The Biorefinery Paradigm: Technologies, Feedstocks, and Retrofitting for Future Sustainable Energy

Abstract

1. Introduction

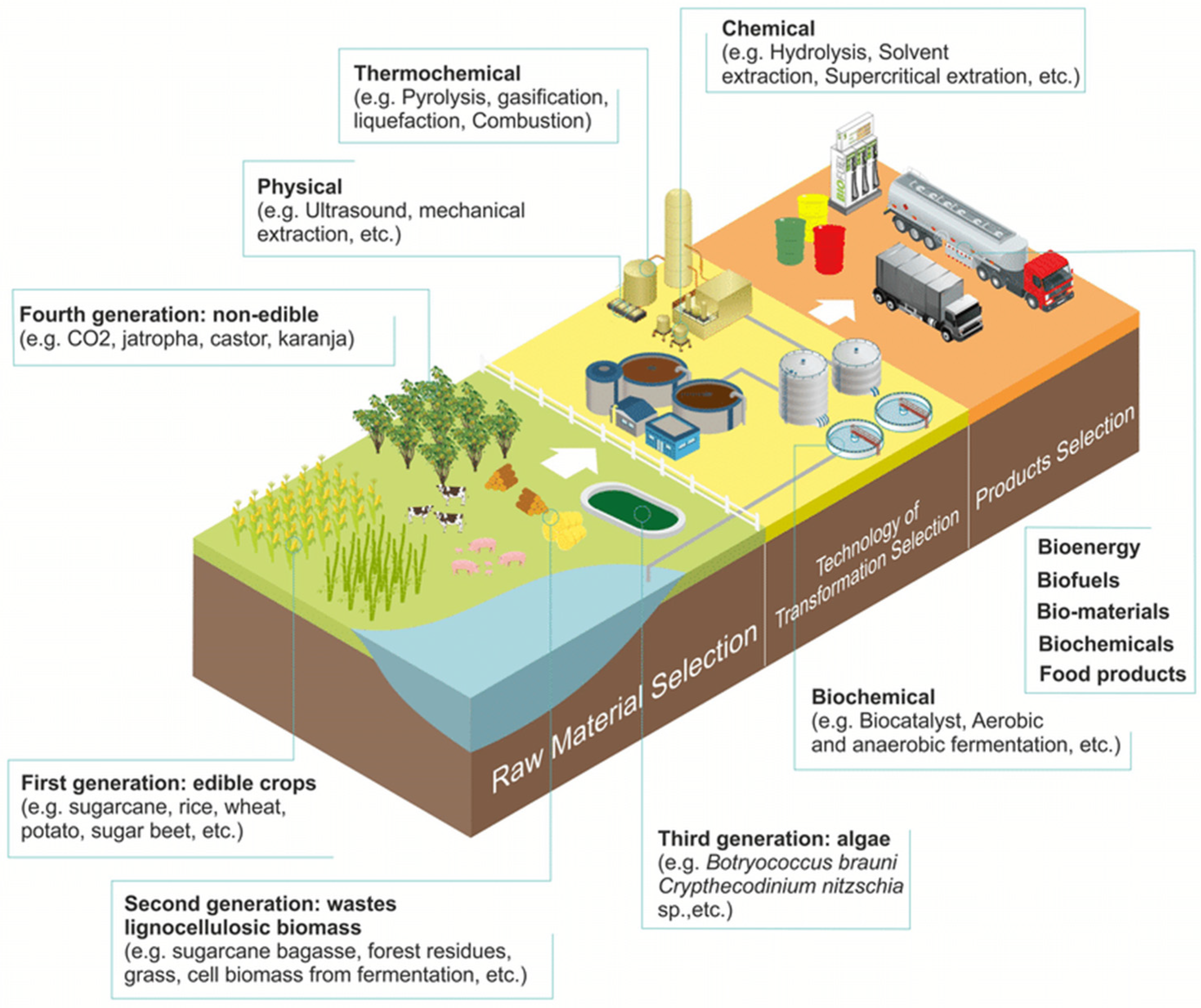

2. Biorefinery Concept

- Pretreatment (the treatment of the feedstock for further processing).

- Conversion of the biomass into useful forms of energy, fuels, chemicals, or other products through four main categories of processes: thermochemical, biochemical, mechanical/physical, and chemical processes.

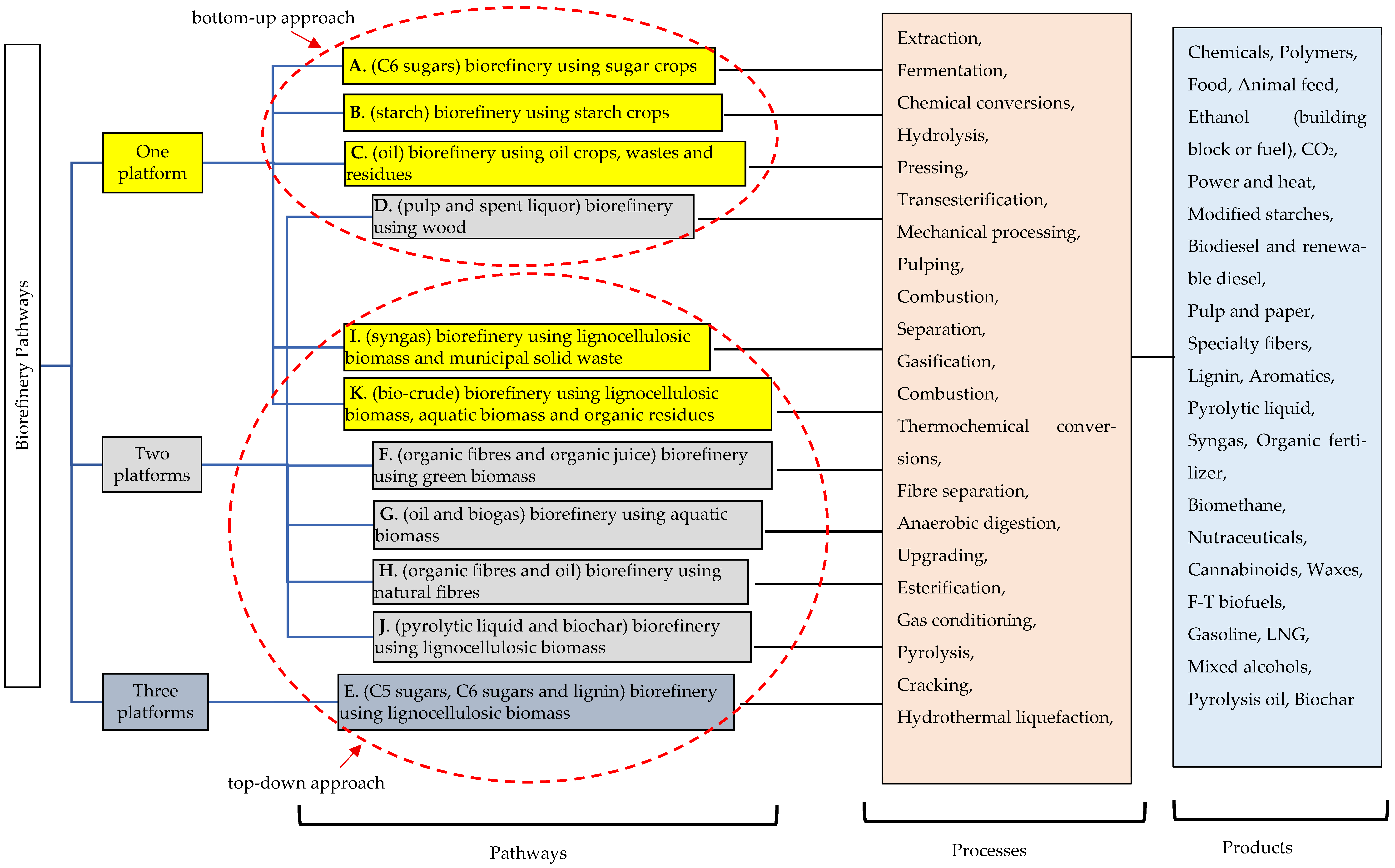

3. Biorefinery Classification

3.1. Platform Classification

| No | Platform Name | Technology Employed | Main Feedstock | Products | Utilization | Ref. |

|---|---|---|---|---|---|---|

| 1 | Biogas | Anaerobic digestion | Manure, food waste, and MSW biosolids | Mixture of gas (mainly CH4 and CO2) | Production of biomethane and hydrogen. Produces fertilizers as byproducts. | [21] |

| 2 | Syngas | Gasification | Organic residues and grasses | Synthesis gas, mainly CO and H2 | Power generation. Production of alcohols, chemicals, Fischer–Tropsch diesel, methanol, ethanol, NH3, and building blocks. | [1,22,23] |

| 3 | Hydrogen | Water–gas shift reaction, steam reforming, water electrolysis, dark fermentation | Organic matters, lignocellulosic crops, and residues | H2 gas | Production of energy and chemicals. | [4,24] |

| 4 | C6 sugar | Hydrolysis process | Starch, cellulose, and hemicellulose | Six-carbon sugars such as glucose, and galactose (C6H12O6) | Production of ethanol. Synthesis of biochemicals and bioplastics | [25] |

| 5 | Mixed C6 and C5 sugars | Hydrolysis process | Starch, lignocellulosic crops, and residues | Mixed streams of six-carbon sugars (C6H12O6) and five-carbon sugars (C5H10O5) | Production of biofuel, furfural, levulinic acid, sorbitol, hydroxymethyl furfural (HMF), and glucaric acid. | [1,26,38] |

| 6 | Lignin | Pretreatment and separation of lignocellulosic crops and wastes | Lignocellulosic crops and residues | Lignin | Production of syngas. Produces liquid hydrocarbons, phenols, oxidized products, and macromolecules | [27,28] |

| 7 | Pyrolysis liquid | Thermal depolymerization (pyrolysis) | Oil-based residues, lignocellulosic crops, and residues | Pyrolysis liquid | Production of levoglucosan, furfural, organic acids, phenols, and polymers. Production of sulfur-free biofuels. | [30,31,32] |

| 8 | Plant-based oil | Pressing/disruption | Oil crops and oil-based residues | A mixture of methyl and/or ethyl esters of fatty acids | Triglycerides, fatty alcohol, epoxides, soap, and biodiesel. | [39] |

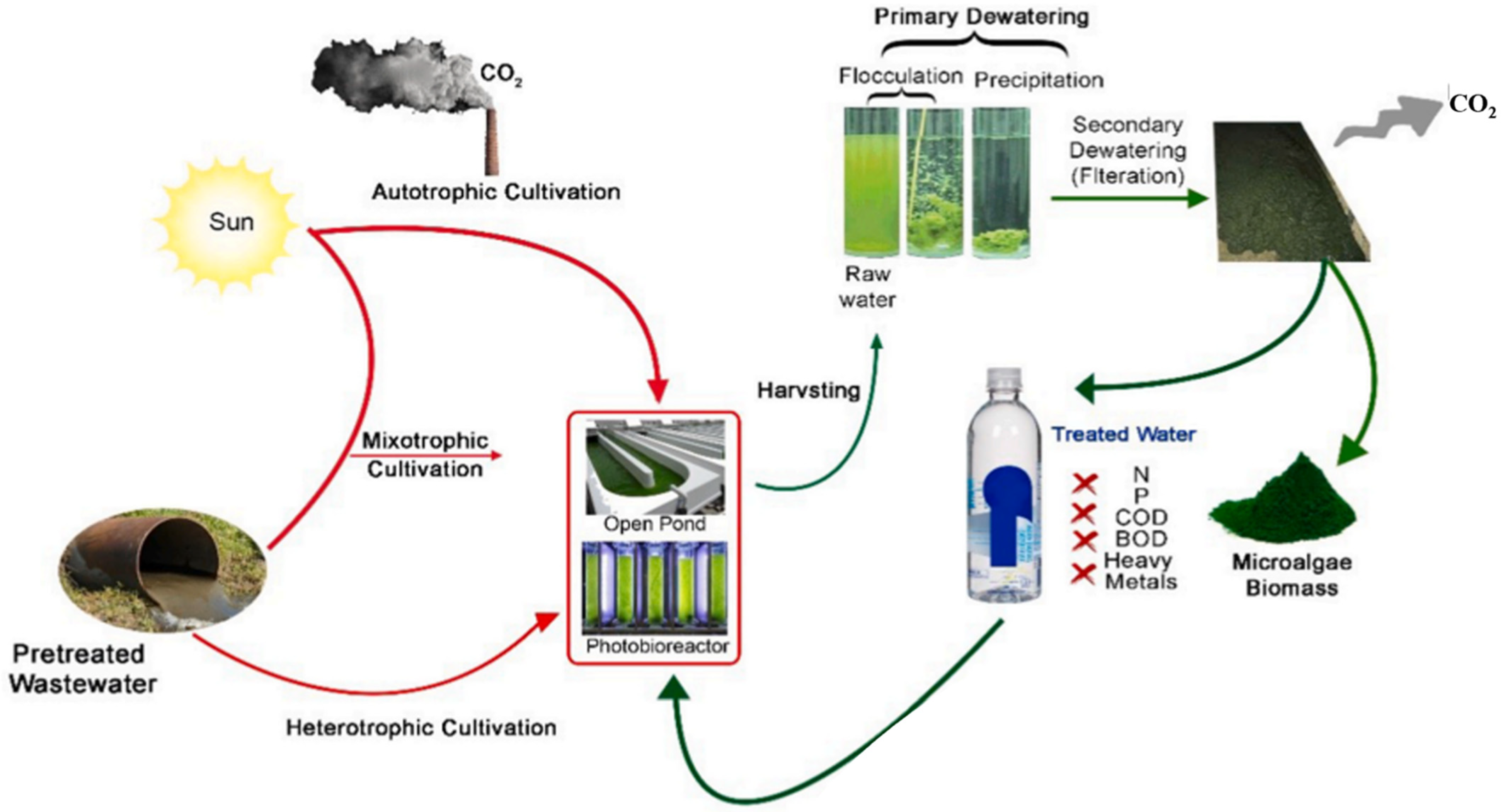

| 9 | Algae-based | Produced in all seasons with sunlight, CO2, nutrients, and water, then cultivated | Marine biomass | Microalgae can include significant amounts of protein, carbohydrates, and lipids | Produces biodiesel, fertilizers, additives for the food industry, nutritional supplements, pigments, fatty acids, vitamins, antimicrobial toxins, and sterols. | [1,35,36,37] |

| 10 | Organic juice | Dewatering and screw pressing | Wet biomass (starch crops, grain, grasses, and organic residues) | A nutrient-rich juice and a fiber-rich lignocellulosic cake | Production of energy. Production of proteins, amino acids, lactic acid, bioethanol, cake as feed pellets, fibers, lignin, syngas, and sugars. | [40] |

| 11 | Electricity and heat | Co-firing | Solid residues (lignin and humins) | Power and heat | Integrated with a combined heat and power (CHP) plant or gasification plant. Economical use of the excess steam and heat from the power plant. | [41] |

