A Review of Phase-Change Material-Based Thermal Batteries for Sustainable Energy Storage of Solar Photovoltaic Systems Coupled to Heat Pumps in the Building Sector

Abstract

1. Introduction

2. Background

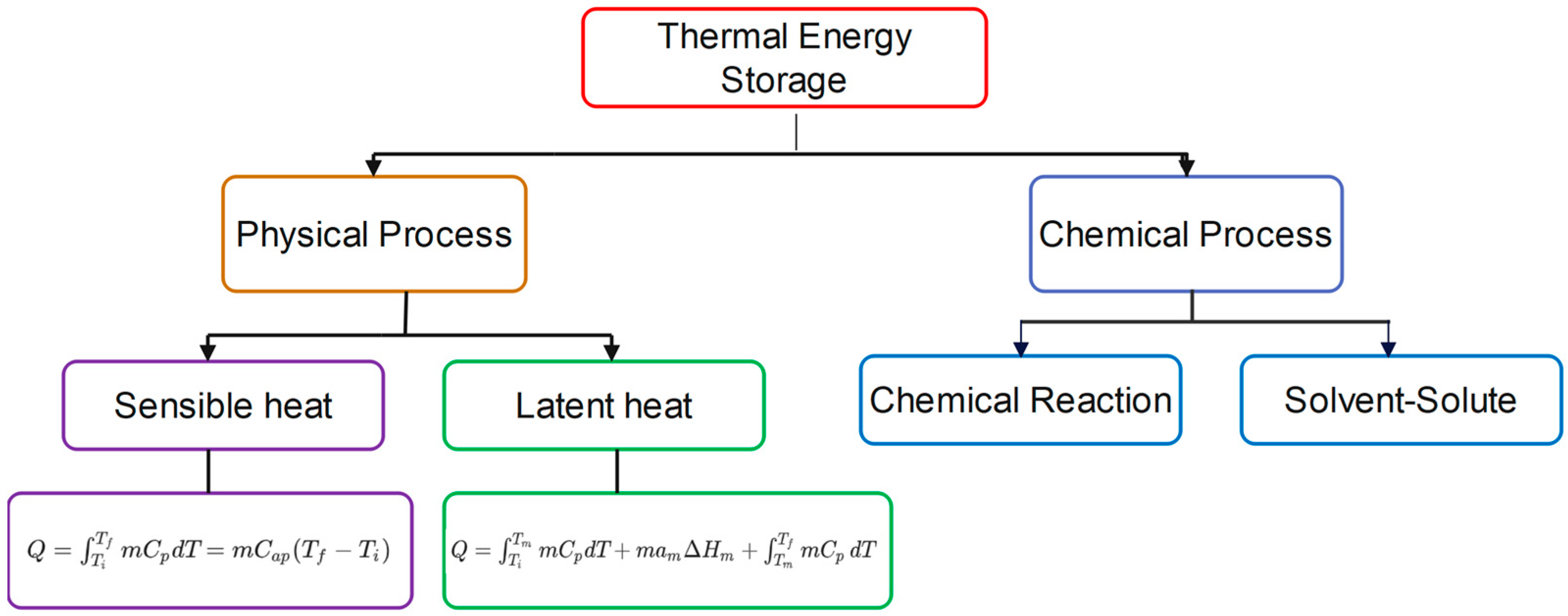

2.1. Thermal Energy Storage

2.1.1. Latent Heat Storage

- (i)

- Thermal Properties

- ○

- Suitable phase-transition temperature: The PCM should match the operating temperature of the heating or cooling application.

- ○

- High latent heat of transition: A high latent heat, especially on a volumetric basis, minimizes the physical size of the storage unit.

- ○

- Good heat transfer: High thermal conductivity facilitates efficient charging and discharging of stored energy.

- (ii)

- Physical Properties

- ○

- Favorable phase equilibrium: Stable phase changes during heating and cooling cycles are desirable.

- ○

- High density: Allows for a more compact storage container, reducing space requirements.

- ○

- Small volume change: Minimal volume expansion or contraction during phase transitions helps maintain structural integrity.

- ○

- Low vapor pressure: Low vapor pressure at operating temperatures reduces the risk of containment issues.

- (iii)

- Kinetic Properties

- ○

- No supercooling: The PCM should avoid supercooling, which can hinder proper heat extraction, especially if it exceeds 5–10 °C.

- ○

- Sufficient crystallization rate: The PCM should crystallize efficiently to release stored heat effectively.

- (iv)

- Chemical Properties

- ○

- Long-term chemical stability: The PCM should maintain stability over time without significant degradation.

- ○

- Compatibility with construction materials: The PCM should not react with or corrode materials used in the storage system.

- ○

- No toxicity: It must be safe for human health.

- ○

- No fire hazard: It should be non-flammable and non-explosive to ensure safety.

- (v)

- Economic Considerations

- ○

- Abundant: It should be readily available in large quantities.

- ○

- Available: Easy access to the PCM in the market is crucial.

- ○

- Cost-effective: It should be affordable for large-scale applications.

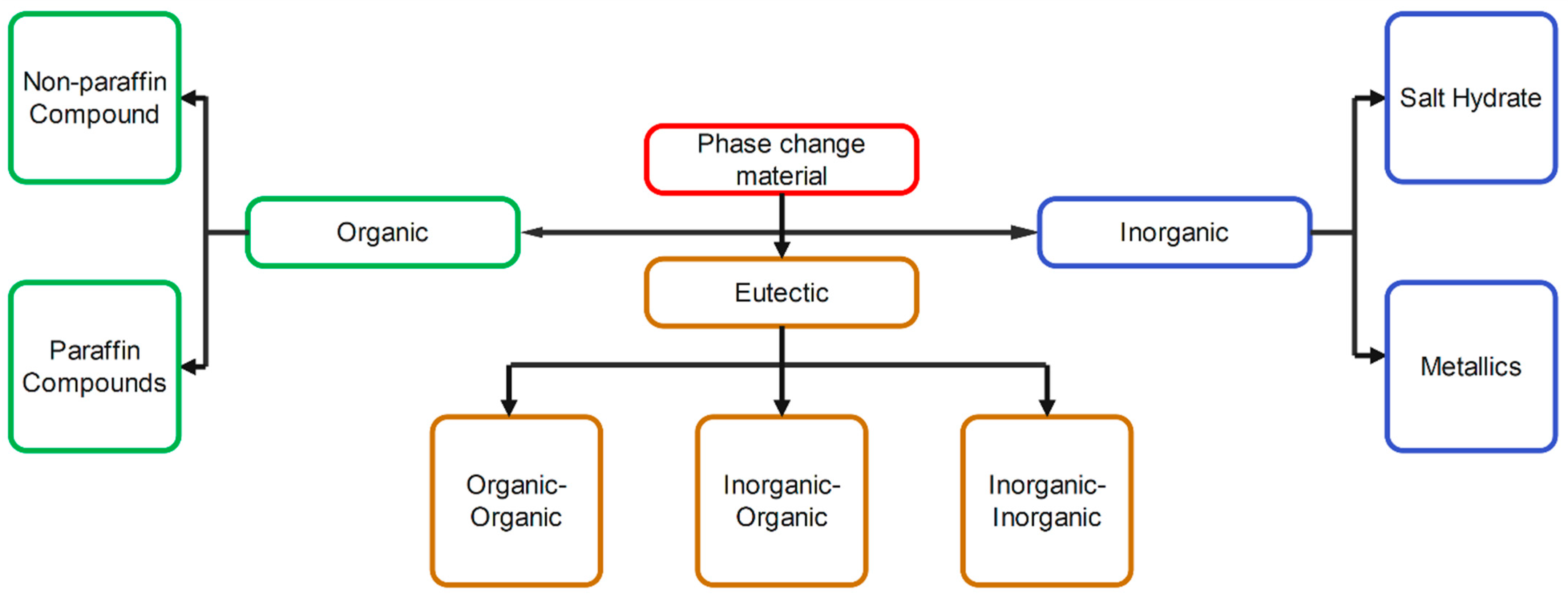

2.1.2. Classification of PCM

2.1.3. Temperature Ranges for PCMs

2.2. Application of PCM-Based Thermal Energy Storage in Different Fields

PCM-Based TES Application in Buildings

2.3. Modelling of PCM-Based TES

- (i)

- Building physics envelopes heat and mass transfer

- (ii)

- Computational fluid dynamics software

- (iii)

- Energy system simulation software

3. PCM-Based TES Integration with Renewable and Mechanical Systems

3.1. Integration of Solar Photovoltaics (PV) with PCM-TES

| PCM Type | Method of Analysis | System Configuration | Location/ Year | Results | Reference |

|---|---|---|---|---|---|

| n-Octadecane | Numerical + experimental | PV/PCM/Thermoelectric generator (TEG) | Laboratory/2010 |

| [255] |

| OM 29 | Experimental | PV-PCM+ aluminum plate | Chennai, India/2019 |

| [256] |

| Paraffin wax | Experimental | PV module, PV-PCM, PV-PCM-thermal | Shanghai, China/2019 |

| [248] |

| Paraffin wax | Experimental + numerical | PCM matrix placed 6mm below the panel | Phitsanulok, Thailand/2020 |

| [257] |

| (i) 82wt% coconut oil + 18wt% sunflower oil. (ii)(i) + Boehmite nano powder | Experimental | Modified geometry of PCM container: PV, PV+composed oil PCM, PV + nano-composed oil | Laboratory/2020 |

| [258] |

| Refined paraffin wax | Numerical +experimental | PCM-embedded PV panel | Laboratory/2021 |

| [224] |

| Paraffin RT27 | Numerical + experimental | PCM encases with PV panel | Chania, Greece/2023 |

| [259] |

| HS 29 | Experimental | PV-PCM embedded with fins placed in still water | Madurai, India/2024 |

| [228] |

3.2. Integration of HP with PCM-TES

- (i)

- Based on driving energy: Electric-driven, heat-driven

- (ii)

- Based on thermal sources: Air source HP (ASHP), water source HP (WSHP), groundwater source HP (GSHP), solar-assisted HP (SAHP), and waste heat source HP (WHSHP).

- (iii)

- Based on temperature range: Low temperature (<60 °C), medium temperature (60–100 °C), high temperature (100–200 °C), and ultra-high temperature (>200 °C)

