Evaluation of Steam Channeling Severity Between Cyclic Steam Simulation Wells in Offshore Heavy Oil Reservoirs Based on Cloud Model and Improved AHP-CRITIC Method

Abstract

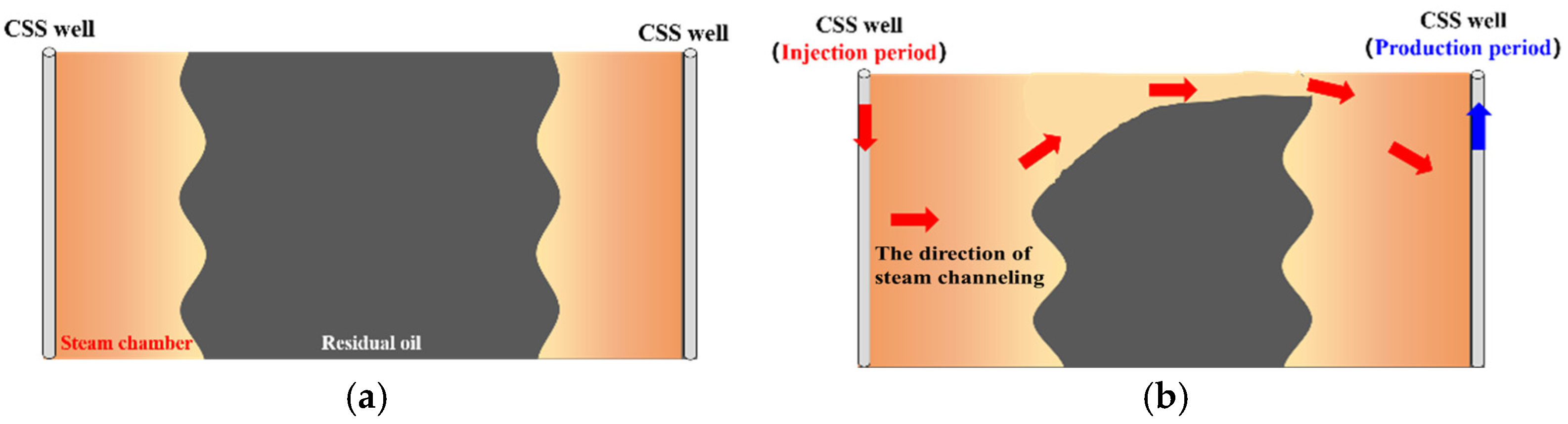

1. Introduction

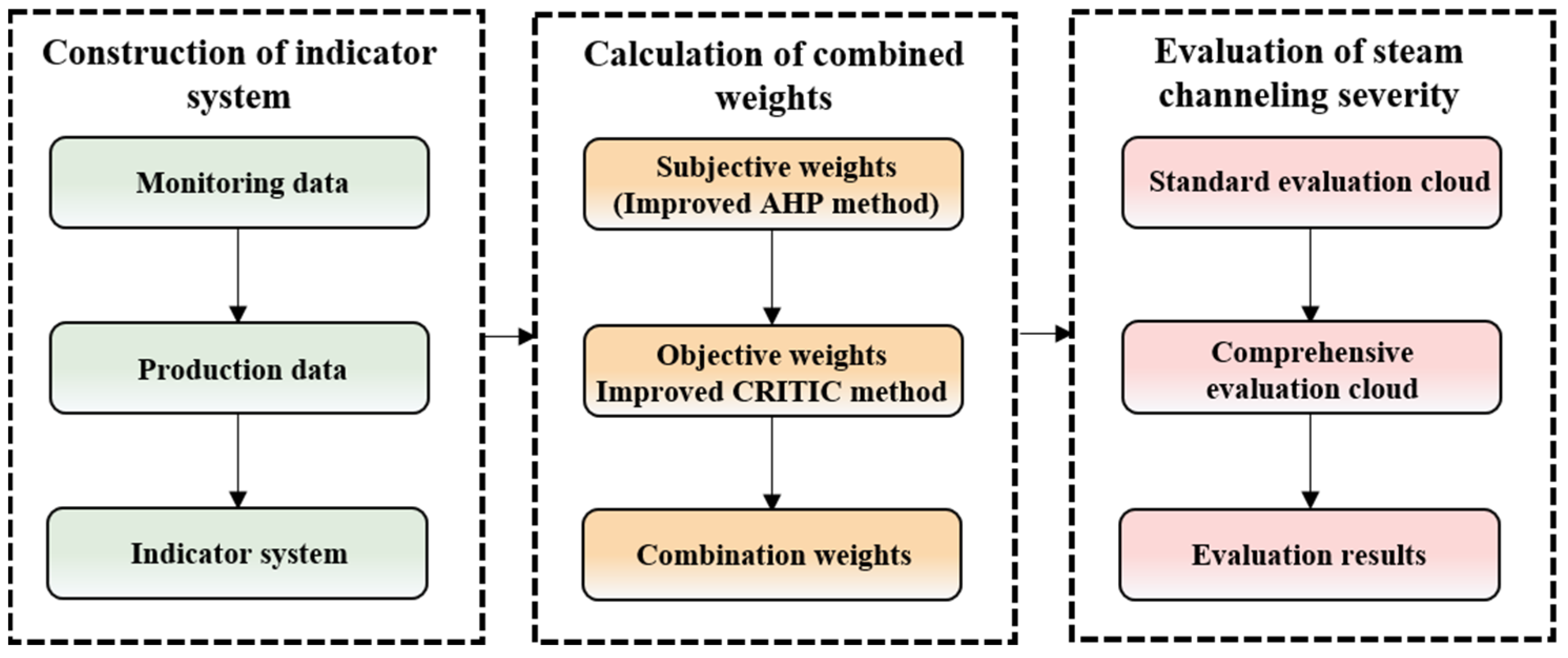

2. Methodology

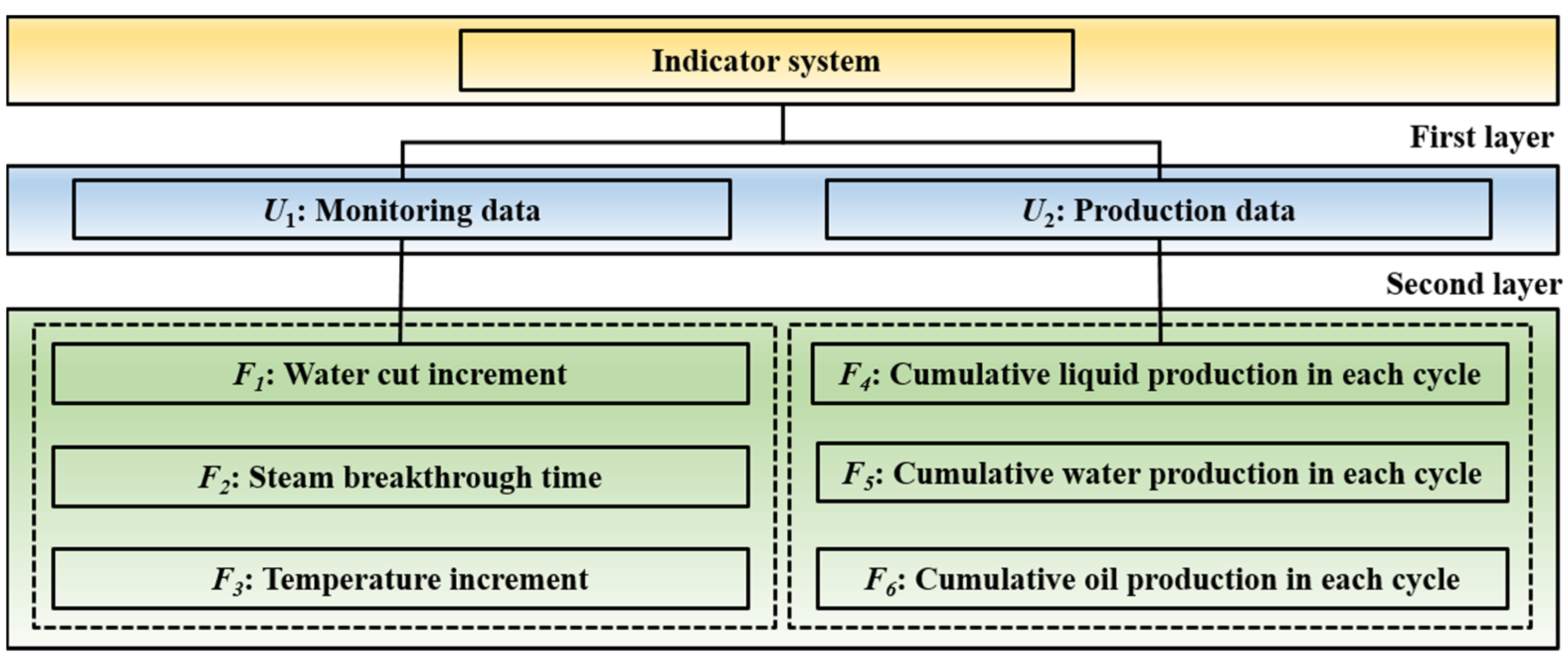

2.1. Construction of the Indicator System

2.2. Calculation of Combined Weights

2.2.1. Improved AHP (IAHP) Method

- (1)

- Construction of a judgment matrix A:

- (2)

- Construction of an antisymmetric matrix

- (3)

- Construction of the optimal transfer matrix

- (4)

- Construction of the optimization matrix:

- (5)

- Determination of the subjective weight of the i-th indicator ωi:

2.2.2. Improved CRITIC (ICRITIC) Method

- (1)

- Normalization of the dimensional heterogeneity among indicators

- (3)

- Calculation of the standard deviation σi of indicator gi and the correlation coefficient between indicators gi and gj.

