Abstract

The rise of hybrid electric vehicles (HEVs) marks a shift away from traditional engines driven by environmental and economic concerns. With the rapid growth of HEVs worldwide, their reliability becomes of utmost concern; thus, guaranteeing the proper operation of HEVs is a crucial quest. Condition-based monitoring (CBM), which intends to observe different kinds of parameters in the system to detect defects and reduce any unwanted breakdowns and equipment failure, plays an efficient role in enhancing HEVs’ reliability and ensuring their healthy operation. The permanent magnet machine (PMM) is the most used electric machine in the electric propulsion system of HEVs, as well as the most expensive. Hence, the condition monitoring of this machine is of great importance. The magnet crack is one of the most severe faults that may arise in this machine. Artificial intelligence (AI) is showing high capability in the field of CBM, fault detection, and fault identification and prevention. Hence, the aim of this paper is to present two data-based fault detection approaches, which are the support vector machine (SVM) and the Hidden Markov Model (HMM). Their capability to detect primitive faults like tiny cracks in the machine’s magnet will be shown. Applying and evaluating various CBM methods is essential to identifying the most effective approach to maximizing reliability, minimizing downtime, and optimizing maintenance strategies. A strategy to specify the remaining useful life (RUL) of the defected element is proposed.

1. Introduction

1.1. Background

An HEV is a vehicle that merges a conventional internal combustion engine (ICE) propulsion system with an electric propulsion system and is also called a hybrid vehicle drivetrain. The electric share of the propulsion mechanism is added to achieve either better fuel economy or better performance compared with conventional vehicles [1]. HEVs can be classified as micro, mild, or full hybrids according to the percentage of conventional engine power versus electrical power [2]. HEVs can run solely on a combustion engine, solely on an electric machine, or on a combination of both [3].

1.2. Electrical Machines Used in HEVs and Relevant Faults

The electrical machines used in HEV applications are direct current (DC) machines, induction motors (IMs), permanent magnet machines (PMMs), and switched reluctance machines (SRMs) [1]. Effectively, the most used ones are IMs and PMMs [4]. PMMs are advantageous over IMs in terms of robustness, power density, and efficiency [1,5]. With the increased use of PMMs in modern hybrid vehicles, relevant faults can arise, leading to serious damage and extremely serious consequences. These faults can be electrical or mechanical, like bearing faults, stator faults, rotor faults, shaft faults, or eccentricity faults [6]. Bearing failure is the most occurring failure in electrical machines; however, in PMMs, the most severe fault is demagnetization because of the price of the defected element, which is the magnet, and its function [7,8]. Demagnetization, which is a partial or total loss of magnet power, is a major problem in PMMs [9]. The causes of demagnetization are numerous [10,11]: cracks in the magnet, loads that need high starting torque, magnet corrosion, high temperature, internal short circuit, etc. Therefore, to ensure reliability, reduce downtime, and optimize maintenance strategies in HEVs, predictive maintenance emerges as a promising approach to achieving these objectives.

1.3. Literature Review

Predictive maintenance techniques such as CBM are efficient in the field of electrical machines. They enable the early detection of equipment degradation and facilitate proactive decision making.

In the early stages of the development of CBM, the model-based approach provided insights into the physical mechanisms, giving rise to condition monitoring signatures [12]. However, while new complex electrical machine systems continue to appear where physical models, analysis, and rules are not developed, model-based methods are inadequate. Relying on real time data and using sensors to continuously assess a system’s condition while it is in use are more effective and responsive. The information gathered can be used to identify patterns, foretell failure, and determine the amount of useful life still left [13].

In these circumstances, data-based approaches had been developed [14]. Therefore, data-driven approaches will be investigated in this study, where data are solely presented as a priori knowledge to the diagnostic system; a physical understanding of the model is not required.

Numerous studies utilizing data-based and machine learning methodologies have been performed to enhance decision making, safety, and efficiency in electrical systems while also contributing to resource preservation and CBM [15]. The most popular techniques are neural network (NN) approaches. Convolutional neural network (CNN) technology was used, for instance, in [16], where the authors propose an online bearing monitoring system for the detection and localization of bearing faults. The trial outcomes demonstrated that this technique successfully identified the bearing damage. For monitoring the state of the flywheel, a CNN was also employed in [17]. Experimental results based on vibration signals from an actual flywheel demonstrated that faulty operational states can be accurately detected. In [18], an artificial neural network (ANN) algorithm optimized by a genetic algorithm was proved to be efficient in the condition monitoring of the gearbox of a turbine. NNs were also used for PMMs. In [19], the recurrent neural network (RNN) was revealed to have a good application prospect in the field of permanent magnet synchronous motor fault detection. However, it is rarely applied in PMM fault detection applications.

The available data to train the selected model are relatively compact, as will be clarified later; hence, neural networks and data mining were eliminated, since they require much bigger data sets than the one available, despite the fact that they have a lot of benefits. The support vector machine was chosen instead because this approach is robust to process knowledge and mainly because it gives great results and high accuracy when dealing with a relatively small data set when compared with neural networks and data mining. In addition, it relies on structural risk minimization, which improves generalization and allows one to account for non-linearity processes by using flexible kernels.

The SVM was published in 1995 and started to be widely applied in the biological and other sciences, in hand-written character recognition, classification by satellite, like SAR, and classification of images. However, researchers who have applied SVM for CBM since it gained popularity are few. In recent years, SVM diagnosis and prognosis is tending to develop toward expertise orientation in CBM. In [20], multi-class fault detection in electrohydraulic systems using SVM and pressure signal analysis was realized. The SVM method is implemented to detect a broken rotor bar in a 15kW induction motor. The experimental results in these articles have demonstrated the ability of the SVM approach to accurately detect failures. Thus, the use of this approach is still rare in the HEV’s PMM applications. The concerned domains are generally restricted to mechanical machinery, such as, for instance, roller bearings, gear box, etc.

In addition, we opt for the hidden Markov model as the second method in our study because it is simple and does not require a large data set. Generally, HMM is utilitarian in its capability to prognosticate the changes in the system’s sequential states based on sequential observations. Consequently, HMM is useful for systems that have a link between their specific inner states and a set of exterior visible observations. The internal states are the unknowns; the on-going state is thoroughly dependent on the instant preceding one. This is known as the Markov process. The HMM can then guess unobservable health states making use of observable sensor signals. In [21], HMM was applied to identify different levels of wear faults in the gear. Vibration signal features were used as the input to this model. The classification rate, based on experimental results, reached 100%. The paper in [22] aims to detect short circuit faults using HMM and predict the RUL of equipment where features such as time and frequency are the input of the model. Due to a lack of data, the HMM is trained using 18 experimental observation probability densities. In [23], an HMM was implemented in order to predict the possibility of failures in PMM used in the HEV application. The input of the model consists of features extracted from vibration, torque, and temperature signals. The faults that may occur are inter-turn short circuit, magnet crack and eccentricity faults.

1.4. Contribution

It is noted that the data-based approaches, like SVM and HMM, used in the fault detection and CBM schemes are very efficient and are used in many applications. However, the most common applications are mechanical fault detection, like gear and bearing fault detection. Few studies have specifically addressed the detection of demagnetization faults. Moreover, prior research has not employed SVM or HMM for the prognosis of demagnetization faults or the detection of magnet crack faults in the PMM of HEVs.

Recognizing the critical role of CBM in HEV applications and considering the availability of several techniques that are suitable for this purpose, the objective of this study is to identify the most effective method for detecting demagnetization faults.

This study will explore two data-driven methodologies, SVM and HMM, for the detection of demagnetization faults, expressed as a crack in the magnet of the PMM used in HEV applications. Both approaches will be applied to the same fault scenario within the same system context, with the objective of comparing their performance and efficiency to determine the most suitable technique for this specific application.

The HEV under consideration is a mild HEV equipped with a 15 kW 12-pole surface permanent magnet machine. The radial length of the surface permanent magnet of the machine is 4.5 mm. The considered fault is a radial crack in a magnet of the PMM used in HEV application. The crack that will be considered in this study is a radial crack with depths of 0.5, 1, 1.5 and 2 mm. A deeper crack is not accounted for because applying CBM is about assuring a predictive action before a fault occurs or when the fault is in its preliminary state.

In this study, the PMM employed in the HEV is modeled in healthy and faulty conditions using dynamic finite element analysis, where the fault scenario is introduced by simulating a crack in one of the magnets [24]. The objective of this model is to generate synthetic data—vibration, temperature, and torque signals, which will be used for training the approaches under evaluation.

