Experimental Validation and Optimization of a Hydrogen–Gasoline Dual-Fuel Combustion Model in a Spark Ignition Engine with a Moderate Hydrogen Ratio

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Engine

2.1.2. Engine Control Unit and Wiring

2.1.3. Combustion Analyzer

2.1.4. Fuel

2.1.5. Environment

2.1.6. Hydrogen Supply and Safety System

- Hydrogen injectors mounted in the intake runners 50 mm from the intake valves;

- A hydrogen mass flow meter for accurate fuel energy share control;

- A pressure regulator, used to maintain steady delivery pressure across the operating range;

- A high-pressure hydrogen storage tank, connected via certified high-pressure tubing.

- Gas detection sensors in the test cell to monitor potential hydrogen leaks (Lower Explosion Limit Sensor);

- Ventilation systems designed to prevent gas accumulation;

- Pressure relief valves and burst disks on the hydrogen tank and supply lines;

- Use of certified high-pressure components (tubing, fittings, valves);

- Emergency stop systems and remote shutdown protocols in case of abnormal pressure or detected leakage.

2.2. Methods

2.2.1. Engine Dyno Test with Gasoline and Hydrogen in Dual-Fuel Operation

2.2.2. Test Matrix

2.2.3. Combustion Analysis

- Mass Fraction Burned (MFB) profiles: Derived using the Rassweiler and Withrow method [13], enabling the calculation of combustion phasing metrics such as MFB10, MFB50, and MFB90.

