Integrated Control Strategies of EGR System and Fuel Injection Pressure to Reduce Emissions and Fuel Consumption in a DI Engine Fueled with Diesel-WCOME Blends and Neat Biodiesel

Abstract

1. Introduction

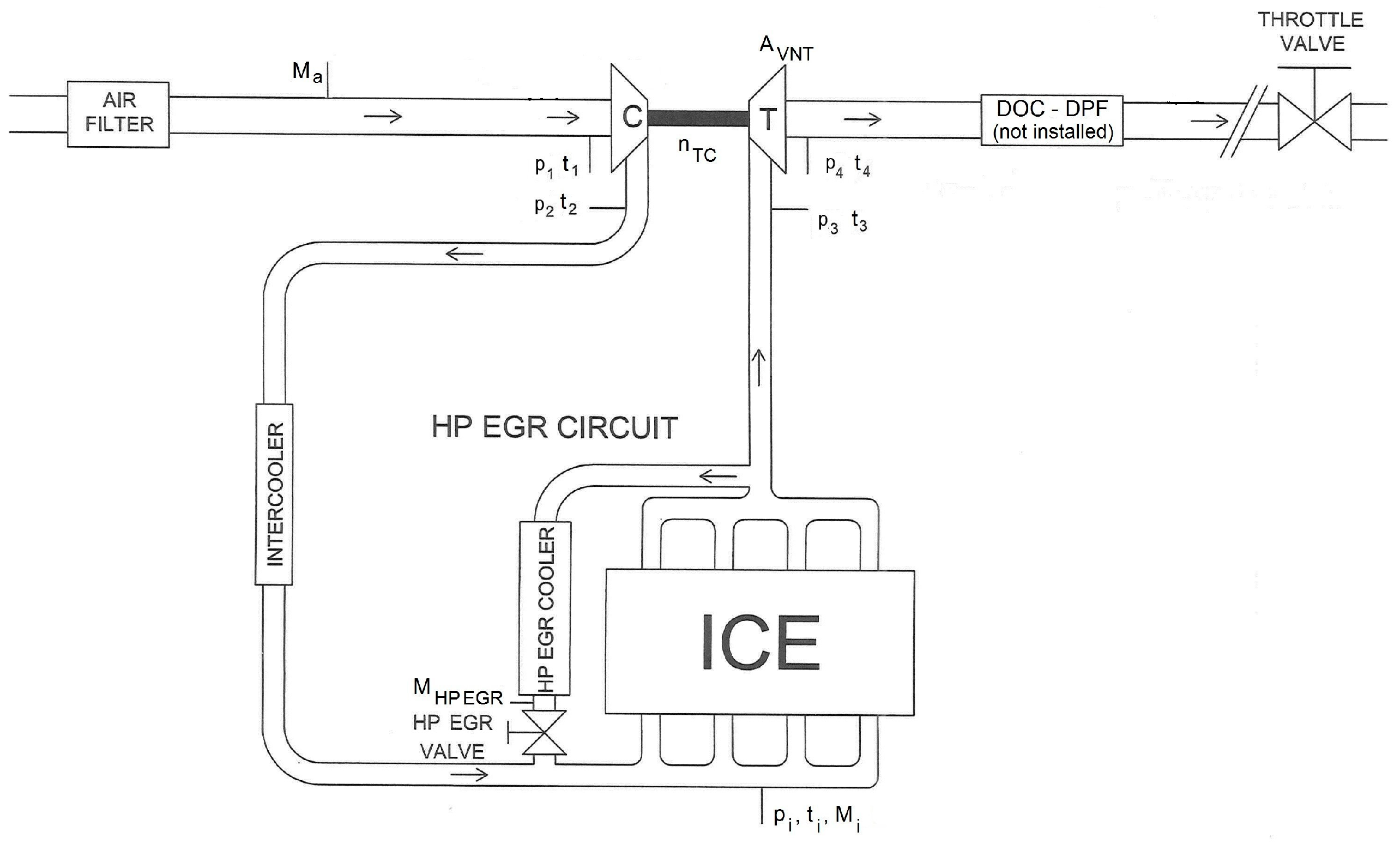

- Give a contribution to the assessment of the WCOME influence on NOX emission using an engine fitted with state-of-the-art sub-systems (HP EGR circuit, fuel injection system with electronic control, turbocharging system including a variable nozzle turbine).

- Analyze biodiesel application considering blends with high content or even neat WCOME, whose behavior is less available in the literature.

- Propose integrated control strategies for EGR rate and rail pressure, to improve benefits offered by biodiesel, matching a proper management of EGR circuit to compensate for the increase in NOX emission, a higher rail pressure values to limit soot emission, and blends with high WCOME content or neat biodiesel to minimize CO2 emission on a WtW base.

