Effects of Natural Fractures on Coal Drilling Response: Implications for CBM Fracturing Optimization

Abstract

1. Introduction

2. Experimental Materials and Procedures

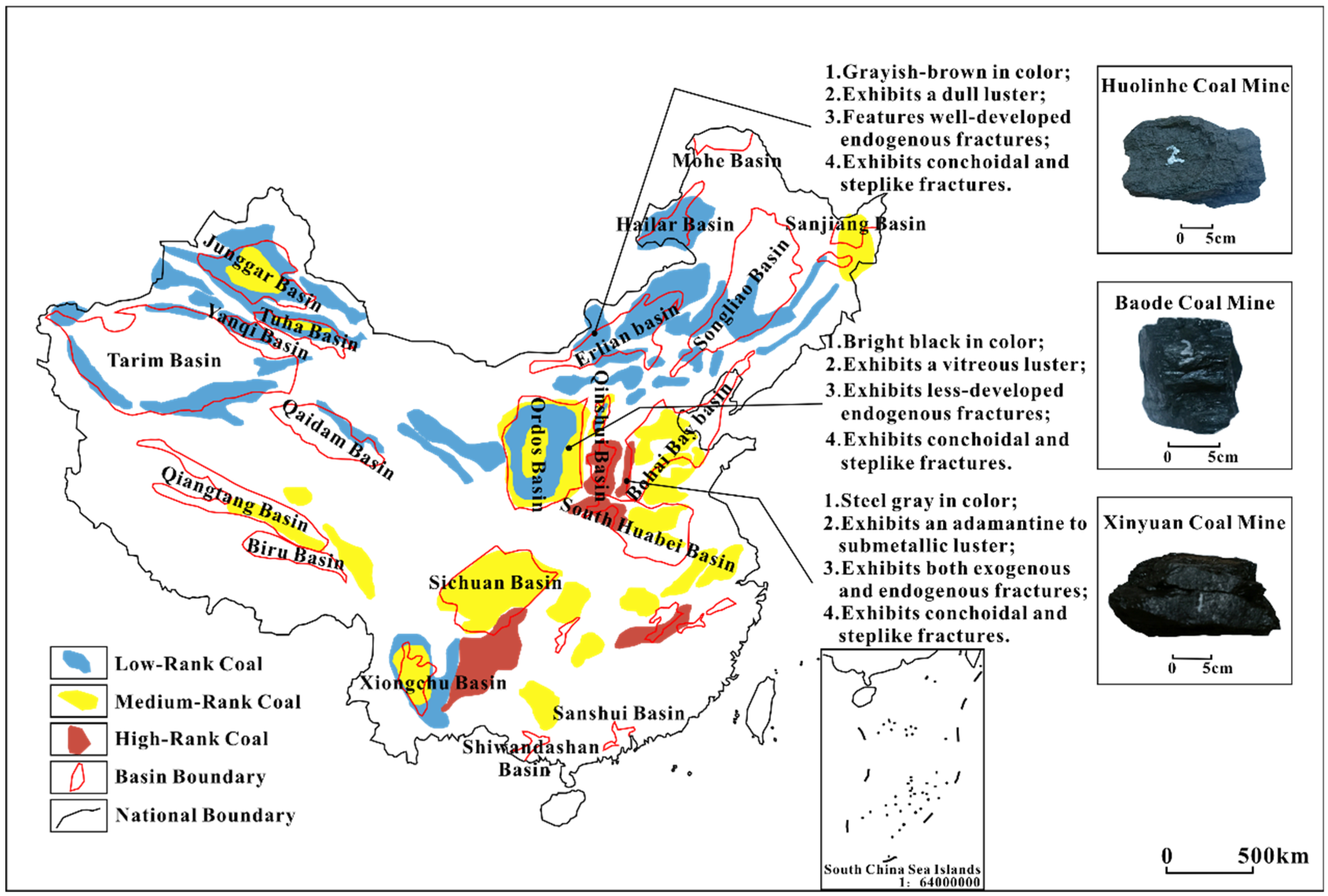

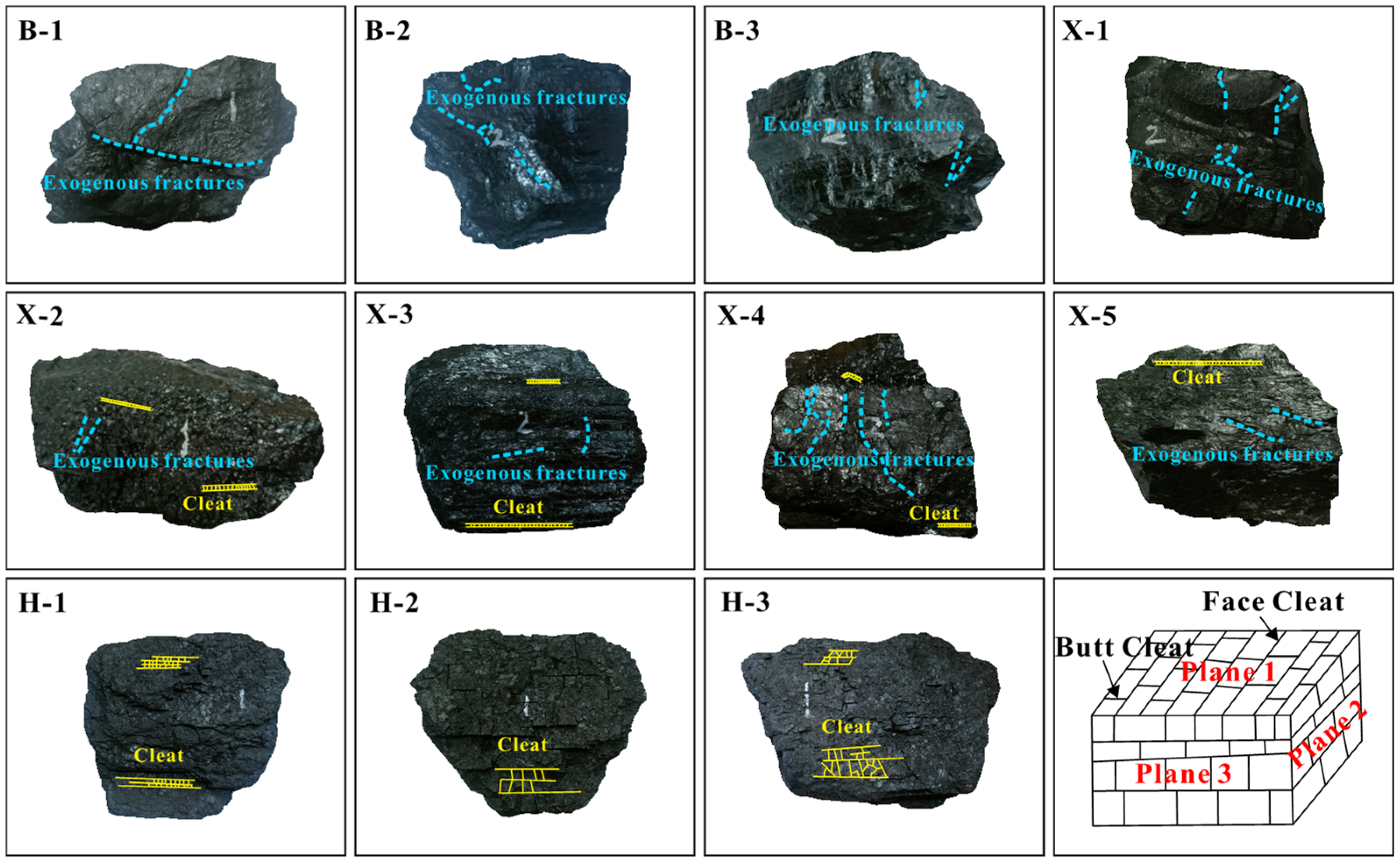

