Biogas Upgrading into Renewable Natural Gas: Part I—An Assessment of Available Technologies

Abstract

1. Introduction

- Describe biogas, natural gas compositions, and the standard requirements for RNG in five European countries and the USA.

- Describe conditioning methods for typical contaminants present in the biogas matrix that yield higher methane compositions.

- Details on technology options for biogas upgrading that are currently being utilized.

- Discuss case studies and process designs.

2. Composition: Natural Gas and Biomethane

- Type of substrate material used.

- Concentrations of carbon contained in each substrate (see Table 1).

- Weather conditions.

- The location of gas production.

- Type of technology used for production.

- Process conditions (Temperature, Residence Time, etc.).

- A conditioning process where trace components like water vapor, hydrogen sulfide, oxygen, nitrogen, ammonium, siloxanes, halogenated hydrocarbons, and particles are removed.

- An upgrading process to yield biogas containing the typical values of natural gas.

| Biogas Component | Units | Poland [15,16] | United Kingdom a [17,18,19] | Germany a,b [16,17,18,19] | France b [17,18,19] | Sweden b [18] | United States [20,21,22] |

|---|---|---|---|---|---|---|---|

| Methane | v/v% | 63.4 ± 1.1 | 50–70 | 54.4 ± 0.9 | 50–75 | 65 | 50–70 |

| v/v% | 60.2–67.7 | 60–70 | 53–70 | 60 | |||

| v/v% | 53–70 | ||||||

| Other Hydrocarbons c | mg/Nm3 | 0–200 | Trace | ||||

| Hydrogen | v/v% | <1 | Trace | ||||

| Carbon Dioxide | v/v% | 36.6 ± 1.0 | 25–45 | 45.5 ± 0.8 | 25–45 | 35 | 25–50 |

| v/v% | 32.2–39.5 | 30–47 | 30–47 | 36 | |||

| v/v% | <2 | <2 | |||||

| Nitrogen | v/v% | 0.003–0.525 | 0–3 | 0.1 ± 0.1 | 0–3 | 0.2 | 0–5 |

| Oxygen | v/v% | 0–0.083 | <2 | Trace | |||

| v/v% | 0–1 | Trace | |||||

| Hydrogen Sulfide | ppmv | <1000 | <1000 | 0–7500 | |||

| ppmv | 0–194 | <500 | 16.0 ± 0.7 | <500 | <500 | 1000–1400 | |

| Ammonium | ppmv | 0–0.84 | <1 | 3.6 ± 1.0 | <1 | 100 | 0–500 |

| ppmv | 100 | 100 | |||||

| Min. Heating Valve | Btu/ft3 | 564 | 893 | ||||

| Btu/ft3 | 617 | ||||||

| Water | v/v% | 2–7 d | 1–5 | ||||

| v/v% | 5–10 | ||||||

| Chlorine | ppmv | 0–40 | 0–5 | ||||

| Fluorine | ppmv | 0–5 | |||||

| Siloxane | mg/Nm3 | 0–41 |

| Biogas Component | Units | Wet a | Dry a | United Kingdom | Germany [11,23] | France [11] | Sweden [11] | United States [24,25,26] |

|---|---|---|---|---|---|---|---|---|

| Methane | v/v% | 84.6 | 96 | ≥70 | 87.0–97.0 | |||

| Other Hydrocarbons | v/v% | 0.1–6.4 | 0.06–2 | 0 | 0–9.0 | |||

| Hydrogen | v/v% | 0–0.02 | ||||||

| Carbon Dioxide | v/v% | <5 | <5 | 0–1.8 | <5 | 2.5 | 3 | 0.05–1.0 |

| Nitrogen | v/v% | <10 | <10 | <10 | 0.2–5.5 | |||

| Oxygen | v/v% | 0–0.2 | 3 | 1 | 1 | 0–0.1 | ||

| Hydrogen Sulfide | ppmv | <5 | <5 | 5 | <6.5 | 5 | 10 | 0.0055 |

| Ammonium | ppmv | 3 | 20 | |||||

| Min. Heating Valve | Btu/ft3 | 1047 | 1047 | 37–47 | 36.0–45.72 | 38.5–46.1 H | 39.6–43.2 | 36.0–40.2 |

