Leveraging Dynamic Pricing and Real-Time Grid Analysis: A Danish Perspective on Flexible Industry Optimization

Abstract

1. Introduction

- The objective function incorporates quadratic penalties on deviations from real-time EKF state estimates, ensuring that the economic optimizer does not propose hydraulically or electrically infeasible actions even in the presence of sensor drift or failure.

- Voltage-band constraints are co-optimized alongside pump operations, transforming the water process from a passive price-taker into an active asset within the distribution grid.

- A unified linearized model simultaneously represents tank mass balances and nodal voltage behavior, enabling integration of hourlyl optimization with second-level dynamic simulation.

2. Materials and Methods

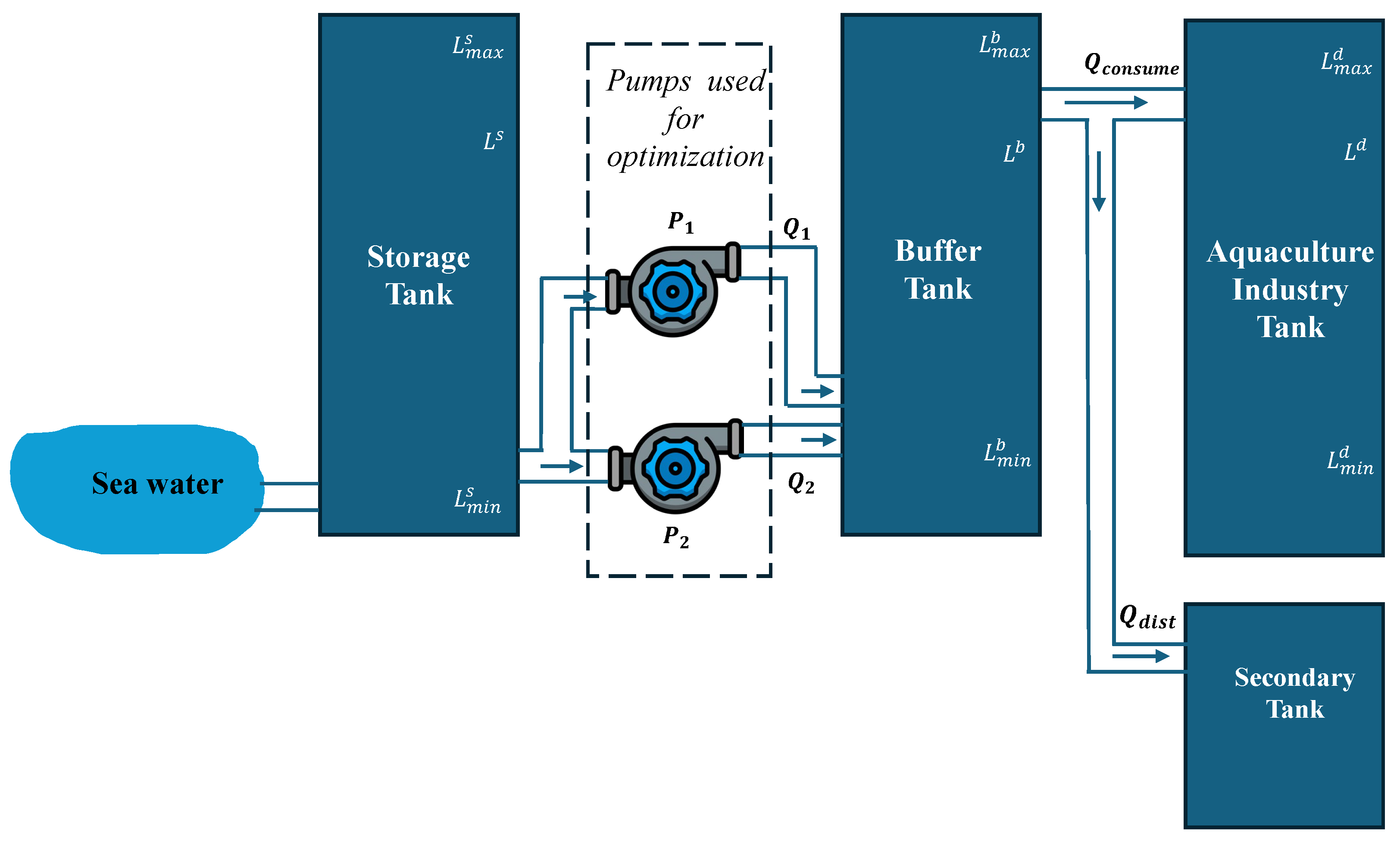

2.1. Description of Saltwater Distribution System

2.2. Optimization Framework of Saltwater Distribution System

| Algorithm 1 MPC Optimization Framework with EKF and MILP |

|

3. Mathematical Formulation for MILP and EKF

3.1. Mathematical Integer Linear Programming

- : Operational cost at time step t, computed based on energy consumption and electricity price.

- : Total energy consumed at time t, derived from pump operation decisions.

- , , : Estimated water levels of the buffer tank, storage tank, and aquaculture tank at time t, respectively.

- , , : Optimized decision variables for tank levels at time t.

- : Estimated voltage at time t.

- : Optimized voltage decision variable at time t.

- : Weighting coefficient for energy consumption.

- , , : Weighting coefficients for the buffer, storage, and aquaculture tank level deviations, respectively.

- : Weighting coefficient for voltage deviation penalty.

- 1.

- , , : Water volumes in buffer, aquaculture, and secondary tanks.

- , : Outflow from secondary stream and demand from aquaculture.

- 2.

- , , : Water levels at time t for buffer, storage, and aquaculture tanks.

- , : Minimum and maximum allowable levels.

- 3.

- 4.

- The Energy Consumption Calculation is given in Equation (10).

- 5.

- : Flow from pump i, linearly dependent on binary state.

- : Auxiliary variable to linearize switching constraint.

- : Minimum flow when pump is active.

- : Minimum runtime once activated.

- : Max switching rate between time steps.

- 6.

- : Electricity price at time t.

- : Transmission price at time t.

- C: Total cost of electricity consumption.

- : Max combined flow rate.

- 7.

- The Voltage Constraints for grid stability are given in Equation (16).

- : Permissible voltage limits (e.g., 0.95–1.05 p.u.).

- : Voltage at time t.

3.2. State Estimation via EKF

- 1.

- 2.

- The Measurement Model is given in Equation (20).

- represents the estimated state variables (buffer tank level and pump flow rates).

- represents the control inputs (pump activation).

- and represent process and measurement noise, respectively.

- : State transition matrix describing the evolution of water levels and voltage.

- : Control input matrix mapping pump actions to state changes.

- : Observation matrix mapping system states to measured outputs.

