Pulsed Power Plasma Stimulation: A Comprehensive Review and Field Insights

Abstract

1. Introduction

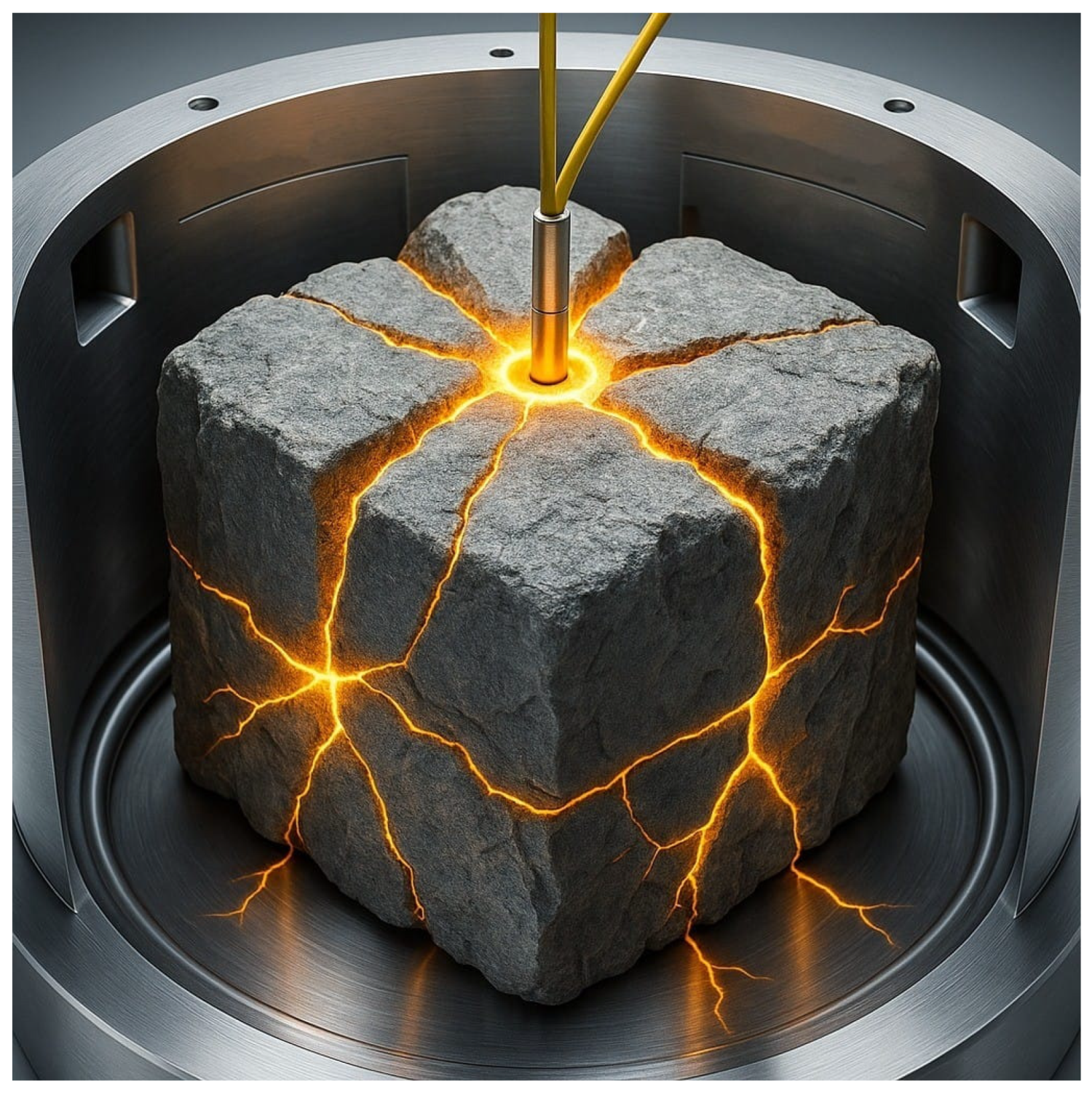

2. Principles of Pulsed Power Plasma Stimulation

2.1. Basic Principles

2.2. Mechanisms of Rock Fracturing

2.3. Key Parameters Influencing Performance

3. Comprehensive Review

3.1. Introduction and Historical Development

3.1.1. Early Developments (1960s–1970s)

3.1.2. Technological Advancement (1980s–1990s)

3.2. Fundamental Mechanisms and Physics (2000s–Early 2010s)

3.2.1. Plasma Generation and Characterization

3.2.2. Application to Permeability Enhancement

3.3. Technical Optimization and Parameter Studies (Mid-2010s)

3.3.1. Discharge Optimization Studies

3.3.2. Material Selection and Configuration

3.4. Application Development and Practical Implementation (2017–2020)

3.4.1. Fracturing Applications

3.4.2. Technical Reviews and Comparative Studies

3.5. Recent Advances and Specialized Applications (2019–2024)

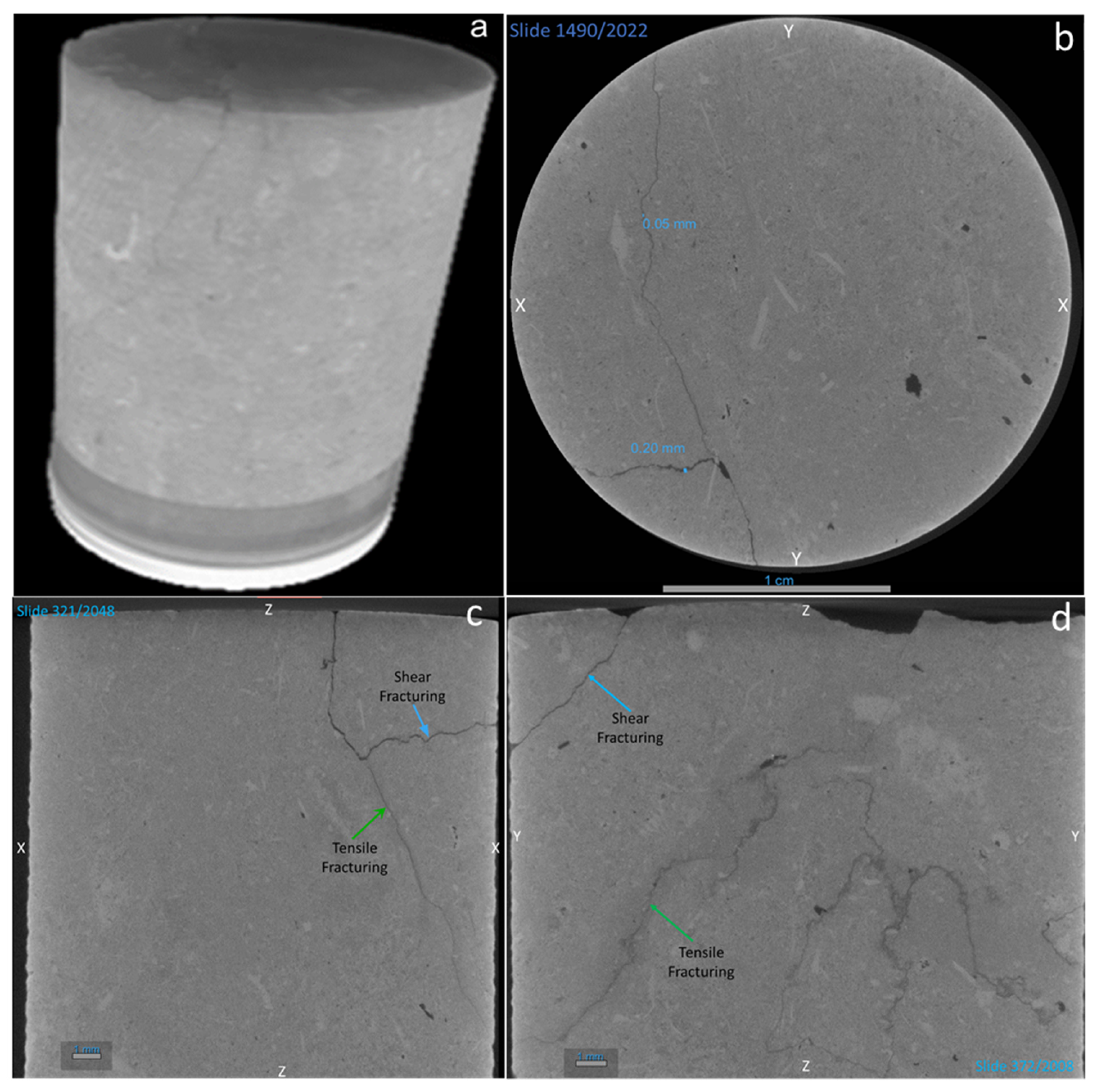

3.5.1. Laboratory-Scale Testing and Characterization

3.5.2. Comparative Studies on Discharge Methods

3.5.3. Recent Advanced Applications (2020–2024)

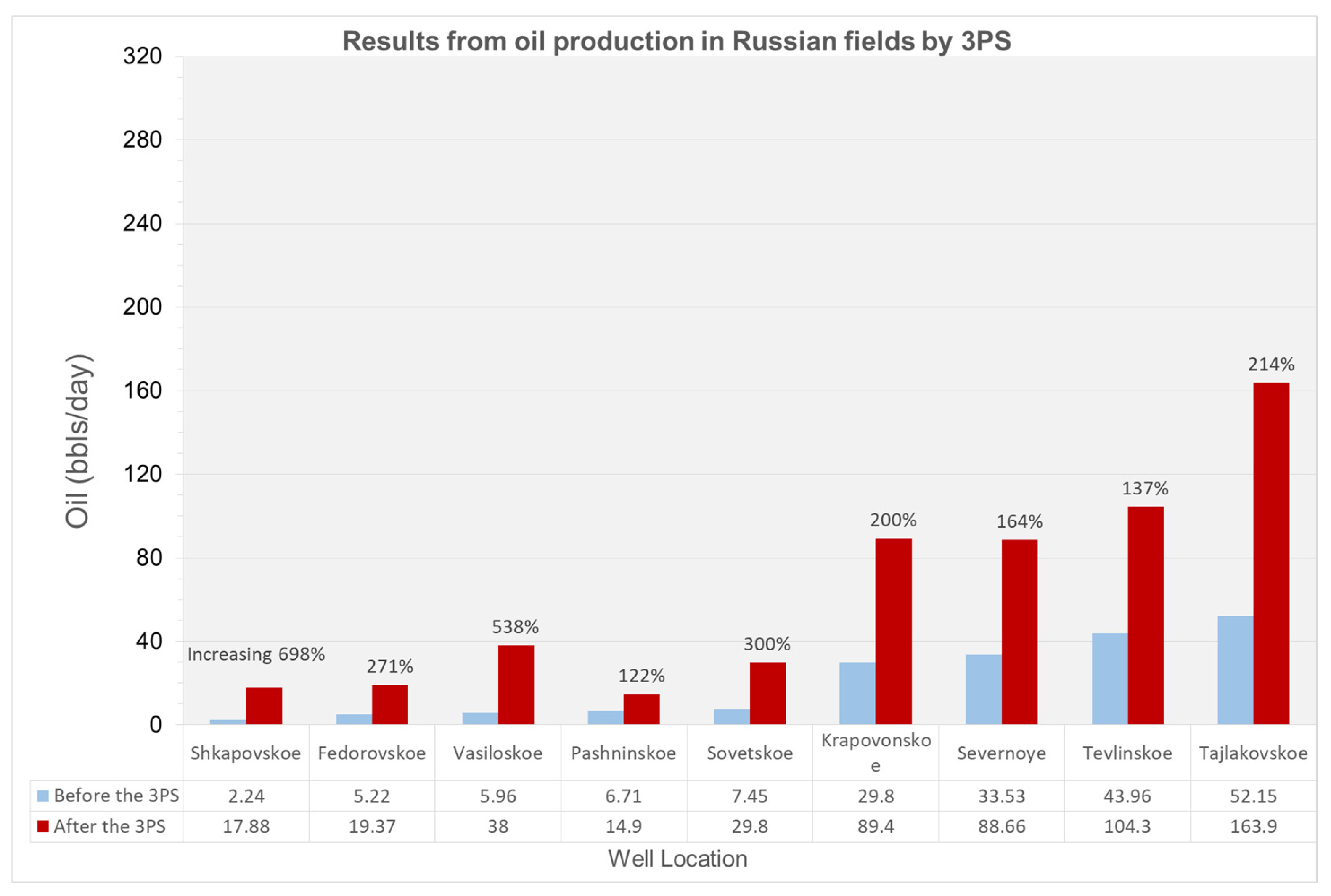

3.6. Field-Scale Applications and Case Studies

3.6.1. Early Field Applications

3.6.2. Recent Field Tests and Case Studies

3.7. Comparative Analysis of Fracturing Technologies

Plasma Fracturing vs. Conventional Hydraulic Fracturing

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| 3PS | Pulsed Power Plasma Stimulation |