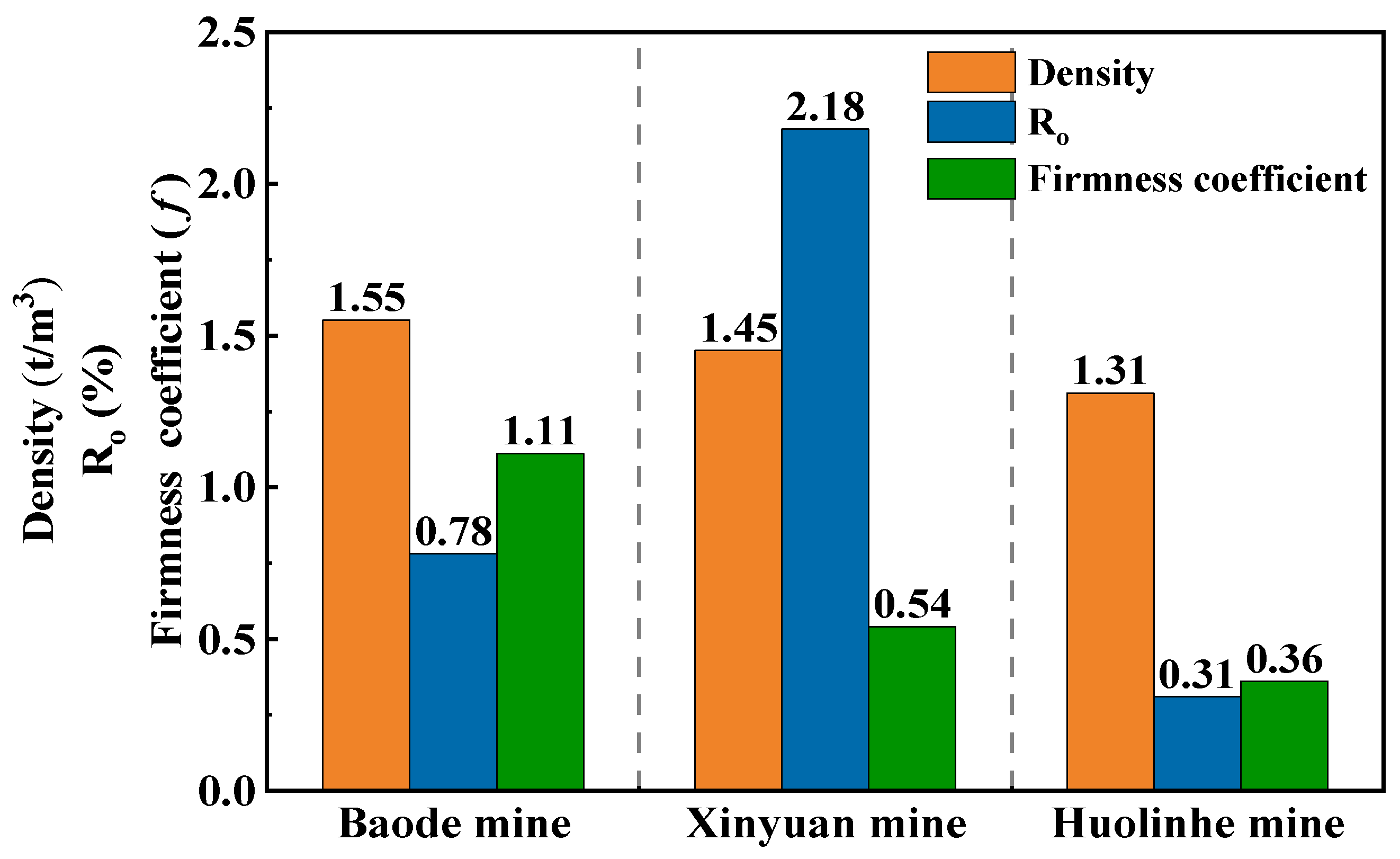

2.1. Experimental Samples

2.2. Experimental Procedures

- (1)

- Fracture characteristics description and analysis

- (2)

- Acoustic wave testing of fractured coal rocks

- (3)

- Drilling tests of fractured coal rocks

- (4)

