A Review of New Technologies in the Design and Application of Wind Turbine Generators

Abstract

1. Introduction

1.1. Wind Energy and the Need for New Technologies

1.2. Requirements for Generators Used in Wind Turbines

2. Types of Generators in Wind Turbines

2.1. Synchronous Generators

2.2. Asynchronous Generators

3. Low-Speed Generators

4. Superconductivity Theory and Its Application in Generators

4.1. Superconductivity Phenomenon—Basic Principles

4.2. Types of Superconductors

4.3. Use of Superconductors in Generators

4.4. Cooling of Superconducting Generators

5. New Generator Concepts—Description of Selected Designs

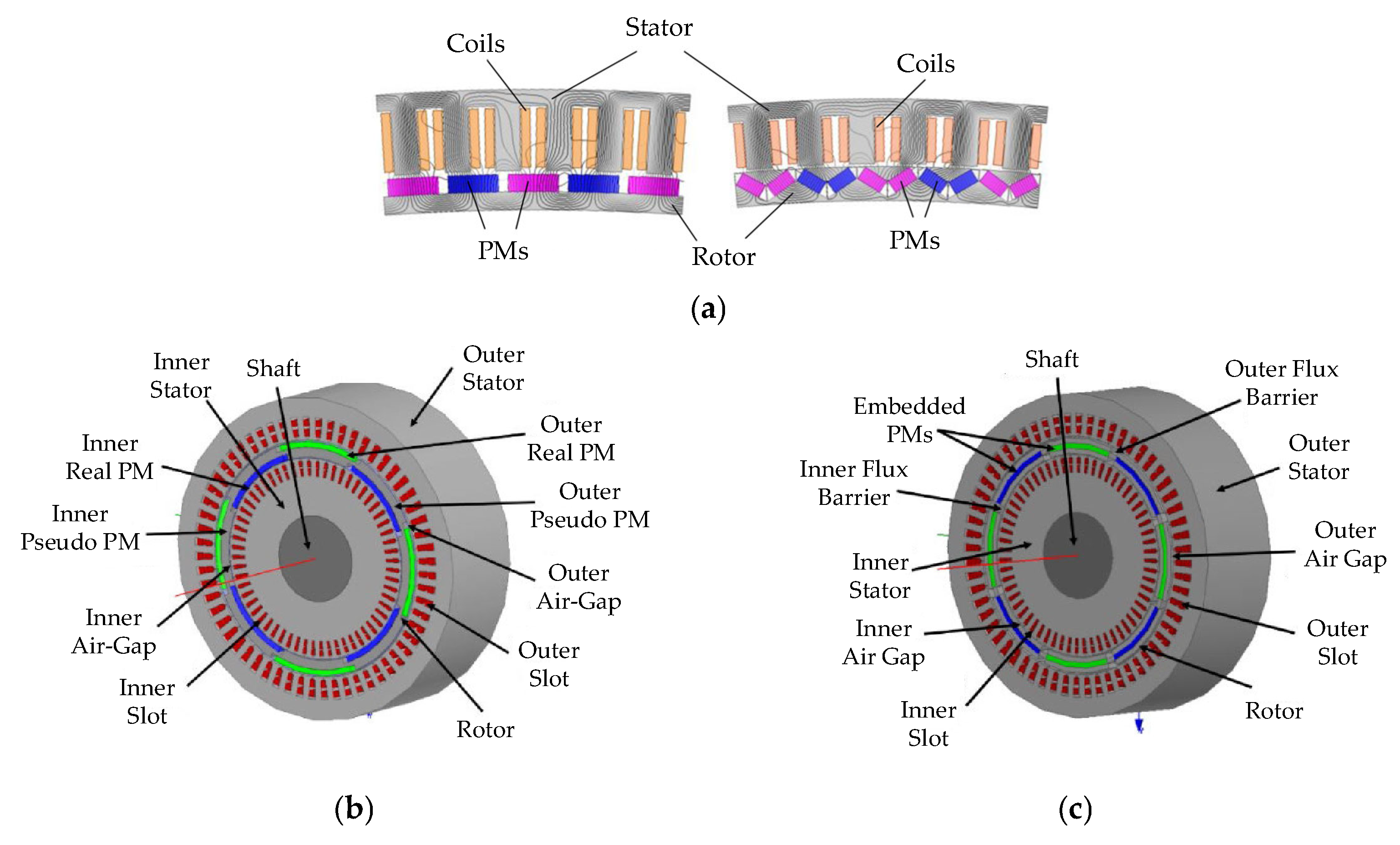

5.1. PMSG

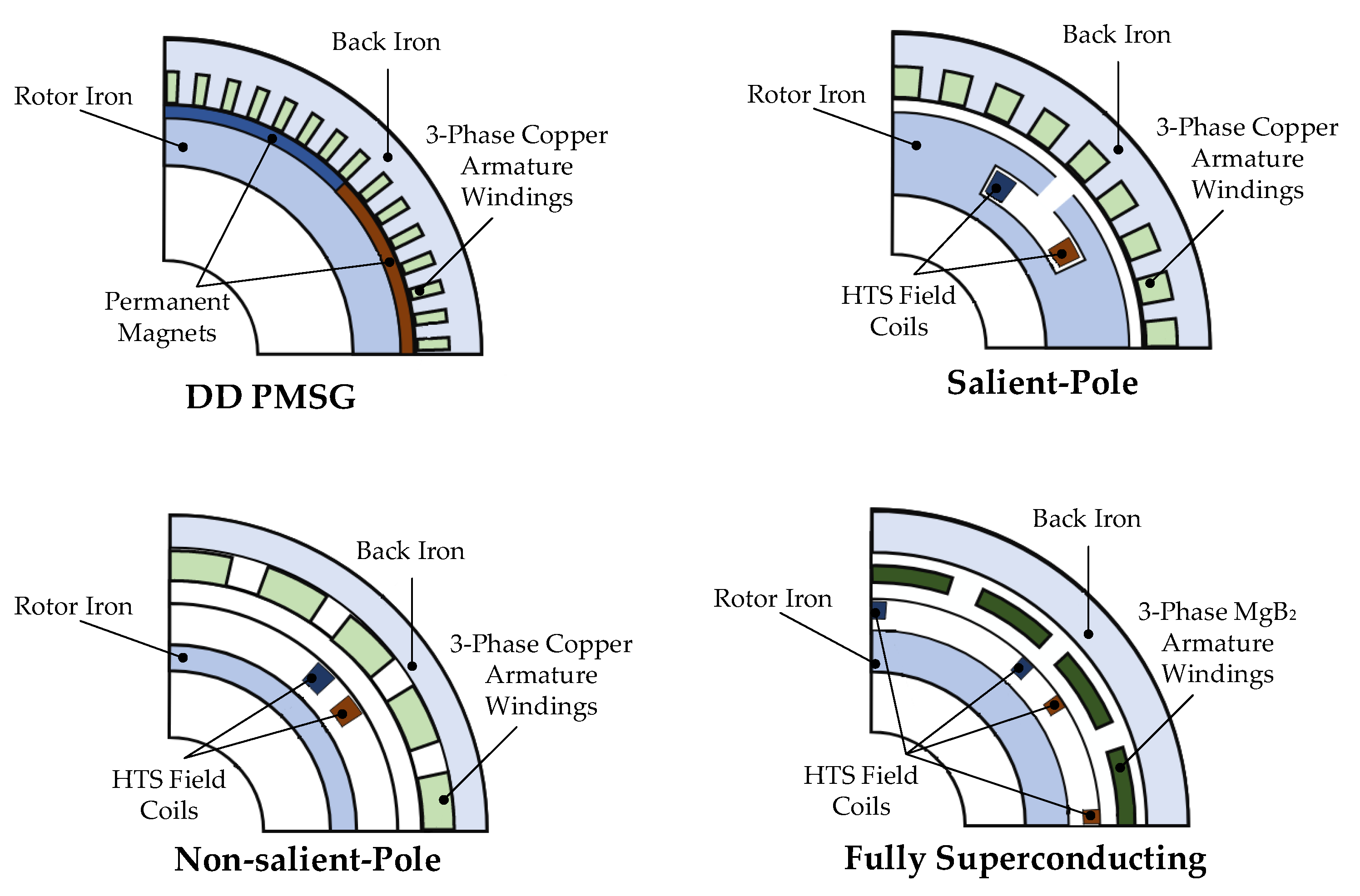

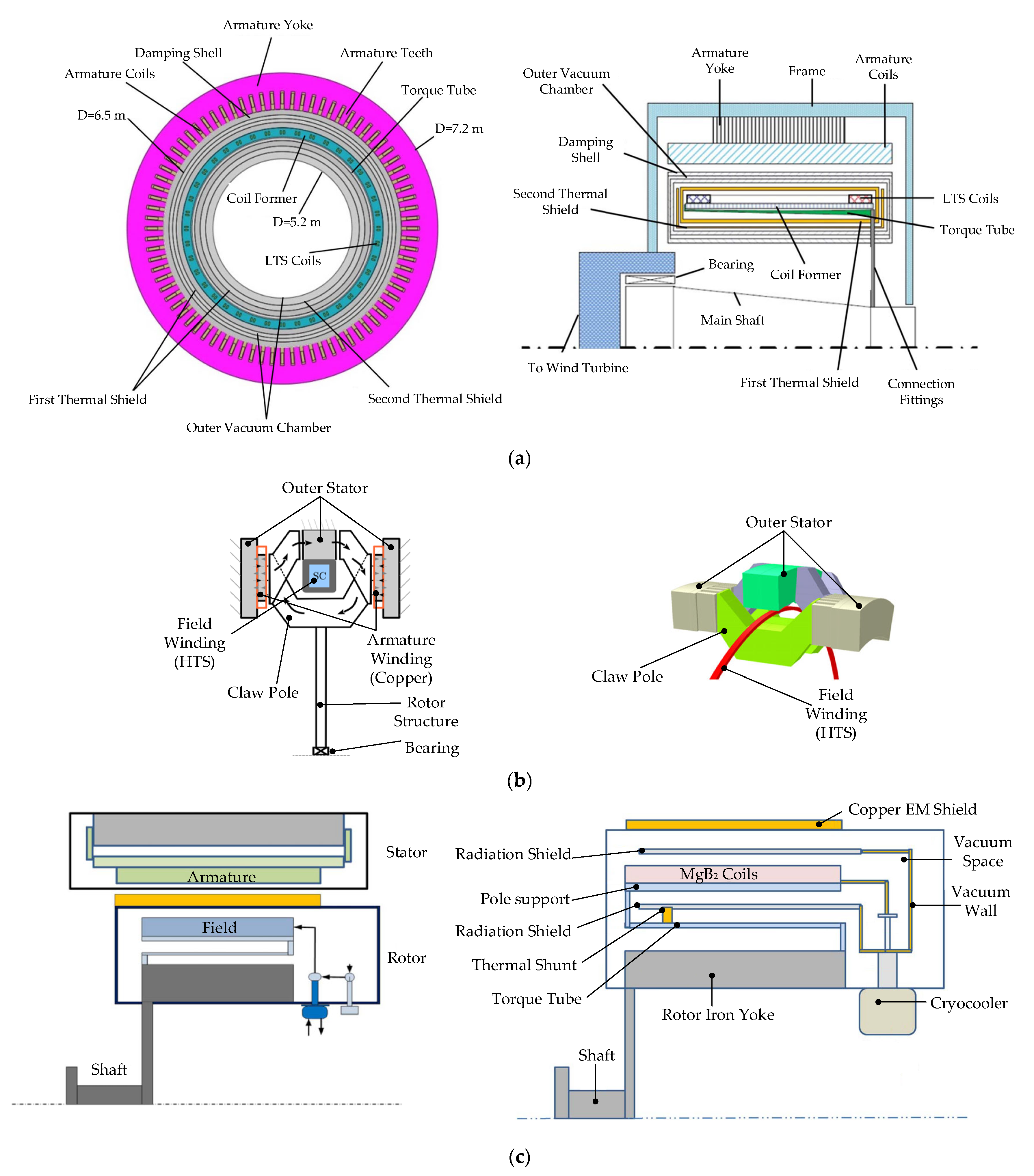

5.2. Superconducting Synchronous Generators

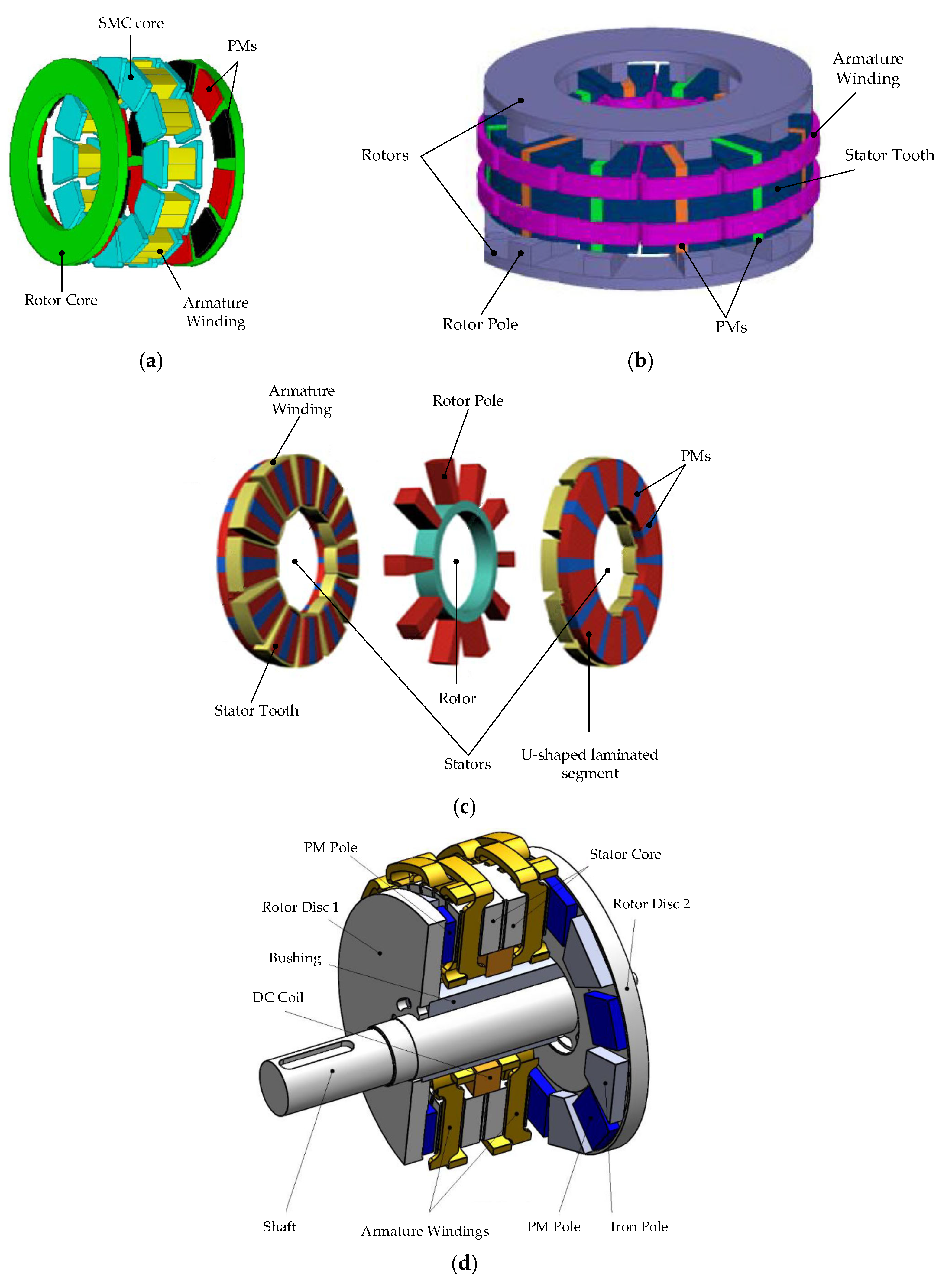

5.3. Axial-Flux Generators

5.4. Comparison

6. Summary and Conclusions

6.1. Commercialisation Opportunities for New Generator Concepts

6.2. The Future of Superconductors in Wind Turbines

6.3. HTS-SG Technology with the Greatest Potential

6.4. The Biggest Barriers to Implementing HTS in Wind Energy

- High cost of HTS materials, particularly YBCO and GdBCO, which significantly impact the overall capital expenditure;

- Complexity and reliability of cryogenic systems, which must operate under harsh offshore conditions with limited access for maintenance;

- Technical challenges related to the cooling of the rotor, which, as a rotating component, complicates the design of efficient and reliable cryogenic systems;

- Risk of quench (sudden loss of superconductivity), which can lead to mechanical damage and lengthy repair procedures;

