Bio-Coal Briquetting as a Potential Sustainable Valorization Strategy for Fine Coal: A South African Perspective in a Global Context

Abstract

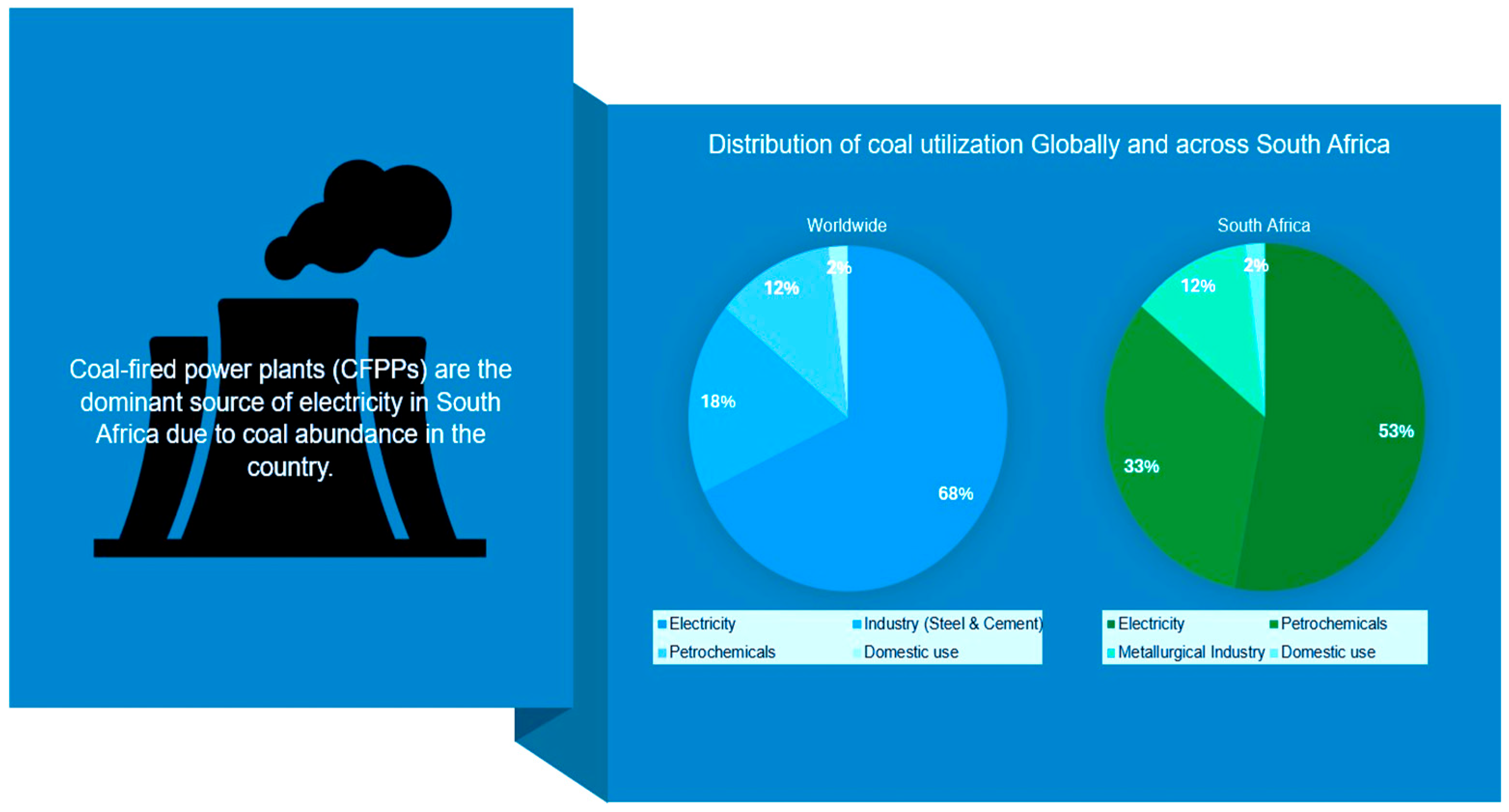

1. Introduction

2. Valorization Strategies of Fine Coal

2.1. Sources and Characteristics of Fine Coal

- (a)

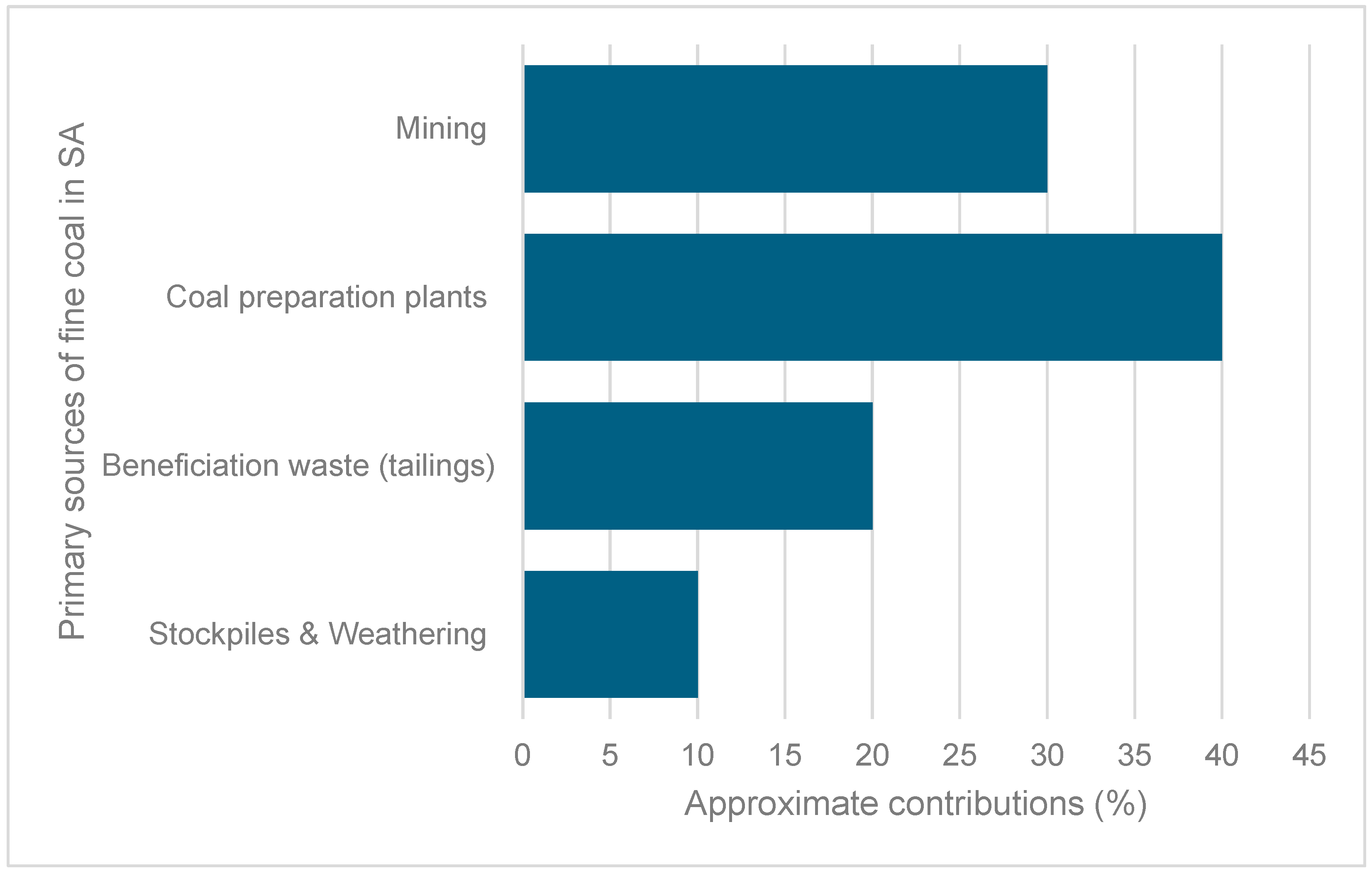

- Mining: Fine coal is initially generated during mining operations, particularly in underground settings. Mechanical actions such as blasting, cutting, and continuous extraction break coal into smaller particles [22,23]. SA coals, being friable, are especially prone to fragmentation during these processes [20,21].

- (b)

- Coal Preparation (Crushing and Screening): Crushing and screening operations further contribute to fines generation due to particle abrasion and breakage [27]. High-speed crushers and dry screening are particularly associated with increased fines, with equipment type and operational settings playing a significant role [22,27,28].

- (c)

- (d)

- Stockpiles and weathering: Storage and handling exacerbate fines formation as coal degrades due to compaction, oxidation, and environmental exposure [20,25]. Weathering from rain, wind, temperature changes, and microbial activity further fragments the coal, especially when stockpiles are unprotected [20,29].

2.2. The Necessity of Developing Valorization Strategies for Fine Coal

3. Technical Viability of Fine Coal Briquetting in South Africa

3.1. Briquetting Process

3.2. Methods of Briquetting

- (a)

- Mechanical densification compresses loose materials like sawdust, rice husks, groundnut shells, and fine coal into dense, transportable briquettes using pressure with or without heat [43,44,45,46]. This improves bulk density, reduces MC, and enhances handling [45,46]. Heated systems activate thermoplastic components like lignin, enabling binderless briquetting with improved strength [47]. Although energy-intensive, the method produces durable briquettes with high combustion efficiency [44].

- (b)

- Piston press technology is widely adopted in developing countries due to its low cost, simplicity, and adaptability to various biomass types [39,48]. A reciprocating piston compresses dry, fibrous feedstock such as straw and husks inside a die, generating frictional heat that softens lignin to act as a natural binder [48]. The result is dense, cylindrical briquettes suitable for domestic heating and cooking [39,43,49]. Efficient operation requires uniform particle size and low MC to minimize wear and maintain quality.

- (c)

- Screw extrusion involves feeding biomass through a rotating screw into a heated die, compressing it under high pressure and temperature (150–300 °C) [39,43,48]. This partial carbonization improves combustion properties and lowers volatile content [48]. Notably, high-quality briquettes can be produced without binders, as demonstrated by Sundar et al. [48], who achieved a higher heating value (HHV) of 16.73 MJ/kg. The resulting briquettes often have a central hole that enhances airflow and combustion efficiency, making them ideal for clean cooking stoves. However, screw extruders are mechanically complex and maintenance-intensive, limiting their suitability for low-resource environments.

- (d)

- Roller press briquetting involves feeding fine material between two counter-rotating rollers equipped with small dies of ~30 mm [39,50]. This method is prevalent in industrial applications involving uniform, fine materials like fine coal [39,43]. It accommodates a variety of binders to enhance strength and moisture resistance, offering high throughput, making it suitable for continuous processing lines [42]. However, it demands the pre-conditioning of feedstocks, including precise moisture control and particle size reduction, to ensure consistent briquette quality [39,50].