- (4)

- Calculation of the information content Ci for indicator gi:

- (5)

- Calculation of the objective weight of indicator gi () as follows:

2.2.3. Combined Weights

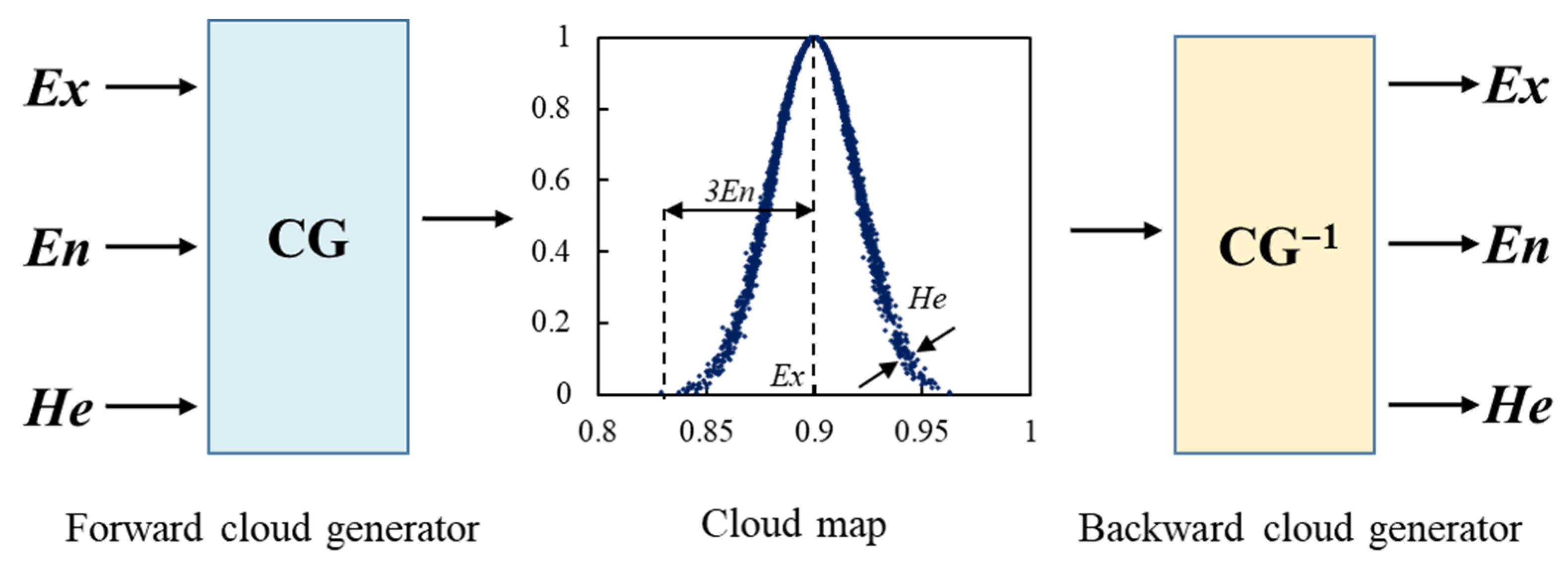

2.3. Construction of the Cloud Model

2.3.1. Cloud Model

- (1)

- Concept of the cloud model

- (2)