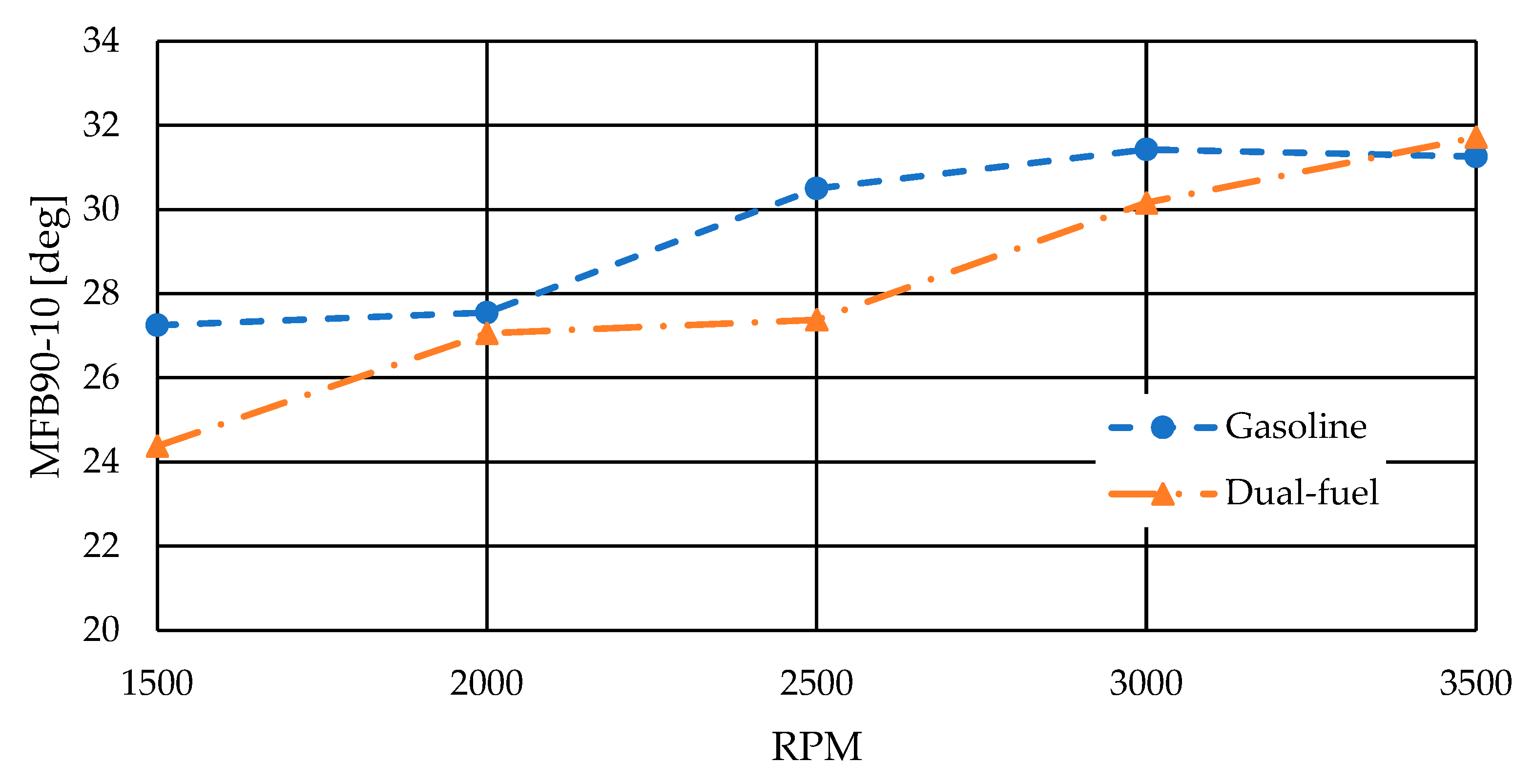

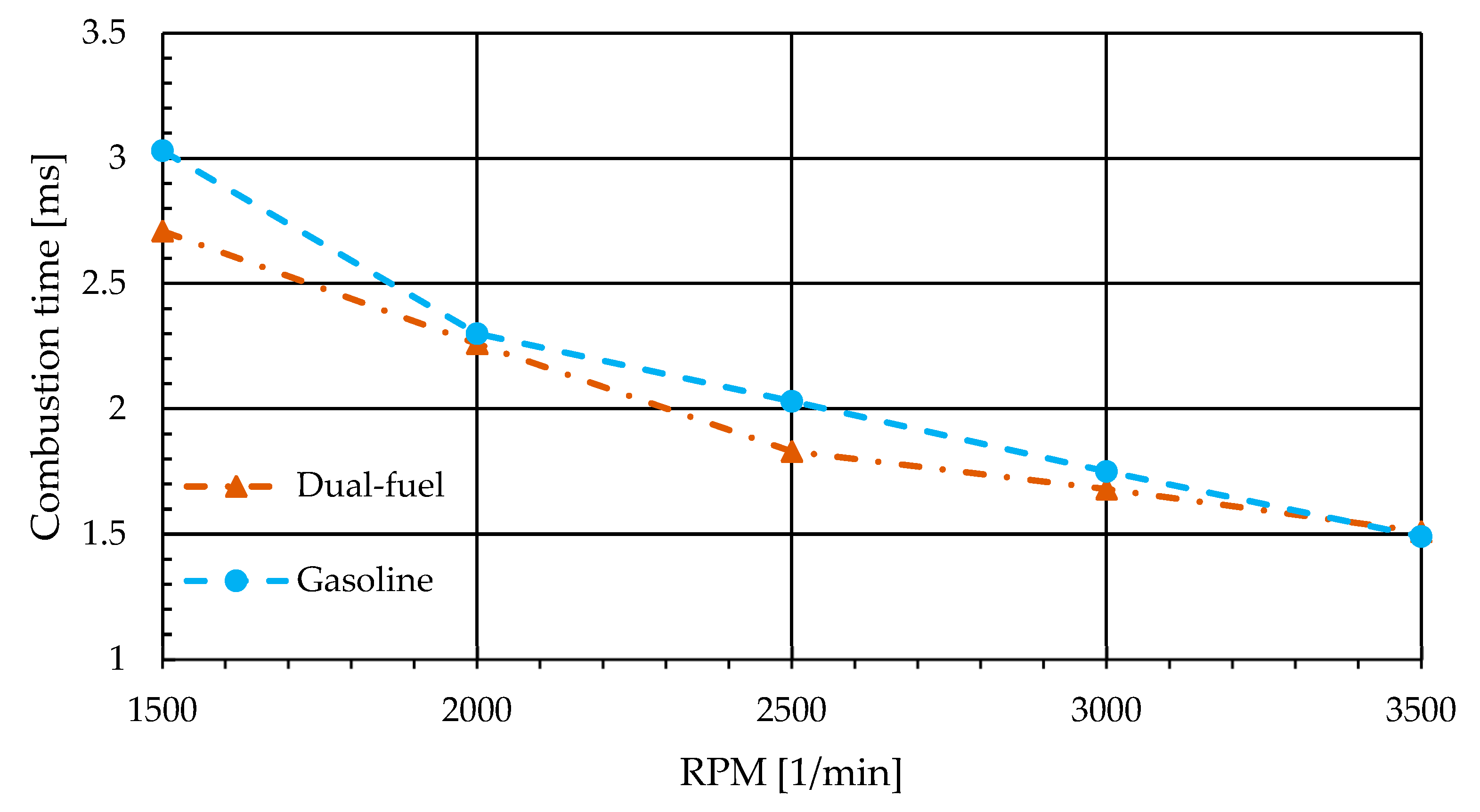

- Combustion duration: Determined by the interval between MFB10 and MFB90, providing insights into the combustion speed and completeness.