- Drill cuttings data processing

3. Experimental Results

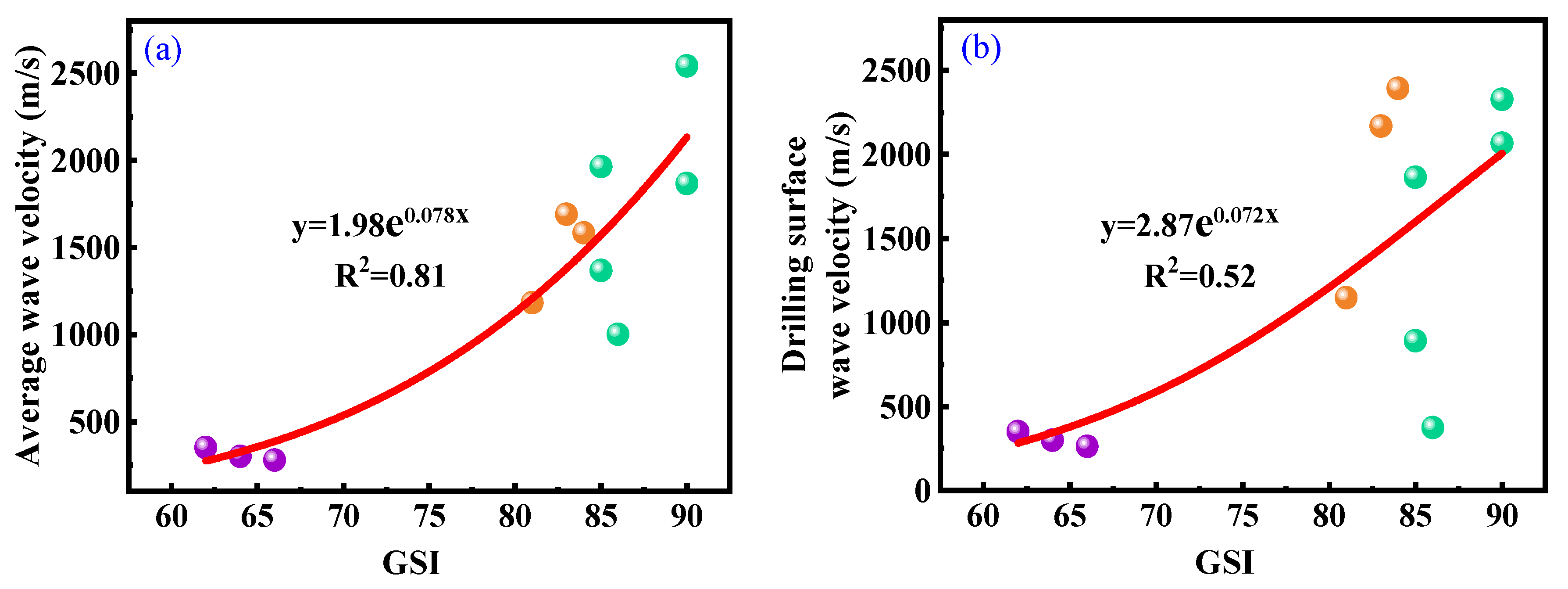

3.1. Quantitative Characterization of Fractures Based on Acoustic Parameters

3.2. Correlations Between Fractures and Drilling Parameters

3.2.1. Fracture Line Density and Drilling Parameters

3.2.2. Fracture Area Ratio and Drilling Parameters

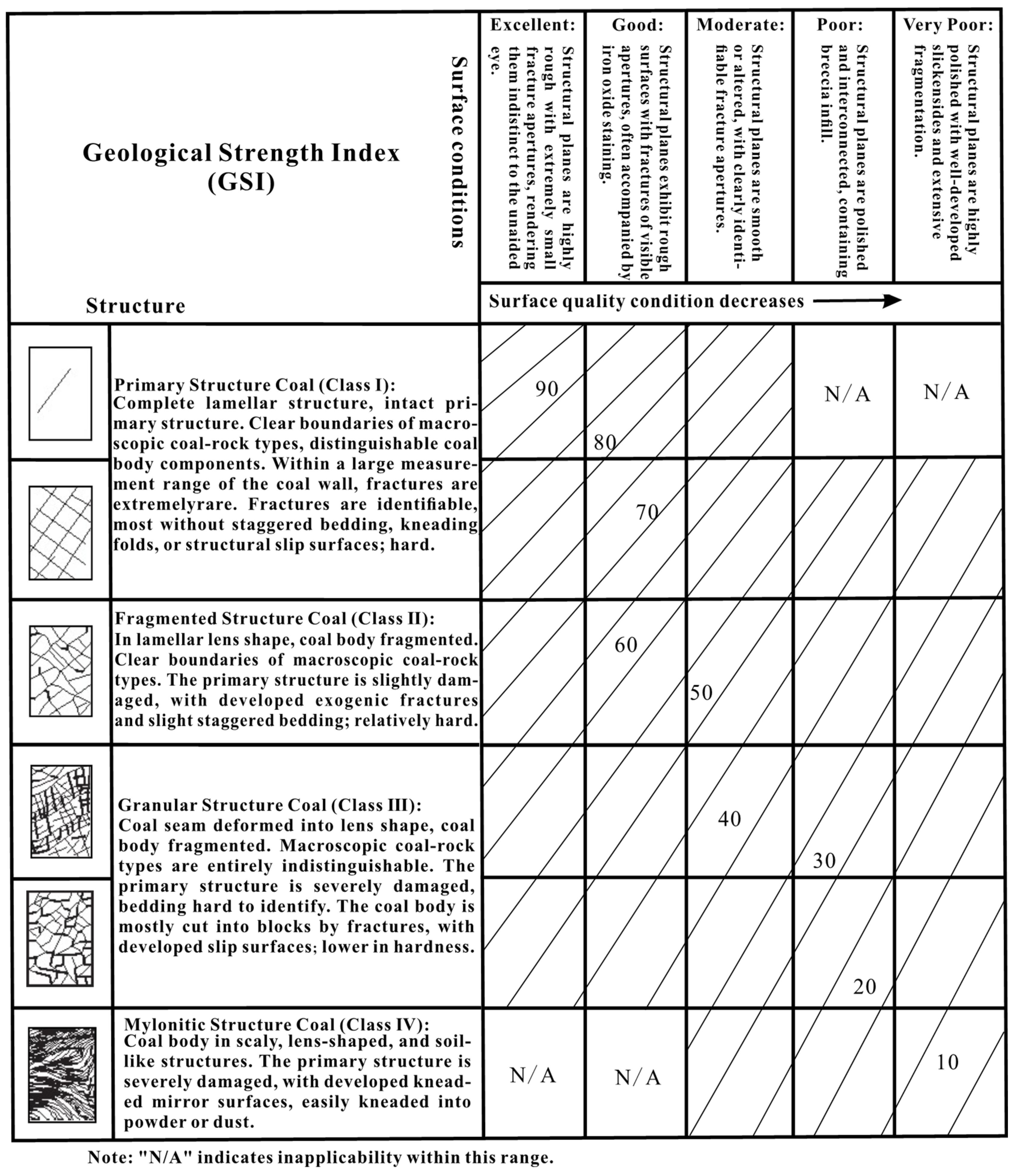

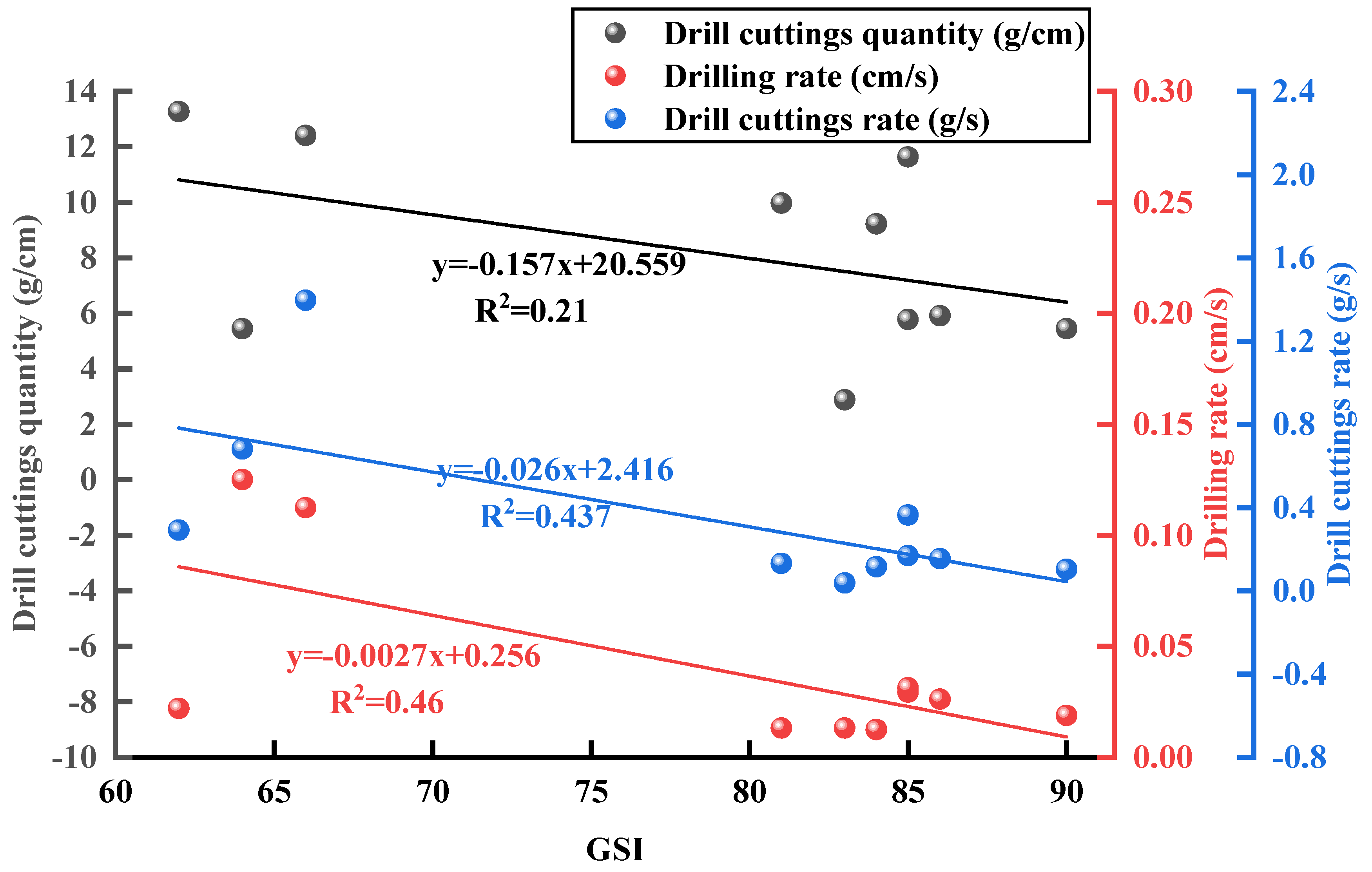

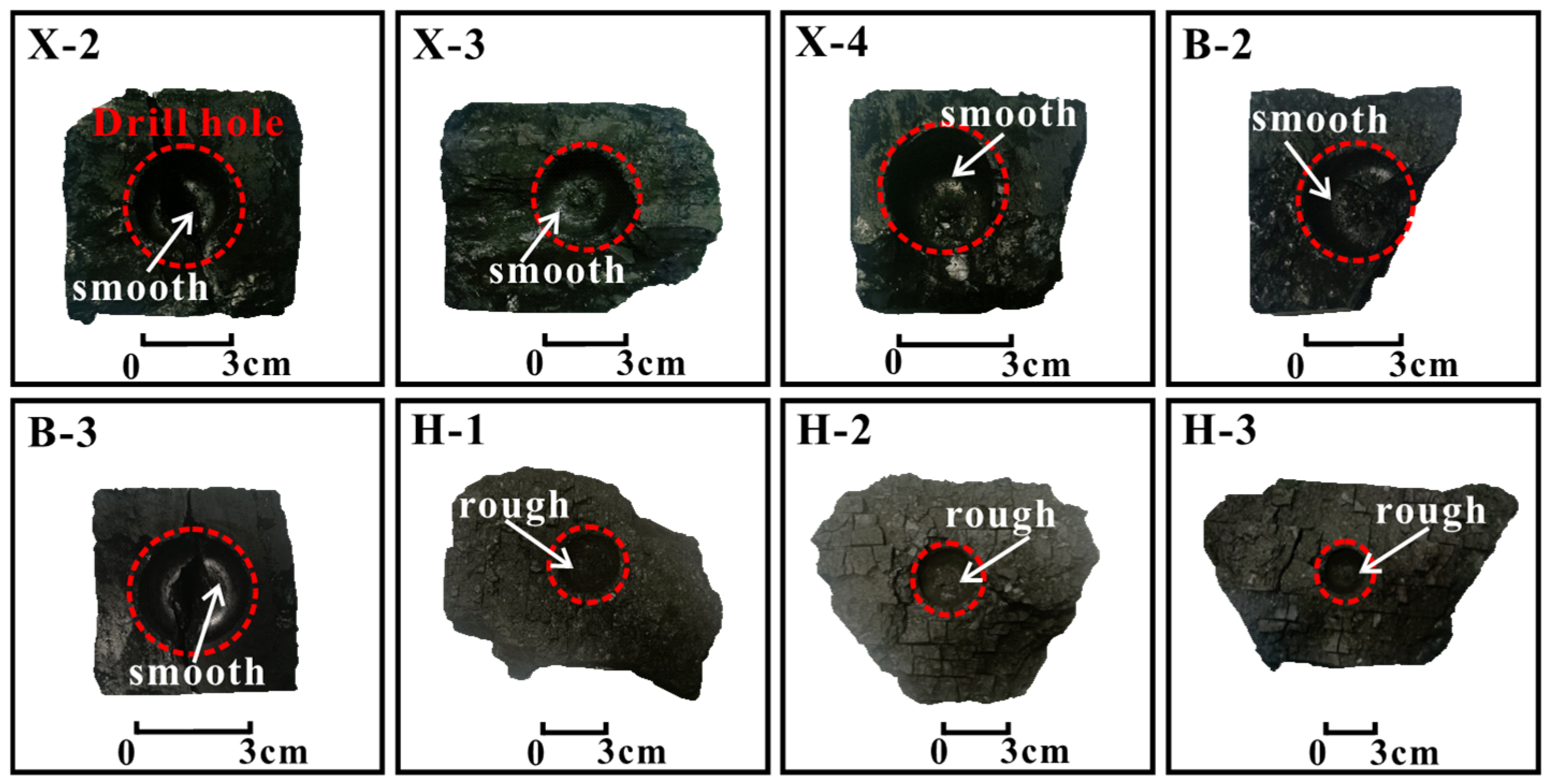

3.2.3. Geological Strength Index and Drilling Parameters

3.3. Correlations Between Fractures and Cuttings Parameters

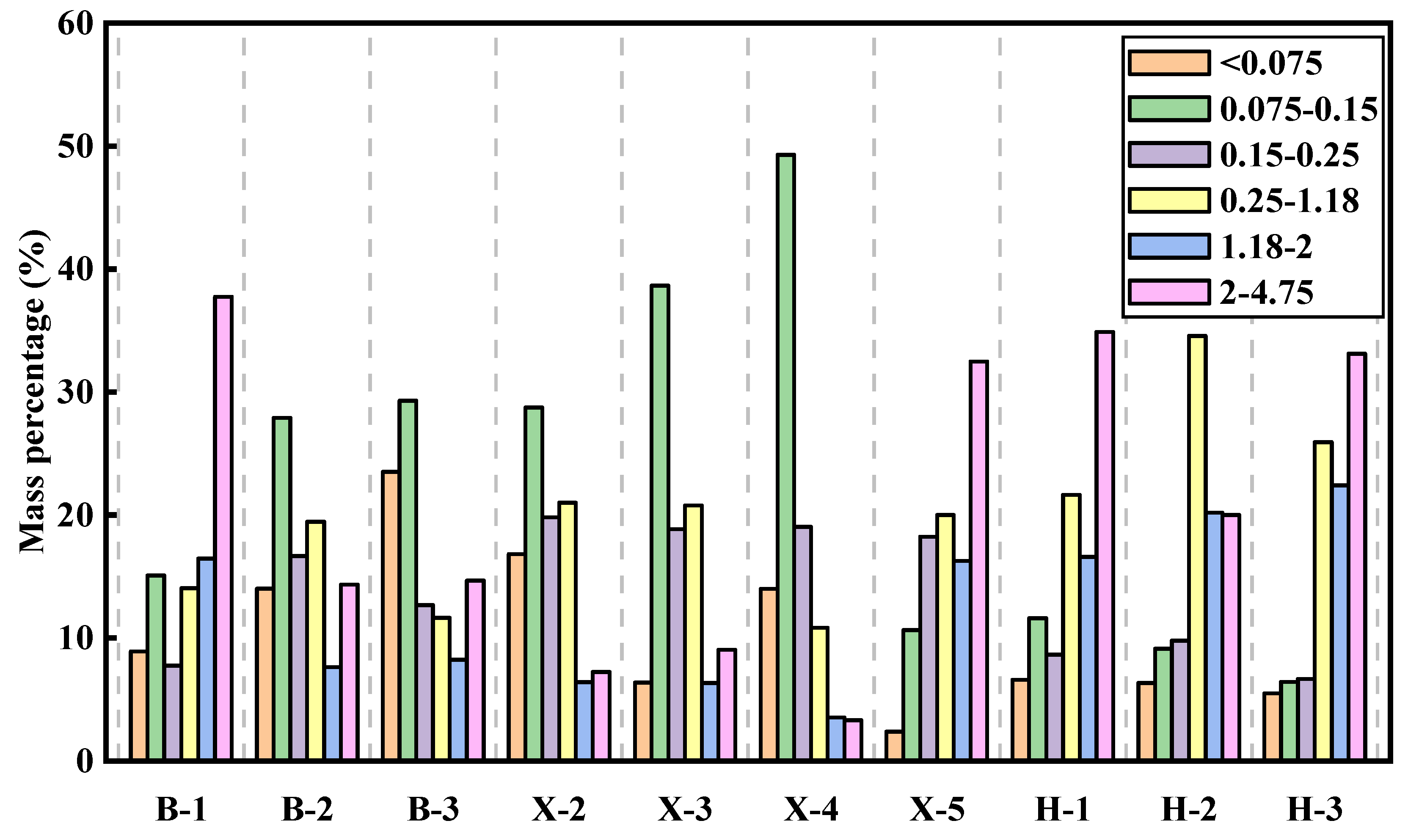

3.3.1. Characteristics of Cuttings Particle Size Distribution

3.3.2. Relationship Between Fractures and Cuttings Parameters

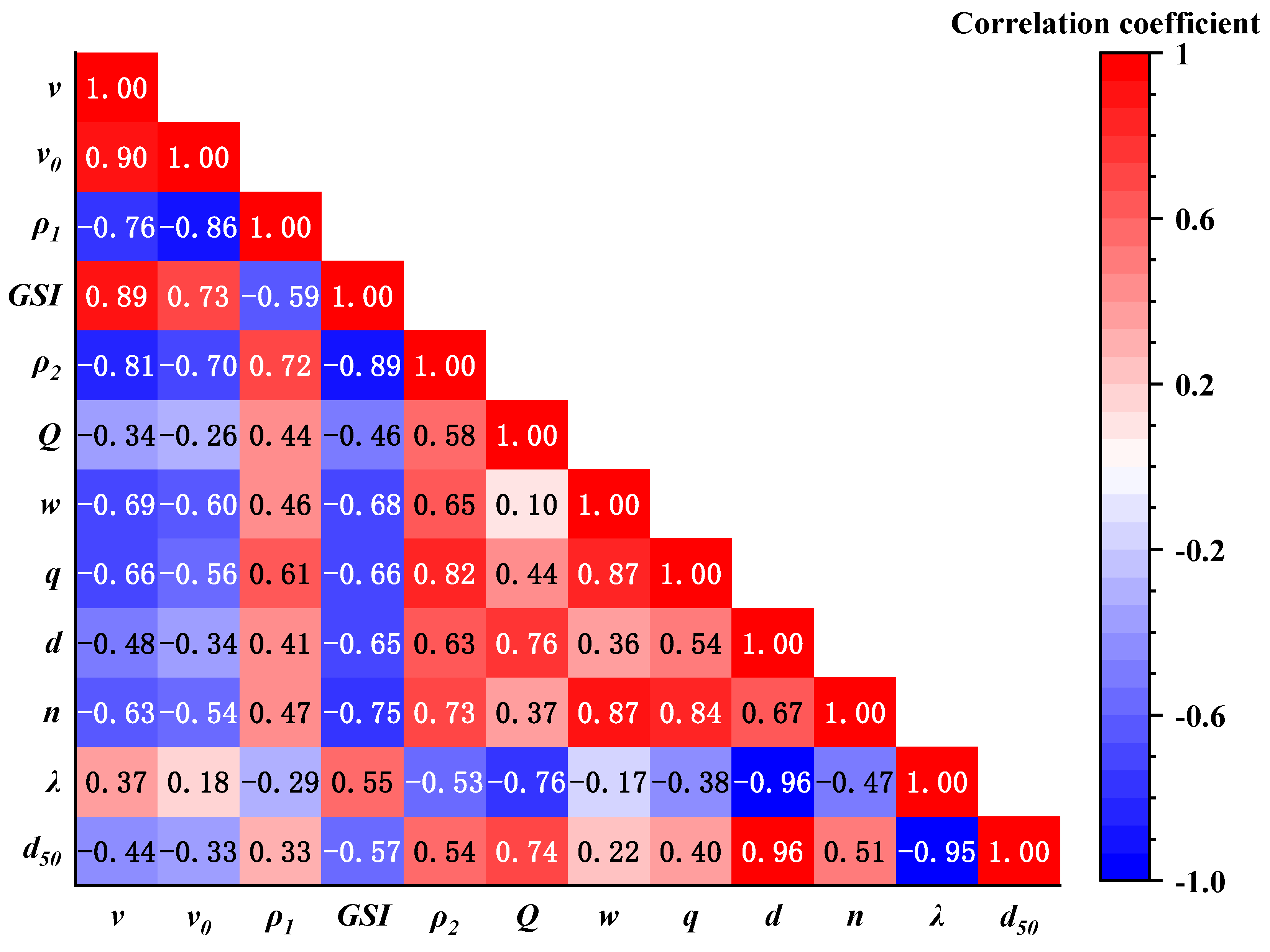

3.4. Correlation Analysis Among Fractures, Acoustic Parameters, Drilling Parameters, and Cuttings Parameters

4. Discussion

4.1. Response of Acoustic Parameters to Fracture Development

4.2. Mechanism Analysis of Cuttings Characteristics for Prediction of Fracture Development

4.3. Analysis of Causes of Variations in Coal Drilling Response

4.4. Implications for Fracturing Sweet Spot Optimization

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Su, X.; Zhang, L.; Zhang, R. The Abnormal Pressure Regime of the Pennsylvanian No. 8 Coalbed Methane Reservoir in Liulin–Wupu District, Eastern Ordos Basin, China. Int. J. Coal Geol. 2003, 53, 227–239. [Google Scholar] [CrossRef]

