1. Introduction

Building heating systems worldwide have long exhibited a high dependence on fossil fuels, posing significant challenges to both energy security and environmental sustainability. According to the International Energy Agency, space heating in buildings accounts for over 30% of global energy consumption, with approximately 75% of this demand still met by fossil fuel sources [

1]. In alignment with the Paris Agreement’s target of limiting global temperature rise to 1.5 °C, many countries are actively accelerating the decarbonization of their heating systems. Electrified heating—particularly technologies based on heat pumps—has emerged as a promising low-carbon solution owing to its high electrothermal conversion efficiency. Nevertheless, during cold seasons, the absence of a stable low-temperature heat source remains a critical bottleneck constraining the large-scale deployment of heat pump systems [

2,

3,

4]. To address the challenge of insufficient heat supply during cold seasons, seasonal thermal energy storage (STES) technologies have gained increasing attention. By integrating multiple heat sources at the regional or urban scale, these systems establish sustainable thermal reserves capable of supplying stable heat during the heating season. STES enables the temporal redistribution of thermal energy across seasons by efficiently storing surplus heat during non-heating periods and releasing it during heating periods. This approach helps balance the thermal energy supply–demand mismatch and mitigate fluctuations in the broader energy system. Among various STES technologies, Borehole Thermal Energy Storage systems (BTES)—which integrate multiple clean heat sources such as solar energy and groundwater to establish a “store in summer, use in winter” recycling model—are increasingly recognized as a promising pathway for achieving clean and sustainable building heating, and have garnered growing attention in recent years [

5].

To characterize the heat transfer processes within thermal energy storage units, various modeling approaches have been proposed by researchers. Among numerical models, Carli et al. [

6] introduced the Capacity Resistance Model, inspired by electrical resistive network analogies, to predict both the fluid outlet temperature and the temperature of the thermal storage unit. While this model accounts for thermal interference effects between boreholes, it neglects the heat capacity within the boreholes and simplifies the process as steady-state heat conduction. Building upon this work, Bauer et al. [

7] introduced the concept of borehole thermal capacity and presented computational results under various operating conditions, including fully transient, borehole transient, and borehole steady-state scenarios, thereby developing the Thermal Resistance and Capacity Model. Although numerical models can accurately predict temperature variations within thermal energy storage units, their computational complexity, slow execution speed, and high demand for computational resources and modeling expertise limit their widespread practical application in engineering contexts.

In contrast, analytical models have garnered increasing attention due to their high computational efficiency [

8]. Ingersoll et al. [

9] proposed the classical infinite line source model, which assumes a uniform initial ground temperature and treats the borehole as an infinitely long line heat source. Subsequently, Carslaw et al. [

10] extended this concept by modeling the borehole as an infinite cylindrical heat source, leading to the development of the infinite cylindrical source model. However, both models neglect the effects of surface boundary conditions, leading to non-convergent temperature fields over extended time scales. As a result, they are unsuitable for long-term thermal performance analysis. To overcome the limitations of previous models, Eskilson [

11] developed a finite line source model, while maintaining the assumptions of a uniform initial ground temperature and neglecting the thermal capacity of borehole materials. He further introduced the concept of a dimensionless temperature response factor, known as the g-function. Each g-function corresponds to a specific borehole field configuration, and its thermal response can be precomputed and tabulated for efficient use. These g-function datasets have been widely implemented in geothermal heat pump design tools such as Earth Energy Designer and Ground Loop Heat Exchanger Design Software [

12]. However, Eskilson’s g-function is derived through numerical pre-calculation, necessitating the prior generation of a function library tailored to specific geological conditions and borehole configurations. This requirement limits the model’s flexibility and general applicability in diverse engineering scenarios [

13].To enhance the practicality of the finite line source models, Zeng [

14] employed virtual heat sources and Green’s function methods to derive an analytical solution for finite line heat sources, and proposed a double integral formulation to calculate the average borehole wall temperature. Building on this work, Lamarche [

15] improved computational efficiency by reducing the formulation to a single integral through mathematical simplification. Subsequently, Du [

16] further optimized the integration sequence and developed a more concise and computationally efficient expression.

In summary, the finite line source model demonstrates clear advantages in computational efficiency over fully three-dimensional numerical models, while adequately accounting for the vertical scale of boreholes and surface boundary effects. Although numerical models yield higher accuracy, their prohibitive computational cost limits their applicability to rapid predictions in large-scale BTES systems. Conversely, the infinite cylindrical source model, despite its concise formulation, neglects surface boundary conditions, resulting in non-convergent temperature fields over extended timescales, which undermines its suitability for seasonal or multi-year storage analysis. By contrast, the finite line source model achieves a rigorous balance between accuracy and efficiency: it incorporates surface effects, retains an analytical solution form, and allows further simplification into engineering-oriented algorithms. Accordingly, this study adopts the finite line source model as the theoretical foundation for establishing a rapid temperature prediction framework.

However, as BTESs evolve toward large-scale, multi-borehole configurations, the volume and complexity of the thermal storage unit increase substantially. Even with simplified analytical formulations, existing models face performance bottlenecks when applied to large-scale scenarios. Furthermore, driven by advancements in clean heating technologies, BTES systems are increasingly being utilized not only for heat extraction but also for thermal energy storage. Under such conditions, relying solely on single-point temperatures or fluid outlet temperatures is no longer sufficient to comprehensively assess the thermal state of the storage unit. This necessitates the development of effective methods for estimating both the average temperature and the spatial temperature field distribution within the thermal storage unit.

To address the aforementioned issues, this study integrates both theoretical modeling and engineering validation. First, a theoretical formulation for calculating the average temperature of the thermal energy storage unit was derived based on the finite line source theory. Second, a simplified engineering algorithm, free from complex functions and integral operations, was developed to enable both single-point temperature calculation and average temperature estimation of the heat storage unit, with the latter derived from an equivalent single-borehole thermal response model. The accuracy of this algorithm was validated through controlled sandbox experiments and real-world engineering data. Finally, a temperature field superposition method based on two-dimensional discrete convolution, enhanced by the fast Fourier transform (FFT), was developed to enable efficient simulation of the temperature distribution in large-scale heat storage bodies.