- Rate of Heat Release (ROHR): Calculated from the pressure data to assess the combustion intensity and identify any abnormal combustion phenomena.

- Peak in-cylinder pressure and pressure rise rate: Monitored to evaluate the impact of hydrogen addition on combustion dynamics and potential knock tendencies.

- Total combustion duration: This refers to the interval between the start of combustion (SOC) and the end of combustion (EOC). The SOC is typically identified as the crank angle at which the first noticeable increase in pressure occurs, while the EOC is when the combustion process concludes. This method captures the entire combustion event, including ignition delay and late-stage combustion.

- MFB90–MFB10 duration: This metric focuses on the interval between 10% and 90% of the mass fraction burned. It effectively captures the main combustion phase, excluding the initial ignition delay and the final stages of combustion. This method is less sensitive to minor fluctuations and provides a consistent basis for comparing combustion speeds across different operating conditions.

- Teodosio et al. (2020) observed that hydrogen port injection in a small turbocharged gasoline engine led to faster combustion rates and improved efficiency due to hydrogen’s favorable combustion properties [41].

- Sarabi and Aghdam (2019) noted that hydrogen addition in dual-fuel SI engines resulted in shorter combustion durations and advanced combustion phasing, contributing to improved engine performance [42].

- Kim et al. (2024) investigated the effects of varying equivalence ratios on combustion efficiency and found that hydrogen enrichment led to more stable and efficient combustion with reduced combustion durations [43].

2.2.4. Two-Zone Vibe Combustion Model Implementation

- Unburned zone: Contains the air–fuel mixture yet to undergo combustion.

- Burned zone: Contains the products of combustion.

2.2.5. Calibration with Experimental Data

2.2.6. Dual-Fuel Operation Modeling

- The gasoline path retained the original stoichiometric calibration.

- The hydrogen path was introduced as a premixed gaseous intake injection, using AVL’s user-defined dual-fuel interface, with split ratios based on 10% and 20% hydrogen energy shares.

3. Results

3.1. Model Refinement in AVL CRUISE M

- In-cylinder pressure: Good alignment with measured pressure curves confirmed the updated burn rate’s accuracy.

- Combustion phasing and duration: Predicted MFB50 and MFB90–MFB10 closely matched experimental trends.

- Performance metrics: Simulated brake torque and indicated efficiency were consistent with measured values.