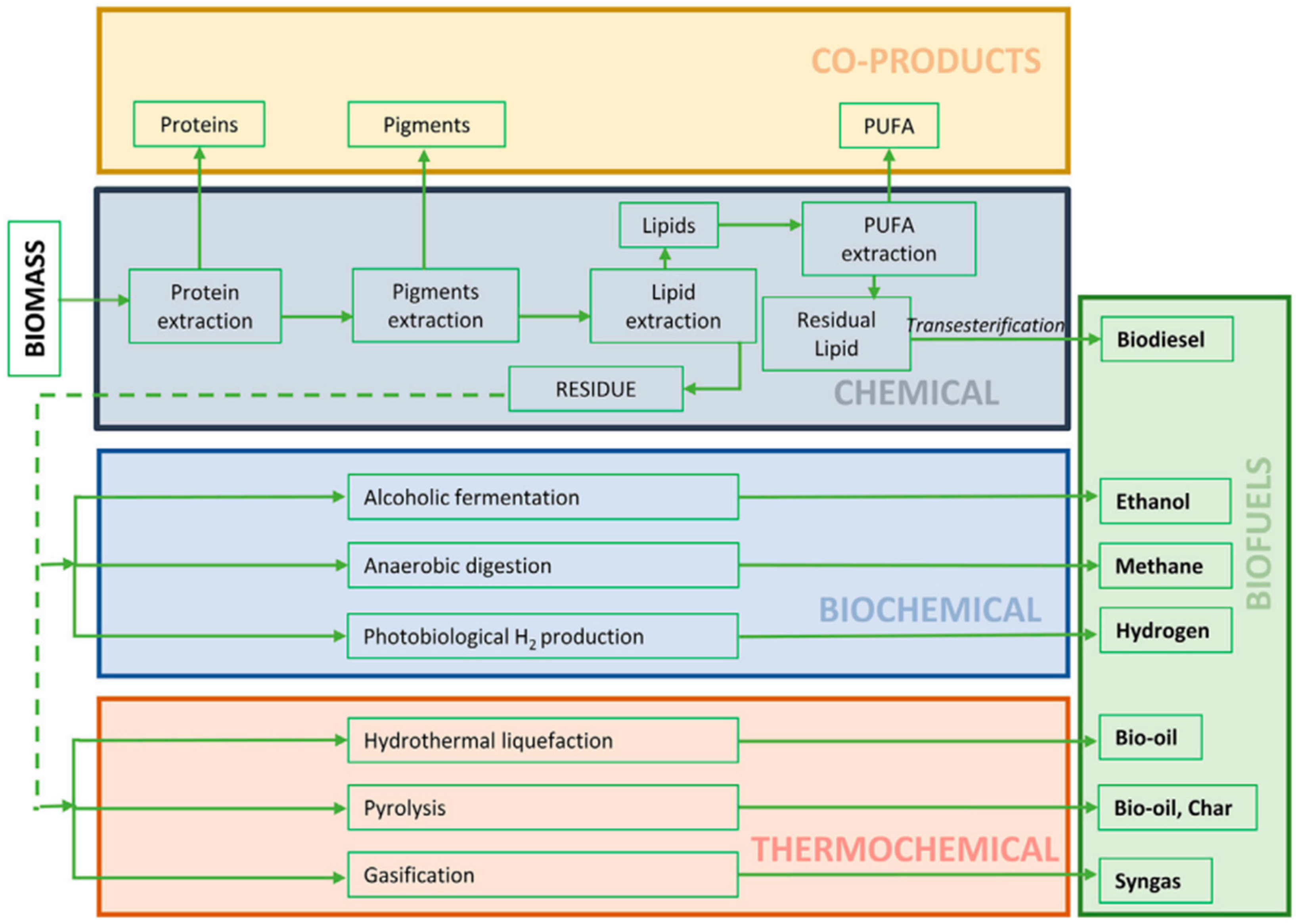

3.2. Process Classification

- Mechanical/physical, such as cleaning, drying, and grinding.

- Biochemical processes such as anaerobic digestion, aerobic and anaerobic fermentation, and enzymatic conversion.

- Chemical processes such as hydrolysis, transesterification, hydrogenation, oxidation, and pulping.

- Thermochemical processes such as pyrolysis, gasification, hydrothermal upgrading, and combustion.

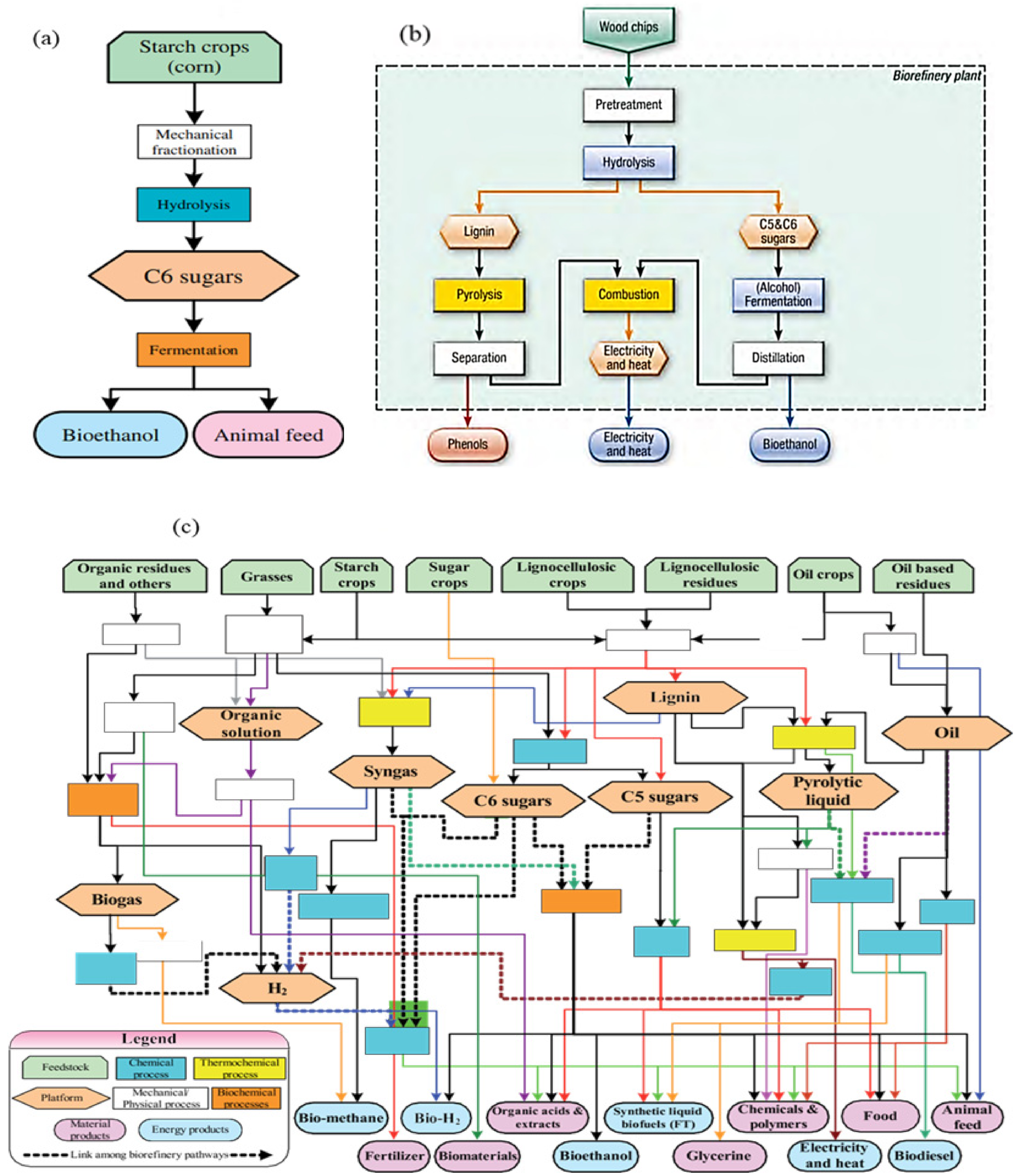

3.3. Biorefinery Pathways

3.4. Biorefinery System Networks and Types

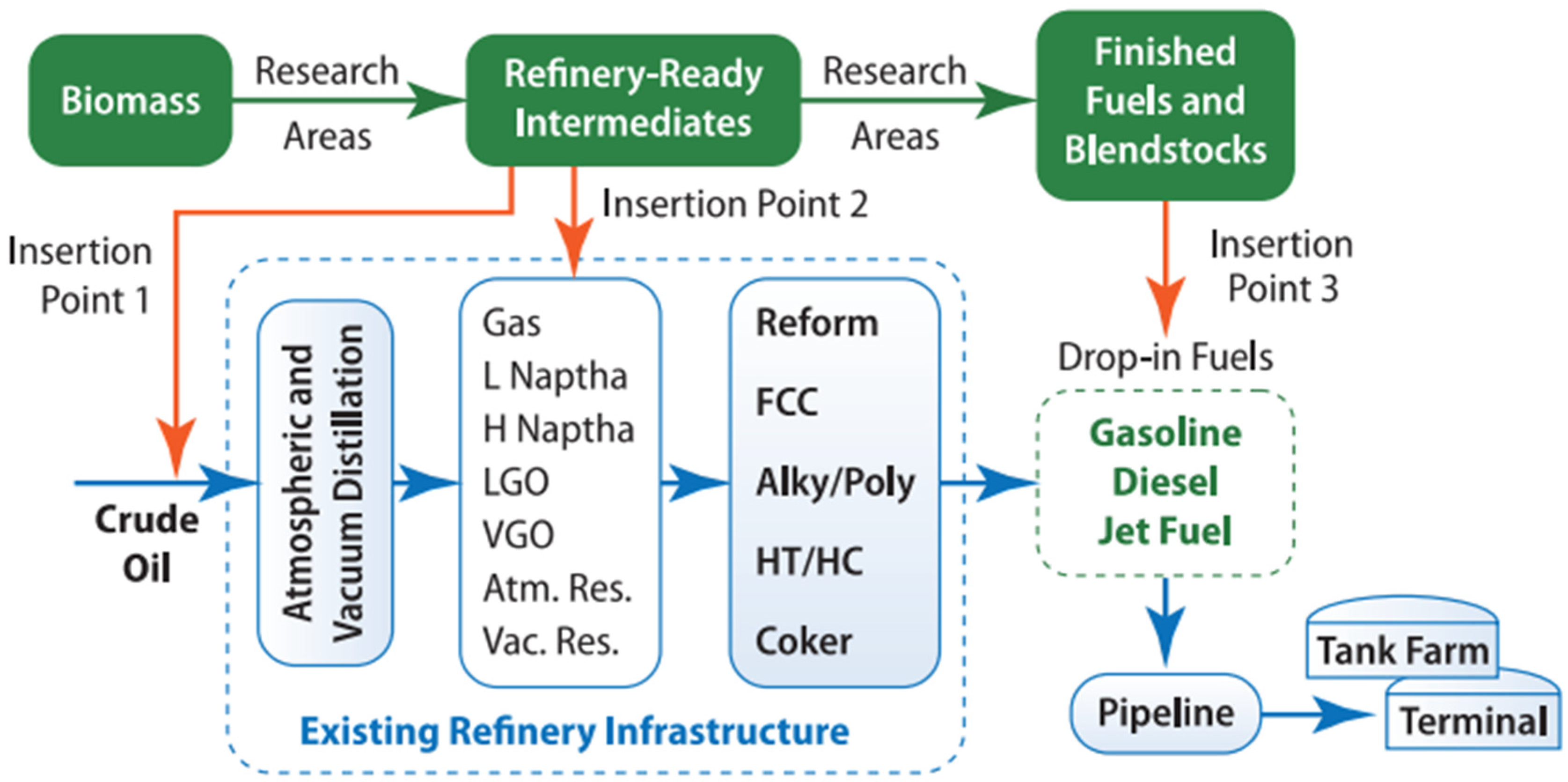

4. Retrofitting for Biomass-Based Processing

- Feedstock conversion by using biomass sources in place of fossil fuel feedstocks, which may involve preprocessing steps like pyrolysis, grinding, or drying.

- Process modification and technological integration, which may involve modifying essential components (e.g., by reforming, hydrotreating, fermentation, gasification, etc.) to manage the various chemical compositions and contaminants present in the biomass.

- Material upgrades to make sure that the materials used in equipment can withstand the more caustic nature of intermediates made from biomass.