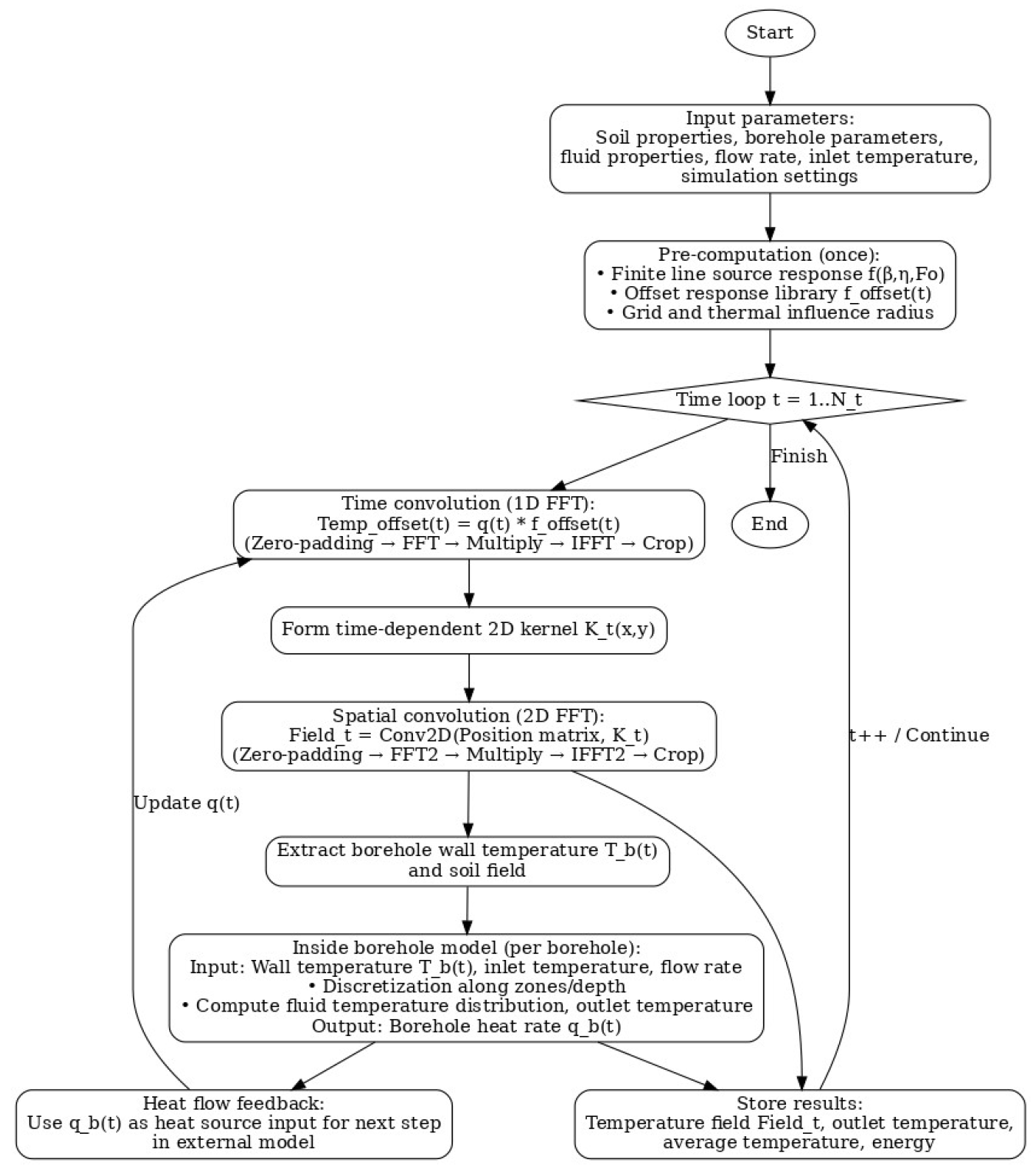

Compared with existing simplified analytical and numerical models such as the g-function approach, TRNSYS, or DST-based tools, the proposed framework offers several novel contributions. First, the model directly integrates the finite line source theory with a two-dimensional convolution formulation, enabling full-field temperature prediction of large-scale BTES units rather than relying solely on point or borehole wall temperatures. Second, by introducing engineering-oriented algorithms, the method eliminates complex integral functions, which makes it more transparent and computationally tractable for design applications. Third, FFT-based acceleration is applied not only in the temporal domain but also in the spatial superposition of borehole clusters, achieving orders-of-magnitude speed-up while maintaining accuracy. This dual acceleration strategy is absent in existing models. Finally, the model bridges the gap between purely theoretical formulations and system-level simulation tools (e.g., TRNSYS), thereby providing both high computational efficiency and sufficient physical fidelity. These features make the framework a significant advancement, offering a practical yet rigorous tool for rapid design and optimization of seasonal BTES systems. The overall computational procedure of the rapid temperature prediction model is illustrated in

Figure A1.

2. Methods

Existing studies on the temperature of thermal storage media have primarily focused on calculating the fluid temperature within U-tubes and the single-point temperature at borehole walls. However, with the widespread application of BTES systems in seasonal storage technologies, the storage unit has increasingly assumed the dual role of storing and releasing heat. To accurately evaluate its storage state and total heat capacity, relying solely on single-point or in-pipe temperatures is no longer sufficient. Therefore, it is necessary to further determine both the average temperature and the temperature distribution of the storage unit. Based on this requirement, this section first derives an analytical expression for the average temperature of the storage unit using the finite line source model. It then proposes an efficient method for computing the internal temperature distribution via two-dimensional discrete convolution, thereby providing theoretical support for the thermal state assessment of seasonal thermal energy storage systems.