- Cloud generator

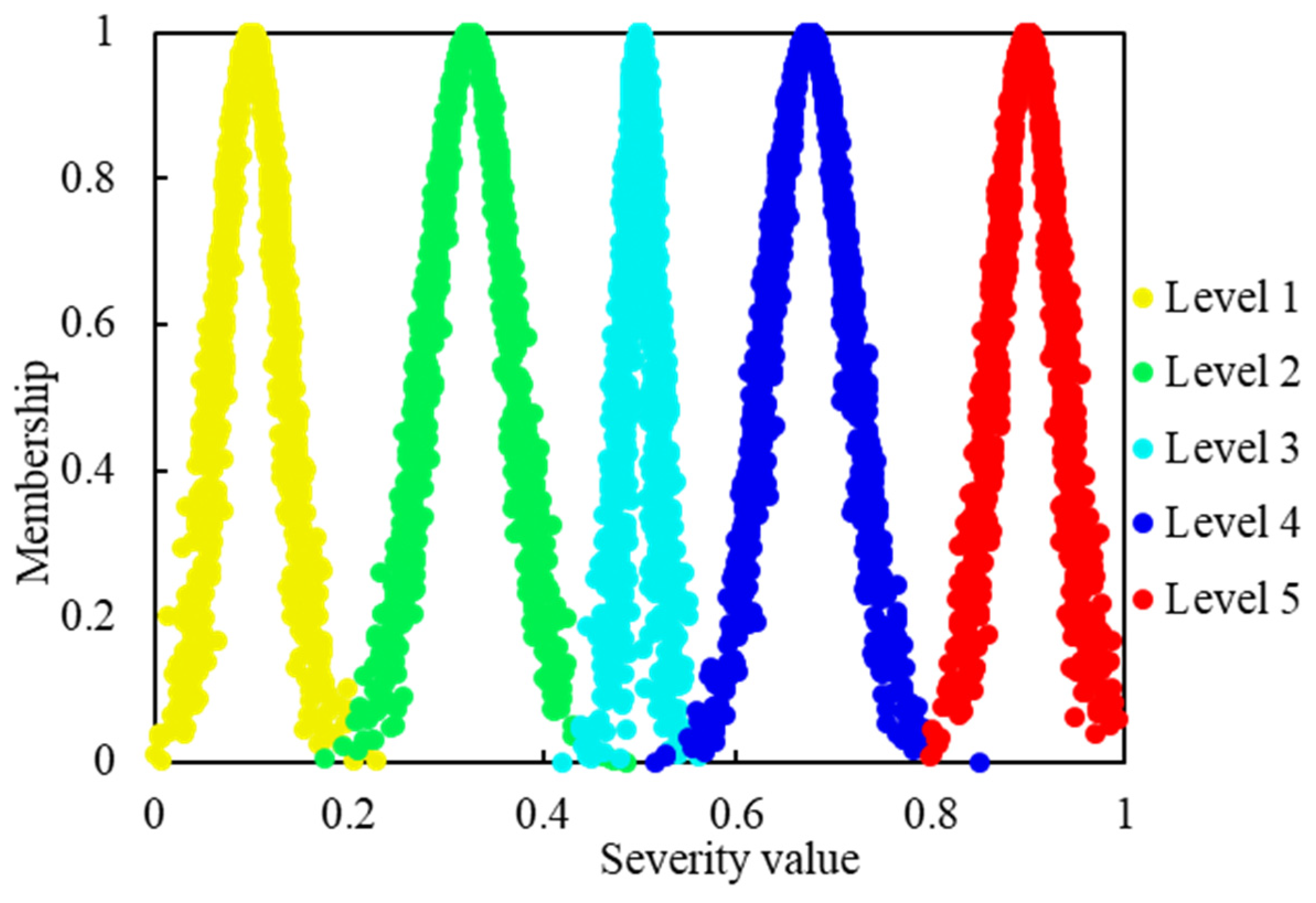

2.3.2. Standard Evaluation Cloud (SEC)

2.3.3. Comprehensive Evaluation Cloud (CEC)

3. Case Study

3.1. Data Collection

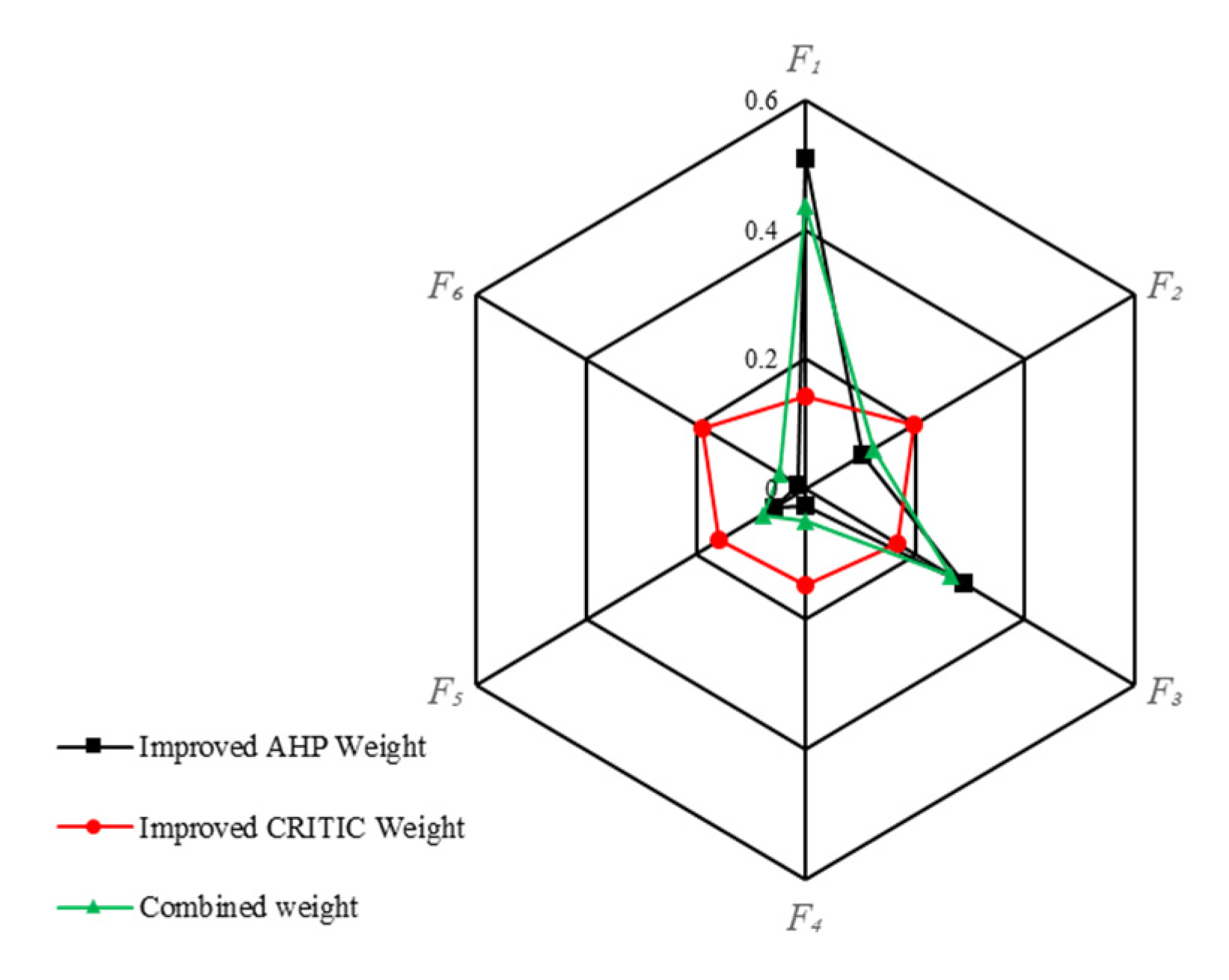

3.2. Calculation of Indicator Weights

3.3. Evaluation of the Steam Channeling Severity Between CSS Wells

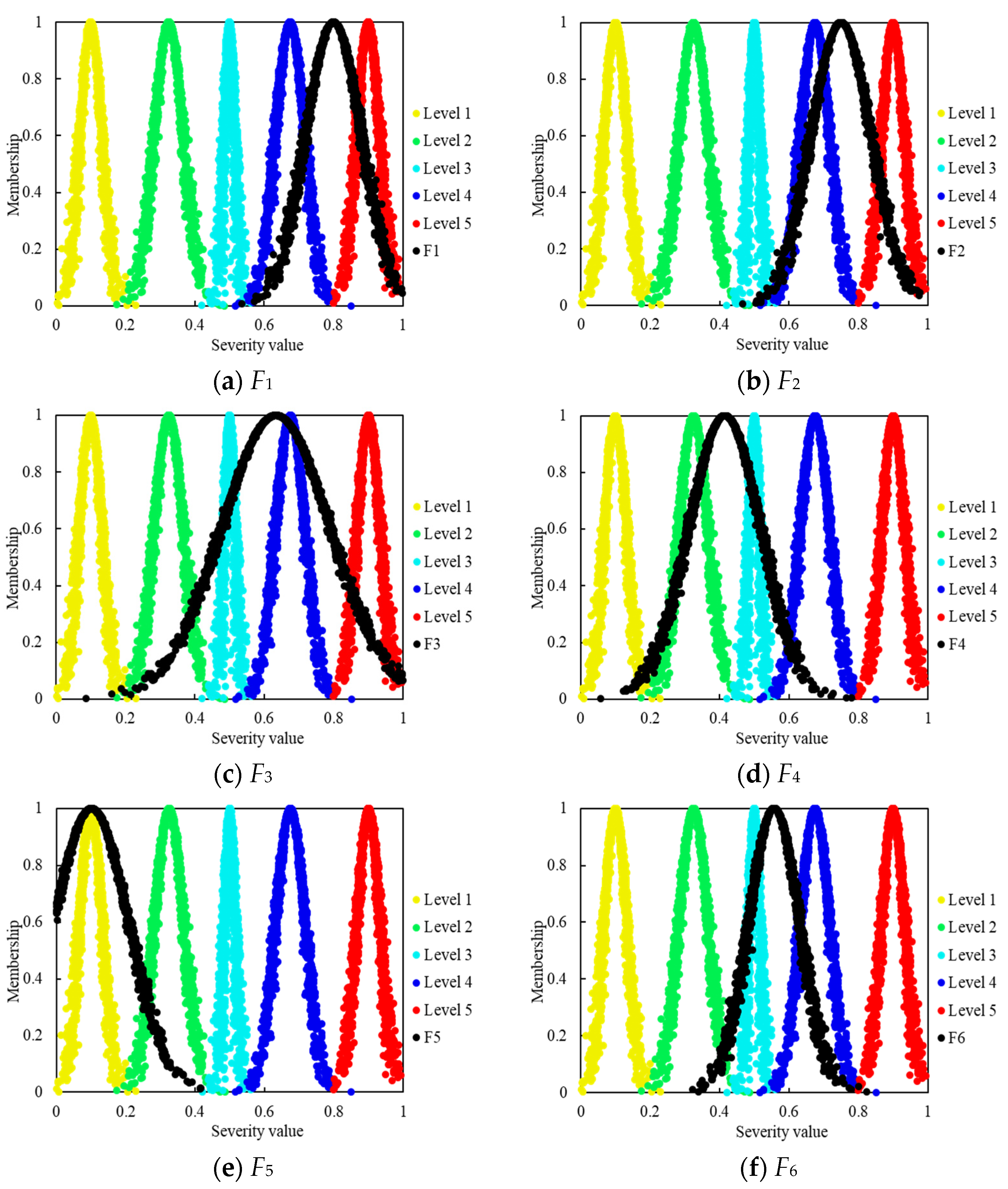

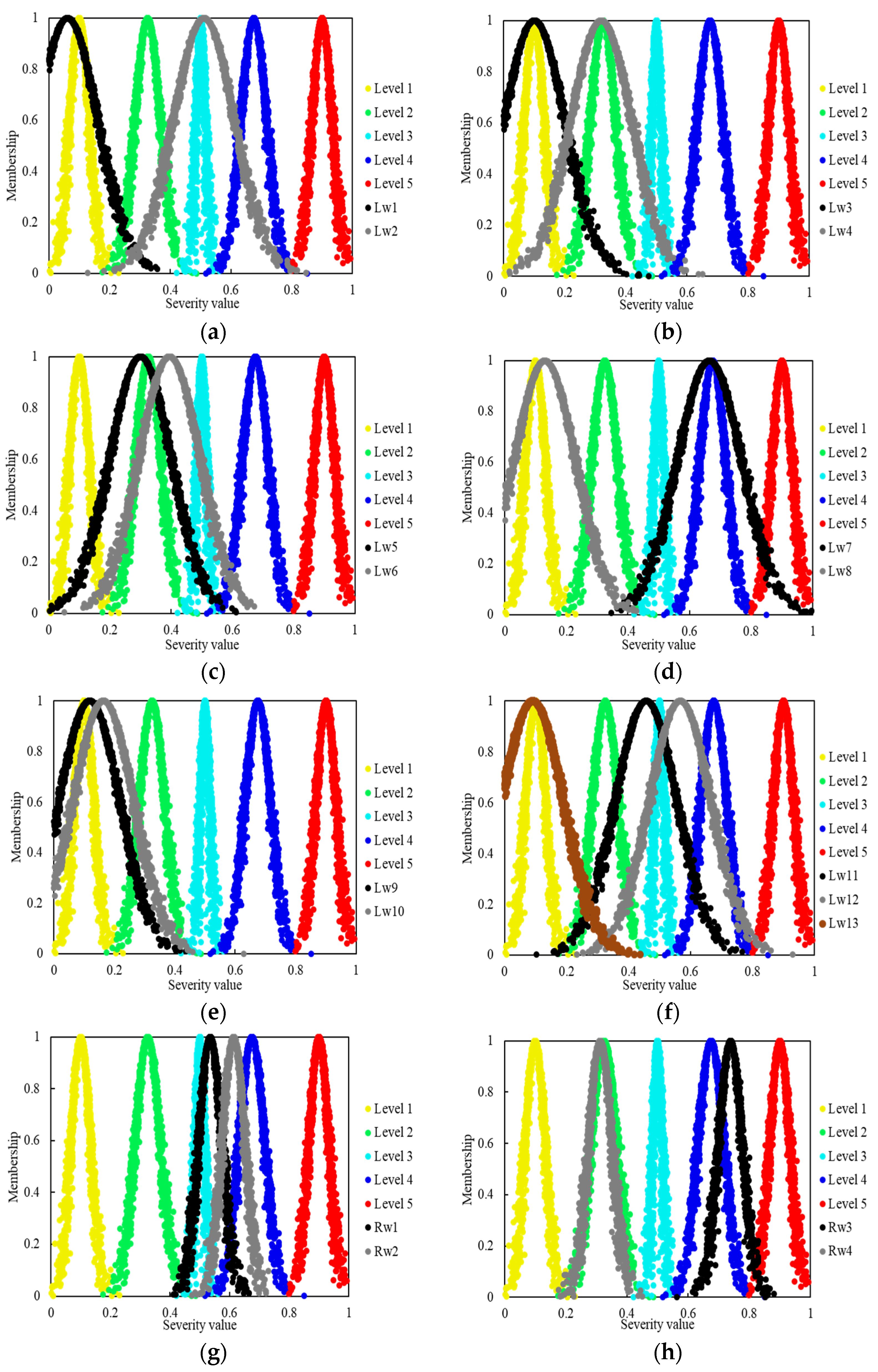

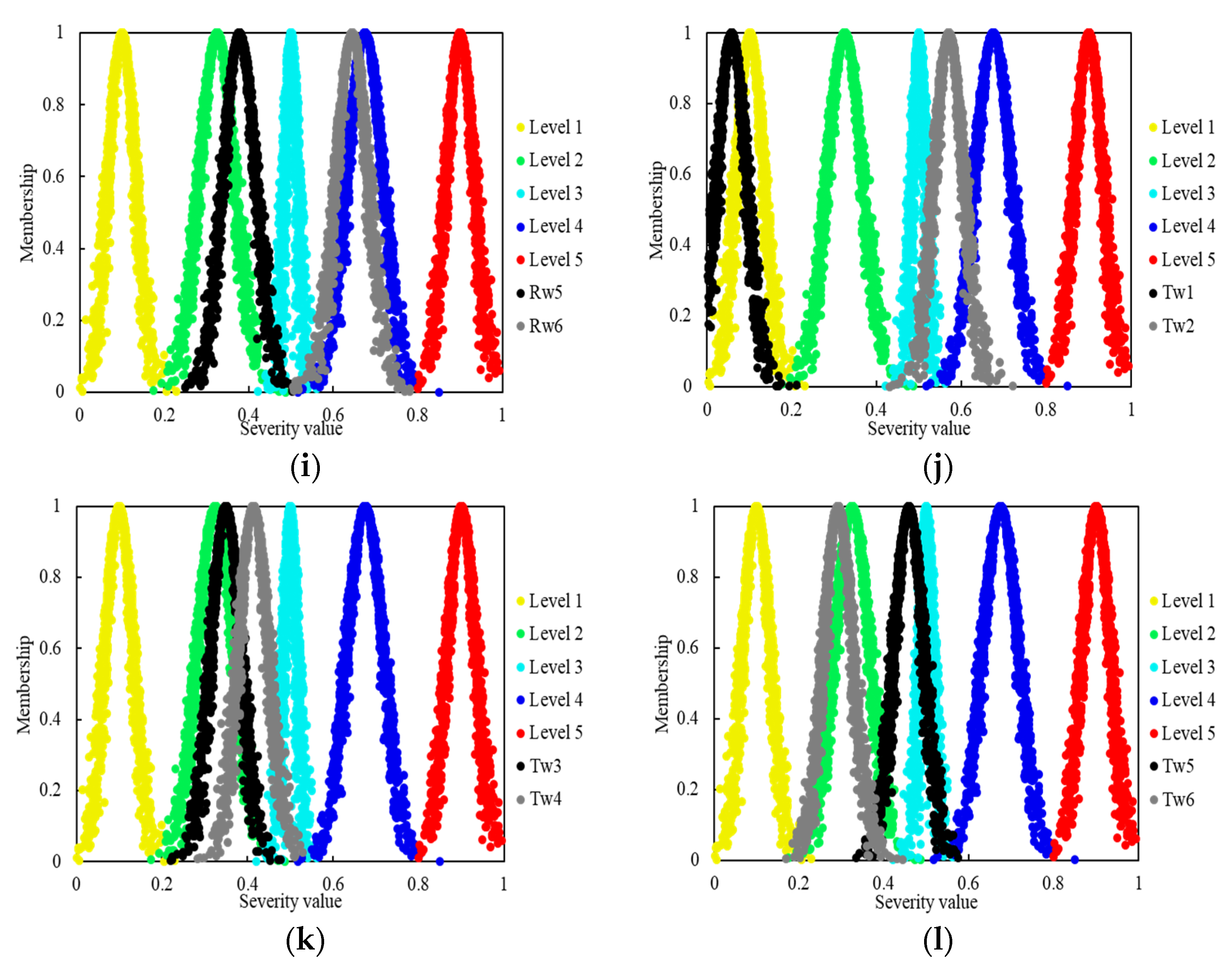

3.3.1. Evaluation Cloud Maps of the Indicators

3.3.2. Comprehensive Evaluation Cloud Maps

3.4. Validation of the Evaluation Results

4. Conclusions and Discussion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CSS | Cyclic steam stimulation |

| AHP | Analytic hierarchy process |

| IAHP | Improved analytic hierarchy process |

| CRITIC | Criteria importance through intercriteria correlation |

| ICRITIC | Improved criteria importance through intercriteria correlation |

| AHP-CRITIC | Analytic hierarchy process–criteria importance through intercriteria correlation |

| IAHP-CRITIC | Improved analytic hierarchy process–criteria importance through intercriteria correlation |

| CG | Forward cloud generator |

| CG-1 | Backward cloud generator |

| SEC | Standard evaluation cloud |

| CEC | Comprehensive evaluation cloud |

| U1,U2 | The indicators of the first layer |

| F1,F2,…,F6 | The indicators of the second layer |

| n | The indicator number |

| A | Judgment matrix |

| i | Variable |

| j | Variable |

| aij | The relative importance of the i-th indicator compared to the j-th indicator |

| Wi, Wj | The relative distributions of the i-th and j-th indicators, respectively |

| B | The antisymmetric matrix B derived from matrix A |

| bij | The value of the common logarithm of aij |

| cij | The cij is determined on the basis of bij |

| C | The optimal transfer matrix |

| The optimization matrix | |

| The is determined based on cij | |

| ωi | The subjective weight of the i-th indicator |

| m | The number of CSS wells |

| The standardized indicator data | |

| The matrix of the standardized indicator data | |

| δi | The information entropy |

| l | Variable |

| σi | The standard deviation of the i-th indicator |

| The correlation coefficient between indicators gi and gj | |

| The average values of the i-th indicator | |

| Ci | The information content for the i-th indicator |

| The objective weight of the i-th indicator | |

| The combined weights of the i-th indicator | |

| φ | Constant |

| Exs, Ens, Hes | The cloud parameters of the standard evaluation cloud |

| s | Variable |

| a, b | The left and right boundaries of the value ranges of each indicator |

| c, d | The left and right boundaries of the value ranges for the Level s |

| hil | The values of the i-th indicator for the l-th CSS well before cloud transformation |

| Hil | The values of the i-th indicator for the l-th CSS well after cloud transformation |

| The average value of the i-th indicator for all the CSS wells | |