This paper is organized as follows. Section 2 represents the machine model and the features extracted from it. Those features are used as inputs of the CBM approaches, to train the SVM and the HMM. The application of SVM and HMM models is illustrated in Section 3 and Section 4, respectively. A comparison between the results of the two approaches will be presented in Section 5. A decision on the more suitable approach for CBM applied in an application like an electrical machine in HEV will be elaborated. At the end, a suggested method based on RUL computation will be proposed in Section 6.

2. System Model and Feature Extraction

2.1. Finite Element Model

Data-based methods, as their name reveals, count on data collected mainly from sensors. Nevertheless, it is hard to have a prototype of PMM where flaws are incorporated and relevant data are gradually assembled with ease. Consequently, building an accurate machine model becomes a crucial requirement.

The finite element method (FEM) plays an essential role in accurately modeling and analyzing electrical machines. It provides deep insight into the machine’s fundamental principles and physical behavior, enabling precise representation of complex magnetic circuit topologies, detailed winding configurations, and nonlinear magnetic material characteristics. FEM excels at calculating key machine parameters—such as magnetic field distribution, flux density, electromagnetic torque, stator current in addition to temperature and vibration—with high accuracy. Furthermore, it is particularly valuable in fault analysis, as it can effectively capture localized magnetic saturation effects, making it an essential tool for reliable machine diagnostics, prognostics and performance evaluation [25,26].

In this paper, we will take advantage of the global electromagnetic, thermal and vibration FEM developed in [27] for PMM under normal conditions of the machine and under faulty conditions, where a fracture is integrated in one magnet of the machine. To validate the model, a comparison was conducted in [28] where the results of the electromagnetic FEM model and the analytical model match. We mention that the machine model is dynamic, where the required data is collected as a function of time. The software used is Matlab 2018. Virtual sensors are placed on the periphery of the machine model, in order to collect the synthetic vibration and temperature data used in this study [29]; a virtual sensor is placed at the shaft of the machine model to collect the synthetic torque data used in this study. Torque, temperature and vibration data will be retrieved from the global FEM under normal conditions and in the case of the magnet crack fault.