2.1. Heat Transfer Model

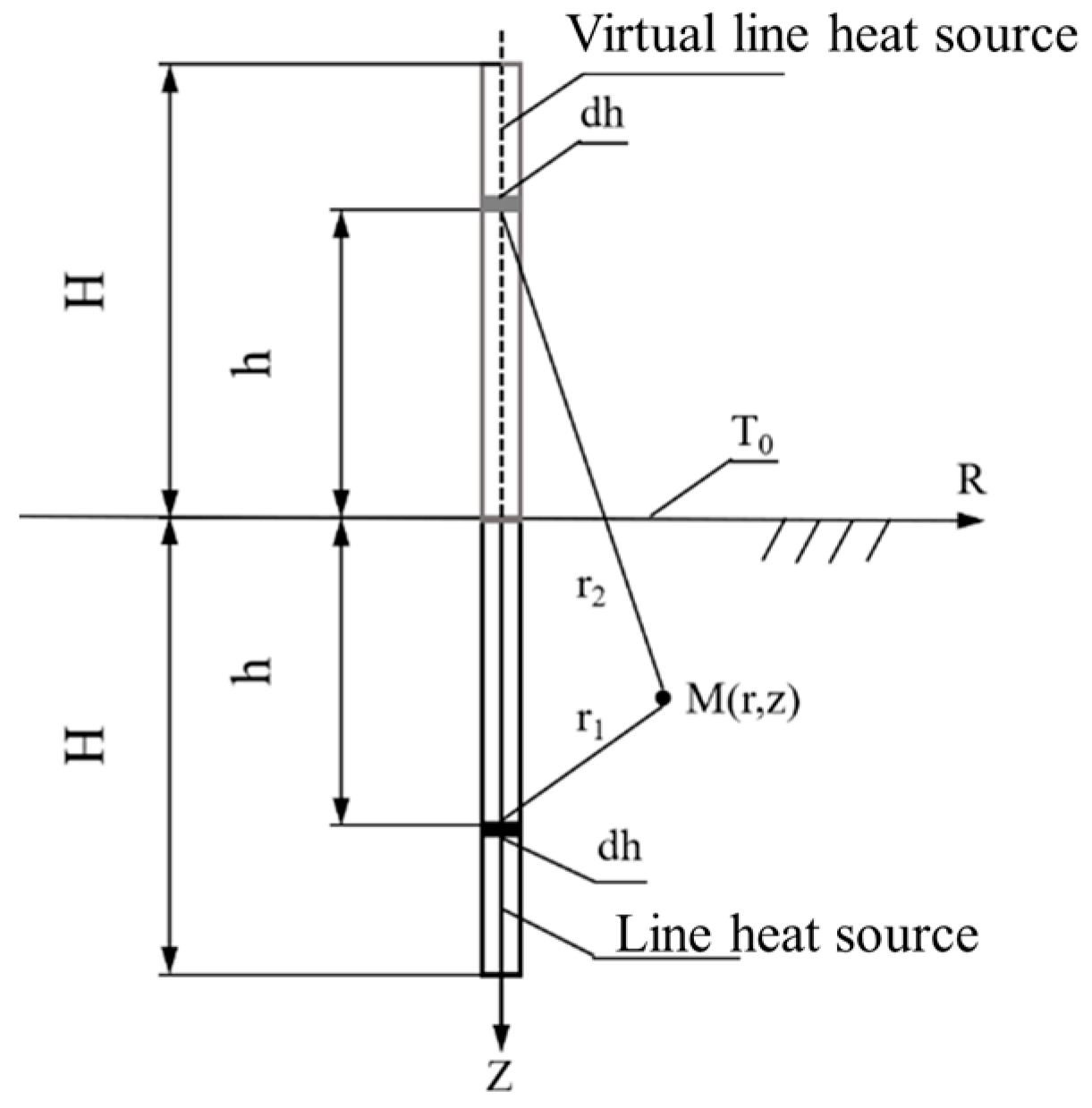

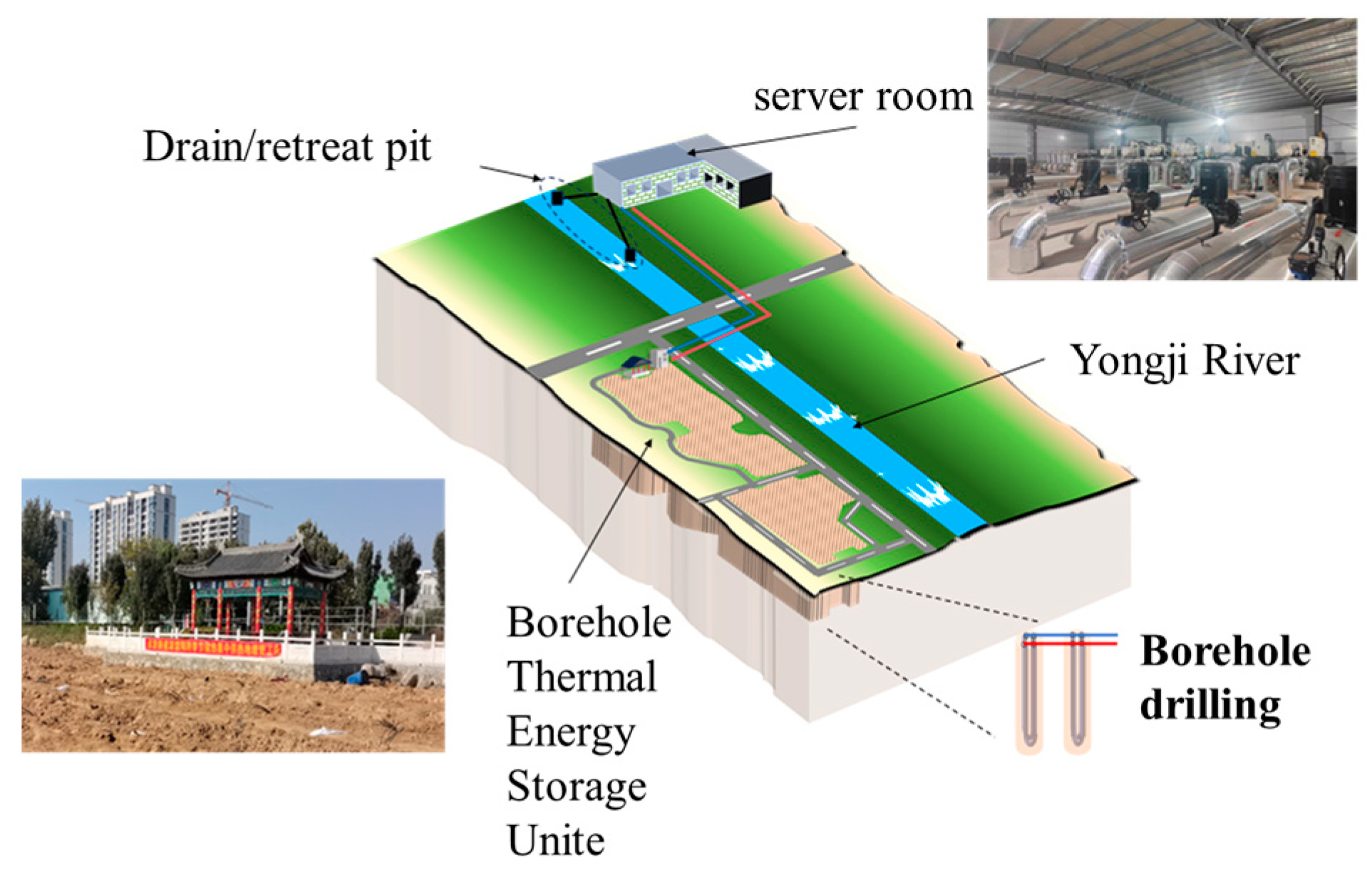

As illustrated in

Figure 1, the system schematic represents a seasonal BTES unit. The boreholes have a depth of

H, and the heat exchangers are arranged in parallel. The fluid enters the system at a uniform inlet temperature,

Tf,in, and exits at an outlet temperature,

Tf,out. For the entire system, the inlet temperature across all boreholes is maintained consistently, while the overall outlet temperature is defined as the average of the outlet temperatures from all individual boreholes.

Research on the heat transfer processes within BTES units is typically divided into two domains: inside the borehole and outside the borehole, with the borehole wall serving as the thermal boundary between them. Within the borehole, the thermal capacity of U-shaped pipes, backfill materials, and other internal components is relatively small compared to that of the surrounding soil. As a result, the borehole interior is often assumed to be in a steady-state thermal condition when calculating the fluid temperature. In contrast to the interior of the borehole, heat transfer in the surrounding soil is more complex due to the presence of thermal interactions between adjacent boreholes. Given that the borehole diameter is negligible compared to its depth, the borehole is typically simplified as a finite-length line heat source. This model represents an analytical solution for the temperature of the thermal storage unit, derived by introducing a virtual heat source based on the classical infinite line source theory. As illustrated in

Figure 2, the concept of the virtual heat source method involves placing a virtual line heat sink at the mirror-symmetric position of the borehole with respect to the ground surface. This virtual sink has the same length and heat flux magnitude as the real borehole but with an opposite heat flow direction. The superposition of the real and virtual sources ensures that the ground surface temperature remains constant. The model is based on the following assumptions: 1. The initial temperature of the subsurface soil is spatially uniform. 2. The ground surface temperature remains constant and is equal to the initial soil temperature. 3. The subsurface soil is treated as a semi-infinite heat transfer unit. 4.The thermal properties of the soil are homogeneous and temperature-independent. 5.The borehole geometry is neglected, and the borehole is approximated as a finite-length line heat source along its vertical axis.