| Ex, En, He | The cloud parameters of the comprehensive evaluation cloud |

| Exi, Eni, Hei | The cloud parameters of the evaluation cloud for the i-th indicator |

| Es | The preliminary similarity |

| Ts | The final similarity |

| xp, Zx, Ens’ | The normal random numbers determined by the cloud parameters of the CEC and SEC for level s |

References

- Pang, Z.-X.; Wang, Q.H.; Meng, Q.; Wang, B.; Liu, D. The mechanisms of thermal solidification agent promoting steam diversion in heavy oil reservoirs. Pet. Sci. 2024, 21, 1902–1914. [Google Scholar] [CrossRef]

- He, H.F.; Li, Q.; Zheng, H.R.; Liu, P.C.; Tang, J.S.; Ma, Y.N. Simulation and evaluation on enhanced oil recovery for steam huff and puff during the later phase in heavy oil reservoir—A case study of block G in Liaohe oilfield, China. J. Pet. Sci. Eng. 2022, 219, 111092. [Google Scholar] [CrossRef]

- Dong, X.H.; Liu, H.Q.; Chen, Z.X.; Wu, K.L.; Lu, N.; Zhang, Q.C. Enhanced oil recovery techniques for heavy oil and oilsands reservoirs after steam injection. Appl. Energy 2019, 239, 1190–1211. [Google Scholar] [CrossRef]

- Wang, Z.J.; Du, H.W.; Li, S.R.; Li, S.P. Experimental study on gas-assisted cyclic steam stimulation under heavy-oil sandstone reservoir conditions: Effect of N2/CO2 ratio and foaming agent. Geoenergy Sci. Eng 2023, 228, 211976. [Google Scholar] [CrossRef]

- Wang, Y.Z.; Liu, H.Q.; Pang, Z.X.; Gao, M. Visualization study on plugging characteristics of temperature-resistant gel during steam flooding. Energy Fuels 2016, 30, 6968–6976. [Google Scholar] [CrossRef]

- Pratama, R.A.; Babadagli, T. Effect of temperature, phase change, and chemical additives on wettability alteration during steam applications in sands and carbonates. SPE Reserv. Eval. Eng. 2020, 23, 292–310. [Google Scholar] [CrossRef]

- Sun, L.X. Xinqian 45 block steam channeling characteristics and genetic analysis of heavy oil steam stimulation. Sichuan Univ. Arts Sci. J. 2012, 5, 54–58. [Google Scholar]

- Li, Y.; Liu, H.Q.; Jiao, P.; Wang, Q.; Liu, D.; Ma, L.Y.; Wang, Z.P.; Peng, H. Machine-learning-assisted identification of steam channeling after cyclic steam stimulation in heavy-oil reservoirs. Geofluids 2023, 1, 1–13. [Google Scholar] [CrossRef]

- Zheng, Q.; Liu, H.Q.; Li, F.; Wang, Q.; Wang, C.J.; Lu, C. Quantitative description of steam channels after steam flooding. Sci. China Technol. Sci 2013, 56, 1164–1168. [Google Scholar] [CrossRef]

- Zheng, J.P.; Dong, X.H.; Liu, H.G.; Sun, R.; Wei, X.G. Study on the characteristics of steam breakthrough during steam injection in heavy oil reservoirs. Spec. Oil Gas Reserv. 2012, 6, 72–75. [Google Scholar]

- Li, D.Y.; Liu, C.Y.; Liu, L.Y. Study on the universality of the normal cloud model. Eng. Sci. 2005, 2, 18–24. [Google Scholar]

- Chen, Z.Y.; Liang, G.H.; Chen, Y.X.; Yang, X.Y.; Liu, Y. Study on the risk assessment of pedestrian-vehicle conflicts in channelized right-turn lanes based on the hierarchical-grey entropy-cloud model. Accid. Anal. Prev. 2024, 205, 107664. [Google Scholar] [CrossRef]