2. Materials and Methods

2.1. Tested Engine

2.2. Instruments and Measuring System

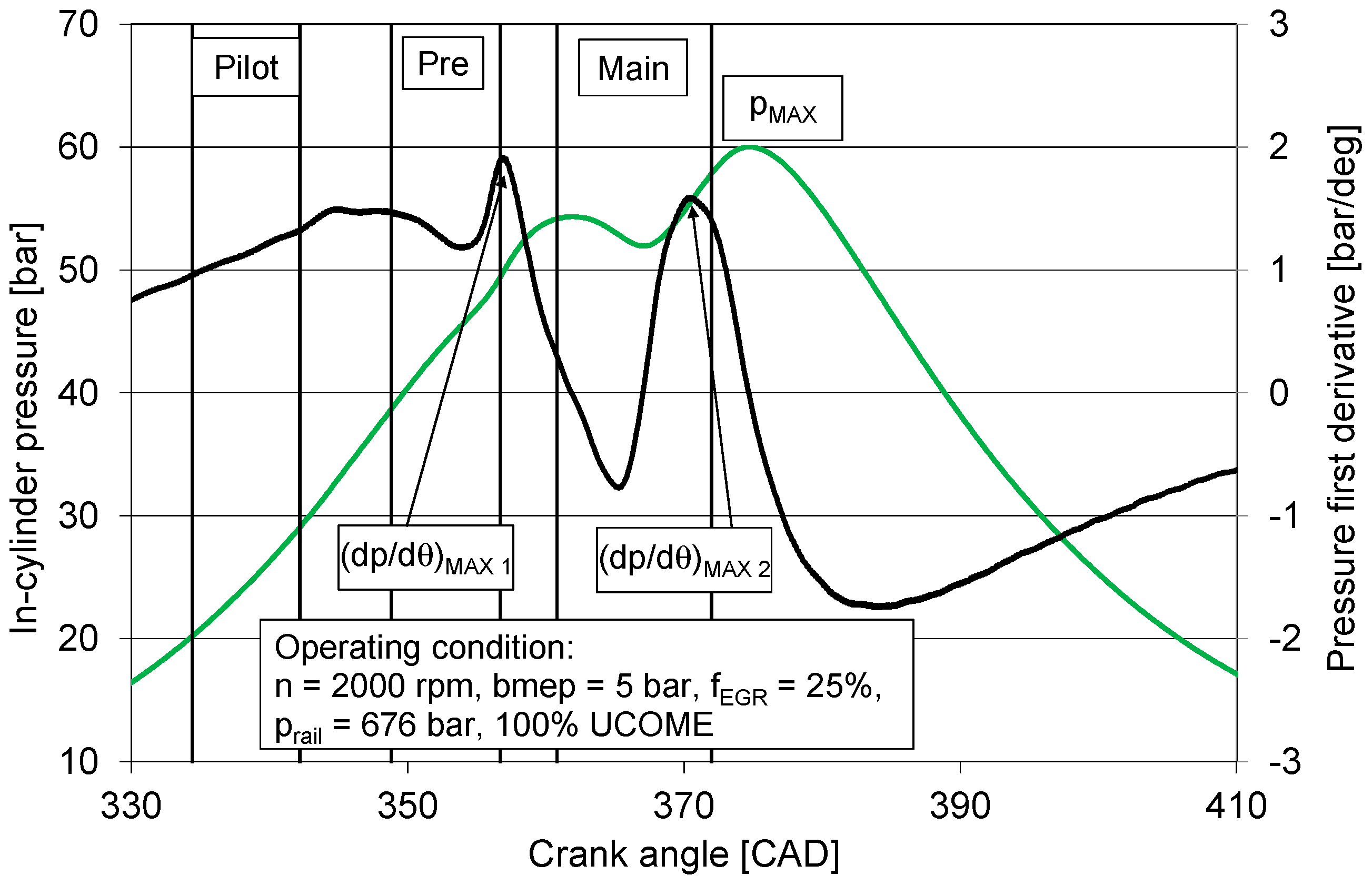

2.3. Pressure Diagrams, Heat Release Rate, and Combustion Parameters Evaluation

2.4. Engine Management System

2.5. Tested Fuels and Blends

2.6. Investigation Program

3. Results and Discussion

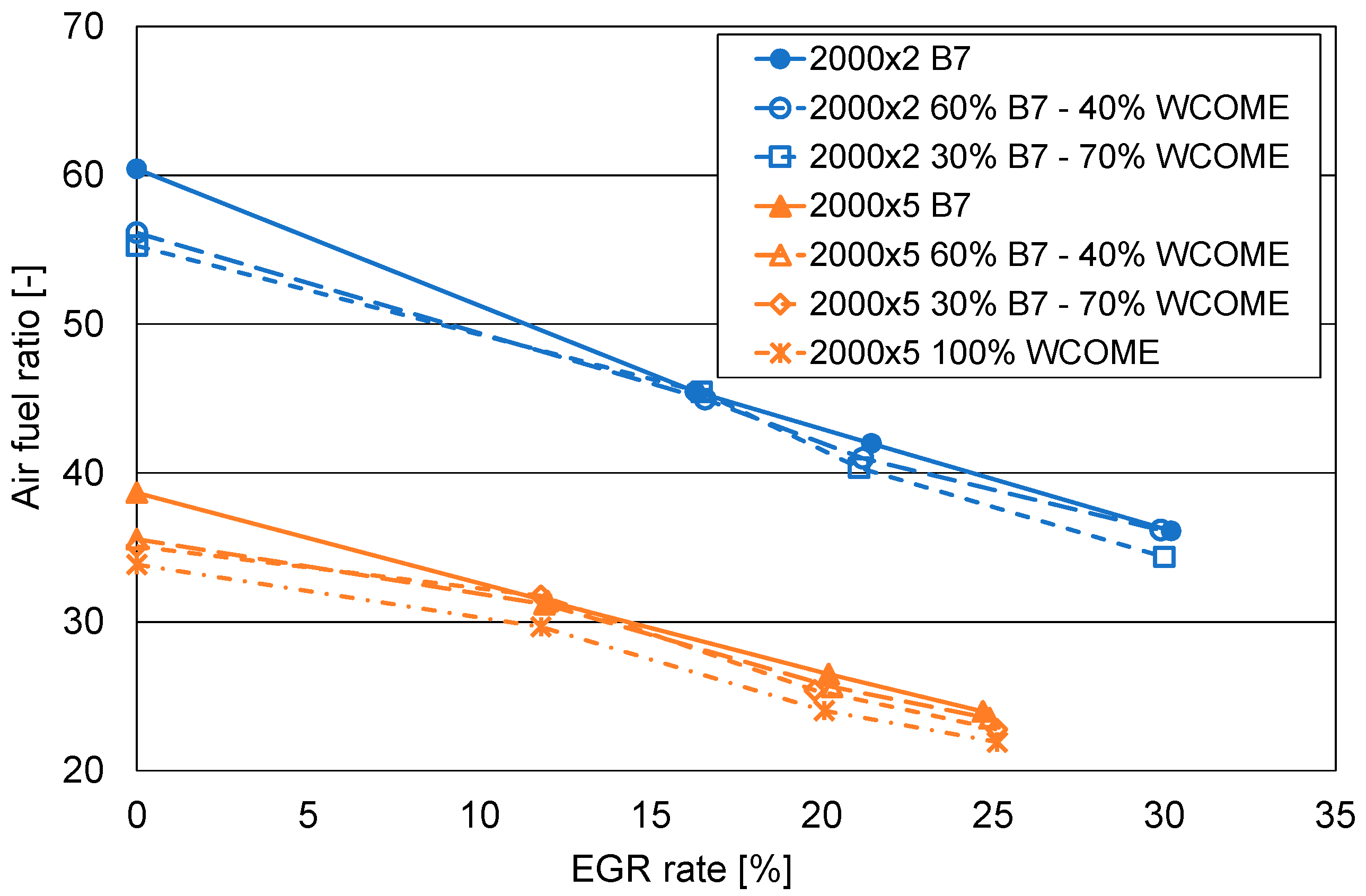

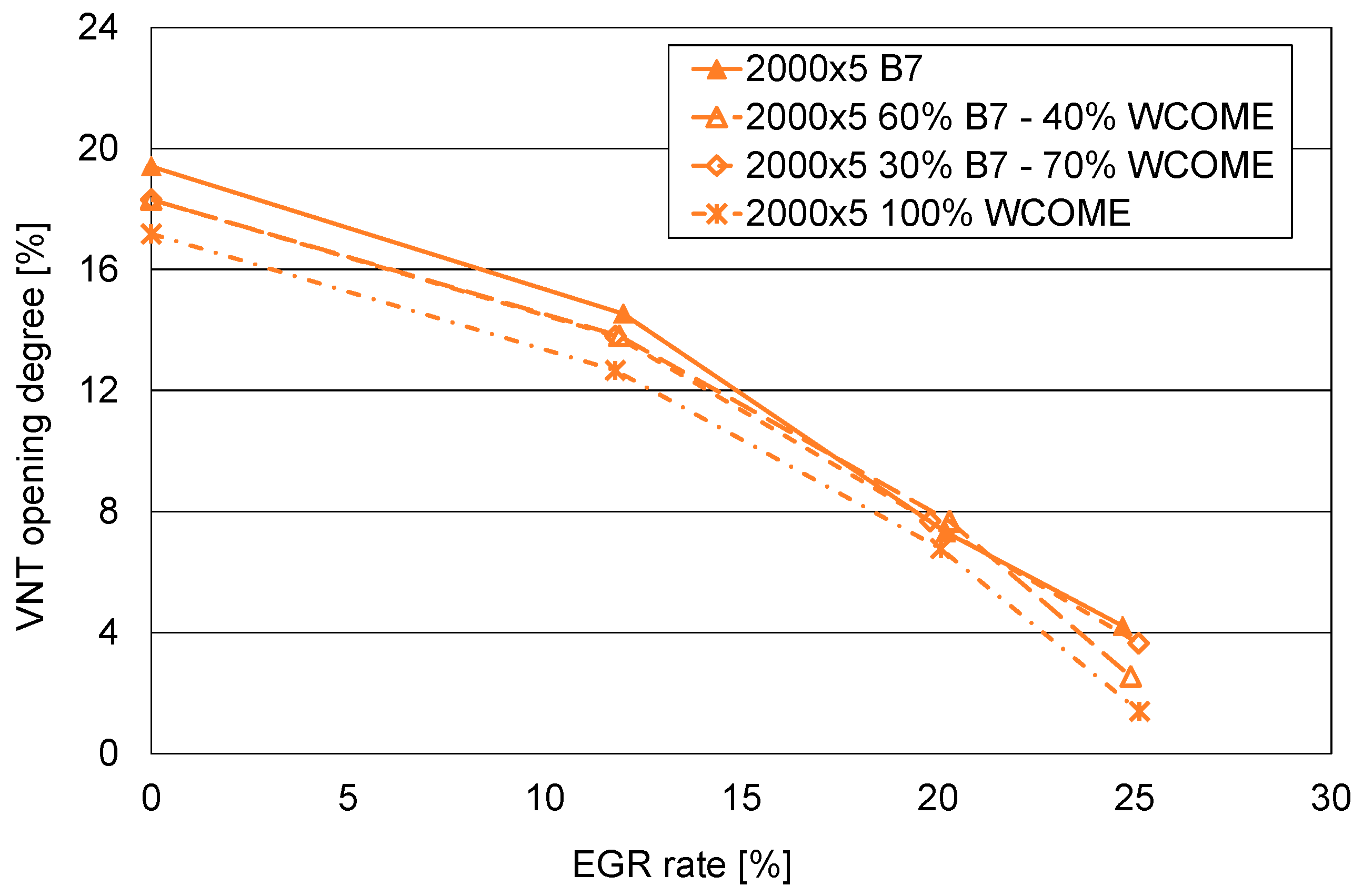

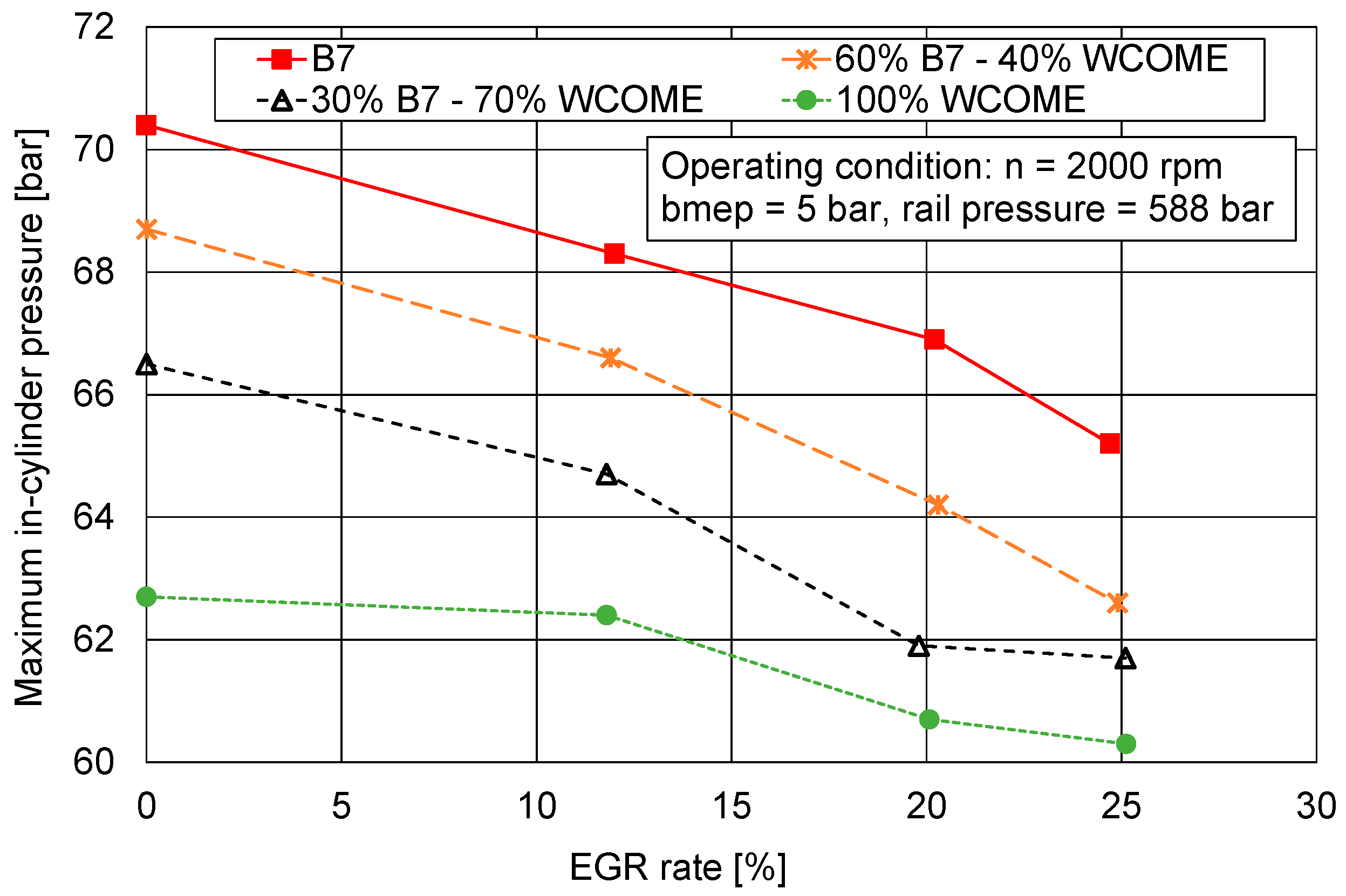

