1. Introduction

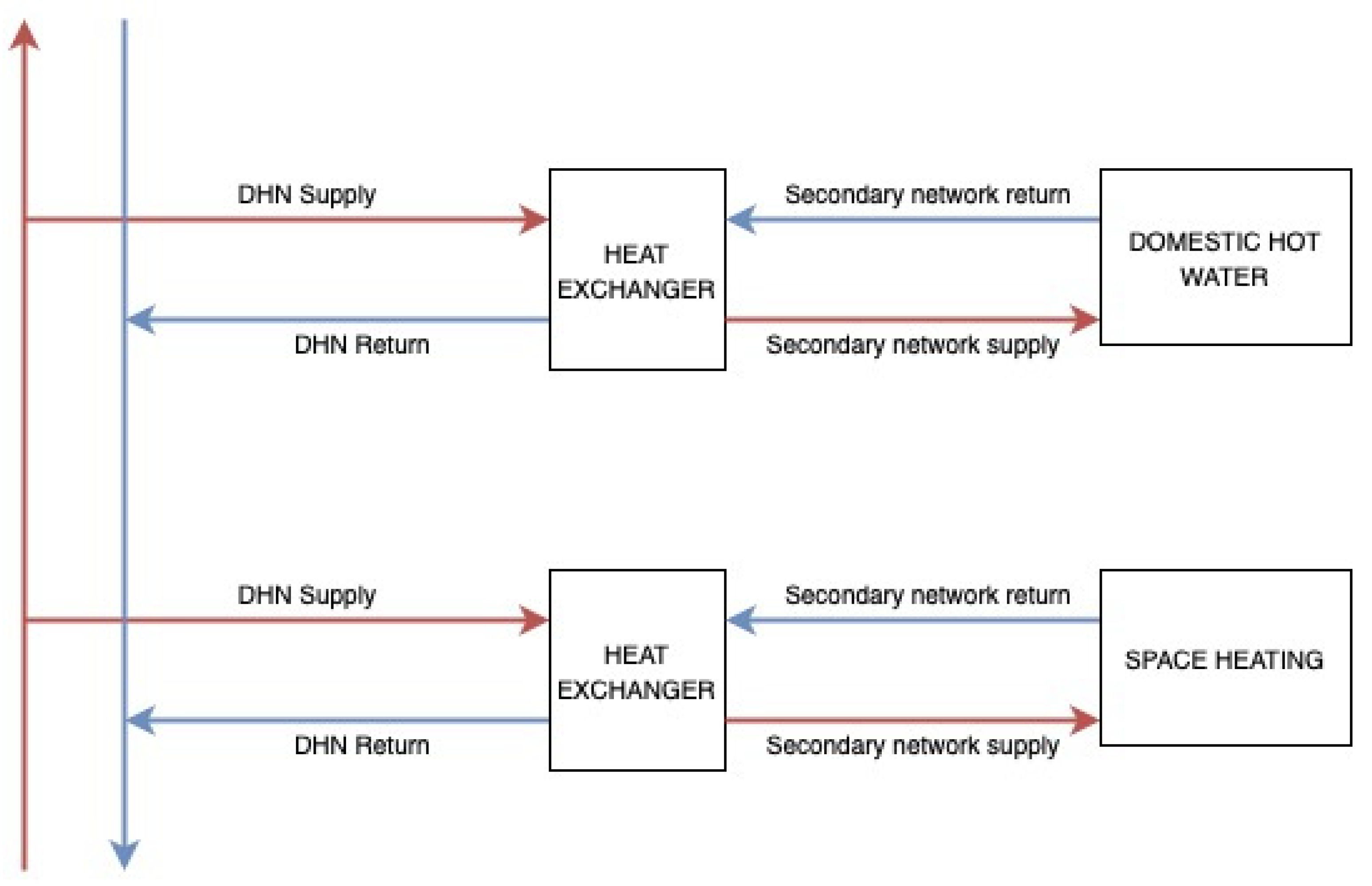

A district heating substation (DHS) is one of the main parts of a large heating system, including elements such as a combined heat and power plant (CHPP) or a district network (DHN). Reference [

1] defined district heating substations as a complex of equipment that separates district heating networks (outside the building) originating from heating installations (inside the building). There are different possibilities for designing a DHS, including parallel and serial connections, as well as the purpose of application, for example, space heating (SH) and domestic hot water (DHW). A simplified example of a district heating substation is shown in

Figure 1.

Nowadays, various aspects pertaining to the subject area of district heating substations are under investigation, including adjusting the operation of local heat source devices, utilizing district substations as elements of strategy control in low-temperature and high-temperature DHNs, recognizing heat’s consumer profiles, energy performance assessments, or new applications for DHSs. This paper reviews and summarizes various configurations of hybrid district heating substations (HDHSs) and their operating strategies reported in the literature. This article discusses the potential for the application of HDHSs considering the perspective of district heating companies.

1.1. New Business Models for DH Companies

One of the main goals in the European Union’s policy is promoting renewable forms of energy. Increased production of energy from renewable sources is an important part of various economic sectors for providing energy security, affordable heat and electricity prices, or technological development [

2]. Even if DH markets across European countries are distinct from others considering local determinants [

3], climate and energy policies define the directions of development in district heating sectors, especially in Poland, through EED, RED, EPBD, and EU ETS directives [

4]. About 50% of final energy consumption stems from heating and cooling demand, while renewable energy sources represent 26% of the total energy demand [

5]. Despite different layouts, ages, lengths, and technical states of DH systems across Europe, there are scenarios for future DH systems arising from the need for higher efficiency, expansion of the range of heat sources, and implementation of renewable energy sources that reduce the consumption of fossil fuels [

6]. These expectations direct future DH systems toward 4th-generation district heating (4GDH) and later to 5th-generation district heating (5GDHC) and the challenges related to their implementation [

7].

