Advancements and Challenges in Floating Photovoltaic Installations Focusing on Technologies, Opportunities, and Future Directions

Abstract

1. Introduction

- What are the latest technological innovations in FPV mooring systems, materials, and hybrid renewable energy integration?

- What are the major cost and durability challenges facing OFPV adoption, and how can they be mitigated?

- What environmental impacts do FPV systems have on aquatic ecosystems, and what regulatory frameworks are needed for sustainable deployment?

Review Methodology

- -

- Quantitative performance or techno-economic data.

- -

- Discussion of offshore FPV design, materials, or environmental interaction.

- -

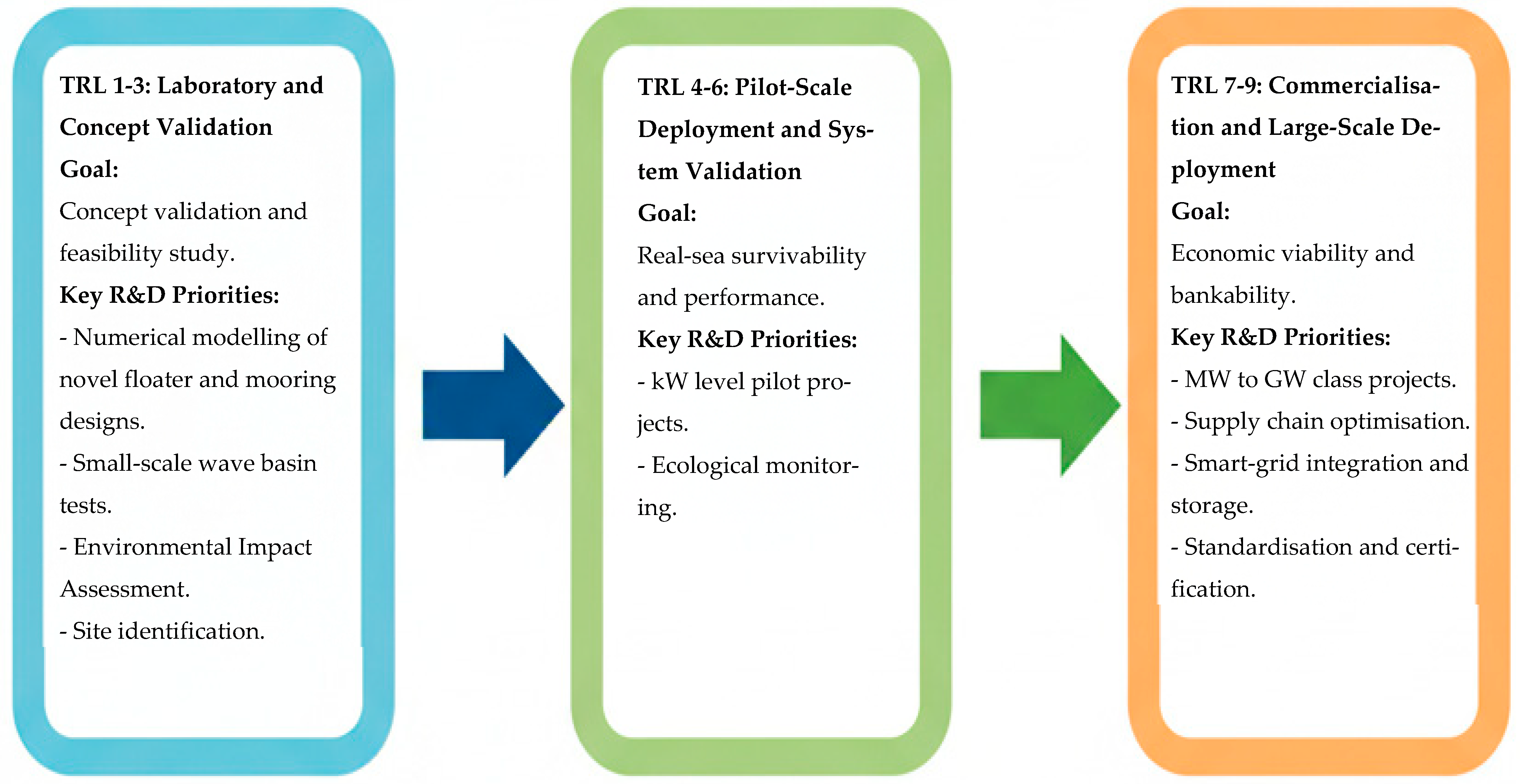

- Practical designs beyond numerical models with either a high technology readiness level (TRL) or a forward vision to advance the current TRL.

2. Benefits and Potential Implementation of FPVs

2.1. Benefits of FPVs

2.2. Potential Implementation of FPVs

3. Floating and Offshore PV Technology

3.1. Concept and Design of Floating, Nearshore, and Offshore PV Systems

- Inland floating PVs (LFPVs) are characterised by the implementation of systems over water bodies such as lakes, lagoons, irrigation and agricultural ponds, canals, dams, fish farms, wineries, and wastewater treatment plants.

- Offshore PVs are located, at a certain distance, off the coast, in deep or shallow waters [26]. These installations can either be floating (OFPVs) or installed on a fixed structure attached to the seabed (OPVs).

- Environmental factors such as solar radiation, shading, or fog that would directly influence electricity generation.

- Elements that might disturb installation and maintenance, namely the depth of water and regions prone to freezing or interference by dam facilities.

- Connection with power systems, such as the distance to load and distribution lines.

- Legal restrictions to ensure that a given aquatic area is not protected, does not require special countermeasures, and is not designated for marine traffic.

