Flexible Demand Side Management in Smart Cities: Integrating Diverse User Profiles and Multiple Objectives

Abstract

1. Introduction

- Smart city context with multiple user profiles (with analysis of differentiated impact of DSM in the different profiles);

- The consideration of multiple objective optimization (cost reduction, emissions reduction, discomfort reduction) given the increasing interest and importance of optimizing solutions, taking into consideration multiple aspects, and comparison with single objective optimization, for the evaluation of Demand Side Management;

- Analysis of the impact of seasonality and annual generation mixes on the optimal outcomes of Demand Side Management;

- The use of real data (electricity prices, Time-of-Use profiles, emissions annual profile, device characteristics);

- Extraction of insights for decision-makers with different preferences, including policy, such as the design of Time-of-Use profiles.

2. Demand Side Management Techniques

- Energy Efficiency: This involves measures that lead to a reduction in the energy used by specific end-use devices and systems, without affecting the services provided. These measures include high-efficiency appliances, improved insulation, and more efficient heating and cooling systems. Energy efficiency programs are cost-effective over time, reducing energy consumption and utility bills.

- Load Shifting: Also frequently known as demand response, this technique encourages consumers to increase or decrease their electricity use during specific periods where energy demand is high or when renewable energy availability is high. Load shifting helps in managing the load curve, reducing the need for peak power plants, and enhancing grid reliability. Technologies such as smart thermostats and appliances capable of responding to signals from energy providers to delay or advance their operation time are central to this strategy.

- Peak Load Reduction: This strategy involves programs designed to cut down energy use during peak demand times, such as on hot summer days. Techniques include offering incentives for reduced consumption and temporary increases in electricity prices during peak periods (Time-of-Use pricing).

- Load Filling: Load filling promotes increased energy usage during periods of low demand to maintain consistent electricity production levels. This technique is particularly relevant in systems with high levels of renewable energy generation, where excess energy can be used more effectively.

- Energy Conservation: Broad programs aimed at promoting a culture of energy savings among consumers through behavioral change. Education and information dissemination play key roles in these programs, encouraging sustained energy-saving habits.

- Integrated DSM: This approach combines several DSM strategies to achieve optimal energy savings. For instance, integrating real-time energy monitoring tools with consumer incentives and education can lead to more significant energy savings and operational efficiencies.

3. Problem Formulation and Algorithm Description

3.1. Problem Formulation

- Cost () Minimization:

- 2.

- Discomfort Minimization:

- 3.

- CO2 Emission Minimization:

- Power Constraint: Ensures that the power consumed at any hour does not exceed the maximum allowable limit:

- ii.

- Operational Constraints: Each appliance must adhere to its operational limits regarding minimum and maximum usage durations and daily usage frequency.

3.2. Algorithm Description

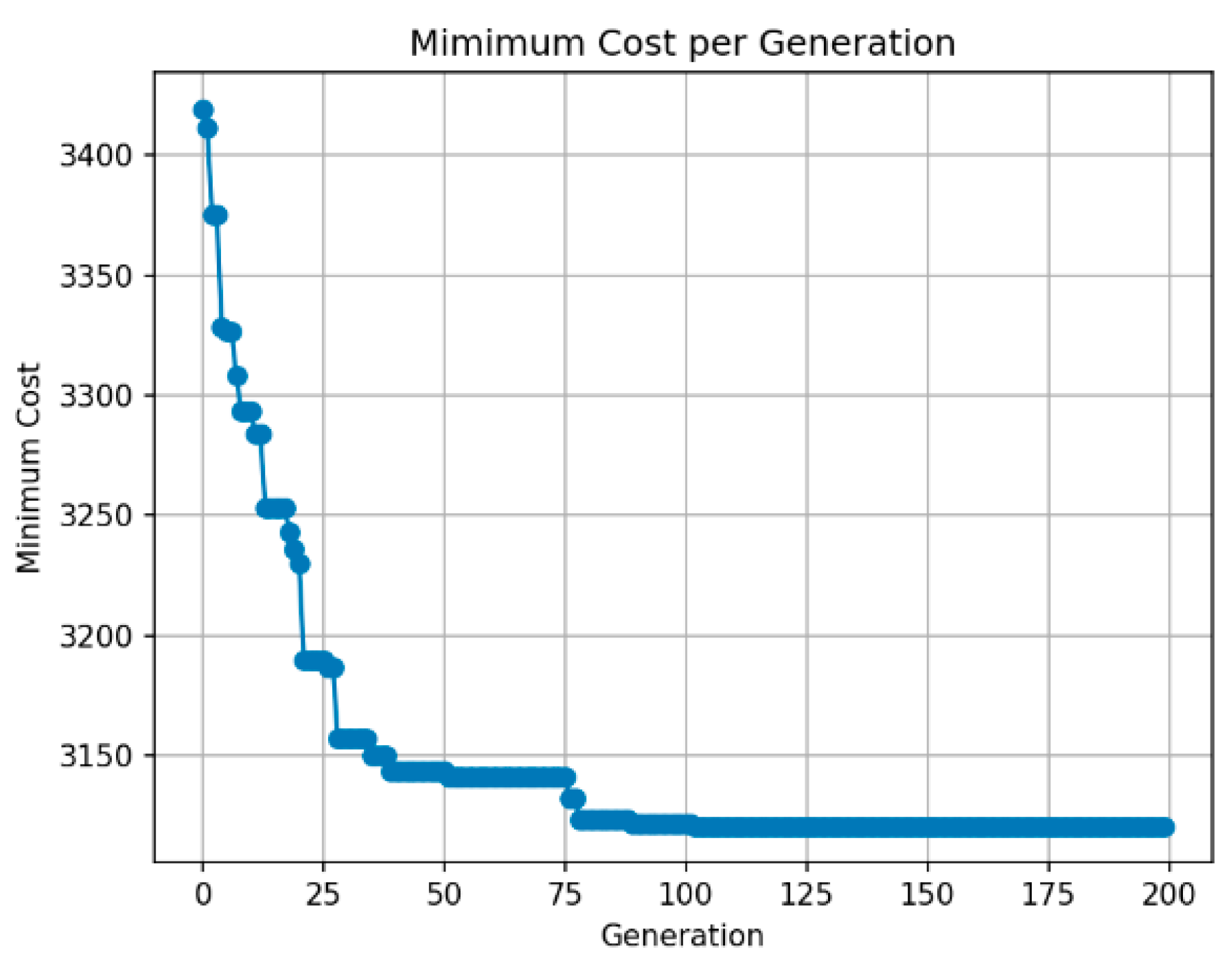

- Genetic Algorithm (GA)

- Population Size: 400;

- Number of Generations: 100;

- Crossover Probability: 0.9 (random single point);

- Mutation Probability: 0.1;

- Tournament size: 3;

- Elite Size: 10.

- B.