Along with the requirements of EU or domestic legislation and changes in heat and electricity markets, there is an opportunity and need for evolving business models for DH companies. This paper [

8] analyzes three business model scenarios for 5GDHC. This research highlights the role of each stakeholder in each scenario. It is indicated that existing high-temperature DH systems in Baltic States, which are well maintained, could be the main barrier for the development of 5GDHC. Additionally, it is pointed out that the main competitor for 5GDHC could be individual heating and cooling solutions. The authors in [

9] analyzed three cases of local application of heat pumps in addition to existing DH connections in Sweden. Two main business model concepts were recognized, both based on spot prices in the electricity market and marginal production cost. The results indicated that both building owners and DH companies can achieve financial and emission savings. The authors in [

10] performed a simulation of three alternative DH systems to examine how large-scale heat pumps could affect DHN from the perspective of DH companies in Finland. The results indicate the potential for applying heat pumps in production systems at a level of approximately 10–25% of heat production, while concurrently emphasizing the need for future investigation of potential business models. Reference [

11] conducted research based on an Austria-wide survey of industrial companies that supply waste heat to DHN. One aim of the study was the evaluation of a business model design associated with external waste heat cooperation. The risk from the perspective of district heating operators and industrial facilities was pointed out.

It is well-known that the role of prosumers will take on increasing significance in the DH system transition. With the transition to 4GDH grids, prosumers could help overcome technical barriers to the inclusion of low-temperature heat or increase the effectiveness of the system. The development of distributed energy sources may cause a loss of market share for district heating companies. The research by [

12] investigated the drivers and barriers for prosumer integration in the Swedish DH sector in terms of DH companies and prosumers. The study presented in [

13] investigated 40 DHNs in operation in Europe that are able to cover heating and cooling demand through installed reverse water heat pumps at customer DHSs. Various configurations of hybrid district heating substations (HDHSs) have been encountered in the survey. The most common technological arrangements of a substation are described. In [

14], the authors evaluated the influence of different prosumer side-system configurations in HDHSs on a DH network by simulating realistic scenarios. The scenarios consisted of various heat sources (heat pumps, solar thermal collectors, and combustion devices).

District heating companies are facing a challenge in the energy transition. Changing conditions in the energy market, the development of “energy societies”, and the promotion of local energy sources require district heating operators to adapt their business model. One of the key approaches could be cooperation with prosumers through the application of hybrid district heating substations. Due to the importance of national regulatory conditions and the local environment of the district heating system, this topic requires further research, especially in the context of Poland.

1.2. Heat Demand Forecasting for DHSs

Presently, the heat source in district heating networks is mainly supplied by the combustion of fossil fuels. As a result, the heat provider does not need to identify heat consumers’ behaviors in detail. Operators of modern DHNs will require more detailed information on how heat systems work to allow for the incorporation of renewable heat sources and their management, as well as the reduction of heat losses and final heat consumption. Paper [

15] devised a methodology to evaluate the effect of lowering district heating supply temperature on the end user. Heat flows for all stages, starting from the primary heat exchanger to the heat released into the room, were mathematically modeled. The researchers in [

16] proposed an operational analysis method for building-side district heating substations. Holistic Operational Signatures analysis provided more insight about district heating substation design, operation, control, and the potential for heating efficiency improvements. In [

17], the authors performed an analysis based on smart-meter data collection from 61 public buildings in Copenhagen to quantify the peak load in the building cluster and to investigate the case study on load shifting. A numerical model of a building was developed, calibrated, and validated using time-series measurements of two heating seasons. Study [

18] examined smart-meter consumption data and identified autocorrelation in the dataset. The paper proposed a distance-transformation method of input data to enable the application of K-means clustering of DH substations, based on a dataset with identified autocorrelation. The authors of [

19] proposed a data-driven approach aiming to discover heat load patterns in district heating. A total of 1222 buildings connected to the district heating network in the south of Sweden were clustered into groups based on customers’ profiles. Their representative load patterns were extracted, and unusual customers with significantly mismatched profiles were identified. Paper [

20] presented an energy performance assessment method for a DH substation based on the energy disaggregation process. Due to the lack of detailed consumption data, the paper illustrated an approach composed of data pre-processing, establishing energy signatures for selected components and determining potential energy savings in comparison with reference benchmarks. The authors in [

21] conducted research to develop energy performance assessment methods for DH substations based on real data. The authors identified the most influential factors for heat exchange stations and divided them into three categories: area, time, and outdoor weather. In the publication, six different multiple linear regression models were developed and examined using the recognized variables. In [

22], the researchers presented a data-driven approach for thermal load forecasting in buildings. A performance comparison among machine learning methods was conducted. The following forecast models were studied in the paper: regression tree, support vector machine, feed-forward neural network, and multiple linear regression. The historical values of heat demand, weather parameters, and time factors (variance in hours per day) were taken as inputs.

The literature review shows that energy efficiency management is crucial for boosting energy savings in district heating networks and for accomplishing energy transition targets. It requires a change in approach to energy performance assessment, the sizing of heat sources and the application of new technologies based on real data-driven tools.

