Polish Farmers′ Perceptions of the Benefits and Risks of Investing in Biogas Plants and the Role of GISs in Site Selection

Abstract

1. Introduction

- −

- How do farmers in Poland perceive the risks and benefits associated with agricultural biogas plants?

- −

- What types of risks are perceived by farmers in relation to the operation of biogas plants?

- −

- What benefits do farmers associate with the construction and operation of such installations?

2. The Use of Biomass and Agricultural Biogas in the Context of the Circular Economy

3. Risks and Constraints Associated with the Expansion of Agricultural Biogas Plants in Poland

- −

- Economic and financial risks;

- −

- Technological, operational, and feedstock-related risks;

- −

- Social risks;

- −

- Environmental and health-related risks;

- −

- Regulatory and legal risks, including those of a political nature.

3.1. Economic and Financial Risks and Constraints

3.2. Technological, Operational and Raw Material Risks and Limitations

- −

- Dry matter (DM) content of the substrate, which determines the choice of fermentation technology. The process may proceed as wet fermentation (DM < 12%) or dry fermentation (DM > 12%).

- −

- Substrate dosing system, which may be implemented in three ways: batch feeding (no input during downtimes), semi-continuous feeding (material added at least once daily), or continuous feeding (a constant inflow of substrate).

- −

- Number of fermentation stages, distinguishing between single-phase systems, in which all reactions occur in one reactor, and two-phase systems, in which hydrolysis and methanogenesis occur in separate chambers, allowing for improved control of individual stages.

- −

- Temperature range of the process, which can be adapted to operating conditions: psychrophilic (below 25 °C), mesophilic (37–42 °C), or thermophilic (50–60 °C).

3.3. Social Risks and Constraints

3.4. Environmental and Health-Related Risks and Constraints

3.5. Regulatory and Legal Risks and Constraints, Including Political Factors

4. Benefits of Constructing and Operating Agricultural Biogas Plants

5. Materials and Methods

- −

- What types of risks do Polish farmers perceive in the operation of agricultural biogas plants?

- −

- Land development—weight 0.05 (indicates existing land use, which affects the development potential of the area);

- −

- Distance to watercourses—weight 0.2 (proximity to watercourses may limit building possibilities and increase flood risk, thereby reducing land value);

- −

- Distance to high-voltage power lines—weight 0.1 (a factor important from the perspective of safety and access to utilities);

- −

- Distance to roads—weight 0.1 (better transport accessibility positively influences the attractiveness of the plot);

- −

- Distance to surface water bodies (PTWP)—weight 0.2;

- −

- Distance to forests—weight 0.05 (esthetic and environmental aspects can constitute an additional advantage of the location);

- −

- Land slope (inclination)—weight 0.1 (affects the possibilities of land development and structural stability).