| Btu/ft3 | 30.2–47.2 | 34.2–37.7 L | ||||||

| Water | mg/Nm3 | <32 | 16–32 |

3. Conditioning of Typical Contaminants

3.1. Water Removal

3.1.1. Condensate Traps

3.1.2. Absorption and Adsorption

3.2. Hydrogen Sulfide Removal

3.2.1. Precipitation

3.2.2. Adsorption Technologies

3.2.3. Photocatalytic Oxidation

3.2.4. Chemical Absorption

3.2.5. Biological Treatment

3.3. Oxygen and Nitrogen Removal

3.4. Ammonium Removal

3.5. Siloxane Removal

3.6. Hydrocarbon Removal

3.7. Particle Removal

4. Current Technologies for Biogas Upgrading

4.1. Physical Absorption via Water Washing

4.2. Physical Absorption Using Organic Solvents

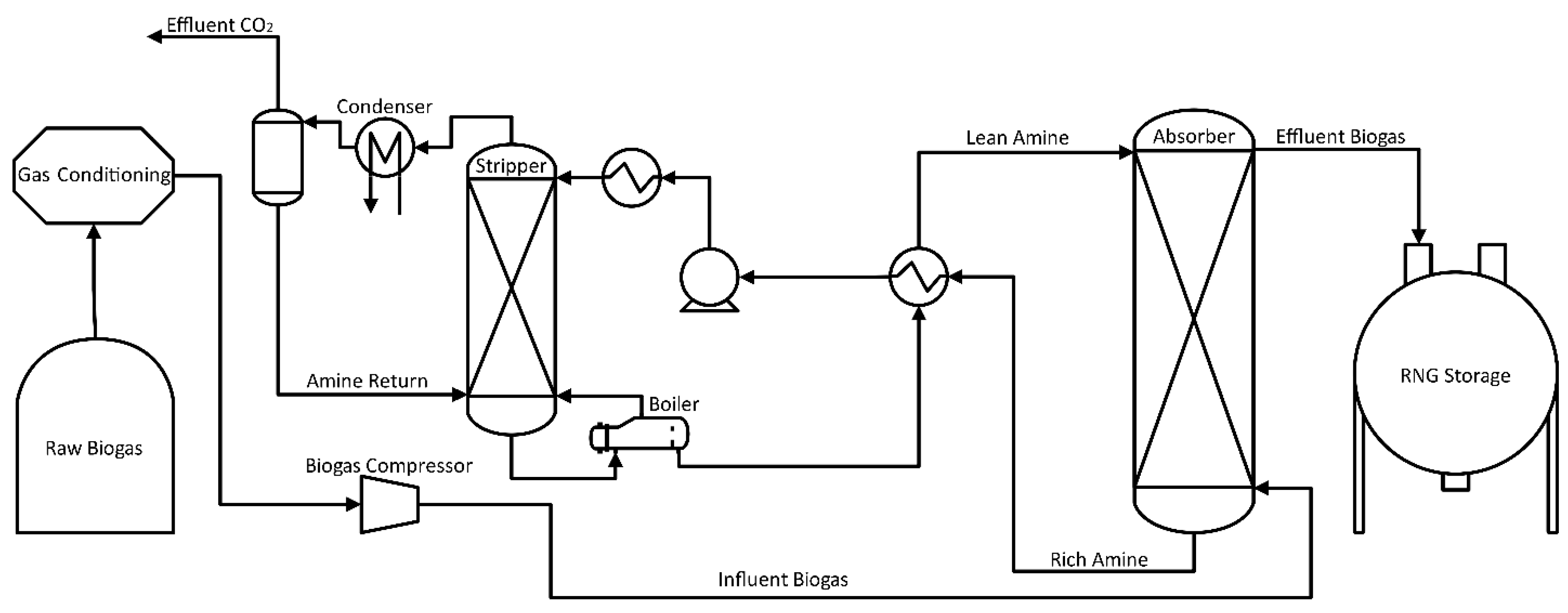

4.3. Chemical Absorption Using Amine Solutions

4.4. Pressure Swing Adsorption

4.5. Membrane Separation

5. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- EIA. Annual Energy Outlook 2018 with Projections to 2050; Office of Energy Analysis, U.S. Department of Energy: Washington, DC, USA, 2018. [Google Scholar]

- Jaffe, A.; Dominguez-Faus, R.; Parker, N.; Scheitrum, D.; Wilcock, J.; Miller, M. The Feasibility of Renewable Natural Gas as a Large-Scale, Low Carbon Substitute; Institute of Transportation Studies, University of California: Davis, CA, USA, 2016. [Google Scholar]

- EIA. Annual Energy Outlook 2017 with Projections to 2050; U.S. Energy Information Administration (EIA), Office of Energy Analysis, U.S. Department of Energy: Washington, DC, USA, 2017. [Google Scholar]

- USEPA. Overview of the Renewable Fuel Standard Program. Available online: https://www.epa.gov/renewable-fuel-standard/overview-renewable-fuel-standard-program (accessed on 10 May 2022).

- Faransso, R. Jumpstarting the Clean Hydrogen Economy—The Final Rule for 45v. ESG Review: 2025. Available online: https://esgreview.net/2025/01/15/jumpstarting-the-clean-hydrogen-economy-the-final-rule-for-45v (accessed on 1 October 2025).

- USDOE, North Wind Inc. 2022 Annual Site Environmental Report. 2023. Available online: https://www.energy.gov/sites/default/files/2024-06/2022%20Site%20Environmental%20Report%2C%20Department%20of%20Energy%2C%20ETEC%20-%20Area%20IV%20Santa%20Susana%20Field%20Laboratory%2C%20October%202023.pdf (accessed on 1 October 2025).

- European Biogas Association. Activity Report 2022; European Biogas Association: Brussels, Belgium, 2022. [Google Scholar]

- Lambert, M. Biogas: A Significant Contribution to Decarbonising Gas Markets? 2017. Available online: https://www.oxfordenergy.org/wpcms/wp-content/uploads/2017/06/Biogas-A-significant-contribution-to-decarbonising-gas-markets.pdf (accessed on 1 October 2025).

