A Review of Cooling Technology Methods for Electric Vehicle Battery Thermal Management Systems

Abstract

1. Introduction

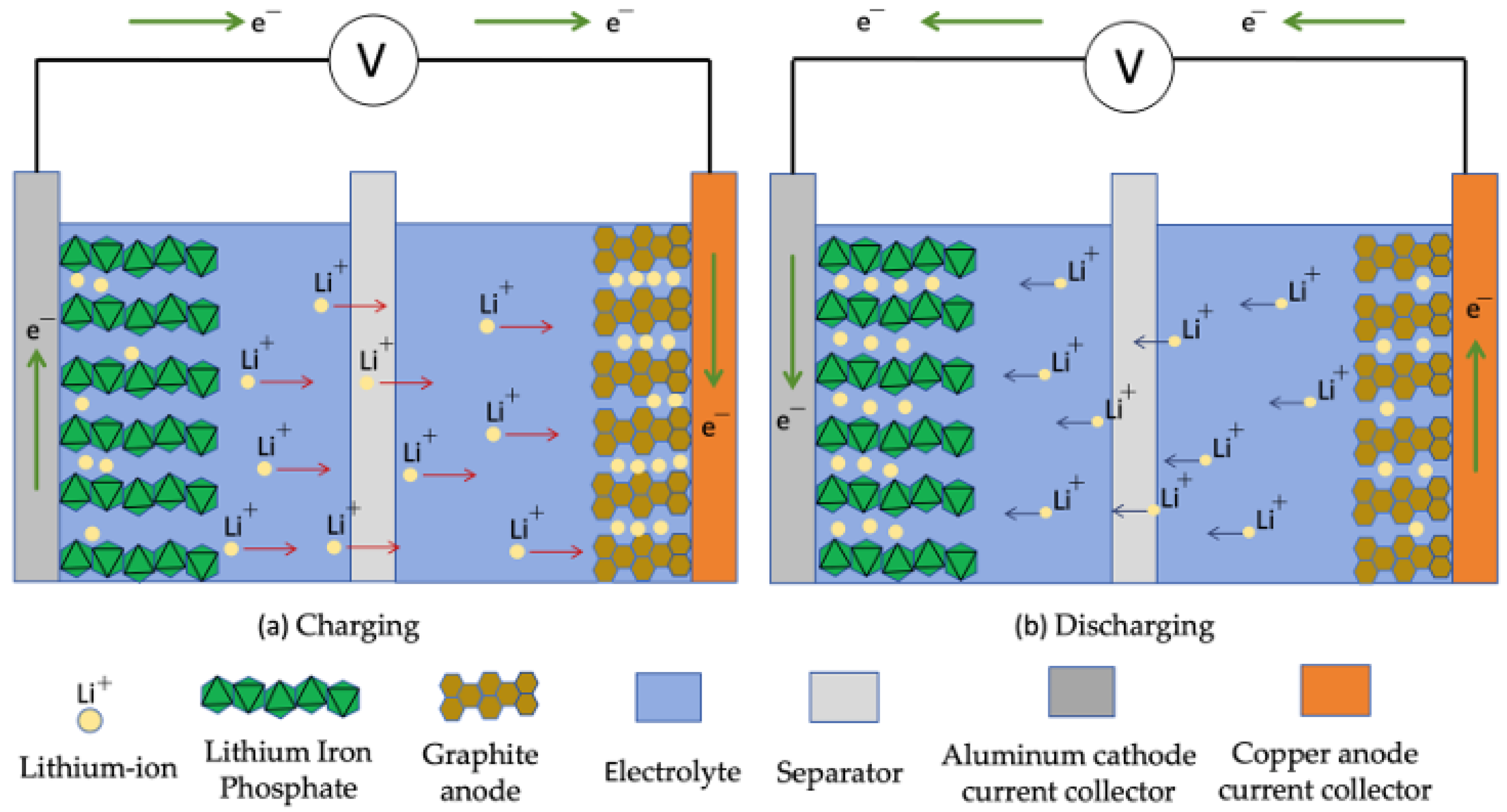

2. Lithium-Ion Battery Heat Generation

2.1. Mechanism of Heat Generation

- Joule heat Qj: The components of batteries, such as electrodes and separators, possess varying levels of electrical resistance, and the heat produced when current passes through these components is referred to as Joule heat. The calculation is expressed in Equation (1).

- 2.

- Polarization heat, denoted as Qp: During the charging and discharging processes, polarization effects take place, resulting in electrode potentials that differ from their equilibrium values. The heat generated due to these polarization effects is referred to as polarization heat, and it is irreversible. The formula for calculation is shown in Equation (2).

- 3.

- Reaction heat Qr: When positive or negative electrodes are added or removed, heat is generated due to the movement of lithium ions, referred to as reaction heat. It is commonly understood that reaction heat takes on a positive value during discharging and a negative value during charging. Reaction heat is reversible. The formula for its calculation is given in Equation (3):

- 4.

- Heat from side reactions Qs: In cases of thermal stress, such as when batteries are overcharged or over-discharged, the electrode materials and electrolytes in lithium batteries produce heat, which adds to the heat from side reactions. If the operating conditions remain normal, this heat can typically be disregarded. Consequently, the total heat produced in the battery pack can be calculated using Equation (4):

