1. Introduction

Climate change and the urgent need to reduce greenhouse gas (GHG) emissions have placed agriculture and the food industry under increasing scrutiny. The wine sector is a relevant case study because of its global economic importance and its significant environmental footprint, especially in Mediterranean countries and other major wine-producing regions [

1,

2].

In recent years, numerous studies have highlighted that viticulture and winemaking processes contribute substantially to carbon emissions, typically expressed as the carbon footprint (CF) of wine production [

3,

4,

5]. For instance, ref. [

3] quantified the contribution of electricity use and thermal energy in Mediterranean wineries, showing that cellar operations represent a dominant share of total CF. The study in [

4] focused on Portuguese case studies and confirmed that process energy and refrigeration are key emission hotspots. Likewise, ref. [

5] identified similar patterns for wineries in Cyprus, where energy demand during vinification and bottling drives the majority of GHG emissions. This indicator is increasingly used to inform sustainability strategies, policy frameworks, and consumer choices in the agri-food sector.

Several life cycle assessment (LCA) studies have quantified the CF of wine across regions, including Europe, South Africa, and the Americas. These assessments consistently show that the main contributors to GHG emissions are agricultural inputs (fertilizers, pesticides, and fuel), packaging materials (especially glass bottles), and energy consumption during vinification and refrigeration [

6,

7,

8,

9]. More specifically, ref. [

6] reviewed more than forty LCAs and emphasized that electricity and packaging dominate the total footprint. The results in [

7,

8] for Italian and Spanish wineries, respectively, demonstrated that glass production and refrigeration energy are critical contributors. The analysis in [

9] extended this observation by showing that renewable energy integration could significantly reduce total CF. Regional analyses in [

10,

11] further confirmed that in Portugal and Spain, energy use within the winery may exceed 40% of per-bottle emissions. Similar findings from comparative studies of conventional and organic systems reinforce the role of energy as a hotspot regardless of production mode [

12].

Despite this growing body of research, important knowledge gaps remain. Most published work focuses on agricultural practices, packaging reduction, or supply chain logistics, but very few explicitly investigate the impact of renewable energy adoption in wineries. The direct replacement of fossil-based electricity with renewable sources such as solar photovoltaics and wind power has rarely been quantified in terms of avoided CO

2e emissions in wine production [

13]. Given the alignment of the wine sector with European climate targets and sustainability certification schemes, this represents a critical gap. Understanding the potential contribution of renewables to emission reductions is essential both for producers seeking to improve their environmental performance and for policymakers promoting low-carbon transitions in agri-food value chains [

14].

At the same time, the literature highlights that consumer demand for sustainable wines is increasing, and producers face growing pressure to demonstrate their climate commitments [

15,

16,

17,

18,

19,

20]. Studies such as [

15,

16] have shown that environmental certifications and eco-labels strongly influence consumer perception of wine sustainability, while ref. [

17] emphasized the growing importance of transparency in energy sourcing and production practices. The surveys reported in [

18,

19] confirmed that renewable energy use and carbon labeling can enhance consumers’ willingness to pay for low-impact wines. Furthermore, ref. [

20] demonstrated that sustainability-oriented communication strengthens brand value and export competitiveness. Renewable energy integration not only provides a technical pathway to reduce CF but also offers reputational and market advantages. It therefore represents a dual benefit: mitigation of climate impacts and enhanced competitiveness in global markets. Nevertheless, empirical and scenario-based evaluations of this pathway remain limited.

This study addresses the gap by applying a standardized CF calculation to isolate and quantify the effect of renewable energy integration on wine production. We evaluate three policy-relevant scenarios: (i) baseline with grid electricity (fossil-dominated mix), (ii) partial substitution with 50% solar and wind electricity, and (iii) full substitution with 100% renewable electricity. Results are reported per liter and per 0.75 L bottle, facilitating comparison with benchmarks. By quantifying achievable reductions in CO2e emissions from energy use, the study provides practical evidence on how renewables can support decarbonization roadmaps in the wine sector and contribute to climate-neutral agriculture in line with European policy goals.