| EGS | Enhanced Geothermal System |

| EHF | Electrohydraulic Fracturing |

| EHSG | Electrohydraulic Shockwave Generation |

| EOR | Enhanced Oil Recovery |

| HF | Hydraulic Fracture |

| HVEI | High-Voltage Electric Impulse |

| HVEP | High-Voltage Electric pulse |

| HVPD | High-Voltage Pulse Discharge |

| PAED | Pulsed Arc Electrohydraulic Discharge |

| PCED | Pulsed Corona Electrohydraulic Discharge |

| PDC | Polycrystalline Diamond Compact |

| PP | Pulsed Power |

| PPBS | Pulse Plasma-Based Shockwave |

| PPS | Pulsed Plasma Stimulation |

| RPM | Revolutions Per Minute |

| SCU | Surface Ground Control Unit |

| SPF | Shots Per Foot |

| SPM | Strokes Per minute |

| UEWE | Underwater Electrical Wire Explosions |

Appendix A

| Authors | Fracturing Technique | Tested Sample | Test Conditions | Studied Parameters | Main Findings |

|---|---|---|---|---|---|

| Melton & Cross, 1968 [14] | High-Voltage Electrical Pulse | Oil shales | Input voltage: (1.2–20) KV Borehole: horizontal and cased hole with 1.5” dia. | Breakdown voltage, electrode spacings, and overburden stress | Electrical discharge induced horizontal fractures and increased permeability near wellbore |

| Shugar & Odell, 1976 [32] | Pulsed Arc Electrohydraulic Discharge | Hydrostone (Gypsum cement) | Input energy: 10.7 KJ Borehole: open hole with 2” dia. | Energy delivery, pulse duration, hole depth, and fracture pattern | Creation of radial fractures Optimizing the pulse settings would improve the potential of electrohydraulic pulses for rock excavation |

