Exploring the Potential of R744 as a Sustainable Refrigerant for Marine Applications: A Comparative Performance Analysis with Current Refrigeration Framework

Abstract

1. Introduction

2. Conventional and Innovative Systems: Description and Numerical Approach

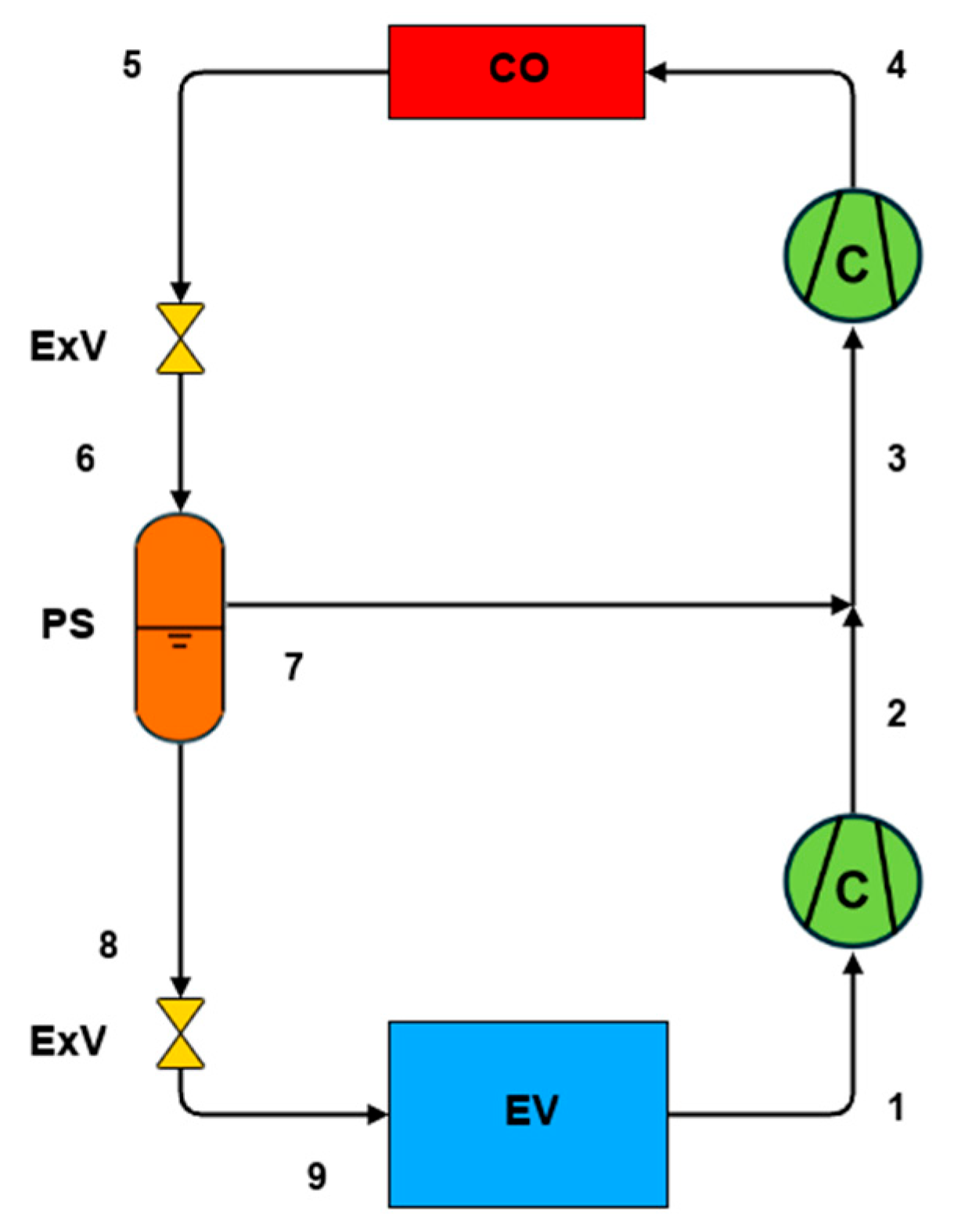

2.1. Conventional Provision System

2.2. Conventional Air Conditioning System

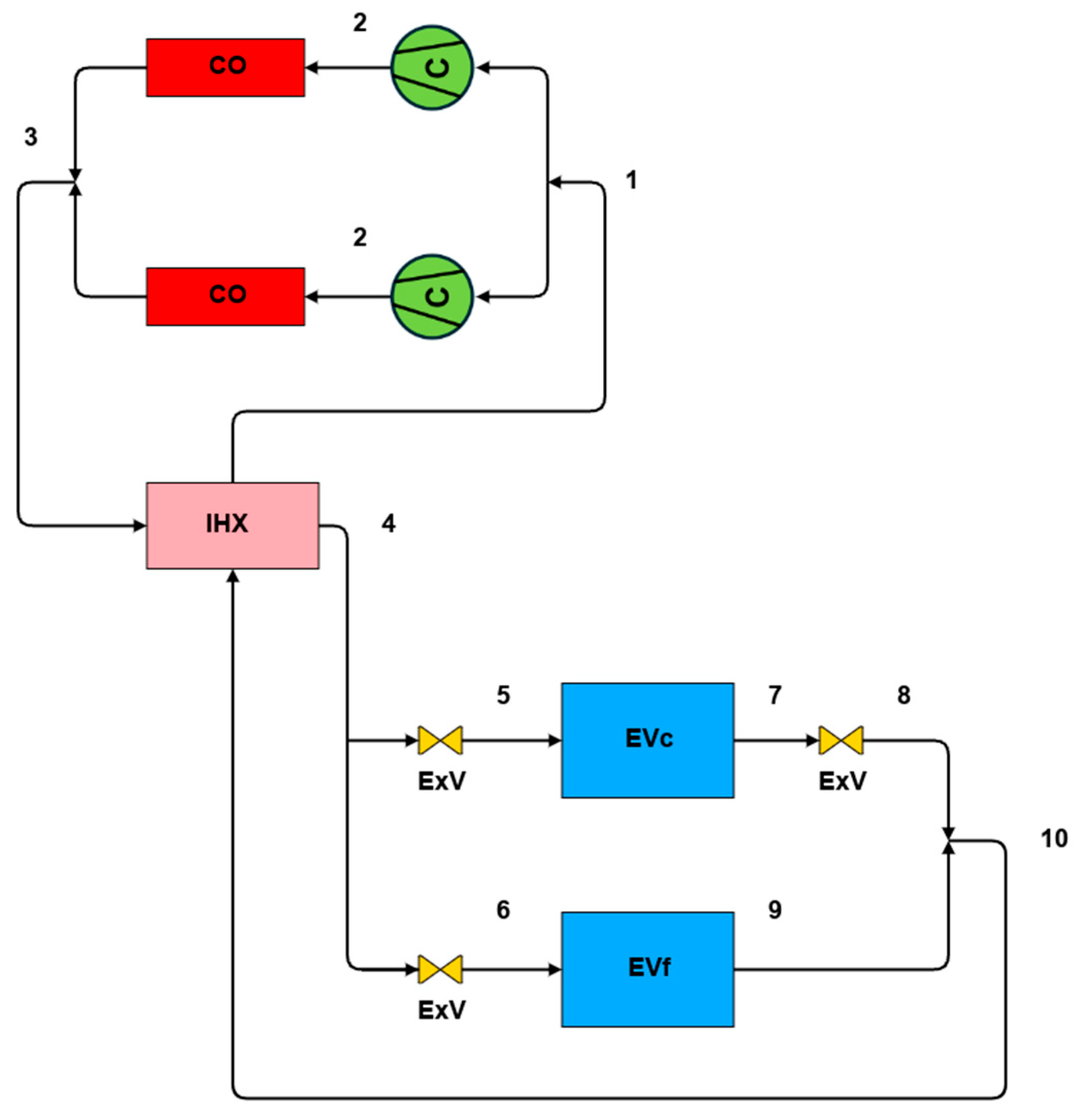

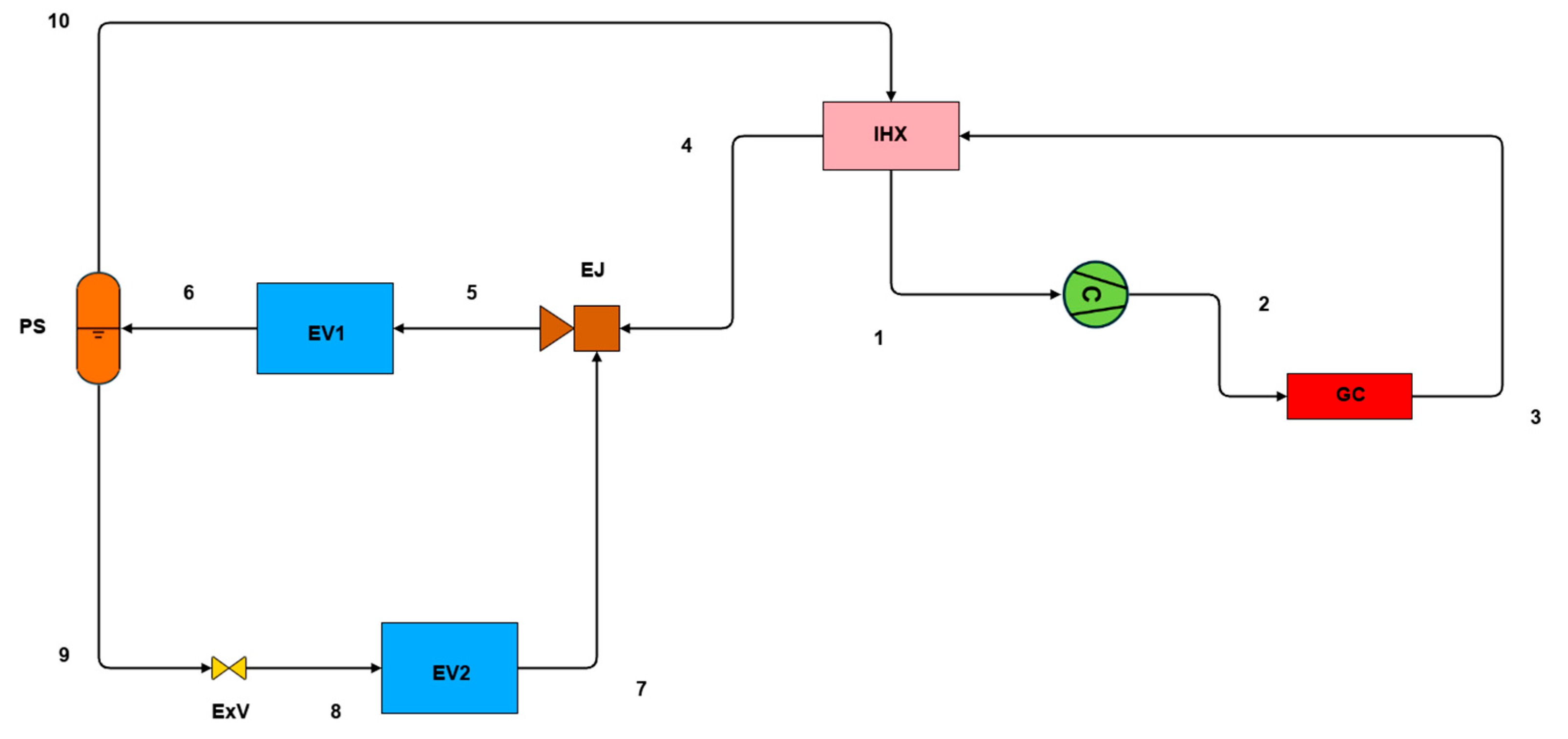

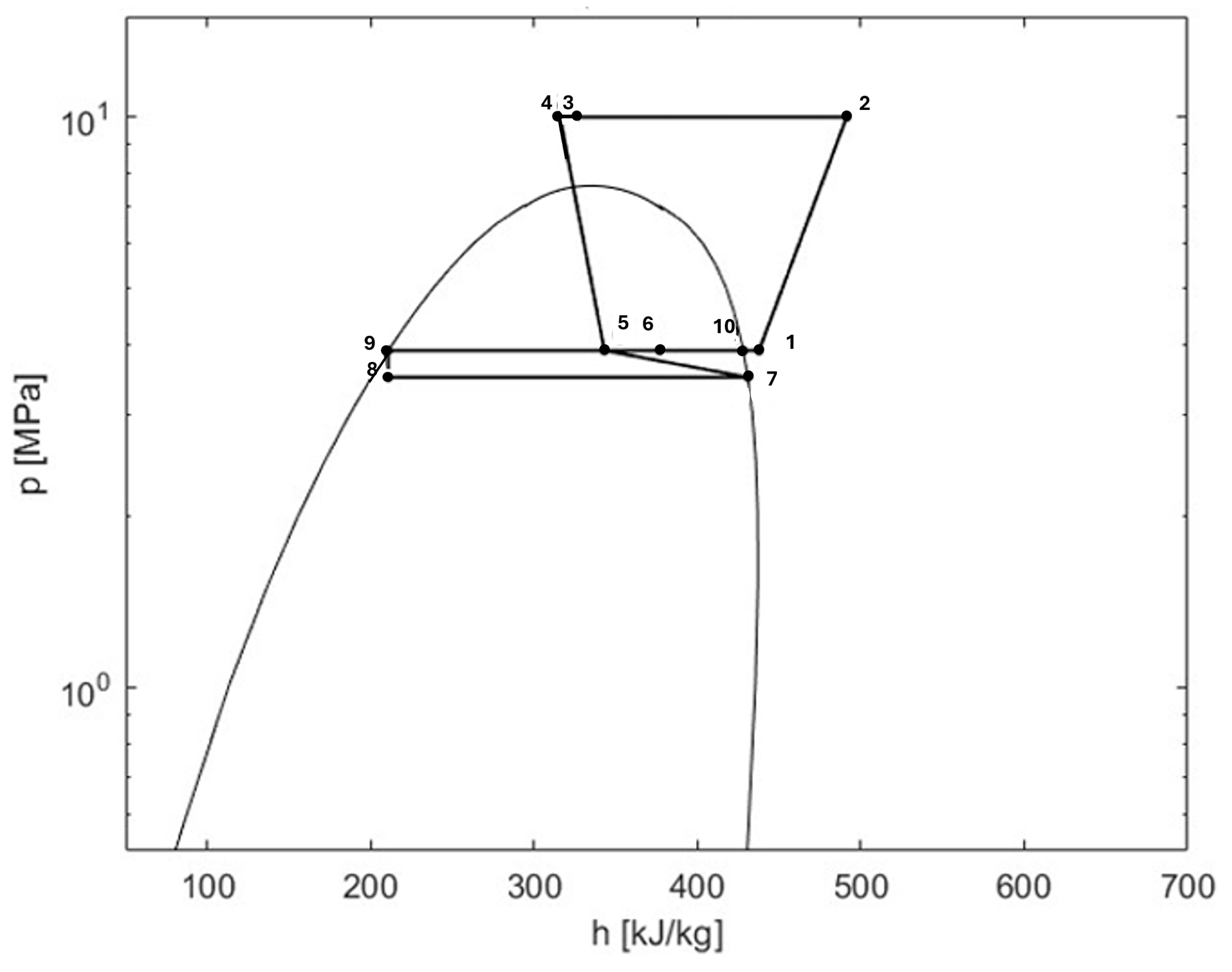

