1. Introduction

One of the key problems standing in the way of sustainable development of the fuel and energy complex of the Russian Federation in the long term is the gradual depletion of fossil hydrocarbon reserves. This, together with the consistent tightening of environmental standards and requirements for energy infrastructure facilities, as well as the introduction of carbon regulation in many countries around the world, determines the relevance of resource conservation and increasing the level of energy efficiency at thermal power plants.

Today, thermal power generation accounts for about 66% of the installed capacity of the Unified Energy System of the Russian Federation, 78% of which consists of steam power plants (SPPs) and 21% of combined-cycle power plant (CCPP) and gas turbine units (GTUs) [

1]. Today, the most efficient way to produce electricity at TPPs is combined-cycle technology. Due to the active improvement of the main components, the gas temperature in front of the nozzle apparatus of the latest gas turbine units already reaches 1650 °C (M701JAC from MHI), which helps to achieve a binary cycle net efficiency of 64% [

2]. In order to achieve the goals of resource conservation and energy efficiency, an important step is to increase the share of the most efficient electricity generation technologies, which determines the relevance of the combined-cycle generation direction.

Despite the high level of energy efficiency of combined-cycle power units, the potential for its further increase has not been exhausted. In particular, due to the use of additional circuits on low-boiling coolants in a combined cycle (thus transforming the binary cycle into a trinary one), it is possible to ensure an increase in the net efficiency of the entire plant by up to 2.2% [

3,

4]. In such cycles on three working bodies, organic heat carriers, as a rule, perform work due to heat recovery of low-potential sources with low temperatures (condenser of the steam turbine unit, exhaust gases after the heat recovery unit), which increases the thermal efficiency of the power unit.

The trend towards using low-potential heat to produce electricity in organic Rankine cycle (ORCs) is confirmed by the active growth of installed capacity in the world. Over the period of 2016–2020, the installed capacity of ORC plants in the world increased by more than 40% to 4 GW [

5]. The main areas of application of such plants are geothermal energy, biomass plants, as well as heat recovery in industrial production (petrochemistry, metallurgy, cement production). Another area is the use of exhaust heat from gas turbine plants: OREG projects I/II/III/IV from Ormat, within the framework of which ORCs, were installed for the utilization of turbine exhaust heat at gas pumping stations in the states of Colorado, Minnesota, and North Dakota (United States), which have a total installed capacity of more than 50 MW [

6].

The use of ORC units at combined-cycle power units is also of interest. Thus, in [

7], the thermodynamic effect of adding an organic Rankine cycle unit to a combined-cycle power unit for additional electricity generation is considered. When using R134a refrigerant as the working medium of the utilization cycle, the efficiency of the combined-cycle unit increases by more than 1.1%, and when using R123 refrigerant, by 1.19%. In [

8], the feasibility of using an organic Rankine cycle to recover waste heat from gas turbine units was examined. In [

9], working fluids were considered for an air-cooled ORC aimed at recovering waste heat from gas turbine units. Novec 649 may be promising because it has a low GWP and is non-flammable. Energy, exergy, and exergoeconomic analyses of an organic Rankine cycle integrated with a combined-cycle power plant were conducted in [

10].

The use of organic working fluids in the power sector imposes additional requirements on plant operational safety. Flammability and toxicity are the key factors governing the safe operation of ORC systems. The former arises because the working fluid must be handled at relatively high temperatures in heat exchangers and turbomachinery, where compression, heating, and friction can occur, potentially leading to ignition of a combustible mixture.

Low toxicity is important from the standpoint of equipment operation, maintenance, and repair. During operation, leakage of the working fluid from turbomachinery seals occurs, and substantial releases may happen during maintenance activities or due to loss of containment. Therefore, the working fluid should have low toxicity to avoid creating hazardous working conditions for personnel. Otherwise, additional measures are required—such as leak and concentration monitoring, forced ventilation, and air-cleaning systems.

According to the ASHRAE safety classification, suitable substances fall into safety group A1: non-flammable and of low toxicity. These include R1233zd, R124, R125, R134a, R227ea, R236ea, R236fa, R417a, R422a, R422d, R423a, R1336mzz, and many others. These organic working fluids may be promising for use in combined-cycle power plants. Other important factors include the impact of organic compounds on the ozone layer, characterized by the ozone depletion potential (ODP), as well as the global warming potential (GWP). When selecting a working fluid, it is important to choose those that minimize these metrics. Taking these metrics into account, for recovering low-grade waste heat (with temperatures not exceeding 200 °C) in combined-cycle power plants, the use of R744, R41, R1336mzz, R1233zd, R124, R236ea, and R134a may be promising.

Today, various layout solutions for the steam turbine section are also implemented at combined-cycle power units: intermediate superheating of steam allows for increasing dryness at the last stages of the low-pressure turbine at a high initial pressure, as well as raising the final efficiency level of the combined-cycle plant. Another solution is the use of afterburners in the flue gas duct of the waste heat boiler. Combustion of additional fuel in the flows of exhaust gases allows for stabilizing the parameters of the HRSG (heat recovery steam generator) and STU (steam turbine unit), as well as ensuring an increase in the capacity of the steam turbine.