2. Hybrid District Heating Substation Systems Configurations

2.1. District Heating Substations for Heating Purposes

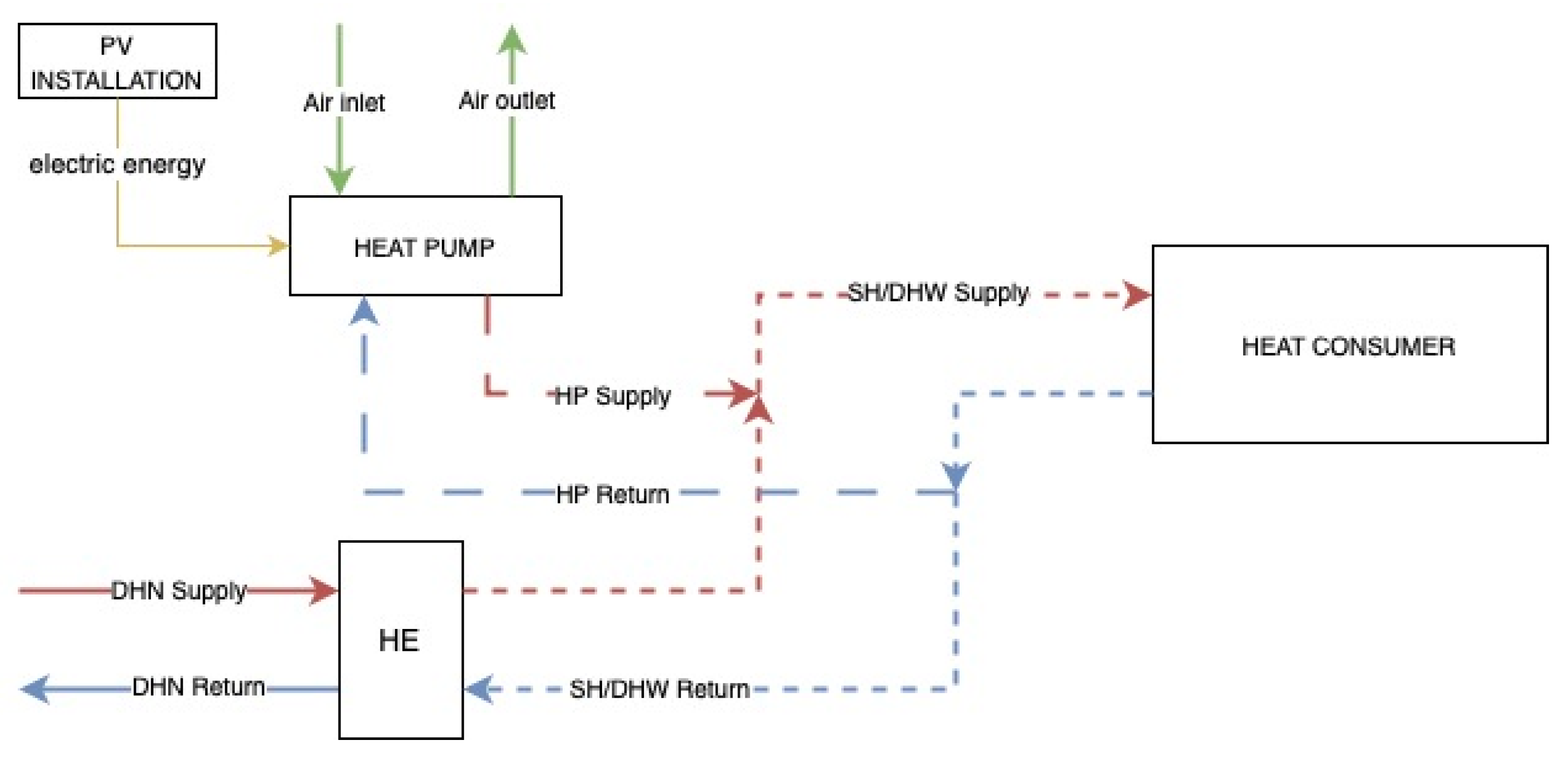

Within the literature, numerous examples of hybrid DH substation configurations can be identified. The most prevalent HDHS systems are those utilizing an additional heat source in the form of a heat pump. The study presented in [

23] developed several distinct variants of a computational model of a district heating substation under Polish climate conditions. Calculations were conducted based on historic data. One of these variants involved the use of a compressor air–water (A-W) heat pump installed on the secondary (consumer) side of the DHS. In this concept, the A-W heat pump is connected to the return of the heating system before the heat exchanger. It was assumed that a certain amount of water would be heated to 55 °C and then mixed with the remaining water flow just before entering the secondary side of the main heat exchanger. The PV installation connection with the heat pump is also considered. The scheme of the system is presented in

Figure 2.

These operating principles enable more efficient utilization of additional heat sources. This is because a heat pump does not have to warm up water to the temperature required by the heating system, which could be higher than 65 °C depending on heat demand and the type of heating installation. The COP (coefficient of performance) of a heat pump is most sensitive to the temperature at the inlet of the heat pump on both the evaporator and condenser sides. The lower the temperature of water at the inlet of the heat pump (condenser side) at a constant outside air temperature, the higher the COP of the heat pump. The study in [

14] pointed out that maintaining a constant temperature difference between supply and return temperatures allows for maximization of the efficiency of the heat pump. Lower temperatures to which the medium is heated also allow for a broader operational range of the heat pump, which might be restricted by the working fluid’s (refrigerant) specification.

In [

24], the authors proposed an innovative thermomodernization of a district heating substation in Polish climate conditions in terms of environmental and economic savings. Several scenarios, including different investments and purposes for heating (domestic hot water, space heating, ventilation), were analyzed. As part of the work, the existing system was converted into a hybrid district heating substation by integrating an additional heat source represented by an A-W heat pump connected to a PV installation. The assumptions of system operations were as follows: the A-W heat pump operates as the main heat source in the HDHS for outdoor temperatures above 2 °C, and the rest of the required heat is supplied from the DHN. A scheme of the system is presented in

Figure 3.

Design assumptions aimed at maximizing system performance enable operation of the heat pump at a relatively high COP before the inflection point of the A-W HP’s efficiency curve, which usually occurs below 2 °C. It should be ensured in the future that the threshold of outside temperature at which the device could operate cost-effectively is investigated for that kind of additional heat source. It is also important to determine if this is the same level for different district heating systems. The application of alternative devices for heat generation in HDHSs such as water–water (W-W) heat pumps, electric, or electrode-type boilers should be evaluated in the future.