3.1. Influence of HP EGR System Control on Operating Parameters

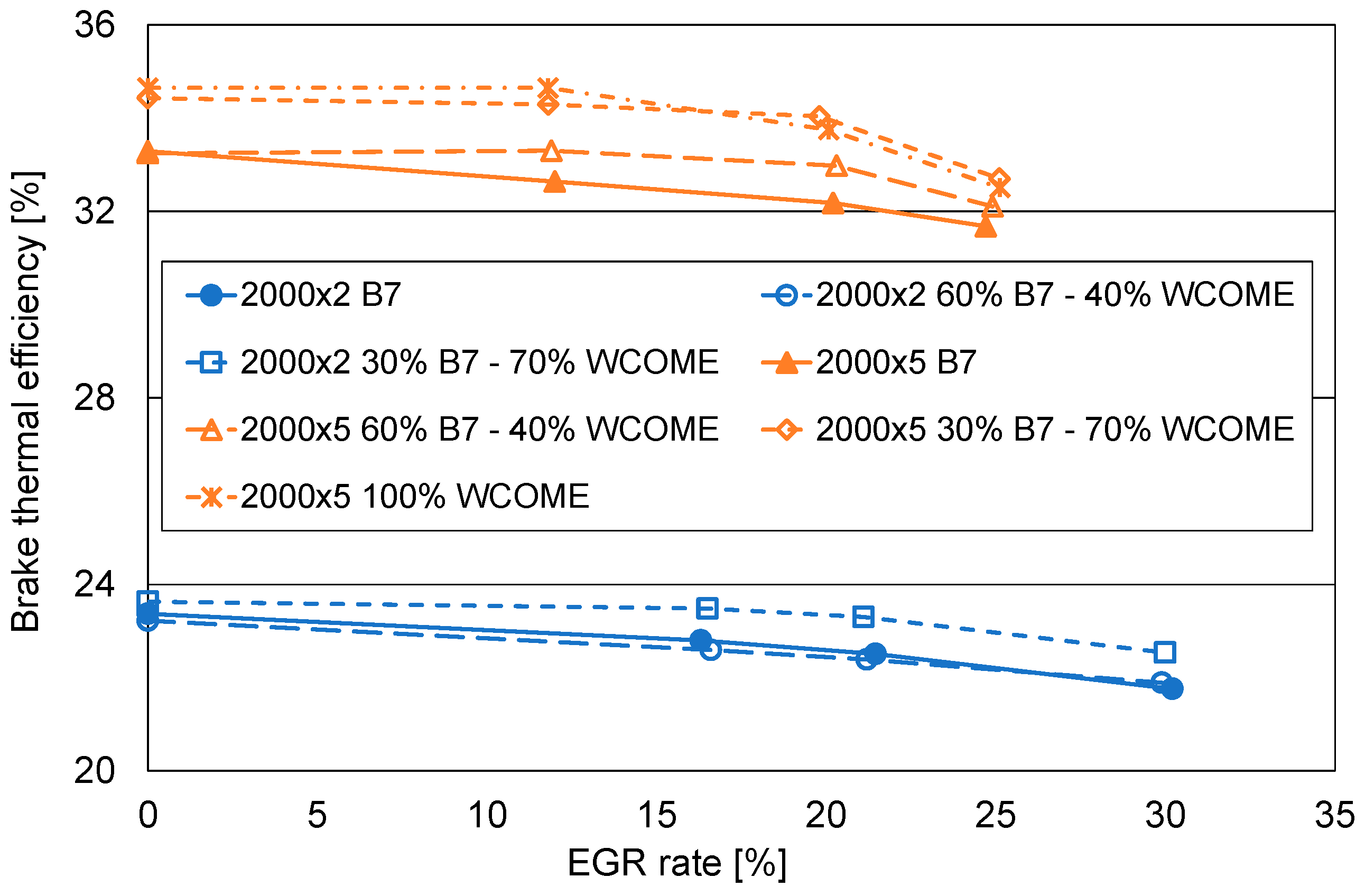

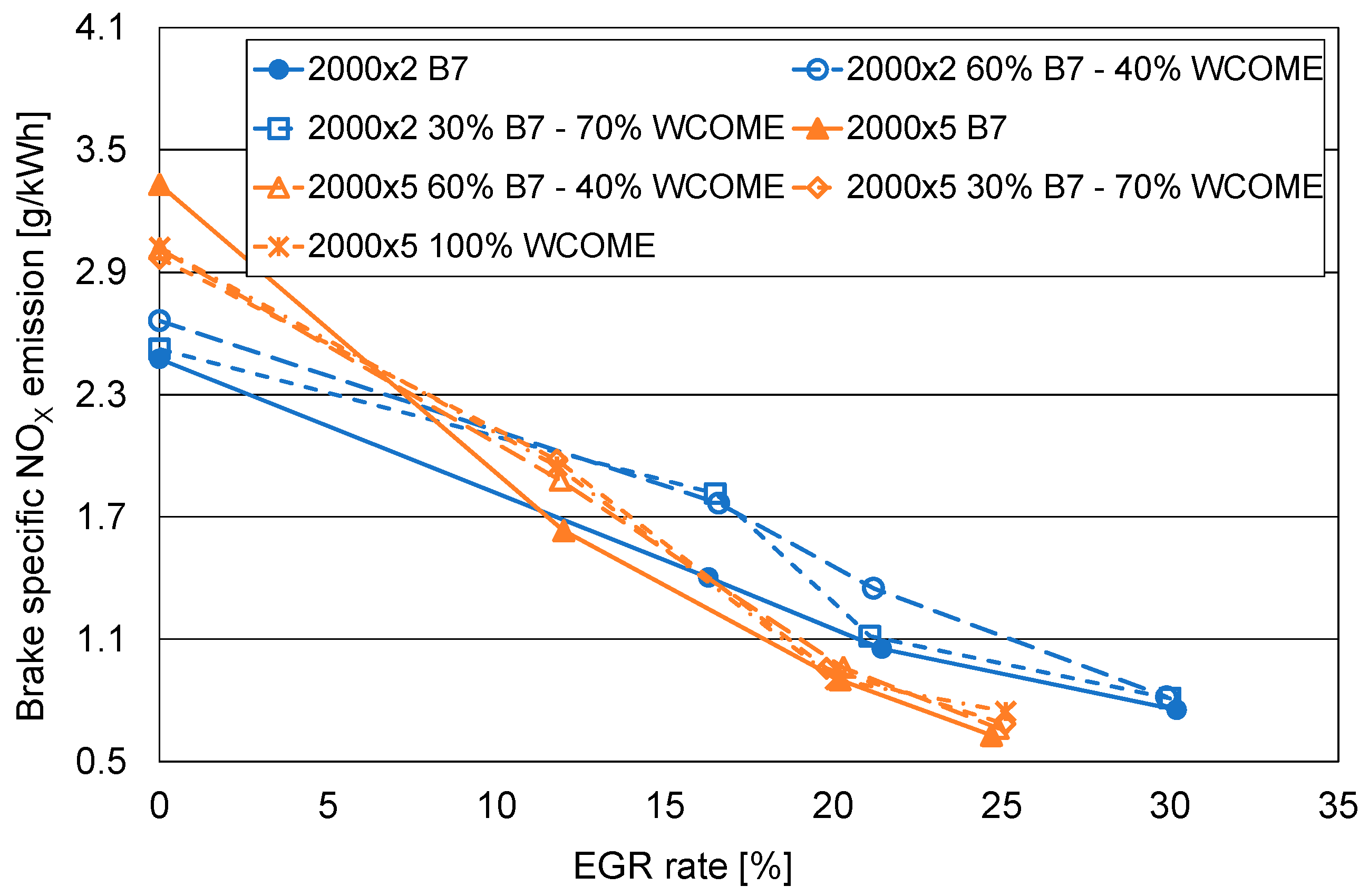

3.2. Influence of HP EGR System Control on Efficiency and Emissions

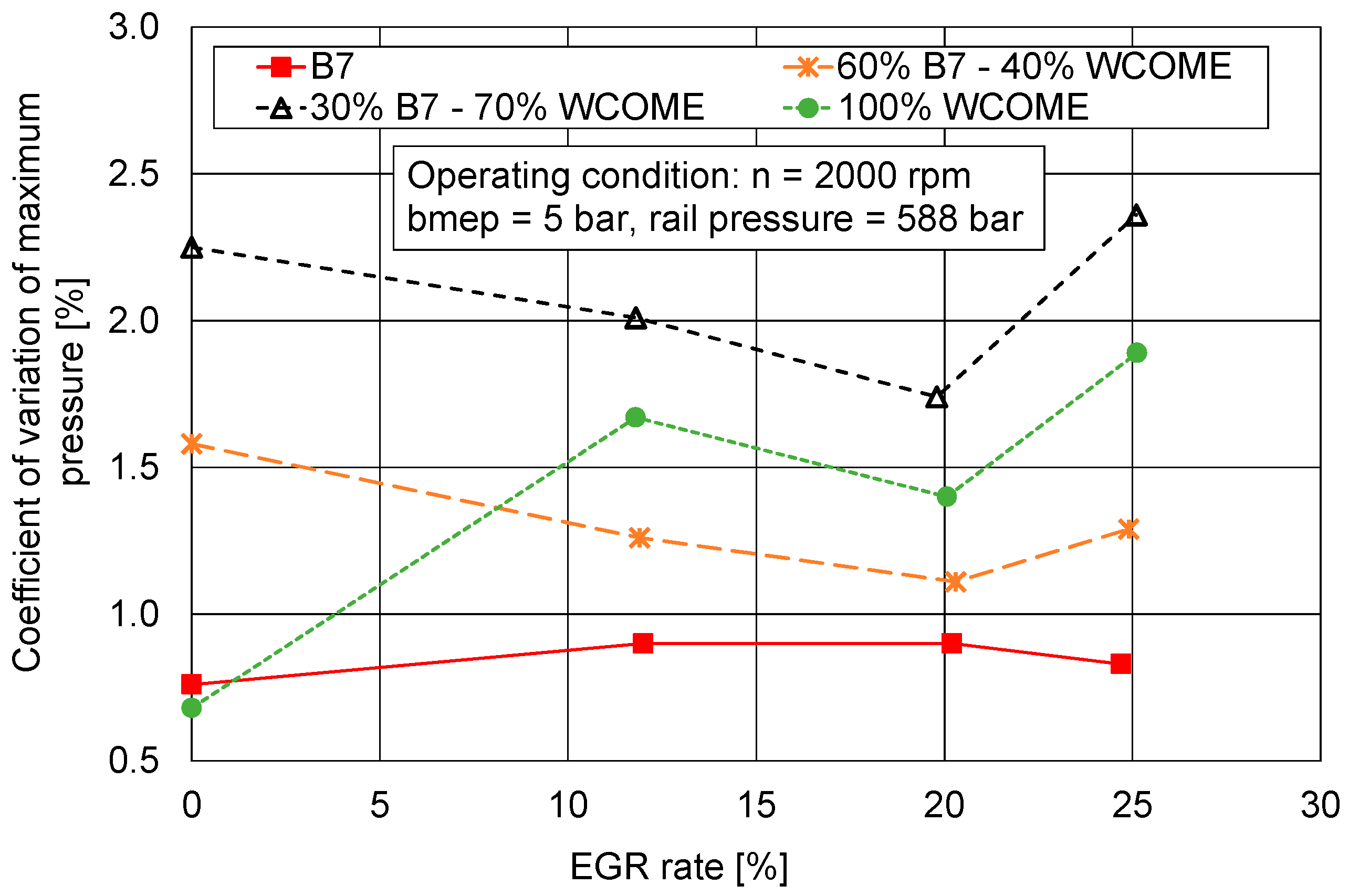

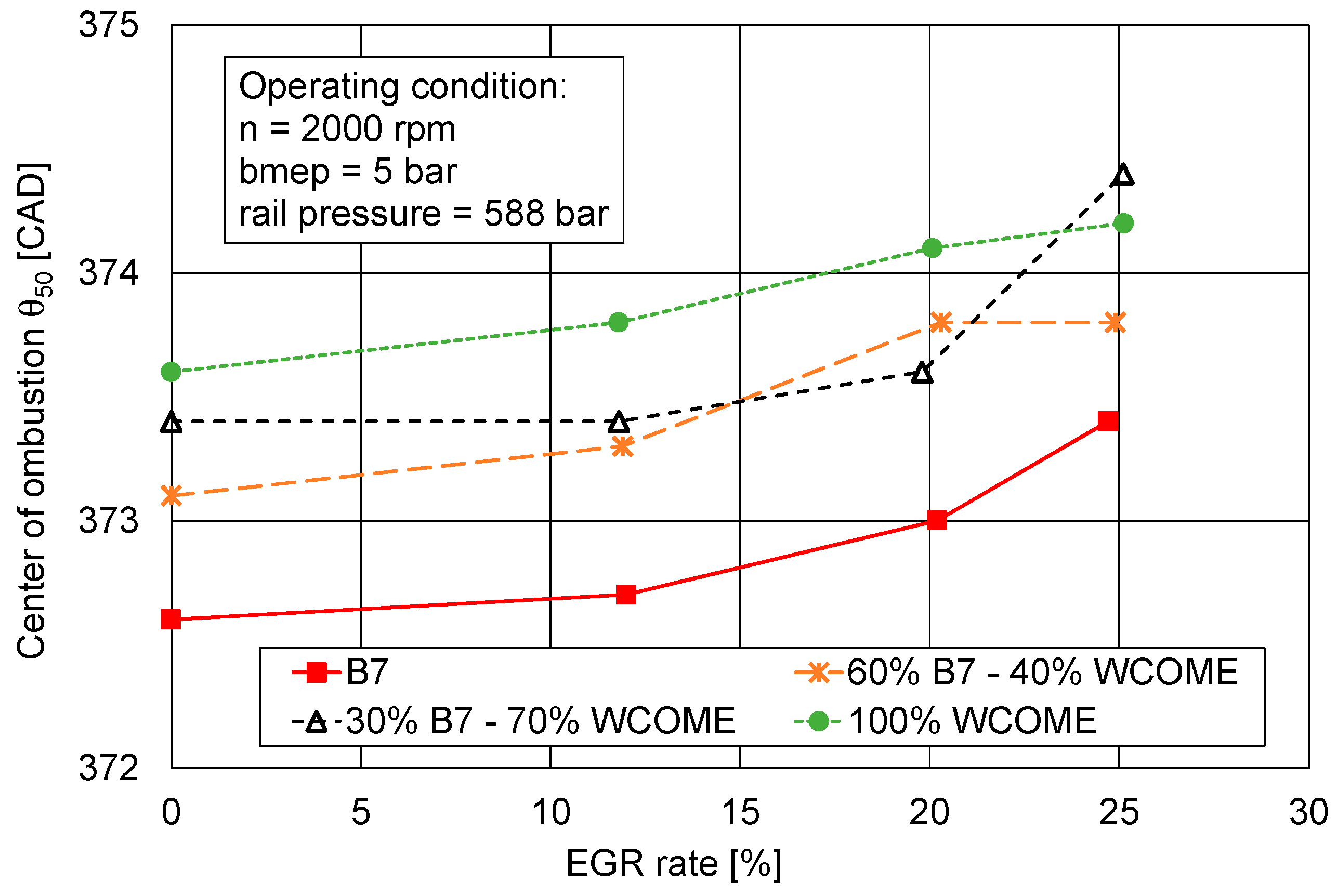

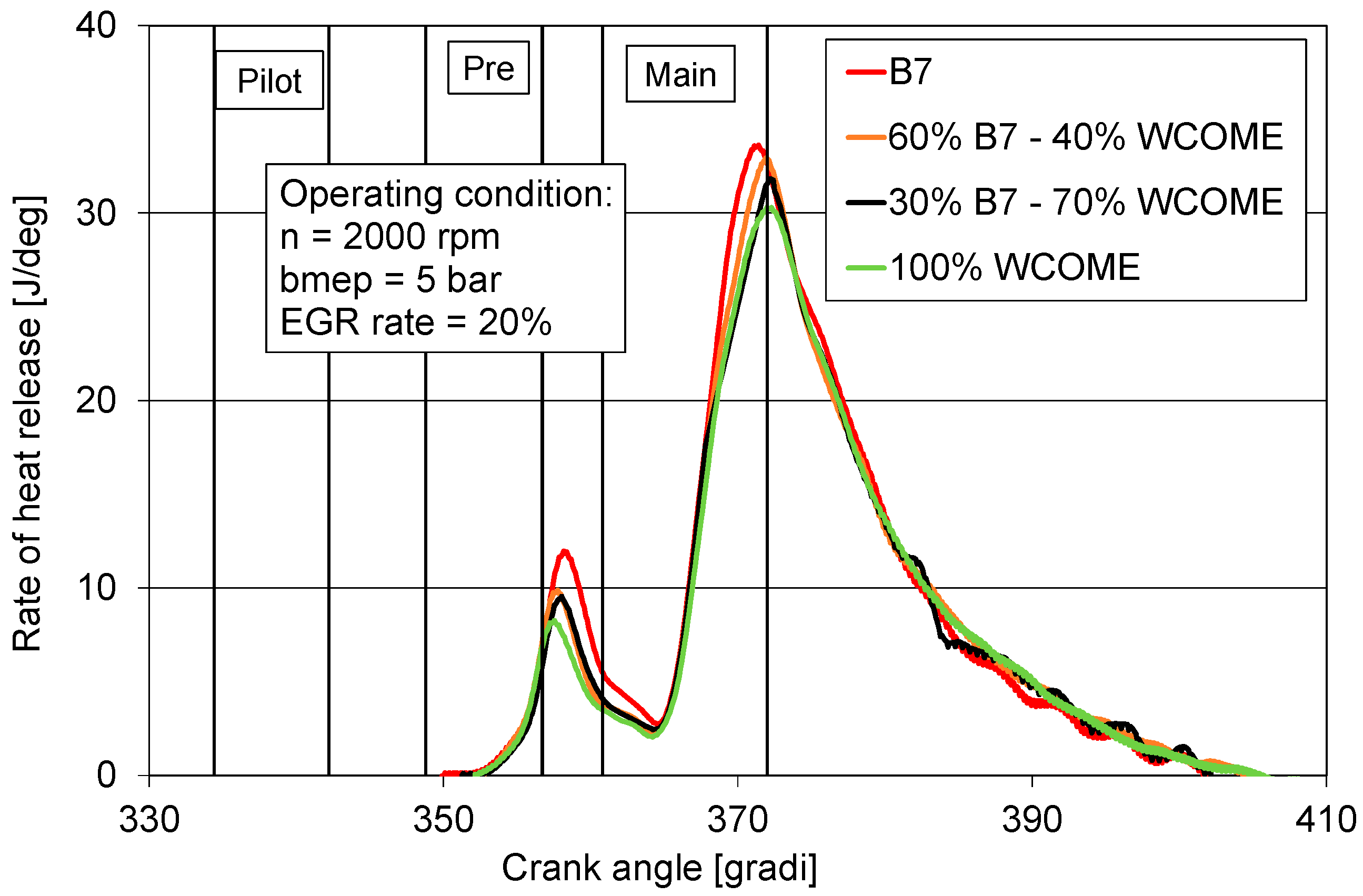

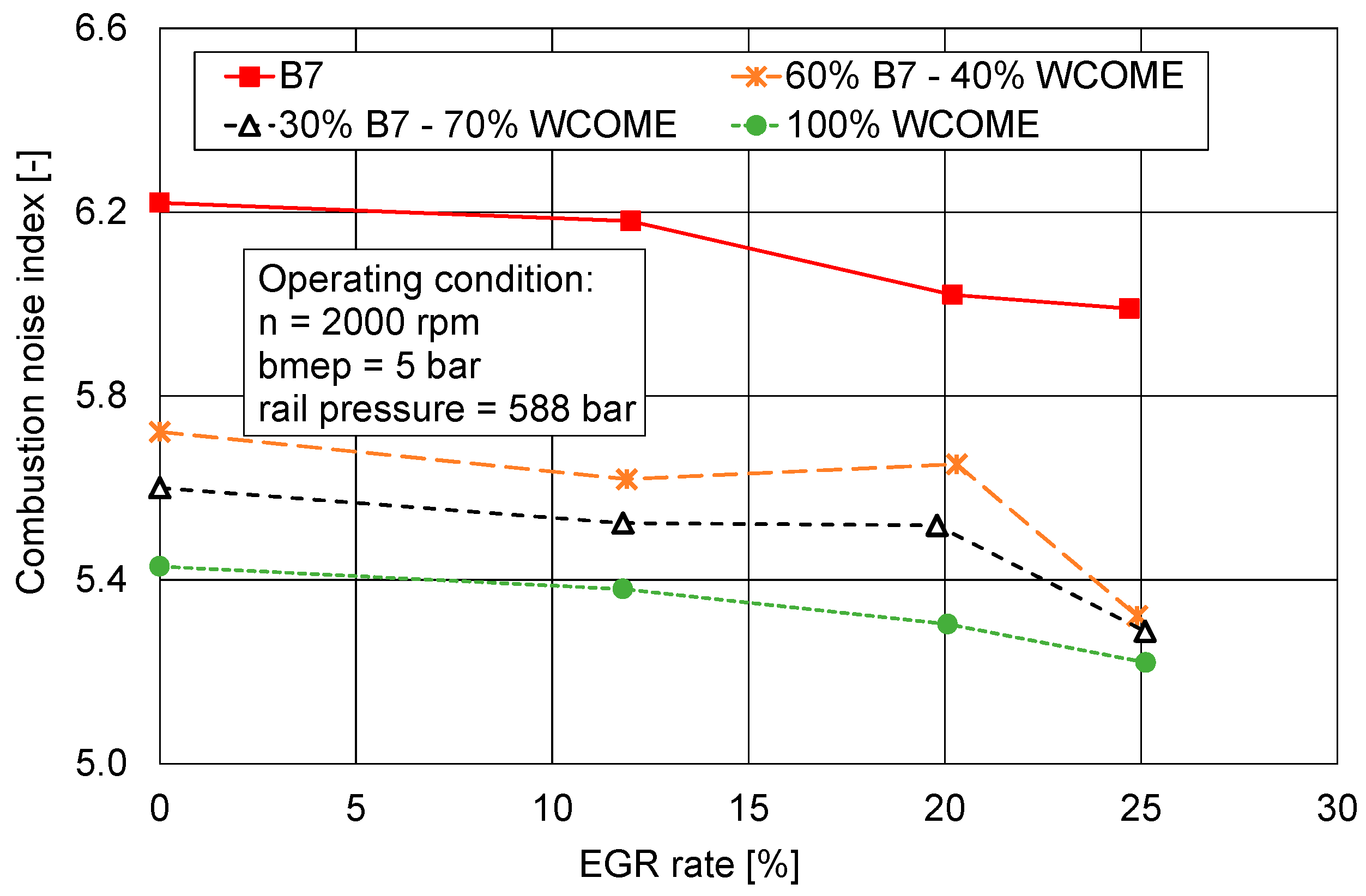