Study [

11] highlights the potential of afterburners, noting that increasing steam capacity, initial temperature, and pressure in the HRSG can boost STU capacity, though afterburning’s effect on thermal efficiency is ambiguous and may reduce it. Reference [

12] shows that afterburners expand the thermal load range of combined-cycle plants, with higher efficiency when placed before the high-pressure evaporator. Calculations in [

13] for PGU-450T indicate an 8% increase in maximum electrical power and 6% in thermal power, while gross efficiency drops by 0.2%. Work [

14] addresses efficient afterburning in gas turbine exhausts and proposes new gas-jet burner designs. For PGU-450, adding a low-pressure combustion chamber to raise the HRSG inlet gas temperature extends the GTU operating range and improves steam turbine reliability under low loads [

15]. Research study [

16] finds that at sufficiently high live steam temperatures, afterburning can increase the gross efficiency by 0.1–0.8%. Study [

17] on optimizing initial parameters and the afterburning degree confirms that fuel afterburning enhances the STU efficiency and power and lowers the exhaust-gas temperature behind single-pressure HRSGs, which can improve the overall CCGT efficiency. However, the HRSG efficiency tends to decline with advanced CCGT configurations and more efficient GTUs.

Research study [

18] was devoted to the features of the transition of the combined-cycle plant from the ALSTOM gas turbine GT26 for partial load modes with a booster installed before the HPSH (high-pressure superheater). Fuel afterburning allowed for increasing the capacity of the CCGT at peak loads, as well as ensuring a more efficient transition from one mode to another. In [

19], a thermodynamic and exergy analysis of a CCGT with a booster located in Kerman, Iran, was carried out. The increase in capacity from using a booster was 26.3 MW, but the gross efficiency of the power unit decreased by 1.2%. In [

20], a CCGT scheme for supercritical steam parameters with afterburning chambers and CO

2 capture was considered. Despite the increase in capacity, the thermal efficiency of such a cycle from using a booster is reduced by more than 5.5%. Thermodynamic analysis and thermoeconomic optimization of a dual-pressure combined-cycle power plant with a supplementary firing unit were conducted in [

21]. The authors determined the optimal parameters of the power plant. In [

22], using Aspen HYSYS, a cogeneration plant with supplementary firing was investigated.

Despite the high level of development of these technologies, the issue of their applicability in the schemes of trinary cycles remains unexplored. The energy effect of using the AB’s and SH (superheater) in the schemes of the combined-cycle power plant with an additional ORC in the tail section of the HRSG remains unclear. This paper presents the results of a thermodynamic analysis of the feasibility of using afterburning chambers, intermediate superheating, and cycles on low-boiling coolants in the thermal schemes of condensing combined-cycle gas turbines, provides estimates of the thermal efficiency of such schemes, and offers a comparison with double-circuit binary power plants with similar improvements.