- Li, S.; Tang, D.; Pan, Z.; Xu, H.; Tao, S.; Liu, Y.; Ren, P. Geological Conditions of Deep Coalbed Methane in the Eastern Margin of the Ordos Basin, China: Implications for Coalbed Methane Development. J. Nat. Gas Sci. Eng. 2018, 53, 394–402. [Google Scholar] [CrossRef]

- Liang, S.; Liang, Y.; Elsworth, D.; Yao, Q.; Fu, X.; Kang, J.; Hao, Y.; Wang, M. Permeability Evolution and Production Characteristics of Inclined Coalbed Methane Reservoirs on the Southern Margin of the Junggar Basin, Xinjiang, China. Int. J. Rock Mech. Min. Sci. 2023, 171, 105581. [Google Scholar] [CrossRef]

- Yang, X.; Tang, S.; Xi, Z.; Zhang, S.; Zhang, Q.; Zhang, K.; Lin, D.; Wang, J. Dynamic Evolution and Differential Enrichment of Deep Coalbed Methane: A Case Study in Qinshui Basin. Int. J. Coal Geol. 2025, 299, 104696. [Google Scholar] [CrossRef]

- Meng, Q.; Li, L.; Li, J.; Tian, W.; Lin, H.; Li, H. Genetic type and gas-generating potential of coalbed methane in the Bayanhua Sag, Erlian Basin. Coal Geol. Explor. 2023, 51, 24–33. [Google Scholar]

- Yao, H.; Lv, W.; Wang, K.; Li, L.; Li, W.; Lin, H.; Li, F.; Li, Z. Key geological factors and evaluation methods for huge low-rank coalbed methane reservoirs:Taking Bayanhua depression in Erlian basin as an example. Coal Geol. Explor. 2020, 48, 85–95. [Google Scholar]