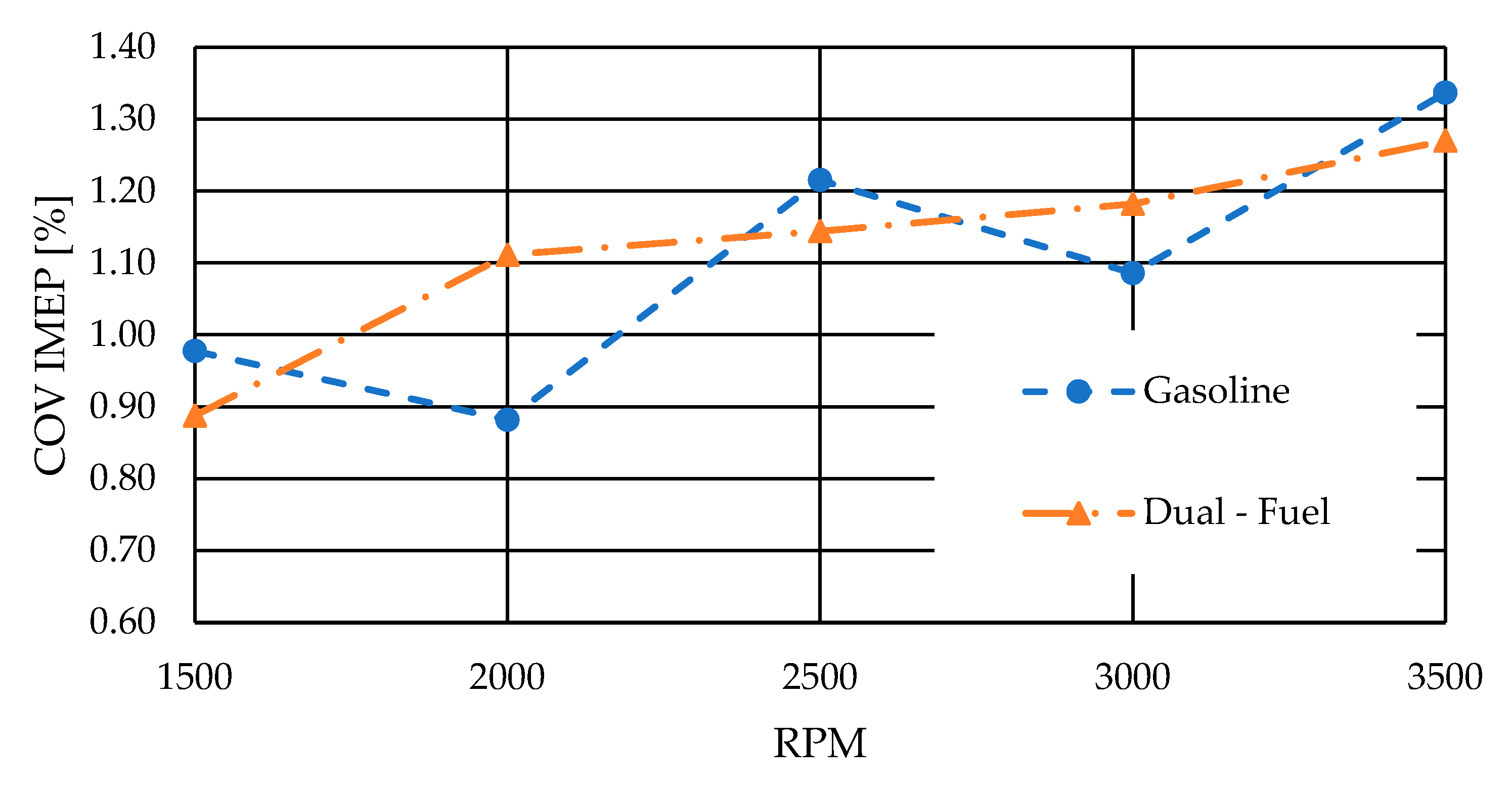

3.2. Testbed Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chintala, V.; Subramanian, K.A. A comprehensive review on utilization of hydrogen in a compression ignition engine under dual fuel mode. Renew. Sustain. Energy Rev. 2017, 70, 472–491. [Google Scholar] [CrossRef]

- Tsujimura, T.; Suzuki, Y. The utilization of hydrogen in hydrogen/diesel dual fuel engine. Int. J. Hydrogen Energy 2017, 42, 14019–14029. [Google Scholar] [CrossRef]

- Deheri, C.; Acharya, S.K.; Thatoi, D.N.; Mohanty, A.P. A review on performance of biogas and hydrogen on diesel engine in dual fuel mode. Fuel 2020, 260, 116337. [Google Scholar] [CrossRef]

- Qin, Z.; Yang, Z.; Jia, C.; Duan, J.; Wang, L. Experimental study on combustion characteristics of diesel–hydrogen dual-fuel engine. J. Therm. Anal. Calorim. 2020, 142, 1483–1491. [Google Scholar] [CrossRef]

- Purayil, S.T.P.; Al-Omari, S.A.B.; Elnajjar, E. Experimental investigation of the effect of CO2 dilution on the performance and hydrogen knock limit of a hydrogen–gasoline dual fuel spark ignition engine 1. Int. J. Hydrogen Energy 2024, 68, 410–427. [Google Scholar] [CrossRef]

- Karthic, S.V.; Kumar, M.S.; Pradeep, P.; Kumar, S.V. Assessment of hydrogen-based dual fuel engine on extending knock limiting combustion. Fuel 2020, 260, 116342. [Google Scholar] [CrossRef]

- Szamrej, G.; Karczewski, M. Exploring Hydrogen-Enriched Fuels and the Promise of HCNG in Industrial Dual-Fuel Engines. Energies 2024, 17, 1525. [Google Scholar] [CrossRef]

- Duan, X.; Feng, L.; Chu, X.; Sun, Z. The performance of a spark ignition gasoline engine with hydrogen addition under low-load conditions. Fuel 2025, 379, 133091. [Google Scholar] [CrossRef]

- Mohamed, M.; Biswal, A.; Wang, X.; Zhao, H.; Hall, J. Experimental investigation for enhancing the performance of hydrogen direct injection compared to gasoline in spark ignition engine through valve timings and overlap optimization. Fuel 2024, 372, 132257. [Google Scholar] [CrossRef]