- Kadam, R.; Panwar, N.L. Recent advancement in biogas enrichment and its applications. Renew. Sustain. Energy Rev. 2017, 73, 892–903. [Google Scholar] [CrossRef]

- Petersson, A.; Wellinger, A. Biogas Upgrading Technologies—Developments and Innovations; IEA Bioenergy Task 37-Energy from Biogas and Landfill Gas Report No. 37; International Energy Agency (IEA): Paris, France, 2009. [Google Scholar]

- Rohstoffe, F.N. Guide to Biogas: From Production to Use, 5th ed.; Fachagentur Nachwachsende Rohstoffe e.V. (FNR): Gülzow, Germany, 2010. [Google Scholar]

- Rotunno, P.; Lanzini, A.; Leone, P. Energy and economic analysis of a water scrubbing based biogas upgrading process for biomethane injection into the gas grid or use as transportation fuel. Renew. Energy 2017, 102, 417–432. [Google Scholar] [CrossRef]

- Ryckebosch, E.; Drouillon, M.; Vervaeren, H. Techniques for transformation of biogas to biomethane. Biomass Bioenergy 2011, 35, 1633–1645. [Google Scholar] [CrossRef]

- Deremince, B.; Königsberger, S. Statistical Report of the European Biogas Association; European Biogas Association (EBA): Brussels, Belgium, 2017. [Google Scholar]

- Budzianowski, W.M. Sustainable biogas energy in poland: Prospects and challenges. Renew. Sustain. Energy Rev. 2012, 16, 342–349. [Google Scholar] [CrossRef]

- Piechota, G.; Igliński, B.; Buczkowski, R. Development of measurement techniques for determination main and hazardous components in biogas utilised for energy purposes. Energy Convers. Manag. 2013, 68, 219–226. [Google Scholar] [CrossRef]

- Centre, S.G. Basic Data on Biogas, 2nd ed.; Swedish Gas Technology Centre Ltd., (SGC): Malmö, Sweden, 2012. [Google Scholar]

- Muñoz, R.; Meier, L.; Diaz, I.; Jeison, D. A review on the state-of-the-art of physical/chemical and biological technologies for biogas upgrading. Rev. Environ. Sci. Bio. Technol. 2015, 14, 727–759. [Google Scholar] [CrossRef]

- Seadi, T.A.; Rutz, D.; Prassl, H.; Köttner, M.; Finsterwalder, T.; Volk, S.; Janssen, R. Biogas Handbook; University of Southern Denmark Esbjerg: Esbjerg, Denmark, 2008. [Google Scholar]

- Boerman, M.; Pronto, J.; Gooch, C. Anaerobic Digestion at Swiss Valley Dairy: Case Study. 2014. Available online: https://ecommons.cornell.edu/server/api/core/bitstreams/5be73af9-0f29-422a-89c2-213754f5b7e5/content (accessed on 23 August 2023).

- Gooch, C.; Labatut, R. Evaluation of the Continuously-Mixed Anaerobic Digester System at Synergy Biogas Following the Protocol for Quantifying and Reporting the Performance of Anaerobic Digestion Systems for Livestock Manures. 2014. Available online: https://lpelc.org/evaluation-of-a-continuously-mixed-farm-based-anaerobic-co-digestion-system-following-the-u-s-epa-protocol-for-quantifying-and-reporting-on-the-performance-of-anaerobic-digestion-systems-for-livestoc/#:~:text=Purpose,manure%2Dbased%20anaerobic%20digestion%20systems (accessed on 23 August 2023).

- Oliver, J.P.; Gooch, C. Emissions from Biogas-Fueled Distributed Generation Units Part 1: What Are the Potential Emissions from Engine-Generation Sets? 2016. Available online: https://ecommons.cornell.edu/server/api/core/bitstreams/305a2148-3a28-456a-b069-725683583f40/content (accessed on 12 November 2023).

- Bulgartransgaz. Invitation to Tender for Natural Gas Supply. 2014. Available online: https://bulgartransgaz.bg/files/useruploads/files/obstestveni_porachki/btg-24-00-1882_en.pdf (accessed on 28 October 2023).

- Aregbe, A.G. Natural gas flaring—Alternative solutions. World J. Eng. Technol. 2017, 5, 139–153. [Google Scholar] [CrossRef]

- Kumar, S.; Suresh, S.; Arisutha, S. Production of renewable natural gas from waste biomass. J. Inst. Eng. (India) Ser. E 2013, 94, 55–59. [Google Scholar] [CrossRef]

- UnionGas. Chemical Composition of Natural Gas. Available online: https://wecanfigurethisout.org/ENERGY/Web_notes/Carbon/Fossil_Fuels_Supporting_Files/Chemical%20Composition%20of%20Natural%20Gas%20-%20Union%20Gas.pdf (accessed on 28 October 2023).

- Faramawy, S.; Zaki, T.; Sakr, A.A.E. Natural gas origin, composition, and processing: A review. J. Nat. Gas Sci. Eng. 2016, 34, 34–54. [Google Scholar] [CrossRef]

- Awe, O.W.; Zhao, Y.; Nzihou, A.; Minh, D.P.; Lyczko, N. A review of biogas utilisation, purification and upgrading technologies. Waste Biomass Valorization 2017, 8, 267–283. [Google Scholar] [CrossRef]

- Dudek, J.; Klimek, P.; Niemczewska, J.; Zaleska-Bartosz, J. Landfill Gas Energy Technologies; Scientific Works of the Oil and Gas Institute; Oil and Gas Institute—National Research Institute: Kraków, Poland, 2010; Volume 174. [Google Scholar]

- OSHA. Occupational Safety and Health Standards—Toxic and Hazardous Substances—Air Contaminants. 2019. Available online: https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.1000 (accessed on 20 October 2023).

