Fault Diagnosis in Electric Generators: Methods, Trends and Challenges

Abstract

1. Introduction

2. Classification of Faults in Electric Generators

2.1. Electric Generator Classification

2.2. Basic Types of Faults in Electric Generators

2.3. Main Factors Leading to Electric Generator Faults

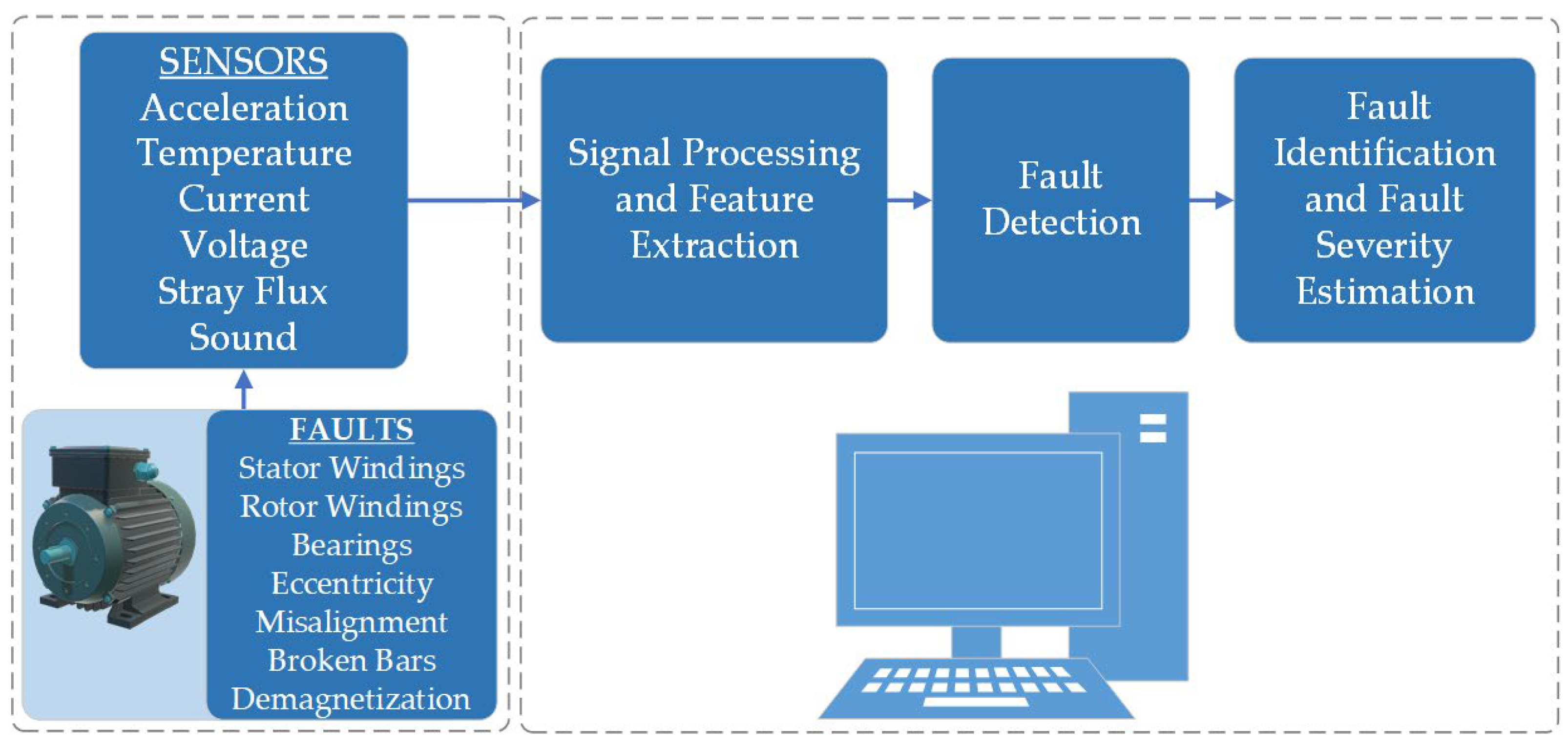

3. Fault Analysis and Diagnostic Methods

3.1. Stator Winding Faults

3.2. Rotor Winding Faults

3.3. Bearing Faults

3.4. Eccentricity Faults

3.5. Misalignment Faults

3.6. Broken Damper Bar Faults

3.7. Demagnetization Faults

4. Condition-Monitoring Methods

4.1. Vibration Monitoring

4.2. Current/Voltage Monitoring

4.3. Magnetic Flux Monitoring

4.4. Temperature Monitoring

5. Signal Processing Methods

5.1. Frequency-Domain Analysis

5.2. Time–Frequency-Domain Analysis

5.3. Comparison of Methods

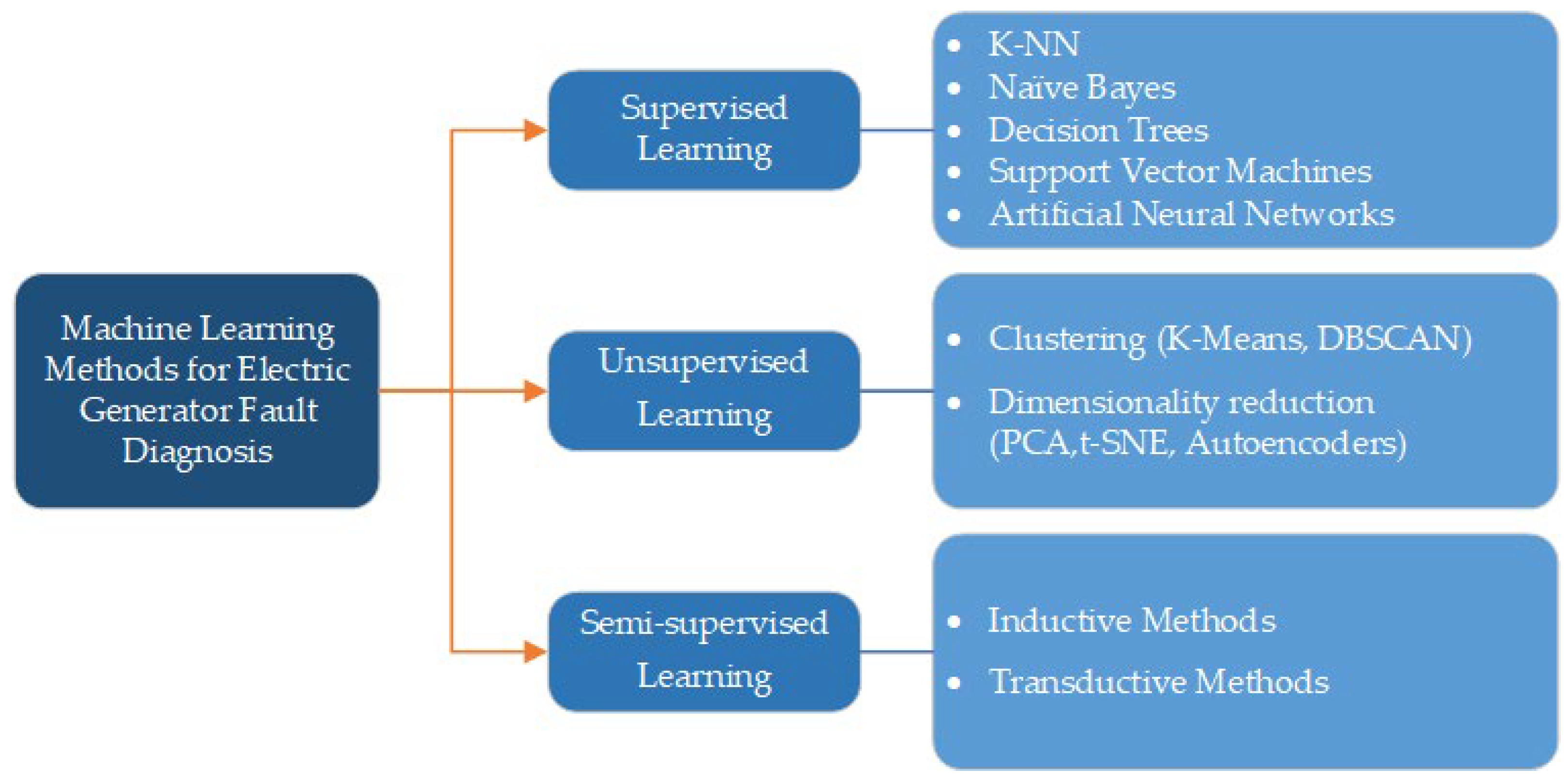

6. Machine Learning Methods

6.1. Supervised Learning

6.2. Unsupervised Learning

6.3. Semi-Supervised Learning

6.4. Deep Learning

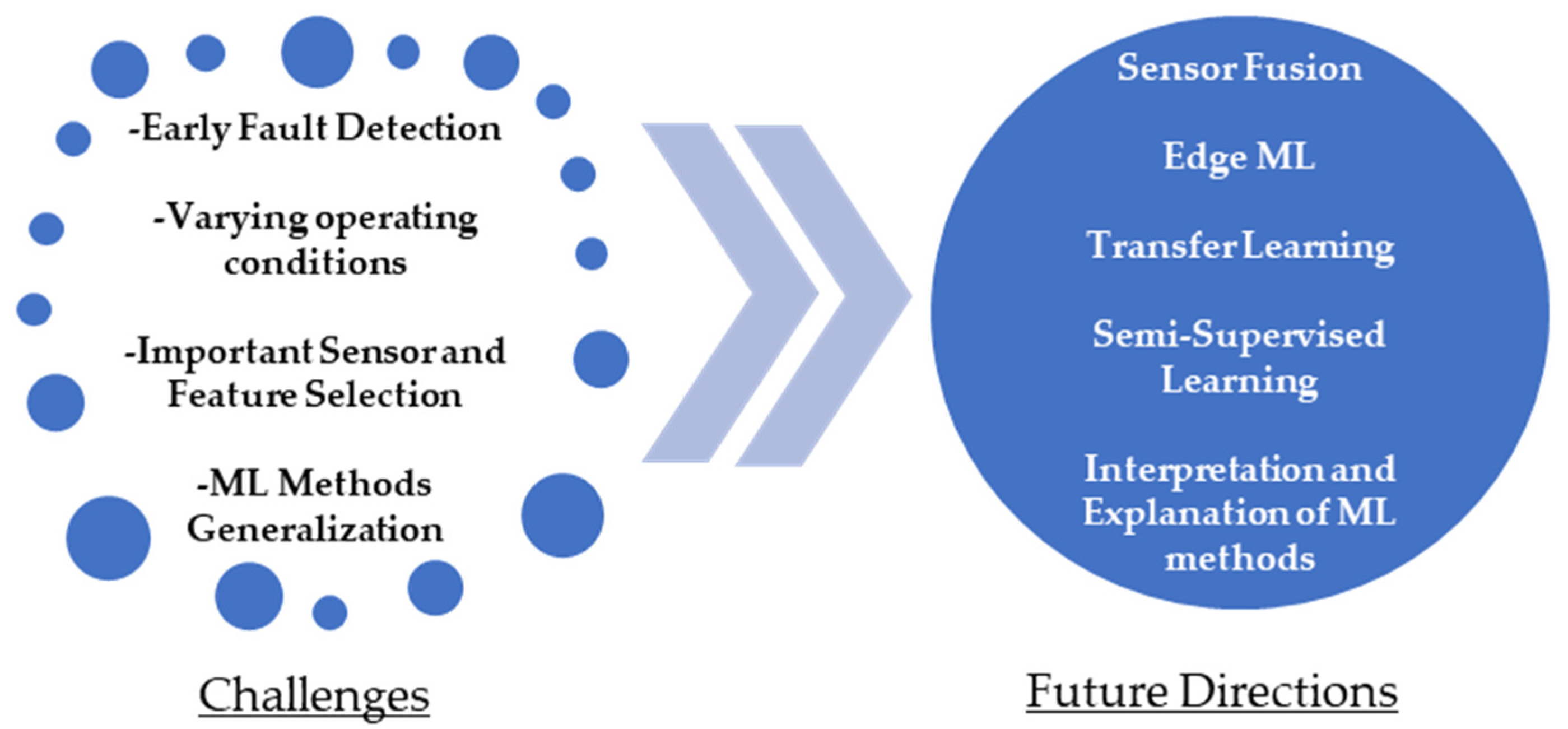

7. Remarks, Limitations, and Future Perspectives

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ML | Machine Learning |

| IoT | Internet of Things |

| AC | Alternating Current |

| DC | Direct Current |

| SGs | Synchronous Generators |

| MMF | Magneto-Motive Force |

| DFIGs | Doubly Fed Induction Generators |

| SCIGs | Squirrel Cage Induction Generators |

| WRIGs | Wound Rotor Induction Generators |

| PMSGs | Permanent Magnet Synchronous Generators |

| WFSGs | Wound Field Synchronous Generators |

| SC | Short Circuit |

| TTF | Turn-To-Turn Fault |

| WT | Wind Turbines |

| PD | Partial Discharge |

| ITSC | Interturn Short Circuit |

| SMF | Stray Magnetic Field |

| FFT | Fast Fourier Transform |

| WTGs | Wind Turbine Generators |

| SE | Static Eccentricity |

| DE | Dynamic Eccentricity |

| ME | Mixed Eccentricity |

| FEM | Finite Element Method |

| MEC | Magnetic Equivalent Circuit |

| MWFA | Modified Winding Function Approach |

| RTDs | Resistance Temperature Detectors |

| HHT | Hilbert–Huang Transform |

| PM | Permanent Magnet |

| MCSA | Motor Current Signature Analysis |

| CSA | Current Signature Analysis |

| EPVA | Extended Park’s Vector Approach |

| PVA | Park’s Vector Approach |

| ZSV | Zero-Sequence Voltage |

| PT | Potential Transformer |

| PSD | Power Spectral Density |

| ZFFT | Zoom Fast Fourier Transform |

| MUSIC | Multiple Signal Classification |

| MLE | Maximum Likelihood Estimation |