- Verhelst, S.; Turner, J.W.G. Hydrogen-Fueled Spark Ignition Engines. In Hydrogen for Future Thermal Engines; Tingas, E.A., Ed.; Green Energy and Technology; Springer: Cham, Switzerland, 2023. [Google Scholar] [CrossRef]

- Matla, J.; Kaźmierczak, A.; Haller, P.; Trocki, M. Hydrogen as a fuel for spark ignition combustion engines—State of knowledge and concept. Combust. Engines 2024, 196, 73–79. [Google Scholar] [CrossRef]

- Abubakar, S.; Said, M.; Abas, M.; Khalid, A.; Roslan, M.F.; Ismail, N.; Umaru, S.; Narayan, S.; Kaisan, M. Recent progress on hydrogen-fueled port fuel injection spark ignition engine—A systematic review. Therm. Sci. 2025, 00, 81. [Google Scholar] [CrossRef]

- Kondor, I.P. Experimental Investigation on the Effect of Heating Oil and Tyre Pyrolysis Oil Combustion in an Evaporative Combustion Chamber. Fuels 2024, 5, 210–221. [Google Scholar] [CrossRef]

- Amaral, L.V.; Malaquias, A.C.T.; Fraga, M.A.; Torres, R.B.; Sebastião, R.C.; Pujatti, F.J. Combustion and specific fuel consumption evaluation of a single-cylinder engine fueled with ethanol, gasoline, and a hydrogen-rich mixture. Case Stud. Therm. Eng. 2024, 57, 104316. [Google Scholar] [CrossRef]

- Gao, J.; Wang, X.; Song, P.; Tian, G.; Ma, C. Review of the backfire occurrences and control strategies for port hydrogen injection internal combustion engines. Fuel 2022, 307, 121553. [Google Scholar] [CrossRef]

- Kumar, M.S.; Muniyappan, M.; Selvan, S.A. Experimental and CFD analysis on the impact of hydrogen as fuel on the behavior of a passenger car gasoline direct injection engine. J. Energy Inst. 2024, 113, 101487. [Google Scholar] [CrossRef]

- Hu, Z.; Zhang, Y.; Ai, Z.; Li, M.; Zhang, Y. Hydrogen doping control method for gasoline engine acceleration transient air-fuel ratio. Heliyon 2024, 10, e30865. [Google Scholar] [CrossRef]

- Gopal, G.; Srinivasa Rao, P.; Gopalakrishnan, K.V.; Murthy, B.S. Use of hydrogen in dual-fuel engines. Int. J. Hydrogen Energy 1982, 7, 267–272. [Google Scholar] [CrossRef]

- Vavra, J.; Bortel, I.; Takats, M. A Dual Fuel Hydrogen-Diesel Compression Ignition Engine and Its Potential Application in Road Transport; No. 2019-01-0564; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2019. [Google Scholar] [CrossRef]

- Bakar, R.A.; Widudo; Kadirgama, K.; Ramasamy, D.; Yusaf, T.; Kamarulzaman, M.; Sivaraos; Aslfattahi, N.; Samylingam, L.; Alwayzy, S.H. Experimental analysis on the performance, combustion/emission characteristics of a DI diesel engine using hydrogen in dual fuel mode. Int. J. Hydrogen Energy 2022, 52, 843–860. [Google Scholar] [CrossRef]

- Serrano, J.; Jiménez-Espadafor, F.J.; López, A. Analysis of the effect of different hydrogen/diesel ratios on the performance and emissions of a modified compression ignition engine under dual-fuel mode with water injection. Hydrogen-diesel dual-fuel mode. Energy 2019, 172, 702–711. [Google Scholar] [CrossRef]

- Saravanan, N.; Nagarajan, G. Experimental investigation on a DI dual fuel engine with hydrogen injection. Int. J. Energy Res. 2009, 33, 295–308. [Google Scholar] [CrossRef]

- Rueda-Vázquez, J.M.; Serrano, J.; Pinzi, S.; Jiménez-Espadafor, F.J.; Dorado, M.P. A Review of the Use of Hydrogen in Compression Ignition Engines with Dual-Fuel Technology and Techniques for Reducing NOx Emissions. Sustainability 2024, 16, 3462. [Google Scholar] [CrossRef]

- Purayil, S.T.P.; Al-Omari, S.A.B.; Elnajjar, E. Experimental investigation on the influence of gasoline injection pressure on the hydrogen knock limit and performance of a hydrogen–gasoline dual fuel engine. Int. J. Hydrogen Energy 2024, 81, 1385–1393. [Google Scholar] [CrossRef]