3.3. Potential Feedstocks Used for Briquetting

3.3.1. Properties of South African Fine Coal

3.3.2. Biomass Residue Availability and Suitability

- (a)

- Sawdust and wood chips: It is generated in abundance by the SA commercial forestry sector and sawmills, particularly in Mpumalanga and KwaZulu-Natal, the same provinces where coal mining is concentrated, reducing logistics costs [1,2]. It offers high carbon content and low sulfur, and has been shown to contribute to briquette structural integrity [61,62]. Manyushi et al. [20] produced briquettes with improved HHV (25–26 MJ/Kg) when blending sawdust with fine coal and molasses as binder. However, the high MC variability (10–50%) may necessitate pre-drying or moisture control to ensure briquette consistency.

- (b)

- Bagasse: A fibrous byproduct of sugarcane processing, produced in sugar mills, especially in KwaZulu-Natal. Bagasse has good energy content and blends well with fine coal [63]. According to Costa et al. [75], the HHV ranges between 15 and 18 MJ/kg. Bagasse is a year-round residue and often treated as waste, offering high potential for circular economy value [63,65]. Despite this, bagasse’s high initial MC (45–55%) requires drying or blending with lower-MC materials to prevent poor briquette stability.

- (c)

- Wheat Straw: A fibrous byproduct of wheat grain cultivation, wheat straw is abundant in the Western Cape and Free State provinces of SA. Although it is naturally low in density, its briquetting performance can be enhanced through pre-treatment methods such as chopping or pelletizing [63,67]. Due to its lignocellulosic composition, wheat straw not only blends well with fine coal but also serves as an effective natural binder [63,76]. According to Kumar et al. [77], incorporating wheat straw into fine ash coal improves both the ignition index (2.81 to 5.14 mass2/min2 °C3) and the overall combustion index (3.58 to 8.11 mass/min2 °C3). Nevertheless, its low bulk density (80–120 kg/m3) poses challenges for cost-effective transport and storage unless pre-compacted

- (d)

- Sunflower husks: A byproduct of oilseed processing that remains when the seeds are taken out. In SA, it is readily available in the Free State and Northwest provinces. Characterized with relatively low mineral content (2–3%) and moderate HHV (16–18 MJ/kg), it makes excellent biomass partners for blending with fine coal, especially for rural or agro-industrial zones [68,69]. Nikiforov et al. [78] recently showed that a percent ratio of 70/30% of sunflower husks and fine coal dust yielded the best combination of strength (80.95%), density (901.48 kg/m3), and HHV (21.33 MJ/Kg). However, their loose structure can affect briquette density and integrity, often requiring stronger binders or higher compaction pressures

- (e)

- Corn Cobs/stalks: The remaining hard core of maize. Corn is SA’s most cultivated crop with 16 million tonnes produced in 2024/25 [63,66]. The cobs generated from this offer good structural properties for briquettes and moderate HHV (14–16 MJ/kg) [66]. Their porous nature supports efficient combustion, while their seasonal abundance allows for storage and batch processing. Lu et al. [79] showed that corn stalks blending with fine coal improved briquette quality, with compressive strength increasing by 3.33 MPa. Still, their seasonal availability may result in inconsistent feedstock supply, necessitating stockpiling and drying facilities.

- (f)

- Macadamia shells: Hard and tough shells are generated during the production of macadamia nuts. In SA, it is primarily produced in Limpopo and Mpumalanga provinces [70]. The shells are high in fixed carbon and dense, yielding durable briquettes with moderate HHV (18–20 MJ/kg) [71]. Thermogravimetric analysis studies conducted by Bada et al. [80] showed that the co-firing of macadamia shells with coal in various ratios (20/80, 50/50, and 80/20%) all resulted in higher reactivity than coal alone. Additionally, this co-firing has found local commercial application, with the company SHISA-Eco briquettes©, which claims to produce a blended briquette product with 80% less fine particles and 75% less carbon monoxide. Yet, their hardness may cause excessive wear on briquetting equipment, often requiring pre-crushing and screening.

- (g)

- Invasive biomass (i.e., black wattle): These are actively removed in ecological restoration projects and offer a dual benefit: restoring native ecosystems and providing bioenergy feedstock. The Working for Water program identifies over 10 million tonnes of potential biomass annually from alien species alone [72,74]. Additionally, the country allows the commercial production of ~130 kilo-hectars of black wattle [72,73,74]. Although studies on the co-densification of wattle with fine coal are limited, its high lignin content, low ash yield, and widespread availability in SA present a significant opportunity for efficient and sustainable briquette production. However, inconsistent harvesting cycles and the lack of established supply chains may limit scalable and year-round availability.

3.4. Binders in Fine Coal Briquetting

3.4.1. Binding Mechanism

3.4.2. Classification and Selection of Binders

- (1)

- Organic Binders

- (a)

- Molasses: A sticky, carbon-rich organic binder derived as a byproduct of the sugar industry that enhances both the energy value and cohesive strength of briquettes [63]. Manyuchi et al. [20] showed that the addition of molasses in the co-densification of fine coal with sawdust increased the HHV and compressive strength of briquettes by 16% and 50%, respectively. This organic binder is extensively used in countries such as India, China, and SA, particularly in molasses–lime compound systems where its performance is complemented by the addition of lime to improve water resistance [104]. However, its hygroscopic nature may compromise briquette stability under humid conditions unless combined with water-resistant additives like lime [105,106].

- (b)

- Starch: The most widely used organic binder derived as a carbohydrate reserve from plants such as maize, cassava, and wheat [12,87]. This binder is clean-burning, making it suitable for high-quality briquettes used in indoor applications [36,87]. Chinyere et al. [90] observed an improved HHV from briquettes produced from sawdust when the amount of binder was increased from 30 mL per 100 g to 40 mL per 100 g, rising from 38.20 MJ/kg to 41.17 MJ/Kg. However, starch is relatively costly, which can limit its use in large-scale or low-budget operations. Its high hygroscopicity may also affect briquette stability in humid conditions, necessitating costly waterproofing additives.

- (c)

- Lignin: Naturally present in lignocellulosic biomass. It can act as a self-binder during high-pressure briquetting processes [107]. Mardiyati et al. [108] showed that binderless, all lignin briquettes from black liquor waste have a 99.7% drop–shatter index (DSI) and HHV equivalent to coal briquettes. In many systems, especially in Europe and North America, additional lignin is introduced to reinforce briquette durability. While effective, its utility is largely confined to woody biomass or feedstocks with high lignin content.

- (d)

- Vegetable oils: These include sunflower oil, palm oil, bio-oil, cooking oil, and castor oil. They are occasionally used as auxiliary binders or combustion enhancers [89]. In the co-densified briquetting of biomass, Zhang et al. [89] showed that the lubricating and combustible nature of both bio-oil and cooking oil can improve the ignition and burning behavior of briquettes. However, they are not primarily used for their binding capacity, as they often lack the cohesive strength necessary for durable briquettes [12,87]. Furthermore, their cost and variable quality are affected by factors like oxidation and purity, limiting their large-scale adoption in industrial briquetting [12,63,87,89].

- (e)

- Plant gums: These are polysaccharide-based organic compounds with natural adhesive properties, including guar gum, gum Arabic and acacia gum [109]. These are especially prevalent in artisanal and small-scale briquetting operations, including in rural or indigenous contexts [109]. Their biodegradability and non-toxic nature are advantageous, but their performance can be inconsistent due to MC sensitivity, microbial degradation, and relatively high costs. In line with this, Hassan et al. [110] observed that briquettes produced using gum Arabic as binder lowered the HHV of raw sawdust from 17.1 MJ/Kg to 15.7 MJ/kg.

- (f)

- Tar pitch: This organic binder is derived from coal tar distillation. It has historically been used in coal briquetting due to its strong adhesion, hydrophobicity, and ability to produce high-strength briquettes [88,111]. Zhong et al. [111] observed that using tar pitch to bind fine coal resulted in briquettes with improved DSI (×50/1 m) and a compressive strength of 6.43 MPa. However, tar pitch is not environmentally friendly, which restricts its use, as it releases toxic and carcinogenic compounds upon combustion [87,111].

- (2)

- Inorganic Binders

- (a)

- Bentonite Clay: Naturally occurring aluminosilicates are among the most common inorganic binders used in coal and biomass briquetting [87,91]. They are inexpensive, abundant, and enhance the structural strength and water resistance of briquettes [8,91,112]. These properties make them particularly useful in applications where briquettes are exposed to handling, moisture, or transport stress. However, their significant downside lies in their contribution to non-combustible residue. Bello et al. [91] recently analyzed the performance of clay as a binder and saw that the briquettes have poor flame propagation within the combustion chamber and delayed ignition time (7–10 min). These limitations make clay-based briquettes less ideal for residential combustion, where quick ignition and clean burn are preferred. As such, they are more suited to industrial or metallurgical briquettes than to those intended for residential or clean [8,112].

- (b)

- Lime (Ca(OH)2): Often used in its hydrated form (Ca(OH)2), lime acts as a binding and stabilizing agent, particularly in combination with organic binders such as molasses. It is frequently used in SA and Southeast Asia for improving the water resistance and long-term durability of bio-coal briquettes. Lime also helps neutralize acidic components and can slightly enhance combustion behavior. However, like other inorganic additives, lime increases mineral content and does not contribute to fuel value, requiring the careful optimization of dosage. Recently, Das et al. [92] compared various briquettes made of both organic (molasses, starch, pitch, and dextrin) and inorganic binders (lime and bentonite) to those made of fly ash bonded flue dust and observed that lime-based briquettes had the poorest compressive strength. Thus, blending it with other binders in a compound manner is a better option than using it solely.

- (c)

- Cement: This inorganic material is employed in briquetting processes where extreme mechanical strength is required, such as in metallurgical briquettes or construction-grade fuel blocks [14,15]. It has been shown to provide excellent compressive strength and resistance to handling damage. Ikelle [93] reported that coal briquettes formulated with cement exhibited exceptional durability but had significantly elevated ash levels (19.18–28.83%) and a long ignition time at 46 s. These trade-offs restrict cement’s use primarily to non-combustion or industrial applications where fuel purity is not the primary concern. In addition, the carbon footprint associated with cement production presents a drawback from a sustainability standpoint.

- (d)

- Gypsum: It is occasionally added to briquette formulations, particularly in coal-based systems, for its sulfur-binding properties. It serves to reduce emissions such as sulfur dioxide during combustion, which is relevant for environmental compliance in industrial settings. However, like other inorganic binders, gypsum adds weight and ash to the final product and is not typically used in domestic fuel applications.