- Lack of operational experience in real-world conditions for high-power machines (>5 MW), affecting the confidence of investors and manufacturers;

- Need for standardization and technical regulations for HTS components in energy applications to ensure interoperability, safety, and certification readiness.

6.5. Further Research Directions

Author Contributions

Funding

Conflicts of Interest

References

- Chang, F.; Khoo, R.; Ongel, A.; Lienkamp, M. Rapid Energy Consumption Assessment of Vehicle Concepts for Public Transport Systems without Detailed Deployment Data. In Proceedings of the 2018 IEEE Innovative Smart Grid Technologies—Asia (ISGT Asia), Singapore, 21–24 May 2018; pp. 452–455. [Google Scholar]

- Valeriy, K.; Viktor, S.; Petro, H.; Myamlin, S.; Yevhen, K.; Vitalij, L. Hybrid Railway Traction Power Supply System. In Proceedings of the 2020 IEEE 4th International Conference on Intelligent Energy and Power Systems (IEPS), Istanbul, Turkey, 7–11 September 2020; pp. 208–211. [Google Scholar]

- Gyurov, V.; Bezhanov, N. Study on Electric Consumption Regimes in Rectifier Stations of Trolleybus Transport. In Proceedings of the 2019 11th Electrical Engineering Faculty Conference (BulEF), Sozopol, Bulgaria, 11–14 September 2019; pp. 1–4. [Google Scholar]

- Zhang, Y.; Hu, F.; Han, Y.; Meng, W.; Guo, Z.; Li, C. AI-Based Energy-Saving for Fog Computing-Empowered Data Centers. In Proceedings of the 2023 International Conference on Mobile Internet, Cloud Computing and Information Security (MICCIS), Suzhou, China, 28–30 July 2023; pp. 16–21. [Google Scholar]

- Dash, S. Green AI: Enhancing Sustainability and Energy Efficiency in AI-Integrated Enterprise Systems. IEEE Access 2025, 13, 21216–21228. [Google Scholar] [CrossRef]