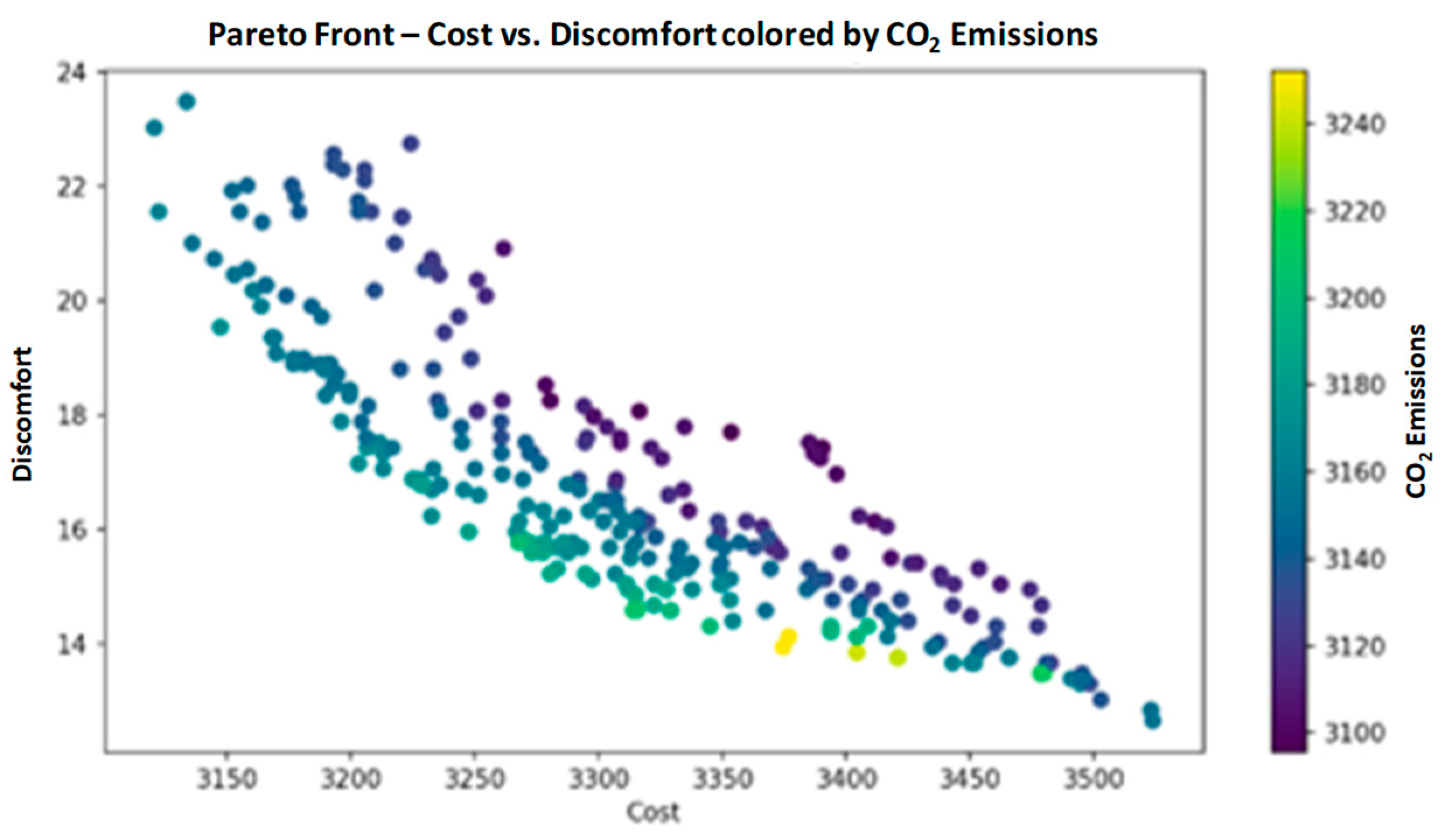

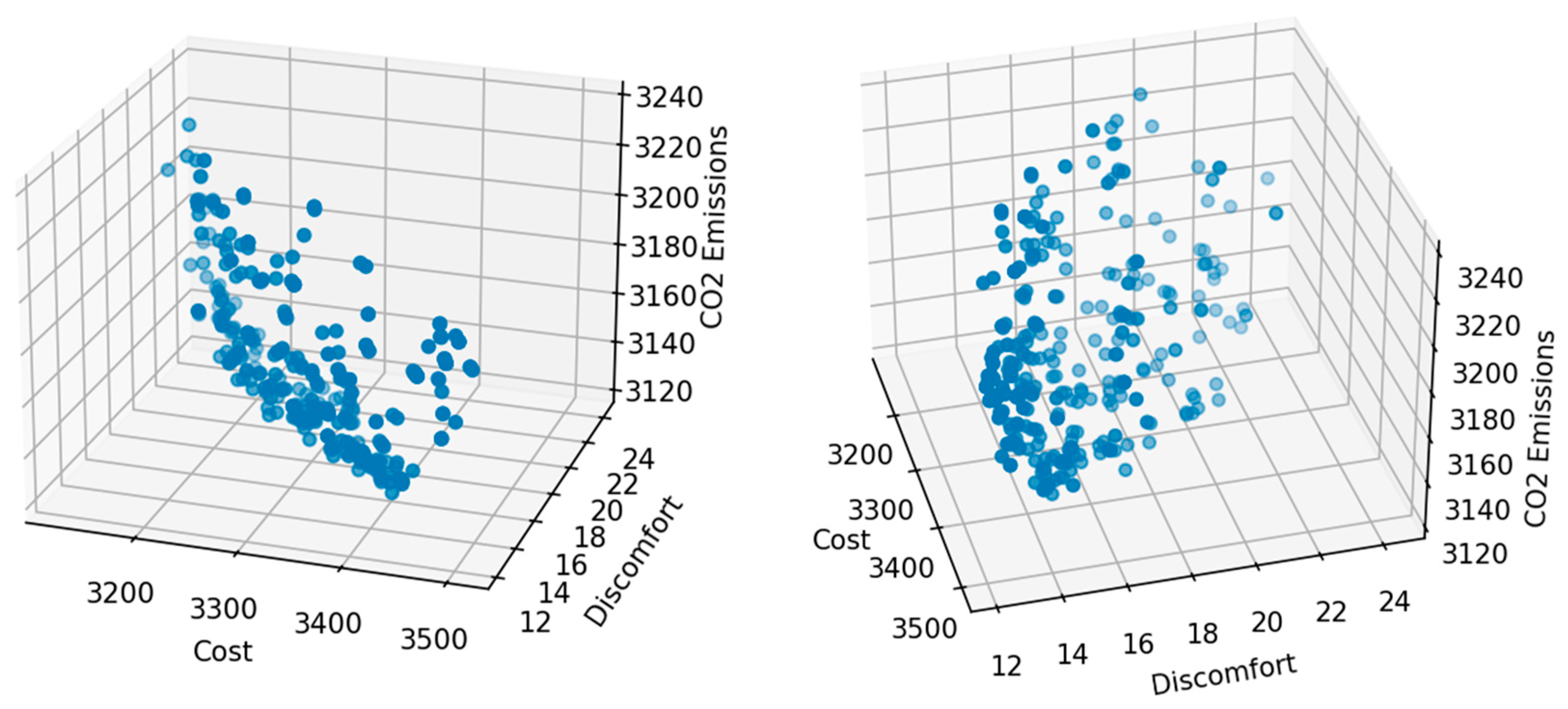

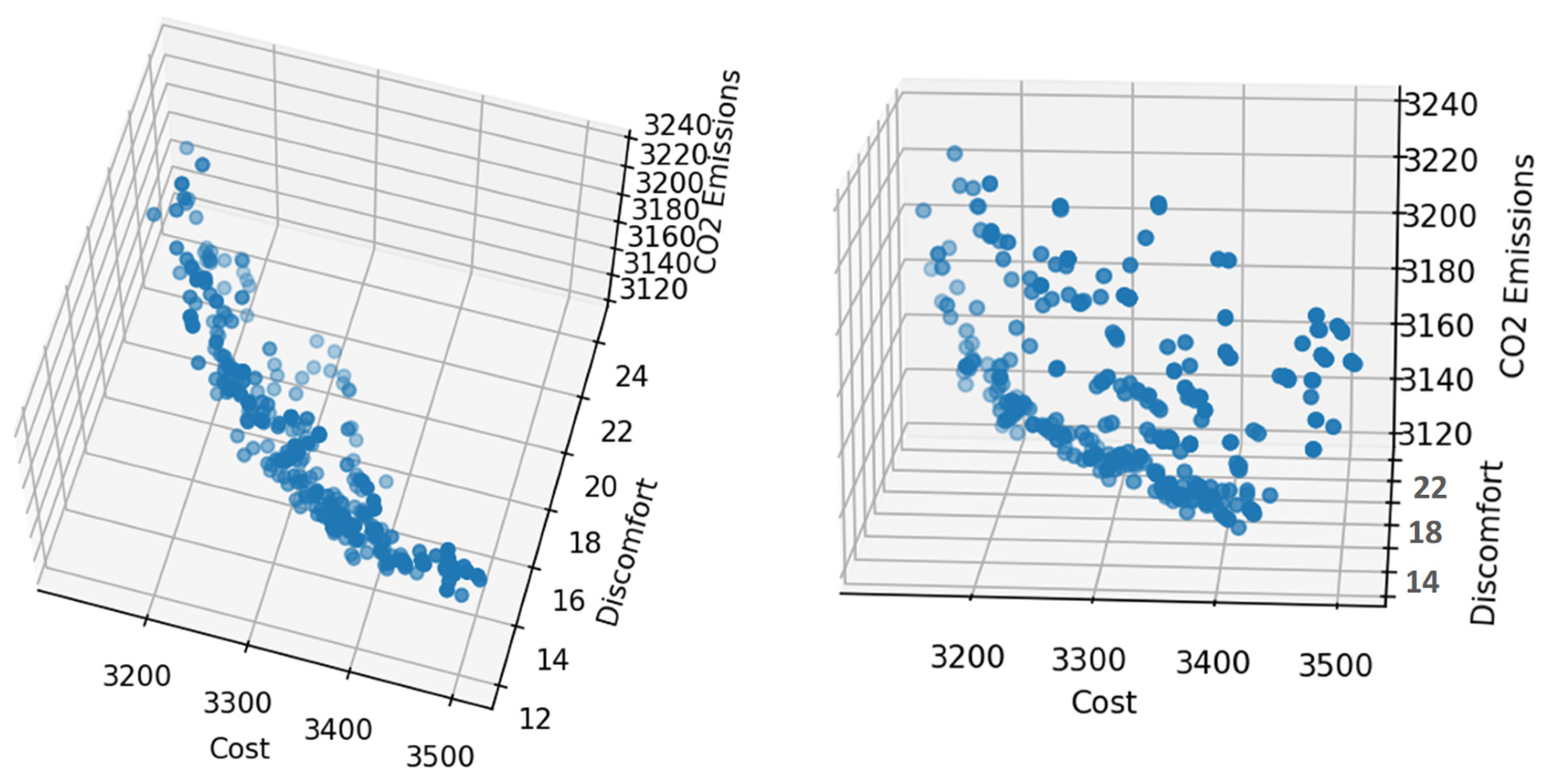

- Non-Dominated Sorting Genetic Algorithm II (NSGA-II)

- Population Size: 400;

- Number of Generations: 100;

- Crossover Probability: 0.9 (random single point);

- Mutation Probability: 0.1.

4. Scenario and Model Specification

4.1. Scenario Details

- Residential Sector: Includes common appliances like refrigerators, washing machines, dryers, and ovens. Each appliance has varying power requirements, preferred operational times, and flexibility in operation, reflecting typical household energy consumption patterns.

- Commercial Sector: Focuses on energy-intensive appliances like water dispensers, ovens, and air conditioning units commonly found in office buildings and small businesses. These appliances typically have less flexibility in operation times but contribute significantly to the energy footprint of commercial establishments.

- Industrial Sector: Comprises heavy machinery such as water heaters, welding machines, and induction motors. These units are high-power consumers with strict operational schedules to maintain industrial productivity.

4.2. Appliance Characterization

4.3. Pricing Schemes

- Peak Hours: 0.30;

- Mid-Peak Hours: 0.18;

- Off-Peak Hours: 0.15;

- Super Off-Peak Hours: 0.11.