2.2. Models for Heat Generation

2.2.1. Electrochemical Thermal Models

2.2.2. Electrical Thermal Models

2.3. The Impact of Temperature on Battery Performance

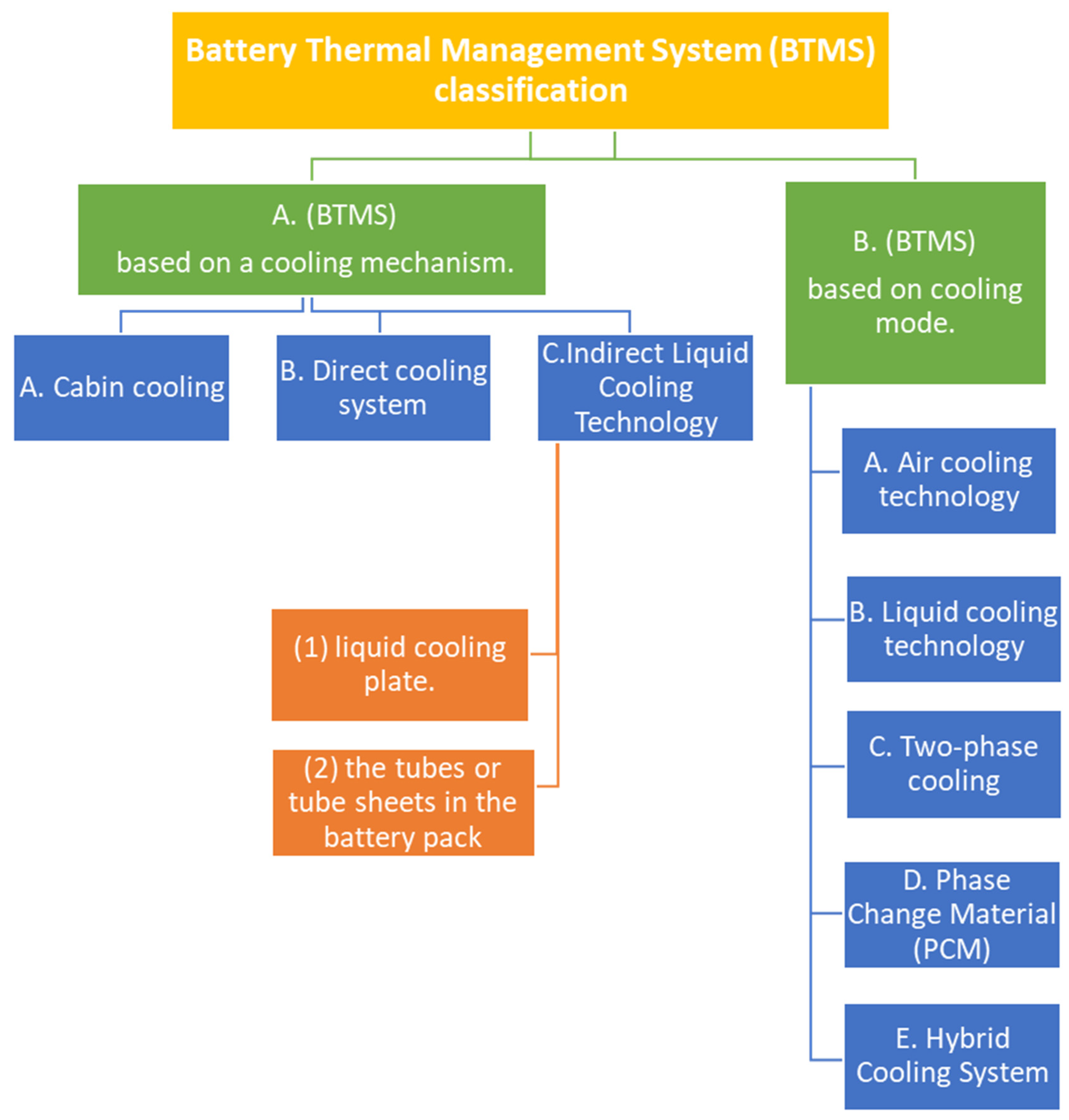

3. Battery Thermal Management System (BTMS)

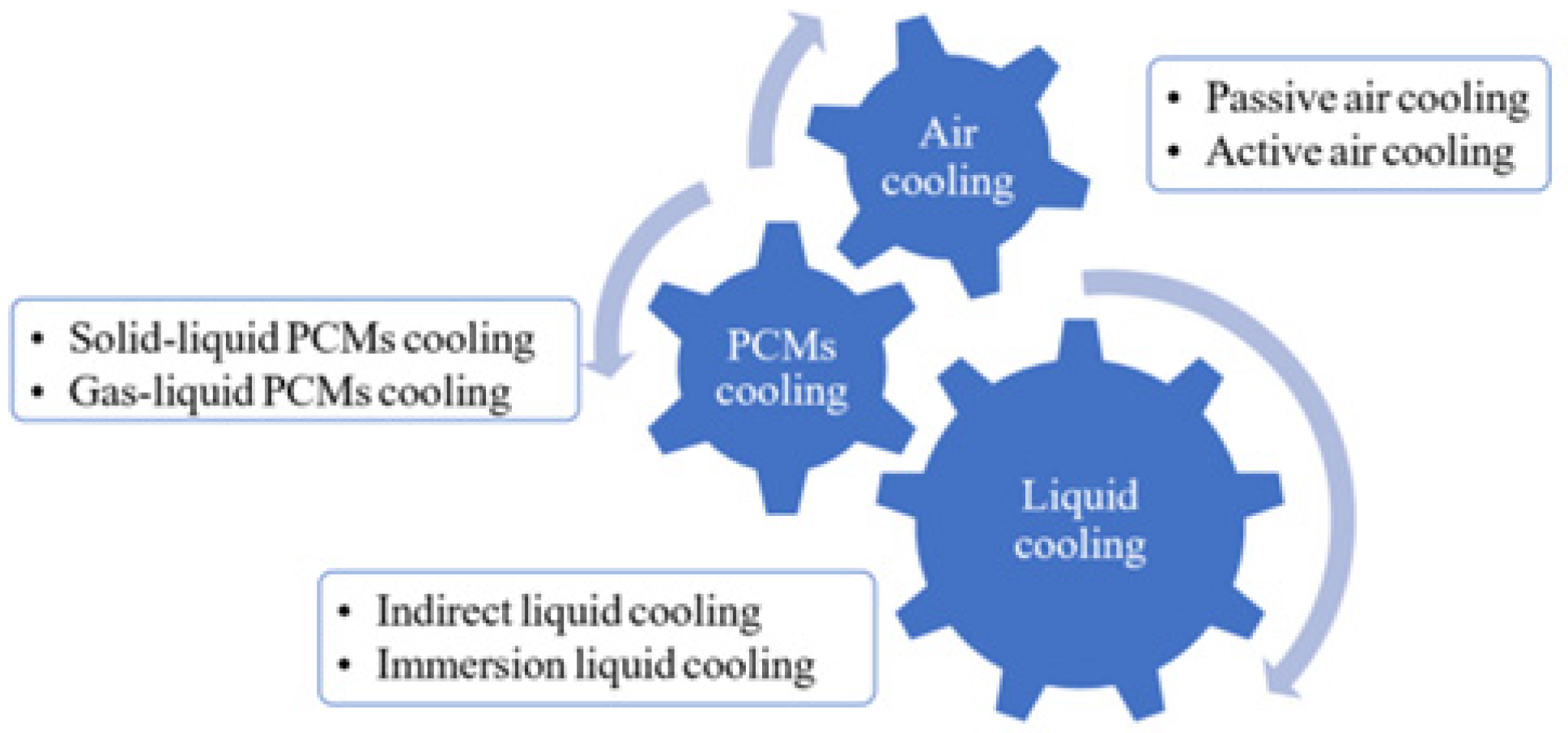

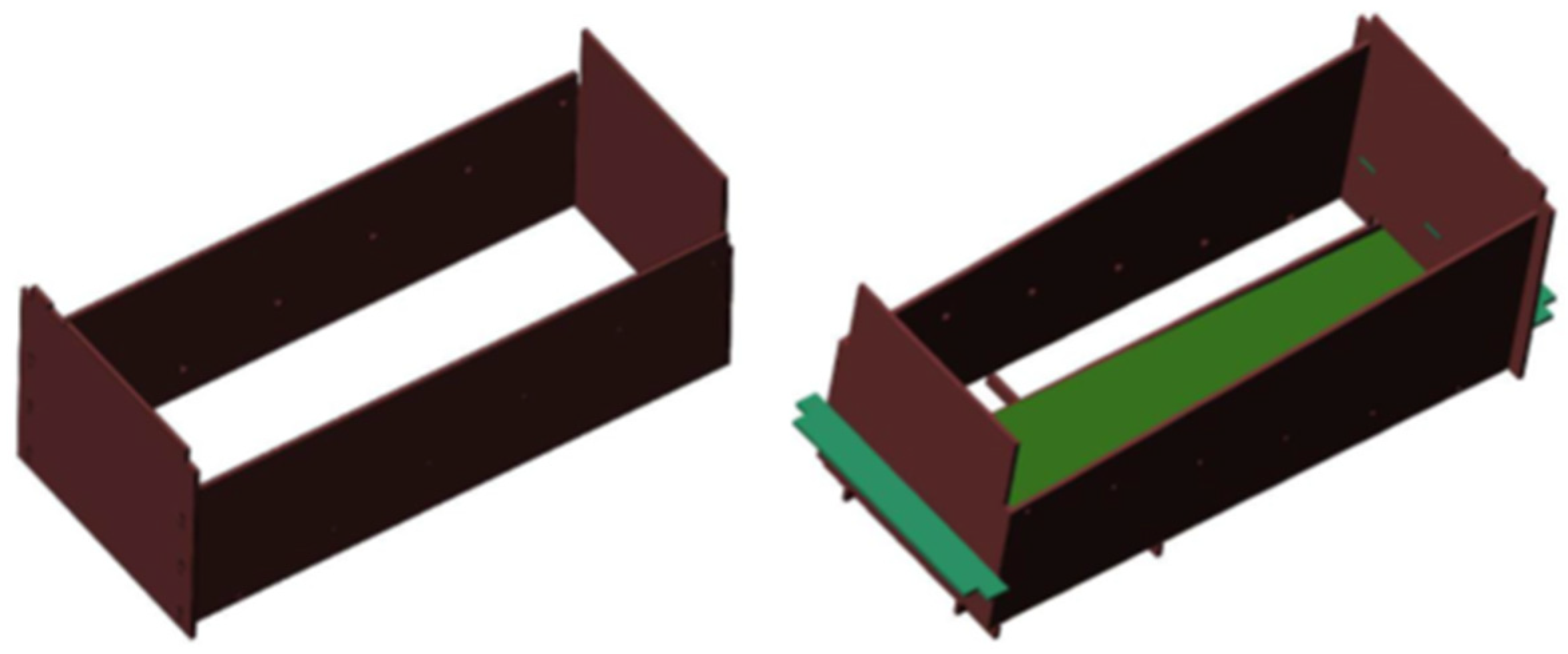

3.1. Battery Thermal Management System Utilizing Cooling Mechanisms

- (a)

- Dispersing heat via the tubes or tube sheets within the battery pack.

- (b)

- Mounting the batteries onto the liquid cooling plate.

3.2. Battery Thermal Management System Utilizing Cooling Mode

3.2.1. Air Cooling Technology

- Electrical vehicle components made from a minivan weighed about 900 kg (about 1984.16 lb). The vehicle was driven for 70 km at a speed of 70–90 km per hour. The temperature display screen was not over 35 °C, and the ambient temperature was 29 °C.

- Battery from 94 pcs NMC CATL 3.6 v and 50 AH connected in series.

- Heat generation model: the heat source from the Li-ion battery is composed of two sources, first from the joule effect and the other from the electrochemical reaction. The temperature increases from heat generation in three cases, which are 34 °C, 60 °C, and 72 °C.

- Battery thermal management system (BTMS): The airflow cooling system consists of 6 fans that move 150 cubic feet per minute. The installed equipment in a converted EV is shown in Figure 1 in Siriboonpanit et al. [47].