| Touryan et al., 1989 [33] | Pulsed Arc Electrohydraulic Discharge | Brea sandstone and Leuders limestone | Input energy: (8–10) KJ Borehole: open hole with 2” dia. | Energy delivery, pulse duration, hole depth, and fracture patterns | Measured pressure was ~1 GPa Focused electrohydraulic shocks produced measurable rock erosion rates, leading to potential scalability for drilling and fracturing |

| Grinenko et al., 2005 [34] | Underwater Electrical Wire Explosion | N/A | Input energy: (2.4) KJ Copper wires with 85 mm in length and 0.5 mm in diameter | Plasma channel parameters, including temperature, density, and pressure distributions | Nonuniform spatial distribution of plasma parameters |

| Veksler et al., 2009 [35] | Underwater Electrical Wire Explosion | N/A | Input energy: (2.4) KJ Copper wires with 0.4 mm in dia. | Wire configurations (straight and zigzag); the impact of shockwave confinement | Characterized influence of wire configurations on underwater explosion dynamics |

| Maurel et al., 2010 [36] | Pulsed Arc Electrohydraulic Discharge | Mortar samples (100 mm dia. × 125 mm height) | Input voltage: 40 KV (maximum) | The impact of applying single and repeated shocks with pressures of up to 250 MPa on the intrinsic permeability of tested samples | Permeability increased linearly after threshold pressure; repeated shocks improved permeability by up to two orders of magnitude |

| Chen et al., 2013 [37] | Pulsed Arc Electrohydraulic Discharge | Mortar samples (100 mm dia. × 125 mm height) | Input voltage: 40 KV (maximum) | Simulating the distributed networks of microcracks created by the PAED using the measured pressure profiles and shockwave dynamics | PAED-generated shockwaves significantly increased rock permeability through dynamic microcracking, with linear permeability growth observed beyond a certain energy threshold |

| Carden, 2012 [38] | Pulsed Arc Electrohydraulic Discharge | N/A | Input energy: (9) KJ | The impact of electrode gap distance and charge voltage on shockwave characteristics | Linear relationship between charge voltage and peak pressure, with optimized electrode gaps to produce maximum pressures of up to 900 psi |

| Zhu et al., 2014 [39] | Pulsed Arc Electrohydraulic Discharge | N/A | Discharge voltage: (3–5) KV | The influence of water conductivity on PAED and energy transfer | Increasing water conductivity will reduce breakdown voltage, discharge current, and pressure wave intensity. However, excessive conductivity could shift the discharge mode from PAED to PCED limiting its efficiency |

| Zhou et al., 2015 [40] | Pulsed Arc Electrohydraulic Discharge | N/A | Testing copper and molybdenum wires of varying diameters under different discharge voltages (14–25) KV | The impact of wire configuration, material type, and charging voltage on ignition of energetic materials and shockwave performance | Higher charging voltages significantly improve ignition efficiency and shockwave strength |

| Cho et al., 2015 [41] | High-Voltage Electrical Pulse and Pulsed Arc Electrohydraulic Discharge | Different granites, limestone, and sandstone | Input energy: (20–80) KJ Borehole: open hole with 0.5” dia. | Understanding the relationship between rocks’ dielectric breakdown properties and fracture patterns | Denser rocks with higher mechanical strength exhibited greater dielectric breakdown resistance, and fractures often followed mineral boundaries |

| Han et al., 2017 [42] | Underwater Electrical Wire Explosion | N/A | Input energy: (13) KV (500 J stored) The wire was 4cm long and had a diameter of (50–300) microns | Investigation of underwater wire explosions under three different discharge types (Type-A, Type-B, and Type-C) to better understand energy deposition and shockwave generation | Type-C leads to optimal energy deposition and peak pressures exceeding 7.5 MPa |

| Liu et al., 2017 [43] | Plasma-Ignited Energetic Materials | Shale samples from Sichuan, China | Discharge voltage: 25 KV (2 KJ) Borehole: open hole with 3” dia. | Testing the fracturing effects of electrohydraulic shockwaves generated by plasma-ignited energetic materials | Creation of networks of cell-shaped and penetration cracks, significantly reducing fracture pressure by approximately 54.5% compared to traditional methods |

| Han et al., 2018 [44] | Underwater Electrical Wire Explosion | N/A | Wires of 15 different metals/alloys (4 cm long, 100–300 µm diameter) Input energy: 500 J Discharge voltage: 12.9 KV | Studying the correlation between material properties and resulting shockwave strengths, optical emissions, and energy deposition | The non-refractory metals (e.g., Al and Cu) absorbed more energy than needed for atomization and generated stronger shockwaves but weaker light emissions, while refractory metals (e.g., W and Ta) produced weaker shockwaves but intense optical radiation |

| Liu et al., 2018 [45] | Pulsed Arc Electrohydraulic Discharge | Cement blocks | Discharge voltage: (25–30) KV, repetitive pulses | Optimizing electrohydraulic shockwaves for rock fracturing and validation through simulation and field tests | The repeated pulses created microcracks that enhanced rock permeability Numerical simulations confirmed that the permeability improved exponentially with stress variations induced by shockwaves Field trials in China showed oil production doubled in treated wells |

| Xiao et al., 2018 [18] | Pulsed Power Plasma Stimulation | Cylindrical cement blocks with different casings and perforations | Input energy: 2 KJ (20 V capacitor) | Assessing mechanical and electromagnetic effects of shockwave-induced fractures Investigating the role of thermite reactions in enhancing mechanical energy output | The exothermic thermite reaction enhanced mechanical energy output by up to two orders of magnitude Generated transient electromagnetic fields were measured and simulated, showing potential for reservoir monitoring applications |

| Riu et al., 2019 [48] | Cement mortar cubes (20 cm), sandstone blocks (18 cm + mortar frame) | Input energy: 2.5–17 KJ Vertical borehole (3.2 cm dia.) at the center of sample | Fracture energy thresholds, stress dependence, bedding plane effects, and fracture orientation | Higher energy leads to more fractures; higher applied stresses result in fewer but longer fractures; plasma blasting enhances permeability by 4 orders | |

| Liu et al., 2020 [50] | Underwater Electrical Wire Explosion | Water-filled test tank with copper wires and tungsten–copper electrodes with gap of 15 mm | Discharge voltage: 20 KV With a capacity for capacitor energy up to 600 KJ | Shockwave peak pressure, rise time, plasma channel radius and velocity, energy deposition rates, and efficiency | Metal wire explosions convert 17.5% of deposited energy into shockwave energy vs. 9.4% for Subsonic Streamer Breakdown Discharge Shockwaves generated by metal wire explosion are faster, stronger, more focused |

| Li et al., 2020 [51] | Underwater Electrical Wire Explosion | 50 mm long copper wires (0.12–0.5 mm) diameter | Input energy: 115 J, 360 J, 1400 J Discharge voltages: 1.1–53 KV, depending on capacitor size | Rise rate of current, deposition energy, deposition power, discharge mode, vaporization threshold, and circuit resistance impact | Faster rise rate improves deposition energy and thereby strength of shockwaves; thinner wires overheat more easily; circuit resistance greatly limits energy deposition in thick wires |