- Nguyen, L.N.; Kumar, J.; Vu, M.T.; Mohammed, J.A.H.; Pathak, N.; Commault, A.S.; Sutherland, D.; Zdarta, J.; Tyagi, V.K.; Nghiem, L.D. Biomethane production from anaerobic co-digestion at wastewater treatment plants: A critical review on development and innovations in biogas upgrading techniques. Sci. Total Environ. 2021, 765, 142753. [Google Scholar] [CrossRef]

- Cheng, Y.; Yuan, T.; Deng, Y.; Lin, C.; Zhou, J.; Lei, Z.; Shimizu, K.; Zhang, Z. Use of sulfur-oxidizing bacteria enriched from sewage sludge to biologically remove H2S from biogas at an industrial-scale biogas plant. Bioresour. Technol. Rep. 2018, 3, 43–50. [Google Scholar] [CrossRef]

- Magomnang, A.-A.S.M.; Villanueva, E.P. Removal of hydrogen sulfide from biogas using dry desulfurization systems. In Proceedings of the International Conference on Agricultural, Environmental and Biological Sciences (AEBS-2014), Phuket, Thailand, 24–25 April 2014. [Google Scholar]

- Aslanidou, S.; Lydakis-Simantiris, N.; Kotsifaki, C.; Pentari, D.; Katsivela, E. Ferric Chloride (FeCl3) as Regulatory agent for the reduction of hydrogen sulfide (H2S) in municipal wastewater. In Proceedings of the 9th International Conference on Protection and Restoration of the Environment (PRE IX), Kefalonia, Greece, 29 June–3 July 2008. [Google Scholar]

- Speight, J.G. Processes. In Natural Gas; Elsevier Inc.: Amsterdam, The Netherlands, 2007; pp. 161–192. Available online: https://linkinghub.elsevier.com/retrieve/pii/B9781933762142500121 (accessed on 27 October 2025). [CrossRef]

- Technologies, M.V. H2S Media Cost Calculator|Mv Technologies. 2019. Available online: https://mvseer.com/resources/tools/h2s-media-cost-calculator/ (accessed on 30 October 2023).

- Bahadori, A. Chapter 10—Natural Gas Sweetening. In Natural Gas Processing; Bahadori, A., Ed.; Gulf Professional Publishing: Boston, MA, USA, 2014; pp. 483–518. [Google Scholar]

- Pipatmanomai, S.; Kaewluan, S.; Vitidsant, T. Economic assessment of biogas-to-electricity generation system with H2S removal by activated carbon in small pig farm. Appl. Energy 2009, 86, 669–674. [Google Scholar] [CrossRef]

- Coppola, G.; Papurello, D. Biogas Cleaning: Activated Carbon Regeneration for H2S Removal. Clean Technol. 2018, 1, 40–57. [Google Scholar] [CrossRef]

- Kulkarni, M.B.; Ghanegaonkar, P.M. Hydrogen sulfide removal from biogas using chemical absorption technique in packed column reactors. Glob. J. Environ. Sci. Manag. 2019, 5, 155–166. [Google Scholar] [CrossRef]

- De Gisi, S.; Lofrano, G.; Grassi, M.; Notarnicola, M. Characteristics and adsorption capacities of low-cost sorbents for wastewater treatment: A review. Sustain. Mater. Technol. 2016, 9, 10–40. [Google Scholar] [CrossRef]

- Samson, M.; Aboyade, A.; Muzenda, E. Enrichment of biogas for use as vehicular fuel: A review of the upgrading techniques. Int. J. Adv. Eng. Sci. Appl. Math. 2013, 1, 89–98. [Google Scholar]

- Awe, O.W.; Minh, D.P.; Lyczko, N.; Nzihou, A.; Zhao, Y. Laboratory-scale investigation of the removal of hydrogen sulfide from biogas and air using industrial waste-based sorbents. J. Environ. Chem. Eng. 2017, 5, 1809–1820. [Google Scholar] [CrossRef]

- Bagreev, A.; Bandosz, T. A role of sodium hydroxide in the process of hydrogen sulfide adsorption/oxidation on caustic-impregnated activated carbons. Ind. Eng. Chem. Res. 2002, 41, 672–679. [Google Scholar] [CrossRef]

- Castrillon, M.; Moura, K.; Alves, C.; Bastos-Neto, M.; Azevedo, D.; Hofmann, J.; Möllmer, J.; Einicke, W.-D.; Gläser, R. CO2 and H2S removal from CH4-rich streams by adsorption on activated carbons modified with K2CO3, NaOH, or Fe2O3. Energy Fuels 2016, 30, 9596–9604. [Google Scholar] [CrossRef]

- Makaruk, A.; Miltner, M.; Harasek, M. Membrane biogas upgrading processes for the production of natural gas substitute. Sep. Purif. Technol. 2010, 74, 83–92. [Google Scholar] [CrossRef]

- Hao, X.; Hou, G.; Zheng, P.; Liu, R.; Liu, C. H2S in-situ removal from biogas using a tubular zeolite/TiO2 photocatalytic reactor and the improvement on methane production. Chem. Eng. J. 2016, 294, 105–110. [Google Scholar] [CrossRef]

- Su, J.-J.; Hong, Y.-Y. Removal of hydrogen sulfide using a photocatalytic livestock biogas desulfurizer. Renew. Energy 2020, 149, 181–188. [Google Scholar] [CrossRef]