| PCM Type | HP Type | Software Simulation | Results | Refs. |

|---|---|---|---|---|

| Paraffin | Air–Water HP | Numerical |

| [295] |

| Paraffin | Low-temperature ASHP | Numerical |

| [297] |

| Modified CH3COONa·3H2O Composite PCM (CPCM) | ASHP | Experimental |

| [298] |

| Modified CH3COONa·3H2O | Hot water HP | Experimental |

| [299] |

| Lauric acid | GSHP | Numerical |

| [300] |

| Palmitic acid | HP | Numerical+ TRNSYS |

| [301] |

| PCM | ASHP | TRNSYS |

| [302] |

| PCM | GSHP | Numerical |

| [303] |

| PCM | Horizontal GSHP | TRNSYS |

| [304] |

| Paraffin | ASHP | MATLAB+TRNSYS |

| [305] |

| Paraffin | ASHP | Experimental |

| [306] |

| Stearic acid–graphite | HP | Numerical+MATLAB-Simulink |

| [47] |

| Paraffin/fatty alcohol | Geothermal HP | Experimental |

| [307] |

| Paraffin | ASHP | Mathematical |

| [308] |

| Paraffin | ASHP | Experimental |

| [309] |

| Expanded graphite/paraffin (EGP) | ASHP water heater | Experimental |

| [310] |

| Paraffin | ASHP | Experimental + Mathematical |

| [311] |

| Enhanced acid | GSHP | Numerical |

| [312] |

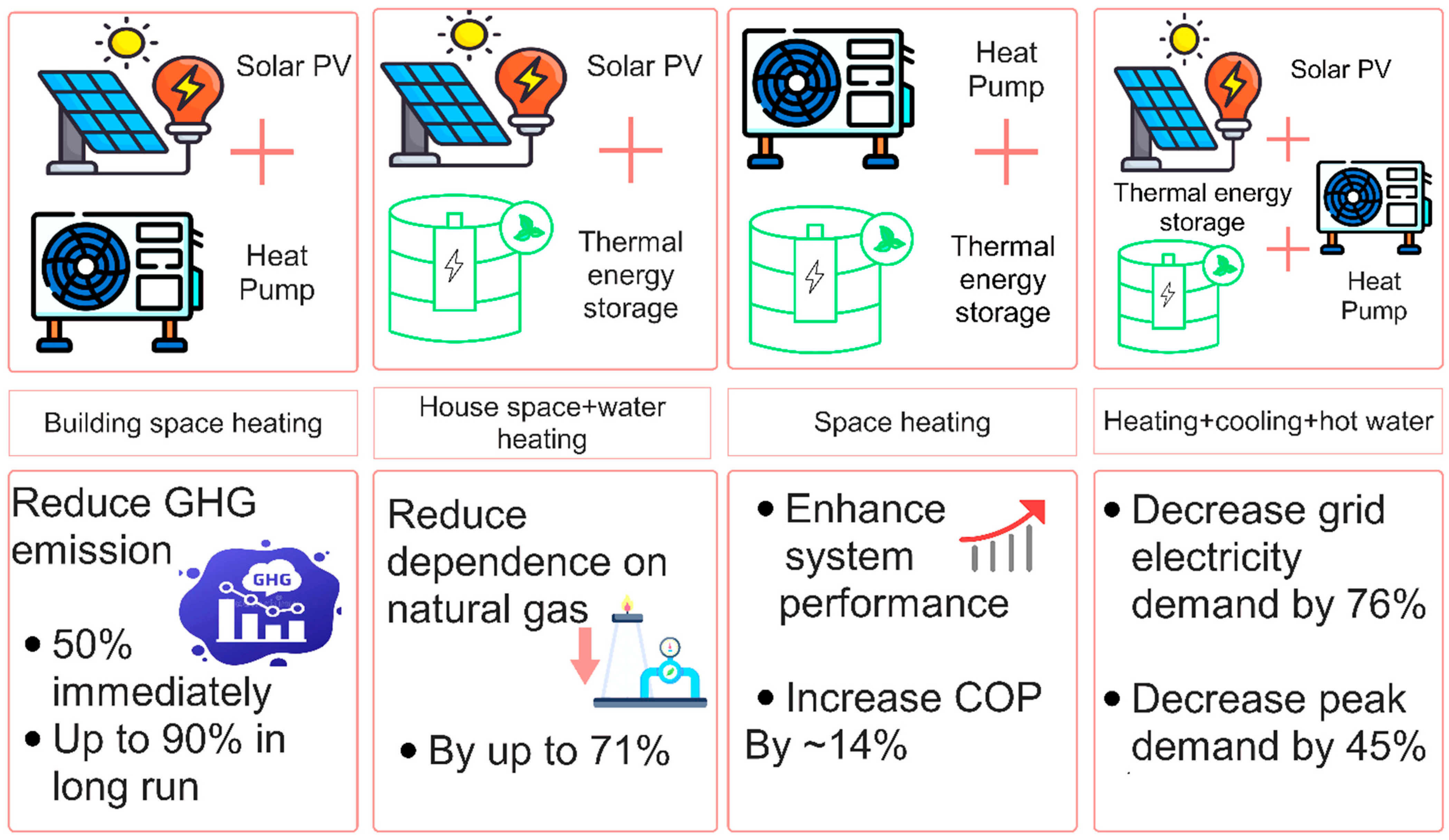

3.3. Integration of Solar PV, HP, and PCM-TES

4. Discussion

5. Conclusions and Policy Implications

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Darmstadter, J.; Teitelbaum, P.D.; Polach, J.G. Energy in the World Economy; National Academic: Washington, DC, USA, 1970. [Google Scholar]

- Ritchie, H.; Rosado, P.; Roser, M. Energy Production and Consumption; Our World in Data: Oxford, UK, 2024. [Google Scholar]

- IEA World—World Energy Balances: Overview—Analysis. Available online: https://www.iea.org/reports/world-energy-balances-overview/world (accessed on 28 August 2024).

- IEA. World Energy Outlook 2017—Analysis. Available online: https://www.iea.org/reports/world-energy-outlook-2017 (accessed on 28 August 2024).

- IEA. Transition to Sustainable Buildings—Analysis. Available online: https://www.iea.org/reports/transition-to-sustainable-buildings (accessed on 28 August 2024).

- Ritchie, H.; Rosado, P.; Roser, M. Energy Mix; Our World in Data: Oxford, UK, 2024. [Google Scholar]

- Ge, M.; Friedrich, J.; Vigna, L. Where Do Emissions Come From? 4 Charts Explain Greenhouse Gas Emissions by Sector; World Resources Institute: Washington, DC, USA, 2024. [Google Scholar]

- United Nations. Renewable Energy—Powering a Safer Future. Available online: https://www.un.org/en/climatechange/raising-ambition/renewable-energy (accessed on 28 August 2024).

- European Parliament. What Is Carbon Neutrality and How Can It Be Achieved by 2050? Available online: https://www.europarl.europa.eu/topics/en/article/20190926STO62270/what-is-carbon-neutrality-and-how-can-it-be-achieved-by-2050 (accessed on 8 February 2025).

- Kumar, C.M.S.; Singh, S.; Gupta, M.K.; Nimdeo, Y.M.; Raushan, R.; Deorankar, A.V.; Kumar, T.A.; Rout, P.K.; Chanotiya, C.; Pakhale, V.D.; et al. Solar Energy: A Promising Renewable Source for Meeting Energy Demand in Indian Agriculture Applications. Sustain. Energy Technol. Assess. 2023, 55, 102905. [Google Scholar] [CrossRef]

- Pearce, J.M. Photovoltaics—A Path to Sustainable Futures. Futures 2002, 34, 663–674. [Google Scholar] [CrossRef]

- Creutzig, F.; Agoston, P.; Goldschmidt, J.C.; Luderer, G.; Nemet, G.; Pietzcker, R.C. The Underestimated Potential of Solar Energy to Mitigate Climate Change. Nat. Energy 2017, 2, 17140. [Google Scholar] [CrossRef]

- Power Quality Understanding Solar Photovoltaic (PV) Power Generation; Power Quality Blog: Bangkok, Thailand, 2023.

- Osmani, K.; Haddad, A.; Lemenand, T.; Castanier, B.; Ramadan, M. A Review on Maintenance Strategies for PV Systems. Sci. Total Environ. 2020, 746, 141753. [Google Scholar] [CrossRef]

- Wigness, S. What Is the Carbon Footprint of Solar Panels? 2023. Available online: https://www.solar.com/ (accessed on 8 February 2025).

- IRENA. Renewable Power Generation Costs in 2017. Available online: https://www.irena.org/publications/2018/Jan/Renewable-power-generation-costs-in-2017 (accessed on 7 May 2024).

- IRENA. Future of Photovoltaic. Available online: https://www.irena.org/publications/2019/Nov/Future-of-Solar-Photovoltaic (accessed on 7 March 2024).

- IEA Solar. Available online: https://www.iea.org/energy-system/renewables/solar-pv (accessed on 12 September 2024).

- Luthander, R.; Widén, J.; Nilsson, D.; Palm, J. Photovoltaic Self-Consumption in Buildings: A Review. Appl. Energy 2015, 142, 80–94. [Google Scholar] [CrossRef]

- Rana, S.; Jamil, U.; Asgari, N.; Hayibo, K.S.; Groza, J.; Pearce, J.M. Residential Sizing of Solar Photovoltaic Systems and Heat Pumps for Net Zero Sustainable Thermal Building Energy. Computation 2024, 12, 126. [Google Scholar] [CrossRef]

- Bonneville Power Adminstration. Intermittent Renewable Energy. Available online: https://www.bpa.gov/energy-and-services/efficiency/demand-response/intermittent-renewable-energy (accessed on 28 August 2024).

- Ali, H.M.; Rehman, T.; Arıcı, M.; Said, Z.; Duraković, B.; Mohammed, H.I.; Kumar, R.; Rathod, M.K.; Buyukdagli, O.; Teggar, M. Advances in Thermal Energy Storage: Fundamentals and Applications. Progress. Energy Combust. Sci. 2024, 100, 101109. [Google Scholar] [CrossRef]

- IEA. Executive Summary—Electricity 2024—Analysis. Available online: https://www.iea.org/reports/electricity-2024/executive-summary (accessed on 28 August 2024).

- IESO. Global Adjustment (GA). Available online: https://www.ieso.ca/power-data/price-overview/global-adjustment (accessed on 28 August 2024).

- Sinsel, S.R.; Riemke, R.L.; Hoffmann, V.H. Challenges and Solution Technologies for the Integration of Variable Renewable Energy Sources—A Review. Renew. Energy 2020, 145, 2271–2285. [Google Scholar] [CrossRef]

- Mehling, H.; Cabeza, L.F. Heat and Cold Storage with PCM. In Heat and Mass Transfer; Springer: Berlin/Heidelberg, Germany, 2008; pp. 11–55. [Google Scholar]

- Muzhanje, A.T.; Hassan, M.A.; Hassan, H. Phase Change Material Based Thermal Energy Storage Applications for Air Conditioning. Appl. Therm. Eng. 2022, 214, 118832. [Google Scholar] [CrossRef]

- Koohi-Fayegh, S.; Rosen, M.A. A Review of Energy Storage Types, Applications and Recent Developments. J. Energy Storage 2020, 27, 101047. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Martorell, I.; Miró, L.; Fernández, A.I.; Barreneche, C. 1—Introduction to Thermal Energy Storage (TES) Systems. In Advances in Thermal Energy Storage Systems; Cabeza, L.F., Ed.; Woodhead Publishing Series in Energy; Woodhead Publishing: Cambridge, UK, 2015; pp. 1–28. ISBN 978-1-78242-088-0. [Google Scholar]

- Jouhara, H.; Żabnieńska-Góra, A.; Khordehgah, N.; Ahmad, D.; Lipinski, T. Latent Thermal Energy Storage Technologies and Applications: A Review. Int. J. Thermofluids 2020, 5–6, 100039. [Google Scholar] [CrossRef]

- Badenhorst, H. A Review of the Application of Carbon Materials in Solar Thermal Energy Storage. Sol. Energy 2019, 192, 35–68. [Google Scholar] [CrossRef]

- Palacios, A.; Cong, L.; Navarro, M.E.; Ding, Y.; Barreneche, C. Thermal Conductivity Measurement Techniques for Characterizing Thermal Energy Storage Materials—A Review. Renew. Sustain. Energy Rev. 2019, 108, 32–52. [Google Scholar] [CrossRef]

- Gasia, J.; Miró, L.; Cabeza, L.F. Review on System and Materials Requirements for High Temperature Thermal Energy Storage. Part 1: General Requirements. Renew. Sustain. Energy Rev. 2017, 75, 1320–1338. [Google Scholar] [CrossRef]

- Sarbu, I.; Sebarchievici, C. A Comprehensive Review of Thermal Energy Storage. Sustainability 2018, 10, 191. Available online: https://www.mdpi.com/2071-1050/10/1/191 (accessed on 26 September 2024). [CrossRef]

- Kalidasan, B.; Pandey, A.K. Next Generation Phase Change Materials: State-of-the-Art towards Sustainable Future. Progress. Mater. Sci. 2025, 148, 101380. [Google Scholar] [CrossRef]

- Bland, A.; Khzouz, M.; Statheros, T.; Gkanas, E.I. PCMs for Residential Building Applications: A Short Review Focused on Disadvantages and Proposals for Future Development. Buildings 2017, 7, 78. [Google Scholar] [CrossRef]

- Aridi, R.; Yehya, A. Review on the Sustainability of Phase-Change Materials Used in Buildings. Energy Convers. Manag. X 2022, 15, 100237. [Google Scholar] [CrossRef]

- Singh Rathore, P.K.; Shukla, S.K.; Gupta, N.K. Potential of Microencapsulated PCM for Energy Savings in Buildings: A Critical Review. Sustain. Cities Soc. 2020, 53, 101884. [Google Scholar] [CrossRef]

- Elias, C.N.; Stathopoulos, V.N. A Comprehensive Review of Recent Advances in Materials Aspects of Phase Change Materials in Thermal Energy Storage. Energy Procedia 2019, 161, 385–394. [Google Scholar] [CrossRef]

- Mselle, B.D.; Zsembinszki, G.; Vérez, D.; Borri, E.; Cabeza, L.F. A Detailed Energy Analysis of a Novel Evaporator with Latent Thermal Energy Storage Ability. Appl. Therm. Eng. 2022, 201, 117844. [Google Scholar] [CrossRef]

- Farid, M.M.; Khudhair, A.M.; Razack, S.A.K.; Al-Hallaj, S. A Review on Phase Change Energy Storage: Materials and Applications. Energy Convers. Manag. 2004, 45, 1597–1615. [Google Scholar] [CrossRef]

- Khudhair, A.M.; Farid, M. A Review on Energy Conservation in Building Applications with Thermal Storage by Latent Heat Using Phase Change Materials. In Thermal Energy Storage with Phase Change Materials; CRC Press: Boca Raton, FL, USA, 2021; ISBN 978-0-367-56769-9. [Google Scholar]

- Agyenim, F.; Hewitt, N.; Eames, P.; Smyth, M. A Review of Materials, Heat Transfer and Phase Change Problem Formulation for Latent Heat Thermal Energy Storage Systems (LHTESS). Renew. Sustain. Energy Rev. 2010, 14, 615–628. [Google Scholar] [CrossRef]

- Lane, G.A. Solar Heat Storage: Latent Heat Materials; CRC Press: Boca Raton, FL, USA, 1983. [Google Scholar]

- Li, Q.; Li, C.; Du, Z.; Jiang, F.; Ding, Y. A Review of Performance Investigation and Enhancement of Shell and Tube Thermal Energy Storage Device Containing Molten Salt Based Phase Change Materials for Medium and High Temperature Applications. Appl. Energy 2019, 255, 113806. [Google Scholar] [CrossRef]

- Fallahi, A.; Guldentops, G.; Tao, M.; Granados-Focil, S.; Van Dessel, S. Review on Solid-Solid Phase Change Materials for Thermal Energy Storage: Molecular Structure and Thermal Properties. Appl. Therm. Eng. 2017, 127, 1427–1441. [Google Scholar] [CrossRef]