| SDFT | Sliding Discrete Fourier Transform |

| TF | Time–Frequency |

| STFT | Short-Time Fourier Transform |

| CWT | Continuous Wavelet Transform |

| DWT | Discrete Wavelet Transform |

| WPT | Wavelet Packet Transform |

| EWT | Empirical Wavelet Transform |

| RMS | Root Mean Square |

| EMD | Empirical Mode Decomposition |

| IMFs | Intrinsic Mode Functions |

| EEMD | Ensemble Empirical Mode Decomposition |

| VMD | Variational Mode Decomposition |

| RCMDE | Refined Composite Multiscale Dispersion Entropy |

| WVD | Wigner–Ville Distribution |

| SNR | Signal-to-Noise Ratio |

| WoS | Web of Science |

| K-NN | K-Nearest Neighbors |

| SVM | Support Vector Machines |

| RF | Random Forest |

| PCA | Principal Component Analysis |

| HVAC | Heating, Ventilation, and Air Conditioning |

| ANNs | Artificial Neural Networks |

| FNNs | Feedforward Neural Networks |

| CNNs | Convolutional Neural Networks |

| RNNs | Recurrent Neural Networks |

| RBFNs | Radial Basis Function Networks |

| SCADA | Supervisory Control and Data Acquisition |

| DL | Deep Learning |

| t-SNE | t-Distributed Stochastic Neighbor Embedding |

| MAE | Mean Absolute Error |

| DBSCAN | Density-Based Spatial Clustering of Applications with Noise |

| iForest | Isolation Forest |

| GAN | Generative Adversarial Network |

| LSTM | Long Short-Term Memory |

| CWRU | Case Western Reserve University |

References

- Al Ameeri, T.A.; Rahman, M.N.A.; Muhamad, N. Analysing Effective and Ineffective Impacts of Maintenance Strategies on Electric Power Plants: A Comprehensive Approach. Energies 2023, 16, 6243. [Google Scholar] [CrossRef]

- Nowlan, F.S.; Heap, H.F. Reliability Centered Maintenance; Report AD-A066-579; United Airlines: Chicago, IL, USA, 1978. [Google Scholar]

- Quatrini, E.; Costantino, F.; Di Gravio, G.; Patriarca, R. Condition-Based Maintenance—An Extensive Literature Review. Machines 2020, 8, 31. [Google Scholar] [CrossRef]

- Stein, J.; Fick, H. The Torsional Stress Analyzer for Continuously Monitoring Turbine-Generators. IEEE Trans. Power Appar. Syst. 1980, PAS-99, 703–710. [Google Scholar] [CrossRef]

- Oliver, J.A. Electric Motor Predictive and Preventive Maintenance; Research Project 2814-35, Final Report; Nuclear Maintenance Applications Center/Nuclear Power Division: Charlotte, NC, USA, 1992. [Google Scholar]

- Perera, C.; Liu, C.H.; Jayawardena, S.; Chen, M. A Survey on Internet of Things from Industrial Market Perspective. IEEE Access 2014, 2, 1660–1679. [Google Scholar] [CrossRef]