4.4. CO2 Emissions

5. Results and Discussion

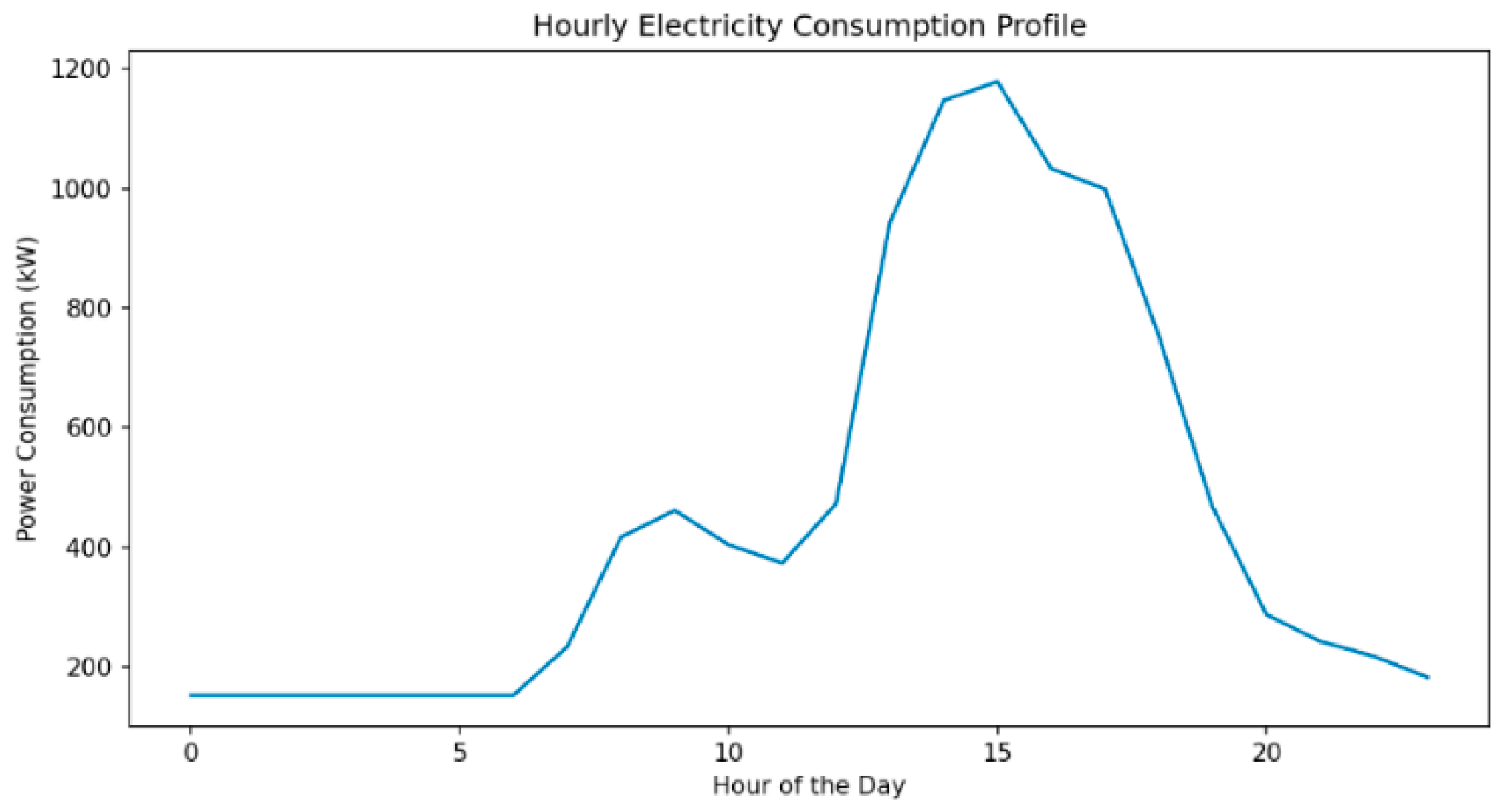

- Single-objective with Genetic Algorithm

- Result for different categories

- 2.

- Results for different periods

- 3.

- Results for different categories

- 4.

- Results for different periods

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mimi, S.; Ben Maissa, Y.; Tamtaoui, A. Optimization Approaches for Demand-Side Management in the Smart Grid: A Systematic Mapping Study. Smart Cities 2023, 6, 1630–1662. [Google Scholar] [CrossRef]

- Leitão, J.; Gil, P.; Ribeiro, B.; Cardoso, A. A Survey on Home Energy Management. IEEE Access 2020, 8, 5699–5722. [Google Scholar] [CrossRef]

- Gaur, G.; Mehta, N.; Khanna, R.; Kaur, S. Demand side management in a smart grid environment. In Proceedings of the 2017 IEEE International Conference on Smart Grid and Smart Cities (ICSGSC), Singapore, 23–26 July 2017; pp. 227–231. [Google Scholar] [CrossRef]

- Logenthiran, T.; Srinivasan, D. Short term generation scheduling of a Microgrid. In Proceedings of the TENCON 2009-2009 IEEE Region 10 Conference, Singapore, 23–26 January 2009; pp. 1–6. [Google Scholar] [CrossRef]

- Nucci, C.; Stecchi, U.; Bruno, S.; Lamonaca, S.; La Scala, M. From Smart Grids to Smart Cities: New Challenges in Optimizing Energy Grids; Wiley: Hoboken, NJ, USA, 2017; pp. 129–175. [Google Scholar] [CrossRef]

- e Silva, N.S.; Castro, R.; Ferrão, P. Smart Grids in the Context of Smart Cities: A Literature Review and Gap Analysis. Energies 2025, 18, 1186. [Google Scholar] [CrossRef]

- Li, D.; Chiu, W.-Y.; Sun, H.; Poor, H.V. Multiobjective Optimization for Demand Side Management Program in Smart Grid. IEEE Trans. Ind. Inform. 2018, 14, 1482–1490. [Google Scholar] [CrossRef]

- Kinhekar, N.; Padhy, N.P.; Gupta, H.O. Multiobjective demand side management solutions for utilities with peak demand deficit. Int. J. Electr. Power Energy Syst. 2014, 55, 612–619. [Google Scholar] [CrossRef]

- Lokeshgupta, B.; Sadhukhan, A.; Sivasubramani, S. Multi-objective optimization for demand side management in a smart grid environment. In Proceedings of the 2017 7th International Conference on Power Systems (ICPS), Pune, India, 21–23 December 2017; pp. 200–205. [Google Scholar] [CrossRef]

- Wang, J.; Ren, X.; Zhjang, S.; Xue, K.; Wang, S.; Dai, H.; Chong, D.; Han, X. Co-optimization of configuration and operation for distributed multi-energy system considering different optimization objectives and operation strategies. Appl. Therm. Eng. 2023, 230, 120655. [Google Scholar] [CrossRef]

- Coello, C. A Short Tutorial on Evolutionary Multiobjective Optimization. Lect. Notes Comput. Sci. 2001, 1993, 21–40. [Google Scholar] [CrossRef]

- Shahsavar, A.; Ghadamian, H.; Saboori, H. Building energy and environmental sustainability. In Building Energy Flexibility and Demand Management; Elsevier: Amsterdam, The Netherlands, 2023; pp. 3–15. [Google Scholar] [CrossRef]

- Koukaras, P.; Gkaidatzis, P.; Bezas, N.; Bragatto, T.; Carere, F.; Santori, F.; Antal, M.; Ioannidis, D.; Tjortjis, C.; Tzovaras, D. A Tri-Layer Optimization Framework for Day-Ahead Energy Scheduling Based on Cost and Discomfort Minimization. Energies 2021, 14, 3599. [Google Scholar] [CrossRef]

- Bakare, M.S.; Abdulkarim, A.; Zeeshan, M.; Shuaibu, A.N. A comprehensive overview on demand side energy management towards smart grids: Challenges, solutions, and future direction. Energy Inform. 2023, 6, 4. [Google Scholar] [CrossRef]

- Alhasnawi, B.N.; Jasim, B.H.; Alhasnawi, A.N.; Hussain, F.F.K.; Homod, R.Z.; Hasan, H.A.; Khalaf, O.I.; Abbassi, R.; Bazooyar, B.; Zanker, M.; et al. A novel efficient energy optimization in smart urban buildings based on optimal demand side management. Energy Strategy Rev. 2024, 54, 101461. [Google Scholar] [CrossRef]

- Iqbal, S.; Sarfraz, M.; Ayyub, M.; Tariq, M.; Chakrabortty, R.K.; Ryan, M.J.; Alamri, B. A Comprehensive Review on Residential Demand Side Management Strategies in Smart Grid Environment. Sustainability 2021, 13, 7170. [Google Scholar] [CrossRef]

- Atefi, A.; Gholaminia, V. Flexible demand-side management program in accordance with the consumers’ requested constraints. Energy Build. 2024, 309, 114013. [Google Scholar] [CrossRef]

- Yahia, Z.; Pradhan, A. Optimal load scheduling of household appliances considering consumer preferences: An experimental analysis. Energy 2018, 163, 15–26. [Google Scholar] [CrossRef]

- O’Reilly, R.; Cohen, J.; Reichl, J. Achievable load shifting potentials for the European residential sector from 2022–2050. Renew. Sustain. Energy Rev. 2024, 189, 113959. [Google Scholar] [CrossRef]

- Awais, M.; Javaid, N.; Shaheen, N.; Iqbal, Z.; Rehman, G.; Muhammad, K. An Efficient Genetic Algorithm Based Demand Side Management Scheme for Smart Grid. In Proceedings of the 2015 18th International Conference on Network-Based Information Systems, Taipei, China, 10 September 2015; pp. 351–356. [Google Scholar] [CrossRef]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A Fast and Elitist Multiobjective Genetic Algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2022, 6, 182–197. [Google Scholar] [CrossRef]

