Abstract

The significant contribution of buildings to the global primary energy consumption necessitates the application of energy management methodologies at a building scale. Although dynamic simulation tools and decision-making algorithms are core components of energy management methodologies, they are often accompanied by excessive computational cost. As future controlling structures tend to become autonomized in building heating layouts, encouraging distributed heating services, the research scope calls for creating lightweight building energy system modeling as well monitoring and controlling methods. Following this notion, the proposed methodology turns a programmable controller into a smart thermostat that utilizes surrogate modeling formed by the ALAMO approach and is applied in a 4-m-by-4-m-by-2.85-m environmental chamber setup heated by a heat pump. The results indicate that the smart thermostat trained on the indoor environmental conditions of the chamber for a one-week period attained a predictive RMSE of 0.082–0.116 °C. Consequently, it preplans the heating hours and applies preheating controlling strategies in real time effectively, using only the computational power of a conventional controller, essentially managing to attain at least 97% thermal comfort on the test days. Finally, the methodology has the potential to meet the requirements of future building energy systems featured in urban-scale RES-based district heating networks.

1. Introduction

1.1. Building Energy Management

The scientific community has recognized the contribution of the building energy demand to the EU’s primary energy consumption [1], which amounts to approximately 40%. Furthermore, the same holds true for the U.S. and Asian building sectors as well [2,3], making approaches on building thermal load management optimization a highly sought out subject. At the same time, actions are being taken to achieve energy autonomy by utilizing renewable energy sources (RESs) [4,5] but also energy demand reduction in the building sector [6,7]. Since building load optimization is such a broad subject, the research community tends to divide it into two distinct categories that have a synergetic link between them, namely demand-side management and supply-side energy management [8,9]. Also, the majority of the end-use of the energy requested by buildings concerns thermal applications, such as heating, cooling, and ventilation.

In a short analysis of supply-side management, this category concerns the optimal operation of energy producers. Examples regarding the implementation of supply-side management methodologies are spotted in several works. For example, ref. [10] have elaborated on various methodologies that include the use of multi-energy systems for energy production and storage, both on a thermal and electrical energy basis. The methodology of [11] achieves the reduction in demanded loads and by extent the minimization of fuel consumption, assisting the energy producers to increase their energy production efficiency and therefore reduce their operational costs. It is observed that the optimization criteria of supply-side management that concern the producers usually relate to their environmental footprint and their operational cost. Moreover, the actions regarding supply-side management are summarized on “when and how” the energy loads have to be produced and supplied to the consumers. At the same time, those actions also extend to the provision of incentives to the consumers, to encourage them to alter their own optimization criteria objectives, which are discussed below, and consequently achieve a “silver lining” between the criteria of the producers and the consumers. The most common incentivization is variable energy tariffs, which incentivize the consumers to request their loads when energy production prices are low [12]. The configuration of those energy tariff profiles depends on the expected environmental footprint and/or energy production cost reduction. It is also emphasized that incentives reach their full potential only when the consumers have the necessary knowledge of the incentive mechanism and use it to suit their best interests.

The complementary aspect of supply-side energy management, the optimal management of demand-side energy loads, is related to the actions that consumers take to satisfy their own needs posed as optimization criteria. More specifically, approaches from previously mentioned works [10,11] utilize the energy storage potential of the end-user systems to be provided to the consumers when needed. Furthermore, in the thermal flexibility enhancement methodology presented by [13], it was observed that the utilization of thermal energy storage and consumer thermal comfort levels significantly encourage RES participation in the coverage of the demanded energy loads of end-users. Summarizing demand-side management, the optimal management of energy loads aims to maximize the thermal comfort levels of the consumers during building occupancy periods while also maintaining the cost of energy used at the lowest levels. The optimization actions of the consumers include the weighing of the optimization criteria between each other, i.e., the thermal comfort and cost of requested energy, as well as the forming of thermal load profile formation, according to those criteria. As already mentioned, the criteria in the weighting process can also be partly influenced by the supply side, namely the energy producers. Consequently, the joint optimization of the demand side and supply side is heavily dependent on a coordination system that supports bidirectional communication between consumers and producers. This is even more crucial in district heating network (DHN) layouts, where the producer and the consumer are individual entities with their own different optimization criteria, which often contradict each other.

The value of utilizing energy flexibility emerges from the above discussion. On a thermal energy basis, thermal flexibility is defined as the ability of the system to alter their thermal energy injection/extraction rate in a system [14]. The primary parameters that affect the thermal flexibility of a system are the thermal storage potential, as well as the thermal power variability enabled by operational control strategies [14,15]. However, thermal comfort should also not be neglected, as there are indications from works that it is also an important parameter to thermal flexibility due to its dynamic nature over the course of a daily system operation, as well as its fluctuating behavior [16]. It is worth mentioning that shifting the occupant thermal comfort zone by 1 °C (reduction during heating operation and increase during cooling operation) can lead to substantial energy savings and a reduction in thermal peak loads [17,18].

1.2. Utilizing Thermal Flexibility with Smart Controlling

At this point, emphasis is placed on the utilization of thermal flexibility for the demand-side energy management of a building. According to the building thermal flexibility analysis above, for its maximum exploitation towards attaining desired thermal comfort settings combined with minimized energy consumption, a control structure is required with the following characteristics:

- Knowledge of the available thermal storage capacity;

- Knowledge of the desired thermal comfort zone of the user/consumer;

- Knowledge of the cost of the primary energy consumption related to the available energy sources;

- Ability to schedule operation controlling strategies of the heating systems of the building to enable power variability.

For the effective use of the four above characteristics of the controlling structure, the ability to predict the future states of the building is crucial. In other words, a dynamic simulation model of the building layout should be available. However, the local installation of such simulation models in building infrastructures becomes more difficult due to the system requirements in terms of computational power, and by extent, investment and operational cost [19]. This is something that should be considered when installing smart controlling layouts of thermal systems in buildings, like smart thermostats. The beforementioned data collection and building operation model construction processes are most used in the following applications related to installed heating, ventilation, and air conditioning (HVAC) systems.

The first category of applications concerns fault detection in HVAC systems. For instance, ref. [20] recommends the identification of the gradual operation duration increase of cooling systems as an indication of the effectiveness and degradation of the heat exchanger connected to it. The second category of applications is related to HVAC operational optimization according to the user’s needs. By using machine learning models, potential changes to the heating/cooling schedules are identified, aspiring to the maximization of the user’s thermal comfort [21]. More specifically, it has been noticed that during instances when occupants enter the indoor space, the indoor air temperature may not be at the level desired by them. This causes thermal discomfort to them during their initial stay in the indoor environment. Similarly, there is an opportunity to save energy by prematurely turning off the heating/cooling systems before the indoor environment is going to become vacant [22]. These ways of utilizing thermal flexibility are achieved by applying optimization methodologies in the controlling aspect of energy management in buildings.

1.3. Limitations of Building Smart Controlling

Optimization cases require the training of a dynamic thermal behavior model of the indoor space. For instance, in the study of [23], a building (called 1-Resistance, 1-Capacitance model, 1R1C) and a system power model is generated using real operational data. However, such a complicated model structure may be too much for a smart thermostat to utilize. Not only that, but attempting to identify the characteristics of the building may be unnecessary for a controller, because a black-box model could do the same work just as accurately, while an interpretable model of the indoor space may not be useful to a user that has not the relevant knowledge background. Another characteristic application is the usage of model predictive controlling (MPC) for continuously adapting the model to its real counterpart (i.e., the building), as well as applying smart controlling strategies. However, this approach is usually accompanied by undesired computational cost that far surpasses the respective capabilities of a smart controller, since most models used resemble the deterministic model, such as that of [23]. Continuously updating the predictions means that simulations should be constantly performed. This means that predictive horizon-based approaches need a model that is easy and cheap to use in conventional programmable controllers.

A way to face this issue is to resort to training the building model on a cloud-based platform, which receives measurement data from the local smart thermostat sensors and sends back to it the recommended course of action that has been decided. This is performed in the work of [24], where a computer is used to simulate multi-zone models. It is also stated that equipping the MPC model into the controller is a challenge to face in their future work. In other words, the decision-making process and the computational requirements accompanied by it are transferred away from the local control, adopting a centralized structure, which requires a cost network connection to be sustained.

