The Steady-State and Dynamic Characteristics of a Humidity-Sensitive Air Inlet: Modeling Based on Measurements

Abstract

1. Introduction

- V—The ventilation airflow, m3/h.

- C—The flow characteristic parameter, m3/(h∙Pan).

- ∆p—The pressure drop across the air inlet, Pa.

- N—The exponent of flow characteristic.

- and parameter C will be considered as a function of

- The indoor relative humidity φi and indoor air temperature Ti.

- The temperature difference between the indoor and outdoor ∆T.

- Hysteresis V = f(φi)∆p =const.

- The dynamic properties of the air inlet.

- and the exponent n is assumed to be a constant value.

2. Materials and Methods

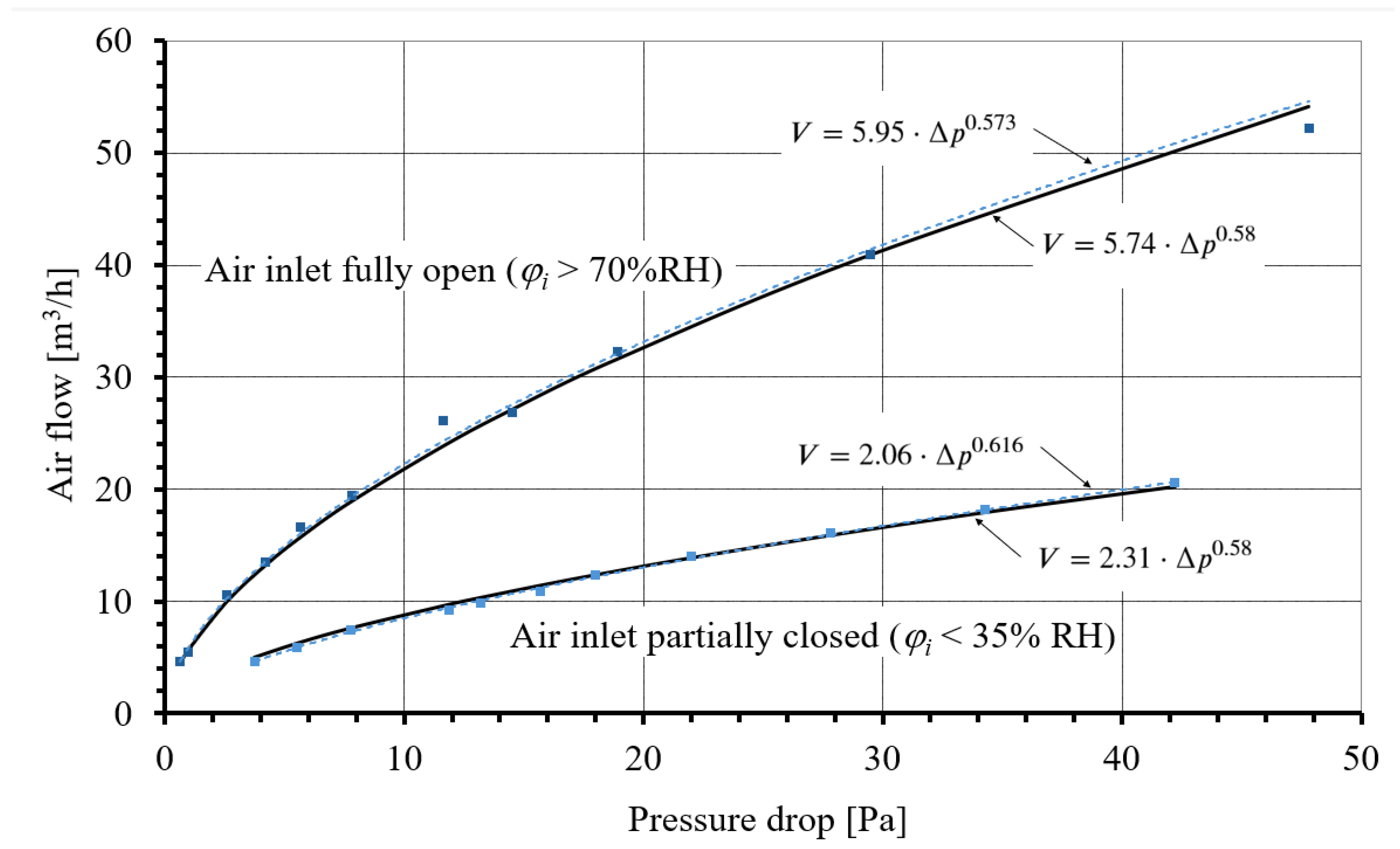

- Measuring series I: Measurement of the pressure drop across the air inlet and the corresponding airflow through the fully open (φi above 70%RH) and partially closed (φi below 35%RH) air inlet. The measurement results are shown in Figure 2.