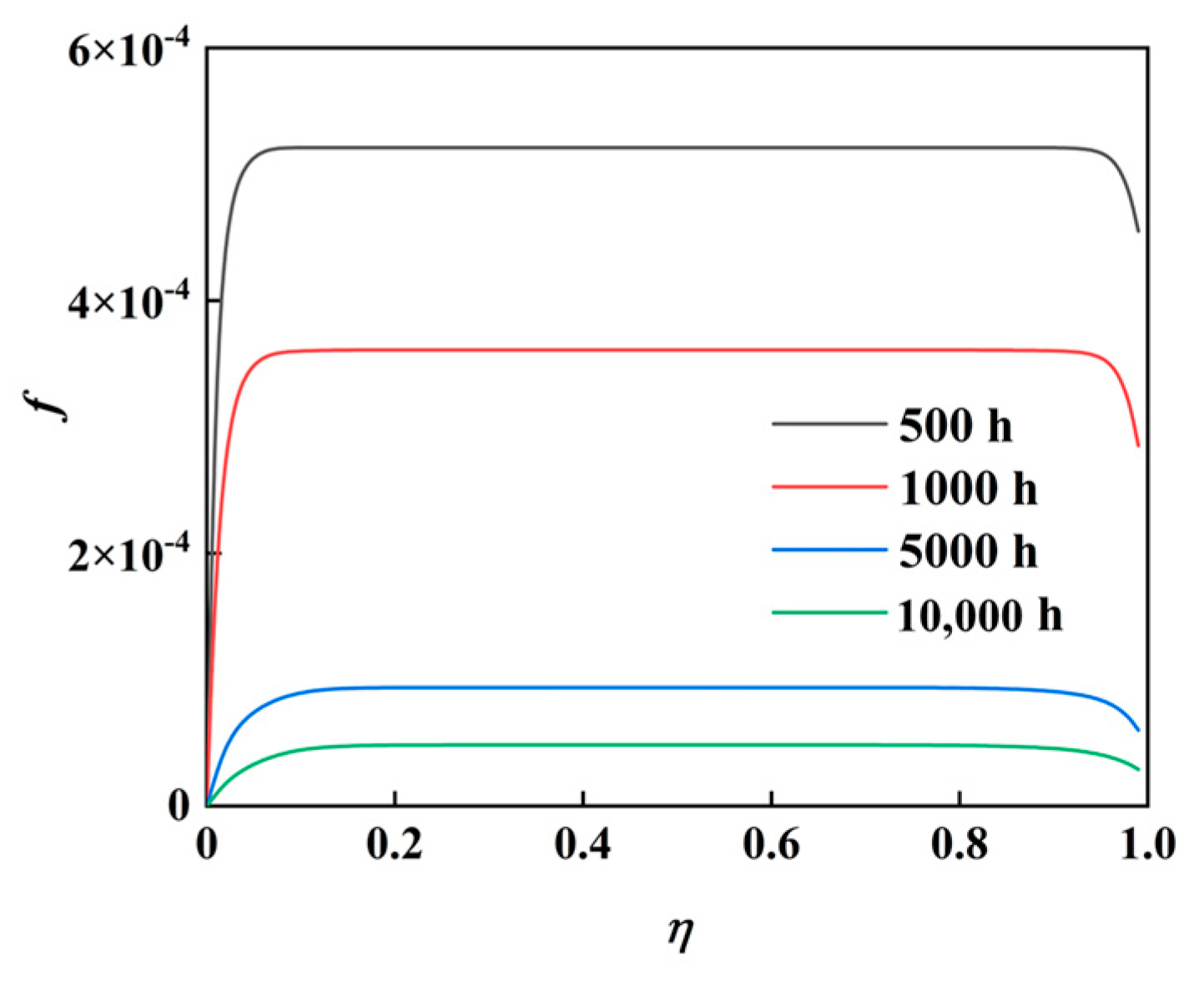

2.1.1. Single-Point Temperature Prediction

Based on the finite line source model, the temperature response at an arbitrary point induced by a step heat input from a single borehole can be expressed as follows:

where

;

;

η =

z/

H (relative depth);

β =

r/

H (relative distance);

ξ =

h/

H (relative vertical distance);

Fo =

ατ/

H2 (Fourier number);

q is the heat injection rate per unit length of the borehole;

H is the borehole depth;

ks is the thermal conductivity of the soil;

α is the thermal diffusivity of the soil;

τ is the time;

T0 is the initial ground temperature.

According to the definition of the

g-function proposed by Eskilson [

11], the single-borehole

g-function for the finite-length line heat source model is expressed as follows:

The temperature at a given point within a borehole field can be determined using the superposition principle, which involves calculating the temperature response of each individual borehole at that point and then summing these responses. Accordingly, the

g-function at a given point within a borehole group is expressed as follows:

Under variable heat flow conditions, the heat flow

q can be approximated as a series of rectangular pulse heat flows

q(

τi) (where

i = 1, 2, 3, …, n). Each pulse heat flow can be considered as the sum of two step heat flows. Therefore, the temperature response at a specific point at time

τj, resulting from a pulse heat flow applied during the interval [

τi−1,

τi], is given by:

The dimensionless temperature response function at a specific point, induced by a rectangular pulse heat flow over a time interval Δ

τ, is defined as follows:

where Δ

Fo = α·Δ

τ/

H2 denotes the Fourier number interval.

Therefore, the temperature response at time

τj can be determined using the superposition principle, by calculating the temperature response of each pulse heat flow segment and subsequently summing these contributions:

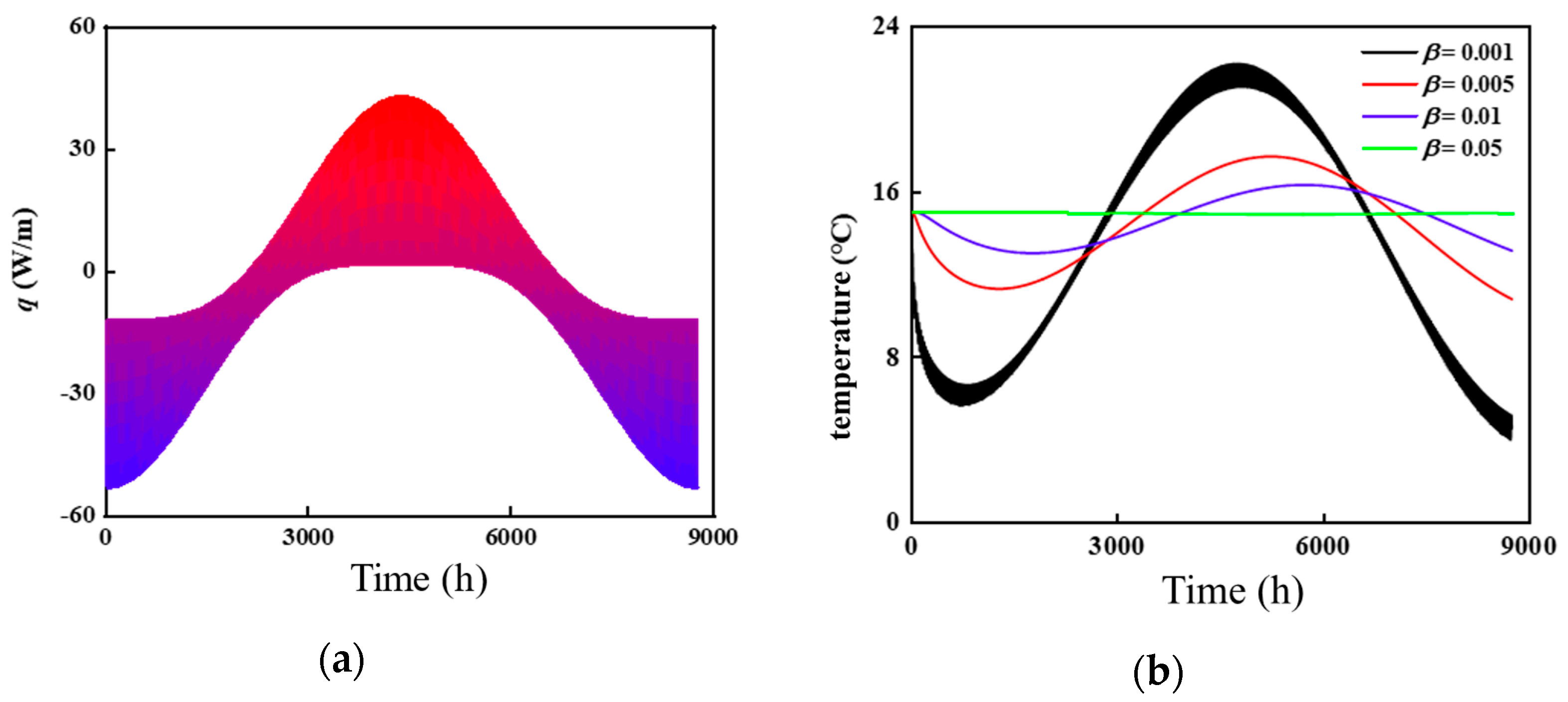

2.1.2. Average Temperature Prediction

According to the finite line heat source model, determining the average temperature of the thermal storage unit is equivalent to evaluating the dimensionless temperature response of the heat input over the entire volume. Once the dimensionless temperature response at a single point is established, the overall response can be obtained by performing a volume-averaged integral. According to Equations (5) and (6), the key to determining the average temperature of the thermal storage unit lies in calculating the partial derivative G′ of the storage unit’s G-function with respect to the Fourier number, as well as the corresponding value of F.