- Lund, H.; Østergaard, P.A.; Connolly, D.; Mathiesen, B.V. Smart Energy and Smart Energy Systems. Energy 2017, 137, 556–565. [Google Scholar] [CrossRef]

- Xu, Y.; Yan, C.; Liu, H.; Wang, J.; Yang, Z.; Jiang, Y. Smart Energy Systems: A Critical Review on Design and Operation Optimization. Sustain. Cities Soc. 2020, 62, 102369. [Google Scholar] [CrossRef]

- Nejad, A.R.; Keller, J.; Guo, Y.; Sheng, S.; Polinder, H.; Watson, S.; Dong, J.; Qin, Z.; Ebrahimi, A.; Schelenz, R.; et al. Wind Turbine Drivetrains: State-of-the-Art Technologies and Future Development Trends. Wind. Energ. Sci. 2022, 7, 387–411. [Google Scholar] [CrossRef]

- Rajendran, S.; Diaz, M.; Cárdenas, R.; Espina, E.; Contreras, E.; Rodriguez, J. A Review of Generators and Power Converters for Multi-MW Wind Energy Conversion Systems. Processes 2022, 10, 2302. [Google Scholar] [CrossRef]

- GWEC’s Global Wind Report 2024. Available online: https://www.gwec.net/reports/globalwindreport (accessed on 5 March 2025).

- Lasemi, M.A.; Arabkoohsar, A.; Hajizadeh, A. Optimal Design of Green Energy Hub Considering Multi-Generation Energy Storage System. In Proceedings of the 2022 IEEE International Conference on Power Systems Technology (POWERCON), Kunming, China, 26–28 September 2022; pp. 1–6. [Google Scholar]

- Lawder, M.T.; Suthar, B.; Northrop, P.W.C.; De, S.; Hoff, C.M.; Leitermann, O.; Crow, M.L.; Santhanagopalan, S.; Subramanian, V.R. Battery Energy Storage System (BESS) and Battery Management System (BMS) for Grid-Scale Applications. Proc. IEEE 2014, 102, 1014–1030. [Google Scholar] [CrossRef]

- Lubosny, Z. Wind Turbine Operation in Electric Power Systems: Advanced Modeling; Power Systems; Springer: Berlin/Heidelberg, Germany, 2003; ISBN 978-3-642-07317-5. [Google Scholar]