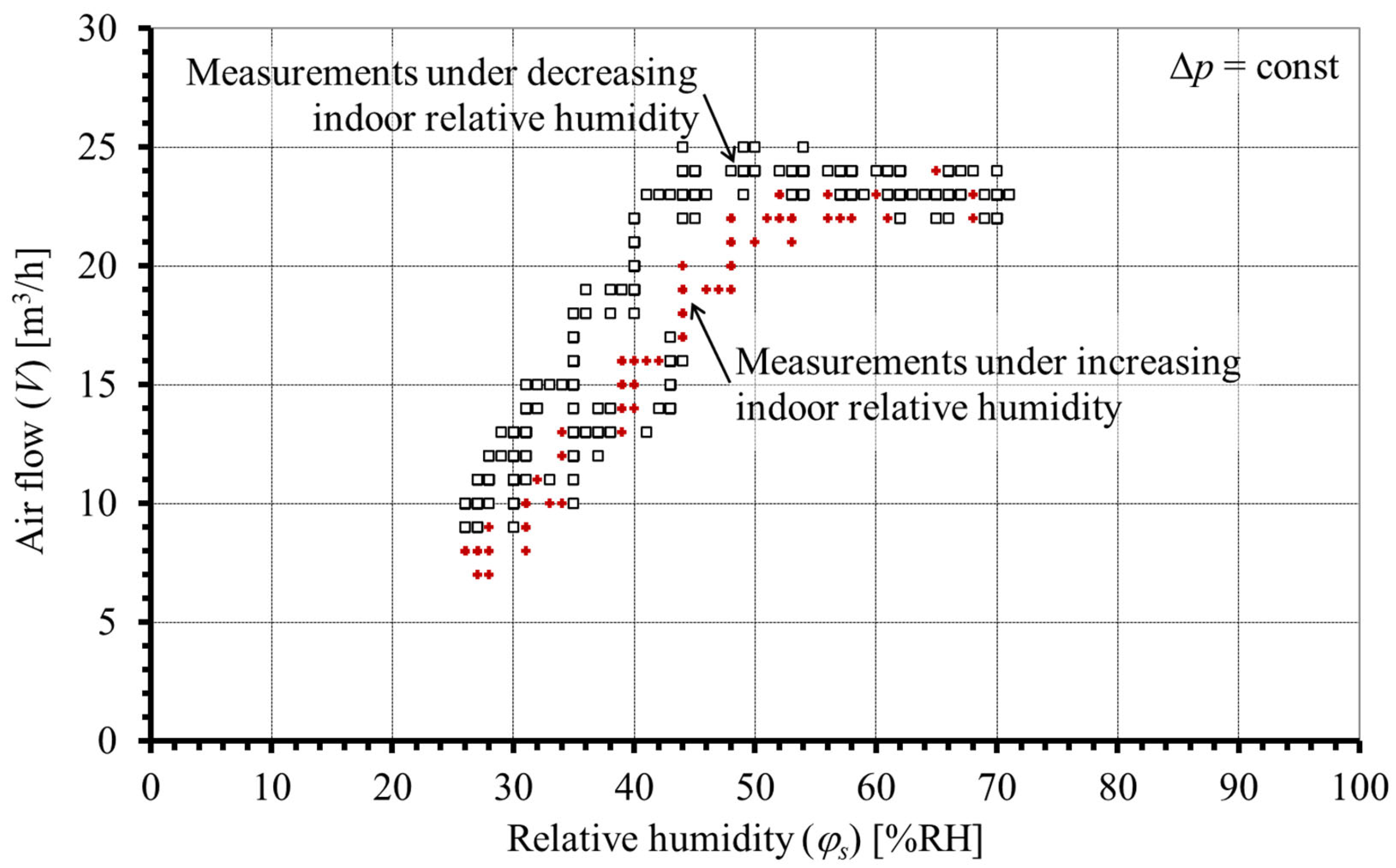

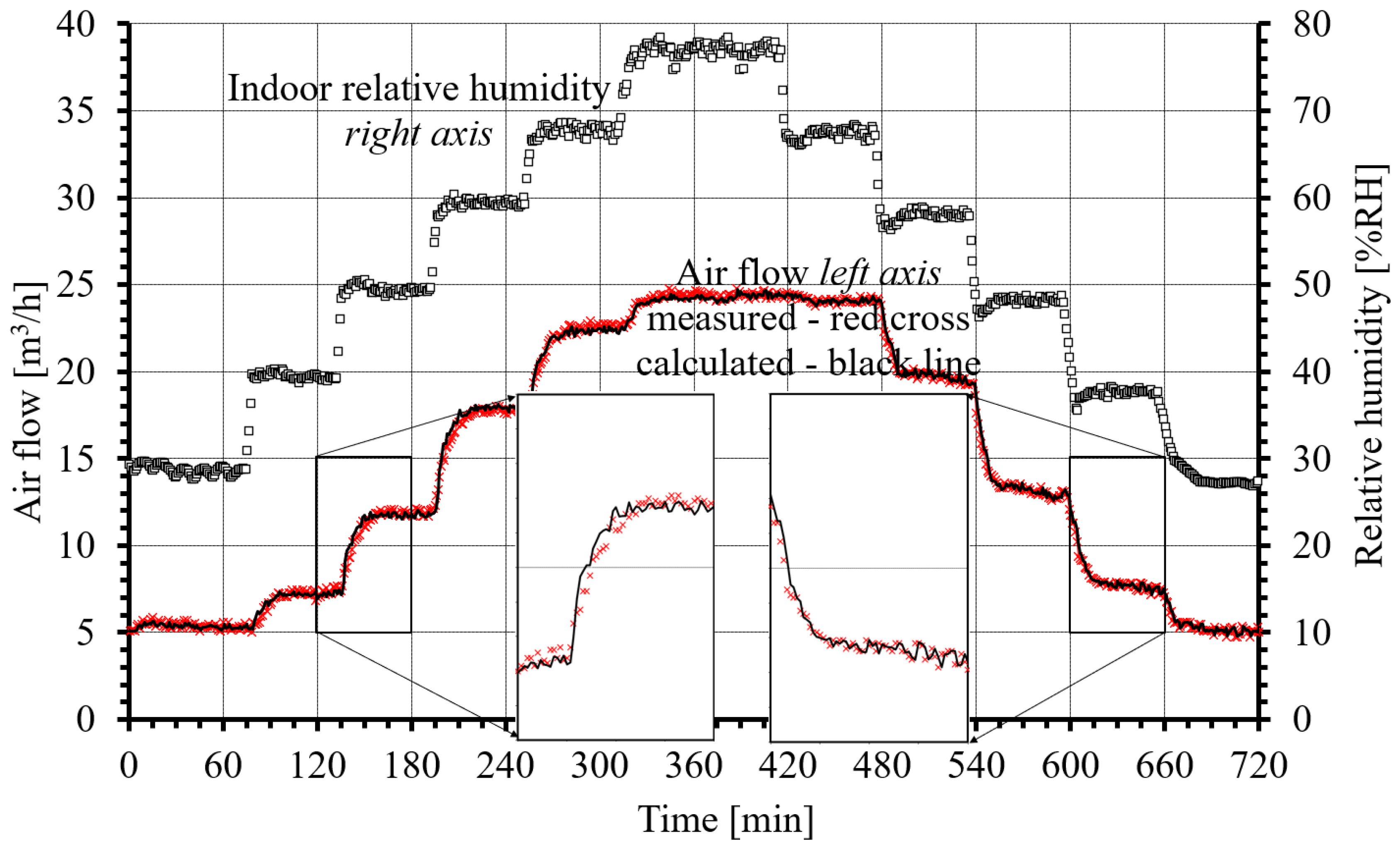

- Measuring series II: Measurement of the airflow through the air inlet under steady-state conditions and under increasing/decreasing indoor relative humidities, a constant pressure drop across the air inlet of 10 Pa, an indoor temperature (Ti) of 21.5 °C, and an outdoor temperature (Te) of 21.5 °C and 10 °C. The measurement results are shown in Figure 3 and Figure 4.