- (3)

- Synthetic and Chemical Binders

- (a)

- Bitumen and resin-based binders: These are widely used in industrial briquette applications where structural integrity must be maintained at high temperatures or under mechanical stress. These binders are particularly effective in forming coke or metallurgical briquettes. Bitumen, being hydrophobic, also imparts water resistance. However, its combustion releases polycyclic aromatic hydrocarbons (PAHs), making it unsuitable for household energy use. A study by Mousa et al. [94] demonstrated that incorporating 2% bitumen as a partial replacement for cement in blast furnace briquettes achieved sufficient mechanical strength and improved reduction rates, highlighting its potential in metallurgical applications.

- (b)

- Sodium silicate: This binder is used in niche applications. It provides excellent water resistance and binding strength, especially in composite or refractory materials [92]. Its chemical stability and fire resistance make it valuable in specialized industries [12,92]. A study on blast furnace dust briquettes conducted by Han et al. [95] found that a 2% addition of sodium silicate, combined with corn starch, enhanced both low-temperature and high-temperature strength, with compressive strength reaching up to 1796 N at 1250 °C. Nonetheless, sodium silicate is brittle when dry, can alter pH balance, and lacks environmental compatibility [87,92].

- (c)

- Polyvinyl alcohol (PVA): This is a water-soluble synthetic polymer sometimes included in the organic binder category due to its carbon-based composition and potential biodegradability under specific conditions [113,114]. It provides excellent adhesive strength and clean-burning properties, making it suitable for premium briquettes [115]. PVA was used as a binder by Henning et al. [113], producing briquettes with a 7% increase in compressive strength at 5% formulation. However, PVA is relatively expensive and thermally unstable above 200 °C, limiting its utility in high-temperature or large-scale industrial applications [12,115]. Moreover, it must be produced under controlled chemical processes, making local sourcing in resource-limited regions difficult.

- (d)

- Other synthetic polymers: These may include acrylic resins, epoxy compounds, and phenol–formaldehyde resins, which are occasionally used in advanced briquetting systems [87]. While these binders offer customizable properties, such as high heat resistance and moisture control, their use is limited to high-cost, high-precision applications due to environmental, safety, and cost concerns.

- (4)

- Emerging and Green Binders

- (a)

- Microbial biopolymers: Polymers such as xanthan gum, exopolysaccharides (EPS’s), and bacterial cellulose are produced through fermentation processes involving bacteria like Bacillus spp. or Xanthomonas spp. [97,98]. These binders offer excellent water-binding properties and biodegradable profiles, making them attractive for bio-coal briquetting [99,100,116]. In SA, institutions like the universities and local R&D institutions are actively exploring the production of these biopolymers using local microbial strains and agro-waste substrates. While promising, these binders are still undergoing pilot-scale testing and require further validation for commercial viability.

- (b)

- Biochar-based binders: Biochar represents another frontier in green binder technology. It is made from pyrolyzed biomass, producing a carbon-rich, structurally stable binder that can enhance the overall carbon content and HHV of briquettes [117]. Their compatibility with a wide range of feedstocks and their potential to serve as carbon-negative materials makes them highly attractive, particularly in regions focused on carbon trading or climate commitments [87,117,118].

- (c)

- Waste-derived binders: These include binders made from paper sludge, sawdust waste, distillery effluents, or other industrial byproducts [87,119]. They are being evaluated for their binding potential in countries like India, Brazil, Kenya, and Indonesia [87,102,119]. These binders support waste valorization while offering cost-effective alternatives to synthetic or imported materials. Their performance varies widely depending on the source material, processing, and formulation, and standardization remains a challenge.

- (5)

- Compound binders

- Improved mechanical strength and moisture resistance of briquettes, particularly under variable storage and transport conditions;

- Enhanced combustion performance with reduced toxic emissions, supporting cleaner energy transition goals;

- Reduced reliance on expensive or imported synthetic binders;

- Local value addition through the utilization of byproducts and biotechnology, stimulating rural and industrial economies.

3.4.3. Binderless Briquetting

- Simplified supply chain: Eliminates the need to procure, store, and handle binders, lowering production complexity and operational costs.

- Sustainability: The process aligns with circular economy principles by avoiding non-renewable or environmentally harmful additives.

- Feedstock specificity: Only feedstocks with sufficient lignin content (e.g., wood, straw, and bagasse) are viable; fine coal or low-lignin biomass requires binders [57].

3.5. Manufacturing Parameters and Process Optimization

3.5.1. Key Manufacturing Variables

- (a)

- Pressure: Compaction pressure is one of the most critical factors affecting briquette strength and durability. High-pressure systems (>100 MPa), such as piston and roller presses, facilitate strong inter-particle bonding through mechanisms like plastic deformation, van der Waals forces, and mechanical interlocking [51,87]. Optimal pressure levels vary depending on feedstock composition and binder type, with a common effective range of 80–150 MPa for coal–biomass blends [51]. However, excessive pressure can lead to equipment wear and high energy consumption. In SA, where high-rank coal fines dominate, pressure must be carefully optimized to overcome coal’s natural rigidity without causing excessive equipment wear or energy consumption.

- (b)

- Temperature: Although the briquetting of coal fines is commonly conducted at ambient temperatures, moderate thermal input (100–200 °C) can significantly improve binding. This was confirmed by Nurek et al. [123], who produced briquettes with higher durability at 72 °C compared to an ambient temperature of 22 °C. In binderless systems, this heat softens lignin in biomass, enhancing cohesion [57]. For binder-based compound systems such as molasses–lime blends widely used in SA, elevated temperatures accelerate chemical curing, improving briquette integrity [92]. However, excessive heat may lead to premature MC loss and material degradation.

- (c)

- Moisture Content: Moisture plays a dual role as both a lubricant during compaction and an activator for certain binders [18,127]. Many researchers have identified that the optimal MC range typically lies between 7 and 15 wt% depending on binder type and feedstock characteristics [14,123,124]. Insufficient moisture reduces compressibility and cohesion, while excess moisture promotes steam formation, cracking, and strength loss during drying [123,124].

- (d)

- Particle Size: Feedstock particle size has been found to directly impact packing density and binding surface area [125,126]. These in turn influence both compressive strength and energy density of the briquettes [126]. Particles <3 mm have been observed to enhance compaction, but excessive fines (<0.2 mm) can impair permeability and slow drying, thereby reducing production efficiency and increasing energy input during curing [86,125,128]. A well-graded particle size distribution, often achieved via crushing and screening, ensures the homogeneity and structural stability of the briquettes. A well-graded distribution, typically 0.5–2 mm is optimal. Mani et al. [129] showed that optimizing particle size improves briquette density, strength, and combustion. Haidai et al. [130] emphasized the need to evaluate granulometric composition in composite fuels to control ash behavior and compaction. This study noted that variations in particle size distribution significantly affect compaction, higher heating value, and ash behavior. Additionally, Nati et al. [131] highlighted how screen selection and blade wear affect size uniformity and energy efficiency. In the SA context, standardizing crushing and screening, coupled with PSD–binder compatibility trials, could enhance briquette quality and process efficiency.

- (e)

- Mixing time: Uniform mixing of binders and feedstocks is essential for producing consistent and high-quality briquettes. Adequate mixing promotes the homogeneous distribution of the binder across all particles, enhancing inter-particle contact and matrix cohesion [83]. Mixing times typically range from 5 to 30 min depending on the binder type, moisture level, and feedstock composition [86,87].

- (f)

- Residence time: Residence time refers to the duration that the material remains under compression within the briquetting chamber. Sufficient residence time is crucial to allow stress relaxation and promote the physical and chemical bond formation between particles [39,83]. This becomes particularly important when using temperature or MC-sensitive binders such as starch, molasses, or microbial biopolymers, which require a short but controlled period to set effectively under pressure.

3.5.2. Optimal Quality Parameters

- (a)

- Higher Heating Value: A key metric for energy output, the target HHV for bio-coal briquettes ranges between 18 and 26 MJ/kg [133]. Blending high HHV fine coal (20–25 MJ/kg) with lower HHV biomass (<15 MJ/kg) must be balanced to achieve a competitive fuel value.

- (b)

- (c)

- Volatile Matter: Higher VM (20–35%) enhances the ease of ignition and flame propagation [135]. Biomass typically increases VM in the blend, which compensates for the low reactivity of high-rank coal.

- (d)

- Fixed Carbon (FC): Indicates the solid carbon available for sustained combustion. Optimal FC (>50%) ensures steady heat release during industrial or domestic use [136]. Biomass has lower FC, so the coal content needs to be sufficient to maintain heat value.

- (e)

- Bulk Density: Higher bulk density (0.9–1.2 g/cm3) improves energy density, transportation economics, and storage efficiency. This is especially important for off-grid or rural distribution in SA.

- (f)

- (g)

- Mineral content and Composition: Lower mineral content (<15%) is preferred to reduce residue disposal and enhance thermal efficiency [91,137]. Inorganic binders like clay or lime raise ash levels, and hence should be used cautiously. In SA, the coal is often ash-rich, necessitating careful blending and binder selection to stay within optimal limits [76].

3.6. Testing and Standardization

3.6.1. Performance Testing of Coal Briquettes

- (a)

- Drop Resistance Index: Drop strength tests simulate accidental handling shocks. The test involves dropping briquettes from a standard height (typically 2 m) onto a hard surface multiple times and measuring the percentage of mass retained. ASTM D-3038 for DSI of coke provides procedures for solid biofuels, while local protocols in SA use simplified adaptations for fuel evaluations [138]. However, the tests are rarely standardized across labs, reducing data comparability. SABS should define uniform drop protocols for rural settings.

- (b)

- Abrasion Resistance: This test determines the friability of briquettes under abrasive conditions (e.g., during transit). It is especially relevant for dusty or loosely bound formulations. ISO 17831-1 standards are often used for wood pellets and biomass briquettes and can be adapted to fine coal applications [115,139]. South African labs such as SABS have begun to incorporate these methods in bio-coal quality assurance protocols.

- (c)

- Water resistance: This test indicates the briquette’s durability in humid or wet conditions. This is particularly important due to possible open-air storage and seasonal rainfall. Water-resistant briquettes retain their shape and strength after short-term water exposure. Testing typically involves immersing briquettes in water for a set time (e.g., 30 min–1 h) and evaluating swelling, disintegration, or strength loss [140]. According to Richards [140], optimum resistance is stability beyond 1 h, which is globally accepted. Hydrophobic binders (e.g., pitch and wax emulsions) and additives like lime improve water resistance. However, SA lacks a formal moisture durability index for bio-briquettes, despite molasses and starch-based binders being hygroscopic. A local ‘wet integrity test’ could guide binder formulation optimization.

- (d)

- Compressive Strength: This test measures the maximum load a briquette can withstand before failure. It is a key indicator of structural integrity, especially during stacking or bulk handling. According to ISO 4700 (originally developed for metallurgical pellets but commonly adapted for solid fuels), a compressive strength above 1.0–1.5 MPa is generally considered acceptable for bio-coal briquettes [141]. South African studies often use similar thresholds when testing molasses- or starch-bound briquettes.