- Logenthiran, T.; Srinivasan, D.; Shun, T.Z. Demand side management in smart grid using heuristic optimization. IEEE Trans. Smart Grid 2012, 3, 1244–1252. [Google Scholar] [CrossRef]

- Rajarajeswari, R.; Vijayakumar, K.; Modi, A. Demand Side Management in Smart Grid using Optimization Technique for Residential, Commercial and Industrial Load. Indian J. Sci. Technol. 2016, 9, 1–7. [Google Scholar] [CrossRef]

- Saravanan, B. DSM in an area consisting of residential, commercial and industrial load in smart grid. Front. Energy 2015, 9, 211–216. [Google Scholar] [CrossRef]

- Nasef, A.; Khattab, H.; Awad, F. Evaluating the Impact of Demand Side Management Techniques on Household Electricity Consumption, A real case. Eng. Res. J. 2021, 44, 149–157. [Google Scholar] [CrossRef]

- Williams, B.; Bishop, D.; Gallardo, P.; Chase, J.G. Demand Side Management in Industrial, Commercial, and Residential Sectors: A Review of Constraints and Considerations. Energies 2023, 16, 5155. [Google Scholar] [CrossRef]

- Shafie-Khah, M.; Siano, P.; Aghaei, J.; Masoum, M.A.S.; Li, F.X.; Catalao, J.P.S. Comprehensive review of the recent advances in industrial and commercial DR. IEEE Trans. Ind. Inform. 2019, 15, 3757–3771. [Google Scholar] [CrossRef]

- Sajini, M.; Suja, S.; Raj, G.; Kowsalyavedi, S.; Maria, C. Finite State Machine-Based Load Scheduling Algorithm for Smart Home Energy Management. IETE J. Res. 2021, 69, 7460–7475. [Google Scholar] [CrossRef]

- Oprea, S.-V.; Bâra, A.; Marales, R.; Florescu, M.-S. Data Model for Residential and Commercial Buildings. Load Flexibility Assessment in Smart Cities. Sustainability 2021, 13, 1736. [Google Scholar] [CrossRef]

- Rong, J.; Liu, W.; Jiang, F.; Cheng, Y.; Li, H.; Peng, J. Privacy-aware optimal load scheduling for energy management system of smart home. Sustain. Energy Grids Netw. 2023, 34, 101039. [Google Scholar] [CrossRef]

- Taha, H.; Haider, H. Multi-Objective Residential Load Scheduling Approach Based Pelican Optimization Algorithm with Multi-Criteria Decision Making. J. Eng. Sustain. Dev. 2025, 29, 242–254. [Google Scholar] [CrossRef]

- Li, Y.; Wang, C.; Li, G.; Chen, C. Optimal Scheduling of Integrated Demand Response-Enabled Integrated Energy Systems with Uncertain Renewable Generations: A Stackelberg Game Approach. Energy Convers. Manag. 2021, 235, 113996. [Google Scholar] [CrossRef]

- Leprince, J.; Schledorn, A.; Guericke, D.; Daminkovic, D.; Madsen, H.; Zeiler, W. Can occupant behaviors affect urban energy planning? Distributed stochastic optimization for energy communities. Appl. Energy 2023, 348, 121589. [Google Scholar] [CrossRef]

- Khan, Z.; Zafar, A.; Javaid, S.; Aslam, S.; Muhammad, R.; Nadeem, J. Hybrid meta-heuristic optimization based home energy management system in smart grid. J. Ambient. Intell. Humaniz. Comput. 2019, 10, 4837–4853. [Google Scholar] [CrossRef]

- TarifarioElectricidade. Available online: https://www.edp.pt/particulares/energia/tarifarios (accessed on 16 May 2025).

- ERSE, “Tarifas e Precos Regulados.”. Available online: https://www.erse.pt/atividade/regulacao/tarifas-e-precos-eletricidade/#tarifas-e-precos-regulados (accessed on 27 May 2025).

- Peters, J.F.; Iribarren, D.; Juez Martel, P.; Burguillo, M. Hourly marginal electricity mixes and their relevance for assessing the environmental performance of installations with variable load or power. Sci. Total Environ. 2022, 843, 156963. [Google Scholar] [CrossRef]

- REN_DataHub. Available online: https://datahub.ren.pt/en/electricity/daily-balance/ (accessed on 16 May 2025).

- ElectricityMaps. Available online: https://app.electricitymaps.com/map (accessed on 16 May 2025).

- EnergyMonitor. Available online: https://www.energymonitor.ai/sectors/power/live-eu-electricity-generation-map/?cf-view (accessed on 16 May 2025).

- Li, Y.; Ma, W.; Li, Y.; Li, S.; Chen, Z.; Shahidehpour, M. Enhancing cyber-resilience in integrated energy system scheduling with demand response using deep reinforcement learning. Appl. Energy 2025, 379, 124831. [Google Scholar] [CrossRef]

- Li, Y.; Han, M.; Yang, Z. Coordinating Flexible Demand Response and Renewable Uncertainties for Scheduling of Community Integrated Energy Systems With an Electric Vehicle Charging Station: A Bi-Level Approach. IEEE Trans. Sustain. Energy 2021, 12, 2321–2331. [Google Scholar] [CrossRef]

- Ye, Q.; Wang, Y.; Li, X.; Guo, J.; Huang, Y.; Yang, B. A power load prediction method of associated industry chain production resumption based on multi-task LSTM. Energy Rep. 2022, 8 (Suppl. S4), 239–249. [Google Scholar] [CrossRef]

- Li, P.; Wang, L.; Zhang, P.; Yan, P.; Li, C.; Nan, Z.; Wang, J. Strategic Demand Response for Economic Dispatch in Wind-Integrated Multi-Area Energy Systems. Energies 2025, 18, 2188. [Google Scholar] [CrossRef]

- Kou, L.; Wang, Y.; Zhang, F.; Yuan, Q.; Wang, Z.; Wen, Z.; Ke, W. A Chaotic Simulated Annealing Genetic Algorithm with Asymmetric Time for Offshore Wind Farm Inspection Path Planning. Int. J. Bio-Inspired Comput. 2025, 25, 69–78. [Google Scholar] [CrossRef]

- Soni, V.; Bhatt, D.P.; Yadav, N.S.; Saxena, S. DAIS: Deep artificial immune system for intrusion detection in IoT ecosystems. Int. J. Bio-Inspired Comput. 2024, 23, 148–156. [Google Scholar] [CrossRef]

- Meng, Q.; Xu, J.; Ge, L.; Wang, Z.; Wang, J.; Xu, L.; Tang, Z. Economic Optimization Operation Approach of Integrated Energy System Considering Wind Power Consumption and Flexible Load Regulation. J. Electr. Eng. Technol. 2024, 19, 209–221. [Google Scholar] [CrossRef]

