1. Introduction

Buildings are among the largest consumers of energy worldwide, accounting for 34% of the global energy demand, and 37% of the energy and process-related CO

2 emissions in 2022 [

1]. In the UAE, the buildings sector contributes to nearly 70% of total national electricity usage, primarily driven by the need for year-round cooling in its hot and arid climate, and generates approximately 540,000 tonnes of greenhouse gas (GHG) emissions [

2]. These energy-intensive characteristics highlight the important role of the buildings sector in tackling climate change, driven by GHG emissions resulting from conventional energy generation using fossil fuels. A study by the Emirates Green Building Council (EGBC) indicated that the UAE’s buildings sector has the potential to contribute over 42% of the energy intensity reductions needed by 2030 to stay within the Paris Agreement’s 1.5 °C target [

3].

Recognizing this opportunity, the UAE launched its Net Zero 2050 initiative in 2021, aligning its commitment with the global goals of the Paris Agreement, with significant emphasis placed on enhancing energy performance in the built environment [

4]. Since then, the UAE has invested in various research and development programs, national schemes, and regulations to improve building design, performance, and operations. Mandating the design of built environments in line with the local green building certifications is one such measure. According to Odriguez-Ubinas et al., buildings complying with national regulatory certifications—such as Estidama in Abu Dhabi, Al Sa’fat in Dubai, and Barjeel in Ras-Al-Khaimah (RAK)—have proven to yield 30–40% long-term cost savings on utility bills compared to traditional buildings [

5]. These certifications not only enforce stricter building performance metrics but also integrate indoor environmental quality (IEQ) requirements, including thermal comfort, as a key certification criterion. Green building rating systems such as LEED, Estidama, and Al Sa’fat mandate compliance with their IEQ requirements, which are aligned with internationally recognized thermal comfort standards such as ASHRAE Standard 55 and ISO 7730 [

6,

7,

8].

Thermal comfort has evolved to be a critical component in measuring building IEQ, playing a vital role in the design and performance of energy-efficient buildings, particularly in the post-COVID era, to address the rising demand for healthier indoor environments and reduce various transmission risks. It reflects the occupants’ level of satisfaction with the thermal conditions in a space and is directly influenced by variables such as air temperature, humidity, air velocity, radiant temperature, metabolic rate, and clothing insulation. Universities and educational institutions now face amplified expectations for occupant well-being, driving the need for integrated retrofit strategies that balance health, comfort, and sustainability. The Fanger model of evaluating thermal comfort remains predominant when measuring levels of occupant comfort, utilizing two key indices: the Predicted Mean Vote (PMV) and the Predicted Percentage of Dissatisfied (PPD). PMV predicts the average thermal sensation of a set of people on a seven-point thermal scale ranging from −3 (cold) to +3 (hot), while the PPD estimates the proportion of individuals likely to feel thermally uncomfortable under those conditions [

9,

10]. According to the ASHRAE Standard 55 and ISO 7730, optimal comfort is achieved when PMV ranges are maintained between −0.5 and +0.5, while stabilizing PPD values below 10% [

7,

8,

9,

10].

While these design standards and guidelines offer a structured framework for evaluating occupant comfort, their direct applicability in hot-arid and semi-arid climates like those in the Middle East has been re-evaluated by several researchers. A review of regional thermal comfort studies reveals a noticeable divergence between predicted and actual occupant responses under local conditions. A study conducted by Al-ajmi et al. in 2010 analyzed thermal comfort conditions among 111 occupants of air-conditioned domestic buildings across Kuwait’s dry-desert climate and found that the optimum operative temperature based on Actual Mean Vote (AMV) was 25.20 °C, while the Predicted Mean Vote (PMV) indicated a lower neutral temperature of 23.30 °C [

11]. Similarly, another study by Al-ajimi on thermal comfort in mosques in Kuwait, based on both physical measurements and occupant feedback, indicated a preferred neutral temperature of 26.10 °C, substantially higher than the 23.30 °C predicted by the PMV range [

12]. This 2.80 °C discrepancy between the perceived and predicted ranges depicted the limitations of conventional comfort models when applied to culturally and climatically distinct contexts. This discrepancy suggests that Fanger’s thermal comfort model, as adopted in ISO 7730 and ASHRAE 55, may not fully capture real comfort responses in arid environments, potentially underestimating what occupants actually find acceptable [

12]. As such, a number of regional studies in the Middle Eastern region revolve around developing adaptive thermal comfort models and design guidelines that are not directly equated with international codes but are tailored to better reflect the region’s specific climatic context and occupant behavior.

Further evidence supporting the need for regionally adapted models is provided by Elnaklah et al., who in 2021 investigated 31 air-conditioned buildings in four Middle Eastern countries involving over 1100 occupants. The findings of this study revealed that despite 58% of indoor measurements falling within ASHRAE 55 and ISO 7730 comfort ranges, only 40% of occupants reported feeling thermally satisfied. Notably, 94% of cases exhibited a mismatch between PMV predictions and actual thermal sensation votes, with many occupants feeling cold despite model projections indicating slight overheating. These findings suggest a fundamental disconnect between standard comfort models and perceived experience in the Middle Eastern region, highlighting the need for adaptive comfort approaches that better reflect the regional climate, as well as occupant behavior and cultural practices [

6].

Moreover, regional studies have emphasized the influence of clothing insulation, which varies significantly due to cultural dress norms. Existing research in Middle Eastern buildings has reported average clothing insulation values ranging from 0.75 to 1.20 clo, with a mean value around 0.9 clo, which is found to be considerably higher than the assumptions typically used in PMV-based assessments [

12].

A growing number of local Green Building Codes (GBCs) have begun to acknowledge these contextual distinctions. Out of fifteen countries in the Middle East, eight have established local GBCs that incorporate ASHRAE 55 and ISO 7730 compliance. These include systems such as Estidama Pearl Building Rating System (based in the UAE), Global Sustainability Assessment System, GSAS (from Qatar), and Mostadam (from Saudi Arabia) [

6]. Common elements among these GBCs include requirements for occupant thermal control, zoning, operable windows, and sensor controls. GSAS mandates the post-occupancy thermal comfort surveys, while both GSAS and Mostadam require thermal comfort modelling at the design stage. This illustrates a regional trend toward integrating international best practices while adapting them to local expectations [

6,

13,

14].

Additionally, adaptive comfort research has demonstrated the potential for energy savings when thermal comfort benchmarks are regionally recalibrated. Elnaklah et al. found that increasing indoor temperatures in offices in Amman and Doha by 2.30 °C and 4.10 °C, respectively, resulted in annual cooling energy reductions of 20% and 13%, respectively. These findings reinforce the dual benefit of tailoring thermal comfort standards to actual occupant preferences, not only enhancing occupant comfort and wellbeing but also improving energy efficiency [

6].

One way of addressing the need for such performance improvements in buildings is through innovative technologies such as digital twin (DT) development. DT technology addresses this challenge by enabling the creation of virtual models that mirror the physical characteristics and real-time performance of buildings. This technology offers a comprehensive approach to modelling energy-efficient buildings by simulating real-world performance and predicting energy consumption patterns. The concept of DT, first proposed by Professor Grieve at the University of Michigan in 2003, involves constructing a digital replica of a physical entity, with continuous interaction between the real and virtual worlds to optimize performance [

15]. Digital twins therefore provide a dynamic digital representation of a building’s lifecycle, integrating real-time data to track energy usage, thermal performance, building systems interactions, and project renewable energy generation. This enables early-stage prediction of building performance from design through construction and into the operational stage, making it more efficient and cost-effective for designers and various stakeholders to undertake informed decisions in sustainable building design and operations.

A study conducted by Sun et al. highlighted the effectiveness of DT technology in evaluating the impact of photovoltaic solar module configuration angles on building energy consumption [

16]. The study revealed that DT technology provided more accurate energy consumption predictions compared to traditional methods like real-time monitoring of similar buildings and Building Information Modelling (BIM). These insights demonstrate the transformative potential of digital twins in achieving energy-efficient and sustainable building designs, aligning with global decarbonization efforts.

Energy consumption of buildings in Arab countries has been found to have steadily increased over the past 25 years, based on a recent study by M Krarti [

17]. The research projected that if the rising trend in Energy Use Intensity (EUI) persists within Arab countries, building energy consumption will reach 1450 TWh by 2030, which would be twice the EUI levels recorded in 2006, and could escalate further to 2000 TWh by 2050, which would be twice the EUI levels recorded in 2015 [

17]. Moreover, the government has realized that the prime hurdle in combating this EUI rise lies in the region’s older building stock, constructed before 2001, lacking energy-efficient systems, energy monitoring, or thermal insulation, for which mandatory retrofitting incentives were launched [

18]. According to research conducted by Alkhateeb et al., it was found that applying feasible retrofitting measures to an old federal building in RAK, such as U-value optimization, chiller Coefficient Of Performance (COP) optimization, and integration of rooftop PV panels, can yield a 63.2% savings in energy consumption [

3]. In 2023, the Dubai Supreme Council of Energy (DSCE) reframed its Building Retrofit Programme to align with the Dubai Net Zero Carbon Emissions Strategy 2050. Since the programme’s launch in 2015, roughly 8000 buildings, including 7791 government-owned facilities, have been retrofitted, targeting improvements in air-conditioning systems, lighting, building envelope performances, and rooftop solar installations. As part of the programme, DSCE aims to scale up to 30,000 retrofitted buildings by 2030, leading to projected savings of 1.4 TWh of electricity, and offsetting over 1 million tonnes of CO

2 emissions [

18,

19,

20]. Similarly, in Abu Dhabi, the Department of Energy (DoE) reported that retrofit projects in 2024 delivered around 185 GWh of energy savings, with plans to retrofit 200 buildings in 2025, and 300 buildings by 2026 as part of an ambition to drive a ten-fold rise in retrofitted assets under the Emirate’s Demand Side Management (DSM) Strategy 2030 [

21]. The Dubai Chamber of Commerce building, having a GFA of 226,042 sq.ft., was able to achieve a LEED Platinum certificate in 2009 by reducing its energy use by nearly 47% [

22]. Another remarkable study by the Dubai International Financial Centre (DIFC) in Dubai revealed that as part of a retrofit and sustainability initiative in 2023, the iconic building received a LEED Platinum certification backed by energy-efficient HVAC systems, LED lighting and controls, and solar PV integration, contributing to overall savings of 0.5 million kWh per year [

23].

A wide array of retrofit measures can therefore be implemented, using passive, active, and behavioral change strategies. This paper specifically examines the effects of implementing various passive and active retrofitting measures on the case study building assessed within the research. Passive retrofitting strategies generally have a greater impact on reducing the space heating or cooling energy demands, while futureproofing the buildings from projected climate change impacts. Hanan M. Taleb’s research on residential buildings in the UAE revealed that passive strategies alone could reduce cooling loads by 23.60% [

24,

25]. The research also observed that active measures such as optimizing cooling or heating set points are highly effective in cutting energy usage without any upfront costs [

24]. A market survey conducted by the EGBC states that the biggest challenges to retrofits in the UAE are the lack of financial incentives and low tariff rates, resulting in long paybacks and high capital costs that lead to a lack of interest from building stakeholders [

18,

26].