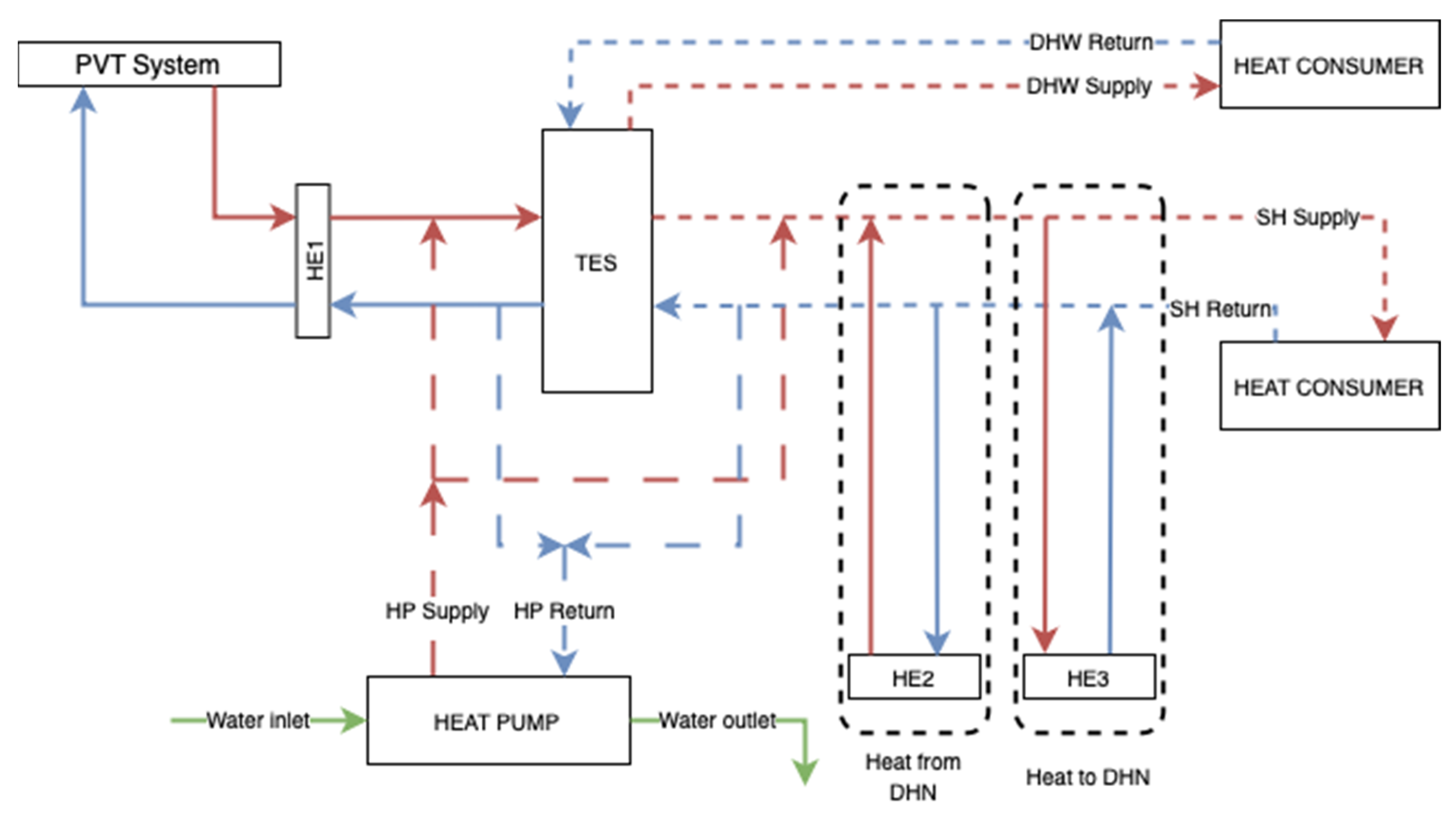

Among the available options for renewable energy integration, the PVT (Photovoltaic Thermal) collector is a promising technology. The potential of PVT systems for heating and cooling purposes is widely described in [

25]. Despite its lower efficiency than solar collectors, which require a larger surface area required for installation, cooperation with a DHS could be profitable. In [

26], the researchers examined three configurations of the PVT system integrated with a DHN for a multifamily building under Central European conditions. Two of the proposed configurations assumed PVT’s heat production for DHW and SH demand and cooperation with thermal energy storage, including one in which the waste heat is directed to the return pipeline of the district heating network. The third configuration assumed that the PVT system operates as a micro-installation producing heat only for DHN purposes. In this configuration, no water tank was used, but the power of the HP had to be increased. All configurations assumed that produced electric energy was sold to the electrical grid. The hybrid system configuration is shown in

Figure 4.

The proposed hybrid system consists of a PVT collector, a water tank with a volume equivalent to one week’s worth of DHW usage, a heat pump, and a connection to the DHN. The thermal storage functions as a heat exchanger between the PVT and the secondary circuit of DHW and SH. As PVT systems are not always able to produce heat at temperatures over 60 °C, the configuration assumed an auxiliary unit, which is a heat pump. Its target is to maintain the temperature of the water tank heat storage at 60 °C. This temperature allows the use of heat for DHW purposes. It would be valuable to consider the application of another additional heat source instead of the HP in future investigations. Integration of electric heaters seems to be a promising option due to their lower investment costs and increased flexibility [

27].

The results show that the configuration with the PVT system could cover 24% of the heat demand of the building. Additionally, the 4% of excess heat produced by the PVT system could be used to supply the DHN. However, the most profitable configuration for consumers is the one where the installation serves as a micro heat source for the DHN. It needs to be investigated how PVT systems could be incorporated into the DHS from the perspective of DH companies. The configuration of PVT as a micro-installation on a large scale may reduce the operational load of central heat generation units, especially during the summer period.