- Inkeri, E.; Tynjälä, T.; Nikku, M. Numerical Modeling of Latent Heat Thermal Energy Storage Integrated with Heat Pump for Domestic Hot Water Production. Appl. Therm. Eng. 2022, 214, 118819. [Google Scholar] [CrossRef]

- Magendran, S.S.; Khan, F.S.A.; Mubarak, N.M.; Vaka, M.; Walvekar, R.; Khalid, M.; Abdullah, E.C.; Nizamuddin, S.; Karri, R.R. Synthesis of Organic Phase Change Materials (PCM) for Energy Storage Applications: A Review. Nano-Struct. Nano-Objects 2019, 20, 100399. [Google Scholar] [CrossRef]

- Rathore, P.K.S.; Shukla, S.K. Potential of Macroencapsulated PCM for Thermal Energy Storage in Buildings: A Comprehensive Review. Constr. Build. Mater. 2019, 225, 723–744. [Google Scholar] [CrossRef]

- Sharma, A.; Tyagi, V.V.; Chen, C.R.; Buddhi, D. Review on Thermal Energy Storage with Phase Change Materials and Applications. Renew. Sustain. Energy Rev. 2009, 13, 318–345. [Google Scholar] [CrossRef]

- Tyagi, V.V.; Buddhi, D. PCM Thermal Storage in Buildings: A State of Art. Renew. Sustain. Energy Rev. 2007, 11, 1146–1166. [Google Scholar] [CrossRef]

- Jose, N.; Ravindra, M.R. Microencapsulation Approaches for the Development of Novel Thermal Energy Storage Systems and Their Applications. Sol. Energy Mater. Sol. Cells 2025, 280, 113271. [Google Scholar] [CrossRef]

- Nagano, K.; Mochida, T.; Takeda, S.; Domański, R.; Rebow, M. Thermal Characteristics of Manganese (II) Nitrate Hexahydrate as a Phase Change Material for Cooling Systems. Appl. Therm. Eng. 2003, 23, 229–241. [Google Scholar] [CrossRef]

- Moorthy, A.S. Chapter 4—Melting and Solidification of Fats. In Structure-Function Analysis of Edible Fats, 2nd ed.; Marangoni, A.G., Ed.; AOCS Press: Champaign, IL, USA, 2018; pp. 101–118. ISBN 978-0-12-814041-3. [Google Scholar]

- Hawes, D.W.; Feldman, D.; Banu, D. Latent Heat Storage in Building Materials. Energy Build. 1993, 20, 77–86. [Google Scholar] [CrossRef]

- Feldman, D.; Shapiro, M.M.; Banu, D. Organic Phase Change Materials for Thermal Energy Storage. Sol. Energy Mater. 1986, 13, 1–10. [Google Scholar] [CrossRef]

- Paris, J.; Falardeau, M.; Villeneuve, C. Thermal Storage by Latent Heat: A Viable Option for Energy Conservation in Buildings. Energy Sources 1993, 15, 85–93. [Google Scholar] [CrossRef]

- Abhat, A. Low Temperature Latent Heat Thermal Energy Storage: Heat Storage Materials. Sol. Energy 1983, 30, 313–332. [Google Scholar] [CrossRef]

- Babich, M.W.; Benrashid, R.; Mounts, R.D. DSC Studies of New Energy Storage Materials. Part 3. Thermal and Flammability Studies. Thermochim. Acta 1994, 243, 193–200. [Google Scholar] [CrossRef]

- Dincer, I. On Thermal Energy Storage Systems and Applications in Buildings. Energy Build. 2002, 34, 377–388. [Google Scholar] [CrossRef]

- Kaizawa, A.; Maruoka, N.; Kawai, A.; Kamano, H.; Jozuka, T.; Senda, T.; Akiyama, T. Thermophysical and Heat Transfer Properties of Phase Change Material Candidate for Waste Heat Transportation System. Heat. Mass. Transf. 2008, 44, 763–769. [Google Scholar] [CrossRef]

- Naumann, R.; Emons, H.-H. Results of Thermal Analysis for Investigation of Salt Hydrates as Latent Heat-Storage Materials. J. Therm. Anal. 1989, 35, 1009–1031. [Google Scholar] [CrossRef]

- Wada, T.; Yokotani, F.; Matsuo, Y. Equilibria in the Aqueous Ternary System Containing Na+, CH3CO2−, and P2O74− between 38 and 85 °C. Bull. Chem. Soc. Jpn. 1984, 57, 1671–1672. [Google Scholar] [CrossRef]

- Din¿er, I.; Rosen, M.A. Thermal Energy Storage: Systems and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2011; ISBN 978-1-119-95662-4. [Google Scholar]

- Heckenkamp, J.; Baumann, H. Sonderdruck Aus Nachrichten. Latent Warme Speicher 1997, 11, 1075–1081. [Google Scholar]

- Hasnain, S.M. Review on Sustainable Thermal Energy Storage Technologies, Part I: Heat Storage Materials and Techniques. Energy Convers. Manag. 1998, 39, 1127–1138. [Google Scholar] [CrossRef]

- Heine, D.; Heess, F. Chemische Und Physikalische Eigenschaften von Latentwaermespeichermaterialien Fuer Solarkraftwerke. 1980. Available online: https://pascal-francis.inist.fr/vibad/index.php?action=getRecordDetail&idt=PASCAL8130287832 (accessed on 25 September 2024).

- Carbon-Enhanced Hydrated Salt Phase Change Materials for Thermal Management Applications. Available online: https://www.mdpi.com/2079-4991/14/13/1077?utm_source=chatgpt.com (accessed on 9 June 2025).

- Department of Energy Low-Cost Composite Phase Change Material. Available online: https://www.energy.gov/eere/buildings/articles/low-cost-composite-phase-change-material (accessed on 2 October 2024).

- Choo, Y.M.; Wei, W. Salt Hydrates as Phase Change Materials for Photovoltaics Thermal Management. Energy Sci. Eng. 2022, 10, 1630–1642. [Google Scholar] [CrossRef]

- A Review of Composite Phase Change Materials Based on Porous Silica Nanomaterials for Latent Heat Storage Applications. Available online: https://www.mdpi.com/1420-3049/26/1/241?utm_source=chatgpt.com (accessed on 9 June 2025).

- Royon, L.; Guiffant, G.; Flaud, P. Investigation of Heat Transfer in a Polymeric Phase Change Material for Low Level Heat Storage. Energy Convers. Manag. 1997, 38, 517–524. [Google Scholar] [CrossRef]

- Li, J.-H.; Zhang, G.; Wang, J.-Y. Investigation of a Eutectic Mixture of Sodium Acetate Trihydrate and Urea as Latent Heat Storage. Sol. Energy 1991, 47, 443–445. [Google Scholar] [CrossRef]

- Wada, T.; Kimura, F.; Yamamoto, R. Studies on Salt Hydrate for Latent Heat Storage. III. Pseudo-Binary System, CH3CO2Na·3H2O–HCONH2. Bull. Chem. Soc. Jpn. 1983, 56, 1575–1576. [Google Scholar] [CrossRef]

- Maldonado, J.M.; Fullana-Puig, M.; Martín, M.; Solé, A.; Fernández, Á.G.; De Gracia, A.; Cabeza, L.F. Phase Change Material Selection for Thermal Energy Storage at High Temperature Range between 210 °C and 270 °C. Energies 2018, 11, 861. [Google Scholar] [CrossRef]

- Kahwaji, S.; White, M.A. Organic Phase Change Materials for Thermal Energy Storage: Influence of Molecular Structure on Properties. Molecules 2021, 26, 6635. [Google Scholar] [CrossRef]

- Du, K.; Calautit, J.; Wang, Z.; Wu, Y.; Liu, H. A Review of the Applications of Phase Change Materials in Cooling, Heating and Power Generation in Different Temperature Ranges. Appl. Energy 2018, 220, 242–273. [Google Scholar] [CrossRef]

- Gude, V.G. Energy Storage for Desalination Processes Powered by Renewable Energy and Waste Heat Sources. Appl. Energy 2015, 137, 877–898. [Google Scholar] [CrossRef]

- Gude, V.G.; Nirmalakhandan, N.; Deng, S. Renewable and Sustainable Approaches for Desalination. Renew. Sustain. Energy Rev. 2010, 14, 2641–2654. [Google Scholar] [CrossRef]

- Wongsuwan, W.; Kumar, S.; Neveu, P.; Meunier, F. A Review of Chemical Heat Pump Technology and Applications. Appl. Therm. Eng. 2001, 21, 1489–1519. [Google Scholar] [CrossRef]

- Meunier, F. Solid Sorption: An Alternative to CFCs. Heat. Recovery Syst. CHP 1993, 13, 289–295. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Castell, A.; Barreneche, C.; de Gracia, A.; Fernández, A.I. Materials Used as PCM in Thermal Energy Storage in Buildings: A Review. Renew. Sustain. Energy Rev. 2011, 15, 1675–1695. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, G.; Lin, K.; Zhang, Q.; Di, H. Application of Latent Heat Thermal Energy Storage in Buildings: State-of-the-Art and Outlook. Build. Environ. 2007, 42, 2197–2209. [Google Scholar] [CrossRef]

- Mazman, M.; Cabeza, L.F.; Mehling, H.; Nogues, M.; Evliya, H.; Paksoy, H.Ö. Utilization of Phase Change Materials in Solar Domestic Hot Water Systems. Renew. Energy 2009, 34, 1639–1643. [Google Scholar] [CrossRef]

- Srikhirin, P.; Aphornratana, S.; Chungpaibulpatana, S. A Review of Absorption Refrigeration Technologies. Renew. Sustain. Energy Rev. 2001, 5, 343–372. [Google Scholar] [CrossRef]

- Demir, H.; Mobedi, M.; Ülkü, S. A Review on Adsorption Heat Pump: Problems and Solutions. Renew. Sustain. Energy Rev. 2008, 12, 2381–2403. [Google Scholar] [CrossRef]

- Kalogirou, S. The Potential of Solar Industrial Process Heat Applications. Appl. Energy 2003, 76, 337–361. [Google Scholar] [CrossRef]

- Nomura, T.; Okinaka, N.; Akiyama, T. Technology of Latent Heat Storage for High Temperature Application: A Review. ISIJ Int. 2010, 50, 1229–1239. [Google Scholar] [CrossRef]

- Brückner, S.; Liu, S.; Miró, L.; Radspieler, M.; Cabeza, L.F.; Lävemann, E. Industrial Waste Heat Recovery Technologies: An Economic Analysis of Heat Transformation Technologies. Appl. Energy 2015, 151, 157–167. [Google Scholar] [CrossRef]

- Kenisarin, M.; Mahkamov, K. Solar Energy Storage Using Phase Change Materials. Renew. Sustain. Energy Rev. 2007, 11, 1913–1965. [Google Scholar] [CrossRef]

- Medrano, M.; Gil, A.; Martorell, I.; Potau, X.; Cabeza, L.F. State of the Art on High-Temperature Thermal Energy Storage for Power Generation. Part 2—Case Studies. Renew. Sustain. Energy Rev. 2010, 14, 56–72. [Google Scholar] [CrossRef]

- Pielichowska, K.; Pielichowski, K. Phase Change Materials for Thermal Energy Storage. Progress. Mater. Sci. 2014, 65, 67–123. [Google Scholar] [CrossRef]

- Patapoutian, A.; Peier, A.M.; Story, G.M.; Viswanath, V. ThermoTRP Channels and beyond: Mechanisms of Temperature Sensation. Nat. Rev. Neurosci. 2003, 4, 529–539. [Google Scholar] [CrossRef]

- Kandasamy, R.; Wang, X.-Q.; Mujumdar, A.S. Application of Phase Change Materials in Thermal Management of Electronics. Appl. Therm. Eng. 2007, 27, 2822–2832. [Google Scholar] [CrossRef]

- ASHRAE’s Data Center Thermal Guidelines- Air-Cooled Evolution—ProQuest. Available online: https://www.proquest.com/openview/88be386805fe446ba0cd9e80d4e14f00/1?cbl=41118&pq-origsite=gscholar&parentSessionId=meB2L2IqOFLzrxPJoM2v1Rgqxc%2FBN07mHpmNiwWD8CQ%3D (accessed on 26 September 2024).