Although green building certification systems aim to promote energy efficiency and thermal comfort, there is a noticeable difference between the expected energy performance during the design phase and the actual energy use once the building is operational. This difference, known as the ‘performance gap’ in the existing literature, has been studied by many researchers. Studies have shown that commercial buildings can emit up to 3.8 times more carbon than predicted during the design stage, despite having a green building certification [

27]. A study by Wilde that evaluated multiple certified buildings to identify their performance gaps revealed that while most LEED-certified buildings demonstrated 18–39% energy savings during the design stage, their actual energy consumption during operational stages was found to be 28–35% more than conventional non-certified buildings [

27].

While existing research focuses on retrofitting older, inefficient buildings, there is limited investigation into improving the energy performance of newer buildings that already meet local design codes and green certification requirements. These structures still have potential for further optimization through the implementation of additional energy-saving measures or the integration of renewable energy sources. This study addresses that gap by evaluating a recently constructed, LEED-certified building to determine how its energy performance can be further optimized beyond the existing standards.

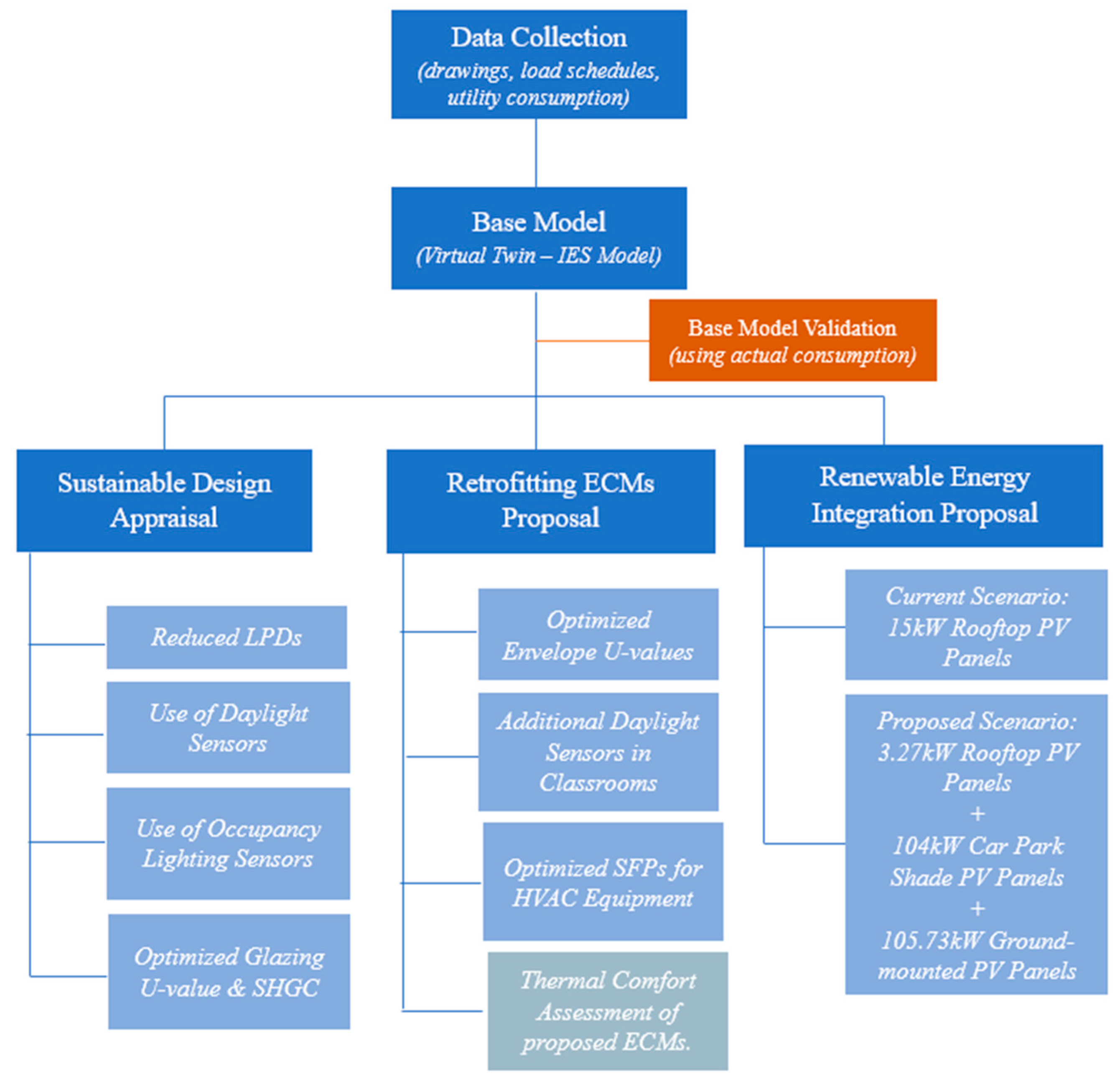