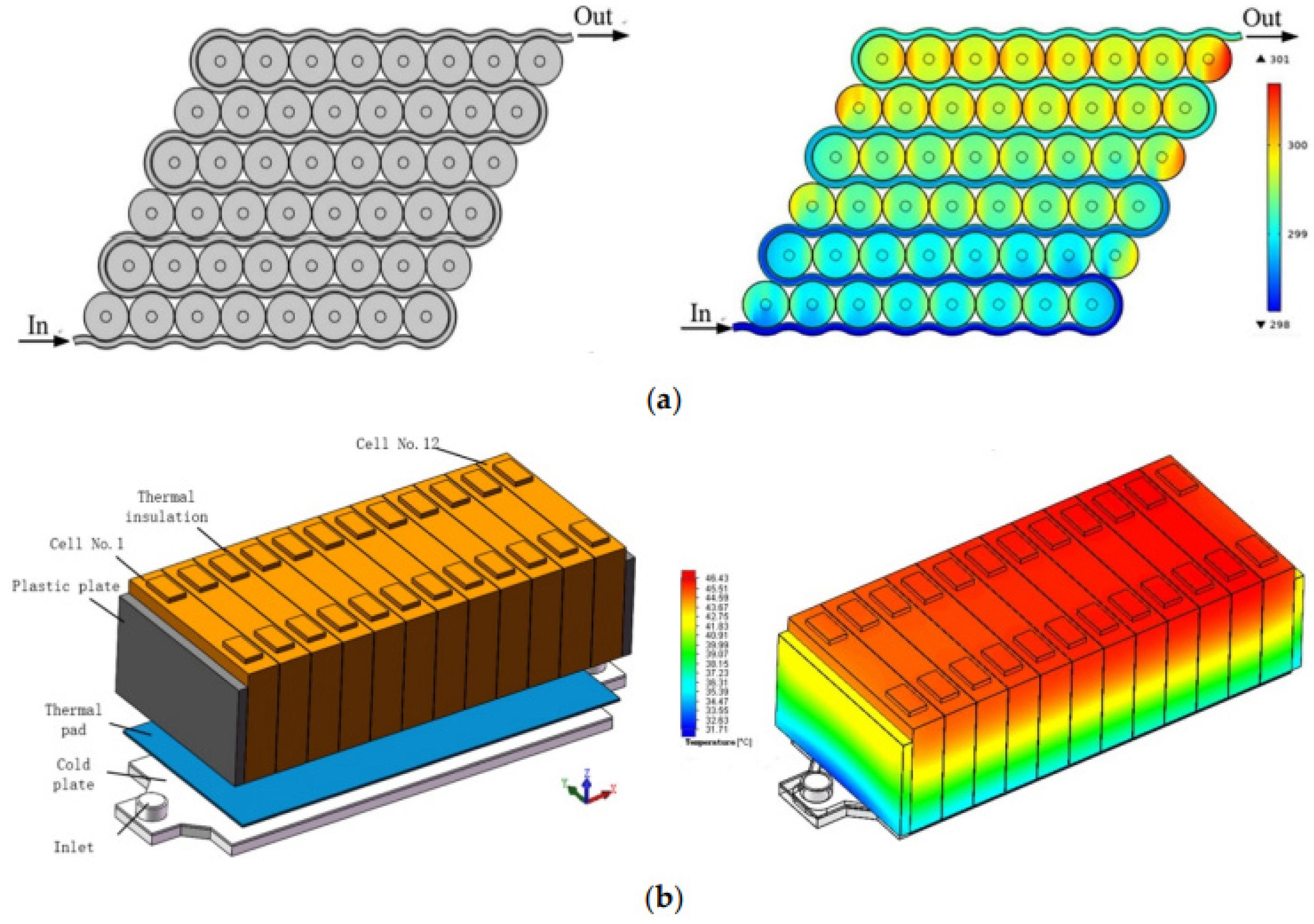

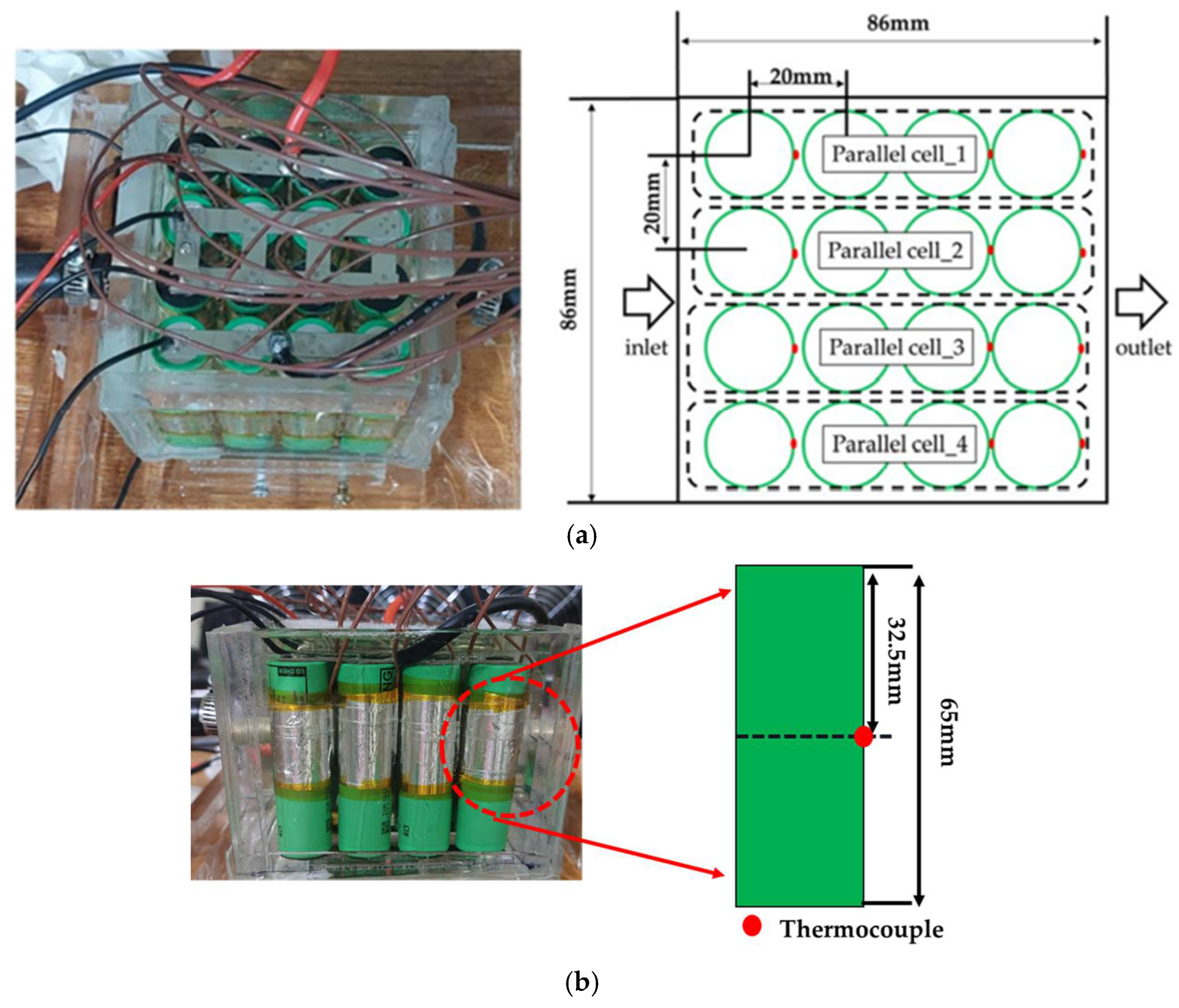

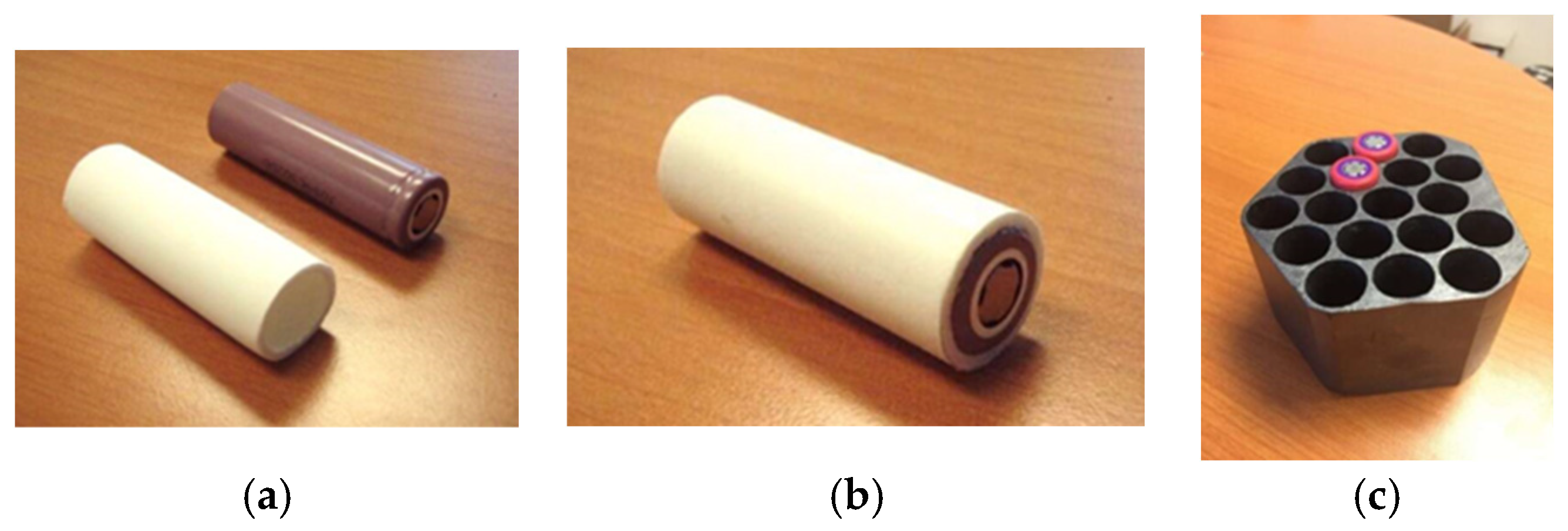

3.2.2. Liquid Cooling Technology

- Four LiFePO4 cylindrical cells connected in parallel. Each cell measures 26 mm in diameter and 65 mm in height, with a capacity of 2.5 Ah and a voltage of 3.3 V.