- Lyu, S.; Wang, S.; Zhang, X.; Li, R.; He, J.; Hu, Q. Pollution characteristics and evaluation of solid-phase materials in CBM drilling. Coal Geol. Explor. 2017, 45, 162–167. [Google Scholar]

- Lyu, S.; Wang, S.; Chen, X.; Shah, S.M.; Li, R.; Xiao, Y.; Dong, Q.; Gu, Y. Experimental Study of a Degradable Polymer Drilling Fluid System for Coalbed Methane Well. J. Pet. Sci. Eng. 2019, 178, 678–690. [Google Scholar] [CrossRef]

- Lyu, S.; Wang, S.; Li, J.; Chen, X.; Chen, L.; Dong, Q.; Zhang, X.; Huang, P. Massive Hydraulic Fracturing to Control Gas Outbursts in Soft Coal Seams. Rock Mech. Rock Eng. 2022, 55, 1759–1776. [Google Scholar] [CrossRef]

- Deisman, N.; Ivars, D.M.; Darcel, C.; Chalaturnyk, R.J. Empirical and Numerical Approaches for Geomechanical Characterization of Coal Seam Reservoirs. Int. J. Coal Geol. 2010, 82, 204–212. [Google Scholar] [CrossRef]

- Sui, L.; Yu, J.; Cang, D.; Miao, W.; Wang, H.; Zhang, J.; Yin, S.; Chang, K. The Fractal Description Model of Rock Fracture Networks Characterization. Chaos Solitons Fractals 2019, 129, 71–76. [Google Scholar] [CrossRef]

- Hu, Q.; Li, M.; Jia, H.; Liu, C.; Cui, X.; Li, L.; Peng, H.; Zhang, G.; Mao, C. Discussion of the geological adaptability of coal-bed methane horizontal wells of high-rank coal formation in southern Qinshui Basin. J. China Coal Soc. 2019, 44, 1178–1187. [Google Scholar]