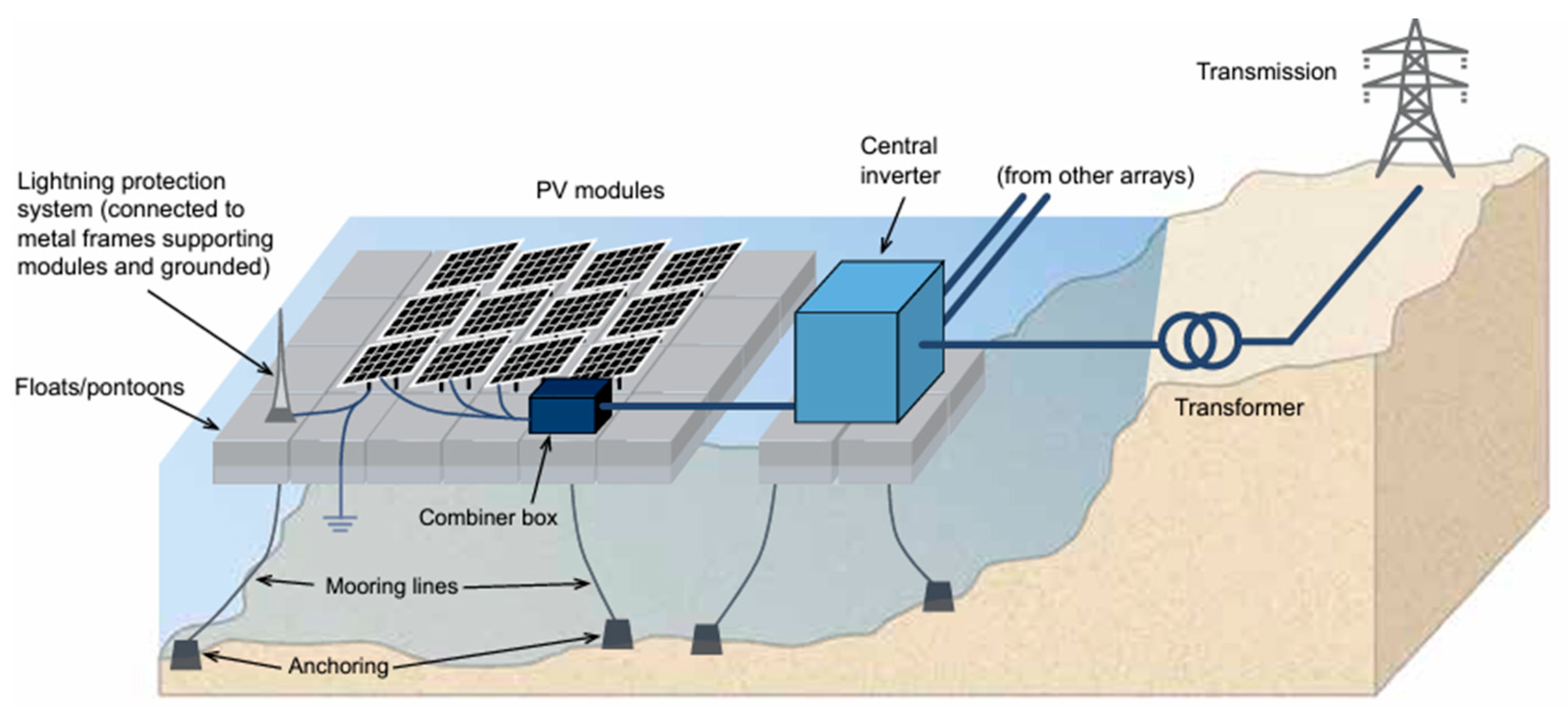

3.2. Components of a Floating PV System

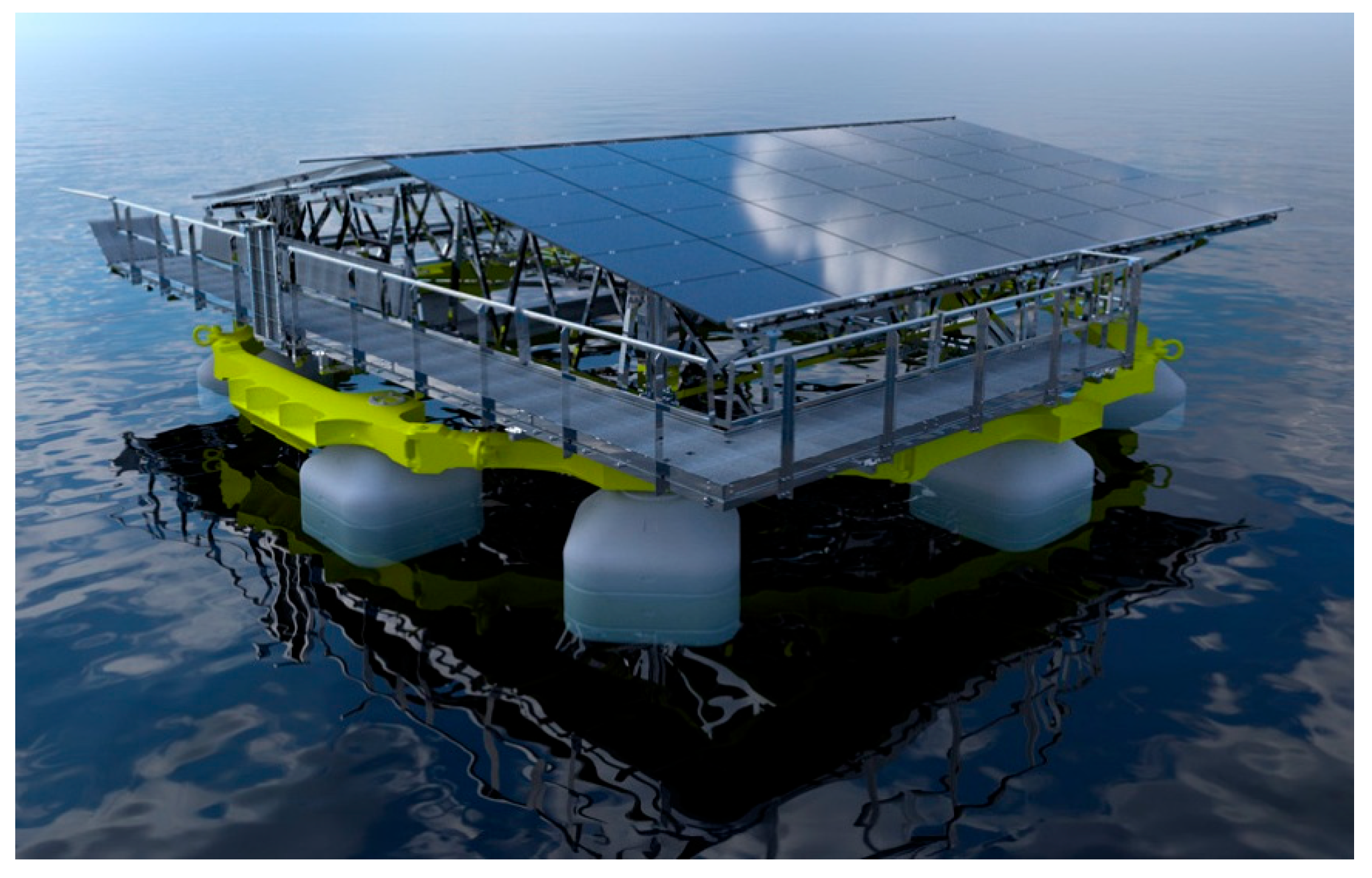

3.3. Floating PV Designs for Water Bodies

3.4. Nearshore PV System Designs

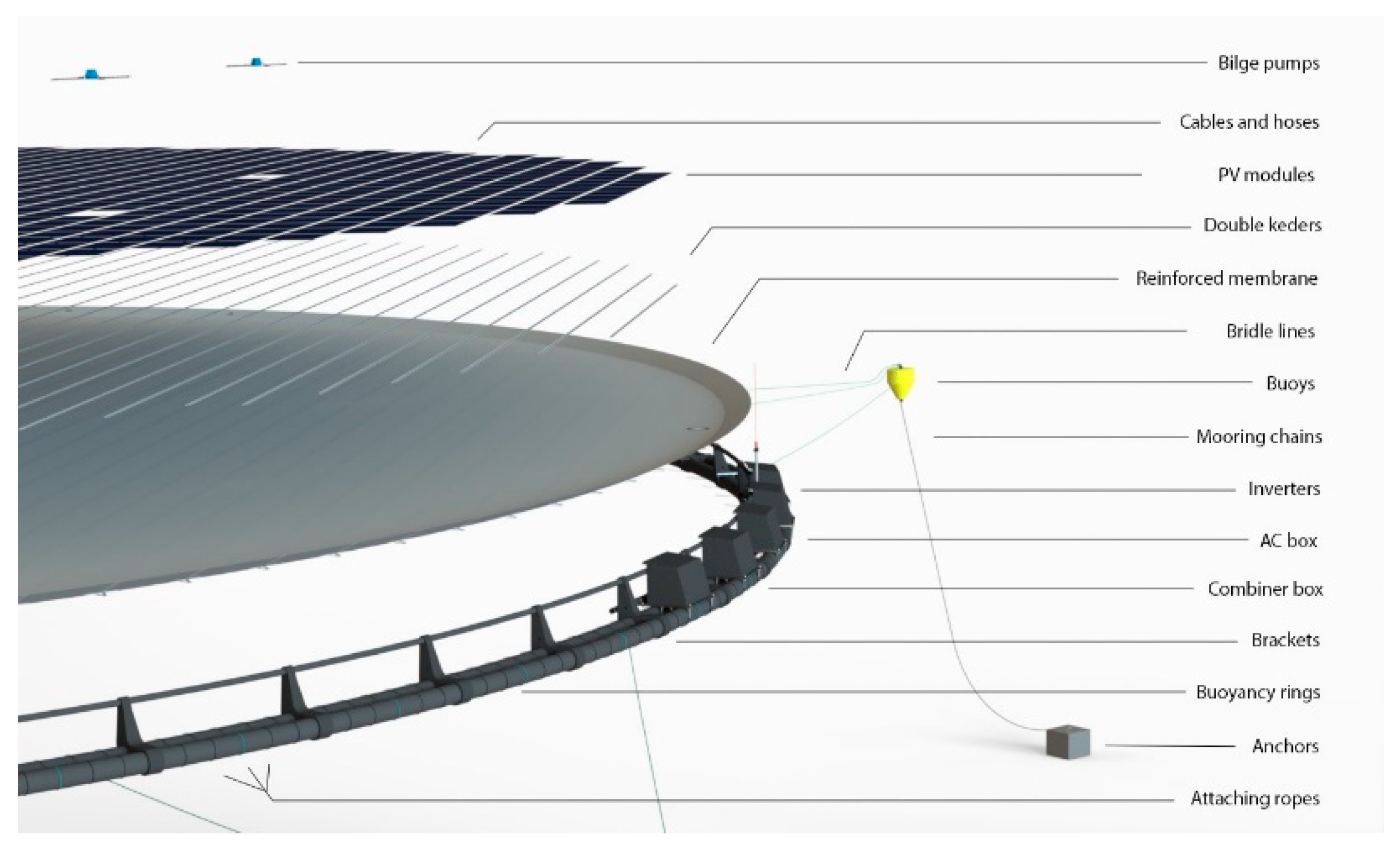

3.5. Offshore PV System Designs

- Reinforced expanded polystyrene (EPS) with thin-film PV modules.

- Crystalline PV module float.

- Steel pipe raft with HDP drums.

- Self-floating spherical shapes with PV modules built into them.

4. Technological Components, Innovations, and Challenges

4.1. Environmental Stresses

4.2. Materials for Floating Structures

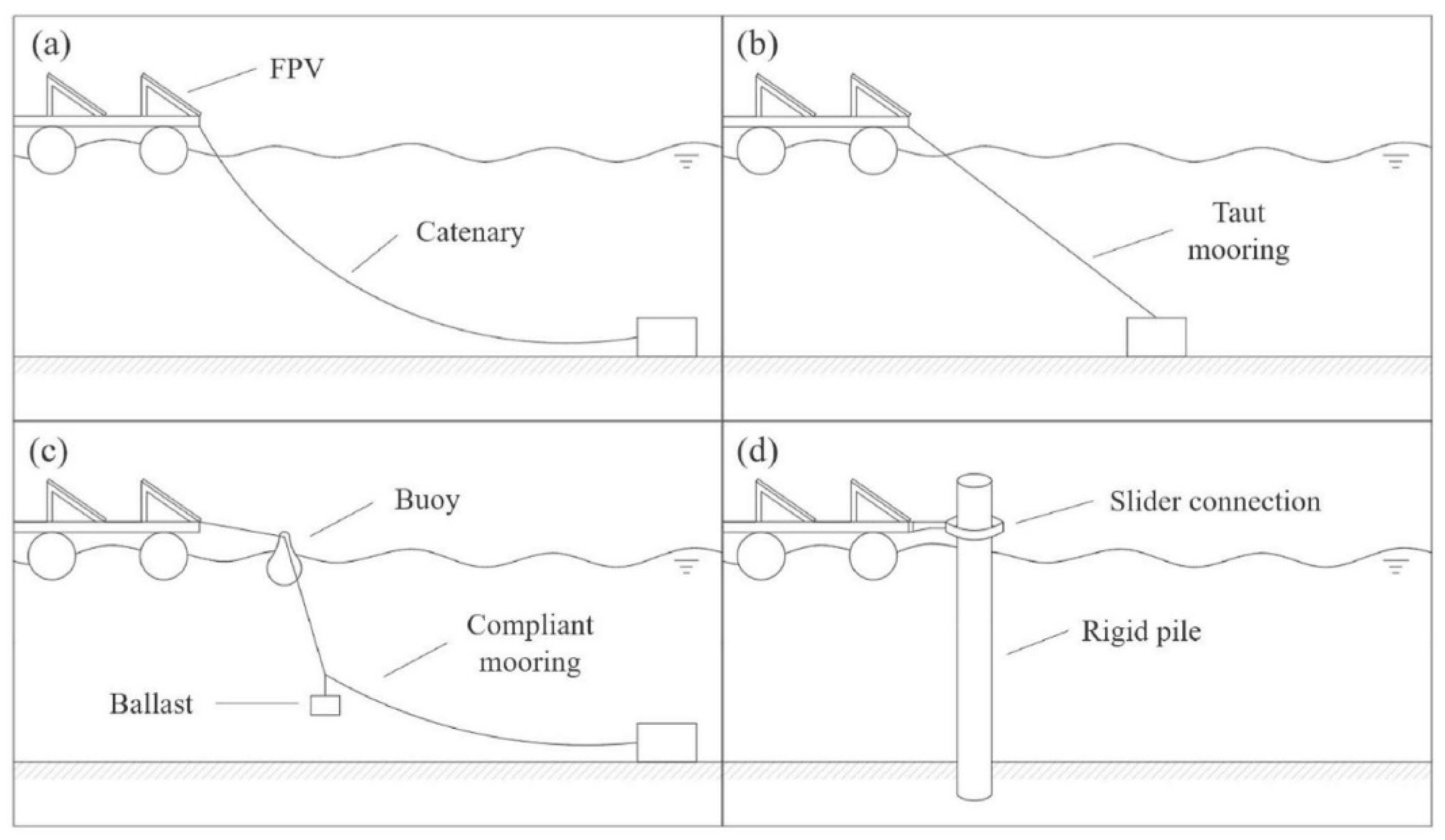

4.3. Mooring Systems and Connectors

4.4. PV Module Technologies

Effect of Oxidation and Microstructural Evolution on Photovoltaic Thin Films

4.5. Energy Storage Systems

- One challenge of offshore storage systems is to deal with a lack of space and weight constraints.

- Offshore energy storage systems must include black start, continuous voltage support, and frequency regulation features.

- The design must be optimised to require as little maintenance as possible to limit high operational costs.

- If the supply does not match the yearly demand, seasonal storage is necessary.

- ▪

- Batteries: Batteries are by far the most common energy storage technology and have recently become synonymous with GPV installations [15,67,68]. Many types of batteries are available today with different chemical combinations such as lead–acid, lithium ion (Li ion), lithium iron phosphate (LiFePO4), nickel–cadmium (Ni-Cd), and sodium–sulfur. In general, batteries have a high readiness level, high integrability, low maintenance, and high efficiency. However, some technologies have very low energy densities, and their environmental impact can be very high [69].

- ▪

- Hydrogen: There are four main types of hydrogen storage technologies, which are hydrogen stored in metal hydride, hydrogen compressed in a tank, hydrogen liquefied in a tank, and hydrogen storage underground. Green hydrogen is considered to be a sustainable fuel, with climate-neutral production [15,70]. Hydrogen storage technologies can have high energy densities and can have a very low environmental impact; however, these technologies have low efficiency and integrability and require advanced and expensive infrastructure [71].

- ▪

- Compressed Air Energy Storage (CAES): Compressed Air Energy Storage involves pumping air into geological reservoirs or storage vessels. This allows energy storage at low cost for a long period of time. This technology has a high readiness level, a long discharge duration, and an incredibly low environmental impact; however, its energy density is very low [67,69,72].

- ▪

- Flywheels (FESSs): Flywheels are accelerated to store energy and decelerated to use the stored energy, with the aid of an electrical motor/generator [73]. This technology has low energy density but a low environmental impact and high power density, readiness level, response time, efficiency, and safety [67].

- ▪

- Supercapacitors: Supercapacitors have a very low energy density, low capacity, and a high environmental impact. Furthermore, their high capital cost [69] makes them inadequate for large-scale storage. However, their maintenance is simple, and their response time is high.

- ▪

- Ammonia fuel: Ammonia fuel is characterised by a remarkably long discharge duration and a good capacity. Furthermore, it has a higher volumetric density than hydrogen and requires more simple storage infrastructure. However, ammonia has very low gravimetric energy, pushing research more towards ammonia-carried hydrogen rather than using it directly as a fuel [74,75,76,77].

- ▪

- Hydro-pneumatic energy: Hydro-pneumatic energy has very low energy density and a low readiness level, but its efficiency is very high, and its environmental impact is very low. For example, the “FLASC”, Floating Liquid-piston Accumulator, uses positive-displacement pumps to compress air in isothermal conditions thanks to a submerged storage vessel [78,79]. This system can be integrated with offshore energy generators, taking advantage of the offshore environment to improve the system’s efficiency. It is also designed to operate with minimal pressure fluctuations.