- Larson, W.J.; Wertz, J.R. Space Mission Analysis and Design; Space Technology Library: New York, NY, USA, 1999. [Google Scholar]

- Dincer, I. Heat Transfer in Food Cooling Applications; CRC Press: Boca Raton, FL, USA, 2023; ISBN 978-1-00-307540-0. [Google Scholar]

- Mondieig, D.; Rajabalee, F.; Laprie, A.; Oonk, H.A.J.; Calvet, T.; Angel Cuevas-Diarte, M. Protection of Temperature Sensitive Biomedical Products Using Molecular Alloys as Phase Change Material. Transfus. Apher. Sci. 2003, 28, 143–148. [Google Scholar] [CrossRef]

- Johnson, R.W.; Evans, J.L.; Jacobsen, P.; Thompson, J.R.; Christopher, M. The Changing Automotive Environment: High-Temperature Electronics. IEEE Trans. Electron. Packag. Manuf. 2004, 27, 164–176. [Google Scholar] [CrossRef]

- Jankowski, N.R.; McCluskey, F.P. A Review of Phase Change Materials for Vehicle Component Thermal Buffering. Appl. Energy 2014, 113, 1525–1561. [Google Scholar] [CrossRef]

- Han, D.; He, X.; Hou, Y.; Geng, B.; Zhang, H.; Guene Lougou, B.; Shuai, Y. Experimental Analysis on Improving Heat Storage Efficiency of High-Temperature Packed Bed System Using Spherical Capsules Filled with MgCl2–KCl–NaCl/Al2O3 Nanoparticles Composite Phase Change Material. Sol. Energy Mater. Sol. Cells 2024, 277, 113106. [Google Scholar] [CrossRef]

- Solomon, A.D. Melt Time and Heat Flux for a Simple PCM Body. Sol. Energy 1979, 22, 251–257. [Google Scholar] [CrossRef]

- Cieśliński, J.T.; Fabrykiewicz, M. Thermal Energy Storage with PCMs in Shell-and-Tube Units: A Review. Energies 2023, 16, 936. [Google Scholar] [CrossRef]

- Fukai, J.; Hamada, Y.; Morozumi, Y.; Miyatake, O. Improvement of Thermal Characteristics of Latent Heat Thermal Energy Storage Units Using Carbon-Fiber Brushes: Experiments and Modeling. Int. J. Heat. Mass. Transf. 2003, 46, 4513–4525. [Google Scholar] [CrossRef]

- Gong, Z.-X.; Mujumdar, A.S. Finite-Element Analysis of Cyclic Heat Transfer in a Shell-and-Tube Latent Heat Energy Storage Exchanger. Appl. Therm. Eng. 1997, 17, 583–591. [Google Scholar] [CrossRef]

- Hamada, Y.; Ohtsu, W.; Fukai, J. Thermal Response in Thermal Energy Storage Material around Heat Transfer Tubes: Effect of Additives on Heat Transfer Rates. Sol. Energy 2003, 75, 317–328. [Google Scholar] [CrossRef]

- Ismail, K.A.R.; Abugderah, M.M. Performance of a Thermal Storage System of the Vertical Tube Type. Energy Convers. Manag. 2000, 41, 1165–1190. [Google Scholar] [CrossRef]

- Lacroix, M. Numerical Simulation of a Shell-and-Tube Latent Heat Thermal Energy Storage Unit. Sol. Energy 1993, 50, 357–367. [Google Scholar] [CrossRef]

- Lecomte, D.; Mayer, D. Design Method for Sizing a Latent Heat Store/Heat Exchanger in a Thermal System. Appl. Energy 1985, 21, 55–78. [Google Scholar] [CrossRef]

- Mohaghegh, M.R.; Tasnim, S.H.; Mahmud, S. A Geometrical Optimization and Comparison Study on the Charging and Discharging Performance of Shell-and-Tube Thermal Energy Storage Systems. J. Energy Storage 2022, 51, 104549. [Google Scholar] [CrossRef]

- Costa, M.; Buddhi, D.; Oliva, A. Numerical Simulation of a Latent Heat Thermal Energy Storage System with Enhanced Heat Conduction. Energy Convers. Manag. 1998, 39, 319–330. [Google Scholar] [CrossRef]

- Demirkıran, İ.G.; Cetkin, E. Emergence of Rectangular Shell Shape in Thermal Energy Storage Applications: Fitting Melted Phase Changing Material in a Fixed Space. J. Energy Storage 2021, 37, 102455. [Google Scholar] [CrossRef]

- Hamdan, M.A.; Elwerr, F.A. Thermal Energy Storage Using a Phase Change Material. Sol. Energy 1996, 56, 183–189. [Google Scholar] [CrossRef]

- Huang, P.; Lovati, M.; Zhang, X.; Bales, C.; Hallbeck, S.; Becker, A.; Bergqvist, H.; Hedberg, J.; Maturi, L. Transforming a Residential Building Cluster into Electricity Prosumers in Sweden: Optimal Design of a Coupled PV-Heat Pump-Thermal Storage-Electric Vehicle System. Appl. Energy 2019, 255, 113864. [Google Scholar] [CrossRef]

- Laouadi, A.; Lacroix, M.; Galanis, N. A Numerical Method for the Treatment of Discontinuous Thermal Conductivity in Phase Change Problems. Int. J. Numer. Methods Heat. Fluid. Flow. 1998, 8, 265–287. [Google Scholar] [CrossRef]

- Ma, Y.; Tao, Y.; Wu, W.L.; Shi, L.; Zhou, Z.; Wang, Y.; Tu, J.Y.; Li, H.R. Experimental Investigations on the Performance of a Rectangular Thermal Energy Storage Unit for Poor Solar Thermal Heating. Energy Build. 2022, 257, 111780. [Google Scholar] [CrossRef]

- Silva, P.D.; Gonçalves, L.C.; Pires, L. Transient Behaviour of a Latent-Heat Thermal-Energy Store: Numerical and Experimental Studies. Appl. Energy 2002, 73, 83–98. [Google Scholar] [CrossRef]

- Zivkovic, B.; Fujii, I. An Analysis of Isothermal Phase Change of Phase Change Material within Rectangular and Cylindrical Containers. Sol. Energy 2001, 70, 51–61. [Google Scholar] [CrossRef]

- Zongqin, Z.; Bejan, A. The Problem of Time-Dependent Natural Convection Melting with Conduction in the Solid. Int. J. Heat. Mass. Transf. 1989, 32, 2447–2457. [Google Scholar] [CrossRef]

- Alomair, M.; Alomair, Y.; Tasnim, S.; Mahmud, S.; Abdullah, H. Analyses of Bio-Based Nano-PCM Filled Concentric Cylindrical Energy Storage System in Vertical Orientation. J. Energy Storage 2018, 20, 380–394. [Google Scholar] [CrossRef]

- Bansal, N.K.; Buddhi, D. An Analytical Study of a Latent Heat Storage System in a Cylinder. Energy Convers. Manag. 1992, 33, 235–242. [Google Scholar] [CrossRef]

- Choi, J.C.; Kim, S.D. Heat-Transfer Characteristics of a Latent Heat Storage System Using MgCl2 · 6H2O. Energy 1992, 17, 1153–1164. [Google Scholar] [CrossRef]

- Esen, M.; Ayhan, T. Development of a Model Compatible with Solar Assisted Cylindrical Energy Storage Tank and Variation of Stored Energy with Time for Different Phase Change Materials. Energy Convers. Manag. 1996, 37, 1775–1785. [Google Scholar] [CrossRef]

- Ghoneim, A.A. Comparison of Theoretical Models of Phase-Change and Sensible Heat Storage for Air and Water-Based Solar Heating Systems. Sol. Energy 1989, 42, 209–220. [Google Scholar] [CrossRef]

- Hasan, A. Phase Change Material Energy Storage System Employing Palmitic Acid. Sol. Energy 1994, 52, 143–154. [Google Scholar] [CrossRef]

- Hirata, T.; Nishida, K. An Analysis of Heat Transfer Using Equivalent Thermal Conductivity of Liquid Phase during Melting inside an Isothermally Heated Horizontal Cylinder. Int. J. Heat. Mass. Transf. 1989, 32, 1663–1670. [Google Scholar] [CrossRef]

- Horbaniuc, B.; Dumitrascu, G.; Popescu, A. Mathematical Models for the Study of Solidification within a Longitudinally Finned Heat Pipe Latent Heat Thermal Storage System. Energy Convers. Manag. 1999, 40, 1765–1774. [Google Scholar] [CrossRef]

- Ismail, K.A.R.; Silva, M.d.G.E.d. Numerical Solution of the Phase Change Problem around a Horizontal Cylinder in the Presence of Natural Convection in the Melt Region. Int. J. Heat Mass Transf. 2003, 46, 1791–1799. [Google Scholar] [CrossRef]

- Ng, K.W.; Gong, Z.X.; Mujumdar, A.S. Heat Transfer in Free Convection-Dominated Melting of a Phase Change Material in a Horizontal Annulus. Int. Commun. Heat. Mass. Transf. 1998, 25, 631–640. [Google Scholar] [CrossRef]

- Sarı, A.; Kaygusuz, K. Thermal and Heat Transfer Characteristics in a Latent Heat Storage System Using Lauric Acid. Energy Convers. Manag. 2002, 43, 2493–2507. [Google Scholar] [CrossRef]

- Velraj, R.; Seeniraj, R.V.; Hafner, B.; Faber, C.; Schwarzer, K. Heat Transfer Enhancement in a Latent Heat Storage System1. Sol. Energy 1999, 65, 171–180. [Google Scholar] [CrossRef]

- Bouadila, S.; Baddadi, S.; Rehman, T.; Ayed, R. Experimental Investigation on the Thermal Appraisal of Heat Pipe-Evacuated Tube Collector-Based Water Heating System Integrated with PCM. Renew. Energy 2022, 199, 382–394. [Google Scholar] [CrossRef]

- Filali Baba, Y.; Al Mers, A.; -ur-Rehman, T.; Ajdad, H.; Bouatem, A.; Faik, A.; Bououlid Idrissi, B. No-Vacuum Mono-Tube Compound Parabolic Collector Receiver for Linear Fresnel Concentrator: Numerical and Experimental Approach for Dynamic Behavior Assessment. Energy Convers. Manag. 2022, 268, 115986. [Google Scholar] [CrossRef]

- Souayfane, F.; Fardoun, F.; Biwole, P.-H. Phase Change Materials (PCM) for Cooling Applications in Buildings: A Review. Energy Build. 2016, 129, 396–431. [Google Scholar] [CrossRef]

- Kuznik, F.; David, D.; Johannes, K.; Roux, J.-J. A Review on Phase Change Materials Integrated in Building Walls. Renew. Sustain. Energy Rev. 2011, 15, 379–391. [Google Scholar] [CrossRef]

- Rehman, T.-U.; Ali, H.M. Experimental Study on the Thermal Behavior of RT-35HC Paraffin within Copper and Iron-Nickel Open Cell Foams: Energy Storage for Thermal Management of Electronics. Int. J. Heat. Mass. Transf. 2020, 146, 118852. [Google Scholar] [CrossRef]

- Gin, B.; Farid, M.M. The Use of PCM Panels to Improve Storage Condition of Frozen Food. J. Food Eng. 2010, 100, 372–376. [Google Scholar] [CrossRef]

- Mondal, S. Phase Change Materials for Smart Textiles—An Overview. Appl. Therm. Eng. 2008, 28, 1536–1550. [Google Scholar] [CrossRef]

- Sajjad, U.; Hamid, K.; Tauseef-ur-Rehman; Sultan, M.; Abbas, N.; Ali, H.M.; Imran, M.; Muneeshwaran, M.; Chang, J.-Y.; Wang, C.-C. Personal Thermal Management—A Review on Strategies, Progress, and Prospects. Int. Commun. Heat. Mass. Transf. 2022, 130, 105739. [Google Scholar] [CrossRef]

- Brough, D.; Ramos, J.; Delpech, B.; Jouhara, H. Development and Validation of a TRNSYS Type to Simulate Heat Pipe Heat Exchangers in Transient Applications of Waste Heat Recovery. Int. J. Thermofluids 2021, 9, 100056. [Google Scholar] [CrossRef]

- Seyitini, L.; Belgasim, B.; Enweremadu, C.C. Solid State Sensible Heat Storage Technology for Industrial Applications—A Review. J. Energy Storage 2023, 62, 106919. [Google Scholar] [CrossRef]

- Kim, T.; Choi, B.-I.; Han, Y.-S.; Do, K.H. A Comparative Investigation of Solar-Assisted Heat Pumps with Solar Thermal Collectors for a Hot Water Supply System. Energy Convers. Manag. 2018, 172, 472–484. [Google Scholar] [CrossRef]

- Shah, N.; Vyas, D.; Shah, K.; Shah, M.; Shah, M. Solar-Assisted Geothermal Heat Pump Models for Space Heating and Cooling. Int. J. Energ. Water Res. 2019, 3, 329–341. [Google Scholar] [CrossRef]

- Chavan, S.; Gumtapure, V.; Perumal, D.A. Preparation of Functionalized Graphene-Linear Low-Density Polyethylene Composites by Melt Mixing Method. AIP Conf. Proc. 2020, 2247, 040010. [Google Scholar] [CrossRef]

- Chavan, S.; Rudrapati, R.; Manickam, S. A Comprehensive Review on Current Advances of Thermal Energy Storage and Its Applications. Alex. Eng. J. 2022, 61, 5455–5463. [Google Scholar] [CrossRef]

- Yadav, D. Electrohydrodynamic Instability in a Heat Generating Porous Layer Saturated by a Dielectric Nanofluid. J. Appl. Fluid. Mech. 2017, 10, 763–776. [Google Scholar] [CrossRef]

- Baby, R.; Balaji, C. Experimental Investigations on Phase Change Material Based Finned Heat Sinks for Electronic Equipment Cooling. Int. J. Heat. Mass. Transf. 2012, 55, 1642–1649. [Google Scholar] [CrossRef]

- Rehman, T.-; Ali, H.M. Experimental Investigation on Paraffin Wax Integrated with Copper Foam Based Heat Sinks for Electronic Components Thermal Cooling. Int. Commun. Heat. Mass. Transf. 2018, 98, 155–162. [Google Scholar] [CrossRef]