- Mikołajewska, E.; Mikołajewski, D.; Mikołajczyk, T.; Paczkowski, T. Generative AI in AI-Based Digital Twins for Fault Diagnosis for Predictive Maintenance in Industry 4.0/5. Appl. Sci. 2025, 15, 3166. [Google Scholar] [CrossRef]

- Lei, L.; Li, W.; Zhang, S.; Wu, C.; Yu, H. Research Progress on Data-Driven Industrial Fault Diagnosis Methods. Sensors 2025, 25, 2952. [Google Scholar] [CrossRef] [PubMed]

- Zayed, S.M.; Attiya, G.; El-Sayed, A.; Sayed, A.; Hemdan, E.E.-D. An Efficient Fault Diagnosis Framework for Digital Twins Using Optimized Machine Learning Models in Smart Industrial Control Systems. Int. J. Comput. Intell. Syst. 2023, 16, 69. [Google Scholar] [CrossRef]

- Ehya, H.; Faiz, J. Electromagnetic Analysis and Condition Monitoring of Synchronous Generators; IEEE Press Series on Power and Energy Systems; John Wiley & Sons: Hoboken, NJ, USA, 2023. [Google Scholar]

- Swana, E.F.; Doorsamy, W. Investigation of Combined Electrical Modalities for Fault Diagnosis on a Wound-Rotor Induction Generator. IEEE Access 2019, 7, 32333–32342. [Google Scholar] [CrossRef]

- Mostafaei, M.; Faiz, J. An overview of various faults detection methods in synchronous generators. IET Electr. Power Appl. 2021, 15, 391–404. [Google Scholar] [CrossRef]

- Yang, B.; Li, F.; Ye, J.; Song, W. Condition Monitoring and Fault Diagnosis of Generators in Power Networks. In Proceedings of the 2019 IEEE Power & Energy Society General Meeting (PESGM), Atlanta, GA, USA, 4–8 August 2019. [Google Scholar] [CrossRef]

- Tang, M.; Zhao, Q.; Wu, H.; Wang, Z.; Meng, C.; Wang, Y. A Review of Recent Advances in Wind Turbine Condition Monitoring and Fault Diagnosis. Front. Energy Res. 2021, 9, 751066. [Google Scholar] [CrossRef]

- Lu, B.; Li, Y.; Wu, X.; Yang, Z. A review of recent advances in wind turbine condition monitoring and fault diagnosis. In Proceedings of the 2009 IEEE Power Electronics and Machines in Wind Applications, Lincoln, NE, USA, 24–26 June 2009. [Google Scholar] [CrossRef]

- Yazidi, A.; Henao, H.; Capolino, G.A.; Casadei, D.; Filippetti, F.; Rossi, C. Simulation of a doubly-fed induction machine for wind turbine generator fault analysis. In Proceedings of the 2005 5th IEEE International Symposium on Diagnostics for Electric Machines, Power Electronics and Drives, Vienna, Austria, 7–9 September 2005. [Google Scholar] [CrossRef]

- Shah, D.; Nandi, S.; Neti, P. Stator-Interturn-Fault Detection of Doubly Fed Induction Generators Using Rotor-Current and Search-Coil-Voltage Signature Analysis. IEEE Trans. Ind. Appl. 2009, 45, 1831–1842. [Google Scholar] [CrossRef]