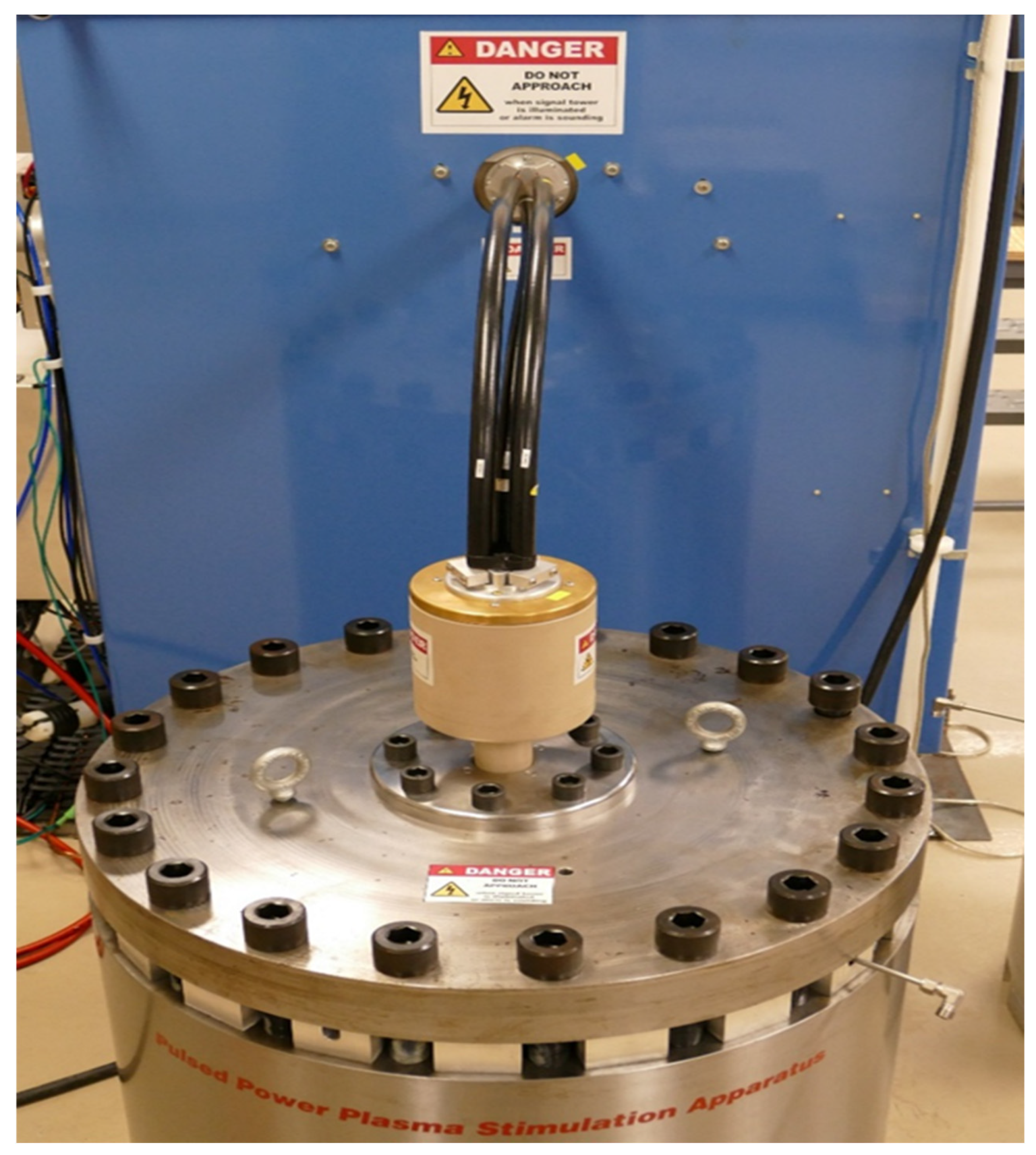

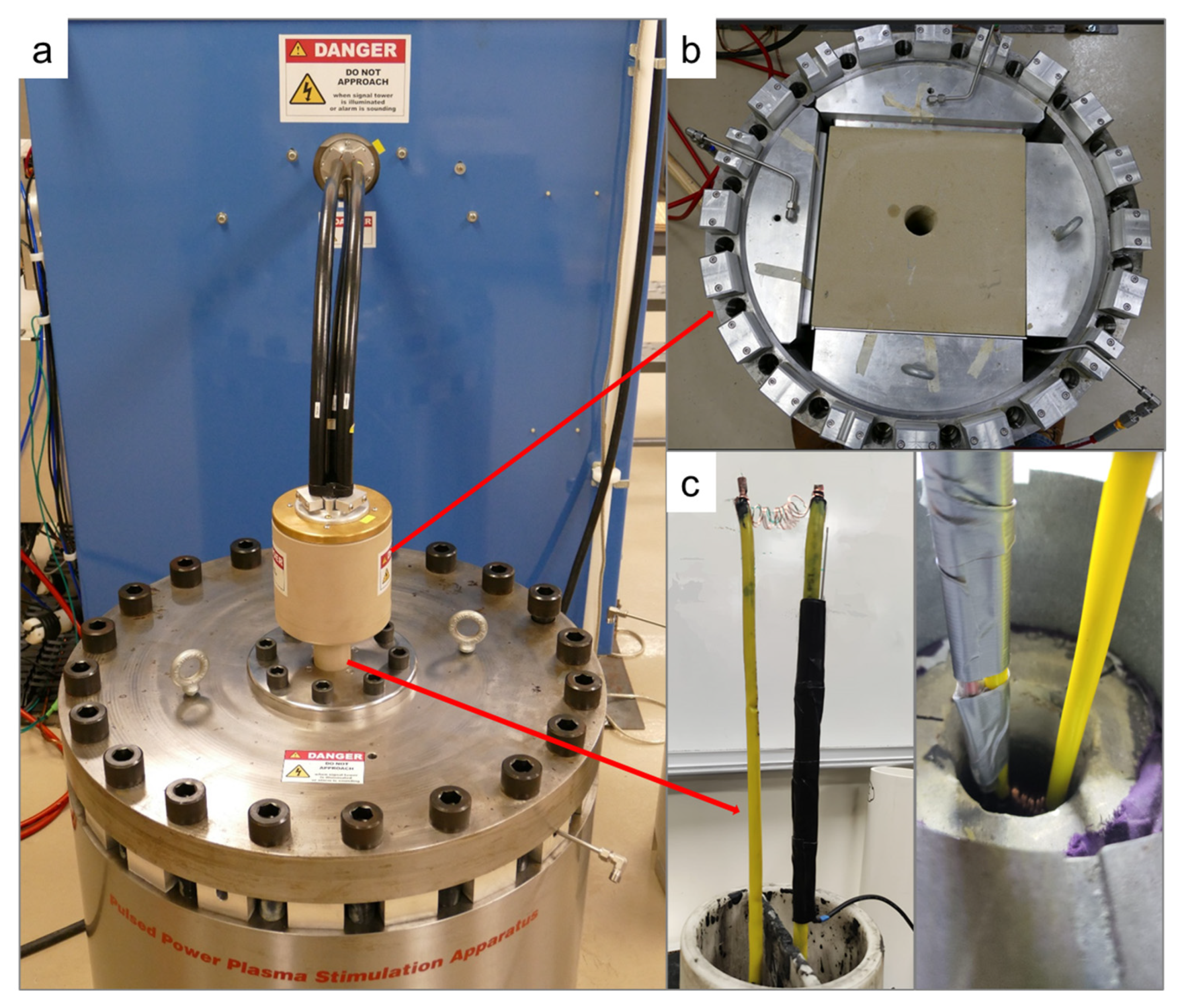

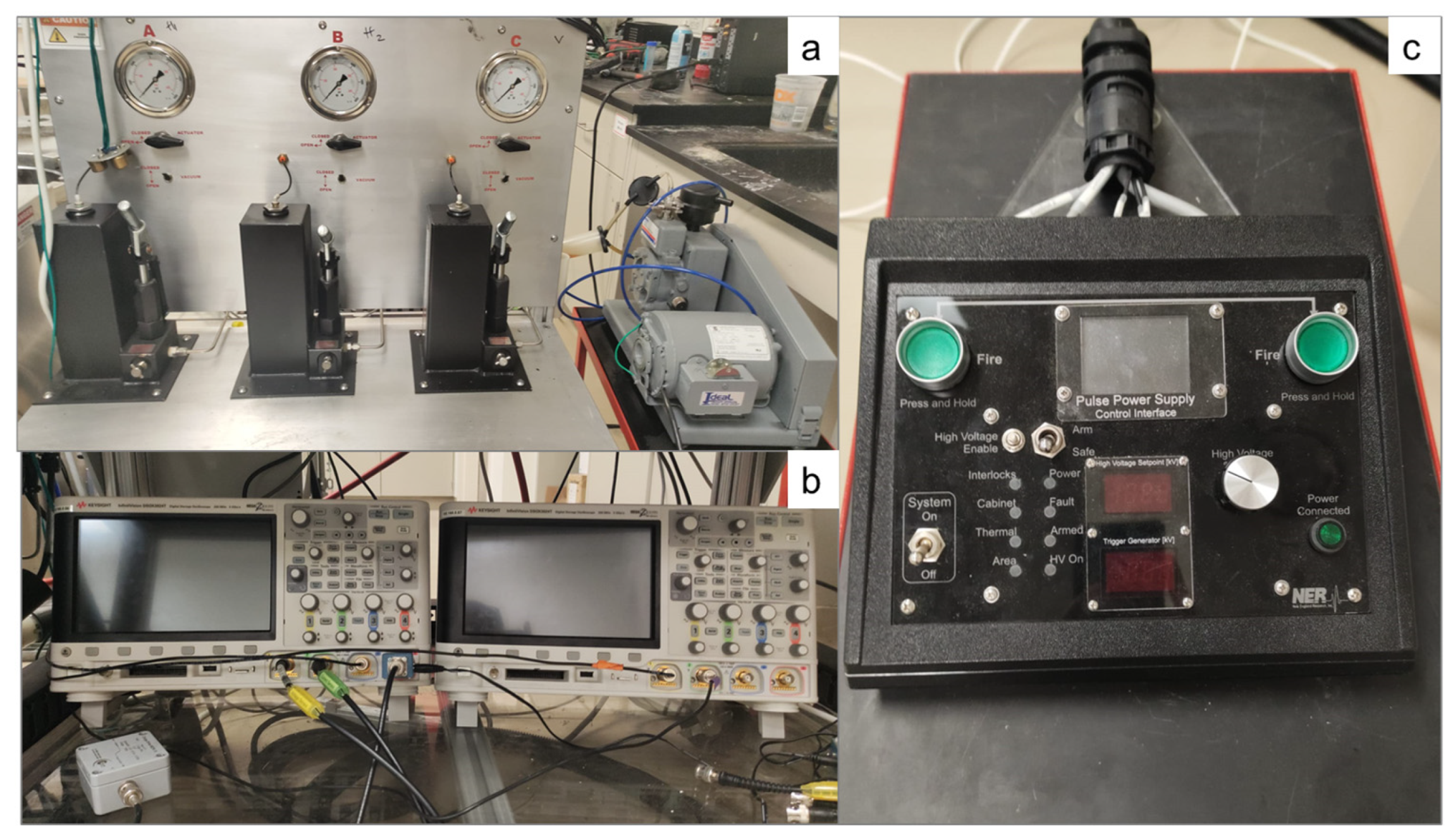

| Rezaei et al., 2020a [27] | Pulsed Power Plasma Stimulation | Cement, limestone, sandstone blocks | Input energy: 2.2–12 KJ Open hole for sandstones and limestones and cased hole for cement | Confining stress, energy levels, and repeated discharges | Fracture initiation energy increased with stress; repeated discharges enhanced permeability |

| Rezaei et al., 2020b [60] | Pulsed Power Plasma Stimulation | Sandstone, limestone, and Austin chalk | Input energy: 8–20 KJ | Stress and fusible link effects | Higher stress needed higher energy for failure; fusible link enhanced fractures |

| Bao et al., 2021 [52] | High-Voltage Electrical Pulse | Anthracite coal blocks | 7–13 KV (single-pulse discharge); 1–8 MPa hydrostatic pressure | Discharge voltage, pressure, crack length/aperture, applied stresses, and stimulated area | Higher voltage resulted in greater damage; voltage has more effect than pressure |

| Xiao et al., 2023 [54] | Pulsed Power Plasma Stimulation | Concrete cylinder | 2 KJ stored energy | Effect of surrounding media on EM signal | Water enhanced EM signal transmission, while air degraded it |

| Zhang et al., 2023 [55] | High-Voltage Electrical Pulse | Binzhou blue granite 30 × 30 × 50 cm | 10 KV, variable capacitance (20–500 µF) | Effect of capacitance on fracture | Capacitance controlled shockwave strength; visible cracks (horizontal and vertical) appeared at high capacitance |

| Li et al., 2024 [53] | Pulsed Arc Electrohydraulic Discharge | Tight sandstone blocks 200 × 200 × 200 mm | Discharge voltage: 9 KV with discharged current 5 kA | Effect of wellhead angle and well spacing | Well spacing/angle influenced fracture patterns and extension |

| Yin et al., 2024 [56] | High-Voltage Electrical Pulse | Fine-grained granite | (80–144) KV, 50 µF capacitance | Peak voltage and thermal effect on breakdown | Temperature reduced breakdown voltage threshold; enhanced crack complexity with heating |

