Analysis of Flow Distribution and Heat Transfer Characteristics in a Multi-Branch Parallel Liquid Cooling Framework

Abstract

1. Introduction

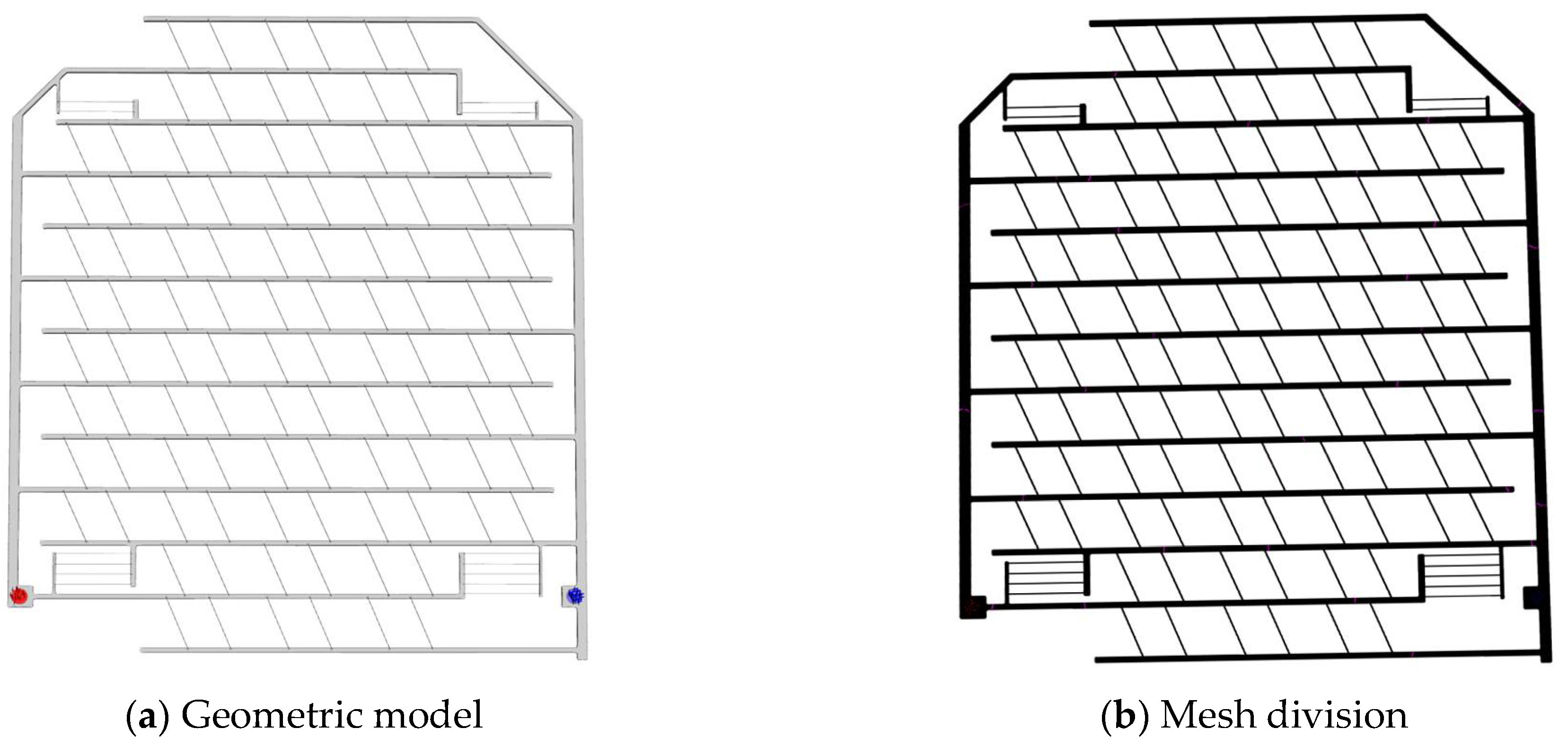

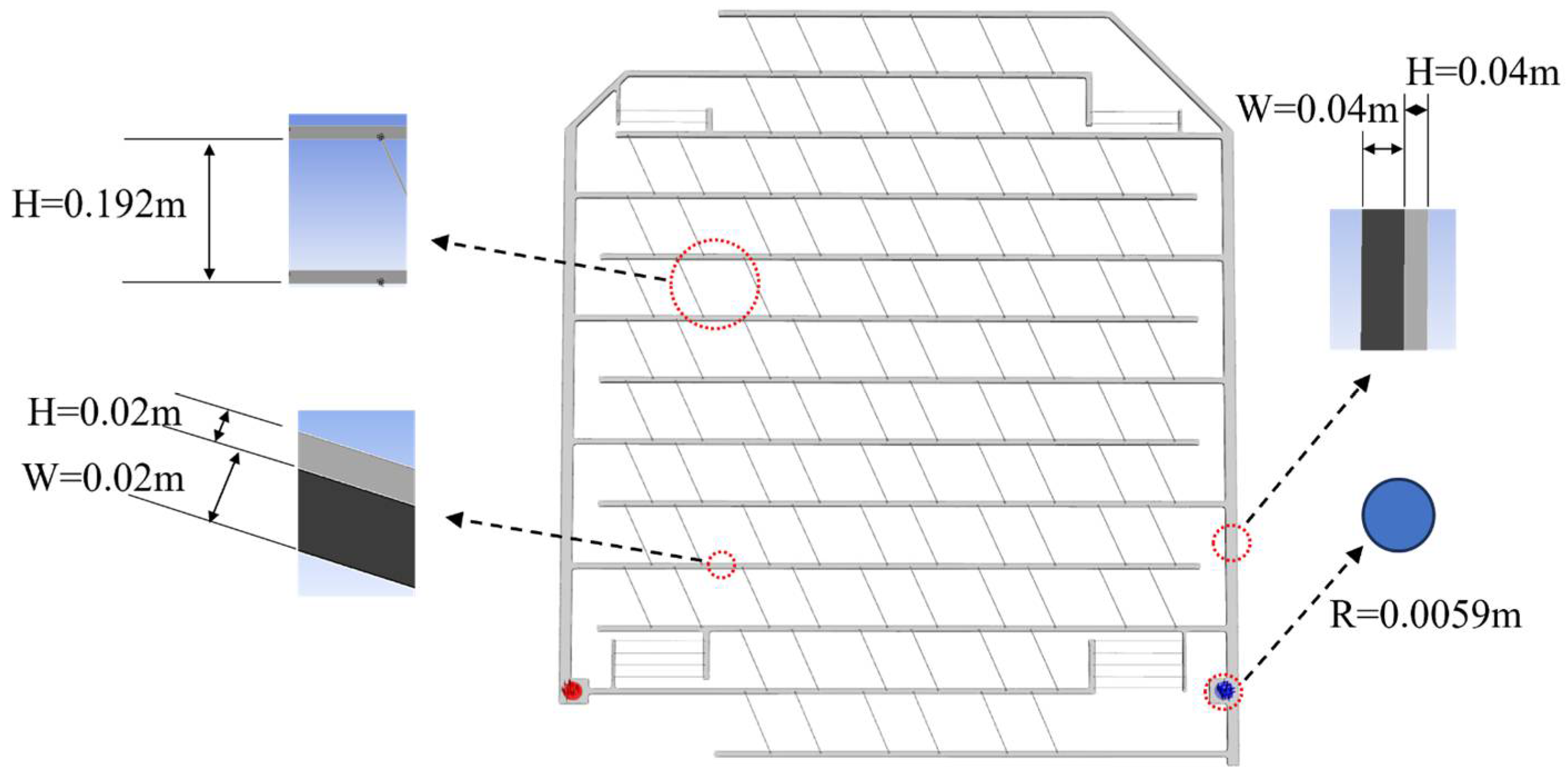

2. Geometric Model, Mesh Division, and Boundary Conditions

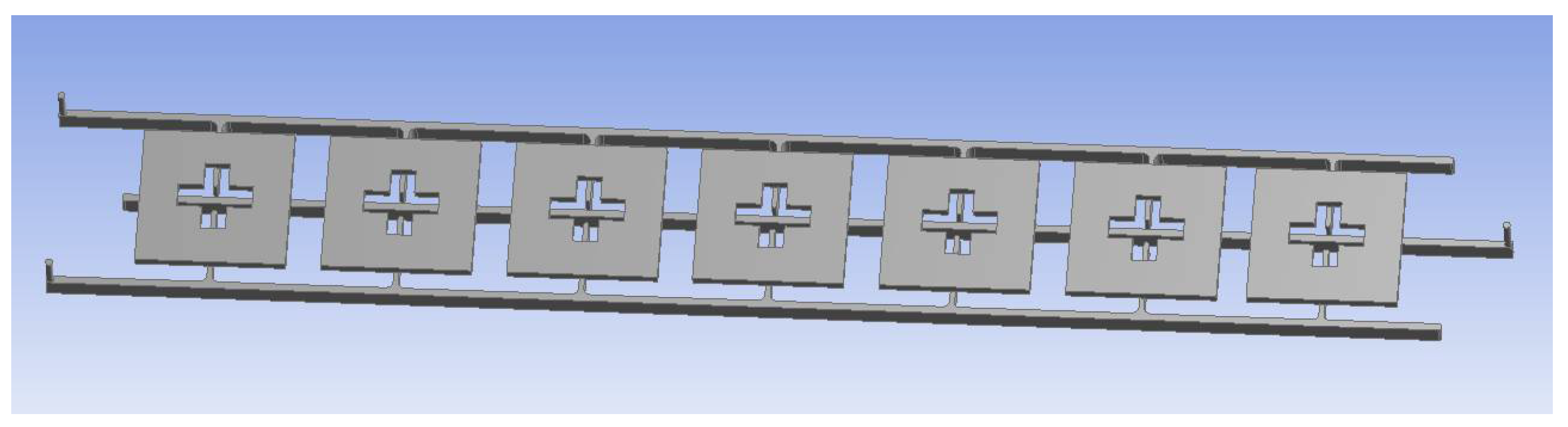

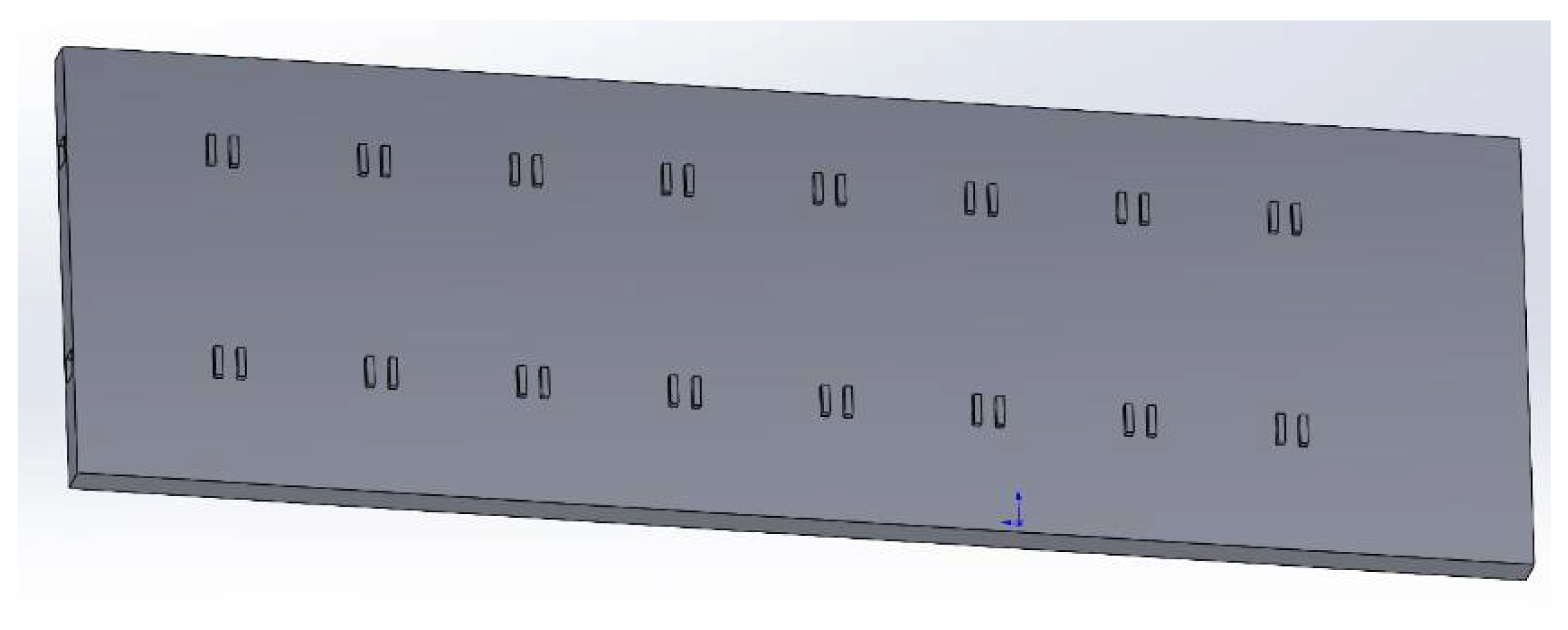

2.1. Geometric Model

2.2. Calculation Method and Boundary Conditions

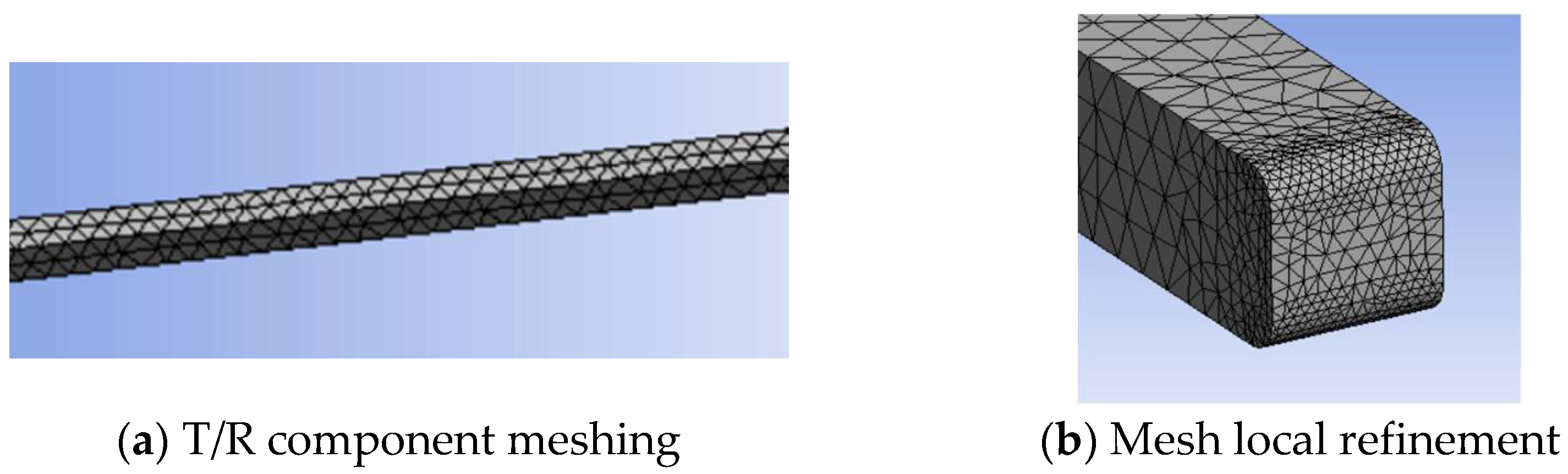

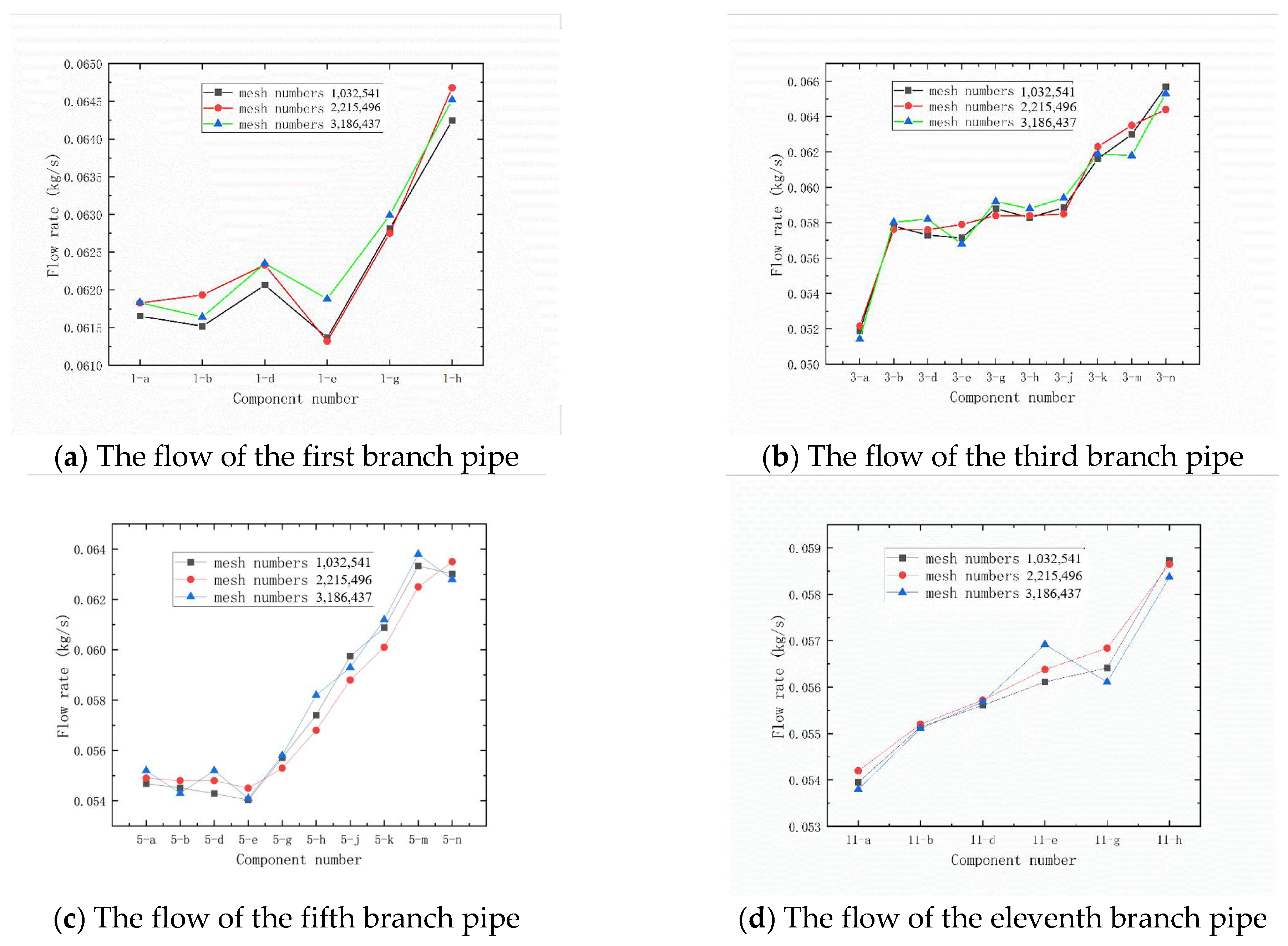

2.3. Mesh Generation and Independence Verification

2.4. Experimental Verification

3. Numerical Simulation Results on Flow Characteristics

3.1. Flow Distribution of the Original Model

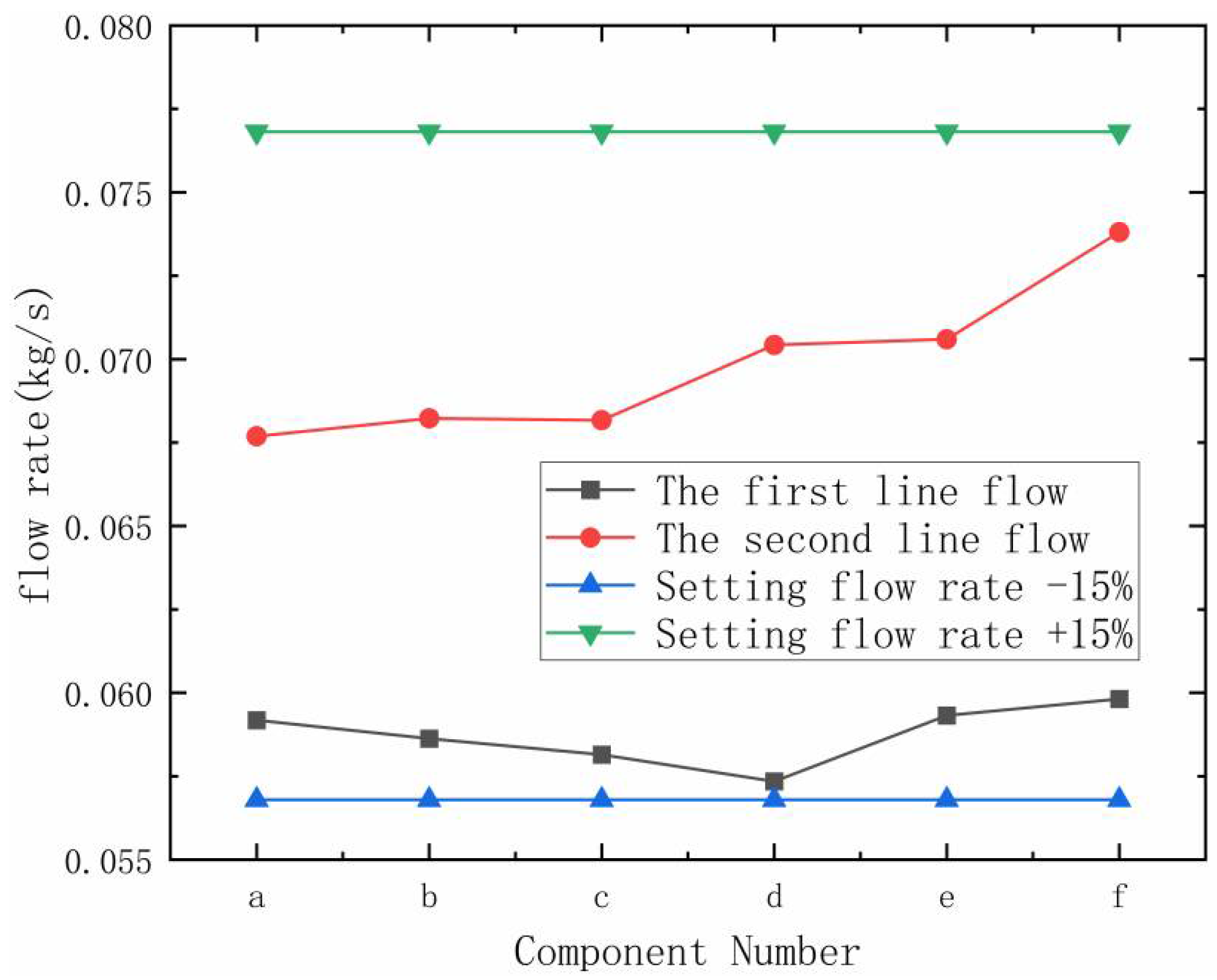

3.2. Flow Distribution of the Improved Model