4.1. Technical and Economic Feasibility of Retrofitting

4.2. Retrofitting Configuration

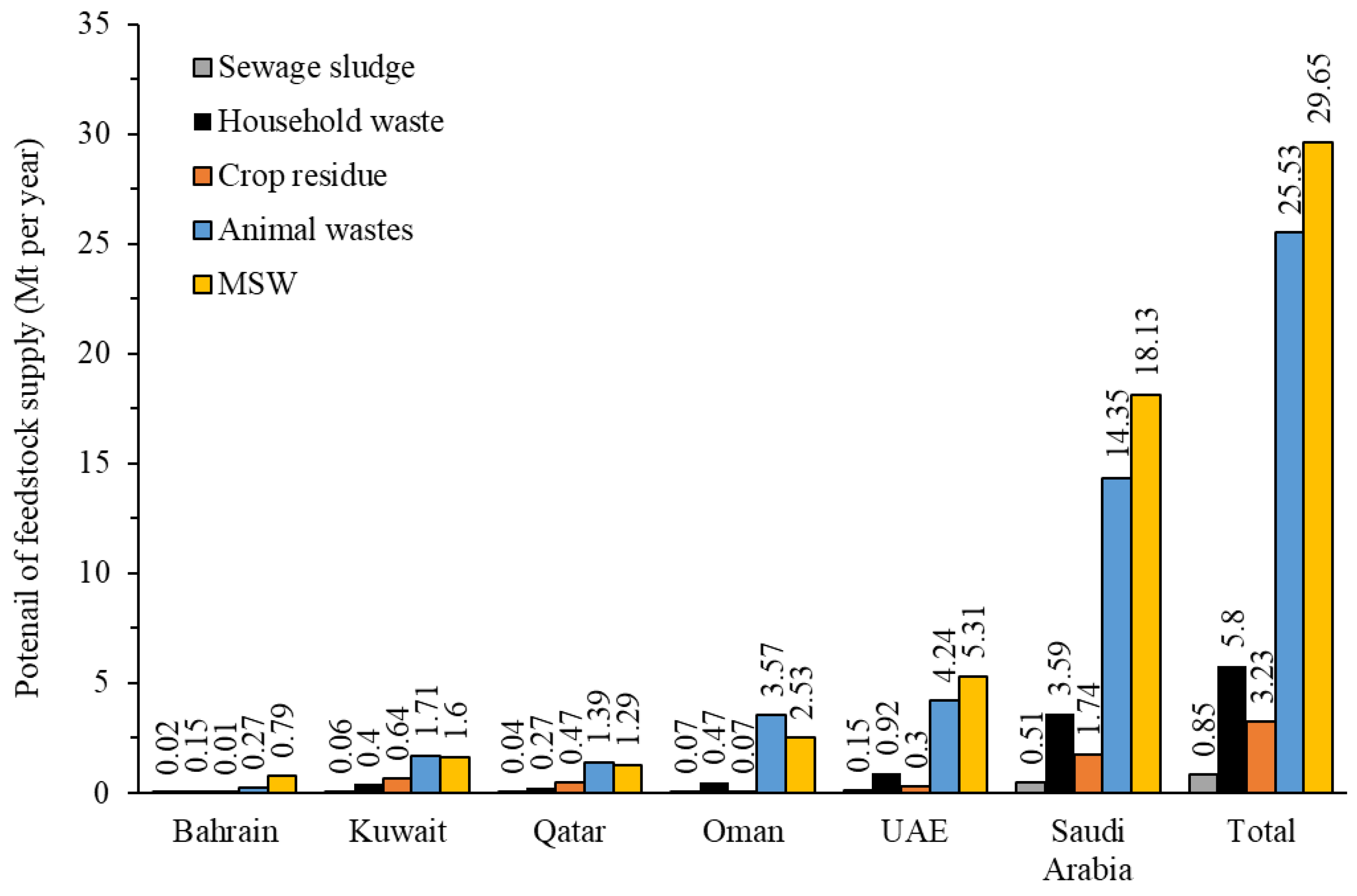

5. GCC Countries Case Study

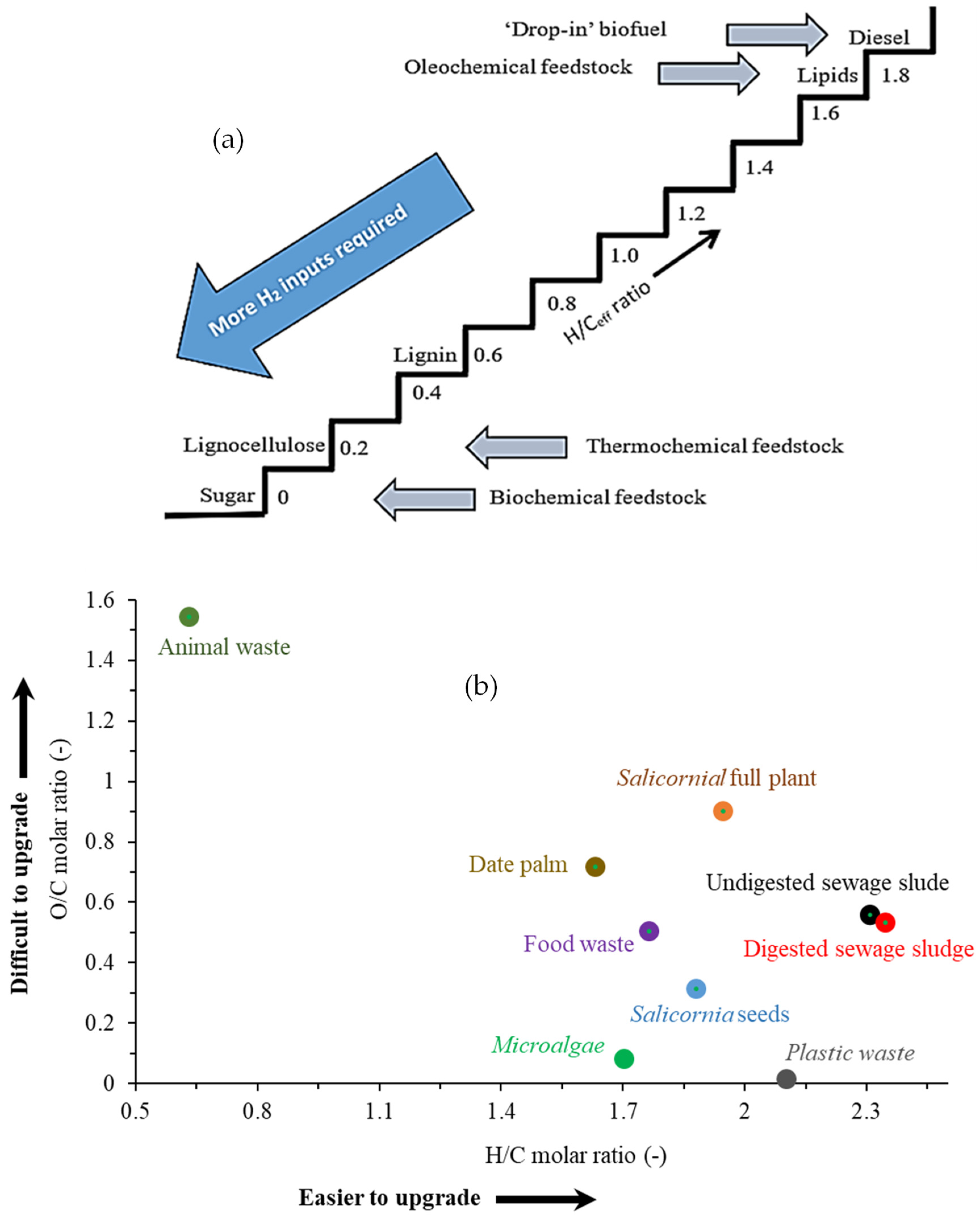

- Group 1: Halophyte crops and agricultural residues (e.g., date palm waste, Salicornia, and vegetable crop residues).

- Group 2: Animal and organic waste (e.g., manure, general household waste, food waste).

- Group 3: Industrial waste (e.g., paper waste, plastic waste, wood construction waste).

- Group 4: Aquaculture (e.g., algae, seaweed, fish waste).