- Wen, X.X.; Nie, Y.; Du, Z.X.; Huang, L.K. Operational safety assessment of straddle-type monorail vehicle system based on cloud model and improved CRITIC method. Eng. Fail. Anal. 2022, 139, 106463. [Google Scholar] [CrossRef]

- Zhang, X.T.; Fang, S.F.; Jin, Y.C.; Huang, Y.; Wang, S.C.; Wang, J.; Xu, Y.H. Comprehensive performance evaluation of valuable medical equipment based on cloud modelling and combined weighting methodologies. Eng. Appl. Artif. Intell. 2025, 154, 110969. [Google Scholar] [CrossRef]

- Pang, Z.X.; Wang, L.T.; Yin, F.H.; Lyu, X.C. Steam chamber expanding processes and bottom water invading characteristics during steam flooding in heavy oil reservoirs. Energy 2021, 234, 121214. [Google Scholar] [CrossRef]

- Cheng, C.; Chen, Y.; Li, T.Y. An AHP Method for Road Traffic Safety. In Proceedings of the 2011 Fourth International Joint Conference on Computational Sciences and Optimization, Kunming and Lijiang City, China, 15–19 April 2011. [Google Scholar]

- Tagavifar, M.; Fortenberry, R.; Rouffignac, E.; Sepehrnoori, K.; Pope, G.A. Heavy-oil recovery by combined hot water and alkali/cosolvent/polymer flooding. SPE J. 2016, 21, 74–86. [Google Scholar] [CrossRef]

- Ayağ, Z.; Özdemir, R.G. A fuzzy AHP approach to evaluating machine tool alternatives. J. Intell. Manuf. 2006, 17, 179–190. [Google Scholar] [CrossRef]

- Wang, W.Q.; Fang, S.E. A Multi-Level Gray and Fuzzy Comprehensive Evaluation of Road Traffic Safety Management Facilities. In Proceedings of the 2009 Second International Conference on Intelligent Computation Technology and Automation, Changsha, China, 10–11 October 2009. [Google Scholar]

- Lu, X.Q.; Zhou, X.; Luo, J.X.; Zeng, F.H.; Peng, X.L. Characterization of foamy oil and gas/oil two-phase flow in porous media for a heavy oil/methane system. J. Energy Resour. Technol. 2018, 141, 032801. [Google Scholar] [CrossRef]

- Wu, Z.B.; Liu, H.Q.; Wang, X. Adaptability research of thermal–chemical assisted steam injection in heavy oil reservoirs. J. Energy Resour. Technol. 2017, 140, 052901. [Google Scholar] [CrossRef]

- Fattore, M. Synthesis of indicators: The non-aggregative approach. Social Indic. Res. 2017, 70, 193–212. [Google Scholar]

- Xie, J.J.; Li, J.X.; Sun, Q. Multidimensional evaluation of the clinical efficacy and potential mechanisms of acupuncture combined with rehabilitation training in the treatment of stroke: A study based on multiple evaluation indicators. Front. Neurol. 2025, 16, 1573073. [Google Scholar] [CrossRef]

- Saaty, R.W. The analytic hierarchy process—What it is and how it is used. Math. Modell. 1987, 9, 161–176. [Google Scholar] [CrossRef]

- Yu, Y. Study on Evaluation of Nanchong Ecological Civilization Construction Based on AHP-Entropy Method. In Proceedings of the 2016 2nd International Conference on Education Technology, Management and Humanities Science, Beijing, China, 23–24 January 2016. [Google Scholar]

- Liu, G.C.; Li, G.J.; Yang, L.N. Risk assessments of debris flow based on improved analytic hierarchy process and efficacy coefficient method. Glob. Geol. 2012, 15, 231–236. [Google Scholar]

- Zheng, X.Y.; Liu, Q.; Li, Y.F.; Wang, B.; Qin, W.T. Safety risk assessment for connected and automated vehicles: Integrating FTA and CM-Improved AHP. Reliab. Eng. Syst. Safty 2025, 257, 110822. [Google Scholar] [CrossRef]

- Yang, J.J.; Wan, Q.L.; Han, J.H.; Xing, S.S. An evaluation model for automobile intelligent cockpit comfort based on improved combination weighting-cloud model. PLoS ONE 2023, 18, e0282602. [Google Scholar] [CrossRef]

- Lu, J.H.; Xu, J.X. Application of Fuzzy Comprehensive Evaluation Model Based on Analytic Hierarchy Process for Rural Drinking Water. In Proceedings of the 2011 5th International Conference on Bioinformatics and Biomedical Engineering, Wuhan, China, 10–12 May 2011. [Google Scholar]

- Huang, H.D.; Xue, Y.H.; Zhu, L.B.; Cui, C.C. Information entropy evaluation method for the disassemblability of smartphones. Procedia CIRP 2024, 127, 212–217. [Google Scholar] [CrossRef]

- Ishizaka, A.; Labib, A. Review of the main developments in the analytic hierarchy process. Expert Syst. Appl. 2011, 38, 14336–14345. [Google Scholar] [CrossRef]

- Cui, C.Q.; Wang, B.; Zhao, Y.X.; Zhang, Y.J.; Xue, L.M. Risk management for mine closure: A cloud model and hybrid semi-quantitative decision method. Int. J. Miner. Metall. Mater. 2020, 8, 1021–1035. [Google Scholar] [CrossRef]

- Shi, L.; Shuai, J.; Xu, K. Fuzzy fault tree assessment based on improved AHP for fire and explosion accidents for steel oil storage tanks. J. Hazard. Mater. 2014, 278, 529–538. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.B.; Liu, D.Q.; Zhang, Z.P.; Wang, S.T.; Wang, Q.; Xia, D.H. Steam channeling control in the steam flooding of super heavy oil reservoirs, Shengli oilfield. Pet. Explor. Dev. 2012, 39, 785–790. [Google Scholar] [CrossRef]

- Ali, M.H.; Zakaria, M.; El-Tawab, S. A comprehensive study of recent maximum power point tracking techniques for photovoltaic systems. Sci. Rep. 2025, 15, 14269. [Google Scholar] [CrossRef] [PubMed]

| Severity Levels | Value Ranges | Exs | Ens | Hes | Instructions |

|---|---|---|---|---|---|

| 1 | [0, 0.2] | 0.1 | 0.033 | 0.005 | No steam channeling |

| 2 | (0.2, 0.45] | 0.325 | 0.042 | 0.005 | Weak steam channeling |

| 3 | (0.45, 0.55] | 0.5 | 0.016 | 0.005 | Moderate steam channeling |

| 4 | (0.55, 0.8] | 0.675 | 0.042 | 0.005 | Strong steam channeling |

| 5 | (0.8, 0.1] | 0.9 | 0.033 | 0.005 | Extremely strong steam channeling |

| Indicators | Value Ranges | ||||

|---|---|---|---|---|---|

| No Steam Channeling | Weak Steam Channeling | Moderate Steam Channeling | Strong Steam Channeling | Extremely Strong Steam Channeling | |

| F1/% | 0 ≤ F1 < 0.1 | 0.1 ≤ F1 < 0.2 | 0.2 ≤ F1 < 0.3 | 0.3 ≤ F1 < 0.6 | F1 ≥ 0.6 |

| F2/day | 100 > F2 ≥ 60 | 60 > F2 ≥ 30 | 30 > F2 ≥ 10 | 10 > F2 ≥ 5 | 5 > F2 ≥ 0 |

| F3/°C | 0 ≤ F3 < 10 | 10 ≤ F3 < 20 | 20 ≤ F3 < 30 | 30 ≤ F3 < 55 | 55 ≤ F3 < 200 |

| F4/×104 m3 | 0 < F4 < 2.5 | 2.5 ≤ F4 < 3 | 3 ≤ F4 < 3.5 | 3.5 ≤ F4 < 4 | 4 ≤ F4 < 8 |

| F5/×104 m3 | 0 < F5 < 1 | 1 ≤ F5 < 1.5 | 1.5 ≤ F5 < 2 | 2 ≤ F5 < 3 | 3 ≤ F5 < 8 |

| F6/×104 m3 | 2.5 > F6 ≥ 1.5 | 1.5 > F6 ≥ 1.4 | 1.4 > F6 ≥ 1.3 | 1.1 > F6 ≥ 1 | 1 > F6 ≥ 0 |

| Reservoir Names | Well Names | F1/% | F2/Day | F3/°C | F4/×104 m3 | F5/×104 m3 | F6/×104 m3 |