3.3. The Flow Characteristics with 30% and 50% Concentration of Ethylene Glycol

4. Numerical Simulation Results on Heat Transfer Characteristics

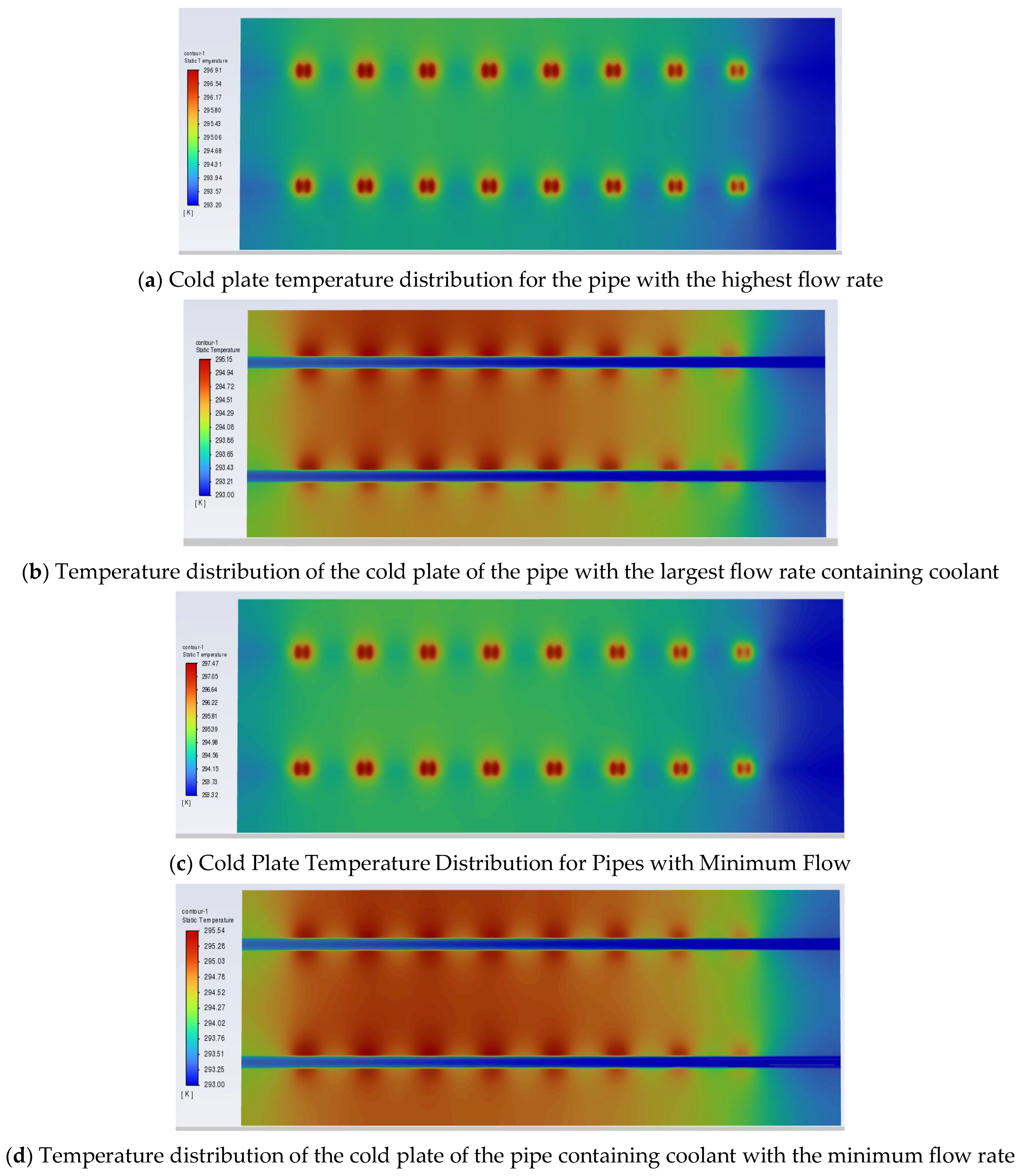

4.1. Different Volume Concentrations of Ethylene Glycol Aqueous Solution

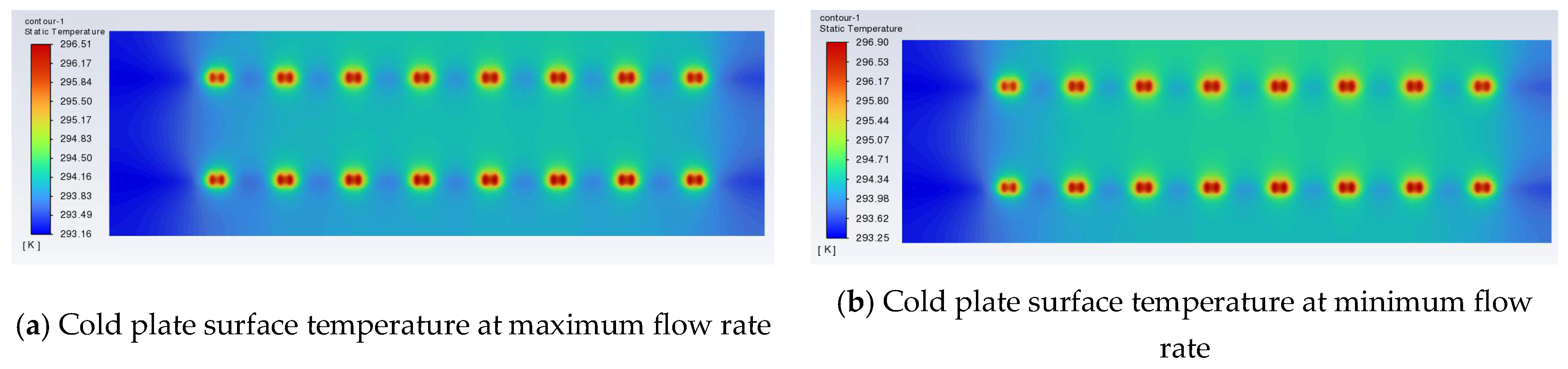

4.1.1. Ethylene Glycol Aqueous Solution of 60% Volume Concentration

4.1.2. Ethylene Glycol Aqueous Solution of 50% and 30% Volume Concentration

4.2. Cooling Effect of the Cold Plate at Different Powers

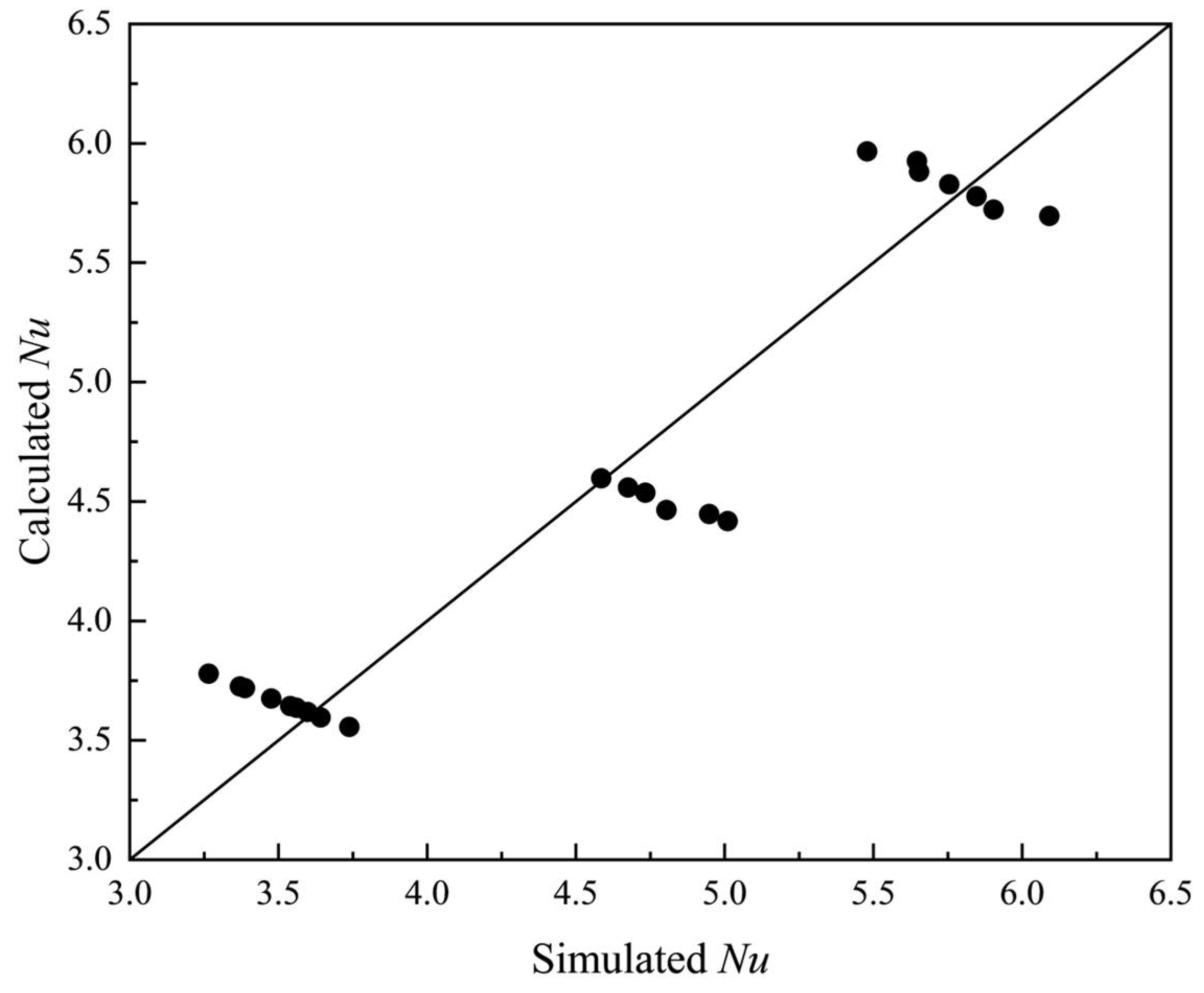

4.3. Analytical Heat Transfer Equation

- —Density, kg/m3;

- u—Flow rate, m/s. The average velocity in the cold plate pipe is used here;

- L—Characteristic length, m. The characteristic length is calculated by the size of the cooling pipe;