2. Materials and Methods

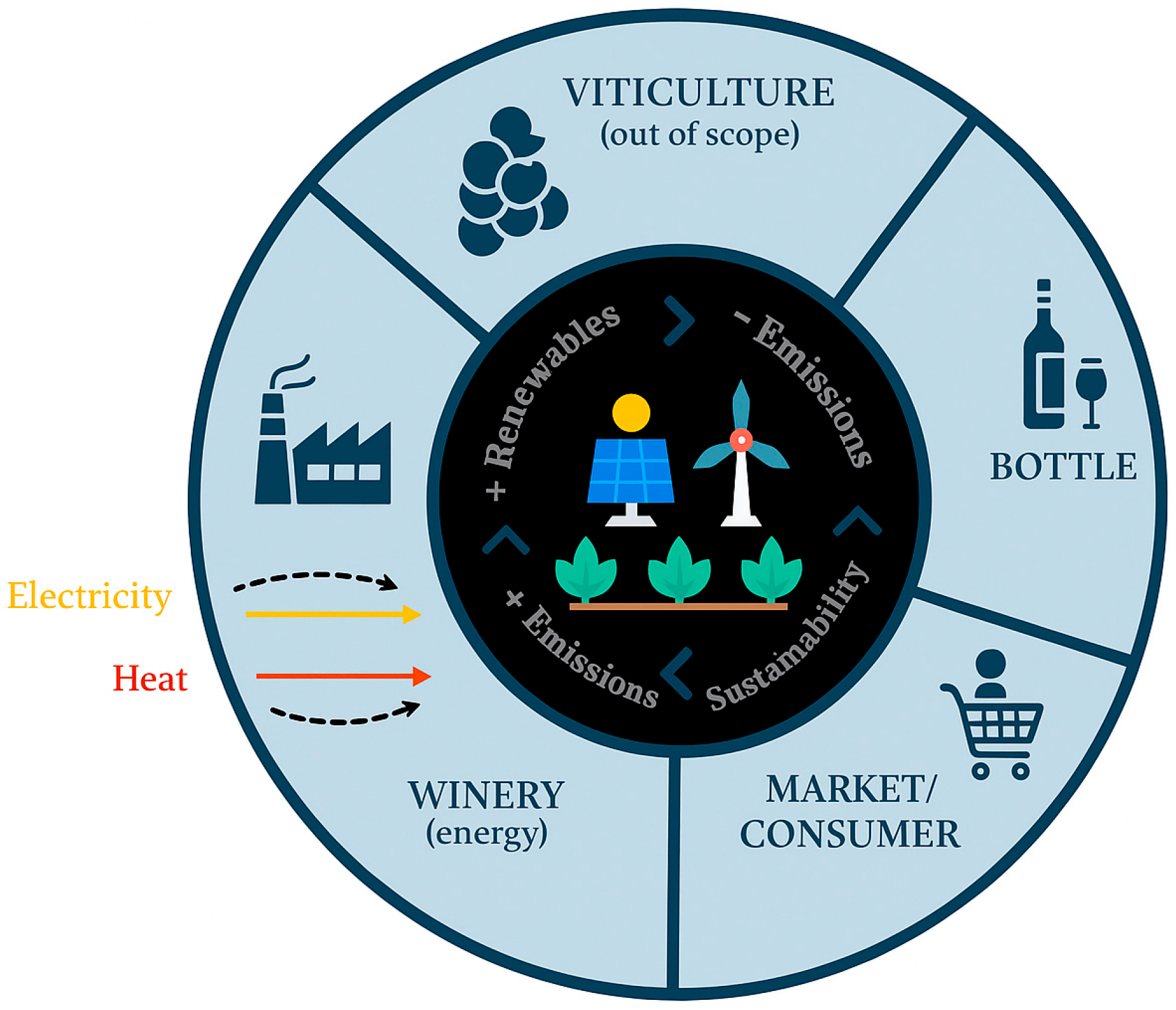

This section outlines the framework to quantify the energy-related carbon footprint (CF) of wine production and assess mitigation via renewable substitution. We specify the goal, scope, and functional unit; describe case selection and primary data; define an inventory focused on utilities in viticulture and winery operations (purchased electricity and process heat), with water for context; compile traceable emission factors; set renewable-substitution scenarios (grid vs. low-carbon electricity and solar heat); present the calculation algorithm for per-liter and per-bottle metrics; and summarize quality-assurance and uncertainty steps, as illustrated in

Figure 1 (system boundary of the study).