- Prieto, C.; Cabeza, L.F. Thermal Energy Storage (TES) with Phase Change Materials (PCM) in Solar Power Plants (CSP). Concept and Plant Performance. Appl. Energy 2019, 254, 113646. [Google Scholar] [CrossRef]

- Khan, R.J.; Bhuiyan, Z.H.; Ahmed, D.H. Investigation of Heat Transfer of a Building Wall in the Presence of Phase Change Material (PCM). Energy Built Environ. 2020, 1, 199–206. [Google Scholar] [CrossRef]

- Li, Y.; Liang, W.; Zhou, J.; Long, E. Experimental Study on Thermal Performance Improvement of Building Envelopes Integrated with Phase Change Materials in an Air-Conditioned Room. Procedia Eng. 2017, 205, 190–197. [Google Scholar] [CrossRef]

- Real, A.; García, V.; Domenech, L.; Renau, J.; Montés, N.; Sánchez, F. Improvement of a Heat Pump Based HVAC System with PCM Thermal Storage for Cold Accumulation and Heat Dissipation. Energy Build. 2014, 83, 108–116. [Google Scholar] [CrossRef]

- Pambudi, N.A.; Sarifudin, A.; Gandidi, I.M.; Romadhon, R. Vaccine Cold Chain Management and Cold Storage Technology to Address the Challenges of Vaccination Programs. Energy Rep. 2022, 8, 955–972. [Google Scholar] [CrossRef]

- Saito, A. Recent Advances in Research on Cold Thermal Energy Storage. Int. J. Refrig. 2002, 25, 177–189. [Google Scholar] [CrossRef]

- Mondal, S. 7—Thermo-Regulating Textiles with Phase-Change Materials. In Functional Textiles for Improved Performance, Protection and Health; Pan, N., Sun, G., Eds.; Woodhead Publishing Series in Textiles; Woodhead Publishing: Cambridge, UK, 2011; pp. 163–183. ISBN 978-1-84569-723-5. [Google Scholar]

- Leungtongkum, T.; Flick, D.; Hoang, H.M.; Steven, D.; Delahaye, A.; Laguerre, O. Insulated Box and Refrigerated Equipment with PCM for Food Preservation: State of the Art. J. Food Eng. 2022, 317, 110874. [Google Scholar] [CrossRef]

- Tong, S.; Nie, B.; Li, Z.; Li, C.; Zou, B.; Jiang, L.; Jin, Y.; Ding, Y. A Phase Change Material (PCM) Based Passively Cooled Container for Integrated Road-Rail Cold Chain Transportation—An Experimental Study. Appl. Therm. Eng. 2021, 195, 117204. [Google Scholar] [CrossRef]

- Berardi, U. A Cross-Country Comparison of the Building Energy Consumptions and Their Trends. Resour. Conserv. Recycl. 2017, 123, 230–241. [Google Scholar] [CrossRef]

- Energy Technology Perspectives 2015—Analysis. Available online: https://www.iea.org/reports/energy-technology-perspectives-2015 (accessed on 26 September 2024).

- Kalaiselvam, S.; Parameshwaran, R. Thermal Energy Storage Technologies for Sustainability: Systems Design, Assessment and Applications; Elsevier: Amsterdam, The Netherlands, 2014; ISBN 978-0-12-417305-7. [Google Scholar]

- Mohseni, E.; Tang, W. Parametric Analysis and Optimisation of Energy Efficiency of a Lightweight Building Integrated with Different Configurations and Types of PCM. Renew. Energy 2021, 168, 865–877. [Google Scholar] [CrossRef]

- Borri, E.; Zsembinszki, G.; Cabeza, L.F. Recent Developments of Thermal Energy Storage Applications in the Built Environment: A Bibliometric Analysis and Systematic Review. Appl. Therm. Eng. 2021, 189, 116666. [Google Scholar] [CrossRef]

- Pasupathy, A.; Velraj, R.; Seeniraj, R.V. Phase Change Material-Based Building Architecture for Thermal Management in Residential and Commercial Establishments. Renew. Sustain. Energy Rev. 2008, 12, 39–64. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Y.; Xiao, W.; Zeng, R.; Zhang, Q.; Di, H. Review on Thermal Performance of Phase Change Energy Storage Building Envelope. Chin. Sci. Bull. 2009, 54, 920–928. [Google Scholar] [CrossRef]

- Zhou, D.; Zhao, C.Y.; Tian, Y. Review on Thermal Energy Storage with Phase Change Materials (PCMs) in Building Applications. Appl. Energy 2012, 92, 593–605. [Google Scholar] [CrossRef]

- Jeon, J.; Lee, J.-H.; Seo, J.; Jeong, S.-G.; Kim, S. Application of PCM Thermal Energy Storage System to Reduce Building Energy Consumption. J. Therm. Anal. Calorim. 2013, 111, 279–288. [Google Scholar] [CrossRef]

- Biçer, A.; Sarı, A. New Kinds of Energy-Storing Building Composite PCMs for Thermal Energy Storage. Energy Convers. Manag. 2013, 69, 148–156. [Google Scholar] [CrossRef]

- Chan, H.-Y.; Riffat, S.B.; Zhu, J. Review of Passive Solar Heating and Cooling Technologies. Renew. Sustain. Energy Rev. 2010, 14, 781–789. [Google Scholar] [CrossRef]

- Rathore, P.K.S.; Shukla, S.K. An Experimental Evaluation of Thermal Behavior of the Building Envelope Using Macroencapsulated PCM for Energy Savings. Renew. Energy 2020, 149, 1300–1313. [Google Scholar] [CrossRef]

- Dardir, M.; Roccamena, L.; Mankibi, M.E.; Haghighat, F. Performance Analysis of an Improved PCM-to-Air Heat Exchanger for Building Envelope Applications—An Experimental Study. Sol. Energy 2020, 199, 704–720. [Google Scholar] [CrossRef]

- Arıcı, M.; Bilgin, F.; Nižetić, S.; Karabay, H. PCM Integrated to External Building Walls: An Optimization Study on Maximum Activation of Latent Heat. Appl. Therm. Eng. 2020, 165, 114560. [Google Scholar] [CrossRef]

- Yang, Y.; Wu, W.; Fu, S.; Zhang, H. Study of a Novel Ceramsite-Based Shape-Stabilized Composite Phase Change Material (PCM) for Energy Conservation in Buildings. Constr. Build. Mater. 2020, 246, 118479. [Google Scholar] [CrossRef]

- Arivazhagan, R.; Arun Prakash, S.; Kumaran, P.; Sankar, S.; Loganathan, G.B.; Arivarasan, A. Performance Analysis of Concrete Block Integrated with PCM for Thermal Management. Mater. Today: Proc. 2020, 22, 370–374. [Google Scholar] [CrossRef]

- Wang, H.; Lu, W.; Wu, Z.; Zhang, G. Parametric Analysis of Applying PCM Wallboards for Energy Saving in High-Rise Lightweight Buildings in Shanghai. Renew. Energy 2020, 145, 52–64. [Google Scholar] [CrossRef]

- Bhamare, D.K.; Rathod, M.K.; Banerjee, J. Numerical Model for Evaluating Thermal Performance of Residential Building Roof Integrated with Inclined Phase Change Material (PCM) Layer. J. Build. Eng. 2020, 28, 101018. [Google Scholar] [CrossRef]

- Kenzhekhanov, S.; Memon, S.A.; Adilkhanova, I. Quantitative Evaluation of Thermal Performance and Energy Saving Potential of the Building Integrated with PCM in a Subarctic Climate. Energy 2020, 192, 116607. [Google Scholar] [CrossRef]

- Chen, D.; Jiang, J.; Kim, G.-H.; Yang, C.; Pesaran, A. Comparison of Different Cooling Methods for Lithium Ion Battery Cells. Appl. Therm. Eng. 2016, 94, 846–854. [Google Scholar] [CrossRef]

- Oró, E.; Gil, A.; Miró, L.; Peiró, G.; Álvarez, S.; Cabeza, L.F. Thermal Energy Storage Implementation Using Phase Change Materials for Solar Cooling and Refrigeration Applications. Energy Procedia 2012, 30, 947–956. [Google Scholar] [CrossRef]

- Browne, M.C.; Norton, B.; McCormack, S.J. Phase Change Materials for Photovoltaic Thermal Management. Renew. Sustain. Energy Rev. 2015, 47, 762–782. [Google Scholar] [CrossRef]

- Javadi, F.S.; Metselaar, H.S.C.; Ganesan, P. Performance Improvement of Solar Thermal Systems Integrated with Phase Change Materials (PCM), a Review. Sol. Energy 2020, 206, 330–352. [Google Scholar] [CrossRef]

- Moreno, P.; Solé, C.; Castell, A.; Cabeza, L.F. The Use of Phase Change Materials in Domestic Heat Pump and Air-Conditioning Systems for Short Term Storage: A Review. Renew. Sustain. Energy Rev. 2014, 39, 1–13. [Google Scholar] [CrossRef]

- Waqas, A.; Ud Din, Z. Phase Change Material (PCM) Storage for Free Cooling of Buildings—A Review. Renew. Sustain. Energy Rev. 2013, 18, 607–625. [Google Scholar] [CrossRef]

- Bonacina, C.; Comini, G.; Fasano, A.; Primicerio, M. Numerical Solution of Phase-Change Problems. Int. J. Heat. Mass. Transf. 1973, 16, 1825–1832. [Google Scholar] [CrossRef]

- Comini, G.; Del Guidice, S.; Lewis, R.W.; Zienkiewicz, O.C. Finite Element Solution of Non-Linear Heat Conduction Problems with Special Reference to Phase Change. Int. J. Numer. Methods Eng. 1974, 8, 613–624. [Google Scholar] [CrossRef]

- Rolph III, W.D.; Bathe, K.-J. An Efficient Algorithm for Analysis of Nonlinear Heat Transfer with Phase Changes. Int. J. Numer. Methods Eng. 1982, 18, 119–134. [Google Scholar] [CrossRef]

- Hsiao, J.S.; Chung, B.T.F. An Efficient Algorithm for Finite Element Solution to Two-Dimensional Heat Transfer with Melting and Freezing. J. Heat. Transf. 1986, 108, 462–464. [Google Scholar] [CrossRef]

- COMSOL. COMSOL: Multiphysics Software for Optimizing Designs. Available online: https://www.comsol.com/ (accessed on 27 September 2024).

- ANSYS Ansys Fluent|Fluid Simulation Software. Available online: https://www.ansys.com/products/fluids/ansys-fluent (accessed on 27 September 2024).

- OpenFOAM. OpenFOAM. Available online: https://www.openfoam.com/ (accessed on 27 September 2024).

- STAR-CCM+ Simcenter STAR-CCM+ CFD Software. Available online: https://plm.sw.siemens.com/en-US/simcenter/fluids-thermal-simulation/star-ccm/ (accessed on 27 September 2024).

- Dahash, A.; Ochs, F.; Janetti, M.B.; Streicher, W. Advances in Seasonal Thermal Energy Storage for Solar District Heating Applications: A Critical Review on Large-Scale Hot-Water Tank and Pit Thermal Energy Storage Systems. Appl. Energy 2019, 239, 296–315. [Google Scholar] [CrossRef]

- WUFI WUFI (En) 2024. Available online: https://wufi.de/en/ (accessed on 27 September 2024).

- Delphin. DELPHIN. Available online: https://bauklimatik-dresden.de/delphin/index.php?aLa=en (accessed on 2 October 2024).

- MATLAB. Learn with MATLAB and Simulink Tutorials. Available online: https://in.mathworks.com/support/learn-with-matlab-tutorials.html (accessed on 27 September 2024).

- TRNSYS. Welcome|TRNSYS: Transient System Simulation Tool. Available online: https://www.trnsys.com/ (accessed on 27 September 2024).

- Dymola. Dymola. Available online: https://www.3ds.com/products/catia/dymola (accessed on 27 September 2024).

- Crawley, D.B.; Hand, J.W.; Kummert, M.; Griffith, B.T. Contrasting the Capabilities of Building Energy Performance Simulation Programs. Build. Environ. 2008, 43, 661–673. [Google Scholar] [CrossRef]

- Harish, V.S.K.V.; Kumar, A. A Review on Modeling and Simulation of Building Energy Systems. Renew. Sustain. Energy Rev. 2016, 56, 1272–1292. [Google Scholar] [CrossRef]

- EnergyPlus. EnergyPlus. Available online: https://energyplus.net/ (accessed on 27 September 2024).

- ESP-r. ESP-r|University of Strathclyde. Available online: https://www.strath.ac.uk/research/energysystemsresearchunit/applications/esp-r/ (accessed on 27 September 2024).