Process of Data Analysis from the Survey Study

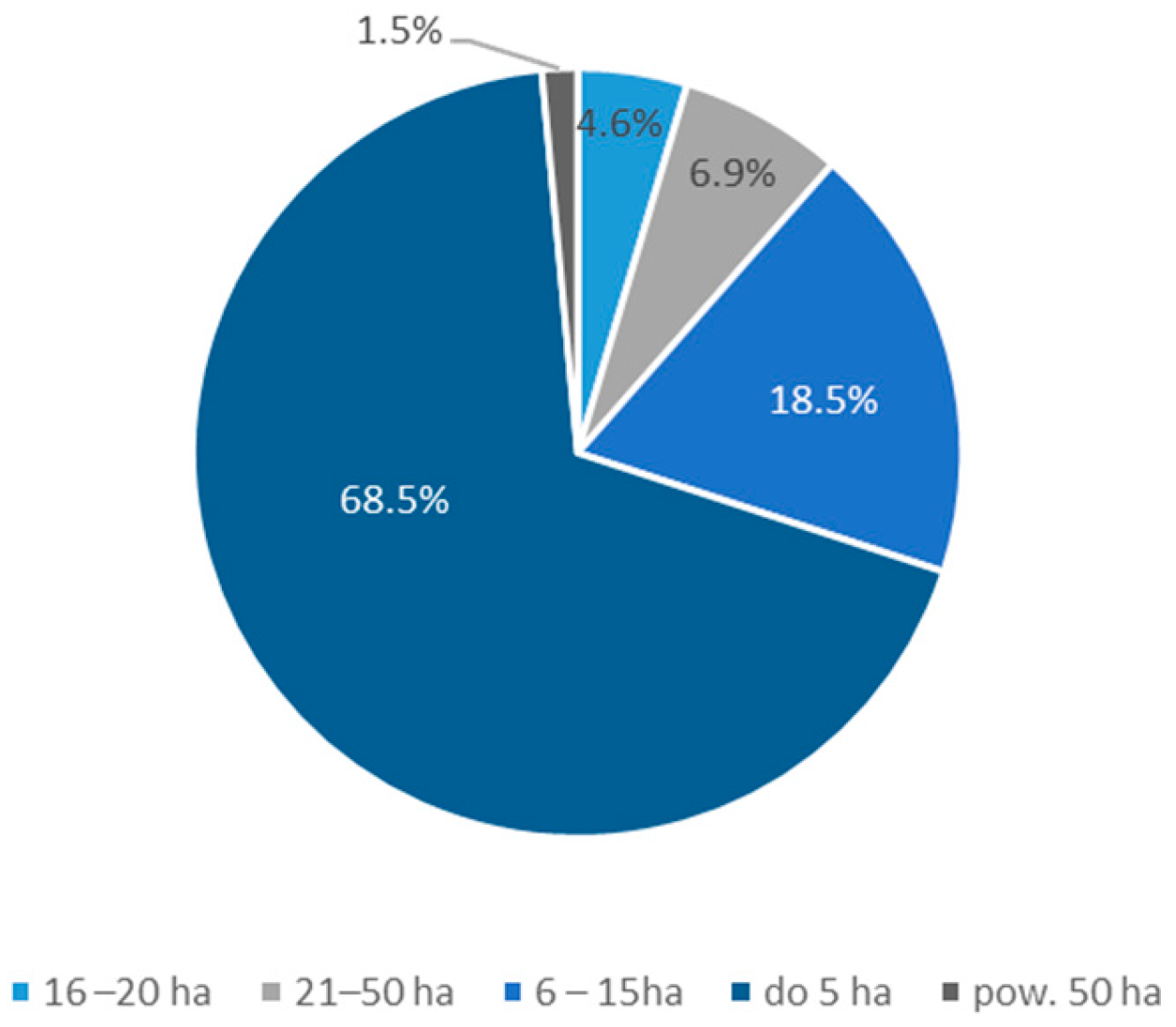

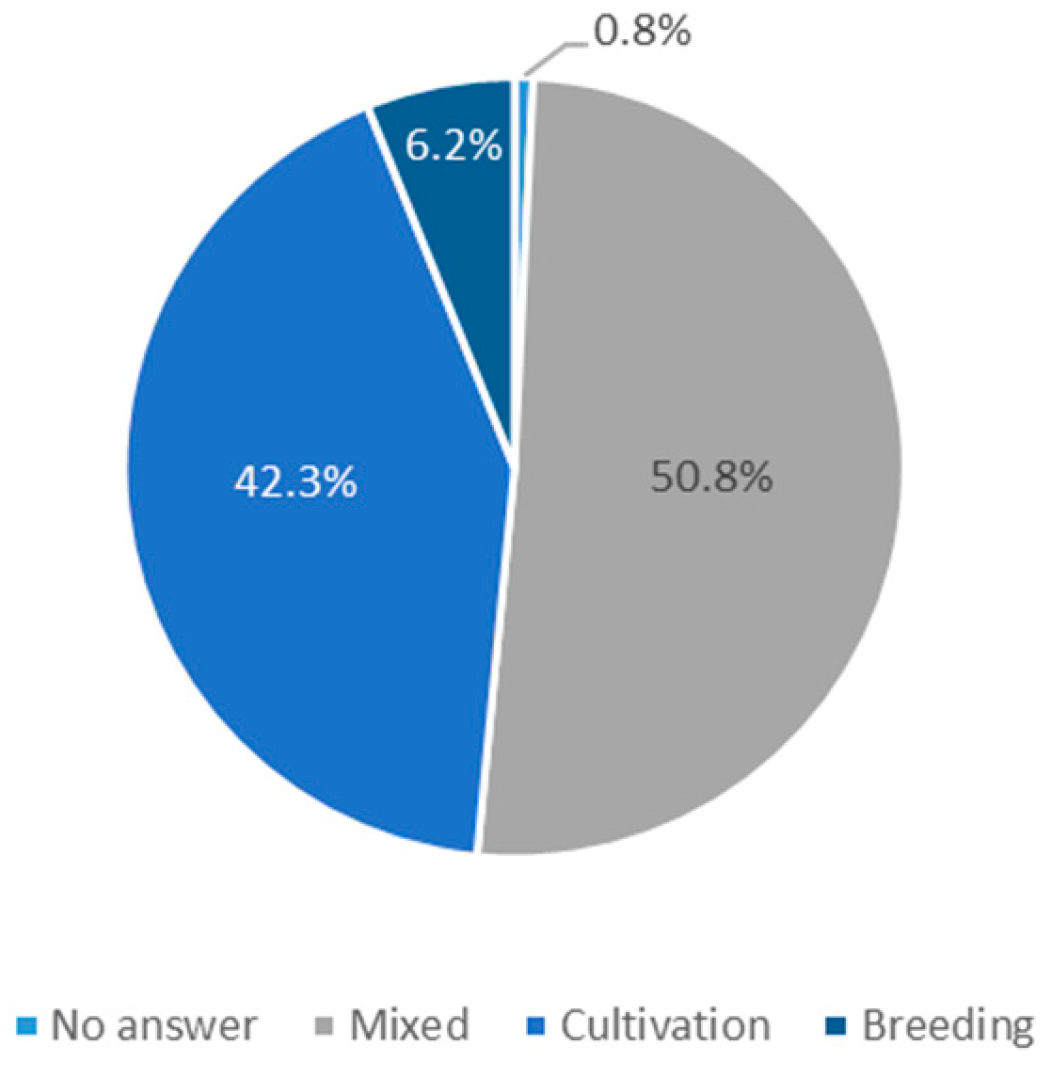

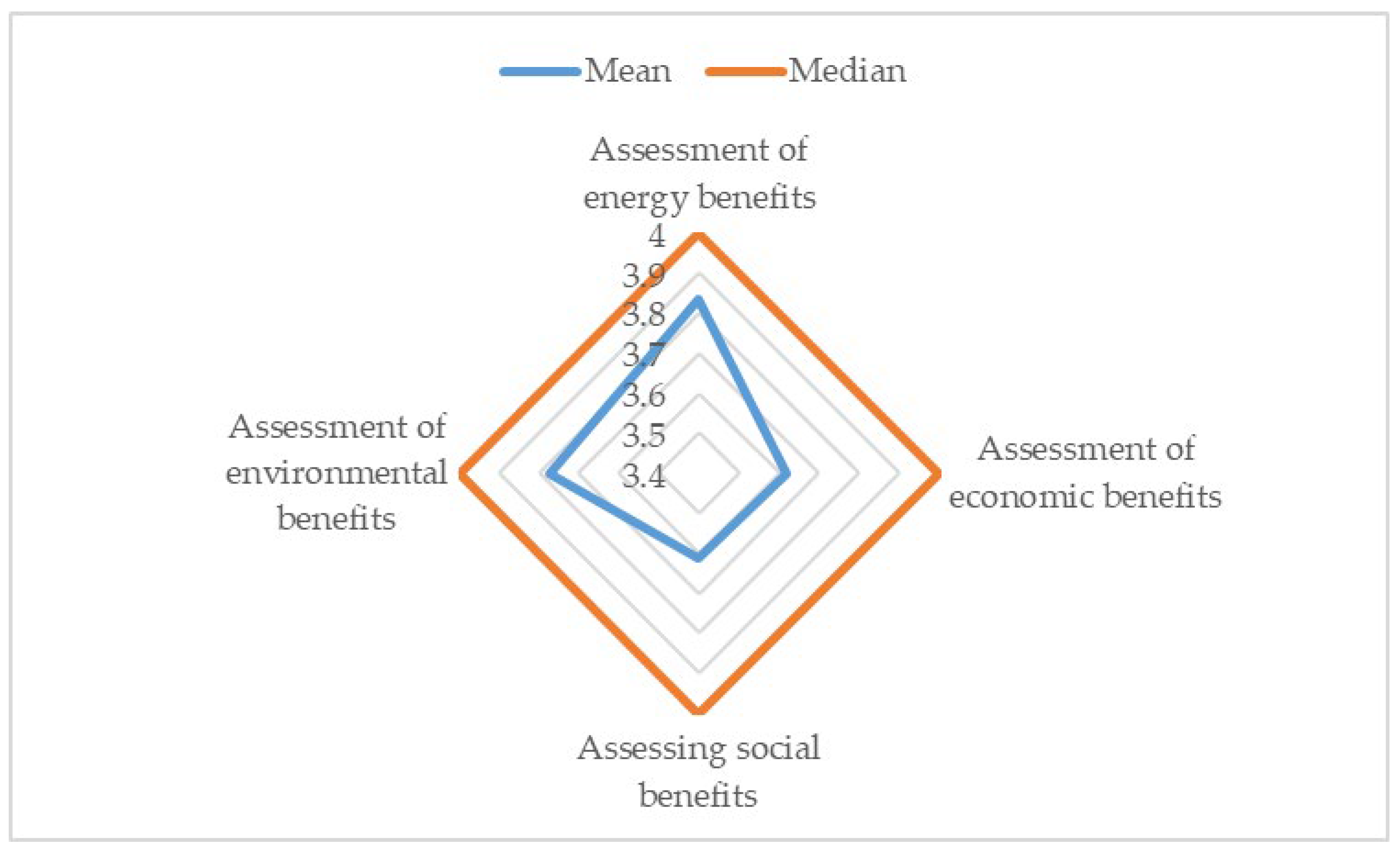

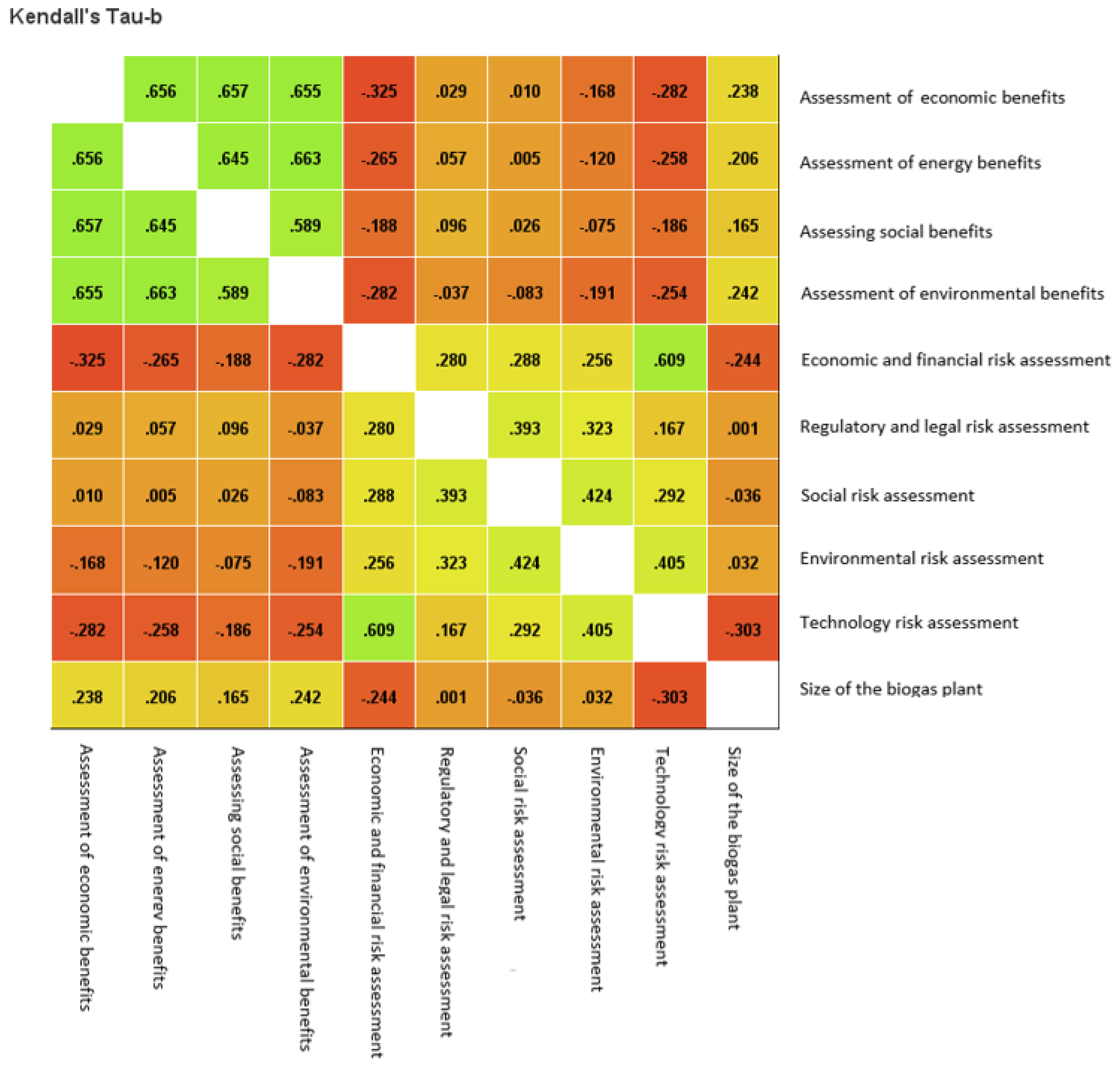

6. Results

7. Discussion

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| GIS | Geographic Information System |

| IEA | International Energy Agency |

| EU | European Union |

| ERO | Energy Regulatory Office |

| NIMBY | Not In My Back Yard |

| ABPR | Agricultural Biogas Producers Registry |

| ETL | Extract, Transform, Load |

| DM | Dry Matter |

| RES | Renewable Energy Sources |

References

- Górzyński, J. Energy Efficiency in Business Activities; Wydawnictwo Naukowe PWN SA: Warszaw, Poland, 2017. (In Polish) [Google Scholar]

- Varun; Prakash, P.; Bhat, I.K. Energy, economics and environmental impacts of renewable energy systems. Renew. Sustain. Energy Rev. 2009, 13, 2716–2721. [Google Scholar] [CrossRef]

- World Energy Outlook 2024. IEA Publications International Energy Agency. France 2024. Available online: https://www.iea.org/reports/world-energy-outlook-2024 (accessed on 10 May 2025).

- Woźniak, A.; Kluczek, A.; Ślusarczyk, B.; Żegleń, P.; Górka, M. The impact of local wind and spatial conditions on geometry blade of wind turbine. Energy Sci. Eng. 2024, 12, 3171–3184. [Google Scholar] [CrossRef]