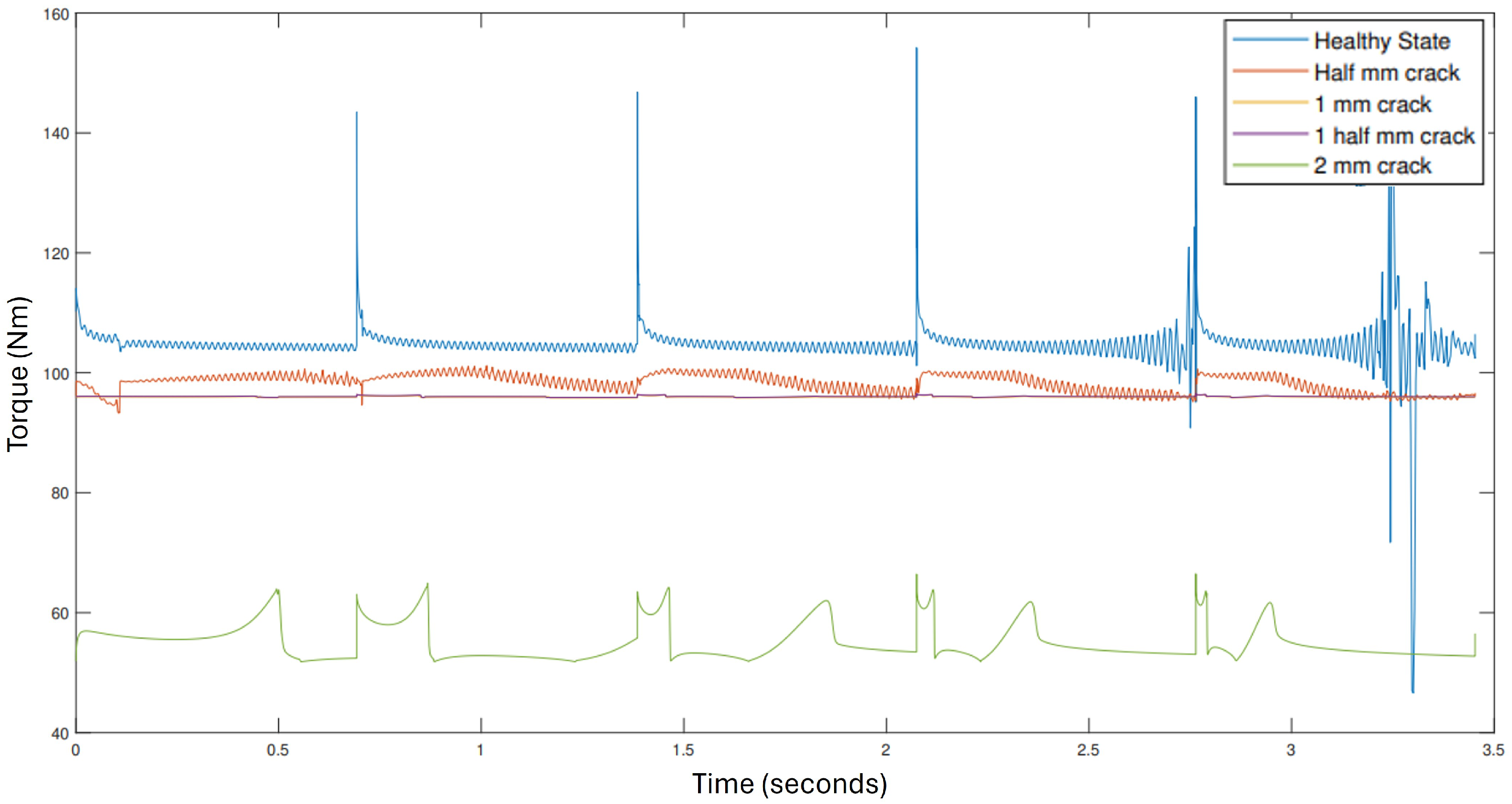

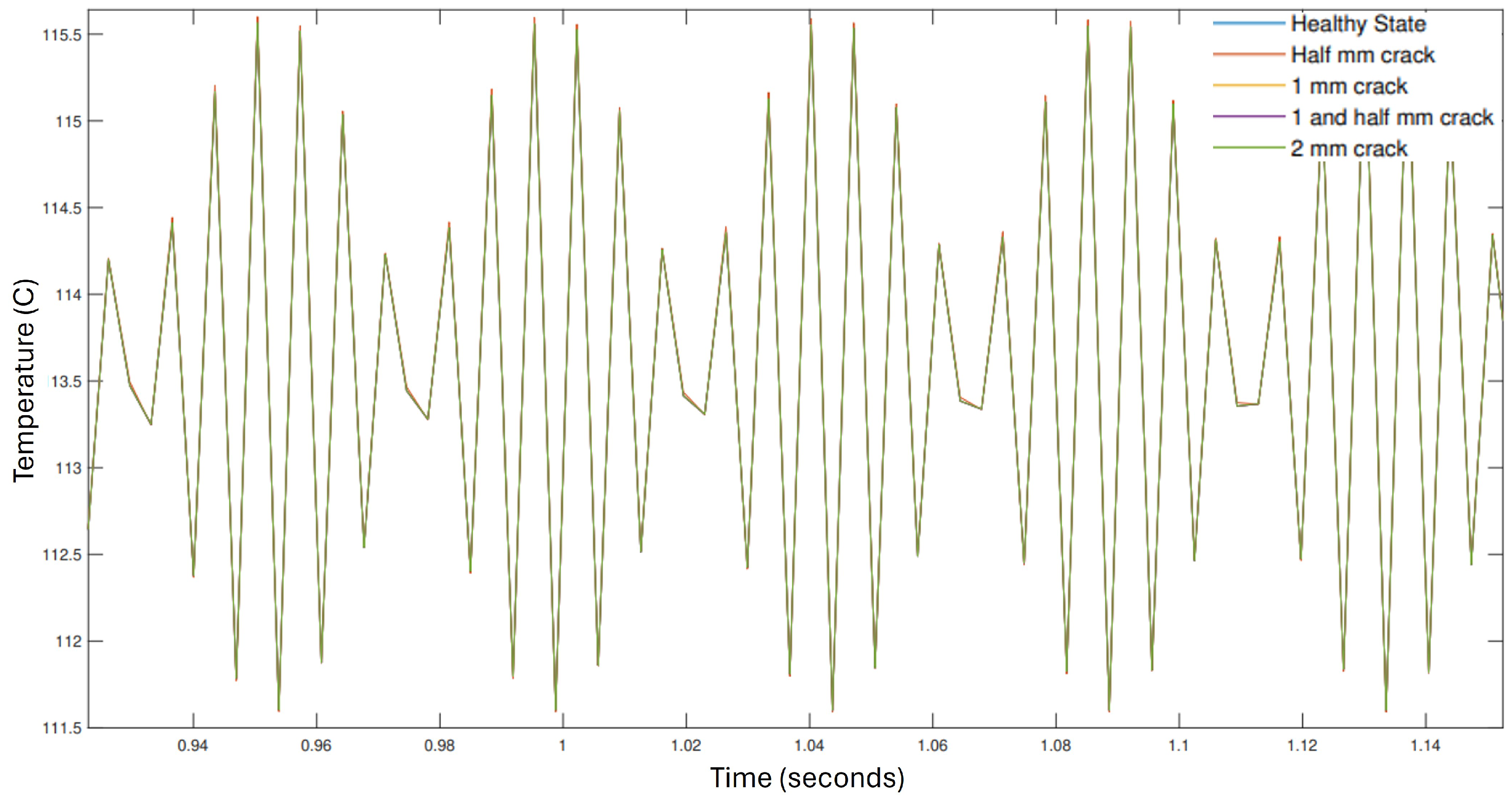

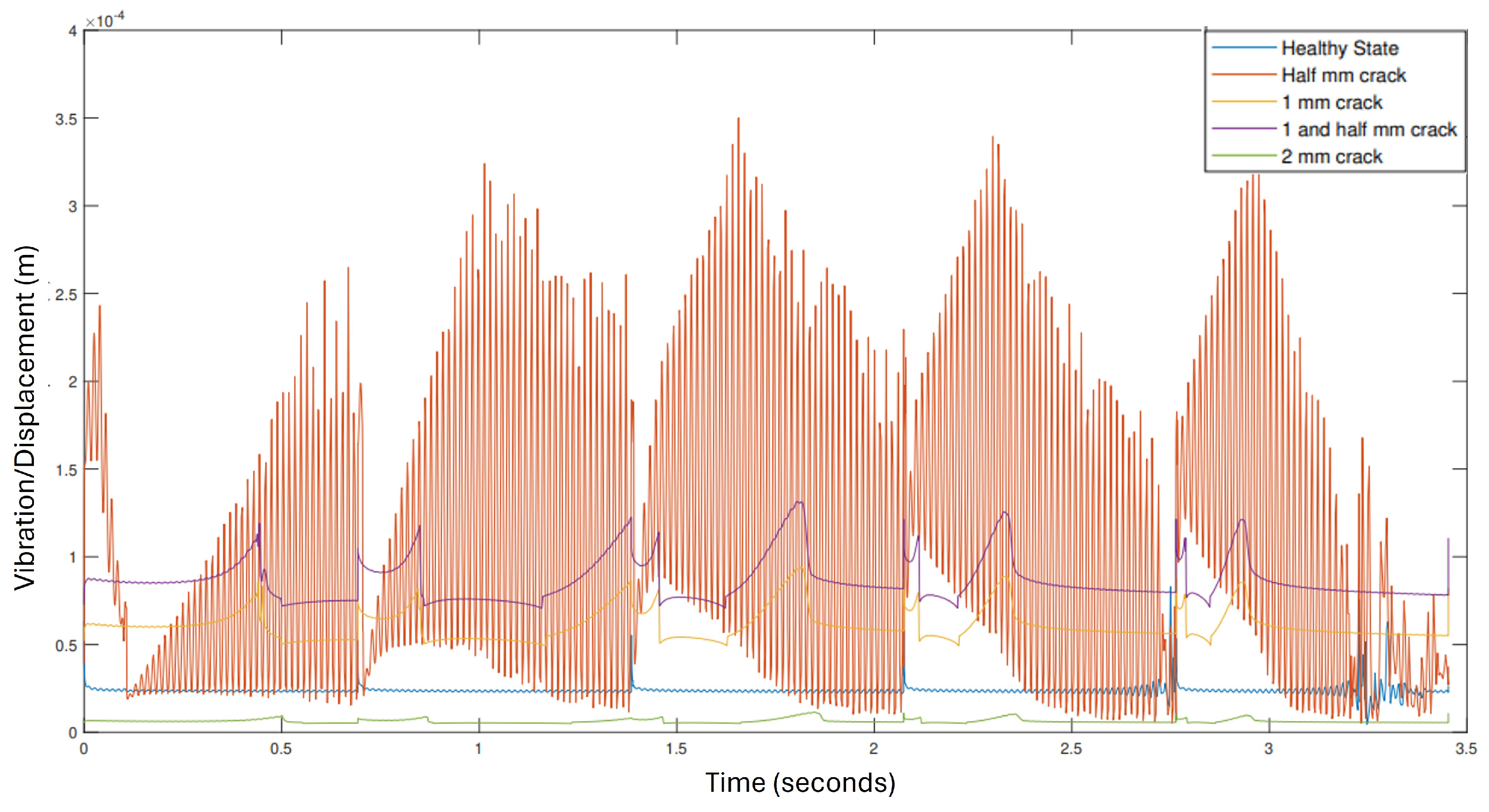

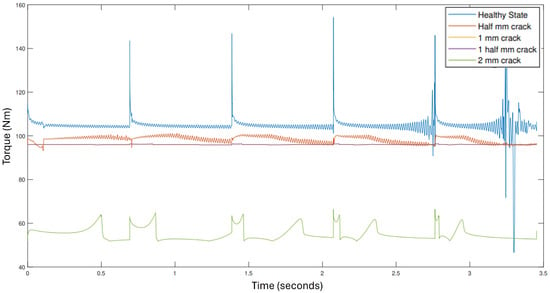

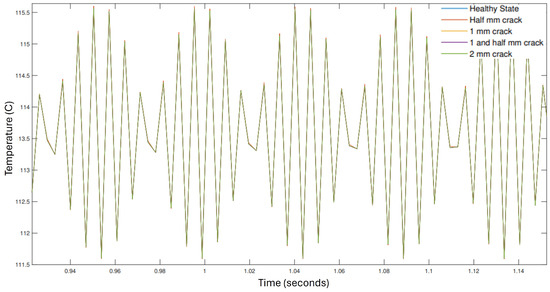

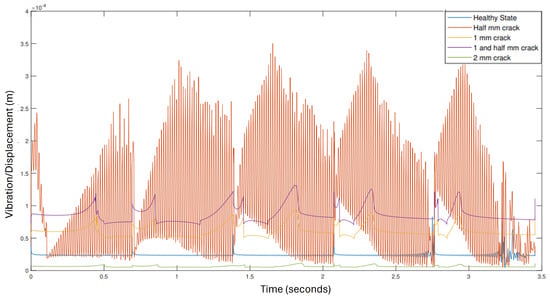

As previously mentioned, we will use the features of the collected signals to train both data-driven methods. Figure 1 shows instantaneous machine torque in different machine states. The considered faulty states in this study are radial cracks with the following depths: 0.5 mm, 1 mm, 1.5 mm and 2 mm. Figure 2 shows temperature for different machine states. Figure 3 shows vibration for different machine states.

Figure 1.

Instantaneous machine torque for different machine states.

Figure 2.

Instantaneous machine temperature for different machine states.

Figure 3.

Instantaneous machine vibration for different machine states.

2.2. Feature Selection

A feature in machine learning is a quantifiable characteristic of an available adequate data sample that is fed into the model to train it. An essential first step in developing effective classification algorithms is the selection of independent, discriminating, and informative features. Traditional and frequently used features for signals in the frequency and temporal domains can be classified as statistical, like mean, peak-to-peak values, RMS, shape factor, crest factor, kurtosis, skewness, standard deviation, and variance, or spectral, like power spectral density, average power spectral density, and the amplitude of the frequency components. The useful features of the three types of signals were examined in the time and frequency domains for fault detection. As a result, some features, like shape factor, are poor fault indicators, since they are nearly constant along machine states, while others, like mean, are very efficient for fault detection, since they show high discrepancy accordingly. Parameters’ features extracted from the FEM are illustrated in Table 1 for different machine states.

Table 1.

Evaluation of the OAA and OAO methods.

The average of the torque, the average of the vibration and the amplitudes of frequency components of the temperature signals over one revolution were the designated features; those will be the input of our data-driven models. We recall that the data are collected from the three previously mentioned sensors placed virtually on the periphery of the machine model. In terms of sensor error and accuracy, the selected sensors are reliable where the torque sensor has a value of ±0.05. The values of the designated features are distinct, and the sensors’ error is very small; hence, this error will not affect the diagnostic decision.