- Gyftakis, K.N.; Platero, C.A.; Bernal, S. Off-Line Detection of Static Eccentricity in Salient-Pole Synchronous Machines. In Proceedings of the 2018 XIII International Conference on Electrical Machines (ICEM), Alexandroupoli, Greece, 3–6 September 2018; pp. 1919–1924. [Google Scholar] [CrossRef]

- Tian, P.; Platero, C.A.; Gyftakis, K.N. On-line Turn-to-Turn Protection Method of the Synchronous Machines Field Winding. In Proceedings of the 2019 IEEE 12th International Symposium on Diagnostics for Electrical Machines, Power Electronics and Drives (SDEMPED), Toulouse, France, 27–30 August 2019; pp. 69–74. [Google Scholar] [CrossRef]

- Akbar, S.; Vaimann, T.; Asad, B.; Kallaste, A.; Sardar, M.U.; Kudelina, K. State-of-the-Art Techniques for Fault Diagnosis in Electrical Machines: Advancements and Future Directions. Energies 2023, 16, 6345. [Google Scholar] [CrossRef]

- Peng, H.; Zhang, H.; Fan, Y.; Shangguan, L.; Yang, Y. A Review of Research on Wind Turbine Bearings’ Failure Analysis and Fault Diagnosis. Lubricants 2022, 11, 14. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, L. A review of failure modes, condition monitoring and fault diagnosis methods for large-scale wind turbine bearings. Measurement 2020, 149, 107002. [Google Scholar] [CrossRef]

- Nie, M.; Wang, L. Review of Condition Monitoring and Fault Diagnosis Technologies for Wind Turbine Gearbox. Procedia CIRP 2013, 11, 287–290. [Google Scholar] [CrossRef]

- Timken Bearing Damage Analysis with Lubrication Reference Guide; The Timken Company: North Canton, OH, USA, 2011.

- Bouzid, M.; Champenois, G.; Bellaaj, N.M.; Signac, L.; Jelassi, K. An Effective Neural Approach for the Automatic Location of Stator Interturn Faults in Induction Motor. IEEE Trans. Ind. Electron. 2008, 55, 4277–4289. [Google Scholar] [CrossRef]

- Liu, H.; Wang, Y.; Zeng, T.; Wang, H.; Chan, S.; Ran, L. Wind turbine generator failure analysis and fault diagnosis: A review. IET Renew. Power Gener. 2024, 18, 3127–3148. [Google Scholar] [CrossRef]

- Alewine, K.; Chen, W. A review of electrical winding failures in wind turbine generators. In Proceedings of the 2011 Electrical Insulation Conference (EIC), Annapolis, MD, USA, 5–8 June 2011; pp. 392–397. [Google Scholar] [CrossRef]

- Bellini, A.; Filippetti, F.; Tassoni, C.; Capolino, G.-A. Advances in Diagnostic Techniques for Induction Machines. IEEE Trans. Ind. Electron. 2008, 55, 4109–4126. [Google Scholar] [CrossRef]

- Ehya, H.; Nysveen, A.; Nilssen, R. Pattern Recognition of Inter-Turn Short Circuit Fault in Wound Field Synchronous Generator via Stray Flux Monitoring. In Proceedings of the 2020 International Conference on Electrical Machines (ICEM), Gothenburg, Sweden, 23–26 August 2020; pp. 2631–2636. [Google Scholar] [CrossRef]

- Ehya, H.; Nysveen, A. Pattern Recognition of Interturn Short Circuit Fault in a Synchronous Generator Using Magnetic Flux. IEEE Trans. Ind. Appl. 2021, 57, 3573–3581. [Google Scholar] [CrossRef]

- Ehya, H.; Nysveen, A.; Akin, B.; Gyftakis, K.N. An Expeditious Algorithm for Identification and Classification of Rotor Faults in Salient Pole Synchronous Generators. IEEE Trans. Ind. Electron. 2024, 71, 2008–2017. [Google Scholar] [CrossRef]

- Kedjar, B.; Merkhouf, A.; Al-Haddad, K. Large Synchronous Machines Diagnosis Based on Air-Gap and Stray Fluxes—An Overview. In Proceedings of the 2020 International Conference on Electrical Machines (ICEM), Gothenburg, Sweden, 23–26 August 2020; pp. 1384–1389. [Google Scholar] [CrossRef]

- Capolino, G.-A.; Romary, R.; Henao, H.; Pusca, R. State of the Art on Stray Flux Analysis in Faulted Electrical Machines. In Proceedings of the 2019 IEEE Workshop on Electrical Machines Design, Control and Diagnosis (WEMDCD), Athens, Greece, 22–23 April 2019; pp. 181–187. [Google Scholar] [CrossRef]

- Stone, S.B.L.G.; Antonino-Daviu, J.; Gyftakis, K.N.; Strangas, E.G.; Maussion, P. Condition Monitoring of Industrial Electric Machines: State of the Art and Future Challenges. IEEE Ind. Electron. Mag. 2020, 14, 158–167. [Google Scholar] [CrossRef]

- Yucai, W.; Yonggang, L.; Heming, L. Diagnosis of turbine generator typical faults by shaft voltage. In Proceedings of the 2012 IEEE Industry Applications Society Annual Meeting, Las Vegas, NV, USA, 7–11 October 2012. [Google Scholar] [CrossRef]

- Henao, H.; Capolino, G.A.; Fernandez-Cabanas, M.; Filippetti, F.; Bruzzese, C.; Strangas, E. Trends in Fault Diagnosis for Electrical Machines: A Review of Diagnostic Techniques. EEE Ind. Electron. Mag. 2014, 8, 31–42. [Google Scholar] [CrossRef]

- Ionescu, L.; Pontius, T. Main Shaft Support for Wind Turbine with a Fixed and Floating Bearing Configuration; Technical Report; The Timkin Company: North Canton, OH, USA, 2009. [Google Scholar]

- Paolone, M.; Napolitano, F.; Borghetti, A.; Nucci, C.A.; Marzinotto, M.; Fiamingo, F. Models of Wind-Turbine Main Shaft Bearings for the Development of Specific Lightning Protection Systems. In Proceedings of the 2007 IEEE Lausanne Power Tech, Lausanne, Switzerland, 1–5 July 2007; pp. 783–789. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, P.; He, S.; Huang, J. A Review of Modeling and Diagnostic Techniques for Eccentricity Fault in Electric Machines. Energies 2021, 14, 4296. [Google Scholar] [CrossRef]

- Whittle, M.; Shin, W.; Trevelyan, J.; Wu, J. A parametric study of the effect of generator misalignment on bearing fatigue life in wind turbines. In Proceedings of the European Wind Energy Conference and Exhibition (EWEC) 2011, Brussels, Belgium, 14–17 March 2011; pp. 24–27. [Google Scholar]