4. Simulation Results

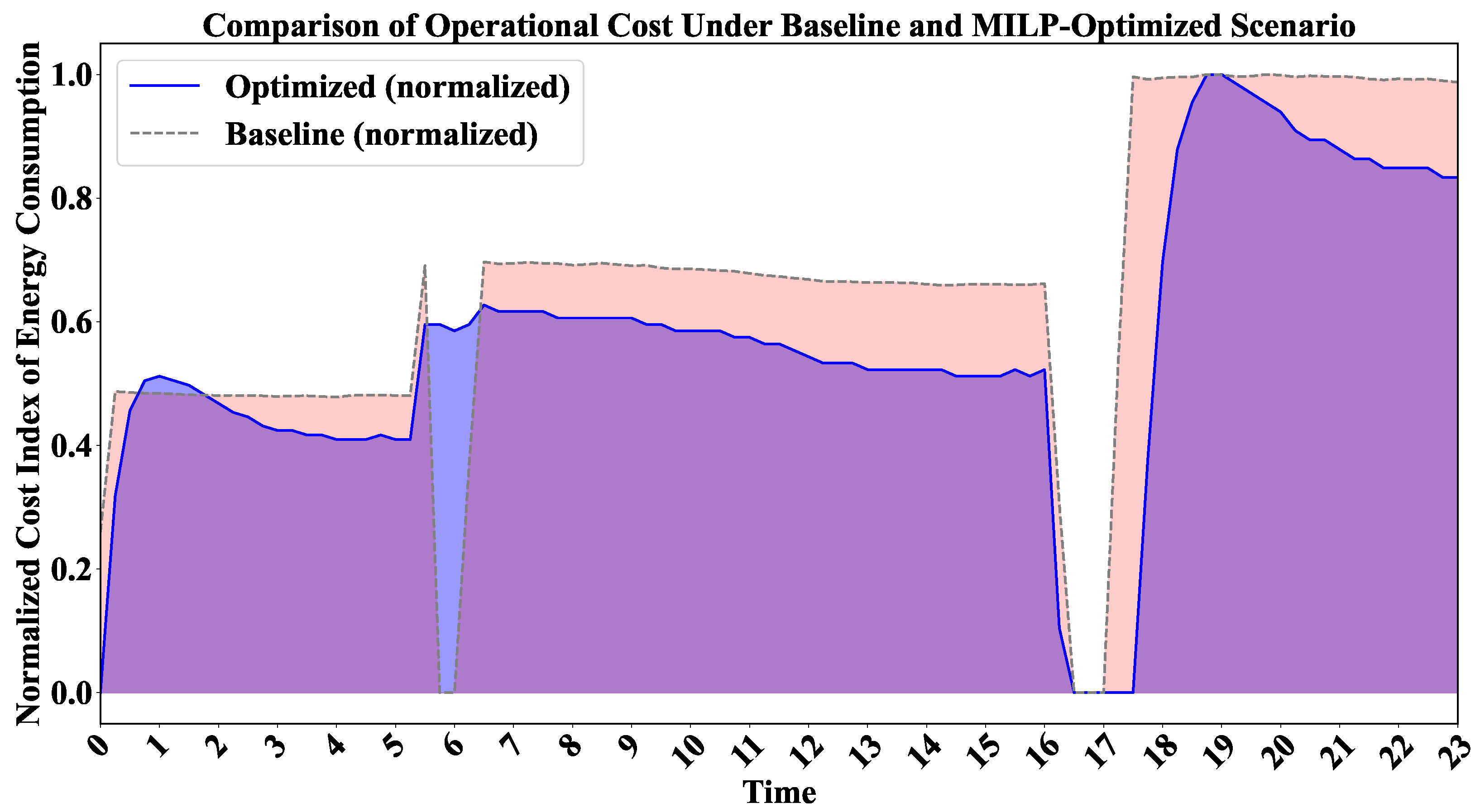

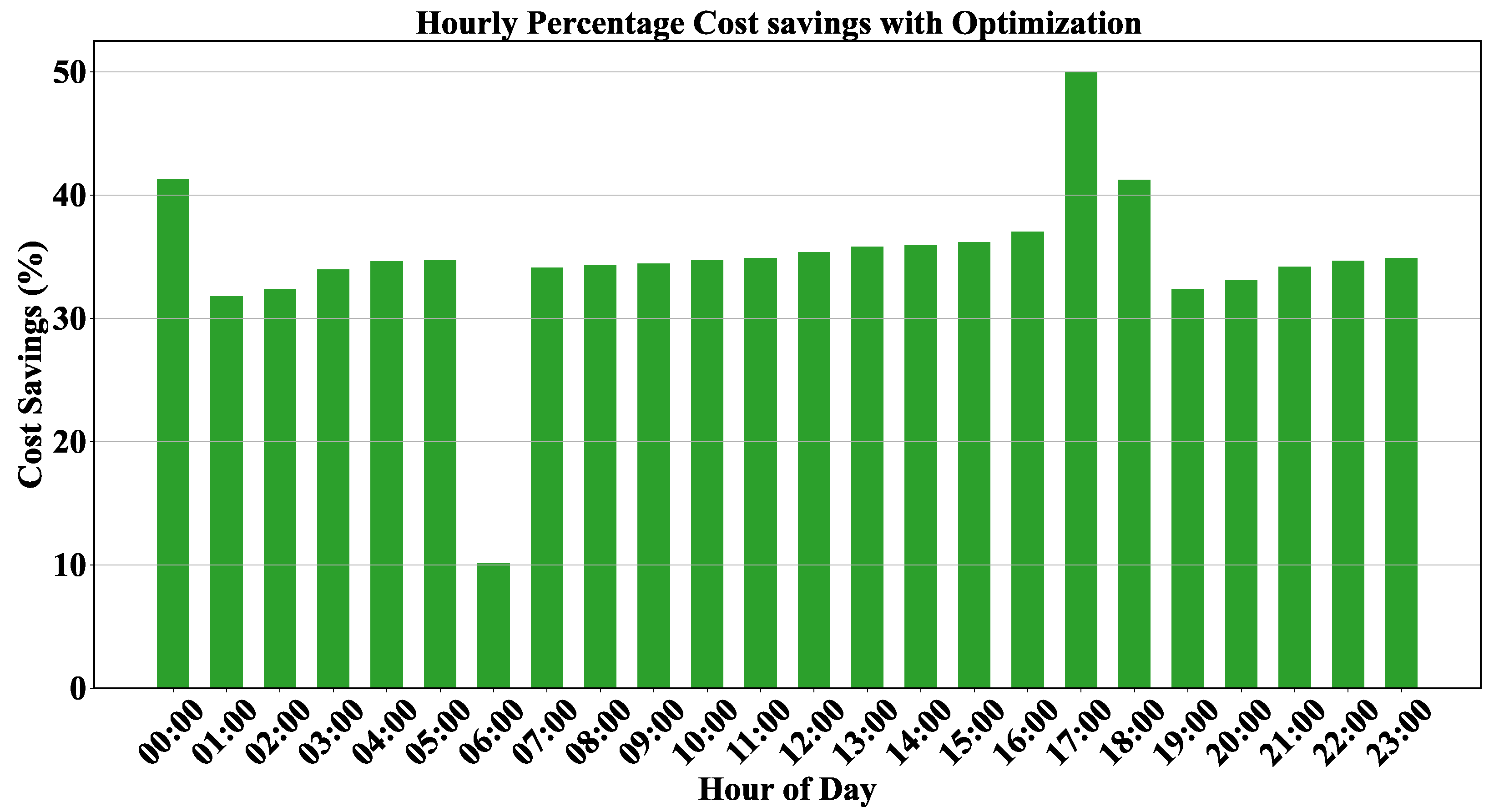

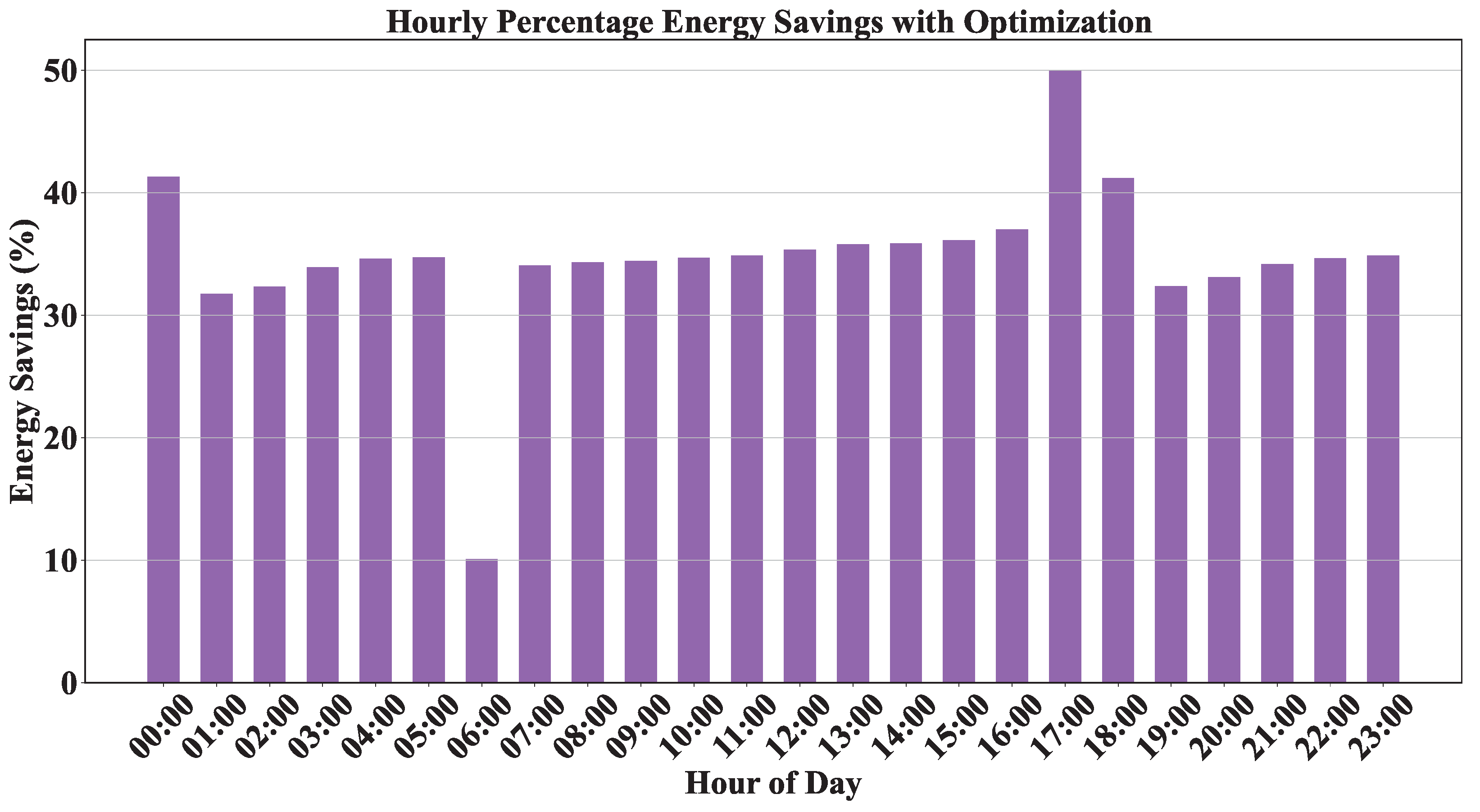

4.1. Economic Benefits of Dynamic Pricing

4.1.1. Cost Dynamics Under Time-Variant Electricity Pricing

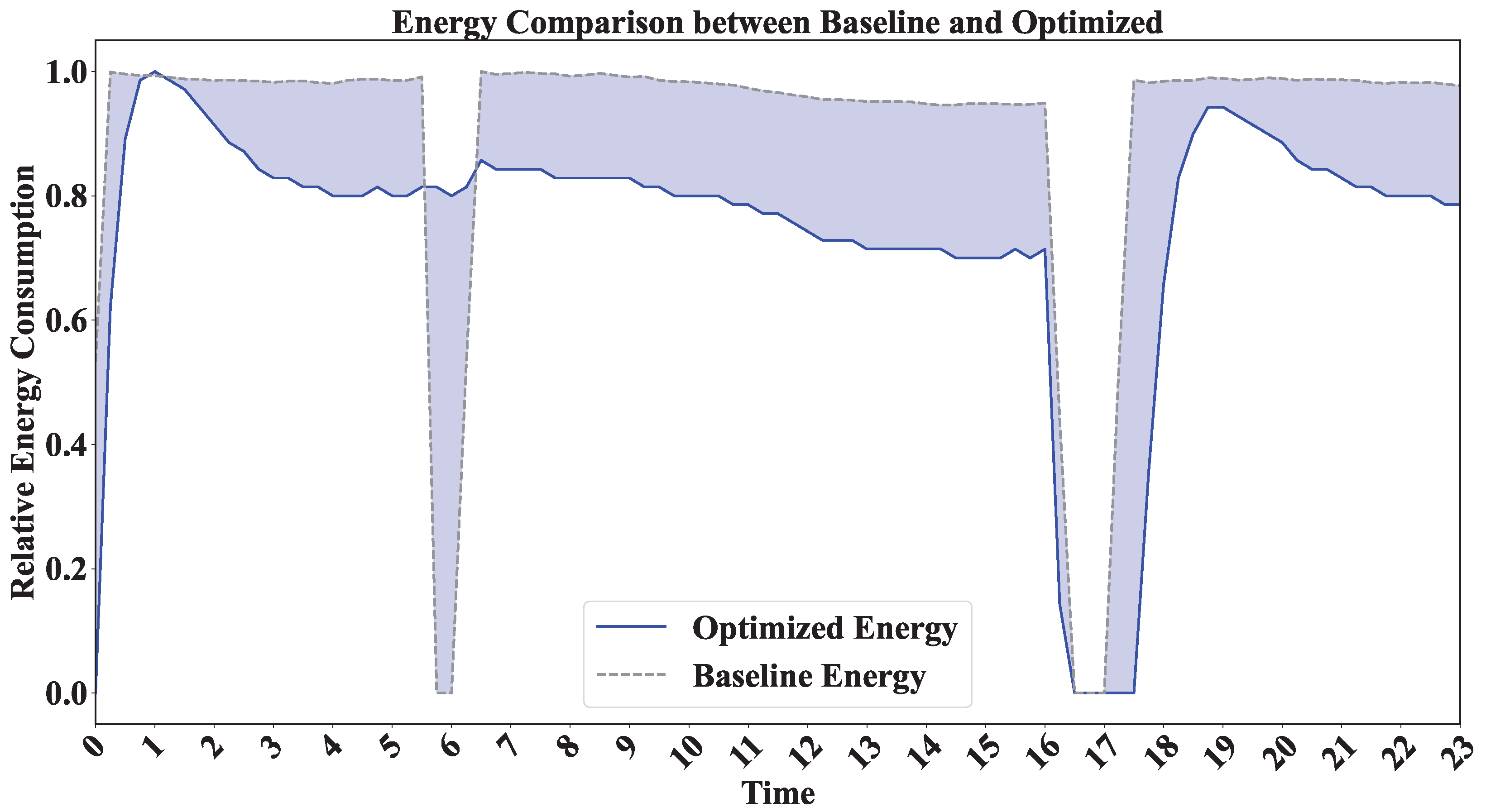

4.1.2. Temporal Shifting of Energy Consumption

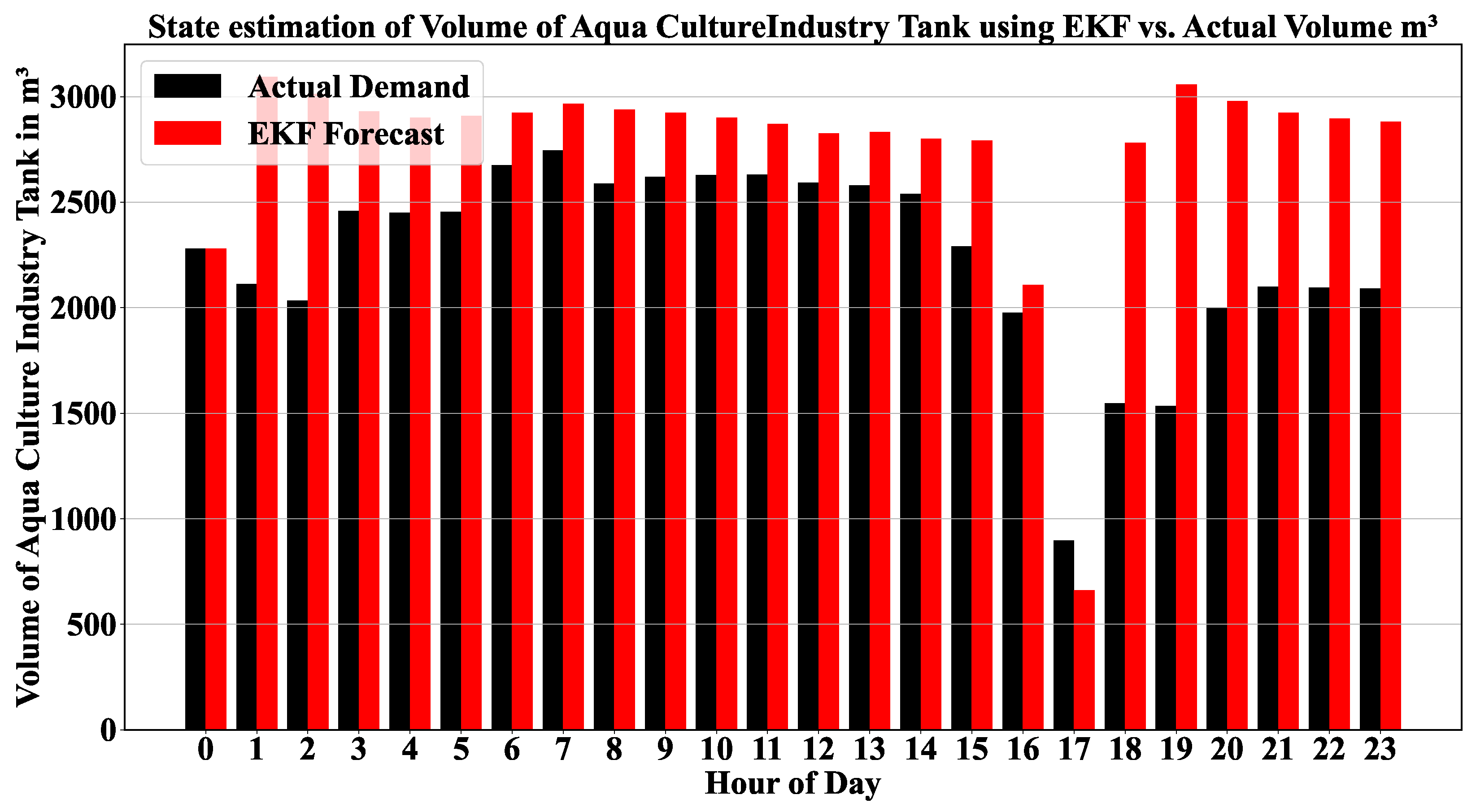

4.2. EKF and Grid Stability

4.2.1. EKF State Estimation vs. Actual Energy Demand

4.2.2. Voltage Stability During Peak Load

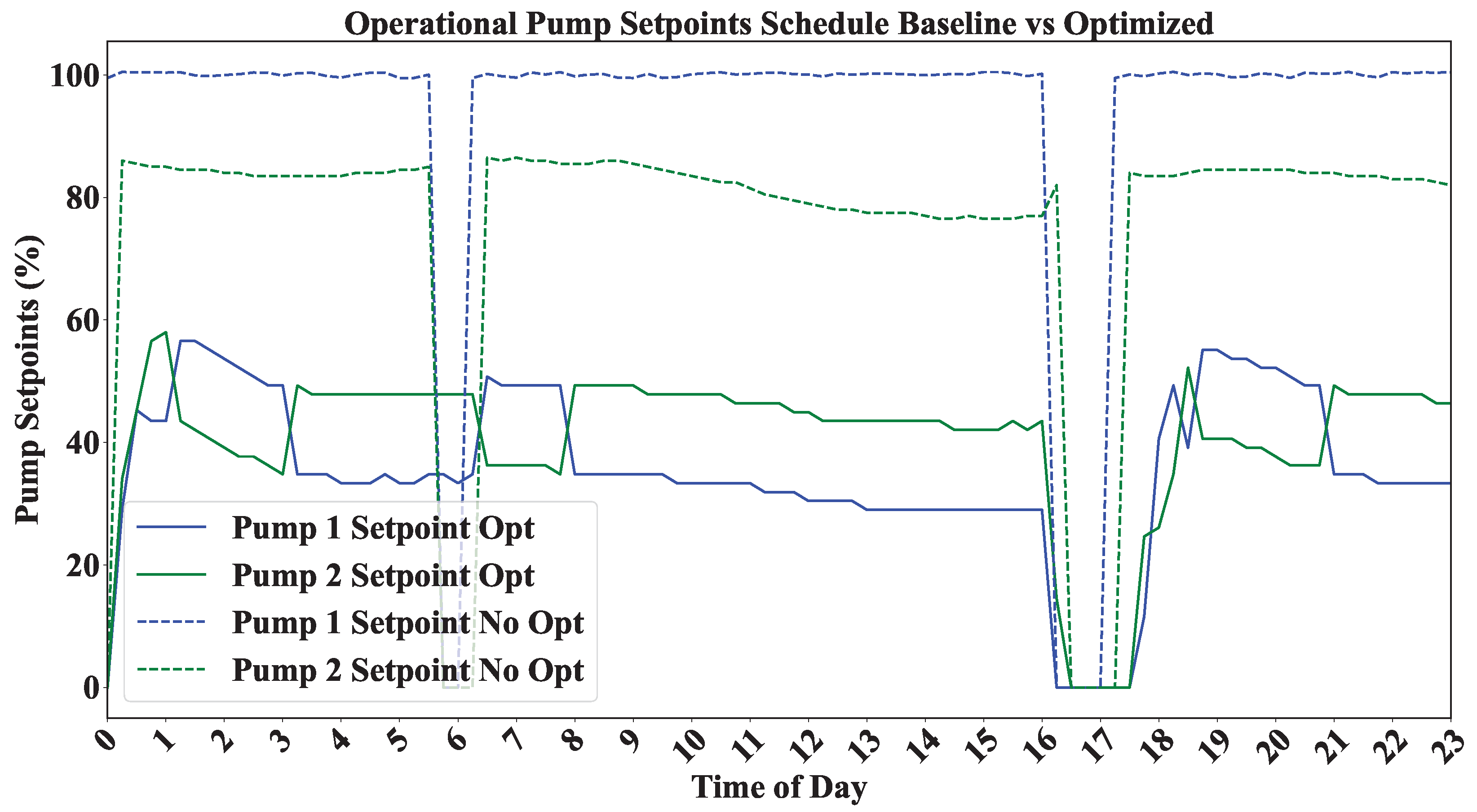

4.3. Industrial Flexibility and Operational Optimization

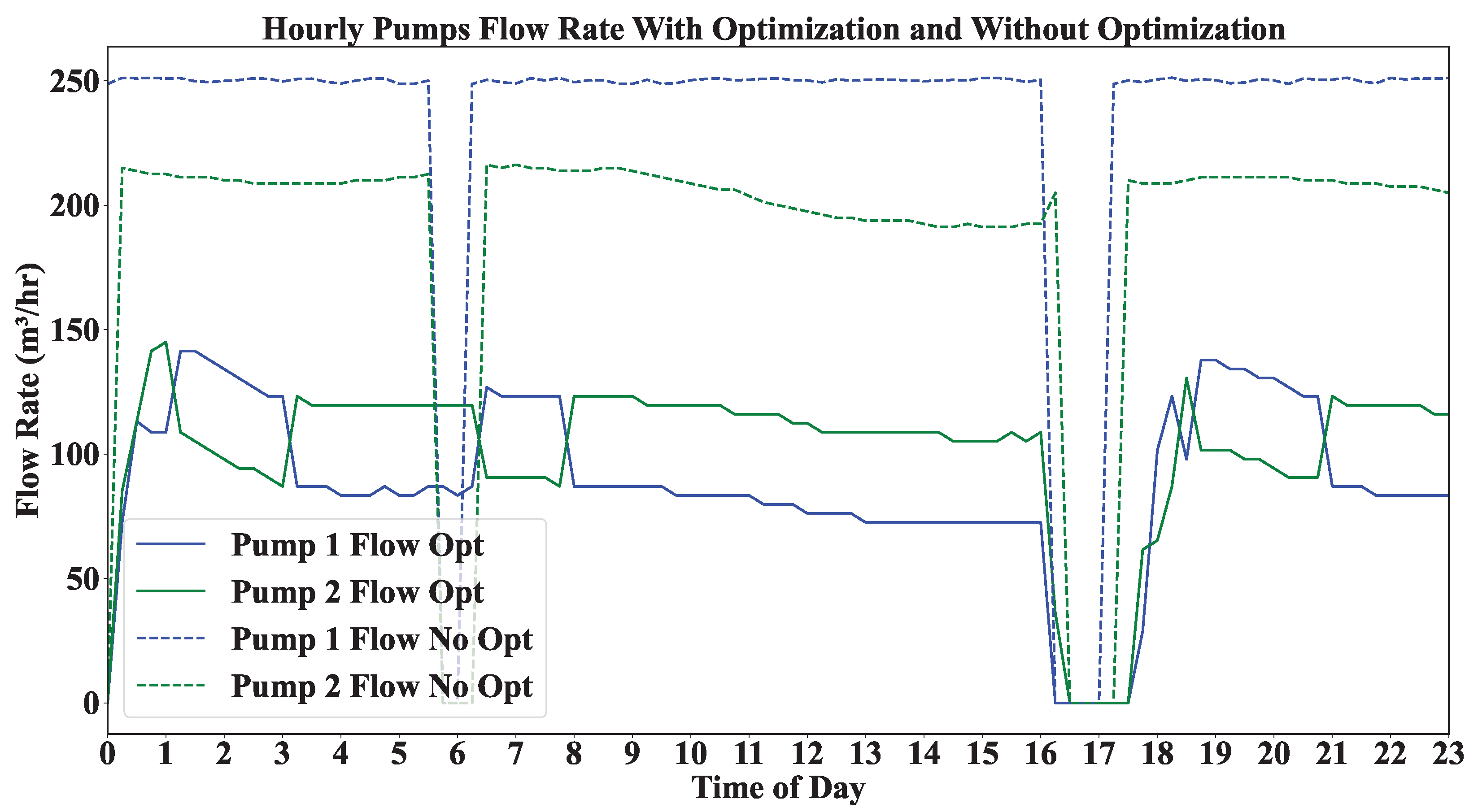

4.3.1. Pump Operation Schedule

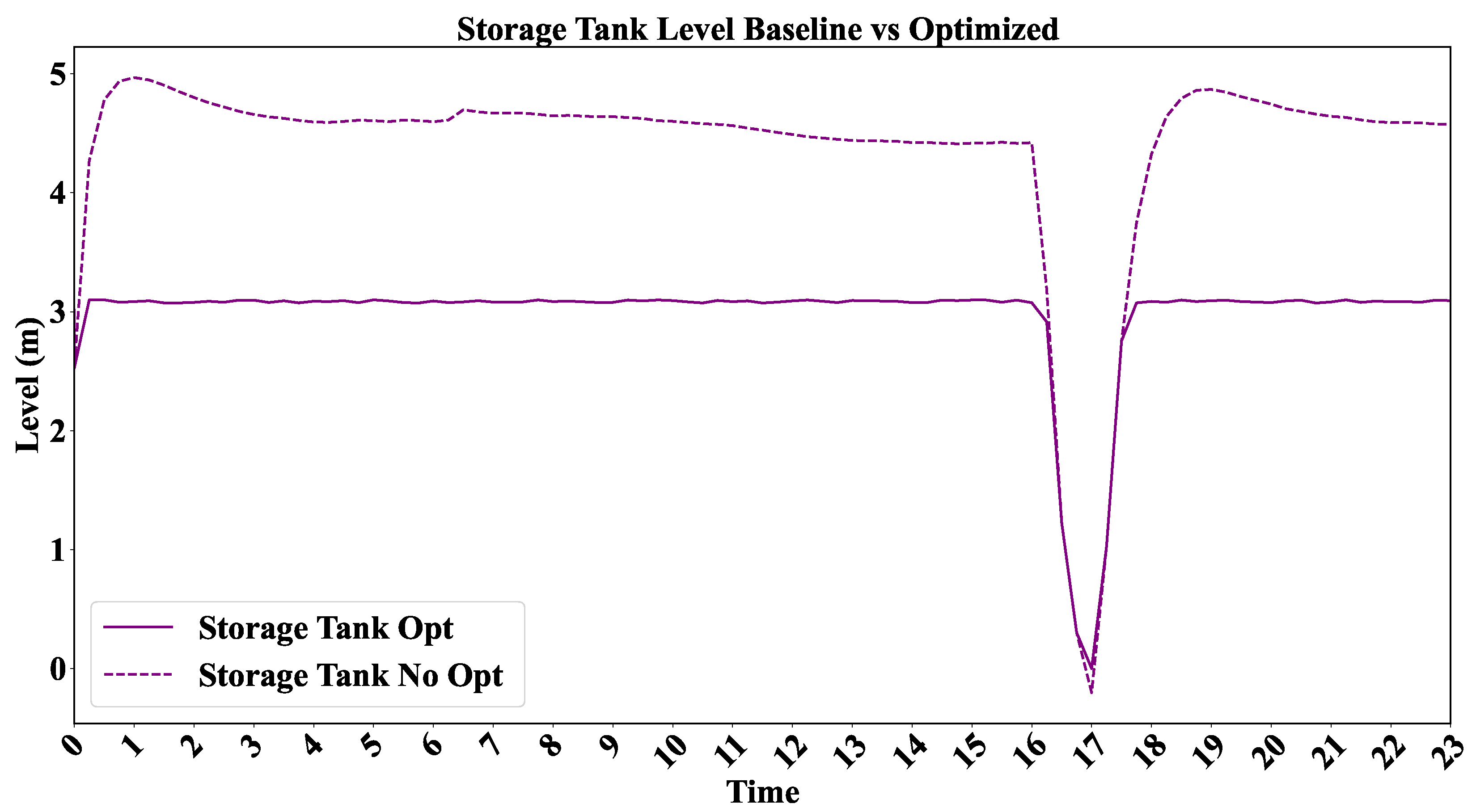

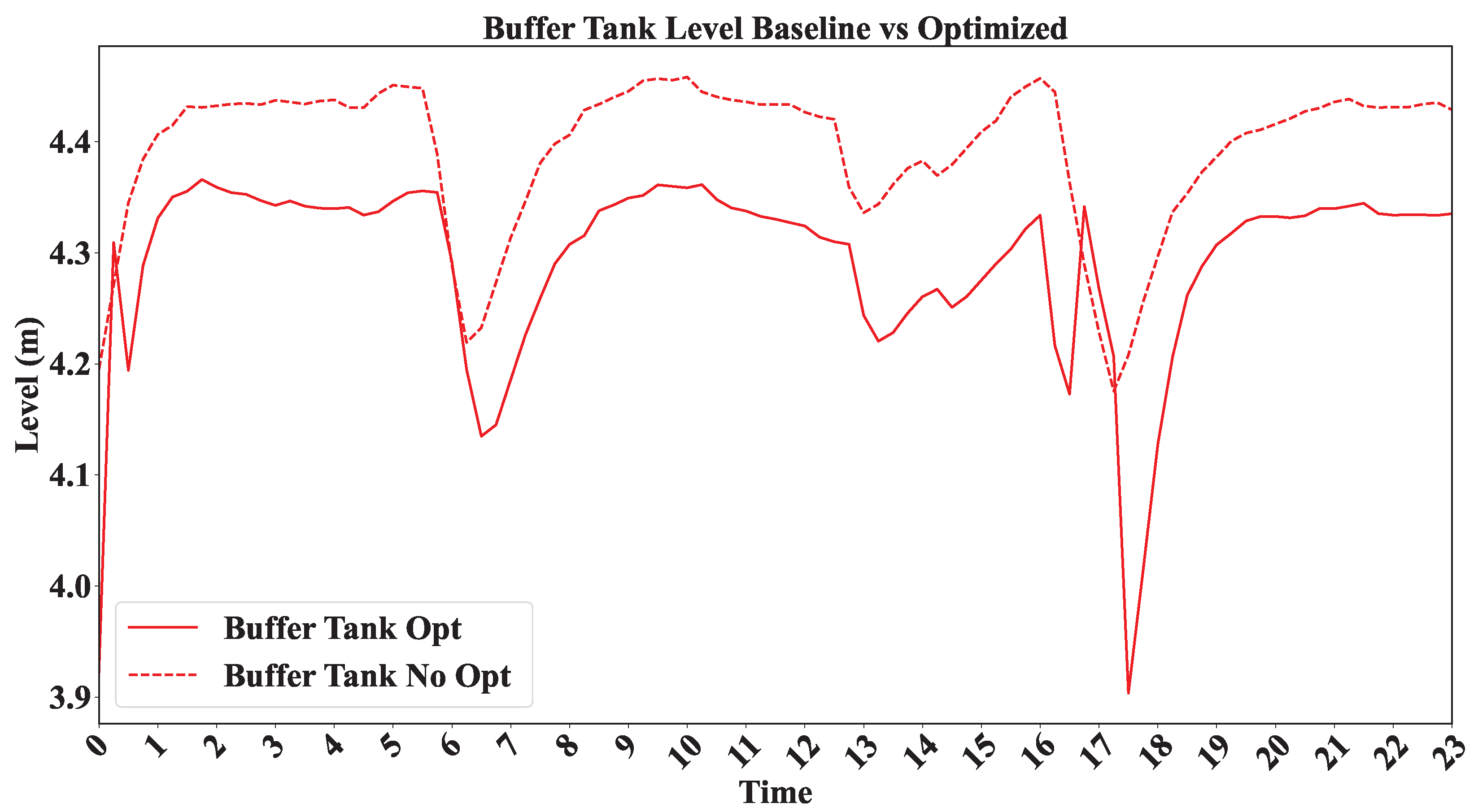

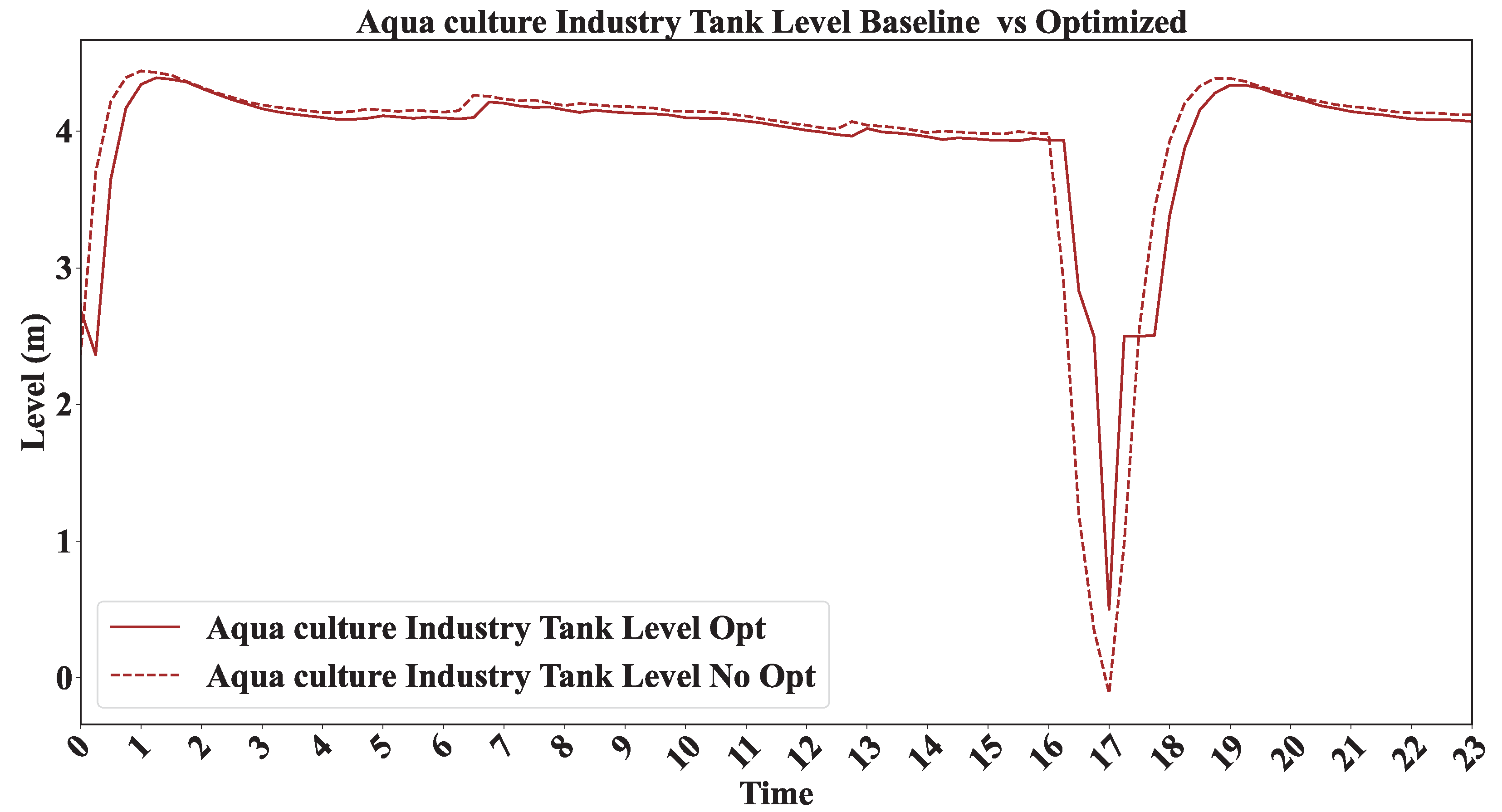

4.3.2. Operational Stability of the Tanks and Water Flow Rate Adjustments