- Jamshaid, M.; Masjuki, H.H.; Kalam, M.A.; Zulkifli, N.W.M.; Arslan, A.; Zulfattah, Z.M. Effect of fatty acid methyl ester on fuel-injector wear characteristics. J. Biobased Mater. Bioenergy 2020, 14, 327–339. [Google Scholar] [CrossRef]

- Gültekin, N.; Ciniviz, M. Examination of the effect of combustion chamber geometry and mixing ratio on engine performance and emissions in a hydrogen-diesel dual-fuel compression-ignition engine. Int. J. Hydrogen Energy 2023, 48, 2801–2820. [Google Scholar] [CrossRef]

- Shepel, O.; Matijošius, J.; Rimkus, A.; Duda, K.; Mikulski, M. Research of parameters of a compression ignition engine using various fuel mixtures of hydrotreated vegetable oil (Hvo) and fatty acid esters (fae). Energies 2021, 14, 3077. [Google Scholar] [CrossRef]

- Patton, K.J.; Nitschke, R.G.; Heywood, J.B. Development and evaluation of a friction model for spark-ignition engines. SAE Trans. 1989, 98, 1441–1461. [Google Scholar]

- Martyr, A.J.; Rogers, D.R. Chapter 16—The combustion process and combustion analysis. In Engine Testing, 5th ed.; Butterworth-Heinemann: Oxford, UK, 2021; pp. 537–597. [Google Scholar] [CrossRef]

- Ma, F.; Ding, S.; Wang, Y.; Wang, M.; Jiang, L.; Naeve, N.; Zhao, S. Performance and emission characteristics of a spark-ignition (SI) hydrogen-enriched compressed natural gas (HCNG) engine under various operating conditions including idle conditions. Energy Fuels 2009, 23, 3113–3118. [Google Scholar] [CrossRef]

- Iliev, S. A Comparison of Ethanol and Methanol Blending with Gasoline Using a 1-D Engine Model. Procedia Eng. 2015, 100, 1013–1022. [Google Scholar] [CrossRef]

- Lawrence, K.R.; Anchupogu, P.; Reddygari, M.R.; Gangula, V.R.; Balasubramanian, D.; Veerasamy, S. Optimization of biodiesel yield and performance investigations on diesel engine powered with hydrogen and acetylene gas injected with enriched Jojoba biodiesel blend. Int. J. Hydrogen Energy 2024, 50, 502–523. [Google Scholar] [CrossRef]

- Purayil, S.T.P.; Hamdan, M.O.; Al-Omari, S.A.B.; Selim, M.Y.E.; Elnajjar, E. Review of hydrogen–gasoline SI dual fuel engines: Engine performance and emission. Energy Rep. 2023, 9, 4547–4573. [Google Scholar] [CrossRef]

- Pham, P.X.; Bodisco, T.A.; Ristovski, Z.D.; Brown, R.J.; Masri, A.R. The influence of fatty acid methyl ester profiles on inter-cycle variability in a heavy duty compression ignition engine. Fuel 2014, 116, 140–150. [Google Scholar] [CrossRef]

- Vass, S.; Zöldy, M. Effects of Boundary Conditions on A Bosch-Type Injection Rate Meter. Transport 2021, 36, 297–304. [Google Scholar] [CrossRef]

- Kondor, I.P.; Zöldy, M.; Mihály, D. Experimental Investigation on the Performance and Emission Characteristics of a Compression Ignition Engine Using Waste-Based Tire Pyrolysis Fuel and Diesel Fuel Blends. Energies 2021, 14, 7903. [Google Scholar] [CrossRef]

- Engine Break-In: Recommended Procedures. Available online: https://www.us.mahle.com/media/usa/motorsports/mms-break-in-recommended-procedure-web.pdf (accessed on 5 May 2025).

- U.S. Department of Energy—Hydrogen Safety Panel. Guidelines for Hydrogen and Fuel Cell Stationary Applications, Rev. 2. 2019. Available online: https://h2tools.org (accessed on 2 April 2025).

- ISO/TR 15916:2015; Basic Considerations for the Safety of Hydrogen Systems. International Organization for Standardization: Geneva, Switzerland, 2015.

- Kotchourko, A. State-of-the-Art and Research Priorities in Hydrogen Safety. 2013. Available online: https://www.h2knowledgecentre.com/content/conference584 (accessed on 2 April 2025).