During the ongoing transformation in the housing sector, there is a diverse range of building types. The significant share of low-quality buildings and their increased energy demand [

28] create the need to supply high-temperature heat to customers (both for the primary circuit of the substation and for building heating installations). Today’s existing DH systems supply heat to diverse buildings. It is expected that a key factor in lowering the energy demand of buildings will be their thermomodernization over the next decades [

29]. This means that district heating networks will deliver heat to buildings equipped with both kinds of installations—radiators and surface heating. The surface heating systems are characterized by a lower supply temperature (in the range of around 35–45 °C) than radiator heating systems (with supply temperatures in the range of 55–65 °C). In [

30], the authors designed a concept and [

31] discussed control strategies for dual-temperature district heating substations, which aimed to improve energy efficiency using the specifications of internal heating distribution systems and two additional heat sources—absorption heat pumps (AHPs). The scheme of the system is presented in

Figure 5.

In this case, the primary circuit is supplied from the DHN with temperatures in the range of 90 to 130 °C, which in turn supplies the AHP’s desorbers connected in series. Then, the water at a temperature of around 65 °C flows into the heat exchanger connected to the radiator’s distribution system. In the next stage, the primary circuit water, cooled to 47 °C, enters the heat exchanger between the floor heating system and the primary circuit. After that, the water at a temperature of 32 °C leaves the heat exchanger and flows into the evaporator of the first AHP in the series. After leaving the second heat exchanger, the primary circuit flow is directed to the evaporator of the second AHP, where it is cooled to around 20 °C and then returned to the DHN. Simultaneously, the secondary flows of radiator and floor heating distributions system circulate through the absorbers and condensers of the AHPs. This approach significantly improves efficiency by reducing the primary circuit return temperature by 75–120 °C depending on the primary circuit supply temperature. This means that the primary circuit return temperature of the DHN is close to the temperature of the return water in new-generation district heating systems. For comparison, for a traditional DH substation, the difference between supply and return temperatures is in the range of 20–55 °C (depending on heat demand, external weather conditions and the heating curve), and the return temperature is reduced to temperatures in the range of 45–65 °C. The COP of the absorption HP in this setup ranges from 1.4 to 1.7 depending on heat demand and the primary circuit hot water inlet temperature. It is important to point out that this kind of hybrid system solution does not contribute to accelerating the transition towards low-temperature district heating networks, as it needs high supply temperatures at the inlet. However, it might be applied in specific cases during the transition period when the supply temperature in the DHN remains high in order to reduce heat losses.

The authors in [

32] investigated the integration of a district heating substation with an absorption heat pump with the aim of improving the utilization of a low-temperature geothermal energy source. The designed system was simulated to assess how different operational parameters could affect the performance of the AHP. The scheme of the system is presented in

Figure 6.

The configuration of the primary side of HDHS comprised two plate heat exchangers, a geothermal well and an absorption heat pump. At the first stage, the supply of primary water at a temperature over 100 °C enters the generator of the AHP. On the other side of the AHP, a portion of secondary network water passes through the absorber and condenser of the AHP. After leaving the AHP, the cooled medium flows into the plate heat exchanger connected to the supply (outlet) and return (inlet) of the secondary side circuit. The supply water flow at a temperature in the range of 50–70 °C from the geothermal well enters the heat exchanger, which transfers heat to the secondary circuit. At the second stage, the water flow at a temperature of 30–40 °C enters the AHP’s evaporator and then returns to the well at a temperature below 25 °C. The secondary heating network supplied the floor heating systems designed for supply/return temperatures of 45 °C/35 °C.

A case study for this HDHS was conducted in the business center within one of the Chinese district heating systems. For the design parameters of the system, the COP of the AHP was 1.78, which is comparable to the values of AHPs in the system proposed by [

30]. The results of the case study show that the application of a district heating substation with an AHP could increase the potential for using renewable energy sources for heating purposes. It could also provide economic and environmental benefits.

2.2. Cooling District Heating Substations

In current large DHSs, the central unit is typically a combined heat and power plant (CHPP). It is designed to prioritize heating demands of the DHN over power generation. In the summer period, the DHN is responsible for supplying heat primarily to meet the heat demand for domestic hot water. While the CHPP is operating in summer mode, the unit operates at lower loads, which results in lower electrical efficiency and higher operational costs [

33]. Moreover, due to low heating demand, there is widely available heat from sources such as solar plants or waste heat. Using heat from these sources could help to achieve Energy Efficiency Directive (EED) criteria, which imposes specific requirements on “Efficient District Heating and Cooling” (EDHC) [

34].

One of the ideas to increase heat demand during the summer period is to produce cold through the use of heat from the district heating network. The incorporation of heat pumps into district heating and cooling systems in centralized and distributed configurations was discussed in [