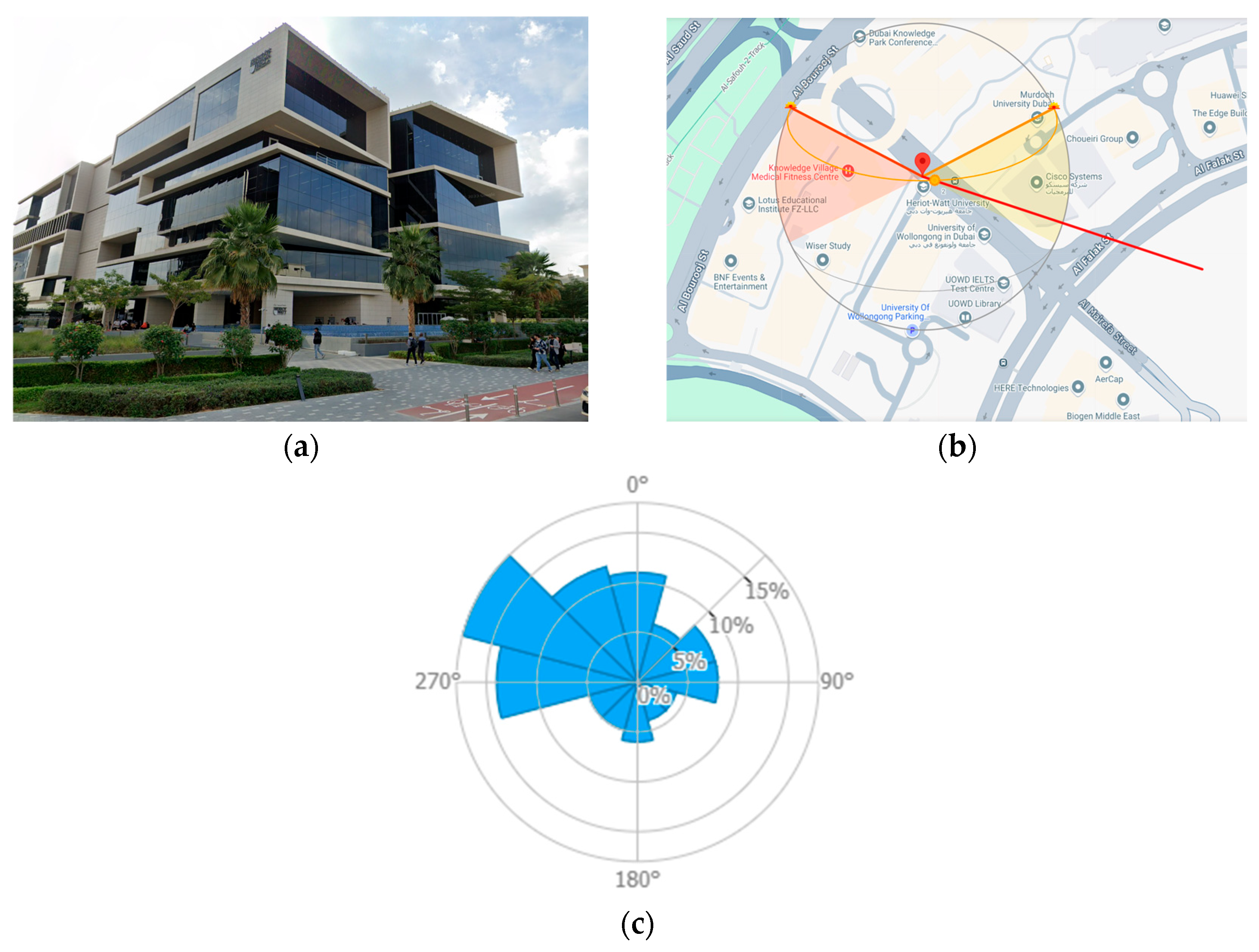

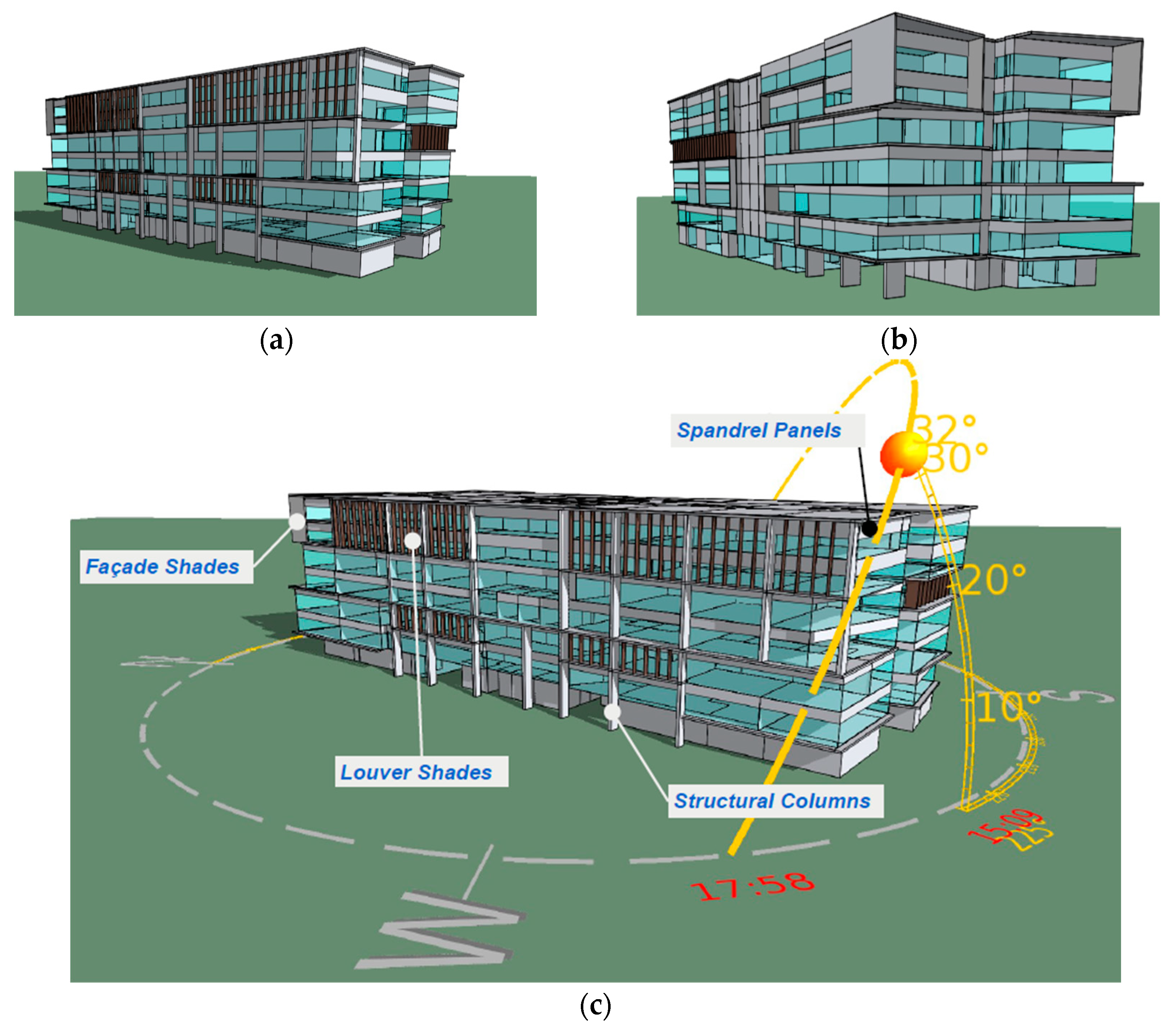

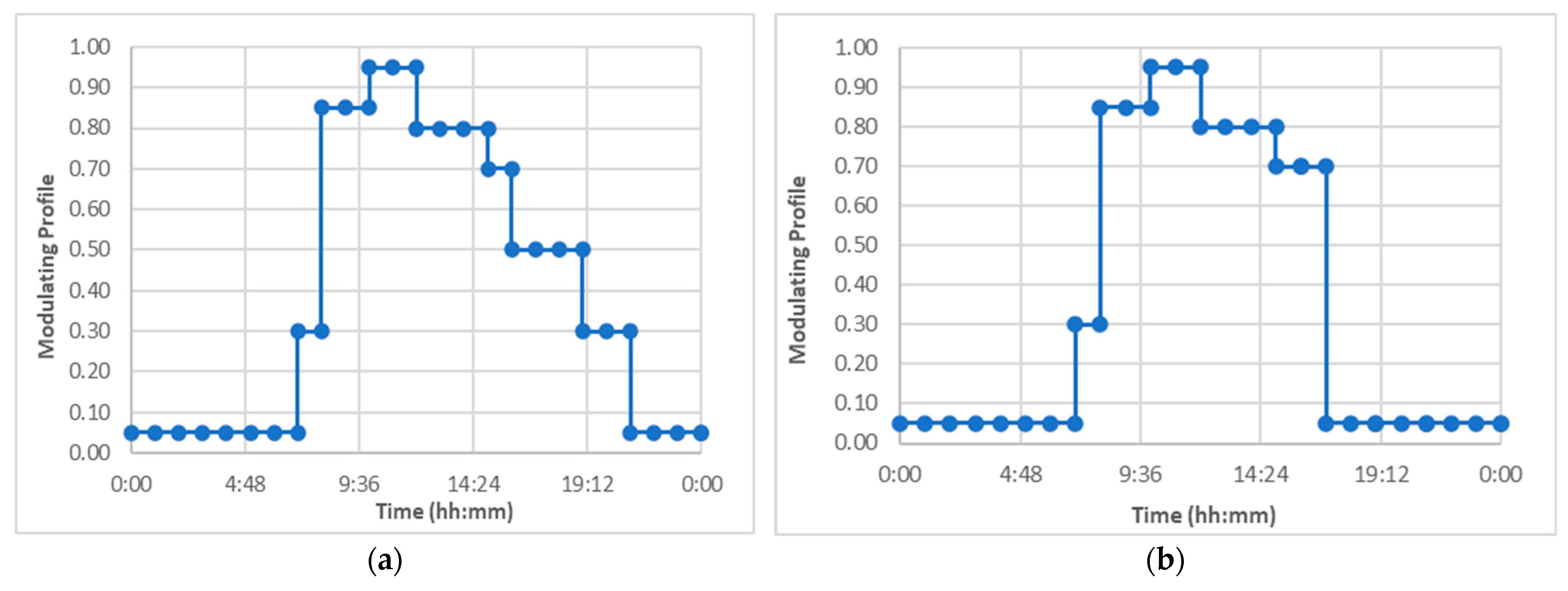

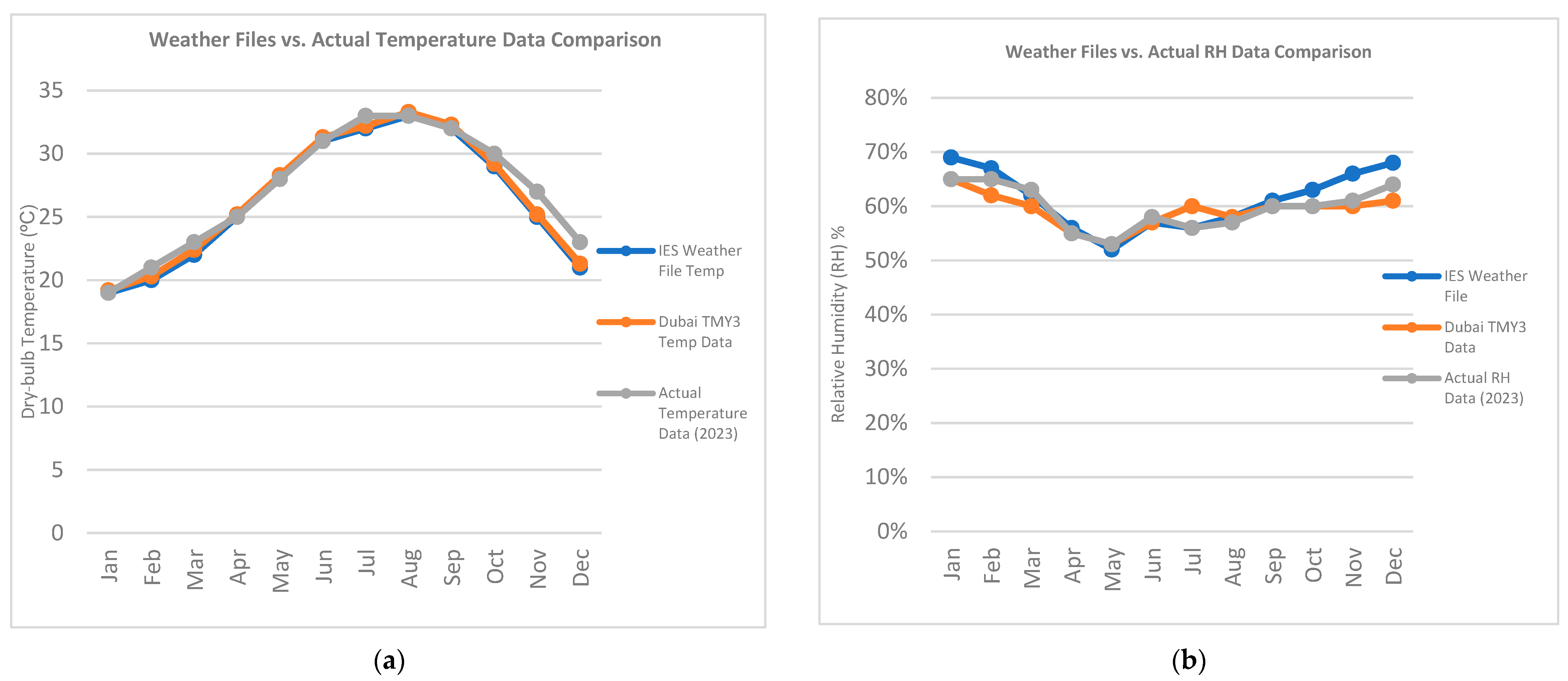

Furthermore, the use of digital twin technology for newer, certified buildings has not been widely explored due to the challenges associated with developing highly accurate digital twins. To support this, a highly accurate and calibrated digital twin of the case study building was developed using Integrated Environment Software (IES), enabling detailed analysis of its current sustainability features and identification of performance gaps. The IES thermal model of the campus building was then used to quantify the benefits of its existing sustainable design features and subsequently explore ECMs to further optimize its energy performance. In addition to evaluating ECMs, this study also examines their impact on occupant thermal comfort using the digital twin. The analysis focused on key comfort indicators such as operative indoor temperatures, PMV, and PPD, in alignment with ASHRAE Standard 55. This dual approach helps identify retrofit strategies that optimize both energy performance and indoor comfort in academic buildings with long operational hours and varying occupancy levels.

The findings of this study further aim to enhance the operational performance of the campus, potentially leading to achieving higher levels of green building certification such as LEED Platinum, LEED Zero, or LEED for Operations and Maintenance (O + M), thereby benefiting the building occupants and owners.