- —Kinematic viscosity, Pa·s.

- —Convective heat transfer coefficient, W/(m2·K). The convective heat transfer coefficient is calculated by the heat flux and its average temperature difference, which is the average convective coefficient of the cold plate;

- —Characteristic Length, m. The characteristic length is calculated by the size of the cooling pipe;

- —Thermal Conductivity, W/(m·K).

- —Kinematic viscosity, m2/s;

- —Thermal diffusivity, m2/s.

- —Heat flux density, W/m2. Here is the heat flux density set in the numerical simulation;

- —Solid surface temperature, K;

- —Mainstream temperature of the fluid, K. Here is the average temperature of the coolant.

5. Conclusions

- (1)

- Uneven flow distribution is an inherent issue in multi-branch cold plates. The flow distribution can be improved by modifying the size of the flow channels. In the 6 × 5 parallel multi-branch cold plate, a significant coolant flow occurs through the bottom component near the inlet, where the pressure is the highest in the entire model. As the coolant continues to flow, the flow rate and pressure gradually decline.

- (2)

- Based on the fluid diversion effect, the flow velocity at the coolant inlet reaches the peak value, and the flow velocity and pressure in the main water supply pipe and the branch pipe show a decreasing trend along the way. The overall model shows the hydrodynamic characteristics of the maximum flow velocity near the water supply end and the gradient attenuation with the extension of the pipe. In the reflux pipe, the confluence effect