As illustrated in

Figure 1, a rectangular coordinate system is established with the center of the buried pipe as the origin. The relative distances

x1,

x2,

y1, and

y2 from the pipe center to the boundaries of the thermal storage unit are determined to define the integration domain. Neglecting the influence of the borehole, the derivative of the G-function for the thermal storage unit,

G, is calculated as follows:

where

l =

L/

H;

w =

W/

H;

A; W and L represent the width and length of the thermal storage unit, respectively.

Let

B. Further derivation then yields:

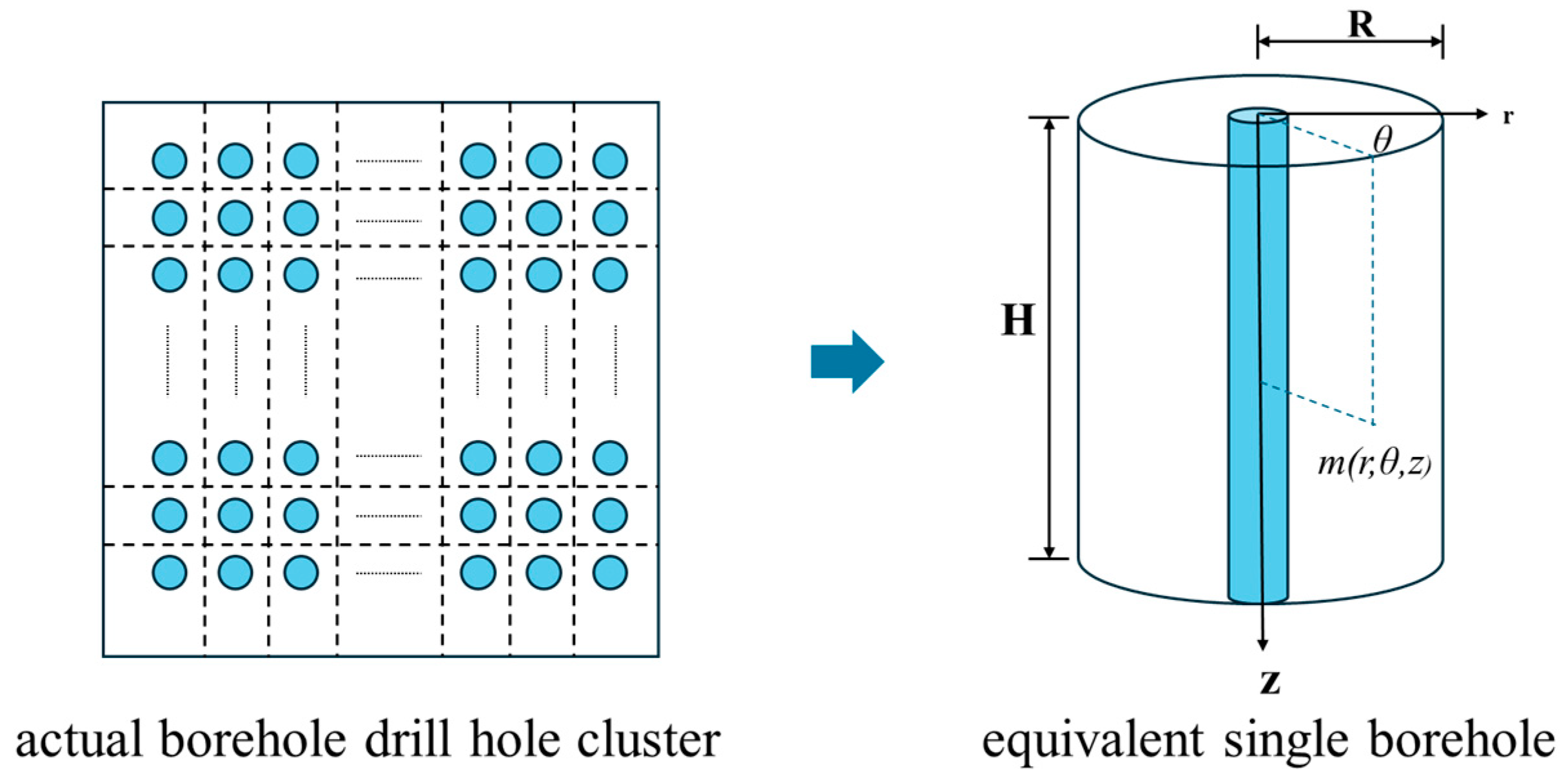

By combining Equations (6) and (8), a thermal response model for the heat flow from a single pipe to the heat storage unit can be established. Owing to the symmetrical arrangement of the buried pipes, it is sufficient to calculate only one-eighth of the domain to obtain the overall temperature response. To address the computational complexity introduced by the large number of buried pipes in practical engineering applications, this study further proposes an equivalent single-pipe model. In this model, the distributed heat sources are represented by a single, centralized line heat source located at the center of a cylindrical heat storage unit, while preserving the total heat input and geometric volume.

Figure 3 illustrates the geometric configuration of the equivalent single-borehole heat storage unit. Similarly to the procedure used for rectangular heat storage bodies, the volume-averaged integral of the G function with respect to the Fourier number (Fo) must be evaluated to obtain its partial derivative, G′.

Following the derivation process of Equation (7), the expression for G′ in the equivalent single-borehole model is given as follows:

where

r =

R/

H represents the dimensionless radius of the equivalent single-borehole heat storage unit.

2.1.3. Heat Transfer Within Boreholes

In the context of heat transfer within boreholes, the temperature of the fluid is the most critical parameter from an engineering perspective. Due to the relatively small structural dimensions and low thermal capacity of borehole components, as well as the slow temporal variation in temperature, the heat transfer process is typically simplified as steady-state. This assumption has been validated as reasonable in long-term thermal simulations of buried pipe systems [

14].

Zeng et al. [

17,

18,

19] accounted for the variation in fluid temperature with depth while neglecting axial heat conduction within the borehole, and thereby established a quasi-three-dimensional steady-state heat transfer model. Based on this model, the fluid temperature within the borehole can be calculated using the following equation:

where

Z is the dimensionless depth parameter of the U-tube, defined as

Z =

z/

H, where

z is the vertical coordinate ranging from 0 to

H;

and

represent the temperatures of the downward- and upward-flowing fluid in the vertical U-tube, respectively,

,

;

Tb denotes the borehole wall temperature;

Td and

Tu represent the temperatures of the downward- and upward-flowing fluid in the vertical U-tube, respectively;

;

S1 and

S12 refer to the dimensionless thermal resistances between the fluid and the borehole wall, and between fluids in adjacent U-tube legs, respectively. The detailed calculation methods for these parameters can be found in [

14].

Then, the dimensionless outlet temperature of the fluid can be expressed as follows:

2.2. Temperature Distribution Calculation Method Based on Two-Dimensional Discrete Convolution

In simulation analyses, the temperature distribution within the thermal storage unit represents a key area of investigation. Due to the temperature superposition effect among boreholes, large-scale temperature field calculations become computationally intensive. As a result, most existing studies are limited to systems with fewer than 300 boreholes. To address this challenge, the concept of thermal influence distance has been introduced [

20], allowing calculations to be restricted to boreholes within a defined influence range, as the thermal impact of distant boreholes is relatively negligible. By first calculating the temperature distribution within the thermal influence zone of a single borehole and then nesting and superimposing this distribution across all boreholes, the complex process of point-by-point computation can be effectively replaced.