- Woźniak, A.; Kluczek, A.; Nycz, P.D. Approach for Identifying the Impact of Local Wind and Spatial Conditions on Wind Turbine Blade Geometry. Int. J. Energy Res. 2024, 1, 7310206. [Google Scholar] [CrossRef]

- Kwaśnicki, P.; Gronba-Chyła, A.; Generowicz, A.; Ciuła, J.; Wiewiórska, I.; Gaska, K. Alternative method of making electrical connections in the 1st and 3rd generation modules as an effective way to improve module efficiency and reduce production costs. Arch. Thermodyn. 2023, 44, 179–200. [Google Scholar] [CrossRef]

- Georgilakis, P.S. Technical challenges associated with the integration of wind power into power systems. Renew. Sustain. Energy Rev. 2008, 12, 852–863. [Google Scholar] [CrossRef]

- Bartle, A. Hydropower potential and development activities. Energy Policy 2002, 30, 1231–1239. [Google Scholar] [CrossRef]

- Jure Margeta, J.; Glasnovic, G. Theoretical settings of photovoltaic-hydro energy system for sustainable energy Production. Sol. Energy 2012, 86, 972–982. [Google Scholar] [CrossRef]

- Igliński, B.; Buczkowski, R.; Cichosz, M. Bioenergy Technologies; Wydawnictwo Naukowe Uniwersytetu Mikołaja Kopernika: Toruń, Poland, 2009. (In Polish) [Google Scholar]

- Faaij, A. Modern Biomass Conversion Technologies. Mitig. Adapt. Strat. Glob. Change 2006, 11, 343–375. [Google Scholar] [CrossRef]

- Bildirici, M.E. Economic growth and biomass energy. Biomass Bioenergy 2013, 50, 19–24. [Google Scholar] [CrossRef]