- The cell module is housed within a steel chamber with internal dimensions of 0.1 m × 0.1 m × 0.2 m and is submerged in the dielectric fluid Novec 7000. The fluid’s saturation temperature is 34 °C at 1 atm. This experiment is constructed from materials that are compatible with the working fluid, minimizing liquid loss and contamination during operation.

- Gaskets and O-rings are used to seal the chamber.

- Polycarbonate windows are positioned on two sides of the chamber, allowing access for charging and discharging processes.

- Power connections to the cells are made through a 6 mm2 tri-rated cable attached to the copper busbar, connecting the cells electrically in parallel. A diagram of battery units inside the testing chamber is shown in Figure 2 in Williams et al. [51].

3.2.3. The Two-Phase Cooling

3.2.4. Phase Change Materials (PCMs)

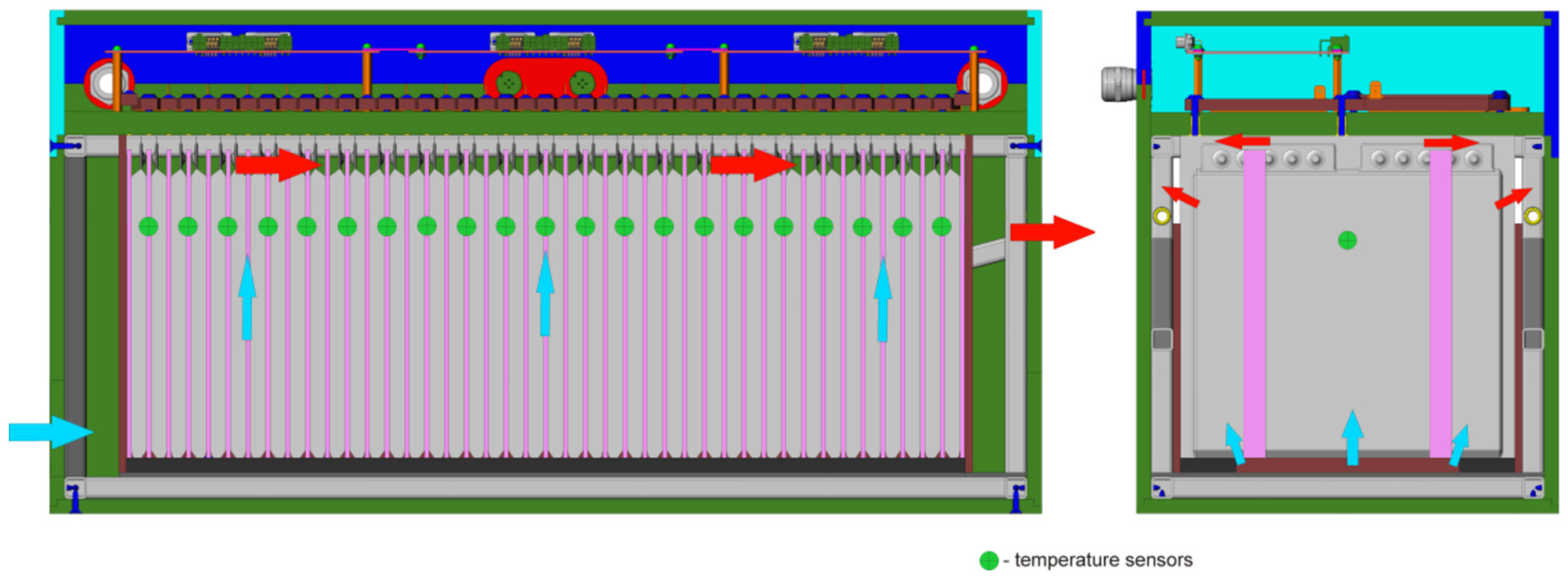

3.2.5. Hybrid Cooling System

- An external cooling system utilizes a forced air-cooling method.

- Control of the external cooling system is managed by a motor (air cooling fan) that regulates the battery’s thermal system at an optimal temperature. The motor’s speed increases as the armature input voltage rises, resulting in the air cooler delivering chilled air into the battery. The air cooler motor utilized in this setup is a DC shunt motor, which accelerates as the battery temperature rises. Furthermore, the DC shunt motor circulates the liquid through the cooling channel for internal cooling. A schematic diagram of the external cooling system of the battery is illustrated in Figure 3 in Surya et al. [58]. A PID (Proportional-Integral-Derivative) controller is a control algorithm used in automation to continuously calculate errors based on input values and send corrective output values to help the system reach the desired state. In this application, the PID controller takes the ambient and battery temperatures as inputs and controls the motor pump that cools the battery pack to maintain the battery temperature in the optimal range.

- Internal cooling uses the liquid Propylene Glycol, a fluid, to cool the battery internally and distribute the temperature evenly. This study shows that double cooling the battery internally and externally leads to the desired performance level. This system can be seen in Figure 2 in [58]. The system improves the battery’s overall performance, durability, and safety standards, emphasizing its effectiveness as an energy storage system.

- The utilization of a non-conductive spray played a vital role in minimizing the maximum temperature variance within the densely arranged battery cells.

- Hydrofluoroether (HFE) droplets with higher flow rates penetrated further into the battery pack, aiding in the reduction in thermal effects on the batteries.

- The liquid jet should be aimed to make contact with the cell surface to enhance cooling efficiency.

- While increasing the mass flow rate has a limited effect on temperature regulation and is not economically viable, it is important to optimize the quantity of liquid spray used. Experimental findings indicate that the hybrid spray and cooling system can effectively manage the heat produced by the battery pack, keeping the temperature within the specified limits. The system’s schematic diagram can be found in Figures 1 and 3 in [59].