35,

36,

37]. Paper [

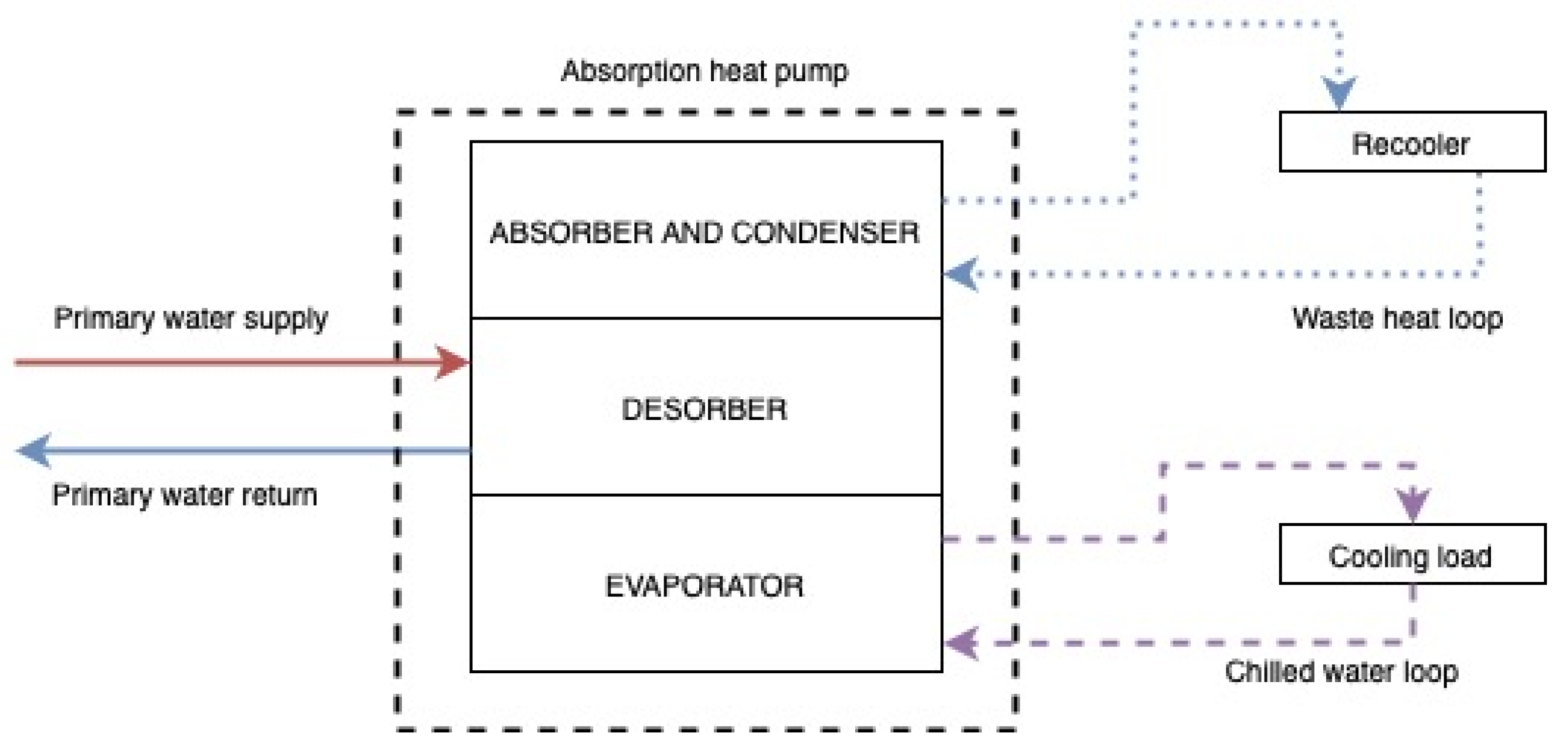

38] examined the possibility of using absorption heat pumps in current high-temperature and future low-temperature district heating substations. One of the advantages of using an AHP in a DHS is its option to operate in cooling mode. The operation of the AHP in cooling mode enables it to cover the cooling demand of buildings, as cooling demand will increase in the future due to changing climate conditions. It also creates new opportunities for the development of new business models by district heating companies. A simplified scheme of the AHP operating in cooling mode is presented in

Figure 7.

In cooling mode, the primary water supply flows into the generator of the AHP, where, due to warming up, the separation of the working fluid from the solution occurs. The vapor of the working fluid is directed into the condenser. In the evaporator, the working fluid evaporates due to heat exchange with a secondary cooling network. The vapor of the working fluid is directed into the absorber, where it is absorbed by the absorbent. This is an exothermic process in which the surplus heat is removed. Based on the values of input parameters, such as temperatures on the inlet to the evaporator and the generator or according to parameters of the selected mixture used as the working fluid, the COP of the AHP in cooling mode is in the range of 0.68 to 0.769 [

38,

39].

An example of a device that can also convert low-temperature heat into cooling generation is an adsorption heat pump. The operating principles of adsorption heat pumps are comprehensively described in [

40,

41]. Despite being a technology known for years, adsorption heat pumps are less common compared to compressor chillers because of higher investment costs, lower efficiency, and larger dimensions. With the increasing importance of energy efficiency enhancement through the use of renewable and waste energy sources, adsorption heat pump technology shows potential for application in the district heating and cooling sector.

In [

42], the authors proposed a hybrid cooling system for a building based on two cold production devices—an electric chiller and an adsorption heat pump driven by heat from the district heating network. Two main parts of the modeled configuration are the chilled water distribution system (operating under variable flow conditions) and the hybrid air conditioning system. Due to the high sensitivity of the adsorption heat pump to external parameters, high thermal inertia resulting in restricted control strategy and high investment costs, the implementation of two complementary cold sources could increase the potential of utilizing primary heat, renewable heat or waste heat in cold production. Sixteen scenarios were evaluated in the study, which varied depending on how the components were connected. The exemplary system configuration is shown in

Figure 8.

In the following system, the chillers are connected in parallel to the cooling and chilled water circuits. Part of the return flow of the chilled water circuit flows into the adsorption heat pump’s evaporator, and then the chilled water is directed to the chilled water supply. The rest is directed to an electrically driven chiller. The heat from the adsorption heat pump and the mechanical chiller is discharged to the cooling water circuit, which is connected to an open cooling tower (or recooler). The cooling water temperature has a significant impact on the efficiency of the process and the relative cooling power. Due to high pressure in the district heating network, the heat is supplied to the adsorption heat pump indirectly through the heat exchanger. The paper shows that a hybrid configuration system of 100 kW cooling power enables the utilization of 0.5–0.9 TJ of low-temperature heat per year depending on the configuration.

In [

43], the authors presented a concept and preliminary study of a hybrid district heating substation extended with a cooling system. The cold production is based on an adsorption heat pump supported by two PCM (phase change material) cold storages. The concept assumes the integration of the cooling part of the HDHS with a PV system, which will enable the use of renewable energy in the HDHS by increasing the temperature of the medium supplying the adsorption heat pump. A scheme of the system is presented in

Figure 9.