- Siemak, J.B.; Gelbs, M. Operating experience with a two-stage H2S scrubber using caustic soda. In Proceedings of the SPE California Regional Meeting CRM 1985, Anaheim, CA, USA, 27–29 March 1985; Society of Petroleum Engineers: Richardson, TX, USA, 1985; pp. 513–518. [Google Scholar]

- Horikawa, M.S.; Rossi, F.; Gimenes, M.L.; Costa, C.M.M.; Da Silva, M.G.C. Chemical absorption of H2S for biogas purification. Braz. J. Chem. Eng. 2004, 21, 415–422. [Google Scholar] [CrossRef]

- Thanakunpaisit, N.; Jantarachat, N.; Onthong, U. Removal of hydrogen sulfide from biogas using laterite materials as an adsorbent. Energy Procedia 2017, 138, 1134–1139. [Google Scholar] [CrossRef]

- van Foreest, F. Perspectives for Biogas in Europe; Oxford Institute for Energy Studies: Oxford, UK, 2012. [Google Scholar]

- Xu, M.; Xue, Z.; Sun, S.; Zhao, C.; Liu, J.; Liu, J.; Zhao, Y. Co-culturing microalgae with endophytic bacteria increases nutrient removal efficiency for biogas purification. Bioresour. Technol. 2020, 314, 123766. [Google Scholar] [CrossRef]

- Soreanu, G.; Beland, M.; Falletta, P.; Edmonson, K.; Svoboda, L.; Al-Jamal, M.; Seto, P. Approaches concerning siloxane removal from biogas—A review. Can. Biosyst. Eng. Le. Genie Des. Biosyst. Au. Can. 2011, 53, 8.1–8.18. [Google Scholar]

- Envitech. Treatment of Siloxanes in Biogas: Origin, Effect and Management. 2018. Available online: https://condorchem.com/en/blog/siloxanes-biogas-treatment/ (accessed on 1 November 2023).

- Gao, R.; Cheng, S.; Li, Z. Research progress of siloxane removal from biogas. Int. J. Agric. Biol. Eng. 2017, 10, 30–39. [Google Scholar] [CrossRef]

- Wellinger, A.; Mandereau, C. Rationale for Siloxane Levels; CEN/TC 408; European Biogas Association: Brussels, Belgium, 2010. [Google Scholar]

- Pierce, J.L. Siloxane Sampling, Analysis and Data Reporting Recommendations on Standardization for the Biogas Utilization Industry. EPA. 2011. Available online: https://www.epa.gov/sites/default/files/2016-06/documents/pierce.pdf (accessed on 9 May 2023).

- Tansel, B.; Surita, S.C. Differences in volatile methyl siloxane (vms) profiles in biogas from landfills and anaerobic digesters and energetics of vms transformations. Waste Manag. 2014, 34, 2271–2277. [Google Scholar] [CrossRef]

- Accettola, F.; Guebitz, G.; Schoeftner, R. Siloxane removal from biogas by biofiltration: Biodegradation studies. Clean Technol. Environ. Policy 2008, 10, 211–218. [Google Scholar] [CrossRef]

- Siirtec, N. Gas Dew Point Control—Siirtec Nigi. 2019. Available online: https://aig-int.com/partner/siirtec-nigi/ (accessed on 4 January 2024).

- Papadias, D.; Ahmed, S. Biogas Impurities and Cleanup for Fuel Cells; U.S. Department of Energy: Washington, DC, USA, 2012. [Google Scholar]

- Ong, M.D.; Williams, R.B.; Kaffka, S.R. Comparative Assessment of Technology Options for Biogas Clean-Up. 2014. Available online: https://ucdavis.app.box.com/s/iaog2diybkvoe5xxdjud97xsrx3ypwmq (accessed on 16 June 2022).

- Persson, M.; Jonsson, O.; Wellinger, A. Biogas upgrading to vehicle fuel standards and grid injection. IEA Bioenergy 2006, 37, 20–21. [Google Scholar]

- Rasi, S.; Läntelä, J.; Veijanen, A.; Rintala, J. Landfill gas upgrading with countercurrent water wash. Waste Manag. 2008, 28, 1528–1534. [Google Scholar] [CrossRef]

- Blanco, G.; Santalla, E.; Córdoba, V.; Levy, A. Generación de Electricidad a Partir de Biogás Capturado de Residuos Sólidos Urbanos: Un Análisis Teórico-Práctico. 2020. Available online: https://publications.iadb.org/es/publicacion/13967/generacion-de-electricidad-partir-de-biogas-capturado-de-residuos-solidos-urbanos (accessed on 10 May 2023).