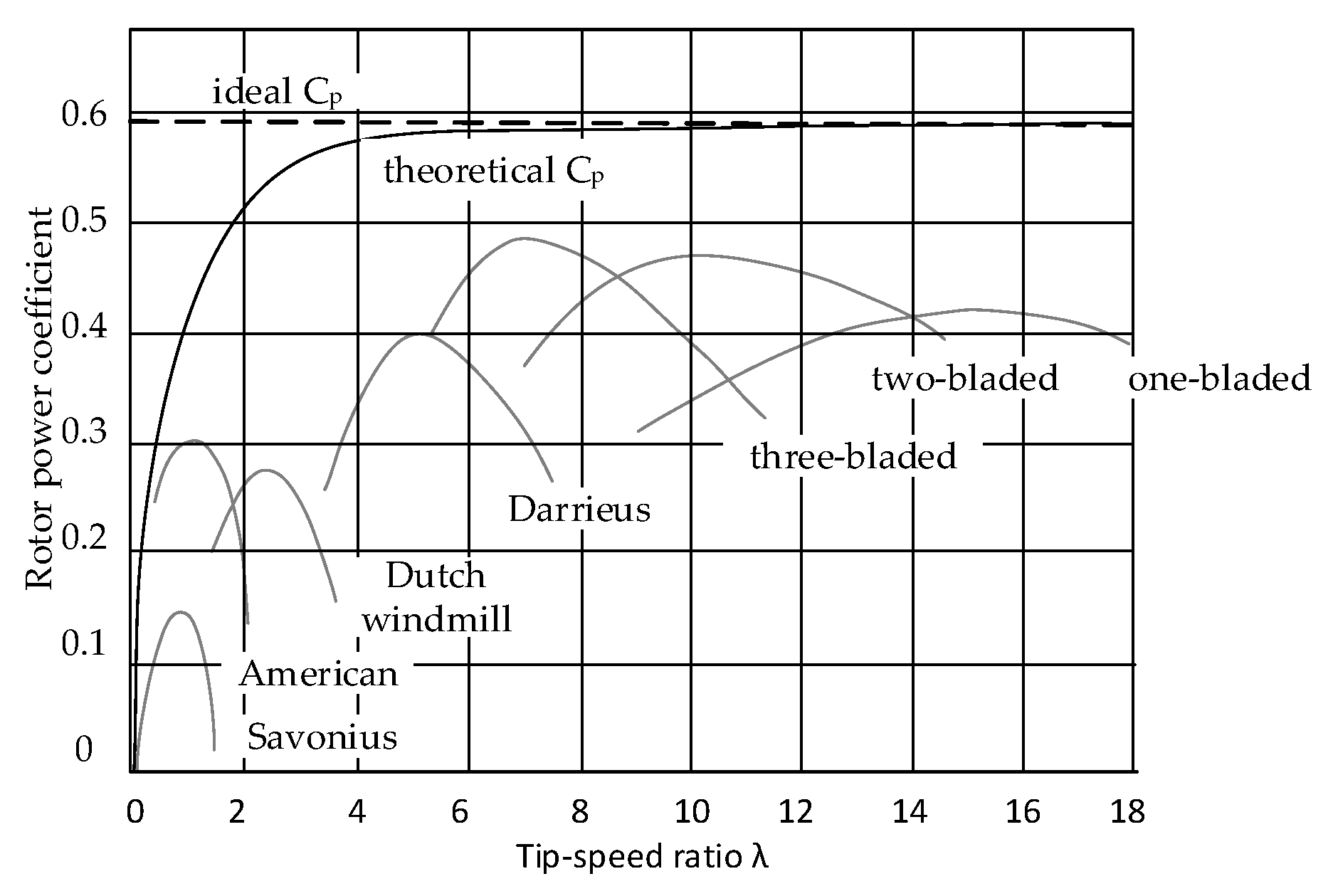

- Castillo, O.C.; Andrade, V.R.; Rivas, J.J.R.; González, R.O. Comparison of Power Coefficients in Wind Turbines Considering the Tip Speed Ratio and Blade Pitch Angle. Energies 2023, 16, 2774. [Google Scholar] [CrossRef]

- Bensalah, A.; Barakat, G.; Amara, Y. Electrical Generators for Large Wind Turbine: Trends and Challenges. Energies 2022, 15, 6700. [Google Scholar] [CrossRef]

- Choe Wei Chang, C.; Jian Ding, T.; Jian Ping, T.; Chia Chao, K.; Bhuiyan, M.A.S. Getting More from the Wind: Recent Advancements and Challenges in Generators Development for Wind Turbines. Sustain. Energ. Technol. Assess. 2022, 53, 102731. [Google Scholar] [CrossRef]

- Udosen, D.; Kalengo, K.; Akuru, U.B.; Popoola, O.; Munda, J.L. Non-Conventional, Non-Permanent Magnet Wind Generator Candidates. Wind 2022, 2, 429–450. [Google Scholar] [CrossRef]

- Alkul, O.; Syed, D.; Demirbas, S. A Review of Wind Energy Conversion Systems. In Proceedings of the 2022 10th International Conference on Smart Grid (icSmartGrid), Istanbul, Turkey, 27–30 June 2022; pp. 72–77. [Google Scholar]

- Sartori, L.; Bellini, F.; Croce, A.; Bottasso, C. Preliminary Design and Optimization of a 20MW Reference Wind Turbine. J. Phys. Conf. Ser. 2018, 1037, 042003. [Google Scholar] [CrossRef]

- Raouf, A.; Tawfiq, K.B.; Eldin, E.T.; Youssef, H.; El-Kholy, E.E. Wind Energy Conversion Systems Based on a Synchronous Generator: Comparative Review of Control Methods and Performance. Energies 2023, 16, 2147. [Google Scholar] [CrossRef]

- Mourabit, Y.E.; Salime, H.; Bossoufi, B.; Motahhir, S.; Derouich, A.; Mobayen, S.; Zhilenkov, A. Enhanced Performance in PMSG-Based Wind Turbine Systems: Experimental Validation of Adaptive Backstepping Control Design. Energies 2023, 16, 7481. [Google Scholar] [CrossRef]

- Moghadam, F.K.; Nejad, A.R. Evaluation of PMSG-based Drivetrain Technologies for 10-MW Floating Offshore Wind Turbines: Pros and Cons in a Life Cycle Perspective. Wind Energ. 2020, 23, 1542–1563. [Google Scholar] [CrossRef]

- Ge, C.; Liu, M.; Chen, J. Modeling of Direct-Drive Permanent Magnet Synchronous Wind Power Generation System Considering the Power System Analysis in Multi-Timescales. Energies 2022, 15, 7471. [Google Scholar] [CrossRef]

- Palomo, R.E.Q.; Gwozdziewicz, M. Effect of Demagnetization on a Consequent Pole IPM Synchronous Generator. Energies 2020, 13, 6371. [Google Scholar] [CrossRef]

- Chen, Y.; Xiong, C.; Li, Y. Additive Manufacturing of Rare Earth Permanent Magnetic Materials: Research Status and Prospects. Metals 2024, 14, 446. [Google Scholar] [CrossRef]

- Lee, O.M.; Abbasian, M. Reducing Rare-Earth Magnet Reliance in Modern Traction Electric Machines. Energies 2025, 18, 2274. [Google Scholar] [CrossRef]

- Ghosh, M.K.; Grainger, B.; McElhinny, S.; Brody, R.; Cui, J.; Sherman, A.; Ohodnicki, P. Multiphysics Design and Optimization of a Rare-Earth Free, Manganese Bismuth Based, Surface Mounted Permanent Magnet Machine. In Proceedings of the 2023 IEEE Transportation Electrification Conference & Expo (ITEC), Detroit, MI, USA, 13–16 June 2023; pp. 1–7. [Google Scholar]