3.3. Influence of HP EGR System Control on Combustion Parameters

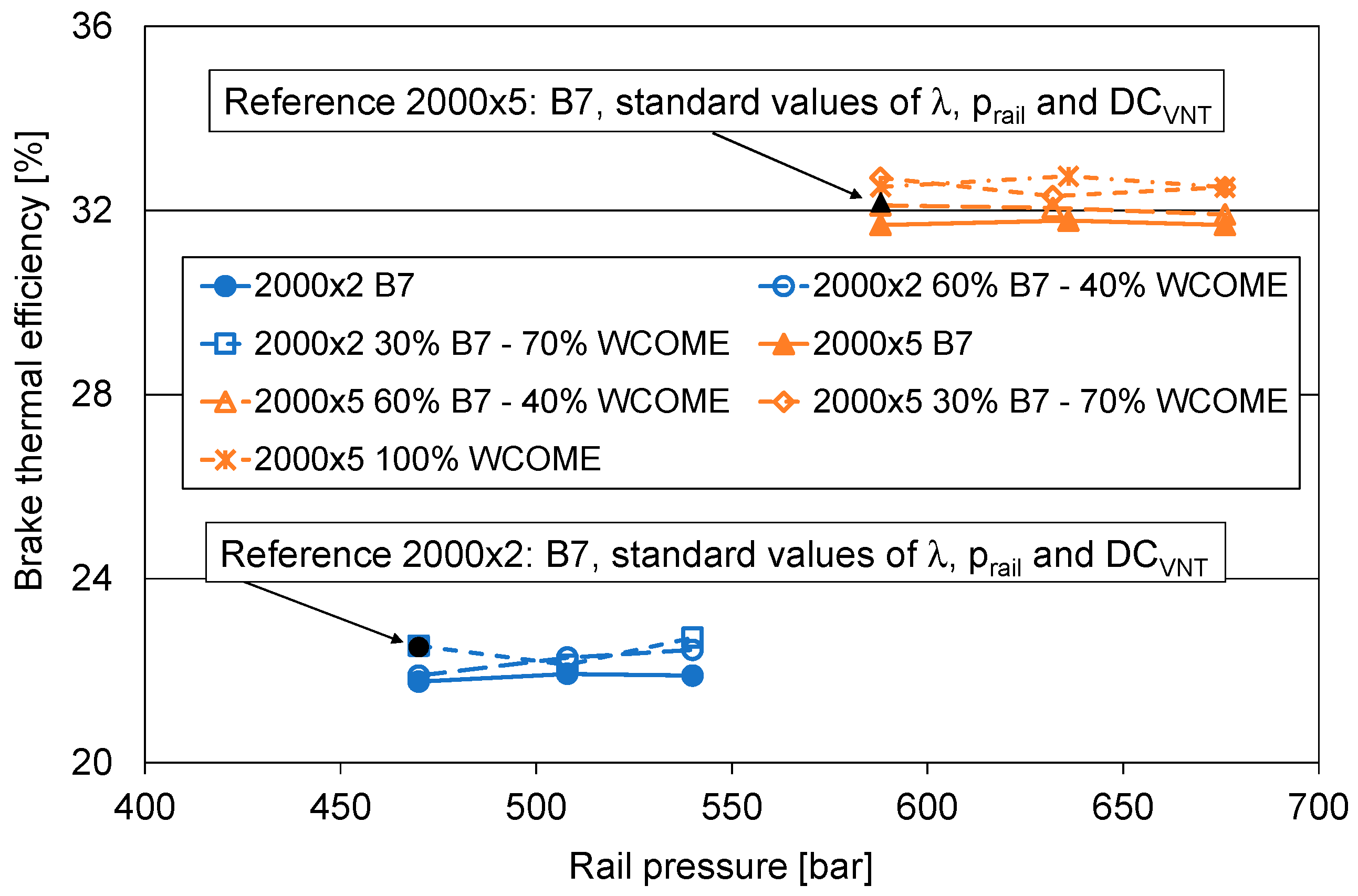

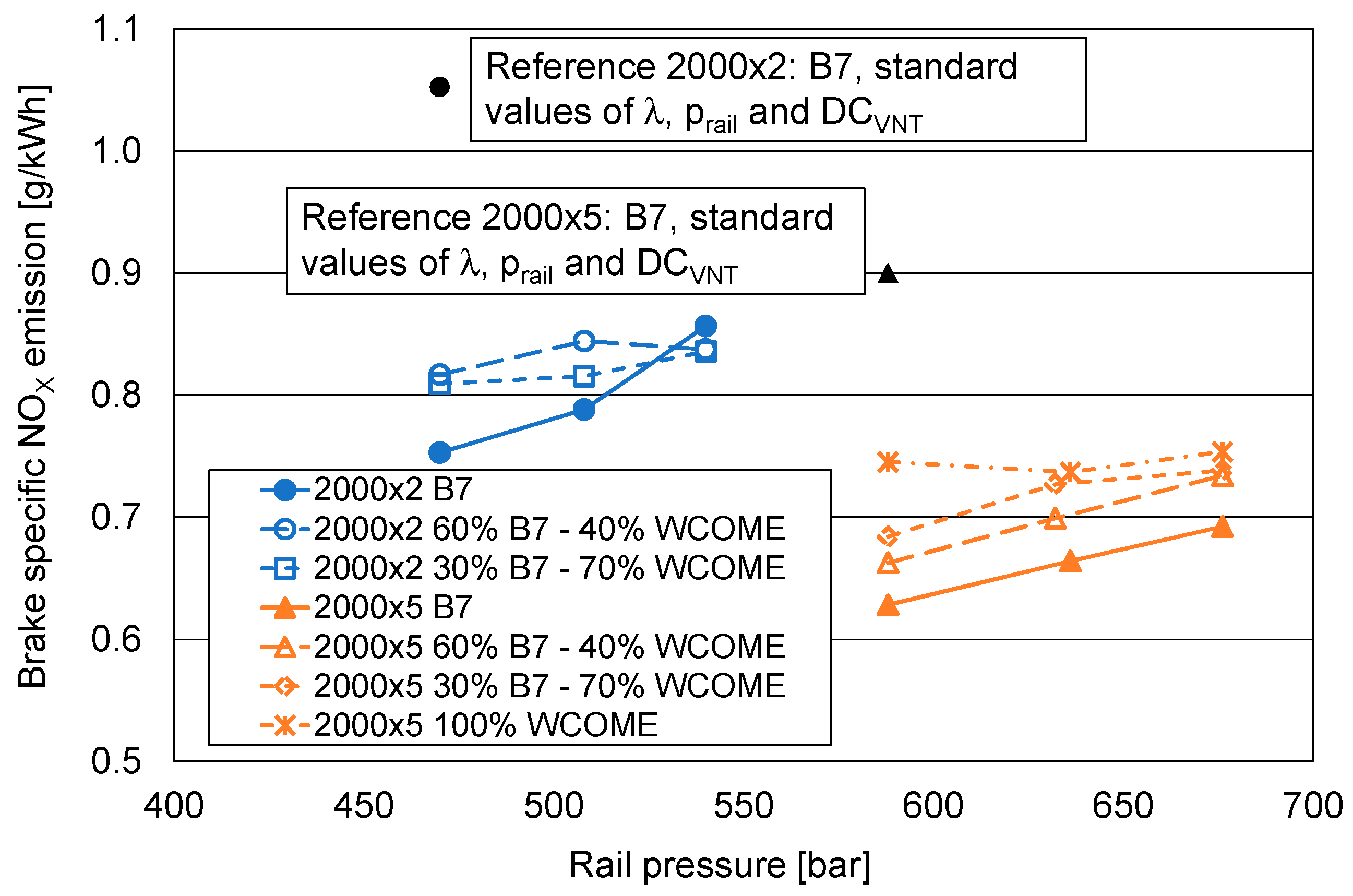

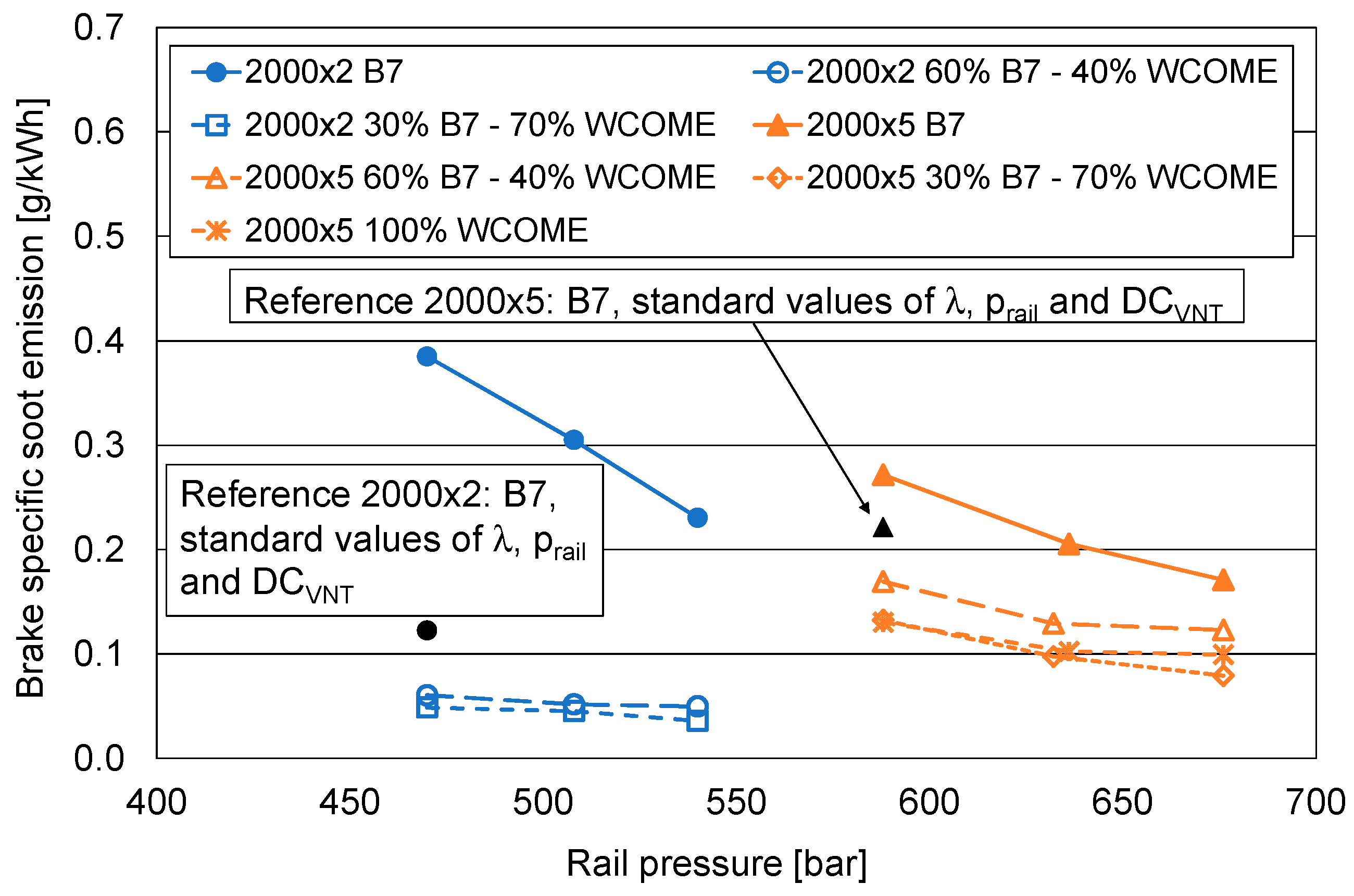

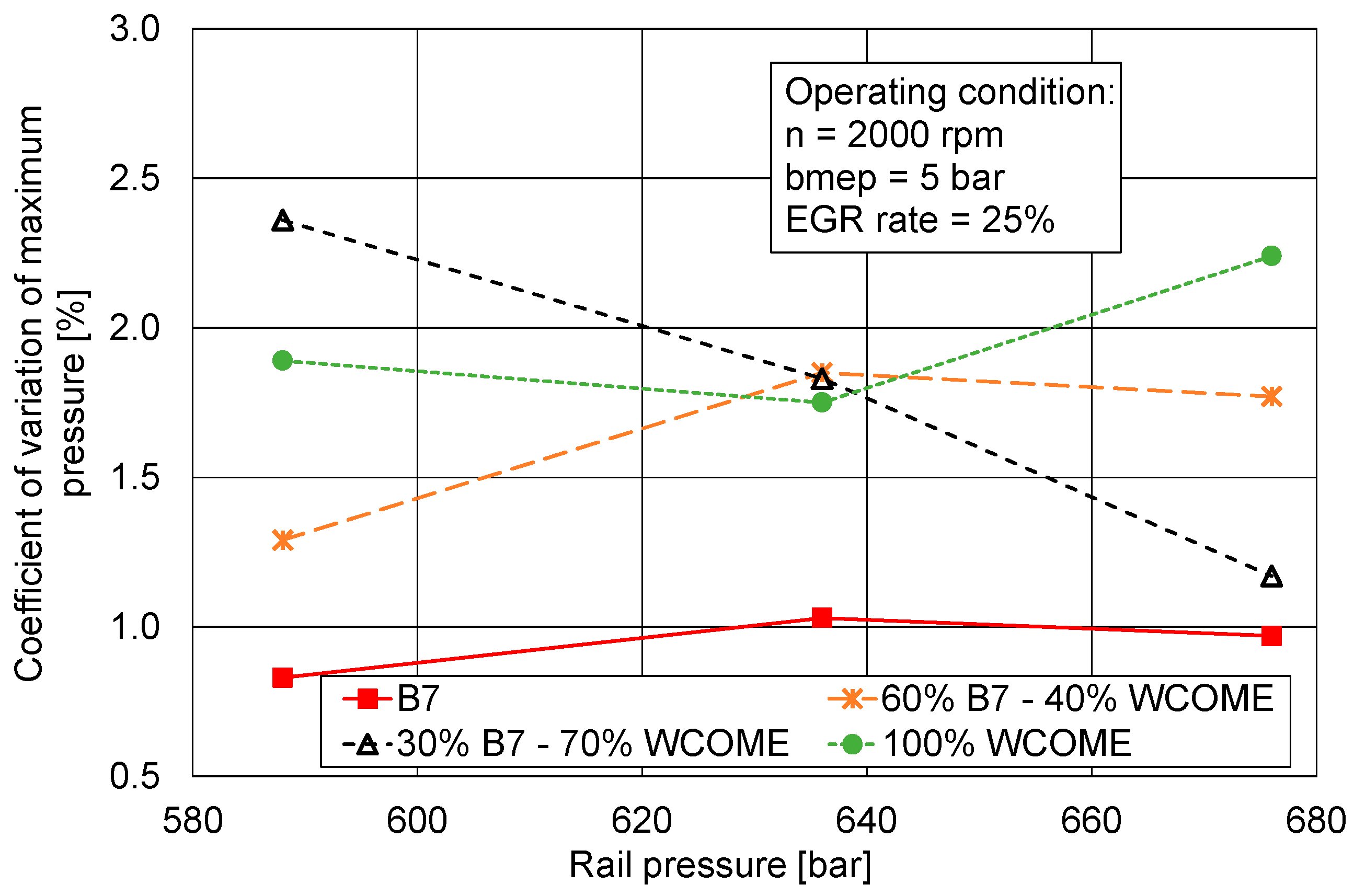

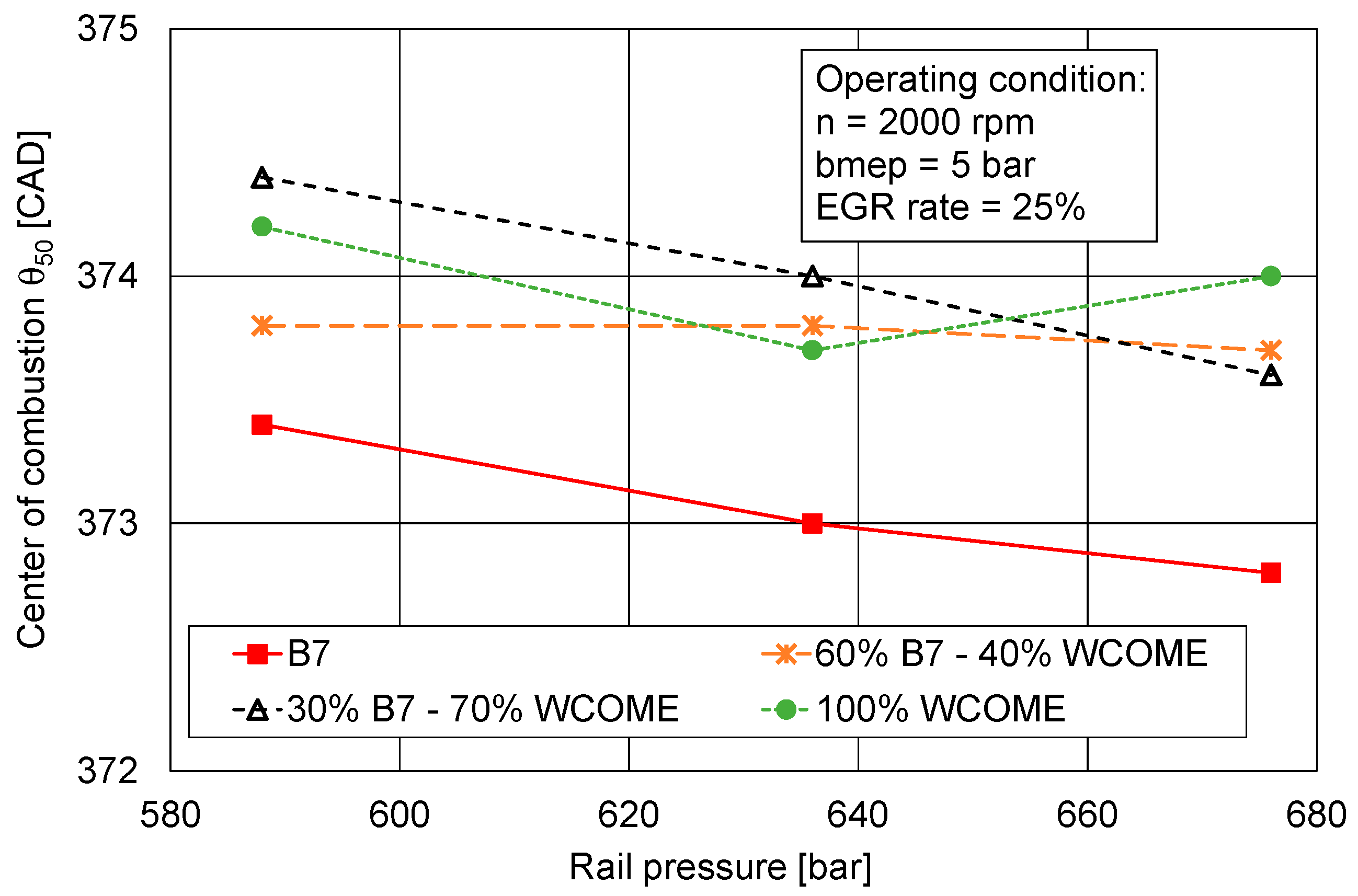

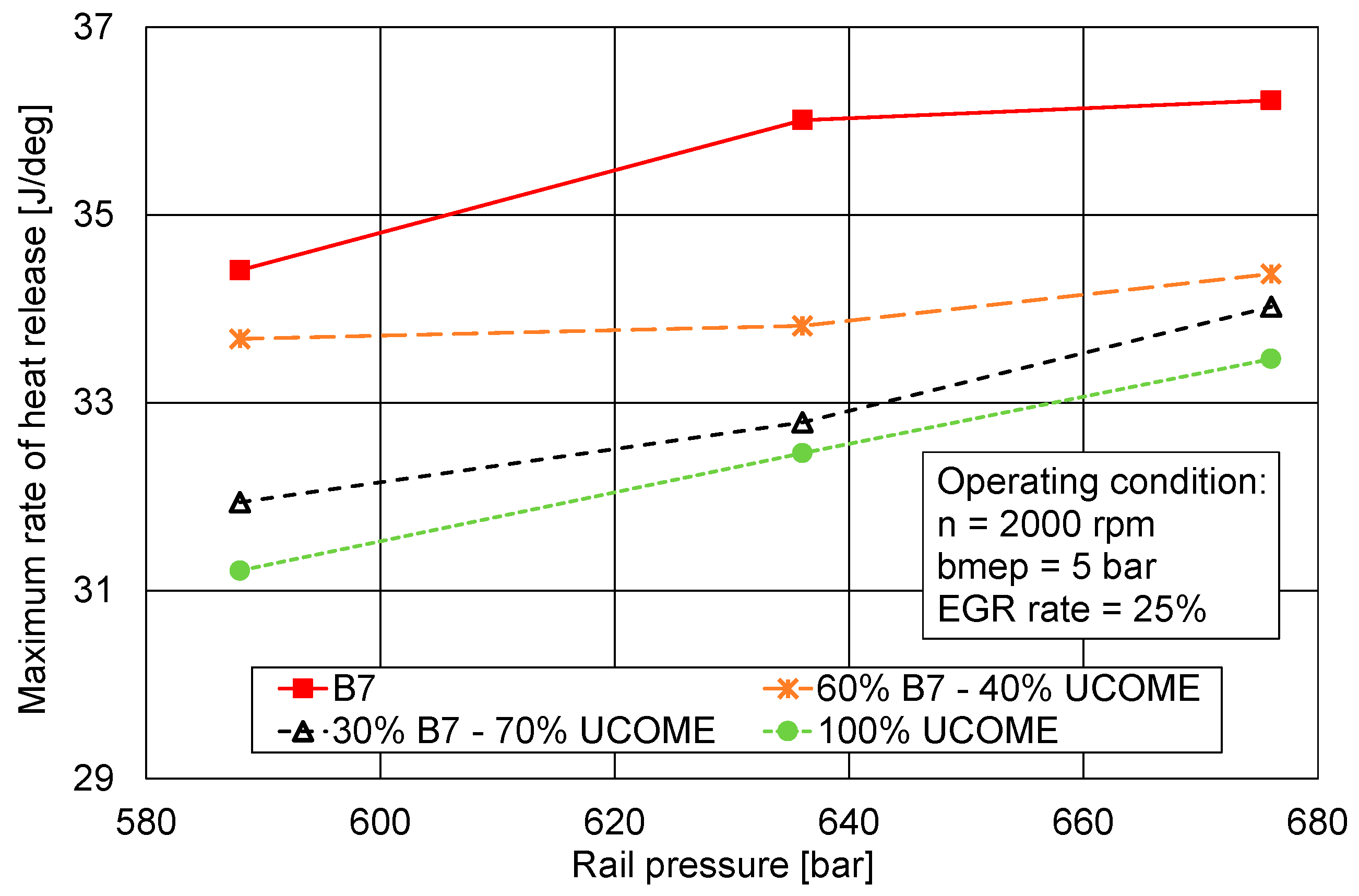

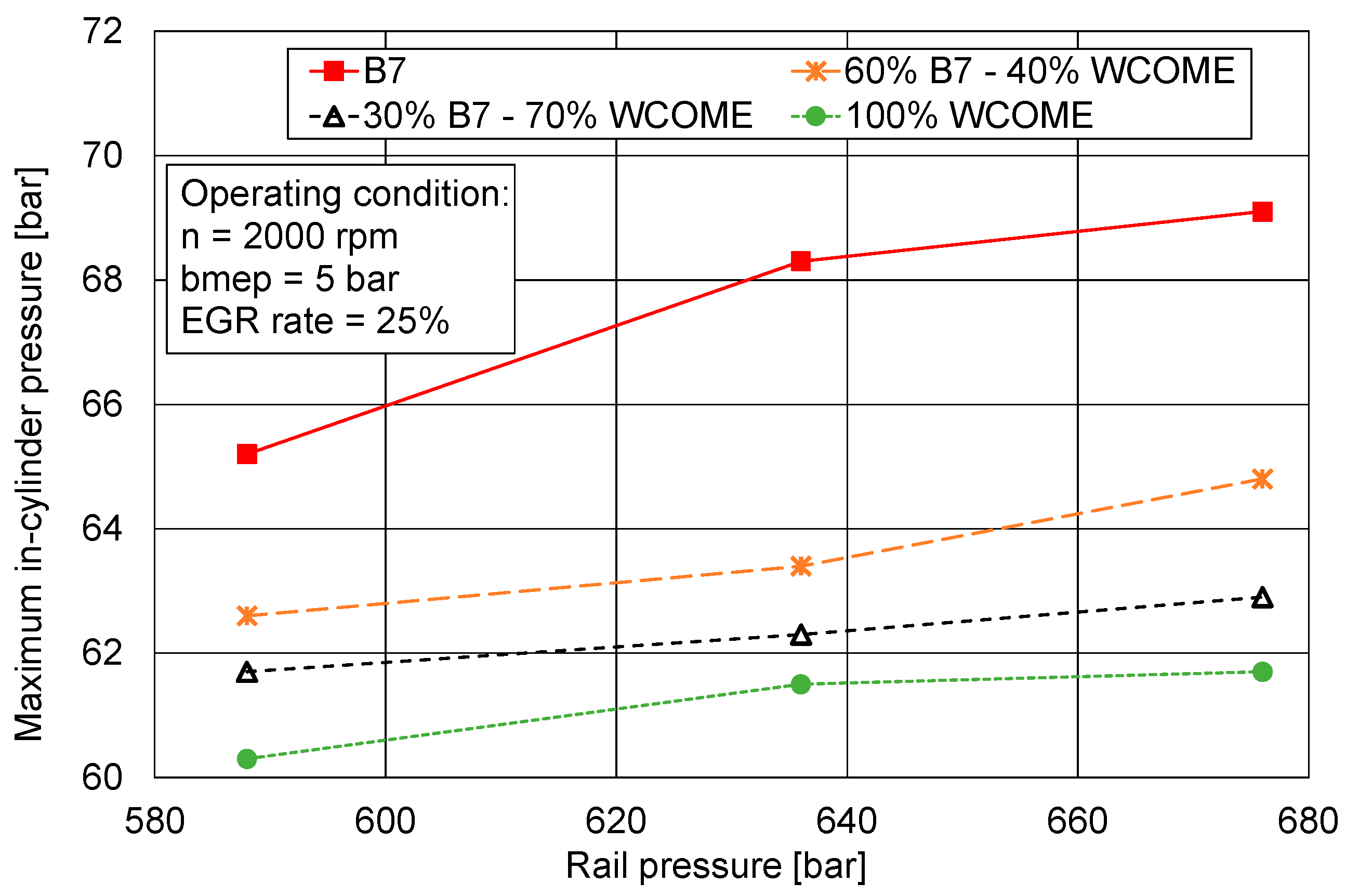

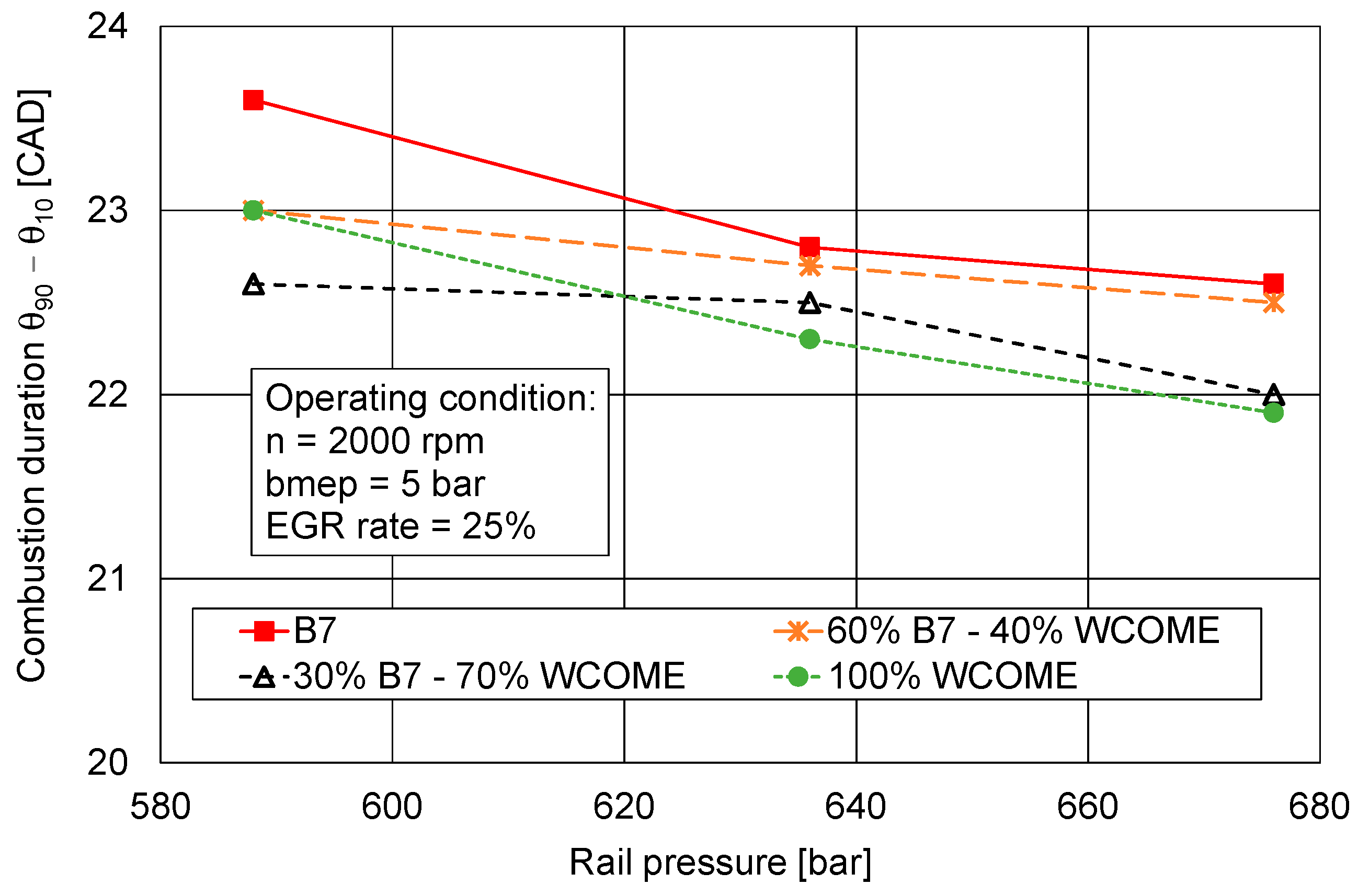

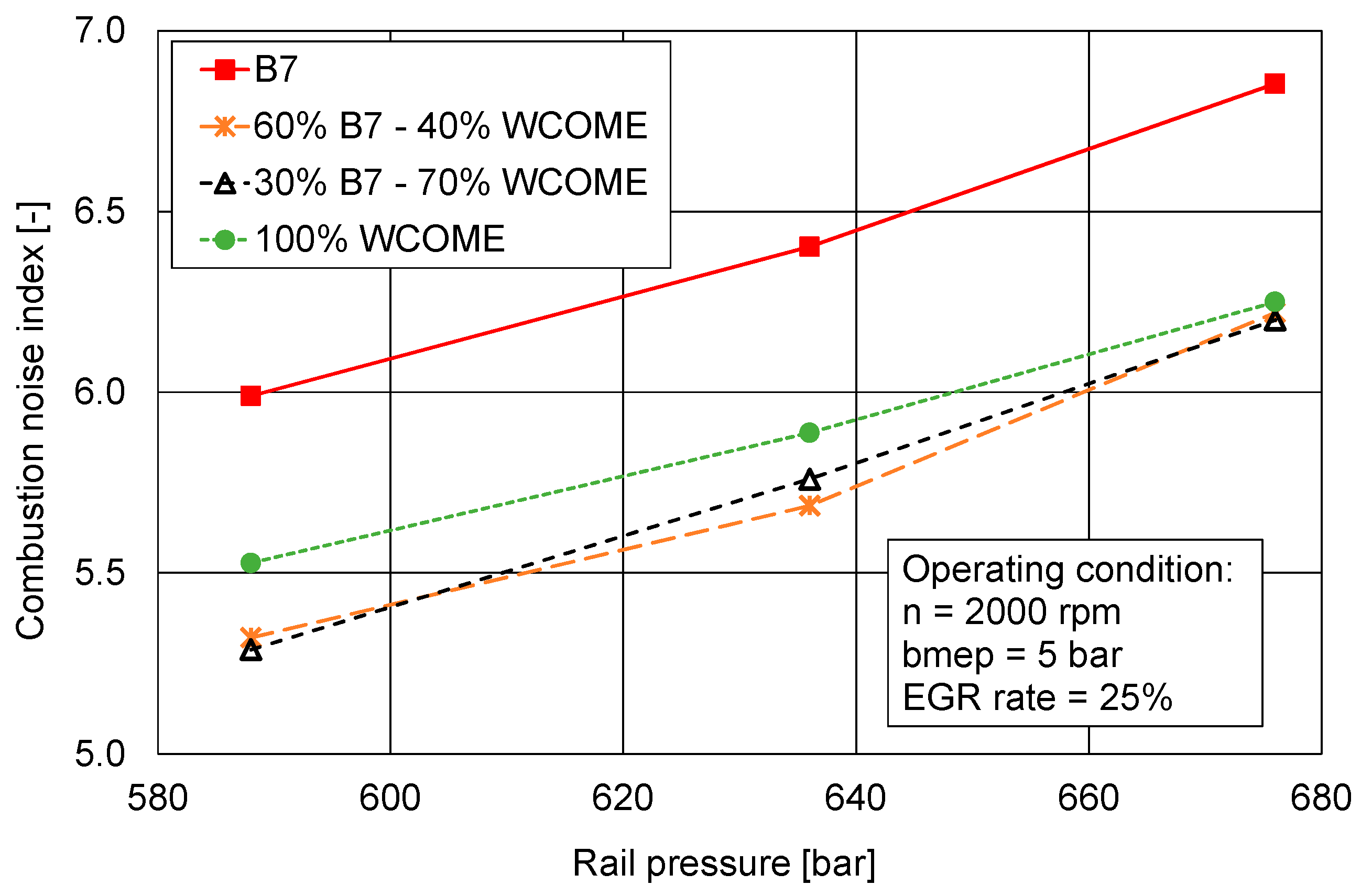

3.4. Influence of Rail Pressure Control at Maximum EGR Rate

4. Conclusions

- At a constant operating mode (i.e., at constant value of EGR rate and rail pressure), increasing biodiesel content led to penalties in fuel consumption, due to the reduced level of Lower Heating Value, but brake thermal efficiency was enhanced because of a shorter combustion duration. At the same time, the oxygen content of biodiesel resulted in higher NOX emissions and lower soot emissions.

- For a fixed fuel/blend, the EGR increase led to the expected reduction in NOX emission and an increase in soot emission. Bsfc was increased because of the control strategy applied to the variable nozzle turbine opening degree, aiming at keeping the intake pressure at a constant level while opening the EGR valve. This strategy results in higher engine pressure gradient and pumping losses.