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bouckaert, S.; Fernandez Pales, A.; McGlade, C.; Remme, U.; Wanner, B.; Varro, L.; D’Ambrosio, D.; Spencer, T. Net Zero by 2050: A Roadmap for the Global Energy Sector; Technical Report; International Energy Agency (IEA): Paris, France, 2021. [Google Scholar]

- Shahzad, S.; Jasińska, E. Renewable Revolution: A Review of Strategic Flexibility in Future Power Systems. Sustainability 2024, 16, 5454. [Google Scholar] [CrossRef]

- Alnahhal, Z.; Shaaban, M.F.; Hamouda, M.A.; Majozi, T.; Al Bardan, M. A Water-Energy Nexus Approach for the Co-Optimization of Electric and Water Systems. IEEE Access 2023, 11, 28762–28770. [Google Scholar] [CrossRef]

- Amusan, O.T.; Nwulu, N.I.; Gbadamosi, S.L. Optimal design and sizing of a hybrid energy system for water pumping applications. IET Renew. Power Gener. 2024, 18, 706–721. [Google Scholar] [CrossRef]

- Oikonomou, K.; Parvania, M.; Burian, S. Integrating water distribution energy flexibility in power systems operation. In Proceedings of the 2017 IEEE Power & Energy Society General Meeting, Chicago, IL, USA, 16–20 July 2017; pp. 1–5. [Google Scholar]

- Oikonomou, K.; Parvania, M. Optimal coordination of water distribution energy flexibility with power systems operation. IEEE Trans. Smart Grid 2018, 10, 1101–1110. [Google Scholar] [CrossRef]

- Oikonomou, K.; Parvania, M. Optimal coordinated operation of interdependent power and water distribution systems. IEEE Trans. Smart Grid 2020, 11, 4784–4794. [Google Scholar] [CrossRef]

- Shmaya, T.; Housh, M.; Pecci, F.; Baker, K.; Kasprzyk, J.; Ostfeld, A. Conjunctive optimal operation of water and power networks. Heliyon 2024, 10, e39136. