Risk Assessment Framework for Power Circuit Breakers Based on Condition, Replacement, and Criticality Indices

Abstract

1. Introduction

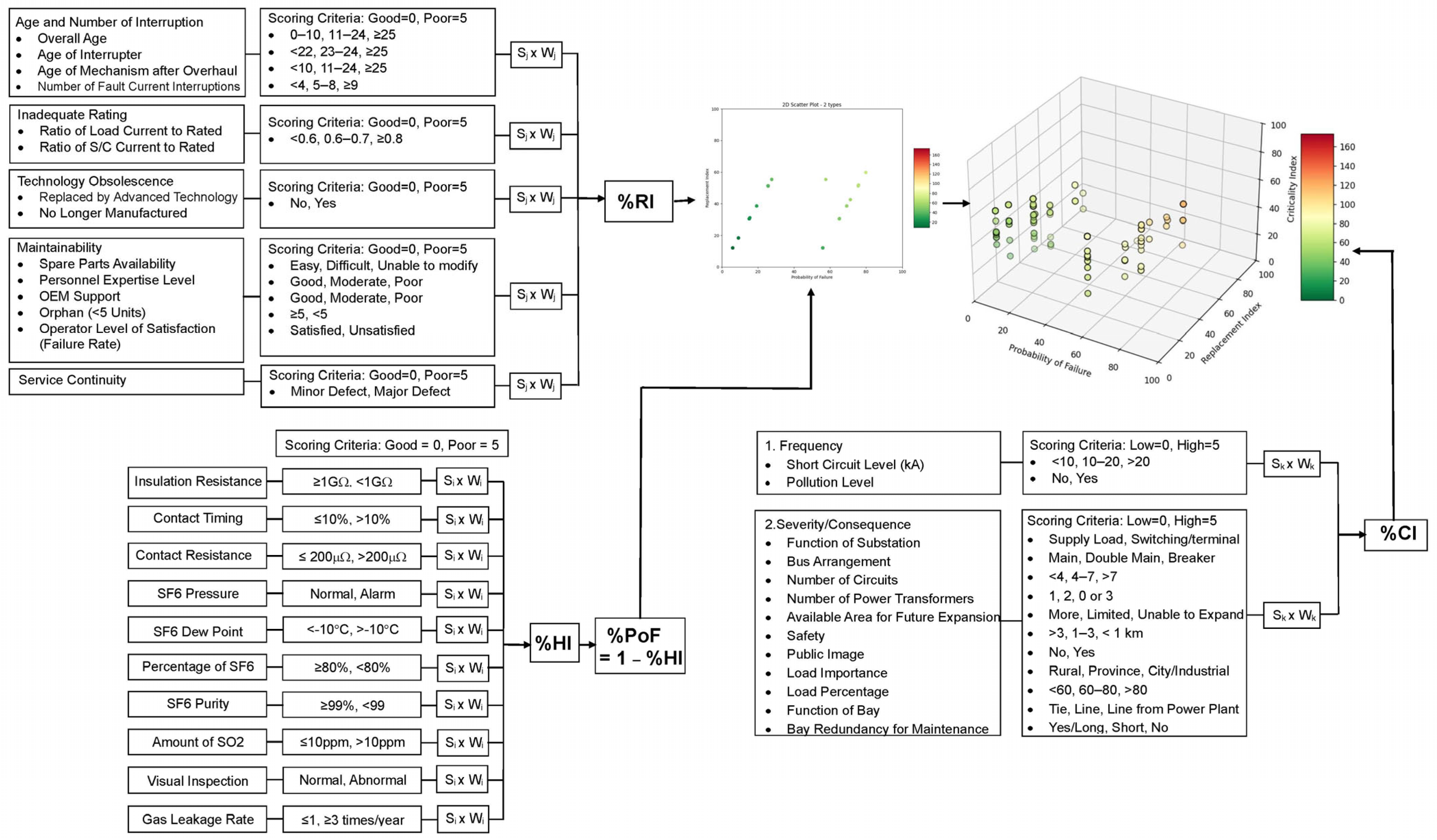

2. Health Index and Probability of Failure Determination

- Insulation resistance: values ≥ 1 GΩ indicate good insulation, lower values increase leakage and breakdown risks;

- Contact timing: a deviation ≤10% from the commissioning test results indicates good performance, a higher deviation suggests mechanical issues and overheating risks;