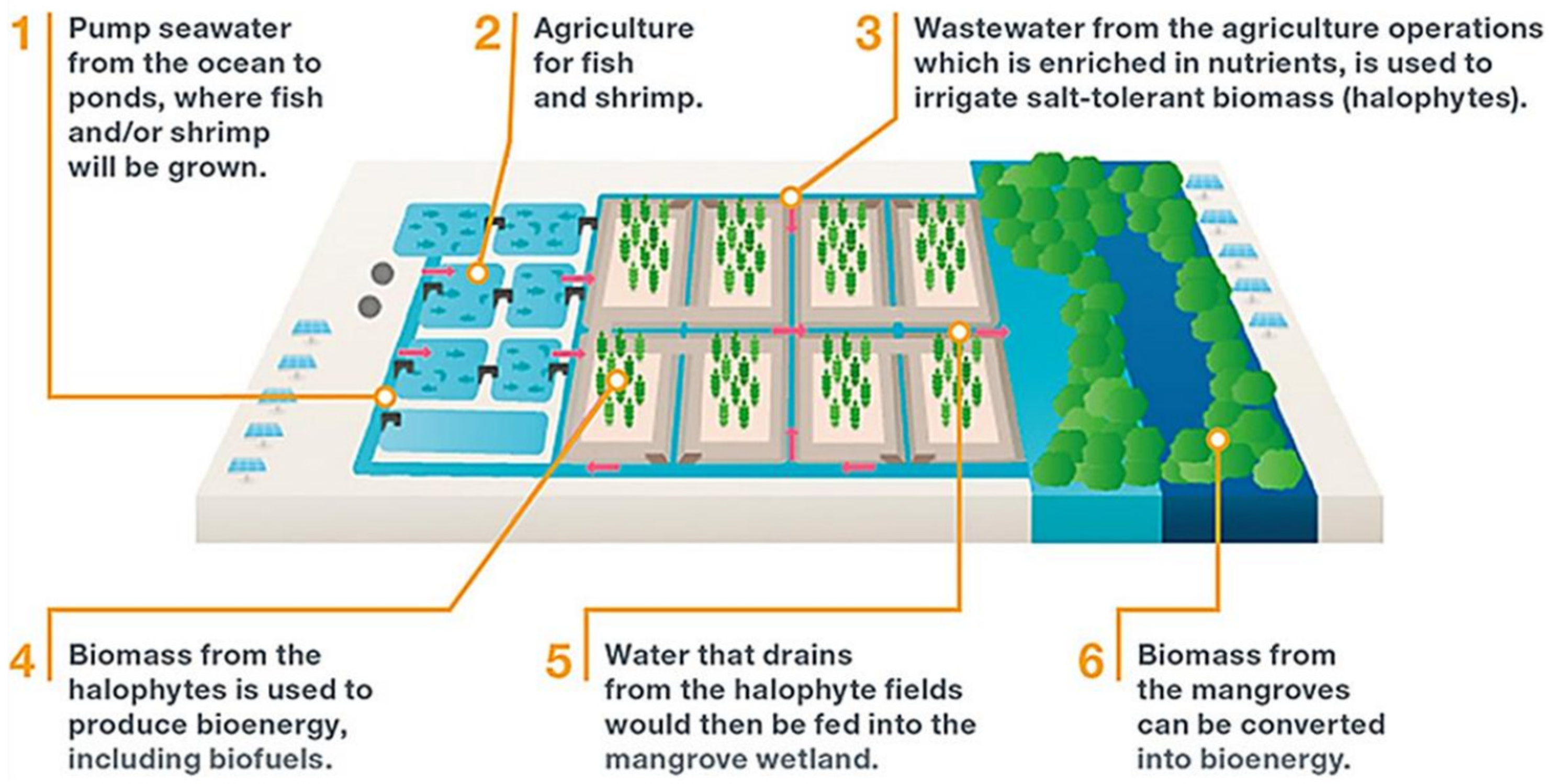

5.1. Feedstocks

5.2. Current Refineries and Transition to Biorefinery

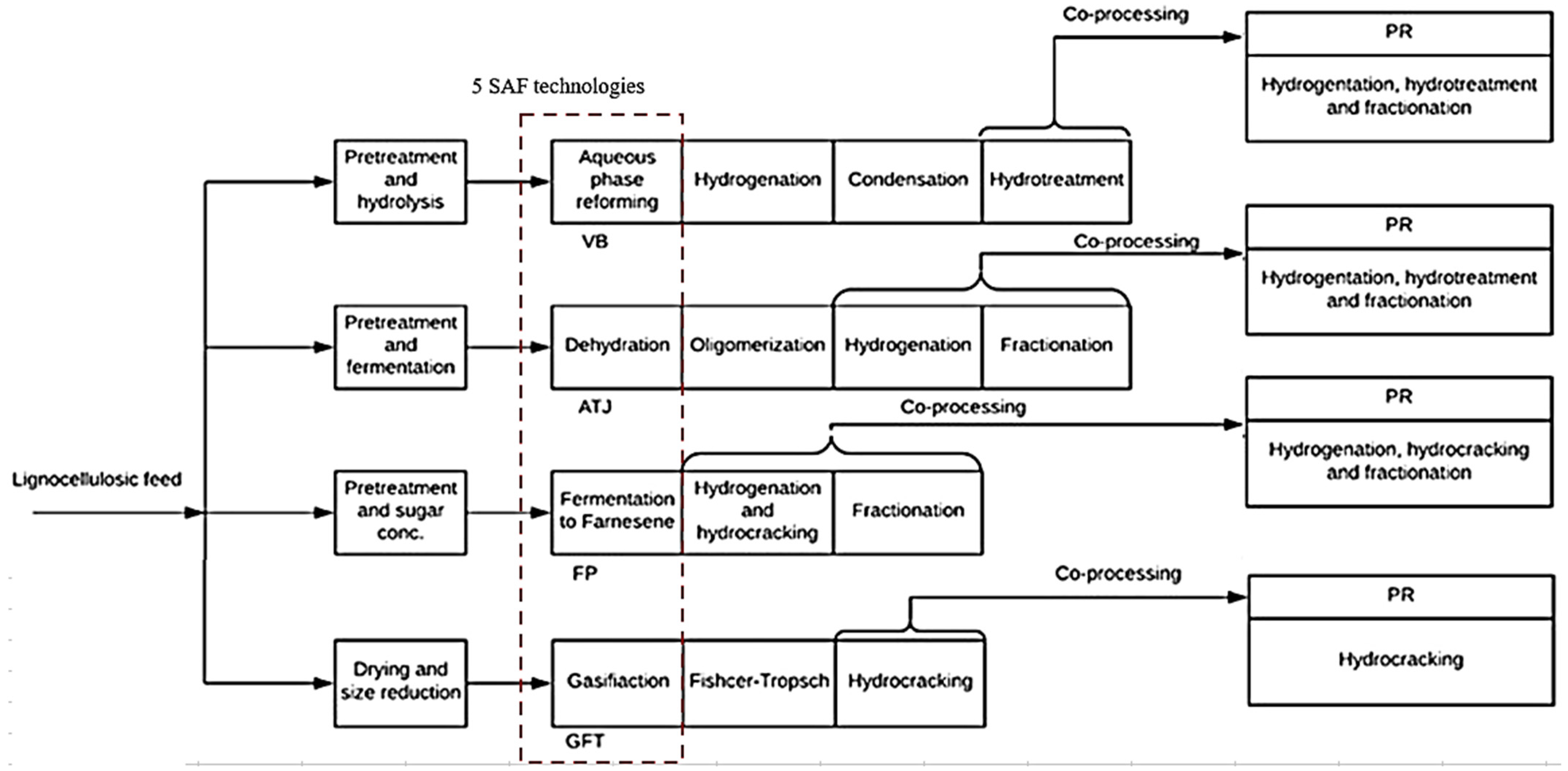

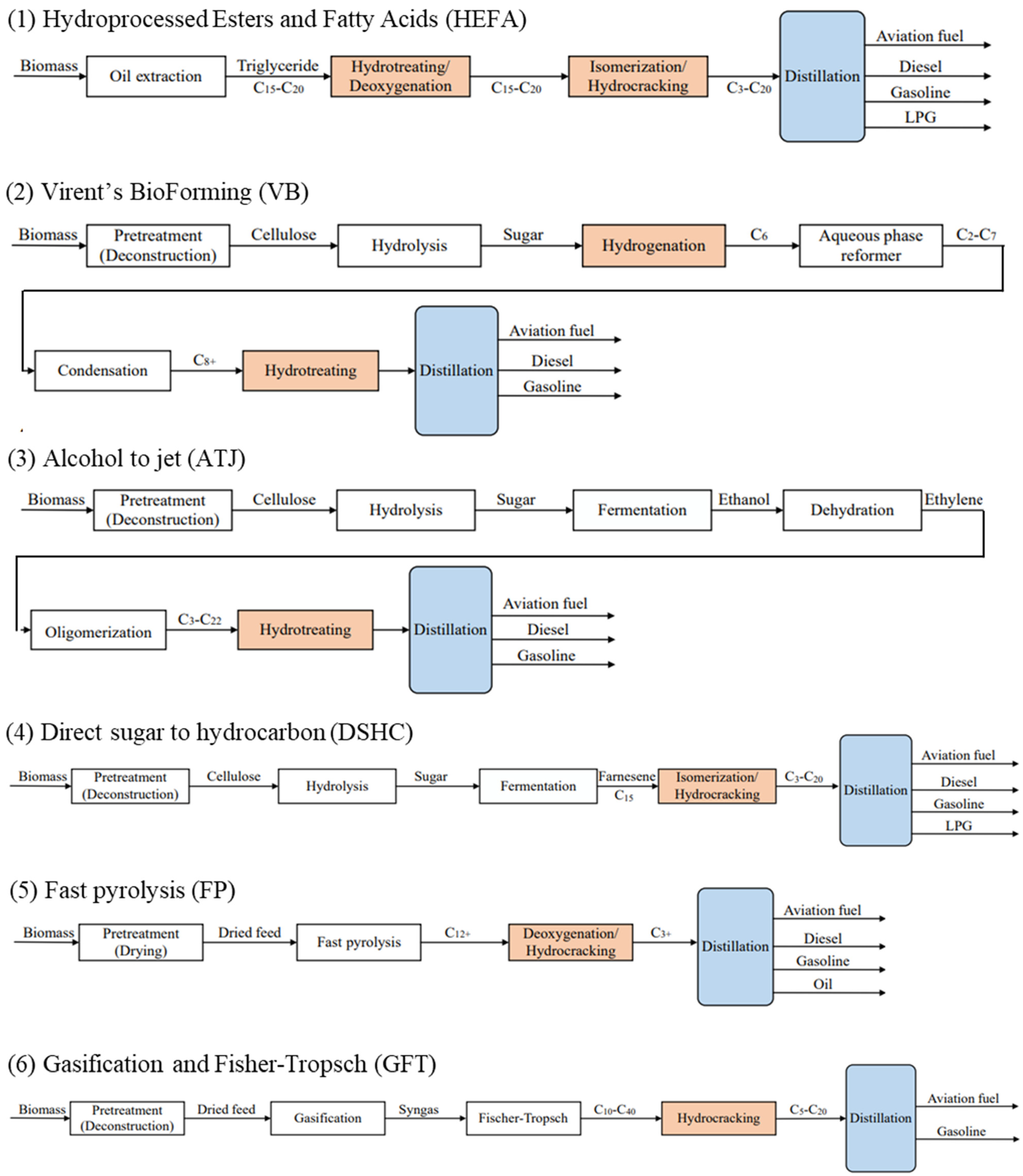

5.3. Upgrade to Drop-In Biofuels

5.4. Challenges and Future Perspectives

5.4.1. Technical Challenges

5.4.2. Commercial Challenges

5.5. Future Perspectives

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| GCC | Gulf Cooperation Council | NCI | Nelson Complexity Index |

| NREL | National Renewable Energy Laboratory | ADNOC | Abu Dhabi National Oil Company |

| CHP | Combined heat and power | BAPCO | Bahrain Petroleum Company |

| FT | Fischer–Tropsch | KNPC | Kuwait National Petroleum Company |

| FAME | Fatty acid methyl ester | ENOC | Emirates National Oil Company Group |

| FAEE | Fatty acid ethyl ester | KPC | Kuwait Petroleum Corporation |

| TRL | Technology readiness level | KIPIC | Kuwait Integrated Petroleum Industries Company |

| BCI | Biorefinery complexity index | MFSP | Minimum fuel selling price |

| IEA | International Energy Agency | HDRD | Hydrogenation-derived renewable diesel |

| MSW | Municipal solid waste | NABC | National Advanced Biofuels Consortium |

| SBRC | Sustainable Bioenergy Research Consortium | CDU | Crude distilling unit |

| SEAS | Seawater Energy and Agriculture System | MILP | Mixed-integer linear programming |

| SAF | Sustainable Aviation Fuel | FP | Fast pyrolysis |

| HVO | Hydrogenated vegetable oil | VB | Virent’s BioForming |

| HTL | hydrothermal liquefaction | CCM | carbon concentration mechanism |

| SIRC | Saudi Investment Recycling Company | BiOD Tech | Biodiesel technology (producer) |

| kTPA | Kilo ton per annum | b/d | Barrel per day |

| CI | carbon intensity | UCO | Used cooking oil |

| HEFAs | hydro-processed esters and fatty acids | LCFS | Low Carbon Fuel Standard |

| LCA | Life cycle assessment | TEA | Techno-economic analysis |

| N/A | Not available |

References

- Calvo-Flores, F.G.; Martin-Martinez, F.J. Biorefineries: Achievements and challenges for a bio-based economy. Front. Chem. 2022, 10, 973417. [Google Scholar] [CrossRef]

- Wagemann, K. Biorefineries: Advances in Biochemical Engineering/Biotechnology; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Annavelink, B.; Chaves, L.G.; van Ree, R.; Gursel, I.V. IEA Bioenergy Task 42 Biorefining in a Circular Economy: Global Biorefinery Status Report 2022; IEA Bioenergy: Paris, France, 2022. [Google Scholar]

- IEA. Bioenergy:T42:2009:01. Biorefineries: Adding value to the sustainable utilisation of biomass. In Technical Typing Tasks; Palgrave: London, UK, 2009; p. 126. [Google Scholar] [CrossRef]

- Naira, V.R.; Mahesh, R.; Panda, S.K.; Maiti, S.K. Biorefinery Approaches for the Production of Fuels and Chemicals from Lignocellulosic and Algal Feedstocks. In Biorefinery of Alternative Resources: Targeting Green Fuels and Platform Chemicals; Nanda, S., N. Vo, D.-V., Sarangi, P.K., Eds.; Springer: Singapore, 2020; pp. 141–170. [Google Scholar] [CrossRef]

- DNV. Energy Transition Outlook 2023 Contents Finance Fossil Fuels Policy Emissions Regions Appendix Electrisity Renewables Demand Highlightes 3 DNV Energy Transition Outlook 20; DNV: Oslo, Norway, 2023. [Google Scholar]

- GCC-Stat. GCC Countries’ Crude Oil Production in 2023 Logged About 17 mbpd, Ranking First Worldwide in Output, Reserves, Exports. Statistical Centre for the Cooperation Council for the Arab Countries of the Gulf. Available online: https://www.wam.ae/en/article/bi7r5vt-gcc-countries-crude-oil-production-2023-logged (accessed on 12 October 2025).

- Wikipedia. List of Oil Refineries. Available online: https://en.wikipedia.org/wiki/List_of_oil_refineries?utm_source=chatgpt.com (accessed on 13 October 2025).

- Ferreira, A.F. Biorefinery Concept BT—Biorefineries: Targeting Energy, High Value Products and Waste Valorisation; Rabaçal, M., Ferreira, A.F., Silva, C.A.M., Costa, M., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 1–20. [Google Scholar] [CrossRef]

- Biernat, K.; Grzelak, P.L. Biorefinery Systems as an Element of Sustainable Development. Biofuels-Status Perspect. 2015, 30, 427–444. [Google Scholar] [CrossRef]

- Singh, V.; Tiwari, R.; Chaturvedi, V.K.; Singh, N.; Mishra, V. Microbiological Aspects of Bioenergy Production: Recent Update and Future Directions. In Bioenergy Research: Revisiting Latest Development; Springer: Singapore, 2021; pp. 29–52. [Google Scholar] [CrossRef]

- Bowyer, J.; Howe, J.; Levins, R.A.; Groot, H.; Fernholz, K.; Pepke, E.; Henderson, C. Third Generation Biofuels: Implications for Wood-Derived; Dovetail Partners, Inc.: Minneapolis, MN, USA, 2018; pp. 1–13. [Google Scholar]

- Shokravi, H.; Shokravi, Z.; Heidarrezaei, M.; Ong, H.C.; Rahimian Koloor, S.S.; Petrů, M.; Lau, W.J.; Ismail, A.F. Fourth generation biofuel from genetically modified algal biomass: Challenges and future directions. Chemosphere 2021, 285, 131535. [Google Scholar] [CrossRef] [PubMed]

- Shokravi, H.; Heidarrezaei, M.; Shokravi, Z.; Ong, H.C.; Lau, W.J.; Din, M.F.M.; Ismail, A.F. Fourth generation biofuel from genetically modified algal biomass for bioeconomic development. J. Biotechnol. 2022, 360, 23–36. [Google Scholar] [CrossRef] [PubMed]

- Gutiérrez, C.D.B.; Serna, D.L.R.; Alzate, C.A.C. A comprehensive review on the implementation of the biorefinery concept in biodiesel production plants. Biofuel Res. J. 2017, 4, 691–703. [Google Scholar] [CrossRef]

- Ghedini, E.; Taghavi, S.; Menegazzo, F.; Signoretto, M. A review on the efficient catalysts for algae transesterification to biodiesel. Sustainability 2021, 13, 10479. [Google Scholar] [CrossRef]

- Nagi, G.K.; Minhas, A.K.; Gaur, S.; Jain, P.; Mandal, S. Integration of Algal Biofuels With Bioremediation Coupled Industrial Commodities Towards Cost-Effectiveness. Front. Energy Res. 2021, 9, 735141. [Google Scholar] [CrossRef]

- Gaffey, J.; Collins, M.N.; Styles, D. Review of methodological decisions in life cycle assessment (LCA) of biorefinery systems across feedstock categories. J. Environ. Manag. 2024, 358, 120813. [Google Scholar] [CrossRef]

- Sudhakar Takkellapati, M.A.G.; Li, T. An Overview of Biorefinery Derived Platform Chemicals from a Cellulose and Hemicellulose Biorefinery. Clean Technol. Environ. Policy 2019, 20, 1615–1630. [Google Scholar] [CrossRef]

- Cherubini, F.; Jungmeier, G.; Wellisch, M.; Willke, T.; Skiadas, I.; Van Ree, R.; de Jong, E. Toward a common classification approach for biorefinery systems. Wiley Intersci. Biofuels Bioprod. Biorefin. 2009, 8, 534–546. [Google Scholar] [CrossRef]

- Hagman, L.; Blumenthal, A.; Eklund, M.; Svensson, N. The role of biogas solutions in sustainable biorefineries. J. Clean. Prod. 2018, 172, 3982–3989. [Google Scholar] [CrossRef]

- Leuter, P.; Fendt, S.; Spliethoff, H. Requirements on synthesis gas from gasification for material and energy utilization: A mini review. Front. Energy Res. 2024, 12, 1382377. [Google Scholar] [CrossRef]

- Tseng, E.J. Technical Report Initiation Decision Report (IDR): Waste to Clean Energy; Naval Facilities Engineering Command: Washington Navy Yard, DC, USA, 2011. [Google Scholar]

- Elsaddik, M.; Nzihou, A.; Delmas, G.H.; Delmas, M. Renewable and high-purity hydrogen from lignocellulosic biomass in a biorefinery approach. Sci. Rep. 2024, 14, 150. [Google Scholar] [CrossRef] [PubMed]

- Piemonte, V. Biorefinery. Biorefinery, Oil Gas Portal, Univ. UCBM–Rome. 2015. Available online: https://www.oil-gasportal.com/biorefinery/ (accessed on 16 September 2024).