- Higher levels of rail pressure resulted in better soot emission and higher NOX emission, because of the better fuel droplet atomization, faster evaporation, enhanced mixture formation, and better combustion.

- To compensate for the different negative effects, a proper selection of EGR rate and rail pressure values (higher than the standard levels) was tested, achieving better efficiency, NOX, and soot emissions when replacing reference B7 with blends and neat biodiesel.

- Heat release analysis and the assessment of combustion parameters provided further details about biodiesel effects. Combustion stability was granted when using WCOME, while the combustion process was modified, with a slower speed at the start, leading to a slight reduction in combustion noise and a limited shift of the center of combustion within the expansion stroke. Combustion duration is then reduced because of a faster speed in the second part of the process.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Notations | |

| bmep | brake mean effective pressure |

| bsfc | brake specific fuel consumption |

| bsNOX | brake specific NOX emission |

| bsS | brake specific soot emission |

| bte | brake thermal efficiency |

| f | mass fraction |

| k | ratio of specific heats |

| n | rotational speed |

| p | pressure |

| t | temperature [°C] |

| A | opening degree |

| AFR | air–fuel ratio |

| B | biodiesel |

| C | compressor |

| CAD | crank angle degree |

| CN | cetane number |

| CO2 | carbon dioxide |

| CoV | coefficient of variation |

| DC | duty-cycle |

| DOC | Diesel Oxidation Catalyst |

| DOU | Degree of Unsaturation |

| DPF | Diesel Particulate Filter |

| ECU | electronic control unit |

| EGR | exhaust gas recirculation |

| FAME | Fatty Acid Methyl Esters |

| FSN | Filter Smoke Number |

| GHG | Greenhouse gas |

| HP | high pressure |

| HVO | Hydrotreated Vegetable Oil |

| ICE | internal combustion engine |

| LHV | lower heating value |

| M | mass flow rate |

| Main | main injection |

| NO | nitric oxide |

| NOX | nitrogen oxides |

| PM | particulate matter |

| Pilot | pilot injection |

| Pre | pre injection |

| Q | Heat |

| ROHR | Rate of heat release |

| S | soot, displacement |

| SOI | Start of injection |

| T | turbine |

| TDC | Top Dead Center |

| TiO2 | Titanium dioxide |

| V | instantaneous cylinder volume |

| VNT | variable nozzle turbine |

| WCOME | waste cooking oil methyl esters |

| WtW | Well-to-Wheels/Well-to-Wake |

| λ | excess air ratio |

| θ | crank angle |

| Δ | variation |

| Subscripts | |

| 1 | compressor inlet, first |

| 2 | compressor outlet, second |

| 3 | turbine inlet |

| 4 | turbine outlet |

| a | air |

| f | fuel |

| i | intake |

| idle | idling mode |

| n | noise |

| rail | common rail |

| EGR | exhaust gas recirculation |

| MAX | maximum |

| MIN | minimum |

| TC | turbocharger |

References

- Available online: https://www.consilium.europa.eu/en/policies/green-deal/fit-for-55/ (accessed on 19 March 2025).

- Joung, T.H.; Kang, S.G.; Lee, J.K.; Ahn, J. The IMO initial strategy for reducing Greenhouse Gas (GHG) emissions, and its follow-up actions towards 2050. J. Int. Marit. Saf. Environ. Aff. Shipp. 2020, 4, 1–7. [Google Scholar] [CrossRef]

- Det Norske Veritas. Energy Transition Outlook 2023—Transport in Transition; Det Norske Veritas: Melbourne, Australia, 2023. [Google Scholar]

- Kalghatgi, G. Is it really the end of internal combustion engines and petroleum in transport? Appl. Energy 2018, 225, 965–974. [Google Scholar] [CrossRef]

- Reitz, R.D.; Ogawa, H.; Payri, R.; Fansler, T.; Kokjohn, S.; Moriyoshi, Y.; Agarwal, A.K.; Arcoumanis, D.; Assanis, D.; Bae, C.; et al. The future of the internal combustion engine. Int. J. Engine Res. Editor. 2019, 21, 3–10. [Google Scholar] [CrossRef]

- Serrano, J.R.; Novella, R.; Piqueras, P. Why the Development of Internal Combustion Engines Is Still Necessary to Fight against Global Climate Change from the Perspective of Transportation. Appl. Sci. 2019, 9, 4597. [Google Scholar] [CrossRef]

- Senecal, K.; Leach, F. Racing Toward Zero—The Untold Story of Driving Green; R-501; SAE International: Warrendale, PA, USA, 2021. [Google Scholar]

- Joint Research Centre of the European Commission. Renewable Fuels of Non-Biological Origin in the European Union—Status Report on Technology Development, Trends, Value Chains and Market; Report JRC130729; Publications Office of the European Union: Luxembourg, 2022. [Google Scholar]

- Joint Research Centre of the European Commission. Advanced Biofuels in the European Union—Status Report on Technology Development, Trends, Value Chains and Market; Report JRC130727; Publications Office of the European Union: Luxembourg, 2022. [Google Scholar]

- European Union. Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources. Off. J. Eur. Union 2018, L 328/82, 82–209. [Google Scholar]

- European Union. Directive (EU) 2023/2413 of the European Parliament and of the Council of 18 October 2023 amending Directive (EU) 2018/2001, Regulation (EU) 2018/1999 and Directive 98/70/EC as regards the promotion of energy from renewable sources and repealing Council Directive (EU) 2015/652. Off. J. Eur. Union 2023, 1–77. [Google Scholar]

- Chong, C.T.; Ng, J.H. Advanced Transport Biofuels. Production, Economics, and Sustainability; Woodhead Series in Bioenergy; Elsevier: Amsterdam, The Netherlands, 2025. [Google Scholar]

- European Union. Regulation (EU) 2023/1805 of the European Parliament and of the Council of 13 September 2023 on the use of renewable and low-carbon fuels in maritime transport and amending Directive 2009/16/EC (Fuel EU Maritime). Off. J. Eur. Union 2023, L 234/48, 48–100. [Google Scholar]

- Zamboni, G.; Scamardella, F.; Gualeni, P.; Canepa, E. Comparative analysis among different alternative fuels for ship propulsion in a well-to-wake perspective. Heliyon 2024, 10, e26016. [Google Scholar] [CrossRef] [PubMed]

- Yang, R.; Shang, T.; Li, L.; Liu, J.; Xie, T.; Liu, Z.; Liu, J. The mechanism of the increased ratio of nitrogen dioxide to nitrogen oxides in methanol/diesel dual fuel engines. Energy 2024, 133701. [Google Scholar] [CrossRef]

- Wang, Z.; Jie, Z.; Liu, X. Combustion and Emission Characteristics of Methanol–Diesel Dual Fuel Engine at Different Altitudes. J. Mar. Sci. Eng. 2024, 12, 2210. [Google Scholar] [CrossRef]

- Liu, Y.; Cai, K.; Qi, Y.; Chen, Q.; Chen, H.; Wang, Z. Experimental investigation on N2O emission characteristics of ammonia-diesel dual-fuel engines. Int. J. Engine Res. 2025, 14680874241307920. [Google Scholar] [CrossRef]

- Dong, P.; Liu, K.; Zhang, L.; Zhang, Z.; Long, W.; Tian, H. Study on the synergistic control of nitrogenous emissions and greenhouse gas of ammonia/diesel dual direct injection two-stroke engine. Energy 2024, 132657. [Google Scholar] [CrossRef]

- Rueda-Vázquez, J.M.; Serrano, J.; Pinzi, S.; Jiménez-Espadafor, F.J.; Dorado, M.P. A Review of the Use of Hydrogen in Compression Ignition Engines with Dual-Fuel Technology and Techniques for Reducing NOx Emissions. Sustainability 2024, 16, 3462. [Google Scholar] [CrossRef]

- Guan, M.; Rochussen, J.; Steiche, P.; Sapkota, N.; Farzam, R.; McTaggart-Cowan, G.; Rogak, S.N.; Kirchen, P. Characterizing hydrogen-diesel dual-fuel performance and emissions in a commercial heavy-duty diesel truck. Int. J. Hydrogen Energy 2024, 86, 1085–1096. [Google Scholar] [CrossRef]

- Lapuerta, M.; Armas, O.; Rodrìguez-Fernàndez, J. Effect of biodiesel fuels on diesel engine emissions. Prog. Energy Combust. Sci. 2008, 34, 198–223. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Gupta, J.G.; Dhar, A. Potential and challenges for large-scale application of biodiesel in automotive sector. Prog. Energy Combust. Sci. 2017, 61, 113–149. [Google Scholar] [CrossRef]

- Razzaq, L.; Mujtaba Abbas, M.; Waseem, A.; Abbas Jauhar, T.; Fayaz, H.; Kalam, M.A.; Soudagar, M.E.M.; Silitonga, A.S.; Ul-Husnain, S.; Ishtiaq, U. Influence of varying concentrations of TiO2 nanoparticles and engine speed on the performance and emissions of diesel engine operated on waste cooking oil biodiesel blends using response surface methodology. Heliyon 2023, 9, e17758. [Google Scholar] [CrossRef]

- Giakoumis, E.G.; Rakopoulos, C.D.; Dimaratos, A.M.; Rakopoulos, D.C. Exhaust emissions of diesel engines operating under transient conditions with biodiesel fuel blends. Prog. Energy Combust. Sci. 2012, 38, 691–715. [Google Scholar] [CrossRef]

- Khalife, E.; Tabatabaei, M.; Demirbas, A.; Aghbashlo, M. Impacts of additives on performance and emission characteristics of diesel engines during steady state operation. Prog. Energy Combust. Sci. 2017, 59, 32–78. [Google Scholar] [CrossRef]

- Sun, J.; Caton, J.A.; Jacobs, T.J. Oxides of nitrogen emissions from biodiesel-fuelled diesel engines. Prog. Energy Combust. Sci. 2010, 36, 677–695. [Google Scholar] [CrossRef]

- Balakrishnan, A.; Parthasarathy, R.N.; Gollahalli, S.R. A review on the effects of biodiesel blends on compression ignition engine NOX emissions. J. Energy Environ. Sustain. 2016, 1, 67–76. [Google Scholar] [CrossRef]

- Zamboni, G.; Capobianco, M. Definition of the optimal content of used cooking oil methyl ester in blends fuelling a turbocharged diesel engine. Biomass Bioenergy 2021, 150, 106098. [Google Scholar] [CrossRef]

- Saputra Nursal, R.; Khalid, A.; Shahridzuan Abdullah, I.; Jaat, N.; Darlis, N.; Koten, H. Autoignition behavior and emission of biodiesel from palm oil, waste cooking oil, tyre pyrolysis oil, algae and jatropha. Fuel 2021, 306, 121695. [Google Scholar] [CrossRef]

- Caliskan, H.; Yildiz, I.; Mori, K. Production and Assessment of New Biofuels from Waste Cooking Oils as Sustainable Bioenergy Sources. Energies 2023, 16, 463. [Google Scholar] [CrossRef]

- Chiavola, O.; Palmieri, F.; Verdoliva, F. Characteristics of High-Pressure Injection Pump Operated with Renewable Fuel for Diesel Engines. Energies 2024, 17, 1656. [Google Scholar] [CrossRef]

- Yusuf, A.A.; Yusuf, D.A.; Jie, Z.; Bello, T.Y.; Tambaya, M.; Abdullahi, B.; Muhammed-Dabo, I.A.; Yahuza, I.; Dandakouta, H. Influence of waste oil-biodiesel on toxic pollutants from marine engine coupled with emission reduction measures at various loads. Atmos. Pollut. Res. 2022, 13, 101258. [Google Scholar] [CrossRef]

- Mofijur, M.; Rasul, M.; Hassan, N.M.S. Investigation of exhaust emissions from a stationary diesel engine fuelled with biodiesel. Energy Procedia 2019, 160, 791–797. [Google Scholar] [CrossRef]

- Mandal, A.; Cha, D.; Cho, H.M. Impact of Waste Fry Biofuel on Diesel Engine Performance and Emissions. Energies 2023, 16, 3711. [Google Scholar] [CrossRef]

- Hawi, M.; Elwardany, A.; Ismail, M.; Ahmed, M. Experimental Investigation on Performance of a Compression Ignition Engine Fueled with Waste Cooking Oil Biodiesel–Diesel Blend Enhanced with Iron-Doped Cerium Oxide Nanoparticles. Energies 2019, 12, 798. [Google Scholar] [CrossRef]

- Meng, J.; Xu, W.; Meng, F.; Wang, B.; Zhao, P.; Wang, Z.; Ji, H.; Yang, Y. Effects of waste cooking oil biodiesel addition on combustion, regulated and unregulated emission characteristics of common-rail diesel engine. Process Saf. Environ. Prot. 2023, 178, 1094–1106. [Google Scholar] [CrossRef]

- Zhang, Y.; Lou, D.; Tan, P.; Hu, Z.; Fang, L. Effects of waste-cooking-oil biodiesel blends on diesel vehicle emissions and their reducing characteristics with exhaust after-treatment system. J. Clean. Prod. 2022, 381, 135190. [Google Scholar] [CrossRef]

- Zamboni, G.; Moggia, S.; Capobianco, M. Effects of a Dual-Loop Exhaust Gas Recirculation System and Variable Nozzle Turbine Control on the Operating Parameters of an Automotive Diesel Engine. Energies 2017, 10, 47. [Google Scholar] [CrossRef]

- Zamboni, G.; Capobianco, M. Effects of rail pressure control on fuel consumption, emissions and combustion parameters in a turbocharged diesel engine. Cogent Eng. 2020, 7, 1724848. [Google Scholar] [CrossRef]

- Working Group 1 of the Joint Committee for Guides in Metrology. Evaluation of Measurement Data—Guide to the Expression of Uncertainty in Measurement, 1st ed.; JCGM 100; BIPM: Sèvres, France, 2008; Available online: https://www.bipm.org/en/ (accessed on 23 May 2025).