- Minutolo, P.; Sgro, L.; Costagliola, M.A.; Prati, M.V.; Sirignano, M.; D’Anna, A. Ultrafine Particle Emission from Combustion Devices Burning Natural Gas. Chem. Eng. Trans. 2010, 22, 239–244. [Google Scholar] [CrossRef]

- Angelidaki, I.; Treu, L.; Tsapekos, P.; Luo, G.; Campanaro, S.; Wenzel, H.; Kougias, P. Biogas upgrading and utilization: Current status and perspectives. Biotechnol. Adv. 2018, 36, 452–466. [Google Scholar] [CrossRef]

- Budzianowski, W.M.; Wylock, C.E.; Marciniak, P.A. Power requirements of biogas upgrading by water scrubbing and biomethane compression: Comparative analysis of various plant configurations. Energy Convers. Manag. 2017, 141, 2–19. [Google Scholar] [CrossRef]

- Kapoor, R.; Subbarao, P.M.V.; Vijay, V.K.; Shah, G.; Sahota, S.; Singh, D.; Verma, M. Factors affecting methane loss from a water scrubbing based biogas upgrading system. Appl. Energy 2017, 208, 1379–1388. [Google Scholar] [CrossRef]

- Deublein, D.; Steinhauser, A. History and Status to Date in Europe. In Biogas from Waste and Renewable Resources; Wiley-VCH: Weinheim, Germany, 2008; pp. 27–33. [Google Scholar]

- Bauer, F.; Hulteberg, C.; Persson, T.; Tamm, D. Biogas Upgrading-Review of Commercial Technologies (Biogasuppgradering-Granskning Av Kommersiella Tekniker) Sgc Rapport 2013:270 Catalyzing Energygas Development for Sustainable Solutions. Available online: https://www.sgc.se (accessed on 2 June 2023).

- Håkansson, A. Preventing Microbial Growth on Pall-Rings when Upgrading Biogas Using Absorption with Water Wash. 2006. Available online: https://www.diva-portal.org/smash/get/diva2:22236/FULLTEXT01 (accessed on 15 May 2023).

- Jecha, D.; Niesner, J.; Stehlík, P. Biogas upgrading technologies: State of art review in biogas upgrading technologies: State of art review in biogas biogas upgrading techniques: State of art review in European region. Chem. Eng. Trans. 2013, 35, 517–522. [Google Scholar] [CrossRef]

- Kapdi, S.S.; Vijay, V.K.; Rajesh, S.K.; Prasad, R. Biogas scrubbing, compression and storage: Perspective and prospectus in Indian context. Renew. Energy 2005, 30, 1195–1202. [Google Scholar] [CrossRef]

- Yliopisto, J. Evaluation of Potential Technologies and Operational Scales Reflecting Market Needs for Low-Cost Gas Upgrading Systems. 2012. Available online: https://www.valorgas.soton.ac.uk/Deliverables/111129_VALORGAS_241334_D5-1_Final_version.pdf (accessed on 11 November 2023).

- Singhal, S.; Agarwal, S.; Arora, S.; Sharma, P.; Singhal, N. Upgrading techniques for transformation of biogas to bio-cng: A review: A review on upgradation techniques to transform biogas to bio-cng. Int. J. Energy Res. 2017, 41, 1657–1669. [Google Scholar] [CrossRef]

- Budzianowski, W.M. A review of potential innovations for production, conditioning and utilization of biogas with multiple-criteria assessment. Renew. Sustain. Energy Rev. 2016, 54, 1148–1171. [Google Scholar] [CrossRef]

- Cordova, S.S.; Gustafsson, M.; Eklund, M.; Svensson, N. What should we do with CO2 from biogas upgrading? J. CO2 Util. 2023, 77, 102607. [Google Scholar] [CrossRef]

- Vilardi, G.; Bassano, C.; Deiana, P.; Verdone, N. Exergy and energy analysis of three biogas upgrading processes. Energy Convers. Manag. 2020, 224, 113323. [Google Scholar] [CrossRef]

- Jankowska, E.; Sahu, A.K.; Oleskowicz-Popiel, P. Biogas from microalgae: Review on microalgae’s cultivation, harvesting and pretreatment for anaerobic digestion. Renew. Sustain. Energy Rev. 2017, 75, 692–709. [Google Scholar] [CrossRef]

- Krzemieniewski, M.; Szwarc, D.; Zielinski, M.; Kupczyk, K.; Rokicka, M.; Debowski, M. The Possibility of Using Carbon Dioxide from Biogas in the Production of Microalgae Biomass; Uniwersytet Warmińsko-Mazurski w Olsztynie: Olsztyn, Poland, 2016. [Google Scholar]

- Shin, Y.S.; Choi, H.I.; Choi, J.; Lee, J.; Sung, Y.; Sim, S. Multilateral approach on enhancing economic viability of lipid production from microalgae: A review. Bioresour. Technol. 2018, 258, 335–344. [Google Scholar] [CrossRef]

- Sahota, S.; Shah, G.; Ghosh, P.; Kapoor, R.; Sengupta, S.; Singh, P.; Vijay, V.; Sahay, A.; Vijay, V.K.; Thakur, I.S. Review of trends in biogas upgradation technologies and future perspectives. Bioresour. Technol. Rep. 2018, 1, 79–88. [Google Scholar] [CrossRef]

- Patterson, T.; Esteves, S.; Dinsdale, R.; Guwy, A. An evaluation of the policy and techno-economic factors affecting the potential for biogas upgrading for transport fuel use in the UK. Energy Policy 2011, 39, 1806–1816. [Google Scholar] [CrossRef]

- Sun, Q.; Li, H.; Yan, J.; Liu, L.; Yu, Z.; Yu, X. Selection of appropriate biogas upgrading technology—A review of biogas cleaning, upgrading and utilisation. Renew. Sustain. Energy Rev. 2015, 51, 521–532. [Google Scholar] [CrossRef]

- Kohl, A.L.; Nielsen, R.B. Alkanolamines for Hydrogen Sulfide and Carbon Dioxide Removal. In Gas Purification, 5th ed.; Kohl, A.L., Nielsen, R.B., Eds.; Gulf Professional Publishing: Houston, TX, USA, 1997; pp. 40–186. [Google Scholar]

