1. Introduction

Aviation and aerospace sectors are inevitably moving towards total or partial (hybrid) electrification [

1,

2,

3]. Such a move is, however, dependent on the achievement of large specific power generated and delivered within the electrical asset. This, in turn, will require nominal voltage values to rise, likely well beyond 1 kV, with unconventional types of voltage waveforms as those provided by a power electronics supply. It is evident that this situation is evolving into “hic sunt leones” territory [

4] if massive research efforts are not promptly promoted, especially in terms of reliability, resilience, and safety areas.

A major challenge is certainly the design of insulation systems of any electrical and electronic asset component, which is not just a problem of voltage, but rather of the electrical field. Indeed, insulation intrinsic and extrinsic aging are driven by the electric field (together with temperature and mechanical stress) [

5], and insulation thickness is often calculated, based on intrinsic-aging life models, using a mean field concept. The underlying assumption is that extrinsic aging, i.e., mostly PD, is absent for all life [

6,

7]. Electrification plans moving towards higher voltage include the massive use of power electronics and a reduction in dimensions and weight that will reflect into large field gradients and peak values in the bulk and surfaces of insulation systems, thus increasing the likelihood of PD inception.

In summary, while increasing voltage is an aspect of this evolution, packaging (rising specific power in weight and volume) and using more effective power supply (modulated AC and DC) are the real challenges for insulation system reliability.

Notably, insulation design concepts and procedures come from AC sinusoidal heritage, as they are based on experience and field returns with AC supply voltage (seldom with DC). Also, creepage and clearance specifications were conceived when examining AC sinusoidal (and DC) supply, and surface electric field distribution was to be mostly uniform. These may not be conditions that one can expect in modern insulation systems of electrified assets. An AC voltage waveform can be significantly distorted, compared to an AC sinusoidal waveshape, by DC components and power electronics. Even DC voltage may not be constant in time and magnitude, being affected by ripple, energization, voltage polarity inversion, and transients. Electric field distribution can be significantly divergent, especially on surfaces at triple points and in insulation bulk around wires and conductive parts (as in printed circuit boards, PCBs, and laminated busbars, LBBs).

Partial discharges are another feature of interest. They are generally measured for quality control and diagnostics of electrical asset components under AC sinusoidal voltage; however, they are currently not well-understood, and not enough scientific work has been performed in the case of DC and power electronic waveforms.

As a consequence, hard times for electrical asset component reliability can be expected as full electrification will become a central development for aviation and aerospace transport evolution.

As mentioned, insulation system design must account for both intrinsic and extrinsic aging, being the former “reaction” of insulating materials to applied stresses, which determines the design stresses and life/reliability, and the latter the extra-aging occurring due to designs, manufacturing, or commissioning flaws, that can significantly reduce life, causing premature failure. The most sought driver of extrinsic aging is partial discharges, which can occur due to defects or design solutions, such as cavities present in bulk insulation, interfaces, insulation surface, and triple points. In the case of organic insulating materials (composing most insulation systems), PD will cause accelerated local degradation, which ends up with insulation perforation and, in general, electrical asset outage. Given that this is an event that cannot even be imagined in aircraft/aerospace structure operation, the study of PD must take central importance in insulation system design and safe operation of any electrical asset component, considering that, to complicate the picture, PD inception voltage (PDIV) can considerably diminish with increasing altitude. Hence, aircraft or spaceship components that are PD-free at standard atmospheric pressure (SAP) may be affected by PD at flying altitude.

U.S. Advanced Research Projects Agency-Energy (ARPA-E) has understood this challenge and put in place projects where insulation system design in electrified aircraft has a central focus, from Aviation-class Synergistically Cooled Electric-motors with Integrated Drives (ASCEND) to Connecting Aviation By Lighter Electrical Systems (CABLES). Under CABLES, General Electric (GE) Research, with Florida State University, has proposed utilizing a revisited concept of GIL (gas-insulated line or cables) for power distribution within an aircraft, where gas made by pressurized carbon dioxide (CO

2) is the main electrical insulating medium. This would allow higher-efficiency and lower-weight power transmissions on electrified aircraft to be achieved at voltage levels around +/−5 kV [

8,

9,

10].

In this project, a driving topic has been the design of cable and connector insulation systems, involving gas and solid insulating materials, focusing on surface insulation sub-system design and relevant triple points. For this purpose, the concept of partial-discharge-free design was developed in order to reach criteria that can ensure that cable and accessories operate at any planned altitude in the absence of extrinsic (PD) aging.

This paper aims to illustrate how robust and PD-free design of aviation/aerospace electrical and electronic components can be achieved by applying a recently developed design procedure (the three-leg approach, [

11]), which involves a new model for the estimation of PD inception field (PDIE) and voltage (PDIV) in bulk defects and on insulation surface. Such a new model has an explicit dependence on pressure and known parameter values. Various experimental investigations on test objects under AC (sinusoidal and modulated) and DC (see, e.g., [

11,

12,

13,

14,

15]) proved the validity of the three-leg approach and allowed model parameter values to be estimated in air, but here, the model is applied to both air and CO

2 insulation. Even if the three-leg approach can work for both internal and surface defects, in this paper, only the latter is used, in relation to the design of gas-insulated cable spacers at variable pressure levels (higher and lower than standard atmospheric pressure, SAP).

Work on the effect of pressure on PD phenomenology, generally without modeling PD inception, can be found already in the literature, e.g., [

16,

17,

18,

19,

20,

21,

22], where the dependence of PD magnitude, associated frequency on pressure/altitude, is illustrated and discussed based on experimental results and theoretical considerations. The innovative contribution of this paper is to present the application of a new approach (the three-leg) to achieve PD-free design of insulation systems at variable pressure levels used in aviation and aerospace, with specific reference to the mentioned new aircraft cable structure. The proposed model, derived from Niemeyer’s work [

23,

24,

25], is simple and practical, with the advantage that it can be applied to any insulation structure, type of defect, and voltage waveform, with unknowns that can be calculated by resorting to electric field calculation. In addition, the first two legs of the approach can provide both PDIE and PDIV.

Section 2 of this paper describes cable and test object setup, while the fundamental tool for PD-free design, i.e., the three-leg approach and the new model for partial discharge inception in insulation bulk defect, surface and interfaces, is dealt with in

Section 3. Results of tests performed for surface discharges at lower and higher-than-SAP levels, precisely from 0.05 bar to 3 bar, and fitting to the estimates provided by the modeling approach, are described and discussed in

Section 4.