2.3. Innovative Provision System

2.4. Innovative Air Conditioning System

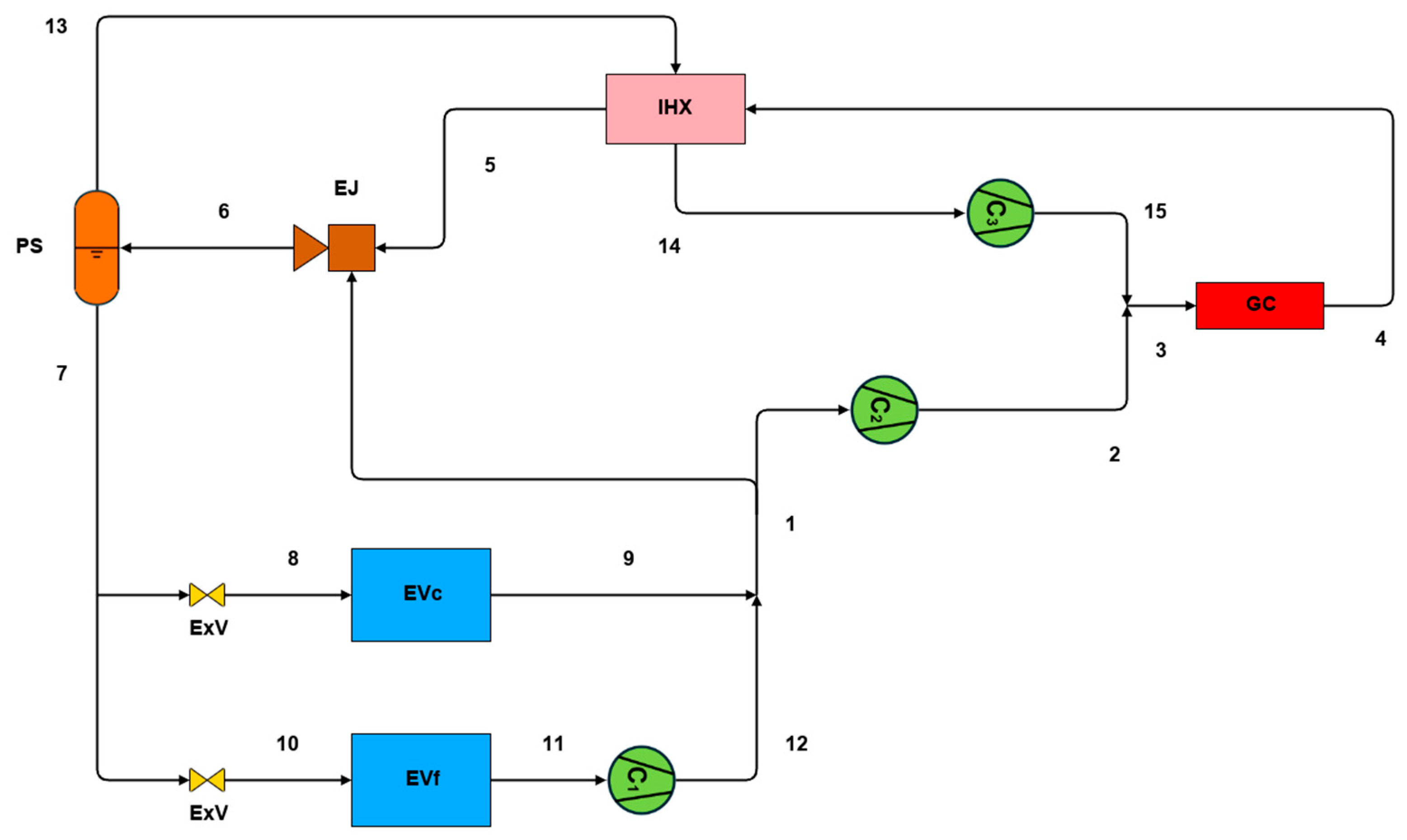

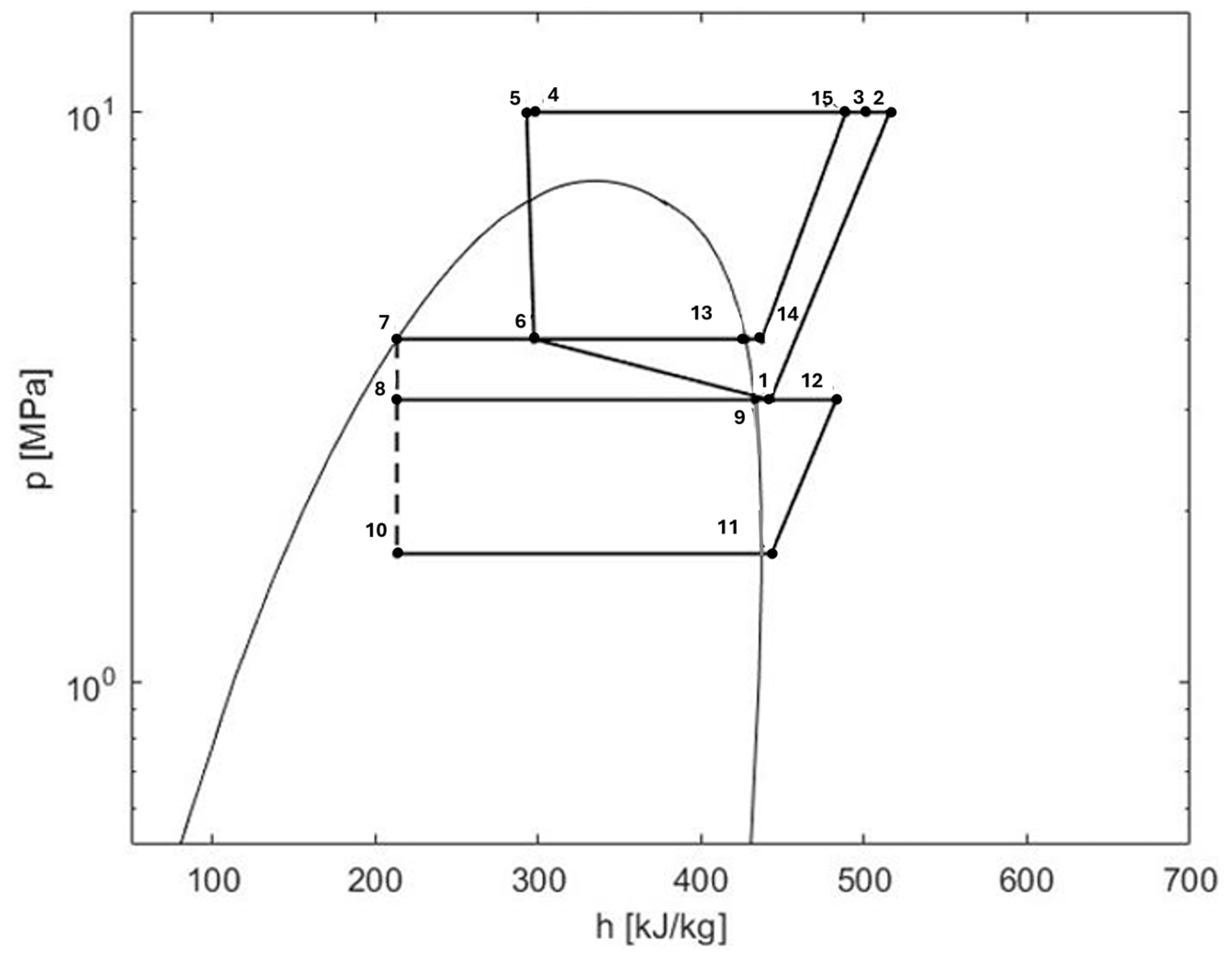

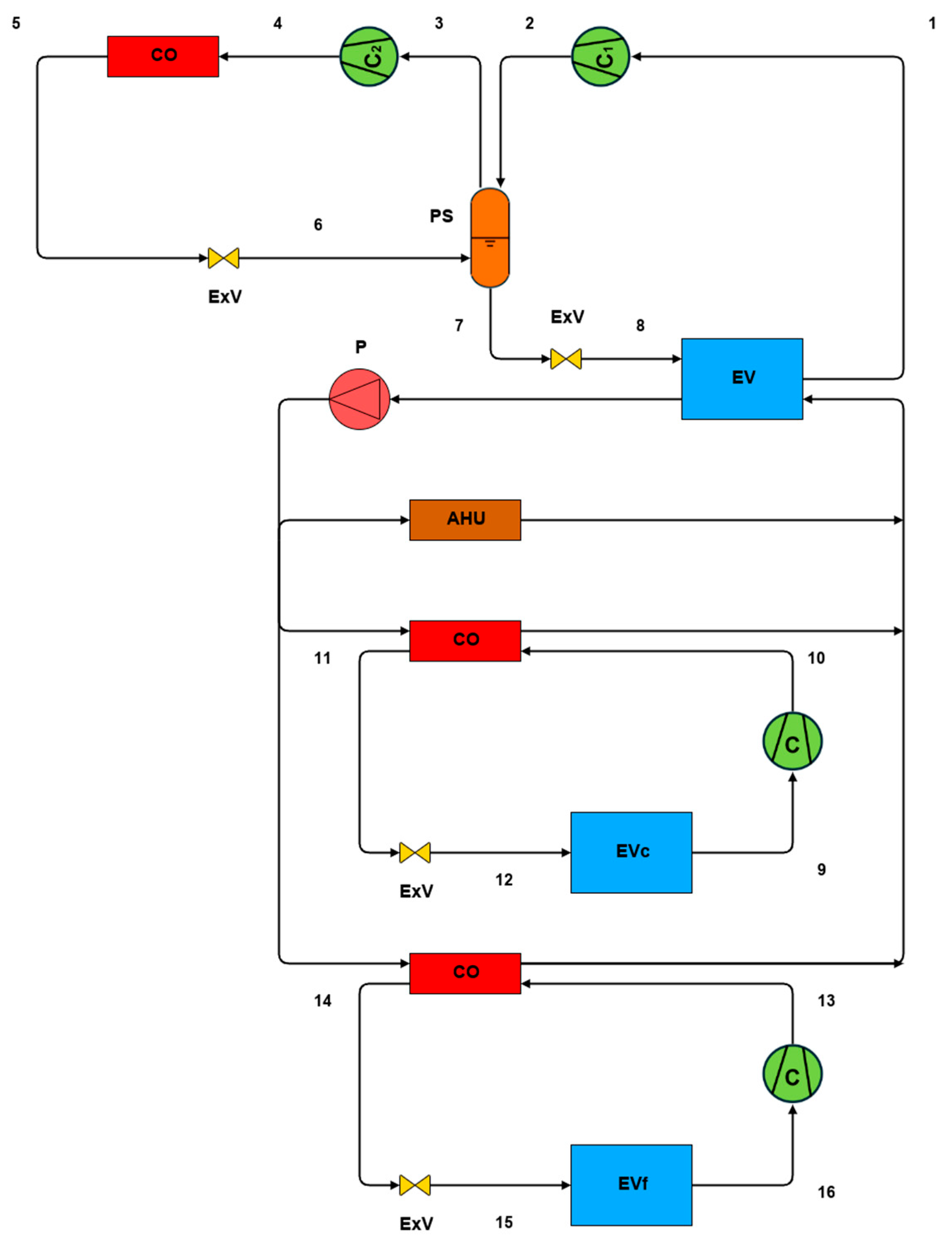

2.5. Cascade System

3. Results and Discussion

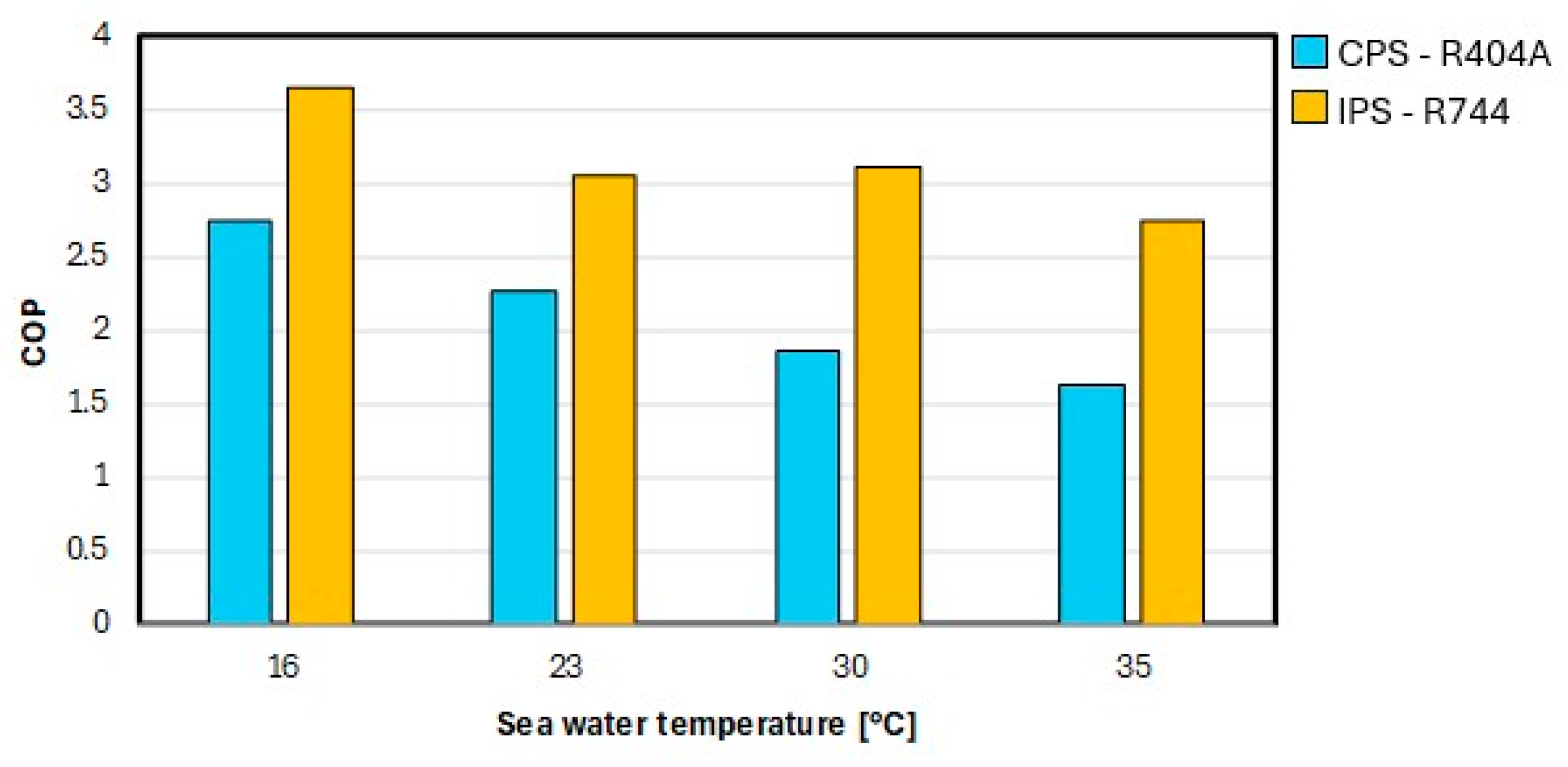

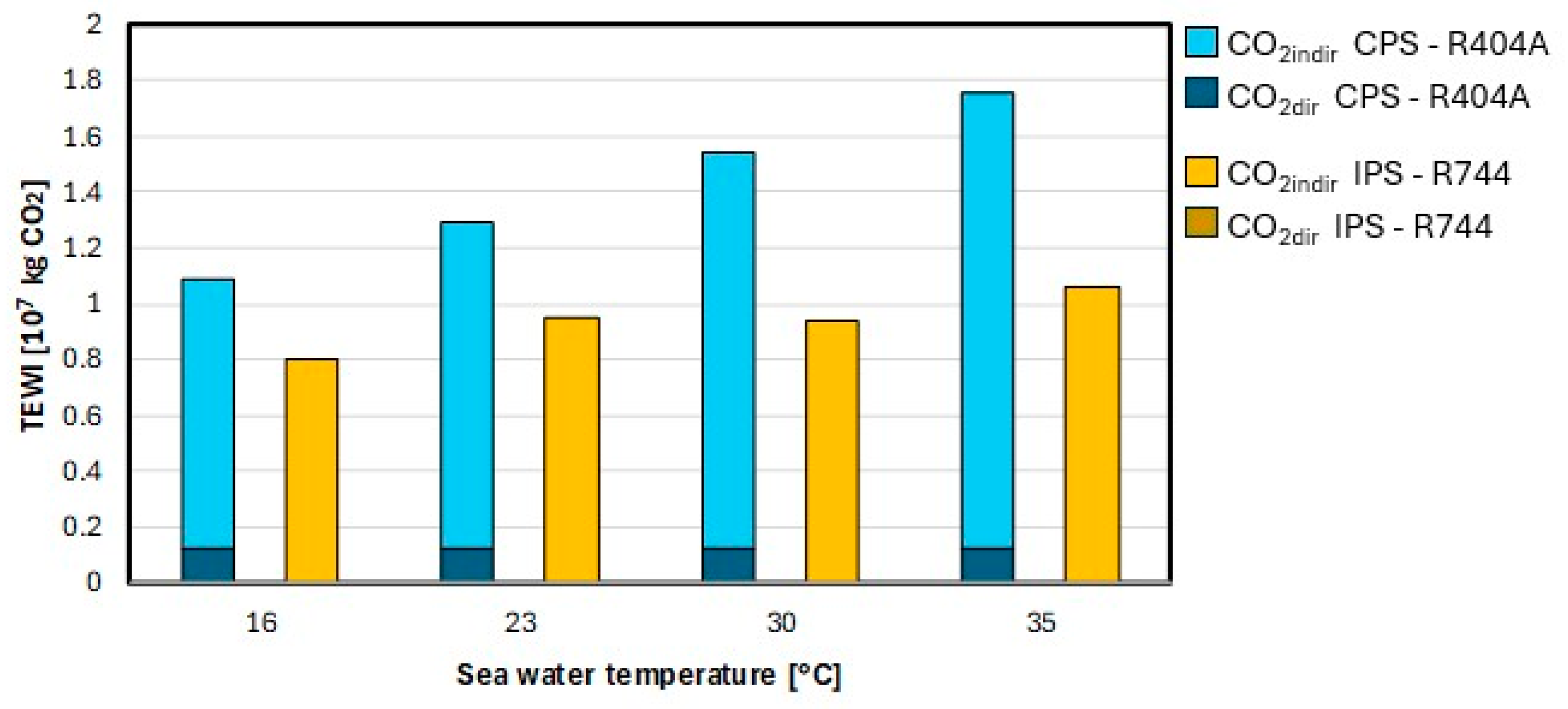

3.1. Provision Systems

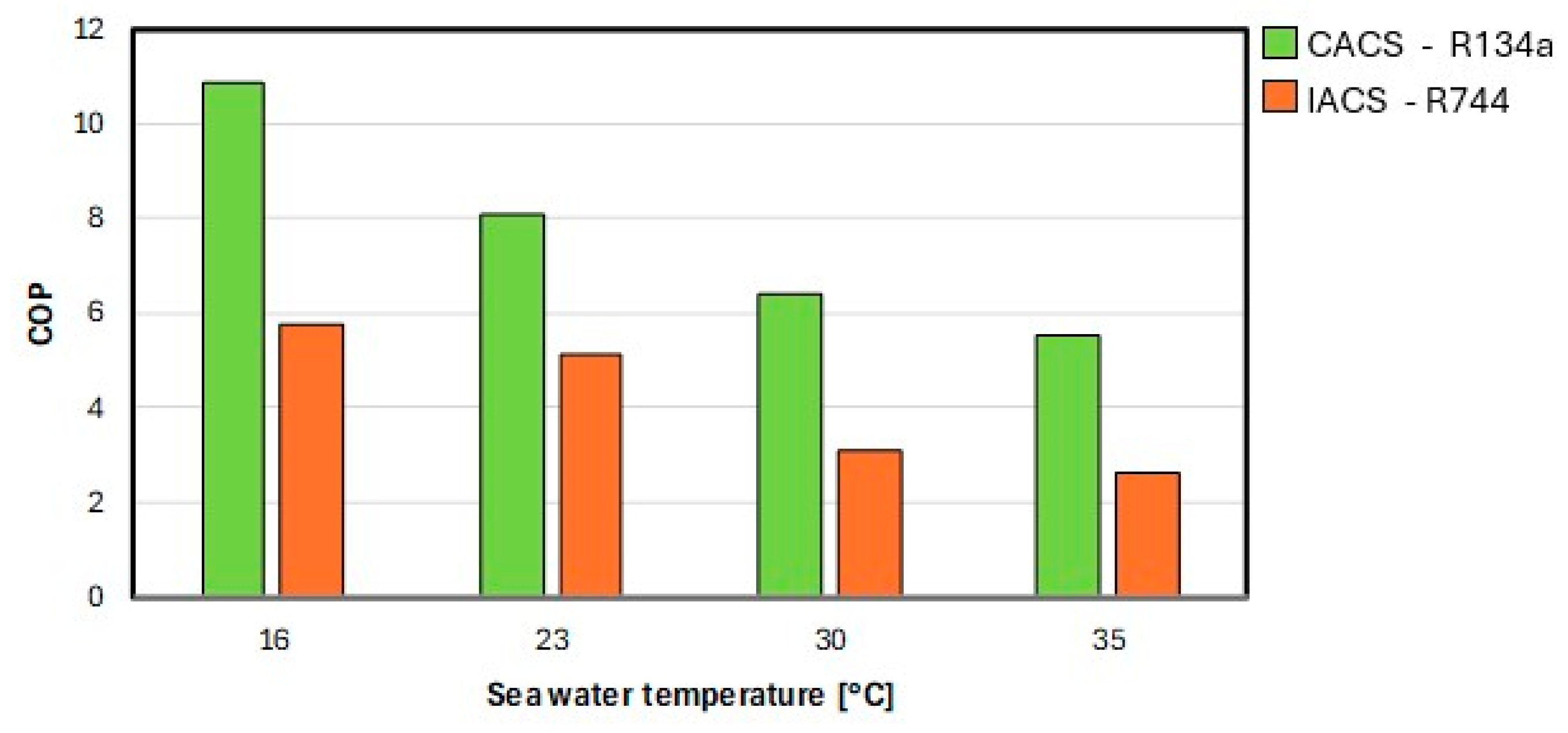

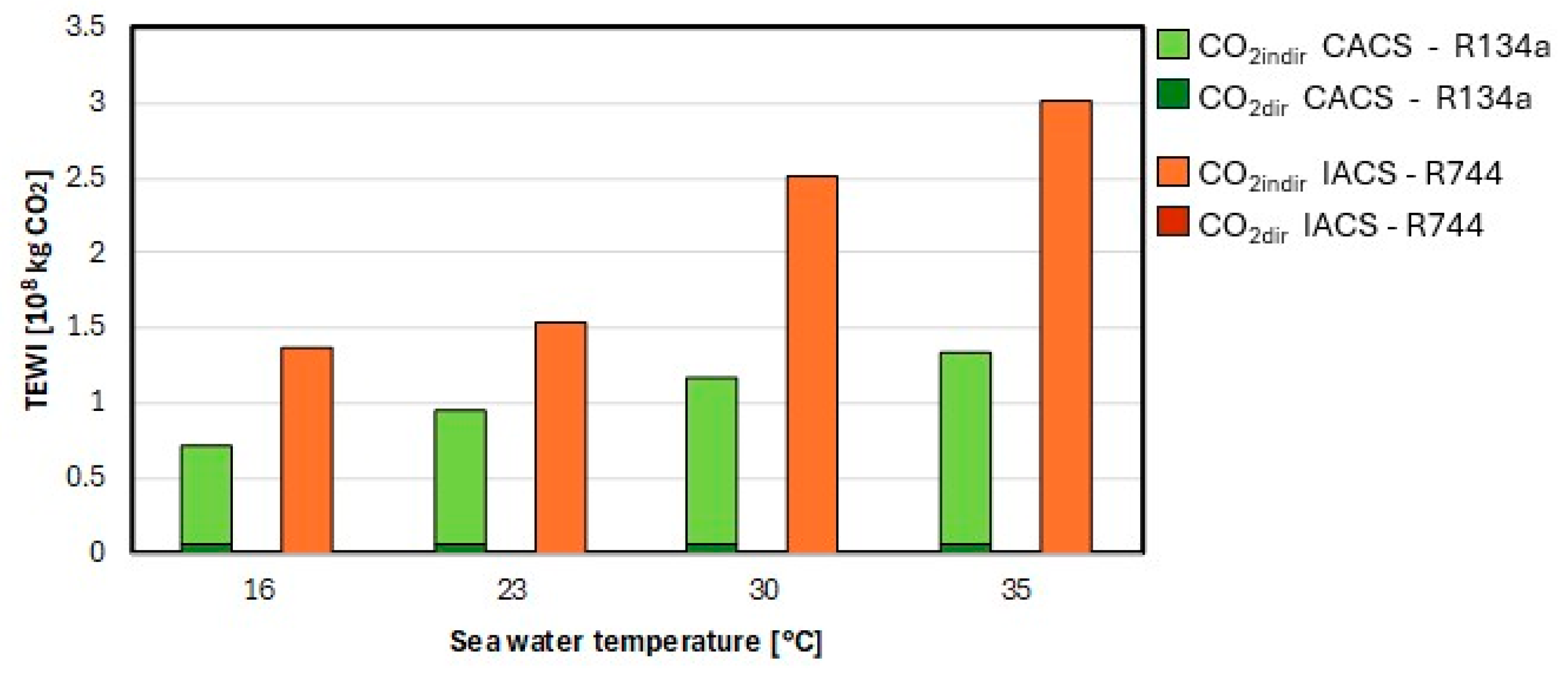

3.2. Air Conditioning Systems

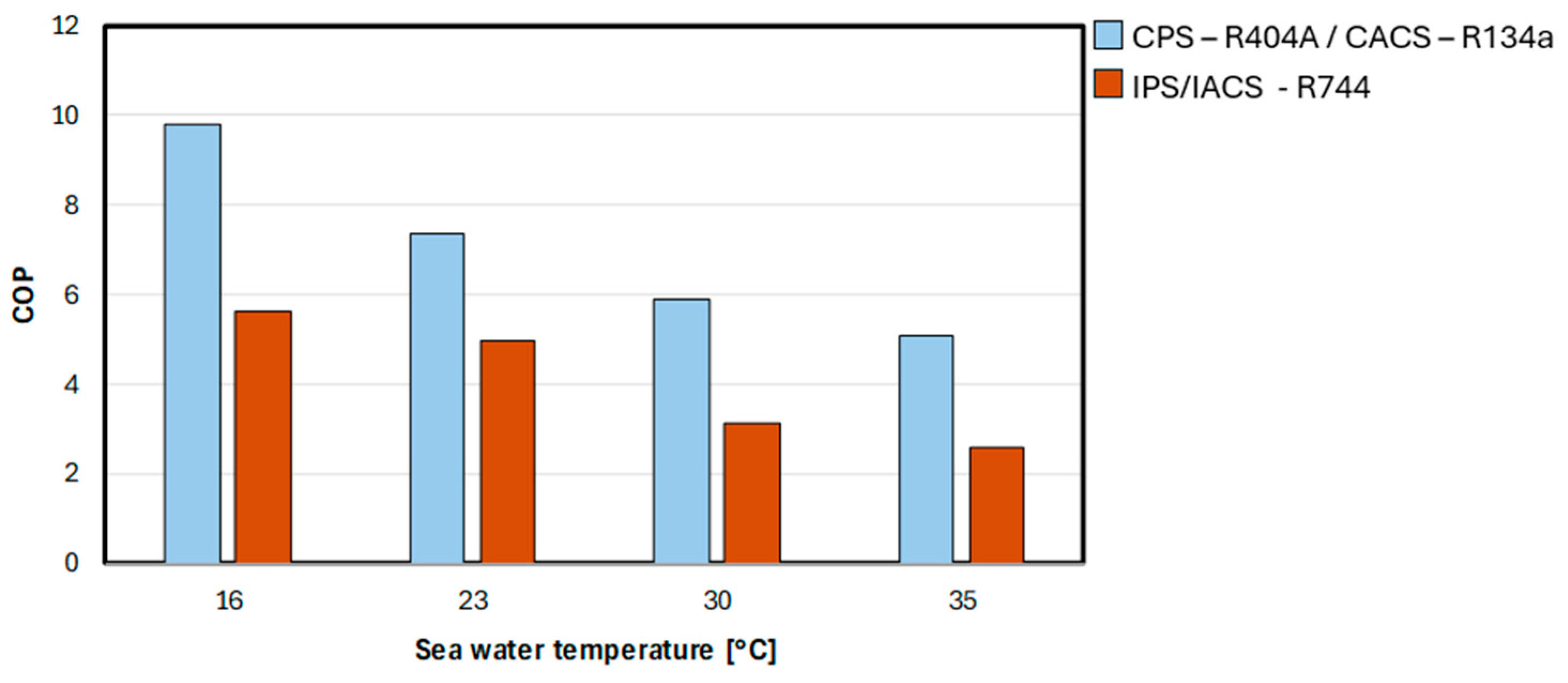

3.3. HVAC&R Systems