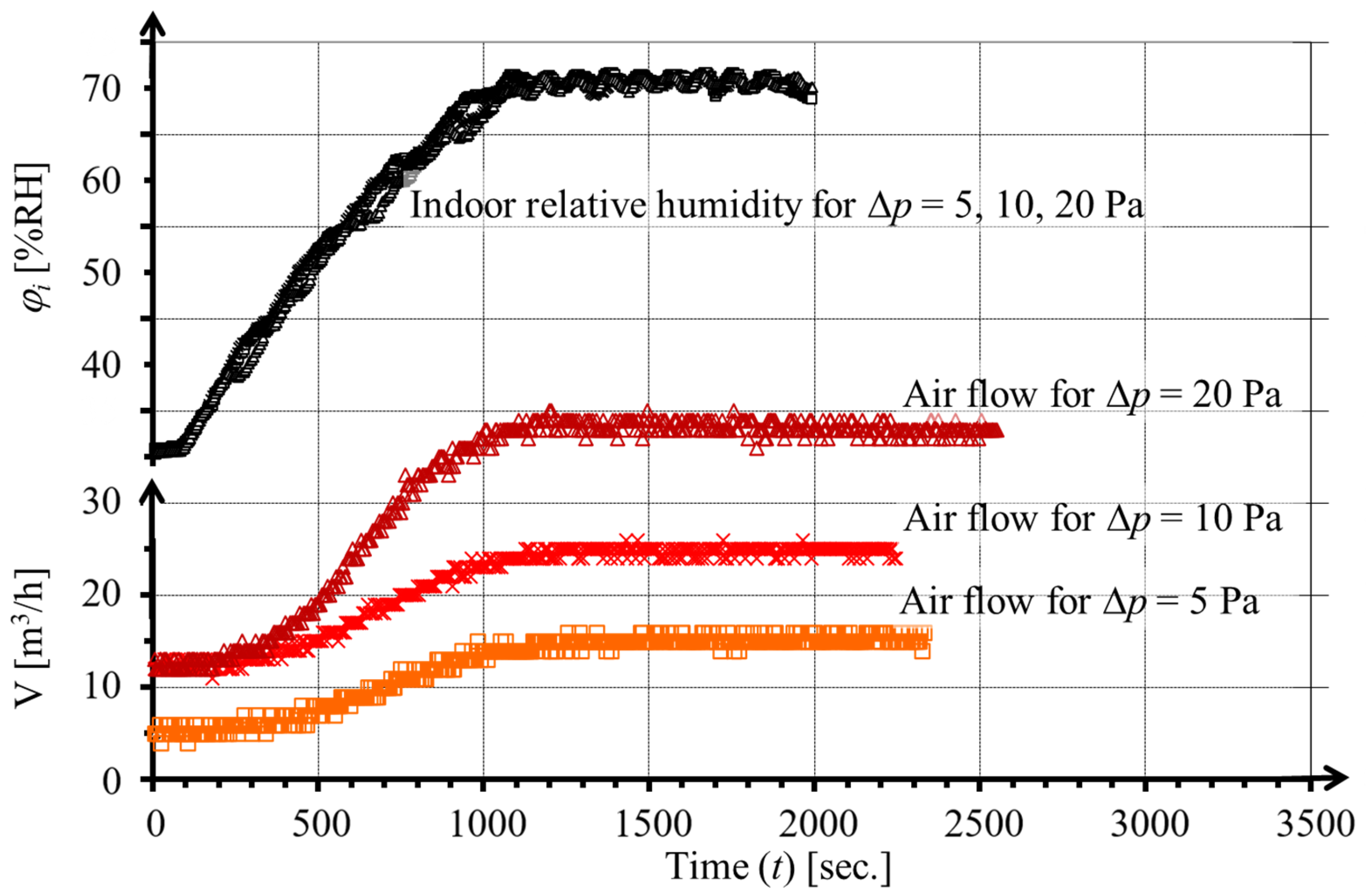

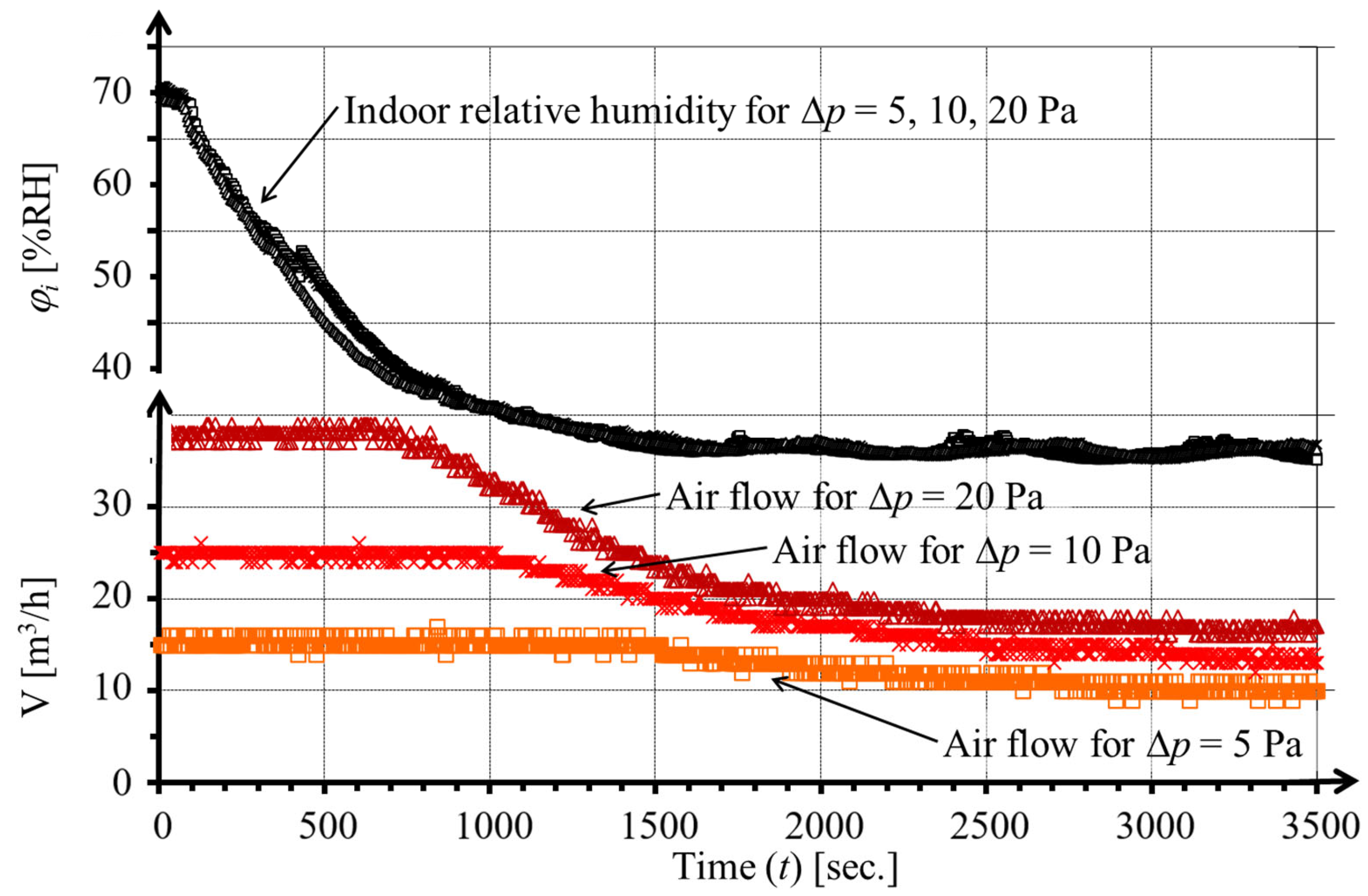

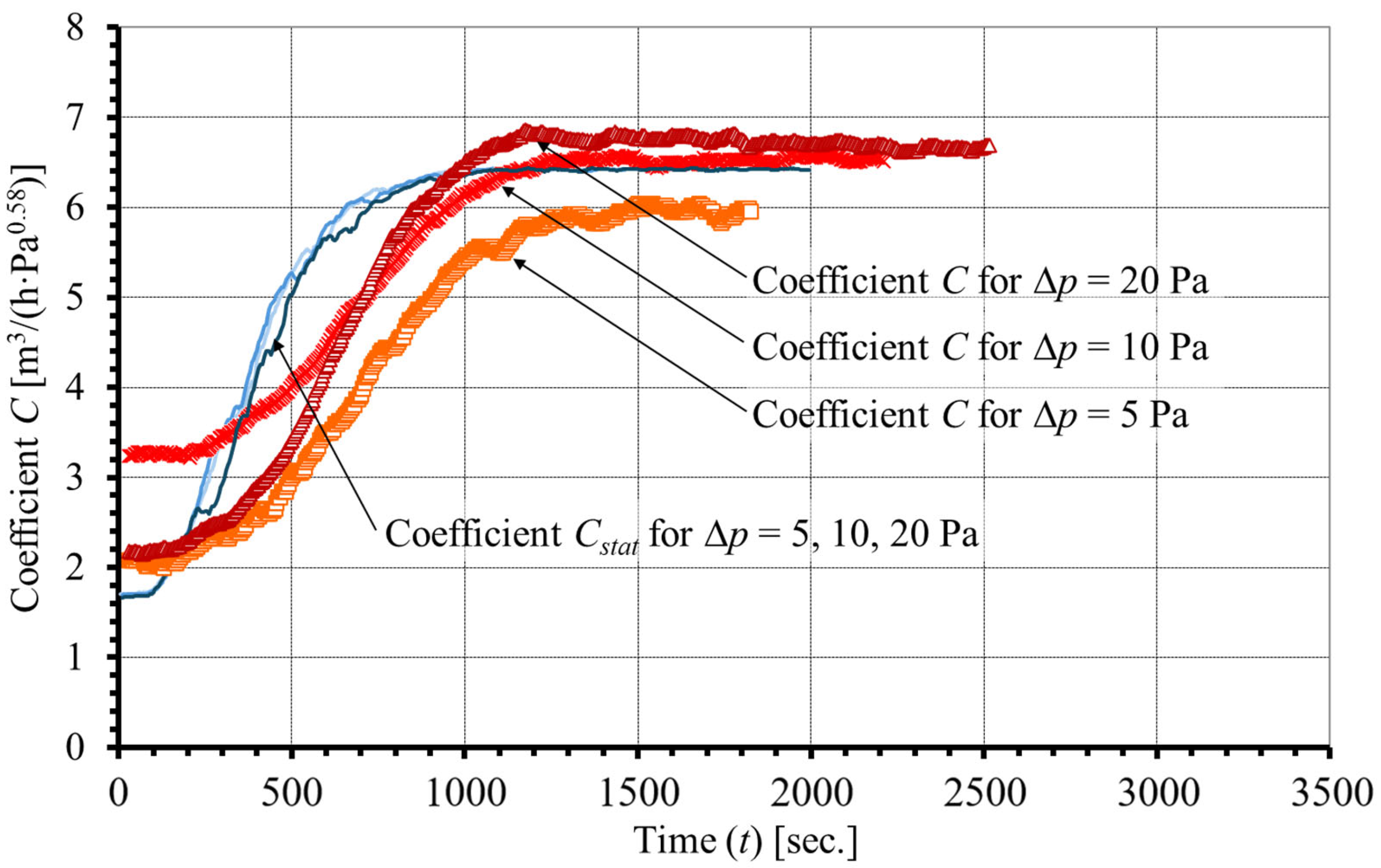

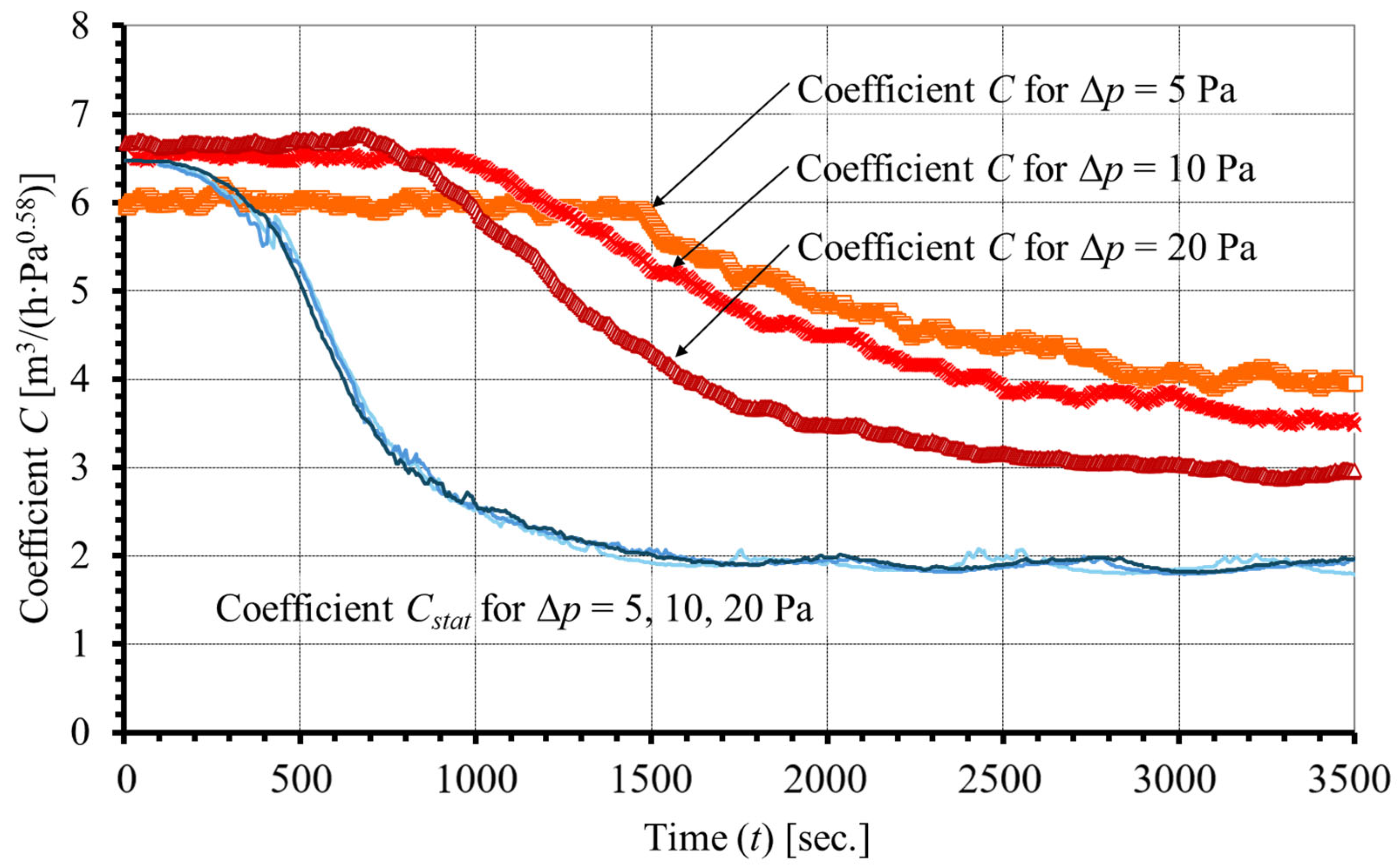

- Measuring series III: Measurement of the time series (sampling time 5 s) of the airflow through the air inlet at a step increase and decrease in indoor relative humidity at a pressure drop at the air inlet of 5, 10, 20 Pa, an indoor temperature of 21.5 °C, and a temperature before the air inlet of 10 °C. The measurement results are shown in Figure 5 and Figure 6.

3. Results

3.1. Steady-State Properties

- φs—The relative humidity of air resulting from the moisture content of the indoor air and the air temperature surrounding the polyamide tape Ts (relationship (7)).

- u—The coefficient vector.

- u0 = −13.63; u1 = 7.36; u2 = 5.27; and u3 = 6.51 for increasing the relative humidity value.