- Beckman, W.A.; Broman, L.; Fiksel, A.; Klein, S.A.; Lindberg, E.; Schuler, M.; Thornton, J. TRNSYS The Most Complete Solar Energy System Modeling and Simulation Software. Renew. Energy 1994, 5, 486–488. [Google Scholar] [CrossRef]

- Fumo, N.; Mago, P.; Luck, R. Methodology to Estimate Building Energy Consumption Using EnergyPlus Benchmark Models. Energy Build. 2010, 42, 2331–2337. [Google Scholar] [CrossRef]

- Bhamare, D.K.; Saikia, P.; Rathod, M.K.; Rakshit, D.; Banerjee, J. A Machine Learning and Deep Learning Based Approach to Predict the Thermal Performance of Phase Change Material Integrated Building Envelope. Build. Environ. 2021, 199, 107927. [Google Scholar] [CrossRef]

- Hu, Y.; Guo, R.; Heiselberg, P.K.; Johra, H. Modeling PCM Phase Change Temperature and Hysteresis in Ventilation Cooling and Heating Applications. Energies 2020, 13, 6455. [Google Scholar] [CrossRef]

- Soni, V.; Kumar, A.; Jain, V.K. Modeling of PCM Melting: Analysis of Discrepancy between Numerical and Experimental Results and Energy Storage Performance. Energy 2018, 150, 190–204. [Google Scholar] [CrossRef]

- Sunku Prasad, J.; Muthukumar, P.; Anandalakshmi, R.; Niyas, H. Comparative Study of Phase Change Phenomenon in High Temperature Cascade Latent Heat Energy Storage System Using Conduction and Conduction-Convection Models. Sol. Energy 2018, 176, 627–637. [Google Scholar] [CrossRef]

- Aljehani, A.; Nitsche, L.C.; Al-Hallaj, S. Numerical Modeling of Transient Heat Transfer in a Phase Change Composite Thermal Energy Storage (PCC-TES) System for Air Conditioning Applications. Appl. Therm. Eng. 2020, 164, 114522. [Google Scholar] [CrossRef]

- Kubiński, K.; Szabłowski, Ł. Dynamic Model of Solar Heating Plant with Seasonal Thermal Energy Storage. Renew. Energy 2020, 145, 2025–2033. [Google Scholar] [CrossRef]

- Yu, J.; Leng, K.; Ye, H.; Xu, X.; Luo, Y.; Wang, J.; Yang, X.; Yang, Q.; Gang, W. Study on Thermal Insulation Characteristics and Optimized Design of Pipe-Embedded Ventilation Roof with Outer-Layer Shape-Stabilized PCM in Different Climate Zones. Renew. Energy 2020, 147, 1609–1622. [Google Scholar] [CrossRef]

- Zhu, L.; Chen, S.; Yang, Y.; Tian, W.; Sun, Y.; Lyu, M. Global Sensitivity Analysis on Borehole Thermal Energy Storage Performances under Intermittent Operation Mode in the First Charging Phase. Renew. Energy 2019, 143, 183–198. [Google Scholar] [CrossRef]

- Todorov, O.; Alanne, K.; Virtanen, M.; Kosonen, R. A Method and Analysis of Aquifer Thermal Energy Storage (ATES) System for District Heating and Cooling: A Case Study in Finland. Sustain. Cities Soc. 2020, 53, 101977. [Google Scholar] [CrossRef]

- EnergyPlus Source code NREL/EnergyPlus 2024. Available online: https://github.com/NREL/EnergyPlus (accessed on 15 October 2024).

- ESP-r Source Code ESP-rCommunity/ESP-rSource 2024. Available online: https://github.com/ESP-rCommunity/ESP-rSource (accessed on 15 October 2024).

- Rengasamy, M.; Gangatharan, S.; Madurai Elavarasan, R.; Mihet-Popa, L. The Motivation for Incorporation of Microgrid Technology in Rooftop Solar Photovoltaic Deployment to Enhance Energy Economics. Sustainability 2020, 12, 10365. [Google Scholar] [CrossRef]

- Madurai Elavarasan, R.; Pugazhendhi, R.; Jamal, T.; Dyduch, J.; Arif, M.T.; Manoj Kumar, N.; Shafiullah, G.; Chopra, S.S.; Nadarajah, M. Envisioning the UN Sustainable Development Goals (SDGs) through the Lens of Energy Sustainability (SDG 7) in the Post-COVID-19 World. Appl. Energy 2021, 292, 116665. [Google Scholar] [CrossRef]

- Gopi, A.; Sudhakar, K.; Ngui, W.K.; Kirpichnikova, I.M.; Cuce, E. Energy Analysis of Utility-Scale PV Plant in the Rain-Dominated Tropical Monsoon Climates. Case Stud. Therm. Eng. 2021, 26, 101123. [Google Scholar] [CrossRef]

- Xia, Z.; Li, Y.; Zhang, W.; Chen, R.; Guo, S.; Zhang, P.; Du, P. Solar Photovoltaic Program Helps Turn Deserts Green in China: Evidence from Satellite Monitoring. J. Environ. Manag. 2022, 324, 116338. [Google Scholar] [CrossRef]

- Dubey, S.; Sarvaiya, J.N.; Seshadri, B. Temperature Dependent Photovoltaic (PV) Efficiency and Its Effect on PV Production in the World—A Review. Energy Procedia 2013, 33, 311–321. [Google Scholar] [CrossRef]

- Libra, M.; Mrázek, D.; Tyukhov, I.; Severová, L.; Poulek, V.; Mach, J.; Šubrt, T.; Beránek, V.; Svoboda, R.; Sedláček, J. Reduced Real Lifetime of PV Panels—Economic Consequences. Sol. Energy 2023, 259, 229–234. [Google Scholar] [CrossRef]

- Dwivedi, P.; Sudhakar, K.; Soni, A.; Solomin, E.; Kirpichnikova, I. Advanced Cooling Techniques of P.V. Modul. A State Art. Case Stud. Therm. Eng. 2020, 21, 100674. [Google Scholar] [CrossRef]

- Khanna, S.; Reddy, K.S.; Mallick, T.K. Performance Analysis of Tilted Photovoltaic System Integrated with Phase Change Material under Varying Operating Conditions. Energy 2017, 133, 887–899. [Google Scholar] [CrossRef]

- Parida, B.; Iniyan, S.; Goic, R. A Review of Solar Photovoltaic Technologies. Renew. Sustain. Energy Rev. 2011, 15, 1625–1636. [Google Scholar] [CrossRef]

- da Fonseca, J.E.F.; de Oliveira, F.S.; Massen Prieb, C.W.; Krenzinger, A. Degradation Analysis of a Photovoltaic Generator after Operating for 15 Years in Southern Brazil. Sol. Energy 2020, 196, 196–206. [Google Scholar] [CrossRef]

- Abdulmunem, A.R.; Mohd Samin, P.; Abdul Rahman, H.; Hussien, H.A.; Izmi Mazali, I.; Ghazali, H. Numerical and Experimental Analysis of the Tilt Angle’s Effects on the Characteristics of the Melting Process of PCM-Based as PV Cell’s Backside Heat Sink. Renew. Energy 2021, 173, 520–530. [Google Scholar] [CrossRef]

- Huang, P.; Wei, G.; Cui, L.; Xu, C.; Du, X. Numerical Investigation of a Dual-PCM Heat Sink Using Low Melting Point Alloy and Paraffin. Appl. Therm. Eng. 2021, 189, 116702. [Google Scholar] [CrossRef]

- Mah, C.-Y.; Lim, B.-H.; Wong, C.-W.; Tan, M.-H.; Chong, K.-K.; Lai, A.-C. Investigating the Performance Improvement of a Photovoltaic System in a Tropical Climate Using Water Cooling Method. Energy Procedia 2019, 159, 78–83. [Google Scholar] [CrossRef]

- Zhao, B.; Hu, M.; Ao, X.; Xuan, Q.; Pei, G. Spectrally Selective Approaches for Passive Cooling of Solar Cells: A Review. Appl. Energy 2020, 262, 114548. [Google Scholar] [CrossRef]

- Elavarasan, R.M.; Nadarajah, M.; Pugazhendhi, R.; Gangatharan, S. An Experimental Investigation on Coalescing the Potentiality of PCM, Fins and Water to Achieve Sturdy Cooling Effect on PV Panels. Appl. Energy 2024, 356, 122371. [Google Scholar] [CrossRef]

- Rahman, N.M.A.; Haw, L.C.; Kamaluddin, K.A.; Abdullah, M.S.I. Investigating Photovoltaic Module Performance Using Aluminium Heat Sink and Forced Cold-Air Circulation Method in Tropical Climate Conditions. Energy Rep. 2023, 9, 2797–2809. [Google Scholar] [CrossRef]

- Almeshaiei, E.; Al-Habaibeh, A.; Mina, N.; Akib, S. Rapid Evaluation of the Design and Manufacture of Cooling Systems of Photovoltaic Solar Panels. Int. J. Interact. Des. Manuf. 2023, 17, 197–214. [Google Scholar] [CrossRef]

- Krauter, S. Increased Electrical Yield via Water Flow over the Front of Photovoltaic Panels. Sol. Energy Mater. Sol. Cells 2004, 82, 131–137. [Google Scholar] [CrossRef]

- Odeh, S.; Behnia, M. Improving Photovoltaic Module Efficiency Using Water Cooling. Heat. Transf. Eng. 2009, 30, 499–505. [Google Scholar] [CrossRef]

- Bahaidarah, H.; Subhan, A.; Gandhidasan, P.; Rehman, S. Performance Evaluation of a PV (Photovoltaic) Module by Back Surface Water Cooling for Hot Climatic Conditions. Energy 2013, 59, 445–453. [Google Scholar] [CrossRef]

- Yang, D.J.; Yuan, Z.F.; Lee, P.H.; Yin, H.M. Simulation and Experimental Validation of Heat Transfer in a Novel Hybrid Solar Panel. Int. J. Heat. Mass. Transf. 2012, 55, 1076–1082. [Google Scholar] [CrossRef]

- Omisanya, M.I.; Hamzat, A.K.; Adedayo, S.A.; Adediran, I.A.; Asafa, T.B. Enhancing the Thermal Performance of Solar Collectors Using Nanofluids. IOP Conf. Ser. Mater. Sci. Eng. 2020, 805, 012015. [Google Scholar] [CrossRef]

- Ramos-Alvarado, B.; Li, P.; Liu, H.; Hernandez-Guerrero, A. CFD Study of Liquid-Cooled Heat Sinks with Microchannel Flow Field Configurations for Electronics, Fuel Cells, and Concentrated Solar Cells. Appl. Therm. Eng. 2011, 31, 2494–2507. [Google Scholar] [CrossRef]

- Royne, A.; Dey, C.J. Design of a Jet Impingement Cooling Device for Densely Packed PV Cells under High Concentration. Sol. Energy 2007, 81, 1014–1024. [Google Scholar] [CrossRef]

- Barrau, J.; Rosell, J.; Chemisana, D.; Tadrist, L.; Ibañez, M. Effect of a Hybrid Jet Impingement/Micro-Channel Cooling Device on the Performance of Densely Packed PV Cells under High Concentration. Sol. Energy 2011, 85, 2655–2665. [Google Scholar] [CrossRef]

- Williams, H.J.; Hashad, K.; Wang, H.; Max Zhang, K. The Potential for Agrivoltaics to Enhance Solar Farm Cooling. Appl. Energy 2023, 332, 120478. [Google Scholar] [CrossRef]

- Song, W.; Ge, J.; Xie, L.; Chen, Z.; Ye, Q.; Sun, D.; Shi, J.; Tong, X.; Zhang, X.; Ge, Z. Semi-Transparent Organic Photovoltaics for Agrivoltaic Applications. Nano Energy 2023, 116, 108805. [Google Scholar] [CrossRef]

- Mamun, M.A.A.; Dargusch, P.; Wadley, D.; Zulkarnain, N.A.; Aziz, A.A. A Review of Research on Agrivoltaic Systems. Renew. Sustain. Energy Rev. 2022, 161, 112351. [Google Scholar] [CrossRef]

- Sutanto, B.; Iacovides, H.; Nasser, A.; Cioncolini, A.; Afgan, I.; Indartono, Y.S.; Prasetyo, T.; Wijayanta, A.T. Design and Analysis of Passively Cooled Floating Photovoltaic Systems. Appl. Therm. Eng. 2024, 236, 121801. [Google Scholar] [CrossRef]

- Cuce, E.; Cuce, P.M.; Saboor, S.; Ghosh, A.; Sheikhnejad, Y. Floating PVs in Terms of Power Generation, Environmental Aspects, Market Potential, and Challenges. Sustainability 2022, 14, 2626. [Google Scholar] [CrossRef]

- Gallardo, A.; Berardi, U. Design and Control of Radiant Ceiling Panels Incorporating Phase Change Materials for Cooling Applications. Appl. Energy 2021, 304, 117736. [Google Scholar] [CrossRef]

- Nižetić, S.; Jurčević, M.; Čoko, D.; Arıcı, M. A Novel and Effective Passive Cooling Strategy for Photovoltaic Panel. Renew. Sustain. Energy Rev. 2021, 145, 111164. [Google Scholar] [CrossRef]

- Velmurugan, K.; Karthikeyan, V.; Kumarasamy, S.; Wongwuttanasatian, T.; Sa-ngiamsak, C. Thermal Mapping of Photovoltaic Module Cooling via Radiation-Based Phase Change Material Matrix: A Case Study of a Large-Scale Solar Farm in Thailand. J. Energy Storage 2022, 55, 105805. [Google Scholar] [CrossRef]

- Stropnik, R.; Stritih, U. Increasing the Efficiency of PV Panel with the Use of PCM. Renew. Energy 2016, 97, 671–679. [Google Scholar] [CrossRef]

- Li, Z.; Ma, T.; Zhao, J.; Song, A.; Cheng, Y. Experimental Study and Performance Analysis on Solar Photovoltaic Panel Integrated with Phase Change Material. Energy 2019, 178, 471–486. [Google Scholar] [CrossRef]