- Harahap, B.M. Degradation Techniques of Hemicellulose Fraction from Biomass Feedstock for Optimum Xylose Production: A Review. J. Keteknikan Pertan. Trop. Biosist. 2020, 8, 107–124. [Google Scholar] [CrossRef]

- Werpy, T.; Petersen, G. (Eds.) Top Value Added Chemicals from Biomass Volume I; U.S. Department of Energy: Washington, DC, USA, 2004; 76p. [CrossRef]

- De Jong, E.; Higson, A.; Walsh, P.; Wellisch, M. Bio-Based Chemicals: Value Added Products from Biorefineries. IEA Bioenergy, Task42 Biorefinery. 2012, p. 36. Available online: http://www.ieabioenergy.com/wp-content/uploads/2013/10/Task-42-Biobased-Chemicals-value-added-products-from-biorefineries.pdf (accessed on 14 August 2024).

- Lachos-Perez, D.; Martins-Vieira, J.C.; Missau, J.; Anshu, K.; Siakpebru, O.K.; Thengane, S.K.; Morais, A.R.C.; Tanabe, E.H.; Bertuol, D.A. Review on Biomass Pyrolysis with a Focus on Bio-Oil Upgrading Techniques. Analytica 2023, 4, 182–205. [Google Scholar] [CrossRef]

- Özbay, G.; Kökten, E.S. Modeling of Bio-Oil Production by Pyrolysis of Woody Biomass: Artificial Neural Network Approach. Politek. Derg. 2020, 23, 1255–1264. [Google Scholar] [CrossRef]

- Branca, C.; Blasi, C.; Galgano, A. Pyrolysis of Corncobs Catalyzed by Zinc Chloride for Furfural Production. Ind. Eng. Chem. Res. 2010, 49, 9743–9752. [Google Scholar] [CrossRef]

- Branca, C.; Galgano, A.; Blasi, C.; Esposito, M.; Blasi, C. H2SO4-Catalyzed Pyrolysis of Corncobs. Energy Fuels 2010, 25, 359–369. [Google Scholar] [CrossRef]

- Demirbas, A.; Fatih Demirbas, M. Importance of algae oil as a source of biodiesel. Energy Convers. Manag. 2011, 52, 163–170. [Google Scholar] [CrossRef]

- Jaradat, A.A. The current potential of algae biofuels in the United Arab Emirates. Biofuels 2013, 4, 347–349. [Google Scholar] [CrossRef]

- Laurens, L.M.L.; Markham, J.; Templeton, D.W.; Christensen, E.D.; Van Wychen, S.; Vadelius, E.W.; Chen-Glasser, M.; Dong, T.; Davis, R.; Pienkos, P.T. Development of algae biorefinery concepts for biofuels and bioproducts; a perspective on process-compatible products and their impact on cost-reduction. Energy Environ. Sci. 2017, 10, 1716–1738. [Google Scholar] [CrossRef]

- Coulombier, N.; Jauffrais, T.; Lebouvier, N. Antioxidant compounds from microalgae: A review. Mar. Drugs 2021, 19, 549. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.-M.D.; Li, X.-C.; Lee, D.-J.; Chang, J.-S. Potential biomedical applications of marine algae. Bioresour. Technol. 2017, 244, 1407–1415. [Google Scholar] [CrossRef] [PubMed]

- Zhou, L.; Li, K.; Duan, X.; Hill, D.; Barrow, C.; Dunshea, F.; Martin, G.; Suleria, H. Bioactive compounds in microalgae and their potential health benefits. Food Biosci. 2022, 49, 101932. [Google Scholar] [CrossRef]

- Shahid, M.K.; Batool, A.; Kashif, A.; Nawaz, M.H.; Aslam, M.; Iqbal, N.; Choi, Y. Biofuels and biorefineries: Development, application and future perspectives emphasizing the environmental and economic aspects. J. Environ. Manag. 2021, 297, 113268. [Google Scholar] [CrossRef]

- de Jong, E.; Stichnothe, H.; Bell, G.; Jørgensen, H. Bio-Based Chemicals, IEA Bioenergy. 2020. Available online: https://www.ieabioenergy.com/blog/publications/new-publication-bio-based-chemicals-a-2020-update (accessed on 8 March 2025).

- Sonnenberg, A.; Baars, J.; Hendrickx, P. IEA Bioenergy Task 42 Biorefinery. IEA Bioenergy. 2013, p. 28. Available online: http://www.biorefinery.nl/fileadmin/biorefinery/docs/Brochure_Totaal_definitief_HR_opt.pdf (accessed on 8 March 2025).

- Maitlo, G.; Ali, I.; Mangi, K.H.; Ali, S.; Maitlo, H.A.; Unar, I.N.; Pirzada, A.M. Thermochemical Conversion of Biomass for Syngas Production: Current Status and Future Trends. Sustainability 2022, 140, 2596. [Google Scholar] [CrossRef]

- Chaturvedi, T.; Torres, A.I.; Stephanopoulos, G.; Thomsen, M.H.; Schmidt, J.E. Developing Process Designs for Biorefineries—Definitions, Categories, and Unit Operations. Energies 2020, 13, 1493. [Google Scholar] [CrossRef]

- Vilas-Boas, A.C.M.; Tarelho, L.A.C.; Oliveira, H.S.M.; Silva, F.G.C.S.; Pio, D.T.; Matos, M.A.A. Valorisation of residual biomass by pyrolysis: Influence of process conditions on products. Sustain. Energy Fuels 2023, 8, 379–396. [Google Scholar] [CrossRef]

- Kariim, I.; Swai, H.; Kivevele, T. Recent advances in thermochemical conversion of biomass into drop-in fuel:a review. Sci. Afr. 2022, 17, e01352. [Google Scholar] [CrossRef]

- Mishra, R.K.; Jaya Prasanna Kumar, D.; Sankannavar, R.; Binnal, P.; Mohanty, K. Hydro-deoxygenation of pyrolytic oil derived from pyrolysis of lignocellulosic biomass: A review. Fuel 2024, 360, 130473. [Google Scholar] [CrossRef]

- Lindorfer, J.; Lettner, M.; Hesser, F.; Fazeni, K.; Rosenfeld, D.; Annevelink, B.; Mandl, M. Technical, Economic and Environmental Assessment of Biorefinery Concepts. 2019. Available online: https://www.ieabioenergy.com/wp-content/uploads/2019/07/TEE_assessment_report_final_20190704-1.pdf (accessed on 13 April 2025).

- Murillo-Alvarado, P.; Ponce-Ortega, J.; Serna-González, M.; Montoya, A.; El-Halwagi, M. Optimization of Pathways for Biorefineries Involving the Selection of Feedstocks, Products, and Processing Steps. Ind. Eng. Chem. Res. 2013, 52, 5177–5190. [Google Scholar] [CrossRef]

- Platt, R.; Bauen, A.; Reumerman, P.; Geier, C.; Van Ree, R.; Gursel, I.V.; Garcia, L.; Behrens, M.; von Bothmer, P.; Howes, J.; et al. EU Biorefinery Outlook to 2030; Publications Office of the European Union: Luxembourg, 2021. [Google Scholar] [CrossRef]

- Jungmeier, G.; Van Ree, R.; Jorgensen, H.; de Jong, E.; Stichnote, H.; Wellisch, M. The Biorefinery Complexity Index. IEA-Bioenergy Task 42. 2014, p. 36. Available online: http://www.iea-bioenergy.task42-biorefineries.com/upload_mm/6/2/f/ac61fa53-a1c0-4cbc-96f6-c9d19d668a14_BCI working document 20140709.pdf (accessed on 2 September 2024).

- Muhammad, H.; Shahzad, A.; Asim, Z.; Jamal, S.; Fares, K.; Khaled, A. Thermochemical and biochemical conversion of agricultural waste for bioenergy production: An updated review. Discov. Environ. 2024, 2, 134. [Google Scholar] [CrossRef]

- Osman, A.I.; Mehta, N.; Elgarahy, A.M.; Al-Hinai, A.; Al-Muhtaseb, A.H.; Rooney, D.W. Conversion of Biomass to Biofuels and Life Cycle Assessment: A Review. Environ. Chem. Lett. 2021, 19, 4075–4118. [Google Scholar] [CrossRef]

- Jha, S.; Nanda, S.; Acharya, B.; Dalai, A.K. A Review of Thermochemical Conversion of Waste Biomass to Biofuels. Energies 2022, 15, 6352. [Google Scholar] [CrossRef]

- Malik, K.; Capareda, S.C.; Kamboj, B.R.; Malik, S.; Singh, K.; Arya, S.; Bishnoi, D.K. Biofuels Production: A Review on Sustainable Alternatives to Traditional Fuels and Energy Sources. Fuels 2024, 5, 157–175. [Google Scholar] [CrossRef]

- Shen, Y.; Jarboe, L.; Brown, R.; Wen, Z. A thermochemical–biochemical hybrid processing of lignocellulosic biomass for producing fuels and chemicals. Biotechnol. Adv. 2015, 33, 1799–1813. [Google Scholar] [CrossRef] [PubMed]

- García-Velásquez, C.A.; Cardona, C.A. Comparison of the biochemical and thermochemical routes for bioenergy production: A techno-economic (TEA), energetic and environmental assessment. Energy 2019, 172, 232–242. [Google Scholar] [CrossRef]

- Van Ree, R.; de Jong, E.; Maria, W.; Heinz, S.; Reinhard, R.; Isabella, D.B. Biofuel Driven Biorefineries. 2013, p. 38. Available online: www.iea-bioenergy.task42-biorefineries.com (accessed on 19 November 2024).

- Thongchul, N.; Songserm, P.; Ngaosuwan, K. Whole Crop Feedstocks in Biorefinery: A Common Classification; Elsevier Inc.: Amsterdam, The Netherlands, 2022. [Google Scholar] [CrossRef]

- Meena, P.K.; Awale, S.D.; Kumar, S.; Kumar, D.; Kumar, N. Thermochemical conversion of agricultural residue for the production of hydrogen, methane, and biofuels: A comprehensive overview. Ind. Crops Prod. 2024, 221, 119340. [Google Scholar] [CrossRef]

- Ravenni, G.; Thomsen, T.P.; Smith, A.M.; Ambye-Jensen, M.; Rohde-Nielsen, K.T.; Henriksen, U.B. Integration of a drying and pyrolysis system in a green biorefinery: Biochar product quality and impacts on the overall energy balance and climate footprint. Biomass Convers. Biorefin. 2023, 14, 25143–25159. [Google Scholar] [CrossRef]

- Boonpiyo, S.; Sittijunda, S.; Reungsang, A. Co-digestion of napier grass with food waste and napier silage with food waste for methane production. Energies 2018, 11, 3200. [Google Scholar] [CrossRef]

- Abendroth, C.; Simeonov, C.; Peretó, J.; Antúnez, O.; Gavidia, R.; Luschnig, O.; Porcar, M. From grass to gas: Microbiome dynamics of grass biomass acidification under mesophilic and thermophilic temperatures. Biotechnol. Biofuels 2017, 10, 171. [Google Scholar] [CrossRef]

- Santamaría-Fernández, M.; Molinuevo-Salces, B.; Lübeck, M.; Uellendahl, H. Biogas potential of green biomass after protein extraction in an organic biorefinery concept for feed, fuel and fertilizer production. Renew. Energy 2018, 129, 769–775. [Google Scholar] [CrossRef]

- Manhongo, T.T.; Chimphango, A.; Thornley, P.; Röder, M. Techno-economic and environmental evaluation of integrated mango waste biorefineries. J. Clean. Prod. 2021, 325, 129335. [Google Scholar] [CrossRef]

- Manhongo, T.T.; Chimphango, A.F.A.; Thornley, P.; Röder, M. Current status and opportunities for fruit processing waste biorefineries. Renew. Sustain. Energy Rev. 2022, 155, 111823. [Google Scholar] [CrossRef]

- AlNouss, A.; McKay, G.; Al-Ansari, T. Production of syngas via gasification using optimum blends of biomass. J. Clean. Prod. 2020, 242, 118499. [Google Scholar] [CrossRef]

- Hirl, K.; Murnen, H.; Richard, T.L. Syngas and Biogas. In Renewable Fuels: Sources, Conversion, and Utilization; O’Connor, J., Noble, B., Lieuwen, T., Eds.; Cambridge University Press: Cambridge, UK, 2022; pp. 195–215. [Google Scholar] [CrossRef]

- Pelagalli, V.; Langone, M.; Matassa, S.; Race, M.; Tuffi, R.; Papirio, S.; Lens, P.N.L.; Lazzazzara, M.; Frugis, A.; Petta, L.; et al. Pyrolysis of municipal sewage sludge: Challenges, opportunities and new valorization routes for biochar, bio-oil, and pyrolysis gas. Environ. Sci. Water Res. Technol. 2024, 10, 2282–2312. [Google Scholar] [CrossRef]