- u0 = −15.03; u1 = 7.55; u2 = 5.27; and u3 = 6.51 for decreasing the relative humidity.

- u0 = −14.00; u1 = 7.33; u2 = 5.27; and u3 = 6.51 without distinguishing the indoor air’s increase or decrease in relative humidity.

3.2. Dynamic Properties

- The relative humidity of the indoor air was recalculated to C values corresponding to the steady-state conditions (Equation (6)).

- The airflow (V) flowing through the air inlet to the Cstat values corresponding to the pressure difference (relationships (4), (5)).

- Cstat—Coefficient C, calculated for steady-state conditions (Equation (6)).

- t—The time moment (sampled time: 1 min).

- r—The model order.

- d—The delay time, min.

- a, b—Coefficients.

- For an increase in the indoor relative humidity:

- −

- r = 1.

- −

- d = 3 min.

- −

- a1 = 0.620.

- −

- b0 = 0.497; b1 = −0.177.

- For an decrease in the indoor relative humidity:

- −

- r = 1.

- −

- d = 65.7∙(∆p)−1 + 5.00; rounded to the nearest integer; for example, for ∆p = 5 Pa, d = 18 min, ∆p = 10 Pa, d = 12 min, ∆p = 20 Pa, and d = 8 min.

- −

- a1 = 0.970.

- −

- b0 = 0.0177∙∆p + 0.0638; b1 = −0.0177∙∆p − 0.0338.

3.3. Flow Characteristics

- φs—The relative humidity of the air, resulting from the moisture content of the indoor air and the air temperature surrounding the polyamide tape Ts (relationship (7)).

- a, b, u, d—The coefficient vectors determined in Section 3.1 and Section 3.2, in general being functions of ∆p and the direction of change φi (increase or decrease in the indoor relative humidity).

4. Discussion

5. Conclusions

- The air inlet reacts to changes in relative humidity of the air (surrounding the polyamide tape) in the range from 30% RH (20% opening of the air inlet) to about 75% RH, which corresponds to the maximum opening.