- Liu, S.; Wang, D.; Yin, G.; Li, M.; Li, X. Experimental Study on the Microstructure Evolution Laws in Coal Seam Affected by Temperature Impact. Rock Mech. Rock Eng. 2020, 53, 1359–1374. [Google Scholar] [CrossRef]

- Lyu, S.; Chen, X.; Li, R.; Wang, S.; Liu, J.; Shen, P. Microstructure Analysis on the Fracture Network in High-Rank Coals. Earth Space Sci. 2021, 8, e2021EA001780. [Google Scholar] [CrossRef]

- Sun, X.; Zhao, K.; Wang, S.; Song, X.; Liu, L. Influence of Supercritical CO2 Fracturing Mode on the Fracture Morphology and Propagation Characteristics of Coal. Energy Fuels 2024, 38, 4325–4336. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, D.; Yu, C.; Zeng, F. Digital coal core construction process and crack characterization based on industrial CT scanning. J. Henan Polytech. Univ. 2019, 38, 10–16. [Google Scholar]

- Tian, F.; Li, X.; Zhu, W.; He, R.; Chen, G. Evaluation of 3D characteristics and optimization of fracturing sections for No. 8 coal seam crack in Daning-Ji County block. China Energy Environ. Prot. 2023, 45, 88–95. [Google Scholar]

- Wang, L.; Chen, Z.; Ji, Z.; Kong, H.; Shen, H. Experimental Study on Mechanical Properties and Drillability Classification for the X# Coal Seam. Saf. Coal Mines 2013, 44, 18–21. [Google Scholar]

- Karasawa, H.; Ohno, T.; Kosugi, M.; Rowley, J.C. Methods to Estimate the Rock Strength and Tooth Wear While Drilling with Roller-Bits—Part 1: Milled-Tooth Bits. J. Energy Resour. Technol.-Trans. Asme 2002, 124, 125–132. [Google Scholar] [CrossRef]