2.1. Goal and Scope

This study quantifies the energy-related carbon footprint (CF) of red wine and evaluates the mitigation effect of replacing grid electricity and fossil process heat with renewables at the winery scale. Two Portuguese organizations with distinct scales and contexts (anonymized as Winery A and Winery B) are analyzed for one complete production year using primary metered data and production records. The primary functional unit (FU) is 0.75 L of finished wine at the winery gate (wine content only; packaging excluded); results per liter are also reported for comparability.

The system boundary covers cradle-to-gate utilities: (i) viticulture site utilities (e.g., irrigation pumping or on-farm cooling where present) and (ii) winery operations (electricity for vinification/cellar services and process heat for hot water/cleaning). Water volumes are recorded for context; only their energy implications (electricity/heat used for abstraction, pumping, or treatment) contribute to CF. To isolate the energy effect, field diesel, fertilizers, and plant-protection products, packaging and outbound distribution are excluded from CF totals and scenario calculations (they are noted qualitatively where relevant). Biogenic CO

2 from fermentation is not counted. No allocation to by-products is required under this energy-only scope. Scenario analysis applies alternative electricity/heat emission factors to the same metered consumption to reflect increasing shares of renewable electricity and solar heat (

Figure 1). Heat-pump operation, where applicable, is considered within the electricity demand of the renewable-substitution scenarios, ensuring that both thermal and electrical effects are captured consistently.

2.2. Case Selection and Primary Data

Two Portuguese wineries were purposively selected to reflect operational diversity (scale, region, energy profile). Sites are anonymized as Winery A (located in Alijo, Trás-os-Montes, Portugal) and Winery B (located in Alijo, Trás-os-Montes, Portugal). Primary data cover one complete production year and were obtained from a structured questionnaire, utility bills, production records, and internal logs. When sub-metered series were not available, annual totals were used to derive the resources’ consumption by normalization to the annual volume of finished wine V (L).

Electricity consumption and heat consumption used in the model are computed in Equations (1)–(3), where

is the total purchased electricity (kW·h),

is the total fossil process heat (kW·hth), and

is total water (m

3):

Only utilities are quantified for the carbon footprint (CF) in this study; water is recorded for context and is not assigned a direct emission factor.

2.3. Inventory Model and Measured Variables

The inventory comprises energy utilities within the study boundary: (i) viticulture site utilities where metered (purchased electricity and thermal energy), and (ii) winery operations (purchased electricity and thermal fuels used to generate hot water or process heat). For each stage, activity data are recorded as quantities Activity

i with units compatible with the corresponding emission factor EF

i. Stage emissions are calculated item-wise using Equation (4).

where

is the total GHG emissions of the stage in kg CO

2e, Activity

i is the metered quantity of item i, and

is its emission factor in kg CO

2e per unit of i. Under the energy-only scope adopted here, non-energy items (e.g., packaging, agro-inputs) are excluded from the CF totals.

2.4. Emission Factors and Traceability

All emission factors are stored in a dedicated register that records their value, unit, reference year or version, geographic scope, and bibliographic source. For electricity, a location-based national grid factor is applied as the baseline, while a low-but-non-zero renewable factor is used in the scenarios. Fossil process heat is represented by the natural gas factor, unless explicitly specified otherwise, whereas the renewable thermal alternative is represented by a solar-thermal factor. Only factors with verifiable metadata are considered. Unit consistency is enforced, such that each product follows the relation described in Equation (5).

2.5. Computational CF Calculation

Totals and normalizations are computed in Equations (6)–(8), where

is the sum of stage emissions and V is the annual volume of finished wine (L):

For clarity, the per-liter result is decomposed into electricity and non-electric components as defined in Equation (9).

where

(kg CO

2e L

−1) is the contribution from purchased electricity and

(kg CO

2e L

−1) aggregates the remaining energy items (e.g., fossil heat when not substituted).

2.6. Electricity Factors and Renewable-Substitution Scenarios

Electricity consumption per liter (kW h L−1) is taken from the inventory and held constant across scenarios. Only the electricity emission factor changes with the renewable share s.

Parameters used in this study are as follows:

Grid electricity factor: kg CO2e kW·h−1;

Renewable electricity factor (PV + wind mix): kg CO2e kW·h−1;

Scenario set for renewable share: S ∈ {0.00, 0.25, 0.50, 0.75, 1.00}.