4. Summary

5. Conclusions and Discussion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, H.; Wei, Z.; He, W.; Zhao, J. Thermal issues about Li-ion batteries and recent progress in battery thermal management systems: A review. Energy Convers. Manag. 2017, 150, 304330. [Google Scholar] [CrossRef]

- Conte, F.V. Battery and battery management for hybrid electric vehicles: A review. Elektrotechnik Inf. 2006, 123, 424–431. [Google Scholar] [CrossRef]

- Silvestri, L.; De Santis, M.; Falcucci, G.; Serao, P.; Bella, G. Evaluation of Battery Power Losses During the LCA Use Phase of Electric Vehicles: An Experimental Analysis of Different Li-Ion Battery Chemistries; SAE Technical Paper; SAE: Warrendale, PA, USA, 2023. [Google Scholar]

- Pesaran, A.A. Battery thermal models for hybrid vehicle simulations. J. Power Sources 2002, 110, 377–382. [Google Scholar] [CrossRef]

- Sato, N. Thermal behavior analysis of lithium-ion batteries for electric and hybrid vehicles. J. Power Sources 2001, 99, 70–77. [Google Scholar] [CrossRef]

- Wang, H.; Tao, T.; Xu, J.; Shi, H.; Mei, X.; Gou, P. Thermal performance of a liquid-immersed battery thermal management system for lithium-ion pouch batteries. J. Energy Storage 2022, 46, 103835. [Google Scholar] [CrossRef]

- Zhao, R.; Zhang, S.; Liu, J.; Gu, J. A review of thermal performance improving methods of lithium-ion battery: Electrode modification and thermal management system. J. Power Sources 2015, 299, 557–577. [Google Scholar] [CrossRef]

- Doyle, M.; Fuller, T.F.; Newman, J. Modeling of Galvanostatic Charge and Discharge of the Lithium/Polymer/Insertion Cell. J. Electrochem. Soc. 1993, 140, 1526–1533. [Google Scholar] [CrossRef]

- Bernardi, D.; Pawlikowski, E.; Newman, J. A General Energy Balance for Battery Systems. J. Electrochem. Soc. 1985, 132, 5–12. [Google Scholar] [CrossRef]

- Hwang, F.S.; Reidy, C.; Picovici, D.; Callaghan, D.; Culliton, D.; Nolan, C. Review of battery thermal management systems in electric vehicles. Renew. Sustain. Energy Rev. 2024, 192, 11417. [Google Scholar] [CrossRef]

- Li, W.; Zhou, Y.; Zhang, H.; Tang, X. A Review of Battery Thermal Management for New Energy Vehicles. Energies 2023, 16, 4845. [Google Scholar] [CrossRef]

- Rao, Z.; Wang, S. A review of power battery thermal energy management. Renew. Sustain. Energy Rev. 2011, 15, 4554–4571. [Google Scholar] [CrossRef]

- Wang, Q.; Jiang, B.; Li, B.; Yan, Y. A critical review of thermal management models and solutions of lithium-ion batteries for the development of pure electric vehicles. Renew. Sustain. Energy Rev. 2016, 64, 106–128. [Google Scholar] [CrossRef]

- An, Z.; Jia, L.; Ding, Y.; Dang, C.; Li, X. A review on lithium-ion power battery thermal management technologies and thermal safety. J. Therm. Sci. 2017, 26, 391–412. [Google Scholar] [CrossRef]

- Xia, G.; Cao, L.; Bi, G. A review on battery thermal management in electric vehicle application. J. Power Sources 2017, 367, 90–105. [Google Scholar] [CrossRef]

- Fu, P.; Zhao, L.; Wang, X.; Sun, J.; Xin, Z. A Review of Cooling Technologies in Lithium-Ion Power Battery Thermal Management Systems for New Energy Vehicles. Processes 2023, 11, 3450. [Google Scholar] [CrossRef]

- Liu, X. Research on Heat Production Model and Thermal Management of High-Rate Soft-Pack Lithium-Ion Battery. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2021. [Google Scholar]

- Maher, K.; Boumaiza, A.; Amin, R. Understanding the heat generation mechanisms and the interplay between joule heat and entropy effects as a function of state of charge in lithium-ion batteries. J. Power Sources 2024, 623, 235504. [Google Scholar] [CrossRef]

- Kemper, P.; Li, S.E.; Kum, D. Simplification of pseudo two-dimensional battery model using dynamic profile of lithium concentration. J. Power Sources 2015, 286, 510–525. [Google Scholar] [CrossRef]

- Nie, P.; Zhang, S.W.; Ran, A.; Yang, C.; Chen, S.; Li, Z.; Zhang, X.; Deng, W.; Liu, T.; Kang, F.; et al. Full-cycle electrochemical-thermal coupling analysis for commercial lithium-ion batteries. Appl. Therm. Eng. 2021, 184, 116258. [Google Scholar] [CrossRef]

- Li, H.; Saini, A.; Liu, C.; Yang, J.; Wang, Y.; Yang, T.; Pan, C.; Chen, L.; Jiang, H. Electrochemical and thermal characteristics of prismatic lithium-ion battery based on a three-dimensional electrochemical-thermal coupled model. J. Energy Storage 2021, 42, 102976. [Google Scholar] [CrossRef]

- Joula, M.; Dilibal, S.; Mafratoglu, G.; Alipour, M.; Alipour, M. Hybrid Battery Thermal Management System with NiTi SMA and Phase Change Material (PCM) for Li-ion Batteries. Energies 2022, 15, 4403. [Google Scholar] [CrossRef]

- Barcellona, S.; Piegari, L. Integrated electro-thermal model for pouch lithium-ion batteries. Math. Comput. Simul. 2020, 183, 5–19. [Google Scholar] [CrossRef]

- Kim, U.S.; Shin, C.B.; Kim, C.S. Modeling for the scale-up of a lithium-ion polymer battery. J. Power Sources 2009, 189, 841–846. [Google Scholar] [CrossRef]

- Xie, Y.; Zheng, J.; Hu, X.; Lin, X.; Liu, K.; Sun, J.; Zhang, Y.; Dan, D.; Xi, D.; Feng, F. An improved resistance-based thermal model for prismatic lithium-ion battery charging. Appl. Therm. Eng. 2020, 180, 115794. [Google Scholar] [CrossRef]

- Li, J.; Sun, D.; Jin, X.; Shi, W.; Sun, C. Lithium-ion battery overcharging thermal characteristics analysis and an impedance-based electro-thermal coupled model simulation. Appl. Energy 2019, 254, 113574. [Google Scholar] [CrossRef]

- Klein, M.; Tong, S.; Park, J. In-plane nonuniform temperature effects on the performance of a large-format lithium-ion pouch cell. Appl. Energy 2016, 165, 639–647. [Google Scholar] [CrossRef]

- Xie, J. Optimization Investigation on the Cooling Structure of Lithium-Ion Battery Packages in Electric Vehicles. Master’s Thesis, South China University of Technology, Guangzhou, China, 2018. [Google Scholar]

- Ramadass, P.; Haran, B.; White, R.; Popov, B. Capacity fade of Sony 18650 cells cycled at elevated temperatures Part II. Capacity fade analysis. J. Power Sources 2002, 112, 614–620. [Google Scholar] [CrossRef]

- Bandhauer, T.M.; Garimella, S.; Fuller, T.F. A Critical Review of Thermal Issues in Lithium-Ion Batteries. J. Electrochem. Soc. 2011, 158, R1. [Google Scholar] [CrossRef]

