1. Introduction

With the increasing global concern about carbon emissions, hydrogen energy is regarded as one of the important choices for a clean energy source [

1,

2,

3,

4,

5]. The rapid growth of the hydrogen industry depends heavily on advances in storage technology, which is reflected in the growing number of hydrogen refueling stations. Fully multilayered high-pressure hydrogen storage vessels are widely used and play an important role in China’s hydrogen refueling stations [

6,

7]. Over time, full multi-layer high-pressure hydrogen storage vessels may fail due to cracks and other reasons. Therefore, in order to ensure the safety and stability of fully multi-layered high-pressure hydrogen storage vessels during use, it is necessary to carry out regular inspections and health monitoring, which involves the non-destructive testing of pressure vessels. Different inspection methods are applicable to different vessel structures, and suitable inspection methods should be selected according to the structural characteristics of the vessel.

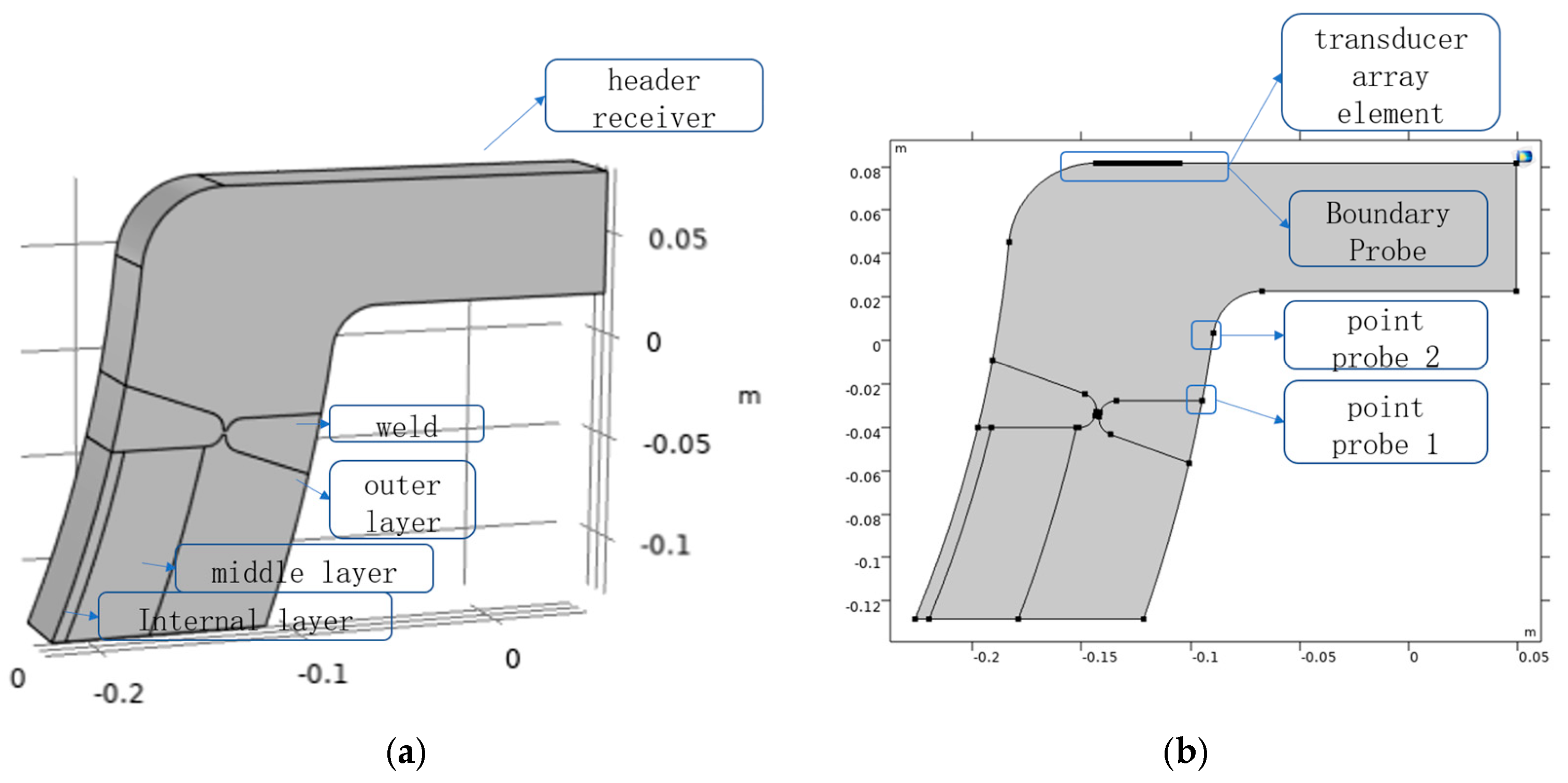

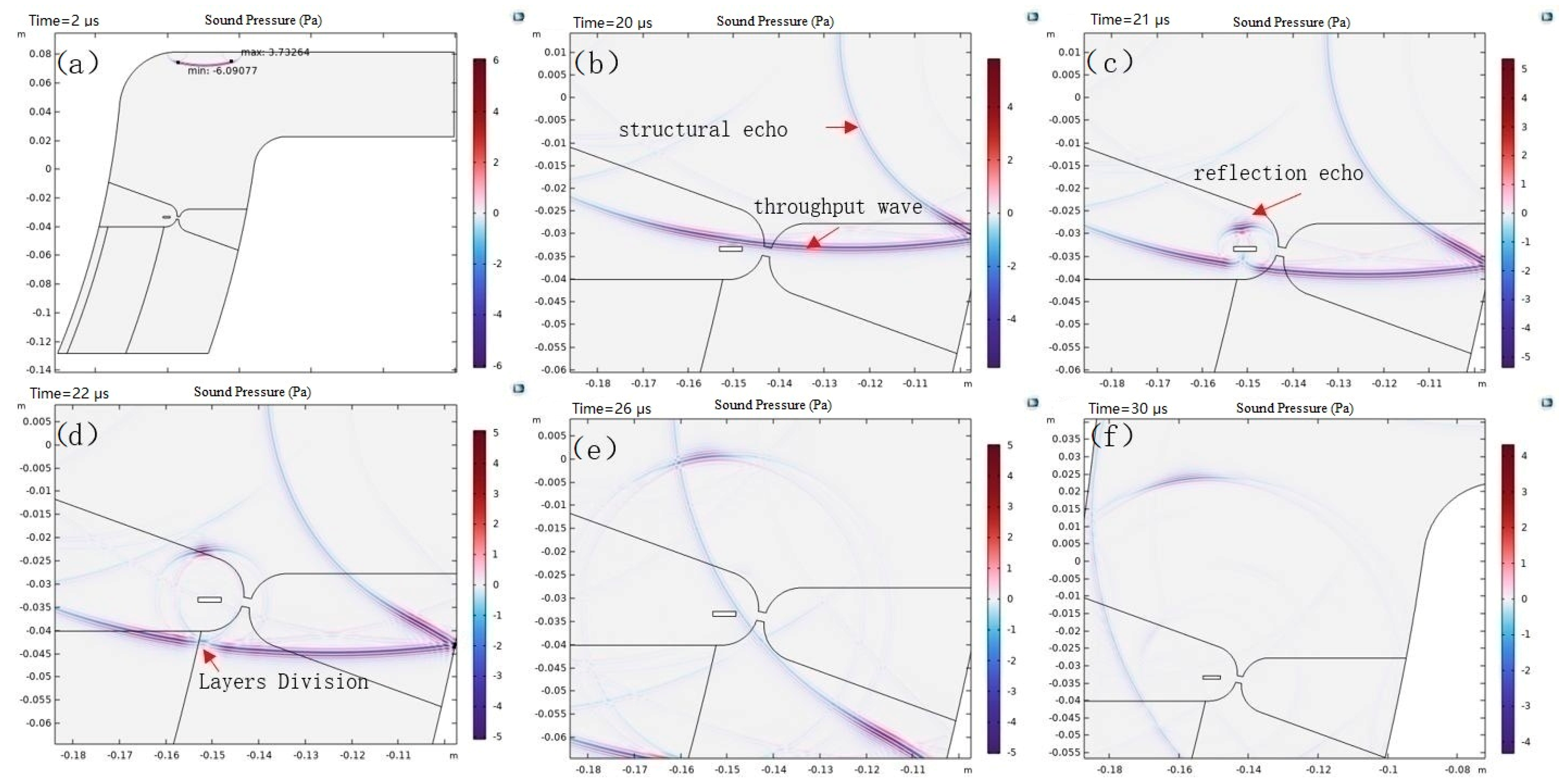

The butt joint of the thick-walled nozzles and hemispherical head in the full multilayer high-pressure hydrogen storage vessel is a critical and challenging area for inspection; the section diagram of the butt joint is shown in

Figure 1. Due to their complex structure and large thickness, if cracks are generated inside the butt joint region during service, a special detection method needs to be developed to locate the defects.