In order to decentralize building energy management, large computational requirements should be gotten rid of altogether. This can be achieved through a simple model structure that supports independent and localized training and decision-making capabilities in building energy systems. Moreover, the application of a simpler smart controlling structure, such as rule-based controlling, allows for a viable controlling solution while reducing the computational tax on the respective controllers [25]. For example, ref. [26] employs a fuzzy rule-based approach control, which features a controlling layout capable of managing the indoor air setpoint according to the optimal external environmental conditions while achieving simplicity and ease of implementation. Moreover, ref. [27] examined the prospects of combining a reinforcement learning (RL) control structure with a decision tree structure in order to increase its interpretability, thus forming an explainable Deep Q-Network structure. An interpretable RL agent is different than an interpretable building model, as the former describes which behavior encourages optimized objectives, which is desired information by every user. This led to a controlling agent that maintains its effectiveness towards energy savings while adopting a rule-based structure, which is more user-friendly and lightweight in its use than conventional RL structures.

The above research has uncovered two significant limitations regarding the operation of building smart controlling devices and, in particular, smart thermostats on the basis of optimal thermal load management in buildings. Firstly, most available controlling methodologies do not possess a simple and lightweight structure, so that they can be implemented by the thermostat itself, which causes concerns regarding its operational autonomy, reducing control from building users. Secondly, a simple yet accurate predictive model that is applied to those methodologies is equally vital to the independence and cost-effectiveness of a smart thermostat. While the model training task can be taken away from the smart thermostat, cases where the model is too complicated in structure hinder the predictive capabilities and consequently the decision-making speed of the thermostat. This leads to either the need for adopting a cloud network for this task or to increase the computational capabilities of the thermostat, both of which reduce its affordability in practical applications while also hindering controlling independency for each building.

Briefly speaking, smart controllers in building thermal load management applications are in need for simple models, as well as controlling structures and strategies. The first issue can be faced with the use of surrogate models [28], which are characterized by low computational requirements and satisfactory training and predictive performance of the thermal behavior of buildings, allowing low-cost smart thermostats to be developed. Their simple structure also allows model training sessions to be performed on site and re-used by the thermostat. Not only that, but their simplicity also allows for an effective combination of multiple surrogate models, each one trained for a specific behavior of the examined system, thus being able to predict system states jointly and potentially more accurately than a single-surrogate structure. These structures are referred to as multi-surrogate model in the literature [29]. Regarding the issue of controlling structure complexity, an answer to the high computational requirements of the MPC is given by [30], who propose that a machine learning model be combined with rule-based controlling strategies in a lightweight controlling layout. Their simulation results indicate that this is a step in the right direction, as both modeling through machine learning and the application of day-ahead planning through rule-based controlling (RBC) seem viable through this work. Still, concrete proof is needed for the fact that rule-based machine learning is suitable to handle building energy management tasks in an experimental approach. Moreover, the need to constantly train models that predict future building states in a localized manner can only be proved possible by displaying methods that can be equipped on programmable logic controllers (PLCs) in an experimental environment as well. A future smart thermostat that not only supports offline training possibilities, but also online ones, will offer autonomy and security of operation of the building energy management system it is equipped on.

Besides the limitations of the scope due to the nature of the models required by modern smart controllers and thermostats, the current research is also limited in experimental applications of smart thermostats implemented in real-time operation cases. On the other hand, an ample number of works have explored thermostat data and developed guidelines on the effect of scheduling and controller programming on energy savings and thermal comfort levels [17,31,32]. Moreover, thermostat data have also been utilized in simulation environments, either to generate building models suitable for day-ahead predictions in MPC applications [33], to create occupancy model generators [34], or to directly estimate the characteristics of the building through time constant evaluation [33,35].

Two works worth mentioning that utilize a first-order building model to simulate a single-room indoor space are those of Sun et al. [36,37], which estimate the preheating time required to set a building room to desired temperature levels at the start of the occupancy. The preheating time estimation in these works is accompanied by an uncertainty period. Two limitations arise from this set of works. The first one is that the preheating time is estimated, and not decided by a controller, as the methodology itself contains a preheating period probability estimation. In order for the preheating algorithm to be implemented practically, this uncertainty needs to be gotten rid of, since a controller needs to make a concrete decision. Secondly, those works implement simplified first-order white-box models, which are too computationally costly for a programmable controller to identify the model parameters based on operational building data, as established in the previous sections. In short, those limitations that are found among the literature need to be addressed.

1.4. Aim of This Work

This approach aspires to a methodology for developing low-cost smart thermostats that maintain autonomous and effective optimized controlling capabilities of the heating schedule, without the need for either cloud based controlling or computational requirements that exceed those of a conventional PLC. Moreover, the presented smart thermostat methodology can be extended to include supply-side management, which consists of the direct control of the heating system itself, providing prospects for a demand-and-supply load management methodology, aiming for the optimized utilization of RES systems, the efficient use of HVAC systems, and the achievement of desired thermal comfort levels at the same time. In other words, the proposed approach attempts to face the current limitations of the existing smart controller development methodologies that have been spotted in the literature, which relate to the restriction of the thermostat training and predictive capabilities to be provided remotely, consequently binding a smart thermostat to a centralized database. Oppositely, enabling the thermostat to predict the building state by itself and helping decision support adopt a more autonomous controlling layout is something desirable in current standalone heating applications. This also holds true for future district heating network (DHN) applications, where thermal loads will be able to be provided in a more distributed manner, surpassing the limitations of centralized thermal load management layouts currently implemented on an urban scale [38]. Developing and testing smart thermostats in practical experimental applications allows for matching the nature of the controlling hierarchy of future DHNs to their distributed thermal load production and provision. This is because developing such devices with autonomy will allow various benefits of distributed energy system networks to be implemented to DHNs, such as the inclusion of prosumers in the network, enhanced renewable-energy-based thermal load self-consumption, and security of supply. Moreover, there is an increased sense of control for the DHN users and more direct communication with the respective producers, leading to the evolution of demand-and-supply-side management techniques. Considering that urban-scale energy networks and energy management strategies are promising structures to be used even more in the near future, the development of autonomous controlling applications through experimental applications such as this work is important.

In a brief description of the presented work, which faces the above issues, it focuses on developing and validating a smart thermostat layout that features a lightweight model and a demand-side management methodology in the form of a rule-based preheating controlling strategy. Methods for generating simple yet accurate models with low computational requirements, such as that of ALAMO modeling [39], paired with a lightweight controlling strategy approach, such as the RBC approach, is a great combination to address not only the reliance of smart thermostats on cloud computing but also to get rid of the large computational loads altogether. Not only that, but the automated machine learning methods (also stated by [30]) such as the ALAMO approach surpasses the hyperparameterization needs posed in other machine learning methods, as well as simplifies both the installation and operation of machine learning libraries into programmable controllers. In short, the two significant limitations posed in the works [36,37], as well as the limitation of scarcity of methodologies that are developed and applied experimentally in real-time operation are faced in this work.

Moving to a more specific analysis of the proposed work, the embedded surrogate model is trained on the thermal behavior data of the environmental chamber, while the smart thermostat employs it in real time to predict the indoor conditions of the environmental chamber and apply the controlling strategy according to the optimization criteria set by a building occupant. Those are the maximization of thermal comfort of the occupant and the use heating systems of the chamber as little as possible. The following sections describe the materials used for the development of the proposed methodology, the results that were produced through its experimental application, as well as the future potential of the approach in thermal networks and the conclusions drawn.

2. Materials and Methods

2.1. General Description

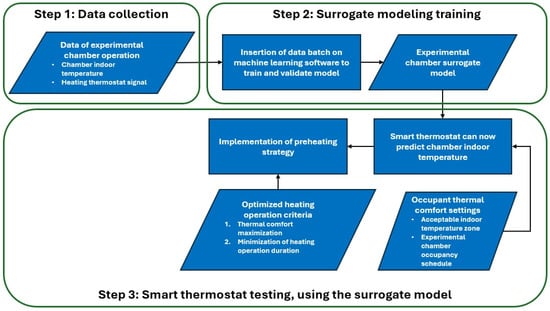

In this section, the methodology of smart thermostat development and validation process is described. The general idea of the smart thermostat is to create a controller that is able to predict the future conditions in the environmental chamber and take necessary actions regarding the heating schedule in advance. Following the order of actions presented in the flow chart of Figure 1, the methodology initiates by collecting measurements linked to the operation of the experimental chamber. These measurements are the indoor air temperature of the chamber and the heating operation signal that correspond to the operation of the chamber during the time period 22 February 2023–28 February 2023. Since the experimental chamber is protected from outside weather conditions, the most prevalent parameters that affect the indoor temperature inside the chamber were deemed to be the previous indoor temperature, as well as the use of heating. Therefore, those two parameters will probably be the most suitable ones for the creation of the surrogate model. The creation of such a data batch enables its use on the training and validation of a surrogate model using a lightweight machine learning software called ALAMO (version 2024.10.25). Data collection was conducted by the controller itself, as it has embedded data-logging capabilities in its default software. The measured data are automatically filtered by mean value filters to mitigate measurement noise. The quality of data were sufficient for this case, so no further preprocessing took place at this stage. The rest of the requirements for providing predictive capabilities to the thermostat is for it to possess information regarding the chamber occupancy schedule, as well as the desired thermal comfort settings of the occupant. Namely, those are the indoor air temperature setpoint and the daily occupancy schedule. The ability of the model to predict is used to optimize the operation of the heating schedule.