- (e)

- Shear Strength: This test evaluates the internal cohesion and resistance to sliding between particles in a briquette under lateral stress, complementing compressive strength assessments [142]. It is particularly relevant for briquettes made with low-viscosity or bio-based binders (e.g., molasses and starch), which may exhibit good compressive integrity but shear failure during handling or bulk transport. Shear strength is commonly measured using a direct shear apparatus based on ASTM D3080, originally developed for soil testing but increasingly adapted for assessing low-cohesion solid fuels [142]. Although no formal threshold exists for briquettes, preliminary studies suggest a minimum shear resistance of 0.5–1.0 MPa to ensure stability under stacking and loading stresses. Integrating shear strength testing can guide binder and feedstock optimization, particularly in humid or rural settings where briquettes face non-uniform stresses during storage and handling.

- (f)

- Higher Heating Value (HHV): The HHV measures the energy released during combustion and is the most important indicator of fuel efficiency. Standard methods include ASTM D5865 and ISO 1928, which use bomb calorimetry [143]. In SA, labs affiliated with universities (e.g., Wits and Stellenbosch) and organizations like SABS apply these methods for both raw coal and bio-coal blends. Target HHV for bio-coal briquettes is 18–26 MJ/kg depending on the blending ratio. However, most tests do not isolate combustion synergy between biomass and coal, which may under- or overestimate real-world efficiency.

- (g)

- Ignition Time and Burn Rate: These tests determine how quickly briquettes ignite and how long they sustain combustion. Biomass-rich briquettes tend to ignite faster due to higher VM content [77,80,87]. Standard protocols for these properties are less uniform but often draw from ISO 18123 (for proximate analysis) and ASTM E870-82 (2019) (wood fuel testing) [144]. Local tests in SA often involve field-based stove trials or controlled combustion chambers to assess real-world performance. Field stove trials or ceramic pot stove (CPS) setups should be standardized for rural contexts to measure practical performance [63,87].

- (h)

- Mineral content: High mineral content reduces HHV and complicates ash disposal. Measurement follows ASTM D1102 and locally for coal–biomass mixtures, SANS 5924 may also be adapted [145]. South African coal typically contains 25–45% ash, necessitating optimized blends with low-ash biomass and careful binder selection [56].

- (i)

- Emissions Testing: Although not nationally mandated in SA, emission testing (e.g., CO, SO2, NOx, and particulate matter) is gaining relevance for regulatory compliance and environmental health. Internationally, ISO 14064 provides guidelines for measurement setups for greenhouse gases [146].

- The development of hybrid testing protocols that evaluate co-firing emissions, volatile matter interactions, and ash fusion characteristics specific to coal–biomass blends;

- The introduction of dedicated water resistance and hygroscopicity indices, particularly for briquettes using bio-binders, which are prone to moisture absorption and mechanical degradation;

- The inclusion of field-appropriate drop strength tests and weathering resistance assessments for SMME and rural production settings;

- The calibration of minimum performance thresholds by SABS (e.g., acceptable density, HHV, and durability ranges) based on real-world end-use conditions in informal or decentralized markets.

3.6.2. Standardization Frameworks for South Africa

3.7. Integrating Bio-Coal Briquetting into South Africa’s Just Energy Transition Framework

- Invest in local R&D focused on low-cost, biodegradable binders, particularly those derived from agricultural or agro-industrial waste such as molasses and starch, and explore the use of microbial exopolymers.

- Promote decentralized briquetting enterprises in coal-rich but energy-poor provinces (e.g., Limpopo and Mpumalanga) to empower SMMEs, support rural livelihoods, and enhance energy security.

- Incentivize briquetting initiatives through inclusion in national waste-to-energy schemes, mine closure plans, and the broader Just Energy Transition framework.

- Collaborate with standards bodies (e.g., SABS) to develop performance-based testing protocols specific to bio-coal briquettes, including water resistance, combustion behavior, and long-term durability.

- Strengthen public–private partnerships to improve market access, scale up infrastructure, and align briquetting initiatives with carbon offset programs and green procurement mandates.

4. End-Use Applications

5. Opportunities and Challenges

5.1. Overview

5.2. Practical Implementation Challenges and Opportunities

6. Conclusions and Recommendations

6.1. Conclusions

- SA possesses diverse biomass resources including macadamia shells, sugarcane bagasse, and corn cobs that are suitable for blending with fine coal.

- Organic binders like molasses and starch, along with emerging microbial biopolymers, are particularly promising for low-emission, high-performance briquettes.

- Optimal briquetting parameters (pressure, particle size, and MC) directly influence briquette quality and need to be localized based on coal type and biomass blend.

- Integration into the JET, mine closure plans, and circular economy policies enhances socio-economic relevance.

6.2. Recommendations

- Investing in local R&D for cost-effective biodegradable binders derived from agro-waste;

- Establishing decentralized briquetting enterprises in energy-poor, coal-rich provinces to support SMMEs and job creation;

- Local research institutes must collaborate with SABS to develop standardized testing protocols tailored to hybrid briquettes;

- Including bio-coal briquetting in national waste-to-energy schemes and carbon offset mechanisms;

- Strengthening public–private partnerships to scale infrastructure and stimulate rural energy markets.

- Pilot-scale validation of compound binder systems (e.g., molasses + microbial EPS);

- Long-term field performance of briquettes under varied storage, weather, and combustion conditions;

- Life-cycle and techno-economic analyses to assess cost-effectiveness and climate impact;

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- International Energy Agency. Coal 2023—Analysis and Forecast to 2026; International Energy Agency: Paris, France, 2023. [Google Scholar]

- ESKOM. Generation Communication: CO 0007—Revision 16 COAL In SOUTH AFRICA; ESKOM: Sandton, South Africa, 2021. [Google Scholar]

- International Energy Agency. Electricity 2024—Analysis and Forecast to 2026; International Energy Agency: Paris, France, 2024. [Google Scholar]

- Statistics South Africa. Statistics South Africa General Household Survey; Statistics South Africa: Pretoria, South Africa, 2021. [Google Scholar]

- Smit, S.; Musango, J.K. Exploring the Connections between Green Economy and Informal Economy in South Africa. S. Afr. J. Sci. 2015, 111, 10. [Google Scholar] [CrossRef] [PubMed]

- Du Venage, G. South Africa Comes to Standstill with Eskom’s Load Shedding. 2020. Available online: http://www.e-mj.com/news/this-month-in-coal/south-africa-comes-to-standstill-with-eskoms-load-shedding/ (accessed on 3 May 2025).

- Grant-Stuart, D.J. Your Tailings Dam; The South African National Committee on Large Dams: Pretoria, South Africa, 2020. [Google Scholar]

- Rebelo, W.B.; Zaccaron, A.; Saviatto, E.; Olivo, E.F.; Acordi, J.; Raupp-Pereira, F.; Ribeiro, M.J. Valorization of the Residual Fraction of Coal Tailings: A Mineral Circularity Strategy for the Clay Ceramic Industry in the Carboniferous Region of Santa Catarina, Southern Brazil. Materials 2024, 17, 2131. [Google Scholar] [CrossRef] [PubMed]

- Amaral, F.J.R.d.; Gcayiya, M.; Kotsiopoulos, A.; Broadhurst, J.L.; Power, D.; Harrison, S.T.L. Valorization of South African Coal Wastes through Dense Medium Separation. Minerals 2022, 12, 1519. [Google Scholar] [CrossRef]

- Cui, C.Q.; Wang, B.; Zhao, Y.X.; Xue, L.M. Waste Mine to Emerging Wealth: Innovative Solutions for Abandoned Underground Coal Mine Reutilization on a Waste Management Level. J. Clean. Prod. 2020, 252, 119748. [Google Scholar] [CrossRef]

- Akinbami, O.M.; Oke, S.R.; Bodunrin, M.O. The State of Renewable Energy Development in South Africa: An Overview. Alex. Eng. J. 2021, 60, 5077–5093. [Google Scholar] [CrossRef]

- Zhang, G.; Sun, Y.; Xu, Y. Review of Briquette Binders and Briquetting Mechanism. Renew. Sustain. Energy Rev. 2018, 82, 477–487. [Google Scholar] [CrossRef]

- Rubio, B.; Izquierdo, M.T.; Segura, E. Effect of Binder Addition on the Mechanical and Physicochemical Properties of Low Rank Coal Char Briquettes. Carbon N. Y. 1999, 37, 1833–1841. [Google Scholar] [CrossRef]

- Venter, P.; Naude, N. Evaluation of Some Optimum Moisture and Binder Conditions for Coal Fines Briquetting. J. S. Afr. Inst. Min. Metall. 2015, 115, 329–333. [Google Scholar] [CrossRef]

- Zhao, Y.; Qiu, J.; Ma, Z.; Sun, X. Eco-Friendly Treatment of Coal Gangue for Its Utilization as Supplementary Cementitious Materials. J. Clean. Prod. 2021, 285, 124834. [Google Scholar] [CrossRef]

- Oluremi, J.R.; Elsaigh, W.H.A. Characterization of Coal Fines as Potential Supplementary Cementitous Additive for Remediation of Non-Polar Substance Contaminated Soil. Mater. Today Proc. 2023, 86, 24–31. [Google Scholar] [CrossRef]

- Mutyavaviri, L.C.; Chihobo, C.H.; Makepa, D.C. The Ecological Effects and Valorization of Coal Fines—A Review. Environ. Sci. Pollut. Res. 2024, 31, 51045–51063. [Google Scholar] [CrossRef] [PubMed]

- Ramudzwagi, M.; Tshiongo-Makgwe, N.; Nheta, W. Recent Developments in Beneficiation of Fine and Ultra-Fine Coal—Review Paper. J. Clean. Prod. 2020, 276, 122693. [Google Scholar] [CrossRef]

- Chen, Y.; Ma, Z.; Ma, D.; Zhang, Z.; Li, W.; Yang, F.; Ji, Y.; Peng, T. Characteristics of the Coal Fines Produced from Low-Rank Coal Reservoirs and Their Wettability and Settleability in the Binchang Area, South Ordos Basin, China. Geofluids 2021, 2021, 1–17. [Google Scholar] [CrossRef]

- Manyuchi, M.M.; Mbohwa, C.; Muzenda, E. Value Addition of Coal Fines and Sawdust to Briquettes Using Molasses as a Binder. S. Afr. J. Chem. Eng. 2018, 26, 70–73. [Google Scholar] [CrossRef]

- Mangena, S.J.; De Korte, G.J.; McCrindle, R.I.; Morgan, D.L. The Amenability of Some Witbank Bituminous Ultra Fine Coals to Binderless Briquetting. Fuel Process. Technol. 2004, 85, 1647–1662. [Google Scholar] [CrossRef]

- Kinnunen, P.H.M.; Kaksonen, A.H. Towards Circular Economy in Mining: Opportunities and Bottlenecks for Tailings Valorization. J. Clean. Prod. 2019, 228, 153–160. [Google Scholar] [CrossRef]