- Anyaoku, C.C.; Baroutian, S. Decentralized anaerobic digestion systems for increased utilization of biogas from municipal solid waste. Renew. Sustain. Energy Rev. 2018, 90, 982–991. [Google Scholar] [CrossRef]

- Act on Renewable Energy Sources of February 20, 2015. Dz. U. 2015 Poz. 478. Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20150000478/U/D20150478Lj.pdf (accessed on 29 December 2022). (In Polish)

- Bongaerts, J.; Evers, S.; Hecker, M.; Daniel, R.; Liesegang, H. Fermentation stage-dependent adaptations of Bacillus licheniformis during enzyme production. Microb. Cell Fact. 2013, 12, 120. [Google Scholar] [CrossRef]

- Maroušek, J.; Gavurová, B. Recovering phosphorous from biogas fermentation residues indicates promising economic results. Chemosphere 2022, 291, 133008. [Google Scholar] [CrossRef]

- Gaj, K. Adsorptive Biogas Purification from Siloxanes-A Critical Review. Energies 2020, 13, 2605. [Google Scholar] [CrossRef]

- Tappen, S.J.; Aschmann, V.; Effenberger, M. Lifetime development and load response of the electrical efficiency of biogas-driven cogeneration units. Renew. Energy 2017, 114, 857–865. [Google Scholar] [CrossRef]

- Eder, A. Measuring and decomposing economies of diversification: An application to biogas-fuelled cogeneration plants in Austria. Int. J. Prod. Econ. 2018, 204, 421–432. [Google Scholar] [CrossRef]

- Gholizadeh, T.; Ghiasirad, H.; Rostami, S.; Skorek-Osikowska, A. A biogas-fired cogeneration (cooling and power) system combined with biomethane facilities: 3E evaluation, sensitivity analyses and optimization. Environ. Dev. Sustain. 2024, 15, 1–53. [Google Scholar] [CrossRef]

- Catalano, G.; D’Adamo, I.; Gastaldi, M.; Nizami, A.S.; Ribichini, M. Incentive policies in biomethane production toward circular economy. Renew. Sustain. Energy Rev. 2024, 202, 114710. [Google Scholar] [CrossRef]

- Molino, A.; Nanna, F.; Ding, Y.; Bikson, B.; Braccio, G. Biomethane production by anaerobic digestion of organic waste. Fuel 2013, 103, 1003–1009. [Google Scholar] [CrossRef]

- Ciuła, J.; Generowicz, A.; Oleksy-Gębczyk, A.; Gronba-Chyła, A.; Wiewiórska, I.; Kwaśnicki, P.; Herbut, P.; Koval, V. Technical and Economic Aspects of Environmentally Sustainable Investment in Terms of the EU Taxonomy. Energies 2024, 17, 2239. [Google Scholar] [CrossRef]

- Scholz, M.; Melin, T.; Wessling, M. Transforming biogas into biomethane using membrane technology. Renew. Sustain. Energy Rev. 2013, 17, 199–212. [Google Scholar] [CrossRef]

- Instalacje Odnawialnych Źródeł Energii—Stan na 31 Marca 2025 r., Urząd Regulacji Energetyki. Available online: https://www.ure.gov.pl/download/9/15413/Mapana31-03-2025nastroneURE.xlsx (accessed on 12 May 2025).

- Available online: https://www.energiazrolnictwa.pl/biogaz-rolniczy-podsumowanie-2024-r/ (accessed on 20 May 2025).

- Kochanek, A.; Janczura, J.; Jurkowski, S.; Zacłona, T.; Gronba-Chyła, A.; Kwaśnicki, P. The Analysis of Exhaust Composition Serves as the Foundation of Sustainable Road Transport Development in the Context of Meeting Emission Standards. Sustainability 2025, 17, 3420. [Google Scholar] [CrossRef]

- Kusz, D.; Kusz, B.; Wicki, L.; Nowakowski, T.; Kata, R.; Brejta, W.; Kasprzyk, A.; Barć, M. Efektywność Ekonomiczna Inwestycji w Biogazownie—Studium Przypadku Biogazowni Wykorzystującej Odpady Z Gospodarstwa Mleczarskiego W Polsce. Energies 2024, 17, 3760. [Google Scholar] [CrossRef]

- Klimek, K.; Kapłan, M.; Syrotyuk, S.; Bakach, N.; Kapustin, N.; Konieczny, R.; Dobrzyński, J.; Borek, K.; Anders, D.; Dybek, B.; et al. Investment Model of Agricultural Biogas Plants for Individual Farms in Poland. Energies 2021, 14, 7375. [Google Scholar] [CrossRef]

- Igliński, B.; Buczkowski, R.; Iglińska, A.; Cichosz, M.; Piechota, G.; Kujawski, W. Agricultural biogas plants in Poland: Investment process, economical and environmental aspects, biogas potential. Renew. Sustain. Energy Rev. 2012, 16, 4890–4900. [Google Scholar] [CrossRef]

- Igliński, B.; Piechota, G.; Iwański, P.; Skarzatek, M.; Pilarski, G. 15 Years of the Polish agricultural biogas plants: Their history, current status, biogas potential and perspectives. Clean. Technol. Environ. Policy 2020, 22, 281–307. [Google Scholar] [CrossRef]

- Iwaszczuk, N.; Szyba, M.; Iwaszczuk, A.; Yakubiv, V.; Stefanyk, V. Production of agricultural biogas from waste–an element of socially responsible actions in the food sector. Acta Innov. 2019, 33, 52–62. [Google Scholar] [CrossRef]

- Piechota, G.; Igliński, B. Biomethane in Poland—Current Status, Potential, Perspective and Development. Energies 2021, 14, 1517. [Google Scholar] [CrossRef]

- Situmeang, R.; Mazancová, J.; Roubík, H. Technological, Economic, Social and Environmental Barriers to Adoption of Small-Scale Biogas Plants: Case of Indonesia. Energies 2022, 15, 5105. [Google Scholar] [CrossRef]

- Nsair, A.; Onen Cinar, S.; Alassali, A.; Abu Qdais, H.; Kuchta, K. Operational Parameters of Biogas Plants: A Review and Evaluation Study. Energies 2020, 13, 3761. [Google Scholar] [CrossRef]

- Pilarski, K.; Pilarska, A.A.; Kolasa-Więcek, A.; Suszanowicz, D. An Agricultural Biogas Plant as a Thermodynamic System: A Study of Efficiency in the Transformation from Primary to Secondary Energy. Energies 2023, 16, 7398. [Google Scholar] [CrossRef]

- Czubaszek, R.; Wysocka-Czubaszek, A.; Banaszuk, P. Importance of Feedstock in a Small-Scale Agricultural Biogas Plant. Energies 2022, 15, 7749. [Google Scholar] [CrossRef]

- Hess, J.; Bernard, O. Zaawansowana analiza ryzyka dynamicznego w monitorowaniu procesu fermentacji beztlenowej. Biotechnol. Prog. 2009, 25, 643–653. [Google Scholar] [CrossRef]