| Peng et al., 2024 [57] | High-Voltage Electrical Pulse | Red sandstone 250 × 250 × 150 mm | Discharge voltage: 70 KV | Plasma channel spacing effects | Creation of horizontal fractures; optimal spacing enhanced fracture coalescence; wider spacing reduced effectiveness |

| Maddirala et al., 2024 [17] | Pulsed Power Plasma Stimulation | Berea sandstone cores | ~300 J per pulse (25–26 KV) | Effect of pulse number on petrophysical characteristics of the tested cores | Porosity and fracture connectivity improved with increased pulses |

| Khalaf et al., 2024 [58] | Pulsed Power Plasma Stimulation | Sandstone and limestone | Input energy: (6–10) KJ Borehole: open hole with 2” dia. Triaxial confinement | Effects of confining stresses and different wire dimensions | Creation of horizontal and radial fractures. Repeated pulses enhanced fracture networks, and the presence of natural fractures affected their propagation |

| Awad et al., 2024 [59] | Pulsed Power Plasma Stimulation | Water tank and cement/limestone rocks | Input energy: (1.5–9) KJ Borehole: open hole with 2” dia. | Optimizing energy design for underwater electrical shockwave fracturing by developing a correlation between minimum discharge energy and aluminum wire parameters | A correlation was developed to determine the minimum energy required to burn the wire based on wire diameter and weight. Limestone exhibited more extensive fracturing, compared to cement, due to its heterogeneity |

| Soliman et al., 2024 [15] | Pulsed Power Plasma Stimulation | Cement, sandstone, limestone, and shale samples | Input energy: (6.4–20) KJ Borehole: open hole with 2” dia. Triaxial confinement | Effects of applied confining stresses, rock type, and energy input | Higher applied stresses required more energy; creation of horizontal and radial fractures; repeated discharges enhanced fractures |