- Kinnunen, P.; Karhu, M.; Yli-Rantala, E.; Kivikytö-Reponen, P.; Mäkinen, J. A Review of Circular Economy Strategies for Mine Tailings. Clean. Eng. Technol. 2022, 8, 100499. [Google Scholar] [CrossRef]

- International Council on Mining and Metals. Tailings Management; International Council on Mining and Metals: London, UK, 2021. [Google Scholar]

- De Korte, G.J. Beneficiation of Fine Coal: Froth Flotation Efficiency; Coaltech: Pretoria, South Africa, 2001. [Google Scholar]

- De Korte, G.J. Beneficiation of Weathered Coal; Coaltech: Pretoria, South Africa, 2001. [Google Scholar]

- Arnold, B.J. A Review of Element Partitioning in Coal Preparation. Int. J. Coal Geol. 2023, 274, 104296. [Google Scholar] [CrossRef]

- Ferreira, L.P.; Müller, T.G.; Cargnin, M.; De Oliveira, C.M.; Peterson, M. Valorization of Waste from Coal Mining Pyrite Beneficiation. J. Environ. Chem. Eng. 2021, 9, 105759. [Google Scholar] [CrossRef]

- Estiaty, L.M.; Fatimah, D. Widodo Bio-Coal Briquettes Using Low-Grade Coal. In IOP Conference Series: Earth and Environmental Science; Institute of Physics Publishing: Bristol, UK, 2018; Volume 118. [Google Scholar]

- Armstrong, M.; Petter, R.; Petter, C. Why Have so Many Tailings Dams Failed in Recent Years? Resour. Policy 2019, 63, 101412. [Google Scholar] [CrossRef]

- Klak, S. Carleton Perspectives on Public Policy 10 On the Brink of Better Tailings Management: Policy Options in the Aftermath of the Mount Polley Mine Disaster. Carlet. Perspect. Public Policy 2016, 3, 10–30. [Google Scholar]

- Leonida, C. Turning the Tide on Tailings: Creating Opportunities Rather Than Risks. Eng. Min. J. 2023. Available online: https://www.e-mj.com/features/turning-the-tide-on-tailings-creating-opportunities-rather-than-risks/ (accessed on 10 May 2025).

- Onalethata, S.; Raymond, S.; Konka, B. Fines Generation and Its Impacts at Morupule Underground Coal Mine, Botswana. In Advances in Science, Technology and Innovation; Springer Nature: Berlin/Heidelberg, Germany, 2024; pp. 465–468. [Google Scholar]

- Marais, L.; Kemp, D.; van der Watt, P.; Matebesi, S.; Cloete, J.; Harris, J.; Ang Li Ern, M.; Owen, J.R. The Catastrophic Failure of the Jagersfontein Tailings Dam: An Industrial Disaster 150 Years in the Making. Int. J. Disaster Risk Reduct. 2024, 109, 104585. [Google Scholar] [CrossRef]

- Adeeyo, R.O.; Edokpayi, J.N.; Volenzo, T.E.; Odiyo, J.O.; Piketh, S.J. Determinants of Solid Fuel Use and Emission Risks among Households: Insights from Limpopo, South Africa. Toxics 2022, 10, 67. [Google Scholar] [CrossRef] [PubMed]

- Tatham, J. The Impact of Solid Cooking Fuels on the Health of Rural South African Households. Master’s Thesis, University of Cape Town, Rondebosch, South Africa, 2021. [Google Scholar]

- SASOL Limited. Climate Change Report. 2022. Available online: https://www.sasol.com/sites/default/files/2022-12/SASOL_CC%20Report%202022%20%202.pdf (accessed on 15 May 2025).

- Marreiro, H.M.P.; Peruchi, R.S.; Lopes, R.M.B.P.; Andersen, S.L.F.; Eliziário, S.A.; Junior, P.R. Empirical Studies on Biomass Briquette Production: A Literature Review. Energies 2021, 14, 8320. [Google Scholar] [CrossRef]

- Dinesha, P.; Kumar, S.; Rosen, M.A. Biomass Briquettes as an Alternative Fuel: A Comprehensive Review. Energy Technol. 2019, 7. [Google Scholar] [CrossRef]

- Rawat, S.; Kumar, S. Critical Review on Processing Technologies and Economic Aspect of Bio-Coal Briquette Production. Prep. Biochem. Biotechnol. 2022, 52, 855–871. [Google Scholar] [CrossRef] [PubMed]

- Adeleke, A.A.; Odusote, J.K.; Ikubanni, P.P.; Olabisi, A.S.; Nzerem, P. Briquetting of Subbituminous Coal and Torrefied Biomass Using Bentonite as Inorganic Binder. Sci. Rep. 2022, 12. [Google Scholar] [CrossRef] [PubMed]

- Vaish, S.; Sharma, N.K.; Kaur, G. A Review on Various Types of Densification/Briquetting Technologies of Biomass Residues. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1228, 012019. [Google Scholar] [CrossRef]

- Shankar, J.; Christopher, T.; Wright, T.; Kenny, K.L.; Hess, J.R. A Review on Biomass Densification Technologies for Energy Application. Biofuels Bioprod. Biorefinin 2010, 5, 720. [Google Scholar]

- Kaliyan, N.; Vance Morey, R. Factors Affecting Strength and Durability of Densified Biomass Products. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Sokhansanj, S.; Turhollow, A.F. Biomass Densification—Cubing Operations and Costs for Corn Stover. Appl. Eng. Agric. 2004, 20, 495–499. [Google Scholar] [CrossRef]

- Rahaman, S.A.; Salam, P.A. Characterization of Cold Densified Rice Straw Briquettes and the Potential Use of Sawdust as Binder. Fuel Process. Technol. 2017, 158, 9–19. [Google Scholar] [CrossRef]

- Grover, P.D.; Mishra, S.K. Regional Wood Energy Development Programme in Asia gcp/ras/154/net Food and Agriculture Organization of the United Nations Bangkok, Biomass Briquetting: Technology and Practices; The FAO Regional Wood Energy Development Programme in Asia: Bangkok, Thailand, 1996. [Google Scholar]

- Sundar, V.J.P.; D’Souza, P.M.; Donipati, J.V.; Kranthi, T. Development and Evaluation of a Screw Press Briquetting Machine for Biomass Fuel Production. Int. J. Adv. Biochem. Res. 2024, 8, 259–267. [Google Scholar] [CrossRef]

- Ikubanni, P.P.; Agboola, O.O.; Olabamiji, T.S.; Adediran, A.A.; Anisere, T.; Oladimeji, S. Development and Performance Assessment of Piston-Type Briquetting Machine. In IOP Conference Series: Earth and Environmental Science; Institute of Physics Publishing: Bristol, UK, 2020; Volume 445. [Google Scholar]

- Bembenek, M.; Zięba, A.; Kopyściański, M.; Krawczyk, J. Analysis of the Impact of the Consolidated Material on the Morphology of Briquettes Produced in a Roller Press. J. Mater. Eng. Perform. 2020, 29, 3792–3799. [Google Scholar] [CrossRef]

- Aransiola, E.F.; Oyewusi, T.F.; Osunbitan, J.A.; Ogunjimi, L.A.O. Effect of Binder Type, Binder Concentration and Compacting Pressure on Some Physical Properties of Carbonized Corncob Briquette. Energy Rep. 2019, 5, 909–918. [Google Scholar] [CrossRef]

- Mdhluli, F.T.; Harding, K.G. Comparative Life-Cycle Assessment of Maize Cobs, Maize Stover and Wheat Stalks for the Production of Electricity through Gasification vs Traditional Coal Power Electricity in South Africa. Clean. Environ. Syst. 2021, 3, 100046. [Google Scholar] [CrossRef]

- Reddick, J.F.; Blottnitz, v.H.; Kothuis, B. A Cleaner Production Assessment of the Ultra-Fine Coal Waste. J. S. Afr. Inst. Min. Metall. 2007, 107, 811–816. [Google Scholar]

- Edison Muzenda Potential Use of South African Coal Fines. In Proceedings of the ICMEME’2014, Abu Dhabi, United Arab Emirates, 19–20 March 2014.

- 2023 Comprehensive Facts and Figures; Minerals Council South Africa. 2023. Available online: https://www.mineralscouncil.org.za/industry-news/publications/facts-and-figures (accessed on 3 May 2025).

- Mangena, S.J.; du Cann, V.M. Binderless Briquetting of Some Selected South African Prime Coking, Blend Coking and Weathered Bituminous Coals and the Effect of Coal Properties on Binderless Briquetting. Int. J. Coal Geol. 2007, 71, 303–312. [Google Scholar] [CrossRef]

- Olugbade, T.O.; Ojo, O.T. Binderless Briquetting Technology for Lignite Briquettes: A Review. Energy Ecol. Environ. 2021, 6, 69–79. [Google Scholar] [CrossRef]

- Jia, J.; Wu, Y.; Zhao, D.; Li, B.; Wang, D.; Wang, F.; Chen, Y. Molecular Structure Characterization Analysis and Molecular Model Construction of Anthracite. PLoS ONE 2022, 17, e0275108. [Google Scholar] [CrossRef] [PubMed]

- MMR. Global Mined Anthracite Coal Market—Growth, Share, Trends, and Forecasts to 2023–2029; Maximize Market Research: Maharashtra, India, 2023. [Google Scholar]

- Department of Forestry, Fisheries and the Environment 2022/23. Annual Report—Vote NO.32; 2022. Available online: http://www.dffe.gov.za/sites/default/files/reports/annualreport202223.pdf (accessed on 3 May 2025).