5. Selected Case Studies and Field Deployments

5.1. Overview of Recent FPV Projects Worldwide

5.2. Reported Incidents

- In September 2019, Typhoon Faxai, one of the strongest typhoons ever recorded, impacted Tokyo’s metropolitan area [90], causing considerable damage along the coast of Tokyo Bay. Faxai’s 54 m/s winds caused a Japanese floating solar plant to catch fire as a result of floaters piling on each other. The installation was floating on an inland water body, specifically on top of the Yamakura dam. As the wind and waves flung panels together, a combination of short circuits, DC arcs, and overheating led to a destructive fire [50].

- Also in 2019, a localised tornado hit the Netherlands and flipped some arrays of floats and PV modules onto each other [50].

- Anchor points positioned a few rows inside the floating array and not at the perimeter floats.

- Perimeter floats are not left empty. Installed PV modules on these floats can capture uplift forces.

- A low water level preventing the mooring cables from effectively absorbing the wind load.

- Larger wave heights than predicted.

- The sudden tensioning of slack mooring lines created peak forces which led to damage to the mooring attachment point.

6. Challenges and Opportunities

6.1. Performance Comparison

6.2. Technical Challenges

- A high moisture content from the water surroundings may accelerate degradation of the solar modules and deteriorate structure strength. SolarinBlue [42] have mitigated this by using PV modules that are resistant to salt mist. Other companies such as Sunergy [81] are producing PV modules that are salt-mist-resistant, designed specifically for offshore installations.

- Durability and survivability of materials used for power transmission from the floating installation to the land area.

- The annual fluctuations in a reservoir’s water level or tide. Mooring systems need to be able to adapt to these possible fluctuations.

- In the marine environment, the installation would be exposed to the overall climate of the sea, including salt, as well as subjected to mechanical loading challenges that arise from the dynamics of wind and waves and tidal regimes [14].

- A high installation cost is not often an investment that will pay back over time but rather becomes an economic concern that restrains expansion of the floating technology on the market. This is further accentuated by economic concerns associated with maintenance.

- There could be environmental and aesthetic concerns, as third parties might not be fully familiar with this type of technology; therefore, concept propagation and careful planning is required to gain public acceptance.

6.3. Regulatory and Standardisation Issues

6.4. Economic Feasibility and Market Potential

- PV modules: 31% of the total cost;

- Balance-of-System (BoS) hardware: 23% of the total cost;

- Installation: 20% of the total cost;

- Soft costs: 20% of the total cost;

- Inverters: 6% of the total cost.

Techno-Economic Assessment

6.5. Environmental Impact

6.5.1. Positive Impacts

6.5.2. Potential Ecological Concerns

6.5.3. Mitigation Strategies

- The area blocking the sunlight should be minimised. This can be achieved by allowing light to pass between rows of panels.

- The coverage ratio should be optimised to allow surrounding waters to dilute and/or compensate for potential environmental impacts.

- The contact area with the water should be minimised to reduce the risks of leaching and biofouling and reduce the effect on the air–water exchange.

- The “contact zone” of mooring lines should be kept to a minimum to reduce the disturbance of the seabed and the resuspension of (in)organic matter.

- Materials should be selected to minimise the potential for releasing toxic substances, such as chemicals, metals, oils or plastics, into the marine environment through leaching or leakage. Any chemicals used for routine cleaning should also be carefully selected.

- Dry transformers should be used to eliminate the risk of oil leaks.

- Limited long-term field performance data under variable hydrodynamic loading;

- Insufficient integration of techno-economic modelling with Environmental Impact Assessment;

- Lack of control strategies for hybrid FPV–storage systems.

6.5.4. Material and Life Cycle Considerations

7. Integration of FPVs with Other Technologies

- Cost reduction: Using the existing infrastructure of HPPs can reduce the cost of LFPV plants. Moreover, combining the natural energy storage of HPPs with LFPV plants can further increase financial feasibility.

- Reduction in power fluctuations: To align power production with demand, an active control system could be implemented, reducing HPP output during the day when the LFPV system is operational and increasing it at night or when low-irradiance conditions occur. This would provide a solution to energy discontinuity because HPPs can supply the energy when the LFPV plant cannot.

- Potential implementation for FPV: Where there is an HPP, there is also an under-used water basin where an LFPV plant can be installed.

- Potential implementation of OFPVs: OFPV systems can be implemented in the empty marine surface areas between wind turbines, increasing energy production density.

- Reduction in power fluctuations: For the same reasons as for combining OPVs with HPPs, combining offshore wind turbines with OPV systems allows for a smoother power output than conventional separate stand-alone systems.

8. FPV Policy and Regulation

8.1. LFPV Policy and Regulation

- Permitting Uncertainty: FPVs lie at the intersection of several regulatory frameworks, including energy, water, mining, and environmental protection. Without specific legislation, authorities struggle to determine if FPVs require a construction permit or a water utilisation permit, creating uncertainty for investors [138].

- Environmental Assessment: The unique ecological impacts of FPVs require specific attention, but policies often lack mandatory Environmental Impact Assessment (EIA) requirements specific to FPV projects [136]. Scientific information regarding the environmental impact is still difficult to assess, which can lengthen permitting procedures [138].

Country-Specific Examples and Incentives

8.2. OFPV Policy and Regulation

8.2.1. EU Policy Context (Innovative Technologies)

8.2.2. Country-Specific Offshore Renewables Strategies

9. Conclusions

- Continuous Monitoring: Measurements of essential water quality parameters, such as the dissolved oxygen (DO) and temperature, should be logged continuously (e.g., at <15 min intervals) at central, edge, and open-water control stations for at least one annual cycle to account for seasonal variations [121,127].

- Benthic Assessment: To assess bio-deposition impacts from biofouling, the collection of sediment samples in a radius using a BACI approach is suggested [121].

- Biofouling Documentation: Periodic biofouling surveys should be included to measure the accumulating biomass and characterise the rapidly colonising communities, such as the blue mussel (Mytilus edulis). Such long-term monitoring is critical for facilitating the design of floating systems, especially concerning the weight of the colonising fauna [120].

- Identify specific barriers and measures (e.g., streamlined permitting with thorough EIAs and public consultation).

- Provide adequate financial support in early stages through public-sector funding and specific feed-in tariffs.

- Ensure the transmission grid is effectively developed to allow connection of offshore solar projects.

- Adopt national targets for offshore floating PVs to support technology development.

- Develop specific guidelines that address technical, environmental, and safety considerations unique to the marine environment.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

List of Abbreviations

| Abbreviation | Definition | Abbreviation | Definition |

| AA-CAES | Advanced Adiabatic Compressed Air Energy Storage | kW/kWp | Kilowatt/Kilowatt-peak |

| BACI | Before–After, Control–Impact | kWh | Kilowatt-hour |

| BoS | Balance of System | LCA | Life Cycle Assessment |

| CAES | Compressed Air Energy Storage | LCOE | Levelised Cost of Energy |

| CAPEX | Capital Expenditure | Li ion | Lithium ion |

| CdTe | Cadmium Telluride | LiFePO4 | Lithium Iron Phosphate |

| CIGS | Copper–Indium–Gallium–Diselenide | LFPV | Inland Floating Photovoltaic |

| D-CAES | Diabatic Compressed Air Energy Storage | MW/MWp | Megawatt/Megawatt-peak |

| DO | Dissolved Oxygen | NDCs | Nationally Determined Contributions |

| DPP | Discounted Payback Period | NPV | Net Present Value |

| EEZ | Exclusive Economic Zone | NREL | National Renewable Energy Laboratory |

| EIA | Environmental Impact Assessment | O&M | Operation and Maintenance |

| EPC | Engineering, Procurement, and Construction | O&G | Oil and Gas |

| EU | European Union | OFPV | Offshore Floating Photovoltaic |

| FESS | Flywheel Energy Storage System | OPV | Offshore Photovoltaic (Fixed or Floating) |

| FPV | Floating Photovoltaic | OSIC | Offshore Solar Irradiance Calculator |

| GPV | Ground-Mounted Photovoltaic | PVT | Photovoltaic Thermal |

| GW/GWp | Gigawatt/Gigawatt-peak | PV | Photovoltaic |

| HDPE | High-Density Polyethylene | R&D | Research and Development |

| HJT | Heterojunction | RED | Renewable Energy Directive |

| HPES | Hydro-Pneumatic Energy Storage | SCESS | Supercapacitor Energy Storage System |

| HPP | Hydropower Plant | SERIS | Solar Energy Research Institute of Singapore |

| H2 | Hydrogen | TLP | Tension-Leg Platform |

| IEC | International Electrotechnical Commission | TRL | Technology Readiness Level |

| IRR | Internal Rate of Return | UV | Ultraviolet |

| ISO | International Organization for Standardisation | WEC | Wave Energy Converter |

| ITC | Investment Tax Credit |

Appendix A

| Technology | Energy Yield | Structural Type | Material Composition | Environmental Durability/Survivability Claims | Authors’ Estimated TRL and Considerations (Evidence-Based) |

|---|---|---|---|---|---|

| Ocean Sun | Company/DNV test reports claim ~8–12% higher energy yield vs. pontoon/ground (cooling effect of membrane cited; company test data in DNV test site summary) [144]. | Flexible hydro-elastic membrane carrying modified rigid silicon PV modules (membrane + keder mounting; low-profile ring/mooring) [145,146]. | Company describes membrane + HDPE/engineered membrane + rigid PV modules (dual-glass modules, alliance with GCL noted in investor slides) [145]. | DNV verification and test site data; vendor claims survivability in harsh conditions (DNV Statement of Conformity; test site noted operation and claimed wind/typhoon survivability in documents). Claims: - Withstand strong storms. - Test site shows better performance vs. pontoon in Q3 2019 test [147]. - Typhoon Cat.4 (≈275 km/h wind) tolerance [146]. | TRL 6–7. Evidence: DNV Statement of Conformity (technology qualification activities) + instrumented prototype test site comparing membrane vs. pontoon (pilot data reported) [147]. Considerations: - Constant seawater overtopping can cause biofouling, staining, and corrosion of PV modules. |

| XolarSurf (Moss/Saipem) | Brochure/project material lists a 300 × 300 m island up to ~13.5 MW (company brochure—implies typical power density for that layout but brochure does not publish a universal W/m2) [38]. | - Basic design and harsh environment version available. - Modular flexible steel frame for basic design. - Rigid frame for harsh environment version. -Rigid floater array (many individual floaters assembled into 300 × 300 m island). - Rigid PV mounting structure [38]. | Company describes steel structure floaters and pretensioned fibre ropes. Specific BoM breakdown not published in brochure [38]. | Base case: - Hs < 4 m (Tp 10 s). - Wind < 35 m/s (1 h). - Current < 2 m/s. - Water depth > 15 m. Harsh environment version: - Hs < 8 m. - Wind < 35 m/s (1 h). - Current < 2 m/s. - Water depth > 30 m [38]. | TRL 5–6—evidence: full-scale prototype launched and undergoing ~1-year sea trial; not yet widely commercial [39]. Considerations: - LCOE of the installed system still to be verified. |