|---|---|---|---|---|---|---|---|

| L | Lw1 | 0 | 100 | 0 | 2.63 | 1.46 | 1.17 |

| Lw2 | 20 | 10 | 35 | 3.49 | 2.38 | 1.11 | |

| Lw3 | 3 | 100 | 0 | 6.24 | 5.45 | 0.78 | |

| Lw4 | 2 | 21 | 40 | 3.62 | 2.76 | 0.85 | |

| Lw5 | 3 | 30 | 20 | 8.19 | 5.86 | 2.32 | |

| Lw6 | 2 | 7 | 50 | 4.9 | 2.64 | 2.26 | |

| Lw7 | 60 | 6 | 40 | 2.93 | 0.9 | 2.02 | |

| Lw8 | 3 | 100 | 0 | 8.52 | 4.29 | 4.23 | |

| Lw9 | 3 | 100 | 0 | 4.34 | 3.01 | 1.33 | |

| Lw10 | 15 | 100 | 0 | 1.98 | 0.94 | 1.04 | |

| Lw11 | 20 | 4 | 0 | 1.74 | 0.64 | 1.09 | |

| Lw12 | 30 | 6 | 0 | 2.95 | 1.13 | 1.81 | |

| Lw13 | 3 | 100 | 0 | 3.48 | 2.2 | 1.28 | |

| R | Rw1 | 24 | 14 | 28 | 5.65 | 4.4 | 1.25 |

| Rw2 | 34 | 8 | 36 | 6.06 | 4.58 | 1.48 | |

| Rw3 | 55 | 5 | 49 | 7.82 | 5.87 | 1.95 | |

| Rw4 | 11 | 25 | 12 | 3.5 | 2.47 | 1.03 | |

| Rw5 | 12 | 20 | 16 | 4.05 | 2.65 | 1.4 | |

| Rw6 | 37 | 6 | 39 | 6.42 | 4.72 | 1.7 | |

| T | Tw1 | 0 | 100 | 0 | 2.54 | 1.51 | 1.03 |

| Tw2 | 31 | 14 | 28 | 5.96 | 4.41 | 1.55 | |

| Tw3 | 12 | 25 | 13 | 3.9 | 2.55 | 1.35 | |

| Tw4 | 15 | 19 | 16 | 4.61 | 3.34 | 1.27 | |

| Tw5 | 16 | 18 | 23 | 4.74 | 3.49 | 1.25 | |

| Tw6 | 10 | 26 | 11 | 3.35 | 1.73 | 1.62 |

| Indicators | |||

|---|---|---|---|

| F1 | 1.884 | 0.2850 | 7.0207 |

| F2 | 2.4458 | 0.2945 | 9.6559 |

| F3 | 1.5714 | 0.3955 | 8.1033 |

| F4 | 2.2115 | 0.3221 | 7.2606 |

| F5 | 2.1909 | 0.3271 | 7.6908 |

| F6 | 2.0966 | 0.2710 | 9.2392 |

| Indicators | Exi | Eni | Hei |

|---|---|---|---|

| F1 | 0.8 | 0.0812 | 0.005 |

| F2 | 0.75 | 0.0867 | 0.005 |

| F3 | 0.63 | 0.1564 | 0.005 |

| F4 | 0.41 | 0.1038 | 0.005 |

| F5 | 0.1 | 0.107 | 0.005 |

| F6 | 0.55 | 0.0735 | 0.005 |

| Reservoir Names | Well Names | Cloud Parameters | Ts | The Severity Levels | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ex | En | He | Level 1 | Level 2 | Level 3 | Level 4 | Level 5 | |||

| L | Lw1 | 0.06 | 0.1005 | 0.005 | 2.2 × 10−1 | 1.6 × 10−2 | 4.6 × 10−138 | 1.1 × 10−12 | 1.5 × 10−54 | 1 |

| Lw2 | 0.51 | 0.1005 | 0.005 | 4.3 × 10−5 | 9.0 × 10−2 | 1.9 × 10−1 | 1.5 × 10−1 | 4.9 × 10−4 | 3 | |

| Lw3 | 0.10 | 0.1005 | 0.005 | 3.2 × 10−1 | 3.6 × 10−2 | 3.4 × 10−6 | 1.6 × 10−8 | 2.6 × 10−40 | 1 | |

| Lw4 | 0.32 | 0.1005 | 0.005 | 4.6 × 10−2 | 3.6 × 10−1 | 3.6 × 10−2 | 1.6 × 10−3 | 6.3 × 10−15 | 2 | |

| Lw5 | 0.30 | 0.1005 | 0.005 | 3.6 × 10−2 | 4.2 × 10−1 | 2.8 × 10−2 | 2.4 × 10−4 | 7.5 × 10−24 | 2 | |

| Lw6 | 0.39 | 0.1005 | 0.005 | 7.1 × 10−3 | 3.8 × 10−1 | 8.3 × 10−2 | 2.3 × 10−2 | 1.6 × 10−10 | 2 | |

| Lw7 | 0.66 | 0.1005 | 0.005 | 6.9 × 10−11 | 2.5 × 10−3 | 4.3 × 10−2 | 3.8 × 10−1 | 3.0 × 10−2 | 4 | |

| Lw8 | 0.13 | 0.1005 | 0.005 | 1.8 × 10−1 | 8.4 × 10−2 | 1.2 × 10−5 | 6.4 × 10−10 | 3.0 × 10−42 | 1 | |

| Lw9 | 0.12 | 0.1005 | 0.005 | 2.4 × 10−1 | 7.0 × 10−2 | 1.4 × 10−5 | 9.8 × 10−10 | 6.7 × 10−32 | 1 | |

| Lw10 | 0.16 | 0.1005 | 0.005 | 3.1 × 10−1 | 1.4 × 10−1 | 1.1 × 10−3 | 5.3 × 10−7 | 2.7 × 10−31 | 1 | |

| Lw11 | 0.46 | 0.1005 | 0.005 | 8.4 × 10−4 | 1.8 × 10−1 | 1.3 × 10−1 | 3.3 × 10−2 | 1.4 × 10−5 | 2 | |

| Lw12 | 0.57 | 0.1005 | 0.005 | 4.1 × 10−11 | 3.0 × 10−2 | 4.4 × 10−2 | 1.8 × 10−1 | 4.3 × 10−3 | 4 | |

| Lw13 | 0.09 | 0.1005 | 0.005 | 3.1 × 10−1 | 3.7 × 10−2 | 4.2 × 10−14 | 2.0 × 10−9 | 3.1 × 10−25 | 1 | |

| R | Rw1 | 0.53 | 0.0385 | 0.005 | 1.2 × 10−24 | 2.9 × 10−4 | 3.1 × 10−1 | 6.2 × 10−2 | 3.7 × 10−11 | 3 |

| Rw2 | 0.61 | 0.0385 | 0.005 | 6.1 × 10−21 | 1.6 × 10−7 | 4.0 × 10−3 | 4.5 × 10−1 | 1.2 × 10−8 | 4 | |

| Rw3 | 0.74 | 0.0385 | 0.005 | 1.8 × 10−74 | 1.0 × 10−18 | 3.9 × 10−23 | 3.5 × 10−1 | 5.9 × 10−3 | 4 | |

| Rw4 | 0.31 | 0.0385 | 0.005 | 6.3 × 10−4 | 7.2 × 10−1 | 9.1 × 10−8 | 9.9 × 10−12 | 7.6 × 10−78 | 2 | |

| Rw5 | 0.38 | 0.0385 | 0.005 | 7.4 × 10−9 | 4.9 × 10−1 | 8.9 × 10−3 | 2.4 × 10−8 | 1.1 × 10−46 | 2 | |

| Rw6 | 0.64 | 0.0385 | 0.005 | 4.8 × 10−28 | 2.9 × 10−8 | 3.4 × 10−3 | 5.8 × 10−1 | 1.5 × 10−10 | 4 | |

| T | Tw1 | 0.06 | 0.0349 | 0.005 | 3.6 × 10−1 | 7.7 × 10−10 | 4.0 × 10−272 | 4.3 × 10−40 | 1.9 × 10−165 | 1 |

| Tw2 | 0.57 | 0.0349 | 0.005 | 1.2 × 10−35 | 1.0 × 10−5 | 8.3 × 10−2 | 7.2 × 10−2 | 4.2 × 10−9 | 3 | |

| Tw3 | 0.35 | 0.0349 | 0.005 | 3.8 × 10−8 | 6.1 × 10−1 | 4.0 × 10−4 | 4.7 × 10−9 | 6.0 × 10−76 | 2 | |

| Tw4 | 0.41 | 0.0349 | 0.005 | 1.4 × 10−15 | 1.8 × 10−1 | 4.0 × 10−2 | 5.5 × 10−6 | 3.0 × 10−32 | 2 | |

| Tw5 | 0.46 | 0.0349 | 0.005 | 7.1 × 10−15 | 3.4 × 10−2 | 1.5 × 10−1 | 1.1 × 10−3 | 1.7 × 10−25 | 3 | |

| Tw6 | 0.29 | 0.0349 | 0.005 | 9.9 × 10−5 | 5.1 × 10−1 | 3.6 × 10−13 | 6.6 × 10−15 | 2.4 × 10−50 | 2 | |

| Reservoir Names | Well Names | Ex | Exs | Relative Errors/% | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| AHP | CRITIC | AHP-CRITIC | IAHP-CRITIC | AHP | CRITIC | AHP-CRITIC | IAHP-CRITIC | |||

| L | Lw1 | 0.079 | 0.157 | 0.059 | 0.061 | 0.1 | 21.50 | 57.40 | 41.20 | 39.30 |

| Lw2 | 0.520 | 0.519 | 0.520 | 0.511 | 0.5 | 3.90 | 3.88 | 3.90 | 2.14 | |

| Lw3 | 0.137 | 0.260 | 0.106 | 0.100 | 0.1 | 36.50 | 159.70 | 5.70 | 0.40 | |

| Lw4 | 0.362 | 0.439 | 0.343 | 0.319 | 0.325 | 11.48 | 35.14 | 5.54 | 1.75 | |

| Lw5 | 0.345 | 0.482 | 0.311 | 0.299 | 0.325 | 6.12 | 48.25 | 4.40 | 7.87 | |

| Lw6 | 0.445 | 0.566 | 0.415 | 0.394 | 0.325 | 36.89 | 74.28 | 27.54 | 21.38 | |

| Lw7 | 0.636 | 0.540 | 0.660 | 0.664 | 0.675 | 5.81 | 19.96 | 2.27 | 1.58 | |

| Lw8 | 0.166 | 0.339 | 0.122 | 0.130 | 0.1 | 65.50 | 238.80 | 22.10 | 30.41 | |

| Lw9 | 0.157 | 0.315 | 0.117 | 0.119 | 0.1 | 56.80 | 214.50 | 17.40 | 18.71 | |

| Lw10 | 0.146 | 0.114 | 0.154 | 0.164 | 0.1 | 45.70 | 14.30 | 53.60 | 64.15 | |

| Lw11 | 0.443 | 0.351 | 0.466 | 0.457 | 0.325 | 36.28 | 7.85 | 43.38 | 40.65 | |