- Stafford, W.H.; De Lange, W.J. Wood-Based Bio-Refineries: Value Adding to Sawmill Waste from the Forestry Industry; Council for Scientific and Industrial Research, CSIR Research Space: Pretoria, South Africa, 2018. [Google Scholar]

- Núñez-Retana, V.D.; Wehenkel, C.; Vega-Nieva, D.J.; García-Quezada, J.; Carrillo-Parra, A. The Bioenergetic Potential of Four Oak Species from Northeastern Mexico. Forests 2019, 10, 869. [Google Scholar] [CrossRef]

- Srinivasan, G.R.; Mahajan, A.; Seth, R.; Mahajan, R. High Potential Organic Feedstocks for Production of Renewable Solid Briquettes—A Comprehensive Review. Waste Manag. Circ. Econ. 2023, 231–277. [Google Scholar] [CrossRef]

- Seroka, N.S.; Taziwa, R.; Khotseng, L. Sugar Cane Bagasse Ash: An Agricultural Residue with Potential Rubber Filler Applications. In Application and Characterization of Rubber Materials; IntechOpen: London, UK, 2023. [Google Scholar]

- De, J.M.; Camargo, O.; Marcela, J.; Ríos, G.; Antonio, G.C.; Leite, J.T.C. Physicochemical Properties of Sugarcane Industry Residues Aiming at Their Use in Energy Processes. In Sugarcane—Biotechnology for Biofuels; IntechOpen: London, UK, 2021. [Google Scholar]

- Mohlala, L.M.; Bodunrin, M.O.; Awosusi, A.A.; Daramola, M.O.; Cele, N.P.; Olubambi, P.A. Beneficiation of Corncob and Sugarcane Bagasse for Energy Generation and Materials Development in Nigeria and South Africa: A Short Overview. Alex. Eng. J. 2016, 55, 3025–3036. [Google Scholar] [CrossRef]

- Kamusoko, R.; Mukumba, P. Potential of Wheat Straw for Biogas Production by Anaerobic Digestion in South Africa: A Review. Energies 2024, 17, 4662. [Google Scholar] [CrossRef]

- Cui, X.; Yang, J.; Shi, X.; Lei, W.; Huang, T.; Bai, C. Pelletization of Sunflower Seed Husks: Evaluating and Optimizing Energy Consumption and Physical Properties by Response Surface Methodology (RSM). Processes 2019, 7, 591. [Google Scholar] [CrossRef]

- Spirchez, C.; Lunguleasa, A.; Croitoru, C. Ecological Briquettes from Sunflower Seed Husk. E3S Web Conf. EDP Sci. 2019, 80, 01001. [Google Scholar] [CrossRef]

- Sibulali, A. Market Intelligence Report: Macadamia Nuts; Western Cape Department of Agriculture: Elsenburg, Stellenbosch, South Africa, 2021. [Google Scholar]

- Maingi, A.M.; Kiraithe, R.M.; Musau, S.K. Study of Combustion Characteristics of Macadamia Shells and Coffee Husks Briquettes in a Fixed Bed Reactor. Mech. Eng. 2023. [Google Scholar] [CrossRef]

- Vera, I.; Goosen, N.; Batidzirai, B.; Hoefnagels, R.; van der Hilst, F. Bioenergy Potential from Invasive Alien Plants: Environmental and Socio-Economic Impacts in Eastern Cape, South Africa. Biomass Bioenergy 2022, 158, 106340. [Google Scholar] [CrossRef]

- Lusizi, Z.; Motsi, H.; Nyambo, P.; Elephant, D.E. Black (Acacia Mearnsii) and Silver Wattle (Acacia Dealbata) Invasive Tree Species Impact on Soil Physicochemical Properties in South Africa: A Systematic Literature Review. Heliyon 2024, 10, e24102. [Google Scholar] [CrossRef] [PubMed]

- Rawat, Y.S.; Singh, G.S.; Tekleyohannes, A.T. Optimizing the Benefits of Invasive Alien Plants Biomass in South Africa. Sustainability 2024, 16, 1876. [Google Scholar] [CrossRef]

- Costa, E.V.S.; Pereira, M.P.d.C.F.; da Silva, C.M.S.; Pereira, B.L.C.; Rocha, M.F.V.; Carneiro, A.d.C.O. Torrefied Briquettes of Sugar Cane Bagasse and Eucalyptus. Rev. Arvore 2019, 43, 231–277. [Google Scholar] [CrossRef]

- Kumar, P.; Nandi, B.K. Impact of Wheat Straw and Petroleum Coke Blending on Combustion Behavior of High Ash Coal. Energy Sources Part A Recovery Util. Environ. Eff. 2023, 45, 3125–3137. [Google Scholar] [CrossRef]

- Kumar, P.; Kumar Nandi, B. Combustion Characteristics of High Ash Indian Coal, Wheat Straw, Wheat Husk and Their Blends. Mater. Sci. Energy Technol. 2021, 4, 274–281. [Google Scholar] [CrossRef]

- Nikiforov, A.; Kinzhibekova, A.; Prikhodko, E.; Karmanov, A.; Nurkina, S. Analysis of the Characteristics of Bio-Coal Briquettes from Agricultural and Coal Industry Waste. Energies 2023, 16, 3527. [Google Scholar] [CrossRef]

- Lu, G.; Cheng, F.; Li, J. Enhancement of Coal Briquette Quality through Corn Stalk Blending and Binder Optimization. Environ. Prog. Sustain. Energy 2015, 34, 613–618. [Google Scholar] [CrossRef]

- Bada, S.O.; Falcon, R.M.S.; Falcon, L.M.; Makhula, M.J. Thermogravimetric Investigation of Macadamia Nut Shell, Coal, and Anthracite in Different Combustion Atmospheres. J. S. Afr. Inst. Min. Metall. 2015, 115, 741–746. [Google Scholar] [CrossRef]

- Keneilwe, R. The South African Energy Sector Report; Department of Mineral Resources and Energy: Pretoria, South Africa, 2022.

- Industrial Policy Action Plan, 2018/19-2020/21. Department of Trade and Industry, 2018. Available online: https://www.thedtic.gov.za/wp-content/uploads/publication-IPAP.pdf (accessed on 18 May 2025).

- Miao, Z.; Zhang, P.; Li, M.; Wan, Y.; Meng, X. Briquette Preparation with Biomass Binder. Energy Sources Part A Recovery Util. Environ. Eff. 2023, 45, 9834–9844. [Google Scholar] [CrossRef]

- Butler, J.W.; Skrivan, W.; Lotfi, S. Identification of Optimal Binders for Torrefied Biomass Pellets. Energies 2023, 16, 3390. [Google Scholar] [CrossRef]

- Oladeji, J.T. Theoretical Aspects of Biomass Briquetting: A Review Study. J. Energy Technol. Policy 2015, 5, 72–81. [Google Scholar]

- Tumuluru, J.S.; Wright, C.T.; Hess, J.R.; Kenney, K.L. A Review of Biomass Densification Systems to Develop Uniform Feedstock Commodities for Bioenergy Application. Biofuels Bioprod. Biorefining 2011, 5, 683–707. [Google Scholar] [CrossRef]

- Obi, O.F.; Pecenka, R.; Clifford, M.J. A Review of Biomass Briquette Binders and Quality Parameters. Energies 2022, 15, 2426. [Google Scholar] [CrossRef]

- Zhong, Q.; Yang, Y.; Li, Q.; Xu, B.; Jiang, T. Coal Tar Pitch and Molasses Blended Binder for Production of Formed Coal Briquettes from High Volatile Coal. Fuel Process. Technol. 2017, 157, 12–19. [Google Scholar] [CrossRef]

- Zhang, T.; Qiu, L.; Wang, Y.; Zhang, C.; Kang, K. Comparison of Bio-Oil and Waste Cooking Oil as Binders during the Codensification of Biomass: Analysis of the Pellet Quality. BioEnergy Res. 2019, 12, 558–569. [Google Scholar] [CrossRef]

- Chinyere, D.C.; Asoegwu, S. An Evaluation of Briquettes from Sawdust and Corn Starch Binder; International Journal of Technology: Owerri, Nigeria, 2016. [Google Scholar]

- Bello, R.S.; Olorunnisola, A.O.; Omoniyi, T.E.; Onilude, M.A. Performance of Briquettes Produced from Sawdust of Gmelina Arborea and Montmorillonite Clay as Binder. Bioenergy Stud. Black Sea Agric. Res. Inst. 2023, 3, 1–13. [Google Scholar] [CrossRef]

- Das, R.; Mondal, M.K.; Pramanik, S. Comparison of Compressive Strength of Fly Ash Bonded Flue Dust Briquettes with That of Briquettes Made with Bentonite, Sodium Silicate, Lime, Starch, Pitch, Molasses and Dextrin Binder. Trans. Indian Inst. Met. 2023, 76, 1253–1262. [Google Scholar] [CrossRef]

- Ikelle, I.I.; Ogbuagu, J.O.; Onuegbu, T.U. Effect of binders on the properties of coal briquette blends produced with different biomasses. Ph.D. Thesis; Nnamdi Azikwe University, AWKA, 2017. Available online: https://phd-dissertations.unizik.edu.ng/repos/81136571150_97363885380.pdf (accessed on 20 May 2025).

- Mousa, E.; Ahmed, H.; Söderström, D. Potential of Alternative Organic Binders in Briquetting and Enhancing Residue Recycling in the Steel Industry. Recycling 2022, 7, 21. [Google Scholar] [CrossRef]

- Han, H.; Duan, D.; Yuan, P. Binders and Bonding Mechanism for RHF Briquette Made from Blast Furnace Dust. ISIJ Int. 2014, 54, 1781–1789. [Google Scholar] [CrossRef]

- Uwaoma, R.C.; Henning, C.N.; Bunt, J.R.; Leokaoke, N.T.; Neomagus, H.W.J.P. Comparison of Industrial Wastes as a Binder in the Agglomeration of Coal Fines. Results Eng. 2022, 16, 100729. [Google Scholar] [CrossRef]

- Díaz-Cornejo, S.; Otero, M.C.; Banerjee, A.; Gordillo-Fuenzalida, F. Biological Properties of Exopolysaccharides Produced by Bacillus spp. Microbiol. Res. 2023, 268, 127276. [Google Scholar] [CrossRef] [PubMed]

- Berekaa, M.M.; Ezzeldin, M.F. Exopolysaccharide from Bacillus Mojavensis DAS10-1; Production and Characterization. J. Pure Appl. Microbiol. 2018, 12, 633–640. [Google Scholar] [CrossRef]

- Moghannem, S.A.M.; Farag, M.M.S.; Shehab, A.M.; Azab, M.S. Exopolysaccharide Production from Bacillus Velezensis KY471306 Using Statistical Experimental Design. Braz. J. Microbiol. 2018, 49, 452–462. [Google Scholar] [CrossRef] [PubMed]

- Sánchez-León, E.; Huang-Lin, E.; Amils, R.; Abrusci, C. Production and Characterisation of an Exopolysaccharide by Bacillus Amyloliquefaciens: Biotechnological Applications. Polymers 2023, 15, 1550. [Google Scholar] [CrossRef] [PubMed]

- Effendi, A.J.; Mastroiani, L.J.; Suhardi, S.H.; Ramadan, B.S. Potential Use of Extracellular Polymeric Substances (EPS) of Bacillus Subtilis for Biosorption of Mercury Produced from Soil-Washing Effluent. Bioresour. Technol. Rep. 2023, 22, 101481. [Google Scholar] [CrossRef]

- Gratitude, C.; Patel, B.; Chigondo, M.; Rusere, M.; Maposa, M. Proof of Concept for Using Banana Waste Based Binders in Sawdust Briquetting: Comparative Studies between Raw and Carbonized Sawdust. E3S Web Conf. 2025, 612, 01003. [Google Scholar] [CrossRef]

- Santos Pimenta, A. Charcoal Briquettes Produced with Recycled Coconut Pith. Ciência Florest. 2015. Available online: https://www.scielo.br/j/cflo/a/9hHMCWLTbfn85T3Pd6pkc9j/abstract/?lang=en (accessed on 25 May 2025).