- Panagiotou, P.A.; Arvanitakis, I.; Lophitis, N.; Antonino-Daviu, J.A.; Gyftakis, K.N. On the broken rotor bar diagnosis using time–frequency analysis: ‘Is one spectral representation enough for the characterisation of monitored signals. IET Electr. Power Appl. 2019, 13, 932–942. [Google Scholar] [CrossRef]

- Salinas, M.; Trachalakis, N.; Panagiotou, P.A.; Gyftakis, K.N. Reliable Detection of Non-Adjacent Broken Rotor Bars via the Analysis of the Zero-Sequence Flux. In Proceedings of the 2024 International Conference on Electrical Machines (ICEM), Torino, Italy, 1–4 September 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Polinder, H.; Mecrow, B.C.; Jack, A.G.; Dickinson, P.G.; Mueller, M.A. Conventional and TFPM Linear Generators for Direct-Drive Wave Energy Conversion. IEEE Trans. Energy Convers. 2005, 20, 260–267. [Google Scholar] [CrossRef]

- Polinder, H.; Bang, D.; Van Rooij, R.P.J.O.M.; McDonald, A.S.; Mueller, M.A. 10 MW Wind Turbine Direct-Drive Generator Design with Pitch or Active Speed Stall Control. In Proceedings of the 2007 IEEE International Electric Machines & Drives Conference, Antalya, Turkey, 3–5 May 2007; pp. 1390–1395. [Google Scholar] [CrossRef]

- Gyftakis, K.; Rasid, S.; Skarmoutsos, G.; Mueller, M. The Demagnetization Harmonics Generation Mechanism in Permanent Magnet Machines with Concentrated Windings. IEEE Trans. Energy Convers. 2021, 36, 2934–2944. [Google Scholar] [CrossRef]

- Urresty, J.-C.; Riba, J.-R.; Romeral, L. Influence of the Stator Windings Configuration in the Currents and Zero-Sequence Voltage Harmonics in Permanent Magnet Synchronous Motors with Demagnetization Faults. IEEE Trans. Magn. 2013, 49, 4885–4893. [Google Scholar] [CrossRef]

- De Bisschop, J.; Abdallh, A.A.-E.; Sergeant, P.; Dupré, L. Analysis and selection of harmonics sensitive to demagnetisation faults intended for condition monitoring of double rotor axial flux permanent magnet synchronous machines. Int. Eng. Technol. Electr. Power Appl. 2018, 12, 486–493. [Google Scholar] [CrossRef]

- Goktas, T.; Zafarani, M.; Lee, K.W.; Akin, B.; Sculley, T. Comprehensive analysis of magnet defect fault monitoring through leakage flux. IEEE Trans. Magn. 2017, 53, 8201010. [Google Scholar] [CrossRef]

- Gyftakis, K.N.; Skarmoutsos, G.A.; Barajas-Solano, I.; Burchell, J.; Mueller, M. Critical Aspects of Demagnetization Faults in Multi-Stage Direct Drive Permanent Magnet Generators for Renewables. IEEE Trans. Ind. Appl. 2023, 59, 6655–6663. [Google Scholar] [CrossRef]

- Sergakis, A.; Skarmoutsos, G.A.; Mueller, M.; Gyftakis, K.N. Demagnetization Detection, Misdiagnosis and Impact in Permanent Magnet Generators. In Proceedings of the 2024 International Conference on Electrical Machines (ICEM), Torino, Italy, 1–4 September 2024; pp. 1–7. [Google Scholar] [CrossRef]

- Rasid, S.A.; Gyftakis, K.N.; Mueller, M. Comparative Investigation of Three Diagnostic Methods Applied to Direct-Drive Permanent Magnet Machines Suffering from Demagnetization. Energies 2023, 16, 2767. [Google Scholar] [CrossRef]

- Skarmoutsos, G.A.; Gyftakis, K.N.; Mueller, M. Detecting Partial Demagnetization in AFPM Generators by Monitoring Speed and EMF Induced in a Supplemental Winding. IEEE Trans. Ind. Inf. 2022, 18, 3295–3305. [Google Scholar] [CrossRef]

- Gurusamy, V.; Capolino, G.-A.; Akin, B.; Henao, H.; Romary, R.; Pusca, R. Recent Trends in Magnetic Sensors and Flux-Based Condition Monitoring of Electromagnetic Devices. IEEE Trans. Ind. Appl. 2022, 58, 4668–4684. [Google Scholar] [CrossRef]

- Albright, D.R. Interturn Short-Circuit Detector for Turbine-Generator Rotor Windings. IEEE Trans. Power Appar. Syst. 1971, PAS-90, 478–483. [Google Scholar] [CrossRef]

- Stone, G.C. Advancements during the Past Quarter Century in On-Line Monitoring of Motor and Generator Winding Insulation. IEEE Trans. Dielectr. Electr. Insul. 2002, 9, 746–751. [Google Scholar] [CrossRef]

- Touret, T.; Changenet, C.; Ville, F.; Lalmi, M.; Becquerelle, S.R.G. On the Use of Temperature for Online Condition Monitoring of Geared Systems—A Review. Mech. Syst. Signal Process. 2018, 101, 197–210. [Google Scholar] [CrossRef]

- Ayhan, B.; Chow, M.-Y.; Trussell, H.J.; Song, M.-H. A case study on the comparison of non-parametric spectrum methods for broken rotor bar fault detection. In Proceedings of the IECON’03—29th Annual Conference of the IEEE Industrial Electronics Society (IEEE Cat. No.03CH37468), Roanoke, VA, USA, 2–6 November 2003; Volume 3, pp. 2835–2840. [Google Scholar] [CrossRef]

- Gliga, L.I.; Ciubotaru, B.D.; Chafouk, H.; Popescu, D.; Lupu, C. Fault Diagnosis of a Direct Drive Wind Turbine Using a Bank of Goertzel Filters. In Proceedings of the 2019 6th International Conference on Control, Decision and Information Technologies (CoDIT), Paris, France, 23–26 April 2019; pp. 1729–1734. [Google Scholar] [CrossRef]

- Bellini, A.; Yazidi, A.; Filippetti, F.; Rossi, C.; Capolino, G.-A. High Frequency Resolution Techniques for Rotor Fault Detection of Induction Machines. IEEE Trans. Ind. Electron. 2008, 55, 4200–4209. [Google Scholar] [CrossRef]

- Kia, S.H.; Henao, H.; Capolino, G.-A. A High-Resolution Frequency Estimation Method for Three-Phase Induction Machine Fault Detection. IEEE Trans. Ind. Electron. 2007, 54, 2305–2314. [Google Scholar] [CrossRef]

- Elbouchikhi, E.; Choqueuse, V.; Benbouzid, M. Induction machine bearing faults detection based on a multi-dimensional MUSIC algorithm and maximum likelihood estimation. ISA Trans. 2016, 63, 413–424. [Google Scholar] [CrossRef]