5. Conclusions

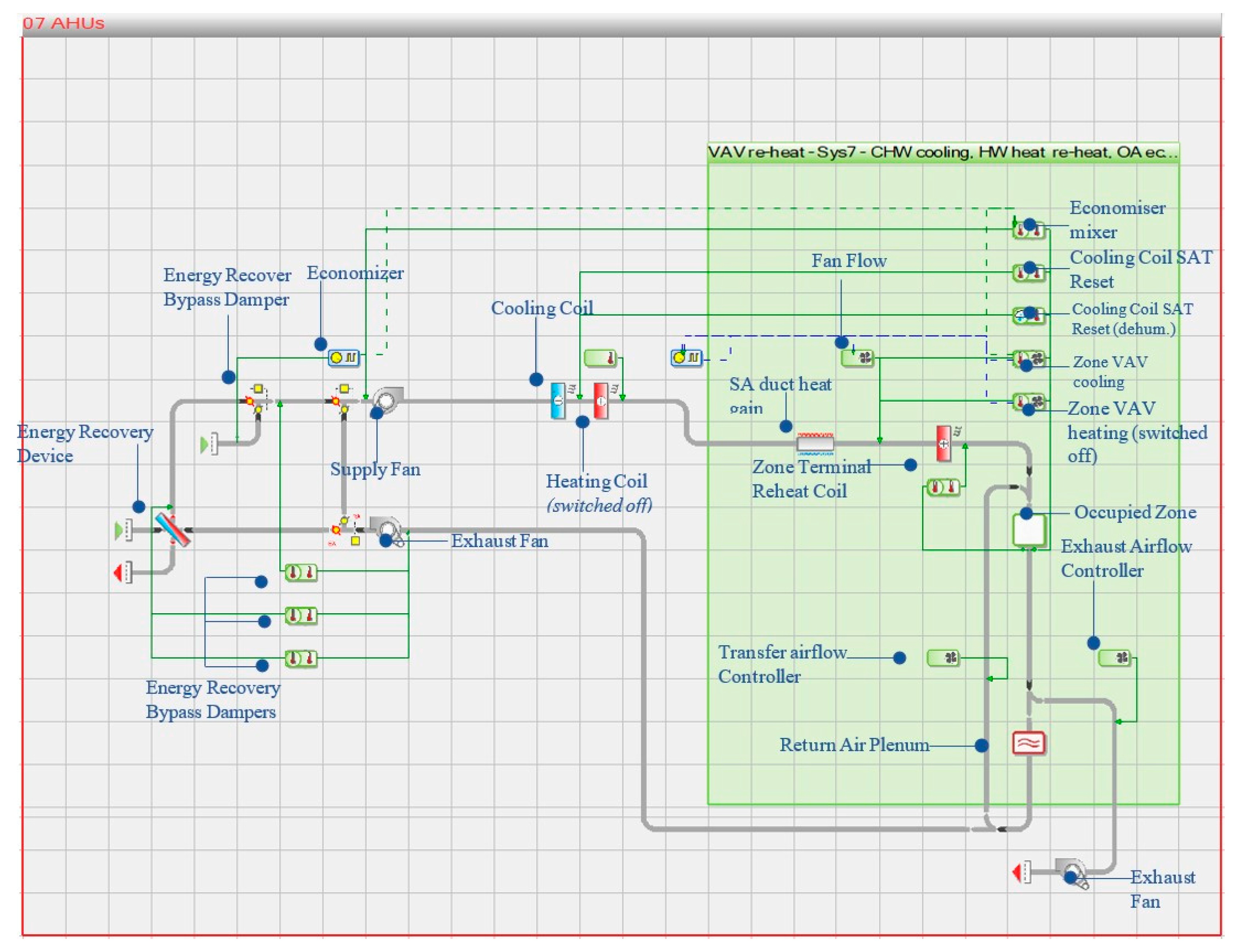

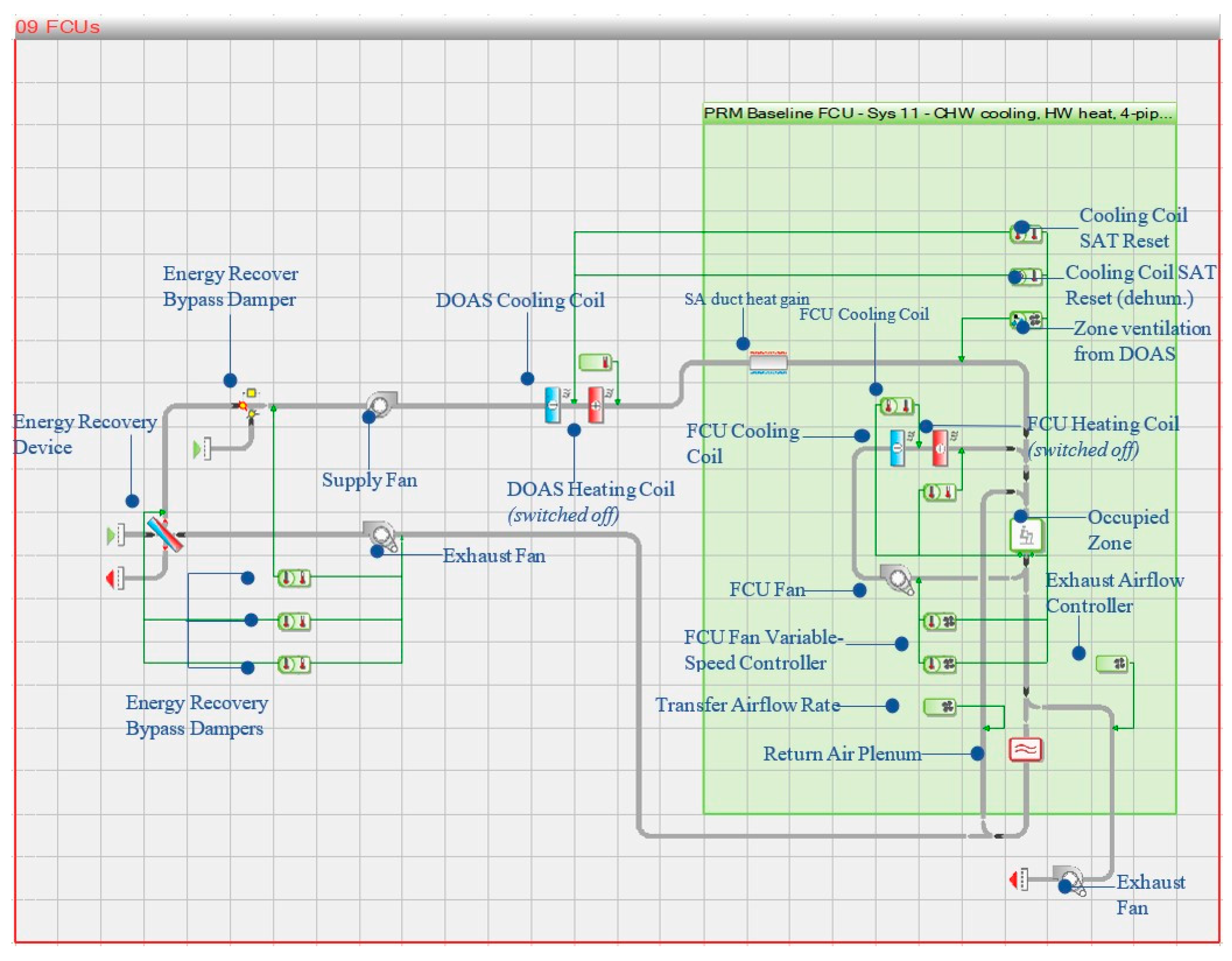

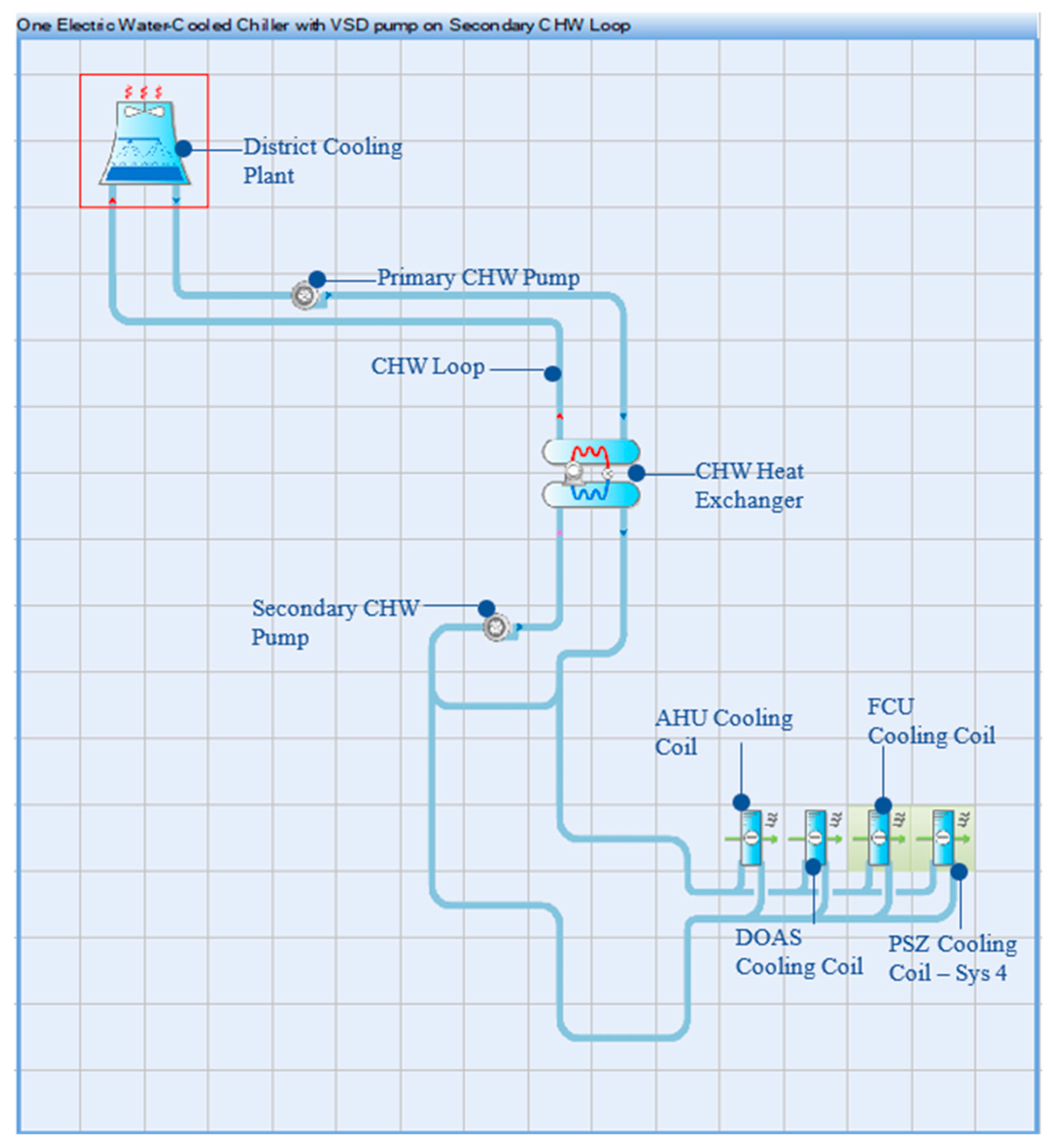

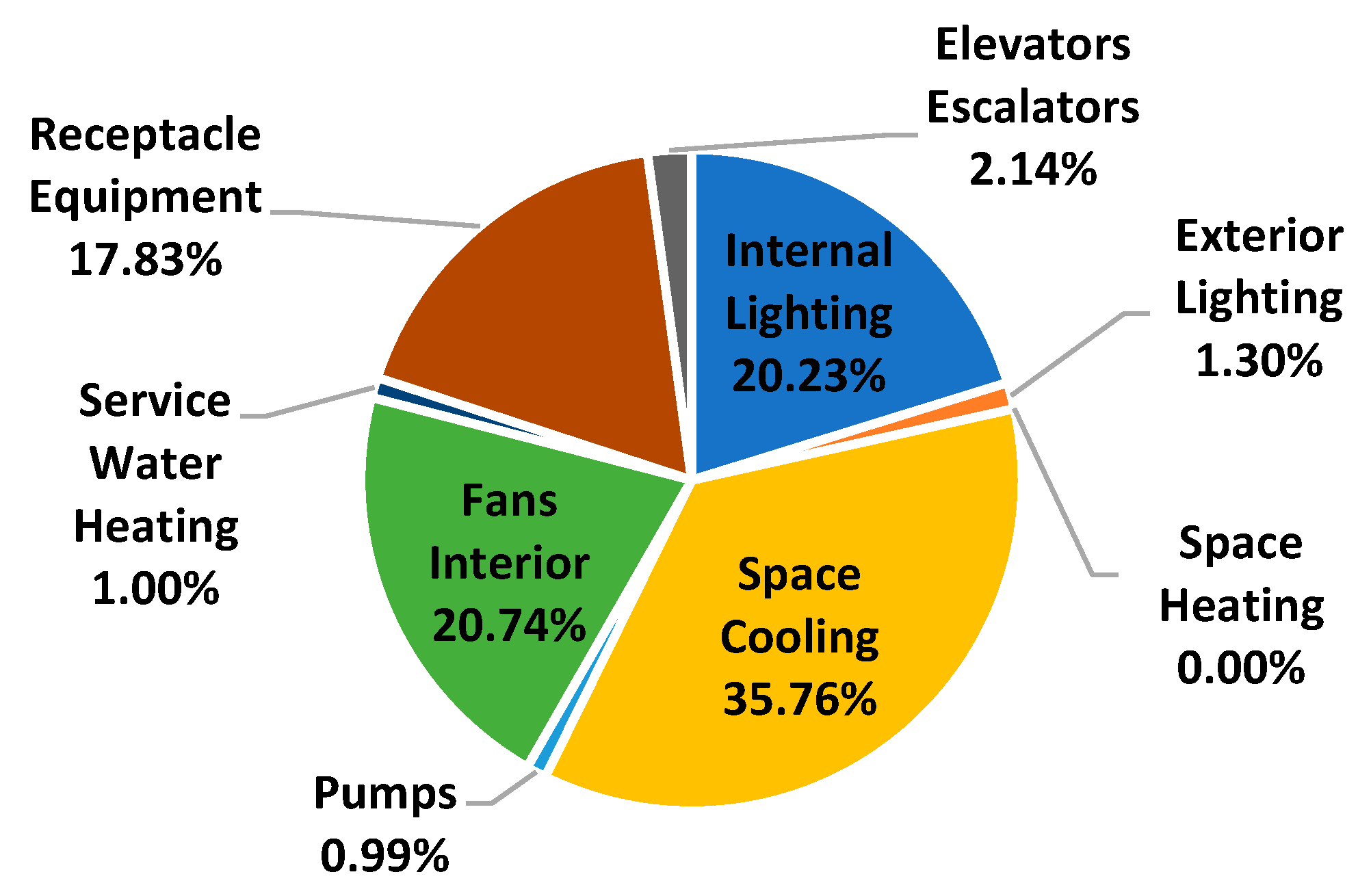

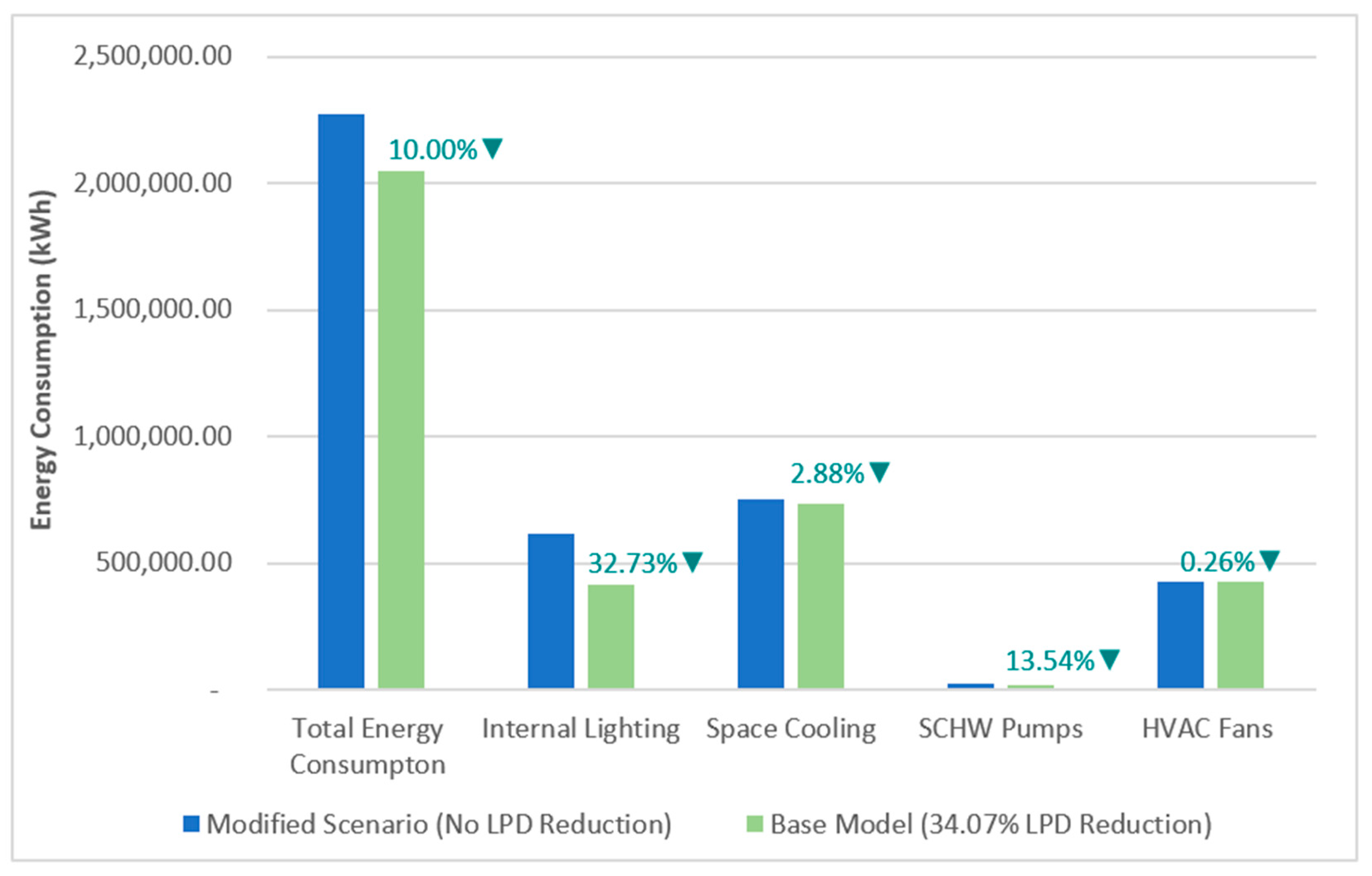

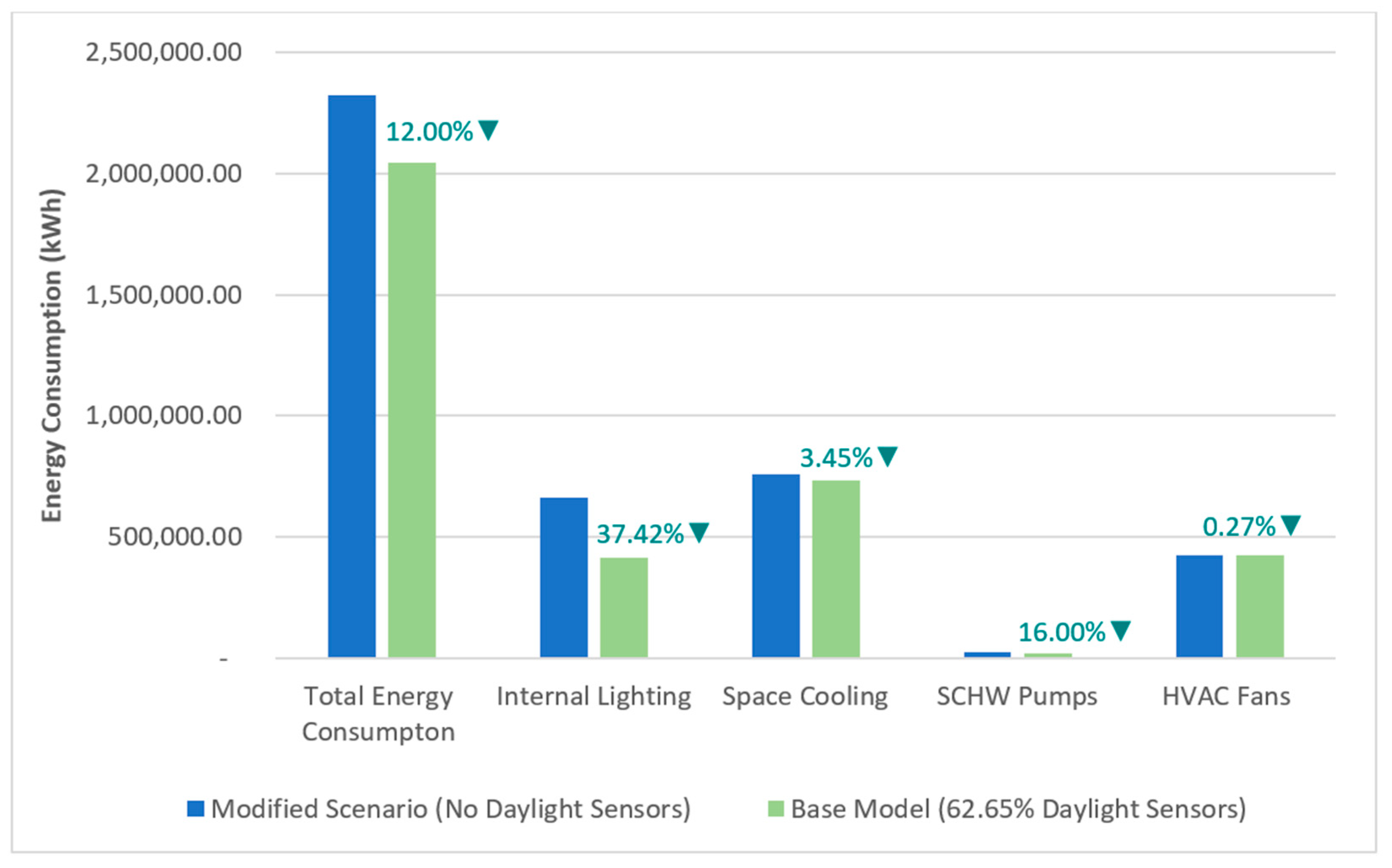

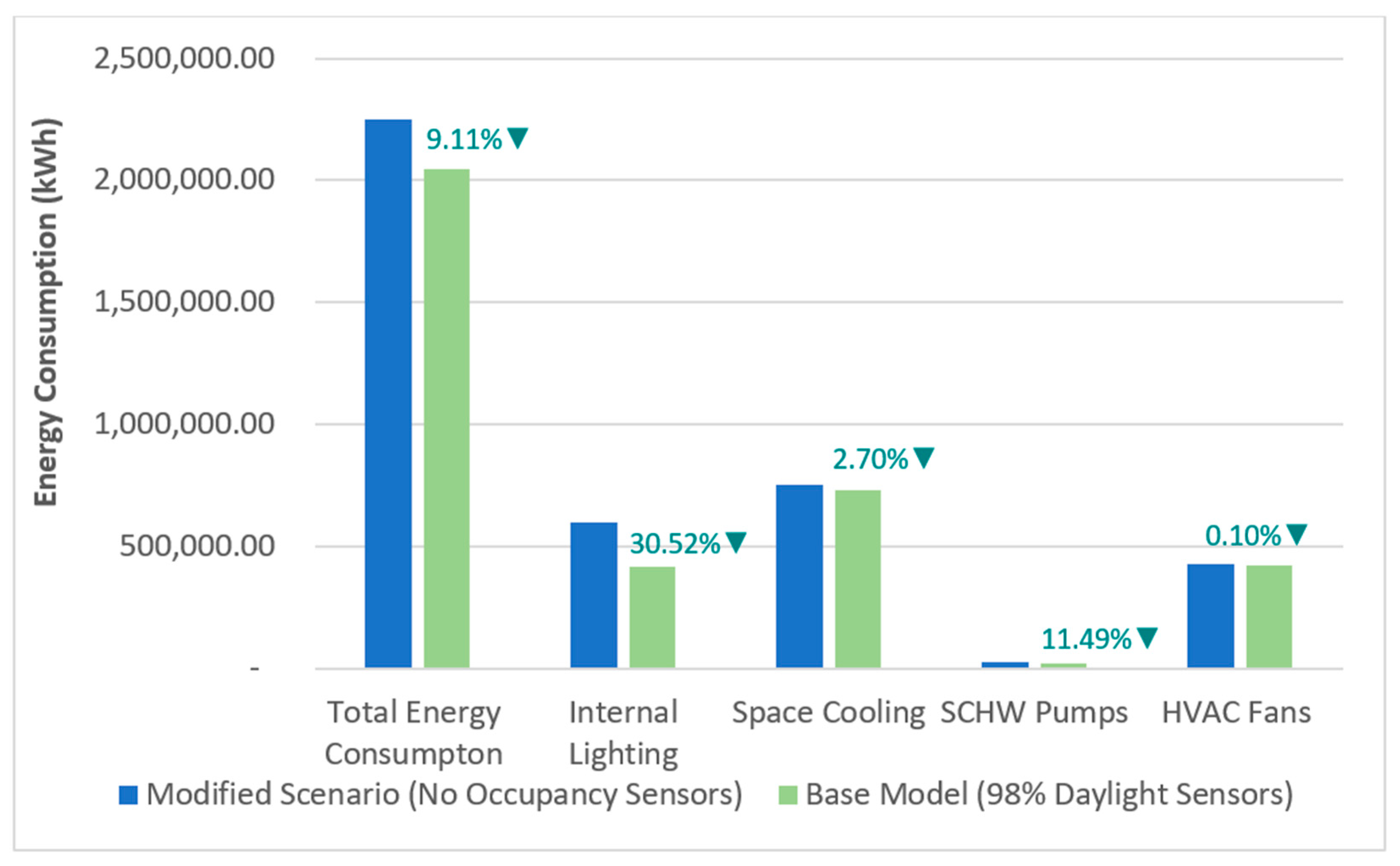

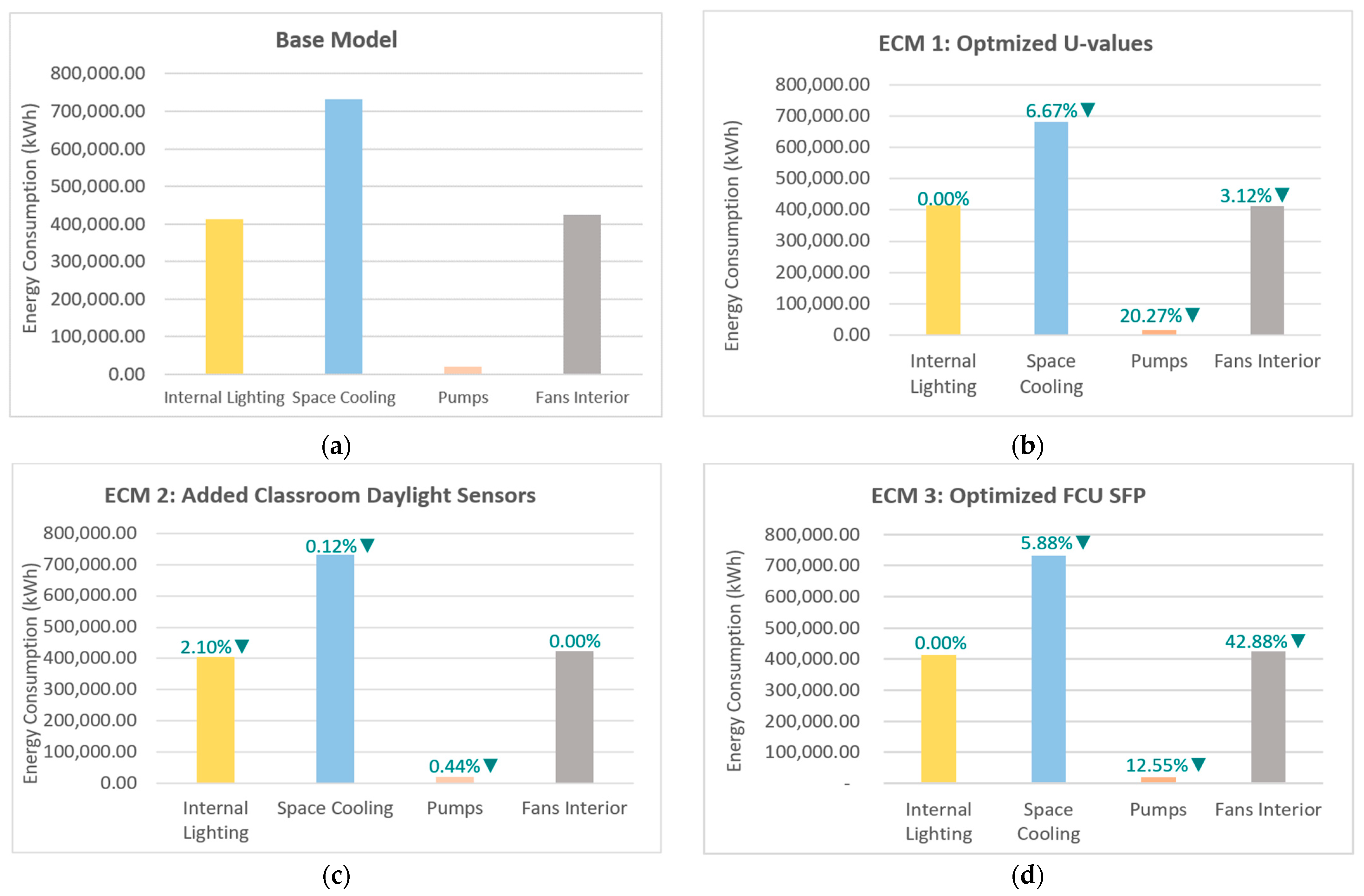

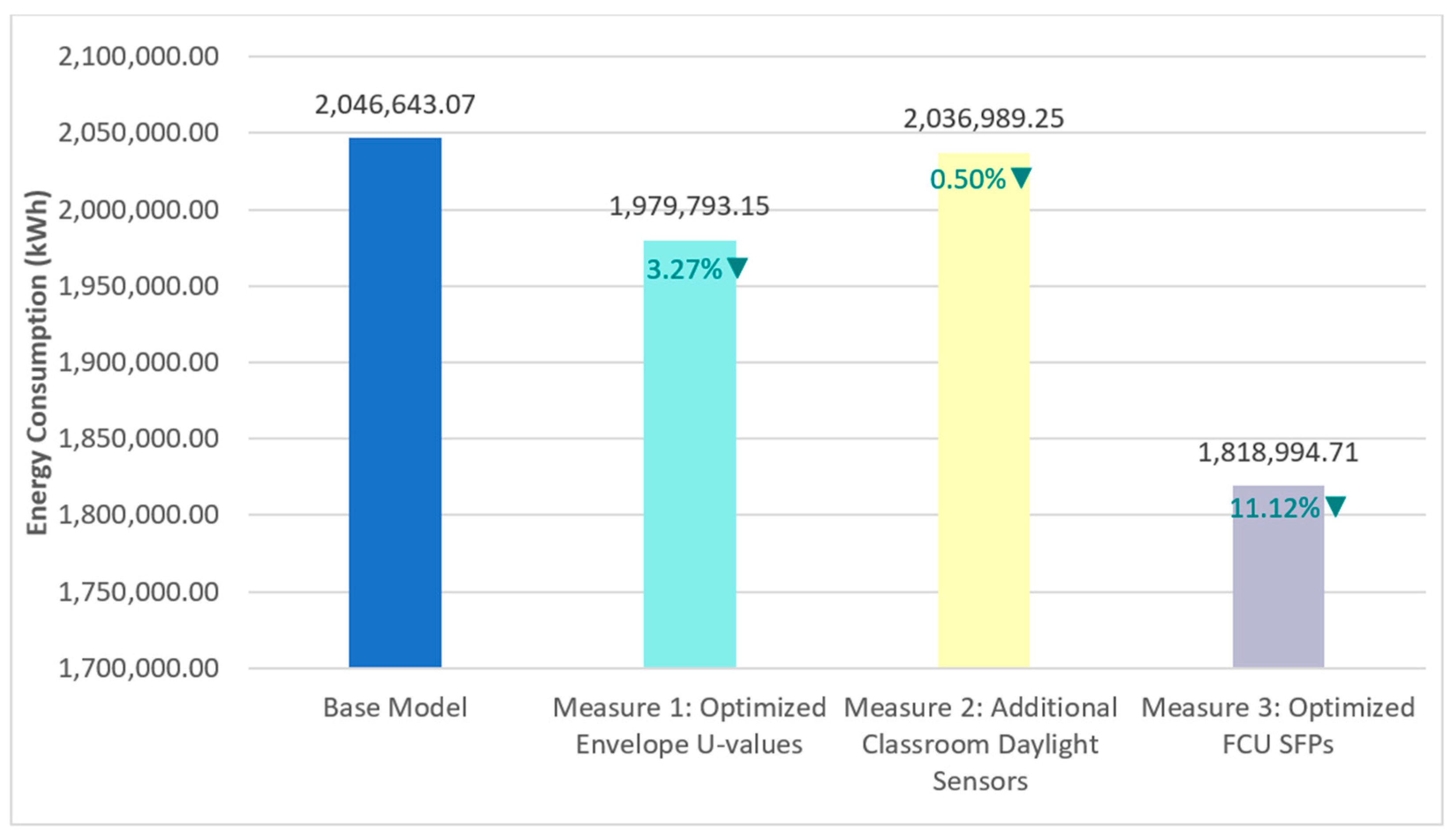

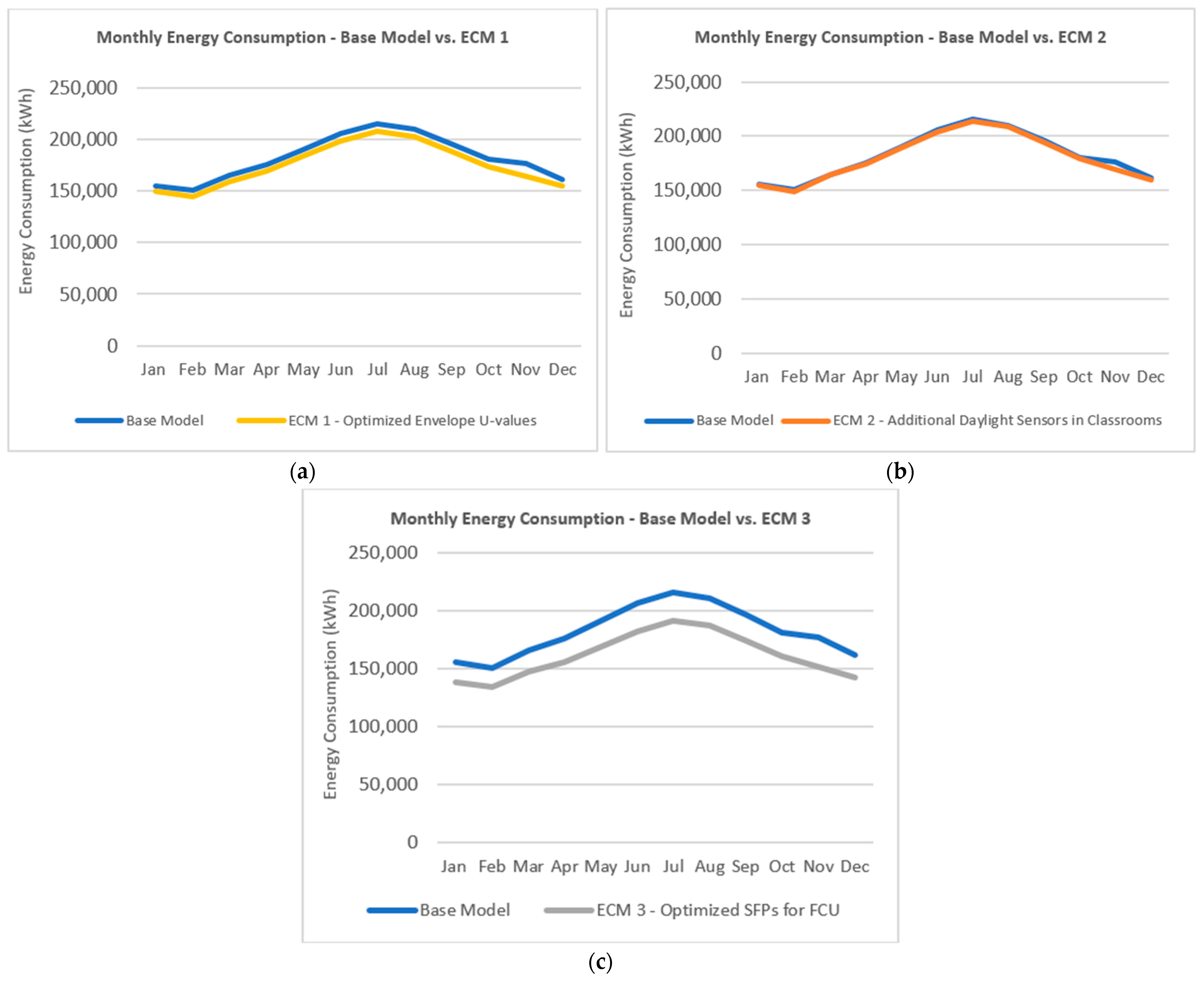

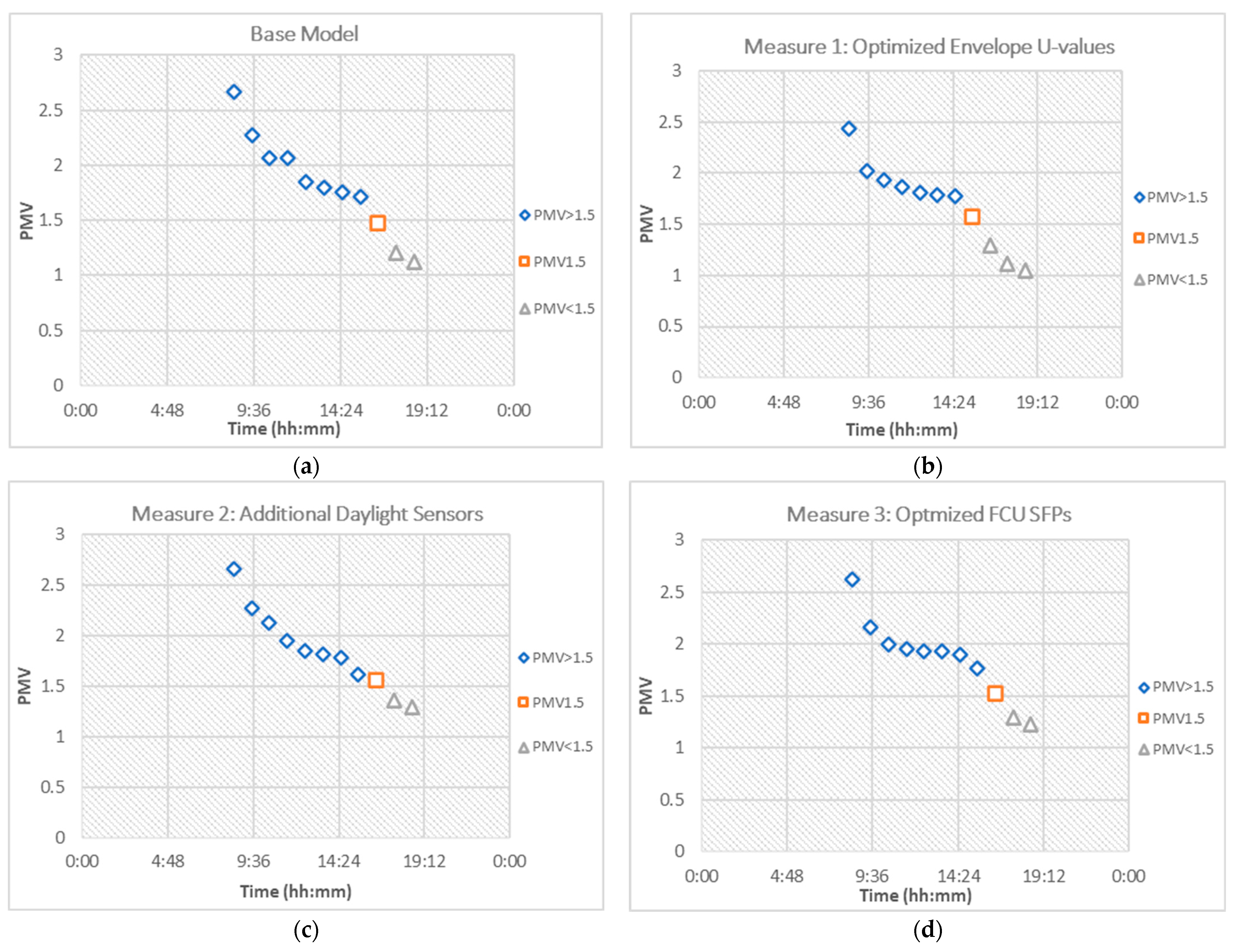

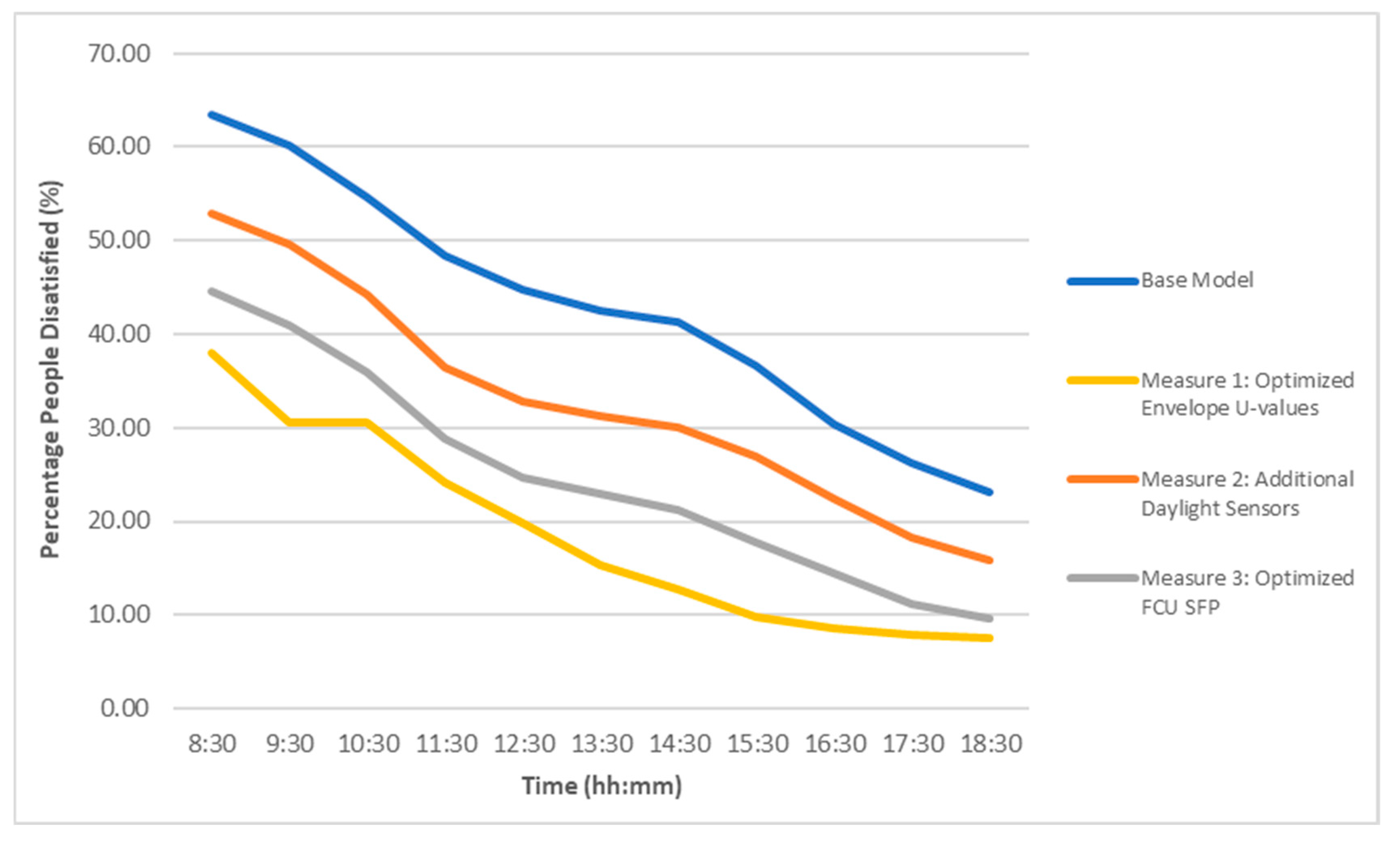

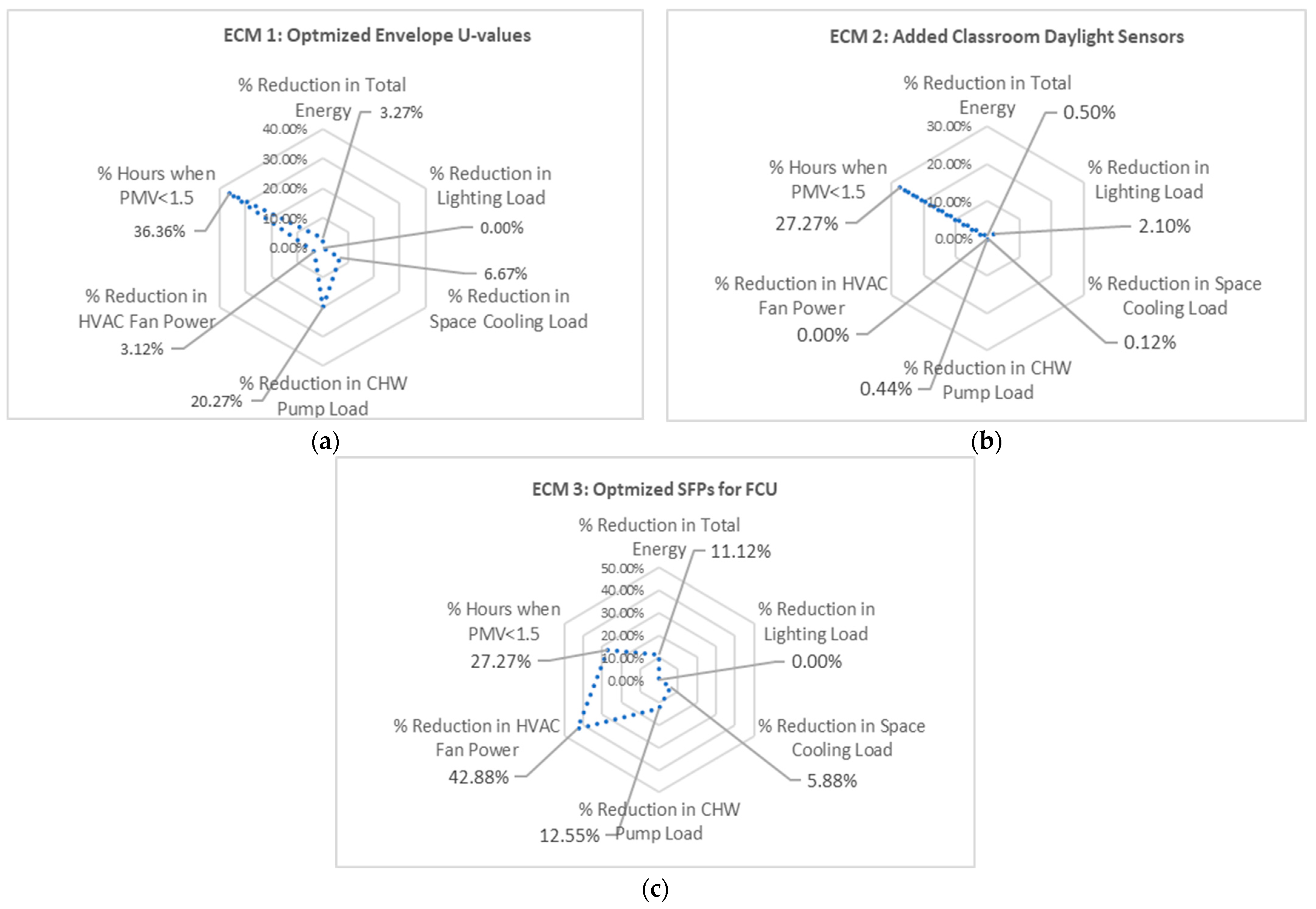

This study evaluated the performance of a LEED Gold-certified university campus building in Dubai through digital twin thermal modelling using IES simulation software, focusing on both energy efficiency and thermal comfort. The campus building