The newly added part of the system is divided by the adsorption heat pump into two subsystems. The hot circuit provides the heat supply to the adsorption heat pump from the DHN, while the cool circuit supplies the cooled medium to the cooling distribution system. The PCM storages are connected to both circuits. The purpose of the PCM storage in the cooling circuit is to balance the cold demand from the building by covering the cooling demand in peak hours. On the heating circuit side, an electric heater connected to the PV system and the PCM storage is included. The electric heater enables an increase in the temperature at the inlet to the storage up to 85 °C and then to the adsorption heat pump, which could result in higher COP and cooling capacity. Both storages could allow the implementation of more efficient control strategies for the HDHS. In [

44], the authors investigated the performance and selection of PCM storage for a similar HDHS system, with one PCM storage connected to the PV system and the supply of an adsorption heat pump. The preliminary study determined that the efficient operation of the chiller could be increased by integration with PCM heat storage. The example calculations proved that the use of storage allowed for raising the supply temperature of the adsorption chiller’s desorber by 4 °C, which resulted in a 2.8% increase in cooling capacity. The COP of the adsorption heat pump is relatively low and ranges from 0.27 to 0.65, depending on design parameters (especially the type of adsorbent and its heating performance) and operational conditions, such as variations in the heat source temperature, excessively high cooling water temperature, or too low regenerative source temperature [

45,

46,

47]. Strategies for improving the COP of the adsorption heat pump are discussed in [

48].

3. Discussion

It is widely recognized that the direction of development for district heating systems is the decentralization of heat sources. Future district heating systems are expected to decentralize large scale fossil fuel heat sources into smaller ones, based on renewable energy sources and waste heat. The hybrid district heating substation configurations presented in

Section 2 are designed to cooperate with district heating networks, which creates opportunities for decentralized energy production and storage. The integration of a hybrid district heating substation solution can play a role in supporting the transition to a decentralized DHN structure. However, the gradual development of HDHSs could enable the potential of distributed heat sources with the reduction of the DHN, especially in older systems requiring significant investments. This would create an opportunity for DH companies to develop new business models aimed at investing in and managing local distributed hybrid heat sources, for example, in multi-family housing complexes. Nevertheless, this topic warrants more detailed investigation.

An overview of all considered configurations is provided in

Table 1.

Some technological layouts may appear similar in terms of configuration or components, and their operational modes can differ significantly depending on design assumptions and control strategies. The authors of [

23,

24] proposed configurations of HDHSs based on an A-W heat pump as an additional heat source. Among the two systems, the function of the HP differs significantly. The authors in [

23] proposed the use of a heat pump for producing heat in exchange with the secondary circuit water return and heating the portion of water to a temperature of 55 °C. This strategy creates opportunities for further optimizations by selecting the HP for lower or higher heating return water temperatures (balancing between the amount of working hours and COP) or by adjusting the installed capacity of HP by considering the share of additional heat in the total heat demand. In [

24], the researchers designed the systems by setting the heat pump function as the main heat source for the water supply, under outdoor temperatures exceeding 2 °C. This approach limits the contribution of heat from the DHN and defines its role as a peak demand source. In [

26], the authors used electric W-W HP in the HDHS but restricted its role to maintaining the temperature in the water tank storage at around 60 °C, mostly during the winter season. A summary of control strategies for HDHSs supported by mechanical heat pumps is shown in

Table 2.

The function assigned to the device can influence its energy performance. The authors in [

24] based their calculations on the manufacturer’s specifications, assuming that the COP of the A-W HP equals 3.4 at an outside temperature equal to 2 °C. On the other hand, in the study by [

23], a simulation was performed based on an hourly resolution model that the A-W HP could work for a quarter of a year with an average COP close to 2.5, whereas other assumptions for the W-W HP (working conditions of 35 °C/60 °C), as proposed by [

26], lead to a COP value of 3.0. The COP values could significantly affect the cost efficiency of the project. The W-W HPs usually achieve the most stable COP, but the investment costs are higher than for the A-W HP, while the performance of the A-W HP strongly depends on external weather conditions. It seems unreasonable to implement W-W HPs as a part of HDHS with a minor share of heat demand. Analyses indicate that all considered variants may offer measurable benefits; however, it is important to correctly identify the design constraints of HDHSs, adopt appropriate design parameters, and design a control strategy for future analyses. Due to the variable nature of system operations, the time-series analysis could be preferred over design point analyses. Another contributing factor could be the introduction of dynamic electricity tariffs by grid operators. This type of tariff structure is gaining popularity in countries where the share of renewable energy on the market is growing. In such a tariff framework, the electricity prices for final customers are not constant and depend on the electricity prices on the market in a 24-h period. The variability of electric energy prices may require alternative control strategies of auxiliary electric heat sources in HDHSs and increase the importance of thermal energy storages. The appropriate control strategy could lead to increased cost savings in heat production. Moreover, if many HDHSs are integrated with district heating systems, this would create opportunities for district heating operators to manage the network by using all these substations as a single distributed heat storage system. Such solutions require further research in the future.

The authors of [

23,

24] analyzed various HDHSs equipped with A-W heat pumps operating in conjunction with PV installations. In [

23], the authors calculated that the installation of a 6 kW PV system can reduce the electric power demand of a 30 kW heat pump compressor by 1%. The study [

24] concluded that the longest payback period was observed for a system that combined a heat pump and a photovoltaic system. It was proven that PV-assisted A-W HPs operating with thermal energy storage (TES) and a proper control strategy can potentially save up to 20% of energy consumption cost in residential buildings [

49]. It is also known that a correlation exists between wind speed and heat demand, which could enable the use of small wind turbines to provide an electric energy supply for heat pump compressors [

50,

51]. Extending the analysis further, particular attention should be paid to hybrid (wind and solar) renewable energy systems for the purpose of electrically driven heat sources. A range of hybrid-based systems can be found in the literature [

52,

53,

54,

55], offering different configurations of heating systems and operational strategies for other types of heat pumps. The issue of additional renewable electrical energy sources in HDHS systems in Polish climate conditions has not been comprehensively examined and needs further investigation.