A review of domestic and international research on non-destructive testing (NDT) methods for hydrogen storage containers shows that current efforts are primarily focused on developing specialized testing technologies tailored to specific container types, which is manifested in two aspects: the development of dedicated equipment to meet the specific testing needs of different containers, and the enhancement of detection accuracy based on existing NDT techniques. These two aspects of the research have achieved some progress and have been applied in practical projects, but there are corresponding limitations. Acoustic emission detection technology is generally used for dynamic assessment of damage during the hydraulic test of pressure vessels, which is irreversible and cannot be used for defect detection of butt joints of full multi-layer high-pressure hydrogen storage containers; conventional radiographic inspection technology is generally used for defect detection during the manufacturing stage of containers, such as defects in the raw materials, which is difficult to be applied to the defect detection of the full multi-layer high-pressure hydrogen storage containers after molding [

8,

9,

10,

11,

12]; eddy current testing is currently limited to assessing raw materials and is not suitable for use after the container has been formed. Additionally, this method imposes strict requirements on both the geometry and electromagnetic properties of the test object, and it can only detect surface-level defects. As such, it is not applicable for inspecting the butt joint structures in fully multilayered high-pressure hydrogen storage vessels [

13,

14,

15,

16,

17]. In the application of multilayer hydrogen storage vessel inspection, conventional ultrasonic testing techniques present certain limitations. The widely used pulse reflecting technique suffers from limited sound field coverage and insufficiently intuitive imaging [

18]. Time of flight diffraction technique is susceptible to noise interference and lacks the ability to directly reconstruct defect morphology [