demonstrated a 31% reduction in energy demand during its design stage, compared to the ASHRAE baseline building with no LEED-recommended energy efficiency design components. This research proposed three energy conservation measures that projected an additional 15% energy reduction in operational energy demand. Among the three ECMs proposed, optimizing FCU fan performance (ECM 3) delivered the highest energy savings of 11.12%, followed by envelope insulation optimization (ECM 1) at 3.27% and additional daylight sensor controls (ECM 2) at 0.50%.

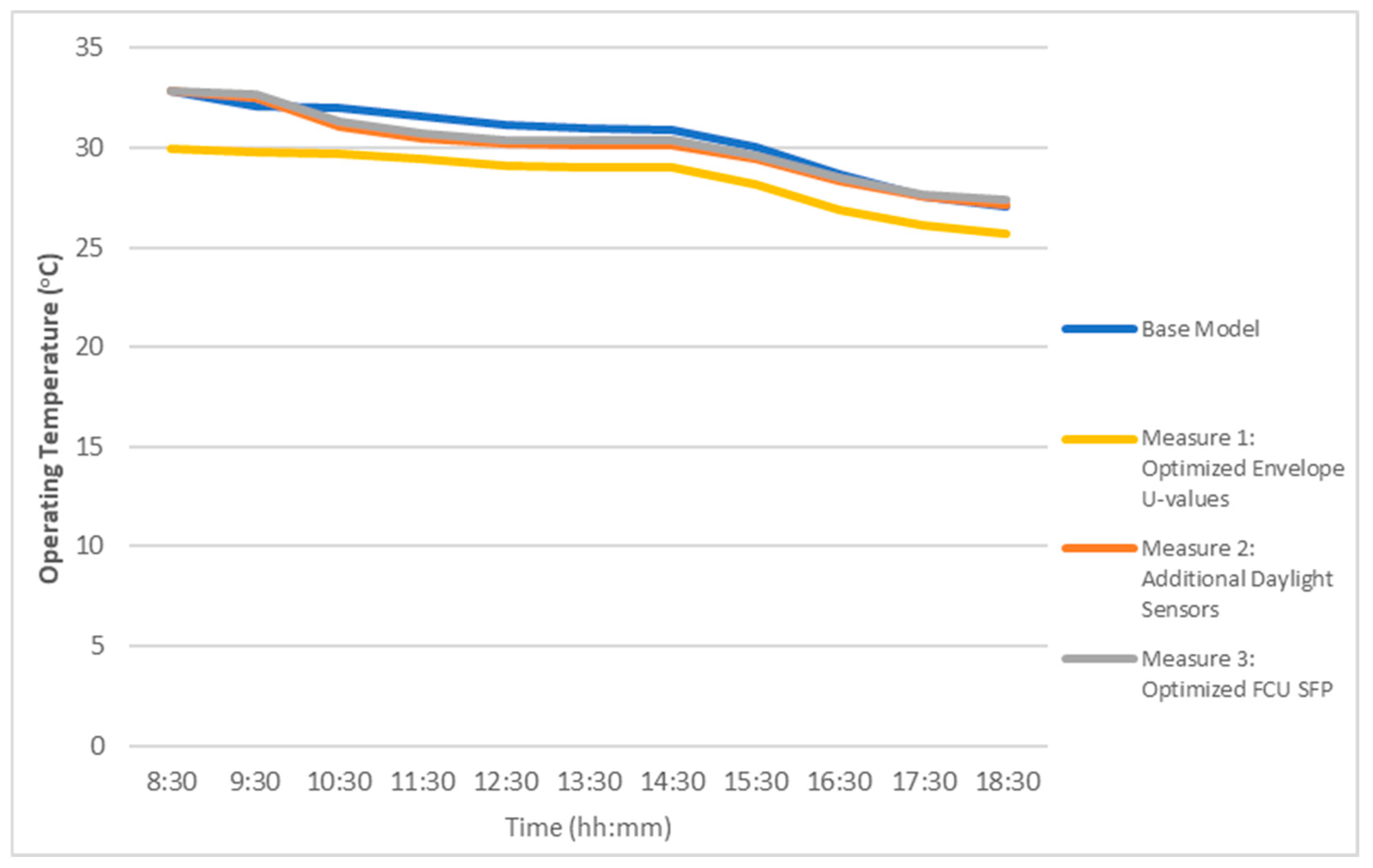

While Measure 3 was the most effective in terms of optimizing the campus’s energy performance, the thermal comfort analysis of the three ECMs revealed that it did not sufficiently improve thermal comfort, with PMV and PPD