- Moussa, M.A.; Boucherma, M.; Khezzar, A. A Detection Method for Induction Motor Bar Fault Using Sidelobes Leakage Phenomenon of the Sliding Discrete Fourier Transform. IEEE Trans. Power Electron. 2017, 32, 5560–5572. [Google Scholar] [CrossRef]

- Pietrzak, P.; Wolkiewicz, M. Stator Winding Fault Detection of Permanent Magnet Synchronous Motors Based on the Short-Time Fourier Transform. Power Electron. Drives 2022, 7, 112–133. [Google Scholar] [CrossRef]

- Zhan, H.; Liu, W.; Lyu, Z.; Niu, S.; Wu, L.; Chau, K.T. Eccentricity Fault Diagnosis in Multimodule Permanent Magnet Synchronous Machines Based on Zero-Sequence Voltage Component. IEEE Trans. Ind. Electron. 2025; early access. [Google Scholar] [CrossRef]

- Faiz, J.; Mazaheri-Tehrani, E. Demagnetization Modeling and Fault Diagnosing Techniques in Permanent Magnet Machines Under Stationary and Nonstationary Conditions: An Overview. IEEE Trans. Ind. Appl. 2017, 53, 2772–2785. [Google Scholar] [CrossRef]

- Strangas, E.G.; Aviyente, S.; Zaidi, S.S.H. Time–Frequency Analysis for Efficient Fault Diagnosis and Failure Prognosis for Interior Permanent-Magnet AC Motors. IEEE Trans. Ind. Electron. 2008, 55, 4191–4199. [Google Scholar] [CrossRef]

- Panagiotou, P.A.; Arvanitakis, I.; Lophitis, N.; Antonino-Daviu, J.A.; Gyftakis, K.N. A New Approach for Broken Rotor Bar Detection in Induction Motors Using Frequency Extraction in Stray Flux Signals. IEEE Trans. Ind. Appl. 2019, 55, 3501–3511. [Google Scholar] [CrossRef]

- Hussain, M.; Kumar, D.; Hussain, I.; Memon, T.; Memon, Z.; Nisar, K.; Chowdhry, B. Stator Winding Fault Detection and Classification in Three-Phase Induction Motor. Intell. Autom. Soft Comput. 2021, 29, 869–883. [Google Scholar] [CrossRef]

- Watson, S.J.; Xiang, B.J.; Yang, W.; Tavner, P.J.; Crabtree, C.J. Condition Monitoring of the Power Output of Wind Turbine Generators Using Wavelets. IEEE Trans. Energy Convers. 2010, 25, 715–721. [Google Scholar] [CrossRef]

- Rehman, A.U.; Chen, Y.; Zhang, M.; Zhao, Y.; Wang, L.; Liu, Y.; Zhao, Y.; Tanaka, Y.C.T. Fault detection and fault severity calculation for rotor windings based on spectral, wavelet and ratio computation analyses of rotor current signals for a doubly fed induction generator in wind turbines. Electr. Eng. 2020, 102, 1091–1102. [Google Scholar] [CrossRef]

- Gong, X.; Qiao, W.; Zhou, W. Incipient bearing fault detection via wind generator stator current and wavelet filter. In Proceedings of the IECON 2010—36th Annual Conference on IEEE Industrial Electronics Society, Glendale, AZ, USA, 7–10 November 2010; pp. 2615–2620. [Google Scholar] [CrossRef]

- Chen, J.; Pan, J.; Li, Z.; Zi, Y.; Chen, X. Generator bearing fault diagnosis for wind turbine via empirical wavelet transform using measured vibration signals. Renew. Energy 2016, 89, 80–92. [Google Scholar] [CrossRef]

- Gao, Q.; Duan, C.; Fan, H.; Meng, Q. Rotating machine fault diagnosis using empirical mode decomposition. Mech. Syst. Signal Process. 2008, 22, 1072–1081. [Google Scholar] [CrossRef]

- Amarnath, M.; Krishna, I.R.P. Local fault detection in helical gears via vibration and acoustic signals using EMD based statistical parameter analysis. Measurement 2014, 58, 154–164. [Google Scholar] [CrossRef]

- Peng, Z.K.; Tse, P.W.; Chu, F.L. A comparison study of improved Hilbert–Huang transform and wavelet transform: Application to fault diagnosis for rolling bearing. Mech. Syst. Signal Process. 2005, 19, 974–988. [Google Scholar] [CrossRef]

- Amirat, Y.; Choqueuse, V.; Benbouzid, M. EEMD-based wind turbine bearing failure detection using the generator stator current homopolar component. Mech. Syst. Signal Process. 2013, 41, 667–678. [Google Scholar] [CrossRef]

- Chen, H.; Chen, P.; Chen, W.; Wu, C.; Li, J.; Wu, J. Wind Turbine Gearbox Fault Diagnosis Based on Improved EEMD and Hilbert Square Demodulation. Appl. Sci. 2017, 7, 128. [Google Scholar] [CrossRef]

- Wang, Y.; Markert, R.; Xiang, J.; Zheng, W. Research on variational mode decomposition and its application in detecting rub-impact fault of the rotor system. Mech. Syst. Signal Process. 2015, 60–61, 243–251. [Google Scholar] [CrossRef]

- Tang, X.; Hu, B.; Wen, H. Fault Diagnosis of Hydraulic Generator Bearing by VMD-Based Feature Extraction and Classification. Iran. J. Sci. Technol. Trans. Electr. Eng. 2021, 45, 1227–1237. [Google Scholar] [CrossRef]

- Koutrakos, K.; Lamprokostopoulos, A.; Mitronikas, E. Application of Signal Decomposition Methods for Axial Flux PMSM Demagnetization Feature Extraction and Fault Diagnosis. In Proceedings of the 2025 IEEE Symposium on Diagnostics for Electric Machines, Power Electronics and Drives (SDEMPED), Dallas, TX, USA, 24–27 August 2025; pp. 1–7. [Google Scholar] [CrossRef]

- Climente-Alarcon, V.; Antonino-Daviu, J.A.; Riera-Guasp, M.; Puche-Panadero, R.; Escobar, L. Application of the Wigner–Ville distribution for the detection of rotor asymmetries and eccentricity through high-order harmonics. Electr. Power Syst. Res. 2012, 91, 28–36. [Google Scholar] [CrossRef]

- Feng, Z.; Liang, M.; Chu, F. Recent advances in time–frequency analysis methods for machinery fault diagnosis: A review with application examples. Mech. Syst. Signal Process. 2013, 38, 165–205. [Google Scholar] [CrossRef]

- Bouchikhi, E.H.; Choqueuse, V.; Benbouzid, M.E.H.; Charpentier, J.F.; Barakat, G. A comparative study of time-frequency representations for fault detection in wind turbine. In Proceedings of the IECON 2011—37th Annual Conference of the IEEE Industrial Electronics Society, Melbourne, VIC, Australia, 7–10 November 2011; pp. 3584–3589. [Google Scholar] [CrossRef]