References

- Boak, J.; Kleinberg, R. Shale Gas, Tight Oil, Shale Oil and Hydraulic Fracturing. In Future Energy: Improved, Sustainable and Clean Options for Our Planet, 3rd ed.; Letcher, T.M., Ed.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 67–95. [Google Scholar] [CrossRef]

- Maugeri, L. Squeezing more oil from the ground. Sci. Am. 2009, 301, 56–63. [Google Scholar] [CrossRef] [PubMed]

- Moska, R.; Labus, K.; Kasza, P. Hydraulic fracturing in enhanced geothermal systems—Field, tectonic and rock mechanics conditions—A review. Energies 2021, 14, 5725. [Google Scholar] [CrossRef]

- Xie, Z.; Han, D.; Li, J.; Li, K. A State-of-the-Art Review of Hydraulic Fracturing in Geothermal Systems. Sustainability 2024, 16, 11087. [Google Scholar] [CrossRef]

- England, K.; Li, P.; Xing, P.; Moore, J.; McLennan, J. 2024 Enhanced Geothermal System Hydraulic Fracturing Campaign at Utah FORGE. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 4–6 February 2025. SPE-223519-MS. [Google Scholar] [CrossRef]

- Cao, X.; Wu, S.; He, Q. Investigation into Influences of Hydraulic Fracturing for Hard Rock Weakening in Underground Mines. Appl. Sci. 2024, 14, 1948. [Google Scholar] [CrossRef]

- Li, H.; Liu, S.; Zhu, Z.; Liu, H.; Zhang, D.; Guo, C. Experimental investigation on rock breaking performance of cutter assisted with hydraulic fracturing. Eng. Fract. Mech. 2021, 248, 107710. [Google Scholar] [CrossRef]

- Li, H.; Liu, B.; He, Q.; Gao, Y.; Ma, D.; Yang, H.; Cheng, J.; Ye, J.; Liu, G. Improving Hard Rock Materials Cuttability by Hydraulic Fracturing at Mining Working Face. Appl. Sci. 2024, 14, 11908. [Google Scholar] [CrossRef]

- Ellsworth, W.L. Injection-induced earthquakes. Science 2013, 341, 1225942. [Google Scholar] [CrossRef]

- USGS. Water Use in Hydraulic Fracturing. Available online: https://www.usgs.gov/ (accessed on 15 December 2023).

- National Research Council. Induced Seismicity Potential in Energy Technologies; National Academies Press: Washington, DC, USA, 2013. [Google Scholar]

- Burnham, A.; Han, J.; Clark, C.E.; Wang, M.; Dunn, J.B.; Palou-Rivera, I. Life-cycle greenhouse gas emissions of shale gas, natural gas, coal, and petroleum. Environ. Sci. Technol. 2012, 46, 619–627. [Google Scholar] [CrossRef]

- La Borderie, C.; Reess, T.; Chen, W.; Maurel, O.; Rey-Berbeder, F.; De Ferron, A. Electrohydraulic Fracturing of Rocks; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar] [CrossRef]

- Melton, N.M.; Cross, T.S. Fracturing oil shale with electricity. J. Pet. Technol. 1968, 20, 37–41. [Google Scholar] [CrossRef]

- Soliman, M.Y.; Rezaei, A.; Khalaf, M.; Gordon, P.; Cipolla, C. Pulse power plasma stimulation: A technique for waterless fracturing, enhancing the near wellbore permeability, and increasing the EUR of unconventional reservoirs. Gas Sci. Eng. 2024, 122, 205201. [Google Scholar] [CrossRef]

- Touya, G.; Reess, T.; Pecastaing, L.; Gibert, A.; Domens, P. Development of subsonic electrical discharges in water and measurements of the associated pressure waves. J. Phys. D Appl. Phys. 2006, 39, 5236. [Google Scholar] [CrossRef]

- Maddirala, R.; Shukla, R.; Pramanik, R.; Mishra, D.A.; Sharma, A.; Jain, R.; Kakati, H. Impact of Pulse Plasma-Based Shockwave Technology on Sandstone Porosity and Pore Connectivity Using Ultrasonic Compressional Wave Velocity and Microtomography. Energy Fuels 2024, 38, 20433–20448. [Google Scholar] [CrossRef]

- Xiao, Y.; House, W.; Unal, E.; Soliman, M.Y. Pulsed power plasma stimulation technique-experimental study on single pulse test for fractures initiation. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, Houston, TX, USA, 23–25 July 2018. URTEC-2881050-MS. [Google Scholar] [CrossRef]

- Chen, W.; Maurel, O.; Reess, T.; De Ferron, A.S.; La Borderie, C.; Pijaudier-Cabot, G.; Rey-Bethbeder, F.; Jacques, A. Experimental study on an alternative oil stimulation technique for tight gas reservoirs based on dynamic shock waves generated by pulsed arc electrohydraulic discharges. J. Pet. Sci. Eng. 2012, 88, 67–74. [Google Scholar] [CrossRef]

- Ledoux, Y. Experimental investigation of the pulse duration on the efficiency and electrode wear of electrohydraulic forming process. Manuf. Rev. 2023, 10, 17. [Google Scholar] [CrossRef]

- He, J.; Zhang, R.; Zhang, J.; Liu, M.; Izuchukwu, O.N. Experimental evaluation of near wellbore stimulation–using electrical explosion shockwave on tight sand reservoir. Oil Gas Sci. Technol. 2018, 73, 60. [Google Scholar] [CrossRef]

- Han, R.; Zhou, H.; Liu, Q.; Wu, J.; Jing, Y.; Chao, Y.; Zhang, Y.; Qiu, A. Generation of electrohydraulic shock waves by plasma-ignited energetic materials: I. Fundamental mechanisms and processes. IEEE Trans. Plasma Sci. 2015, 43, 3999–4008. [Google Scholar] [CrossRef]

- Xiao, Y. Pulsed Power Plasma Stimulation-Experimental and Numerical Study on Single-Pulse Test. Ph.D. Dissertation, Texas Tech University, Lubbock, TX, USA, 2017. Available online: https://hdl.handle.net/2346/82042 (accessed on 22 June 2025).

- Campin, D. An assessment of the application of propellant enhancement to conventional wells. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Virtual, 17–19 November 2020. SPE-202305-MS. [Google Scholar] [CrossRef]

- Lati, S. An Experimental Investigation to Study the Effect of Pulsed-Power Discharge on Rock Fracturing for Well Stimulation. Master’s Thesis, Texas Tech University, Lubbock, TX, USA, 2010. Available online: http://hdl.handle.net/2346/46018 (accessed on 22 June 2025).