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Yu, S.; Al-Sumaiti, A.; Turitsyn, K. Modeling and co-optimization of a micro water-energy nexus for smart communities. In Proceedings of the 2018 IEEE PES Innovative Smart Grid Technologies Conference Europe (ISGT-Europe), Sarajevo, Bosnia and Herzegovina, 21–25 October 2018; pp. 1–5. [Google Scholar] [CrossRef]

- Iwakin, O.M.; Moazeni, F. Hardware-in-the-Loop Simulation of Data-Driven Economic Dispatch Problem for Integrated Water–Energy Systems. In Proceedings of the World Environmental and Water Resources Congress, Anchorage, AK, USA, 18–21 May 2025; pp. 886–897. [Google Scholar] [CrossRef]

- Yao, Y.; Li, C.; Shao, C.; Hu, B.; Xie, K. Efficient operation of integrated electrical-water system for wind power accommodation. IEEE Trans. Ind. Inform. 2022, 19, 9382–9393. [Google Scholar] [CrossRef]

- Yao, Y.; Li, C.; Xie, K.; Tai, H.M.; Hu, B.; Niu, T. Optimal design of water tank size for power system flexibility and water quality. IEEE Trans. Power Syst. 2021, 36, 5874–5888. [Google Scholar] [CrossRef]

- Yao, Y.; Li, C.; Hu, B.; Shao, C. Optimal Joint Capacity Planning for Electricity Storage and Water Storage. In Proceedings of the 2023 13th International Conference on Power and Energy Systems (ICPES), Chengdu, China, 8–10 December 2023; pp. 484–489. [Google Scholar] [CrossRef]

- Zhou, M.; Zhang, K.; Liu, X.; Ma, F. Data-assisted coordinated robust optimization method for urban water-power systems. Appl. Energy 2025, 388, 125670. [Google Scholar] [CrossRef]

- Yao, Y.; Li, C.; Tai, H.M.; Shao, C. Modeling of water transfer delay for optimal operation of integrated electrical-water system. IEEE Trans. Power Syst. 2022, 38, 331–348. [Google Scholar] [CrossRef]

- Bakır, H.; Merabet, A.; Kiehbadroudinezhad, M. Optimized control of a hybrid water pumping system integrated with solar photovoltaic and battery storage: Towards sustainable and green water-power supply. Energies 2023, 16, 5209. [Google Scholar] [CrossRef]

- Szpak, D.; Tchórzewska-Cieślak, B.; Stręk, M. A New Method of Obtaining Water from Water Storage Tanks in a Crisis Situation Using Renewable Energy. Energies 2024, 17, 874. [Google Scholar] [CrossRef]

- Colajanni, G.; Sciacca, D.; Paone, L. Optimal energy management of water networks under quality conditions. Int. Trans. Oper. Res. 2025, 1–26. [Google Scholar] [CrossRef]

- Rasheed, M.B.; R-Moreno, M.D. An integrated model with interdependent water storage for optimal resource management in Energy–Water–Food Nexus. J. Clean. Prod. 2024, 462, 142648. [Google Scholar] [CrossRef]