2. Research Object and Methodology

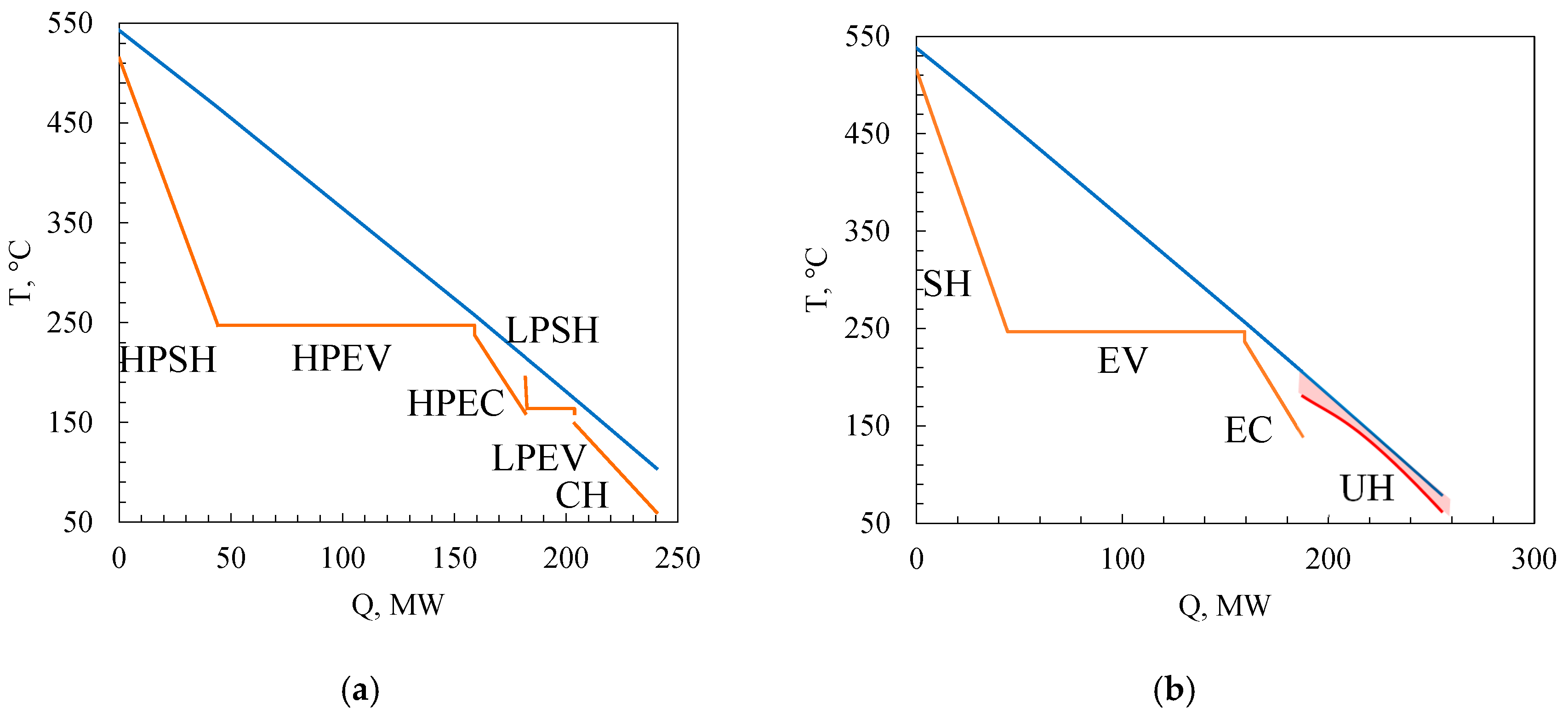

This paper examines the schemes of binary and trinary power plants with afterburning chambers installed in the waste heat boiler before the superheater section. The main configuration is a combined-cycle plant with one gas turbine, a waste heat boiler at one pressure, and a condensing steam turbine (

Figure 1a).

All schemes are considered for use on a combined-cycle power unit with a GTE-170 gas turbine unit, whose capacity and efficiency at the terminals are 155.3 MW and 34.1%, and the flow rate and temperature of the exhaust gases are 509 kg/s and 538 °C, respectively [

23]. The relatively low temperature of the exhaust gases (compared to the parameters of the most efficient Siemens, GE, and MHI units) predetermines the possibility of a significant increase in the steam parameters in the waste heat boiler due to the afterburning of additional fuel.

In a traditional binary cycle, the main cold sources are the exhaust gases after the last HRSG heating surface and the STU condenser. To reduce heat removed in the condenser, advanced regenerative heating of condensate and feedwater is used to lower the flow rate of steam exhausted to the cold sink. While common in STUs, in CCGTs, increasing the coolant temperature via regeneration raises heat losses in exhaust gases. Therefore, condensate is usually heated in the gas condensate heater (CH), and feedwater in the HRSG economizer.

This limits the heat recovery efficiency in binary cycles. However, adding an extra heat recovery circuit along the gas flow, which utilizes residual gas energy, makes regenerative heating in the STU beneficial. Since the gas temperature before this circuit remains relatively low despite regeneration, steam-water coolants are inefficient; instead, organic fluids with low critical parameters (e.g., refrigerants) offer a better heat recovery. The trinary cycle scheme studied here (

Figure 1b) uses a regeneration system with two low-pressure mixing heaters and one high-pressure heater in the STU, and an organic Rankine cycle (ORC) with a recuperator for heat recovery.