- Singh, B.; Kovács, K.L.; Bagi, Z.; Nyári, J.; Szepesi, G.L.; Petrik, M.; Siménfalvi, Z.; Szamosi, Z. Enhancing Efficiency of Anaerobic Digestion by Optimization of Mixing Regimes Using Helical Ribbon Impeller. Fermentation 2021, 7, 251. [Google Scholar] [CrossRef]

- Gadirli, G.; Pilarska, A.A.; Dach, J.; Pilarski, K.; Kolasa-Więcek, A.; Borowiak, K. Fundamentals, Operation and Global Prospects for the Development of Biogas Plants—A Review. Energies 2024, 17, 568. [Google Scholar] [CrossRef]

- Booker Nielsen, M. Identifying Challenges and Drivers for Deployment of Centralized Biogas Plants in Denmark. Sustainability 2022, 14, 8021. [Google Scholar] [CrossRef]

- Krekel, C.; Rechlitz, J.; Rode, J.; Zerrahn, A. Quantifying the Externalities of Renewable Energy Plants Using Well-Being Data: The Case of Biogas. IZA Discussion Paper No. 13959. 2020. Available online: https://www.iza.org/publications/dp/13959 (accessed on 19 May 2025).

- Eichenauer, E.; Gailing, L. What Triggers Protest?—Understanding Local Conflict Dynamics in Renewable Energy Development. Land 2022, 11, 1700. [Google Scholar] [CrossRef]

- Dima, F.A.F.J.; Li, Z.; Mang, H.-P.; Zhu, L. Feasibility Analysis of Biogas Production by Using GIS and Multicriteria Decision Aid Methods in the Central African Republic. Sustainability 2022, 14, 13418. [Google Scholar] [CrossRef]

- Goodchild, M.F. GIScience for a driverless age. Int. J. Geogr. Inf. Sci. 2018, 32, 849–855. [Google Scholar] [CrossRef]

- Jażdżewska, I.; Urbański, J. Gis w Nauce (Gis in Science), Acta Universitatis Lodziensis. Folia Geographica Socio-Oeconomica, 14; Wydawnictwo Uniwersytetu Łódzkiego: Łódź, Poland, 2013. [Google Scholar]

- Ellul, C. Geography and Geographical Information Science: Interdisciplinary integrators. J. Geograpgy High. Educ. 2015, 39, 191–194. [Google Scholar] [CrossRef]

- Drzewiecki, W. Systemy Informacji Geograficznej (Geographical Information Systems). Available online: www.home.agh.edu.pl.pdf (accessed on 23 May 2025). (In Polish).

- Wadowska, A.; Pęska-Siwik, A.; Maciuk, K. Problematyka gromadzenia, przetwarzania i udostępniania danych geoprzestrzennych (Problems of collecting, processing and sharing geospatial data). Acta Sci. Pol. Form. Circumiectus 2022, 21, 5–16. [Google Scholar] [CrossRef]

- Izdebski, W.; Seremet, A. Praktyczne Aspekty Infrastruktury Danych Przestrzennych W Polsce, Główny Urząd Geodezji I Kartografii. Warszawa. 2020. Available online: http://www.gugik.gov.pl/__data/assets/pdf_file/0004/223159/Praktyczne-aspekty-InfrastrukturyDanychPrzestrzenych-w-Polsce.pdf (accessed on 23 May 2025). (In Polish)

- Biu, P.W.; Nwasike, C.H.N.; Tula, O.A.; Ezeigweneme, C.A.; Gidiagba, J.O. A review of GIS applications in public health surveillance. World J. Adv. Res. Rev. 2024, 21, 30–039. [Google Scholar] [CrossRef]

- Li, X.; Zhang, J. Application of GIS in Business and Marketing: A Review of Literature and Opportunities for Future Research. Int. J. Bus. Anal. 2020, 7, 45–57. [Google Scholar]

- Tomor, Z. The Role of GIS in Smart City Development: A Review of Applications and Challenges. J. Urban Plan. Dev. 2021, 147, 05021007. [Google Scholar]

- Al Yousif, M.A.; Chabuk, A. Assessment of the Al-Abbasiyah River (Iraq) Water Quality for Drinking Purposes Using the Water Quality Index and GIS Software. J. Ecol. Eng. 2023, 24, 310–321. [Google Scholar] [CrossRef] [PubMed]

- Benezienne, G.; Zouhri, A.; Koulali, Y. AHP and GIS-Based Site Selection for a Sanitary Landfill: Case of Settat Province, Morocco. J. Ecol. Eng. 2022, 23, 1–13. [Google Scholar] [CrossRef]

- Mousawi, E.A.; Jahad, U.A.; Mahmoud, A.S.; Chabuk, A.; Naje, A.S.; Al-Ansari, N.; Laue, J. Implementation of the Quality and Creating GIS Maps for Groundwater in Babylon, Iraq. J. Ecol. Eng. 2023, 24, 310–321. [Google Scholar] [CrossRef]

- Mesthrige, T.G.; Kaparaju, P. Decarbonisation of Natural Gas Grid: A Review of GIS-Based Approaches on Spatial Biomass Assessment, Plant Siting and Biomethane Grid Injection. Energies 2025, 18, 734. [Google Scholar] [CrossRef]

- Mahal, Z.; Yabar, H. A Spatial Modeling Approach for Optimizing the Locations of Large-Scale Biogas Plants from Livestock Manure in Bangladesh. Land 2025, 14, 79. [Google Scholar] [CrossRef]

- Martinát, S.; Chodkowska-Miszczuk, J.; Kulla, M.; Navrátil, J.; Klusáček, P.; Dvořák, P.; Novotný, L.; Krejčí, T.; Pregi, L.; Trojan, J.; et al. Best Practice Forever? Dynamics behind the Perception of Farm-Fed Anaerobic Digestion Plants in Rural Peripheries. Energies 2022, 15, 2533. [Google Scholar] [CrossRef]

- Wereda, W.; Zacłona, T. Shaping the image as a management instrument in the contemporary enterprise. Sci. Pap. Silesian Univ. Technol. Organ. Manag. Ser. 2020, 2020, 597–611. [Google Scholar] [CrossRef]

- Tamburini, M.; Pernetti, R.; Anelli, M.; Oddone, E.; Morandi, A.; Osuchowski, A.; Villani, S.; Montomoli, C.; Monti, M.C. Analysing the Impact on Health and Environment from Biogas Production Process and Biomass Combustion: A Scoping Review. Int. J. Environ. Res. Public Health 2023, 20, 5305. [Google Scholar] [CrossRef]

- Møller, H.B.; Sørensen, P.; Olesen, J.E.; Petersen, S.O.; Nyord, T.; Sommer, S.G. Agricultural Biogas Production—Climate and Environmental Impacts. Sustainability 2022, 14, 1849. [Google Scholar] [CrossRef]

- Macor, A.; Benato, A. A Human Health Toxicity Assessment of Biogas Engines Regulated and Unregulated Emissions. Appl. Sci. 2020, 10, 7048. [Google Scholar] [CrossRef]