- Vo, T.T.Q.; Wall, D.M.; Ring, D.; Rajendran, K.; Murphy, J.D. Techno-economic analysis of biogas upgrading via amine scrubber, carbon capture and ex-situ methanation. Appl. Energy 2018, 212, 1191–1202. [Google Scholar] [CrossRef]

- Gong, H.; Chen, Z.; Yu, H.; Wu, W.; Wang, W.; Pang, H.; Du, M. Methane recovery in a combined amine absorption and gas steam boiler as a self-provided system for biogas upgrading. Energy 2018, 157, 744–751. [Google Scholar] [CrossRef]

- Eskandari, M.; Khaksar, S.A.N.; Keshavarz, P. CO2 absorption using benzylamine as absorbent and promoter in a hollow fiber membrane contactor: A numerical study. J. CO2 Util. 2022, 66, 102287. [Google Scholar] [CrossRef]

- Yoo, M.; Han, S.J.; Wee, J.H. Carbon dioxide capture capacity of sodium hydroxide aqueous solution. J. Environ. Manag. 2013, 114, 512–519. [Google Scholar] [CrossRef]

- Grande, C.A. Biofuel’s Engineering Process Technology; dos Santos Bernardes, M.A., Ed.; IntechOpen: Rijeka, Croatia, 2011. [Google Scholar]

- Santos, M.; Grande, C.; Rodrigues, A. Pressure swing adsorption for biogas upgrading. Effect of recycling streams in pressure swing adsorption design. Ind. Eng. Chem. Res. 2010, 50, 974–985. [Google Scholar] [CrossRef]

- Rocha, L.A.M.; Andreassen, K.A.; Grande, C.A. Separation of CO2/CH4 using carbon molecular sieve (CMS) at low and high pressure. Chem. Eng. Sci. 2017, 164, 148–157. [Google Scholar] [CrossRef]

- Augelletti, R.; Conti, M.; Annesini, M.C. Pressure swing adsorption for biogas upgrading. A new process configuration for the separation of biomethane and carbon dioxide. J. Clean. Prod. 2017, 140, 1390–1398. [Google Scholar] [CrossRef]

- Zhao, Q.; Leonhardt, E.; Macconnell, C.; Frear, C.; Chen, S. Purification Technologies for Biogas Generated by Anaerobic Digestion. 2010. Available online: https://www.build-a-biogas-plant.com/PDF/BiogasPurificationTech2010.PDF (accessed on 11 November 2023).

- Ali Abd, A.; Roslee Othman, M. Biogas upgrading to fuel grade methane using pressure swing adsorption: Parametric sensitivity analysis on an industrial scale. Fuel 2022, 308, 121986. [Google Scholar] [CrossRef]

- Vaughn, J.T.; Koros, W.J. Analysis of feed stream acid gas concentration effects on the transport properties and separation performance of polymeric membranes for natural gas sweetening: A comparison between a glassy and rubbery polymer. J. Membr. Sci. 2014, 465, 107–116. [Google Scholar] [CrossRef]

- Baker, R.W. Membrane Technology and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Chen, X.; Vinh, H.; Ramirez, A.; Rodrigue, D.; Kaliaguine, S. Membrane gas separation technologies for biogas upgrading. RSC Adv. 2015, 5, 24399–24448. [Google Scholar] [CrossRef]

- Schell, W.J.; Wensley, C.G.; Chen, M.S.K.; Venugopal, K.G.; Miller, B.D.; Stuart, J.A. Recent advances in cellulosic membranes for gas separation and pervaporation. Gas Sep. Purif. 1989, 3, 162–169. [Google Scholar] [CrossRef]

- Chatterjee, G.; Houde, A.A.; Stern, S.A. Poly(ether urethane) and poly(ether urethane urea) membranes with high H2S/CH4 selectivity. J. Membr. Sci. 1997, 135, 99–106. [Google Scholar] [CrossRef]

- Lokhandwala, K.A.; Baker, R.W. Sour Gas Treatment Process. U.S. Patent 5,407,467, 18 April 1995. [Google Scholar]

- Zito, P.F.; Brunetti, A.; Barbieri, G. Multi-step membrane process for biogas upgrading. J. Membr. Sci. 2022, 652, 120454. [Google Scholar] [CrossRef]

| Substance Group | Digestion Biogas Yield (L/Kg VS) | Methane Content |

|---|---|---|

| (%v) Digestible Fat | 1000–1250 | 70–75 |

| Digestible Protein | 600–700 | 68–73 |

| Digestible Carbohydrates | 700–800 | 50–55 |

| Biogas Component | Units | France [10,28] | Germany [10] | Sweden [10,28] | United States [24,25,26] |