The blended electricity emission factor and its associated contribution are defined in Equations (10) and (11).

The total per-liter and per 0.75 L bottle CFs under scenario s are then computed using Equations (12) and (13).

The percentage reduction in electricity-related emissions relative to the baseline (s = 0) is calculated by Equation (14).

Given constant electricity consumption C

elec, this is simplified in Equation (15)

.This approach ensures a direct, proportional relationship between renewable share and emission reduction, maintaining transparency for scenario comparisons.

2.7. Optional Substitution of Process Heat (Sensitivity)

When a renewable thermal supply is considered, a heat-substitution share t is introduced. Let

denote the fossil heat factor (natural gas) and

the renewable heat factor (solar-thermal). The blended factor and resulting heat contribution are expressed in Equations (16) and (17).

The combined total CF per liter and per 0.75 L bottle under combined electricity (s) and heat (t) substitution is calculated by Equations (18) and (19).

where E

other represents any residual in-scope energy terms not captured by electricity or heat. Under the present energy-only boundary—focused on purchased electricity and fossil/renewable heat—E

other = 0. If no heat substitution is modeled, t = 0, and fossil heat remains within E

nonElec.

2.8. Quality Assurance, Unit Consistency, and Uncertainty

All activity data are checked for unit consistency against their paired emission factors so that

. Plausibility ranges for intensities (e.g., kW·h L

−1 and kW·hth·L

−1) are applied, and annual production volumes V are reconciled against cellar records. Missing or partial data are handled transparently using the intensity formulas in

Section 2.3. Deterministic sensitivity explores the influence of

, and electricity factors, with

bounded in the interval

kg CO

2e kW·h

−1. A first-order sensitivity of the bottle metric with respect to the renewable electricity factor is expressed as Equation (20).

All input data, emission factors, and intermediate calculations are archived in a version-controlled workbook (including inventory sheets, factor registers, and scenario outputs) to ensure reproducibility and auditability.

2.9. Computational Framework and Flowchart Overview

The computational workflow of the carbon footprint (CF) model is summarized in

Figure 2. The framework directly implements the governing equations (Equations (1)–(20), proceeding systematically from inventory activity data and emission factors through stage-level aggregation, normalization to batch, liter, and bottle levels, and finally the renewable-substitution scenarios for electricity (s) and process heat (t).

Each computation step in the model corresponds directly to a mathematical expression introduced in

Section 2.3,

Section 2.4,

Section 2.5,

Section 2.6,

Section 2.7 and

Section 2.8, ensuring full traceability between methodological description and implementation logic. This integrated structure guarantees transparency, reproducibility, and internal consistency of the CF calculations.

To maintain numerical integrity, all parameters and intermediate results are stored in a structured digital workbook. This includes (i) the inventory dataset, (ii) the emission-factor register with bibliographic sources, (iii) batch-level aggregation sheets, and (iv) scenario outputs for renewable substitution. The modular design of this computational framework allows it to be adapted to other agri-food systems where energy substitution effects need to be quantified under similar boundary conditions.

3. Results and Discussion

This section reports the energy-related carbon footprint (CF) of two Portuguese wineries and quantifies the mitigation potential of renewable substitution. Consistent with the stated scope (

Figure 1), results include purchased electricity and process heat only; agro-inputs, packaging, and distribution are excluded to isolate the decarbonization leverage of utilities. This focus aligns with the methodological boundary defined in

Section 2 and reflects prior LCA findings that repeatedly identify winery energy operations as major CF hotspots [

8].

3.1. Case Context and Inventory Intensities

Table 1 compiles the structural characteristics and the measured specific energy consumption values used in the scenario model. Winery A (medium/large scale) operates with electricity-dominated energy consumption, whereas Winery B (micro/small scale) is heat-dominated due to legacy hot-water provision. Water use is reported for context in the survey but is not assigned an emission factor within this energy-only boundary; irrigation electricity, when present, is discussed contextually in

Section 3.7. The specific consumption indicators (C

elec, C

heat) correspond directly to the parameters defined in Equations (1)–(3) and provide the basis for calculating per-liter and per-bottle carbon footprint results in the subsequent scenarios.