Figure 1.

Flow chart depicting the smart thermostat development and validation process.

The primary objective of the smart thermostat in this case is to maximize the thermal comfort of the occupant, while the secondary objective is to minimize the necessary operation duration for this task. For this purpose, a preheating controlling strategy is employed, which will be analyzed in Section 2.2.4. It is noted that in this experimental case, the energy consumption measurements are not available and therefore, the operation duration of the heating system is planned by the thermostat to be as little as possible.

In order to verify the effectiveness of this methodology, an operation validation phase takes place, which includes the following steps:

- Operational data gathering (22 February 2023–1 March 2023);

- Occupancy/heating schedule: 21:00–01:00;

- Surrogate model training phase using gathered operational data;

- Real-time smart thermostat testing, equipped with the trained surrogate model, during the period 14 February 2024–16 February 2024. The characteristics of the operation during test operation are the following:

- b.

- Occupancy schedule: 18:00–21:00;

- c.

- Heating schedule: 18:00–21:00 + preheating period (to be calculated autonomously in real-time by the thermostat);

- d.

- Environmental chamber temperature setpoint: [19.5–20.5] °C.

2.2. Experimental Chamber

2.2.1. Chamber Characteristics

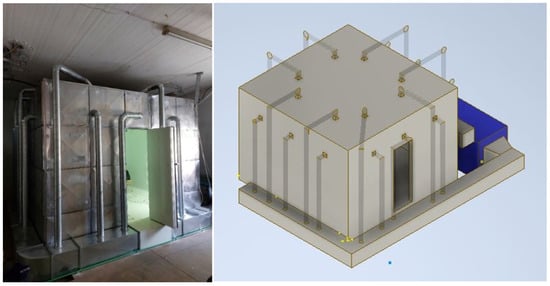

In this section the environmental chamber is presented, of which the operational data is collected (Figure 2). This chamber can be characterized as a box-in-a-box structure and is situated in the facilities of University of Western Macedonia campus near Koila, Kozani, Greece. Table 1 displays the dimensions of the experimental chamber, which are close to that of typical building rooms that are used in existing works in the present literature. The box-in-a-box structure allows for achieving a controlled environment inside the chamber, while the air conditioners outside the chamber have slow transitions with small fluctuations, mitigating the effect of outdoor conditions. This also means that the effects of direct sunlight on the chamber are mitigated, as it is entirely covered by the surrounding building environment. In other words, a potential simulation of the environmental chamber is easier than the case of real buildings, as many parameters and thermal mechanics are not considered to be fluctuating during the simulation.

Figure 2.

Environmental chamber.

Table 1.

Environmental chamber general characteristics.

The control of the indoor chamber environment is achieved by a heating system (Table 2). More specifically, it consists of an air duct system, where a heat pump is also embedded. The latter is responsible for providing heating or cooling loads to the chamber, depending on the thermal demands of the indoor chamber environment. The nominal heating power capacity for this experiment is stable at 4.7 kW, since on/off heat control is implemented. Besides heating and cooling, the use of an air duct system enables the import of fresh air in the environmental chamber, as well as configuration of the relative humidity of the indoor air through water spraying. It is noted that the air duct provides an air supply that reaches 1725 m3/h. While the import of fresh air is possible, no fresh air is imported in the current experimental case. Moreover, water spraying allows for controlled humidification that can lead to relative humidity levels reaching 90%, although this study case does not include air humidity control and therefore, the relative humidity levels remain mostly stable around 40% throughout the experimental periods mentioned in Section 2.1.

Table 2.

General characteristics of the chamber heating/humidity control system.

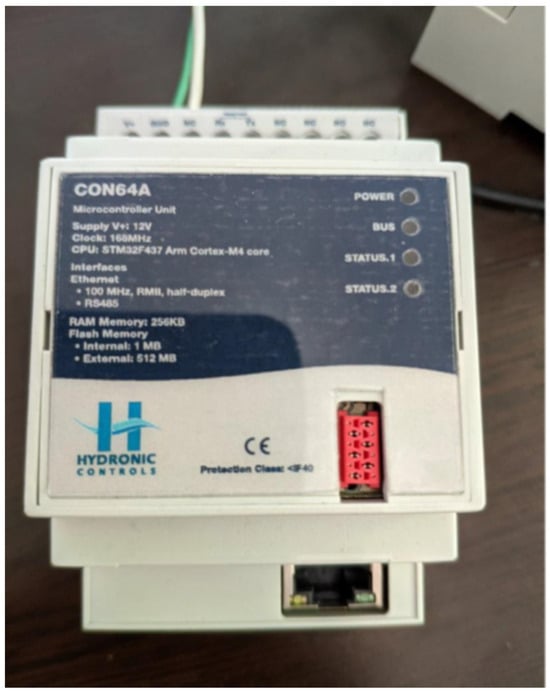

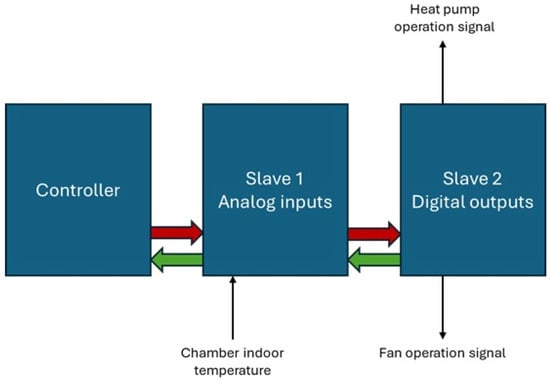

2.2.2. Smart Thermostat Setup

The smart thermostat setup consists of a PLC layout, which is programmable using embedded Python (MicroPython version 1.14) environment. The controller layout consists of a “master” controller which is linked to “slave” micro-controllers, which are responsible for providing the signal inputs and output that the “master” controller instructs, as well as the collection of measured data with data filtering equipped to prevent excessive measurement noise. Figure 3 displays the controller that is operating as a smart thermostat during this experiment. Additionally, Figure 4 displays the setup configuration of the controllers used, along with the input and output signals that are utilized from the controller, when acting as a smart thermostat. Table 3 displays the specifications of the programmable controller. As can be seen, the controller has pretty low computational power with the additional benefit that it enables the user to freely implement various controlling strategies through coding in the embedded Python environment. Moreover, it possesses inherent data logging capabilities and the ability to be equipped with external Python libraries, such as available open-source ALAMO approach libraries in Python environment. The above characteristics not only allow the controller to host externally trained surrogate models and use them in predictive controlling strategies, as it will be made clear in Section 3, but is also expected to be able to host the ALAMO surrogate model training process in future efforts, should it be equipped with the respective ALAMO Python (ALAMOPY) library.

Figure 3.

Programmable controller operating as smart thermostat.

Figure 4.

Controller setup in the current work. Arrows indicate the directions of data and signals.

Table 3.

Programmable controller specifications.

During the experiment, the controller is equipped with the surrogate model that is created using collected temperature and heating signal data, so that it can essentially become capable of predicting the indoor air temperature of the environmental chamber and attempting to maximize thermal comfort, by adding a preheating period, besides its conventional heating operation.

2.2.3. Chamber Surrogate Model

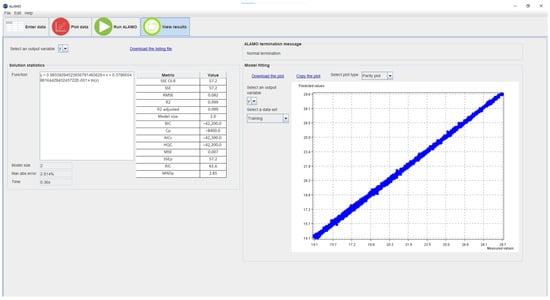

Surrogate models are able to imitate the operational behavior of the system they are trained on. In the experimental case, the surrogate models that are created attempt to depict the fluctuation of temperature of the experimental chamber throughout its operation. In order to create those models, the software called ALAMO (Figure 5), which is based on the ALAMO approach [39], is used.

Figure 5.

ALAMO environment.