|---|---|---|---|---|---|

| Wobble Index | MJ/Nm3 | 48.2–56.5 H | 46.1–56.5 | 44.7–46.4 | 43.4–44.4 |

| MJ/Nm3 | 42.5–46.8 L | 37.8–46.8 | |||

| Methane | v/v% | ≥86 | ≤70 | 95–99 | 87.0–97.0 |

| Carbon Dioxide | v/v% | <2 | <6 | ≤3 | 0.05–1.0 |

| v/v% | 2.5 | <3 | ≤1 | 0–0.1 | |

| Oxygen (Dry Gas) | v/v% | 3 | |||

| Oxygen (Wet Gas) | v/v% | 0.5 | |||

| Hydrogen | v/v% | <6 | ≤5 | ≤0.5 | 0.0055 |

| CO2 + O2 + N2 | v/v% | ≤5 | |||

| Water Dew Point | °C | <5 a | <T c | ≤T d–5 | |

| Sulfur | mg/Nm3 | 75 b | <30 | ≤23 | |

| mg/Nm3 | 30 |

| Contaminant | Removal Benefit |

|---|---|

| Water |

|

| Hydrogen Sulfide |

|

| Oxygen and Nitrogen |

|

| Ammonium |

|

| Siloxane |

|

| Hydrocarbons |

|

| Particles |

|

| Material | Surface Area (m2/g) |

|---|---|

| Industrial Carbonate Waste | 3.6 |

| Garden Grass | 21.28 |

| Slag | 107 |

| Sewage Sludge a | 390 |

| Sugarcane Bagasse | 606.8 |

| Pinewood a | 902 |

| Corncob a | 943 |

| Sugarcane Bagasse a | 1433 |

| Commercial Carbon a | 2000 |

| Source | (mg/Nm3) a |

|---|---|

| European Union [57] | |

| 3.4–15.4 (10) |

| t—12.4 (1.3) |

| t—0.6 |

| t—25.3 (10) |

| United States [58,59] | |

| 4.5–161 |

| 9.6–15.6 |

| 5.2–8.2 |

| Available Technologies | Objective | Benefits |

|---|---|---|

| Physical Absorption with Water | CO2 Removal | Simple process, non-toxic |

| Physical Absorption with Organic Solvents | CO2 Removal | High capacity, low regeneration energy |

| Chemical Absorption with Amines | CO2 Removal | High CH4 purity |

| Pressure Swing Adsorption | CO2 Removal | No reagent disposal issues |

| Membrane Separation | CO2 Removal | Compact equipment, long life |

| 2009 | 2015 | 2016 | 2017 | 2020 | 2024 | |

|---|---|---|---|---|---|---|

| Total Number of Upgrading Plants | 127 | 428 | 480 | 532 | 606 | 795 |

| Physical Absorption with Water | 34% | 34% | 34% | 30% | 30% | 18% |

| Physical Absorption with Organic Solvents | 9% | 5% | 4% | 4% | 3% | 3% |

| Chemical Absorption with Amines | 11% | 22% | 19% | 18% | 17% | 14% |

| Pressure Swing Adsorption | 36% | 17% | 17% | 14% | 13% | 12% |

| Membrane Separation | 10% | 21% | 24% | 25% | 29% | 48% |

| Other Technologies | - | 2% | 2% | 9% | 8% | 4% |

| Gas Components | 0 °C | 25 °C |

|---|---|---|

| Hydrogen Sulfide | 205 | 102 |

| Carbon Dioxide | 75 | 34 |

| Methane | 2.45 | 1.32 |

| Membrane Type | Pure Gas CO2 | Permeability [Barrier] CH4 | Selectivity CO2/CH4 |

|---|---|---|---|

| PDMS (Silicone Rubber) | 464 | 136 | 3.4 |

| Natural Rubber | 13.7 | 2.9 | 4.7 |

| Poly(4-methyl-1-pentane) | 8.5 | 1.3 | 6.3 |

| MatrimiⓇ (Polyimide) | 6.5 | 0.19 | 34 |

| P84 (Polyimide) | 1.2 | 0.02 | 50 |

| Kapton (Polyimide) | 0.866 | 0.026 | 33.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Laines Canepa, J.R.; Foret, B.; Núñez-Nogueira, G.; Dufreche, S.; Hernandez, R.; Gang, D.; Sharp, W.; Revellame, E.; Fortela, D.L.B.; Simoneaux, S.; et al. Biogas Upgrading into Renewable Natural Gas: Part I—An Assessment of Available Technologies. Energies 2025, 18, 5750. https://doi.org/10.3390/en18215750

Laines Canepa JR, Foret B, Núñez-Nogueira G, Dufreche S, Hernandez R, Gang D, Sharp W, Revellame E, Fortela DLB, Simoneaux S, et al. Biogas Upgrading into Renewable Natural Gas: Part I—An Assessment of Available Technologies. Energies. 2025; 18(21):5750. https://doi.org/10.3390/en18215750

Chicago/Turabian StyleLaines Canepa, José Ramón, Blake Foret, Gabriel Núñez-Nogueira, Stephen Dufreche, Rafael Hernandez, Daniel Gang, Wayne Sharp, Emmanuel Revellame, Dhan Lord B. Fortela, Sarah Simoneaux, and et al. 2025. "Biogas Upgrading into Renewable Natural Gas: Part I—An Assessment of Available Technologies" Energies 18, no. 21: 5750. https://doi.org/10.3390/en18215750

APA StyleLaines Canepa, J. R., Foret, B., Núñez-Nogueira, G., Dufreche, S., Hernandez, R., Gang, D., Sharp, W., Revellame, E., Fortela, D. L. B., Simoneaux, S., Hulin, H., Holmes, W. E., & Zappi, M. E. (2025). Biogas Upgrading into Renewable Natural Gas: Part I—An Assessment of Available Technologies. Energies, 18(21), 5750. https://doi.org/10.3390/en18215750