- Yang, Z.; Patil, D.; Fahimi, B. Online estimation of capacity fade and power fade of lithium-ion batteries based on in-put-output response technique. IEEE Trans. Transp. Electrif. 2017, 4, 147–156. [Google Scholar] [CrossRef]

- Jaguemont, J.; Boulon, L.; Venet, P.; Dubé, Y.; Sari, A. Lithium-ion battery aging experiments at subzero temperatures and model de-elopement for capacity fade estimation. IEEE Trans. Veh. Technol. 2016, 65, 4328–4343. [Google Scholar] [CrossRef]

- Huang, Q.; Li, X.; Zhang, G.; Zhang, J.; He, F.; Li, Y. Experimental investigation of the thermal performance of heat pipe assisted phase change material for battery thermal management system. Appl. Therm. Eng. 2018, 141, 1092–1100. [Google Scholar] [CrossRef]

- Zhao, C.; Sousa, A.C.; Jiang, F. Minimization of thermal non-uniformity in lithium-ion battery pack cooled by channeled liquid flow. Int. J. Heat Mass Transf. 2019, 129, 660–670. [Google Scholar] [CrossRef]

- Kim, J.; Oh, J.; Lee, H. Review on battery thermal management system for electric vehicles. Appl. Therm. Eng. 2019, 149, 192–212. [Google Scholar] [CrossRef]

- Scrosati, B.; Garche, J.; Tillmetz, W. Advances in Battery Technologies for Electric Vehicles; Woodhead Publishing: Sawston, UK, 2015. [Google Scholar]

- Wu, W.; Wang, S.; Wu, W.; Hong, S.; Lai, Y. A critical review of battery thermal performance and liquid based battery thermal management. Energy Convers. Manag. 2019, 182, 262–281. [Google Scholar] [CrossRef]

- Xie, L.; Huang, Y.; Lai, H. Coupled prediction model of liquid-cooling based thermal management system for cylindrical lithium-ion module. Appl. Therm. Eng. 2020, 178, 115599. [Google Scholar] [CrossRef]

- Kim, G.-H.; Pesaran, A. Battery Thermal Management System Design Modeling, National Renewable Energy Laboratory; NREL: Golden, CO, USA, 2006.

- Fan, Y.; Bao, Y.; Ling, C.; Chu, Y.; Tan, X.; Yang, S. Experimental study on the thermal management performance of air cooling for high energy density cylindrical lithium-ion batteries. Appl. Therm. Eng. 2019, 155, 96–109. [Google Scholar] [CrossRef]

- Park, C.-W.; Jaura, A.K. Thermal Analysis of Cooling System in Hybrid Electric Vehicles; SAE Technical Paper Series; SAE: Warrendale, PA, USA, 2002. [Google Scholar]

- Yu, K.; Yang, X.; Cheng, Y.; Li, C. Thermal analysis and two directional air flow thermal management for lithium-ion battery pack. J. Power Sources 2014, 270, 193–200. [Google Scholar] [CrossRef]

- Yu, X.; Lu, Z.; Zhang, L.; Wei, L.; Cui, X.; Jin, L. Experimental study on transient thermal characteristics of stagger-arranged lithium-ion battery pack with air cooling strategy. Int. J. Heat Mass Transf. 2019, 143, 118576. [Google Scholar] [CrossRef]

- Zhao, G.; Wang, X.; Negnevitsky, M.; Zhang, H. A review of air-cooling battery thermal management systems for electric and hybrid electric vehicles. J. Power Sources 2021, 501, 230001. [Google Scholar] [CrossRef]

- Ivanov, I.D.; Velikoretskiy, A.; Sergeevich, A.; Nekrasov, A.; Papkin, I. Lithium-Ion Batteries with Forced Air Cooling: Simulation and Laboratory Tests. Int. J. Eng. Adv. Technol. IJEAT 2019, 9, 5552–5558. [Google Scholar] [CrossRef]

- Park, H. A design of air flow configuration for cooling lithium-ion battery in hybrid electric vehicles. J. Power Sources 2013, 239, 30–36. [Google Scholar] [CrossRef]

- Siriboonpanit, E.; Sasiwimonrit, K.; Saelao, J.; Patcharaprakiti, N. An Air Force Cooling of Lithium–ion Battery Thermal Management System for Heat Eliminating in Modified Electric Vehicle. In Proceedings of the International Electrical Engineering Congress (iEECON2022), Khon Kaen, Thailand, 9–11 March 2022. [Google Scholar]

- Han, J.-W.; Garud, K.S.; Hwang, S.-G.; Lee, M.-Y. Experimental Study on Dielectric Fluid Immersion Cooling for Thermal Management of Lithium-Ion Battery. Symmetry 2022, 14, 2126. [Google Scholar] [CrossRef]

- Park, S.; Jung, D. Battery cell arrangement and heat transfer fluid effects on the parasitic power consumption and the cell temperature distribution in a hybrid electric vehicle. J. Power Sources 2013, 227, 191–198. [Google Scholar] [CrossRef]

- Gomathi, S.; Janani, G.; Jothishwaren, R.; Nalien, A. Thermo Electric Cooling System for E-Vehicle. In Proceedings of the 5th International Conference on Mobile Computing and Sustainable Informatics (ICMCSI), Lalitpur, Nepal, 18–19 January 2024. [Google Scholar] [CrossRef]

- Williams, N.; Trimble, D.; O’Shaughnessy, S. Thermal Management of Lithium-ion Batteries for Electric Vehicles through Immersion Cooling. In Proceedings of the 2023 22nd IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), Orlando, FL, USA, 30 May–2 June 2023. [Google Scholar] [CrossRef]

- Al-Zareer, M.; Dincer, I.; Rosen, M.A. Development and evaluation of a new ammonia boiling based battery thermal management system. Electrochem. Acta 2018, 280, 340–352. [Google Scholar] [CrossRef]

- Smith, J.; Singh, R.; Hinterberger, M.; Mochizuki, M. Battery thermal management system for electric vehicle using heat pipes. Int. J. Therm. Sci. 2018, 134, 517–529. [Google Scholar] [CrossRef]

- Steve Wener, S. Passive Thermal Management Optimizes Lithium-Ion Battery Pack Performance. Available online: https://www.edn.com/passive-thermal-management-optimizes-lithium-ion-battery-pack-performance/ (accessed on 8 May 2019).