The authors of [

30,

32] investigated hybrid configurations with absorption heat pumps supplied by high-temperature heat from the DHN. For design parameters of the system, the COP of the absorption heat pumps was 1.78, which is comparable for both configurations. Both systems are designed to use the potential of low-temperature heat and improve the energy efficiency of heat distribution. However, the discussed configurations strongly depend on local conditions and their intended use. Such solutions are unlikely to be applied more broadly in district heating networks, especially due to the high-temperature heat requirements for absorption heat pump desorbers, but under certain conditions, absorption heat pump systems can contribute to the utilization of low-temperature energy sources. In future district heating systems, the configurations of HDHSs based on absorption heat pumps for heating purposes could be justified only when high-temperature waste heat or geothermal energy is available. However, the application of the absorption heat pumps in district heating substations could extend heat demand (and consequently, CHPP source utilization) in the summer period. In [

38], the authors investigated an absorption system for cooling purposes. This application can offer significant benefits for district heating companies, as it creates an opportunity to broaden the heat market in the summer when heat demand is low. Such solutions also enable greater utilization of renewable energy sources, as cooling demand is correlated with insolation.

Concepts based on the assumption of extending heat demand during summer were proposed in [

42,

43]. Both concepts assumed the implementation of adsorption heat pumps as an element of cooling HDHSs. Due to the limited control flexibility of the adsorption heat pumps, both configurations incorporate elements to improve energy management potential and peak load reduction. The authors in [

42] proposed a compressor chiller as an additional component of HDHSs, whereas the paper by [

43] incorporated two PCM storages into the concept. This kind of solution could effectively increase heat demand in off-heating periods and create new business opportunities for DH companies, but due to the relatively low COP of adsorption heat pumps, the configurations could not be sufficiently competitive compared to electric cooling technologies.

This literature review has shown that the implementation of HDHSs into district heating networks can increase the share of renewable energy or waste heat sources in the heating system. This was confirmed in the analyses presented in [

26,

32,

43]. However, the authors of [

23,

43] have shown that in the configurations involving the use of the PV for reducing the necessity of electric energy purchases, the application of PV had a marginal impact on the advancement of energy balance and could produce even worse economic indicators.

The modernization of existing DHSs could be subject to limitations due to restricted area, outdated heating installation, or the possibility of using new heat sources, like waste or geothermal heat. Therefore, not every HDHS configuration could be commonly used, which leads to the conclusion that the implementation of hybrid solutions should be preceded by thorough analysis.

The implementation of HDHS into district heating systems involves potential risks from the perspective of district heating companies. Auxiliary heat units in HDHSs will reduce the heat contribution from the central system. Consequently, in the case of many hybrid installations integrated with the network, central heat sources would produce less heat and electricity in cogeneration because of lower heat demand. Decreasing the load of production systems will result in lower efficiency of production units. Consequently, the costs of heat production will be higher due to increased fuel consumption and lower electricity sales revenue. Moreover, numerous heat production units operate under obligations arising from support mechanism conditions, such as a bonus tariff for cogeneration systems. Reduced production of heat at CHPP could cause difficulties in meeting the requirements of support mechanisms. This also may extend the payback period of investments.

In order to gain a clearer understanding of the differences between each configuration and to prepare a reliable comparative analysis of HDHSs, further research should be directed toward the development of scalable thermodynamic models capable of representing different types of HDHSs, including novel configurations not yet described in the literature. Such models would enable carrying out a comparative analysis under unified boundary conditions. These include identical customer heat-load profiles, energy market price scenarios, DHN operating parameters and the structure of heat generation sources. This approach could provide more comprehensive environmental and technical analysis. Moreover, this approach is fundamental for calculating the economic indicators; however, it is essential to discuss the perspective of DH companies, as they are mostly owners and operators of DHSs.

4. Conclusions

Along with increasing environmental and efficiency-related measures, the implementation of hybrid district heating substations has become more widespread. This research proves that hybrid configurations with proper control solutions could represent an efficient solution for enhancing the utilization of renewable energy sources, reducing emissions from fossil fuel combustion and prices for heat consumers. Along with the development of next-generation district heating systems, such solutions are likely to be implemented more broadly in the future, but under certain conditions. It is essential to develop suitable regulatory frameworks. Nowadays, the law in Poland does not define if the heat produced by additional heat sources in HDHSs could be considered as heat delivered from the district heating system and accounted for regulatory reporting and energy balances. Appropriately formulated legislation could encourage district heating companies to invest in the modernization of existing district heating substations or in designing new configurations. The lack of such a regulatory framework could lead to investments in HDHS solutions being made privately by building owners or local housing cooperatives seeking to reduce heating costs. From the perspective of district heating companies, such initiatives result in a risk of heat market loss. However, the development of cooling HDHSs creates opportunities for strengthening their market presence, especially during summer periods. This requires the development and implementation of new business models by district heating companies.

Based on the discussed configurations, it can be concluded that hybrid district heating substations can be effectively applied in modern and future district heating systems. These solutions may improve energy efficiency and environmental indicators, reduce the cost of heat for consumers, and create new opportunities for extending the heat market for district heating companies. HDHSs also provide new possibilities in energy management for district heating operators. However, it is important to ensure proper design and control strategy adapted to local conditions. According to the discussed literature, the heat pumps show the highest potential for application, but not all possible configurations have been described in the literature, and the topic requires further investigation.