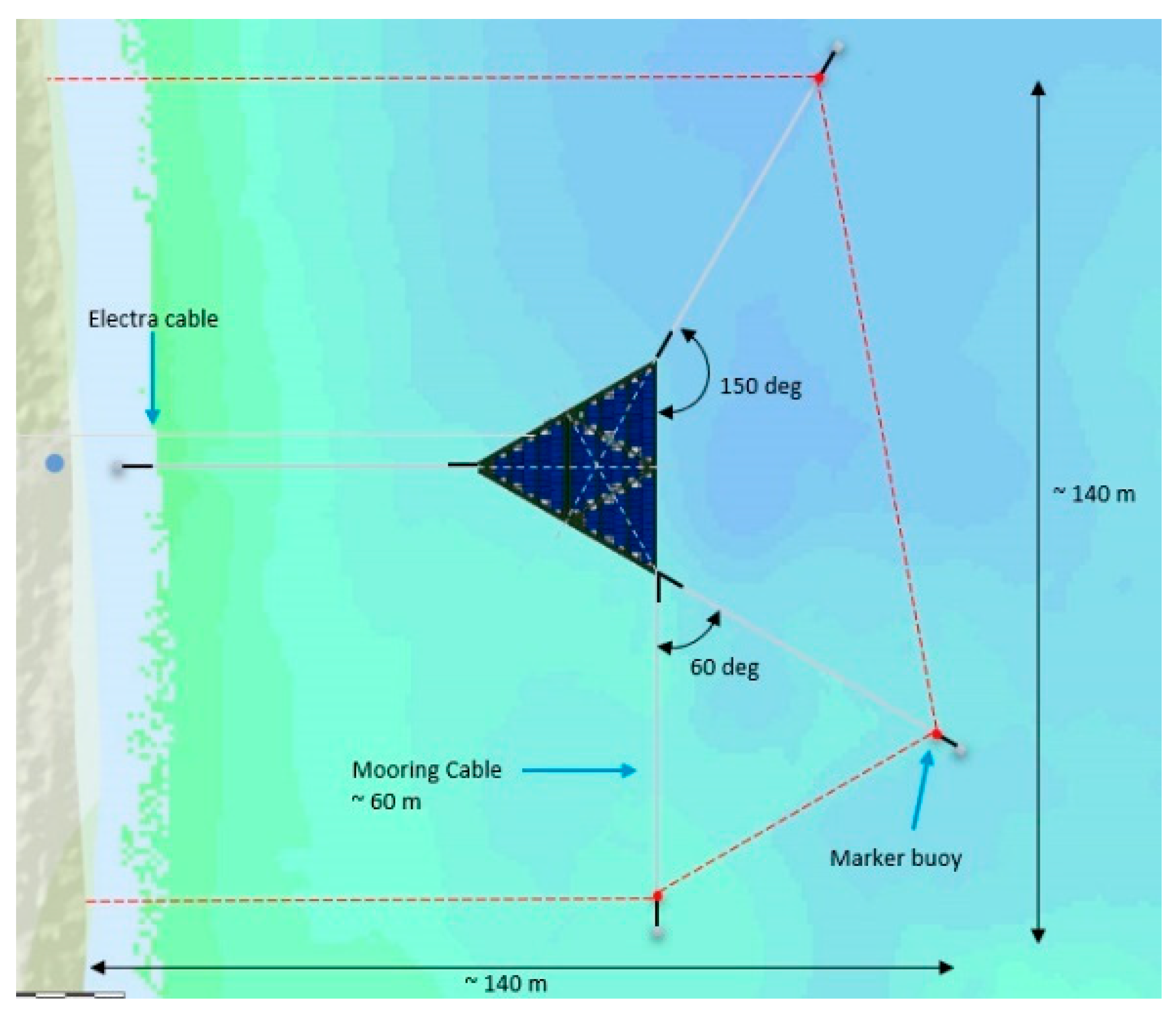

| SolarDuck | Company reports the following: - 520 kWp (Merganser) pilot. - Improved yield (cooling, reduced soiling) vs. conventional FPV. - 680 Wp PV modules. - 131 PV modules per platform [57]. - Estimated 142.5 W/m2 [148]. | - Triangular elevated platforms. - Panels elevated by several meters. - Modular interconnected platforms [149]. | - Semi-submersible platform built with marine-grade aluminium with rigid mounting). - Standard PV modules and inverters. - Steel anchors. - Combination of polyester line, steel chains, and steel ropes [149]. | - Prototype certification from Bureau Veritas. - Wave height < 11.6 m. - Water depth = 21.5 m [148]. - Wind speed: 32.5 m/s (10 min); hurricane- and typhoon-proof design up to 65 m/s [149]. | TRL 7. Evidence: full pilot installed, certified, and undergoing operational monitoring in the North Sea. Considerations: - LCOE of the installed system still to be verified. |

| HelioSea | - Peer-reviewed concept and experimental papers report significant modelled energy gains from dual-axis tracking vs. fixed arrays. - Prototype-scale tests (75 kW prototype/lab models) [37]. | - Tension-leg platform (TLP) with dual-axis trackers. - Concept couples high-stability TLP with pole/tracker systems to keep modules above waves [37]. | - Steel TLP structure + tracker mechanics + PV modules (material specifics are engineering/conceptual; full supply BoM not published) [37]. | - Hydrodynamic 1:30 model tests and numerical modelling show reduced motions vs. pontoon suitable for trackers; environmental durability still under lab/scale validation (fatigue and corrosion flagged as critical R&D areas) [150]. | Estimated TRL 3. Evidence: peer-reviewed concept + experimental proof of concept and scaled model testing. Considerations: - Moving parts are susceptible to high maintenance costs in offshore environments. |

| SolarinBlue (Sun’Sète/Méga Sète) | - Sun’Sète demonstrator installed (first French Mediterranean OFPV). - Méga Sète aims for 1 MWp demonstrator covering 1 hectare of sea area. This results in a power density of 100 W/m2. - Each solar unit has an area of 400 m2 with a 92 kWp capacity. This results in a power density of 230 W/m2 [42]. | Modular island/floater arrays for open sea (company describes modular floaters and anchoring adapted for Mediterranean conditions) [42]. | - Treated steel frame. - HDPE floats [151]. | - Environmental/anchor validation completed [151]. - Wave heights > 12 m. - Resistance to cyclonic wind conditions of 200 km/h. - 30-year service life [42]. | TRL 6–7. Evidence: operational demonstrator [42] and funded pre-commercial 1 MWp project [151] moving into field validation and monitoring. Considerations: - LCOE of the installed system still to be verified. |

| Oceans of Energy | - North Sea 1 = 50 kWp [43]. - North Sea 2 = 400 kWp set to expand to 1 MWp [44]. - North Sea 3 = projected to reach multiple MWp [44]. - HKN1 = 0.5 MWp [43]. | Modular floater arrays made for offshore deployment; designed for installation between wind turbines (hybrid co-location) [43]. | - Reported use of metals (70% of which is reused metal) and polymers (80% of which is reused polymer) [152]. - BoM not publicly disclosed. | - Wave height < 14 m. - Wind speed < 200 km/h. - Design life = 25 years. - Proven track record: 4 years, continuous, North Sea [43]. | TRL 7+. Evidence: commercial-scale pilots assembled and integration contracts for hybrid wind–solar farms; operational pilot experience in the North Sea (ongoing monitoring and scaling). Considerations: - Constant seawater overtopping can cause biofouling, staining, and corrosion of PV modules. |

| Solaqua (University of Malta project) | - Design involves hexagonal rafts with an area of 41.57 m2. - Each raft will have 14 PV modules, resulting in an estimated power density of 185 W/m2. | - Modular semi-submersed hexagonal floating rafts. | - Cement-based outer shell. - Buoyancy possibly from recycled materials. - Steel and fibre reinforcement. | - First design demonstrated in sheltered/open coastal trials (2012–2016 pilot) [153]. - Hexagonal design tasted in a wave tank (1:25 model) and survived wave heights of more than 6 m. | Estimated TRL 4. Evidence: academic project with small-scale prototypes, lab and coastal tests, and techno-economic assessments—not commercialised. Considerations: - Full-scale prototype still to be constructed and tested. |

| CIMC Raffles (semi-submersible) | - 400 kWp demo. - Deck area ~1900 m2. - Estimated power density of 210.5 W/m2 [154]. | Semi-submersible platform (multi-body float arrays with mooring, subsea dynamic cable, fenders, monitoring systems) [154]. | - CIMC describes modular float arrays, buoyancy materials, dynamic subsea cable systems, and standard PV modules/inverters; specific material inventory not published beyond press. - A previous publication described a bamboo-based composite [46]. | - Wave heights < 6.5 m. - Wind < 34 m/s. - Tidal differences < 4.6 m [155]. | TRL 6–7. Evidence: commercial demo delivered and towed (2023); vendor documentation and press coverage; demonstration of system integration. Considerations: - Limited long-term field lifetime data publicly available. |

| Storage Type | Efficiency (Round-Trip/Cycle) | Corrosion Resistance (Offshore Environment) | Maintenance Requirements |

|---|---|---|---|

| Batteries | Lead–acid is 80–82% or ~82% [67], with cycle efficiencies typically 63–90% [69]. Li ion is 92–96% (approximately 95%). Ni-Cd is 60–85% [67]. | Batteries for offshore applications are typically offered in container modules. These systems must be tested against off-gas risk propagation and explosion and adhere to guidelines from bodies like DNV. Ni-Cd batteries are used for oil and gas (O&G) installations and are resistant to mechanical and electrical abuse [67]. | Li ion generally has low operation and maintenance (O&M) requirements. Ni-Cd features easy installation and low maintenance. Lead–acid (flooded) requires more maintenance and periodic water replacement. Lead–acid (VRLA) requires very low maintenance and no water addition [67]. |

| Hydrogen (H2) | H2 gas storage system (round-trip efficiency) is typically 25–40%. H2 liquid storage system is 12–25% [67]. H2 fuel cells, converting chemical energy to electricity, typically exhibit energy efficiencies of approximately 70–80% [73]. Overall fuel cell systems are typically 20–50% [69]. | Hydrogen storage vessels should be subjected to periodic non-destructive examination and recertification due to the risk of failure from fatigue and hydrogen embrittlement in cyclic service. Alternative storage solutions include utilising existing offshore structures like wind towers or platform jackets [67]. | Metal hydrides can operate for decades without major losses. Storage vessels require maintenance activities such as non-destructive examination at planned intervals [67]. |

| Compressed Air Energy Storage (CAES) | Large-scale CAES has achieved efficiencies of 42% and 54% [69]. Diabatic CAES (D-CAES) plants show efficiencies of 0.42 and 0.54 [156]. Advanced Adiabatic CAES (AA-CAES) is expected to reach 70% [69]. | The safety risk associated with compressed air stored in vessels (catastrophic rupture) is mitigated by safety regulations and features like pressure relief valves. In offshore locations, air storage in tanks would be more suitable in the short term, which avoids environmental concerns regarding excavation [67]. | Maintenance requirements are similar to those of a simple cycle combustion engine (~0.30 USD/MWh generated) [67]. Large CAES systems have an estimated annual O&M cost of 19–25 USD/kW/year [69]. |

| Flywheels (FESSs) | High efficiency, up to 95% at rated power. Round-trip efficiency typically ranges from 78 to 95% [67,69]. | Flywheel components are placed in a vacuum to reduce wind shear and energy loss [67,69]. Sealed, frictionless bearings with no lubrication and little maintenance are preferred for offshore flywheel systems [67,69]. | FESSs generally have easy maintenance [69]. Most systems may require little maintenance due to sealed, frictionless bearings. However, replacement of components is often required every 5 to 8 years, and if coupled to a generator, regular maintenance is needed (e.g., coolant and oil changes) [67]. |

| Supercapacitors (SCESSs) | High cycle efficiency, ranging from 90 to 98% [69,73]. Coulombic efficiencies can reach up to 99%. Round-trip efficiency is typically above 80% [67]. | These systems are used for transport and grid applications, including in the marine and offshore industries. They can operate in a wide range of temperatures [67]. | Supercapacitors can be cycled more often than batteries [73]. |

| Ammonia Fuel (NH3) | Round-trip efficiency is above 22% [67]. An islanded ammonia power system for a generic northern Europe location achieved a round-trip efficiency of 61% [157]. | Ammonia is a potential marine fuel. Safety concerns exist regarding poison gas and corrosive problems during loading. Ammonia is classified as a toxic gas for humans and aquatic life [67]. | O&M for the production system is estimated at 24–39 EUR/kW-yr. Ammonia has a 30 times lower cost per unit of stored energy compared to hydrogen [67]. |

| Hydro-Pneumatic Energy (HPES) | Full-scale round-trip efficiency is around 75% [67]. A small-scale prototype demonstrated a consistently high thermal efficiency (>93%) across the year [79]. The electrical round-trip efficiency is comparable to adiabatic and near-isothermal CAES [78]. | Although the technology utilises seawater, posing challenges like corrosion, wear, and entrapment, these issues have been managed in related fields like the desalination industry and underwater tools [78]. | Fixed O&M: 20 USD/kW [158]. Variable O&M: 0.002 USD/kWh [158]. |