3. Support Vector Machines (SVM)

SVM is a supervised machine learning technology that has recently been used for both classification and regression in applications including face detection, image recovery, and defect detection. This approach is advantageous since it uses less computing power and has high precision. It tends to find the most effective hyperplane for splitting a dataset into two entities. Since the classifier’s error decreases as the margin widens, the hyperplane that has the greatest distance to the nearest training data point for each class obtains a satisfactory separation [30]. There are three different SVM types: Multi-Class SVM, Non-Linear SVM, and Linear SVM.

3.1. Linear SVM

SVM aims to locate the best hyperplane in two dimensions or more in order to divide the studied space into distinctive entities. The hyperplane is defined at the maximum margin [31].

Consider a dataset with n points, expressed as (), ......, () and used for training. is set to 1 or −1 according to the class to which the point fits. Every is a real vector in p-dimension. The aim of the model is to find the “maximum-margin hyperplane” that separates the set of points having = −1 from other ones. This hyperplane is chosen so as to maximize the distance between it and the closest point from each group. The hyperplane can be expressed as a set of points fulfilling the following equation: · − b = 0. is the normal vector to the hyperplane. The offset of the hyperplane from the origin along the normal vector is given by . The SVM mechanism consists of placing a line between the two classes and arranging it so as to maximize the margin. The SVM tries to align this linear boundary so that there is a maximum distance between it and the closest data point for each class. The middle of this margin between the two points is where the boundary will be established. The closest data points are recognized as support vectors and are utilized to set the margins [32]. To train data that is separated linearly, a hard margin is used. Otherwise, a soft margin is used.

3.2. Non-Linear SVM

The non-linear SVM was first suggested by Vapnik in 1992, and it is suitable for data points that are not linearly distinguishable in p-dimensional space. Mapping p-dimensional space onto a much higher one is a solution to model the system. The model proposes applying the Kernel trick to draw a customized non-linear hyperplane. Each kernel clutches a non-linear kernel function K(x,y), expressed as ·. Several kernels have been developed; we mention the polynomial (homogeneous) kernel, the polynomial (non-homogeneous) kernel and the radial basis function kernel.

3.3. Multi-Class SVM

The aim of multi-class SVM is assigning labels to patterns by utilizing support vector machines, where the labels are extracted from a defined set of distinct constituents. This is achieved by reducing a single multi-class problem to multiple binary ones. This reduction can be ensured by two approaches [32]:

- One against all: The one-against-all (OAA) approach was among the first SVM multi-class classification methods. A number of classes ‘n’ of the SVM models are constructed. The ith SVM is trained with all the examples in the ith class with positive tags, while all the other examples are considered negative tags.

- One against one: The OAO “one-against-one” strategy consists of building an SVM for every pair of classes. Consequently, to assign each sample to the relevant distinct ‘n’ classes, SVMs are trained. Generally, each SVM votes for one class, then according to the maximum vote, the classification of an unknown pattern is executed.

3.4. SVM in Our Application

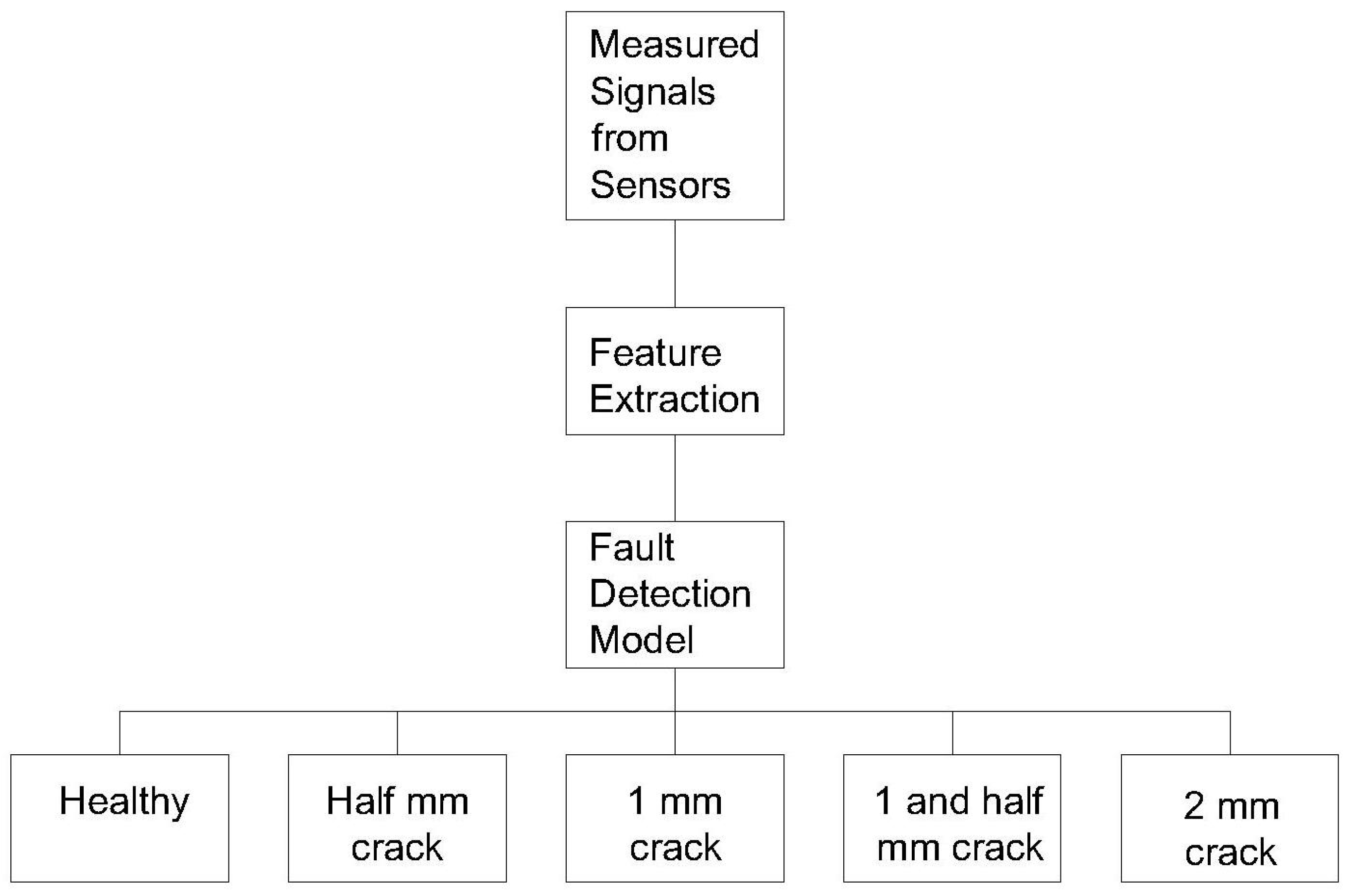

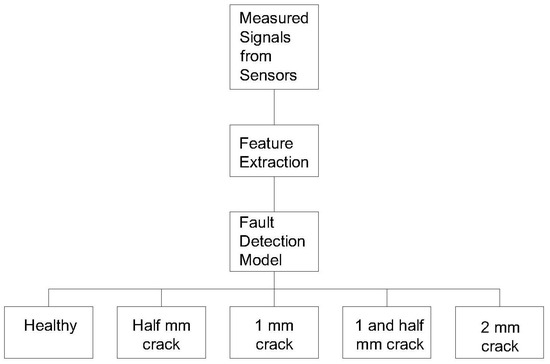

A fault detection strategy using the multi-class support vector machine will be implemented to discover the presence of a magnet’s crack at an early stage and determine the precise length of this crack. Our model will be trained on features extracted from torque, vibration and temperature measurements. The raw dataset acquired from the three sensors is analyzed over a single machine revolution, consisting of 200 sampling points. The output will be the state of the machine, whether it is a machine in good condition or a machine with a magnet crack of different lengths. The chart in Figure 4 represents this procedure.

Figure 4.

Fault detection strategy.

Typically, developing an SVM model for fault identification is not that difficult. When performing a classification, testing and training datasets are required. Each training set instance consists of two components: a target value, which is the class label, in our application the depth of the magnet’s crack, and numerous attributes, which are the observed variables. The basis for classifying data using the SVM algorithm is as follows. In order to predict the target value of the data in the testing set, when only the attributes are available, a classifier based on the training set must first be built. In order to build a classifier model, the following procedure is applied [33]:

- Collect simulated data from the three sensors: vibration, torque, and temperature.

- Extract the corresponding features from the data in order to transform data collected to a format for the SVM classifier.

- Try out a few different kernel types to determine which one is the best, then select the optimal parameters. The Gaussian RBF kernel was used in this work, and a cross-validation algorithm is used to optimize parameters.