- Teodosio, L.; Pirrello, D.; Marchitto, L. 1D numerical study on hydrogen injection enabling ultra-lean com-bustion in a small gasoline Spark Ignition engine. Energy Rep. 2020, 6, 104–112. [Google Scholar] [CrossRef]

- De Simio, L.; Gambino, M.; Iannaccone, S. Experimental and numerical study of hydrogen addition in a natural gas heavy duty engine for a bus vehicle. Int. J. Hydrogen Energy 2013, 38, 6865–6873. [Google Scholar] [CrossRef]

- Lee, J.; Chu, S.; Kang, J.; Min, K. Effects of Varying Equivalence Ratios on the Combustion Efficiency Characteristic of a Dual-Fuel Compression Ignition Engine by Changing Intake Pressures and Exhaust Gas Recirculation Rates. Int. J. Automot. Technol. 2024, 25, 173–182. [Google Scholar] [CrossRef]

- Rassweiler, G.M.; Withrow, L. Studying Engine Combustion by Means of the Indicator Diagram. SAE Trans. 1938, 42, 185–204. [Google Scholar] [CrossRef]

- Fiveland, S.B.; Assanis, D.N. Development of a Two-Zone HCCI Combustion Model Accounting for Boundary Layer Effects; SAE Technical Paper 2001-01-1028; SAE International: Warrendale, PA, USA, 2001. [Google Scholar] [CrossRef]

- Rakopoulos, C.D.; Rakopoulos, D.C.; Kyritsis, D.C. Development and validation of a comprehensive two-zone model for combustion and emissions formation in a DI diesel engine. Int. J. Energy Res. 2003, 27, 1221–1249. [Google Scholar] [CrossRef]

- Abd Alla, G.H.; Soliman, H.A.; Badr, O.A.; Abd Rabbo, M.F. Using of Quasi-Two Zone Combustion Model to Predict the Performance of a Dual Fuel Engine; SAE Technical Paper 2000-01-2936; SAE International: Warrendale, PA, USA, 2000. [Google Scholar] [CrossRef]

- Liu, Y.; Jia, B.; Yang, Z.; Zhang, Z.; Liu, C.; Wang, W.; Feng, H.; Zuo, Z.; Roskilly, T.; Quah, H.J. Numerical Investigation on the Indicated Mean Effective Pressure and Integral Heat Release Rate Variations under Different Key Operating Parameters of a Spark-Ignited Free Piston Engine Generator. Int. J. Energy Res. 2024, 2024, 1341603. [Google Scholar] [CrossRef]

- Fu, Z.; Li, Y.; Chen, H.; Du, J.; Li, Y.; Gao, W. Effect of Hydrogen Blending on the Combustion Performance of a Gasoline Direct Injection Engine. ACS Omega 2022, 7, 13022–13030. [Google Scholar] [CrossRef] [PubMed]

- Gong, C.; Li, Z.; Chen, Y.; Liu, J.; Liu, F.; Han, Y. Influence of ignition timing on combustion and emissions of a spark-ignition methanol engine with added hydrogen under lean-burn conditions. Fuel 2019, 235, 227–238. [Google Scholar] [CrossRef]

- Gao, W.; Fu, Z.; Li, Y.; Li, Y.; Zou, J. Progress of Performance, Emission, and Technical Measures of Hydrogen Fuel Internal-Combustion Engines. Energies 2022, 15, 7401. [Google Scholar] [CrossRef]

- Zhou, J.H.; Cheung, C.S.; Zhao, W.Z.; Leung, C.W. Diesel–hydrogen dual-fuel combustion and its impact on unregulated gaseous emissions and particulate emissions under different engine loads and engine speeds. Energy 2016, 94, 110–123. [Google Scholar] [CrossRef]

- Ali, R.; Kumar, M.; Dhar, A. Experimental evaluation of hydrogen-enriched CRDI diesel engine: Impact on combustion, performance and emissions under varying speed and load. Energy Convers. Manag. 2023, 284, 116932. [Google Scholar]