2. Cable and Test Set

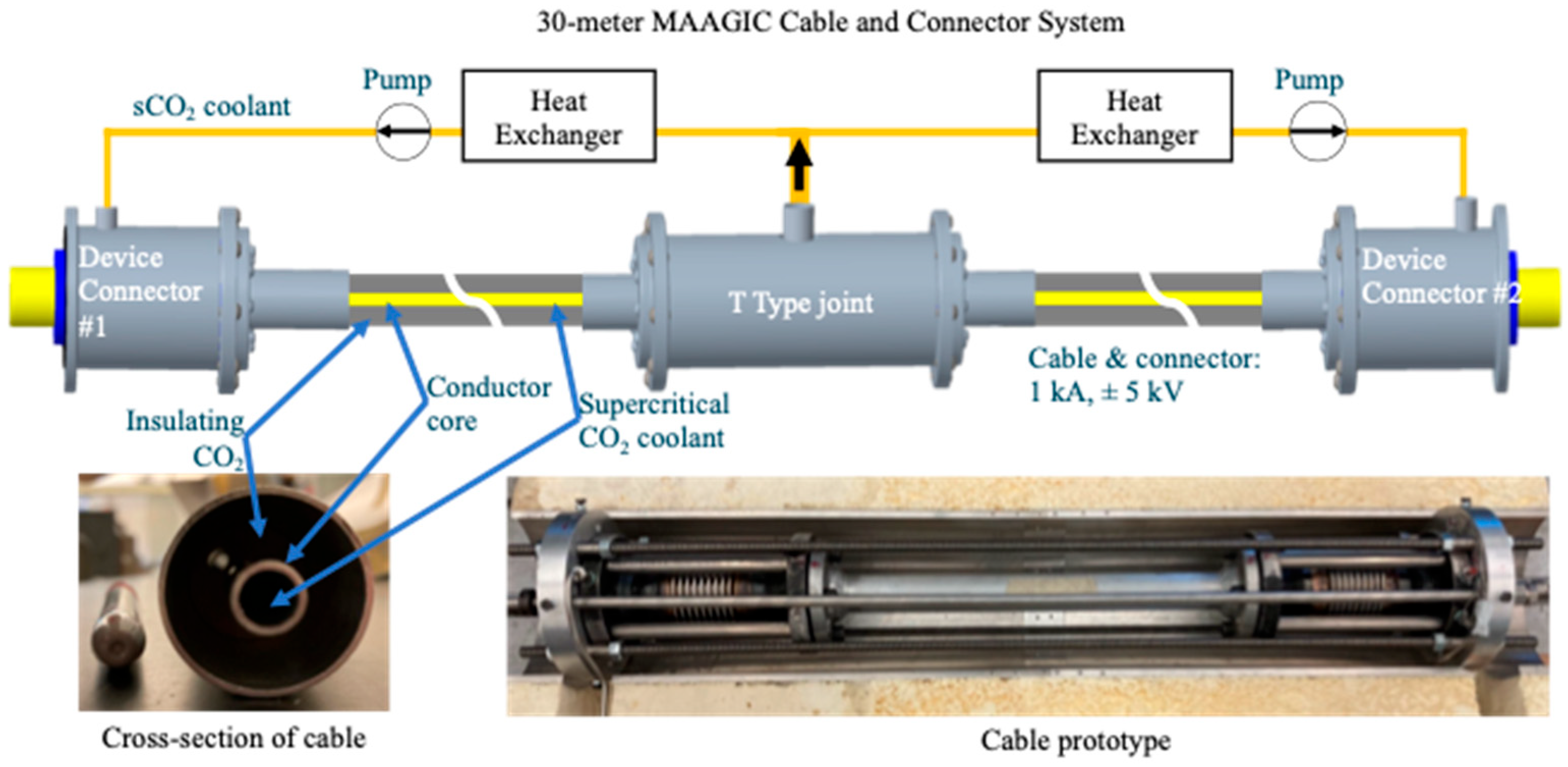

The drawing and picture of the project cable model are in

Figure 1. Gas insulation was chosen to be CO

2 at a pressure of 5 bar, considering that CO

2 is also used in the same aircraft concept as a cooler. There is no expectation of much better dielectric performance than dry air, but the latter can easily increase humidity content due to ambient contamination penetrating the cable system, thus showing worse performance with operation time. Also, the typical compressed air available at airports might not have the purity required for HV insulation. On the other hand, air at low pressure will be the typical environment of most insulation components of an aircraft at cruise altitude; thus, air has been included in a global evaluation of PD inception model performance, from low to high pressure (lower and higher than SAP).

As regards solid insulation used, e.g., for cable spacers and connectors, various materials were considered. In this paper, we focus on Alumina, i.e., Al

2O

3, a typical inorganic insulating material for aerospace and aircraft applications where high operating temperatures are sought, and FR4, a fiberglass-reinforced epoxy laminated (thus, organic–inorganic materials) often used for PCB insulation. Variation in insulation system dimensions can be taken into consideration by using the size effect algorithm, which provides the expression that can be able to transform the value of the electric field (or electric strength) as derived by laboratory tests on small test objects, to that which can be used in the full-size insulation [

26].

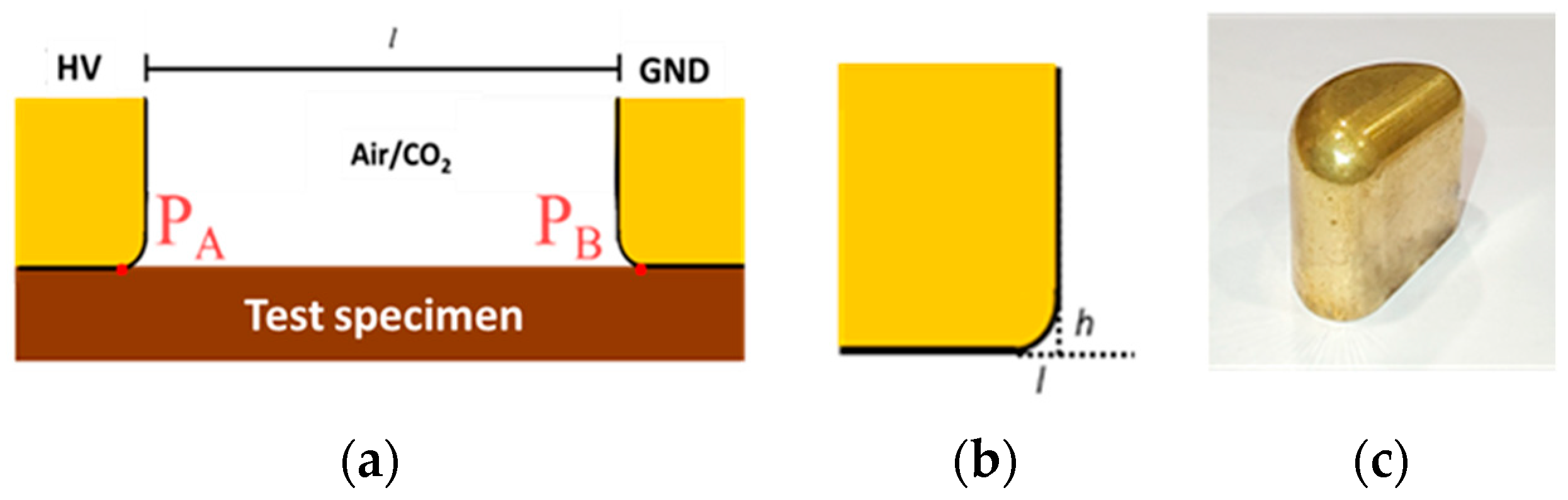

PD inception voltage tests were performed in two types of chambers, using the same electrode arrangement of