- Contact resistance: values ≤200 μΩ indicate good conductivity, higher values suggest wear, overheating, or failure risk;

- SF6 pressure: normal pressure ensures proper functioning, low pressure signals leakage or malfunction;

- SF6 dew point: a value below −10 °C means dry gas is present, higher values indicate humidity, reducing insulation reliability;

- SF6 percentage: a value >80% ensures good insulation, lower levels suggest depletion and failure risk;

- SF6 purity: >99% purity ensures dielectric strength, lower purity increases failure risk;

- SO2 level (ppm): a value <10 ppm is normal, higher levels suggest gas decomposition from internal arcing and damage;

- Visual inspection: detects physical defects like cracks or rust, abnormalities require repair or replacement;

- Gas leakage rate: ≤1 leak/year indicates proper sealing, >3 leaks/year suggests poor sealing and environmental concerns.

- Si = Scoring value of each criterion for the health assessment;

- Smax,i = Maximum score of each criterion for the health assessment;

- Wi = Weighted value of each criterion for the health assessment;

- i = Number of criteria for the health assessment.

3. Replacement Index Determination

- Overall age: ≥25 years indicates high failure risk and urgent replacement, <10 years reflects low risk, 11–24 years requires regular inspection and testing;

- Interrupter age: ≥25 years signals degraded interruption performance and high failure risk, requiring replacement;

- Mechanism age after overhaul: ≥25 years suggests end-of-life status and the need for major refurbishment;

- Fault current interruptions: more than nine interruptions indicates severe contact wear, requiring detailed interrupter inspection;

- Load current to rating ratio: a ratio >0.8 means that operation is near capacity, suggesting the need for relocation or a higher rated replacement;

- Short-circuit current to interrupting capacity ratio: a ratio >0.8 indicates high electrical stress, requiring immediate replacement to avoid failure;

- Technology obsolescence: incompatible or outdated technology justifies replacement or a system upgrade;

- Manufacturing status: discontinued models with unavailable parts should be replaced with current alternatives;

- Spare parts availability: limited availability suggests end of life and supports replacement or the need for major refurbishment;

- Personnel expertise: a lack of trained personnel for maintenance increases risks and supports the use of more maintainable equipment;

- OEM support: the absence of OEM technical or parts support often necessitates replacement or refurbishment;

- Similar units remaining: fewer than five similar units in operation complicates support and part sourcing, justifying replacement;

- Operator satisfaction: frequent failures or negative feedback reflects poor reliability and supports upgrades or replacement;

- Repair cost and effort: high repair costs or maintenance effort suggests that replacement may be more cost effective.

- Sl = Scoring of each criterion for the replacement assessment;

- Smax,l = Maximum score of each criterion for the replacement assessment;

- Wl = Weighted value of each criterion for the replacement assessment;

- l = Number of criteria for the replacement assessment.

4. Criticality Index Determination

- Possibility of Equipment Failure

- Short-circuit current: the maximum current during a fault. Currents below 10 kA pose low risk, while those above 20 kA indicate high electrical stress and greater failure risk.

- Pollution level: Environmental contaminants like bird droppings or sea spray can degrade insulation and cause flashovers. Higher pollution levels increase equipment criticality.

- Severity/Consequence of Equipment Failure

- Function of substation: Substations serving load supply are less critical, while switching or terminal substations are more critical due to their role in power flow control.

- Bus arrangement: Redundancy in bus configurations reduces failure risk. H-bus or main and transfer schemes offer low redundancy, while the breaker-and-a-half substation provides the highest reliability and criticality.

- Number of circuits: indicates network importance. Fewer than four circuits suggests low criticality, more than seven indicates high criticality.

- Number of power transformers: More than three transformers signifies higher capacity and greater system importance.

- Available area for future expansion: Sufficient space reduces criticality by allowing future upgrades, limited or no space increases it.

- Safety (distance from community): Substations near urban or industrial areas pose higher safety risks and are more critical.

- Public image: Substations in visible, populated, or tourist areas are more critical due to public and environmental concerns.

- Substation location (load importance): rural locations are less critical; urban, tourist, or industrial locations are highly critical due to their role in the operation of key infrastructure.

- Loading percentage: above 80% indicates high operational stress and criticality, below 60% suggests low stress.

- Function of bay: tie bays are least critical; transformer and transmission line bays are highly critical for power distribution.