19]. Phased array ultrasonic testing (PAUT) is an innovation and improvement developed on the basis of conventional ultrasonic testing. Therefore, it not only retains the advantages of traditional ultrasonic testing, but also extends its applicability to the inspection of more complex structures [

20]. The most significant difference between PAUT and conventional ultrasonic testing lies in the probe design. By varying the arrangement of elements and precisely controlling the excitation timing of each element, PAUT enables the ultrasonic beam to be focused and steered within the inspected object, thereby achieving multiple forms of inspection. Nardo et al. developed an optimized phased array ultrasonic testing (PAUT) technique for the detection and sizing of hydrogen-induced cracking (HIC) type defects [

21]. De Zuniga et al. developed an ultrasonic phased array signal filtering system for thick austenitic stainless steel, which enables the selection of effective and usable weld inspection information, thereby improving the efficiency of ultrasonic phased array testing [

22]. Yin et al. developed a novel flexible ultrasonic phased array probe, which can be applied to inspection of objects with complex curved surfaces, and experimentally verified the effectiveness of this probe for imaging [

23].

When using ultrasonic technology to detect the butt joints of hydrogen storage containers, due to the special characteristics of the container structure, it is necessary to extend the phased array probe into the inner wall surface of the nozzles for detection [

24]. Several challenges are encountered during actual inspection. The distance between the acoustic excitation point and the target inspection area ranges from 100 mm to 120 mm, making defect detection and localization difficult; compared to conventional welds, butt joints have a more complex structure and a significantly thicker cross-section; the sound wave in the austenitic stainless steel attenuation is serious, affecting defect localization When the ultrasonic phased array inspection technology is applied to the inspection of butt joints of hydrogen storage vessels, no relevant research has been carried out for the crack defects in the critical positions of butt joints of hydrogen storage vessels. At the same time, due to the special characteristics of the structure of the full-multilayer high-pressure hydrogen storage vessel, it is difficult for the existing conventional phased array inspection technology to solve the problem of detecting such defects, especially at the service stage.