- Sarangi, P.K.; Singh, A.K.; Sonkar, S.; Shadangi, K.P.; Srivastava, R.K.; Gupta, V.K.; Parikh, J.; Sahoo, U.K.; Govarthanan, M. Biorefinery solutions for food processing wastes: A sustainable bioeconomic perspective. Ind. Crops Prod. 2023, 205, 117488. [Google Scholar] [CrossRef]

- Tsegaye, B.; Jaiswal, S.; Jaiswal, A.K. Food Waste Biorefinery: Pathway towards Circular Bioeconomy. Foods 2021, 10, 1174. [Google Scholar] [CrossRef]

- Mozhiarasi, V.; Natarajan, T.S. Slaughterhouse and poultry wastes: Management practices, feedstocks for renewable energy production, and recovery of value added products. Biomass Convers. Biorefin. 2022, 15, 1705–1728. [Google Scholar] [CrossRef]

- Álvarez-Castillo, E.; Guerrero, P.; de la Caba, K.; Bengoechea, C.; Guerrero, A. Biorefinery concept in the meat industry: From slaughterhouse biowastes to superaborbent materials. Chem. Eng. J. 2023, 471, 144564. [Google Scholar] [CrossRef]

- Mohanty, A.; Ajmera, S.; Chinnam, S.; Kumar, V.; Mishra, R.K.; Acharya, B. Pyrolysis of waste oils for biofuel production: An economic and life cycle assessment. Fuel Commun. 2024, 18, 100108. [Google Scholar] [CrossRef]

- Carrasco-Suárez, M.T.; Romero-Izquierdo, A.G.; Gutiérrez-Antonio, C.; Gómez-Castro, F.I.; Hernández, S. Production of renewable aviation fuel by waste cooking oil processing in a biorefinery scheme: Intensification of the purification zone. Chem. Eng. Process.-Process Intensif. 2022, 181, 109103. [Google Scholar] [CrossRef]

- Parthasarathy, P.; Tahir, F.; Pradhan, S.; Al-Ansari, T.; McKay, G. Life cycle assessment of biofuel production from waste date stones using conventional and microwave pyrolysis. Energy Convers. Manag. X 2024, 21, 100510. [Google Scholar] [CrossRef]

- Fadhil, A.B.; Alhayali, M.A.; Saeed, L.I. Date (Phoenix dactylifera L.) palm stones as a potential new feedstock for liquid bio-fuels production. Fuel 2017, 210, 165–176. [Google Scholar] [CrossRef]

- Serna-Loaiza, S.; Zikeli, F.; Adamcyk, J.; Friedl, A. Towards a wheat straw biorefinery: Combination of Organosolv and Liquid Hot Water for the improved production of sugars from hemicellulose and lignin hydrolysis. Bioresour. Technol. Rep. 2021, 14, 100667. [Google Scholar] [CrossRef]

- Nickel, D.B.; Fornell, R.; Janssen, M.; Franzén, C.J. Multi-Scale Variability Analysis of Wheat Straw-Based Ethanol Biorefineries Identifies Bioprocess Designs Robust Against Process Input Variations. Front. Energy Res. 2020, 8, 55. [Google Scholar] [CrossRef]

- Bressanin, J.M.; Klein, B.C.; Chagas, M.F.; Watanabe, M.D.B.; de Mesquita Sampaio, I.L.; Bonomi, A.; de Morais, E.R.; Cavalett, O. Techno-economic and environmental assessment of biomass gasification and fischer-tropsch synthesis integrated to sugarcane biorefineries. Energies 2020, 13, 4576. [Google Scholar] [CrossRef]

- Alavijeh, R.S.; Shahvandi, A.; Okoro, O.V.; Denayer, J.F.M.; Karimi, K. Biorefining of corn stover for efficient production of bioethanol, biodiesel, biomethane, and value-added byproducts. Energy Convers. Manag. 2023, 283, 116877. [Google Scholar] [CrossRef]

- Yu, H.; Xu, Y.; Hou, J.; Ni, Y.; Liu, S.; Liu, Y.; Yu, S.; Nie, S.; Wu, Q.; Wu, C. Efficient Fractionation of Corn Stover for Biorefinery Using a Sustainable Pathway. ACS Sustain. Chem. Eng. 2020, 8, 3454–3464. [Google Scholar] [CrossRef]

- Matos, J.S.; Justi, A.C.A.; Souza, R.F.; de Carvalho Miranda, J.C. Building and evaluating prospective scenarios for corn-based biorefineries. Discov. Chem. Eng. 2023, 3, 20. [Google Scholar] [CrossRef]

- Ekman, A.; Campos, M.; Lindahl, S.; Co, M.; Börjesson, P.; Karlsson, E.N.; Turner, C. Bioresource utilisation by sustainable technologies in new value-added biorefinery concepts—Two case studies from food and forest industry. J. Clean. Prod. 2013, 57, 46–58. [Google Scholar] [CrossRef]

- Tamantini, S.; Del Lungo, A.; Romagnoli, M.; Paletto, A.; Keller, M.; Bersier, J.; Zikeli, F. Basic steps to promote biorefinery value chains in forestry in Italy. Sustainability 2021, 13, 11731. [Google Scholar] [CrossRef]

- Stafford, W.; De Lange, W.; Nahman, A.; Chunilall, V.; Lekha, P.; Andrew, J.; Johakimu, J.; Sithole, B.; Trotter, D. Forestry biorefineries. Renew. Energy 2020, 154, 461–475. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, L.; Khoo, K.S.; Gupta, V.K.; Sharma, M.; Show, P.L.; Yap, P.S. Exploitation of lignocellulosic-based biomass biorefinery: A critical review of renewable bioresource, sustainability and economic views. Biotechnol. Adv. 2023, 69, 108265. [Google Scholar] [CrossRef] [PubMed]

- K.N, Y.; T.M, M.U.; S, K.; Sachdeva, S.; Thakur, S.; S, A.K.; J, R.B. Lignocellulosic Biorefinery Technologies: A Perception into Recent Advances in Biomass Fractionation, Biorefineries, Economic Hurdles and Market Outlook. Fermentation 2023, 9, 238. [Google Scholar] [CrossRef]

- Chandel, A.K.; Garlapati, V.K.; Singh, A.K.; Antunes, F.A.F.; da Silva, S.S. The path forward for lignocellulose biorefineries: Bottlenecks, solutions, and perspective on commercialization. Bioresour. Technol. 2018, 264, 370–381. [Google Scholar] [CrossRef]

- Lama, S.; Thapa, L.P.; Upadhayaya, S.K.; Gauchan, D.P.; Singh, A. Metabolic engineering in lignocellulose biorefining for high-value chemicals: Recent advances, challenges, and outlook for enabling a bioeconomy. Front. Ind. Microbiol. 2024, 1, 1319774. [Google Scholar] [CrossRef]

- Gautam, R.; Nagaraja, S.S.; Alturkistani, S.; Zhai, Y.; Shao, C.; Albaqshi, M.; Fiene, G.M.; Tester, M.; Sarathy, S.M. Combustion of Salicornia bigelovii Pyrolysis Bio-oil and Surrogate Mixtures: Experimental and Kinetic Study. Energy Fuels 2023, 37, 385–400. [Google Scholar] [CrossRef]

- Iaccarino, A.; Gautam, R.; Sarathy, S.M. Bio-oil and biochar production from halophyte biomass: Effects of pre-treatment and temperature onSalicornia bigeloviipyrolysis. Sustain. Energy Fuels 2021, 5, 2234–2248. [Google Scholar] [CrossRef]

- Makepa, D.C.; Fumhirwa, D.V.; Tambula, S.; Chihobo, C.H. Performance analysis, techno-economic and life cycle assessment of Jatropha curcas L. (Euphorbiaceae) seedcake gasification and Fischer-Tropsch integrated process for bio-methanol production. Biofuels 2024, 15, 57–66. [Google Scholar] [CrossRef]

- Drabek, A.; Chey, K.L. Pyrolysis of Switchgrass to Fuels. Available online: http://www.ou.edu/class/che-design/a-design/projects-2008/Switchgrass.pdf (accessed on 11 November 2024).

- Gheewala, S.H.; Jaroenkietkajorn, U.; Nilsalab, P.; Silalertruksa, T.; Somkerd, T.; Laosiripojana, N. Sustainability assessment of palm oil-based refinery systems for food, fuel, and chemicals. Biofuel Res. J. 2022, 9, 1750–1763. [Google Scholar] [CrossRef]

- Ali, A.; Othman, M.; Shirai, Y.; Hassan, M. Sustainable and integrated palm oil biorefinery concept with value-addition of biomass and zero emission system. J. Clean. Prod. 2015, 91, 96–99. [Google Scholar] [CrossRef]

- Malik, S.; Shahid, A.; Haider, M.N.; Amin, M.; Betenbaugh, M.J.; Mehmood, M.A.; Haq, M.A.U.; Syafiuddin, A.; Boopathy, R. Prospects of Multiproduct Algal Biorefineries Involving Cascading Processing of the Biomass Employing a Zero-Waste Approach. Curr. Pollut. Rep. 2022, 8, 147–158. [Google Scholar] [CrossRef]

- Yadav, G.; Dash, S.K.; Sen, R. A biorefinery for valorization of industrial waste-water and flue gas by microalgae for waste mitigation, carbon-dioxide sequestration and algal biomass production. Sci. Total Environ. 2019, 688, 129–135. [Google Scholar] [CrossRef]

- Petersen, H.I.; Deskur, H.; Rudra, A.; Ørberg, S.B.; Krause-Jensen, D.; Sanei, H. Pyrolysis of macroalgae: Insight into product yields and biochar morphology and stability. Int. J. Coal Geol. 2024, 286, 104498. [Google Scholar] [CrossRef]

- Kuo, C.M.; Sun, Y.L.; Lin, C.H.; Lin, C.H.; Wu, H.T.; Lin, C.S. Cultivation and biorefinery of microalgae (Chlorella sp.) for producing biofuels and other byproducts: A review. Sustainability 2021, 13, 13480. [Google Scholar] [CrossRef]

- Ağbulut, Ü.; Sirohi, R.; Lichtfouse, E.; Chen, W.H.; Len, C.; Show, P.L.; Le, A.T.; Nguyen, X.P.; Hoang, A.T. Microalgae bio-oil production by pyrolysis and hydrothermal liquefaction: Mechanism and characteristics. Bioresour. Technol. 2023, 376, 128860. [Google Scholar] [CrossRef] [PubMed]

- Mehariya, S.; Goswami, R.K.; Verma, P.; Lavecchia, R.; Zuorro, A. Integrated approach for wastewater treatment and biofuel production in microalgae biorefineries. Energies 2021, 14, 2282. [Google Scholar] [CrossRef]

- Mahmoud, A.; Shuhaimi, M. Systematic methodology for optimal enterprise network design between Bio-Refinery and petroleum refinery for the production oftransportation fuels. Energy 2013, 59, 224–232. [Google Scholar] [CrossRef]

- Fogassy, G.; Thegarid, N.; Toussaint, G.; van Veen, A.C.; Schuurman, Y.; Mirodatos, C. Biomass derived feedstock co-processing with vacuum gas oil for second-generation fuel production in FCC units. Appl. Catal. B Environ. 2010, 96, 476–485. [Google Scholar] [CrossRef]

- Tanzil, A.H.; Brandt, K.; Zhang, X.; Wolcott, M.; Stockle, C.; Garcia-Perez, M. Production of Sustainable Aviation Fuels in Petroleum Refineries: Evaluation of New Bio-Refinery Concepts. Front. Energy Res. 2021, 9, 735661. [Google Scholar] [CrossRef]

- Eschenbacher, A.; Myrstad, T.; Bech, N.; Thi, H.D.; Auersvald, M.; Van Geem, K.M.; Jensen, A.D. Fluid catalytic co-processing of bio-oils with petroleum intermediates: Comparison of vapour phase low pressure hydrotreating and catalytic cracking as pretreatment. Fuel 2021, 302, 121198. [Google Scholar] [CrossRef]

- Han, X.; Wang, H.; Zeng, Y.; Liu, J. Advancing the application of bio-oils by co-processing with petroleum intermediates: A review. Energy Convers. Manag. X 2021, 10, 100069. [Google Scholar] [CrossRef]

- National Advanced Biofuels Consortium. Biofuels for Advancing America; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2010. [CrossRef][Green Version]

- Lindfors, C.; Elliott, D.C.; Prins, W.; Oasmaa, A.; Lehtonen, J. Co-processing of Biocrudes in Oil Refineries. Energy Fuels 2023, 37, 799–804. [Google Scholar] [CrossRef]

- Bouzouita, D.; Lelevic, A.; Lorentz, C.; Venderbosch, R.; Pedersen, T.H.; Geantet, C.; Schuurman, Y. Co-processing bio-liquids with vacuum gasoil through hydrocracking. Appl. Catal. B Environ. 2022, 304, 120911. [Google Scholar] [CrossRef]

- Seiser, R.; Olstad, J.L.; Magrini, K.A.; Jackson, R.D.; Peterson, B.H.; Christensen, E.D.; Talmadge, M.S. Co-processing catalytic fast pyrolysis oil in an FCC reactor. Biomass Bioenergy 2022, 163, 106484. [Google Scholar] [CrossRef]

- Zhang, L.; Torres, A.I.; Chen, B.; Yuan, Z.; Grossmann, I.E. Optimal retrofitting of conventional oil refinery into sustainable bio-refinery under uncertainty. AIChE J. 2024, 70, e18371. [Google Scholar] [CrossRef]

- Basha, J.S.; Jafary, T.; Vasudevan, R.; Bahadur, J.K.; Al Ajmi, M.; Al Neyadi, A.; Soudagar, M.E.M.; Mujtaba, M.A.; Hussain, A.; Ahmed, W.; et al. Potential of utilization of renewable energy technologies in gulf countries. Sustainability 2021, 13, 10261. [Google Scholar] [CrossRef]

- Thabit, Q.; Nassour, A.; Nelles, M. Facts and Figures on Aspects of Waste Management in Middle East and North Africa Region. Waste 2022, 1, 52–80. [Google Scholar] [CrossRef]

- Al-Rashed, S.A.; Ibrahim, M.M.; Hatata, M.M.A.; El-Gaaly, G.A. Biodiesel production and antioxidant capability from seeds of Salicornia begelovii collected from Al Jubail, Eastern province, Saudi Arabia. Pak. J. Bot. 2016, 48, 2527–2533. [Google Scholar]

- Abideen, Z.; Ansari, R.; Hasnain, M.; Flowers, T.J.; Koyro, H.W.; El-Keblawy, A.; Abouleish, M.; Khan, M.A. Potential use of saline resources for biofuel production using halophytes and marine algae: Prospects and pitfalls. Front. Plant Sci. 2023, 14, 1026063. [Google Scholar] [CrossRef]

- Mahroogi, F.O.; Narayan, S.; Kaisan, M.U.; Aliyu, A.; Yahuza, I.; Grujić, I.; Stojanović, N. A critical review of biofuels as an alternative fuel to diesel in gulf regional corporation (gcc) region: Current market trends and future opportunitie. Commun. Sci. Lett. Univ. Žilina 2022, 24, B67–B73. [Google Scholar] [CrossRef]

- Makkawi, Y.; Hassan Pour, F.; Moussa, O. Waste-to-Energy: Case Study in Arid and Semi-Arid Regions. In Waste-to-Energy; Springer: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Tribune, T.D. Only 13 Percent of Waste Produced in Bahrain Is Recyclable. Available online: https://www.newsofbahrain.com/bahrain/81809.html (accessed on 19 July 2025).