- Qiao, W.; Lu, D. A Survey on Wind Turbine Condition Monitoring and Fault Diagnosis—Part II: Signals and Signal Processing Methods. IEEE Trans. Ind. Electron. 2015, 62, 6546–6557. [Google Scholar] [CrossRef]

- Merizalde, Y.; Hernández-Callejo, L.; Duque-Perez, O.; López-Meraz, R.A. Fault Detection of Wind Turbine Induction Generators through Current Signals and Various Signal Processing Techniques. Appl. Sci. 2020, 10, 7389. [Google Scholar] [CrossRef]

- Al Ahmar, E.; Choqueuse, V.; Benbouzid, M.E.H.; Amirat, Y.; El Assad, J.; Karam, R. Advanced signal processing techniques for fault detection and diagnosis in a wind turbine induction generator drive train: A comparative study. In Proceedings of the 2010 IEEE Energy Conversion Congress and Exposition, Atlanta, GA, USA, 12–16 September 2010; pp. 3576–3581. [Google Scholar] [CrossRef]

- Urbanek, J.; Barszcz, T.; Uhl, T. Comparison of advanced signal-processing methods for roller bearing faults detection. Metrol. Meas. Syst. 2012, 19, 715–726. [Google Scholar] [CrossRef]

- Ehya, H.; Nysveen, A.; Skreien, T.N. Performance Evaluation of Signal Processing Tools Used for Fault Detection of Hydrogenerators Operating in Noisy Environments. IEEE Trans. Ind. Appl. 2021, 57, 3654–3665. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, S.; Wang, B.; Habetler, T.G. Deep Learning Algorithms for Bearing Fault Diagnostics—A Comprehensive Review. IEEE Access 2020, 8, 29857–29881. [Google Scholar] [CrossRef]

- Huang, R.; Liao, Y.; Zhang, S.; Li, W. Deep Decoupling Convolutional Neural Network for Intelligent Compound Fault Diagnosis. IEEE Access 2019, 7, 1848–1858. [Google Scholar] [CrossRef]

- Cao, L.; Qian, Z.; Zareipour, H.; Huang, Z.; Zhang, F. Fault Diagnosis of Wind Turbine Gearbox Based on Deep Bi-Directional Long Short-Term Memory Under Time-Varying Non-Stationary Operating Conditions. IEEE Access 2019, 7, 155219–155228. [Google Scholar] [CrossRef]

- Biet, M. Rotor Faults Diagnosis Using Feature Selection and Nearest Neighbors Rule: Application to a Turbogenerator. IEEE Trans. Ind. Electron. 2013, 60, 4063–4073. [Google Scholar] [CrossRef]

- Tang, Y.; Chang, Y.; Li, K. Applications of K-nearest neighbor algorithm in intelligent diagnosis of wind turbine blades damage. Renew. Energy 2023, 212, 855–864. [Google Scholar] [CrossRef]

- Zhang, D.; Qian, L.; Mao, B.; Huang, C.; Huang, B.; Si, Y. A Data-Driven Design for Fault Detection of Wind Turbines Using Random Forests and XGboost. IEEE Access 2018, 6, 21020–21031. [Google Scholar] [CrossRef]

- Li, C.; Sanchez, R.-V.; Cerrada, G.Z.M.; Cabrera, D.; Vásquez, R.E. Gearbox fault diagnosis based on deep random forest fusion of acoustic and vibratory signals. Mech. Syst. Signal Process. 2016, 76–77, 283–293. [Google Scholar] [CrossRef]

- Dhibi, R.F.K.; Mansouri, M.; Trabelsi, M.; Hajji, M.; Bouzrara, K. Effective Random Forest-Based Fault Detection and Diagnosis for Wind Energy Conversion Systems. IEEE Sens. J. 2021, 21, 6914–6921. [Google Scholar] [CrossRef]

- Widodo, A.; Yang, B.-S. Support vector machine in machine condition monitoring and fault diagnosis. Mech. Syst. Signal Process. 2007, 21, 2560–2574. [Google Scholar] [CrossRef]

- Zhang, X.; Zhou, J.; Guo, J.; Zou, Q.; Huang, Z. Vibrant fault diagnosis for hydroelectric generator units with a new combination of rough sets and support vector machine. Expert Syst. Appl. 2012, 39, 2621–2628. [Google Scholar] [CrossRef]

- Al-Ajmi, A.; Wang, Y.; Djurović, S. Wind Turbine Generator Controller Signals Supervised Machine Learning for Shaft Misalignment Fault Detection: A Doubly Fed Induction Generator Practical Case Study. Energies 2021, 14, 1601. [Google Scholar] [CrossRef]

- Attallah, O.; Ibrahim, R.A.; Zakzouk, N.E. Fault diagnosis for induction generator-based wind turbine using ensemble deep learning techniques. Energy Rep. 2022, 8, 12787–12798. [Google Scholar] [CrossRef]

- Qiao, L.; Zhang, Y.; Wang, Q. Fault Detection in Wind Turbine Generators Using a Meta-Learning-Based Convolutional Neural Network. Mech. Syst. Signal Process. 2023, 200, 110528. [Google Scholar] [CrossRef]

- Wang, J.; Dou, Y.; Wang, Z.; Jiang, D. Multi-fault diagnosis method for wind power generation system based on recurrent neural network. Proc. Inst. Mech. Eng. Part A J. Power Energy 2019, 233, 604–615. [Google Scholar] [CrossRef]

- Rodriguez, P.C.; Marti-Puig, P.; Caiafa, C.F.; Serra-Serra, M.; Cusidó, J.; Solé-Casals, J. Exploratory Analysis of SCADA Data from Wind Turbines Using the K-Means Clustering Algorithm for Predictive Maintenance Purposes. Machines 2023, 11, 270. [Google Scholar] [CrossRef]

- Wang, B.; Zhou, B.; Zou, M.; Liu, Q.; Zhao, R.; Dai, M. Research on condition monitoring of offshore wind turbine gearbox based on K-means clustering and extreme learning machine model. In Proceedings of the 2023 International Conference on Artificial Intelligence and Power Engineering (AIPE), Tokyo, Japan, 20–22 October 2023; pp. 71–76. [Google Scholar] [CrossRef]

- Zhang, J.; Jiang, N.; Li, H.; Li, N. Online health assessment of wind turbine based on operational condition recognition. Trans. Inst. Meas. Control 2018, 41, 2970–2981. [Google Scholar] [CrossRef]

- Yiakopoulos, C.T.; Gryllias, K.C.; Antoniadis, I.A. Rolling element bearing fault detection in industrial environments based on a K-means clustering approach. Expert Syst. Appl. 2011, 38, 2888–2911. [Google Scholar] [CrossRef]

- Swana, E.; Doorsamy, W. An Unsupervised Learning Approach to Condition Assessment on a Wound-Rotor Induction Generator. Energies 2021, 14, 602. [Google Scholar] [CrossRef]