- Kim, H.; Kim, E.; Seo, M.; Kim, T.; Angani, A.; Shin, K. Design of Battery Thermal Management Unit with PCM for Electrical Vehicle: Part II: Experimental Investigation on Pouch Type Battery Cell. In Proceedings of the IEEE Eurasia Conference on IOT, Communication and Engineering, Yunlin, Taiwan, 3–6 October 2019; pp. 255–258. [Google Scholar]

- Goli, P.; Legedza, S.; Dhar, A.; Salgado, R.; Renteria, J.; Balandin, A.A. Graphene-enhanced hybrid phase change materials for thermal management of Li-ion batteries. J. Power Sources 2014, 248, 37–43. [Google Scholar] [CrossRef]

- Rangappa, R.; Rajoo, S. Effect of thermo-physical properties of cooling mass on hybrid cooling for lithium-ion battery pack using design of experiments. Int. J. Energy Environ. Eng. 2019, 10, 67–83. [Google Scholar] [CrossRef]

- Surya, M.; Aravindhan, A.; Yokeshwar, N.; Geetha, N.; Kavitha, D. Thermal Management of Li-ion Battery by Dual Cooling Systems. In Proceedings of the 2024 Second International Conference on Emerging Trends in Information Technology and Engineering (ICETITE), Vellore, India, 22–23 February 2024. [Google Scholar] [CrossRef]

- Saechan, P.; Dhuchakallaya, I. Investigation of the Cooling Characteristics of Hybrid Liquid Spray and Air Cooling for an EV Battery Pack. In Proceedings of the 6th International Conference on Electrical Engineering and Green Energy (CEEGE), Grimstad, Norway, 6–9 June 2023. [Google Scholar] [CrossRef]

- Zhao, R.; Gu, J.; Liu, J. Optimization of a phase change material based internal cooling system for cylindrical Li-ion battery pack and a hybrid cooling design. Energy 2017, 135, 811–822. [Google Scholar] [CrossRef]

- Wei, Y.; Angelin-Chaab, M. Experimental investigation of a novel hybrid cooling method for lithium-ion batteries. Appl. Therm. Eng. 2018, 136, 375–387. [Google Scholar] [CrossRef]

| Author Name | Research Method | Cooling Method | Strength | Weakness |

|---|---|---|---|---|

| 1. Kim et al. [39] | Simulation | Passive air cooling | Low cost | Limited effectiveness |

| 2. Fan et al. [40] | Experiment | Air cooling | The author shows the active air-cooling effects on the batteries during the operation. | High cost |

| 3. Yu et al. [43] | Experiment Simulation | Air cooling. Forced air. | Effective practical work, simple design. | Unclear experimental steps and results |

| 4. Zhao et al. [44] | Experiment and Simulation | Air cooling | The advantages of air cooling consist of its straightforward design, which eliminates the need for cooling loops, ease of packing, minimal maintenance costs, zero chance of liquid seeping into electronics or the cabin, and reduced weight and energy usage. | Air cooling is inefficient for cooling electric vehicle batteries in high ambient temperatures |

| 5. Ivanov et al. [45] | Experiment and Simulation | Air cooling | The simple description of the developer battery module and the simple experiment | The experiment’s steps are missing, which would show the major changes in the batteries. |

| 6. Park [46] | Simulation | Air cooling. Forced air method. | The research focused on the benefits of the air-cooling method | Affected by high ambient temperatures. |

| 7. Siriboonpanit et al. [47] | Experiment Simulation | Air cooling. Forced air method. | The research focused on compact electric vehicles, and it is not only the safest but also the most cost-effective way to install batteries in EVs. | An additional battery pack might be necessary to maintain the battery’s current and prevent the battery from overheating. |

| 8. Han et al. [48] | Experiment | Liquid cooling. Dielectric immersion cooling systems. | Enhancing the volume flow rate while lowering the coolant inlet temperature improves the cooling effect to increase the battery performance | Probability of liquid leaks and low performance. |

| 9. Park and Jung [49] | Simulation | Liquid cooling, direct cooling performance. | Low cost | Water cooling demands more power, particularly under high cooling loads |

| 10. Gomathi et al. [50] | Experiment | Indirect cooling liquid | The research is optimizing the thermal management system to minimize the maximum temperature. | Low cooling efficiency. |

| 11. Williams et al. [51] | Experiment | Liquid cooling. Dielectric fluid Novec 7000. | The research proved the effectiveness of applying the two-phase immersion cooling on the BTSM | High cost, and significant weight. |

| 12. Al-Zareer [52] | Experiment | Two-phase cooling. Ammonia boiling process. | The paper practically investigates the use of ammonia as a cooling liquid for the batteries | Significant safety risks and operational complexities. |

| 13. Smith et al. [53] | Experiment | Two-phase cooling. Heat pipe | The paper provides a practical investigation into the use of a heat pipe in the cooling system for electric vehicle batteries. | unsymmetrical temperature over the battery pack. |

| 14. Himchan et al. [55] | Experiment | Phase change material. Paraffin. RT31, RT15, EG26, and EG5 PCM. | The paper presents a practical investigation into the use of phase change materials (PCMs) in the cooling system for electric vehicle batteries, demonstrating the positive results achieved with a specific material and thickness. | Low heat transfer and the likelihood of paraffin leakage. |

| 15. Goli et al. [56] | Experiment | Phase change material | Practical investigation into the use of phase change materials (PCMs) in the cooling system for electric vehicle batteries, showing the positive results of using a specific material, resulting in a reduction in the battery temperature by more than 4 °C. | Low heat transfer. |

| 16. Surya et al. [58] | Experiment | Hybrid cooling. External air cooler fan and internal propylene glycol pumping system. | This study demonstrates that double cooling of the battery, both internally and externally, enhances performance, durability, and safety, highlighting its effectiveness as an energy storage system. | The system adds more weight to the vehicle. |

| 17. Saechan et al. [59] | Simulation | Hybrid cooling. Forced air and liquid spray. | The investigation into the use of a hybrid spray and cooling system can be effective in the cooling system for electric vehicle batteries. | Not applicable to practical applications due to the limited water volume in the tank. |

| 18. Zhao et al. [60] | Experiment | PCM-air cooling. Hybrid design. | The proposed design successfully reduced the battery peak temperature by using this hybrid combination. | The system increases the vehicle’s weight and has a low heat transfer capability. |

| 19. Wei and Angelin-Chaab [61] | Experiment | Hybrid cooling with a two-phase air-cooling system | Experimentally, using hybrid cooling with two-phase air-cooling systems improves the cooling system. | A complex system incurs additional costs. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohamed, M.; Elleithy, K.; Elmannai, W. A Review of Cooling Technology Methods for Electric Vehicle Battery Thermal Management Systems. Energies 2025, 18, 6143. https://doi.org/10.3390/en18236143

Mohamed M, Elleithy K, Elmannai W. A Review of Cooling Technology Methods for Electric Vehicle Battery Thermal Management Systems. Energies. 2025; 18(23):6143. https://doi.org/10.3390/en18236143

Chicago/Turabian StyleMohamed, Mohamed, Khaled Elleithy, and Wafa Elmannai. 2025. "A Review of Cooling Technology Methods for Electric Vehicle Battery Thermal Management Systems" Energies 18, no. 23: 6143. https://doi.org/10.3390/en18236143

APA StyleMohamed, M., Elleithy, K., & Elmannai, W. (2025). A Review of Cooling Technology Methods for Electric Vehicle Battery Thermal Management Systems. Energies, 18(23), 6143. https://doi.org/10.3390/en18236143