3.2. Emission Factors and Scenario Parameters

The baseline emission factors adopted for this study represent location-based national averages for electricity and fossil heat, as well as their renewable alternatives. Specifically, the baseline electricity factor corresponds to the Portuguese grid mix, while the renewable electricity factor represents a low but non-zero PV–wind mix, consistent with the methodological assumptions in

Section 2.4. For process heat, the baseline assumes natural gas, and the renewable alternative assumes solar-thermal hot water. These values establish the limits for the scenario simulations and are compiled in

Table 2.

Renewable electricity penetration is modeled with the discrete share . The effective electricity factor is . For Winery B, a heat-substitution share is also tested: .

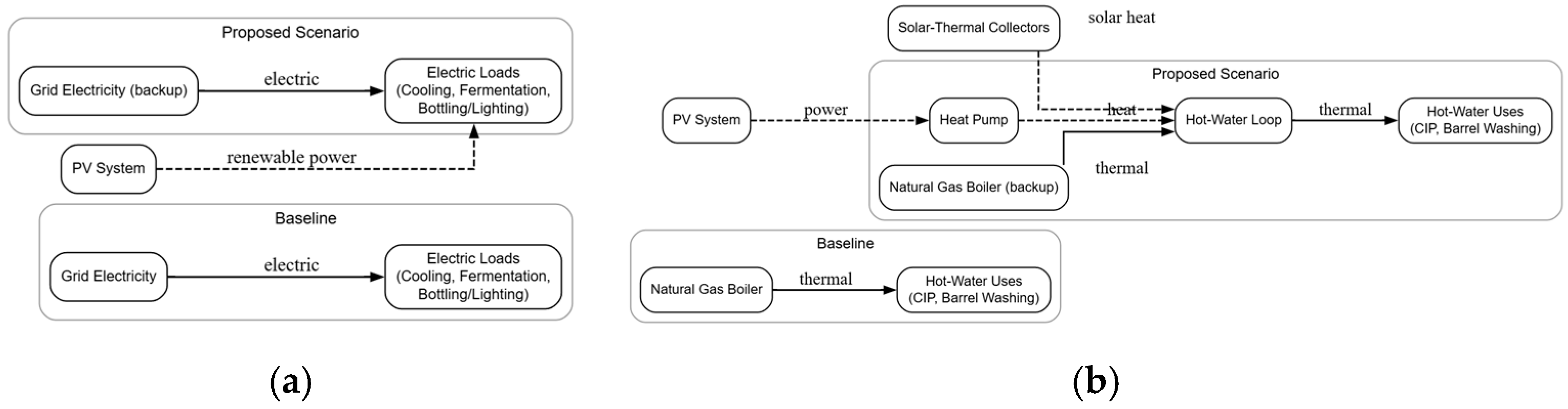

Figure 3a,b presents a functional view of how energy is supplied and used in the two wineries before and after the proposed upgrades. In the baseline configuration, the cellars depend entirely on grid electricity for refrigeration, fermentation control, bottling, and lighting, and on natural gas for hot-water production. The proposed configuration introduces renewable and high-efficiency technologies: photovoltaic panels generate most of the electricity demand on-site, while a heat pump and solar-thermal loop deliver low-carbon heat, while the existing gas boiler is retained as a backup. Together, these schemes illustrate the transition from a fossil-dominated to a renewable-integrated winery energy system and form the basis for the scenario analysis that follows.

