, A.; Goi, D.; Mainardis, M. Integrating renewable energy in sewage sludge treatment through greenhouse solar drying: A review. Sci. Total Environ. 2025, 965, 178634. [Google Scholar] [CrossRef] [PubMed]

- Huber. HUBER Solar Sludge Dryer SRT—Unique in Variability of Sludge Feeding and Removal; HUBER: Berching, Germany, 2025; Available online: https://www.huber-se.com/case-studies/detail/huber-solar-sludge-dryer-srt-unique-in-variability-of-sludge-feeding-and-removal/ (accessed on 24 August 2025).

- Viega. Il Più Grande Impianto Solare-Termico di Essiccamento dei Fanghi di Depurazione al Mondo; Viega: Attendorn, Germany, 2025; Available online: https://www.viega.it/it/azienda/referenze/impianto-solare-termico-di-essiccamento-fanghi-di-depurazione.html (accessed on 24 August 2025).

- TVA. Fanghi di Depurazione, con le Serre Solari un Problema in Meno e una Grossa Risorsa in Più. Voce dell’Acqua. 2021. Available online: https://vocedellacqua.aqp.it (accessed on 24 August 2025).

- BMU—German Federal Ministry for the Environment. Verordnung zur Neuordnung der Klärschlammverwertung—AbfKlärV [Ordinance on the Reorganisation of Sewage Sludge Management]; BGBl. I S. 3465, 27 September 2017; BMU: Berlin, Germany, 2017. [Google Scholar]

- BMK—Federal Ministry for Climate Action, Environment, Energy, Mobility, Innovation and Technology of Austria. Waste Incineration Ordinance 2024 (Abfallverbrennungsverordnung—AVV 2024). Federal Law Gazette II No. 118/2024; Republic of Austria: Vienna, Austria, 2024. [Google Scholar]

- Federal Council of Switzerland. Waste Ordinance (VVEA/OLED) of 4 December 2015. RS 814.600; Swiss Federal Government: Bern, Switzerland, 2016; Available online: https://www.fedlex.admin.ch/eli/cc/2015/891/en (accessed on 24 August 2025).

- Swedish Government. Hållbar Slamhantering (SOU 2020:3); Statens Offentliga Utredningar: Stockholm, Sweden, 2020; Available online: https://www.regeringen.se/rattsliga-dokument/statens-offentliga-utredningar/2020/01/sou-20203/ (accessed on 24 August 2025).

- Ministère de la Transition Écologique. Plan Eau 2023–2027—Pour une Gestion Résiliente, Sobre et Concertée de L’eau; Gouvernement de la République Française: Paris, France, 2023; Available online: https://www.ecologie.gouv.fr/politiques-publiques/plan-daction-gestion-resiliente-concertee-leau (accessed on 24 August 2025).

- ENEA. Italian Phosphorus Platform; ENEA: Rome, Italy, 2025; Available online: https://www.piattaformaitalianafosforo.it/en/ (accessed on 24 August 2025).

- Bianchini, A.; Rossi, J. An integrated industry-based methodology to unlock full-scale implementation of phosphorus recovery technology. Sustainability 2020, 12, 10632. [Google Scholar] [CrossRef]

- Magrí, A.; Carreras-Sempere, M.; Biel, C.; Colprim, J. Recovery of phosphorus from waste water profiting from biological nitrogen treatment: Upstream, concomitant or downstream precipitation alternatives. Agronomy 2020, 10, 1039. [Google Scholar] [CrossRef]

- European Commission. Regulation on ensuring secure and sustainable supply of critical raw materials (Critical Raw Materials Act). Off. J. Eur. Union 2023, L 262, 1–49.

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions—A New Circular Economy Action Plan COM(2020) 98 Final; European Commission: Brussels, Belgium, 2020; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52020DC0098 (accessed on 24 August 2025).

- European Commission. Proposal for a Directive Concerning Urban Wastewater Treatment (Recast of Directive 91/271/EEC). COM(2022) 501 Final; European Commission: Brussels, Belgium, 2022. [Google Scholar]

- European Commission. Sustainable Sewage Sludge Management Fostering Phosphorus Recovery and Energy Efficiency. CORDIS EU Research Results. 2017. Available online: https://cordis.europa.eu/project/id/308645 (accessed on 24 August 2025).

- Federal Ministry of Education and Research (BMBF). Modified Rhenania Phosphate from Sewage Sludge Ash for Bavaria (R-Rhenania); BMBF-RePhoR: Berlin, Germany, 2021; Available online: https://www.bmbf-rephor.de/en/joint-projects/r-rhenania/ (accessed on 24 August 2025).