- Rom, C.L.; Smaha, R.W.; O’Donnell, S.; Dugu, S.; Bauers, S.R. Emerging Magnetic Materials for Electric Vehicle Drive Motors. MRS Bull. 2024, 49, 738–750. [Google Scholar] [CrossRef]

- Yadav, V.; Singh, B.; Verma, A. Seema Robust Control for PMBLDCG Based WEC System and Seamless Grid Synchronization. In Proceedings of the 2021 International Conference on Sustainable Energy and Future Electric Transportation (SEFET), Hyderabad, India, 21–23 January 2021; pp. 1–5. [Google Scholar]

- Rezkallah, M.; Ibrahim, H.; Dubuisson, F.; Chandra, A.; Singh, S.; Singh, B.; Issa, M. Hardware Implementation of Composite Control Strategy for Wind-PV-Battery Hybrid Off-Grid Power Generation System. Clean Technol. 2021, 3, 821–843. [Google Scholar] [CrossRef]

- Yadav, V.; Singh, B.; Verma, A. Robust Control for Improving Performance of Grid-Synchronized Solar PV-BES-Wind Based Microgrid. Sustain. Energy Technol. Assess. 2024, 64, 103677. [Google Scholar] [CrossRef]

- Jafari, M.; Popat, M.; Wu, B. Power Factor Control in a Wind Energy Conversion System via Synchronous Generator Excitation. Can. J. Electr. Comput. Eng. 2014, 37, 145–150. [Google Scholar] [CrossRef]

- Wang, R.; Liu, W.; Meng, T.; Jiao, N.; Han, X.; Sun, C.; Yang, Y. Rotor Position Estimation Method of Brushless Electrically Excited Synchronous Starter/Generator Based on Multistage Structure. IEEE Trans. Power Electron. 2022, 37, 364–376. [Google Scholar] [CrossRef]

- Rosyadi, M.; Abel, D.H.; Rajendra; Umemura, A.; Takahashi, R.; Tamura, J. Control System Design of Variable Speed Wind Turbine Based EESG for Stabilizing Distribution Plant System During Fault and Islanding. In Proceedings of the 2019 IEEE PES Asia-Pacific Power and Energy Engineering Conference (APPEEC), Macao, China, 1–4 December 2019; pp. 1–5. [Google Scholar]

- Li, H.; Chen, Z.; Polinder, H. Optimization of Multibrid Permanent-Magnet Wind Generator Systems. IEEE Trans. Energ. Convers. 2009, 24, 82–92. [Google Scholar] [CrossRef]

- Ahyaten, S.; Bahaoui, J.E. Modeling of Wind Turbines Based on DFIG Generator. Proceedings 2020, 63, 16. [Google Scholar] [CrossRef]

- Domínguez-García, J.L.; Gomis-Bellmunt, O.; Trilla-Romero, L.; Junyent-Ferré, A. Indirect Vector Control of a Squirrel Cage Induction Generator Wind Turbine. Comput. Math. Appl. 2012, 64, 102–114. [Google Scholar] [CrossRef]

- Chen, H.; Aliprantis, D.C. Analysis of Squirrel-Cage Induction Generator With Vienna Rectifier for Wind Energy Conversion System. IEEE Trans. Energ. Convers. 2011, 26, 967–975. [Google Scholar] [CrossRef]

- Mohssine, C.; Nasser, T.; Essadki, A. Contribution of Variable Speed Wind Turbine Generator Based on DFIG Using ADRC and RST Controllers to Frequency Regulation. Int. J. Renew. Energ. Res. (IJRER) 2021, 11, 320–331. [Google Scholar]

- Datta, R.; Ranganathan, V.T. Variable-Speed Wind Power Generation Using Doubly Fed Wound Rotor Induction Machine-a Comparison with Alternative Schemes. IEEE Trans. Energ. Convers. 2002, 17, 414–421. [Google Scholar] [CrossRef]

- Satpathy, A.S.; Kastha, D.; Kishore, N.K. Vienna Rectifier-Fed Squirrel Cage Induction Generator Based Stand-Alone Wind Energy Conversion System. IEEE Trans. Power Electron. 2021, 36, 10186–10198. [Google Scholar] [CrossRef]

- da Silva Santos, M.; Barros, L.S. Offshore Wind Energy Conversion System Based on Squirrel Cage Induction Generator Connected to the Grid by VSC-HVDC Link. In Proceedings of the 2019 IEEE PES Innovative Smart Grid Technologies Conference—Latin America (ISGT Latin America), Gramado, Brazil, 15–18 September 2019; pp. 1–6. [Google Scholar]

- Tartt, K.; Kazemi Amiri, A.; McDonald, A.; Jaen-Sola, P. Structural Optimisation of Offshore Direct-Drive Wind Turbine Generators Including Static and Dynamic Analyses. J. Phys. Conf. Ser. 2021, 2018, 012040. [Google Scholar] [CrossRef]

- McDonald, A.; Bhuiyan, N.A. On the Optimization of Generators for Offshore Direct Drive Wind Turbines. IEEE Trans. Energy Convers. 2017, 32, 348–358. [Google Scholar] [CrossRef]

- Touw, L.; Jaen Sola, P.; Oterkus, E. Towards an Integrated Design of Direct-Drive Wind Turbine Electrical Generator Supporting Structures. Wind 2023, 3, 343–360. [Google Scholar] [CrossRef]

- Taras, P.; Nilifard, R.; Zhu, Z.-Q.; Azar, Z. Cooling Techniques in Direct-Drive Generators for Wind Power Application. Energies 2022, 15, 5986. [Google Scholar] [CrossRef]

- Ginzburg, V.L.; Landau, L.D. On the Theory of Superconductivity. In On Superconductivity and Superfluidity: A Scientific Autobiography; Ginzburg, V.L., Ed.; Springer: Berlin/Heidelberg, Germany, 2009; pp. 113–137. ISBN 978-3-540-68008-6. [Google Scholar]

- Biasion, M.; Fernandes, J.F.P.; Vaschetto, S.; Cavagnino, A.; Tenconi, A. Superconductivity and Its Application in the Field of Electrical Machines. In Proceedings of the 2021 IEEE International Electric Machines & Drives Conference (IEMDC), Hartford, CT, USA, 17–20 May 2021; pp. 1–7. [Google Scholar]

- Haran, K.S.; Kalsi, S.; Arndt, T.; Karmaker, H.; Badcock, R.; Buckley, B.; Haugan, T.; Izumi, M.; Loder, D.; Bray, J.W.; et al. High Power Density Superconducting Rotating Machines—Development Status and Technology Roadmap. Supercond. Sci. Technol. 2017, 30, 123002. [Google Scholar] [CrossRef]

- Prikhna, T.A.; Shaternik, A.V.; Moshchil, V.E.; Eisterer, M.; Shaternik, V.E. Investigation of Properties of Nanostructured MgB2 Films Deposited by Magnetron Sputtering. In Proceedings of the 2018 IEEE 8th International Conference Nanomaterials: Application & Properties (NAP), Zatoka, Ukraine, 9–14 September 2018; pp. 1–5. [Google Scholar]

- Larbalestier, D.; Gurevich, A.; Feldmann, D.M.; Polyanskii, A. High-Tc Superconducting Materials for Electric Power Applications. Nature 2001, 414, 368–377. [Google Scholar] [CrossRef]