- Shastry, D.M.C.; Arunachala, U.C. Thermal Management of Photovoltaic Module with Metal Matrix Embedded PCM. J. Energy Storage 2020, 28, 101312. [Google Scholar] [CrossRef]

- Sheikh, Y.; Jasim, M.; Hamdan, M.O.; Abu-Nabah, B.A.; Gerner, F. Design and Performance Assessment of a Solar Photovoltaic Panel Integrated with Heat Pipes and Bio-Based Phase Change Material: A Hybrid Passive Cooling Strategy. J. Energy Storage 2024, 100, 113706. [Google Scholar] [CrossRef]

- Sheikh, Y.; Jasim, M.; Qasim, M.; Qaisieh, A.; Hamdan, M.O.; Abed, F. Enhancing PV Solar Panel Efficiency through Integration with a Passive Multi-Layered PCMs Cooling System: A Numerical Study. Int. J. Thermofluids 2024, 23, 100748. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Khalili, Z. Enhancing Photovoltaic Solar Panel Performance with Integration of PCM-Based Spectral Filter and Self-Cleaning Coating. J. Build. Eng. 2024, 94, 110019. [Google Scholar] [CrossRef]

- Ortiz Lizcano, J.C.; Ziar, H.; de Mooij, C.; Verheijen, M.P.F.; van Nierop Sanchez, C.; Ferlito, D.; Connelli, C.; Canino, A.; Zeman, M.; Isabella, O. Long-Term Experimental Testing of Phase Change Materials as Cooling Devices for Photovoltaic Modules. Sol. Energy Mater. Sol. Cells 2024, 277, 113133. [Google Scholar] [CrossRef]

- Lamba, R.; Javier Montero, F.; Rehman, T.; Singh, S.; Manikandan, S. PCM-Based Hybrid Thermal Management System for Photovoltaic Modules: A Comparative Analysis|Environmental Science and Pollution Research. Available online: https://link.springer.com/article/10.1007/s11356-023-27809-1 (accessed on 30 September 2024).

- Darkwa, J.; Calautit, J.; Du, D.; Kokogianakis, G. A Numerical and Experimental Analysis of an Integrated TEG-PCM Power Enhancement System for Photovoltaic Cells. Appl. Energy 2019, 248, 688–701. [Google Scholar] [CrossRef]

- Rajvikram, M.; Leoponraj, S.; Ramkumar, S.; Akshaya, H.; Dheeraj, A. Experimental Investigation on the Abasement of Operating Temperature in Solar Photovoltaic Panel Using PCM and Aluminium. Sol. Energy 2019, 188, 327–338. [Google Scholar] [CrossRef]

- Karthikeyan, V.; Sirisamphanwong, C.; Sukchai, S.; Sahoo, S.K.; Wongwuttanasatian, T. Reducing PV Module Temperature with Radiation Based PV Module Incorporating Composite Phase Change Material. J. Energy Storage 2020, 29, 101346. [Google Scholar] [CrossRef]

- Abdollahi, N.; Rahimi, M. Potential of Water Natural Circulation Coupled with Nano-Enhanced PCM for PV Module Cooling. Renew. Energy 2020, 147, 302–309. [Google Scholar] [CrossRef]

- Foteinis, S.; Savvakis, N.; Tsoutsos, T. Energy and Environmental Performance of Photovoltaic Cooling Using Phase Change Materials under the Mediterranean Climate. Energy 2023, 265, 126355. [Google Scholar] [CrossRef]

- Zhi, Y.; Gao, D.; Sun, T.; Yang, X. Experimental Investigation of a Distributed Photovoltaic Heating System Based on Building Envelope Thermal Storage. Energy Build. 2024, 319, 114586. [Google Scholar] [CrossRef]

- Domjan, S.; Arkar, C.; Begelj, Ž.; Medved, S. Evolution of All-Glass Nearly Zero Energy Buildings with Respect to the Local Climate and Free-Cooling Techniques. Build. Environ. 2019, 160, 106183. [Google Scholar] [CrossRef]

- Pomianowski, M.; Heiselberg, P.; Zhang, Y. Review of Thermal Energy Storage Technologies Based on PCM Application in Buildings. Energy Build. 2013, 67, 56–69. [Google Scholar] [CrossRef]

- Li, M.; Shi, J. Review on Micropore Grade Inorganic Porous Medium Based Form Stable Composite Phase Change Materials: Preparation, Performance Improvement and Effects on the Properties of Cement Mortar. Constr. Build. Mater. 2019, 194, 287–310. [Google Scholar] [CrossRef]

- Ayadi, B.; Al-Ebrahim, M.A.; Rajhi, W.; Abu-Hamdeh, N.H.; Nusier, O.K.; Pham, V.; Karimipour, A. Simultaneous Use of Renewable Energies and Phase Change Materials to Reduce Energy Consumption in Saudi Buildings: Examine the Photovoltaic Cells. Case Stud. Therm. Eng. 2024, 55, 104143. [Google Scholar] [CrossRef]

- Rawa, M.J.H.; Abu-Hamdeh, N.H.; Karimipour, A.; Nusier, O.K.; Ghaemi, F.; Baleanu, D. Phase Change Material Dependency on Solar Power Plant Building through Examination of Energy-Saving. J. Energy Storage 2022, 45, 103718. [Google Scholar] [CrossRef]

- Tang, H.; Long, Q.; Li, C.; Li, C. Experimental Study of a PV-PCM Window under Hot Summer and Warm Winter Climate. J. Energy Storage 2024, 96, 112724. [Google Scholar] [CrossRef]

- Goia, F.; Perino, M.; Serra, V. Improving Thermal Comfort Conditions by Means of PCM Glazing Systems. Energy Build. 2013, 60, 442–452. [Google Scholar] [CrossRef]

- Jiang, W.; Liu, B.; Zhang, X.; Zhang, T.; Li, D.; Ma, L. Energy Performance of Window with PCM Frame. Sustain. Energy Technol. Assess. 2021, 45, 101109. [Google Scholar] [CrossRef]

- Wang, X.; Li, W.; Luo, Z.; Wang, K.; Shah, S.P. A Critical Review on Phase Change Materials (PCM) for Sustainable and Energy Efficient Building: Design, Characteristic, Performance and Application. Energy Build. 2022, 260, 111923. [Google Scholar] [CrossRef]

- Ke, W.; Ji, J.; Zhang, C.; Xie, H. Field Experimental Test and Performance Analysis of a Novel Hybrid CdTe PV Glass Module Integrated with Phase Change Materials. Renew. Energy 2023, 217, 119196. [Google Scholar] [CrossRef]

- Ke, W.; Ji, J.; Zhang, C.; Xie, H. Modelling Analysis and Performance Evaluation of a Novel Hybrid CdTe-PCM PV Glass Module for Building Envelope Application. Energy 2023, 284, 129182. [Google Scholar] [CrossRef]

- Ke, W.; Ji, J.; Wang, C.; Zhang, C.; Xie, H.; Tang, Y.; Lin, Y. Comparative Analysis on the Electrical and Thermal Performance of Two CdTe Multi-Layer Ventilated Windows with and without a Middle PCM Layer: A Preliminary Numerical Study. Renew. Energy 2022, 189, 1306–1323. [Google Scholar] [CrossRef]

- Sudha, D.; Gopal, S.R.; Sowmiya, J.K.; Kannadasan, B.; Narayan, P.; Ghosh, T. Study on the Heat Gain through a Twin Glass Window (TGW) Using an Organic PCM. Mater. Today: Proc. 2022, 69, 927–933. [Google Scholar] [CrossRef]

- Kaushik, N.; Saravanakumar, P.; Dhanasekhar, S.; Saminathan, R.; Rinawa, M.L.; Subbiah, R.; Sharma, R.; Manoj Kumar, P. Thermal Analysis of a Double-Glazing Window Using a Nano-Disbanded Phase Changing Material (NDPCM). Mater. Today: Proc. 2022, 62, 1702–1707. [Google Scholar] [CrossRef]

- Szajding, A.; Kuta, M.; Cebo-Rudnicka, A.; Rywotycki, M. Analysis of Work of a Thermal Energy Storage with a Phase Change Material (PCM) Charged with Electric Heaters from a Photovoltaic Installation. Int. Commun. Heat. Mass. Transf. 2023, 140, 106547. [Google Scholar] [CrossRef]

- Su, C.; Madani, H.; Palm, B. Building Heating Solutions in China: A Spatial Techno-Economic and Environmental Analysis. Energy Convers. Manag. 2019, 179, 201–218. [Google Scholar] [CrossRef]

- Jiang, J.; Hu, B.; Ge, T.; Wang, R.Z. Comprehensive Selection and Assessment Methodology of Compression Heat Pump System. Energy 2022, 241, 122831. [Google Scholar] [CrossRef]

- Ni, L.; Qv, D.; Shang, R.; Yao, Y.; Niu, F.; Hu, W. Experimental Study on Performance of a Solar-Air Source Heat Pump System in Severe External Conditions and Switchover of Different Functions. Sustain. Energy Technol. Assess. 2016, 16, 162–173. [Google Scholar] [CrossRef]

- Kelly, N.J.; Cockroft, J. Analysis of Retrofit Air Source Heat Pump Performance: Results from Detailed Simulations and Comparison to Field Trial Data. Energy Build. 2011, 43, 239–245. [Google Scholar] [CrossRef]

- Sarbu, I.; Sebarchievici, C. General Review of Ground-Source Heat Pump Systems for Heating and Cooling of Buildings. Energy Build. 2014, 70, 441–454. [Google Scholar] [CrossRef]

- Jiang, J.; Hu, B.; Wang, R.Z.; Deng, N.; Cao, F.; Wang, C.-C. A Review and Perspective on Industry High-Temperature Heat Pumps. Renew. Sustain. Energy Rev. 2022, 161, 112106. [Google Scholar] [CrossRef]

- Staffell, I.; Brett, D.; Brandon, N.; Hawkes, A. A Review of Domestic Heat Pumps. Energy Environ. Sci. 2012, 5, 9291–9306. [Google Scholar] [CrossRef]

- Kohlhepp, P.; Harb, H.; Wolisz, H.; Waczowicz, S.; Müller, D.; Hagenmeyer, V. Large-Scale Grid Integration of Residential Thermal Energy Storages as Demand-Side Flexibility Resource: A Review of International Field Studies. Renew. Sustain. Energy Rev. 2019, 101, 527–547. [Google Scholar] [CrossRef]

- Baeten, B.; Rogiers, F.; Helsen, L. Reduction of Heat Pump Induced Peak Electricity Use and Required Generation Capacity through Thermal Energy Storage and Demand Response. Appl. Energy 2017, 195, 184–195. [Google Scholar] [CrossRef]

- Siddiqui, S.; Macadam, J.; Barrett, M. The Operation of District Heating with Heat Pumps and Thermal Energy Storage in a Zero-Emission Scenario. Energy Rep. 2021, 7, 176–183. [Google Scholar] [CrossRef]

- Lin, B.; Chen, J.; Wesseh, P.K. Peak-Valley Tariffs and Solar Prosumers: Why Renewable Energy Policies Should Target Local Electricity Markets. Energy Policy 2022, 165, 112984. [Google Scholar] [CrossRef]

- Cao, Y.; Zeng, Z.; Huang, D.; Chen, Y.; Zhang, L.; Sheng, X. Multifunctional Phase Change Composites Based on Biomass/MXene-Derived Hybrid Scaffolds for Excellent Electromagnetic Interference Shielding and Superior Solar/Electro-Thermal Energy Storage. Nano Res. 2022, 15, 8524–8535. [Google Scholar] [CrossRef]

- Li, Z.; Lu, Y.; Huang, R.; Chang, J.; Yu, X.; Jiang, R.; Yu, X.; Roskilly, A.P. Applications and Technological Challenges for Heat Recovery, Storage and Utilisation with Latent Thermal Energy Storage. Appl. Energy 2021, 283, 116277. [Google Scholar] [CrossRef]

- Yu, M.; Li, S.; Zhang, X.; Zhao, Y. Techno-Economic Analysis of Air Source Heat Pump Combined with Latent Thermal Energy Storage Applied for Space Heating in China. Appl. Therm. Eng. 2021, 185, 116434. [Google Scholar] [CrossRef]

- Huang, H.; Xiao, Y.; Lin, J.; Zhou, T.; Liu, Y.; Zhao, Q. Improvement of the Efficiency of Solar Thermal Energy Storage Systems by Cascading a PCM Unit with a Water Tank. J. Clean. Prod. 2020, 245, 118864. [Google Scholar] [CrossRef]

- Parvin, K.; Hannan, M.A.; Hui Mun, L.; Hossain Lipu, M.S.; Abdolrasol, M.G.M.; Jern Ker, P.; Muttaqi, K.M.; Dong, Z.Y. The Future Energy Internet for Utility Energy Service and Demand-Side Management in Smart Grid: Current Practices, Challenges and Future Directions. Sustain. Energy Technol. Assess. 2022, 53, 102648. [Google Scholar] [CrossRef]

- Osterman, E.; Stritih, U. Review on Compression Heat Pump Systems with Thermal Energy Storage for Heating and Cooling of Buildings. J. Energy Storage 2021, 39, 102569. [Google Scholar] [CrossRef]