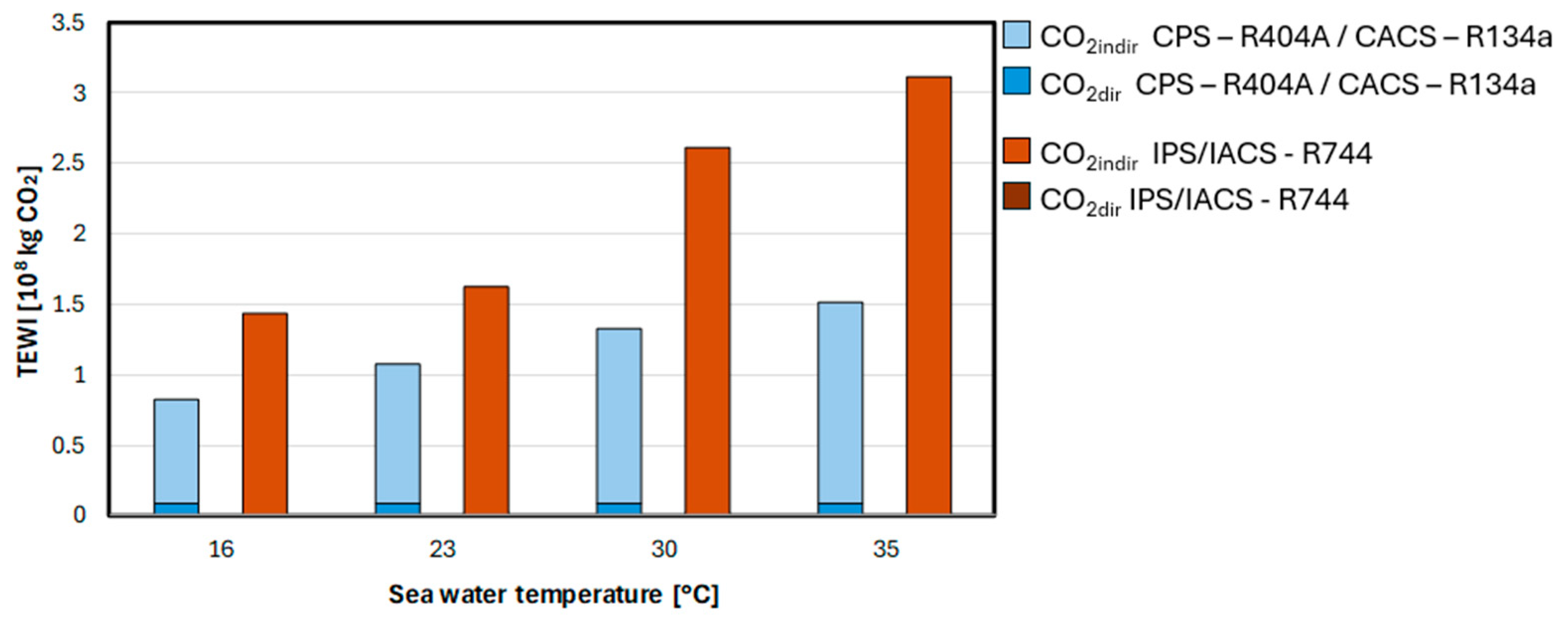

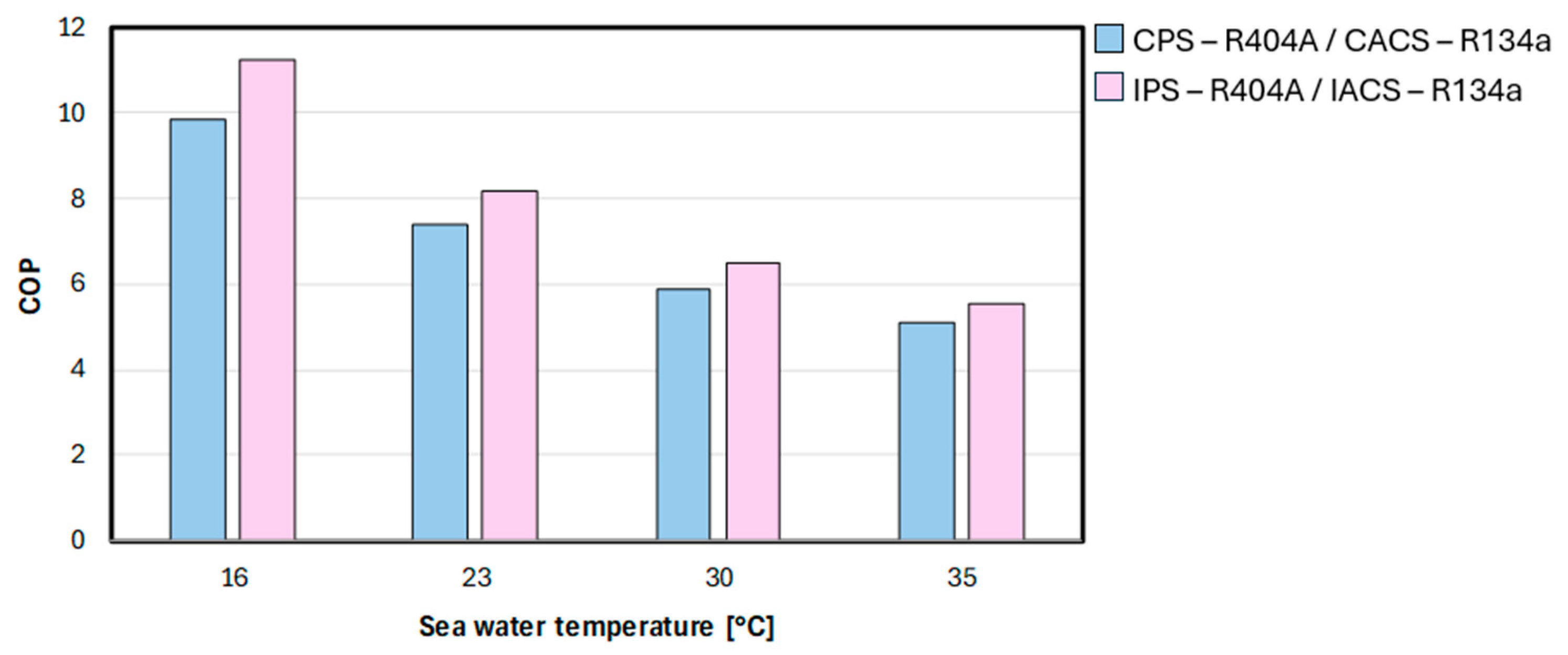

3.3.1. CPS/CACS with HFCs and IPS/IACS with R744

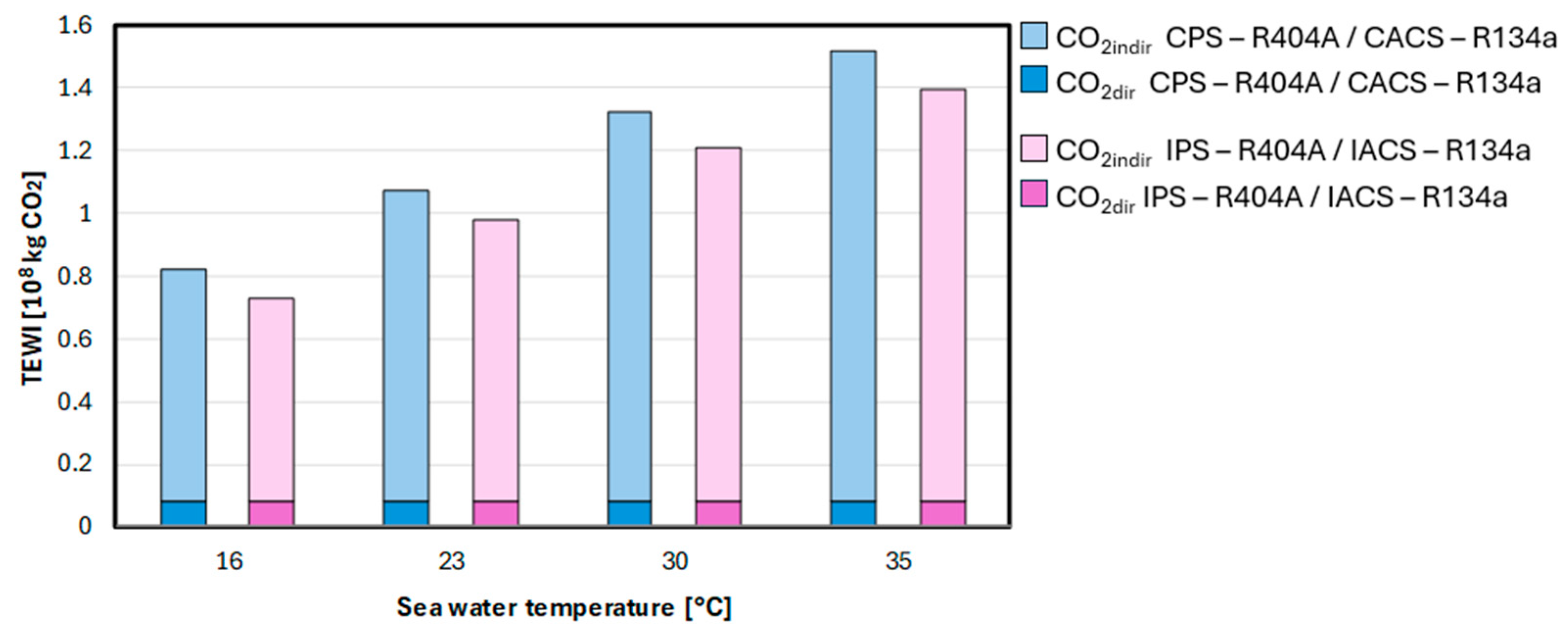

3.3.2. CPS/CACS with HFCs and IPS/IACS with HFCs

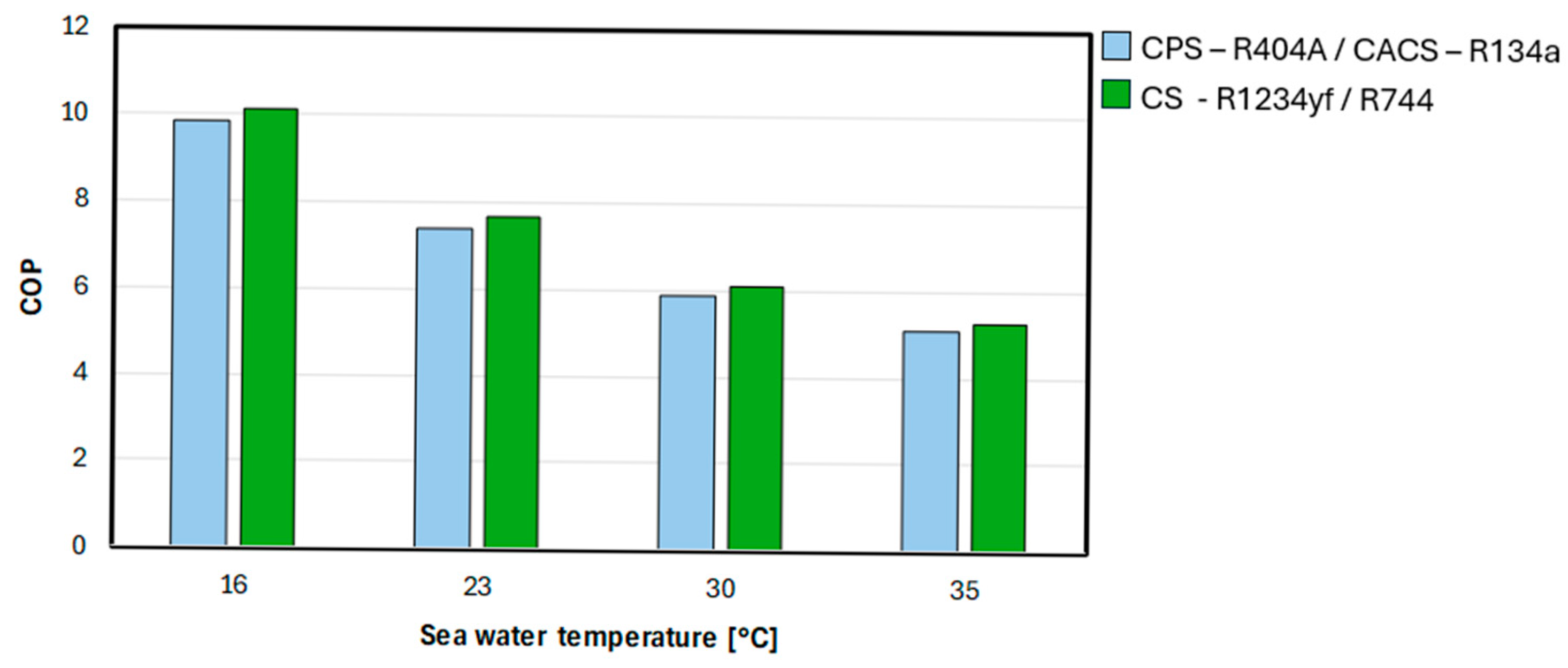

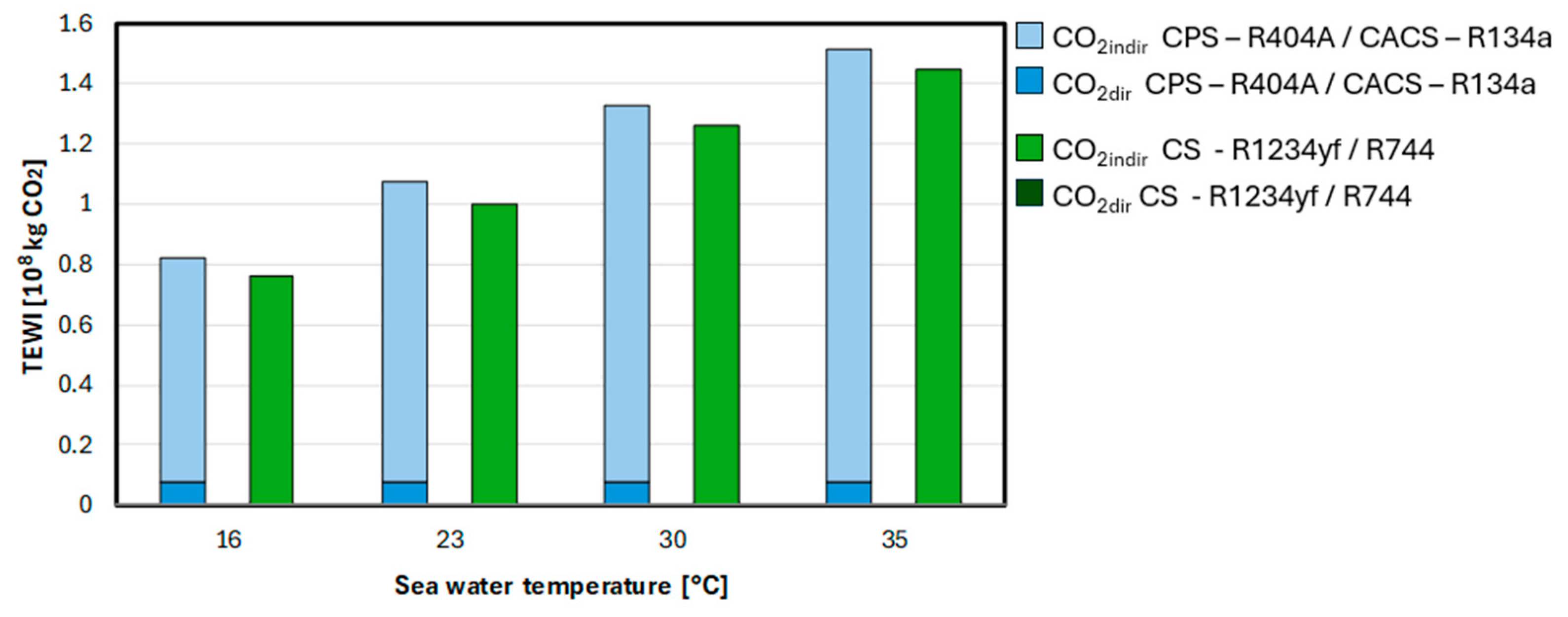

3.3.3. CPS/CACS with HFCs and CS with R1234yf-R744

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbols | |

| Cooling capacity [kW] | |

| T | Temperature [°C] |

| p | Pressure [bar] |