- Sousa, J.; Soares, I. Benefits and barriers concerning demand response stakeholder value chain: A systematic literature review. Energy 2023, 280, 128065. [Google Scholar] [CrossRef]

| Appliance | Power (W) | Min Duration (h) | Max Duration (h) | Preferred Start Time (h) | Start Time Flexibility (h) | Discomfort Penalty | Quantity |

|---|---|---|---|---|---|---|---|

| Dryer | 1200 | 1 | 1 | 21 | 24 | 1 | 189 |

| Dish washer | 700 | 1 | 2 | 21 | 24 | 1 | 288 |

| Washing machine | 500 | 1 | 2 | 21 | 24 | 1 | 268 |

| Oven | 1300 | 1 | 1 | 19 | 3 | 2 | 279 |

| Iron | 1000 | 1 | 1 | 18 | 10 | 1 | 340 |

| Vacuum cleaner | 400 | 1 | 1 | 11 | 10 | 1 | 158 |

| Fan | 200 | 2 | 5 | 13 | 5 | 1 | 288 |

| Kettle | 2000 | 1 | 1 | 17 | 2 | 1 | 406 |

| Toaster | 900 | 1 | 1 | 8 | 1 | 1 | 48 |

| Rice cooker | 850 | 1 | 1 | 19 | 3 | 2 | 59 |

| Hair dryer | 1500 | 1 | 1 | 8 | 1 | 1 | 58 |

| Blender | 300 | 1 | 1 | 17 | 10 | 1 | 66 |

| Frying pan | 1100 | 1 | 1 | 19 | 3 | 2 | 101 |

| Coffee maker | 800 | 1 | 1 | 8 | 1 | 2 | 56 |

| Tv | 300 | 2 | 4 | 20 | 1 | 1 | 300 |

| Lights | 200 | 3 | 6 | 19 | 1 | 2 | 400 |

| Continuous loads | 400 | 24 | 24 | 0 | 0 | 2 | 400 |

| Appliance | Power (W) | Min Duration (h) | Max Duration (h) | Preferred Start Time (h) | Start Time Flexibility (h) | Discomfort Penalty | Quantity |

|---|---|---|---|---|---|---|---|

| Water dispenser am | 2500 | 5 | 7 | 11 | 3 | 5 | 78 |

| Water dispenser pm | 2500 | 5 | 7 | 16 | 3 | 5 | 78 |

| Dryer | 3500 | 4 | 6 | 11 | 3 | 5 | 117 |

| Kettle | 3000 | 2 | 3 | 16 | 3 | 5 | 123 |

| Oven | 5000 | 1 | 2 | 13 | 2 | 5 | 77 |

| Coffee maker | 2000 | 2 | 3 | 13 | 2 | 5 | 99 |

| AC/fan | 3000 | 2 | 3 | 14 | 3 | 5 | 93 |

| AC | 3500 | 3 | 3 | 14 | 3 | 5 | 56 |

| Lights | 1750 | 24 | 24 | 0 | 0 | 5 | 87 |

| Appliance | Power (W) | Min Duration (h) | Max Duration (h) | Preferred Start Time (h) | Start Time Flexibility (h) | Discomfort Penalty | Quantity |

|---|---|---|---|---|---|---|---|

| water heater | 12,500 | 3 | 5 | 10 | 3 | 10 | 39 |

| welding machine | 25,000 | 5 | 5 | 9 | 1 | 10 | 35 |

| fan/AC | 30,000 | 5 | 6 | 11 | 2 | 10 | 16 |

| arc furnace | 50,000 | 6 | 7 | 9 | 2 | 10 | 8 |

| induction motor | 100,000 | 6 | 6 | 9 | 2 | 10 | 5 |

| dc motor am | 150,000 | 3 | 4 | 9 | 2 | 10 | 3 |

| dc motor pm | 150,000 | 3 | 4 | 15 | 2 | 10 | 3 |

| Hour | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | |

| Price | Summer | 0.15 | 0.15 | 0.11 | 0.11 | 0.11 | 0.11 | 0.15 | 0.15 | 0.18 | 0.18 | 0.18 | 0.3 |

| Winter | 0.15 | 0.15 | 0.11 | 0.11 | 0.11 | 0.11 | 0.15 | 0.15 | 0.18 | 0.3 | 0.3 | 0.18 | |

| Hour | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | |

| Price | Summer | 0.3 | 0.18 | 0.18 | 0.18 | 0.18 | 0.18 | 0.18 | 0.18 | 0.3 | 0.18 | 0.15 | 0.15 |

| Winter | 0.18 | 0.18 | 0.18 | 0.18 | 0.18 | 0.18 | 0.3 | 0.3 | 0.3 | 0.18 | 0.15 | 0.15 |

| Period | Date | Characterization | |

|---|---|---|---|

| 0 | 6 July 2023 | Summer sunny | 41% RES |

| 1 | 30 January 2023 | Winter sunny | 62% RES |

| 2 | 10 January 2023 | Winter wet/natural gas | 70% RES |

| 3 | 10 September 2023 | Low RES (annual minimum) | 21% RES |

| 4 | 11 November 2023 | High RES (annual maximum) | 85% RES |

| Hour | Period | ||||

|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | |

| 0 | 221.6 | 67.9 | 77.6 | 162.9 | 29.8 |

| 1 | 231 | 68.5 | 74.5 | 179.5 | 31.3 |

| 2 | 233.2 | 63.8 | 73 | 189.7 | 33.9 |

| 3 | 234.3 | 75.3 | 79.9 | 195.1 | 34.9 |

| 4 | 240.5 | 90 | 84 | 196.9 | 33.9 |

| 5 | 210.8 | 103.6 | 84.2 | 196 | 32 |

| 6 | 185.9 | 94.9 | 87.7 | 178.6 | 28.8 |

| 7 | 205.8 | 89.7 | 96.7 | 148 | 29.2 |

| 8 | 211.6 | 100.1 | 108.8 | 126.6 | 33.3 |

| 9 | 199.9 | 128 | 115 | 119.7 | 42.1 |

| 10 | 193.5 | 148.9 | 108.1 | 111.1 | 36.3 |

| 11 | 194.2 | 162.3 | 108.9 | 108.5 | 37 |

| 12 | 191.1 | 170.8 | 117.4 | 109.9 | 40.7 |

| 13 | 180.8 | 177.9 | 124 | 113.8 | 41 |

| 14 | 177.5 | 192 | 119 | 114.7 | 38.7 |

| 15 | 176.9 | 196.3 | 118.7 | 113.3 | 35.4 |

| 16 | 186.5 | 207.3 | 112.1 | 129.4 | 35.4 |

| 17 | 192.5 | 179.4 | 106.4 | 136.3 | 34.4 |

| 18 | 187.4 | 162.7 | 107.2 | 147.1 | 29.7 |

| 19 | 183.2 | 157.6 | 112.7 | 155.3 | 30 |

| 20 | 170.45 | 149.2 | 90.4 | 168 | 34.3 |

| 21 | 168.8 | 143.4 | 81.4 | 193 | 36.4 |

| 22 | 190.1 | 152.8 | 78.8 | 203 | 42.1 |

| 23 | 206.3 | 167.7 | 62.3 | 215.2 | 32.8 |

| Period 0 | 6 July 2023 | Summer Sunny | 41% RES | |

|---|---|---|---|---|

| - | Cost Reduction (with DSM vs. w/o DSM) | CO2 Reduction (with DSM vs. w/o DSM) | Discomfort Index (with DSM/w/o DSM) | PAR Reduction (with DSM vs. w/o DSM) |