- Smol, M.; Kulczycka, J.; Lelek, Ł.; Gorazda, K.; Wzorek, Z. Life cycle assessment (LCA) of the integrated technology for the phosphorus recovery from sewage sludge ash (SSA) and fertilizers production. Arch. Environ. Prot. 2020, 46, 42–52. [Google Scholar] [CrossRef]

- Abdolrezayi, A.; Puricelli, S.; Dolci, G.; Turolla, A.; Canziani, R.; Rigamonti, L. Phosphorus recovery from sewage sludge ash: Life cycle inventory and critical review of LCA case studies. J. Environ. Manag. 2025, 389, 125620. [Google Scholar] [CrossRef]

- Castello, D.; Haider, M.S.; Rosendahl, L.A. Catalytic upgrading of hydrothermal liquefaction biocrudes: Different challenges for different feedstocks. Renew. Energy 2019, 141, 420–430. [Google Scholar] [CrossRef]

- Hu, M.; Ye, Z.; Zhang, H.; Chen, B.; Pan, Z.; Wang, J. Thermochemical conversion of sewage sludge for energy and resource recovery: Technical challenges and prospects. Environ. Pollut. Bioavailab. 2021, 33, 145–163. [Google Scholar] [CrossRef]

- Śpiewak, K. Gasification of sewage sludge—A review. Energies 2024, 17, 4476. [Google Scholar] [CrossRef]

- Eurostat. Sewage Sludge Production and Disposal; Eurostat: Luxembourg, 2022. [Google Scholar]

- Đurđević, D.; Trstenjak, M.; Hulenić, I. Sewage sludge thermal treatment technology selection by utilizing the analytical hierarchy process. Water 2020, 12, 1255. [Google Scholar] [CrossRef]

- European Union. Council Directive 1999/31/EC of 26 April 1999 on the Landfill of Waste. Off. J. Eur. Communities 1999, L 182, 1–19. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:31999L0031 (accessed on 24 August 2025).

- Fijalkowski, K.; Rorat, A.; Grobelak, A.; Kacprzak, M.J. The presence of contaminations in sewage sludge and the current situation. J. Environ. Manag. 2017, 203, 1126–1136. [Google Scholar] [CrossRef]

- Feng, J.; Burke, I.T.; Chen, X.; Stewart, D.I. Assessing metal contamination and speciation in sewage sludge: Implications for soil application and environmental risk. Rev. Environ. Sci. Biotechnol. 2023, 22, 1037–1058. [Google Scholar] [CrossRef]

- Urbaniak, M.; Baran, A.; Giebułtowicz, J.; Bednarek, A.; Serwecińska, L. The occurrence of heavy metals and antimicrobials in sewage sludge and their predicted risk to soil—Is there anything to fear? Sci. Total Environ. 2024, 912, 168856. [Google Scholar] [CrossRef]

- Latosińska, J.; Czapik, P. The ecological risk assessment and the chemical speciation of heavy metals in ash after the incineration of municipal sewage sludge. Sustainability 2020, 12, 6517. [Google Scholar] [CrossRef]

- Buss, W. Pyrolysis solves the issue of organic contaminants in sewage sludge while retaining carbon—Making the case for sewage sludge treatment via pyrolysis. ACS Sustain. Chem. Eng. 2021, 9, 10048–10053. [Google Scholar] [CrossRef]

- Moško, J.; Pohořelý, M.; Cajthaml, T.; Jeremiáš, M.; Robles-Aguilar, A.A.; Skoblia, S.; Beňo, Z.; Innemanová, P.; Linhartová, L.; Michalíková, K.; et al. Effect of pyrolysis temperature on removal of organic pollutants present in anaerobically stabilized sewage sludge. Chemosphere 2021, 265, 129082. [Google Scholar] [CrossRef]

- Méndez, A.; Tarquis, A.M.; Saa-Requejo, A.; Guerrero, F.; Gascó, G. Influence of pyrolysis temperature on composted sewage sludge biochar priming effect in a loamy soil. Chemosphere 2013, 93, 668–676. [Google Scholar] [CrossRef]

- Li, S.; Tasnady, D. Biochar for soil carbon sequestration: Current knowledge, mechanisms, and future perspectives. C 2023, 9, 67. [Google Scholar] [CrossRef]

- Marazza, D.; Pesce, S.; Greggio, N.; Vaccari, F.P.; Balugani, E.; Buscaroli, A. The long-term experiment platform for the study of agronomical and environmental effects of the biochar: Methodological framework. Agriculture 2022, 12, 1244. [Google Scholar] [CrossRef]