References

- Sahu, A.; Yadav, N.; Sudhakar, K. Floating photovoltaic power plant: A review. Sustain. Energy Rev. 2016, 66, 815–824. [Google Scholar] [CrossRef]

- Curioni, M.; Galli, N.; Manzolini, G.; Rulli, M.C. Global Land-Water Competition and Synergy Between Solar Energy and Agriculture. Earths Future 2025, 13, e2024EF005291. [Google Scholar] [CrossRef]

- Nisar, H.; Janjua, A.K.; Hafeez, H.; Shakir, S.; Shahzad, N.; Waqas, A. Thermal and electrical performance of solar floating PV system compared to on-ground PV system-an experimental investigation. Sol. Energy 2022, 241, 231–247. [Google Scholar] [CrossRef]

- Grech, M.; Stagno, L.M.; Aquilina, M.; Cadamuro, M.; Witzke, U. Floating photovoltaic installations in Maltese sea waters. In Proceedings of the 32nd European Photovoltaic Solar Energy Conference and Exhibition, Munich, Germany, 20–24 June 2016. [Google Scholar]

- Sukarso, A.P.; Kim, K.N. Cooling effect on the floating solar PV: Performance and economic analysis on the case of west Java province in Indonesia. Energies 2020, 13, 2126. [Google Scholar] [CrossRef]

- López, M.; Rodríguez, N.; Iglesias, G. Combined floating offshore wind and solar PV. J. Mar. Sci. Eng. 2020, 8, 576. [Google Scholar] [CrossRef]

- Scavo, F.B.; Tina, G.M.; Gagliano, A.; Nižetić, S. An assessment study of evaporation rate models on a water basin with floating photovoltaic plants. Int. J. Energy Res. 2021, 45, 167–188. [Google Scholar] [CrossRef]

- Farrar, L.W.; Bahaj, A.B.S.; James, P.; Anwar, A.; Amdar, N. Floating solar PV to reduce water evaporation in water stressed regions and powering water pumping: Case study Jordan. Energy Convers. Manag. 2022, 260, 115598. [Google Scholar] [CrossRef]

- Elminshawy, N.A.S.; Osama, A.; Gagliano, A.; Oterkus, E.; Tina, G.M. A technical and economic evaluation of floating photovoltaic systems in the context of the water-energy nexus. Energy 2024, 303, 131904. [Google Scholar] [CrossRef]

- Cazzaniga, R.; Rosa-Clot, M.; Rosa-Clot, P.; Tina, G.M. Integration of PV floating with hydroelectric power plants. Heliyon 2019, 5, e01918. [Google Scholar] [CrossRef]

- Schoefs, F.; Oumouni, M.; Ahmadivala, M.; Luxcey, N.; Dupriez-Robin, F.; Guerin, P. Unified system analysis for time-variant reliability of a floating offshore substation. J. Mar. Sci. Eng. 2023, 11, 1924. [Google Scholar] [CrossRef]

- Tricco, A.C.; Lillie, E.; Zarin, W.; O’Brien, K.K.; Colquhoun, H.; Levac, D.; Moher, D.; Peters, M.D.J.; Horsley, T.; Weeks, L.; et al. PRISMA Extension for Scoping Reviews (PRISMA-ScR): Checklist and Explanation. Ann. Intern. Med. 2018, 169, 467–473. [Google Scholar] [CrossRef]

- Yousuf, H.; Khokhar, M.Q.; Zahid, M.A.; Kim, J.; Kim, Y.; Cho, E.C.; Cho, Y.H.; Yi, J. A review on Floating Photovoltaic Technology (FPVT). Curr. Photovolt. Res. 2020, 8, 67–78. [Google Scholar]

- Wang, J.; Lund, P.D. Review of recent offshore photovoltaics development. Energies 2022, 15, 7462. [Google Scholar] [CrossRef]

- Garrod, A.; Hussain, S.N.; Ghosh, A.; Nahata, S.; Wynne, C.; Paver, S. An assessment of floating photovoltaic systems and energy storage methods: A comprehensive review. Results Eng. 2024, 21, 101940. [Google Scholar] [CrossRef]

- Tian, W.; Liu, X.; Wang, K.; Bai, P.; Liu, C.; Liang, X. Estimation of global reservoir evaporation losses. J. Hydrol. 2022, 607, 127524. [Google Scholar] [CrossRef]

- Cuce, E.; Cuce, P.M.; Saboor, S.; Ghosh, A.; Sheikhnejad, Y. Floating PVs in terms of power generation, environmental aspects, market potential, and challenges. Sustainability 2022, 14, 2626. [Google Scholar] [CrossRef]

- Srinivasan, C.V.C.; Soori, P.K.; Ghaith, F.A. Techno-Economic Feasibility of the Use of Floating Solar PV Systems in Oil Platforms. Sustainability 2024, 16, 1039. [Google Scholar] [CrossRef]

- IRENA. Renewable Capacity Statistics 2024; IRENA: Abu Dhabi, United Arab Emirates, 2024. [Google Scholar]

- European Court of Auditors. Special Report 22/2023: Offshore Renewable Energy in the EU. 18 September 2023. Available online: https://www.eca.europa.eu/en/publications?ref=SR-2023-22 (accessed on 21 October 2024).

- Rauf, H.; Gull, M.S.; Arshad, N. Integrating floating solar PV with hydroelectric power plant: Analysis of Ghazi barotha reservoir in Pakistan. Energy Procedia 2019, 158, 816–821. [Google Scholar] [CrossRef]

- Manolache, M.; Manolache, A.I.; Andrei, G. Floating Solar Energy Systems: A Review of Economic Feasibility and Cross-Sector Integration with Marine Renewable Energy, Aquaculture and Hydrogen. J. Mar. Sci. Eng. 2025, 13, 1404. [Google Scholar] [CrossRef]

- Silalahi, D.F.; Blakers, A. Global atlas of marine floating solar PV potential. Solar 2023, 3, 416–433. [Google Scholar] [CrossRef]

- Masson, G.; de l’Epine, M.; Kaizuka, I. Trends in Photovoltaic Applications 2023. 2023. Available online: https://iea-pvps.org/trends_reports/trends-2023/ (accessed on 3 January 2025).

- Creative Commons. CC BY 4.0—Attribution 4.0 International Deed. Available online: https://creativecommons.org/licenses/by/4.0/ (accessed on 31 July 2025).

- Engie. Marine Solar Offshore Power: There is a Future for Solar Energy Offshore. Engie. Available online: https://innovation.engie.com/en/news/interview/emerging-sustainable-technologiesnbsp/marine-floating-solar-power/29533 (accessed on 26 August 2024).

- World Bank Group; Energy Sector Management Assistance Program; Solar Energy Research Institute of Singapore. Where Sun Meets Water: Floating Solar Market Report, (C) World Bank. 2019. Available online: https://hdl.handle.net/10986/31880 (accessed on 8 October 2025).

- Ciel & Terre. HYDRELIO®aiR Optim: The Proven Floating Solar Technology. Available online: https://ciel-et-terre.net/our-products/hydrelio-air-optim/ (accessed on 24 September 2024).

- Dang, N.; Thi, A. The Global Evolution of Floating Solar PV. 2017. Available online: https://www.researchgate.net/publication/321461989 (accessed on 7 November 2025).

- Ocean Sun. Ocean Sun Benefits. Available online: https://oceansun.no/benefits/ (accessed on 30 June 2023).

- Ocean Sun. The Innovation. Available online: https://oceansun.no/the-innovation/ (accessed on 29 August 2024).

- Kjeldstad, T.; Lindholm, D.; Marstein, E.; Selj, J. Cooling of floating photovoltaics and the importance of water temperature. Sol. Energy 2021, 218, 544–551. [Google Scholar] [CrossRef]

- Regulator for Energy & Water Services (Malta). Planning Authority Guidelines for Solar Installations. Development Control Design Policy, Guidance and Standards 2015 (DC 15). Available online: https://www.rews.org.mt/#/en/a/46-planning-authority-guidelines-for-solar-installations (accessed on 5 December 2024).

- Bugeja, R.; Stagno, L.M.; Branche, N. The effect of wave response motion on the insolation on offshore photovoltaic installations. Sol. Energy Adv. 2021, 1, 100008. [Google Scholar] [CrossRef]

- Aquilina, M.; Stagno, L.M.; Grech, M.; Sant, T. Determining the Optimum Shape and Size of a Platform for an Offshore Floating Photovoltaic System; Offshore Energy and Storage Symposium (OSES), University of Malta Valletta Campus: Valletta, Malta, 2016. [Google Scholar]

- Stagno, L.M. Floating Offshore Structure. EP4412899A1. 2024. Available online: https://worldwide.espacenet.com/patent/search/family/085803986/publication/EP4412899A1?q=PCT%2FIL2022%2F051044 (accessed on 23 September 2024).

- López, M.; Claus, R.; Soto, F.; Hernández-Garrastacho, Z.A.; Cebada-Relea, A.; Simancas, O. Advancing offshore solar energy generation: The HelioSea concept. Appl. Energy 2024, 359, 122710. [Google Scholar] [CrossRef]

- Saipem and Moss Maritime. XolarSurf Offshore Floating Solar Power. Available online: https://www.saipem.com/sites/default/files/2023-03/Xolarsurf_web.pdf (accessed on 27 October 2024).

- Saipem. Saipem, Key Milestone Reached in Floating Solar Technology XolarSurf. October 2024. Available online: https://www.saipem.com/en/saipem-key-milestone-reached-in-floating-solar-technology-xolarsurf (accessed on 3 January 2025).

- Zerina Maksumic. ‘China’s First Large-Scale Offshore PV Project’ Ready for Operation,” Offshore-Energy.biz. Available online: https://www.offshore-energy.biz/chinas-first-large-scale-offshore-pv-project-ready-for-operation/ (accessed on 26 August 2024).

- Offshore Channel Magazine. Offshore Renewable Energy Wind Energy Wave Energy Tidal Energy Solar Energy; Offshore Channel Magazine: Saratoga, CA, USA, 2024. [Google Scholar]

- SolarinBlue. Revolutionizing Offshore Solar: Explore All Our Innovative Projects. Available online: https://solarinblue.com (accessed on 10 October 2024).

- Oceans of Energy. Oceans of Energy: Worldwide Leader in Offshore Solar in Harmony with Nature. Available online: https://oceansofenergy.blue/ (accessed on 21 October 2024).

- Zerina Maksumic. Oceans of Energy Launches Floating Solar Farm in Belgium. Offshore Energy. Available online: https://www.offshore-energy.biz/oceans-of-energy-launches-floating-solar-farm-in-belgium/ (accessed on 29 October 2024).

- Solar Duck. Unique Solution. Available online: https://solarduck.tech/unique-solution/ (accessed on 29 October 2024).

- CIMC Raffles Offshore Engineering. The World’s First Bamboo-Based Composite Floating Photovoltaic System Has Been Delivered to Help Develop Floating Photovoltaic Systems at a Low Cost. Available online: https://www.cimc-raffles.com/show-29-633-1.html (accessed on 13 May 2025).

- L. China International Marine Containers (Group) Co. China’s First Semi-Submersible Offshore Photovoltaic Power Platform Delivered by CIMC Raffles. Available online: https://www.cimc.com/en/index.php?m=content&c=index&a=show&catid=17&id=2177 (accessed on 13 May 2025).

- Solarbe Photovoltaic Network and Zhouzhenkun. The Offshore Floating Photovoltaic Demonstration Platform Independently Developed by State Power Investment Corporation Shandong Institute Has Been Successfully Put Into Operation! SDEPCI in Hezhou. Available online: https://news.solarbe.com/202309/04/371412.html (accessed on 13 May 2025).