| Residential | 8.3 % | −1.0 % | 3.9/0 | 56.2 % |

| Commercial | 10.7 % | 3.1 % | 8.5/0 | 21.0 % |

| Industrial | 32.5 % | 4.3 % | 37.8/0 | 7.8 % |

| Period 1 | 30 January 2023 | Winter Sunny | 62% RES | |

|---|---|---|---|---|

| Cost Reduction (with DSM vs. w/o DSM) | CO2 Reduction (with DSM vs. w/o DSM) | Discomfort Index (with DSM/w/o DSM) | PAR Reduction (with DSM vs. w/o DSM) | |

| Residential | 6.2 % | 2.7 % | 4.1/0 | 54.3 % |

| Commercial | 5.4 % | 5.5 % | 7.4/0 | 19 % |

| Industrial | 23.3 % | 0.5 % | 32.6/0 | 12.3 % |

| Period 2 | 10 January 2023 | Winter Wet/Natural Gas | 70% RES | |

|---|---|---|---|---|

| - | Cost Reduction (with DSM vs. w/o DSM) | CO2 Reduction (with DSM vs. w/o DSM) | Discomfort Index (with DSM/w/o DSM) | PAR Reduction (with DSM vs. w/o DSM) |

| Residential | 5.9 % | 0.7 % | 4.0/0 | 54.0 % |

| Commercial | 4.4 % | 3.3 % | 7.0/0 | 14.9 % |

| Industrial | 25.6 % | 7.8 % | 30.8/0 | 9.6 % |

| Period 3 | 10 September 2023 | Low RES (Annual Minimum) | 21% RES | |

|---|---|---|---|---|

| - | Cost Reduction (with DSM vs. w/o DSM) | CO2 Reduction (with DSM vs. w/o DSM) | Discomfort Index (with DSM/w/o DSM) | PAR Reduction (with DSM vs. w/o DSM) |

| Residential | 8.6 % | 1.1 % | 4.0/0 | 55.1 % |

| Commercial | 10.8 % | 0.3 % | 8.7/0 | 21.3 % |

| Industrial | 31.9 % | −15.7 % | 37.2/0 | 8.2 % |

| Period 4 | 11 November 2023 | High RES (Annual Maximum) | 85% RES | |

|---|---|---|---|---|

| - | Cost Reduction (with DSM vs. w/o DSM) | CO2 Reduction (with DSM vs. w/o DSM) | Discomfort Index (with DSM/w/o DSM) | PAR Reduction (with DSM vs. w/o DSM) |

| Residential | 5.6 % | 0.2 % | 4.0/0 | 55.1 % |

| Commercial | 5.9 % | 4.8 % | 7.1/0 | 13.4 % |

| Industrial | 26.0 % | 11.0 % | 31.1/0 | 12.8 % |

| Period 0 | 6 July 2023 | Summer Sunny | 41% RES | |

|---|---|---|---|---|

| - | Cost Reduction (with DSM vs. w/o DSM) | CO2 Reduction (with DSM vs. w/o DSM) | Discomfort Index (with DSM) | PAR Reduction (with DSM vs. w/o DSM) |

| Residential | 6.5–7.6 % | 0.3–0.5 % | 3.2–3.4 | 51.7–54.4 % |

| Commercial | 7.0–8.0 % | 4.1–4.5 % | 5.6–6.0 | 19.5–21.2 % |

| Industrial | 10.3–19.9 % | 4.2–7.0 % | 13.1–24.4 | 20.2–49.6% |

| Period 1 | 30 January 2023 | Winter Sunny | 62% RES | |

|---|---|---|---|---|

| - | Cost Reduction (with DSM vs. w/o DSM) | CO2 Reduction (with DSM vs. w/o DSM) | Discomfort Index (with DSM) | PAR Reduction (with DSM vs. w/o DSM) |

| Residential | 2.5–4.1 % | 2.5–3.6 % | 3.4–3.7 | 51.9–55.4 % |

| Commercial | 2.3–3.3 % | 7.9–9.2 % | 5.9–6.6 | 26.3–30.6 % |

| Industrial | 11.6–17.3 % | 8.0–21.4 % | 12.3–24.4 | 22.1–50.3 % |

| Period 2 | 10 January 2023 | Winter Wet/Natural Gas | 70% RES | |

|---|---|---|---|---|

| - | Cost Reduction (with DSM vs. w/o DSM) | CO2 Reduction (with DSM vs. w/o DSM) | Discomfort Index (with DSM) | PAR Reduction (with DSM vs. w/o DSM) |

| Residential | 3.4–4.3 % | 0.6–1.1 % | 3.4–3.6 | 52.2–53.7 % |

| Commercial | 3.6–4.3 % | 6.2–6.7 % | 5.9–6.4 | 25.0–28.1 % |

| Industrial | 13.2–18.7 % | 6.4–12.3 % | 12.9–23.4 | 21.7–46.7% |

| Period 3 | 10 September 2023 | Low RES (Annual Minimum) | 21% RES | |

|---|---|---|---|---|

| - | Cost Reduction (with DSM vs. w/o DSM) | CO2 Reduction (with DSM vs. w/o DSM) | Discomfort Index (with DSM) | PAR Reduction (with DSM vs. w/o DSM) |

| Residential | 5.7–7.0 % | 1.6–2.4 % | 3.4–3.8 | 56.6–58.8 % |

| Commercial | 5.2–7.1 % | 3.2–4.0 % | 5.7–6.2 | 19.6–22.5 % |

| Industrial | 8.8–19.5 % | −1.6–6.6 % | 12.3–24.1 | 14.6–45.4 % |

| Period 4 | 11 November 2023 | Hi RES (Annual Maximum) | 85% RES | |

|---|---|---|---|---|

| - | Cost Reduction (with DSM vs. w/o DSM) | CO2 Reduction (with DSM vs. w/o DSM) | Discomfort Index (with DSM) | PAR Reduction (with DSM vs. w/o DSM) |

| Residential | 2.9–4.2 % | 0.4–1.0 % | 3.4–3.7 | 52.9–57.8 % |

| Commercial | 3.8–4.4 % | 6.0–6.5 % | 5.6–5.9 | 20.2–24.1 % |

| Industrial | 10.7–17.8 % | 8.2–12.4 % | 12.8–20.1 | 19.8–45.9 % |

| Residential | ||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cost Reduction (%) | CO2 Reduction (%) | Discomfort Index (#) | PAR Reduction (%) | Period | ||||||||||||||||||||

| GA | NSGA-II | NSGA-II Midpoint | GA | NSGA-II | NSGA-II Midpoint | GA | NSGA-II | NSGA-II Midpoint | GA | NSGA-II | NSGA-II Midpoint | |||||||||||||

| 8.3% | → | 6.5% | – | 7.6% | 7.1% | −1.0% | → | 0.3% | – | 0.5% | 0.4% | 3.9 | → | 3.2 | – | 3.4 | 3.3 | 56.2% | → | 51.7% | – | 54.4% | 53.1% | 0 (41% RES) |

| 6.2% | → | 2.5% | – | 4.1% | 3.3% | 2.7% | → | 2.5% | – | 3.6% | 3.1% | 4.1 | → | 3.4 | – | 3.7 | 3.6 | 54.3% | → | 51.9% | – | 55.4% | 53.7% | 1 (62% RES) |

| 5.9% | → | 3.4% | – | 4.3% | 3.9% | 0.7% | → | 0.6% | – | 1.1% | 0.9% | 4 | → | 3.4 | – | 3.6 | 3.5 | 54.0% | → | 52.2% | – | 53.7% | 53.0% | 2 (70% RES) |