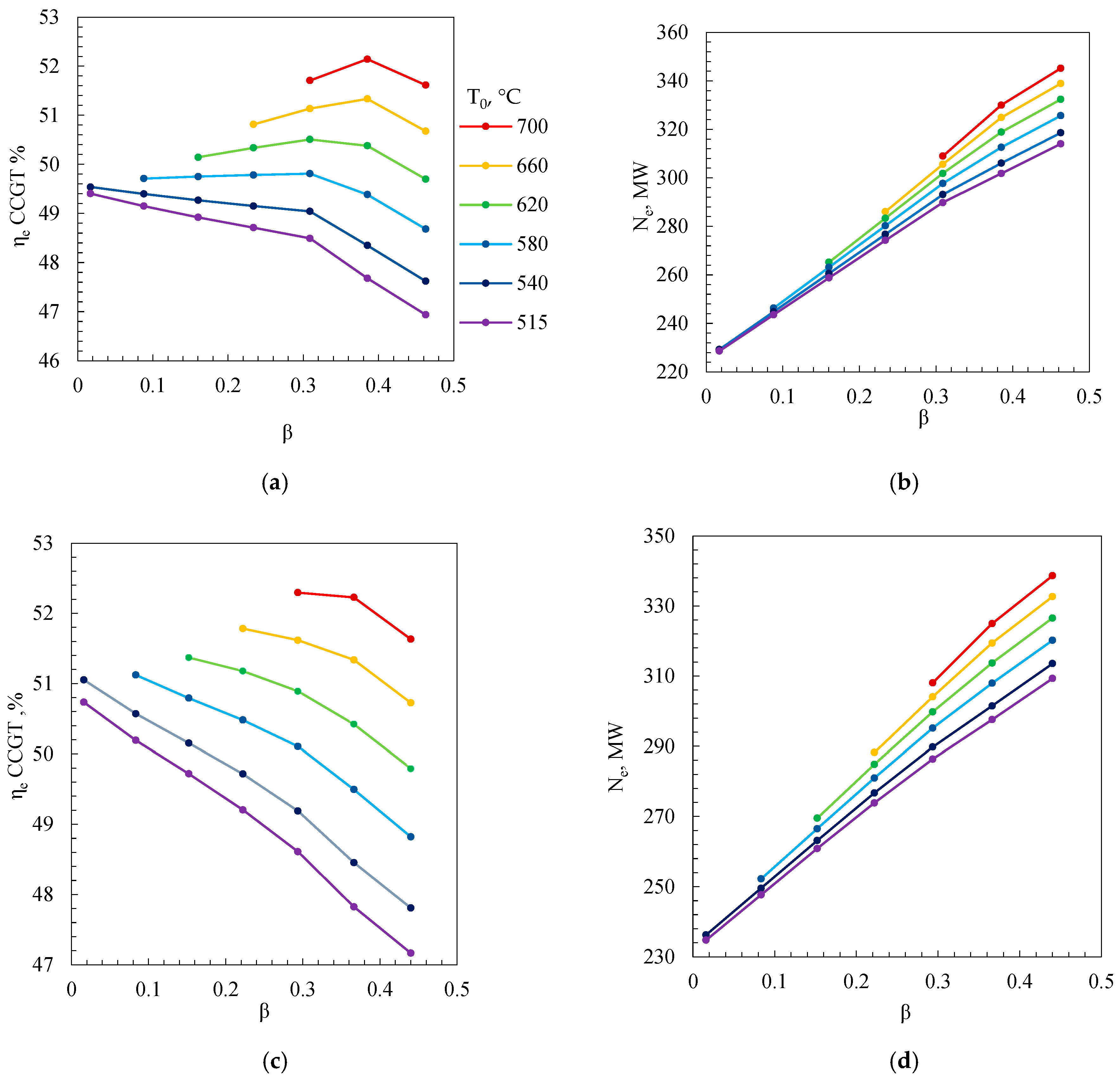

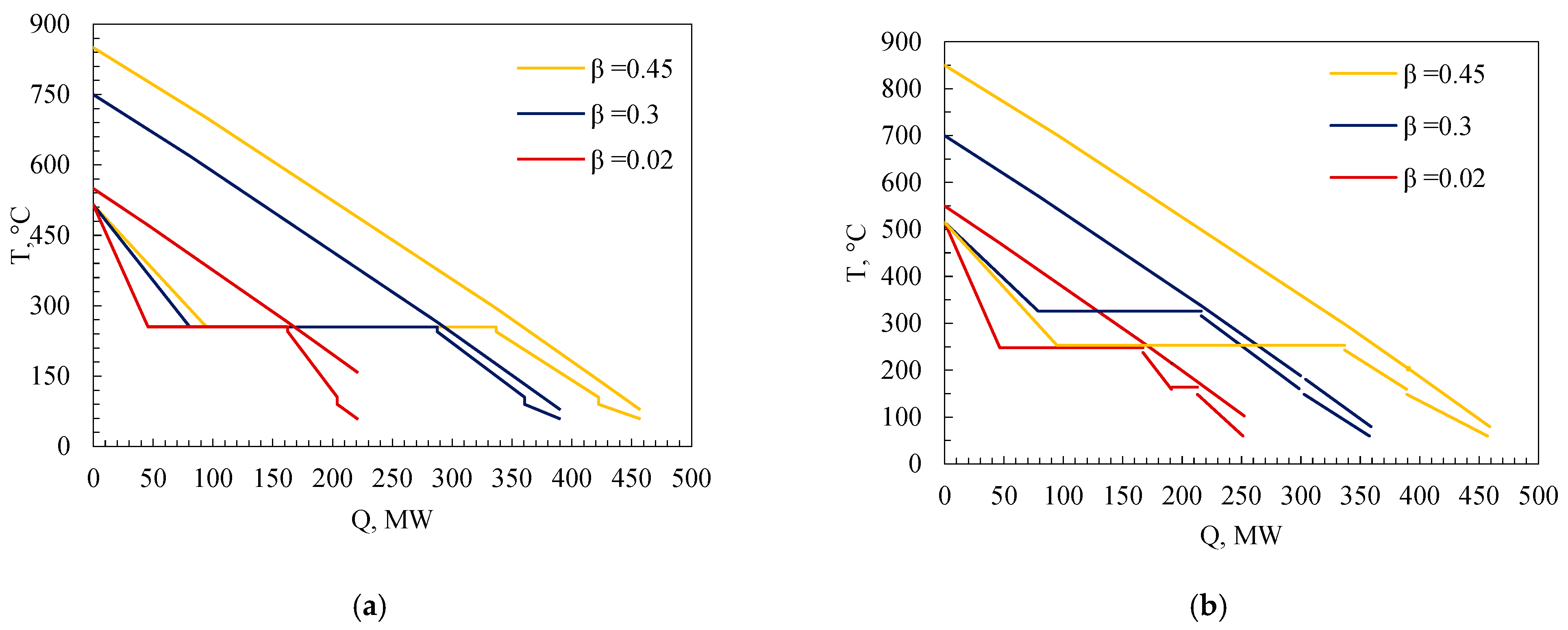

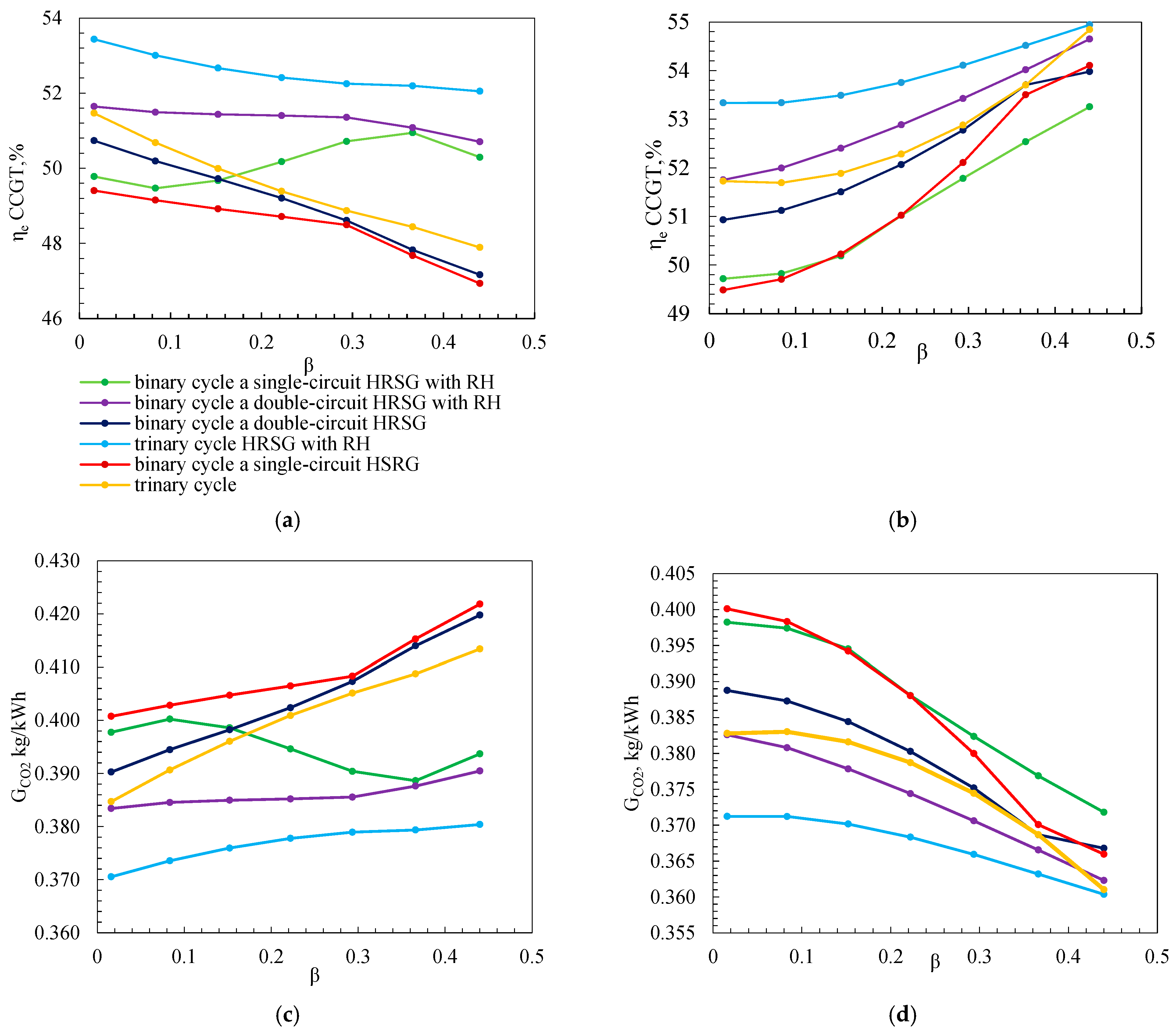

The use of fuel afterburning in the flows of the exhaust gases of the gas turbine allows for increasing the parameters of gases before the HRSG, and, as a consequence, increasing the parameters of superheated steam. On the other hand, it becomes possible to change the layout of the STU circuit: switching to a two- or three-part circuit, introducing intermediate steam superheating, etc. The authors consider introducing intermediate steam superheating by installing an intermediate superheater in the STU circuit parallel to the surface of the main superheater. For the final comparison of the indicators of a trinary power plant with intermediate superheating and an afterburning chamber, a two-circuit CCGT was simulated with similar circuit solutions, namely, intermediate steam superheating and an afterburning chamber (

Figure 1e,f).