- Torregrosa, A.J.; Broatch, A.; Martin, J.; Monelletta, L. Combustion noise level assessment in direct injection Diesel engines by means of in-cylinder pressure components. Meas. Sci. Technol. 2007, 18, 2131–2142. [Google Scholar] [CrossRef]

- Liang, X.; Yang, G.; Dai, P.; Lin, X.; Zhang, X.; Li, L. Experimental investigation on the relationship between in-cylinder pressure rise rate and combustion noise of the diesel engine. Appl. Acoust. 2024, 223, 110084. [Google Scholar] [CrossRef]

- Hsu, B.D. Practical Diesel-Engine Combustion Analysis; SAE International: Warrendale, PA, USA, 2002; ISBN 0-7680-0914-6. [Google Scholar]

- Heywood, J.B. Internal Combustion Engine Fundamentals, 2nd ed.; Mc Graw-Hill: Columbus, OH, USA, 2018; ISBN 0-07-028637-X. [Google Scholar]

- Hohenberg, J.F. Advanced Approaches for Heat Transfer Calculations; SAE International: Warrendale, PA, USA, 1979. [Google Scholar]

- Benson, R.S.; Whitehouse, N.D. Internal Combustion Engines; Pergamon Press: Oxford, UK, 1979; ISBN 978-0080227177. [Google Scholar]

- Badami, M.; Mallamo, F.; Millo, F.; Rossi, E.E. Influence of Multiple Injection Strategies on Emissions, Combustion Noise and BSFC of a DI Common Rail Diesel Engine; SAE International: Warrendale, PA, USA, 2002. [Google Scholar]

- Zamboni, G. A study on combustion parameters in an automotive turbocharged diesel engine. Energies 2018, 11, 2531. [Google Scholar] [CrossRef]

- Zamboni, G. Influence of fuel injection, turbocharging and EGR systems control on combustion parameters in an automotive diesel engine. Appl. Sci. 2019, 9, 484. [Google Scholar] [CrossRef]

- Lapuerta, M.; Herreros, J.M.; Lyons, L.L.; García-Contreras, R.; Briceño, Y. Effect of the alcohol type used in the production of waste cooking oil biodiesel on diesel performance and emissions. Fuel 2008, 87, 3161–3169. [Google Scholar] [CrossRef]

- Madheshiya, A.K.; Vedrtnam, A. Energy-exergy analysis of biodiesel fuels produced from waste cooking oil and mustard oil. Fuel 2018, 214, 386–408. [Google Scholar] [CrossRef]

- Dhanasekaran, R.; Ganesan, S.; Rajesh Kumar, B.; Saravanan, S. Utilization of waste cooking oil in a light-duty DI diesel engine for cleaner emissions using bio-derived propanol. Fuel 2019, 235, 832–837. [Google Scholar] [CrossRef]

- Attia, A.M.A.; Hassaneen, A.E. Influence of diesel fuel blended with biodiesel produced from waste cooking oil on diesel engine performance. Fuel 2016, 167, 316–328. [Google Scholar] [CrossRef]

- Richards, P. Automotive Fuels Reference Book, 3rd ed.; SAE International: Warrendale, PA, USA, 2014. [Google Scholar]

- Balakrishnan, A.; Parthasarathy, R.N.; Gollahalli, S.R. Effects of degree of fuel unsaturation on NOx emission from petroleum and biofuel flames. Fuel 2016, 182, 798–806. [Google Scholar] [CrossRef]

- Gad, M.S.; Abu-Elyazeed, O.S.; Mohamed, M.A.; Hashim, A.M. Effect of oil blends derived from catalytic pyrolysis of waste cooking oil on diesel engine performance, emissions and combustion characteristics. Energy 2021, 223, 120019. [Google Scholar] [CrossRef]

- Mahfouz, A.; Gad, M.S.; El Fatih, A.; Emara, A. Comparative study of combustion characteristics and exhaust emissions of waste cooking-diesel oil blends. Ain Shams Eng. 2018, 9, 3123–3134. [Google Scholar] [CrossRef]

- Zamboni, G.; Moggia, S.; Capobianco, M. Hybrid EGR and turbocharging systems control for low NOX and fuel consumption in an automotive diesel engine. Appl. Energy 2016, 165, 839–848. [Google Scholar] [CrossRef]

- Hossain, A.K.; Davies, P.A. Combustion and Emission Characteristics of a Typical Biodiesel Engine Operated on Waste Cooking Oil Derived Biodiesel; SAE International: Warrendale, PA, USA, 2012. [Google Scholar]

- Jaliliantabar, F.; Ghobadian, B.; Carlucci, A.P.; Najafi, G.; Mamat, R.; Ficarella, A.; Strafella, L.; Santino, A.; De Domenico, S. A comprehensive study on the effect of pilot injection, EGR rate, IMEP and biodiesel characteristics on a CRDI diesel engine. Energy 2020, 194, 116860. [Google Scholar] [CrossRef]

- Knothe, G.; Razon, L.F. Biodiesel fuels. Prog. Energy Combust. Sci. 2017, 58, 36–59. [Google Scholar] [CrossRef]

- Balakrishnan, A.; Parthasarathy, R.N.; Gollahalli, S.R. Experimental correlation of laminar flame pollutant emission indices with methyl ester fuel degree of unsaturation and equivalence ratio. Fuel 2019, 238, 139–148. [Google Scholar] [CrossRef]

- da Silva, M.J.; de Oliveira, A.; Sodré, J.R. Analysis of processing methods for combustion pressure measurement in a diesel engine. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 282. [Google Scholar] [CrossRef]

| Characteristic | Value |

|---|---|

| Engine type | Four-stroke, Diesel |

| Cylinders | 4 in-line |

| Bore [mm] × stroke [mm] | 69.9 × 82 |

| Displacement [cm3] | 1248 |

| Compression ratio | 16.8:1 |

| Connecting rod [mm] | 131.3 |

| Valves for cylinder | 4 |

| Maximum Power [kW] | 70 @ 4000 rpm |

| Maximum Torque [Nm] | 200 @ 1500–3000 rpm |

| Fuel injection system | Direct injection, Multijet II common rail with solenoid injectors, maximum pressure 1650 bar |

| Turbocharging system | Single stage, variable nozzle turbine, intercooler |

| EGR system | High pressure, cooled |

| Measured Quantity | Instrument | Range | Accuracy |

|---|---|---|---|

| Engine speed | Inductive pick-up | 0–5000 rpm | ±10 rpm |

| Engine torque | Eddy current dynamometer | 0–250 Nm | ±1.25 Nm |

| Fuel mass flow rate | AVL 733S dynamic measuring equipment | 0–37.5 kg/h | 0.81% for a measured value of 5 g, 0.42% for 10 g, 0.2% for 25 g |

| Air mass flow rate | Hot wire air flow meter | 0–1000 mg/stroke | ±5 mg/stroke |

| Exhaust smoke | AVL 415 variable sampling smoke meter | 0–10 FSN | ±0.1 FSN |

| NOX concentration | Rosemount 951 CLA analyzer | 0–250 ppm 0–1000 ppm | ±1.25 ppm ±5 ppm |

| Turbocharger rotational speed | Eddy current probe | 200–400,000 rpm | 36 rpm |

| Temperatures (intake circuit, lubricant, coolant, etc.) | 4-wire RTD | 0–350 °C | 0.15 °C + 0.002 × measured value |

| Temperatures (exhaust and EGR circuits) | K type TC | 0–1200 °C (class 2) | ±2.5 °C or ±0.75% × measured value (class 2) |

| Pressures | Strain gauge | −1–0.6 bar | <±0.2% × full scale |

| In-cylinder pressure | Kistler 6125B | 0–2.5 bar | <±0.5% × full scale |

| Kiag Swiss 5001 charge amplifier | <±1% × full scale | ||

| Fuel pressure | Kistler 4067A2000 | 0–2000 bar | <±0.5% × full scale |

| Kistler 4618A2 amplifier | <±0.2% × full scale |

| Operating Condition ID = n × bmep [rpm × bar] | ||

|---|---|---|

| 2000 × 2 | 2000 × 5 | |

| bsfc | 1.5 | 1.3 |

| bsNOX | 1.8 | 1.8 |

| bsS | 3.2 | 3.1 |

| Fuel/Blends | Density @ 15 °C [g/dm3] | LHV [MJ/kg] | Oxygen Content [%] | Stoichiometric Air–Fuel Ratio | Cetane Number |

|---|---|---|---|---|---|

| B7 | 830 | 43 | - | 14.57 | 52 |

| WCOME | 874 | 37.1 (−13.7%) | 10.9 | 12.55 | 51.9 |

| 60% B7 + 40% WCOME | 843 | 40.3 (−6.3%) | 4.8 | 13.80 | 52 |

| 30% B7 + 70% WCOME | 853 | 38.8 (−9.7%) | 7.9 | 13.41 | 51.9 |

| Fatty Acid | Sunflower Oil | Olive Oil | Waste Cooking Oil |

|---|---|---|---|

| C16:0 Palmitic | 6–7 a/6.40 b | 5–13 a/11.47 b | 1–30 a/6.7 c/28.78 d/10.54 e/6 f |

| C18:0 Stearic | 3–5 a | 1–3 a | 2–6 a/1.6 c/6.41 d/4.02 e/0.8 f |

| C18:1 Oleic | 17–29 a/17.70 b | 71–75 a/74.52 b | 5–53 a/18.3 c/34.94 d/54.74 e/54 f |

| C18:2 Linoleic | 58–74 a/72.90 b | 10–18 a/9.54 b | 2–51 a/73.4 c/21.19 d/28.03 e/25.7 f |

| Operating Mode | Engine Speed [rpm] | Brake Mean Effective Pressure [bar] | Excess Air Ratio [−] | Rail Pressure [bar] | DCVNT [%] |

|---|---|---|---|---|---|

| 1 | 2000 | 2 | 6.0 | 470 * | 82.0 |

| 2 | 3.2 | 89.0 | |||

| 3 | 2.8 * | 93.0 * | |||

| 4 | 2.4 | 95.0 | |||

| 5 | 2.4 | 508 | 95.0 | ||

| 6 | 2.4 | 540 | 95.0 | ||

| 7 | 2500 | 5 | 6.0 | 588 * | 78.0 |

| 8 | 2.2 | 82.0 | |||

| 9 | 1.8 * | 87.4 * | |||

| 10 | 1.65 | 92.0 | |||

| 11 | 1.65 | 636 | 92.0 | ||

| 12 | 1.65 | 676 | 92.0 |

| Engine Speed [rpm] | Brake Mean Effective Pressure [bar] | Intake Pressure [bar] | Pilot | Pre | Main | |||

|---|---|---|---|---|---|---|---|---|

| SOI [CAD] | Duration [CAD] | SOI [CAD] | Duration [CAD] | SOI [CAD] | Duration * [CAD] | |||

| 2000 | 2 | 1.204 | 334.0 | 7.5 | 348.7 | 7.5 | 360.8 | 9.8 |

| 2500 | 5 | 1.316 | 334.4 | 7.8 | 348.8 | 7.8 | 360.8 | 11.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zamboni, G.; Capobianco, M. Integrated Control Strategies of EGR System and Fuel Injection Pressure to Reduce Emissions and Fuel Consumption in a DI Engine Fueled with Diesel-WCOME Blends and Neat Biodiesel. Energies 2025, 18, 2791. https://doi.org/10.3390/en18112791

Zamboni G, Capobianco M. Integrated Control Strategies of EGR System and Fuel Injection Pressure to Reduce Emissions and Fuel Consumption in a DI Engine Fueled with Diesel-WCOME Blends and Neat Biodiesel. Energies. 2025; 18(11):2791. https://doi.org/10.3390/en18112791

Chicago/Turabian StyleZamboni, Giorgio, and Massimo Capobianco. 2025. "Integrated Control Strategies of EGR System and Fuel Injection Pressure to Reduce Emissions and Fuel Consumption in a DI Engine Fueled with Diesel-WCOME Blends and Neat Biodiesel" Energies 18, no. 11: 2791. https://doi.org/10.3390/en18112791

APA StyleZamboni, G., & Capobianco, M. (2025). Integrated Control Strategies of EGR System and Fuel Injection Pressure to Reduce Emissions and Fuel Consumption in a DI Engine Fueled with Diesel-WCOME Blends and Neat Biodiesel. Energies, 18(11), 2791. https://doi.org/10.3390/en18112791