- Redundancy/planned outage: high redundancy and tolerance for outages reduce criticality; systems with low tolerance are highly critical.

- Sk = Scoring value of each criterion for the criticality assessment;

- Smax,k = Maximum score of each criterion for the criticality assessment;

- Wk = Weighted value of each criterion for the criticality assessment;

- k = Number of criteria for the criticality assessment.

5. Results and Discussion

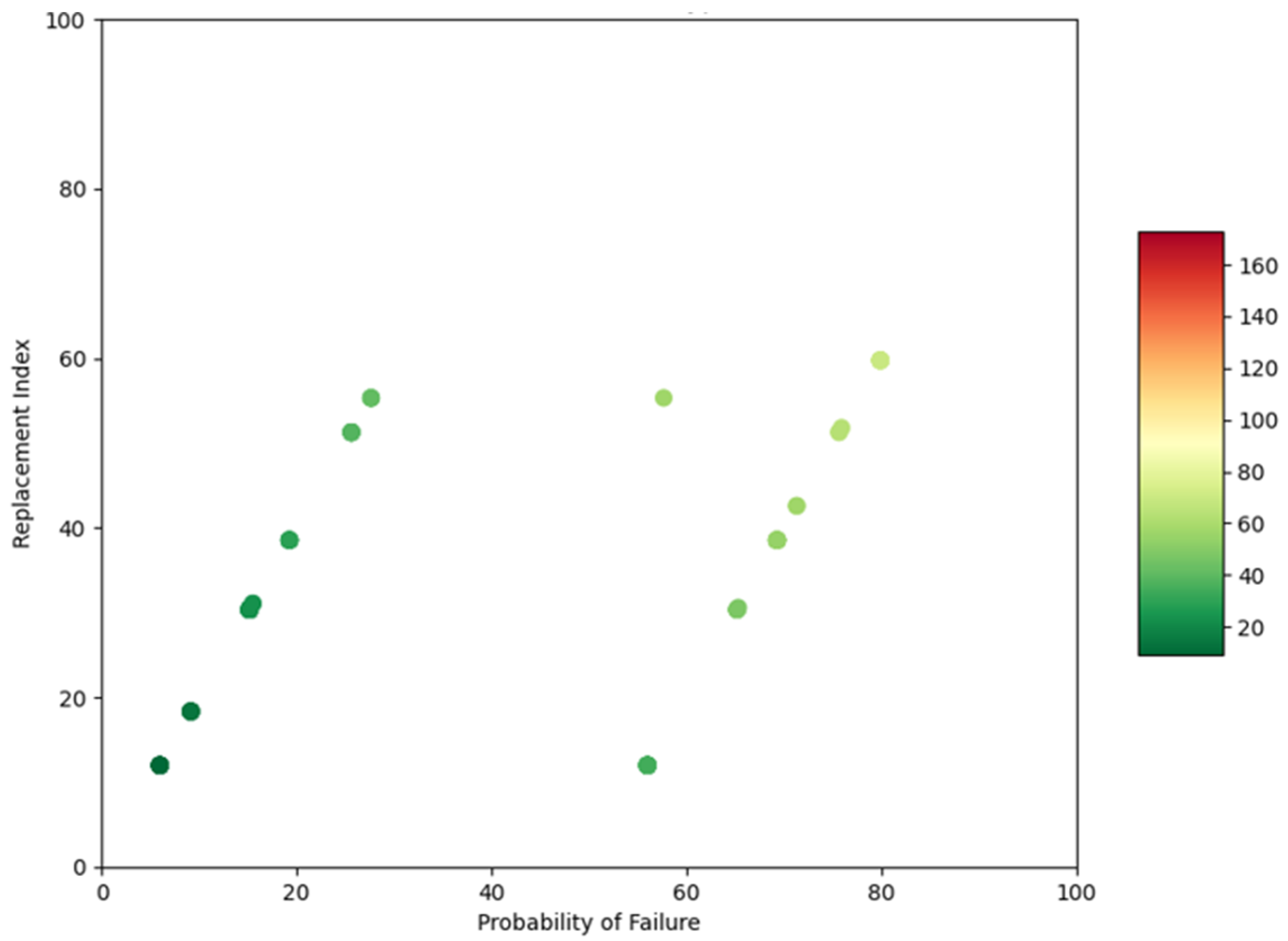

5.1. Results of Probability of Failure, Replacement Index, and Criticality Index

5.2. The 2D Plotting of %PoF vs. %RI

5.3. The 3D Plotting by Adding the %CI to 2D Plotting of %PoF Versus %RI

5.4. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lee, W.-Y.; Jun, J.-U.; Oh, H.-S.; Park, J.-K.; Oh, Y.-H.; Song, K.-D.; Jang, H.-J. Comparison of the interrupting capability of gas circuit breaker according to SF6, g3, and CO2/O2 mixture. Energies 2020, 13, 6388. [Google Scholar] [CrossRef]