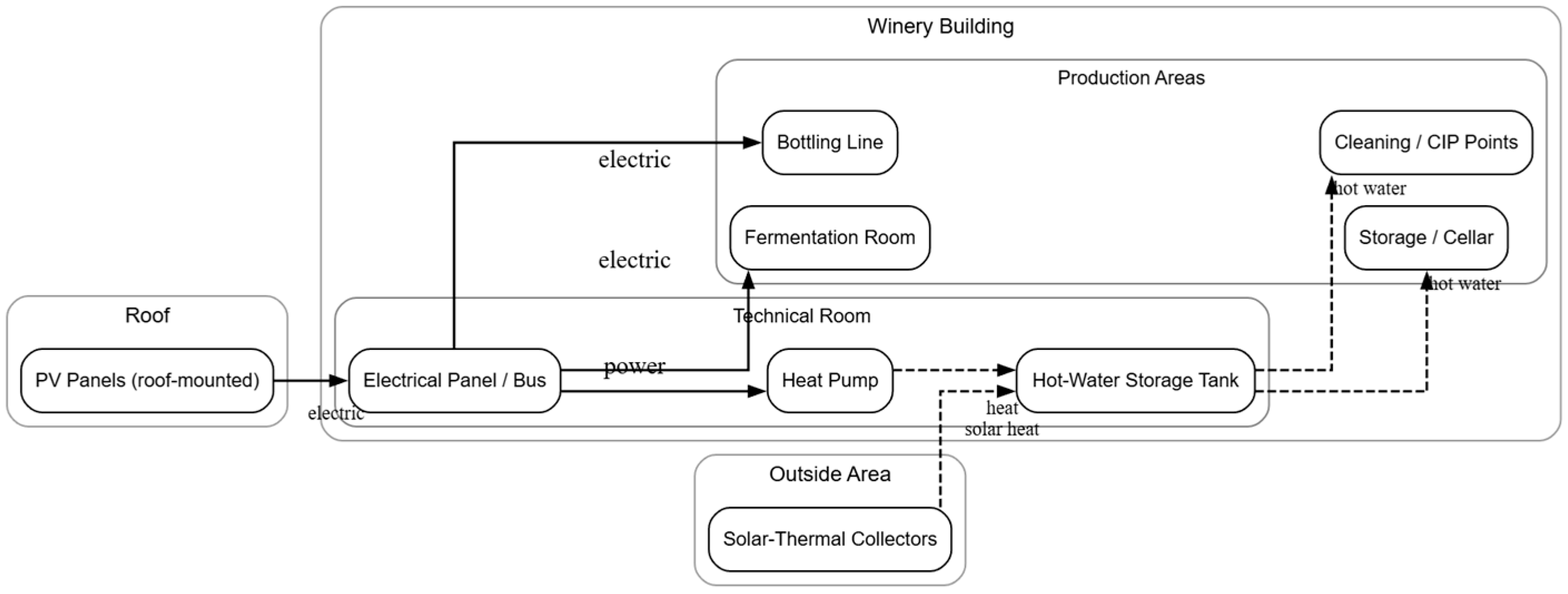

A spatial overview of the proposed energy system is shown in

Figure 4, which depicts the positioning of roof-mounted PV panels, solar-thermal collectors, the heat pump, and the hot-water storage tank, and their integration with the main production areas (fermentation, bottling, cleaning/CIP, and cellar). This layout reflects the conceptual retrofit strategy adopted for the case studies and supports the technical parameters summarized in

Table 3.

The configuration assumptions derived from the schematic and spatial representations (

Figure 3 and

Figure 4) are parameterized using the characteristic performance data summarized in

Table 3. This table compiles typical technical parameters for renewable and hybrid systems relevant to winery applications, including photovoltaic panels, solar-thermal collectors, heat pumps, and storage components. The selected values represent realistic operational ranges reported in the literature for systems of comparable scale in agri-food and industrial facilities. These parameters were used to ensure that the renewable-substitution scenarios developed in this study remain technically consistent and aligned with practical implementation feasibility.

To ensure conceptual integrity across the modeling framework, the cost data summarized in

Table 3 were derived from the same empirical sources that underpin the technical parameters in

Table 4. This approach establishes a consistent reference base for linking technological performance with indicative investment and operational costs. The resulting values provide an order-of-magnitude estimate of implementation feasibility rather than a detailed financial assessment.

Although the cost data in

Table 4 are indicative, they provide a realistic order of magnitude for assessing the financial feasibility of renewable retrofits in small- and medium-scale wineries. The investment ranges align with values reported for comparable agri-food facilities, where photovoltaic and solar-thermal installations typically represent the largest capital components. However, operating cost reductions of 30–60% and the potential to integrate heat-pump systems with renewable electricity supply suggest that the payback period can remain competitive relative to conventional energy costs. These figures thus provide a consistent techno-economic context for interpreting the carbon-footprint mitigation scenarios presented in the following sections.

3.3. Baseline Energy Carbon Footprint

The baseline configuration represents the current operating conditions at both wineries, with electricity supplied from the national grid and process heat generated from fossil fuels.

Table 5 summarizes the calculated baseline energy-related carbon footprint (CF) per liter and per 0.75 L bottle, decomposed into electricity and heat contributions according to Equation (4). These values provide the reference point for the renewable-substitution scenarios defined in

Section 2.6.