- Fandi, J. My Country’s First Wave-Resistant Floating Photovoltaic Platform Was Loaded and Put into the Sea. CCTV News Channel CCTV-13. Available online: https://mp.weixin.qq.com/s?__biz=MzA5ODMxNTY1Mg==&mid=2651343404&idx=1&sn=c3020c268df3081920a82cc5f57a3406 (accessed on 13 May 2025).

- World Bank Group; ESMAP; SERIS. Where Sun Meets Water: Floating Solar Handbook for Practitioners. World Bank Group: Washington, DC, 2019. Available online: https://documents1.worldbank.org/curated/en/418961572293438109/pdf/Where-Sun-Meets-Water-Floating-Solar-Handbook-for-Practitioners.pdf (accessed on 7 November 2025).

- Ghanadi, M.; Padhye, L.P. Revealing the long-term impact of photodegradation and fragmentation on HDPE in the marine environment: Origins of microplastics and dissolved organics. J. Hazard. Mater. 2024, 465, 133509. [Google Scholar] [CrossRef] [PubMed]

- Choi, S.M.; Park, C.D.; Cho, S.H.; Lim, B.J. Effects of wind loads on the solar panel array of a floating photovoltaic system—Experimental study and economic analysis. Energy 2022, 256, 124649. [Google Scholar] [CrossRef]

- Ghigo, A.; Faraggiana, E.; Sirigu, M.; Mattiazzo, G.; Bracco, G. Design and Analysis of a Floating Photovoltaic System for Offshore Installation: The Case Study of Lampedusa. Energies 2022, 15, 8804. [Google Scholar] [CrossRef]

- Rebollo, E.; Blanquez, F.R.; Lopez, I.; Platero, C.A.; Carrero, C. Overall feasibility of low cost conversion from PV to PVTw. In Proceedings of the 2013 International Conference on Renewable Energy Research and Applications, ICRERA, Madrid, Spain, 20–23 October 2013. [Google Scholar] [CrossRef]

- Grand Sunergy. Grand Sunergy Powers China’s First Large-Scale Yantai Zhaoyuan 400MW Offshore HJT Solar Project. PR Newswire. Available online: https://www.prnewswire.com/news-releases/grand-sunergy-powers-chinas-first-large-scale-yantai-zhaoyuan-400mw-offshore-hjt-solar-project-302226231.html (accessed on 26 August 2024).

- ACTEON. How do Suction Piles Work? Available online: https://acteon.com/blog/how-do-suction-piles-work/# (accessed on 20 August 2024).

- SolarDuck. Merganser Pilot. Available online: https://solarduck.tech/merganser-pilot/ (accessed on 13 January 2025).

- Xu, W.; Sun, Y.; He, Z. Hydrodynamic performance study of floating photovoltaic arrays with multiple floating bodies. Appl. Ocean Res. 2024, 153, 104286. [Google Scholar] [CrossRef]

- Yan, C.; Shi, W.; Han, X.; Li, X.; Verma, A.S. Assessing the dynamic behavior of multiconnected offshore floating photovoltaic systems under combined wave-wind loads: A comprehensive numerical analysis. Sustain. Horiz. 2023, 8, 100072. [Google Scholar] [CrossRef]

- Ji, C.; Gao, X.; Xu, S. Study on the influence of connector designs on the hydrodynamic performance of an offshore floating photovoltaic. Ocean Eng. 2024, 308, 118298. [Google Scholar] [CrossRef]

- Shi, Q.; Xu, D.; Zhang, H. Design of a flexible-base hinged connector for very large floating structures. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering—OMAE, Madrid, Spain, 17–22 June 2018. [Google Scholar] [CrossRef]

- Hasan, A.; Dincer, I. A new performance assessment methodology of bifacial photovoltaic solar panels for offshore applications. Energy Convers. Manag. 2020, 220, 112972. [Google Scholar] [CrossRef]

- Tina, G.M.; Scavo, F.B.; Merlo, L.; Bizzarri, F. Comparative analysis of monofacial and bifacial photovoltaic modules for floating power plants. Appl. Energy 2021, 281, 116084. [Google Scholar] [CrossRef]

- Ghaemi, A.; Eslami, N.; Shahverdi, S.; Shojaadini, P.; Derakhshandeh, R.; Amjad, A. Offshore Channel World Trend & Technology for Offshore Energy Sector. Offshore Channel Magazine, April 2023. Available online: https://offshore-channel.com/wp-content/uploads/2022/07/offshore-mag4-1.pdf (accessed on 3 January 2025).

- Werner, F.; Veith-Wolf, B.; Spindler, C.; Barget, M.R.; Babbe, F.; Guillot, J.; Schmidt, J.; Siebentritt, S. Oxidation as Key Mechanism for Efficient Interface Passivation in Cu (In,Ga)Se2 Thin-Film Solar Cells. Phys. Rev. Appl. 2020, 13, 054004. [Google Scholar] [CrossRef]

- Ţălu, Ş.; Yadav, R.P.; Šik, O.; Sobola, D.; Dallaev, R.; Solaymani, S.; Man, O. How topographical surface parameters are correlated with CdTe monocrystal surface oxidation. Mater. Sci. Semicond. Process 2018, 85, 15–23. [Google Scholar] [CrossRef]

- Arellano-Prieto, Y.; Chavez-Panduro, E.; Rossi, P.S.; Finotti, F. Energy Storage Solutions for Offshore Applications. Energies 2022, 15, 6153. [Google Scholar] [CrossRef]

- Okafor, C.E.; Folly, K.A. Optimal placement of BESS in a power system network for frequency support during contingency. Energy Rep. 2023, 10, 3681–3695. [Google Scholar] [CrossRef]

- Luo, X.; Wang, J.; Dooner, M.; Clarke, J. Overview of current development in electrical energy storage technologies and the application potential in power system operation. Appl. Energy 2015, 137, 511–536. [Google Scholar] [CrossRef]

- Temiz, M.; Javani, N. Design and analysis of a combined floating photovoltaic system for electricity and hydrogen production. Int. J. Hydrogen Energy 2020, 45, 3457–3469. [Google Scholar] [CrossRef]

- Midilli, A.; Dincer, I. Hydrogen as a renewable and sustainable solution in reducing global fossil fuel consumption. Int. J. Hydrogen Energy 2008, 33, 4209–4222. [Google Scholar] [CrossRef]

- Venkataramani, G.; Parankusam, P.; Ramalingam, V.; Wang, J. A review on compressed air energy storage—A pathway for smart grid and polygeneration. Renew. Sustain. Energy Rev. 2016, 62, 895–907. [Google Scholar] [CrossRef]

- Koohi-Fayegh, S.; Rosen, M.A. A review of energy storage types, applications and recent developments. J. Energy Storage 2020, 27, 101047. [Google Scholar] [CrossRef]

- Takahashi, C.; Matsuda, C.; Hitomi, T.; Ozawa, T.; Sakurai, H.; Arimoto, N.; Takeshima, S. Ammonia as Marine Fuel. Mar. Eng. 2024, 59, 317–320. [Google Scholar] [CrossRef]

- Campion, N.; Nami, H.; Swisher, P.R.; Hendriksen, P.V.; Münster, M. Techno-economic assessment of green ammonia production with different wind and solar potentials. Renew. Sustain. Energy Rev. 2023, 173, 113057. [Google Scholar] [CrossRef]

- Tawalbeh, M.; Murtaza, S.Z.M.; Al-Othman, A.; Alami, A.H.; Singh, K.; Olabi, A.G. Ammonia: A versatile candidate for the use in energy storage systems. Renew. Energy 2022, 194, 955–977. [Google Scholar] [CrossRef]

- ABS. Ammonia As Marine Fuel: Sustainability White Paper; ABS: Canberra, Australia, 2022. [Google Scholar]

- Buhagiar, D.; Sant, T. Modelling of a novel hydro-pneumatic accumulator for large-scale offshore energy storage applications. J. Energy Storage 2017, 14, 283–294. [Google Scholar] [CrossRef]

- Buhagiar, D.; Sant, T.; Farrugia, R.N. Marine testing of a small-scale prototype of the FLASC offshore energy storage system. In Proceedings of the 2019 Offshore Energy and Storage Summit, OSES 2019, BREST, France, 10–12 July 2019. [Google Scholar] [CrossRef]

- Evwind. Inauguration of China’s First 400 MW Offshore Photovoltaic Park. World-Energy. Available online: https://www.world-energy.org/article/44265.html (accessed on 26 August 2024).

- Grand Sunergy. Embarking on a New Era of Offshore Photovoltaics! Grand Sunergy Secures the Largest HJT Offshore Photovoltaic Project in China. Available online: https://en.grandsunergy.com/embarking-on-a-new-era-of-offshore-photovoltaics-grand-sunergy-secures-the-largest-hjt-offshore-photovoltaic-project-in-china/ (accessed on 3 September 2024).

- Solar, T. Trina solar Offshore PV Module White Paper; Trina solar: Changzhou, China, 1997. [Google Scholar]

- Chenli, L. My Country’s Largest Single Floating Photovoltaic Power Station Connected to the Grid. Available online: https://www.guancha.cn/industry-science/2023_12_27_720459.shtml (accessed on 13 May 2025).

- Polaris. 72MW! Mibet Jiangsu Peixian Floating Photovoltaic Power Station Project is Launched! Mibet. Available online: https://guangfu.bjx.com.cn/news/20230725/1321487.shtml (accessed on 13 May 2025).

- Polaris. The First Batch of Grid-Connected Power Generation of Guoneng Liaocheng 202MW Reservoir Photovoltaic Project, LONGi Modules Help to Open a New Chapter in Water Photovoltaic. LONGi. Available online: https://guangfu.bjx.com.cn/news/20230329/1297668.shtml (accessed on 13 May 2025).

- HelioRec. Floating Solar in Brest Port. Available online: https://www.heliorec.com/post/brest-port (accessed on 19 August 2024).

- GroenLeven. Floating Solar Park Sellingen with Battery Storage. Available online: https://groenleven.nl/projecten/drijvend-zonnepark-sellingen-met-batterijopslag/ (accessed on 9 January 2025).

- Power Technology. Power Plant Profile: Sellingen Floating Solar PV Park, Netherlands. Available online: https://www.power-technology.com/marketdata/power-plant-profile-sellingen-floating-solar-pv-park-netherlands/ (accessed on 1 September 2024).

- Zimmermann PV-Floating. Zimmermann PV-Floating: Structural Concept and Design. Zimmermann PV-Floating. Available online: https://pv-floating.com/our-system/design-development/ (accessed on 1 September 2024).

- Tamura, H.; Kawaguchi, K.; Iwamoto, T.; Fujiki, T. Coastal destruction and unusual wave spectra induced by Typhoon Faxai in 2019. Coast. Eng. J. 2021, 63, 92–105. [Google Scholar] [CrossRef]

- Dahe Financial Cube. The First Floating Photovoltaic Power Station on the Sea Surface ‘Ran Away’? QQ. Available online: https://news.qq.com/rain/a/20230425A04J7K00 (accessed on 13 May 2025).

- Garanovic, A. Weather Likely the Culprit for Ocean Sun’s Floating Solar unit Failure in Albania. Offshore Energy. Available online: https://www.offshore-energy.biz/weather-likely-the-culprit-for-ocean-suns-floating-solar-unit-failure-in-albania/ (accessed on 27 October 2025).

- Bellini, E.; Floating PV System Mysteriously Washes up on Hong Kong Beach. PV Magazine. Available online: https://www.pv-magazine.com/2023/03/29/floating-pv-system-mysteriously-washes-up-on-hong-kong-beach/ (accessed on 27 October 2025).

- Golroodbari, S.Z.; Ayyad, A.W.A.; van Sark, W. Offshore floating photovoltaics system assessment in worldwide perspective. Prog. Photovolt. Res. Appl. 2023, 31, 1061–1077. [Google Scholar] [CrossRef]

- Bugeja, R.; Stagno, L.M.; Dexarcis, L. An Offshore Solar Irradiance Calculator (OSIC) Applied to Photovoltaic Tracking Systems. Energies 2023, 16, 3735. [Google Scholar] [CrossRef]

- Bugeja, R.; Stagno, L.M. Wave Response Modelling and Innovative Cooling Technologies for Offshore Photovoltaics. 2023. Available online: https://www.um.edu.mt/library/oar/handle/123456789/119496 (accessed on 4 June 2024).