- Keck, M.; Mager, K.; Weber, K.; Keller, M.; Frei, M.; Steiner, B.; Schrade, S. Odour Impact from Farms with Animal Husbandry and Biogas Facilities. Sci. Total Environ. 2018, 645, 1432–1443. [Google Scholar] [CrossRef] [PubMed]

- Atelge, M.R.; Senol, H.; Djaafri, M.; Hansu, T.A.; Krisa, D.; Atabani, A.; Eskicioglu, C.; Muratçobanoğlu, H.; Unalan, S.; Kalloum, S.; et al. A Critical Overview of the State-of-the-Art Methods for Biogas Purification and Utilization Processes. Sustainability 2021, 13, 11515. [Google Scholar] [CrossRef]

- Mazur-Pączka, A.; Pączka, G.; Garczyńska, M.; Jaromin, M.; Hajduk, E.; Kostecka, J.; Butt, K.R. Effects of Energy Crop Monocultures and Sewage Sludge Fertiliser on Soils and Earthworm Community Attributes. Agriculture 2023, 13, 323. [Google Scholar] [CrossRef]

- Regulation of the Minister of Infrastructure of 12 April 2002 on the Technical Conditions to be Met by Buildings and Their Location, Dz.U. 2002 nr 75 poz. 690. Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20020750690/O/D20020690.pdf (accessed on 30 August 2024). (In Polish)

- Funkcje Techniczne w Budownictwie. In Przewodnik Po Inwestycyjnym i Eksploatacyjnym Procesie Budowlanym; Polcen: Warszawa, Poland, 2015.

- Kuna-Kasorzyk, A.; Maj, J. Proces Inwestycyjno-Budowlany. In Poradnik Dla Organów Administracji I Inwestorów; Wolters Kluwer: Warszawa, Poland, 2023; pp. 35–48. [Google Scholar]

- Siwkowska, A. Proces Inwestycyjno-Budowlany Dla Instalacji OZE. In Environmental Protection; C.H. Beck: Warszawa, Poland, 2023; pp. 11–108. [Google Scholar]

- Kochanek, A.; Ciuła, J.; Generowicz, A.; Mitryasova, O.; Jasińska, A.; Jurkowski, S.; Kwaśnicki, P. The Analysis of Geospatial Factors Necessary for the Planning, Design, and Construction of Agricultural Biogas Plants in the Context of Sustainable Development. Energies 2024, 17, 5619. [Google Scholar] [CrossRef]

- Act of 10 April 1997—Energy Law, Dz. U. 1997 nr 54 poz. 348. Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU19970540348/U/D19970348Lj.pdf (accessed on 20 May 2025). (In Polish)

- Act of 17 August 2023 Amending the Act on Renewable Energy Sources and Certain Other Acts, Dz.U. z 2023 r. poz.1762. Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20230001762/U/D20231762Lj.pdf (accessed on 20 May 2025). (In Polish)

- Act of 27 March 2003 on Spatial Planning and Development; Journal of Laws 2003, No. 80, item 717. Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20030800717/U/D20030717Lj.pdf (accessed on 20 May 2025). (In Polish)

- Act of 3 February 1995 on the Protection of Agricultural and Forest Land; Journal of Laws 1995, No. 16, item 78. Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU19950160078/U/D19950078Lj.pdf (accessed on 20 May 2025). (In Polish)

- Act of 3 October 2008 on Access to Environmental Information, Public Participation in Environmental Protection and Environmental Impact Assessments; Journal of Laws 2008, No. 199, item 1227. Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20081991227/U/D20081227Lj.pdf (accessed on 20 May 2025). (In Polish)

- Regulation of the Council of Ministers of 9 November 2004 on the Determination of the Types of Projects that May Have a Significant Impact on the Environment and Detailed Conditions Connected with the Qualification of a Project to Draw up a Report on the Environment, Dz.U. 2004 nr 257 poz. 2573. Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20042572573/O/D20042573.pdf (accessed on 20 May 2025). (In Polish)

- Regulation of the Minister of the Environment of 9 December 2014 on the Waste Catalogue, Dz. U. 2014 poz. 1923. Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20140001923/O/D20141923.pdf (accessed on 20 May 2025). (In Polish)

- Act of 27 April 2001. Environmental Protection Law, Dz. U. z 2022 poz. 2556 z późn. zm. Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20010620627/U/D20010627Lj.pdf (accessed on 20 May 2025). (In Polish)

- Regulation of the Minister of Agriculture and Rural Development of 13 January 2023 on the Technical Conditions to be Met by Agricultural Structures and Their Location, Dz.U. 2023 poz. 297. Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20230000297/O/D20230297.pdf (accessed on 20 May 2025). (In Polish)

- Law of 7 July 1994 on Spatial Planning, Dz.U. 2003 nr 80 poz. 717. Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU19940890415/U/D19940415Lj.pdf (accessed on 20 May 2025). (In Polish)

- Act of 13 July 2023 on Facilitations in the Preparation and Implementation of Investments in Agricultural Biogas Plants and Their Operation, Dz.U. z 2023 r. poz. 1597. Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20230001597/O/D20231597.pdf (accessed on 20 May 2025). (In Polish)

- Polish Parliament. Act of 14 December 2012 on Waste (consolidated text); Journal of Laws 2023, item 1587, as amended. Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20230001587/U/D20231587Lj.pdf (accessed on 20 May 2025). (In Polish)

- Jajuga, K.; Zabawa, J.; Daszyńska-Żygadło, K. Finansowanie inwestycji w energetykę odnawialną przez polskie banki. Raport opracowany na zlecenie Programu Analityczno-Badawczego Fundacji Warszawski Instytut Bankowości. 2020. Available online: https://pabwib.pl/wp-content/uploads/2024/07/PAB_WIB_Finansowanie-energetyki-odnawialnej_Jajuga.pdf (accessed on 19 May 2025).

- Ministerstwo Klimatu i Środowiska. Kierunki rozwoju biogazowni rolniczych w Polsce w latach 2010–2020; MkiŚ: Warszawa, Poland, 2021. [Google Scholar]

- Izdebski, W. Spatial data infrastructure in Poland. Geo-System Sp. z.o.o. 2020. Available online: https://www.researchgate.net/publication/377234233_Practical_aspects_of_Spatial_Data_Infrastructure_in_Poland (accessed on 20 May 2025). (In Polish).