- Mehmood, Z.; Wang, Z. Hybrid iForest-DBSCAN for anomaly detection and wind power curve modelling. Expert Syst. Appl. 2025, 289, 128381. [Google Scholar] [CrossRef]

- Hsu, J.-Y.; Wang, Y.-F.; Lin, K.-C.; Chen, M.-Y.; Hsu, J.H.-Y. Wind Turbine Fault Diagnosis and Predictive Maintenance Through Statistical Process Control and Machine Learning. IEEE Access 2020, 8, 23427–23439. [Google Scholar] [CrossRef]

- Zhong, J.-H.; Liang, J.; Yang, Z.-X.; Wong, P.K.; Wang, X.B. An Effective Fault Feature Extraction Method for Gas Turbine Generator System Diagnosis. Shock Vib. 2016, 2016, 9359426. [Google Scholar] [CrossRef]

- Wang, Y.; Ma, X.; Qian, P. Wind Turbine Fault Detection and Identification Through PCA-Based Optimal Variable Selection. IEEE Trans. Sustain. Energy 2018, 9, 1627–1635. [Google Scholar] [CrossRef]

- Zheng, J.; Jiang, Z.; Pan, H. Sigmoid-based refined composite multiscale fuzzy entropy and t-SNE based fault diagnosis approach for rolling bearing. Measurement 2018, 129, 332–342. [Google Scholar] [CrossRef]

- Ding, Y.; Ma, L.; Ma, J.; Wang, C.; Lu, C. A Generative Adversarial Network-Based Intelligent Fault Diagnosis Method for Rotating Machinery Under Small Sample Size Conditions. IEEE Access 2019, 7, 149736–149749. [Google Scholar] [CrossRef]

- Tang, G.; Cheng, L.; Xu, Z.; Sun, K.; Wu, X.; Wang, X. Multimodal Data Enhanced Wind Generator Fault Diagnosis Considering Small Sample Conditions. IEEE Trans. Ind. Electron. 2025; early access. [Google Scholar] [CrossRef]

- Zhao, D.; Liu, S.; Gu, D.; Sun, X.; Wang, L.; Wei, Y.; Zhang, H. Enhanced data-driven fault diagnosis for machines with small and unbalanced data based on variational auto-encoder. Meas. Sci. Technol. 2019, 31, 035004. [Google Scholar] [CrossRef]

- Neupane, D.; Seok, J. Bearing Fault Detection and Diagnosis Using Case Western Reserve University Dataset with Deep Learning Approaches: A Review. IEEE Access 2020, 8, 93155–93178. [Google Scholar] [CrossRef]

- Yan, J.; Liu, Y.; Meng, H.; Li, L.; Ren, X. Wind turbine generator early fault diagnosis using LSTM-based stacked denoising autoencoder network and stacking algorithm. Int. J. Green Energy 2024, 21, 2477–2492. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, G.; Jin, Q. Imbalanced sample fault diagnosis of rotating machinery using conditional variational auto-encoder generative adversarial network. Appl. Soft Comput. 2020, 9, 106333. [Google Scholar] [CrossRef]

- Yu, K.; Lin, T.R.; Ma, H.; Li, X.; Li, X. A multi-stage semi-supervised learning approach for intelligent fault diagnosis of rolling bearing using data augmentation and metric learning. Mech. Syst. Signal Process. 2020, 146, 107043. [Google Scholar] [CrossRef]

- Wu, X.; Zhang, Y.; Cheng, C.; Peng, Z. A hybrid classification autoencoder for semi-supervised fault diagnosis in rotating machinery. Mech. Syst. Signal Process. 2020, 149, 107327. [Google Scholar] [CrossRef]

- Ramírez-Sanz, J.M.; Maestro-Prieto, J.; Arnaiz-González, Á.; Bustillo, A. Semi-supervised learning for industrial fault detection and diagnosis: A systemic review. ISA Trans. 2023, 143, 255–270. [Google Scholar] [CrossRef]

- Han, T.; Xie, W.; Pei, Z. Semi-Supervised Adversarial Discriminative Learning Approach for Intelligent Fault Diagnosis of Wind Turbine. Inf. Sci. 2023, 648, 119496. [Google Scholar] [CrossRef]

- Helbing, G.; Ritter, M. Deep Learning for fault detection in wind turbines. Renew. Sustain. Energy Rev. 2018, 98, 189–198. [Google Scholar] [CrossRef]

- Lu, S.; Lu, J.; An, K.; Wang, X.; He, Q. Edge Computing on IoT for Machine Signal Processing and Fault Diagnosis: A Review. IEEE Internet Things J. 2023, 10, 11093–11116. [Google Scholar] [CrossRef]

- Agrawal, A.; Sinha, A.; Das, D. Fault-See-Through: An Explainable AI Approach for Edge-Assisted Electrical Fault Diagnosis in 3-phase Generators Using Vibration Signal. SN Comput. Sci. 2025, 6, 885. [Google Scholar] [CrossRef]

| Methods | Characteristics | Computational Complexity | Advantages | Disadvantages |

|---|---|---|---|---|

| FFT | Non-parametric Fourier-based | Fast, Simple, well-established | Unsuitable for non-stationary signals | |

| Welch’s Periodogram | Non-parametric Fourier-based | More robust and noise-resistant than FFT | Unsuitable for non-stationary signals | |

| MUSIC | Parametric, High-resolution Spectral Estimation | Very high frequency resolution | Sensitive to noise, high computational cost | |

| STFT | Fourier-based Time–Frequency Analysis | Simple, well-established | Resolution limited due to fixed window | |

| CWT, DWT | Multiresolution Time–Frequency Analysis | Muti-scale analysis, deals well with non- stationary and transient signals | Choice of mother wavelet | |

| HHT | Adaptive, Data Driven | Data adaptive | Mode mixing, end effects | |

| WVD | Quadratic Time–Frequency | High time–frequency resolution | Cross-terms, high computational complexity |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ptochos, K.; Koutrakos, K.; Mitronikas, E. Fault Diagnosis in Electric Generators: Methods, Trends and Challenges. Energies 2025, 18, 6210. https://doi.org/10.3390/en18236210

Ptochos K, Koutrakos K, Mitronikas E. Fault Diagnosis in Electric Generators: Methods, Trends and Challenges. Energies. 2025; 18(23):6210. https://doi.org/10.3390/en18236210

Chicago/Turabian StylePtochos, Konstantinos, Konstantinos Koutrakos, and Epameinondas Mitronikas. 2025. "Fault Diagnosis in Electric Generators: Methods, Trends and Challenges" Energies 18, no. 23: 6210. https://doi.org/10.3390/en18236210

APA StylePtochos, K., Koutrakos, K., & Mitronikas, E. (2025). Fault Diagnosis in Electric Generators: Methods, Trends and Challenges. Energies, 18(23), 6210. https://doi.org/10.3390/en18236210