- There is a hysteresis in the course of the V = f(φi)∆p =const characteristic, which can be seen in Figure 8.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jardinier, L. Humidity sensitive system is 20 years old. In Proceedings of the 23rd AIVC Conference, Washington, DC, USA, 12–14 October 2003. [Google Scholar]

- Savin, J.L.; Jardinier, M. Humidity controlled exhaust ventilation in moderate climate. AIVC VIP 2009, 31, 12. [Google Scholar]

- Guyot, G.; Walker, I.; Sherman, M.H. Performance based approaches in Standards and Regulations for smart ventilation in residential buildings: A summary review. Int. J. Vent. 2018, 18, 96–112. [Google Scholar] [CrossRef]

- Guyot, G.; Leprince, V.; Poirier, B.; Kolarik, J. State-of-the art on the use of performance-based approaches for residential ventilation in 2024. REHVA Eur. HVAC J. 2025, 62, 16–19. [Google Scholar]

- Andrade, R.; Guyot, G. IEQ and energy performance of residential smart ventilation strategies in France. In Proceedings of the 44th AIVC 12th TightVent & 10th Venticool Conference “Retrofitting the Building Stock: Challenges and Opportunities for Indoor Environmental Quality “, Dublin, Ireland, 9–10 October 2024. [Google Scholar]

- Woloszyn, M.; Kalamees, T.; Abadie, M.; Steeman, M.; Sasic Kalagasidis, A. The effect of combining a relative-humidity-sensitive ventilation system with the moisture-buffering capacity of materials on indoor climate and energy efficiency of buildings. Build. Environ. 2009, 44, 515–524. [Google Scholar] [CrossRef]

- Miracco, G.; Nicoletti, F.; Ferraro, V.; Kaliakatsos, D. Innovative Mechanical Ventilation Control for Enhanced Indoor Air Quality and Energy Efficiency. Energy Eng. 2025, 122, 861. [Google Scholar] [CrossRef]

- Psomas, T.; Teli, D.; Langer, S.; Wahlgren, P.; Wargocki, P. Indoor humidity of dwellings and association with building characteristics, behaviors and health in a northern climate. Build. Environ. 2021, 198, 107885. [Google Scholar] [CrossRef]

- Liu, P.; Alonso, M.J.; Mathisen, H.M.; Halfvardsson, A. Understanding the role of moisture recovery in indoor humidity: An analytical study for a Norwegian single-family house during heating season. Build. Environ. 2023, 229, 109940. [Google Scholar] [CrossRef]

- Poirier, B.; Guyot, G.; Woloszyn, M. Uncertainty quantification: For an IAQ and energy performance assessment method for smart ventilation strategies. Build. Environ. 2024, 266, 112115. [Google Scholar] [CrossRef]

- Tognon, G.; Marigo, M.; De Carli, M.; Zarrella, A. Mechanical, natural and hybrid ventilation systems in different building types: Energy and indoor air quality analysis. J. Build. Eng. 2023, 76, 107060. [Google Scholar] [CrossRef]

- Mijakowski, M.; Sowa, J. An attempt to improve indoor environment by installing humidity-sensitive air inlets in a naturally ventilated kindergarten building. Build. Environ. 2017, 111, 180–191. [Google Scholar] [CrossRef]

- Cho, H.; Cabrera, D.; Sardy, S.; Kilchherr, R.; Yilmaz, S. Evaluation of performance of energy efficient hybrid ventilation system and analysis of occupants’ behavior to control windows. Build. Environ. 2021, 188, 107434. [Google Scholar] [CrossRef]

- Jardinier, L.; Jardinier, M.; Savin, J.L.; Siret, F. Hygrothermal behavior of a humidity controlled air inlet. In Proceedings of the 23rd AIVC Conference, Washington, DC, USA, 12–14 October 2003. [Google Scholar]

- Parekh, A.; Ruest, K.; Lemoine, Y. Operating characteristics and performance of the AERECO humidity-controlled ventilation system. In Phase II: Monitoring and Performance Analisis, Efficiency and Alternative Energy Technology Branch Energy, Mines and Resources Canada; Scanada Consultants Ltd.: Ottawa, ON, Canada, 1990. [Google Scholar]

- Berthin, S.; Savin, J.L.; Jardinier, M. Measurements on humidity controlled ventilation systems in 55 occupied apartments. In Whole Building Heat, Air and Moisture Response; Publications and Work Reports, Annex 41; Aereco S.A.: Collégien, France, 2007. [Google Scholar]

- Guyot, G. Lessons learned from a ten-year monitoring in residential buildings equipped with humidity based demand controlled ventilation in France. In Proceedings of the 40th AIVC Conference ”From Energy Crisis to Sustainable Indoor Climate 40 Years of AIVC”, Ghent, Belgium, 15 October 2019; Available online: https://hal.science/hal-02348874v1 (accessed on 17 May 2025).

- Guyot, G.; Jardinier, E.; Parsy, F.; Berthin, S.; Roux, E.; Charrier, S. Smart Ventilation Performance Durability Assessment: Preliminary Results from a Long-Term Residential Monitoring of Humidity-Based Demand-Controlled Ventilation. In Proceedings of the IAQ 2020: Indoor Environmental Quality Performance Approaches Transitioning from IAQ to IEQ, AIVC-ASHRAE, Athens, Greece, 14–16 September 2020. [Google Scholar]

- Mélois, A.; Legree, M.; Rios Mora, S.; Depoorter, J.; Jardinier, E.; Berthin, S.; Parsy, F.; Guyot, G. Durability of humidity-based ventilation components after 13 years of operation in French residential buildings-Assessment of components performance in laboratory. Energy Build. 2023, 292, 113154. [Google Scholar] [CrossRef]

- Woloszyn, M.; Shen, J.; Mordelet, A.; Brau, J. Numerical simulations of energy performance of a ventilation system controlled by relative humidity. In Proceedings of the AIVC Conference ‘Ventilation in Relation to the Energy Performance of Buildings’, Brussels, Belgium, 21–23 September 2005. [Google Scholar]