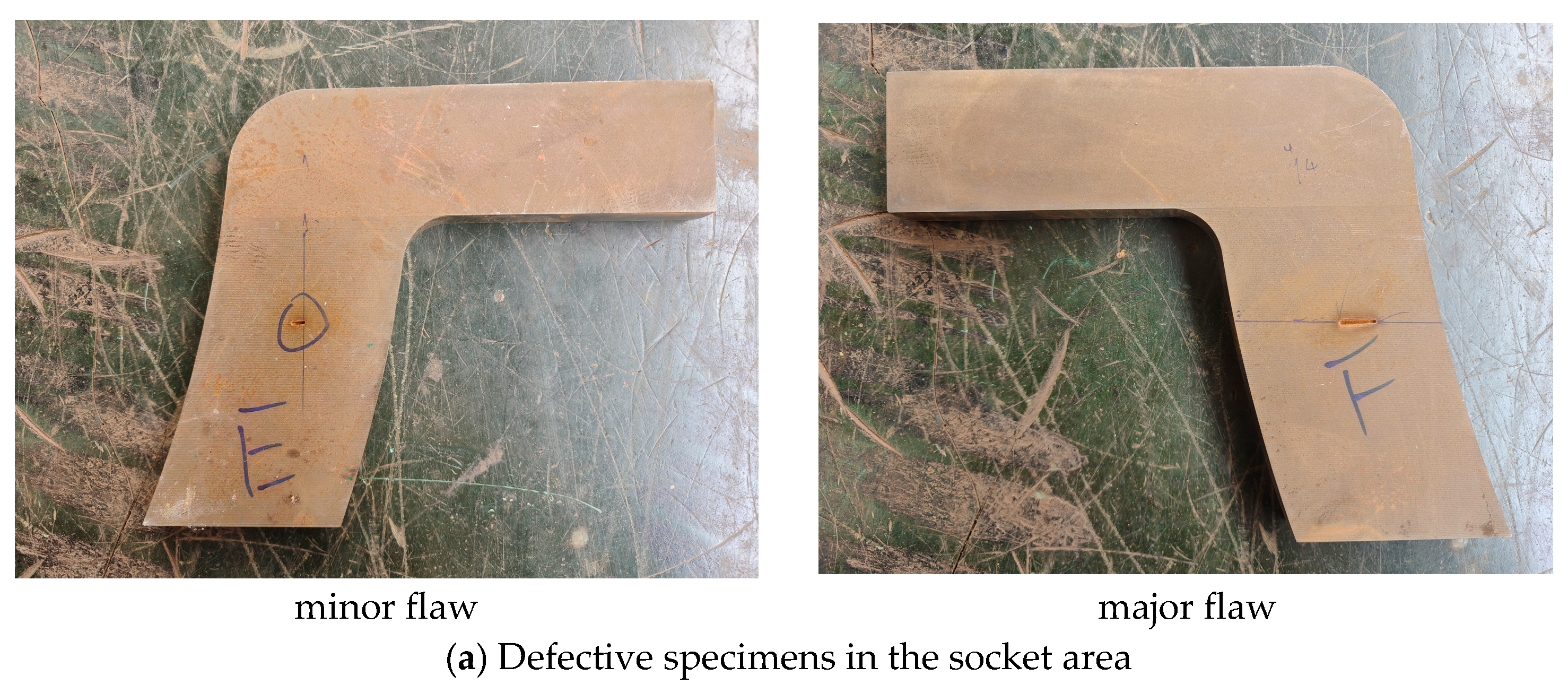

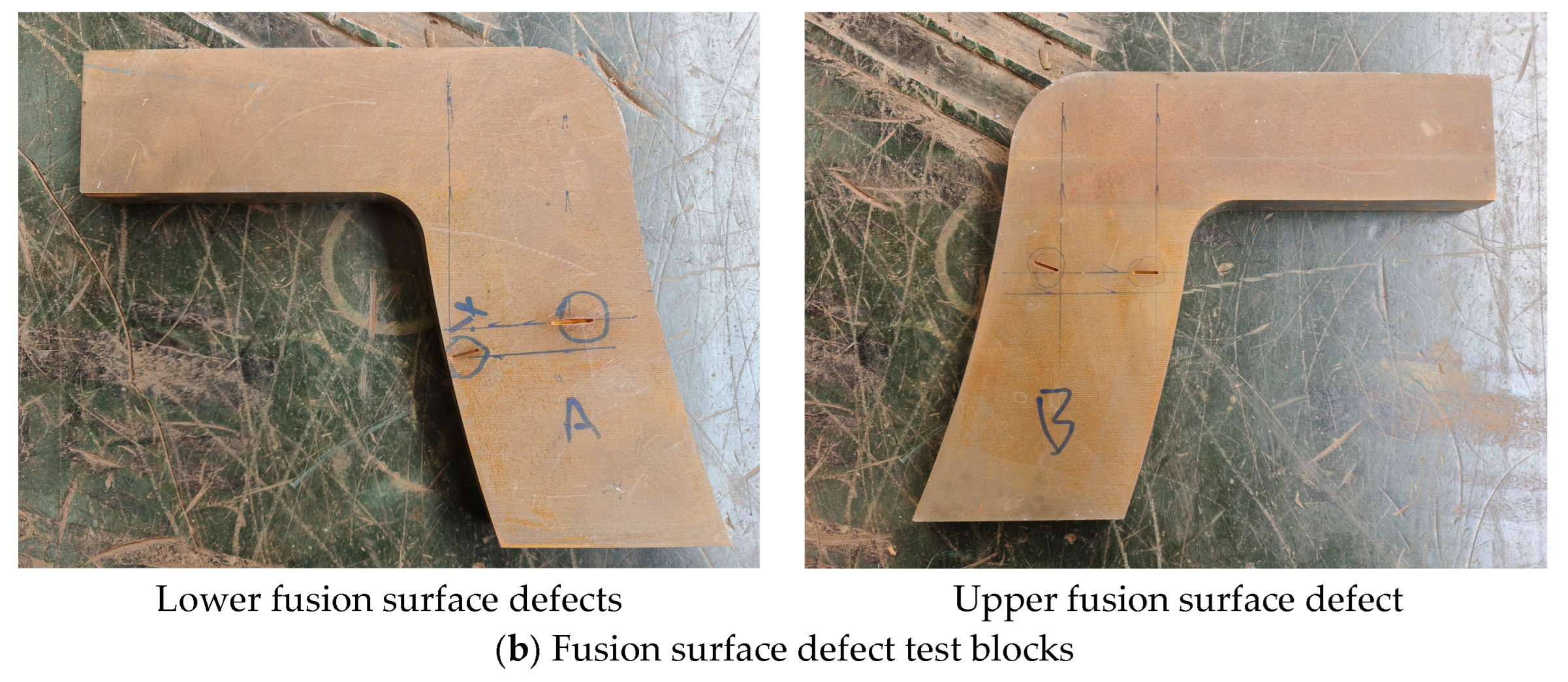

Therefore, this study developed a one-shot multi-receiver defect detection and localization method, based on finite element analysis of the interaction between ultrasonic waves and crack defects at key locations of butt joints, to achieve the localization of crack endpoints. Based on the experimental test blocks designed and fabricated, corresponding phased-array detection tests were carried out to validate the feasibility of the detection method.