- Deniz, V. Production of Water-Resistant Briquettes from a Mixture of an Imported Bituminous Coal and a Turkish Lignite with Copolymer Binder. Int. J. Coal Prep. Util. 2013, 33, 26–35. [Google Scholar] [CrossRef]

- Dogbe, E.S.; Mandegari, M.; Görgens, J.F. Revitalizing the Sugarcane Industry by Adding Value to A-Molasses in Biorefineries. Biofuels Bioprod. Biorefining 2020, 14, 1089–1104. [Google Scholar] [CrossRef]

- Blesa, M.J.; Miranda, J.L.; Izquierdo, M.T.; Moliner, R. Curing Temperature Effect on Mechanical Strength of Smokeless Fuel Briquettes Prepared with Molasses. Fuel 2003, 82, 943–947. [Google Scholar] [CrossRef]

- Koskela, A.; Suopajärvi, H.; Fabritius, T. Interaction between Coal and Lignin Briquettes in Co-Carbonization. Fuel 2022, 324, 124823. [Google Scholar] [CrossRef]

- Mardiyati, Y.; Tarigan, E.Y.; Prawisudha, P.; Shoimah, S.M.; Rizkiansyah, R.R.; Steven, S. Binderless, All-Lignin Briquette from Black Liquor Waste: Isolation, Purification, and Characterization. Molecules 2021, 26, 650. [Google Scholar] [CrossRef] [PubMed]

- Ezéchiel, K.; Joel, T.K.; Abdon, A.; Roger, D.D. Accessibility and Effects of Binder Types on the Physical and Energetic Properties of Ecological Coal. Heliyon 2022, 8, e11410. [Google Scholar] [CrossRef] [PubMed]

- Baba Hassan, A.; Okegbile, O.J.; Hassan, A.B.; Mohammed, A.; Irekeola, B.J. Effect of Starch and Gum Arabic Binders in the Combustion Characteristics of Briquette Prepared from Sawdust. Artic. Int. J. Sci. Eng. Res. 2014, 5. Available online: https://www.academia.edu/77921924/Effect_of_Starch_and_Gum_Arabic_Binders_in_the_Combustion_Characteristics_of_Briquette_Prepared_from_Sawdust (accessed on 25 May 2025).

- Yan, L.; Liu, Q.Q.; Dong, H.S.; Wang, Y.F.; Li, J.; Zhong, X.; Wang, X.J.; Shi, Q. Manufacturing High-Performance Formcoke from Pulverized Coal Using Potato Residue-Based Biomass Binders. Mater. Today Sustain. 2022, 20, 100237. [Google Scholar] [CrossRef]

- Sabah, E. Utilization of Waste Clay from Coal Preparation Tailings for Brick Production. J. Ore Dress. 2011. Available online: https://www.academia.edu/10899111/Utilization_of_Waste_Clay_from_Coal_Preparation_Tailings_for_Brick_Production (accessed on 25 May 2025).

- Botha, D.L.; Leokaoke, N.T.; Bunt, J.R.; Neomagus, H.W.J.P. Evaluation of Polymer Binders in Briquetting of Coal Fines for Combustion Applications. J. South. Afr. Inst. Min. Metall. 2021, 121, 113–118. [Google Scholar] [CrossRef]

- Henning, C.; Leokaoke, N.; Bunt, J. Waanders FB Testing of Briquettes Made from Witbank Coal Fines with Polyvinyl Alcohol as Binder. In Proceedings of the 10th International Conference on Advances in Science, Engineering, Technology and Healthcare; Universal Researchers, Cape Town, South Africa, 19 November 2018. [Google Scholar]

- Makgobelele, N.W.; Mbaya, R.K.K.; Bunt, J.R.; Leokaoke, N.T.; Neomagus, H.W.J.P. Evaluation of the Mechanical Properties of Wood-Derived Charcoal Briquettes for Use as a Reductant. J. S. Afr. Inst. Min. Metall. 2021, 121, 187–192. [Google Scholar] [CrossRef]

- Chen, J.; Wu, J.; Yan, L.; Zhang, Y.; Guo, Z.; Xie, S.Y.; Li, J.; Yuan, L. The Effect of Alkalized Biomass on Pulverized Coal Molding and Carbonization of Bio-Briquette. Mater. Today Sustain. 2024, 25, 100626. [Google Scholar] [CrossRef]

- Himbane, P.B.; Ndiaye, L.G.; Napoli, A.; Goli, T.; Rozis, J.F.; Ba, M.S.; Ndioukane, R. Influence of Binder Rate, Pyrolysis Temperature and Volume of Biochar Briquettes on CO and PM2.5 Emission Factors and Thermal Efficiency. Energy Sustain. Dev. 2022, 68, 525–531. [Google Scholar] [CrossRef]

- Murakami, K.; Sato, S. Optimization of Mixing Ratios of Binders and Organic Matter for Charcoal Briquette Using Biochars Derived from Water Hyacinth. Solid Fuel Chem. 2024, 58, 226–231. [Google Scholar] [CrossRef]

- Ferronato, N.; Calle Mendoza, I.J.; Gorritty Portillo, M.A.; Conti, F.; Torretta, V. Are Waste-Based Briquettes Alternative Fuels in Developing Countries? A Critical Review. Energy Sustain. Dev. 2022, 68, 220–241. [Google Scholar] [CrossRef]

- Lohmeier, L.; Thaler, C.; Harris, C.; Wollenberg, R.; Schröder, H.W.; Braeuer, A.S. Use of Bentonite and Organic Binders in the Briquetting of Particulate Residues from the Midrex Process for Improving the Thermal Stability and Reducibility of the Briquettes. Steel Res. Int. 2021, 92, 2100210. [Google Scholar] [CrossRef]

- Yunusa, S.U.; Mensah, E.; Preko, K.; Narra, S.; Saleh, A.; Sanfo, S. A Comprehensive Review on the Technical Aspects of Biomass Briquetting. Biomass Convers. Biorefinery 2024, 14, 21619–21644. [Google Scholar] [CrossRef]

- Singh, V.; Singh, A. Briquetting Technologies for Minerals and Metallurgical Applications: A Review. Miner. Process. Extr. Metall. Rev. 2025, 1–20. [Google Scholar] [CrossRef]

- Nurek, T.; Gendek, A.; Roman, K.; Dąbrowska, M. The Effect of Temperature and Moisture on the Chosen Parameters of Briquettes Made of Shredded Logging Residues. Biomass Bioenergy 2019, 130, 105368. [Google Scholar] [CrossRef]

- Saeed, A.A.H.; Harun, N.Y.; Bilad, M.R.; Afzal, M.T.; Parvez, A.M.; Roslan, F.A.S.; Rahim, S.A.; Vinayagam, V.D.; Afolabi, H.K. Moisture Content Impact on Properties of Briquette Produced from Rice Husk Waste. Sustainability 2021, 13, 3069. [Google Scholar] [CrossRef]

- Pang, L.; Yang, Y.; Wu, L.; Wang, F.; Meng, H. Effect of Particle Sizes on the Physical and Mechanical Properties of Briquettes. Energies 2019, 12, 3618. [Google Scholar] [CrossRef]

- Setter, C.; Ataíde, C.H.; Mendes, R.F.; De Oliveira, T.J.P. Influence of Particle Size on the Physico-Mechanical and Energy Properties of Briquettes Produced with Coffee Husks. Environ. Sci. Pollut. Res. 2021, 28, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.; Bhattarai, R.; Li, Y.; Si, B.; Dong, X.; Wang, T.; Yao, Z. Towards Sustainable Coal Industry: Turning Coal Bottom Ash into Wealth. Sci. Total Environ. 2022, 804, 149985. [Google Scholar] [CrossRef] [PubMed]

- Lv, B.; Luo, Z.; Fu, Y.; Zhang, B.; Qin, X.; Zhu, X. Particle Mixing Behavior of Fine Coal in Density Control of Gas–Solid Separation Fluidized Bed. Particuology 2020, 50, 76–87. [Google Scholar] [CrossRef]

- Mani, T.; Murugan, P.; Abedi, J.; Mahinpey, N. Pyrolysis of Wheat Straw in a Thermogravimetric Analyzer: Effect of Particle Size and Heating Rate on Devolatilization and Estimation of Global Kinetics. Chem. Eng. Res. Des. 2010, 88, 952–958. [Google Scholar] [CrossRef]

- Haidai, O.A.; Pavlychenko, A.V.; Koveria, A.S.; Ruskykh, V.V.; Lampika, T.V. Determination of granulometric composition of technogenic raw materials for producing composite fuel. Nauk. Visnyk Natsionalnoho Hirnychoho Universytetu 2022, 4, 52–58. [Google Scholar] [CrossRef]

- Nati, C.; Spinelli, R.; Fabbri, P. Wood Chips Size Distribution in Relation to Blade Wear and Screen Use. Biomass Bioenergy 2010, 34, 583–587. [Google Scholar] [CrossRef]

- Leokaoke, N.T.; Bunt, J.R.; Neomagus, H.W.J.P.; Waanders, F.B.; Strydom, C.A.; Mthombo, T.S. Manufacturing and Testing of Briquettes from Inertinite-Rich Low-Grade Coal Fines Using Various Binders. J. S. Afr. Inst. Min. Metall. 2018, 118, 83–88. [Google Scholar] [CrossRef]

- Tamilvanan, A. Preparation of Biomass Briquettes Using Various Agro- Residues and Waste Papers. J. Biofuels 2013, 4, 47–55. [Google Scholar] [CrossRef]

- Wang, X.D.; Xue, J.J.; Zhu, Y.J.; Liu, C.R.; Hu, X.Y.; Liang, H.; Dong, C.Q. The Study of Combustion Characteristics of Corn Stalks and Cobs via TGA-DTG-DSC Analysis. IOP Conf. Ser. Earth Environ. Sci. 2019, 354, 012130. [Google Scholar] [CrossRef]

- Miao, M.; Deng, B.; Kong, H.; Yang, H.; Lyu, J.; Jiang, X.; Zhang, M. Effects of Volatile Matter and Oxygen Concentration on Combustion Characteristics of Coal in an Oxygen-Enriched Fluidized Bed. Energy 2021, 220, 119778. [Google Scholar] [CrossRef]

- Imran, A.M.; Widodo, S.; Irvan, U.R. Correlation of Fixed Carbon Content and Calorific Value of South Sulawesi Coal, Indonesia. IOP Conf. Ser. Earth Environ. Sci. 2020, 473, 012106. [Google Scholar]

- Adeleke, A.A.; Odusote, J.K.; Ikubanni, P.P.; Orhadahwe, T.A.; Lasode, O.A.; Ammasi, A.; Kumar, K. Ash Analyses of Bio-Coal Briquettes Produced Using Blended Binder. Sci. Rep. 2021, 11, 1–9. [Google Scholar] [CrossRef] [PubMed]

- ASTM D3038-93; Standard Test Method for Drop Shatter Test for Coke. American Society for Testing and Materials: West Conshohocken, PA, USA, 1999.