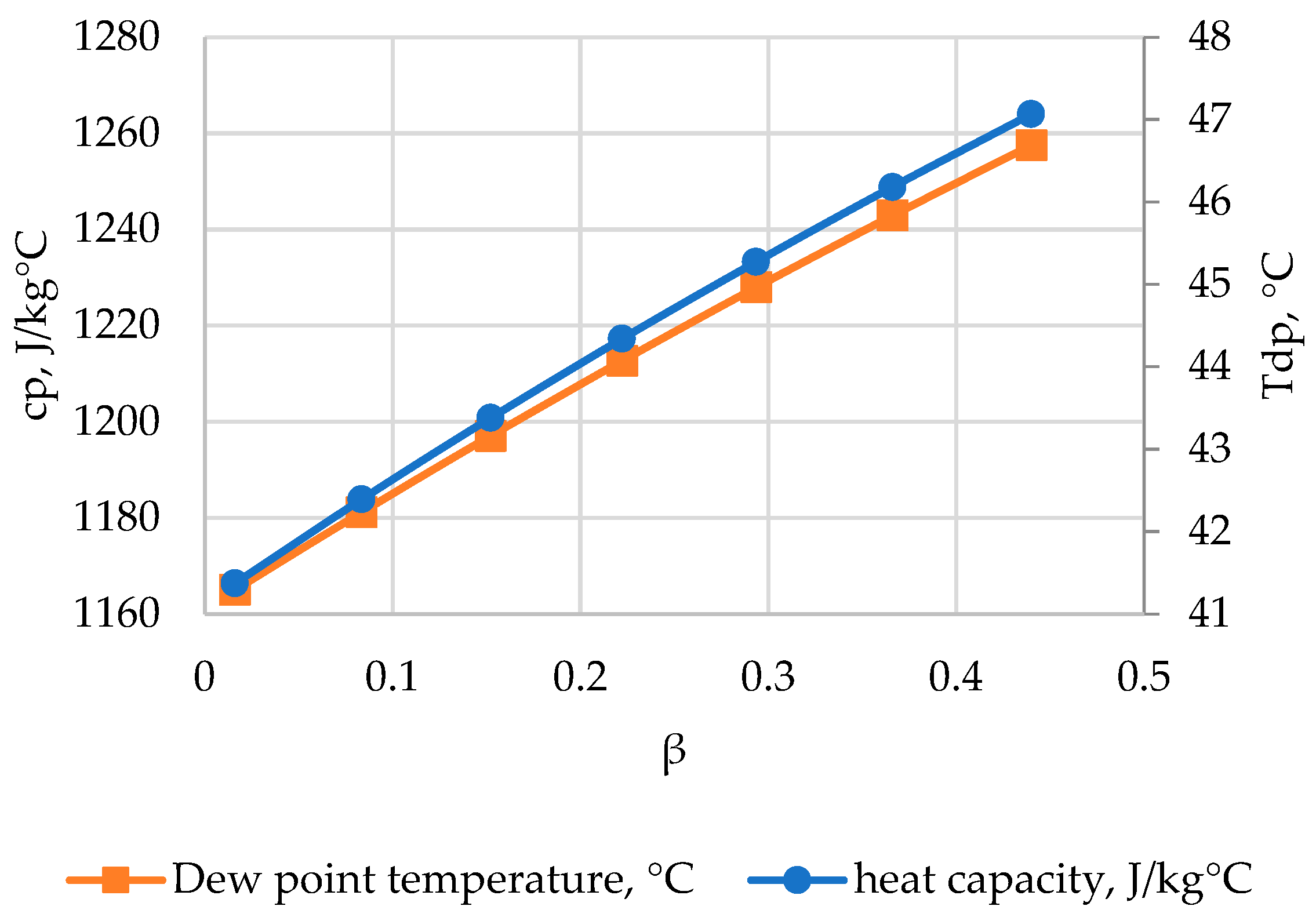

Calculation models of combined-cycle power units consist of several modules: a gas turbine, a waste heat boiler with a steam turbine plant, and an organic Rankine cycle with a recuperator. The calculation is performed sequentially: the parameters of the GTU exhaust are determined, and then the HRSG with the STU is calculated and the parameters behind the last heating surface are determined, after which the refrigerant cycle is calculated (for a trinary plant) and the main energy indicators of the power unit are determined. Mathematical models are based on systems of equations of heat and material balances for each element of the cycle; the NIST database was used to determine the thermophysical properties of the working fluids (combustion products, steam, and refrigerants), REFPROP.