leads to the reverse characteristics of the velocity distribution. The difference in physical parameters of the cooling medium will significantly affect the flow field distribution characteristics of the system. The maximum inlet pressure in the gas supply pipeline is 178,356.92 Pa, which gradually decreases along the main gas supply pipeline. In the cold plate gas supply model, the end of the seventh branch pipe reaches 145,669.109 Pa. In the reflux pipe, the highest pressure appears at the sixth reflux branch pipe, which is 82,896.326 Pa, and the lowest pressure appears at the outlet, which is −4854.48 Pa, resulting in negative pressure.

- (3)

- The overall flow distribution of the 6 × 5 parallel multi-branch cold plate is relatively uniform under the design size. The flow near the inlet is large, and the flow away from the inlet is small. In the single liquid supply branch pipe assembly, the flow rate shows an increasing trend from the liquid supply main pipe to the return main pipe. In the return pipe, the velocity trend is the opposite. When the inlet temperature of 293 K is adopted, the actual flow rate of each component is within the error range of 20% of the design flow rate.

- (4)

- Under the heat source power of 48 W/cm2, the change in ethylene glycol concentration in the cold plate has little effect on the cooling effect of the cold plate. With the increase in the heat flux density of the T/R module, the 6 × 5 parallel multi-branch cooling plate can cool the heating module with the heat flux density less than 500 W/cm2 at the design flow rate.