The decomposition confirms the well-documented dichotomy in winery energy profiles: electricity-intensive cellars dominated by cooling and auxiliary systems versus heat-intensive cellars dominated by hot-water and cleaning-in-place (CIP) utilities [

10,

14].

3.4. Electricity Substitution Scenarios (Heat Unchanged)

Varying only the electricity emission factor as a function of the renewable share s, according to Equation (10), yields the trajectories in

Table 6. Because of the linear mixing of emission factors, the per-liter electricity term decreases linearly with

s, and total CF reduction is proportional to the baseline electricity share.

For Winery A, substituting grid electricity with low-carbon supply (e.g., on-site PV, renewable PPAs, or certified green tariffs) almost eliminates the energy-related CF. In contrast, for Winery B, electricity-only measures have a negligible effect due to the heat-dominated baseline—a pattern widely reported in winery energy assessments [

17,

18].

3.5. Joint Decarbonization of Electricity and Heat (Winery B)

Recognizing the dominance of thermal utilities at Winery B, joint scenarios were simulated by combining full renewable electricity (s = 1) with incremental solar-thermal substitution for process heat (t), following Equation (11). Substantial CF reductions are achieved only when thermal loads are decarbonized.

Table 7 presents the resulting carbon footprint values under these combined scenarios, detailing the evolution of the effective emission factor for heat and the corresponding per-liter and per-bottle results.

For the heat-dominated winery, the electricity required to operate the heat pumps was conceptually accounted for. Using the measured heat consumption (Cheat = 4.545 kW·hth·L−1), a coefficient of performance (COP) of 3–4 corresponds to an additional 1.52–1.14 kW·hel·L−1 of electricity. If supplied from renewable power (EF(ren) = 0.031 kg CO2e·kW·hel−1), this contributes only 0.047–0.035 kg CO2e·L−1, substantially lower than the baseline fossil heat (0.920 kg CO2e·L−1) and even below the solar-thermal alternative (~0.070 kg CO2e·L−1).

Even when powered by grid electricity (EF(grid) = 0.324 kg CO2e·kW·hel−1), heat-pump operation remains advantageous due to its high thermal efficiency. The resulting footprint decreases to 0.491–0.368 kg CO2e·L−1 for COP = 3–4 (≈47–60% reduction vs. baseline). The break-even condition (EF(elec)/COP = EF(fuel)) occurs at COP ≈ 1.6, well below typical operational values. Thus, thermal electrification remains a robust mitigation strategy under both renewable and grid-mix electricity supplies.

These results reinforce a differentiated strategy: heat-dominated cellars must prioritize thermal decarbonization (solar-thermal systems, heat pumps powered by renewable electricity, and heat-recovery measures), whereas electricity-dominated wineries can achieve nearly linear CF reductions through renewable electricity and efficiency improvements [

15,

17,

18,

19,

20].

3.6. Sensitivity to Renewable Electricity Factor

Once renewable electricity is assumed to be low-carbon but non-zero, the residual emission factor EF

ren becomes a source of uncertainty, particularly for electricity-dominated wineries. To test the robustness of results, EF

ren was varied within a plausible range of 0.02–0.06 kg CO

2e·kW·h

−1 at full renewable penetration (s = 1). The resulting variation in total carbon footprint is shown in

Table 8.

The sensitivity is significant only for electricity-intensive wineries (e.g., Winery A), where the residual carbon intensity of renewable electricity directly influences the total CF. For heat-dominated facilities (Winery B), the effect is negligible because electricity contributes less than 1% of the baseline CF. This outcome is consistent with literature on location-based versus market-based emission factor accounting in the wine sector [

8,

14,

16,

17].

3.7. Integrated Discussion

The scenario analysis quantifies the isolated contribution of winery energy utilities and examines the mitigation potential of renewable integration under technically and economically feasible conditions. Two operational archetypes emerge with distinct abatement pathways. In electricity-dominated cellars, the energy-related carbon footprint (CF) is driven primarily by grid electricity for refrigeration, temperature control during fermentation and maturation, pumping, compressed air, and cold stabilization. Because the electricity component in the model varies linearly with the renewable share in the supply mix, replacing location-based grid factors with verifiable low-carbon supply, such as on-site photovoltaics, renewable power purchase agreements, or certified green tariffs, yields approximately proportional reductions in CF. Demand-side measures such as high-efficiency chillers and compressors, variable-speed drives, targeted insulation, and process control to minimize cold-stabilization requirements further enhance the effectiveness of renewable integration. These priorities align with numerous winery life-cycle assessments that consistently identify energy-intensive operations as persistent hotspots and emphasize electricity decarbonization and efficiency as first-order interventions [

1,

2,

3].