| h | Specific enthalpy [kJ kg−1] |

| Q | Quality |

| Mass flow rate [kJ s−1] | |

| rc | Compression ratio |

| ηis | Compression isentropic efficiency |

| ε | Internal heat exchanger efficiency |

| Ф | Entrainment ratio |

| ηej | Ejector efficiency |

| ηem | Electric motor efficiency |

| CO2,dir | Direct contribution to global warming [kgCO2] |

| CO2,indir | Indirect contribution to global warming [kgCO2] |

| COP | Coefficient of performance |

| GHG | Greenhouse gas |

| GWP | Global warming potential [kgCO2∙kgrefrigerant−1] |

| H | Annual operating hours [h∙years−1] |

| PL | Accidental refrigerant leaks per year [% refrigerant∙years−1] |

| PR | Recycling rate [% refrigerant charge] |

| RC | Refrigerant charge [kg] |

| TEWI | Total equivalent warming impact [kgCO2] |

| V | Plant useful life [years] |

| α | CO2 emissions from power conversion [kgCO2∙kWhe−1] |

| Abbreviations | |

| C | Compressor |

| CO | Condenser |

| GC | Gas cooler |

| EV | Evaporator |

| ExV | Expansion valve |

| IHX | Internal heat exchanger |

| PS | Phase separator |

| EJ | Ejector |

| P | Pump |

| AHU | Air handling unit |

| Subscripts | |

| c | Cooling |

| f | Freezing |

| ac | Air conditioning |

| l | Liquid |

| v | Vapour |

References

- Saeed, M.Z.; Hafner, A.; GabrielII, C.; Tolstorebrov, I.; Widell, K. CO2 Refrigeration System Design and Optimization for LNG Driven Cruise Ships. In Proceedings of the 9th Conference on Ammonia and CO2 Refrigeration Technologies, Ohrid, North Macedonia, 16–17 September 2021. [Google Scholar]