- Abdollah, M.; Razi-Kazemi, A.A. Intelligent failure diagnosis for gas circuit breakers based on dynamic resistance measurements. IEEE Trans. Instrum. Meas. 2019, 68, 3066–3077. [Google Scholar] [CrossRef]

- Li, L.; Wang, B.; Liu, Y.; Yu, H.; Zhang, S.; Huang, M. Early detection of health condition degradation of circuit breaker based on electrical quantity monitoring. Energies 2023, 16, 5581. [Google Scholar] [CrossRef]

- Grant, J.A.; Sperstad, I.B.; Vadlamudi, V.V.; Perkin, S.; Kiel, E.S. The impact of high-voltage circuit breaker condition on power system reliability indices. IET Gener. Transm. Distrib. 2024, 18, 3980–3994. [Google Scholar] [CrossRef]

- Neumann, C.; Rusek, B.; Schneider, J.; Balzer, G.; Schnettler, A.; Federrein, S.; Zickler, U.; Schorn, C.H. Strategy for end of life assessment for high voltage circuit breakers. In Proceedings of the CIGRE A3-101, Paris, France, 24–29 August 2008. [Google Scholar]

- Muhr, M. Aging and degradation, their detection and monitoring and asset management. In Proceedings of the International Symposium on Electrical Insulating Materials, Yokkaichi, Japan, 7–11 September 2008; pp. 183–186. [Google Scholar] [CrossRef]

- Zhao, M.-X.; Su, J.; Liu, S.-G. Risk assessment based maintenance management for distribution network. J. Int. Counc. Electr. Eng. 2012, 2, 84–89. [Google Scholar] [CrossRef]

- IEEE Standard C37.10.1-2018; IEEE Guide for the Selection of Monitoring for Circuit Breakers. IEEE: New York, NY, USA, 2019. [CrossRef]

- Balzer, G.; Schmitt, O.; Schneider, A.; Gal, S.; Balasiu, F.; Bakic, K. Life cycle assessment of substations: A procedure for an optimized asset management. In Proceedings of the CIGRE 23-302, Paris, France, 25–30 August 2002. [Google Scholar]

- Balzer, G.; Degen, W.; Halfmann, M.; Neumann, C.; Hartkopf, T. Strategies for optimizing the use of substation assets. In Proceedings of the CIGRE B3-101, Paris, France, 29–30 August 2004. [Google Scholar]

- Gunjan, S.B.; Srinivasu, D.S.; Babu, R.N. A new approach for product reliability prediction by considering the production factory lifecycle information. Reliab. Eng. Syst. Saf. 2025, 258, 110915. [Google Scholar] [CrossRef]

- Osuchukwu, O.A.; Salihi, A.; Ibrahim, A.; Audu, A.A.; Makoyo, M.; Mohammed, S.A.; Lawal, M.Y.; Etinosa, P.O.; Isaac, I.O.; Oni, P.G.; et al. Weibull analysis of ceramics and related materials: A review. Heliyon 2024, 10, 32495. [Google Scholar] [CrossRef]

- Namazian, A.; Yakhchali, S.H.; Yousefi, V.; Tamošaitiene, J. Combining monte carlo simulation and bayesian networks methods for assessing completion time of projects under risk. Int. J. Environ. Res. Public Health 2019, 16, 5024. [Google Scholar] [CrossRef]

- Joshua, K.T.; Lating, P.O.; Edimu, M. Development of a predictive model for industrial circuit breaker degradation in stochastic environments. Int. J. Innov. Sci. Res. Technol. 2023, 8, 1. [Google Scholar] [CrossRef]

- IEC 62271-100; High-Voltage Switchgear and Controlgear—Part 100: Alternating-Current Circuit-Breakers. International Electrotechnical Commission: Geneva, Switzerland, 2021.