- Schoefs, F.; Bakhtiari, A.; Ameryoun, H. Evaluation of Hydrodynamic Force Coefficients in Presence of Biofouling on Marine/Offshore Structures, a Review and New Approach. J. Mar. Sci. Eng. 2022, 10, 558. [Google Scholar] [CrossRef]

- IEC 61701; Photovoltaic (PV) Modules—Salt Mist Corrosion Testing. International Electrotechnical Commission: Geneva, Switzerland, 2020. Available online: https://webstore.iec.ch/en/publication/59588 (accessed on 19 November 2024).

- IEC 60068-2-5; Environmental Testing-Part 2-5: Tests-Test S: Simulated Solar Radiation at Ground Level and Guidance for Solar Radiation Testing and Weathering. International Electrotechnical Commission: Geneva, Switzerland, 2018. Available online: https://webstore.iec.ch/en/publication/32126 (accessed on 19 November 2024).

- IEC 61730-1; Photovoltaic (PV) Module Safety Qualification—Part 1: Requirements for Construction. International Electrotechnical Commission: Geneva, Switzerland, 2023. Available online: https://webstore.iec.ch/en/publication/59803 (accessed on 19 November 2024).

- DNV. DNV-RP-0584 Design, Development and Operation of Floating Solar Photovoltaic Systems. October 2021. Available online: https://www.dnv.com/energy/standards-guidelines/dnv-rp-0584-design-development-and-operation-of-floating-solar-photovoltaic-systems/ (accessed on 5 June 2025).

- Brent, A.C.; Crossland, A.; Ranusa, D. An assessment of the economic feasibility of the floating PV technology in Aotearoa–New Zealand. Sustain. Energy Technol. Assess. 2023, 57, 103284. [Google Scholar] [CrossRef]

- Goswami, A.; Sadhu, P.; Goswami, U.; Sadhu, P.K. Floating solar power plant for sustainable development: A techno-economic analysis. Environ. Prog. Sustain. Energy 2019, 38, e13268. [Google Scholar] [CrossRef]

- Enkhardt, S. German Coal Mines Could Host 3 GW of Floating PV. PV Magazine. 3 February 2020. Available online: https://www.pv-magazine.com/2020/02/03/german-coal-mines-could-host-3-gw-of-floating-pv/ (accessed on 12 November 2024).

- Liu, G.; Guo, J.; Peng, H.; Ping, H.; Ma, Q. Review of Recent Offshore Floating Photovoltaic Systems. Mar. Sci. Eng. 2024, 12, 1942. [Google Scholar] [CrossRef]

- Ramanan, C.J.; Lim, K.H.; Kurnia, J.C.; Roy, S.; Bora, B.J.; Medhi, B.J. Towards sustainable power generation: Recent advancements in floating photovoltaic technologies. Renew. Sustain. Energy Rev. 2024, 194, 114322. [Google Scholar] [CrossRef]

- Goswami, A.; Aizpurua, J.I. Reliability-aware techno-economic assessment of floating solar power systems. Sustain. Energy Grids Netw. 2024, 40, 101536. [Google Scholar] [CrossRef]

- He, Z.; Xu, W.; Sun, Y.; Zhang, X. A GIS-based techno-economic comparative assessment of offshore fixed and floating photovoltaic systems: A case study of Hainan. Appl. Energy 2025, 391, 125854. [Google Scholar] [CrossRef]

- Martins, B.P. Techno-Economic Evaluation of a Floating PV System for a Wastewater Treatment Facility. KTH School of Industrial Engineering and Management Energy Technology. 2019. Available online: https://www.diva-portal.org/smash/get/diva2:1332527/FULLTEXT01.pdf (accessed on 21 October 2025).

- Wei, Y.; Khojasteh, D.; Windt, C.; Huang, L. An interdisciplinary literature review of floating solar power plants. Renew. Sustain. Energy Rev. 2025, 209, 115094. [Google Scholar] [CrossRef]

- Ramasamy, V.; Margolis, R. Floating Photovoltaic System Cost Benchmark: Q1 2021 Installations on Artificial Water Bodies. 2021. Available online: https://www.nrel.gov/docs/fy22osti/80695.pdf (accessed on 7 November 2025).

- Saeed, A.; Rehman, S.; Al-Sulaiman, F.A. Study of a grid-connected floating photovoltaic power plant of 1.0 MW installed capacity in Saudi Arabia. Heliyon 2024, 10, e35180. [Google Scholar] [CrossRef]

- Baptista, J.J. A techno-economic analysis of floating photovoltaic systems, for southern-European countries. Renew. Energ. Environ. Power Qual. J. 2023, 1, 1–7. [Google Scholar] [CrossRef]

- Sun, M.; Phillips, T.B.; Hussain, T.; Felipe, J.; Calderon, G. Techno-economic assessment of electricity market potential for co-located hydro-floating PV systems. In Proceedings of the 2024 IEEE Green Technologies Conference (GreenTech), Springdale, AR, USA, 3–5 April 2024. [Google Scholar] [CrossRef]

- Aman, M.; Solangi, K.; Hossain, M.; Badarudin, A.; Jasmon, G.; Mokhlis, H.; Bakar, A.; Kazi, S. A review of Safety, Health and Environmental (SHE) issues of solar energy system. Renew. Sustain. Energy Rev. 2015, 41, 1190–1204. [Google Scholar] [CrossRef]

- Benjamins, S.; Williamson, B.; Billing, S.-L.; Yuan, Z.; Collu, M.; Fox, C.; Hobbs, L.; Masden, E.A.; Cottier-Cook, E.J.; Wilson, B. Potential environmental impacts of floating solar photovoltaic systems. Renew. Sustain. Energy Rev. 2024, 199, 114463. [Google Scholar] [CrossRef]

- Satthong, S.; Saego, K.; Kitrungloadjanaporn, P.; Nuttavut, N.; Amornsamankul, S.; Triampo, W. Modeling the effects of light sources on the growth of algae. Adv. Differ. Equ. 2019, 2019, 170. [Google Scholar] [CrossRef]

- United Nations Framework Convention on Climate Change (UNFCCC). The Paris Agreement. Paris, France. 2015. Available online: https://unfccc.int/process-and-meetings/the-paris-agreement/the-paris-agreement (accessed on 6 December 2024).

- Schneider, L.; Heye, S.; Troost, T. Impact of Offshore Floating Solar on the Marine Environment, 11208338-000-ZKS-0008, 25 October 2023. Available online: https://publications.deltares.nl/11208338_000_0008.pdf (accessed on 7 November 2025).

- Mavraki, N.; Bos, O.G.; Vlaswinkel, B.M.; Roos, P.; de Groot, W.; van der Weide, B.; Bittner, O.; Coolen, J.W.P. Fouling community composition on a pilot floating solar-energy installation in the coastal Dutch North Sea. Front. Mar. Sci. 2023, 10, 1223766. [Google Scholar] [CrossRef]

- Vlaswinkel, B.; Roos, P.; Nelissen, M. Environmental Observations at the First Offshore Solar Farm in the North Sea. Sustainability 2023, 15, 6533. [Google Scholar] [CrossRef]

- Baars, M.A.; Fransz, H.G. Grazing pressure of copepods on the phytoplankton stock of the central North Sea. Neth. J. Sea Res. 1984, 18, 120–142. [Google Scholar] [CrossRef]

- Karpouzoglou, T.; Vlaswinkel, B.; Van Der Molen, J. Effects of large-scale floating (solar photovoltaic) platforms on hydrodynamics and primary production in a coastal sea from a water column model. Ocean Sci. 2020, 16, 195–208. [Google Scholar] [CrossRef]

- Al-Widyan, M.; Khasawneh, M.; Abu-Dalo, M. Potential of floating photovoltaic technology and their effects on energy output, water quality and supply in Jordan. Energies 2021, 14, 8417. [Google Scholar] [CrossRef]

- Andini, S.; Suwartha, N.; Setiawan, E.A.; Ma’arif, S. Analysis of Biological, Chemical, and Physical Parameters to Evaluate the Effect of Floating Solar PV in Mahoni Lake, Depok, Indonesia: Mesocosm Experiment Study. J. Ecol. Eng. 2022, 23, 201–207. [Google Scholar] [CrossRef]

- Château, P.A.; Wunderlich, R.F.; Wang, T.W.; Lai, H.T.; Chen, C.C.; Chang, F.J. Mathematical modeling suggests high potential for the deployment of floating photovoltaic on fish ponds. Sci. Total Environ. 2019, 687, 654–666. [Google Scholar] [CrossRef]

- Ray, N.E.; Holgerson, M.A.; Grodsky, S.M. Immediate Effect of Floating Solar Energy Deployment on Greenhouse Gas Dynamics in Ponds. Environ. Sci. Technol. 2024, 58, 22104. [Google Scholar] [CrossRef]

- Liu, Z.; Ma, C.; Li, X.; Deng, Z.; Tian, Z. Aquatic environment impacts of floating photovoltaic and implications for climate change challenges. J. Environ. Manag. 2023, 346, 118851. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, Y.; Tian, D.; Liu, Z.; Ma, Z. Water-surface photovoltaic systems have affected water physical and chemical properties and biodiversity. Commun. Earth Environ. 2024, 5, 1–12. [Google Scholar] [CrossRef]

- Da Silva, G.D.P.; Branco, D.A.C. Is floating photovoltaic better than conventional photovoltaic? Assessing environmental impacts. Impact Assess. Proj. Apprais. 2018, 36, 390–400. [Google Scholar] [CrossRef]

- Clemons, S.K.C.; Salloum, C.R.; Herdegen, K.G.; Kamens, R.M.; Gheewala, S.H. Life cycle assessment of a floating photovoltaic system and feasibility for application in Thailand. Renew. Energy 2021, 168, 448–462. [Google Scholar] [CrossRef]

- Glasnovic, Z.; Margeta, J. The features of sustainable Solar Hydroelectric Power Plant. Renew. Energy 2009, 34, 1742–1751. [Google Scholar] [CrossRef]

- Golroodbari, S.Z.M.; Vaartjes, D.; Meit, J.; van Hoeken, A.; Eberveld, M.; Jonker, H.; van Sark, W. Pooling the cable: A techno-economic feasibility study of integrating offshore floating photovoltaic solar technology within an offshore wind park. Sol. Energy 2021, 219, 65–74. [Google Scholar] [CrossRef]

- Bi, C.; Law, A.W.K. Co-locating offshore wind and floating solar farms—Effect of high wind and wave conditions on solar power performance. Energy 2023, 266, 126437. [Google Scholar] [CrossRef]

- Ghosh, A. A comprehensive review of water based PV: Flotavoltaics, under water, offshore & canal top. Ocean Eng. 2023, 281, 115044. [Google Scholar] [CrossRef]

- Abd Rani, M.N. Assessing the Legal Framework for Floating Solar Photovoltaics in Malaysia: Opportunities and Challenges in Water Law and Environmental Regulation. Int. J. Law Gov. Commun. 2024, 9, 132–153. [Google Scholar] [CrossRef]

- Gal, N. Dual Use PV Overview and Policy Recommendations. December 2024. Available online: http://www.iadb.org (accessed on 24 October 2025).

- European Commission. Commission Notice On Innovative Technologies and Forms of Renewable Energy Deployment. Brussels, July 2025. Available online: https://energy.ec.europa.eu/document/download/02f8d3f4-289e-4c6a-8de4-ccff382d306f_en?filename=C_2025_4011_1_EN_annexe_acte_autonome_cp_part1_v3.pdf (accessed on 24 October 2025).

- Vandest, E. SolarPower Europe (2023): Floating PV Best Practice Guidelines Version 1.0. December 2023. Available online: www.solarpowereurope.org (accessed on 24 October 2025).