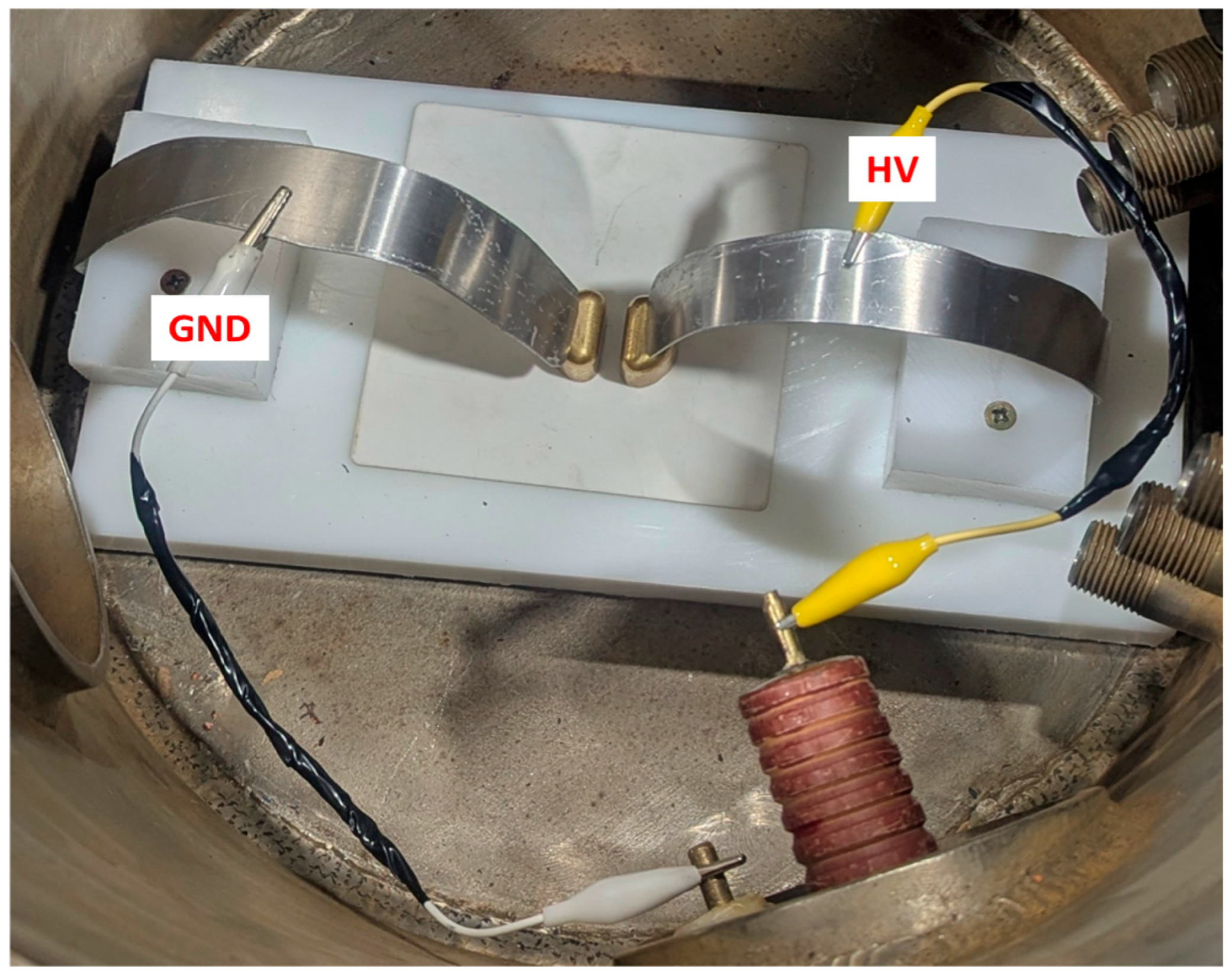

Figure 2, which is able to generate surface discharges on the insulation on which they are placed.

Figure 3 displays the test electrode setup placed inside the pressure chamber with surface discharge electrodes and insulation specimen mounted on the test platform. The electrodes were made from brass, and their curvature radius at the triple points (P

A and P

B) is 0.1 mm. An aluminum holder, as shown in

Figure 3, keeps the electrodes such that the distance between them is maintained undisturbed (from mechanical actions that might occur while closing the pressure chamber lid). The distance between the electrodes is manually adjusted to the required value with the help of a vernier caliper.

PDIV measurements were performed by increasing the supply voltage (through steps of 0.1 kV each lasting 30 s) until detection of steady PD phenomena, according to IEC 60270 [

6]. AC sinusoidal voltage was used, rather than power electronics waveforms (as pulse-width modulated, PWM), since modeling and experiments indicate that in simple test object geometries, as flat specimens or twisted pairs, the difference between AC sinusoidal PDIV (peak-to-peak value) and AC-modulated repetitive PDIV (RPDIV) is generally small [

27]. This assumption was validated during the research described in this paper, carrying out PDIV tests under AC sinusoidal and 2-level bipolar PWM (AC modulated) waveforms, the latter with modulation and carrier frequency of 60 Hz and 1 kHz, respectively, on the same specimen at SAP and 500 mbar. PDIV mean values (over 5 repetitions) differing by only 4% at SAP, and 9% at 500 mbar were obtained (referring to peak voltage and distance between electrodes

l = 5 mm). PDIV tests were repeated at least 5 times to obtain robust mean values, waiting for 30 min between one test and the other (to allow the disappearance of space charge deposited by PD activity). Also, at least three specimens were tested at each pressure level and electrode distance, from 5 to 10 mm.

Figure 4 sketches the test arrangement. The sensor for PD was a high-frequency current transformer, HFCT, with a bandwidth from 10 kHz to 50 MHz. The PD detector had a software filter that could be used to comply with an IEC 60270 bandwidth and sensitivity of 1 mV (corresponding to about 1 pC after calibration). The PD detection system has innovative software, based on the Separation, Recognition, Identification (SRI) approach, which allows automatic measurements and analytics to be performed. The identification output (based on fuzzy logic) is the likelihood of PD typology in descending order of harmfulness, that is, internal, surface and corona PD. For the tests performed by the electrode system of

Figure 2 and

Figure 3, identification was mostly surface PD, with likelihood ranging from 1 at SAP and high pressures to 0.8 at 200 mbar and below. The nature (surface) and location (triple point) of PD were confirmed by simultaneous UV camera observation at SAP.

Tests at low pressure (specifically, 0.5, 0.2 and 0.05 bar) in air were performed in a pressure chamber that can reach 0.01 bar, 90 °C, with variable humidity and up to 50 kV. Tests at high pressure (2 and 3 bar) were carried out in a cell specifically designed for this project [

8], able to reach 10 bar. Tests at low pressure (0.8 and 0.5 bar) in a CO

2 environment were also performed using the above-mentioned pressure chamber.