- Małysa-Sulińska, K. Administracyjnoprawne Aspekty Inwestycji Budowlanych; Wolters Kluwer: Warszawa, Poland, 2012. (In Polish) [Google Scholar]

- Lu, W.; Qi, S.; Zheng, B.; Zhang, W.; Wang, Z.; Ru, Y.; Zhang, Y.; Ma, L.; Diao, Y.; Fu, L. Optimisation Study of Carbon Dioxide Geological Storage Sites Based on GIS and Machine Learning Algorithms. Geomech. Geophys. Geo-Energy Geo-Resour. 2025, 11, 45. [Google Scholar] [CrossRef]

- Kochanek, A.; Kobylarczyk, S. The Analysis of the Main Geospatial Factors Using Geoinformation Programs Required for the Planning, Design and Construction of a Photovoltaic Power Plant. J. Ecol. Eng. 2024, 25, 49–65. [Google Scholar] [CrossRef]

- Tymińska, M.; Skibko, Z.; Borusiewicz, A. The Effect of Agricultural Biogas Plants on the Quality of Farm Energy Supply. Energies 2023, 16, 4600. [Google Scholar] [CrossRef]

- Trypolska, G.; Kyryziuk, S.; Krupin, V.; Wąs, A.; Podolets, R. Economic Feasibility of Agricultural Biogas Production by Farms in Ukraine. Energies 2022, 15, 87. [Google Scholar] [CrossRef]

- Dębicka, A.; Olejniczak, K.; Radomski, B.; Kurz, D.; Poddubiecki, D. Renewable Energy Investments in Poland: Goals, Socio-Economic Benefits, and Development Directions. Energies 2024, 17, 2374. [Google Scholar] [CrossRef]

- Sobczak, A.; Chomać-Pierzecka, E.; Kokiel, A.; Różycka, M.; Stasiak, J.; Soboń, D. Economic Conditions of Using Biodegradable Waste for Biogas Production, Using the Example of Poland and Germany. Energies 2022, 15, 5239. [Google Scholar] [CrossRef]

- Sørensen, J.F.L.; Jørgensen, H.P. Rural Development Potential in the Bioeconomy in Developed Countries: The Case of Biogas Production in Denmark. Sustainability 2022, 14, 11077. [Google Scholar] [CrossRef]

- Tahir, F.; Rasheed, R.; Fatima, M.; Batool, F.; Nizami, A.-S. Sustainability Analysis of Commercial-Scale Biogas Plants in Pakistan vs. Germany: A Novel Analytic Hierarchy Process—SMARTER Approach. Sustainability 2025, 17, 2168. [Google Scholar] [CrossRef]

- Muradin, M.; Foltynowicz, Z. Potential for Producing Biogas from Agricultural Waste in Rural Plants in Poland. Sustainability 2014, 6, 5065–5074. [Google Scholar] [CrossRef]

- Koryś, K.A.; Latawiec, A.E.; Grotkiewicz, K.; Kuboń, M. The Review of Biomass Potential for Agricultural Biogas Production in Poland. Sustainability 2019, 11, 6515. [Google Scholar] [CrossRef]

- Koval, V.; Atstāja, D.; Filipishyna, L.; Udovychenko, V.; Kryshtal, H.; Gontaruk, Y. Sustainability Assessment and Resource Utilization of Agro-Processing Waste in Biogas Energy Production. Climate 2025, 13, 99. [Google Scholar] [CrossRef]

- Efron, B.; Tibshirani, R.J. An Introduction to the Bootstrap, 1st ed.; Chapman and Hall/CRC: New York, NK, USA, 1994. [Google Scholar] [CrossRef]

- Cialdini, R.B. Influence: Science and Practice, 5th ed.; Pearson Education: Boston, MA, USA, 2009. [Google Scholar]

- Available online: https://pap-mediaroom.pl/nauka-i-technologie/prezes-organizacji-pracodawcow-biogazu-i-biometanu-polska-ma-potencjal-do (accessed on 20 May 2025).

- Carifio, J.; Perla, J.R. Ten Common Misunderstandings, Misconceptions, Persistent Myths and Urban Legends about Likert Scales and Likert Response Formats and their Antidotes. J. Soc. Sci. 2007, 3, 106–116. [Google Scholar] [CrossRef]

- Norman, G. likert scales, levels of measurement and the “laws” of statistics. Adv. Health Sci. Educ. Theory Pract. 2010, 15, 625–632. [Google Scholar] [CrossRef]

| Country | 2010 | 2014 | 2018 | 2022 |

|---|---|---|---|---|

| Australia | 0.50 | 0.65 | 0.60 | 0.74 |

| Austria | 0.75 | 1.3 | 1.20 | 0.71 |

| Belgium | 0.50 | 0.56 | 0.68 | 0.89 |

| Brazil | 0.05 | 0.12 | 0.18 | 0.21 |

| Canada | 0.30 | 0.42 | 0.37 | 0.34 |

| China | 0.18 | 0.22 | 0.19 | 0.18 |

| Denmark | 0.75 | 0.94 | 2.16 | 4.91 |

| Finland | 0.28 | 0.76 | 1.37 | 1.30 |

| France | 0.24 | 0.37 | 0.55 | 1.12 |

| Germany | 2.41 | 3.58 | 3.76 | 4.12 |

| India | 0.14 | 0.21 | 0.47 | 0.72 |

| Ireland | 0.45 | 0.38 | 0.36 | 0.40 |

| Italy | 0.35 | 1.41 | 1.30 | 1.48 |

| Japan | 0.0 | 0.00 | 0.00 | 0.00 |

| Korea | 0.19 | 0.21 | 0.17 | 0.22 |

| The Netherlands | 0.71 | 0.76 | 0.78 | 0.13 |

| New Zealand | 0.55 | 0.58 | 0.60 | 1.15 |

| Norway | 0.24 | 0.21 | 0.38 | 0.54 |

| South Africa | 0.00 | 0.00 | 0.00 | 0.00 |

| Sweden | 0.45 | 0.61 | 0.70 | 0.78 |

| Switzerland | 0.27 | 0.51 | 0.63 | 0.74 |

| UK | 1.18 | 1.31 | 1.78 | 1.55 |

| USA | 0.31 | 0.51 | 0.44 | 0.33 |

| UE 27 | 0.67 | 1.28 | 1.36 | 1.58 |

| Stage of the Construction Process | Applicable Legal Acts | Threats and Constraints | |

|---|---|---|---|

| Concept and feasibility study | Energy law [72] Renewable Energy Sources Act [14,73] | Low profitability, financing uncertainty, and limited expertise | |

| Investment location | Act on Spatial Planning and Development [74], Act on the Protection of Agricultural and Forest Land [75] | Difficulties in obtaining a suitable location, social conflicts, and planning restrictions | |

| Environmental impact assessment | Providing access to environmental information [76], Regulation of the Council of Ministers of 9 November 2004 [77], Regulation of the Minister of the Environment of 9 December 2014 on the Waste Catalogue [78], Environmental Protection Law [79] | The risk of having to prepare an Environmental Impact Assessment report, lengthy procedures, and the possibility of public opposition | |

| Zoning decision, development plan | Act on Spatial Planning and Development [74] | Plan non-compliance and zoning issues | |

| Installation design | Regulation of the Minister of Agriculture and Rural Development of 20 April 2023 [80] Renewable Energy Sources Act [14,73] | Human resource or technological deficiencies and challenges in complying with technical and environmental regulations | |

| Notification of construction works—building permit procedure | Construction Law [81] Act of 13 July 2023 on Facilitating the Preparation and Implementation of Investments in Agricultural Biogas Plants and Their Operation [82] | Lengthy decision-making timelines and complicated administrative procedures | |

| Environmental and waste management decisions | Act of 14 December 2012 on Waste [83] Regulation of the Minister of the Environment of 9 December 2014 on the Waste Catalogue [78] | Stringent waste management and emission regulations, along with high compliance costs | |