2. One-Shot, Multi-Receiver Defect Location Method

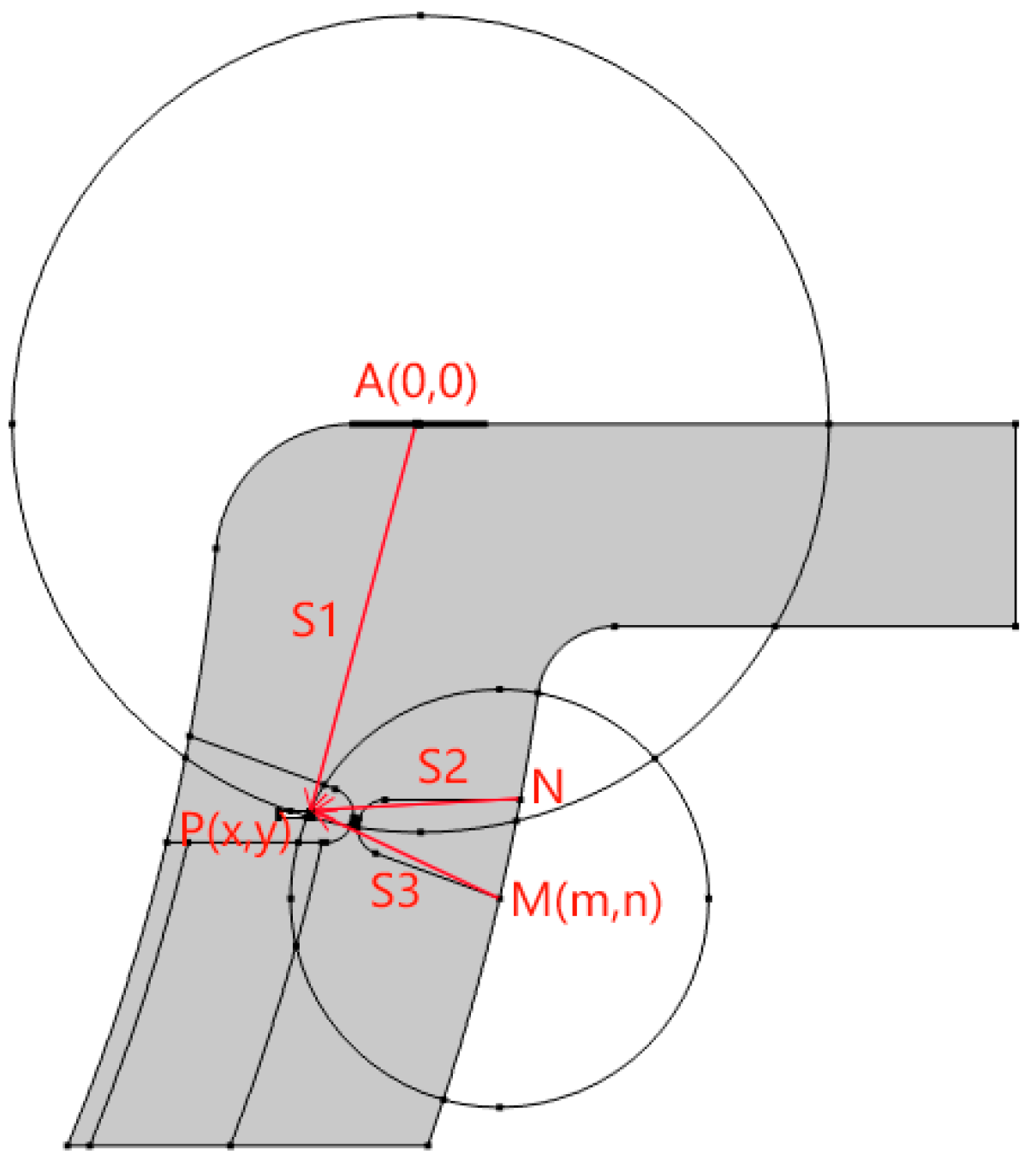

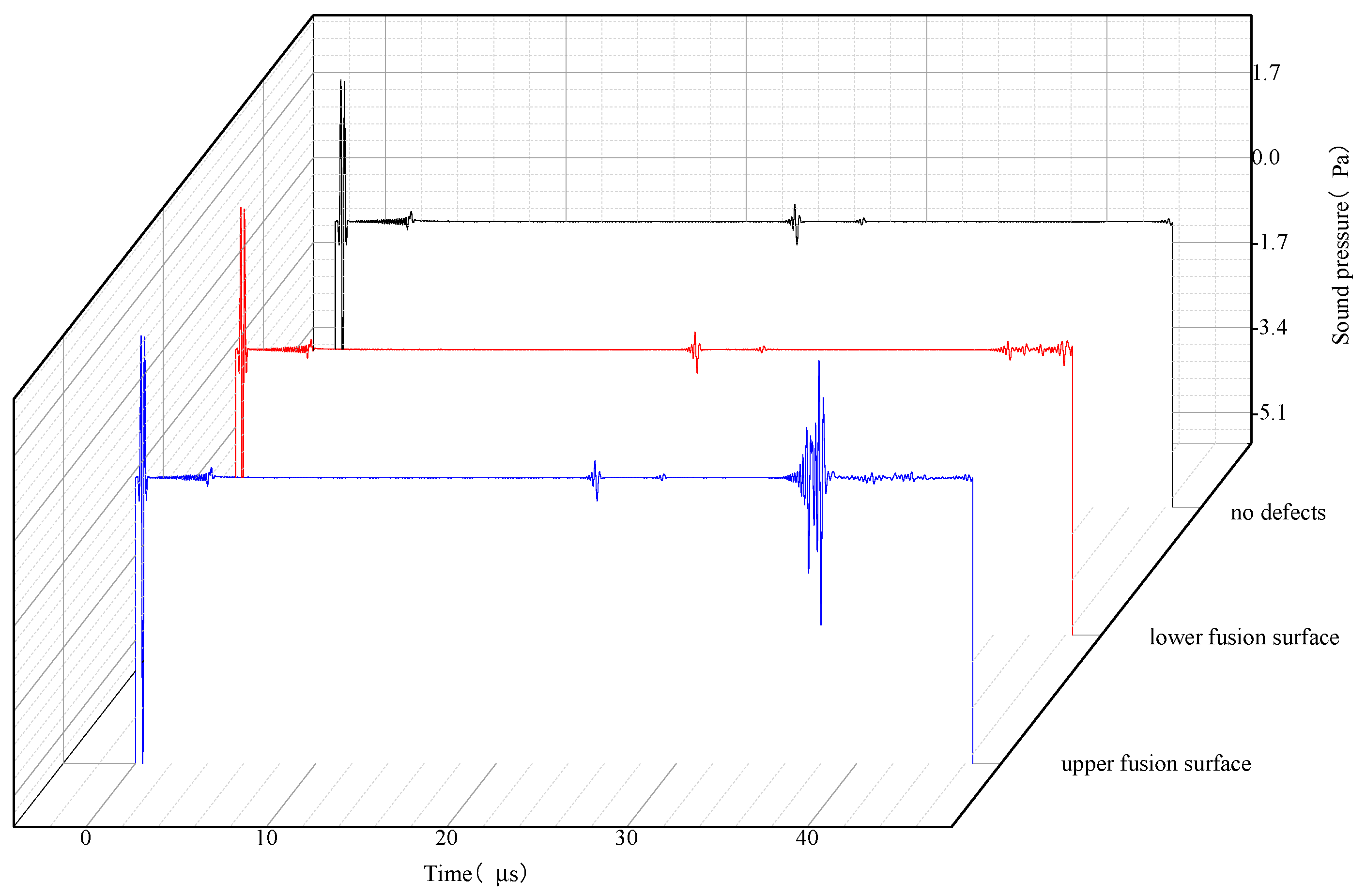

The hydrogen storage vessel head is made of austenitic stainless steel welded to Q345R, and the part to be inspected is the butt joint area with double U-bevels. It is known from previous studies that austenitic stainless steel has coarse grains and high acoustic attenuation coefficients, and the high attenuation, as well as the coarse grains, lead to more scattering. Therefore, a custom-made curved surface-coupled phased-array probe is placed on the inside of the nozzles, at point A as shown in

Figure 2, to achieve focusing and at the same time, a large-angle deflection can be realized without moving the probe, which can cover the whole area of the weld seam under this cross-section, in order to satisfy the detection demand in the radial direction. The surface-coupled phased array probe is placed on the inner surface of the nozzles as the transmitting and receiving probes, and is located in the deepest part where good coupling can be achieved; the second receiving probe is placed on the outer surface of the nozzles, between the surfaces MN, and the two points M and N are the two limit positions in this area. The surface-coupled phased array probe emits longitudinal waves on the inside of the nozzles, and waveform conversion occurs at the weld seam and defects, generating reflected and transmitted waves, which propagate to the surface-coupled phased array probe and the receiving probe located on the outside wall of the nozzles, and are received by the two probes. In the transmission and reception process, the acoustic wave travelled as shown in

Figure 2, the acoustic wave starts from point A and propagates to the defect at point P with a travel distance of S1, and then the defect echo propagates to the receiving probe with a travel distance of S1, S2 and S3, respectively, of which S2 and S3 are the travel distance of the defect echo propagating to the two limit positions.