- IEEE C37.09-2019; Standard Test Procedures for AC High-Voltage Circuit Breakers with Rated Maximum Voltage Above 1000 V. IEEE Standards Association: Piscataway, NJ, USA, 2019.

- Yang, Q.; Ruan, J.; Zhuang, Z.; Huang, D.; Qiu, Z. A new vibration analysis approach for detecting mechanical anomalies on power circuit breakers. IEEE Access 2019, 7, 14070–14080. [Google Scholar] [CrossRef]

- Naranpanawe, L.; Ma, H.; Saha, T.K.; Lee, C.; Ghosal, A. A practical health index for overhead conductors: Experience from Australian distribution networks. IEEE Access 2020, 8, 218863–218873. [Google Scholar] [CrossRef]

- Foros, J.; Istad, M. Health index, risk and remaining lifetime estimation of power transformers. IEEE Trans. Power Deliv. 2020, 35, 2612–2620. [Google Scholar] [CrossRef]

- Høidalen, H.K.; Runde, M. Continuous monitoring of circuit breakers using vibration analysis. IEEE Trans. Power Deliv. 2005, 20, 2458–2465. [Google Scholar] [CrossRef]

- Tanaka, H.; Tsukao, S.; Yamashita, D.; Niimura, T.; Yokoyama, R. Multiple criteria assessment of substation conditions by pair-wise comparison of analytic hierarchy process. IEEE Trans. Power Deliv. 2010, 25, 3017–3023. [Google Scholar] [CrossRef]

- Taherdoost, H.; Madanchian, M. Multi-criteria decision making (MCDM) methods and concepts. Encyclopedia 2023, 3, 77–87. [Google Scholar] [CrossRef]

- Cinelli, M.; Burgherr, P.; Kadzinskim, M.; Slowinski, R. Proper and improper uses of MCDA methods in energy systems analysis. Decis. Support Syst. 2022, 163, 113848. [Google Scholar] [CrossRef]

- Jahani, F.; Mohammadi, M.; Pourdaryaei, A.; Shayesteh, E.; Karimi, M. A novel multi-criteria decision-making framework in electrical utilities based on gray number approach. IEEE Access 2017, 10, 121508–121519. [Google Scholar] [CrossRef]

- Aydin, F.; Gumus, B. Comparative analysis of multi-criteria decision making methods for the assessment of optimal SVC location. Bull. Pol. Acad. Sci. Tech. Sci. 2022, 70, 140555. [Google Scholar] [CrossRef]

- Shishavan, A.P.; Razi-Kazemi, A.A. A practical knowledge-based ranking approach to identify critical circuit breakers in large power systems. Knowl.-Based Syst. 2021, 227, 107237. [Google Scholar] [CrossRef]

- Lu, Y.; Li, Y. A novel data-driven method for maintenance prioritization of circuit breakers based on the ranking SVM. Int. J. Electr. Power Energy Syst. 2021, 129, 106779. [Google Scholar] [CrossRef]

- Velimirovic, J.D.; Janjic, A. Risk assessment of circuit breakers using influence diagrams with interval probabilities. Symmetry 2021, 13, 737. [Google Scholar] [CrossRef]

- Geng, S.; Wang, X. Research on data-driven method for circuit breaker condition assessment based on back propagation neural network. Comput. Electr. Eng. 2020, 86, 106732. [Google Scholar] [CrossRef]

- Dehghanian, P.; Guan, Y.; Kezunovic, M. Real-time life-cycle assessment of high-voltage circuit breakers for maintenance using online condition monitoring data. IEEE Trans. Ind. Appl. 2019, 55, 1135–1146. [Google Scholar] [CrossRef]

- Rodrigues, A.J.S.; Cavakcante, C.A.V.; Lee, C.-G. A general inspection and replacement policy for protection systems subject to shocks with state dependent effect. Reliab. Eng. Syst. Saf. 2024, 251, 110397. [Google Scholar] [CrossRef]

- Geng, S.; Wang, X. Predictive maintenance scheduling for multiple power equipment based on data-driven fault prediction. Comput. Ind. Eng. 2022, 164, 107898. [Google Scholar] [CrossRef]