| Construction of an installation | Act of 13 July 2023 on Facilitating the Preparation and Implementation of Investments in Agricultural Biogas Plants and Their Operation [82] | Implementation delays, increased construction costs, and contractor-related issues | |

| Notification of construction completion occupancy permit | Act of 13 July 2023 on Facilitating the Preparation and Implementation of Investments in Agricultural Biogas Plants and Their Operation [82] | Obligation to comply with technical standards and the risk of denial of use permit (occupancy approval) | |

| Risks and Benefits of Owning a Biogas Plant | N | Range | Mean | Median | Mode | Std. Error | Std. Dev. | Variance |

|---|---|---|---|---|---|---|---|---|

| Economic and financial risk associated with investing in a biogas plant (e.g., investment costs, payback period)? | 129 | 4 | 2.64 | 3 | 3 | 0.098 | 1.110 | 1.231 |

| Technological, operational and raw material risks of the biogas plant (e.g., potential failure, complexity of operation)? | 130 | 4 | 2.47 | 2 | 2 | 0.100 | 1.136 | 1.290 |

| Social risk associated with a biogas plant (e.g., acceptance by the local community, impact on the neighborhood)? | 130 | 4 | 2.77 | 3 | 3 | 0.096 | 1.096 | 1.202 |

| Environmental risks associated with a biogas plant (e.g., odor emissions, water pollution)? | 130 | 4 | 2.38 | 2 | 1 | 0.103 | 1.176 | 1.384 |

| Regulatory and legal risks (including political): planning, design, construction and operation of an agricultural biogas plant? | 130 | 4 | 2.79 | 3 | 3 | 0.094 | 1.069 | 1.143 |

| Economic benefits of owning a biogas plant (e.g., additional income from energy sales, savings on fertilizers, subsidies)? | 129 | 4 | 3.62 | 4 | 4 | 0.106 | 1.200 | 1.441 |

| Environmental benefits of a biogas plant (e.g., reduced greenhouse gas emissions, better management of agricultural waste)? | 129 | 4 | 3.78 | 4 | 5 | 0.108 | 1.226 | 1.504 |

| Social and local benefits of biogas plants (e.g., creation of new jobs, development of local infrastructure, increase in income of local farms, improvement of household well-being)? | 129 | 4 | 3.61 | 4 | 5 | 0.109 | 1.233 | 1.520 |

| Energy benefits of biogas plants (saving energy costs, energy independence)? | 128 | 4 | 3.84 | 4 | 5 | 0.103 | 1.169 | 1.367 |

| Title 1 | Economic and Financial Risk Assessment | Technology Risk Assessment | Social Risk Assessment | Environmental Risk Assessment | Regulatory and Legal Risk Assessment | Assessment of Economic Benefits | Assessment of Environmental Benefits | Assessing Social Benefits | Assessment of Energy Benefits |

|---|---|---|---|---|---|---|---|---|---|

| H Kruskal–Wallis | 19.194 | 33.850 | 1.155 | 10.705 | 2.545 | 14.722 | 11.487 | 6.889 | 10.886 |

| df | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Asymptotic Significance | 0.001 | 0.000 | 0.885 | 0.030 | 0.637 | 0.005 | 0.022 | 0.142 | 0.028 |

| Risks | Size of the Biogas Plant | N | Average Rank | Benefits | Size of the Biogas Plant | N | Average Rank |

|---|---|---|---|---|---|---|---|

| Economic and financial risk assessment | 0 | 80 | 72.55 | Assessment of economic benefits | 0 | 80 | 56.47 |

| 1 | 16 | 58.03 | 1 | 16 | 76.16 | ||

| 2 | 21 | 36.55 | 2 | 21 | 86.14 | ||

| 3 | 9 | 62.78 | 3 | 9 | 58.67 | ||

| 4 | 2 | 95.50 | 4 | 2 | 91.50 | ||

| Total | 128 | Total | 128 | ||||

| Technology risk assessment | 0 | 81 | 75.77 | Assessment of environmental benefits | 0 | 80 | 57.19 |

| 1 | 16 | 47.81 | 1 | 16 | 68.41 | ||

| 2 | 21 | 29.24 | 2 | 21 | 81.26 | ||

| 3 | 9 | 74.11 | 3 | 9 | 74.56 | ||

| 4 | 2 | 100.75 | 4 | 2 | 104.50 | ||

| Total | 129 | Total | 128 | ||||

| Social risk assessment | 0 | 81 | 66.65 | Assessing social benefits | 0 | 80 | 59.14 |

| 1 | 16 | 56.78 | 1 | 16 | 69,06 | ||

| 2 | 21 | 64.05 | 2 | 21 | 79,60 | ||

| 3 | 9 | 64.94 | 3 | 9 | 62,94 | ||

| 4 | 2 | 74.00 | 4 | 2 | 91.00 | ||

| Total | 129 | Total | 128 | ||||

| Environmental risk assessment | 0 | 81 | 65.86 | Assessment of energy benefits | 0 | 79 | 57.32 |

| 1 | 16 | 46.13 | 1 | 16 | 73.13 | ||

| 2 | 21 | 64.31 | 2 | 21 | 80.19 | ||

| 3 | 9 | 80.00 | 3 | 9 | 60.22 | ||

| 4 | 2 | 120.75 | 4 | 2 | 102.00 | ||

| Total | 129 | Total | 127 | ||||

| Regulatory and legal risk assessment | 0 | 81 | 65.30 | Legend: | |||

| 1 | 16 | 56.53 | 0—no biogas plant | ||||

| 2 | 21 | 71.76 | 1—up to 50 kW | ||||

| 3 | 9 | 66.94 | 2—from 50 to 150 kW | ||||

| 4 | 2 | 41.00 | 3—from 150 to 500 kW | ||||

| Total | 129 | 4—over 500 kW | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kochanek, A.; Ciuła, J.; Cembruch-Nowakowski, M.; Zacłona, T. Polish Farmers′ Perceptions of the Benefits and Risks of Investing in Biogas Plants and the Role of GISs in Site Selection. Energies 2025, 18, 3981. https://doi.org/10.3390/en18153981

Kochanek A, Ciuła J, Cembruch-Nowakowski M, Zacłona T. Polish Farmers′ Perceptions of the Benefits and Risks of Investing in Biogas Plants and the Role of GISs in Site Selection. Energies. 2025; 18(15):3981. https://doi.org/10.3390/en18153981

Chicago/Turabian StyleKochanek, Anna, Józef Ciuła, Mariusz Cembruch-Nowakowski, and Tomasz Zacłona. 2025. "Polish Farmers′ Perceptions of the Benefits and Risks of Investing in Biogas Plants and the Role of GISs in Site Selection" Energies 18, no. 15: 3981. https://doi.org/10.3390/en18153981

APA StyleKochanek, A., Ciuła, J., Cembruch-Nowakowski, M., & Zacłona, T. (2025). Polish Farmers′ Perceptions of the Benefits and Risks of Investing in Biogas Plants and the Role of GISs in Site Selection. Energies, 18(15), 3981. https://doi.org/10.3390/en18153981