- Emhofer, J.; Marx, K.; Barz, T.; Hochwallner, F.; Cabeza, L.F.; Zsembinszki, G.; Strehlow, A.; Nitsch, B.; Wiesflecker, M.; Pink, W. Techno-Economic Analysis of a Heat Pump Cycle Including a Three-Media Refrigerant/Phase Change Material/Water Heat Exchanger in the Hot Superheated Section for Efficient Domestic Hot Water Generation. Appl. Sci. 2020, 10, 7873. [Google Scholar] [CrossRef]

- Kong, M.; Alvarado, J.L.; Thies, C.; Morefield, S.; Marsh, C.P. Field Evaluation of Microencapsulated Phase Change Material Slurry in Ground Source Heat Pump Systems. Energy 2017, 122, 691–700. [Google Scholar] [CrossRef]

- Wang, Z.; Li, G.; Wang, F.; Liu, Z.; Wang, M. Performance Analysis and Operation Optimization of Air-to-Water CO2 Heat Pump with Phase Change Thermal Storage. Energy Build. 2020, 209, 109738. [Google Scholar] [CrossRef]

- Zhang, D.; Fang, C.; Qin, X.; Li, H.; Liu, H.; Wu, X. Performance Study of Transcritical CO2 Heat Pump Integrated with Ejector and Latent Thermal Energy Storage for Space Heating. Energy Convers. Manag. 2022, 268, 115979. [Google Scholar] [CrossRef]

- Gao, X.; Zhang, W.; Fang, Z.; Hou, X.; Zhang, X. Analysis of Melting and Solidification Processes in the Phase-Change Device of an Energy Storage Interconnected Heat Pump System. AIP Adv. 2020, 10, 055021. [Google Scholar] [CrossRef]

- Jin, X.; Wu, F.; Xu, T.; Huang, G.; Wu, H.; Zhou, X.; Wang, D.; Liu, Y.; Lai, A.C.K. Experimental Investigation of the Novel Melting Point Modified Phase–Change Material for Heat Pump Latent Heat Thermal Energy Storage Application. Energy 2021, 216, 119191. [Google Scholar] [CrossRef]

- Li, M.; Lin, Z.; Sun, Y.; Wu, F.; Xu, T.; Wu, H.; Zhou, X.; Wang, D.; Liu, Y. Preparation and Characterizations of a Novel Temperature-Tuned Phase Change Material Based on Sodium Acetate Trihydrate for Improved Performance of Heat Pump Systems. Renew. Energy 2020, 157, 670–677. [Google Scholar] [CrossRef]

- Teamah, H.M.; Lightstone, M.F. Numerical Study of the Electrical Load Shift Capability of a Ground Source Heat Pump System with Phase Change Thermal Storage. Energy Build. 2019, 199, 235–246. [Google Scholar] [CrossRef]

- Hirmiz, R.; Teamah, H.M.; Lightstone, M.F.; Cotton, J.S. Analytical and Numerical Sizing of Phase Change Material Thickness for Rectangular Encapsulations in Hybrid Thermal Storage Tanks for Residential Heat Pump Systems. Appl. Therm. Eng. 2020, 170, 114978. [Google Scholar] [CrossRef]

- Cabrol, L.; Rowley, P. Towards Low Carbon Homes—A Simulation Analysis of Building-Integrated Air-Source Heat Pump Systems. Energy Build. 2012, 48, 127–136. [Google Scholar] [CrossRef]

- Dehdezi, P.; Hall, M.; Dawson, A. Enhancement of Soil ThermoPhysical Properties Using Microencapsulated Phase Change Materials for Ground Source Heat Pump Applications. Appl. Mech. Mater. 2011, 110–116, 1191–1198. [Google Scholar] [CrossRef]

- Ju, H.; Li, X.; Chang, C.; Zhou, W.; Wang, G.; Tong, C. Heating Performance of PCM Radiant Floor Coupled with Horizontal Ground Source Heat Pump for Single-Family House in Cold Zones. Renew. Energy 2024, 235, 121306. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, N.; Ding, Z. Investigation on the Energy Performance of Using Air-Source Heat Pump to Charge PCM Storage Tank. J. Energy Storage 2020, 28, 101270. [Google Scholar] [CrossRef]

- Zou, D.; Ma, X.; Liu, X.; Zheng, P.; Cai, B.; Huang, J.; Guo, J.; Liu, M. Experimental Research of an Air-Source Heat Pump Water Heater Using Water-PCM for Heat Storage. Appl. Energy 2017, 206, 784–792. [Google Scholar] [CrossRef]

- Dogkas, G.; Konstantaras, J.; Koukou, M.K.; Vrachopoulos, M.G.; Pagkalos, C.; Stathopoulos, V.N.; Pandis, P.K.; Lymperis, K.; Coelho, L.; Rebola, A. Development and Experimental Testing of a Compact Thermal Energy Storage Tank Using Paraffin Targeting Domestic Hot Water Production Needs. Therm. Sci. Eng. Progress. 2020, 19, 100573. [Google Scholar] [CrossRef]

- Yu, M.; Zhang, C.; Fan, Y.; Zhang, X.; Zhao, Y. Performance Study of Phase Change Charging/Discharging Processes of Condensing Heat Storage in Cold Regions Based on a Mathematical Model. Appl. Therm. Eng. 2021, 182, 115805. [Google Scholar] [CrossRef]

- Koşan, M.; Aktaş, M. Experimental Investigation of a Novel Thermal Energy Storage Unit in the Heat Pump System. J. Clean. Prod. 2021, 311, 127607. [Google Scholar] [CrossRef]

- Wu, J.; Feng, Y.; Liu, C.; Li, H. Heat Transfer Characteristics of an Expanded Graphite/Paraffin PCM-Heat Exchanger Used in an Instantaneous Heat Pump Water Heater. Appl. Therm. Eng. 2018, 142, 644–655. [Google Scholar] [CrossRef]

- Lin, Y.; Fan, Y.; Yu, M.; Jiang, L.; Zhang, X. Performance Investigation on an Air Source Heat Pump System with Latent Heat Thermal Energy Storage. Energy 2022, 239, 121898. [Google Scholar] [CrossRef]

- Qi, D.; Pu, L.; Sun, F.; Li, Y. Numerical Investigation on Thermal Performance of Ground Heat Exchangers Using Phase Change Materials as Grout for Ground Source Heat Pump System. Appl. Therm. Eng. 2016, 106, 1023–1032. [Google Scholar] [CrossRef]

- Wang, Z.; Luther, M.; Horan, P.; Matthews, J.; Liu, C. Performance Investigation of Transitioning Building Services System in Photovoltaic Homes. J. Build. Eng. 2024, 84, 108540. [Google Scholar] [CrossRef]

- Sommerfeldt, N.; Pearce, J.M. Can Grid-Tied Solar Photovoltaics Lead to Residential Heating Electrification? A Techno-Economic Case Study in the Midwestern U.S. Appl. Energy 2023, 336, 120838. [Google Scholar] [CrossRef]

- Pearce, J.M.; Sommerfeldt, N. Economics of Grid-Tied Solar Photovoltaic Systems Coupled to Heat Pumps: The Case of Northern Climates of the U.S. Canada. Energies 2021, 14, 834. [Google Scholar] [CrossRef]

- Langer, L.; Volling, T. An Optimal Home Energy Management System for Modulating Heat Pumps and Photovoltaic Systems. Appl. Energy 2020, 278, 115661. [Google Scholar] [CrossRef]

- Galvin, R. Why German Households Won’t Cover Their Roofs in Photovoltaic Panels: And Whether Policy Interventions, Rebound Effects and Heat Pumps Might Change Their Minds. Renew. Energy Focus. 2022, 42, 236–252. [Google Scholar] [CrossRef]

- Prehoda, E.; Pearce, J.M.; Schelly, C. Policies to Overcome Barriers for Renewable Energy Distributed Generation: A Case Study of Utility Structure and Regulatory Regimes in Michigan. Energies 2019, 12, 674. [Google Scholar] [CrossRef]

- Alnaser, S.W.; Althaher, S.Z.; Long, C.; Zhou, Y.; Wu, J.; Hamdan, R. Transition towards Solar Photovoltaic Self-Consumption Policies with Batteries: From the Perspective of Distribution Networks. Appl. Energy 2021, 304, 117859. [Google Scholar] [CrossRef]

- Campana, P.E.; Cioccolanti, L.; François, B.; Jurasz, J.; Zhang, Y.; Varini, M.; Stridh, B.; Yan, J. Li-Ion Batteries for Peak Shaving, Price Arbitrage, and Photovoltaic Self-Consumption in Commercial Buildings: A Monte Carlo Analysis. Energy Convers. Manag. 2021, 234, 113889. [Google Scholar] [CrossRef]

- Roberts, M.B.; Bruce, A.; MacGill, I. Impact of Shared Battery Energy Storage Systems on Photovoltaic Self-Consumption and Electricity Bills in Apartment Buildings. Appl. Energy 2019, 245, 78–95. [Google Scholar] [CrossRef]

- Yu, H.J.J. A Prospective Economic Assessment of Residential PV Self-Consumption with Batteries and Its Systemic Effects: The French Case in 2030. Energy Policy 2018, 113, 673–687. [Google Scholar] [CrossRef]

- Azzuni, A.; Breyer, C. Energy Security and Energy Storage Technologies. Energy Procedia 2018, 155, 237–258. [Google Scholar] [CrossRef]

- Baniasadi, A.; Habibi, D.; Al-Saedi, W.; Masoum, M.A.S.; Das, C.K.; Mousavi, N. Optimal Sizing Design and Operation of Electrical and Thermal Energy Storage Systems in Smart Buildings. J. Energy Storage 2020, 28, 101186. [Google Scholar] [CrossRef]

- Brandt, M.; Woods, J.; Tabares-Velasco, P.C. An Analytical Method for Identifying Synergies between Behind-the-Meter Battery and Thermal Energy Storage. J. Energy Storage 2022, 50, 104216. [Google Scholar] [CrossRef]

- Dunn, B.; Kamath, H.; Tarascon, J. Electrical Energy Storage for the Grid: A Battery of Choices|Science. Available online: https://www.science.org/doi/full/10.1126/science.1212741?casa_token=KW36X8lyKegAAAAA%3Ap_izskMkXYEtyYcIvfpHkcsQdJa26ybELLgW94uBjzNScrdb52eYb7YF9F5EsA1r7y8pGrriVbyFIA (accessed on 23 October 2024).

- Williams, C.J.; Binder, J.O.; Kelm, T. Demand Side Management through Heat Pumps, Thermal Storage and Battery Storage to Increase Local Self-Consumption and Grid Compatibility of PV Systems. In Proceedings of the 2012 3rd IEEE PES Innovative Smart Grid Technologies Europe (ISGT Europe), Berlin, Germany, 14–17 October 2012; IEEE: New York City, NY, USA, 2012; pp. 1–6. [Google Scholar]

- Thygesen, R.; Karlsson, B. Simulation and Analysis of a Solar Assisted Heat Pump System with Two Different Storage Types for High Levels of PV Electricity Self-Consumption. Sol. Energy 2014, 103, 19–27. [Google Scholar] [CrossRef]

- Nkwetta, D.N.; Haghighat, F. Thermal Energy Storage with Phase Change Material—A State-of-the Art Review. Sustain. Cities Soc. 2014, 10, 87–100. [Google Scholar] [CrossRef]

- Li, Y.; Rosengarten, G.; Stanley, C.; Mojiri, A. Electrification of Residential Heating, Cooling and Hot Water: Load Smoothing Using Onsite Photovoltaics, Heat Pump and Thermal Batteries. J. Energy Storage 2022, 56, 105873. [Google Scholar] [CrossRef]

- Li, Y.; Mojiri, A.; Rosengarten, G.; Stanley, C. Residential Demand-Side Management Using Integrated Solar-Powered Heat Pump and Thermal Storage. Energy Build. 2021, 250, 111234. [Google Scholar] [CrossRef]

- Li, Y.; Rosengarten, G.; Mojiri, A. Performance Sensitivity of Hot and Cold Thermal Storage with Onsite Photovoltaics and Heat Pumps. Sol. Energy 2023, 263, 111946. [Google Scholar] [CrossRef]

- Schwarz, H.; Bertsch, V.; Fichtner, W. Two-Stage Stochastic, Large-Scale Optimization of a Decentralized Energy System: A Case Study Focusing on Solar PV, Heat Pumps and Storage in a Residential Quarter. OR Spectr. 2018, 40, 265–310. [Google Scholar] [CrossRef]

- Arteconi, A.; Ciarrocchi, E.; Pan, Q.; Carducci, F.; Comodi, G.; Polonara, F.; Wang, R. Thermal Energy Storage Coupled with PV Panels for Demand Side Management of Industrial Building Cooling Loads. Appl. Energy 2017, 185, 1984–1993. [Google Scholar] [CrossRef]

- Abdelsalam, M.Y.; Teamah, H.M.; Lightstone, M.F.; Cotton, J.S. Hybrid Thermal Energy Storage with Phase Change Materials for Solar Domestic Hot Water Applications: Direct versus Indirect Heat Exchange Systems. Renew. Energy 2020, 147, 77–88. [Google Scholar] [CrossRef]