- Use the chosen parameters and the relevant kernel function to construct a classifier.

- Evaluate the testing data using the constructed classifier and perform a test for all system states. The testing is performed using both the one against all and one against one methods. The one giving the best results is chosen.

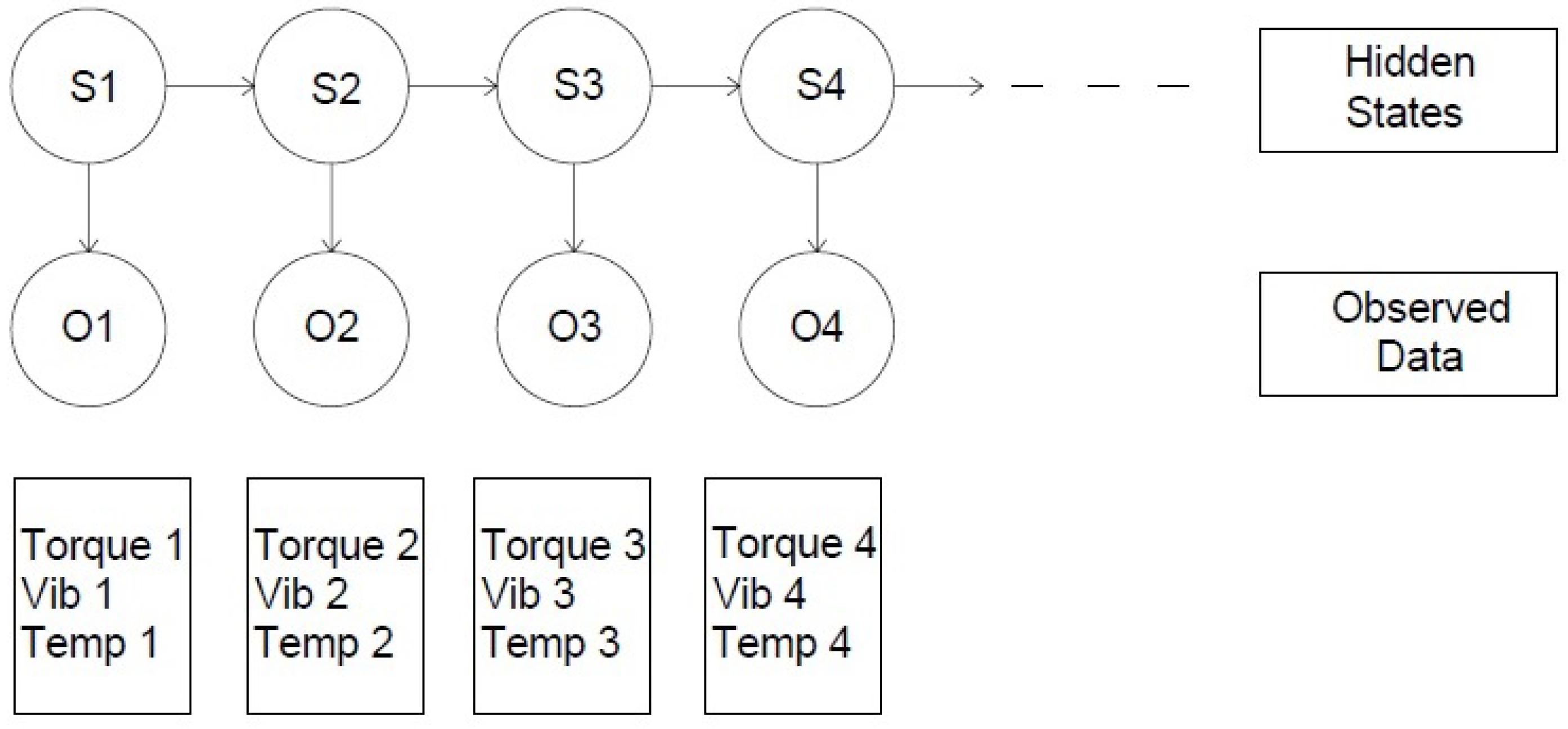

4. Hidden Markov Model (HMM)

HMM is a statistical model. The system is based on hidden states X. HMM aims to learn about X by observing Y that is dependent on X. Consequently, for each instance , the conditional probability distribution of given the history = . For , the condition must not depend on for . This technique may foresee changes in the system’s state, in order, based on the order of observations. Hence, it is helpful in situations where systems produce a collection of exterior observations from finite internal states. The internal states of the system are invisible for an outward observer. The current state is directly dependent on the immediate previous state; these sequences are the Markov process.

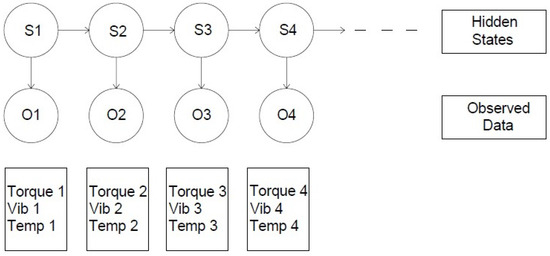

HMM’s elements are [34,35] ‘N’ the number of states, ‘’ the initial probability value for each state, TM the transition probability matrix that represents the likelihood of transitioning between states, ‘EM’ the output emission probability distribution matrix that shows the probability that a certain measure value comes from a certain state. HMM is usually expressed as (TM, EM, ). In general, we can differentiate between two types of HMMs depending on the input form: continuous, which suits systems with real number input, and discrete, which suits systems with a restricted number of observations. Then comes the training stage, which is the process of finding the HMM parameters, the matrices TM and EM, from measured data. The iterative algorithm that forms the foundation of the training process is the “Baum–Welch algorithm”. In [29], details about HMM steps are developed where the HMM model was utilized to apply a prognostic methodology aimed at identifying different types of faults in the electrical machine.

4.1. HMM in Our Application

In our application, a fault detection approach, utilizing the HMM, will be implemented to discover the presence of a magnet’s crack at an early stage and precisely determine the length of this crack. Retrieved features of data coming from torque, vibration, and temperature will be the input of our model. The output will be the state of the machine, whether it is healthy or a magnet crack exists, in addition to the length of the crack. The same fault strategy in Figure 2 is applied.

4.2. Building the HMM

The number of HMM models, the number of states and the amount of data required should be defined. The selected type of HMM is continuous because the available observation data is composed of a set of numbers, which are the features of the three types of signals (vibration, torque, and temperature). After that, two options were revealed: representing the system as one or a variety of HMMs. In the case of a sole HMM, the HMM’s states are the health state of the magnet. However, when various HMMs are implemented, each one will be trained for a distinct health state of the system. In fact, choosing the one-HMM configuration is better when sufficient data is available [34]. Nevertheless, when a compact amount of data is available, adopting the multi-HMM configuration to represent system health states is preferable. Highlighting that, using multiple HMMs is advantageous when an upgrade for the system may be needed. Sometimes, more states are revealed due to extra information or data, and this needs to be added and represented in the model. In the multiple-HMM configuration, this will be achieved easily by adding a new HMM to the existing model that represents this new state and training it accordingly. Multiple HMMs are chosen in this study to facilitate the easy addition of additional states indicating new system faults in the future. In this paper, five HMMs will be created according to the number of health sates, which are the healthy condition and the four defective conditions representing the magnet crack length (half mm, one mm, one and a half mm and two mm). To represent the possible health states, five HMMs have been trained.

4.3. Training the HMM

To train the five HMM models, the iterative algorithm of Baum–Welch was used. The training process utilizes 80% of the treated data. Accordingly, for each model, the number of observations should be determined. For each state, we select three unique observations that best capture the observed data. The torque, temperature, or vibration sensor measured values will be the observation in our application. It is important to supervise three observers in every state to avoid false alarms. For each state of the machine, the raw data set, coming from the three sensors, is examined over one machine revolution with 200 sampling points. Figure 5 represents the HMM trellis diagram of the healthy state. Five HMMs are created similar to this one.

Figure 5.

HMM trellis diagram of the healthy state.

4.4. Fault Detection

Once the models were built, the fault detection phase can be achieved. The testing data, which represents 20% of the whole dataset, is used to compute the log-likelihood of the sequence using each model. The predicted class is the one that gives the highest log-likelihood.

5. Results

The SVM and HMM methods were expansively explained in the preceding section. A MATLAB simulation of these methods is elaborated so that their performance and efficiency may be compared. In the following, results of the simulation are presented for each method, and a comparison between the two is realized, taking into consideration many factors; on top of them is the accuracy.