- Brentan, B.; Mota, F.; Menapace, A.; Zanfei, A.; Meirelles, G. Optimizing pump operations in water distribution networks: Balancing energy efficiency, water quality and operational constraints. J. Water Process Eng. 2024, 63, 105374. [Google Scholar] [CrossRef]

- Jan, F.; Min-Allah, N.; Saeed, S.; Iqbal, S.Z.; Ahmed, R. IoT-Based Solutions to Monitor Water Level, Leakage, and Motor Control for Smart Water Tanks. Water 2022, 14, 309. [Google Scholar] [CrossRef]

- Kandukuri, S.; Kishore, D.R.; Prakash, S.B.; Ashok, P.; Jayadeep, K. Neuro Fuzzy Logic Algorithm Based WECS-PMSG Interfaced Water pumping System Along with Battery-Energy Management System. In Proceedings of the 2024 International Conference on Recent Innovation in Smart and Sustainable Technology (ICRISST), Bengaluru, India, 15–16 March 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Ben Safia, Z.; Allouche, M.; Chaabane, M. Renewable energy management of an hybrid water pumping system (photovoltaic/wind/battery) based on Takagi–Sugeno fuzzy model. Optim. Control Appl. Methods 2023, 44, 373–390. [Google Scholar] [CrossRef]

- Naval, N.; Yusta, J.M. Water-Energy Management for Demand Charges and Energy Cost Optimization of a Pumping Stations System under a Renewable Virtual Power Plant Model. Energies 2020, 13, 2900. [Google Scholar] [CrossRef]

- Pathak, R.; Kumar, S.; Das, V.; Pravin, P.S. Optimization-based Pump Operation Scheduling for Optimal Energy Management and Pumping Costs. In Proceedings of the 2024 10th International Conference on Control, Decision and Information Technologies (CoDIT), Vallette, Malta, 1–4 July 2024; pp. 2576–3547. [Google Scholar] [CrossRef]

- Cekalovic, F.; Sbarbaro, D.; Moran, L. Efficient Energy Management in Seawater Pumping Systems: Solar Hybridization and Storage for Demand Optimization. IEEE Trans. Ind. Appl. 2025, 61, 1854–1862. [Google Scholar] [CrossRef]

- Energinet. Current Tariffs. 2025. Available online: https://en.energinet.dk/electricity/tariffs/current-tariffs/ (accessed on 28 December 2024).

- Trefor El-Net. Oversigt Over Forbrugstariffer. 2025. Available online: https://www.trefor.dk/globalassets/mediebibliotek-trefor/3.-elnet/filer/historiske-priser/trefor-el-net---Prisstatistik-1.-maj-2024.pdf (accessed on 28 December 2024).

| Paper (Ref.) | Optimisation/Control Method | Closed-Loop | Grid-Voltage | Price/DR | Storage Modelled | Experimental/ Validation |

|---|---|---|---|---|---|---|

| [3] | MINLP, day-ahead co-optimization | — | — | ✓ | Water tanks | — |

| [4] | Hybrid PV/wind sizing | — | — | ✓ | Battery | — |

| [5] | Conceptual flexibility model | — | — | ✓ | Water tanks | — |

| [6] | MILP, day-ahead scheduling | — | — | ✓ | Water tanks | — |

| [7] | MILP, day-ahead scheduling | — | — | ✓ | Water tanks | — |

| [8] | Nonlinear conjunctive optimization | — | — | ✓ | Water tanks | — |

| [9] | MILP, micro WEN | — | — | ✓ | Battery + tanks | — |

| [10] | Data-driven economic dispatch | ∼ | — | ✓ | Tanks | HIL bench |

| [11] | Three-step cost minimization | — | — | ✓ | Tanks | — |

| [12] | Tank-size optimization | — | — | — | Water tanks | — |

| [13] | Joint electricity–water storage sizing | — | — | — | Battery + tanks | — |

| [14] | Two-stage robust optimization | — | — | ✓ | Battery + tanks | — |

| [15] | Delay-aware scheduling | — | — | ✓ | Tanks | — |

| [16] | MPC for PV-pump | ∼ | — | — | Battery | Lab |

| [17] | Stand-alone PV sizing | — | — | — | Battery | Field (crisis) |

| [18] | MILP with water-quality limits | — | — | ✓ | Tanks | — |

| [19] | Integrated E-W-F resource planning | — | — | — | Water storage | — |

| [20] | Meta-heuristic pump scheduling | — | — | ✓ | — | — |

| [21] | IoT monitoring/control | — | — | — | — | Prototype |

| [22] | Neuro-fuzzy EMS | ∼ | — | — | Battery | — |

| [23] | Takagi–Sugeno EMS | ∼ | — | — | Battery | — |

| [24] | MINLP virtual power plant | — | — | ✓ | Battery | — |

| [25] | ML pump scheduling | — | — | ✓ | — | — |

| [26] | Economic MPC, seawater pumps | ∼ | — | ✓ | Battery | Simulation |

| This Paper | MILP + EKF + MPC | ✓ | ✓ | ✓ | Water Tank | Industrial field data |

| Metric | Baseline | Optimized (MILP + EKF + MPC) | Improvement |

|---|---|---|---|

| Energy Cost (Normalized) | 1.00 | 0.73 | 27% Reduction |

| Voltage Range (p.u.) | [0.94, 1.06] | [0.95, 1.05] | Regulatory-compliant |

| Pump Flow Rate (/h) | Constant 180 | Adaptive [40–240] | Load shifting enabled |

| Storage Tank Level (m) | Up to 5.0 | 4.0–4.5 | Reduced fluctuation |

| Buffer Tank Level (m) | 4.2 (variable) | 3.9–4.0 | More stable |

| Aquaculture Tank Level (m) | 3.5 (flat) | 1.0–3.8 (adaptive) | Responsive to demand |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Subramanyam, S.A.; Ghaemi, S.; Golmohamadi, H.; Anvari-Moghaddam, A.; Bak-Jensen, B. Leveraging Dynamic Pricing and Real-Time Grid Analysis: A Danish Perspective on Flexible Industry Optimization. Energies 2025, 18, 4116. https://doi.org/10.3390/en18154116

Subramanyam SA, Ghaemi S, Golmohamadi H, Anvari-Moghaddam A, Bak-Jensen B. Leveraging Dynamic Pricing and Real-Time Grid Analysis: A Danish Perspective on Flexible Industry Optimization. Energies. 2025; 18(15):4116. https://doi.org/10.3390/en18154116

Chicago/Turabian StyleSubramanyam, Sreelatha Aihloor, Sina Ghaemi, Hessam Golmohamadi, Amjad Anvari-Moghaddam, and Birgitte Bak-Jensen. 2025. "Leveraging Dynamic Pricing and Real-Time Grid Analysis: A Danish Perspective on Flexible Industry Optimization" Energies 18, no. 15: 4116. https://doi.org/10.3390/en18154116

APA StyleSubramanyam, S. A., Ghaemi, S., Golmohamadi, H., Anvari-Moghaddam, A., & Bak-Jensen, B. (2025). Leveraging Dynamic Pricing and Real-Time Grid Analysis: A Danish Perspective on Flexible Industry Optimization. Energies, 18(15), 4116. https://doi.org/10.3390/en18154116