In this experimental case, two surrogate models are going to be created and compared, in order to use the most accurate one. More specifically, the surrogate models that are created have structures that are displayed in Equations (1)–(3). Both models are trained using the indoor air temperatures (Tin) and the heating activation signal sent by the controller-thermostat (Ut). The general idea of the models is to estimate the chamber indoor air temperature during the next simulation timestep Tin,t+dt, by using the temperature in the current timestep (Tin,t), as well as the chamber heating request signal (Ut). The first surrogate model “fmono” is a single-surrogate model, as it possesses a single equation structure and is trained on the whole temperature data set.

On the contrary, the second model is a multi-surrogate model. The logic behind the multi-surrogate model is that multiple models are trained on a part of the dataset, which satisfies certain conditions. Therefore, during prediction, the multi-surrogate model employs a different sub-model, depending on which of the conditions hold true during the predictive horizon. This allows for having more specialized sub-models and, therefore, improving predictive accuracy.

To specify, two surrogate model equations are used in this model, with each one training on a part of the dataset. As Equations (2) and (3) display, one model (Equation (2)) is trained on the part of the dataset, in which the heating request signal is absent, resulting in absence of heating in the chamber. Essentially, the dataset used to train this model captures the free-floating behavior of the temperature in the chamber. On the other hand, Equation (3) is trained on part of the dataset, where heating of the environmental chamber is activated.

The fitting criterion in all the surrogate model training cases is the Root Mean Square Error (RMSE) (Equation (4)) and the Mean Absolute Error (MAE) (Equation (5)) between the measured and the predicted indoor air temperature value of the experimental chamber.

2.2.4. Proposed Smart Thermostat Strategy

The main characteristics that set the proposed smart thermostat apart from programmable ones are the following:

- Heating periods of the indoor space are independent from the building occupancy periods and are decided by the smart thermostat.

- Since the smart thermostat is free to act independently, regarding the heating period configuration, indoor air temperature does not concern the user anymore. In other words, Tsetback is no longer a configurable parameter, whereas Tsetpoint can still be used.

- Heating periods are now configured by the smart thermostat according to the value of Tsetpoint the user has provided.

- The proposed smart thermostat is able to predict the indoor air temperature using model training methods and data (i.e., indoor air temperature, heating request signal).

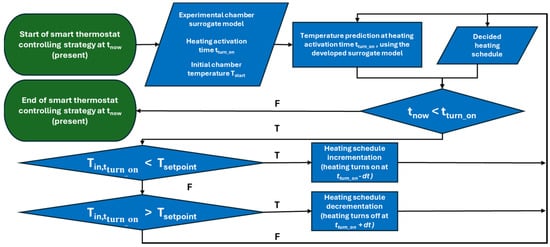

The smart thermostat heating strategy, which is used daily, is presented below (Figure 6). Essentially, this algorithm uses the moving horizon predictive control, which is commonly used among model predictive control (MPC). However, in this case the length of the moving predictive horizon is not constant, as in most MPC practices, but is variable and is calculated according to the temporal distance (Δτ) between the present moment and the moment when occupancy starts, which also coincides with the start of heating (Equation (6)).

Figure 6.

Smart thermostat heating algorithm used to heat the indoor air of the chamber. Letters “T” and “F” stand for “True” and “False”, respectively.

Note that this is an initiation of the heating turn-on scheduling and is subject to changes when preheating algorithm is used. In other words, when the smart thermostat algorithm initiates, the heating schedule is the same as the occupancy schedule. Then, the preheating strategy is applied, and an additional preheating period is added. The variable moving horizon strategy ensures a satisfactory initial estimation of the preheating schedule, which becomes more accurate as the moving horizon length is reduced, namely as the present moment tnow approaches the heating enabling moment tturn_on. This implementation is necessary for time-dependent problems like temperature prediction, as the indoor temperature each moment (else called timestep in simulations) depends on the value of the moment before that. Therefore, as the thermostat predicts further into the future its prediction accuracy reduces, and vice versa. This approach makes the prediction robust and independent of the initial indoor temperature conditions after the occupancy period ends and preheating duration calculation initiates.

Regarding the preheating strategy of the smart thermostat, the procedure is initiated by defining the occupancy schedule of the user. Consequently, the time of occupant’s arrival (tarrival) is set as the starting point of conventional heating schedule. From this point on, the thermostat uses the developed surrogate model and the indoor air temperature at present to predict the temperature for every time interval until time interval tarrival. Depending on whether the predicted temperature reaches the desired temperature setpoint, the thermostat adjusts the heating schedule by configuring the preheating schedule in a continuous manner.

This algorithm has been formed with the aim of maximizing the occupant’s thermal comfort, while also minimizing the heating schedule size. It is also noted that the current approach focuses entirely on optimally managing the demanded heating load, while ignoring any potential changes in thermal energy production efficiency or cost that could occur depending on the chosen schedule. In other words, this methodology does not consider the supply-side management of the heating energy used for the environmental chamber.

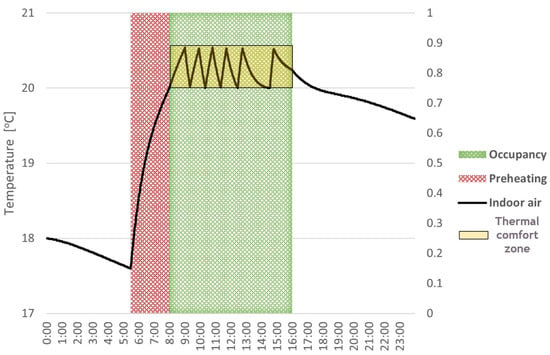

The result is a formed heating schedule which resembles that of Figure 7. As observed in the figure, the heating schedule is divided into two areas: the occupancy period (green area), and the preheating period (red area). The proposed smart thermostat aims at maintaining the indoor air temperature in the thermal comfort zone (yellow area), and utilizes the preheating controlling strategy to do so. As it is also evident in the figure, the thermostat still operates as a conventional one during the occupancy period, turning the heating off when the indoor air tends to be overheated or overcool, i.e., turning on and off the heating as the temperature approaches the lower and upper thermal comfort temperature limits, respectively.

Figure 7.

Example of implementation of the smart thermostat controlling algorithm.

Preheating Strategy

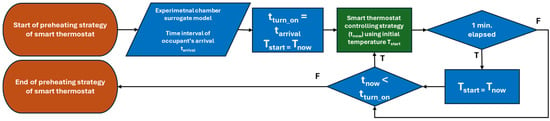

As already mentioned, the use of a preheating strategy is crucial to the maximization of thermal comfort and has been proven in our previous work that it is able to maximize thermal comfort levels to 100% [18], as well as increase the thermal flexibility of buildings. This strategy has also been used by [36,37] to increase the thermal comfort and counter the presence of thermal inertia that leads to thermal discomfort during the first moments of occupancy. Figure 8 displays the algorithm of the preheating strategy used by the smart thermostat.

Figure 8.

Smart preheating strategy algorithm. Letters “T” and “F” stand for words “True” and “False”, respectively.

The preheating algorithm initiates when the controlled indoor space becomes unoccupied. Then, the next occupancy period is examined, and the respective preheating period begins to form. This is done by initiating the heating period to be the same as the occupancy period. Therefore, as displayed in Figure 8, the moment that the occupant enters the controlled indoor space, tarrival, is equal to the time that the heating period initiates. Then, the smart thermostat uses the surrogate model to predict the indoor air temperature using the current heating schedule, depending on whether the indoor air temperature when the occupant arrives during tarrival deviates from the lower bound of the occupant thermal comfort zone temperature, which is also considered the chosen temperature setpoint in this case. It is reminded that the current approach focuses on the demand-side load management, namely the heating loads requested by the energy consumer, ignoring potential energy consumption cost, as this is included in the supply-side management.

Implementing the Smart Preheating Strategy

For the purpose of validating the methodology that is used by the proposed smart thermostat, the most representative surrogate model (i.e., the one with the lowest RMSE during the training phase) is embedded in the thermostat and smart preheating controlling strategy is utilized for three consecutive days. The heating optimization aims to maximize the thermal comfort, while requesting as little heating as possible. Therefore, daily occupant thermal comfort TC is calculated according to Equation (7). More specifically, thermal comfort is calculated as the percentage of the n minutes contained in the occupancy period, during which indoor air temperature Tin,i (for each timestep i) is bigger than the temperature setpoint Tin,set that the user has chosen. It is noted that while comfort zones have lower and upper temperature bounds, potential overheating may be observed during occupancy periods, which skew the evaluation of the smart thermostat performance. This is because temperature overheating is the result of heating turnoff delay which may be linked to sensor hysteresis. In any case, thermal comfort is evaluated in two ways, where the Equation (8) considers indoor air temperature overheating due to sensor hysteresis, while Equation (7) does not. The overheating effect will be observable in the smart thermostat testing phase of the Section 3.