- Sowa, J.; Mijakowski, M. Humidity-Sensitive, Demand-Controlled Ventilation Applied to Multiunit Residential Building-Performance and Energy Consumption in Dfb Continental Climate. Energies 2020, 13, 6669. [Google Scholar] [CrossRef]

- Savin, J.L.; Laverge, J. Demand-controlled ventilation: An outline of assessment methods and simulations tools. In Proceedings of the AIVC & TIGHTVENT, Montreal, QC, Canada, 12–13 October 2011. [Google Scholar]

- Van Den Bossche, N.; Janssens, A.; Heijmans, N.; Wouters, P. Performance Evaluation of Humidity-Controlled Ventilation Strategies in Residential Buildings. In Proceedings of the Buildings X Conference, Clearwater Bach, FL, USA, 2–7 December 2007; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2007. [Google Scholar]

- Baptiste, P.; Jakub, K.; Guyot, G.; Woloszyn, M. Design of residential ventilation systems using performance-based evaluation of Indoor Air Quality: Application to a Danish study case. E3S Web Conferences. 2022, 362, 09004. [Google Scholar] [CrossRef]

- Poirier, B.; Guyot, G.; Woloszyn, M.; Geoffroy, H.; Ondarts, M.; Gonze, E. Development of an assessment methodology for IAQ ventilation performance in residential buildings: An investigation of relevant performance indicators. J. Build. Eng. 2021, 43, 103140. [Google Scholar] [CrossRef]

- Dols, W.S.; Polidoro, B.J. CONTAM User Guide and Program Documentation, Version 3.4; NIST Technical Note 1887; National Institute of Standards and Technology: Gaithersburg, MD, USA, August 2020; Section Airflow Element Types; pp. 52–54. [Google Scholar] [CrossRef]

- Mijakowski, M.; Sowa, J. Modelowanie wilgotności względnej powietrza w budynkach – możliwości i ograniczenia programu CONTAMW 3.0. Fiz. Budowli w Teor. i Praktyce 2011, VI, 79–84. [Google Scholar]

- Sowa, J.; Mijakowski, M. Whole year simulation of humidity based demand controlled hybrid ventilation in multiapartment building. In Proceedings of the 32nd AIVC Conference “Towards Optimal Airtightness Performance”, Brussels, Belgium, 12–13 October 2011. [Google Scholar]

- Heim, D.; Miszczuk, A. Modelling building infiltration using the airflow network model approach calibrated by air-tightness test results and leak detection. Build. Serv. Eng. Res. Technol. 2020, 41, 681–693. [Google Scholar] [CrossRef]

- Directive 2010/31/EU of the European Parliament and of the Council of 19 May 2010 on the Energy Performance of Buildings (Recast). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=OJ:L:2010:153:TOC (accessed on 3 April 2025).

- Directive (EU) 2023/1791 of the European Parliament and of the Council of 13 September 2023 on Energy Efficiency and Amending Regulation (EU) 2023/955 (Recast) (Text with EEA Relevance). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=OJ:L:2023:231:TOC (accessed on 3 April 2025).

- Ventilation and Infiltration. In 2009 ASHRAE Handbook Fundamentals; American Society Of Heating Refrigerating And Air-Conditioning Engineers: Atlanta, GA, USA, 2009; Chapter 16.

- Janiszowski, K. Podstawy Wyznaczania Opisu I Sterowania Obiektów Dynamicznych; Wydawnictwo Politechniki Warszawskiej: Warszawa, Poland, 2008. [Google Scholar]

- Jonge De, K.; Ghijsels, J.; Laverge, J. Energy savings and exposure to VOCs of different household sizes for three residential smart ventilation systems with heat recovery. Energy Build. 2023, 290, 113091. [Google Scholar] [CrossRef]

| Parameter | Value for Equation (9) | Value for Equation (10) | Value for Equation (11) |

|---|---|---|---|

| Residuum sum of squares | 4219 | 4645 | 21,950 |

| Mean square error, [m3/h] | 0.699 | 0.733 | 1.594 |

| Average value of absolute value of residuum, [m3/h] | 0.517 | 0.584 | 1.168 |

| Maximum of absolute value of residuum, [m3/h] | 2.945 | 3.078 | 6.587 |

| Standard deviation of the absolute value of residuum, [m3/h] | 0.470 | 0.443 | 1.084 |

| Coefficient R2 | 0.991 | 0.990 | 0.954 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mijakowski, M.; Narowski, P. The Steady-State and Dynamic Characteristics of a Humidity-Sensitive Air Inlet: Modeling Based on Measurements. Energies 2025, 18, 3444. https://doi.org/10.3390/en18133444

Mijakowski M, Narowski P. The Steady-State and Dynamic Characteristics of a Humidity-Sensitive Air Inlet: Modeling Based on Measurements. Energies. 2025; 18(13):3444. https://doi.org/10.3390/en18133444

Chicago/Turabian StyleMijakowski, Maciej, and Piotr Narowski. 2025. "The Steady-State and Dynamic Characteristics of a Humidity-Sensitive Air Inlet: Modeling Based on Measurements" Energies 18, no. 13: 3444. https://doi.org/10.3390/en18133444

APA StyleMijakowski, M., & Narowski, P. (2025). The Steady-State and Dynamic Characteristics of a Humidity-Sensitive Air Inlet: Modeling Based on Measurements. Energies, 18(13), 3444. https://doi.org/10.3390/en18133444