- Huebener, R.P. The Path to Type-II Superconductivity. Metals 2019, 9, 682. [Google Scholar] [CrossRef]

- Liebrich, J.; Kreischer, C. Novel Method for Characterization of the Influence of Axial Tensile Stress on the Critical Temperature of High-Temperature Superconductor Windings in Electrical Machines. In Proceedings of the 2022 International Symposium on Power Electronics, Electrical Drives, Automation and Motion (SPEEDAM), Sorrento, Italy, 22–24 June 2022; pp. 1–6. [Google Scholar]

- Zhu, F.; Peck, M.A.; Jones-Wilson, L.L. Reduced Embedded Magnetic Field in Type-II Superconductor of Finite Dimension. IEEE Trans. Appl. Supercond. 2020, 30, 8000505. [Google Scholar] [CrossRef]

- Margiani, N.G.; Mumladze, G.A.; Kvartskhava, I.G.; Kuzanyan, A.S.; Badalyan, G.R.; Zhghamadze, V.V. Impact of Ca(BO2)2 Doping on High-Tc Phase Formation and Transport Properties of Bi(Pb)-2223 Superconductor. IEEE Trans. Appl. Supercond. 2022, 32, 7200205. [Google Scholar] [CrossRef]

- Zhang, H.; Wen, Z.; Grilli, F.; Gyftakis, K.; Mueller, M. Alternating Current Loss of Superconductors Applied to Superconducting Electrical Machines. Energies 2021, 14, 2234. [Google Scholar] [CrossRef]

- Marino, I.; Pujana, A.; Sarmiento, G.; Sanz, S.; Merino, J.M.; Tropeano, M.; Sun, J.; Canosa, T. Lightweight MgB2 Superconducting 10 MW Wind Generator. Supercond. Sci. Technol. 2015, 29, 024005. [Google Scholar] [CrossRef]

- Sklyarova, A.; Presmanes, L.; Baylac, V.; Chevallier, G.; Estournès, C.; Duployer, B.; Noudem, J.; Bernstein, P.; Tailhades, P.; Thimont, Y. Processing of Bulk MgB2 Superconductors by Coupling Laser Powder Bed Fusion and Spark Plasma Sintering Techniques. Materials 2025, 18, 2367. [Google Scholar] [CrossRef] [PubMed]

- Tolendiuly, S.; Nur-Akasyah, J.; Fomenko, S.; Turan, A.; Assylkhan, S.; Abisheva, A. High-Temperature Synthesis of Superconducting MgB2 Materials in a Centrifuge. J. Compos. Sci. 2024, 8, 267. [Google Scholar] [CrossRef]

- Zhang, C.; Shen, L.; Wu, X.; Shan, F.; Chen, L.; Liu, S.; Zheng, Z.; Zhu, L.; Wang, J.; Zhai, Y. Review of Offshore Superconducting Wind Power Generation for Hydrogen Production. Energies 2025, 18, 1889. [Google Scholar] [CrossRef]

- Go, B.-S. Characteristic Analysis of Electromagnetic Force in an HTS Field Coil Using a Performance Evaluation System. Energies 2024, 17, 4366. [Google Scholar] [CrossRef]

- Shimoyama, J.; Motoki, T. Current Status of High Temperature Superconducting Materials and Their Various Applications. IEEJ Trans. Electr. Electron. Eng. 2024, 19, 292–304. [Google Scholar] [CrossRef]

- Russo, G.; Morandi, A. A Numerical Study on the Energization of the Field Coils of a Full-Size Wind Turbine with Different Types of Flux Pumps. Energies 2022, 15, 5392. [Google Scholar] [CrossRef]

- Liu, Y.; Grilli, F.; Cao, J.; Li, L.; Zhang, C.; Wang, M.; Xu, F.; Lin, J.; Noe, M. An Electromagnetic Design of a Fully Superconducting Generator for Wind Application. Energies 2021, 14, 7811. [Google Scholar] [CrossRef]

- Wu, A.; Bai, Y.; Xu, M.; Parizh, M.; Huang, S.; Torrey, D. Design and Test of Quench Protection for Superconducting Generator Field Coils. IEEE Trans. Appl. Supercond. 2023, 33, 5202605. [Google Scholar] [CrossRef]

- Ferreira da Silva, F.; Fernandes, J.F.P.; da Costa Branco, P.J. Superconducting Electric Power Systems: R&D Advancements. Energies 2022, 15, 7350. [Google Scholar] [CrossRef]

- Marchevsky, M. Quench Detection and Protection for High-Temperature Superconductor Accelerator Magnets. Instruments 2021, 5, 27. [Google Scholar] [CrossRef]

- He, J.; Tang, Y.; Li, J.; Ren, L.; Shi, J.; Wang, J.; Qu, R.; Su, L.; Li, X.; Xu, Y.; et al. Conceptual Design of the Cryogenic System for a 12 MW Superconducting Wind Turbine Generator. IEEE Trans. Appl. Supercond. 2014, 24, 5201105. [Google Scholar] [CrossRef]

- Green, M.A. The Integration of Liquid Cryogen Cooling and Cryocoolers with Superconducting Electronic Systems. Supercond. Sci. Technol. 2003, 16, 1349. [Google Scholar] [CrossRef]

- Chang, H.-M.; Lee, S.I. Conduction-Cooling System for Superconducting Magnets at 20–30 K. IEEE Trans. Appl. Supercond. 2014, 24, 3800204. [Google Scholar] [CrossRef]

- Van Sciver, S.W. Forced Flow He II Cooling for Superconducting Magnets—Design Considerations. Cryogenics 1998, 38, 503–512. [Google Scholar] [CrossRef]

- Biasion, M.; Fernandes, F.J.; da Costa Branco, P.J.; Vaschetto, S.; Cavagnino, A.; Tenconi, A. A Comparison of Cryogenic-Cooled and Superconducting Electrical Machines. In Proceedings of the 2021 IEEE Energy Conversion Congress and Exposition (ECCE), Vancouver, BC, Canada, 10–14 October 2021; pp. 4045–4052. [Google Scholar]

- Chen, H.; Qu, R.; Li, J.; Zhao, B. Comparison of Interior and Surface Permanent Magnet Machines with Fractional Slot Concentrated Windings for Direct-Drive Wind Generators. In Proceedings of the 2014 17th International Conference on Electrical Machines and Systems (ICEMS), Hangzhou, China, 22–25 October 2014; pp. 2612–2617. [Google Scholar]

- Wu, Y.-K.; Yang, S.-M.; Wu, W.-C. Design of a Large Commercial PMSG-Based Wind Generator. In Proceedings of the 2019 IEEE 2nd International Conference on Knowledge Innovation and Invention (ICKII), Seoul, Republic of Korea, 19–21 July 2019; pp. 5–8. [Google Scholar]

- Kumar, R.R.; Devi, P.; Chetri, C.; Vardhan, A.S.S.; Elavarasan, R.M.; Mihet-Popa, L.; Saket, R.K. Design and Characteristics Investigation of Novel Dual Stator Pseudo-Pole Five-Phase Permanent Magnet Synchronous Generator for Wind Power Application. IEEE Access 2020, 8, 175788–175804. [Google Scholar] [CrossRef]