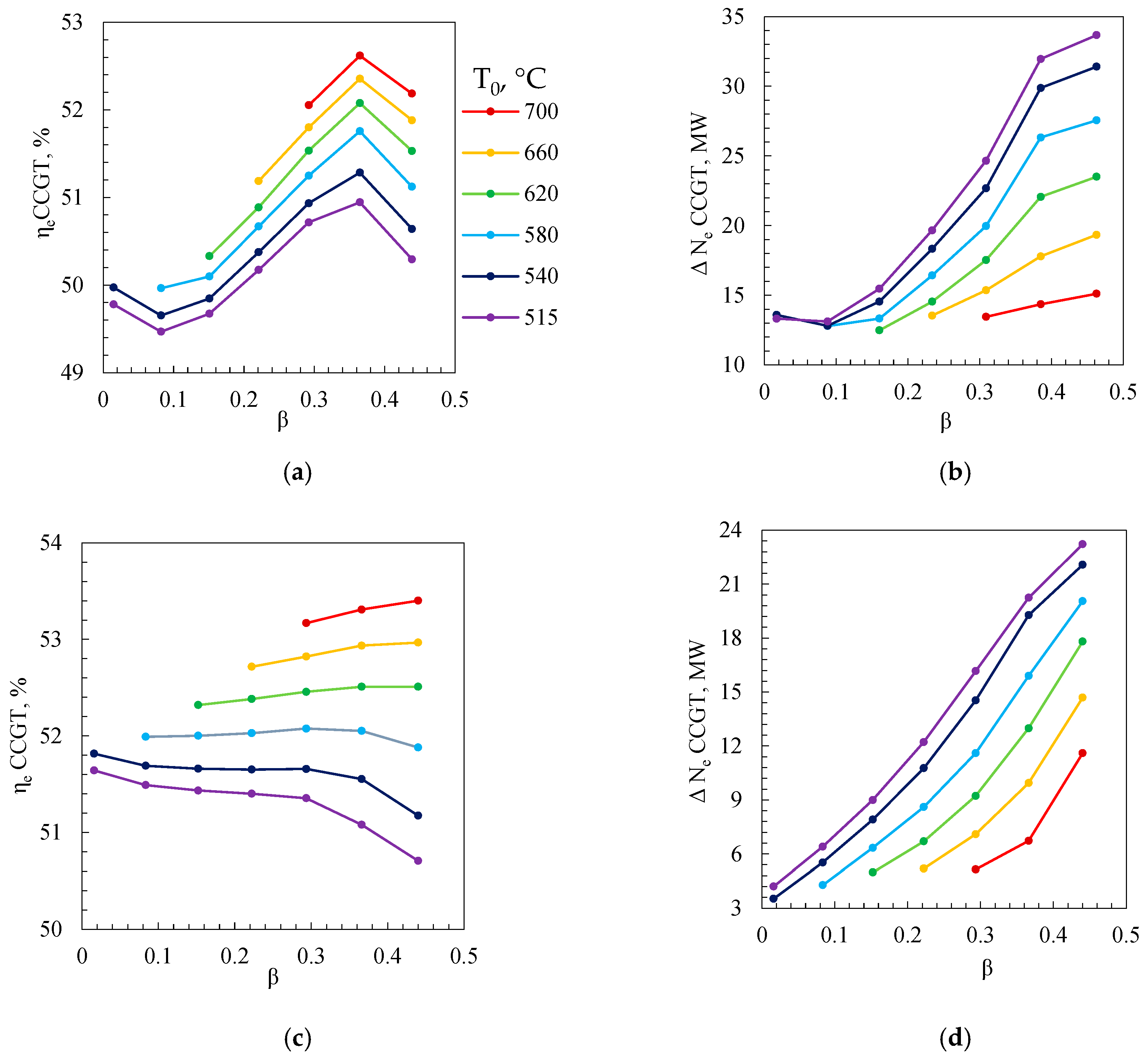

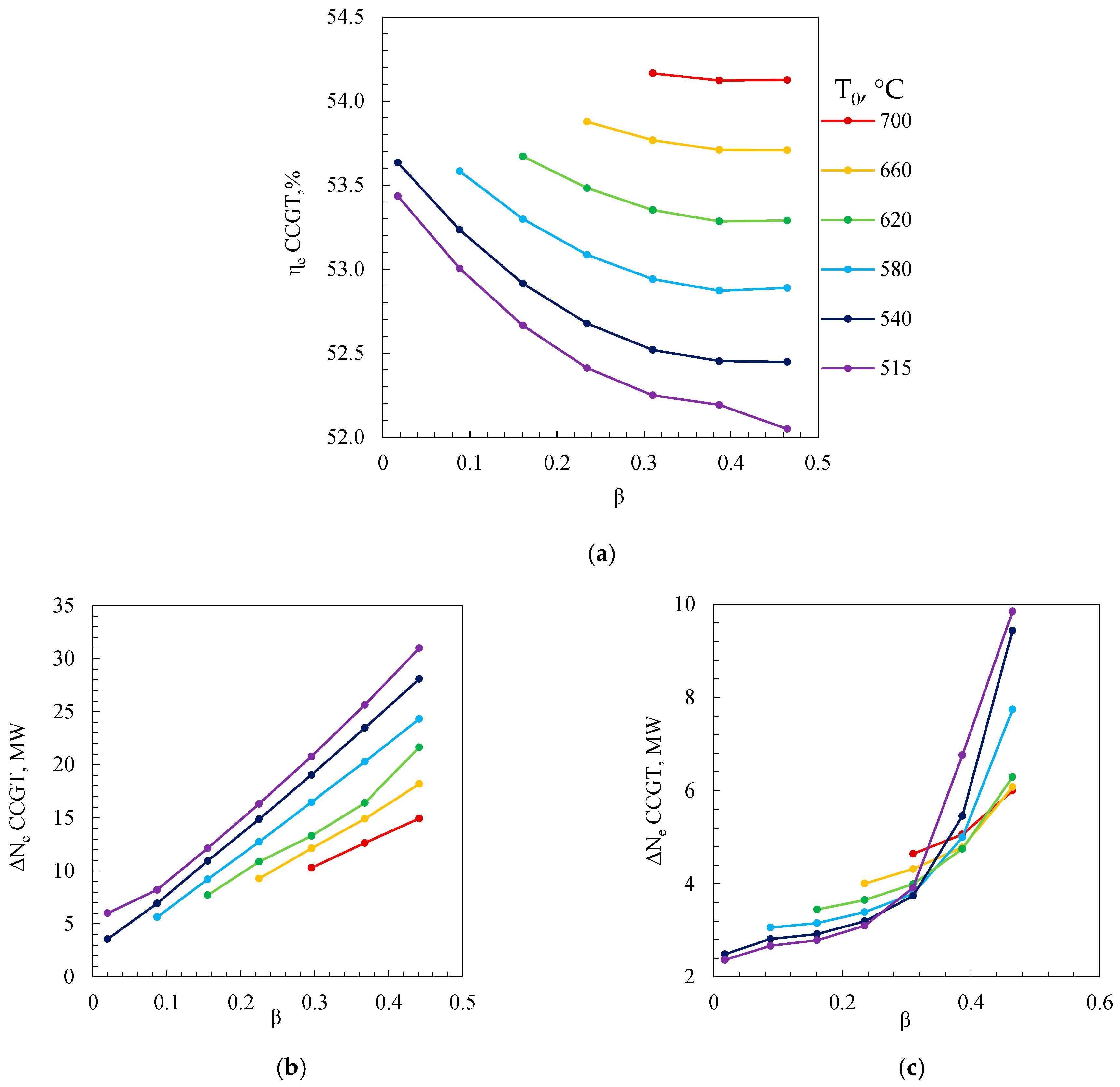

For each scheme, it is necessary to conduct optimization studies, including variation, in order to achieve the maximum net efficiency of various parameters. The studies were carried out with variation in fuel consumption for the afterburner in order to obtain the dependencies of the power and efficiency of the schemes with this parameter. Afterburning provides the possibility of increasing the initial parameters of steam in the STU; therefore, for a correct comparison of the schemes, a series of initial temperatures after the superheater T0 = [515; 540; 580; 620; 660; 700] was considered. This series covers both standard temperatures corresponding to the plant without an AB, and a promising level corresponding to advanced foreign plants.

The expansion and compression processes in turbomachines were calculated with a constant relative internal efficiency using the equations given below.

The enthalpy at the turbine outlet was calculated using the formula

where

and

are the specific enthalpies of the working medium at the turbine inlet and outlet, kJ/kg;

is the theoretical enthalpy at the turbine outlet during isentropic expansion, kJ/kg; and

is the relative internal efficiency of the turbine.

The enthalpy resulting from compression in the compressor/pump was calculated using the formula

where

is the internal relative efficiency of the compressor or pump.

The heat balance of the combustion chamber and the afterburning chamber is made up of the sum of the heat of the combustion reaction of the fuel and the physical heats of the fuel and oxidizer:

where

and

—fuel and oxidizer consumption in the combustion/afterburning chamber, kg/s;

—higher heating value of fuel, kJ/kg

;

—specific enthalpy of fuel and oxidizer entering the combustion chamber, kJ/kg;

—specific enthalpy of combustion products, kJ/kg.

The power of a group of turbomachine stages was determined as

where

is the mass flow rate of the working medium in a group of stages, kg/s; and

and

are the mass enthalpy at the input and output of a group of stages, kJ/kg.

The net power of the gas turbine plant was determined as

where

and

are the turbine and compressor power, determined as the sum of the power of a group of stages, kW;

—power of the fuel compressor, kW;

, and —mechanical, electric generator, and electric drive efficiency.

The calculation of the thermal scheme of the combined-cycle plant was carried out according to the method described in [

3]. The work considers schemes with an initial steam temperature equal to 515, 540, 580, 620, 660, or 700 °C, while the minimum temperature difference at the hot end of the superheater should not be less than 20 °C.

The heat balance of the heat exchange surfaces of the waste heat boiler is determined as

where

and

—mass enthalpy of gases at the inlet and outlet of the waste heat boiler section, kJ/kg;