4. Experimental Results and Model Fitting

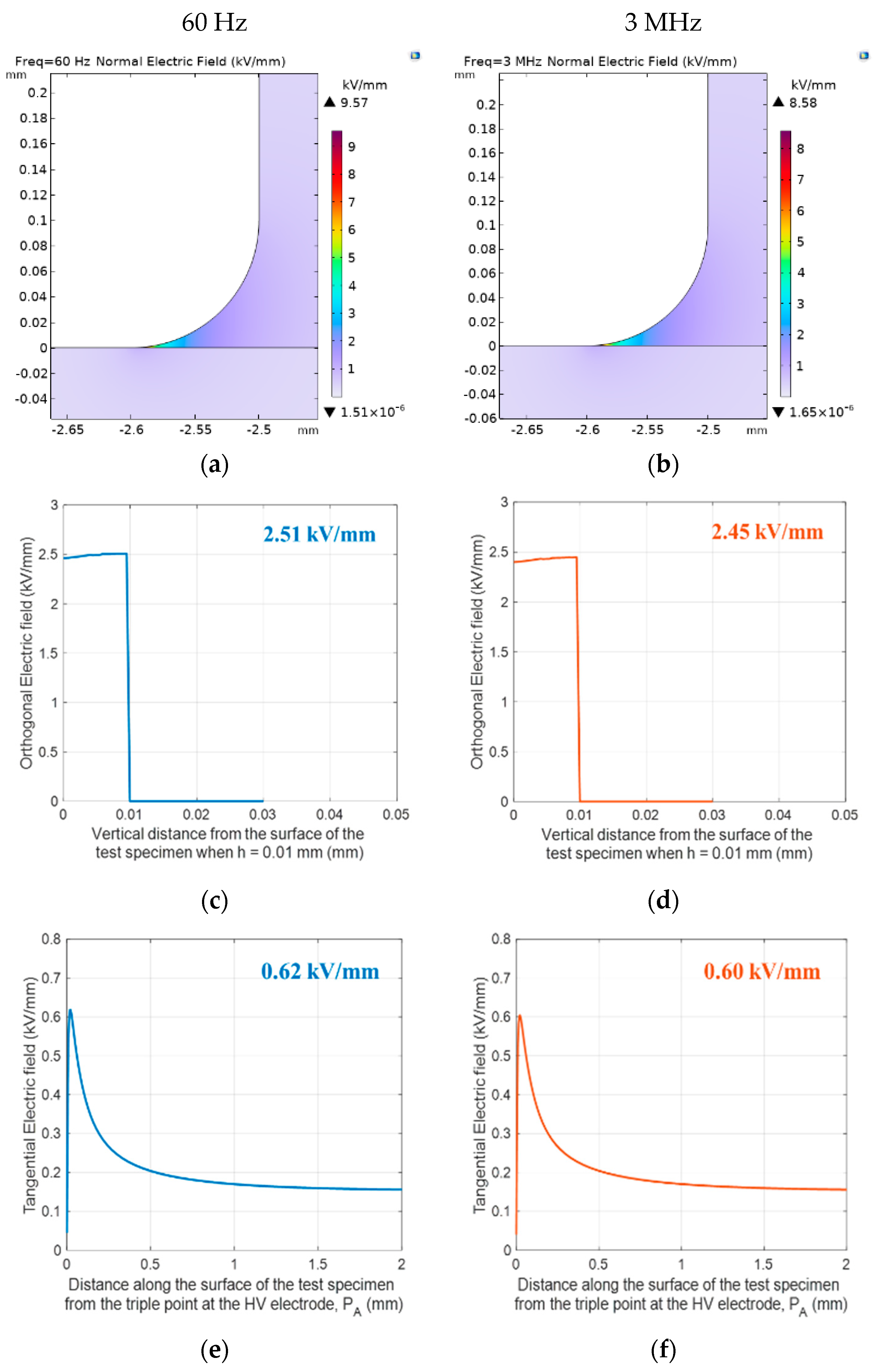

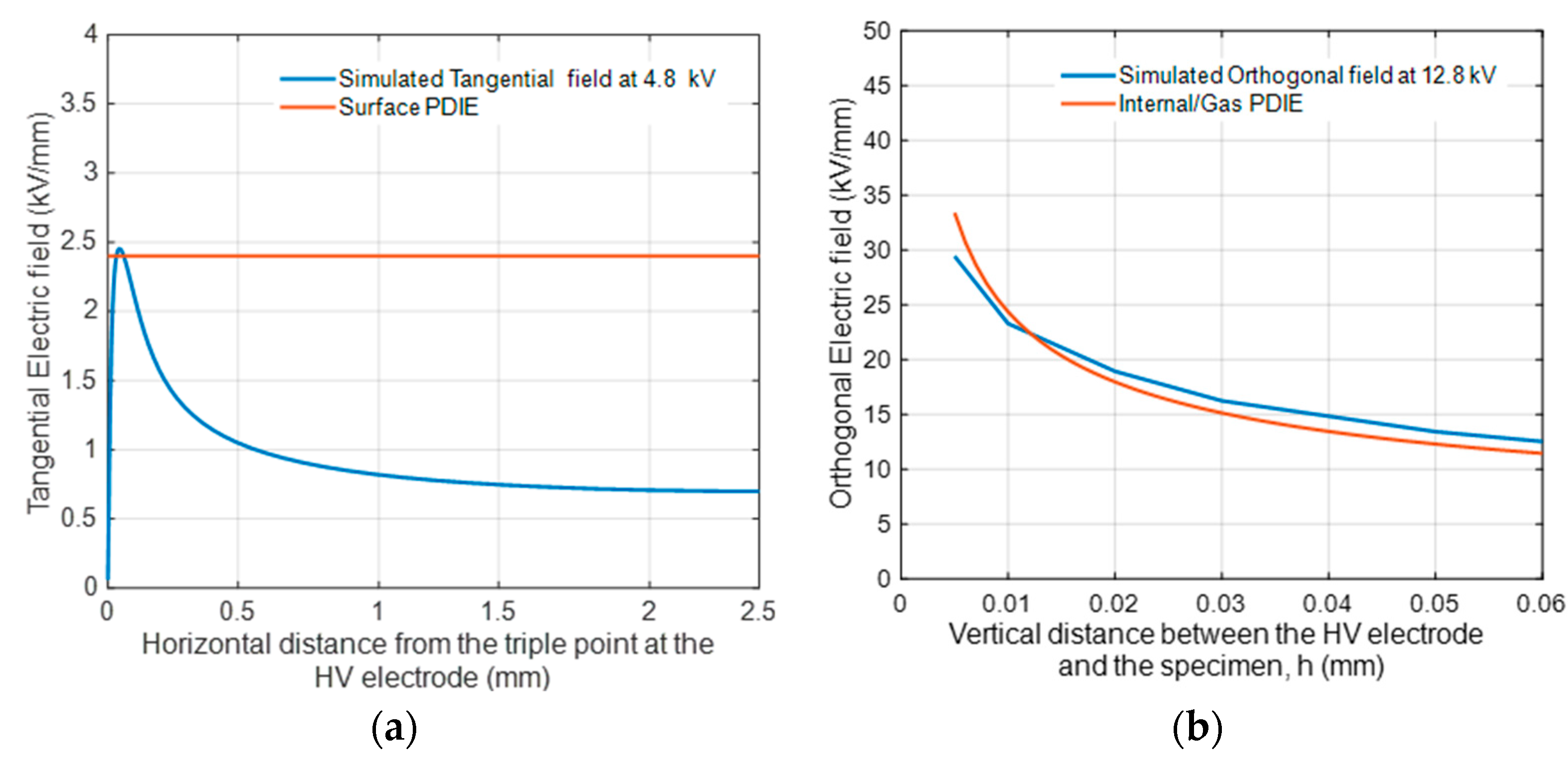

Electric field calculations on Alumina and FR4, in air and CO

2, using the test electrode configuration shown in

Figure 2, were carried out by COMSOL for an excitation voltage of 1 kV, AC sinusoidal 60 Hz (the field profiles do not change increasing the frequency; thus, they would hold also for PWM modulation waveform, at least for non-extreme slew rates). The mesh used for electric field calculation is a user-controlled mesh, which is refined and is smaller near the electrodes in order to obtain an accurate representation of the simulated electric field profile. A minimum element size of 1 µm was considered to avoid interface spikes/instability. Material permittivity was taken from measurements performed by a dielectric analyzer. The values of the maximum (peak) field,

and

ks, for Alumina and FR4 specimens, which are calculated from the simulated electric field profile, and (2), at a distance of 5, 7.5 and 10 mm between the electrodes, are reported in

Table 2.

and

ks values were noticed to change slightly with the change in surrounding ambiance (air/CO

2), due to the minimum difference in the relative permittivity values of CO

2 and air, i.e., 1.009 for the former.

PDIV measurements were performed on Alumina and FR4 specimens using the surface discharge electrode setup of

Figure 2, with 5, 7.5 and 10 mm distances between electrodes, at SAP, pressures lower than SAP (0.5, 0.2 and 0.05 bar) and higher than SAP (1.5, 2 and 3 bar) in an air and CO

2 environment. As mentioned, measurements were carried out in controlled humidity and using the same set of electrodes. Tests were stopped after PDIV was detected, avoiding insulation and surrounding gas degradation.