- Zhu, X.; Luo, Y.; Liu, W. On the rock-breaking mechanism of plasma channel drilling technology. J. Pet. Sci. Eng. 2020, 194, 107356. [Google Scholar] [CrossRef]

- Rezaei, A.; Siddiqui, F.; Callen, N.; Gordon, P.; House, W.; Soliman, M.Y. Pulsed power plasma to enhance near wellbore permeability and improve well performance. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 4–6 February 2020. SPE-199753-MS. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, J.; Xue, Q.; Liu, J.; Li, H.; Fang, S. Research Status and Prospects of High-Voltage Pulse Plasma Rock-Fracturing Technology. Appl. Sci. 2024, 14, 7261. [Google Scholar] [CrossRef]

- Thomas, L.; Tang, H.; Kalyon, D.M.; Aktas, S.; Arthur, J.D.; Blotevogel, J.; Carey, J.W.; Filshill, A.; Fu, P.; Hsuan, G.; et al. Toward better hydraulic fracturing fluids and their application in energy production: A review of sustainable technologies and reduction of potential environmental impacts. J. Pet. Sci. Eng. 2019, 173, 793–803. [Google Scholar] [CrossRef]

- Ren, Z.; Wang, S.; Dong, K.; Yu, W.; Lu, L. Exploring the Mechanism of Pulse Hydraulic Fracturing in Tight Reservoirs. Processes 2023, 11, 3398. [Google Scholar] [CrossRef]

- Kasri, N.F.; Piah, M.A.M.; Adzis, Z. Compact higg-voltage pulse generator for pulsed electric field applications: Lab-scale development. J. Electr. Comput. Eng. 2020, 2020, 6525483. [Google Scholar] [CrossRef]

- Shugar, T.A.; Odello, R.J. Fracture Tests with an Electrohydraulic Pulser; Civil Engineering Laboratory Technical Memorandum TM-51-76; Naval Construction Battalion Center: Port Hueneme, CA, USA, 1979; Available online: https://apps.dtic.mil/sti/tr/pdf/ADA047422.pdf (accessed on 13 October 2024).

- Touryan, K.J.; Moeny, W.M.; Aimone, C.T.; Benze, J.W. Electrohydraulic rock fracturing by pulsed power generated focused shocks. In Proceedings of the 7th Pulsed Power Conference, Monterey, CA, USA, 11–14 June 1989; pp. 69–72. [Google Scholar] [CrossRef]

- Grinenko, A.; Gurovich, V.T.; Saypin, A.; Efimov, S.; Krasik, Y.E.; Oreshkin, V.I. Strongly coupled copper plasma generated by underwater electrical wire explosion. Phys. Rev. E 2005, 72, 066401. [Google Scholar] [CrossRef] [PubMed]

- Veksler, D.; Sayapin, A.; Efimov, S.; Krasik, Y.E. Characterization of different wire configurations in underwater electrical explosion. IEEE Trans. Plasma Sci. 2009, 37, 88–94. [Google Scholar] [CrossRef]

- Maurel, O.; Reess, T.; Matallah, M.; De Ferron, A.; Chen, W.; La Borderie, C.; Pijaudier-Cabot, G.; Jacques, A.; Rey-Bethbeder, F. Electrohydraulic shock wave generation as a means to increase intrinsic permeability of mortar. Cem. Concr. Res. 2010, 40, 1631–1638. [Google Scholar] [CrossRef]

- Chen, W.; Maurel, O.; La Borderie, C.; Reess, T.; De Ferron, A.; Matallah, M.; Pijaudier-Cabot, G.; Jacques, A.; Rey-Bethbeder, F. Experimental and numerical study of shock wave propagation in water generated by pulsed arc electrohydraulic discharges. Heat Mass Transf. 2014, 50, 673–684. [Google Scholar] [CrossRef]

- Carden, A.E. Analysis of electrohydraulic shock wave generation. In Proceedings of the ASME 2012 International Mechanical Engineering Congress & Exposition, Houston, TX, USA, 9–15 November 2012. Paper IMECE2012-85527. [Google Scholar] [CrossRef]

- Zhu, L.; He, Z.; Gao, Z.; Tan, F.; Yue, X.; Chang, J. Research on the influence of conductivity to pulsed arc electrohydraulic discharge in water. J. Electrostat. 2014, 72, 53–58. [Google Scholar] [CrossRef]

- Zhou, H.; Han, R.; Liu, Q.; Jing, Y.; Wu, J.; Zhang, Y.; Qiu, A.; Zhao, Y. Generation of electrohydraulic shock waves by plasma-ignited energetic materials: II. Influence of wire configuration and stored energy. IEEE Trans. Plasma Sci. 2015, 43, 4009–4016. [Google Scholar] [CrossRef]

- Cho, S.H.; Cheong, S.S.; Yokota, M.; Kaneko, K. The dynamic fracture process in rocks under high-voltage pulse fragmentation. Rock Mech. Rock Eng. 2016, 49, 3841–3853. [Google Scholar] [CrossRef]

- Han, R.; Wu, J.; Zhou, H.; Ding, W.; Qiu, A.; Clayson, T.; Wang, Y.; Ren, H. Characteristics of exploding metal wires in water with three discharge types. J. Appl. Phys. 2017, 122, 033302. [Google Scholar] [CrossRef]

- Liu, Q.; Ding, W.; Han, R.; Wu, J.; Jing, Y.; Zhang, Y.; Zhou, H.; Qiu, A. Fracturing effect of electrohydraulic shock waves generated by plasma-ignited energetic materials explosion. IEEE Trans. Plasma Sci. 2017, 45, 423–431. [Google Scholar] [CrossRef]

- Han, R.; Zhou, H.; Wu, J.; Qiu, A.; Ding, W.; Zhang, Y. Electrical explosions of Al, Ti, Fe, Ni, Cu, Nb, Mo, Ag, Ta, W, W-Re, Pt, and Au wires in water: A comparison study. J. Appl. Phys. 2018, 124, 044901. [Google Scholar] [CrossRef]

- Liu, S.; Miao, S.; Liu, X.; Zheng, X.; Lu, Z.; Li, P. Enhanced oil recovery by repetitive electrohydraulic shock waves: Fracturing and Enhanced-Permeability. In Proceedings of the 2018 IEEE International Conference on High Voltage Engineering and Application (ICHVE), Athens, Greece, 10–13 September 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Zhang, Z.; Mao, J.; Yang, X.; Zhao, J.; Smith, G.S. Advances in waterless fracturing technologies for unconventional reservoirs. Energy Sources Part A 2019, 41, 237–251. [Google Scholar] [CrossRef]

- Tariq, Z.; Mahmoud, M.; Abdulraheem, A.; Al-Nakhli, A.; BaTaweel, M. A review of pulse fracturing treatment: An emerging stimulation technique for unconventional reservoirs. In Proceedings of the SPE Middle East Oil and Gas Show and Conference, Manama, Bahrain, 18–21 March 2019. SPE-194870-MS. [Google Scholar] [CrossRef]

- Riu, H.; Jang, H.S.; Lee, B.J.; Wu, C.; Jang, B.A. Laboratory-scale fracturing of cement and rock specimen by plasma blasting. Episodes 2019, 42, 213–223. [Google Scholar] [CrossRef]

- Li, S.; Tian, S.; Jiang, L. Research on the resonance characteristics of rock under harmonic excitation. Shock Vib. 2019, 2019, 326510. [Google Scholar] [CrossRef]

- Liu, Y.; Ren, Y.J.; Liu, S.W.; Lin, F.C.; Liu, Y.; Shen, Y.K. Comparison and analysis of shockwave characteristics between underwater pulsed discharge and metal wire explosion. Phys. Plasmas 2020, 27, 033510. [Google Scholar] [CrossRef]

- Li, L.; Qian, D.; Liu, Z.; Zou, X.; Wang, X. Comparison of underwater electrical wire explosions with large and small capacitors charged to a same energy. Phys. Plasmas 2020, 27, 063401. [Google Scholar] [CrossRef]

- Bao, X.; Cao, J.; Zheng, W.; Guo, J.; Liu, Y.; Zhao, J. Study on the damage model of coal rock caused by hydraulic pressure and electrical impulse in borehole. Geofluids 2021, 2021, 6627242. [Google Scholar] [CrossRef]

- Li, Z.; Wang, S.; Pan, Y.; Zhang, R.; Chen, J. Effects of Drilling Number and Distribution on Fracture Using the Pulse Plasma on Tight Sand Reservoir. SPE J. 2024, 29, 1802–1817. [Google Scholar] [CrossRef]