- (5)

- The heat transfer of the cold plate under different working conditions can be calculated by the fitting formula. The fitting formula can provide a more basic theoretical basis for practical engineering.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yin, Y.L.; Zhu, Z.; Li, P.; Zhang, X.; Liu, X.; Jiang, H.; Zhang, C. Opinions on the research status and development trend of airborne radar cooling technology. Front. Energy Res. 2022, 10, 1047600. [Google Scholar] [CrossRef]

- Park, J.S.; Shin, D.-J.; Yim, S.-H.; Kim, S.-H. Evaluate the cooling performance of transmit/receive module cooling system in active electronically scanned array radar. Electronics 2021, 10, 1044. [Google Scholar] [CrossRef]

- Kubo, T.; Ueda, T. On the characteristics of divided flow and confluent flow in headers. Trans. Jpn. Soc. Mech. Eng. 2008, 12, 802–809. [Google Scholar]

- Qian, S.H.; Wang, W.; Ge, C.; Lou, S.; Miao, E.; Tang, B. Topology optimization of fluid flow channel in cold plate for active phased array antenna. Struct. Multidiscip. Optim. 2018, 57, 2223–2232. [Google Scholar] [CrossRef]

- An, Z.; Gao, W.; Zhang, J.; Liu, H.; Gao, Z. Bionic capillary/honeycomb hybrid lithium-ion battery thermal management system for electric vehicle. Appl. Therm. Eng. 2024, 242, 122444. [Google Scholar] [CrossRef]

- Zuo, W.; Zhang, Y.; Li, J.; Li, Q.; Zhang, G. Performance comparison between single S-channel and double S-channel cold plate for thermal management of a prismatic LiFePO4 battery. Renew. Energy 2022, 192, 46–57. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, X.; Zeng, Q.; Gao, K. Thermal management performance of cavity cold plates for pouch Li-ion batteries using in electric vehicles. Energy Sci. Eng. 2020, 8, 4082–4093. [Google Scholar] [CrossRef]

- Huo, Y.; Rao, Z.; Liu, X.; Zhao, J. Investigation of power battery thermal management by using mini-channel cold plate. Energy Convers. Manag. 2015, 89, 387–395.7. [Google Scholar] [CrossRef]

- Qian, Z.; Li, Y.; Rao, Z. Thermal performance of lithium-ion battery thermal management system by using mini-channel cooling. Energy Convers. Manag. 2016, 126, 622–631. [Google Scholar] [CrossRef]

- Yang, M.; Wang, D.; Fu, Y.; Che, B.; Chen, L.; Zheng, H.; Yu, X.; Huang, L.; Cao, J.; Huang, J. Analysis of factors affecting the flow distribution of multi-branch parallel fluid circuits. Shanghai Aerosp. 2023, 40, 51–58. [Google Scholar]

- Alshare, A.A.; Calzone, F.; Muzzupappa, M. Hydraulic manifold design via additive manufacturing optimized with CFD and fluid-structure interaction simulations. Rapid Prototyp. J. 2019, 25, 1516–1524. [Google Scholar] [CrossRef]

- Urbanowicz, K.; Bergant, A.; Stosiak, M.; Deptuła, A.; Karpenko, M. Navier-Stokes Solutions for Accelerating Pipe Flow—A Review of Analytical Models. Energies 2023, 16, 1407. [Google Scholar] [CrossRef]

- Yang, L.; Wei, Y.; Song, G.; Liu, Z.; Wang, W. Selection and evaluation of turbulence models. In Committee of Science and Technology, China Academy of Aerospace Electronic Technology, Proceedings of the 2020 Academic Annual Meeting of the Science and Technology Committee of China Academy of Aerospace Electronics Technology; Aerospace Times Feihong Technology Co., Ltd.: Beijing, China, 2020; p. 6. [Google Scholar]

- Duan, Z. ANSYS FLUENT Fluid Analysis and Engineering Example; Electronics Industry Press: Beijing, China, 2015. [Google Scholar]

- Wang, G.; Zhang, M. Numerical simulation and cavitation research of throttle valve based on Fluent. Mech. Des. Manuf. Eng. 2025, 54, 24–28. [Google Scholar]

- Zheng, K.J. Study on Natural Convection Heat Transfer Characteristics of Inner Wall of Outer Window under Louver Inner Shading. Master’s Thesis, Southwest Jiaotong University, Chengdu, China, 2022. [Google Scholar]

- Xu, Y.; Li, Q.; Wang, Y.; Tang, W.; Dawar, A.; Kosonen, R.; Zhang, Y.; Zhou, N. Study on heat transfer characteristics of Z-type parallel multi-branch pipe group. Therm. Sci. 2024, 00, 269. [Google Scholar] [CrossRef]

- Cao, Y. Performance Analysis and Optimization of Radar Microwave T/R Module Heat Sink. Master’s Thesis, Changzhou University, Changzhou, China, 2022. [Google Scholar]

- Zheng, J.; Yu, S.; Li, Y.; Yu, P.; Ren, R. Application analysis of liquid circulating heat recovery in lead-acid battery production plant in severe cold and cold regions. Battery 2024, 61, 127–132+146. [Google Scholar]

- Dong, Z. Study on Heat Transfer Enhancement and Parameter Optimization of Plate Solar Collector. Ph.D. Thesis, Huazhong University of Science and Technology, Wuhan, China, 2023. [Google Scholar]

- Hudear, H.R.; Shehab, S.N. Cross Flow Characteristics and Heat Transfer of Staggered Tubes Bundle: A Numerical Study. Front. Heat Mass Transf. 2023, 21, 367–383. [Google Scholar]

- Karpenko, M. Aircraft Hydraulic Drive Energy Losses and Operation Delay Associated with the Pipeline and Fitting Connection. Aviation 2024, 28, 1–8. [Google Scholar] [CrossRef]

- Karpenko, M.; Prentkovskis, O.; Šukevičius, Š. Research on high-pressure hose with repairing fitting and influence on energy parameter of the hydraulic drive. Eksploat. I Niezawodn. 2022, 24, 25–32. [Google Scholar] [CrossRef]

| Type | Boundary Conditions |

|---|---|

| Inlet | Mass flow inlet with a mass flow rate of 6.946 kg/s |

| Outlet | Pressure outlet |

| Wall | Static non-slip wall |

| Adiabatic | |

| Roughness: Ra3.2 | |

| Fluid properties | Viscosity 0.0067 kg/m·s |

| Density 1089 kg/m3 | |

| Ambient temperature Ambient pressure Runner material | Material: aluminum 297 K 101,325 Pa |