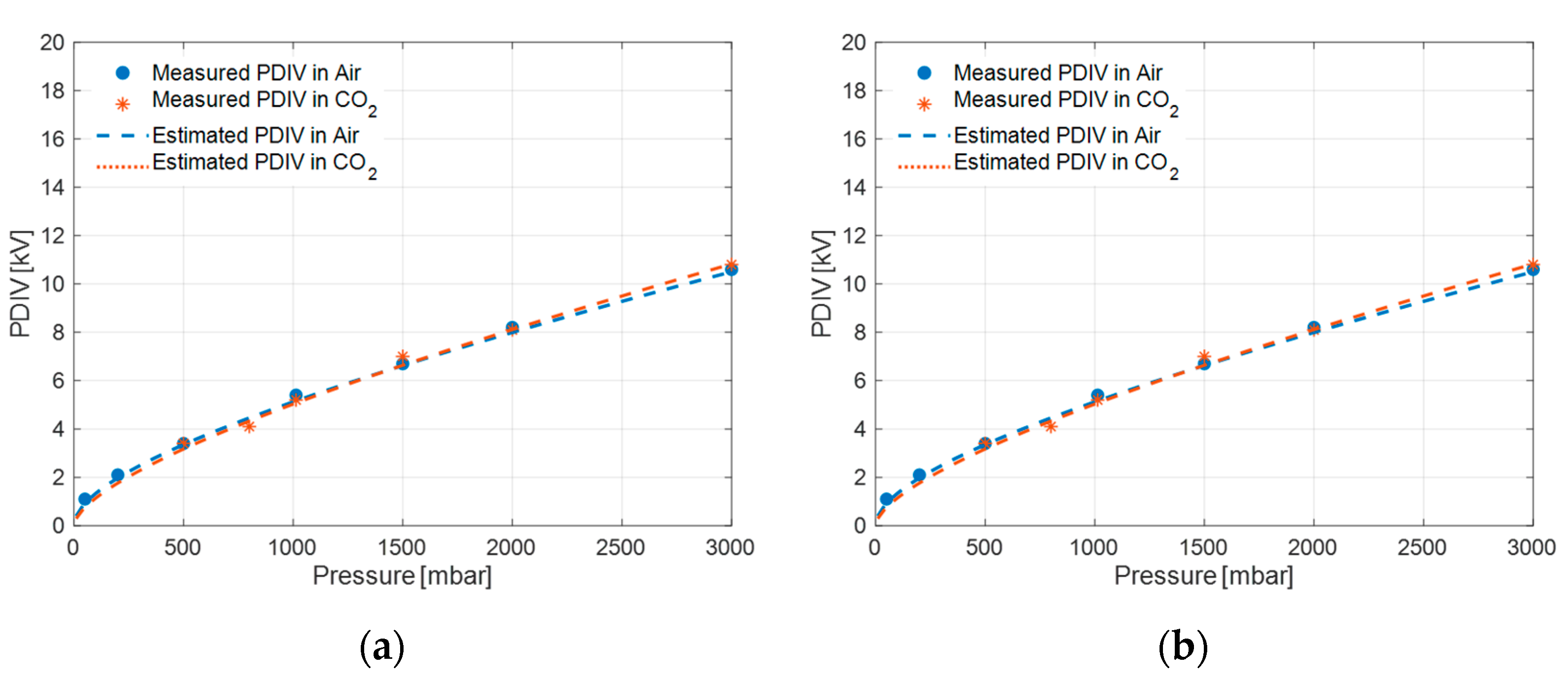

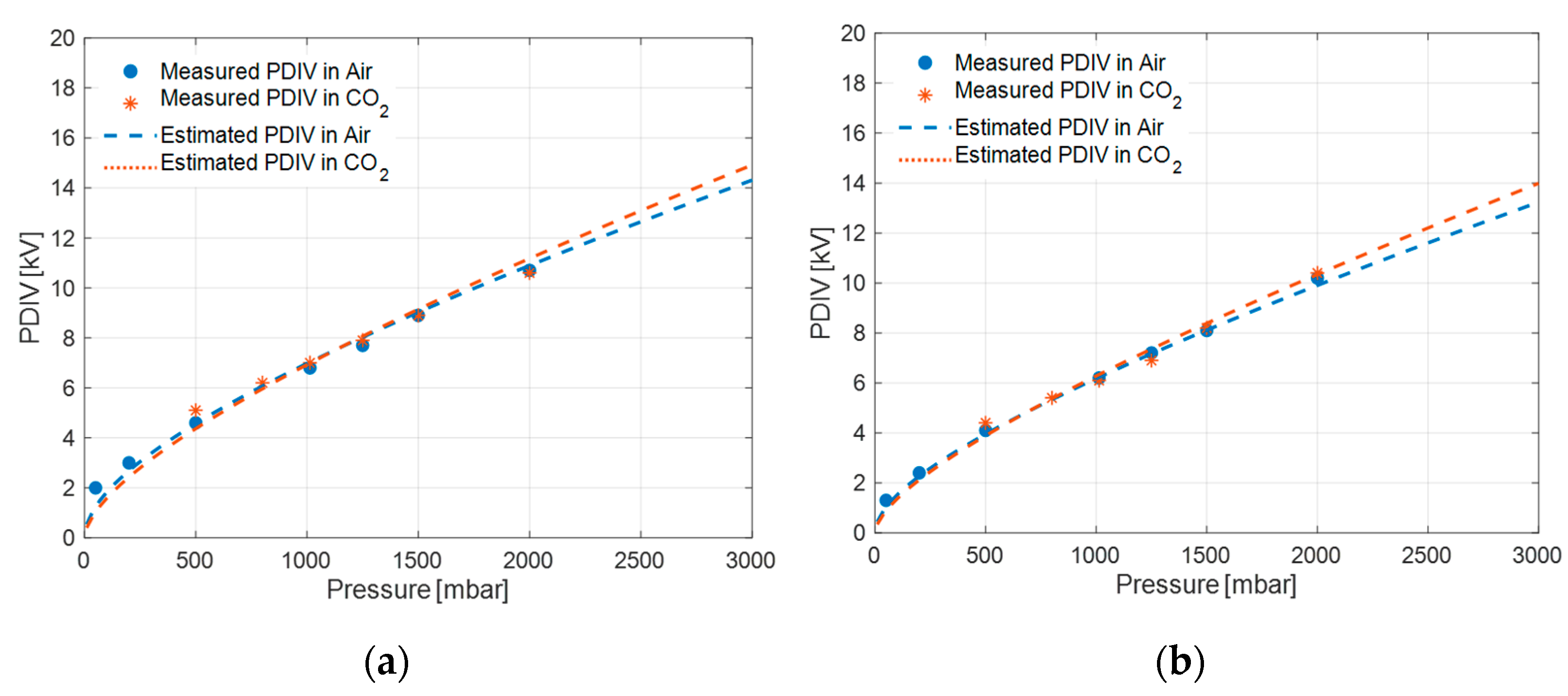

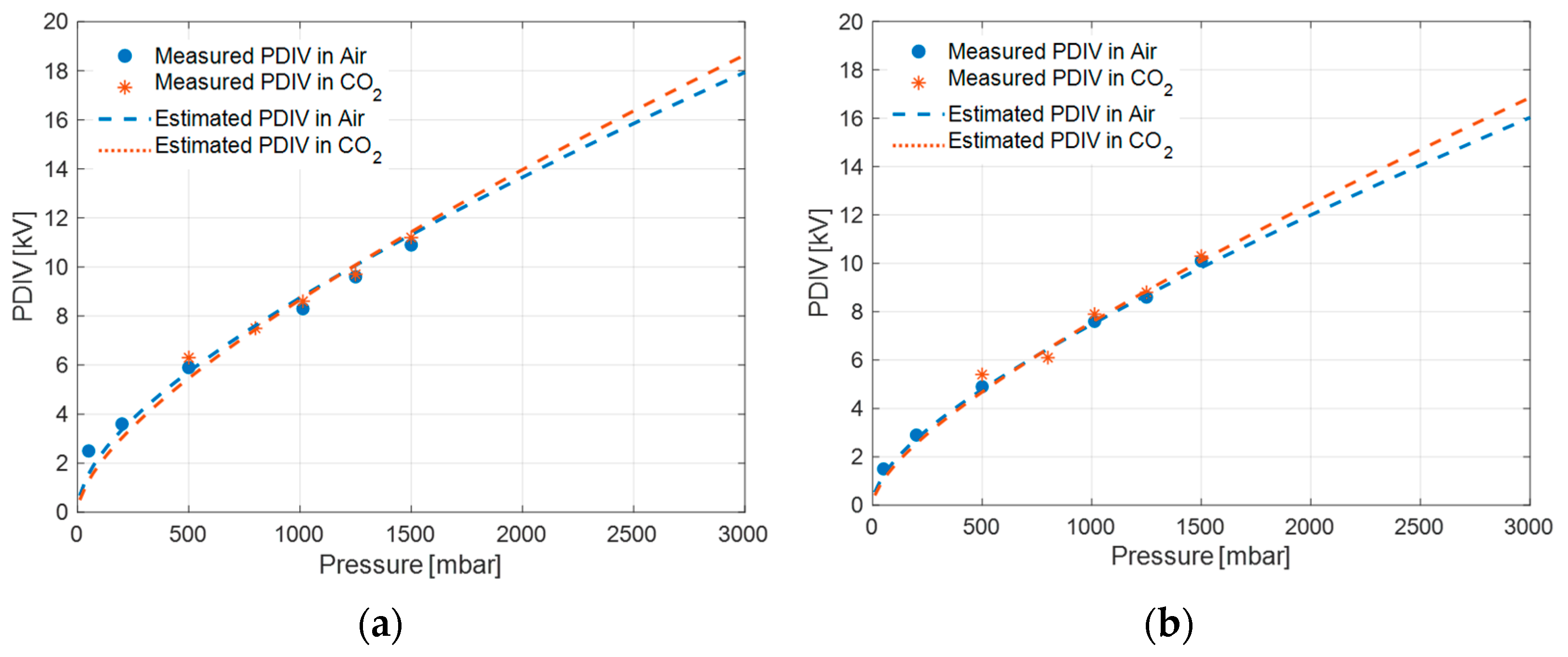

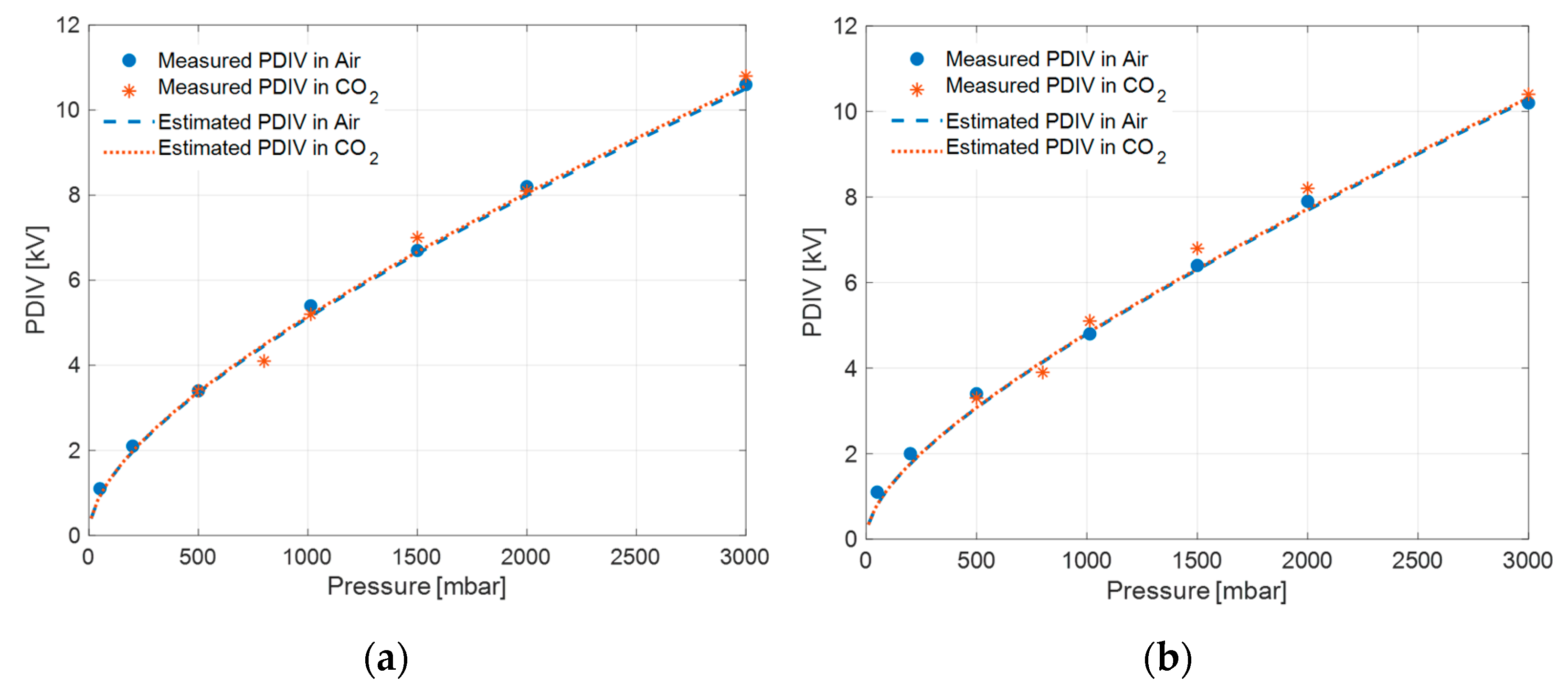

The measured and theoretical PDIV values (from model (1)) of Alumina and FR4 specimens, at a distance of 5, 7.5 and 10 mm between electrodes in air and CO

2, at different pressures above and below SAP, are plotted in

Figure 7,

Figure 8 and

Figure 9. The experimental points are fitted to the discharge model (1) in a broad range of pressure values, keeping model parameters constant, i.e.,

B = 4.0,

= 2.3 in CO

2 and

B = 4.3,

= 2.0 in air and (

E/

p)cr = 8.0 in both cases.

It can be seen from

Figure 7,

Figure 8 and