5.1. SVM Results

An example simulation is presented to show how well the SVM works for fault detection. Data coming from healthy and faulty machine states are merged to evaluate the classifier’s detection performance. After models are built with training data, we use testing data to evaluate the prediction result through the following indices. The first one is the accuracy (acc), which is assessed using the quantity of data correctly predicted (QDCP), and the quantity of all data (QAD) (see Equation (1)), and the second one is the fault detection rate (FDR), counted as a function of the number of faulty data correctly predicted (FDCP) and the quantity of all faulty data (QFD) (see Equation (2)). Then, the result for each fault is shown in Table 1 using the one against all classifier and the one against one classifier.

Comparing the methods and taking into consideration the different examined parameters, both have the same accuracy and FDR. However, the one against one method appears more suitable in our application, having less training and testing time. We note that those results are a consequence of the optimal model. The high accuracy emphasizes the good predictive ability of the classifier based on the SVM algorithm. We mention that the technique of cross-validation was used to optimize the classifier hyper-parameters. Plus, the calculation time is considered short because few algorithms were employed.

5.2. HMM Results

The simulation of this method via MATLAB is generated to check the efficacy of this method. The same evaluating parameters of SVM are used. Results are illustrated in Table 2.

Table 2.

Evaluation of the the HMM method.

This method is clearly effective for fault detection in our application due to the high accuracy and the relatively small training time.

5.3. Comparison Between SVM and HMM

According to the previous results, both of these two methods have the same performance in our application in terms of accuracy when the three attributes of the three signal types were used. In order to differentiate between the two approaches more precisely, a comparison will be presented when one out of three of the attributes is used. The following statistical measures will be calculated: accuracy, FDR, precision, specificity, recall, and F1 score. These will be calculated for the two methods when only the vibration attribute is studied, which is the most significant feature between the three. Precision is the ratio of accurately anticipated positive observations to all predicted positive observations.

Recall is the ratio of all positive observations in the actual class to those that were correctly predicted.

F1 is the core weighted mean of Precision and Recall.

Specificity is ratio of cases accurately tagged by the system to all that are actually healthy.

TP: true positives; TN: true negatives; FP: false positives; FN: false negatives.

Results in Table 3 show that the accuracy, FDR, precision, recall, specificity, and F1 are the same for SVM and HMM when there are three sensors. When there is one sensor, SVM performs better.

Table 3.

Statistical measurement results of SVM and HMM.

The training time of the SVM is higher than the HMM. The testing time of the SVM is less than the HMM. The data training is executed offline. Hence, this factor is not of big importance in our application, but testing time is more significant since the condition monitoring is online. Accordingly, having a smaller testing time, SVM is more suitable for our application.

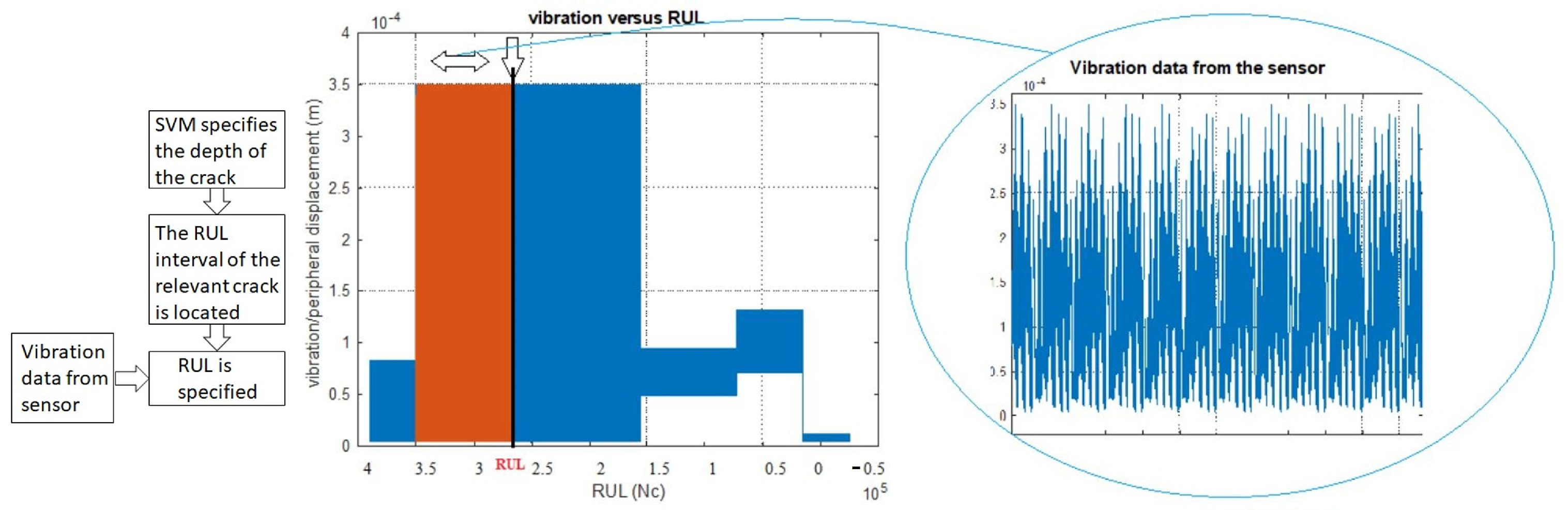

6. RUL Calculation Strategy

The prompt detection of a defect in the system will help with rapid corrective action and prevention of total failure. Among the crucial elements of condition-based monitoring are the maintenance measures that will be taken accordingly; this could not be ensured without the remaining useful life predictive calculation [36]. In the previous parts of the paper, it has been shown that SVM is more advantageous for the studied application. Now, after detecting the presence of a fault crack in the machine’s magnet using the SVM model, RUL should be calculated. A suggested method will be presented based on a combination of model-based and real-time data-based prediction to calculate the RUL of the defected element, which is the magnet in our case. One of the best methods to model the propagation of cracks of any nature is the Paris equation. In [37], the magnet’s crack propagation of the studied machine is modeled; RUL calculation for the relevant depth is executed. The governance equation relating the number of cycles to the depth of the occurring crack, deduced from Paris’ equation, is illustrated below.

‘Nc’ is the number of cycles. ‘C’ and ‘n’ are calibration parameters dependent on the type of material where the crack is propagating. is the Maxwell stress tensor. ‘Q’ is a parameter that depends on the system’s geometry. ‘a0’ and ‘af’ are the current and the final depth of the crack, respectively.