| Lw12 | 0.561 | 0.522 | 0.570 | 0.567 | 0.675 | 16.96 | 22.71 | 15.53 | 16.05 | |

| Lw13 | 0.119 | 0.239 | 0.089 | 0.091 | 0.1 | 18.70 | 139.20 | 11.40 | 9.40 | |

| R | Rw1 | 0.54 | 0.58 | 0.55 | 0.53 | 0.5 | 8.24 | 15.48 | 9.69 | 6.97 |

| Rw2 | 0.62 | 0.64 | 0.60 | 0.61 | 0.675 | 8.30 | 5.48 | 11.11 | 9.12 | |

| Rw3 | 0.74 | 0.72 | 0.74 | 0.74 | 0.675 | 10.14 | 5.98 | 9.30 | 9.46 | |

| Rw4 | 0.32 | 0.40 | 0.34 | 0.31 | 0.325 | 1.58 | 22.28 | 3.20 | 3.84 | |

| Rw5 | 0.38 | 0.50 | 0.41 | 0.38 | 0.325 | 18.02 | 52.80 | 24.97 | 16.18 | |

| Rw6 | 0.65 | 0.67 | 0.65 | 0.64 | 0.675 | 3.55 | 1.33 | 3.11 | 4.47 | |

| T | Tw1 | 0.06 | 0.14 | 0.07 | 0.06 | 0.10 | 43.89 | 44.53 | 26.20 | 43.35 |

| Tw2 | 0.57 | 0.60 | 0.58 | 0.57 | 0.5 | 14.54 | 20.84 | 15.80 | 14.04 | |

| Tw3 | 0.35 | 0.46 | 0.38 | 0.35 | 0.325 | 8.81 | 42.37 | 15.52 | 7.45 | |

| Tw4 | 0.42 | 0.51 | 0.44 | 0.41 | 0.325 | 29.12 | 58.24 | 34.95 | 27.27 | |

| Tw5 | 0.47 | 0.54 | 0.48 | 0.46 | 0.5 | 6.56 | 8.76 | 3.49 | 8.21 | |

| Tw6 | 0.29 | 0.39 | 0.31 | 0.29 | 0.325 | 9.58 | 18.47 | 3.97 | 10.18 | |

| Average relative errors/% | / | 20.98 | 53.30 | 16.61 | 16.57 | |||||

| Reservoir Names | Well Names | AHP | CRITIC | AHP-CRITIC | IAHP-CRITIC | Reservoir Survey Results |

|---|---|---|---|---|---|---|

| L | Lw1 | 1 | 1 | 1 | 1 | 1 |

| Lw2 | 4 | 3 | 4 | 3 | 3 | |

| Lw3 | 1 | 2 | 1 | 1 | 1 | |

| Lw4 | 2 | 2 | 2 | 2 | 2 | |

| Lw5 | 2 | 3 | 2 | 2 | 2 | |

| Lw6 | 2 | 4 | 2 | 2 | 2 | |

| Lw7 | 4 | 4 | 4 | 4 | 4 | |

| Lw8 | 1 | 2 | 1 | 1 | 1 | |

| Lw9 | 1 | 2 | 1 | 1 | 1 | |

| Lw10 | 1 | 1 | 1 | 1 | 1 | |

| Lw11 | 3 | 2 | 2 | 2 | 2 | |

| Lw12 | 4 | 3 | 4 | 4 | 4 | |

| Lw13 | 1 | 2 | 1 | 1 | 1 | |

| R | Rw1 | 3 | 3 | 3 | 3 | 3 |

| Rw2 | 4 | 4 | 4 | 4 | 4 | |

| Rw3 | 4 | 4 | 4 | 4 | 4 | |

| Rw4 | 2 | 3 | 2 | 2 | 2 | |

| Rw5 | 2 | 3 | 3 | 2 | 2 | |

| Rw6 | 3 | 4 | 4 | 4 | 4 | |

| T | Tw1 | 1 | 1 | 1 | 1 | 1 |

| Tw2 | 3 | 3 | 3 | 3 | 3 | |

| Tw3 | 2 | 3 | 2 | 2 | 2 | |

| Tw4 | 2 | 3 | 2 | 2 | 2 | |

| Tw5 | 3 | 3 | 3 | 3 | 3 | |

| Tw6 | 2 | 3 | 2 | 2 | 2 | |

| Accuracy/% | / | 88 | 52 | 92 | 100 | / |

| Reservoir Names | Well Names | F11/% | F2/Day | F33/°C | F4/×104 m3 | F5/×104 m3 | F6/×104 m3 |

|---|---|---|---|---|---|---|---|

| L | Lw1 | 90 | 100 | 55 | 2.63 | 1.46 | 1.17 |

| Lw2 | 61 | 10 | 90 | 3.49 | 2.38 | 1.11 | |

| Lw3 | 52 | 100 | 61 | 6.24 | 5.45 | 0.78 | |

| Lw4 | 45 | 21 | 100 | 3.62 | 2.76 | 0.85 | |

| Lw5 | 53 | 30 | 86 | 8.19 | 5.86 | 2.32 | |

| Lw6 | 50 | 7 | 112 | 4.90 | 2.64 | 2.26 | |

| Lw7 | 95 | 6 | 100 | 2.93 | 0.90 | 2.02 | |

| Lw8 | 46 | 100 | 60 | 8.52 | 4.29 | 4.23 | |

| Lw9 | 49 | 100 | 65 | 4.34 | 3.01 | 1.33 | |

| Lw10 | 52 | 100 | 60 | 1.98 | 0.94 | 1.04 | |

| Lw11 | 71 | 4 | 60 | 1.74 | 0.64 | 1.09 | |

| Lw12 | 78 | 6 | 60 | 2.95 | 1.13 | 1.81 | |

| Lw13 | 42 | 100 | 60 | 3.48 | 2.20 | 1.28 | |

| R | Rw1 | 65 | 14 | 80 | 5.65 | 4.4 | 1.25 |

| Rw2 | 77 | 8 | 88 | 6.06 | 4.58 | 1.48 | |

| Rw3 | 79 | 5 | 130 | 7.82 | 5.87 | 1.95 | |

| Rw4 | 50 | 25 | 80 | 3.5 | 2.47 | 1.03 | |

| Rw5 | 55 | 20 | 84 | 4.05 | 2.65 | 1.4 | |

| Rw6 | 67 | 6 | 101 | 6.42 | 4.72 | 1.7 | |

| T | Tw1 | 55 | 100 | 60 | 2.54 | 1.51 | 1.03 |

| Tw2 | 71 | 14 | 90 | 5.96 | 4.41 | 1.55 | |

| Tw3 | 63 | 25 | 82 | 3.9 | 2.55 | 1.35 | |

| Tw4 | 66 | 19 | 79 | 4.61 | 3.34 | 1.27 | |

| Tw5 | 65 | 18 | 94 | 4.74 | 3.49 | 1.25 | |

| Tw6 | 68 | 26 | 82 | 3.35 | 1.73 | 1.62 |

| Indicators | Value Ranges | ||||

|---|---|---|---|---|---|

| No Steam Channeling | Weak Steam Channeling | Moderate Steam Channeling | Strong Steam Channeling | Extremely Strong Steam Channeling | |

| F11/% | 0 ≤ F11 < 30 | 30 ≤ F11 < 50 | 50 ≤ F11 < 70 | 70 ≤ F11 < 90 | 90 ≤ F11 < 1 |

| F2/day | 100 > F2 ≥ 60 | 60 > F2 ≥ 30 | 30 > F2 ≥ 10 | 10 > F2 ≥ 5 | 5 > F2 ≥ 0 |

| F33/°C | 0 ≤ F33 < 60 | 60 ≤ F33 < 80 | 80 ≤ F33 < 100 | 100 ≤ F33 < 120 | 120 ≤ F33 < 200 |

| F4/×104m3 | 0 < F4 < 2.5 | 2.5 ≤ F4 < 3 | 3 ≤ F4 < 3.5 | 3.5 ≤ F4 < 4 | 4 ≤ F4 < 8 |

| F5/×104m3 | 0 < F5 < 1 | 1 ≤ F5 < 1.5 | 1.5 ≤ F5 < 2 | 2 ≤ F5 < 3 | 3 ≤ F5 < 8 |

| F6/×104m3 | 2.5 > F6 ≥ 1.5 | 1.5 > F6 ≥ 1.4 | 1.4 > F6 ≥ 1.3 | 1.1 > F6 ≥ 1 | 1 > F6 ≥ 0 |

| Reservoir Names | Well Names | Cloud Parameters | Ts | The Severity Levels | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ex | En | He | Level 1 | Level 2 | Level 3 | Level 4 | Level 5 | |||

| L | Lw1 | 0.49 | 0.042 | 0.005 | 3.3 × 10−25 | 1.2 × 10−2 | 1.1 × 10−1 | 1.1 × 10−3 | 3.8 × 10−23 | 3 |

| Lw2 | 0.51 | 0.042 | 0.005 | 2.5 × 10−27 | 1.1 × 10−4 | 1.5 × 10−1 | 3.5 × 10−3 | 7.9 × 10−41 | 3 | |

| Lw3 | 0.36 | 0.042 | 0.005 | 2.0 × 10−8 | 6.7 × 10−1 | 4.9 × 10−6 | 9.9 × 10−12 | 3.7 × 10−52 | 2 | |