Figure 9 that the theoretical values obtained from the surface discharge model (1) for Alumina and FR4 specimens, and the test cell of

Figure 2, are in very good agreement with the experimental values for both a CO

2 and an air environment, by considering slightly different values for model parameters

B and

. However, a good fit is also observed using

B = 4.3 and

= 2.0 for both environments, which are the values already estimated based on SAP measurements on different materials in air; see

Figure 10. This latter observation fits to breakdown voltage measurements presented in the literature, e.g., [

29], according to which breakdown voltage (BV) with divergent field does not change significantly from dry air to CO

2, if not increasing electrode distance significantly. This indicates that the selection of CO

2 is convenient mostly since the quality of the gas remains constant with time and aging, while air can become less pure and more humid, thus displaying unpredictable PDIV variation with operation time. Also, it seems that the performance of Alumina is marginally better when compared to FR4 (

Figure 7,

Figure 8 and

Figure 9).

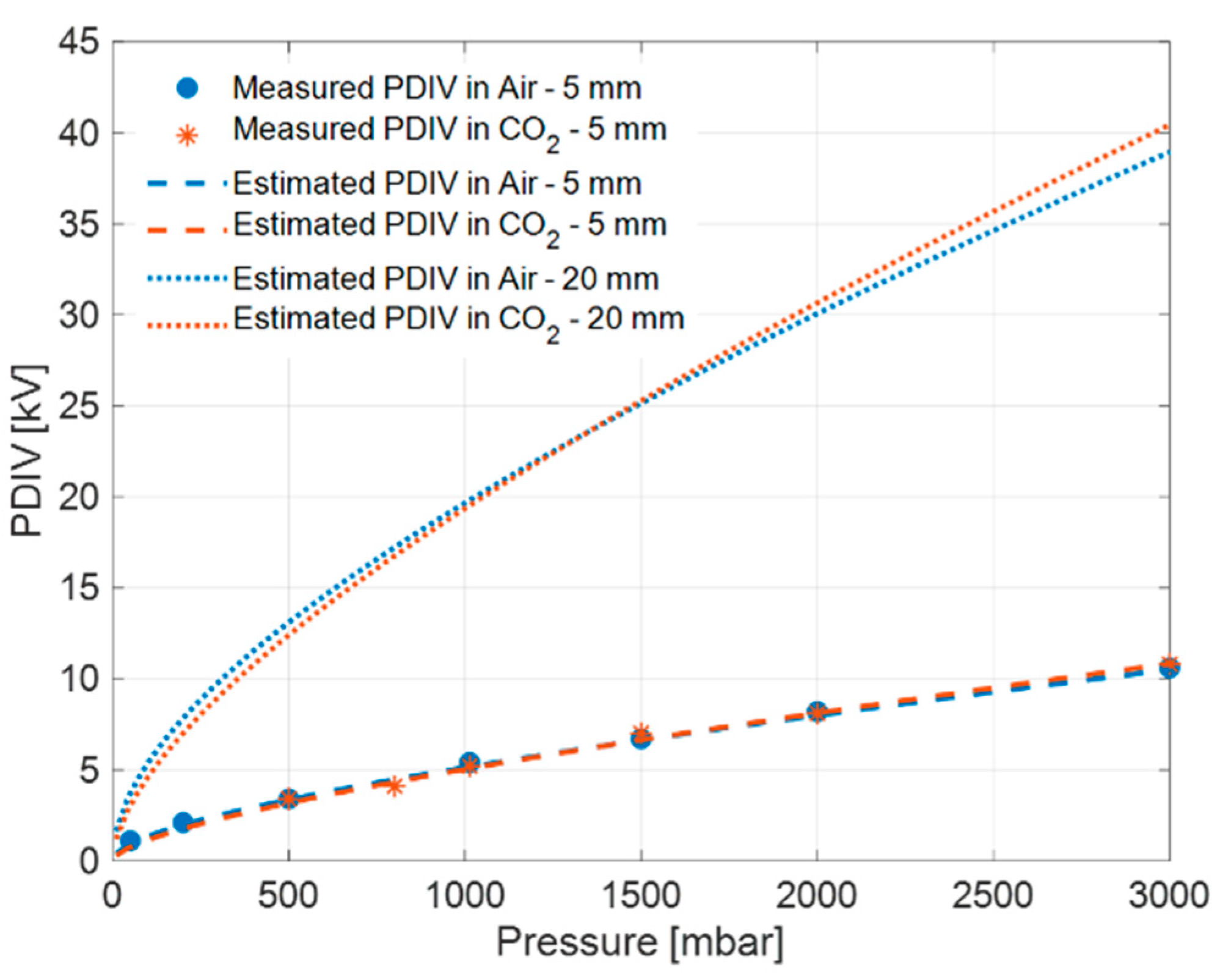

Applying the general inception model (1) to the distance of 20 mm, the curves in

Figure 11 for CO

2 and air are obtained. PDIV values almost coincide in air and CO

2, and they are significantly larger than for 5 mm creepage.