In addition, since no measurement regarding energy consumption is available during this experiment, the minimization of heating operation is described in operational hours.

3. Results

3.1. Operational Data Gathering

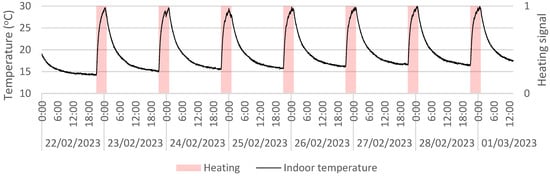

In this section, the implementation of the experimental methodology is presented. To begin with, the measured data that are used in the training of the surrogate models are related to the operational period of the environmental chamber 22 February 2023–1 March 2023. Figure 9 presents the measured data, namely the chamber indoor air temperature and the heating operation signal.

Figure 9.

Collected measurement data.

As can be seen from Figure 9, heating periods take place during 21:00–01:00 each day, while no temperature setpoint is chosen, in order to achieve uninterrupted heating of the chamber. Consequently, the indoor air of the heated environmental chamber reaches 30 °C, and then after 01:00 it enters the free-floating temperature state, where it gradually cools down, due to heat thermal losses. An interesting observation is that the lowest temperature the chamber reaches each day gradually increases after day, starting at 13.5 °C and finishing at 17.5 °C at the end of the sequence of days. This might be caused by either of two reasons: (a) The environmental chamber walls gradually build up heating energy each day, leading to the indoor air not dropping to the same temperature that it was before heating, or (b) the hysteresis of the measuring instrument is affected by the consecutive heating and cooling of the air during the examined period, leading to measurement errors [40].

3.2. Surrogate Model Training

Since data are collected, the training of the proposed surrogate models follows. By using the ALAMO software and examining the behavior of the temperature in the experimental data batch, the model structures are created, and coefficients are calculated by data fitting. Equations (9)–(11) below are provided, where Equation (9) represents the single-surrogate model (fmono), whereas Equations (10) and (11) represent the multi-surrogate model (fs1, fs2). As elaborated in Section 2, both models describe the temperature during the next timestep and depend on the indoor temperature during the previous timestep, as well as whether the heating signal is on (fs1) or off (fs2).

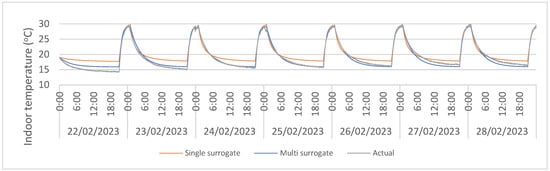

The metric values for each model training phase are also provided in Table 4 below. As observed, the produced models have satisfying accuracy. However, the multi-surrogate model containing specialized sub-models gives it an extra edge in performance. While the differences are almost indistinguishable, propagating errors throughout time horizon predictions is able to increase the magnitude of errors among models, as it becomes clear below, in Figure 10.

Table 4.

Data training results of the surrogate models.

Figure 10.

Visual comparison of the surrogate model performance.

In order to understand the difference in performances of the surrogate models, a demonstration of them predicting the chamber operation is presented in Figure 10. More specifically, each of the models has a predictive horizon of 24 h, which means they predict the whole day of operation by having available only the initial indoor air temperature of the chamber of each day. As can be seen, the multi-surrogate model (fs1, fs2) performs satisfactorily. On the other hand, the single-surrogate model is able to capture the behavior of the indoor air temperature during heating periods, the same cannot be said for the free-floating periods. It should be noted that since the surrogate model predicts the indoor air temperature accurately during the next time interval, which is 1 min, high accuracy is expected only when predicting the next few hours. This means that RMSE metrics produced by the model fitting procedure that corresponds to the training performance may not provide a clear picture of predictive performance in cases of extended prediction horizon. This is why comparing models on the training dataset with large predictive horizons, like in Figure 10, gives a better image of which model is more suitable for application. In any case, as explained in Section 2, the predictive horizon used is not going to be static, so the predictive performance of the surrogate model used is going to improve as the predictive horizon reduces in size. This means that such accuracy in a 24 h horizon (Figure 10) is more than enough for the smart thermostat to form the preheating period effectively during the smart preheating implementation phase.

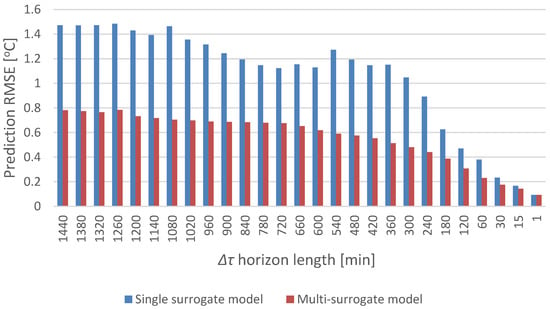

Initially, it may seem contradictory that models with similar RMSE metrics may have different prediction performances when the predictive horizon is large. To expand on this, Figure 11 displays the RMSE metrics when the prediction horizon length Δτ gradually reduces in size, for both the single-surrogate and multi-surrogate models. Essentially, Figure 10 displays the temperature predictions of both models when Δτ is equal to 1440 min (24 h), whereas when Δτ equal to 1 min, the RMSE values are the similar to those in Table 4.

Figure 11.

Sensitivity analysis of predictive horizon length on the predictive performance of both models when using the training dataset.

By examining Figure 11, it can be deduced that the multi-surrogate model tends to predict better, while it has a more robust performance than the single-surrogate model, as horizon length decreases. This might be attributed to the fact that the multi-surrogate model contains sub-models that are specialized in predicting different building behavior types (i.e., heating and free-fall periods), while the single surrogate is less specialized in each behavior, leading to it predicting less accurately. Moreover, it can be illustrated that as the horizon is reduced in size, the prediction propagation error also decreases for both cases. This means that even a slightly less accurate prediction will improve as tnow approaches tarrival, which has also been mentioned in Section 2.2.4. This is why the variable predictive horizon provides robustness to the preheating algorithm, regardless of the initial temperature and length of the predictive horizon. Furthermore, this also explains the predictive performance difference of the models in large predictive horizons, even if the training metrics are the same. Regardless, while the surrogate model was chosen as more suitable in this case, the authors cannot confidently state that multi-surrogate models are better in every case, as this requires a more systematic model comparison, which is not the focus of the current work. Consequently, the multi-surrogate model will be used by the smart thermostat during the testing phase.

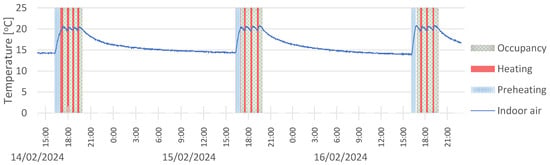

3.3. Smart Thermostat Testing

After finishing the surrogate model training and evaluation process, the testing phase of the smart thermostat takes place. As mentioned in Section 2, the occupancy schedule period is 18:00–21:00, while the preheating period is calculated by the smart thermostat in real time using the temperature prediction and smart preheating strategy. It is noted that while the occupancy schedule of the testing phase differs from the respective schedule of the training period, this poses a good opportunity to test the generality of the developed model, namely it being able to predict and calculate the preheating periods at any given time of day. The resulting test is displayed in Figure 12, where the thermostatic control is applied in real time. More specifically, the conventional heating periods (Heating) are taking place in the occupancy period, while preheating periods manifest before the occupancy periods, as intended. Three consecutive days of operation display three characteristic operational versions of preheating through prediction.

Figure 12.

Testing smart thermostat operation in real time.

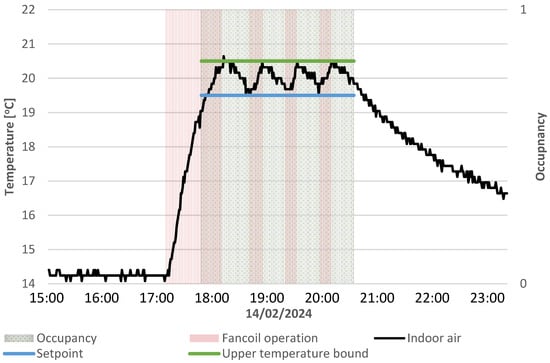

Starting with 14 February (Figure 13), a slight delay of the preheating start is manifested, which can be spotted because of the heating that takes place during the start of the occupancy phase at 18:00. This means by the time the occupant would have entered the indoor space, the indoor temperature had not reached the comfort desired value according to the comfort zone [19.5–20.5] °C. Therefore, thermal comfort of the occupant was calculated to be 97.2% for this occupancy period, when overheating is not considered. In this case, the overheating was almost negligible, as indoor air temperature surpassed the upper temperature bound during the occupancy period for a very short interval just before 18:30.