and —mass enthalpy of water/steam at the outlet and inlet of the section, kJ/kg;

—water/steam consumption, kJ/kg;

—heat loss coefficient.

The relative internal efficiency of the steam turbine was determined separately for the high-pressure and low-pressure turbines using the following formulas.

For HPT:

where

—steam flow rate into the turbine head, kg/s;

—average specific volume of steam in the turbine, m3/kg;

—available heat drop in the turbine, kJ/kg.

For LPT:

where

is the correction factor for steam humidity, defined as

—coefficient for taking into account the influence of average humidity on the internal efficiency depending on the design of the flow part, adopted as 0.1;

and —steam humidity at the beginning and at the end of the group of stages;

—heat drop in the wet steam region, kJ/kg;

—losses with output speed, depending on the turbine design, where the value of 20 kJ/kg is taken.

The capacity of the steam turbine circuit of the combined-cycle plant was determined as

where

and

—power of the groups of stages of the HPT and LPT, kW;

,

and

—power of condensation, feed, and recirculation pumps, kW.

The net capacity of the ORC plant was determined as

where

and

are the power of the refrigerant turbine and pump, respectively, kW.

The net efficiency of binary and trinary cycles with afterburning chambers was calculated as

The main constants adopted for modeling are given in

Table 1.

To assess the adequacy of the developed CCPP mathematical model and to confirm the reliability of the simulation results, we verified the models by comparing the main calculated performance indicators with data published in the literature and by equipment manufacturers. The verification was carried out using calculated characteristics for the GTE-160 and GTE-110, which are the closest in parameters and design.

In [

24], engineers from Leningrad Metal Plant presented an analysis of the thermodynamic efficiency of condensing CCPP configurations with the GTE-160 V94.2, carried out scheme optimization, and determined the unit efficiency levels. Based on these data, the single-pressure CCPP model was verified using the identical input data listed in

Table 2. The validation results are reported in

Table 3.

In [

25], a dual-pressure combined-cycle scheme with a dual-pressure heat-recovery steam generator is calculated for a CCPP employing the GTE-110. The input set is provided in

Table 4, and validation outcomes are shown in

Table 5. Discrepancies can be attributed to the property models adopted for water and flue-gas constituents and to neglect of the influence of pump compression on the working-fluid parameters in the literature source.

The overall efficiency metrics obtained with the developed mathematical model differ from those reported by other authors (including equipment manufacturers) by no more than 0.5% in relative terms. This supports the applicability of the model for further studies.