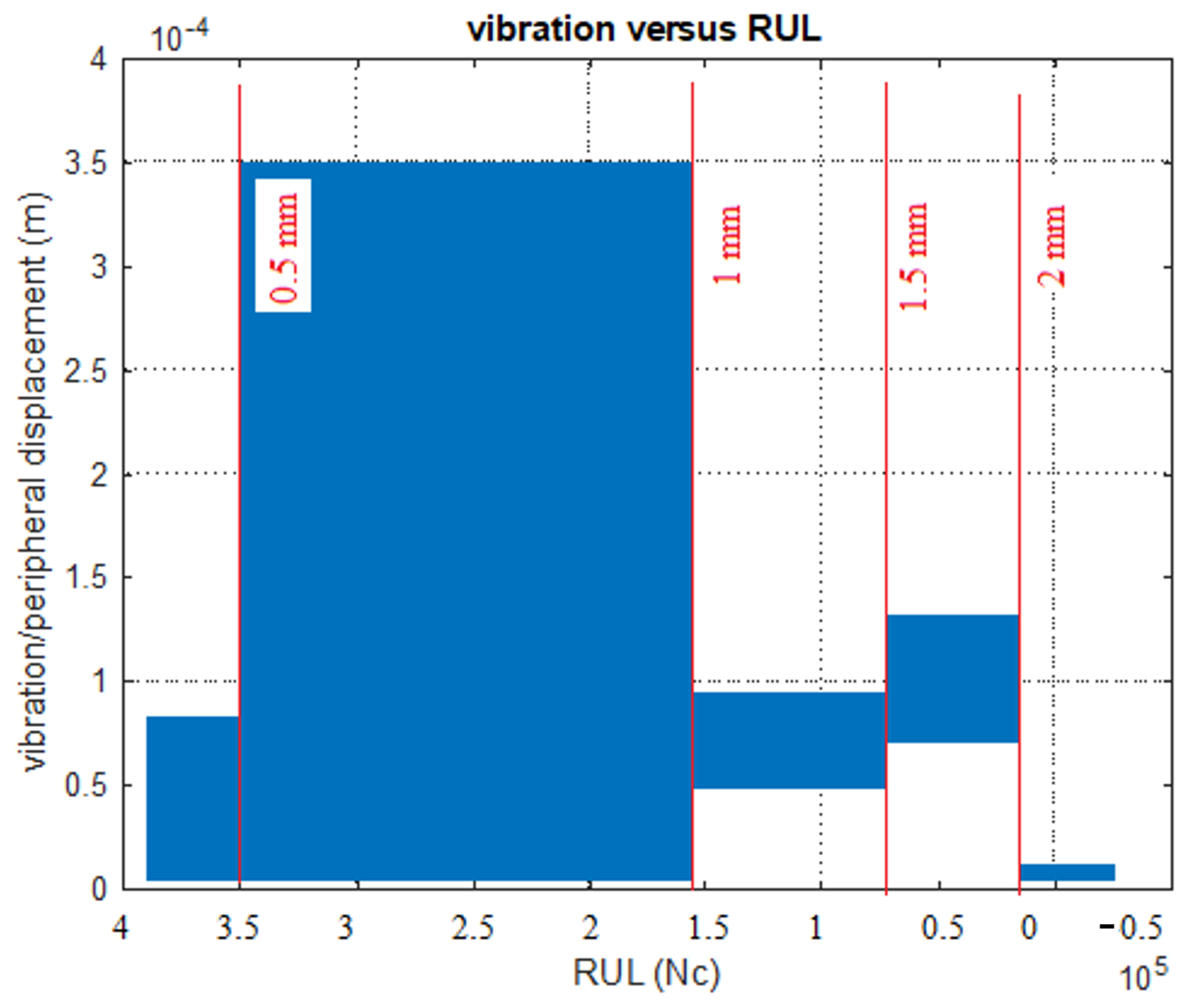

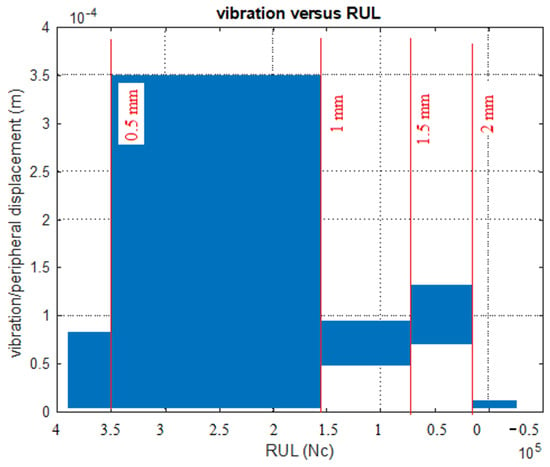

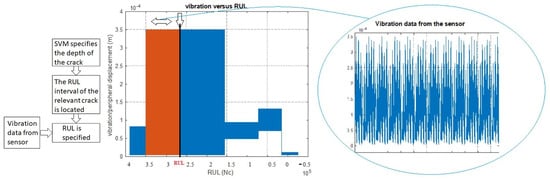

The Paris equation helps in calculating the remaining cycles of the system before it reaches the final state. The considered crack depths are 0.5, 1, 1.5, and 2 mm. The RUL model will be linked to one of the machine’s vital monitored parameters in the CBM, and that is largely affected by the studied fault. The considered parameter to be used in the RUL calculation is the vibration. The relevant vibration for each crack depth is collected from an FEM model built in [27]. The RUL is expressed in cycles. Vibration versus system cycles is shown in Figure 6.

Figure 6.

Vibration versus number of cycles for the relevant considered crack depth.

The suggested RUL calculation strategy in this section is based on a merge between lifetime data and real-time data. The lifetime data is the vibration versus life cycle of the machine for different crack depths coming from the Paris equation model, and the real time data is the monitored vibration data coming from the vibration sensor. The block diagram of this RUL calculation strategy with an illustrative application is shown in Figure 7. First, the SVM model specifies the radial depth of the crack; then, the RUL interval of the relevant crack will be located. Then, vibration data from the beginning of the defect will be collected and checked. And the corresponding RUL will be specified.

Figure 7.

RUL calculation block diagram with illustrative application.

7. Conclusions

With fossil fuels depleting and environmental concerns rising, hybrid electric vehicles offer a sustainable alternative. As their global adoption accelerates, ensuring their reliability becomes a critical priority. Condition monitoring, fault detection, and prognosis, which intends to detect a defect before a breakdown occurs in machines, play an efficient role in assuring HEVs’ healthy operation. The electrical machine is the most important part of the electric propulsion of the HEV and the most expensive. PMM, being the most used electrical machine, is examined in our study. Consequently, condition monitoring of this machine is a must. The considered fault is a tiny defect in a magnet, the most severe fault that may arise in the PMM.

Various approaches can be employed to achieve this objective; however, this study focuses on aligning the most suitable method with the specific faulty condition and system. Following the previously presented review of the literature, the range of potential approaches has been narrowed down to two. Two data-driven fault detection methods, support vector machine (SVM) and the hidden Markov model (HMM), were applied to assess magnet health, and a comparative analysis was conducted to determine the more effective approach. The inputs of both of these approaches are torque, vibration, and temperature signals obtained by virtual sensors located in a permanent magnet machine modeled using FEM.

The two approaches performed well in the magnet crack detection, especially with a small data set, such as our application. Also, both classifiers performed well in terms of accuracy; however, it was found that SVM outperformed HMM because testing takes less time, which is an essential requirement for defect identification. The prompt detection of a defect in the system will help in rapid corrective action and prevention of total failure. A key aspect of condition-based monitoring is estimating the Remaining Useful Life (RUL), for which a real-time, data-driven strategy was proposed at the end of the paper.

In future works, several perspectives offer insights from different perspectives. First, the fault detection problem will be expanded to encounter other flaws such as internal short circuit and eccentricity faults. In addition, further condition monitoring approaches will be evaluated, like random forest, deep learning, etc., highlighting the need for a standardized framework that prescribes the most suitable method for detecting specific faults in this particular application. Second, to improve the model’s performance, reduce computational complexity, and enhance discriminative power, feature selection or dimensionality reduction techniques will be employed, such as LASSO, Minimum Redundancy Maximum Relevance (mRMR), or Principal Component Analysis (PCA). Third, although the RUL calculation is based extensively on real-time data, the adopted model is trained offline using previously saved data in different machine states. The risk that the results become outdated is significant. Hence, a continual learning framework tailored for predicting the RUL of a dynamic model like an electrical machine under varying conditions is very significant. This will ensure accurate and resilient RUL predictions in real-world and non-stationary environments. In this context, a method proposed in [38] will be applied to maintain the model’s adaptability over time by incorporating knowledge compression and redundancy elimination, thereby isolating the most informative feature space.

Author Contributions

Conceptualization, N.M., G.H. and R.G.; methodology and approach, R.G., M.A. and H.K.; software, R.G.; validation, H.K., R.G., A.M. and G.H.; formal analysis, R.G.; investigation, G.H.; resources, G.H.; data curation, R.G.; writing—original draft preparation, H.K.; writing—review and editing, A.M., M.A. and G.H.; visualization, A.M. and R.G.; supervision, N.M., G.H. and R.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Finken, T.; Felden, M.; Hameyer, K. Comparison and design of different electrical machine types regarding their applicability in hybrid electrical vehicles. In Proceedings of the 2008 18th International Conference on Electrical Machines, Vilamoura, Portugal, 6–9 September 2008; pp. 1–5. [Google Scholar]

- Emadi, A.; Rajashekara, K.; Williamson, S.S.; Lukic, S.M. Topological overview of hybrid electric and fuel cell vehicular power system architectures and configurations. IEEE Trans. Veh. Technol. 2005, 54, 763–770. [Google Scholar] [CrossRef]

- Chris, M.; Masrur, M.A.; Gao, D.W. Hybrid Electric Vehicles: Principles and Applications with Practical Perspectives; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Zheng, J.Q.; Zhao, W.X.; Ji, J.H.; Liu, G.H. Design and comparison of interior permanent-magnet machines for hybrid electric vehicles. In Proceedings of the 2015 IEEE International Conference on Applied Superconductivity and Electromagnetic Devices (ASEMD), Shanghai, China, 20–23 November 2015; pp. 234–235. [Google Scholar]

- Barcaro, M.; Bianchi, N.; Magnussen, F. PM motors for hybrid electric vehicles. In Proceedings of the 2008 43rd International Universities Power Engineering Conference, Padua, Italy, 1–4 September 2008; pp. 1–5. [Google Scholar]

- Thamba, N.B.; Himamshu, H.; Nayak, P.K.; Chiluar, N.; Rama, P.; Nishant, C. Journal bearing fault detection based on Daubechies wavelet. Arch. Acoust. 2017, 42, 401–414. [Google Scholar]