Figure 13.

Testing phase, 14 February 2024.

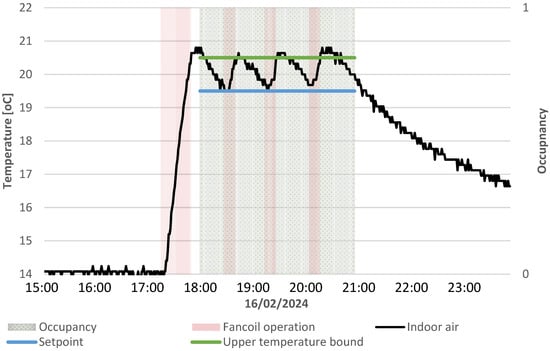

On the other hand, the exact opposite phenomenon occurred on 16 February (Figure 14), where preheating mode was activated slightly earlier than the optimal, resulting in the indoor temperature reaching comfortable temperature conditions, though this leads to the chamber indoor air being maintained at higher temperature levels at the start of the occupancy, leading to increased heat losses and therefore, more energy required to maintain comfortable temperature levels. On another note, slight overheating is spotted, which may be attributed to the temperature sensor hysteresis. This overheating essentially manifests when the indoor air temperature (black line) surpasses the upper temperature bound (green line) during the occupancy period.

Figure 14.

Testing phase, 16 February 2024.

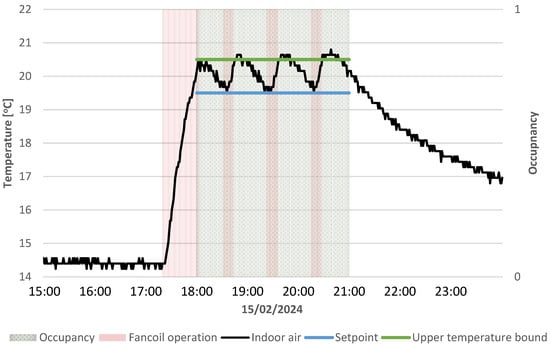

Finally, on 15 February (Figure 15), preheating leads perfectly to the indoor temperature being at the lower end of the occupant thermal comfort zone (19.5 °C) at the start of the occupancy period. In addition, slight overheating of the chamber is also spotted in this case, when indoor air temperature (black line) surpasses the upper temperature bound (green line), during the occupancy period. What is also interesting, however, by carefully examining 15 February (Figure 15) and 16 February (Figure 14), it might be noticed that the operation periods of the heating may not differ so much, in contrast to 14 February (Figure 13). This is verified by examining Table 5, where the occupancy and the heating periods (fan coil operation) are displayed.

Figure 15.

Testing phase, 15 February 2024.

Table 5.

Characteristic periods and results of chamber operation during the testing phase.

By examining Table 5, it can be seen that 14 February involves larger heating operation periods, as temperature increases more slowly in the chamber. If the indoor temperature had risen at the same rate as in the other days, then there would have not been such a great difference from the other testing days. At this time, the cause of such a difference is not known, and it might be attributed to faulty sensor readings. On the other hand, 15 February and 16 February display consistency in their results. Despite that, 16 February has reduced heating operation, as indoor temperature during occupancy period increases at a faster rate than the case of 15 February. Therefore, even in a controlled environment, temperature sensor characteristics play a crucial role in successfully implementing heating strategies. It should be noted that this fan coil operation reduction across 14 February–16 February indicates a faster temperature increase of the indoor air. While this is a phenomenon worth looking into, the main scope of this work is the ability of the smart thermostat algorithm to maximize thermal comfort levels; therefore, this is something that should be investigated in the future.

4. Discussion

Generally speaking, the downscaling of the computational demand required for model training, as well as decision-making through the use of controlling strategies, is also a great benefit in multiple aspects. First and foremost, the economic aspect: Namely, the investment cost has the potential to drop significantly, making smart thermostats a much more affordable tool used in either residential or service buildings, where most people spend their time nowadays and, subsequently, most building thermal load requests manifest [1]. Secondly, the recent focus of the EU on developing large-scale RES-based communities [7] to secure energy provision to buildings has opened discussion on the layouts that support its successful implementation, such as DHNs. It has been discussed in [38] that such layouts are possible, while it is also hinted that heating distribution in latest-generation DHNs will possibly adopt a decentralized layout, enabling autonomy between heating producers. This leads to an opportunity to help the DHNs to include a multi-energy thermal market, where each producer and each consumer has its own autonomy and independent aims in terms of decision-making. This transition from a centralized DHN to distributed DHNs will also benefit the inclusion of RESs, as not only will RES producers have individualized aims and courses of action, but distributed systems will also allow anyone to become an energy producer at any time, encouraging “prosumers”, namely consumers that can also produce energy (usually through locally installed RES systems) to participate in the thermal energy market of the respective DHN. Nevertheless, for all that to be possible, building consumers should also have high levels of decision-making autonomy. This means that a controlling structure in such systems should also be distributed equally among producers and consumers. Therefore, the development methodologies of independent smart controllers, such as the one in the proposed work, strive to be both affordable and implementable in a distributed controlling layout, bringing substantial contribution value to the table.

According to the observed results, it can be inferred that developing simplified smart controlling tools in practical applications is implementable. When comparing the works mostly related to the proposed one, namely that of [36,37], various challenges have been faced. To begin with, this work implements a model-equipped controller that automatically predicts the future states of the indoor air temperature, which was not conducted in those works. The use of surrogate modeling surpasses the limitations of the physical models used in these works because it gives the controller the potential to create simple models by itself, as well as use them in real time. Furthermore, the use of simple models allowed us to face the second limitations of the referred works: They can be used to continuously predict and adjust the future heating scheduling by utilizing a variable predicting horizon. This is something that has been utilized in MPCs and proves the potential of that method when paired with models that are easy to simulate with. This ability to continuously predict the future state of the indoor air allows for updating the preheating schedule as the time to enable heating approaches. Therefore, there is no need to evaluate uncertainty, as the predictive uncertainty mitigates when the preheating period comes closer to the present and the predictive horizon reduces in size, making the prediction more accurate as time passes by. In short, the controller initially estimates the heating period, but in contrast to [36,37], the estimation slowly transitions into a decision to be taken by the controller. All the above improvements allowed the preheating strategy to be evolved to be suitable for use in real-time applications. Finally, it should be noted that while the environmental chamber is not affected by the outdoor environment, its indoor space is similar in size to the indoor spaces that the methodologies of [36,37] are tested on.

Regarding other benefits this work brings, setting a basis for model development on an environmental chamber such as that of this work helps bring forth potential modeling issues (such as dealing with sensor drifts, which are identifiable in this case), which are difficult to observe in real building cases, where the air temperature behavior is affected by more parameters. For example, even in a controlled environment such as the current environmental chamber, an increase in heating duration was displayed on 14 February, which may be attributed to possible energy accumulation inside the chamber envelope. Performing experiments on days that are not consecutive, as well as including wall temperature measurements of the environmental chamber, could potentially answer whether this effect is linked to heat accumulation in the chamber envelope. This is something that should be done before applying the proposed smart thermostat methodology to more complex buildings. This helps ensure the reliability of the developed models in future efforts, as well as provides insight into issues likely to manifest during the validation of a smart thermostat, which are more difficult to discern in a real building operation. On another note, despite the existing measurement drift spotted in the training phase, the model prediction and the preheating were mostly successful, indicating it did not affect the implementation of the methodology that much. Regardless, whether this drift results from either sensor hysteresis or the thermal capacity of the environmental chamber needs to be identified in the future. Future energy consumption measurements will be able to give a more concrete indication of which of the two is true. Furthermore, those measurements allow for estimating the potential energy savings of the implemented controlling strategies. Therefore, this is considered one of the high-priority future tasks of this work. Additionally, the presence of sensor hysteresis when consecutively heating during occupancy periods, which leads to occasional overheating, is not connected to the performance of the preheating algorithm in this case. However, it is something that should be addressed in the conventional heating algorithm in future experimental runs.