| Aluminum alloy |

| Materiality | Parameter Value |

|---|---|

| Density (kg/m3) | 1176 |

| Thermal conductivity (W/m·K) | 0.078 |

| Specific heat capacity (kJ/kg·K) | 1.461 |

| Kinematic coefficient of viscosity (kg/m·s) | 1.8 × 10−4 |

| Temperature (°C) | 20 |

| T/R Component Name | Mass Flow Rate kg/s | Average Value kg/s |

|---|---|---|

| 1-a | 0.0711 | 0.0736 |

| 1-b | 0.0788 | |

| 1-c | 0.0710 | |

| 1-d | 0.0733 | |

| 1-e | 0.0735 | |

| 1-f | 0.0738 | |

| 2-a | 0.0685 | 0.0709 |

| 2-b | 0.0717 | |

| 2-c | 0.0706 | |

| 2-d | 0.0697 | |

| 2-e | 0.0709 | |

| 2-f | 0.0737 |

| Numbering | a | b | c | d | e | f | g | h | i | J |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.0659 | 0.0749 | 0.0671 | 0.0698 | 0.0700 | 0.0709 | / | / | / | / |

| 2 | 0.0642 | 0.0681 | 0.0647 | 0.0661 | 0.0663 | 0.0696 | / | / | / | / |

| 3 | 0.0579 | 0.0643 | 0.0622 | 0.0657 | 0.0628 | 0.0638 | 0.0653 | 0.0664 | 0.0711 | 0.0725 |

| 4 | 0.0631 | 0.0624 | 0.0675 | 0.0662 | 0.0663 | 0.0701 | 0.0695 | 0.0702 | 0.0719 | 0.0712 |

| 5 | 0.0492 | 0.0560 | 0.0561 | 0.0581 | 0.0609 | 0.0596 | 0.0602 | 0.0645 | 0.0660 | 0.0636 |

| 6 | 0.0541 | 0.0579 | 0.0605 | 0.0537 | 0.0619 | 0.0644 | 0.0622 | 0.0657 | 0.0658 | 0.0688 |

| 7 | 0.0503 | 0.0509 | 0.0517 | 0.0556 | 0.0548 | 0.0540 | 0.0560 | 0.0587 | 0.0621 | 0.0650 |

| 8 | 0.0522 | 0.0594 | 0.0596 | 0.0554 | 0.0608 | 0.0570 | 0.0565 | 0.0588 | 0.0602 | 0.0624 |

| 9 | 0.0493 | 0.0558 | 0.0506 | 0.0567 | 0.0560 | 0.0593 | 0.0575 | 0.0577 | 0.0604 | 0.0643 |

| 10 | 0.0548 | 0.0524 | 0.0566 | 0.0557 | 0.0573 | 0.0560 | 0.0604 | 0.0601 | 0.0583 | 0.0616 |

| 11 | 0.0527 | 0.0552 | 0.0588 | 0.0580 | 0.0605 | 0.0507 | / | / | / | / |

| 12 | 0.0574 | 0.0547 | 0.0566 | 0.0588 | 0.0613 | 0.0607 | / | / | / | / |

| Volume Concentration | Density | Specific Heat Capacity | Dynamic Viscosity | Thermal Conductivity |

|---|---|---|---|---|

| Unit | kg/m3 | J/(kg·K) | mPa·s | W/(m·K) |

| 60% | 1086 | 3084 | 5.38 | 0.349 |

| 50% | 1073 | 3281 | 3.94 | 0.380 |

| 30% | 1045 | 3645 | 2.2 | 0.453 |

| Name | Heat Flow Density (W/cm2) | |||

|---|---|---|---|---|

| numerical value | 125 | 300 | 500 | 1000 |

| Maximum temperature of the T/R module K | 312.7 | 338.7 | 358.2 | 445.9 |

| Minimum temperature of the T/R module K | 302.5 | 316.3 | 331.8 | 370.2 |

| Maximum temperature of cold plate K | 304.6 | 320.9 | 339.5 | 386.6 |

| Minimum temperature of cold plate K | 293.8 | 295.3 | 296.3 | 299.6 |

| Flow Velocity kg/s | Re | Nu |

|---|---|---|

| 0.0537 | 6974.026 | 5.479 |

| 0.0538 | 2857.142 | 3.265 |

| 0.0561 | 2979.288 | 4.585 |

| 0.0561 | 7285.714 | 5.647 |

| 0.0588 | 3122.676 | 3.370 |

| 0.0588 | 7636.363 | 5.653 |

| 0.0592 | 3143.919 | 4.675 |

| 0.0595 | 3159.851 | 3.387 |

| 0.0610 | 3239.511 | 4.733 |

| 0.0622 | 8077.922 | 5.755 |

| 0.0657 | 8532.467 | 5.846 |

| 0.0675 | 3584.705 | 4.804 |

| 0.0677 | 3595.326 | 3.539 |

| 0.0685 | 3637.812 | 3.560 |

| 0.0691 | 3669.676 | 4.948 |

| 0.0698 | 9064.935 | 5.904 |

| 0.0706 | 3749.336 | 3.598 |

| 0.0719 | 9337.662 | 6.091 |

| 0.0721 | 3828.996 | 5.010 |

| 0.0735 | 3903.345 | 3.641 |

| 0.0788 | 4184.811 | 3.738 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Q.; Wang, Y.; Tang, W.; Kosonen, R.; Xu, L.; Yang, X.; Yang, Z.; Sun, X. Analysis of Flow Distribution and Heat Transfer Characteristics in a Multi-Branch Parallel Liquid Cooling Framework. Energies 2025, 18, 3266. https://doi.org/10.3390/en18133266

Li Q, Wang Y, Tang W, Kosonen R, Xu L, Yang X, Yang Z, Sun X. Analysis of Flow Distribution and Heat Transfer Characteristics in a Multi-Branch Parallel Liquid Cooling Framework. Energies. 2025; 18(13):3266. https://doi.org/10.3390/en18133266

Chicago/Turabian StyleLi, Qipeng, Yu Wang, Wenhui Tang, Risto Kosonen, Lujiang Xu, Xuejing Yang, Zhengchao Yang, and Xiaoyi Sun. 2025. "Analysis of Flow Distribution and Heat Transfer Characteristics in a Multi-Branch Parallel Liquid Cooling Framework" Energies 18, no. 13: 3266. https://doi.org/10.3390/en18133266

APA StyleLi, Q., Wang, Y., Tang, W., Kosonen, R., Xu, L., Yang, X., Yang, Z., & Sun, X. (2025). Analysis of Flow Distribution and Heat Transfer Characteristics in a Multi-Branch Parallel Liquid Cooling Framework. Energies, 18(13), 3266. https://doi.org/10.3390/en18133266