- Scarpellini, M.; Perdon, K.; Cavalli, L.; Testa, M. Innovative analytics to estimate the probability of failure and remaining useful life of medium-voltage breakers. IET J. 2017, 2017, 2379–2382. [Google Scholar] [CrossRef][Green Version]

| Criteria | Good (0) | Moderate (3) | Poor (5) | Remark |

|---|---|---|---|---|

| Insulation Resistance (GΩ) | ≥1 | <1 | The worst score is used as a representative for further evaluation | |

| Contact Timing Test (%Deviation) | ≤10 | >10 | ||

| Contact Resistance (μΩ) (Model Dependent) | ≤200, 40 | >200, 40 | ||

| SF6 Pressure Inspection | Normal | Alarm #1 | Alarm #2 | |

| SF6 Dew Point (Temperature, °C) | <−10 | >−10 | ||

| SF6 Percentage (Amount of SF6, %) | ≥80 | <80 | ||

| SF6 Purity (%) | ≥99 | <99 | ||

| Amount of SO2 (ppm) | ≤10 | >10 | ||

| Visual Inspection | Normal | Abnormal | ||

| Gas Leakage Rate (times/year) | ≤1 | ≥3 |

| Criteria | Low (0) | Moderate (3) | High (5) | Wi |

|---|---|---|---|---|

| Overall Age | <10 | 11–24 | ≥25 | 30.60 |

| Age of Interrupter | <22 | 23–24 | ≥25 | |

| Age of Mechanism after Overhaul | <10 | 11–24 | ≥25 | |

| Number of Fault Current Interruptions | <4 | 5–8 | ≥9 | |

| Ratio of Load Current to the Rating of the Equipment | <0.6 | 0.6–0.7 | ≥0.8 | 21.00 |

| Ratio of Short-Circuit Current to the Rating of the Equipment | <0.6 | 0.6–0.7 | ≥0.8 | |

| Already Replaced by Advanced Technology | No | - | Yes | 8.20 |

| No Longer Manufactured | No | - | Yes | |

| Spare Parts Availability | Easy to find | Difficult to find, possible to modify | Unable to modify | 20.00 |

| Personnel Expertise Level | Good | Moderate | Poor | |

| OEM Support/After-sale Service Quality | Good | Moderate | Poor | |

| Number of Units Remaining in Use | ≥5 | - | <5 | |

| Operator Level of Satisfaction (Failure Rate) | Satisfied | - | Not satisfied | |

| Major/Minor Failure, Cost and Effort to Repair | Minor defect | - | Major defect | 20.0 |

| Criteria | Low | Moderate | High | Wi |

|---|---|---|---|---|

| 1. Possibility of Equipment Failure | ||||

| 1.1 Short-Circuit Current (kA) | <10 | 10–20 | >20 | 2.559 |

| 1.2 Pollution level (Bird Droppings, Sea Spray) | No | Yes | 2.559 | |

| 2. Severity/Consequence | ||||

| 2.1 Function of Substation | Supply Load | Switching/Terminal | 3.089 | |

| 2.2 Bus Arrangement | Main and Trans. H bus | Double Main and Trans. | Breaker and a Half | 3.089 |

| 2.3 Number of Circuits | <4 | 4–7 | >7 | 1.828 |

| 2.4 Number of Power Transformers | 1 | 2 | 0, 3 | 1.828 |

| 2.5 Available Area for Future Expansion | Greater Area | Limited Area | Unable to Expand | 0.898 |

| 2.6 Safety (Distance from Community) | >3 km | 1–3 km | <1 km | 0.898 |

| 2.7 Public Image | No | Yes | 0.898 | |

| 2.8 Substation Location (Load Importance) | Rural, District | Province | City, Industrial Estate, Tourist Area | 2.694 |

| 2.9 Loading Percentage | <60 | 60–80 | >80 | 33.82 |

| 2.10 Function of Bay | Tie Bay | Transmission Line | Transformer/Line from Power Plant | 29.13 |

| 2.11 Redundancy/Planned Outage | Yes/Long Duration | Sometimes/Short Duration | No | 15.71 |

| (%PoF, %CI, %RI) | No. of Units | (%PoF, %CI, %RI) | No. of Units | (%PoF, %CI, %RI) | No. of Units | (%PoF, %CI, %RI) | No. of Units |

|---|---|---|---|---|---|---|---|

| (6, 35.51, 12) | 1 | (15.18, 43.95, 30.36) | 2 | (27.66, 40.50, 55.32) | 1 | (69.28, 23.86, 38.56) | 3 |