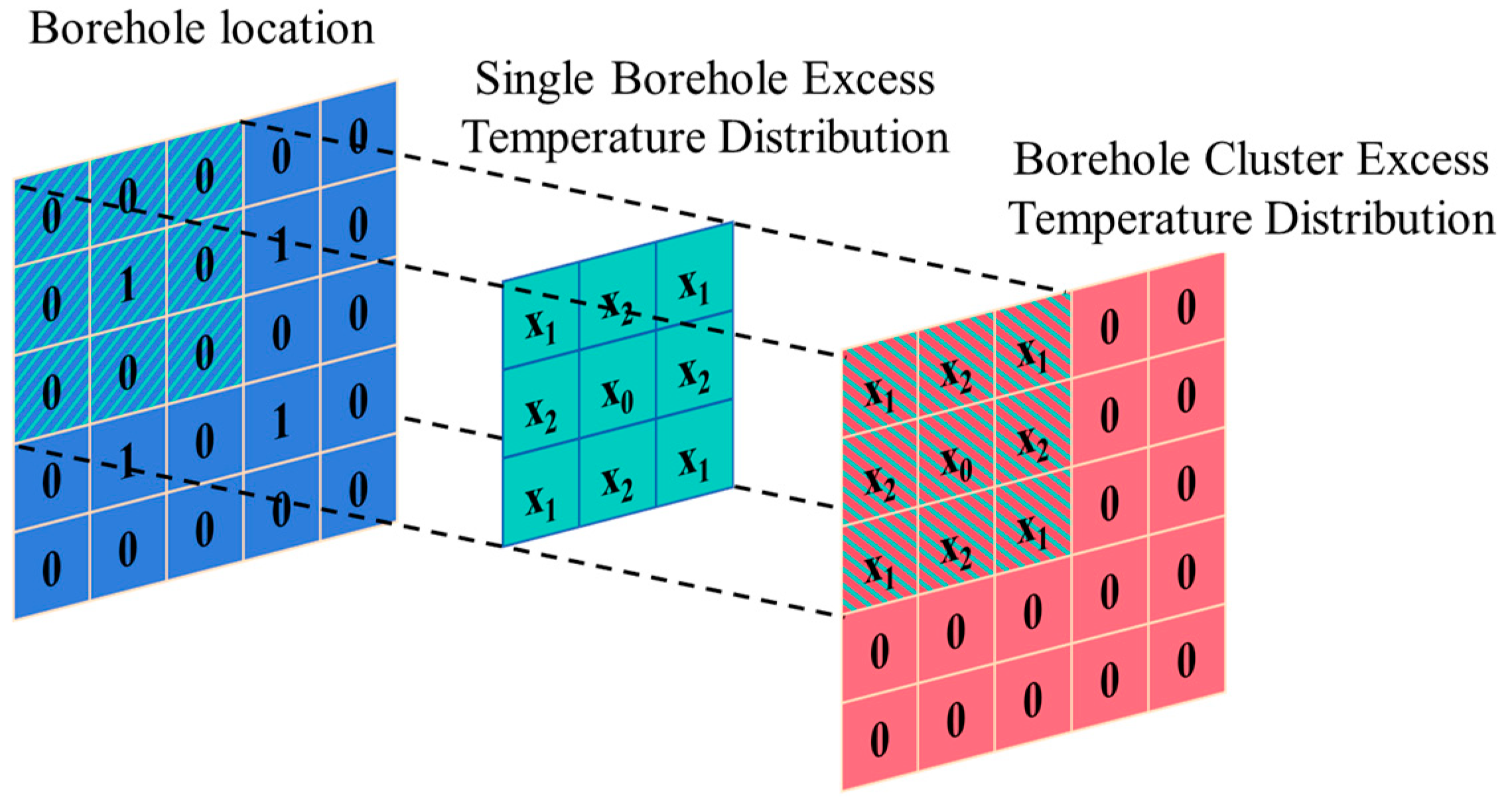

In

Figure 4, the borehole location matrix is defined using binary values, where 1 denotes a borehole location and 0 represents soil. The excess temperature distribution for a single borehole is denoted as

xi, with

x0 corresponding to the temperature at the borehole wall. By shifting the single-borehole temperature distribution matrix and aligning its center with each borehole location, the excess temperatures in overlapping regions are progressively nested and summed, thereby constructing the overall temperature distribution. Based on this principle, this study proposes a temperature superposition method using two-dimensional discrete convolution:

where

A,

B, and

C represent the input layer, kernel, and output layer, respectively.

Two-dimensional discrete convolution produces the output layer C by sliding the convolution kernel B across the input layer A, performing element-wise multiplication, and summing the results. There are three common convolution modes—FULL, VALID, and SAME—which correspond to different traversal strategies and output dimensions. In this study, the SAME mode is employed to ensure that the output layer maintains the same size as the input layer, thereby satisfying the dimensional requirements of the calculation. When solving temperature fields of non-uniformly spaced borehole groups using two-dimensional discrete convolution, the borehole spacing must satisfy the commensurability condition: there must exist a common measure length Δ such that all physical spacings are integer multiples of Δ. This Δ then serves as the spatial step size for discrete grids, enabling the construction of position matrices. Consider four non-uniformly arranged boreholes with successive spacings of 1 m, 3 m, and 3.5 m as an example. Here, Δ = 0.5 m may be selected as the unified discretization step. Borehole nodes are subsequently assigned values of 1 in the position matrix, while 2, 6, and 7 zero-value nodes representing soil are sequentially inserted between adjacent boreholes. This procedure achieves the regular grid mapping required for convolutional operations. For completely random borehole arrangements violating the commensurability condition, one must revert to a stepwise superposition method. Temperature responses are then calculated by progressively superimposing pairwise temperature fields.

In SAME mode, the center of the convolution kernel traverses every position within the input layer. As illustrated in

Figure 5, the input layer corresponds to the borehole location matrix, the convolution kernel (with odd dimensions) represents the temperature distribution of a single borehole, and the output layer yields the residual temperature distribution of the entire borehole group. Due to the symmetrical nature of the single borehole temperature distribution, the convolution operation becomes equivalent to a cross-correlation, meaning that flipping the kernel has no effect on the outcome. Throughout the traversal process, a stride of 1 is used. When the kernel extends beyond the input boundaries, zero-padding is applied to the input layer (indicated by the gray regions in

Figure 5) to ensure that a complete output of consistent size is generated.

As shown in

Figure 5, when the input layer region corresponding to the convolution kernel contains 1, it indicates that the position is affected by borehole heat. After calculation, only the positions with a value of 1 in the input layer generate excess temperature, while positions with a value of 0 have no heat contribution. The calculation results are assigned to the corresponding output layer positions. When the convolution kernel covers multiple drill holes, the thermal effects of multiple drill holes are automatically superimposed, making the two-dimensional discrete convolution results completely consistent with the direct nesting method. Let the drill hole position matrix be

n ×

n, the number of drill holes be

m ×

m, and the convolution kernel be

k ×

k. Then, the computational complexity of the direct nesting method is O(

m2k2), and that of the two-dimensional discrete convolution is O(

n2k2). Although the two-dimensional discrete convolution has slightly increased computational complexity, it can significantly improve computational efficiency through parallel processing, fast Fourier transforms, and other techniques. Therefore, this method is more advantageous for handling large-scale data and provides a reliable solution for calculating the temperature distribution of large-scale borehole clusters.