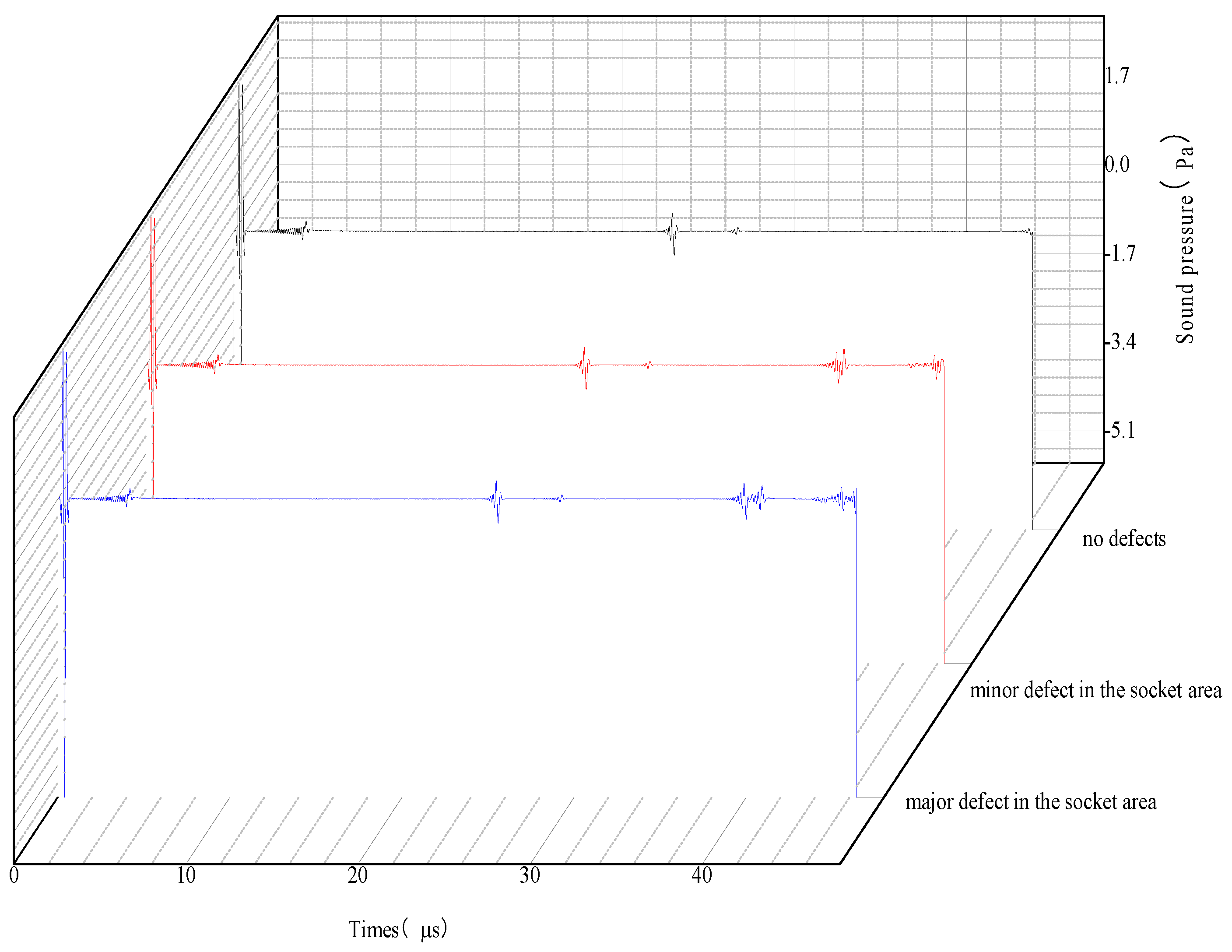

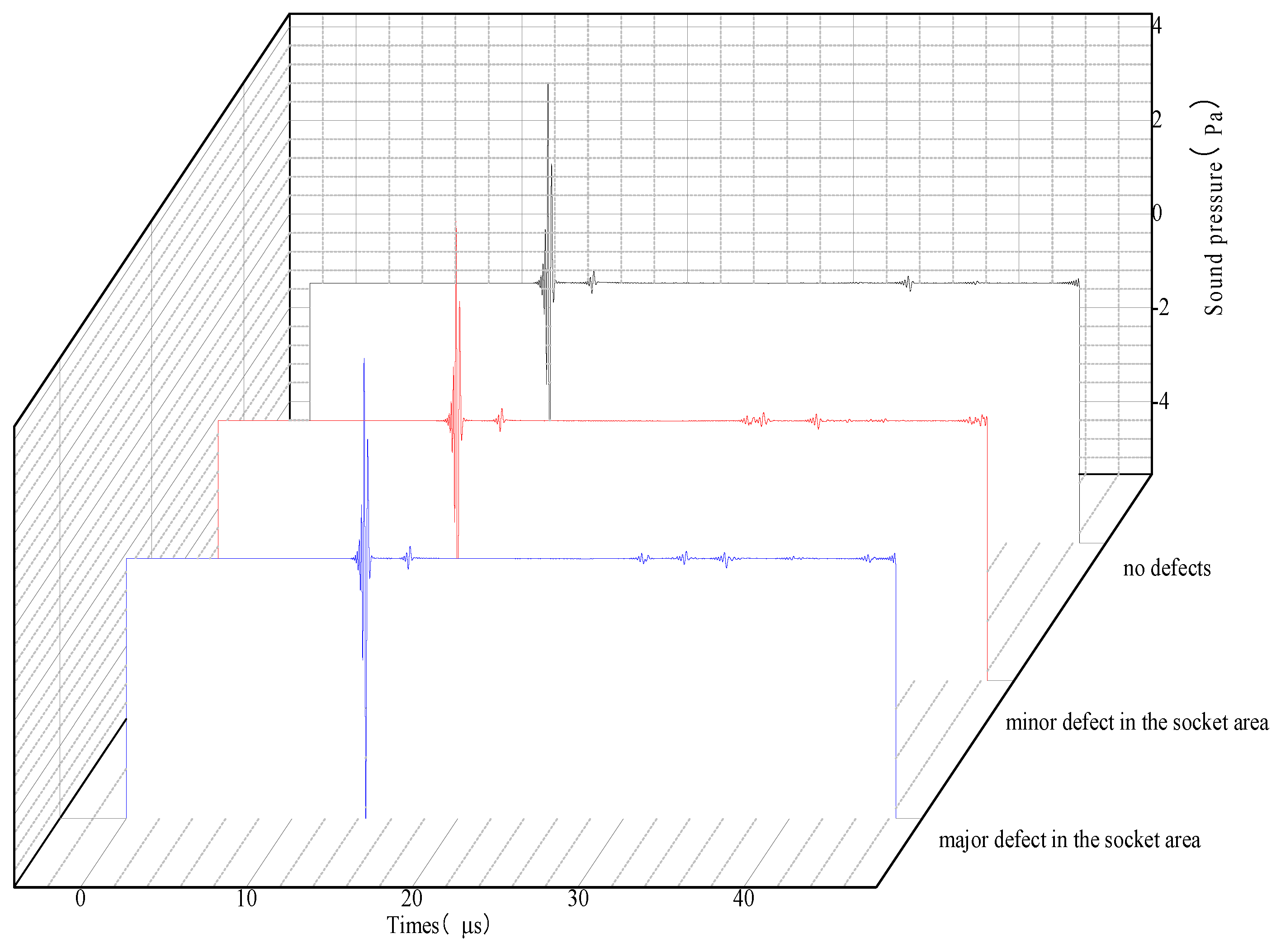

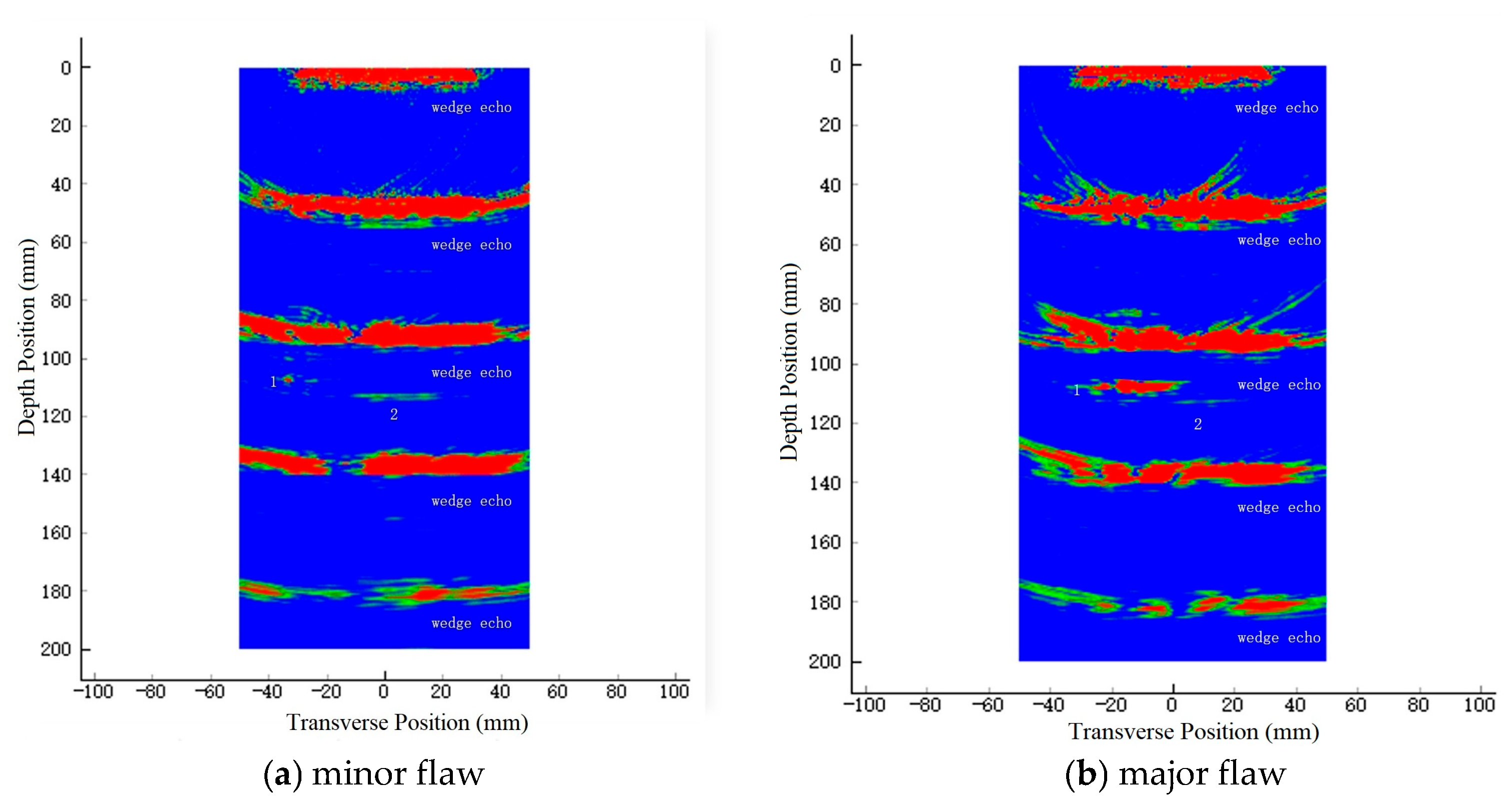

From the A-sweep signal integration of the synthetic acoustic beam, the waveforms of the excitation signal, the structural echo and the defect echo can be identified. Based on the time difference between the defect echo and the excitation signal, the distance S1 travelled by the excited ultrasonic wave propagating in the structure and returning from the defects to be picked up by the boundary probe can be calculated, and based on this distance, it can be determined that the defects are located in the circumference of a circle with the center point of the boundary probe as the center and S1 as the radius of the circle. Similarly, according to the point probe data can be determined to point probe position as the center of the circle, and the intersection of the two circles is the location of the defect. The key to the positioning of defects in the determination of ultrasonic propagation time, this paper through the excitation signal and defects in the peak echo point detection time value to determine.

The excitation and receiving probe center point A as the coordinate origin (0, 0), so the relative position of the second receiving probe M point is also determined, set to (m, n), defect point P is set to (x, y), so there are Equations (1) and (2):

The calculated distance S1 of the excited ultrasonic wave propagating in the structure and returning to the boundary probe when encountering the defect, and the distance S2 of the ultrasonic wave reflected from the defect to the point probe are, respectively, substituted into Formulas (1) and (2). The coordinates (m, n) of the point probe are known values, and the horizontal and vertical coordinate values of the defect point P can be solved by simultaneously establishing two binary equations.

The one-shot, multi-receiver defect location method places two receiving probes on the outer surface of the butt joint of a full multi-layer hydrogen storage vessel. In practical inspection applications, this method is relatively easy to implement without causing damage to the vessel itself. Moreover, processing the ultrasonic signals received by multiple probes enables more precise localization of defects.