- Addin Yousefian, H.; Kelk, H.M. A Unique Optimized Double-Stator Permanent-Magnet Synchronous Generator in High-Power Wind Plants. Energy 2018, 143, 973–979. [Google Scholar] [CrossRef]

- Ghoneim, W.A.M.; Hebala, A.; Ashour, H.A. Sensitivity Analysis of Parameters Affecting the Performance of Radial Flux Low-Speed PMSG. In Proceedings of the 2018 XIII International Conference on Electrical Machines (ICEM), Alexandroupoli, Greece, 3–6 September 2018; pp. 968–974. [Google Scholar]

- Lewis, C.; Muller, J. A Direct Drive Wind Turbine HTS Generator. In Proceedings of the 2007 IEEE Power Engineering Society General Meeting, Tampa, FL, USA, 24–28 June 2007; pp. 1–8. [Google Scholar]

- Keysan, O.; Mueller, M. A Modular and Cost-Effective Superconducting Generator Design for Offshore Wind Turbines. Supercond. Sci. Technol. 2015, 28, 034004. [Google Scholar] [CrossRef]

- Fukui, S.; Ogawa, J.; Sato, T.; Tsukamoto, O.; Kashima, N.; Nagaya, S. Study of 10 MW-Class Wind Turbine Synchronous Generators With HTS Field Windings. IEEE Trans. Appl. Supercond. 2011, 21, 1151–1154. [Google Scholar] [CrossRef]

- Bergen, A.; Andersen, R.; Bauer, M.; Boy, H.; Brake, M.T.; Brutsaert, P.; Bührer, C.; Dhallé, M.; Hansen, J.; Ten Kate, H.; et al. Design and In-Field Testing of the World’s First ReBCO Rotor for a 3.6 MW Wind Generator. Supercond. Sci. Technol. 2019, 32, 125006. [Google Scholar] [CrossRef]

- Abrahamsen, A.B.; Mijatovic, N.; Seiler, E.; Sorensen, M.P.; Koch, M.; Norgard, P.B.; Pedersen, N.F.; Traeholt, C.; Andersen, N.H.; Ostergard, J. Design Study of 10 kW Superconducting Generator for Wind Turbine Applications. IEEE Trans. Appl. Supercond. 2009, 19, 1678–1682. [Google Scholar] [CrossRef]

- Scuotto, M.; Muñoz, G.S.; Azcárraga, J.M.M.; Perez, J.G.-T.; Ereño, P.I.; Apiñaniz, S.A. Direct-Action Superconducting Synchronous Generator for a Wind Turbine 2011. EP2521252B1, 7 July 2011. [Google Scholar]

- Kalsi, S.S. Superconducting Wind Turbine Generator Employing MgB2 Windings Both on Rotor and Stator. IEEE Trans. Appl. Supercond. 2014, 24, 47–53. [Google Scholar] [CrossRef]

- Sindram, J.; Kalla, M.; Lengsfeld, S.; Jung, M. Short Circuit Analysis of a Fully Superconducting 10 MW Wind Generator. IEEE Trans. Appl. Supercond. 2025, 35, 5202405. [Google Scholar] [CrossRef]

- Lengsfeld, S.; Sprunck, S.; Frank, S.R.; Jung, M.; Hiller, M.; Ponick, B.; Mersche, S. An Approach to the Design and the Interactions of a Fully Superconducting Synchronous Generator and Its Power Converter. Energies 2022, 15, 3751. [Google Scholar] [CrossRef]

- Hwang, Y.J.; Ahn, M.C.; Lee, J.; Yoon, Y.S.; Kim, H.M.; Chung, Y.D.; Jo, Y.-S.; Kim, T.J.; Ko, T.K. Electromagnetic Design of a 15 MW-Class HTS Flux Switching Synchronous Generator Considering Mechanical Stress of the Rotor Core. IEEE Trans. Appl. Supercond. 2014, 24, 5202305. [Google Scholar] [CrossRef]

- Chimento, F.; Raciti, A. A Low-Speed Axial-Flux PM Generator for Wind Power Systems. In Proceedings of the 2004 IEEE International Symposium on Industrial Electronics, Ajaccio, France, 4–7 May 2004; Volume 2, pp. 1479–1484. [Google Scholar]

- Lin, M.; Hao, L.; Li, X.; Zhao, X.; Zhu, Z.Q. A Novel Axial Field Flux-Switching Permanent Magnet Wind Power Generator. IEEE Trans. Magn. 2011, 47, 4457–4460. [Google Scholar] [CrossRef]

- Xu, L.; Xu, Y.; Gong, J. Analysis and Optimization of Cogging Torque in Yokeless and Segmented Armature Axial-Flux Permanent-Magnet Machine With Soft Magnetic Composite Core. IEEE Trans. Magn. 2018, 54, 8106005. [Google Scholar] [CrossRef]

- Hao, L.; Lin, M.; Xu, D.; Zhang, W. Cogging Torque Reduction of Axial Field Flux-Switching Permanent Magnet Machine by Adding Magnetic Bridge in Stator Tooth. IEEE Trans. Appl. Supercond. 2014, 24, 8208304. [Google Scholar] [CrossRef]

- Fard, J.R.; Ardebili, M. Design and Control of a Novel Yokeless Axial Flux-Switching Permanent-Magnet Motor. IEEE Trans. Energy Convers. 2019, 34, 631–642. [Google Scholar] [CrossRef]

- Prajzendanc, P.; Paplicki, P. Performance Evaluation of an Axial Flux Machine with a Hybrid Excitation Design. Energies 2022, 15, 2733. [Google Scholar] [CrossRef]

- Xu, Y.; Maki, N.; Izumi, M. Performance Comparison of 10-MW Wind Turbine Generators With HTS, Copper, and PM Excitation. IEEE Trans. Appl. Supercond. 2015, 25, 5204006. [Google Scholar] [CrossRef]

- Tsunata, R.; Takemoto, M.; Imai, J.; Saito, T.; Ueno, T. Comparison of Thermal Characteristics in Various Aspect Ratios for Radial-Flux and Axial-Flux Permanent Magnet Machines. IEEE Trans. Ind. Appl. 2023, 59, 3353–3367. [Google Scholar] [CrossRef]

| TRL | Name | Description |

|---|---|---|

| TRL 1 | Basic principles observed | Scientific research begins—basic principles are identified. |

| TRL 2 | Technology concept formulated | Potential applications are identified; initial concept of the technology. |

| TRL 3 | Experimental proof of concept | Analytical and laboratory studies confirm the feasibility of the concept. |

| TRL 4 | Technology validated in the lab | Basic technological components are integrated and tested in a laboratory environment. |

| TRL 5 | Technology validated in relevant environment | Technology tested in a simulated or relevant environment. |

| TRL 6 | Technology demonstrated in relevant environment | Prototype demonstrated in an environment close to operational. |

| TRL 7 | System prototype demonstration in operational environment | Prototype tested in real operational conditions. |

| TRL 8 | System complete and qualified | Technology is complete and qualified through testing and demonstration. |

| TRL 9 | Actual system proven in operational environment | Technology proven in full-scale use under real conditions. |

| Advantages | Disadvantages and Challenges |

|---|---|

| high efficiency—particularly in PM variants, which minimize energy losses | higher capital cost, particularly for PMSGs utilizing PMs |