- Jongman, H.; Hyun, D.; Kang, T.J.; Lee, S.B.; Kral, C.; Haumer, A. Detection and Classification of Rotor Demagnetization and Eccentricity Faults for PM Synchronous Machines. In Proceedings of the IEEE Energy Conversion Congress & Exposition, ECCE 2012, Raleigh, NC, USA, 15–20 September 2012; pp. 1–9. [Google Scholar]

- Verma, A.K.; Sarangi, S.; Kolekar, M.H. Misalignment fault detection in induction motor using rotor shaft vibration and stator current signature analysis. Int. J. Mechatronics Manuf. Syst. 2013, 6, 422–436. [Google Scholar] [CrossRef]

- Ginzarly, R.; Hoblos, G.; Moubayed, N. Severity faults classification in hybrid electric vehicles’ permanent magnet machines for prognostic purposes. Int. J. Comput. Aided Eng. Technol. 2017, 9, 480–496. [Google Scholar] [CrossRef]

- Pietrzak, P.; Wolkiewicz, M. Demagnetization Fault Diagnosis of Permanent Magnet Synchronous Motors Based on Stator Current Signal Processing and Machine Learning Algorithms. Sensors 2023, 23, 1757. [Google Scholar] [CrossRef]

- Moosavi, S.S.; Djerdir, A.; Amirat, Y.A.; Khaburi, D.A. Demagnetization fault diagnosis in permanent magnet synchronous motors: A review of the state-of-the-art. J. Magn. Magn. Mater. 2015, 391, 203–212. [Google Scholar] [CrossRef]

- Verma, N.K.; Agrawal, A.K.; Sevakula, R.K.; Prakash, D.; Salour, A. Improved signal preprocessing techniques for machine fault diagnosis. In Proceedings of the 2013 IEEE 8th International Conference on Industrial and Information Systems, Peradeniya, Sri Lanka, 17–20 December 2013; pp. 403–408. [Google Scholar]

- Surucu, O.; Gadsden, S.A.; Yawney, J. Condition Monitoring using Machine Learning: A Review of Theory, Applications, and Recent Advances. Expert Syst. Appl. 2023, 221, 119738. [Google Scholar] [CrossRef]

- Verma, N.K.; Salour, A. Intelligent Condition Based Monitoring; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Marinković, D.; Dezső, G.; Milojević, S. Application of machine learning during maintenance and exploitation of electric vehicles. Adv. Eng. Lett. 2024, 3, 132–140. [Google Scholar] [CrossRef]

- Sankavaram, C.; Pattipati, B.; Pattipati, K.; Zhang, Y.; Howell, M.; Salman, M. Data-driven fault diagnosis in a hybrid electric vehicle regenerative braking system. In Proceedings of the 2012 IEEE Aerospace Conference, Big Sky, MT, USA, 3–10 March 2012; pp. 1–11. [Google Scholar]

- Hasegawa, T.; Saeki, M.; Ogawa, T.; Nakano, T. Vibration-based fault detection for flywheel condition monitoring. Procedia Struct. Integr. 2019, 17, 487–494. [Google Scholar] [CrossRef]

- Telford, J.W. Pivoted Blade Barrel Rotor Wind Turbine. U.S. Patent 4,137,009, 30 January 1979. [Google Scholar]

- Luo, Y.; Qiu, J.; Shi, C. Fault detection of permanent magnet synchronous motor based on deep learning method. In Proceedings of the 2018 21st International Conference on Electrical Machines and Systems (ICEMS), Jeju, Republic of Korea, 7–10 October 2018; pp. 699–703. [Google Scholar]

- Laouti, N.; Sheibat-Othman, N.; Othman, S. Support vector machines for fault detection in wind turbines. IFAC Proc. Vol. 2011, 44, 7067–7072. [Google Scholar] [CrossRef]

- Kang, J.S.; Zhang, X.H.; Wang, Y.J. Continuous hidden Markov model based gear fault diagnosis and incipient fault detection. In Proceedings of the 2011 International Conference on Quality, Reliability, Risk, Maintenance, and Safety Engineering, Xi’an, China, 17–19 June 2011; pp. 486–491. [Google Scholar]

- Heng, A.; Zhang, S.; Tan, A.C.; Mathew, J. Rotating machinery prognostics: State of the art, challenges and opportunities. Mech. Syst. Signal Process. 2009, 23, 724–739. [Google Scholar] [CrossRef]

- Ginzarly, R.; Hoblos, G.; Moubayed, N. Hidden Markov Model-Based Failure Prognosis for Permanent Magnet Synchronous Machine. In Proceedings of the 15th European Workshop on Advanced Control and Diagnosis, Bologna, Italy, 21–22 November 2019; Springer: Cham, Switzerland, 2018; pp. 599–611. [Google Scholar]

- Ginzarly, R.; Alameh, K.; Hoblos, G.; Moubayed, N. Numerical versus analytical techniques for healthy and faulty surface permanent magnet machine. In Proceedings of the 2016 Third International Conference on Electrical, Electronics, Computer Engineering and their Applications (EECEA), Beirut, Lebanon, 21–23 April 2016; pp. 83–87. [Google Scholar]

- Liang, X.; Ali, M.Z.; Zhang, H. Induction motors fault diagnosis using finite element method: A review. IEEE Trans. Ind. Appl. 2019, 56, 1205–1217. [Google Scholar] [CrossRef]

- Salon, S.J. Finite Element Analysis of Electrical Machines; Kluwer Academic Publishers: Boston, MA, USA, 1995; Volume 101. [Google Scholar]

- Ginzarly, R.; Hoblos, G.; Moubayed, N. Electromagnetic and vibration finite element model for early fault detection in permanent magnet machine. IFAC-PapersOnLine 2018, 51, 902–907. [Google Scholar] [CrossRef]

- Alameh, K.; Ginzarly, R.; Hoblos, G.; Barakat, G. Fault Detection and Identification Approach for Brushless Direct Current (DC) Motors based on Vibration Signal Analysis. In Proceedings of the 3rd Conference on Control and Fault-Tolerant Systems, Systol, Barcelona, Spain, 7–9 September 2016; Volume 16. [Google Scholar]

- Ginzarly, R.; Hoblos, G.; Moubayed, N. From modeling to failure prognosis of permanent magnet synchronous machine. Appl. Sci. 2020, 10, 691. [Google Scholar] [CrossRef]

- Cortes, C.; Vapnik, V. Support-vector networks. Mach. Learn. 1995, 20, 273–297. [Google Scholar] [CrossRef]

- Scholkopf, B.; Sung, K.K.; Burges, C.J.; Girosi, F.; Niyogi, P.; Poggio, T.; Vapnik, V. Comparing support vector machines with Gaussian kernels to radial basis function classifiers. IEEE Trans. Signal Process. 1997, 45, 2758–2765. [Google Scholar] [CrossRef]

- Li, H.; Qi, F.; Wang, S. A comparison of model selection methods for multi-class support vector machines. In Proceedings of the International Conference on Computational Science and Its Applications, Singapore, 9–12 May 2005; Springer: Berlin/Heidelberg, Germany, 2005; pp. 1140–1148. [Google Scholar]

- Yin, S.; Gao, X.; Karimi, H.R.; Zhu, X. Study on support vector machine-based fault detection in tennessee eastman process. Abstr. Appl. Anal. 2014, 2014, 836895. [Google Scholar] [CrossRef]

- Bjerkeseth, M. Using Hidden Markov Models for Fault Diagnostics and Prognosis in Condition Based Maintenance Systems. Master’s Thesis, University of Agder, Kristiansand, Norway, 2010. [Google Scholar]

- Arpaia, P.; Cesaro, U.; Chadli, M.; Coppier, H.; De Vito, L.; Esposito, A.; Gargiulo, F.; Pezzetti, M. Fault detection on fluid machinery using Hidden Markov Models. Measurement 2020, 151, 107126. [Google Scholar] [CrossRef]

- Phuc, D.V.; Levrat, E.; Voisin, A.; Benoit, I. Remaining useful life (rul) based maintenance decision making for deteriorating systems. IFAC Proc. Vol. 2012, 45, 66–72. [Google Scholar]

- Jiang, S.; Zhang, W.; Li, X.; Sun, F. An analytical model for fatigue crack propagation prediction with overload effect. Math. Probl. Eng. 2014, 2014, 713678. [Google Scholar] [CrossRef]

- Ren, X.; Qin, Y.; Li, B.; Wang, B.; Yi, X.; Jia, L. A core space gradient projection-based continual learning framework for remaining useful life prediction of machinery under variable operating conditions. Reliab. Eng. Syst. Saf. 2024, 252, 110428. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).