| Lw4 | 0.47 | 0.042 | 0.005 | 1.9 × 10−22 | 1.7 × 10−2 | 5.0 × 10−1 | 4.2 × 10−4 | 3.7 × 10−38 | 3 | |

| Lw5 | 0.51 | 0.042 | 0.005 | 1.6 × 10−28 | 1.8 × 10−3 | 7.0 × 10−1 | 1.0 × 10−2 | 2.5 × 10−19 | 3 | |

| Lw6 | 0.59 | 0.042 | 0.005 | 6.9 × 10−30 | 3.4 × 10−7 | 6.4 × 10−3 | 2.2 × 10−1 | 4.5 × 10−10 | 4 | |

| Lw7 | 0.71 | 0.042 | 0.005 | 1.1 × 10−51 | 1.7 × 10−12 | 3.0 × 10−6 | 5.6 × 10−1 | 3.2 × 10−4 | 4 | |

| Lw8 | 0.36 | 0.042 | 0.005 | 1.2 × 10−10 | 6.5 × 10−1 | 2.8 × 10−4 | 7.9 × 10−9 | 7.8 × 10−70 | 2 | |

| Lw9 | 0.38 | 0.042 | 0.005 | 8.8 × 10−8 | 4.8 × 10−1 | 4.3 × 10−5 | 4.8 × 10−7 | 1.6 × 10−40 | 2 | |

| Lw10 | 0.28 | 0.042 | 0.005 | 4.7 × 10−4 | 4.9 × 10−1 | 8.5 × 10−42 | 2.9 × 10−14 | 2.5 × 10−85 | 2 | |

| Lw11 | 0.41 | 0.042 | 0.005 | 1.7 × 10−14 | 2.1 × 10−1 | 6.5 × 10−3 | 1.3 × 10−5 | 4.5 × 10−25 | 2 | |

| Lw12 | 0.50 | 0.042 | 0.005 | 6.6 × 10−32 | 5.3 × 10−3 | 5.7 × 10−1 | 4.1 × 10−3 | 6.9 × 10−17 | 3 | |

| Lw13 | 0.30 | 0.042 | 0.005 | 2.0 × 10−5 | 7.8 × 10−1 | 6.8 × 10−15 | 7.4 × 10−14 | 2.4 × 10−49 | 2 | |

| R | Rw1 | 0.53 | 0.011 | 0.005 | 6.8 × 10−35 | 2.5 × 10−6 | 3.1 × 10−1 | 3.9 × 10−2 | 2.6 × 10−22 | 3 |

| Rw2 | 0.61 | 0.011 | 0.005 | 5.3 × 10−63 | 3.3 × 10−10 | 6.9 × 10−8 | 2.5 × 10−1 | 6.5 × 10−15 | 4 | |

| Rw3 | 0.73 | 0.011 | 0.005 | 7.2 × 10−78 | 2.9 × 10−20 | 3.2 × 10−29 | 5.3 × 10−1 | 1.0 × 10−5 | 4 | |

| Rw4 | 0.46 | 0.011 | 0.005 | 5.4 × 10−14 | 2.1 × 10−2 | 1.8 × 10−1 | 2.4 × 10−5 | 3.0 × 10−36 | 3 | |

| Rw5 | 0.51 | 0.011 | 0.005 | 4.5 × 10−23 | 5.3 × 10−4 | 6.8 × 10−1 | 2.2 × 10−4 | 9.8 × 10−18 | 3 | |

| Rw6 | 0.60 | 0.011 | 0.005 | 1.9 × 10−36 | 6.9 × 10−8 | 1.7 × 10−9 | 3.2 × 10−1 | 1.1 × 10−20 | 4 | |

| T | Tw1 | 0.32 | 0.007 | 0.005 | 3.6 × 10−10 | 9.7 × 10−1 | 8.2 × 10−15 | 2.4 × 10−14 | 1.1 × 10−49 | 2 |

| Tw2 | 0.56 | 0.007 | 0.005 | 3.1 × 10−26 | 1.8 × 10−6 | 1.2 × 10−8 | 2.7 × 10−2 | 1.5 × 10−29 | 4 | |

| Tw3 | 0.51 | 0.007 | 0.005 | 4.2 × 10−22 | 2.0 × 10−5 | 7.8 × 10−1 | 2.3 × 10−3 | 4.3 × 10−25 | 3 | |

| Tw4 | 0.53 | 0.007 | 0.005 | 1.1 × 10−33 | 2.2 × 10−4 | 5.3 × 10−1 | 1.0 × 10−3 | 2.9 × 10−36 | 3 | |

| Tw5 | 0.55 | 0.007 | 0.005 | 1.3 × 10−50 | 4.8 × 10−7 | 7.9 × 10−2 | 1.5 × 10−2 | 2.6 × 10−13 | 3 | |

| Tw6 | 0.50 | 0.007 | 0.005 | 1.3 × 10−21 | 6.3 × 10−5 | 8.9 × 10−1 | 6.4 × 10−4 | 1.6 × 10−18 | 3 | |

| accuracy/% | / | 32 | ||||||||

| Well Names | Cloud Parameters | Ts | The Severity Levels | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Ex | En | He | Level 1 | Level 2 | Level 3 | Level 4 | Level 5 | ||

| Rw1 | 0.54 | 0.0385 | 0.001 | 5.47 × 10−34 | 6.77 × 10−6 | 2.56 × 10−1 | 2.05 × 10−3 | 7.46 × 10−28 | 3 |

| 0.003 | 1.74 × 10−38 | 1.22 × 10−6 | 1.47 × 10−2 | 1.28 × 10−2 | 1.23 × 10−23 | 3 | |||

| 0.005 | 1.27 × 10−24 | 2.97 × 10−4 | 3.05 × 10−1 | 6.22 × 10−2 | 3.73 × 10−11 | 3 | |||

| 0.007 | 1.05 × 10−42 | 2.50 × 10−7 | 1.08 × 10−2 | 2.01 × 10−2 | 1.76 × 10−24 | 4 | |||

| 0.01 | 8.93 × 10−39 | 8.62 × 10−7 | 1.54 × 10−2 | 1.72 × 10−2 | 2.03 × 10−24 | 4 | |||

| Tw2 | 0.57 | 0.0349 | 0.001 | 8.49 × 10−38 | 3.62 × 10−7 | 7.64 × 10−3 | 1.48 × 10−2 | 1.86 × 10−26 | 4 |

| 0.003 | 1.34 × 10−44 | 2.76 × 10−6 | 1.18 × 10−2 | 1.49 × 10−2 | 2.47 × 10−21 | 4 | |||

| 0.005 | 1.19 × 10−35 | 1.01 × 10−5 | 8.33 × 10−2 | 7.17 × 10−2 | 4.24 × 10−9 | 3 | |||

| 0.007 | 1.87 × 10−66 | 8.84 × 10−7 | 6.61 × 10−2 | 3.19 × 10−2 | 4.50 × 10−25 | 3 | |||

| 0.01 | 8.45 × 10−54 | 1.43 × 10−5 | 2.50 × 10−2 | 1.75 × 10−2 | 1.03 × 10−16 | 3 | |||

| Tw5 | 0.46 | 0.0349 | 0.001 | 4.31 × 10−26 | 1.06 × 10−2 | 2.76 × 10−2 | 1.18 × 10−6 | 3.29 × 10−39 | 3 |

| 0.003 | 5.68 × 10−25 | 8.73 × 10−3 | 4.24 × 10−2 | 1.46 × 10−8 | 1.75 × 10−27 | 3 | |||

| 0.005 | 7.16 × 10−15 | 3.44 × 10−2 | 1.53 × 10−1 | 1.12 × 10−3 | 1.78 × 10−25 | 3 | |||

| 0.007 | 1.59 × 10−2 | 4.55 × 10−1 | 2.14 × 10−1 | 3.39 × 10−2 | 1.53 × 10−5 | 2 | |||

| 0.01 | 5.84 × 10−39 | 8.93 × 10−2 | 3.57 × 10−3 | 4.74 × 10−7 | 2.84 × 10−28 | 2 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Bai, J.; Wang, Q.; Zhao, Y.; Wang, Z.; Wen, J.; Sun, X. Evaluation of Steam Channeling Severity Between Cyclic Steam Simulation Wells in Offshore Heavy Oil Reservoirs Based on Cloud Model and Improved AHP-CRITIC Method. Energies 2025, 18, 5407. https://doi.org/10.3390/en18205407

Liu Y, Bai J, Wang Q, Zhao Y, Wang Z, Wen J, Sun X. Evaluation of Steam Channeling Severity Between Cyclic Steam Simulation Wells in Offshore Heavy Oil Reservoirs Based on Cloud Model and Improved AHP-CRITIC Method. Energies. 2025; 18(20):5407. https://doi.org/10.3390/en18205407

Chicago/Turabian StyleLiu, Yigang, Jianhua Bai, Qiuxia Wang, Yongbin Zhao, Zhiyuan Wang, Jia Wen, and Xiaofei Sun. 2025. "Evaluation of Steam Channeling Severity Between Cyclic Steam Simulation Wells in Offshore Heavy Oil Reservoirs Based on Cloud Model and Improved AHP-CRITIC Method" Energies 18, no. 20: 5407. https://doi.org/10.3390/en18205407

APA StyleLiu, Y., Bai, J., Wang, Q., Zhao, Y., Wang, Z., Wen, J., & Sun, X. (2025). Evaluation of Steam Channeling Severity Between Cyclic Steam Simulation Wells in Offshore Heavy Oil Reservoirs Based on Cloud Model and Improved AHP-CRITIC Method. Energies, 18(20), 5407. https://doi.org/10.3390/en18205407