- Biswal, B.K.; Balasubramanian, R. Use of biomass-derived biochar as a sustainable material for carbon sequestration in soil: Recent advancements and future perspectives. npj Mater. Sustain. 2025, 3, 26. [Google Scholar] [CrossRef]

- Righi, S.; Baioli, F.; Marazza, D.; Porcelli, R.; Contin, A. Life cycle assessment applied to biofuels from sewage sludge: Definition of system boundaries and scenarios. In Proceedings of the XII Italian LCA Network Conference: Life Cycle Thinking in Decision-Making for Sustainability: From Public Policies to Private Businesses, Messina, Italy, 11–12 June 2018. [Google Scholar]

- Baioli, F.; Marazza, D.; Contin, A.; Vogli, L.; Porcelli, R.; Righi, S. Life Cycle Assessment of TCR-PSA-HDO Integrated System to Produce Biofuels from Sewage Sludge. In Proceedings of the 9th International Conference on Life Cycle Management (LCM), Poznań, Poland, 1–4 September 2019. [Google Scholar]

- Lama, V.; Macrelli, S.; Contin, A.; Marazza, D.; Righi, S. Greenhouse Gas Emission Savings of Biogasoline Produced from Municipal Sewage Sludge with Respect to Its Fossil Equivalent. In Proceedings of the XVI Conference of the Italian LCA Network: Sustainability in the Context of the PNRR—The Contribution of Life Cycle Assessment, Palermo, Italy, 22–24 June 2022. [Google Scholar]

| Process | Data Source |

|---|---|

| Sludge thickening and dewatering | Bianchini et al., 2015 [37] |

| Sludge transport | Marazza et al., 2019 [38] |

| Sludge drying | GaBi Professional Database [34] |

| TCR | Engineering and design data |

| PSA | Operating data |

| HDO | Operating data |

| CHP generation | Operating data |

| Biochar gasification | Engineering and experimental data |

| WWTP | Engineering and experimental data |

| Phosphorus recovery | GaBi Professional Database [34] |

| HDO bio-oil distillation | Remy, 2015 [36] |

| Fuel distribution | Iribarren et al., 2012 [39] |

| Fuel combustion | GaBi Professional Database [34] |

| Categories | Flow | Amount | Unit |

|---|---|---|---|

| Feedstock | Sludge (water content 99% w/w) | 4.05 × 101 | kg |

| Chemicals | Polyelectrolyte consumption | 6.61 × 10−5 | kg |

| Sodium hydroxide | 3.25 × 10−3 | kg | |

| Hydrochloric acid | 1.87 × 10−2 | kg | |

| Materials | Silicon carbide | 3.52 × 10−3 | kg |

| Catalyst 1: TK-455 | 2.32 × 10−4 | kg | |

| Catalyst 2: TK-341 | 1.85 × 10−4 | kg | |

| Activated coal | 5.66 × 10−6 | kg | |

| Cationic resin | 5.07 × 10−6 | kg | |

| Lubricating oil | 7.62 × 10−5 | kg | |

| Utilities | Tap water | 8.17 × 10−2 | kg |

| Water (desalinated; deionized) | 1.42 × 10−1 | kg | |

| Nitrogen gaseous | 1.23 × 10−2 | kg | |

| Compressed air | 1.31 × 10−2 | Nm3 | |

| Steam | 7.06 × 10−1 | kg | |

| Energy | Power | 7.19 × 10−1 | MJ |

| Thermal energy for TCR/PSA/HDO | 4.24 × 100 | MJ | |

| Thermal energy from natural gas for other processes | 2.48 × 10−2 | MJ | |

| Waste | Wastewater | 2.17 × 10−1 | kg |

| Silicon carbide | 3.52 × 10−3 | kg | |

| Catalyst 1: TK-455 | 2.32 × 10−4 | kg | |

| Catalyst 2: TK-341 | 1.85 × 10−4 | kg | |

| Activated coal | 5.66 × 10−6 | kg | |

| Cationic resin | 5.07 × 10−6 | kg | |

| Residual ash | 1.56 × 10−1 | kg | |

| Products | Gasoline | 1.00 × 100 | MJ |

| Electricity | 1.03 × 100 | MJ | |

| Thermal energy | 1.26 × 100 | MJ | |

| H3PO4 | 5.52 × 10−2 | kg |

| Impact Cat. | U.M. | Natural Gas | Biogas | Wood Gasification | Heat Pump | Greenhouse | Conventional Gasoline |