- International Chamber of Shipping; World Shipping Council. MEPC 76/7/29 Reduction of GHG Emissions from Ships: Refrigerated Container Cargoes; International Maritime Organization: London, UK, 2021. [Google Scholar]

- Ruiz, V. Analysis of Existing Refrigeration Plants Onboard Fishing Vessels and Improvement Possibilities. In Proceedings of the Second International Symposium on Fishing Vessel Energy Efficiency E-Fishing, Vigo, Spain, 22–24 May 2012. [Google Scholar]

- Carrasco, P.; Bendaña, R.; Paredes, A.; Michinel, H.; Fernández de Córdoba, P.; Arce, M.E.; Zaragoza, S. Analysis of Key Variables for Energy Efficiency in Warships. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2020, 234, 234. [Google Scholar] [CrossRef]

- Jasper, F.; Shinichi, H.; Shuang, Z.; Paula, P. Fourth IMO GHG Study 2020 Full Report; International Maritime Organization: London, UK, 2021. [Google Scholar]

- Mallouppas, G.; Yfantis, E.A. Decarbonization in Shipping Industry: A Review of Research, Technology Development, and Innovation Proposals. J. Mar. Sci. Eng. 2021, 9, 415. [Google Scholar] [CrossRef]

- Winfried Schwarz, B.; Rhiemeier, J.-M. The Analysis of the Emissions of Fluorinated Greenhouse Gases from Refrigeration and Air Conditioning Equipment Used in the Transport Sector Other than Road Transport and Options for Reducing These Emissions Maritime, Rail, and Aircraft Sector Prepared for the European Commission (DG Environment); European Commission: Brussels, Belgium, 2007. [Google Scholar]

- Heath, E.A. Amendment to the Montreal Protocol on Substances That Deplete the Ozone Layer (Kigali Amendment). Int. Leg. Mater. 2017, 56, 56. [Google Scholar] [CrossRef]

- Regulation (EU) 2024/573 of the European Parliament and of the Council; Official Journal of the European Union: Luxembourg, 2024.

- Glavan, I.; Poljak, I.; Mustać, M.; Lonić, I. Natural Refrigerant on Board Marine Vessels. Pomor. Zb. 2022, 62, 62. [Google Scholar] [CrossRef]

- Minetto, S.; Fabris, F.; Marinetti, S.; Rossetti, A. A Review on Present and Forthcoming Opportunities with Natural Working Fluids in Transport Refrigeration. Int. J. Refrig. 2023, 152, 152. [Google Scholar] [CrossRef]

- Hafner, I.A.; Gabrielii, C.H.; Widell, K. Refrigeration Units in Marine Vessels; TemaNord; Nordic Council of Ministers: Copenhagen, Denmark, 2019; ISBN 9789289359412. [Google Scholar]

- ASHRAE Standard 34; Designation and Safety Classification of Refrigerants. ASHRAE: Peachtree Corners, GA, USA, 2019.

- Kim, M.H.; Pettersen, J.; Bullard, C.W. Fundamental Process and System Design Issues in CO2 Vapor Compression Systems. Prog. Energy Combust. Sci. 2004, 30, 30. [Google Scholar] [CrossRef]

- Bansal, P. A Review—Status of CO2 as a Low Temperature Refrigerant: Fundamentals and R&D Opportunities. Appl. Therm. Eng. 2012, 41, 41. [Google Scholar]

- Rhiemeir, J.-M.; Harnisch, J.; Ters, C. Comparative Assessment of the Climate Relevance of Supermarket Refrigeration Systems and Equipment Climate Change; Federal Environment Agency: Dessau-Roßlau, Germany, 2009; ISSN 1862-4359. [Google Scholar]

- Aprea, C.; Maiorino, A. An Experimental Evaluation of the Transcritical CO2 Refrigerator Performances Using an Internal Heat Exchanger. Int. J. Refrig. 2008, 31, 31. [Google Scholar] [CrossRef]

- Sánchez, D.; Patiño, J.; Llopis, R.; Cabello, R.; Torrella, E.; Fuentes, F.V. New Positions for an Internal Heat Exchanger in a CO2 Supercritical Refrigeration Plant. Experimental Analysis and Energetic Evaluation. Appl. Therm. Eng. 2014, 63, 63. [Google Scholar] [CrossRef]

- Liu, S.; Wang, J.; Dai, B.; Yang, X.; Nian, V.; Li, H.; Yuan, J. Alternative Positions of Internal Heat Exchanger for CO2 Booster Refrigeration System: Thermodynamic Analysis and Annual Thermal Performance Evaluation. Int. J. Refrig. 2021, 131, 131. [Google Scholar] [CrossRef]

- Llopis, R.; Nebot-Andrés, L.; Sánchez, D.; Catalán-Gil, J.; Cabello, R. Subcooling Methods for CO2 Refrigeration Cycles: A Review. Int. J. Refrig. 2018, 93, 93. [Google Scholar] [CrossRef]

- Nebot-Andrés, L.; Calleja-Anta, D.; Sánchez, D.; Cabello, R.; Llopis, R. Experimental Assessment of Dedicated and Integrated Mechanical Subcooling Systems vs Parallel Compression in Transcritical CO2 Refrigeration Plants. Energy Convers. Manag. 2022, 252, 252. [Google Scholar] [CrossRef]

- Fangtian, S.; Yitai, M. Thermodynamic Analysis of Transcritical CO2 Refrigeration Cycle with an Ejector. Appl. Therm. Eng. 2011, 31, 31. [Google Scholar] [CrossRef]

- Elbarghthi, A.F.A.; Hafner, A.; Banasiak, K.; Dvorak, V. An Experimental Study of an Ejector-Boosted Transcritical R744 Refrigeration System Including an Exergy Analysis. Energy Convers. Manag. 2021, 238, 238. [Google Scholar] [CrossRef]

- Chesi, A.; Esposito, F.; Ferrara, G.; Ferrari, L. Experimental Analysis of R744 Parallel Compression Cycle. Appl. Energy 2014, 135, 135. [Google Scholar] [CrossRef]

- Gullo, P.; Elmegaard, B.; Cortella, G. Advanced Exergy Analysis of a R744 Booster Refrigeration System with Parallel Compression. Energy 2016, 107, 107. [Google Scholar] [CrossRef]

- Pigani, L.; Boscolo, M.; Pagan, N. Marine Refrigeration Plants for Passenger Ships: Low-GWP Refrigerants and Strategies to Reduce Environmental Impact. Int. J. Refrig. 2016, 64, 64. [Google Scholar] [CrossRef]

- Syngounas, E.; Tsimpoukis, D.; Bellos, E.; Koukou, M.K.; Tzivanidis, C.; Vrachopoulos, M.G. Energy and Exergy Performance Investigation of a Transcritical CO2 Vapor Ejector-Based Refrigeration System for Marine Provision Plants. Appl. Therm. Eng. 2025, 269, 269. [Google Scholar] [CrossRef]

- Andersen, H.; Saeed, M.Z.; Hafner, A.; Gabriellii, C.H. Investigation of CO2 Refrigeration System and Thermal Energy Storage for Passenger Ships. In Proceedings of the 10th Conference on Ammonia and CO2 Refrigeration Technologies, Ohrid, North Macedonia, 27–29 April 2023. [Google Scholar]

- Available online: https://weatherspark.com (accessed on 3 July 2024).

- World Sea Temperatures. Available online: https://www.seatemperature.org/ (accessed on 3 July 2024).

- Lemmon, E.W.; Bell, I.H.; Huber, M.L.; McLinden, M.O. NIST Standard Reference Database 23, version 10.0; Reference Fluid Thermodynamic and Transport Properties-REFPROP; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2018. [Google Scholar]

- Aprea, C.; Greco, A.; Maiorino, A. An Experimental Evaluation of the Greenhouse Effect in the Substitution of R134a with CO2. Energy 2012, 45, 45. [Google Scholar] [CrossRef]

- Gullo, P.; Cortella, G. Theoretical Evaluation of Supermarket Refrigeration Systems Using R1234ze(E) as an Alternative to High-Global Warming Potential Refrigerants. Sci. Technol. Built Environ. 2016, 22, 22. [Google Scholar] [CrossRef]

- Hansen, T.M.; Haukås, H.T. Alternatives to HCFC as Refrigerant in Shipping Vessels; Nordic Council of Ministers: Copenhagen, Denmark, 2000. [Google Scholar]

- Wajs, J.; Mrozek, M.; Fornalik-Wajs, E. Combined Cold Supply System for Ship Application Based on Low GWP Refrigerants—Thermo-Economic and Ecological Analyses. Energy Convers. Manag. 2022, 258, 258. [Google Scholar] [CrossRef]

- Shestopalov, K.; Khliyeva, O.; Ierin, V.; Konstantinov, O.; Khliiev, N.; Neng, G.; Kozminykh, M. Novel Marine Ejector-Compression Waste Heat-Driven Refrigeration System: Technical Possibilities and Environmental Advantages. Int. J. Refrig. 2024, 158, 158. [Google Scholar] [CrossRef]

- Abdan, S.; Stosic, N.; Kovacevic, A.; Smith, I.; Deore, P. Identification and Analysis of Screw Compressor Mechanical Losses. In IOP Conference Series: Materials Science and Engineering; Institute of Physics Publishing: Bristol, UK, 2018; Volume 425. [Google Scholar]

- Zhang, Y.; Cai, M.; Kong, D. Overall Energy Efficiency of Lubricant-Injected Rotary Screw Compressors and Aftercoolers. In Proceedings of the 2009 Asia-Pacific Power and Energy Engineering Conference, Wuhan, China, 28–30 March 2009; pp. 1–5. [Google Scholar]

- Carrier AquaEdgeTM. Available online: https://www.carrier.com/marine-offshore/en/worldwide/products/chillers/water-cooled-chillers/19xr-xrv-two-stage/ (accessed on 30 June 2024).