- Times, A. Arab Times, Food Wastage in Kuwait Is Among the Highest in World 400,000 Tons of Food Surpluses Are Wasted Every Year. Available online: https://www.arabtimesonline.com/news/food-wastage-in-kuwait-is-among-the-highest-in-world/ (accessed on 19 July 2025).

- United Nations Economic and Social Commission for Western Asia (ESCWA). ESCWA Mainstreaming a Circular Economy in the Arab Region: Guidelines for a Cross-Sectoral Transition. Beirut, Lebanon. 2024. Available online: www.unescwa.org (accessed on 19 July 2025).

- Makkawi, Y.; El Sayed, Y.; Lyra, D.A.; Pour, F.H.; Khan, M.; Badrelzaman, M. Assessment of the pyrolysis products from halophyte Salicornia bigelovii cultivated in a desert environment. Fuel 2021, 290, 119518. [Google Scholar] [CrossRef]

- Ahmad, W.; Makkawi, Y.; Samara, F. Co-Pyrolysis of Date Palm Waste and Salicornia bigelovii: Insights for Bioenergy Development in Arid and Semi-Arid Regions. ACS Omega 2024, 9, 24082–24094. [Google Scholar] [CrossRef] [PubMed]

- Alherbawi, M.; McKay, G.; Mackey, H.R.; Al-Ansari, T. Jatropha curcas for jet biofuel production: Current status and future prospects. Renew. Sustain. Energy Rev. 2021, 135, 110396. [Google Scholar] [CrossRef]

- Farzanah, R.; Dansoh, C.; Augousti, A.; Wang, J. A Review of UAE Native Seaweed as Potential Bio-Refinery Feedstock for Jet Fuel and High Value Chemicals. Adv. Environ. Waste Manag. Recycl. 2020, 3, 10–15. [Google Scholar] [CrossRef]

- Almardeai, S.; Bastidas-Oyanedel, J.-R.; Haris, S.; Schmidt, J.E. Characterization of Avicennia Marina: An Arid-Coastal Biomass—Toward Biorefinery Products BT—Biorefinery: Integrated Sustainable Processes for Biomass Conversion to Biomaterials, Biofuels, and Fertilizers; Bastidas-Oyanedel, J.-R., Schmidt, J.E., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 669–677. [Google Scholar] [CrossRef]

- Ashour, M.; Mansour, A.T.; Alkhamis, Y.A.; Elshobary, M. Usage of Chlorella and diverse microalgae for CO2 capture—Towards a bioenergy revolution. Front. Bioeng. Biotechnol. 2024, 12, 1387519. [Google Scholar] [CrossRef]

- Adhikari, S.; Moon, E.; Paz-ferreiro, J.; Timms, W. Comparative analysis of biochar carbon stability methods and implications for carbon credits. Sci. Total Environ. 2024, 914, 169607. [Google Scholar] [CrossRef]

- Lootah This Dubai-Based Company Turns Used Cooking Oil into Biofuels. Available online: https://www.weforum.org/videos/cooking-oil-biofuels/?utm_source=chatgpt.com (accessed on 19 July 2025).

- Al-Rajhi, A.; Abdelghany, T. Fiber Wastes of Date Palm for Bioethanol Production in Saudi Arabia. BioResources 2023, 18, 6827–6841. [Google Scholar] [CrossRef]

- Ministry of Energy and Infrastructure in UAE; General Civil Aviation Authority (GCAA). National Sustainable Aviation Fuel Roadmap of the United Arab Emirates; Ministry of Energy and Infrastructure: Abu Dhabi, United Arab Emirates, 2022.

- Mujtaba, I.M.; Srinivasan, R.; Elbashir, N.O. The Water–Food–Energy Nexus: Processes, Technologies, and Challenges. In The Water–Food–Energy Nexus; Routledge: London, UK, 2019; p. 33487. [Google Scholar] [CrossRef]

- Ali, H.E.A.; El-fayoumy, E.A.; Soliman, R.M.; Elkhatat, A.; Al-Meer, S.; Elsaid, K.; Hussein, H.A.; Zul Helmi Rozaini, M.; Azmuddin Abdullah, M. Nanoparticle applications in Algal-biorefinery for biofuel production. Renew. Sustain. Energy Rev. 2024, 192, 114267. [Google Scholar] [CrossRef]

- Nasser, A.H.; Pouyanné, P.; Al-Sheha, E.Z. Aramco, TotalEnergies and SIRC Develop SAF Unit. Biofuels International. Available online: https://biofuels-news.com/news/aramco-totalenergies-and-sirc-develop-saf-unit/?utm_source=chatgpt.com (accessed on 30 September 2025).

- Ericson, S.; Engel Cox, J.; Arent, D. Approaches for Integrating Renewable Energy Technologies in Oil and Gas Operations; Joint Institute for Strategic Energy Analysis: Lakewood, CO, USA, 2019; pp. 1–26.

- Zhang, W.; Luo, Y.; Yuan, X. Optimization of biofuel supply chain integrated with petroleum refineries under carbon trade policy. Front. Chem. Sci. Eng. 2024, 18, 34. [Google Scholar] [CrossRef]

- UAE. National Hydrogen Strategy; Ministry of Energy and Infrastructure: Abu Dhabi, United Arab Emirates, 2023.

- Vogt, E.T.C.; Weckhuysen, B.M. The refinery of the future Market Assessment. Worley Consult. Gr. Nat. 2024, 629, 295–306. [Google Scholar] [CrossRef]

- Mawhood, R.; Gazis, E.; de Jong, S.; Hoefnagels, R.; Slade, R. Production pathways for renewable jet fuel: A review of commercialization status and future prospects. Biofuels Bioprod. Biorefin. 2016, 10, 462–484. [Google Scholar] [CrossRef]

- Reuters Portugal’s Galp Plans to Start Producing Biofuels in 2026. Available online: https://www.reuters.com/business/energy/portugals-galp-plans-start-producing-biofuels-2026-2024-12-19/?utm_source=chatgpt.com (accessed on 13 April 2025).

- Masdar. Masdar and Total Energies to Develop a Commercial Green Hydrogen to Methanol to SAF project in Abu Dhabi. Available online: https://masdar.ae/en/news/newsroom/masdar-and-totalenergies-to-develop-a-commercial-green-hydrogen (accessed on 13 April 2025).

- Oxford. Evolution of the Middle East Oil Scene: Transformations in Refining and Oil Flows; Oxford Institute for Energy Studies: Oxford, UK, 2024. [Google Scholar]

- Offshore Technology; GlobalData’s Oil & Gas Intelligence Center. Top Ten Active Oil Refineries in Middle East. Available online: https://www.offshore-technology.com/data-insights/top-ten-active-oil-refineries-in-middle-east/?cf-view (accessed on 6 April 2025).

- S&P Global Commodity Insights. Middle East Refinery Focus. Available online: https://storymaps.arcgis.com/stories/4477ae3dc5e94c5b9ad9c89d75b234fb (accessed on 21 November 2024).

- ENI. World Gas and Renewables Review 2020; International Energy Agency: Paris, France, 2020; Volume 2. [Google Scholar]

- Turner, E. New Refneries to Increase Middle East Product Sales; S&P Global: Andover, MA, USA, 2021; pp. 1–17. [Google Scholar]

- van Dyk, S.; Su, J.; Mcmillan, J.D.; Saddler, J. Potential synergies of drop-in biofuel production with further co-processing at oil refineries. Biofuels Bioprod. Biorefin. 2019, 13, 760–775. [Google Scholar] [CrossRef]

- van Dyk, S.; Su, J.; Mcmillan, J.D.; Saddler, J.J.N. ‘Drop-In’ Biofuels: The Key Role That Co-Processing Will Play in its Production; IEA Bioenergy: Paris, France, 2019. [Google Scholar]

- Huber, G.W.; Corma, A. Synergies between bio- and oil refineries for the production of fuels from biomass. Angew. Chem.-Int. Ed. 2007, 46, 7184–7201. [Google Scholar] [CrossRef] [PubMed]

- Han, Y.; Gholizadeh, M.; Tran, C.C.; Kaliaguine, S.; Li, C.Z.; Olarte, M.; Garcia-Perez, M. Hydrotreatment of pyrolysis bio-oil: A review. Fuel Process. Technol. 2019, 195, 106140. [Google Scholar] [CrossRef]

- French, R.; Hrdlicka, J.; Baldwin, R. Mild Hydrotreating of Biomass Pyrolysis Oils to Produce a Suitable Refinery Feedstock. Environ. Prog. Sustain. Energy 2010, 29, 142–150. [Google Scholar] [CrossRef]

- Talmadge, M.S.; Baldwin, R.M.; Biddy, M.J.; McCormick, R.L.; Beckham, G.T.; Ferguson, G.A.; Czernik, S.; Magrini-Bair, K.A.; Foust, T.D.; Metelski, P.D.; et al. A perspective on oxygenated species in the refinery integration of pyrolysis oil. Green Chem. 2014, 16, 407–453. [Google Scholar] [CrossRef]

- Junghare, M.; Saxena, S.; Ingle, A.P.; Moharil, M.P. Biorefineries: Current scenario, feedstocks, challenges, and future perspectives. In Nanotechnology for Biorefinery; Elsevier: Amsterdam, The Netherlands, 2023; pp. 1–25. [Google Scholar] [CrossRef]

- Sayles, S.; Ohmes, R. Conversion to a Green Refinery, Decarbonisation Technology, Powering the Transition to Sustainable Fuels & Energy. Shell Catayst @ Technologies. 2023. Available online: https://becht.com/becht-blog/entry/conversion-to-a-green-refinery/ (accessed on 13 April 2025).

- Mukarakate, C.; Zhang, X.; Stanton, A.R.; Robichaud, D.J.; Ciesielski, P.N.; Malhotra, K.; Donohoe, B.S.; Gjersing, E.; Evans, R.J.; Heroux, D.S.; et al. Real-time monitoring of the deactivation of HZSM-5 during upgrading of pine pyrolysis vapors. Green Chem. 2014, 16, 1444–1461. [Google Scholar] [CrossRef]

- UAE. National Policy on Biofuels. Available online: https://u.ae/en/about-the-uae/strategies-initiatives-and-awards/policies/environment-and-energy/national-policy-on-biofuels?utm_source=chatgpt.com (accessed on 1 October 2025).

- Sanfilippo, A.; Vermeersch, M.; Benito, V.B. Energy transition strategies in the Gulf Cooperation Council countries. Energy Strateg. Rev. 2024, 55, 101512. [Google Scholar] [CrossRef]

- EY Global. EU Council Adopts New Renewable Energy Rules and Rules for Promotion of Sustainable Aviation Fuels Under Fit for 55. Available online: https://www.ey.com/en_gl/technical/tax-alerts/eu-council-adopts-new-renewable-energy-rules-and-rules-for-promotion-of-sustainable-aviation-fuels-under-fit-for-55?utm_source=chatgpt.com (accessed on 1 October 2025).

- LCFS. Low Carbon Fuel Standard, Fuel Prices; California Air Resources Board: Sacramento, CA, USA, 2024; pp. 1–5.

- van der Linden, R.; Azouagh, M. Tax & Cash Incentives for Sustainable Real Estate: An Overview of Key Cash Grants & Tax Incentives Across Various European Countries; PwC: London, UK, 2025. [Google Scholar]

- Brelsford, R. European, US refiners accelerate energy transition initiatives. Oil Gas J. 2021, 119, 24–34. [Google Scholar]

- Agri. UCO Supply Outlook. GlobalData, No. August. 2023. Available online: https://cleanfuels.org/wp-content/uploads/GlobalData_UCO-Supply-Outlook_Sep2023.pdf (accessed on 1 October 2025).