- BS EN ISO 17831-2:2015; Solid Biofuels-Determination of Mechanical Durability of Pellets and Briquettes. International Organization for Standardization: Geneva, Switzerland, 2015.

- Richards, S.R. Physical Testing of Fuel Briquettes. Fuel Process. Technol. 1990, 25, 89–100. [Google Scholar] [CrossRef]

- ISO 4700:2015; Iron Ore Pellets for Blast Furnace and Direct Reduction Feedstocks-Determination of the Crushing Strength. International Organization for Standardization: Geneva, Switzerland, 2015.

- ASTM D3080/D3080M-23; Standard Test Method for Direct Shear Test of Soils Under Consolidated Drained Conditions 1. ASTM: West Conshohocken, PA, USA, 2011.

- ASTM D5865-07a; Test Method for Gross Calorific Value of Coal and Coke. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM E871; Test Methods for Analysis of Wood Fuels. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM D1102-84; Test Method for Ash in Wood. ASTM International: West Conshohocken, PA, USA, 2021.

- ISO 14064; International Standard for GHG Emissions Inventories and Verification. International Organization for Standardization: Geneva, Switzerland, 2018.

- Liu, Z.; Zhang, Y.; Zhong, L.; Orndroff, W.; Zhao, H.; Cao, Y.; Zhang, K.; Pan, W.P. Synergistic Effects of Mineral Matter on the Combustion of Coal Blended with Biomass. J. Therm. Anal. Calorim. 2013, 113, 489–496. [Google Scholar] [CrossRef]

- Theron, J.A.; Le Roux, E. Representation of Coal and Coal Derivatives in Process Modelling. J. S. Afr. Inst. Min. Metall. 2015, 115, 339–349. [Google Scholar] [CrossRef]

- The Presidency Just Energy Transition Implementation Plan (JET IP). 2024. Available online: https://justenergytransition.co.za/wp-content/uploads/2024/12/Just-Energy-Transition_Progress-Report-v2.pdf (accessed on 18 May 2025).

- Acordi, J.; Simão, L.; Faraco, M.N.S.; Borgert, C.H.; Olivo, E.; Montedo, O.R.K.; Raupp-Pereira, F. Waste Valorization of Coal Mining Waste from a Circular Economy Perspective: A Brazilian Case Study Based on Environmental and Physicochemical Features. Resour. Policy 2023, 80, 103243. [Google Scholar] [CrossRef]

- Chitranshi, J. Global Coal Briquettes Market Overview; Market Research Future: Pune, India, 2024. [Google Scholar]

- Advancing the Future of Sustainable Coal;Coaltech 2025. Available online: https://coaltech.co.za/wp-content/uploads/2025/02/Coaltech-Reasons-to-Join-our-Community.pdf (accessed on 18 May 2025).

| Coal Type | Fine Coal Generation (% of Total) | Size Range | Typical Uses | Processing Methods | Raw Coal HHV (MJ/kg) | Fine Coal HHV (MJ/kg) | Suitability for Briquetting | References |

|---|---|---|---|---|---|---|---|---|

| Anthracite | ~20% | <6 mm (fines); <0.15 mm (ultrafines) | Reductants, filtration, and domestic heating | Screening, drying, and briquetting | 30–33 | 20–25 | High—low moisture; strong structure | [1,58,59] |

| Bituminous | ~15% | 0.15 mm–6 mm; <0.15 mm | Power gen., export, cement kilns, and industrial boilers | Dense medium cyclones, spirals, flotation, and dewatering | 24–30 | 17–24 | High—commonly briquetted globally | [1,25,56] |

| Sub-bituminous | ~10% | 0.15 mm–6 mm; <0.15 mm | Power generation (Eskom) and synthetic fuels (Sasol) | Screening, flotation, and drying | 18–23 | 15–20 | Moderate—needs additives/drying | [1,2,56] |

| Lignite | <5% | <6 mm; <0.15 mm | Low-grade fuel (limited economic use) | Minimal processing | 10–18 | 8–14 | Low—high moisture, poor binding | [1,57] |

| Biomass Type | Source Regions | Availability (Est.) | Suitability | Physiochemical Characteristics | References |

|---|---|---|---|---|---|

| Sawdust and wood chips | Mpumalanga, Eastern Cape, and KwaZulu-Natal | >440 kilotonnes/annum | High heating value; low ash. | Moisture: 10–50% Higher Heating Value: 16–20 MJ/kg Mineral content: 1–3% Bulk density: 160–190 kg/m3 | [61,62,63] |

| Bagasse | KwaZulu-Natal and Mpumalanga | >7 million kilotonnes/annum | Readily available from sugar mills. | Moisture: 45–55% Higher Heating Value: 15–19 MJ/kg Mineral content: 1–3% Bulk density: 150–300 kg/m3 | [63,64,65,66] |

| Wheat/maize straw | Free State, North West, and Gauteng | >600 tonnes/annum | Fibrous; good structural filler. | Moisture: 10–15% Higher Heating Value: 13–15 MJ/kg Mineral content: 5–8% Bulk density: 80–120 kg/m3 | [63,67] |

| Sunflower husks | North West and Limpopo | ~733 kilotonnes/annum | Good blend with coal fines. | Moisture: 8–12% Higher Heating Value: 16–18 MJ/kg Mineral content: 2–3% Bulk density: 160–200 kg/m3 | [68,69] |

| Corn cobs/Stalks | Free State, North West, and Limpopo | >8 million tonnes/annum | Improves combustion efficiency. | Moisture: 12–20% Higher Heating Value: 14–16 MJ/kg Mineral content: 2–4% Bulk density: 180–220 kg/m3 | [63,66] |

| Macadamia shells | Mpumalanga and Limpopo | ~68 kilotonnes/annum | High energy density; low sulfur. | Moisture: 6–10% Higher Heating Value: 18–20 MJ/kg Mineral content: <1% Bulk density: 350–450 kg/m3 | [70,71] |

| Alien invasive biomass—black wattle | National (Working for Water program) | ~130 kilo-hectars (commercial) | Ecological benefit + fuel value. | Moisture: 15–35% Higher Heating Value: 16–19 MJ/kg Mineral content: 1–3% Bulk density: 200–300 kg/m3 | [72,73,74] |

| Binder Type | Examples | Characteristics | Advantages | Limitations | References |

|---|---|---|---|---|---|

| Organic Binders | Molasses, starch, lignin, tar pitch, and gums | Renewable, combustible, and biodegradable | Clean-burning (e.g., starch); improves cohesion; renewable sources. | Poor thermal stability, high cost (e.g., PVA), and tar-based binders emit pollutants. | [88,89,90] |

| Inorganic Binders | Bentonite clay, cement, lime, and gypsum | Non-combustible and thermally stable | Readily available; improves mechanical strength and water resistance. | Increases mineral content, reduces the higher heating value, and unsuitable for domestic use. | [91,92,93] |

| Synthetic/Chemical | Bitumen, resins, sodium silicate, PVA, and synthetic polymers | Industrial-grade strength and chemically engineered | High performance in metallurgical settings. | Expensive, potential for toxic emissions, and not eco-friendly. | [94,95,96] |

| Emerging/Green | Microbial biopolymers, biochar binders, and waste binders | Biodegradable, carbon-neutral potential, and locally sourced | Eco-friendly; supports circular economy; often cost-effective. | Still under research, performance may vary, and scalability challenges. | [97,98,99,100,101] |

| Compound Binders | Molasses + lime; starch + clay; and biomass + bentonite | Combination of organic and inorganic or synthetic types | Balanced performance; tailored to specific applications. | Requires optimization, and may increase complexity or cost. | [102,103] |

| Variable | Optimal Range | Function/Effect | References |

|---|---|---|---|

| Pressure | 80–150 MPa | Facilitates particle bonding through plastic deformation, friction, and van der Waals forces. | [51,87] |

| Temperature | Ambient to 200 °C | Enhances binder reactivity and softens biomass lignin in binderless briquetting. | [89,106,123] |

| Moisture Content | 8–15 wt% | Acts as binder activator and lubricant; affects compaction and drying behavior. | [14,123,124] |

| Particle Size | ≤3 mm (ideal: 0.5–2 mm) | Impacts packing density and inter-particle contact area. | [125,126] |

| Mixing Time | Mixing: 5–30 min | Ensures uniform binder dispersion and sufficient bond formation under pressure. | [79,118] |

| Residence Time | 1–5 s (press dwell time) | Allows stress relaxation and bond formation during compression. | [39,49,51] |

| Sector | Source Material | Agglomeration Technique | Application/End Product | Key Benefit | Region | References |

|---|---|---|---|---|---|---|

| Residential and Small Industry | Coal fines and lignite | Briquetting | Domestic fuel for stoves and boilers | Improved combustion and easier handling | Global/SA | [17] |

| Metallurgy (Steel) | Fine coal and pitch binder | Partial briquetting | Coke oven feedstock (e.g., Iscor) | Enhanced coke strength and reduced dust loss | SA | [80,122,132] |

| Energy Conversion | Fine coal (binderless) | High-pressure briquetting | Gasifier feedstock (e.g., Sasol) | Feedstock densification and binder cost reduction | SA | [14,21,56,57] |

| Industrial Processes | Coal fines and biomass | Briquetting | Co-firing fuel in boilers and furnaces | Renewable blending and reduced emissions | Global/SA | [87,89,127] |

| Circular Economy | Coal waste and rejects | Agglomeration and briquetting | Fuel or additives for other industries | Waste valorization and reduced disposal cost | SA | [150] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramdas, V.; Njokweni, S.G.; Letsoalo, P.; Motaung, S.; Ramchuran, S.O. Bio-Coal Briquetting as a Potential Sustainable Valorization Strategy for Fine Coal: A South African Perspective in a Global Context. Energies 2025, 18, 3746. https://doi.org/10.3390/en18143746

Ramdas V, Njokweni SG, Letsoalo P, Motaung S, Ramchuran SO. Bio-Coal Briquetting as a Potential Sustainable Valorization Strategy for Fine Coal: A South African Perspective in a Global Context. Energies. 2025; 18(14):3746. https://doi.org/10.3390/en18143746

Chicago/Turabian StyleRamdas, Veshara, Sesethu Gift Njokweni, Parsons Letsoalo, Solly Motaung, and Santosh Omrajah Ramchuran. 2025. "Bio-Coal Briquetting as a Potential Sustainable Valorization Strategy for Fine Coal: A South African Perspective in a Global Context" Energies 18, no. 14: 3746. https://doi.org/10.3390/en18143746

APA StyleRamdas, V., Njokweni, S. G., Letsoalo, P., Motaung, S., & Ramchuran, S. O. (2025). Bio-Coal Briquetting as a Potential Sustainable Valorization Strategy for Fine Coal: A South African Perspective in a Global Context. Energies, 18(14), 3746. https://doi.org/10.3390/en18143746