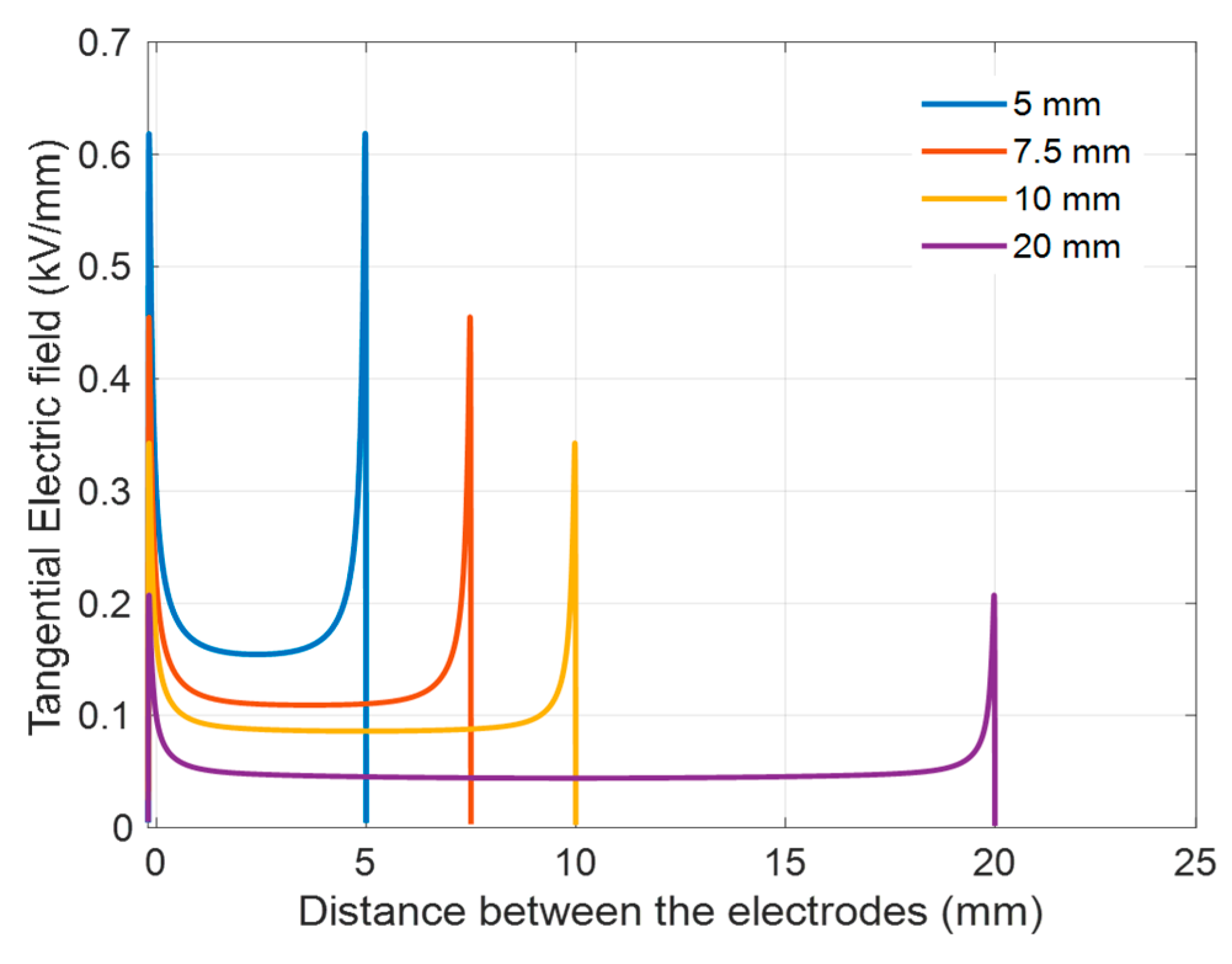

This result, i.e., larger surface PDIV with increasing creepage, seems to be obvious, but it is not. It has been shown [

12] that PDIV increases with distance only when the electrical field profile is not too divergent, so that the maximum (peak) field decreases significantly when the distance between electrodes increases. Indeed,

Figure 12, which reports the electric field simulations with different creepage distances considering the HV electrode of

Figure 2, highlights that the peak field at triple points decreases noticeably increasing the creepage distance,

d. As regards PD inception, model (1) provides

Ei values having little variation, in spite of increasing

d, since

ks keeps a very low value (thus, the product

ksd at the denominator of (1) is almost constant). Hence, the increase in PDIV is due mostly to the decrease in peak electric field. On the contrary, as shown in [

11], if the field distribution is highly divergent so that the peak value does not change with distance, the PDIV becomes almost insensitive to the distance between electrodes.

These considerations highlight that the concept of designing an insulation system according to creepage and clearance may be questionable when, as for electrified transportation applications, significant electric field gradients occur on the insulation surface. If the electric field peak does not vary greatly with distance and Ei is almost constant, increasing the distance of the HV electrode to ground does not actually raise the PDIV. Other solutions, as changing electrode/contact shape, should be pursued for this purpose, thus allowing an insulation system to operate at a nominal voltage lower than PDIV (PD-free design).

5. Conclusions

The approach proposed in this paper would make it possible to predict the PDIV at variable pressure in insulation systems involving solid and gas insulation, at least referring to air and CO2. In particular, focus here is on the design of surface insulation sub-systems, relevant to gas-insulated cable spacers and connectors. Applying the first two legs of the three-leg approach, spacers of different geometry and shape can be designed as PD-free at any altitude of interest, choosing the best solution for each candidate material. Other gases and solid insulating materials can be investigated, checking the validity of the model parameter values used here (and for several other materials).

Such a modeling and simulation framework would work to carry out PD-free insulation system designs in electrified aircraft/aerospace electrical and electronic assets, which can be validated by PD tests performed at SAP (or any other pressure). Having the possibility to predict PDIV variation with pressure at the design stage would drastically increase the safety and reliability of asset components, as well as reduce design and testing costs. However, the objective of making available smart, automatic PD monitoring systems to be installed in aircraft and aerospace assets shall not be forgotten, since the extent of aging could not be fully predictable at the design stage (due, e.g., to modification of asset layout, type and intensity of stresses or use of inaccurate life models for insulation system design).

It has also been shown that a PD-free design cannot simply rely upon concepts that, as creepage and clearance, are based on the risk of destructive discharges (flashover). It must be pointed out, indeed, that already the inception of PD is prejudicial for equipment and related asset reliability (without having to consider destructive macroscopic surface processes).

Eventually, it is noteworthy that this model-based design approach is completely scalable; thus, once the design parameters (materials, voltage waveform and amplitude) have been defined, it can be applied to any type of insulation system dimension and configuration.

The work to be completed is still significant, including model behavior varying temperature and humidity, and different voltage waveforms, especially DC, where the electric field distribution is driven by conductivity (temperature and field dependent). It can also be speculated that considering gases with higher attachment coefficients might require experiments to re-estimate model parameter values. This does not affect, however, model validity and use.