- Chetcuti Cauchi Advocates. Renewable Energy in Malta: Laws and Their Application Explained; Legal500: London, UK, 2025. [Google Scholar]

- The Energy and Water Agency. Malta’s National Energy and Climate Plan. 2024. Available online: https://energywateragency.gov.mt/wp-content/uploads/2025/01/MT—FINAL-UPDATED-NECP-2021-2030-English.pdf (accessed on 24 October 2025).

- International Energy Agency. Photovoltaic Power Systems Programme: Annual Report 2023; International Energy Agency: Paris, France, 2023. [Google Scholar]

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development. 2015. Available online: https://www.un.org/sustainabledevelopment/development-agenda/ (accessed on 13 January 2025).

- Gloersen, A. OCEAN SUN; ACEF 2020. Available online: https://asiacleanenergyforum.adb.org/wp-content/uploads/2020/06/are-glersen-ocean-sun-a-unique-solution-to-floating-solar.pdf (accessed on 7 November 2025).

- Ocean Sun. Ocean Sun|Investor Presentation NOK 150 Million Private Placement and Subsequent Listing on Merkur Market. 2020. Available online: https://oceansun.no/wp-content/uploads/2020/11/Ocean-Sun-IP-12-Oct-2020.pdf (accessed on 23 October 2025).

- 1Ocean Sun. Ocean Sun Pioneering Floating Solar Power Solutions; Business Norway: Oslo, Norway. 24 March 2023. Available online: https://businessnorway.com/solutions/ocean-sun-pioneering-floating-solar-power-solutions (accessed on 7 November 2025).

- Berghall, A. DNV GL Verifies Innovative Floating Solar Design Methodology for Ocean Sun. DNV. Available online: https://www.dnv.com/news/2020/dnv-gl-verifies-innovative-floating-solar-design-methodology-for-ocean-sun-168977/ (accessed on 23 October 2025).

- Solar Duck. Merganser Receives Certification from Bureau Veritas; Solar Duck: Rotterdam, The Netherlands. 27 March 2024. Available online: https://solarduck.tech/merganser-receives-certification-from-bureau-veritas/ (accessed on 7 November 2025).

- Gattu, R. Floating Solar Technology from SolarDuck. Taiyang News. Available online: https://taiyangnews.info/technology/floating-solar-technology-from-solarduck#:~:text=The%20company%20prefers%20the%20drag,the%20perimeters%20of%20the%20floats (accessed on 23 October 2025).

- Claus, R.; Soto, F.; Cebada, A.; López, M.; Clemente, D.; Giannini, G.; Rosa-Santos, P. Experimental proof-of-concept of HelioSea: A novel marine floating photovoltaic device. Ocean Eng. 2024, 299, 117184. [Google Scholar] [CrossRef]

- Maksumić, Z. SolarinBlue Validates Anchoring System for 1 MW Offshore Solar Project. Offshore Energy. Available online: https://www.offshore-energy.biz/solarinblue-validates-anchoring-system-for-1-mw-offshore-solar-project/ (accessed on 23 October 2025).

- Todorović, I. Floating Solar Farm Ready to Be Merged with North Sea Offshore Wind Park; Balkan Green Energy News: Belgrade, Serbia, 2025. Available online: https://balkangreenenergynews.com/floating-solar-farm-ready-to-be-merged-with-north-sea-offshore-wind-park/ (accessed on 7 November 2025).

- Stagno, L.M.; Bugeja, R. Solaqua. Available online: https://offshoresolar.org/ (accessed on 23 October 2025).

- Garanovic, A. China Launches Its First Semi-Submersible Offshore Solar Platform. Available online: https://www.offshore-energy.biz/china-launches-its-first-semi-submersible-offshore-solar-platform/ (accessed on 23 October 2025).

- CIMC. CIMC RAFFLES Delivers China’s First Semi-Submersible Offshore Solar Power Platform. Available online: https://www.prnewswire.com/news-releases/cimc-raffles-delivers-chinas-first-semi-submersible-offshore-solar-power-platform-301794188.html (accessed on 23 October 2025).

- Budt, M.; Wolf, D.; Span, R.; Yan, J. A review on compressed air energy storage: Basic principles, past milestones and recent developments. Appl. Energy 2016, 170, 250–268. [Google Scholar] [CrossRef]

- Valera-Medina, A.; Amer-Hatem, F.; Azad, A.K.; Dedoussi, I.C.; de Joannon, M.; Fernandes, R.X.; Glarborg, P.; Hashemi, H.; He, X.; Mashruk, S.; et al. Review on ammonia as a potential fuel: From synthesis to economics. Energy Fuels 2021, 35, 6964–7029. [Google Scholar] [CrossRef]

- Silva, J.; Alves, J.M. Sensitivity analysis of levelized cost of hydro-pneumatic electricity storage for grid support applications. Renew. Energy 2023, 219, 119285. [Google Scholar] [CrossRef]

| Component | Characteristic |

|---|---|

| Floating system (floater + structure) | A pontoon is a flotation device with sufficient buoyancy to be able to float both by itself and with a heavy load. There are several plastic hollow floaters attached underneath, frequently made of glass fibre-reinforced plastic or, in most cases, high-density polyethylene (HDPE). For OFPV installation, stainless steel or bamboo-based material is also used. |

| Mooring system | A type of permanent structure consisting of an anchor, line, and connectors that adjust the platform to water level fluctuations and keep it secure. For example, nylon wire ropes can be utilised for such an application and fixed tight to bollards. Steel chains or polyester lines or their combination may be used in offshore areas. |

| PV modules | PV modules are installed on top of the floating structure, and standard silicon modules are mostly incorporated. However, the advancement of the technology into offshore environments has led to the development of specifically fabricated modules able to withstand highly corrosive environments. |

| Cables and connectors | Special water-proof and high-temperature-resistant electrical components transmit electrical energy from the solar array to land. The wiring is routed either above or under water. |

| Study Location/ Type | System Size (MWp) | Base Year and Key Assumptions | Total CAPEX/ Installed Cost | LCOE or Payback Period (Reported) |

|---|---|---|---|---|

| U.S. Inland (NREL Benchmark) [111] | 10 | - Base year: Q1 2021 - Lifetime: 30 years - Real discount rate: 5.1% - Debt fraction: 71.8% - Annual PV degradation rate: 0.7% - Float cost: 0.30 USD/Wp - O&M FPV: 15.5 USD/kW/year - O&M GPV: 18 USD/kW/year - Wind load: 40 m/s - Snow load: 20 psf - Water depth: 50 m - Water level variation: 10 m - Swell height: 1 m - Inflation: 2.5% | - Total CAPEX: USD 12.9 million. - Installed Cost: 1.29 USD/Wp. | - 0.0566 USD/kWh without Investment Tax Credit (ITC). 20% higher than GPV. - 0.0378 USD/kWh with ITC. 17% higher than GPV. |

| India (Inland Reservoir) [107] | 1 | - Base year: 2021–2022 - Lifetime: 25 years - PV modules: 0.22 USD/Wp - Inverter cost: 0.04 USD/Wp - Civil structure cost: 0.46 USD/Wp - BOS: 0.42 USD/Wp (higher than GPV due to insulated cables) - Floaters and mooring: 0.683 USD/Wp - O&M: 0.039 USD/Wp | - Total CAPEX: USD 1,903,246.80. This is 24% higher than GPVs. - Installed Cost: 1.70 USD/Wp. | 0.0551 USD/kWh (normal-condition FPVs). |

| Saudi Arabia (Inland Dams) [112] | 1 | - Base year: 2022 - Lifetime: 25 years - Discount rate: 5% - Inflation rate: 3% - O&M: 1% of CAPEX ≈ 14.14 USD/kWp/year - PV modules: USD 680,680 - Floating system: USD 500,000 - Inverters: USD 126,000 | Total CAPEX: USD 1,413,880. Installed Cost: approx. 1.41 USD/Wp. | Riyadh: 0.053 USD/kWh. Mecca: 0.057 USD/kWh. Bisha: 0.063 USD/kWh. |

| Portugal (Inland Dam) [113] | 1 | - Base year: 2020 - Lifetime: 25 years - Discount rate: 6% - Starting energy price: 40 EUR/MWh (2020 tariffs) - O&M: 10 EUR/kWp - Inflation: 2% - PV modules: 300 USD/kWp - Inverters: 200 USD/kWp - Floating structure: 300 USD/kWp - Anchoring: 36 USD/kWp - BOS: 100 USD/kWp - Transport: 20 USD/kWp | Total CAPEX: 1000 EUR/kWp. | - LCOE not reported. - Net Present Value (NPV): EUR 329,235. - Internal Rate of Return (IRR): 5.8%. - Payback Period: 14 years. |

| U.S. Inland (California) [109] | 3 | - Base year: 2019 - Business-as-usual scenario used to compare to GPVs - Discount rate: 6.75% - Lifetime: 25 years - O&M: 0.026 USD/Wp | Total CAPEX: USD 6,019,000 (no ITC). Installed Cost: approx. 2.00 USD/Wp (no ITC). | - 107.88 USD/MWh (no ITC). - 83.58 USD/MWh (with 26% ITC). |

| UAE Offshore (Oil Platform) [18] | 0.530 (battery-integrated) | - Base year: 2023/4 - Discount rate: 3% - System includes battery bank (USD 1,535,475) - O&M: 7950 USD/year - Floating system: USD 111,300 - Anchoring: USD 145,750 | Total CAPEX: USD 2,290,825. Installed Cost: approx. 4.32 USD/Wp. | - LCOE: 261 USD/MWh. - Discounted Payback Period (DPP): 9.5 years. |

| U.S. Hybrid Hydro-FPV [114] | 1 (assumed size) | - Base year: 2021 - Life expectancy: 30 years - Annual discount rate: 5% - Incentives modelled: ITC (30%) or Production Tax Credit (PTC) (2.75 cents/kWh for 10 years) - O&M: 7900 USD/MW/year | - Total CAPEX: 1,180,000/MWp. - Installed Cost: 1.18 USD/Wp. | - LCOE sensitive to market structure and incentive type (ITC vs. PTC). - LCOE min: 46.5 USD/MWh for CAISO market. - LCOE max: 75.6 USD/MWh for PJM market. - Minimum LCOE is 16% higher than in GPV case. |

| Feature | FPVs | GPVs |

|---|---|---|

| Land Use | No land required; ideal for urban/agricultural areas. | Require significant land area. |

| Cooling Effect | Water cooling increases efficiency, resulting in yield gains of up to 10% [3,4,5,6]. | Panels heat up, reducing efficiency. |

| Water Conservation | Reduce evaporation by 17–83% [7,8,9]. | No impact on water bodies. |

| Economic Feasibility | Higher initial cost (100,000 USD/MWp for offshore [17]) but potentially higher profits due to higher generation [3,4,5,6]. | Lower cost per MWp, but land is expensive, and PVs are affected by increase in temperature and dusty environment. |

| Hybrid Integration | Can be combined with hydropower and wind farms [10,21]. | Limited co-location options. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bugeja, R.; Mule' Stagno, L.; Godin, C.; Luo, W.; Zhang, X. Advancements and Challenges in Floating Photovoltaic Installations Focusing on Technologies, Opportunities, and Future Directions. Energies 2025, 18, 5908. https://doi.org/10.3390/en18225908

Bugeja R, Mule' Stagno L, Godin C, Luo W, Zhang X. Advancements and Challenges in Floating Photovoltaic Installations Focusing on Technologies, Opportunities, and Future Directions. Energies. 2025; 18(22):5908. https://doi.org/10.3390/en18225908

Chicago/Turabian StyleBugeja, Ryan, Luciano Mule' Stagno, Cyprien Godin, Wenping Luo, and Xiantao Zhang. 2025. "Advancements and Challenges in Floating Photovoltaic Installations Focusing on Technologies, Opportunities, and Future Directions" Energies 18, no. 22: 5908. https://doi.org/10.3390/en18225908

APA StyleBugeja, R., Mule' Stagno, L., Godin, C., Luo, W., & Zhang, X. (2025). Advancements and Challenges in Floating Photovoltaic Installations Focusing on Technologies, Opportunities, and Future Directions. Energies, 18(22), 5908. https://doi.org/10.3390/en18225908