2.3. Convolution Algorithm Based on Fast Fourier Transform

When dealing with long time scales and small time steps, the volume of data associated with heat flux and thermal response factors becomes substantial, resulting in a significant slowdown in computational efficiency. To address this issue, Denis [

21] introduced the use of the discrete Fourier transform (DFT) and its fast implementation, the fast Fourier transform (FFT), to accelerate convolution calculations. According to the convolution theorem, the DFT of the convolution of two sequences is equal to the element-wise product of their respective DFTs. For two sequences

x(

n) and

h(

n) each of length N, their convolution

y(

n) =

x(

n) *

h(

n) can be computed through the following steps:

Discrete Fourier Transform: Calculate the DFT of

x(

n) and

h(

n) to obtain their frequency-domain representations

X(

k) and

H(

k), respectively.

Product: Compute the element-wise product of

X(

k) and

H(

k) to obtain

Y(

k), the frequency-domain representation of the convolution result.

Inverse DFT: Perform the inverse DFT on

Y(

k) to obtain

y(

n), the final convolution result in the time domain.

The FFT algorithm enables both the DFT and its inverse to be computed in O(NlogN) time. As a result, the overall computational complexity of convolution operations is reduced to O(NlogN), which is significantly more efficient than the O(N2) complexity associated with direct convolution methods.

Since Equation (6) represents a linear convolution, modifications are necessary to adapt the FFT—which inherently performs cyclic convolution—for linear convolution computations. To meet the requirements of linear convolution, both the sequence

q(

τi) and the index of

Foi must begin at zero, which involves applying zero-padding and shifting the data one position to the left. Consequently, the index of the temperature sequence

Tj should also be adjusted to start from zero.

Since the effective length of the sequence is

j, the heat flow sequence

q(

τi) and the thermal response factor sequence

f(

β,

Foi) are defined as zero when

i < 0 or

i ≥

j. Under this condition, Equation (17) can be further expressed as:

Therefore, to satisfy the conditions for linear convolution, both q(τi) and f(β,Foi) must undergo a (2j − 1)-point FFT. After computing the product of the transformed sequences, an inverse FFT is performed, and the first j points of the result are taken as the effective temperature values.