Implementing this smart thermostat methodology in a real building could prove challenging because of various thermal loads that are present in a respective structure, such as internal and ventilation loads. Besides that, the variable weather conditions, such as solar irradiance and outdoor air temperature can also affect the heating requirements of a building. Not only that, but different climate zones and building types add variance to the possible behavior types that the smart thermostat will come up against. To face this challenge, further preprocessing of the data may potentially increase the accuracy of the model (via outlier removal or data normalization), which is also something to be considered in future modeling efforts of the operation of real buildings. In addition, multi-surrogate model structures could assist in capturing real building behavior across different seasons of the year, which have been proven a significant parameter in smart controlling of HVAC systems [26], while they could be beneficial in multi-zone or multi-consumer applications, such as DHNs [38]. In fact, multi-surrogate modeling has displayed its viability in seasonal DHN heating load prediction applications [41], with each sub-model mimicking the heating load behavior of the DHN in a distinct season. Moreover, multi-surrogate modeling has also been used in a spatial manner, i.e., each sub-model being able to predict the heating loads of a single consumer, leading to an aggregated heating load prediction approach [42]. In a similar fashion, this work could more systematically utilize the surrogate models in real buildings, where each one can capture different states and behavior of the buildings, such as those proposed in this work (i.e., heating and free-float states).

Moreover, as the results displayed, testing the model effectiveness on heating patterns that are the same as those on which it was trained would provide no additional value to this work. Instead, this is something that should be done in real building cases. By addressing the above, produced methodologies such as the proposed one have the potential to be scaled and adapted to real building cases, which are typically larger and more complex in structure than the environmental chamber. Not only that, but building cases could include building consumers of the local DHN, and even multi-zone buildings, such as offices or public service buildings.

In terms of the further refinement of smart thermostat capabilities in the future, the smart thermostat can enhance their own communication capabilities with the users by assessing their preferred comfort settings (e.g., indoor air temperature setpoints) by using information such as activity level, clothing, and user feedback on their perception of air temperature [43]. More specifically, the smart thermostat can include an adaptive comfort model that is trained directly from user feedback and available data from smart devices that occupants commonly wear or use (e.g., activity level or heart rate from smart watches) [44]. In case online learning is difficult to implement, offline trained model alternatives include the provision of representative occupancy schedules created by clustering collected smart thermostat data [32]. The development and implementation of such methodologies provide supplementary value to the effectiveness of a smart thermostat, i.e., its ability to optimally preplan the thermal schedule. On another note, the development of the proposed thermostat currently focuses on the aspect of the demand-side management. The potential use of a smart controller responsible for the supply-side management of the chamber’s heating system would provide a good opportunity for developing a smart controlling methodology for energy producers, which is a core component of future DHNs [38].

5. Conclusions

All in all, this approach presents the process of developing and experimentally validating a smart thermostat, accompanied by the respective development and testing of its controlling strategies. The training of a surrogate model through the use of easily acquired operational data that are commonly accessible to all thermostats (heating signal and indoor air temperature) enables its implementation on an environmental chamber in order to optimize the thermal comfort requests from a user during real-time operation.

In the present case, the developed smart thermostat methodology is able to address the issue of achieving desired temperature levels during initial occupancy time intervals by implementing a smart preheating strategy in real-time indoor space operation, which is a presently discussed matter in the current literature. More specifically, the optimized operation is conducted according to maximizing occupant comfort, while using as little heating as possible. By utilizing a variable predictive horizon (a customized variant of the respective predictive horizon commonly found in MPC applications) in combination with surrogate models, it can continuously adjust its course of controlling strategy implementation planning with increasing accuracy when approaching the scheduling events. Therefore, the current setup is able to face limitations of predictive heating control applications such as predictive uncertainty and heavy computational requirements at the same time. Furthermore, the operation of the smart thermostat embedded model, namely the indoor space surrogate model can be independent from its training, which can take place either outside or inside of the thermostat environment and have low computational requirements, providing a low-cost way to address the limitations of thermostats existing in the current literature. It is worth noting that the implementation of the model in the real-time operation of the environmental chamber provides insight into potential issues the model faces that could manifest when trained on indoor conditions unaffected by the external environment, which are difficult to identify when applying the developed models in more complex building cases. It is also worth mentioning that the environmental chamber provides an indoor space of a size comparable to single-zone building rooms that are usually examined in simulation efforts in the literature.

The results of the testing phase show that the current methodology has a promising model training and usage process, which does not require a lot of data and maintains a generalizable model that can be used in any heating schedule. In addition, its implementation on a preheating controlling strategy can lead to maximized thermal comfort levels, as test results provided TC percentage in the range 97.2–100%. However, present heating turnoff delays can significantly reduce thermal comfort. Besides that, the use of multi-surrogate model structure appears to be effective in increasing model predictive capabilities. Another observation made from the results of the experiment is that a potential measurement drift has been identified in the training measurement of this work. This can currently be presumed to be attributed to either existing thermal inertia in the chamber or innate sensor drift, although it will be addressed in future efforts.

Despite the benefits the proposed smart thermostat experimental setup provides, there is room for improvement in the following aspects. First of all, the implementation of the experiments could consider the thermal inertia phenomena discussed. For instance, measurement periods could avoid being conducted in consecutive days, to ensure that the initial conditions of the environmental chamber remain the same, while wall temperature measurements could be conducted after each operation session. Additionally, effective model training requires the provision of high-quality measured data. While temperature can be measured through relatively inexpensive means, the accuracy and precision of measurements can affect the quality of the developed model and, by extent, its ability to optimize the thermal operations of the building. Therefore, it is important that the measurement and data collection processes (preprocessing) are established more systematically. Future efforts could also focus on collecting energy measurements related to the heating system operation of the environmental chamber, leading to the development of energy-saving thermostat strategies.

Moreover, the current experiment took place in a closed environmental chamber, which is a controlled environment. Implementing this smart thermostat methodology in a real building could prove challenging because of the various thermal loads that are present in a particular structure, such as internal and ventilation loads. Besides that, the variable weather conditions, such as solar irradiance and outdoor air temperature, can also affect the heating requirements of a building. Furthermore, the thermal load profiles can vary depending on the use of the building, its characteristics, and the climate zone it is located in. Employing multi-surrogate modeling may be the answer to validating building models in different climate zones, as well as adapting to related heating patterns and behaviors that are linked to the location of the building and the complex heat loads of large-scale thermal networks. This makes a future pilot study worth conducting, in which smart controllers embedded with various types of surrogate models will be tested in real building cases of the local DHN. Such a study will be able to provide insight into the next steps for further developing and validating the smart thermostat modeling methodology, while examining the performance of the produced smart thermostat models on multiple types of indoor thermal zones, variable external environment conditions and heating load patterns. Lastly, regarding the broader aspect of energy management, having a controller with communicative abilities towards both its users and energy suppliers will be of great significance to establishing an integrated demand-and-supply management structure, while still allowing for autonomy in the actions of consumers. Not only that, but lightweight controlling strategies are a core part of future urban-scale DHNs because they encourage the inclusion of RES producers and prosumers in thermal networks, consequently facing upcoming needs of future thermal networks. In any case, in order to maintain effectiveness, surrogate modeling techniques used in smart thermostats should emphasize maintaining low-cost data acquisition techniques in order to lead to the development of autonomous and widely affordable smart thermostats with satisfying accuracy that can participate in urban-scale energy management efforts.

Author Contributions

Conceptualization, L.Z., G.P. and N.P.; methodology, L.Z., N.T., N.P. and G.P.; software, N.P.; validation, L.Z. and N.P.; formal analysis, L.Z.; investigation, L.Z.; resources, G.P. and N.T.; data curation, L.Z.; writing—original draft preparation, L.Z.; writing—review and editing, N.T., N.P. and G.P.; visualization, L.Z.; supervision, G.P.; project administration, G.P. and N.T.; funding acquisition, G.P. and N.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Dataset available on request from the authors.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| 1R1C | 1-Resistance, 1-Capacitance model |

| ALAMO | Automatic Learning of Algebraic Models |

| DHN | District Heating Network |

| HVAC | Heating, Ventilation, and Air Conditioning |

| MPC | Model Predictive Control |

| PLC | Programmable Logic Controller |

| RBC | Rule-Based Controlling |

| RES | Renewable Energy Source |

| RL | Reinforcement Learning |

References

- EU. Energy Statistics—An Overview. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Energy_statistics_-_an_overview (accessed on 25 October 2023).

- U.S. Energy Information Administration. Monthly Energy Review—February 2025. Available online: https://www.eia.gov/totalenergy/data/monthly/ (accessed on 19 March 2025).

- Zhou, X.; Huang, Z.; Scheuer, B.; Wang, H.; Zhou, G.; Liu, Y. High-Resolution Estimation of Building Energy Consumption at the City Level. Energy 2023, 275, 127476. [Google Scholar] [CrossRef]

- Directive (EU) 2018/2001; Directive (EU) 2018/2001 of the European Parliament and the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources. The European Parliament and the Council of the European Union: Strasbourg, France, 2018.