- Xiao, Y.; House, W.; Soliman, M.Y.; Dindoruk, B.; Ibraguimov, A. Experimental, analytical and numerical study of the electromagnetic distribution in pulsed power plasma stimulation (PPPS). Geoenergy Sci. Eng. 2023, 225, 211686. [Google Scholar] [CrossRef]

- Zhang, D.; Yang, T.; Zhao, L. Experimental investigation on high-voltage electrical pulse fracturing Binzhou blue stone: Influence of capacitance on fracture initiation and propagation. Energy Fuels 2023, 37, 9692–9703. [Google Scholar] [CrossRef]

- Yin, G.; Lin, B.; Wu, Y.; Wen, Z.; Tian, J.; Huang, Y.; Lin, S. Experimental study on pre-damage of hot dry rock using high-voltage electric pulse discharge. J. Cent. South Univ. 2024, 31, 1526–1541. [Google Scholar] [CrossRef]

- Peng, J.; Zhou, Y.; Zhang, F.; Li, J.; Yan, G. Effects of the spacing between plasma channels on the fracture behavior of red sandstone under high-voltage pulse discharge. Geomech. Geophys. Geo-Energy Geo-Resour. 2024, 10, 74. [Google Scholar] [CrossRef]

- Khalaf, M.; Soliman, M.; Farouq-Ali, S.M.; Cipolla, C.; Dusterhoft, R. Experimental study on pulsed plasma stimulation and matching with simulation work. Appl. Sci. 2024, 14, 4752. [Google Scholar] [CrossRef]

- Awad, M.M.; Eltaleb, I.; Soliman, M.Y. Experimental study of energy design optimization for underwater electrical shockwave for fracturing applications. Geosciences 2024, 14, 24. [Google Scholar] [CrossRef]

- Rezaei, A.; Siddiqui, F.; Awad, M.M.; Mansi, M.; Gordon, P.; Callen, N.; House, W.; Soliman, M.Y. Pulse plasma stimulation: Effect of discharge energy on rock damage under various confining stresses. In Proceedings of the ARMA US Rock Mechanics/Geomechanics Symposium, Virtual, 28 June–1 July 2020; ARMA-2020-1572. Available online: https://onepetro.org/ARMAUSRMS/proceedings-abstract/ARMA20/All-ARMA20/447737 (accessed on 22 June 2025).

- Akhter, M.; Tang, X.; Mallams, J.; Kao, Y.T.; Kazi, A.; Kumar, S.; Antao, D.S.; Tai, B.L.; Staack, D. Shockwave and plasma assisted rock cracking for geothermal drilling. Renew. Energy 2025, 241, 122351. [Google Scholar] [CrossRef]

- Ezzat, M.; Börner, J.; Kammermann, B.; Rossi, E.; Adams, B.M.; Wittig, V.; Biela, J.; Schiegg, H.O.; Vogler, D.; Saar, M.O. Impact of temperature on the performance of plasma-pulse geo-drilling (PPGD). Rock Mech. Rock Eng. 2024, 57, 3531–3542. [Google Scholar] [CrossRef]

- Ezzat, M.; Börner, J.; Vogler, D.; Wittig, V.; Kammermann, B.; Biela, J.; Saar, M.O. Lithostatic pressure effects on the plasma-pulse geo-drilling (PPGD). In Proceedings of the 48th EPS Conference on Plasma Physics, Virtual, 27 June–1 July 2022; p. 316. [Google Scholar] [CrossRef]

- Ezzat, M.; Vogler, D.; Saar, M.O.; Adams, B.M. Simulating plasma formation in pores under short electric pulses for plasma pulse geo drilling (PPGD). Energies 2021, 14, 4717. [Google Scholar] [CrossRef]

- Gajdos, M.; Kocis, I.; Kristofic, T. Update in Development and Deployment of Advanced Pulsed Plasma Drilling Technology. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, SPE-207852-MS, Abu Dhabi, United Arab Emirates, 15–18 November 2021. [Google Scholar] [CrossRef]

- Liu, W.; Hu, H.; Zhu, X. The rock breaking mechanism of a combined high-voltage electric impulse-PDC bit drilling technology. Geothermics 2023, 111, 102723. [Google Scholar] [CrossRef]

- Kazi, A.A.; Akhter, M.; Antao, D.; Staack, D.; Tai, B.L. The effects of plasma pre-cracking on drilling of hard rocks: A single insert cutting experiment. J. Manuf. Sci. Eng. 2023, 145, 061006. [Google Scholar] [CrossRef]

- Energy Global. GA Drilling Collaborates with NREL to Commercialise Geothermal Power Technology. Available online: https://www.energyglobal.com/ (accessed on 10 May 2025).

- Gajdos, M.; Watson, G.; Webb, M.; Glover, D.; Kristofic, T.; Kocis, I.; Lines, L.; Murray, W.; Codazzi, D.; Jeffryes, B. Progress in Development and Testing of Anchoring Technology for Hard and Abrasive Drilling Conditions. In Proceedings of the Conference Proceedings, 49th Workshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 12–14 February 2024. [Google Scholar]

- Fraser, M.D. Method and Apparatus for Creating Elastic Waves in a Fluid-Filled Environment. U.S. Patent 9,181,788, 10 November 2015. [Google Scholar]

- NOVAS Energy. Plasma Pulse Technology Overview and Tool Specifications. Available online: http://novasenergy.ca/technology/equipment.html (accessed on 13 May 2025).

- NOVAS Energy. Plasma Pulse Technology—A Reservoir Treatment Technology for Enhanced Hydrocarbon Recovery. Available online: https://content.equisolve.net/novasenergy/media/d37cb740e7ee3419fa2e949037b5394f.pdf (accessed on 10 January 2025).

- NOVAS Energy. Applications and Field Results. Available online: http://novasenergy.ca/technology/presentations.html (accessed on 13 May 2025).

- Bazargan, M.; Soliman, M.Y.; Habibpour, M.; Rezaei, A. Plasma torch perforation to route hydraulic fracturing operation in unconventional reservoirs. In Proceedings of the 48th US Rock Mechanics/Geomechanics Symposium, Minneapolis, MN, USA, 1–4 June 2014. [Google Scholar]

- Soliman, M.Y. Fracturing Treatment of Subterranean Formations Using Shock Waves. U.S. Patent 10,309,202, 4 June 2019. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, S.T.; El-Tayeb, M.E.-S.; Adel Gabry, M.; Y. Soliman, M. Pulsed Power Plasma Stimulation: A Comprehensive Review and Field Insights. Energies 2025, 18, 3334. https://doi.org/10.3390/en18133334

Nguyen ST, El-Tayeb ME-S, Adel Gabry M, Y. Soliman M. Pulsed Power Plasma Stimulation: A Comprehensive Review and Field Insights. Energies. 2025; 18(13):3334. https://doi.org/10.3390/en18133334

Chicago/Turabian StyleNguyen, Son T., Mohamed E.-S. El-Tayeb, Mohamed Adel Gabry, and Mohamed Y. Soliman. 2025. "Pulsed Power Plasma Stimulation: A Comprehensive Review and Field Insights" Energies 18, no. 13: 3334. https://doi.org/10.3390/en18133334

APA StyleNguyen, S. T., El-Tayeb, M. E.-S., Adel Gabry, M., & Y. Soliman, M. (2025). Pulsed Power Plasma Stimulation: A Comprehensive Review and Field Insights. Energies, 18(13), 3334. https://doi.org/10.3390/en18133334