levels exceeding comfort thresholds during most occupied hours. In contrast, Measure 1 demonstrated a more balanced performance, reducing energy use while maintaining indoor thermal conditions within the ASHRAE Standard 55 comfort range. The findings of this research emphasize the importance of evaluating retrofit strategies not only on energy metrics but also their implications for occupant comfort and well-being.

The proposed integration of a 228.87 kW solar PV system further supports the building’s transition towards Net Zero energy efficiency, offsetting 8.09% of its annual energy consumption. By applying thermal modelling to a newer, green-rated building and assessing retrofitting impacts on both operational energy and thermal comfort, this research addresses a substantial gap in the existing literature. It offers a practical and replicable framework for advancing building performance in hot climate regions, contributing meaningfully to the UAE’s Net Zero 2050 ambitions.

While envelope insulation retrofits demonstrated a balanced improvement in both energy performance and thermal comfort, their higher capital costs and potential operational disruptions require a detailed lifecycle cost-benefit analysis. In contrast, active retrofits such as FCU fan power optimization offer quicker returns with less invasive implementation. A multi-criteria decision-making framework that considers cost, energy savings, occupant comfort, installation complexity, and environmental impact would better guide stakeholders in identifying optimal retrofit strategies for hot-climate contexts such as the UAE. To promote wider adoption of such retrofitting schemes in large institutional buildings, several targeted policy actions can be introduced by the local authorities. Introducing retrofit-specific incentives under existing demand-side management programs in Dubai will encourage adoption of cost-intensive yet effective retrofitting strategies. Furthermore, integrating retrofit performance requirements within building permit renewal processes for facilities over a defined GFA threshold and mandating annual improvements in energy performance would enhance alignment with the UAE’s Net Zero by 2050 goals. Moreover, upgrading existing green building regulations, such as the DGBR, by mandating retrofit compliance paths for existing buildings would further support systematic improvements in building performance.