- Zhao, K.; Haoyun, S.; Tielong, S. Combustion Variation Control of SI Engines via Hypothesis Testing and EGR Step Valve. IFAC-PapersOnLine 2021, 54, 96–101. [Google Scholar] [CrossRef]

| Name | Data |

|---|---|

| Engine code | M43B18 |

| Stroke | Four strokes |

| Cylinder bore | 84 [mm] |

| Fuel pressure | 3.5 [Bar] |

| Displacement | 1796 cm3 |

| Valves | 8, 2 valves per cylinder |

| Fuel system | Manifold injection |

| Compression ration | 9.7:1 |

| Name | Data | Name | Data |

|---|---|---|---|

| Pressure sensor | AVL GH01D | Amplifier | AVL AT6356E |

| Sensitivity | 5.3 [pC/bar] | Linearity error | 0.01% [−] |

| Linearity | +/−0.3% [−] | Low-pass filter | 50 [kHz] |

| Natural frequency | 170 [kHz] | Output signal | 0–10 [V] |

| Cyclik temperature drift | +/−0.7 [bar] | Offset | 0 [V] |

| Measuring range | 0–300 [bar] |

| Name | Data | Sensor |

|---|---|---|

| Air pressure | 998 [hPa] | AVL APT100 |

| Ambition temperature | 19 [°C] | AVL FSA |

| Fuel temperature | 20 [°C] | AVL 753 |

| Gasoline pressure | 3.5 [Bar] | AVL 753 |

| Hydrogen pressure | 5.0 [Bar] | PressureTech GS4241H0040AB |

| Figure | Name | Type |

|---|---|---|

| S1 | Intake manifold temperature sensor | BOSCH 0 280 130 039 |

| S2 | Intake manifold pressure sensor | BOSCH 0 281 002 389 |

| S3 | Oxygen sensor | BOSCH 0 258 017 025 |

| S4 | Exhaust temperature sensors (4 pcs) | BOSCH B 261 209 385-01 |

| S5 | Throttle position sensor | BOSCH 0 280 122 016 |

| S6 | AVL indication spark plug | AVL ZI45 |

| S7 | Camshaft position sensor | BOSCH 0 232 103 037 |

| S8 | Crankshaft position sensor | BOSCH 0 261 210 136 |

| IG | Gasoline injectors (4 pcs) | BOSCH 0 280 155 968 |

| IH | Hydrogen injectors (4 pcs) | BOSCH 0 280 158 821 |

| TB | Throttle body | BMW OEM |

| Parameter | Value | Note |

|---|---|---|

| Engine speed [RPM] | 1500, 2000, 2500, 3000, 3500 | Representative of low to mid-range operating conditions |

| Load [%] | 100 | To treat the loss at the throttle valve as a constant |

| Hydrogen energy share [%] | 0 (baseline), 20 | To evaluate the impact of hydrogen enrichment |

| Spark timing [°CA BTDC] | Optimized for each test condition | Adjusted to achieve maximum brake torque (MBT) |

| Equivalence ratio [λ] | 1 | To stoichiometric mixtures |

| RPM | m | a | SOC | Dur. | R2 |

|---|---|---|---|---|---|

| 1500 | 6 | 2.05 | 676.2 | 61 | 0.9995 |

| 2000 | 5.54 | 1.91 | 677 | 61 | 0.9994 |

| 2500 | 5.45 | 2.18 | 679.5 | 62 | 0.9987 |

| 3000 | 5.15 | 1.95 | 676.3 | 62 | 0.9987 |

| 3500 | 5.15 | 1.5 | 670 | 66 | 0.9985 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kiss, A.; Szabó, B.; Kun, K.; Hanula, B.; Weltsch, Z. Experimental Validation and Optimization of a Hydrogen–Gasoline Dual-Fuel Combustion Model in a Spark Ignition Engine with a Moderate Hydrogen Ratio. Energies 2025, 18, 3501. https://doi.org/10.3390/en18133501

Kiss A, Szabó B, Kun K, Hanula B, Weltsch Z. Experimental Validation and Optimization of a Hydrogen–Gasoline Dual-Fuel Combustion Model in a Spark Ignition Engine with a Moderate Hydrogen Ratio. Energies. 2025; 18(13):3501. https://doi.org/10.3390/en18133501

Chicago/Turabian StyleKiss, Attila, Bálint Szabó, Krisztián Kun, Barna Hanula, and Zoltán Weltsch. 2025. "Experimental Validation and Optimization of a Hydrogen–Gasoline Dual-Fuel Combustion Model in a Spark Ignition Engine with a Moderate Hydrogen Ratio" Energies 18, no. 13: 3501. https://doi.org/10.3390/en18133501

APA StyleKiss, A., Szabó, B., Kun, K., Hanula, B., & Weltsch, Z. (2025). Experimental Validation and Optimization of a Hydrogen–Gasoline Dual-Fuel Combustion Model in a Spark Ignition Engine with a Moderate Hydrogen Ratio. Energies, 18(13), 3501. https://doi.org/10.3390/en18133501