- European Commission. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions. The European Green Deal. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:b828d165-1c22-11ea-8c1f-01aa75ed71a1.0002.02/DOC_1&format=PDF (accessed on 3 June 2025).

- European Commission. Stakeholder Consultation on the Renovation Wave Initiative—A Synthesis Report. Available online: https://energy.ec.europa.eu/system/files/2020-10/stakeholder_consultation_on_the_renovation_wave_initiative_0.pdf (accessed on 2 June 2025).

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. A Renovation Wave for Europe—Greening Our Buildings, Creating Jobs, Improving Lives. Available online: https://energy.ec.europa.eu/system/files/2020-10/eu_renovation_wave_strategy_0.pdf (accessed on 3 June 2025).

- Guelpa, E.; Verda, V. Demand Response and Other Demand Side Management Techniques for District Heating: A Review. Energy 2021, 219, 119440. [Google Scholar] [CrossRef]

- Péan, T.Q.; Salom, J.; Costa-Castelló, R. Review of Control Strategies for Improving the Energy Flexibility Provided by Heat Pump Systems in Buildings. J. Process Control 2019, 74, 35–49. [Google Scholar] [CrossRef]

- Liu, J.; Li, Y.; Ma, Y.; Qin, R.; Meng, X.; Wu, J. Coordinated Energy Management for Integrated Energy System Incorporating Multiple Flexibility Measures of Supply and Demand Sides: A Deep Reinforcement Learning Approach. Energy Convers. Manag. 2023, 297, 117728. [Google Scholar] [CrossRef]

- Craparo, E.M.; Sprague, J.G. Integrated Supply- and Demand-Side Energy Management for Expeditionary Environmental Control. Appl. Energy 2019, 233–234, 352–366. [Google Scholar] [CrossRef]

- Logenthiran, T.; Srinivasan, D.; Vanessa, K.W.M. Demand Side Management of Smart Grid: Load Shifting and Incentives. J. Renew. Sustain. Energy 2014, 6, 033136. [Google Scholar] [CrossRef]

- Li, Y.; Wang, C.; Li, G.; Wang, J.; Zhao, D.; Chen, C. Improving Operational Flexibility of Integrated Energy System with Uncertain Renewable Generations Considering Thermal Inertia of Buildings. Energy Convers. Manag. 2020, 207, 112526. [Google Scholar] [CrossRef]

- Vandermeulen, A.; van der Heijde, B.; Helsen, L. Controlling District Heating and Cooling Networks to Unlock Flexibility: A Review. Energy 2018, 151, 103–115. [Google Scholar] [CrossRef]

- Bessa, R.; Moreira, C.; Silva, B.; Matos, M. Handling Renewable Energy Variability and Uncertainty in Power Systems Operation. WIREs Energy Environ. 2014, 3, 156–178. [Google Scholar] [CrossRef]

- Martinez, S.; Vellei, M.; Dréau, J.L. Demand-Side Flexibility in a Residential District: What Are the Main Sources of Uncertainty? Energy Build. 2021, 255, 111595. [Google Scholar] [CrossRef]

- Luo, M.; Zheng, Q.; Zhao, Y.; Zhao, F.; Zhou, X. Developing Occupant-Centric Smart Home Thermostats with Energy-Saving and Comfort-Improving Goals. Energy Build. 2023, 299, 113579. [Google Scholar] [CrossRef]

- Zouloumis, L.; Ploskas, N.; Panaras, G. Quantifying Flexibility Potential on District Heating Local Thermal Substations. Sustain. Energy Grids Netw. 2023, 35, 101135. [Google Scholar] [CrossRef]

- Magni, M.; Ochs, F.; de Vries, S.; Maccarini, A.; Sigg, F. Detailed Cross Comparison of Building Energy Simulation Tools Results Using a Reference Office Building as a Case Study. Energy Build. 2021, 250, 111260. [Google Scholar] [CrossRef]

- Guo, F.; Rasmussen, B. Predictive Maintenance for Residential Air Conditioning Systems with Smart Thermostat Data Using Modified Mann-Kendall Tests. Appl. Therm. Eng. 2023, 222, 119955. [Google Scholar] [CrossRef]

- Jiang, Y.; Andrew Ejenakevwe, K.; Wang, J.; Tang, C.Y.; Song, L. Development, Implementation, and Impact Analysis of Model Predictive Control-Based Optimal Precooling Using Smart Home Thermostats. Energy Build. 2024, 303, 113790. [Google Scholar] [CrossRef]

- Zouloumis, L.; Panaras, G. Development of a Smart Thermostat. In Proceedings of the IAQ 2020: Indoor Environmental Quality Performance Approaches, Athens, Greece, 4–6 May 2022. [Google Scholar]

- Arias, J.; Khan, A.A.; Rodriguez-Uría, J.; Sama, M. Analysis of Smart Thermostat Thermal Models for Residential Building. Appl. Math. Model. 2022, 110, 241–261. [Google Scholar] [CrossRef]

- Vallianos, C.; Abtahi, M.; Athienitis, A.; Delcroix, B.; Rueda, L. Online Model-Based Predictive Control with Smart Thermostats: Application to an Experimental House in Québec. J. Build. Perform. Simul. 2024, 17, 94–110. [Google Scholar] [CrossRef]

- De Coninck, R.; Baetens, R.; Saelens, D.; Woyle, A.; Helsen, L. Rule-Based Demand-Side Management of Domestic Hot Water Production with Heat Pumps in Zero Energy Neighbourhoods. J. Build. Perform. Simul. 2014, 7, 271–288. [Google Scholar] [CrossRef]

- Safdari, M.; Janaideh, M.A.; Siddiqui, K.; Aliabadi, A.A. Weather-Adaptive Fuzzy Control of Setpoints for Energy-Efficient HVAC in Urban Buildings. J. Build. Eng. 2025, 104, 112317. [Google Scholar] [CrossRef]

- Cho, S.; Park, C.S. Rule Reduction for Control of a Building Cooling System Using Explainable AI. J. Build. Perform. Simul. 2022, 15, 832–847. [Google Scholar] [CrossRef]

- Queipo, N.V.; Haftka, R.T.; Shyy, W.; Goel, T.; Vaidyanathan, R.; Tucker, K.P. Surrogate-Based Analysis and Optimization. Prog. Aerosp. Sci. 2005, 41, 1–28. [Google Scholar] [CrossRef]

- Lv, Z.; Niu, D.; Li, S.; Sun, H. Multi-Surrogate Assisted PSO with Adaptive Speciation for Expensive Multimodal Multi-Objective Optimization. Appl. Soft Comput. 2023, 147, 110724. [Google Scholar] [CrossRef]

- Zhu, J.; Tian, Z.; Niu, J.; Lu, Y.; Cheng, B.; Zhou, H. Machine Learning-Enhanced Lightweight Rule-Based Control Strategy for Building Energy Demand Response. Build. Simul. 2025. [Google Scholar] [CrossRef]

- Stopps, H.; Touchie, M.F. Residential Smart Thermostat Use: An Exploration of Thermostat Programming, Environmental Attitudes, and the Influence of Smart Controls on Energy Savings. Energy Build. 2021, 238, 110834. [Google Scholar] [CrossRef]

- Jung, W.; Wang, Z.; Hong, T.; Jazizadeh, F. Smart Thermostat Data-Driven U.S. Residential Occupancy Schedules and Development of a U.S. Residential Occupancy Schedule Simulator. Build. Environ. 2023, 243, 110628. [Google Scholar] [CrossRef]

- Vallianos, C.; Candanedo, J.; Athienitis, A. Thermal Modeling for Control Applications of 60,000 Homes in North America Using Smart Thermostat Data. Energy Build. 2024, 303, 113811. [Google Scholar] [CrossRef]

- Doma, A.; Prajapati, S.N.; Ouf, M.M. Developing a Residential Occupancy Schedule Generator Based on Smart Thermostat Data. Build. Environ. 2024, 261, 111713. [Google Scholar] [CrossRef]

- Hou, D.; Allan, L.; Awad, H.; Bahiraei, F.; Evins, R. Estimating the Time Constant Using Smart Thermostat Data Acquisition and Manipulation: A Whole Building Experimental Study. J. Build. Eng. 2025, 105, 112485. [Google Scholar] [CrossRef]

- Sun, S.; Xing, X.; Wang, J.; Sun, X.; Zhao, C. Preheating Time Estimation in Intermittent Heating with Hot-Water Radiators by Considering Model Uncertainties. Build. Environ. 2022, 226, 109734. [Google Scholar] [CrossRef]