- Wang, Q.; Gao, H.; Jiang, B.; Yang, J.; Lv, Z. Relationship Model for the Drilling Parameters from a Digital Drilling Rig versus the Rock Mechanical Parameters and Its Application. Arab. J. Geosci. 2018, 11, 357. [Google Scholar] [CrossRef]

- Yue, Z.Q.; Lee, C.F.; Law, K.T.; Tham, L.G. Automatic Monitoring of Rotary-Percussive Drilling for Ground Characterization—Illustrated by a Case Example in Hong Kong. Int. J. Rock Mech. Min. Sci. 2004, 41, 573–612. [Google Scholar] [CrossRef]

- Xie, Z.; Chang, X.; Yang, L.; Pi, Y. Classification method of coal and rock drillability based on Mechanical Specific Energy theory. Coal Geol. Explor. 2021, 49, 236–243. [Google Scholar]

- Liu, C.; Zhan, Q.; Yang, L.; Zheng, X.; Li, P.; Shahani, N.M. Recognition of Interface and Category of Roadway Roof Strata Based on Drilling Parameters. J. Pet. Sci. Eng. 2021, 204, 108724. [Google Scholar] [CrossRef]

- Liu, C.; Song, J.-J.; Kim, J.; Zheng, X.; Shahani, N.M.; Xu, W. Fracture Identification under Unstable Drilling Conditions Based on Proposed Multi-Parameter Voting Method. Rock Mech. Rock Eng. 2023, 56, 3805–3823. [Google Scholar] [CrossRef]

- Zhu, J.; Chen, M.; Wang, L.; Sun, H.; Wang, C.; Azhar, N.; Oduro, N.B. Characterization of 10 Nm–10 Μm Coal Dust Particles Generated by Simulated Different Cutting and Drilling Parameters: Mass Concentration Distribution, Number Concentration Distribution, and Fractal Dimension. Int. J. Coal Sci. Technol. 2023, 10, 89. [Google Scholar] [CrossRef]

- Geng, J.; Cao, L.; Zhong, C.; Wang, H.; Chen, B. Investigation of Dynamic Response of Drilling Parameters and Deformation Characteristics of Coal around Borehole during Multi-Stage Reaming in Tectonic Coal. Int. J. Rock Mech. Min. Sci. 2023, 170, 105540. [Google Scholar] [CrossRef]

- Xiao, S.; Ge, Z.; Lu, Y.; Zhou, Z.; Li, Q.; Wang, L. Investigation on Coal Fragmentation by High-Velocity Water Jet in Drilling: Size Distributions and Fractal Characteristics. Appl. Sci. 2018, 8, 1988. [Google Scholar] [CrossRef]

- Zhang, Z.; Lan, X.; Wen, G.; Long, Q.; Yang, X. An Experimental Study on the Particle Size and Shape Distribution of Coal Drill Cuttings by Dynamic Image Analysis. Geofluids 2021, 2021, 5588248. [Google Scholar] [CrossRef]

- Wolf, K.-H.A.A.; van Bergen, F.; Ephraim, R.; Pagnier, H. Determination of the Cleat Angle Distribution of the RECOPOL Coal Seams, Using CT-Scans and Image Analysis on Drilling Cuttings and Coal Blocks. Int. J. Coal Geol. 2008, 73, 259–272. [Google Scholar] [CrossRef]

- Kumar, S.; Talreja, R.; Murthy, V.M.S.R. Development of a Drill Energy Utilization Index for Aiding Selection of Drill Machines in Surface Mines. Int. J. Min. Sci. Technol. 2017, 27, 393–399. [Google Scholar] [CrossRef]

- Mohammadi, M.; Khademi Hamidi, J.; Rostami, J.; Goshtasbi, K. A Closer Look into Chip Shape/Size and Efficiency of Rock Cutting with a Simple Chisel Pick: A Laboratory Scale Investigation. Rock Mech. Rock Eng. 2020, 53, 1375–1392. [Google Scholar] [CrossRef]

- Zhou, Y.; Liang, B.; Sun, W.; Liu, X. Distribution laws of particle size of drilling cuttings with drilling depth in deep coal seams. J. Saf. Sci. Technol. 2020, 16, 66–72. [Google Scholar]

- Wang, C.; Cheng, Y.; Yi, M.; Lei, Y.; He, X. Powder Mass of Coal after Impact Crushing: A New Fractal-Theory-Based Index to Evaluate Rock Firmness. Rock Mech. Rock Eng. 2020, 53, 4251–4270. [Google Scholar] [CrossRef]

- Zhao, L.; Cao, Y.; Lyu, S.; Li, J.; Tian, L. Coal Structure Characteristics in the Northern Qinshui Basin and Their Discrimination Method Based on the Particle Size of Drilling Cuttings. ACS Omega 2022, 7, 22956–22968. [Google Scholar] [CrossRef]

- Lv, S.; Wang, S.; Li, R.; Li, G.; Yuan, M.; Wang, J. Prediction of Coal Structure Using Particle Size Characteristics of Coalbed Methane Well Cuttings. Int. J. Min. Sci. Technol. 2019, 29, 209–216. [Google Scholar] [CrossRef]

- Haghshenas, B.; Clarkson, C.R.; Aquino, S.D.; Chen, S. Characterization of Multi-Fractured Horizontal Shale Wells Using Drill Cuttings: 2. Permeability/Diffusivity Estimation. J. Nat. Gas Sci. Eng. 2016, 32, 586–596. [Google Scholar] [CrossRef]

- Hoek, E.; Brown, E.T. Practical Estimates of Rock Mass Strength. Int. J. Rock Mech. Min. Sci. 1997, 34, 1165–1186. [Google Scholar] [CrossRef]

- Guo, H.; Su, X.; Xia, D.; Ni, X.; Li, G. Relationship of the permeability and geological strength index( GSI) of coal reservoir and its significance. J. China Coal Soc. 2010, 35, 1319–1322. [Google Scholar]

- Gao, X.; Wang, Y.; Zhang, C. Study and analysis on coal structure features during drilling operation and well wall stability. Coal Sci. Technol. 2016, 44, 95–99. [Google Scholar]

- Gonzalez-Tello, P.; Camacho, F.; Vicaria, J.M.; Gonzalez, P.A. A Modified Nukiyama-Tanasawa Distribution Function and a Rosin-Rammler Model for the Particle-Size-Distribution Analysis. Powder Technol. 2008, 186, 278–281. [Google Scholar] [CrossRef]

- Alderliesten, M. Mean Particle Diameters. Part VII. The Rosin-Rammler Size Distribution: Physical and Mathematical Properties and Relationships to Moment-Ratio Defined Mean Particle Diameters. Part. Part. Syst. Char. 2013, 30, 244–257. [Google Scholar] [CrossRef]

- Jin, J.; Zhao, K.; Huang, F.; Wang, Y.; Fang, L. Experimental study on acoustic time domain propagation characteristics of rock under high water pressure and ground stress. J. China Coal Soc. 2024, 49, 3074–3089. [Google Scholar]