- Tanninen, T. Passenger Ship Refrigeration—Dimensioning and Energy Saving Options. Master’s Thesis, Lappeenranta-Lahti University of Technology (LUT), Lappeenranta, Finland, 2020. [Google Scholar]

- Yang, C.; Liu, Z.; Liu, Y.; Wang, H.; Wang, Y.; Hu, D.; Wang, B.; Yang, J.; Chen, Y. Influence of Diffuser Vane Thickness on Centrifugal Compressor Performance. J. Phys. Conf. Ser. 2022, 2437, 2437. [Google Scholar] [CrossRef]

- Benini, E. Optimal Navier-Stokes Design of Compressor Impellers Using Evolutionary Computation. Int. J. Comut Fluid. Dyn. 2003, 17, 17. [Google Scholar] [CrossRef]

- Astolfi, S.P.M.; Gaetani, P. Politecnico Di Milano Design and Off-Design Analysis of a Multistage Centrifugal Compressor for an A-CAES Plant Co-Supervisor. Available online: https://www.politesi.polimi.it/retrieve/e463ca4a-b219-4b1e-a380-2e4f00a87595/Design%20and%20Off-Design%20Analysis%20of%20a%20Multistage%20Centrifugal%20Compressor%20for%20an%20A-CAES%20Plant.pdf (accessed on 15 October 2025).

- Moore, J.C. Electric Motors for Centrifugal Compressor Drives; General Electric Co.: Schenectady, NY, USA, 1974. [Google Scholar] [CrossRef]

- Bodys, J.; Hafner, A.; Banasiak, K.; Smolka, J.; Ladam, Y. Design and Simulations of Refrigerated Sea Water Chillers with CO2 Ejector Pumps for Marine Applications in Hot Climates. Energy 2018, 161, 161. [Google Scholar] [CrossRef]

- Gullo, P.; Hafner, A.; Banasiak, K. Transcritical R744 Refrigeration Systems for Supermarket Applications: Current Status and Future Perspectives. Int. J. Refrig. 2018, 93, 93. [Google Scholar] [CrossRef]

- Singh, S.; Selvnes, H.; Pardiñas, Á.Á.; Reddy, S.K.; Gupta, P.; Vaishak, S.; Arun, B.S.; Widell, K.N.; Elarga, H.; Hafner, A. Advanced R744 Solution for Supermarkets, Hotel Chillers and Maritime Applications in India. In Proceedings of the 15th IIR-Gustav Lorentzen Conference on Natural Refrigerants, Trondheim, Norway, 13–15 June 2022. [Google Scholar] [CrossRef]

- Hafner, A.; Försterling, S.; Banasiak, K. Multi-Ejector Concept for R-744 Supermarket Refrigeration. Int. J. Refrig. 2014, 43, 43. [Google Scholar] [CrossRef]

- Gullo, P.; Tsamos, K.M.; Hafner, A.; Banasiak, K.; Ge, Y.T.; Tassou, S.A. Crossing CO2 Equator with the Aid of Multi-Ejector Concept: A Comprehensive Energy and Environmental Comparative Study. Energy 2018, 164, 164. [Google Scholar] [CrossRef]

- Gambini, M.; Manno, M.; Vellini, M. Energy and Exergy Analysis of Transcritical CO2 Cycles for Heat Pump Applications. Sustainability 2024, 16, 7511. [Google Scholar] [CrossRef]

- Elbel, S.; Lawrence, N. Review of Recent Developments in Advanced Ejector Technology. Int. J. Refrig. 2016, 62, 62. [Google Scholar] [CrossRef]

- Elbel, S. Historical and Present Developments of Ejector Refrigeration Systems with Emphasis on Transcritical Carbon Dioxide Air-Conditioning. Int. J. Refrig. 2011, 34, 34. [Google Scholar] [CrossRef]

- Chen, X.; Su, Y.; Omer, S.; Riffat, S. Theoretical Investigations on Combined Power and Ejector Cooling System Powered by Low-Grade Energy Source. Int. J. Low-Carbon Technol. 2016, 11, 11. [Google Scholar] [CrossRef]

- Saeed, M.Z.; Widell, K.N.; Hafner, A.; Nordtvedt, T.S.; Svendsen, E.S. Integrated Thermal Storage and Heat Recovery of the CO2 Refrigeration System for Fishing Vessels. In Proceedings of the 14th IIR-Gustav Lorentzen Conference on Natural Refrigerants Refrigeration Science and Technology, Kyoto, Japan, 7–9 December 2020; International Institute of Refrigeration: Paris, France, 2020; Volume 2020, pp. 549–554. [Google Scholar]

- Fornasier, E.; Zilio, C.; Cecchinato, L.; Corradi, M.; Minetto, S. Natural Refrigerant CO2; Reulens, W., Ed.; International Institute of Refrigeration: Paris, France, 2009; ISBN ISBN9789081346733. [Google Scholar]

- Ribas, F.A.; Deschamps, C.J.; Fagotti, F.; Morriesen, A.; Dutra, T. Thermal Analysis of Reciprocating Compressors—A Critical Review. In Proceedings of the International Compressor Engineering Conference, West Lafayette, IN, USA, 14–17 July 2008. [Google Scholar]

- Andersen, H. Development of CO2 Refrigeration Systems and Thermal Energy Storage for Cruise Ships. Master’s Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2022. [Google Scholar]

- Shi, B.; Chen, M.; Chi, W.; Yang, Q.; Liu, G.; Zhao, Y.; Li, L. Effects of Internal Heat Exchanger on Two-Stage Compression Trans-Critical CO2 Refrigeration Cycle Combined with Expander and Intercooling. Energies 2022, 16, 115. [Google Scholar] [CrossRef]

- Elbarghthi, A.F.A.; Dvořák, V. Evaluation of Various Ejector Profiles on CO2 Transcritical Refrigeration System Performance. Entropy 2022, 24, 1173. [Google Scholar] [CrossRef]

- Yang, D.; Li, Y.; Xie, J.; Wang, J. Energetic and Entropy Analysis of a Novel Transcritical CO2 Two-Stage Compression/Ejector Refrigeration Cycle for Shipboard Cold Chamber. Therm. Sci. 2023, 27, 27. [Google Scholar] [CrossRef]

- Nekså, P.; Walnum, H.T.; Hafner, A. CO2—A Refrigerant from the Past with Prospects of Being One of the Main in the Future. In Proceedings of the 2010 9th IIR Gustav Lorentzen Conference 2010—Natural—Real Alternatives, Sydney, Australia, 12–14 April 2010. [Google Scholar]

- Javerschek, O.; Dittrich, G. Advanced Compressor Design and Various Systems for Commercial Applications with CO2. In Refrigeration Science and Technology Proceedings; C. A. Inc., Ed.; 2009; pp. 302–309. Available online: https://archive.r744.com/files/pdf_759.pdf (accessed on 24 November 2025).

- Nekså, P.; Hafner, A.; Bredsen, A.M.; Eikevik, T.M. CO2 as Working Fluid—Technological Development on the Road to Sustainable Refrigeration. In Proceedings of the 12th IIR Gustav Lorentzen Natural Working Fluids Conference, Edinburgh, UK, 21– 24 August 2016; pp. 21–24. [Google Scholar]

- Yu, A.; Su, W.; Lin, X.; Zhou, N.; Zhao, L. Thermodynamic Analysis on the Combination of Supercritical Carbon Dioxide Power Cycle and Transcritical Carbon Dioxide Refrigeration Cycle for the Waste Heat Recovery of Shipboard. Energy Convers. Manag. 2020, 221, 221. [Google Scholar] [CrossRef]

- Zhang, Q.; Luo, Z.; Zhao, Y.; Pavel, S. Thermodynamic Analysis and Multi-Objective Optimization of a Transcritical CO2 Waste Heat Recovery System for Cruise Ship Application. Energy Convers. Manag. 2021, 227, 227. [Google Scholar] [CrossRef]

- Zhang, F.; Zhou, J.; Liao, G.; You, M.; Yang, C. Improvement Design and Performance Assessment of Combined Cooling and Power System Using CO2 for Waste Heat Recovery. Appl. Therm. Eng. 2023, 228, 228. [Google Scholar] [CrossRef]

- Liang, Y.; Sun, Z.; Dong, M.; Lu, J.; Yu, Z. Investigation of a Refrigeration System Based on Combined Supercritical CO2 Power and Transcritical CO2 Refrigeration Cycles by Waste Heat Recovery of Engine. Int. J. Refrig. 2020, 118, 118. [Google Scholar] [CrossRef]

- Hou, S.; Zhang, F.; Yu, L.; Cao, S.; Zhou, Y.; Wu, Y.; Hou, L. Optimization of a Combined Cooling, Heating and Power System Using CO2 as Main Working Fluid Driven by Gas Turbine Waste Heat. Energy Convers. Manag. 2018, 178, 178. [Google Scholar] [CrossRef]

- Stoecker, W.F. Industrial Refrigeration Handbook; McGraw-Hill: New York, NY, USA, 1998; Volume 10. [Google Scholar]

- Suess, J.; Kruse, H. Efficiency of the Indicated Process of CO2 -Compressors. Int. J. Refrig. 1998, 21, 21. [Google Scholar]

- Giampaolo, T. Compressor Handbook: Principles and Practice; River Publishers: Gistrup, Denmark, 2010. [Google Scholar]

- Bellos, E.; Tzivanidis, C. A Theoretical Comparative Study of CO2 Cascade Refrigeration Systems. Appl. Sci. 2019, 9, 790. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

D’Onofrio, M.; Petruzziello, F.; Grilletto, A.; Aprea, C.; Maiorino, A. Exploring the Potential of R744 as a Sustainable Refrigerant for Marine Applications: A Comparative Performance Analysis with Current Refrigeration Framework. Energies 2025, 18, 6211. https://doi.org/10.3390/en18236211

D’Onofrio M, Petruzziello F, Grilletto A, Aprea C, Maiorino A. Exploring the Potential of R744 as a Sustainable Refrigerant for Marine Applications: A Comparative Performance Analysis with Current Refrigeration Framework. Energies. 2025; 18(23):6211. https://doi.org/10.3390/en18236211

Chicago/Turabian StyleD’Onofrio, Martina, Fabio Petruzziello, Arcangelo Grilletto, Ciro Aprea, and Angelo Maiorino. 2025. "Exploring the Potential of R744 as a Sustainable Refrigerant for Marine Applications: A Comparative Performance Analysis with Current Refrigeration Framework" Energies 18, no. 23: 6211. https://doi.org/10.3390/en18236211

APA StyleD’Onofrio, M., Petruzziello, F., Grilletto, A., Aprea, C., & Maiorino, A. (2025). Exploring the Potential of R744 as a Sustainable Refrigerant for Marine Applications: A Comparative Performance Analysis with Current Refrigeration Framework. Energies, 18(23), 6211. https://doi.org/10.3390/en18236211