| 8.6% | → | 5.7% | – | 7.0% | 6.4% | 1.1% | → | 1.6% | – | 2.4% | 2.0% | 4 | → | 3.4 | – | 3.8 | 3.6 | 55.1% | → | 56.6% | – | 58.8% | 57.7% | 3 (21% RES) |

| 5.6% | → | 2.9% | – | 4.2% | 3.6% | 0.2% | → | 0.4% | – | 1.0% | 0.7% | 4 | → | 3.4 | – | 3.7 | 3.6 | 55.1% | → | 52.9% | – | 57.8% | 55.4% | 4 (85% RES) |

| Commercial | ||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cost Reduction (%) | CO2 Reduction (%) | Discomfort Index (#) | PAR Reduction (%) | Period | ||||||||||||||||||||

| GA | NSGA-II | NSGA-II Midpoint | GA | NSGA-II | NSGA-II Midpoint | GA | NSGA-II | NSGA-II Midpoint | GA | NSGA-II | NSGA-II Midpoint | |||||||||||||

| 10.7% | → | 7.0% | – | 8.0% | 7.5% | 3.1% | → | 4.1% | – | 4.5% | 4.3% | 8.5 | → | 5.6 | – | 6.0 | 5.8 | 21.0% | → | 19.5% | – | 21.2% | 20.4% | 0 (41% RES) |

| 5.4% | → | 2.3% | – | 3.3% | 2.8% | 5.5% | → | 7.9% | – | 9.2% | 8.6% | 7.4 | → | 5.9 | – | 6.6 | 6.3 | 19.0% | → | 26.3% | – | 30.6% | 28.5% | 1 (62% RES) |

| 4.4% | → | 3.6% | – | 4.3% | 4.0% | 3.3% | → | 6.2% | – | 6.7% | 6.5% | 7 | → | 5.9 | – | 6.4 | 6.2 | 14.9% | → | 25.0% | – | 28.1% | 26.6% | 2 (70% RES) |

| 10.8% | → | 5.2% | – | 7.1% | 6.2% | 0.3% | → | 3.2% | – | 4.0% | 3.6% | 8.7 | → | 5.7 | – | 6.2 | 6.0 | 21.3% | → | 19.6% | – | 22.5% | 21.1% | 3 (21% RES) |

| 5.9% | → | 3.8% | – | 4.4% | 4.1% | 4.8% | → | 6.0% | – | 6.5% | 6.3% | 7.1 | → | 5.6 | – | 5.9 | 5.8 | 13.4% | → | 20.2% | – | 24.1% | 22.2% | 4 (85% RES) |

| Industry | ||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cost Reduction (%) | CO2 Reduction (%) | Discomfort Index (#) | PAR Reduction (%) | Period | ||||||||||||||||||||

| GA | NSGA-II | NSGA-II Midpoint | GA | NSGA-II | NSGA-II Midpoint | GA | NSGA-II | NSGA-II Midpoint | GA | NSGA-II | NSGA-II Midpoint | |||||||||||||

| 32.5% | → | 10.3% | – | 19.9% | 15.1% | 4.3% | → | 4.2% | – | 7.0% | 5.6% | 37.8 | → | 13.1 | – | 24.4 | 18.8 | 7.8% | → | 20.2% | – | 49.6% | 34.9% | 0 (41% RES) |

| 23.3% | → | 11.6% | – | 17.3% | 14.5% | 0.5% | → | 8.0% | – | 21.4% | 14.7% | 32.6 | → | 12.3 | – | 24.4 | 18.4 | 12.3% | → | 22.1% | – | 50.3% | 36.2% | 1 (62% RES) |

| 25.6% | → | 13.2% | – | 18.7% | 16.0% | 7.8% | → | 6.4% | – | 12.3% | 9.4% | 30.8 | → | 12.9 | – | 23.4 | 18.2 | 9.6% | → | 21.7% | – | 46.7% | 34.2% | 2 (70% RES) |

| 31.9% | → | 8.8% | – | 19.5% | 14.2% | −15.7% | → | −1.6% | – | 6.6% | 2.5% | 37.2 | → | 12.3 | – | 24.4 | 18.4 | 8.2% | → | 14.6% | – | 45.4% | 30.0% | 3 (21% RES) |

| 26.0% | → | 10.7% | – | 17.8% | 14.3% | 11.0% | → | 8.2% | – | 12.4% | 10.3% | 31.1 | → | 12.8 | – | 20.1 | 16.5 | 12.8% | → | 19.8% | – | 45.9% | 32.9% | 4 (85% RES) |

| Period | Cost Reduction Ratio | CO2 Reduction Ratio | Discomfort Index Ratio | PAR Reduction Ratio |

|---|---|---|---|---|

| 0 (41% RES) | 0.85 | n/a | 0.85 | 0.94 |

| 1 (62% RES) | 0.53 | 1.13 | 0.87 | 0.99 |

| 2 (70% RES) | 0.65 | 1.21 | 0.88 | 0.98 |

| 3 (21% RES) | 0.74 | 1.82 | 0.90 | 1.05 |

| 4 (85% RES) | 0.63 | 3.50 | 0.89 | 1.00 |

| Period | Cost Reduction Ratio | CO2 Reduction Ratio | Discomfort Index Ratio | PAR Reduction Ratio |

|---|---|---|---|---|

| 0 (41% RES) | 0.70 | 1.39 | 0.68 | 0.97 |

| 1 (62% RES) | 0.52 | 1.55 | 0.84 | 1.50 |

| 2 (70% RES) | 0.90 | 1.95 | 0.88 | 1.78 |

| 3 (21% RES) | 0.57 | 12.00 | 0.68 | 0.99 |

| 4 (85% RES) | 0.69 | 1.30 | 0.81 | 1.65 |

| Period | Cost Reduction Ratio | CO2 Reduction Ratio | Discomfort Index Ratio | PAR Reduction Ratio |

|---|---|---|---|---|

| 0 (41% RES) | 0.46 | 1.30 | 0.50 | 4.47 |

| 1 (62% RES) | 0.62 | 29.40 | 0.56 | 2.94 |

| 2 (70% RES) | 0.62 | 1.20 | 0.59 | 3.56 |

| 3 (21% RES) | 0.44 | n/a | 0.49 | 3.66 |

| 4 (85% RES) | 0.55 | 0.94 | 0.53 | 2.57 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Souza e Silva, N.; Ferrão, P. Flexible Demand Side Management in Smart Cities: Integrating Diverse User Profiles and Multiple Objectives. Energies 2025, 18, 4107. https://doi.org/10.3390/en18154107

Souza e Silva N, Ferrão P. Flexible Demand Side Management in Smart Cities: Integrating Diverse User Profiles and Multiple Objectives. Energies. 2025; 18(15):4107. https://doi.org/10.3390/en18154107

Chicago/Turabian StyleSouza e Silva, Nuno, and Paulo Ferrão. 2025. "Flexible Demand Side Management in Smart Cities: Integrating Diverse User Profiles and Multiple Objectives" Energies 18, no. 15: 4107. https://doi.org/10.3390/en18154107

APA StyleSouza e Silva, N., & Ferrão, P. (2025). Flexible Demand Side Management in Smart Cities: Integrating Diverse User Profiles and Multiple Objectives. Energies, 18(15), 4107. https://doi.org/10.3390/en18154107