- Zhang, M.; Liu, P.; Fan, H.; Li, Z.; Zhao, H.; Jiang, J.; Feng, Z.; Wang, K.; Li, Y.; Wu, H. Response Characteristics of Acoustic Reflection Imaging Logging of Fractures and Formation Interfaces Outside Horizontal Wells in Tight Reservoirs. Chin. J. Geophys.-Chin. Ed. 2024, 67, 2439–2454. [Google Scholar]

- Chen, Q.; Liu, X.; Liang, L.; Wang, S.; Yang, C. Numerical simulation of the fractured model acoustic attenuation coefficient. Chin. J. Geophys. 2012, 55, 2044–2052. [Google Scholar]

- Li, H.; Wang, W.; Liu, Y.; Ma, J.; Gao, H. An Integrated Drilling, Protection and Sealing Technology for Improving the Gas Drainage Effect in Soft Coal Seams. Energy Rep. 2020, 6, 2030–2043. [Google Scholar] [CrossRef]

- Lai, X.; Ren, J.; Cui, F.; Shan, P.; Dai, J.; Xu, H.; Wang, Z. Study on Vertical Cross Loading Fracture of Coal Mass through Hole Based on AE-TF Characteristics. Appl. Acoust. 2020, 166, 107353. [Google Scholar] [CrossRef]

- Zhu, L.; Xie, Z.; Li, X.; Zhao, Y.; Wang, T.; Yang, X. Study on the Law of Rock Drillability under High-Temperature and High-Pressure Conditions in the Western Margin of the Ordos Basin. Processes 2024, 12, 1261. [Google Scholar] [CrossRef]

- Zhu, G.; Xu, Z.; Liu, H. Experimental study on mechanical behavior and response mechanism of triaxial loading-unloading drilling in impact coal under the effect of water content. Coal Sci. Technol. 2024. [Google Scholar] [CrossRef]

- Wang, D.; Pang, X.; Wei, J.; Zhang, H.; Yao, B.; Wei, L.; Guo, Y.; Yuan, M.; Tang, J. Effect of gas properties and pore pressure on the microcrack propagation in coal. Coal Sci. Technol. 2023, 51, 183–192. [Google Scholar]

- Zhou, W.; Gao, K.; Xue, S.; Han, Y.; Shu, C.-M.; Huang, P. Experimental Study of the Effects of Gas Adsorption on the Mechanical Properties of Coal. Fuel 2020, 281, 118745. [Google Scholar] [CrossRef]

- Lyu, S.; Wang, S.; Chen, X.; Wang, S.; Wang, T.; Shi, X.; Dong, Q.; Li, J. Natural Fractures in Soft Coal Seams and Their Effect on Hydraulic Fracture Propagation: A Field Study. J. Pet. Sci. Eng. 2020, 192, 107255. [Google Scholar] [CrossRef]

- Zhao, Z.; Ni, X.; Liu, Z.; Wu, X. Attenuation characteristics of coal fissure induced by gas-water two-phase drive. J. China Coal Soc. 2020, 45, 3853–3863. [Google Scholar]

| Mining Area | Inorganic Minerals | Organic Macerals | ||

|---|---|---|---|---|

| Aad (%) | Vitrinite (%) | Inertinite (%) | Liptinite (%) | |

| Xinyuan Mine | 17.82 | 74.32 | 25.68 | 0 |

| Baode Mine | 10.95 | 79.36 | 20.14 | 0.50 |

| Huolinhe Mine | 6.28 | 92.10 | 7.64 | 0.26 |

| Sample Number | Wave Velocity of Plane 1 (m/s) | Wave Velocity of Plane 2 (m/s) | Wave Velocity of Plane 3 (m/s) |

|---|---|---|---|

| B-2 | 919 | 2168 | 1984 |

| B-3 | 777 | 2392 | 1581 |

| X-1 | 2586 | 2326 | 2718 |

| X-2 | 1900 | 2066 | 1635 |

| X-4 | 1808 | 1403 | 891 |

| X-5 | 1864 | 2463 | 1563 |

| H-1 | 286 | 350 | 414 |

| H-2 | 268 | 300 | 332 |

| Serial Number | B-1 | B-2 | B-3 | X-2 | X-3 | X-4 | X-5 | H-1 | H-2 | H-3 |

|---|---|---|---|---|---|---|---|---|---|---|

| Q/(g/cm) | 9.97 | 2.88 | 9.23 | 5.45 | 5.91 | 5.78 | 11.64 | 13.27 | 5.44 | 12.41 |

| w/(cm/s) | 0.013 | 0.013 | 0.0125 | 0.019 | 0.026 | 0.029 | 0.0313 | 0.022 | 0.125 | 0.113 |

| q/(g/s) | 0.13 | 0.04 | 0.12 | 0.1 | 0.15 | 0.17 | 0.36 | 0.29 | 0.68 | 1.4 |

| Mining Area | Macrofracture Area Ratio (%) | Number of Microfractures (Counts/9 cm2) | Porosity (%) | Average Wave Velocity (m/s) |

|---|---|---|---|---|

| Xinyuan | 0.31 | 451 | 2.1 | 1748 |

| Baode | 0.54 | 219 | 4.87 | 1485 |

| Huolinhe | 4.6 | 636 | 14.21 | 283 |

| Fracture Development Degree | Fracture Area Ratio (%) | GSI | Wave Velocity (m/s) | n |

|---|---|---|---|---|

| Low | <0.36 | >84 | >1583 | 0.43–0.76 |

| Medium | 0.36–1.8 | 73–86 | 675–1690 | 0.46–0.57 |

| High | >1.8 | <73 | <675 | 0.72–0.98 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, Z.; Lyu, S.; Xiao, Y.; Zhang, H.; Chen, Q.; Lu, A. Effects of Natural Fractures on Coal Drilling Response: Implications for CBM Fracturing Optimization. Energies 2025, 18, 3404. https://doi.org/10.3390/en18133404

Han Z, Lyu S, Xiao Y, Zhang H, Chen Q, Lu A. Effects of Natural Fractures on Coal Drilling Response: Implications for CBM Fracturing Optimization. Energies. 2025; 18(13):3404. https://doi.org/10.3390/en18133404

Chicago/Turabian StyleHan, Zixiang, Shuaifeng Lyu, Yuhang Xiao, Haijun Zhang, Quanming Chen, and Ao Lu. 2025. "Effects of Natural Fractures on Coal Drilling Response: Implications for CBM Fracturing Optimization" Energies 18, no. 13: 3404. https://doi.org/10.3390/en18133404

APA StyleHan, Z., Lyu, S., Xiao, Y., Zhang, H., Chen, Q., & Lu, A. (2025). Effects of Natural Fractures on Coal Drilling Response: Implications for CBM Fracturing Optimization. Energies, 18(13), 3404. https://doi.org/10.3390/en18133404