| wide operational speed range—when integrated with power electronic systems, synchronous generators can operate efficiently across a broad range of rotor speeds | requirement for power converters, which increases system complexity and necessitates advanced control strategies |

| improved power quality—compared to asynchronous generators, synchronous machines facilitate more stable voltage and frequency regulation | greater mass in the case of EESGs, which can pose structural and design challenges in large-scale wind turbines |

| Advantages | Disadvantages and Limitations |

|---|---|

| simple construction and high reliability—particularly in squirrel cage designs, which are mechanically robust and require minimal maintenance | lower efficiency compared to synchronous generators, particularly in squirrel cage configurations |

| lower cost compared to synchronous generators, making them an attractive choice for less demanding or cost-sensitive applications | mandatory grid connection (with or without inverter)—they cannot operate in standalone (island) mode without additional equipment |

| good dynamic performance—DFIGs enable active and reactive power control, allowing better adaptation to fluctuating wind conditions | dependence on power electronics in the case of DFIGs, which increases system complexity and may lead to higher maintenance and service costs |

| Advantages | Disadvantages and Challenges |

|---|---|

| higher reliability—the absence of a mechanical gearbox eliminates one of the most failure-prone components in wind turbines | increased generator size and weight—the use of large-diameter, multi-pole generators significantly adds to the overall mass of the system |

| lower operating costs—fewer moving parts result in reduced wear and lower maintenance expenses | higher initial cost—the need for advanced materials (e.g., neodymium magnets) and larger generator structures raises the capital investment |

| quieter operation—the elimination of the gearbox significantly reduces noise levels, which is especially important for onshore wind installations | requirement for advanced power electronics—modern inverters and converters are necessary to regulate voltage and frequency, adding complexity and cost to the system |

| improved efficiency—mechanical losses are minimized compared to geared turbine systems | |

| reduced failure risk under extreme weather conditions—DD systems are frequently used in offshore turbines, where difficult maintenance access makes reliability a critical factor |

| Parameter | Superconducting Generator | PM Generator | EESG |

|---|---|---|---|

| Efficiency | Highest (>98%, incl. cryogenic losses) | High (~96–97%) | Lowest (~94–95%) |

| Mass | Lowest (very compact for 10 MW class) | Moderate | Highest |

| Torque Density | Very high | High | Moderate to low |

| Cooling Requirements | Cryogenic (20–77 K), complex | Passive or air/water cooling | Air or water cooling |

| Use of Critical Materials | Superconducting wire (e.g., YBCO, MgB2) | Rare-earth magnets (e.g., NdFeB) | Copper only |

| System Complexity | High (cryogenics, insulation, monitoring) | Moderate | Low |

| Commercial Readiness (TRL) | Medium (TRL 6–7) | High (TRL 8–9) | Very high (TRL 9) |

| Maintenance Requirements | Specialized, low frequency | Low to moderate | High (brushes, field windings) |

| Offshore Suitability | Excellent (low mass, high efficiency, modularity) | Good | Poor (weight and logistics issues) |

| Cost (CAPEX) | High (materials + cryogenics) | High (magnet cost) | Lowest (simple construction) |

| Design Flexibility | High (field controllability, compactness) | Limited (fixed field from magnets) | High (field regulation possible) |

| Risk of Demagnetization | None (field generated electrically) | Present (temperature, short circuits) | None |

| Commercial status (2025) | Prototype (EcoSwing, SupraPower) | Commercial (Siemens, GE, Vestas) | Commercial (Enercon; mainly onshore) |

| No. | Reference | Power [MW] | Speed [rpm] | Efficiency [%] | 2 WAP [t] | Volume [m3] | Voltage [kV] | Current [kA] | 3 AG [mm] | Losses [MW] |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | [84] SG with MgB2 | 10.6 | 10 | 98 | 52.49 | 4.25 | 4.5 | 1.4 | 20 | 0.2 |

| 2 | [79] Claw-pole | 10 | 10 | 94.5 | 181 | 31.7 | 3.3 | 1.8 | 0.6 | |

| 3 | [22] DD PMSG | 10 | 9.6 | 93.09 | 56.4 (all 324.24) | 9.87 | 3.5 | 1.7 | 1 | 0.7 |

| 4 | [22] med. speed PMSG | 10 | 480 | 98.41 (1 w.g. 95.8) | 12.5 (all 65.03) (1 w.g. 111.7) | 1.66 | 10.4 | 0.55 | 2 | 0.2 |

| 5 | [22] high-speed PMSG | 10 | 1498 | 98.34 (1 w.g. 96.5) | 13.6 t (all 53.4) (1 w.g. 100) | 1.75 | 10.5 | 0.55 | 2 | 0.2 |

| 6 | [73] surface PM | 7 | 12 | 96 | 37.1 | 51.4 | 3.3 | 1.3 | 7 | 0.3 |

| 7 | [73] interior PM | 7 | 12 | 96.7 | 40.5 | 49.3 | 3.3 | 1.3 | 7 | 0.2 |

| 8 | [81] SG with ReBCO | 3.6 | 15 | 92 | 1.2 | 1.8 | 13 | 0.3 | ||

| 9 | [76] 4 DSCR PMSG | 0.66 | 125 | 96.5 | 2.45 | 0.51 | 0.69 | 0.6 | 0.02 | |

| 10 | [76] PMSG | 0.5 | 134 | 94.9 | 2.69 | 0.35 | 0.69 | 0.4 | 2 | 0.03 |

| Generator Type | Commercialization Potential | TRL | Key Implementation Challenges | Future Development Directions |

|---|---|---|---|---|

| HTS | High (long-term) | 6–7 | High cost of HTS tapes and cryogenics; quench risk; lack of operational experience; complexity of cooling systems | Cheaper materials (e.g., MgB2); efficient cryogenics; AC loss reduction; standardization and reliability |

| PM | Very high (current market standard) | 9 | Cost and supply of rare-earth materials; risk of demagnetization; fixed field strength | Rare-earth-free magnets; thermal management; magnet recycling and circular economy |

| EESG | Moderate | 9 | High mass; lower efficiency; increased maintenance requirements | Design and weight optimization; use in hybrid or low-cost systems |

| DFIG | High (up to ~5 MW turbines) | 9 | Requires grid synchronization; dependence on power electronics; limited scalability | Improved control systems; enhanced grid fault tolerance; HVDC integration |

| SCIG | Low (for large turbines) | 9 | No field control; needs reactive power compensation; low efficiency at variable speeds | Potential in simple, low-cost configurations; integration with full-scale AC–DC–AC conversion systems |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prajzendanc, P.; Kreischer, C. A Review of New Technologies in the Design and Application of Wind Turbine Generators. Energies 2025, 18, 4082. https://doi.org/10.3390/en18154082

Prajzendanc P, Kreischer C. A Review of New Technologies in the Design and Application of Wind Turbine Generators. Energies. 2025; 18(15):4082. https://doi.org/10.3390/en18154082

Chicago/Turabian StylePrajzendanc, Pawel, and Christian Kreischer. 2025. "A Review of New Technologies in the Design and Application of Wind Turbine Generators" Energies 18, no. 15: 4082. https://doi.org/10.3390/en18154082

APA StylePrajzendanc, P., & Kreischer, C. (2025). A Review of New Technologies in the Design and Application of Wind Turbine Generators. Energies, 18(15), 4082. https://doi.org/10.3390/en18154082