In heat-dominated cellars, electricity decarbonization alone produces limited abatement because process heat and hot-water provision constitute the bulk of baseline emissions. Significant reductions require thermal measures such as solar-thermal systems for hot water and cleaning-in-place, electrification of process heat via high-COP heat pumps powered by renewable electricity, and systematic heat recovery across hot and cold process streams. Where compatible with sustainability and air-quality constraints, valorization of biomass residues (for example, grape marc and prunings) can complement solar and heat-pump options [

4,

5]. Although vineyard utilities are outside the present boundary, prior work shows that in dry regions, irrigation electricity can become a hotspot; on-farm photovoltaics, efficient pumping, and flow management are therefore relevant levers in cradle-to-gate decarbonization strategies [

10,

12].

Quantitatively, the baseline energy-only CF per 0.75 L bottle spans approximately 0.152 kg CO

2e for the electricity-dominated case and 0.693 kg CO

2e for the heat-dominated case. Under electricity-only renewable integration, the electricity-dominated case exhibits substantial decreases (about 89% at full renewable share), while electricity substitution in the heat-dominated case yields negligible change (less than 1%) because electricity represents a very small share of baseline CF. When thermal measures are introduced—solar-thermal heat or heat pumps supplied by renewable power—the heat-dominated case shows large absolute reductions of about 47% to 93% relative to baseline. Across all scenarios, the modeled energy-only CFs (0.05–0.69 kg CO

2e·bottle

−1) are consistent with recent studies reporting values between 0.1 and 1.2 kg CO

2e·bottle

−1 for Mediterranean wineries [

1,

2], confirming that the results align with the latest literature.

These energy-only findings, when viewed within the broader literature, represent a partial perspective of the total wine carbon footprint. Packaging and distribution, particularly glass bottle production and transport, often dominate cradle-to-grave impacts [

1,

6,

7]. This reinforces a sequential mitigation strategy, where decarbonizing winery energy use through renewable procurement and efficiency serves as the first and most auditable step, followed by packaging and logistics optimization to approach net-zero wine [

2,

6,

7,

17].

From a management perspective, these findings demonstrate that renewable retrofits are technically and economically viable. Electricity-dominated cellars should prioritize renewable electricity procurement or generation and efficiency upgrades in refrigeration and compression, coupled with load shifting to align consumption with on-site photovoltaic generation. Heat-dominated cellars should focus on solar-thermal integration, electrification of process heat via high-efficiency heat pumps powered by renewable electricity, and systematic heat recovery. Maintaining a traceable emission-factor register and metered intensities enables year-on-year CF accounting and verification of claimed reductions. Extending the boundary to include packaging and distribution, as emphasized by previous studies, represents the next logical step toward comprehensive decarbonization of the wine sector [

1,

2,

3,

6,

7,

17,

19,

20].

4. Conclusions

This study quantified the energy-related carbon footprint (CF) of wine production and evaluated renewable integration as a practical decarbonization pathway for wineries. Primary metered data from two Portuguese case studies revealed two operational archetypes. In electricity-dominated cellars, where nearly 98% of emissions originate from grid power, replacing this supply with renewable electricity achieved an 88.7% CF reduction, confirming a linear relationship between renewable share and emission decrease. In heat-dominated cellars, where more than 99% of emissions stem from fossil process heat, combining renewable electricity with solar-thermal or high-efficiency heat-pump systems yielded up to 92.6% emission reduction.

These results demonstrate that renewable retrofits are technically feasible and economically realistic for small and medium wineries. The proposed framework, based on traceable emission factors, reproducible calculations, and scenario modeling, can support energy transition planning, carbon accounting, and sustainability certification in the agri-food sector.

Future research should extend the system boundary to packaging and logistics, include irrigation electricity where relevant, and explore dynamic operational strategies such as load shifting and renewable-heat hybridization to achieve full cradle-to-grave decarbonization.