- Mabee, W.; Walker, B. Review of Feedstock Supply for Bioenergy in IEA Bioenergy Task 43 Member Countries; IEA Bioenergy: Paris, France, 2025. [Google Scholar]

- Deng, B.; Meng, W.; Advincula, P.A.; Eddy, L.; Ucak-Astarlioglu, M.G.; Wyss, K.M.; Chen, W.; Carter, R.A.; Li, G.; Cheng, Y.; et al. Heavy metal removal from coal fly ash for low carbon footprint cement. Commun. Eng. 2023, 2, 13. [Google Scholar] [CrossRef]

- Yan, B.; Hu, Y.; Wang, J.; Tao, J.; Xia, S.; Yang, W.; Zhang, Y.; Chen, G.; Zhou, W.; Chen, G. State-of-the-art conceptual design of supercritical carbon dioxide as a green technology involved in bioresource conversion processes. Chem. Eng. J. 2024, 486, 150166. [Google Scholar] [CrossRef]

- Lachos-Perez, D.; Brown, A.B.; Mudhoo, A.; Martinez, J.; Timko, M.T.; Rostagno, M.A.; Forster-Carneiro, T. Applications of subcritical and supercritical water conditions for extraction, hydrolysis, gasification, and carbonization of biomass: A critical review. Biofuel Res. J. 2017, 4, 611–626. [Google Scholar] [CrossRef]

- Morais, A.R.C.; Da Costa Lopes, A.M.; Bogel-Łukasik, R. Carbon dioxide in biomass processing: Contributions to the green biorefinery concept. Chem. Rev. 2015, 115, 3–27. [Google Scholar] [CrossRef]

- Rita, C.; Morais, A.; Lukasik, R. Highly efficient and selective CO2-adjuncted dehydration of xylose to furfural in aqueous media with THF. Green Chem. 2016, 18, 2331–2334. [Google Scholar] [CrossRef]

- Drax. Drax Group. Bioenergy with Carbon Capture and Storage (BECCS). Available online: https://www.drax.com/bioenergy-with-carbon-capture-and-storage-beccs/#:~:text=“Power BECCS is such a,scale carbon removal option available (accessed on 13 April 2025).

- Osman, A.I.; Fang, B.; Zhang, Y.; Liu, Y.; Yu, J.; Farghali, M. Life Cycle Assessment and Techno—Economic Analysis of Sustainable Bioenergy Production: A Review; Springer International Publishing: Cham, Switzerland, 2024. [Google Scholar] [CrossRef]

- van Dyk, S.; Su, J.; Saddler, J. Update on Drop-In Biofuel and Co-Processing Commercialization; Task 39; IEA Bioenergy: Paris, France, 2024. [Google Scholar]

| Type of Biorefinery | Processing Techniques | Feedstock | Products | References |

|---|---|---|---|---|

| Type 1: Green biorefineries | Pretreatment, Gasification, Compression, Methanation, Digestion, Pyrolysis, Adsorption, Distillation | Organic waste fractions and agricultural waste | Syngas, methanol, Fischer–Tropsch fuels, pyrolytic oil, biochar, and hydrogen | [59,60] |

| Grass and silage | Lactic acid, proteins, and methane | [61,62] | ||

| Red clover, clover grass, and oil seed radish | Methane, byproducts (press cake and brown juice) | [63] | ||

| Mango waste | Pectin, oil seeds, polyphenols, and cattle feed | [64,65] | ||

| Type 2: Blended types of waste biorefineries | Pretreatment, Gasification, Compression, Methanation, Anaerobic Digestion, Distillation | Sludge and manure | Biogas, syngas, methanol, Fischer–Tropsch fuels | [66,67] |

| Pretreatment, Gasification, Compression, Methanation, Adsorption, Distillation, Size Reduction, Heat Steam Recovery, Pyrolysis, Separation, Anaerobic Digestion | Municipal solid waste | Syngas, methanol, Fischer–Tropsch fuels, hydrogen, biogas, biochar, bio-oil, pyrolysis gas, olefins, aromatics, and energy | [67,68] | |

| Hydrolysis, Size Reduction, Pyrolysis, Adsorption, Saccharification, Fermentation, Separation, Anaerobic Digestion | Food waste | Biogas, biochar, bio-oil, pyrolysis gas, hydrogen, and lactic acid | [69,70] | |

| Hydrolysis, Fermentation, Separation, Anaerobic Digestion | Slaughter waste | Polyhydroxyalkanoate (PHA) | [71,72] | |

| Pretreatment, Transesterification, Separation | Waste oil | Fatty acid methyl esters (FAMEs), and glycerol | [73,74] | |

| Grinding, pyrolysis, Extraction, Transesterification | Date palm pits | Pyro-gas, pyrolytic oil, biochar, and biodiesel | [75,76] | |

| Type 3: Whole-crop biorefineries | Pretreatment, Hydrolysis, Size Reduction, Enzymatic Hydrolysis, Dark Fermentation, Saccharification, Separation, Distillation | Wheat straw | Butanol, bioethanol, hydrogen, and biogas, butyric acid, ethanol, biomethane, electricity, and phenols | [77,78] |

| Pretreatment, Drying, Hydrolysis, Size Reduction, Gasification, Fermentation, Dehydration, Distillation | Sugarcane | Ethanol, electricity, gypsum, fertilizers, animal feed, sugar, power, n-butanol, acetone, and butanol | [79] | |

| Type 4: Lignocellulose-based biorefineries | Dilute Acid Pretreatment, Hydrolysis, Size Reduction, Enzymatic Hydrolysis, Pyrolysis, Combustion, Saccharification, Fermentation, Dehydration, Heat Recovery, Evaporation, Separation, Distillation | Corn stover | Ethanol, succinic and acid electricity, biomethane, phenols, gypsum, methane, phthalic anhydride, naphtha, diesel range fuels, and bioethanol | [80,81] |

| Dilute Acid Pretreatment, Simultaneous Saccharification, Fermentation, Distillation | Corn | Ethanol | [82] | |

| Drying, Aerobic Digestion | Yellow onion | Quercetin and biogas | [83] | |

| Incineration, Extraction | Birch forest | Electricity and betulin | [83] | |

| Pretreatment, Gasification, Compression, Methanation, Adsorption, Heat Steam Recovery, Separation, Distillation | Wood and forest waste | Gas, methanol, dimethyl ether, Fischer–Tropsch fuel, ammonia, hydrogen | [84,85] | |

| Pretreatment, Hydrolysis, Size Reduction, Gasification, Pyrolysis, Compression, Adsorption, Fermentation, Heat Steam Recovery Separation, Distillation | Lignocellulose | Gasoline, diesel, Fischer–Tropsch fuel, biochar, methanol intermediates, bio-oil, ethylene, propylene, acetone, butanol, ethanol, biogas, and hydrogen | [86,87,88,89] | |

| Pretreatment, Drying, Dilute Acid, Washing, Hydrolysis, Enzymatic Hydrolysis, Simultaneous Saccharification and Fermentation, Pyrolysis, Aerobic Digestion, Distillation | Salicornia bigelovii | Ethanol, biogas, biochar, and bio-oil | [90,91] | |

| Size Reduction, Pyrolysis, Dehydration, Separation, Distillation | Jatropha curcas | Light gases, naphtha, jet fuel, and diesel | [92] | |

| Pretreatment, Hydrolysis, Combustion, Fermentation, Aerobic Digestion | Switch grass | Bioethanol, biomethane, electricity, and phenols | [93] | |

| Pretreatment, Size Reduction, Saccharification, and Distillation | Palm oil tree | Bioplastic and poly(3-hydroxybutyrate) | [94,95] | |

| Type 5: Marine biorefineries | Drying, Harvesting, Transesterification, Extraction, Anaerobic Digestion, Pyrolysis, Distillation | Microalgae | High-value products, power, biodiesel, bioethanol, biogas, glycerol, and bio-oil | [96,97,98] |

| Pretreatment, Washing, Fermentation, Separation, Anaerobic Digestion, Distillation | Microalgae (Chlorella strain) | Naphtha, biogas, renewable diesel blendstock, and anaerobic digestate | [99,100] | |

| Dilute Acid Pretreatment, Dark Fermentation, Anaerobic Digestion, Pyrolysis | Brown macroalgae | Hydrogen, pyrolytic oil, biochar, and methane | [98,101] |

| Country | Food Waste | Date Palm Waste | S. bigelovii 1 | |||

|---|---|---|---|---|---|---|

| Tons/Year | Kg/Capita/Year | Tons/Year | Kg/Capita/Year | Tons/Year | Kg/Capita/Year | |

| Saudi Arabia | 3,594,080 | 94.6 | 1,539,756 | 40.5 | 7,695,890 | 198.1 |

| United Arab Emirates | 923,675 | 81.9 | 323,478 | 28.7 | 299,288 | 25.9 |

| Oman | 470,322 | 62.6 | 372,572 | 49.6 | 1,108,010 | 144.1 |

| Qatar | 267,739 | 74.5 | 39,651 | 11.0 | 41,460 | 11.3 |

| Bahrain 2 | 230,000 | 140.0 | NA 3 | NA | 2792 | 1.7 |

| Kuwait 2 | 400,000 | 91.2 | 118,953 | 27.1 | 63,788 | 14.2 |

| Total | 5,885,816 | 2,394,410 | 9,211,229 | |||

| Name/Location | Capacity | Country | Owner |

|---|---|---|---|

| Upgraded refineries [145] (b/d) | |||

| Ruwais | 837,000 | United Arab Emirates | ADNOC |

| Sitra | 267,000 | Barain | Bapco |

| SASREF | 305,000 | Saudi Arabia | Aramco |

| Petro Rabigh | 400,000 | Saudi Arabia | Rabigh |

| Mina al-Ahmadi | 466,000 | Kuwait | KNPC |

| Mina Abdullah | 270,000 | Kuwait | KNPC |

| Riyadh | 140,000 | Saudi Arabia | Saudi Aramco |

| Jebel Ali | 140,000 | United Arab Emirates | ENOC |

| New refineries [145] (b/d) | |||

| Al-Zour | 615,000 | Kuwait | KPC |

| Duqm | 230,000 | Oman | Joint |

| Lizan/Jazan | 400,000 | Saudi Arabia | Saudi Aramco |

| Kuwait | NA | Kuwait | KNPC |

| Brooge | 180,000 | United Arab Emirates | BPGIC |

| Upcoming refinery [137] (kTPA) | |||

| Amiral complex | 1650 (ethylene and propylene) | Saudi Arabia | Aramco and Total |

| Ras Laffan Petrochemical | 2080 (ethylene) | Qatar | Chevron Philips and Qatar Energy |

| Borouge 4 | 6400 (polyolefins) | United Arab Emirates | ADNOC and Borealis |

| Al Zour Petrochemicals | 2340 (ethylene) | Kuwait | KIPIC |

| Duqm Petrochemical | 1600 (ethylene) | Oman | Joint |

| No. | Policy Elements | The Best Global Practice | GCC Practice | Gaps/Strengths |

|---|---|---|---|---|

| 1 | Demand certainty | Binding blending mandates and clear SAF/renewable fuel trajectories as the best practice creates large, predictable markets that justify refinery retrofits [157]. | Limited mandatory blending quotas or tradable obligations at scale in general, and limited binding, long-term offtake mandates, or regional targets for the United Arab Emirates. | Gap |

| 2 | Carbon/credit markets | Provide ongoing revenue streams for low-CI fuels and let markets set prices [158]. | No widely adopted LCFS equivalent at the national level. The GCC’s carbon markets are still in their early stages, and investment depends on export markets or direct funding. | Strength/gap |

| 3 | Feedstock sustainability and traceability | Using strict sustainability criteria such as LCA rules ensures positive climate outcomes. | As a partial strength, United Arab Emirates policy emphasizes recycling UCO and infrastructure, but region-wide robust sustainability standards and enforcement mechanisms for a diverse set of feedstocks are still developing. | Partial strength/gap |

| 4 | Capital and operating incentives | Direct grants, state aid packages, concessional finance, tax credits, and loans reduce CAPEX barriers and accelerate retrofits [159]. | Although there is a considerable sovereign capacity to provide incentives, there have not been many targeted national programs for refinery rehabilitation up to this point. | Opportunity |

| 5 | Technical enabling measures | Funding for pilots, streamlined permitting, and technical standards help de-risk retrofits. Internationally, these have proven effective to scale integration trials [160]. | The GCC has a strong advantage due to its major refineries with technological capabilities, existing hydrogen and utility infrastructure, and the ability to fund pilot plants quickly [133]. However, there is currently no regional standard for regulatory testing of environments or systematic co-processing of trial frameworks. | Strength |

| 6 | Feedstock mobilization | Municipal collection mandates, UCO bans/controls, feedstock pooling, and preprocessing hubs are used globally to aggregate feedstock at a commercial scale [161,162]. | UCO collection pilots and export restrictions are positive steps for the GCC in the United Arab Emirates. But for larger streams of MSW organics and agricultural residues, collection infrastructure and preprocessing hubs need scaling and policy support. | Partial strength |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, A.; Makkawi, Y. The Biorefinery Paradigm: Technologies, Feedstocks, and Retrofitting for Future Sustainable Energy. Energies 2025, 18, 5919. https://doi.org/10.3390/en18225919

Ahmed A, Makkawi Y. The Biorefinery Paradigm: Technologies, Feedstocks, and Retrofitting for Future Sustainable Energy. Energies. 2025; 18(22):5919. https://doi.org/10.3390/en18225919

Chicago/Turabian StyleAhmed, Aisha, and Yassir Makkawi. 2025. "The Biorefinery Paradigm: Technologies, Feedstocks, and Retrofitting for Future Sustainable Energy" Energies 18, no. 22: 5919. https://doi.org/10.3390/en18225919

APA StyleAhmed, A., & Makkawi, Y. (2025). The Biorefinery Paradigm: Technologies, Feedstocks, and Retrofitting for Future Sustainable Energy. Energies, 18(22), 5919. https://doi.org/10.3390/en18225919