4. Conclusions

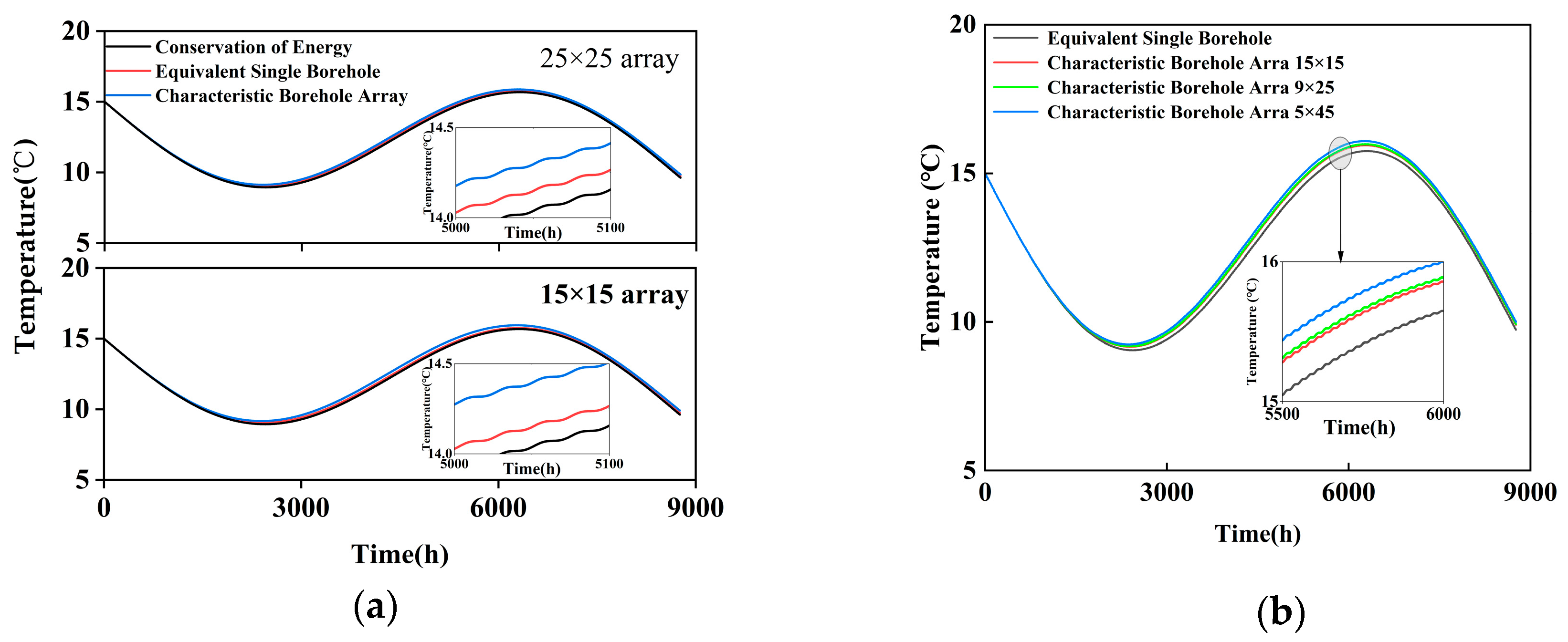

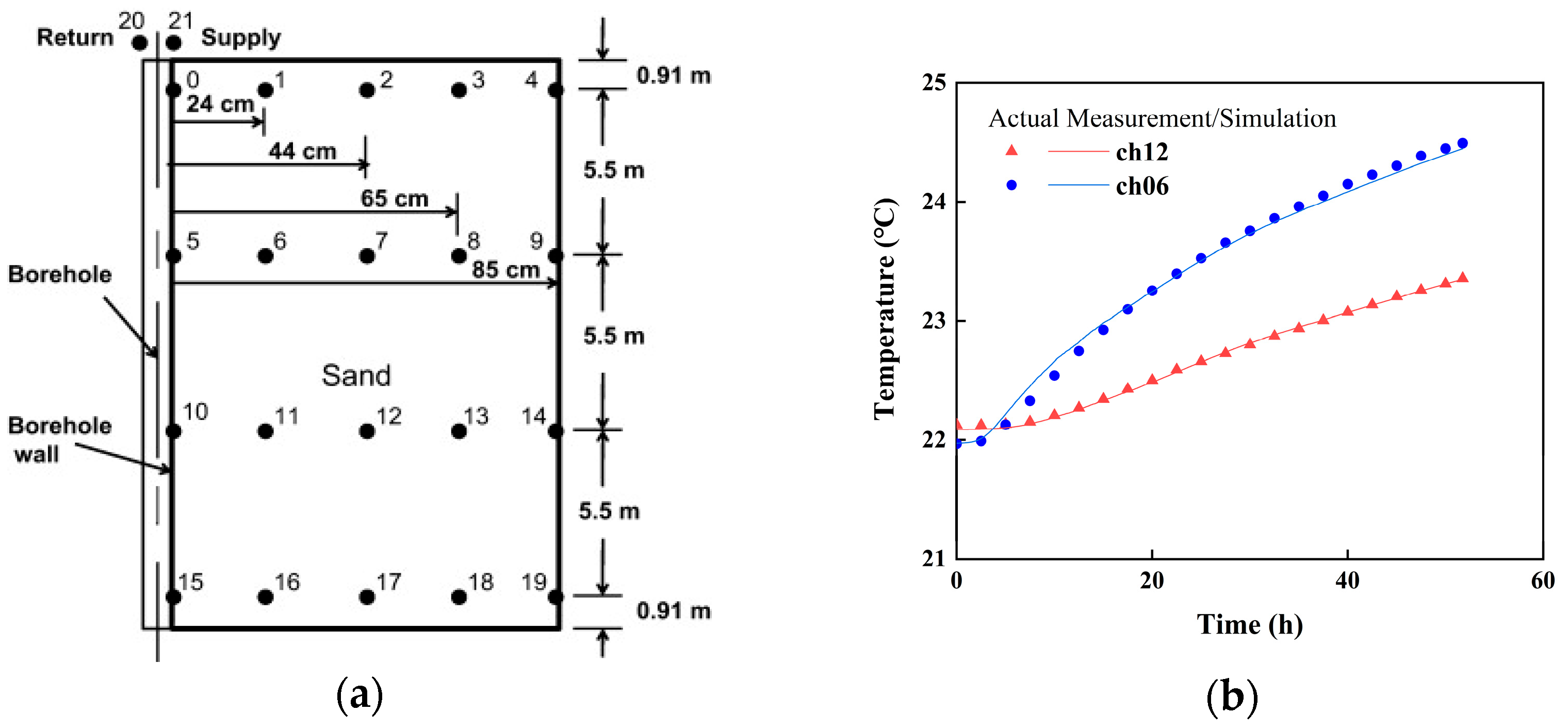

This study addresses the need for efficient prediction and evaluation of heat storage unit temperatures in STES systems. A rapid calculation framework—free from complex functions and integral operations—is developed at three levels: single-point temperature, average temperature, and temperature distribution. The model is validated using both laboratory experiments and real-world engineering data. The main findings are summarized as follows:

- (1)

Single-point temperature prediction: The study explores the variation patterns of thermal influence factors under different parameter conditions. Based on curve-fitting techniques, an engineering-oriented prediction algorithm is proposed that avoids the use of complex functions or integral calculations. Validation against sandbox experimental data shows a maximum temperature deviation of 0.07 °C and a maximum relative error of 0.3%, confirming the algorithm’s high accuracy and practical applicability.

- (2)

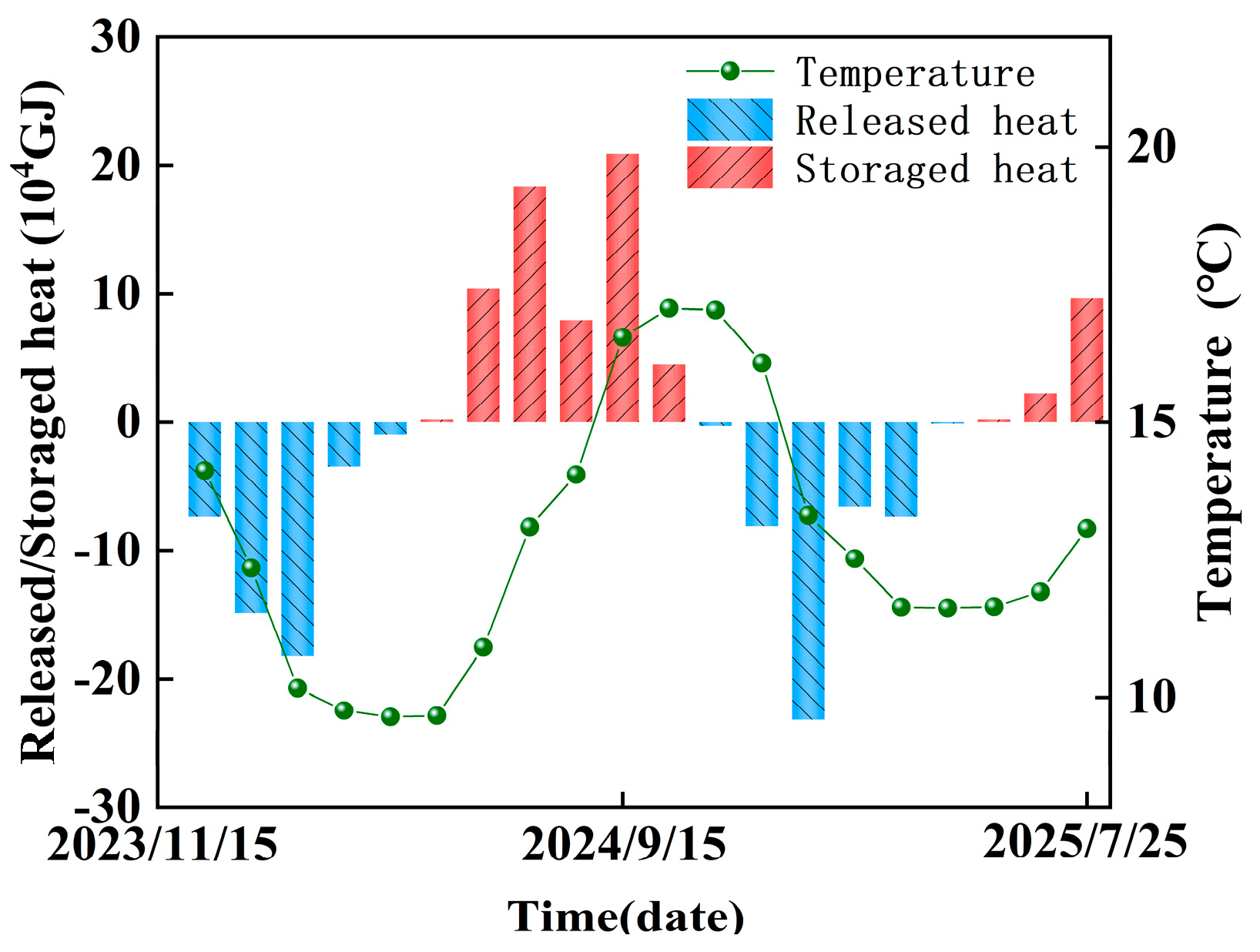

Average temperature estimation: A theoretical model for the average temperature of the heat storage unit is derived from the finite line source theory. By simplifying the multi-borehole configuration into an equivalent single-borehole cylindrical model, a fast and robust engineering algorithm is developed. Using data from a large-scale cross-seasonal thermal energy storage project in Handan City, Hebei Province, the proposed method demonstrates strong agreement with the established DST (Duct Storage with Pipes) model, with a maximum temperature difference of 0.19 °C and a maximum relative error of 1.2%. These results confirm the model’s reliability and applicability.

- (3)

Temperature distribution simulation: To enable efficient modeling of temperature fields in large-scale STES systems, a superposition algorithm based on two-dimensional discrete convolution is introduced. The method limits the thermal influence range, applies convolution between the position matrix and single-borehole response matrix, and further integrates Fast Fourier Transform (FFT) techniques to enhance computational speed. The results indicate that the computation time for single-point and average temperature predictions is reduced by more than 90%, while the simulation time for temperature distribution is reduced to just 0.14% of the original method—significantly improving efficiency without compromising accuracy.

Beyond rapid temperature prediction capabilities, the proposed engineering model serves as a practical tool for optimizing ground-coupled thermal storage system designs. Owing to its avoidance of complex functions and integral operations, the algorithm is well-suited for embedding within optimization frameworks requiring large-scale iterative computations. For instance, it enables techno-economic evaluations to analyze the impacts of borehole depth, spacing, and layout configurations under diverse operational scenarios—including inlet temperature variations, seasonal load characteristics, and charge/discharge imbalance cycles. With its dual capacity for simultaneous point-specific and average temperature predictions, the model quantitatively assesses design schemes in terms of system stability, operational efficiency, and long-term thermal equilibrium performance. Consequently, this framework functions not merely as a theoretical research instrument but more significantly as an engineering-oriented decision-support methodology, facilitating optimization of system scale, borehole configurations, and operational strategies in practical projects.