|---|---|---|---|---|---|---|---|

| GWPebc | kg CO2 eq. | 1.35 × 10−1 | 3.55 × 10−2 | −2.22 × 10−2 | 1.03 × 10−2 | −6.79 × 10−2 | 8.59 × 10−2 |

| ACP | Mole of H+ eq. | −2.21 × 10−3 | −4.61 × 10−4 | −2.14 × 10−3 | −2.21 × 10−3 | −2.38 × 10−3 | 1.46 × 10−4 |

| FAETP | CTUe | 1.51 × 100 | 1.64 × 100 | 1.74 × 100 | 1.51 × 100 | 1.50 × 100 | 1.21 × 10−2 |

| FETP | kg P eq. | −4.25 × 10−5 | −3.45 × 10−5 | −3.70 × 10−5 | −4.23 × 10−5 | −4.26 × 10−5 | 3.37 × 10−7 |

| METP | kg N eq. | 1.61 × 10−4 | 7.78 × 10−4 | 1.73 × 10−4 | 1.40 × 10−4 | 9.88 × 10−5 | 3.44 × 10−5 |

| TETP | Mole of N eq. | 1.61 × 10−3 | 7.84 × 10−3 | 1.71 × 10−3 | 1.34 × 10−3 | 9.36 × 10−4 | 5.32 × 10−4 |

| HTPc | CTUh | −3.79 × 10−8 | −3.70 × 10−8 | −3.64 × 10−8 | −3.80 × 10−8 | −3.80 × 10−8 | 5.31 × 10−10 |

| HTPnc | CTUh | 1.60 × 10−7 | 1.86 × 10−6 | 1.64 × 10−7 | 1.57 × 10−7 | 1.54 × 10−7 | 4.88 × 10−9 |

| IRPhh | kBq U235 eq. | −7.83 × 10−3 | −6.79 × 10−3 | 5.36 × 10−3 | 1.63 × 10−2 | −2.16 × 10−2 | 4.33 × 10−4 |

| LUCP | kg C def. eq. | −4.19 × 10−1 | 2.61 × 100 | 4.99 × 10−2 | −3.91 × 10−1 | −4.35 × 10−1 | 3.26 × 10−2 |

| ODP | kg CFC-11 eq. | −5.60 × 10−9 | −5.60 × 10−9 | −3.76 × 10−9 | −5.59 × 10−9 | −5.60 × 10−9 | 1.19 × 10−14 |

| RIPpm | kg PM2.5 eq. | −1.50 × 10−4 | −8.45 × 10−5 | −1.43 × 10−4 | −1.50 × 10−4 | −1.58 × 10−4 | 5.47 × 10−6 |

| POFP | kg NMVOC eq. | 1.75 × 10−4 | 7.64 × 10−4 | 2.32 × 10−4 | 1.00 × 10−4 | −9.31 × 10−7 | 1.05 × 10−4 |

| WRDP | m3 eq. | −9.23 × 10−4 | 5.69 × 10−3 | −8.84 × 10−4 | 2.28 × 10−3 | −3.13 × 10−3 | 1.73 × 10−4 |

| ADP | kg Sb eq. | −6.50 × 10−7 | −5.99 × 10−7 | −2.27 × 10−7 | −5.22 × 10−7 | −8.09 × 10−7 | 3.48 × 10−8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Righi, S.; Baioli, F.; Contin, A.; Marazza, D. TO-SYN-FUEL Project to Convert Sewage Sludge in Value-Added Products: A Comparative Life Cycle Assessment. Energies 2025, 18, 5283. https://doi.org/10.3390/en18195283

Righi S, Baioli F, Contin A, Marazza D. TO-SYN-FUEL Project to Convert Sewage Sludge in Value-Added Products: A Comparative Life Cycle Assessment. Energies. 2025; 18(19):5283. https://doi.org/10.3390/en18195283

Chicago/Turabian StyleRighi, Serena, Filippo Baioli, Andrea Contin, and Diego Marazza. 2025. "TO-SYN-FUEL Project to Convert Sewage Sludge in Value-Added Products: A Comparative Life Cycle Assessment" Energies 18, no. 19: 5283. https://doi.org/10.3390/en18195283

APA StyleRighi, S., Baioli, F., Contin, A., & Marazza, D. (2025). TO-SYN-FUEL Project to Convert Sewage Sludge in Value-Added Products: A Comparative Life Cycle Assessment. Energies, 18(19), 5283. https://doi.org/10.3390/en18195283