| (6, 40.70, 12) | 2 | (15.18, 46.43, 30.36) | 1 | (27.66, 52.15, 55.32) | 2 | (69.28, 26.73, 38.56) | 2 |

| (6, 42.74, 12) | 1 | (15.18, 47.93, 30.36) | 3 | (27.66, 52.15, 55.32) | 1 | (69.28, 38.38, 38.56) | 1 |

| (6, 43.95, 12) | 2 | (15.18, 54.16, 30.36) | 2 | (56, 20.73, 12) | 1 | (69.28, 41.79, 38.56) | 1 |

| (6, 44.66, 12) | 2 | (15.18, 54.39, 30.36) | 8 | (56, 32.38, 12) | 1 | (69.28, 44.67, 38.56) | 4 |

| (6, 52.35, 12) | 1 | (15.18, 55.60, 30.36) | 2 | (56, 39.37, 12) | 1 | (69.28, 47.16, 38.56) | 1 |

| (6, 59.60, 12) | 6 | (15.18, 59.59, 30.36) | 9 | (56, 44.03, 12) | 1 | (69.28, 53.44, 38.56) | 3 |

| (9.18, 23.86, 18.36) | 1 | (15.54, 48.16, 31.08) | 2 | (56, 46.79, 12) | 1 | (69.28, 56.32, 38.56) | 2 |

| (9.18, 35.51, 18.36) | 1 | (19.28, 21.09, 38.56) | 1 | (56, 47.70, 12) | 1 | (71.3, 44.31, 42.6) | 1 |

| (9.18, 47.16, 18.36) | 2 | (19.28, 22.523, 38.56) | 2 | (56, 50.95, 12) | 1 | (71.3, 56.32, 42.6) | 1 |

| (9.18, 49.26, 18.36) | 6 | (19.28, 27.90, 38.56) | 1 | (56, 61.27, 12) | 12 | (75.64, 49.44, 51.28) | 1 |

| (9.18, 60.91, 18.36) | 6 | (19.28, 44.39, 38.56) | 1 | (57.66, 28.84, 55.32) | 1 | (75.64, 55.72, 51.28) | 1 |

| (15.18, 23.12,30.36) | 1 | (19.28, 45.83, 38.56) | 3 | (65.18, 23.48, 30.36) | 1 | (75.9, 53.37, 51.8) | 1 |

| (15.18, 30.86, 30.36) | 1 | (19.28, 50.678, 38.56) | 1 | (65.18, 35.14, 30.36) | 2 | (79.88, 31.47, 59.76) | 1 |

| (15.18, 32.29, 30.36) | 1 | (19.28, 51.20, 38.56) | 2 | (65.18, 35.51, 30.36) | 1 | (79.88, 49.41, 59.76 | 3 |

| (15.18, 34.78, 30.36) | 2 | (25.64, 48.16, 51.28) | 6 | (65.18, 46.79, 30.36) | 1 | (79.88, 61.06, 59.76) | 6 |

| (15.18, 42.51, 30.36) | 2 | (25.64, 59.81, 51.28) | 3 | (65.3, 44.31, 30.6) | 1 | total no. of PCBs | 149 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumpalavalee, S.; Suwanasri, T.; Suwanasri, C.; Phadungthin, R. Risk Assessment Framework for Power Circuit Breakers Based on Condition, Replacement, and Criticality Indices. Energies 2025, 18, 3298. https://doi.org/10.3390/en18133298

Kumpalavalee S, Suwanasri T, Suwanasri C, Phadungthin R. Risk Assessment Framework for Power Circuit Breakers Based on Condition, Replacement, and Criticality Indices. Energies. 2025; 18(13):3298. https://doi.org/10.3390/en18133298

Chicago/Turabian StyleKumpalavalee, Suphon, Thanapong Suwanasri, Cattareeya Suwanasri, and Rattanakorn Phadungthin. 2025. "Risk Assessment Framework for Power Circuit Breakers Based on Condition, Replacement, and Criticality Indices" Energies 18, no. 13: 3298. https://doi.org/10.3390/en18133298

APA StyleKumpalavalee, S., Suwanasri, T., Suwanasri, C., & Phadungthin, R. (2025). Risk Assessment Framework for Power Circuit Breakers Based on Condition, Replacement, and Criticality Indices. Energies, 18(13), 3298. https://doi.org/10.3390/en18133298