Experimental Study of the Effect by Double-Stage Throttling on the Pressure Relief Characteristics of a Large-Scale CO2 Transportation Pipeline

Abstract

1. Introduction

2. Experimental Setup

- (1)

- First, inject gas-phase CO2 into the main pipeline for evacuation to sweep out the gas in the pipeline.

- (2)

- Inject liquid-phase CO2 into the main pipeline.

- (3)

- Turn on the heating system to heat the CO2 inside the pipeline so that its temperature and pressure reach the set experimental value.

- (4)

- Notify the experimenter to arrive at the designated location and check all data acquisition systems for normal operation.

- (5)

- Turn on the data acquisition system and open the throttle valve to conduct the venting experiment. The pressure and temperature were obtained by pressure sensors and type-K thermocouples, respectively. The pressure sensor had a response frequency of 5 Hz and a pressure measurement range of 0 to 16 MPa, while the type-K thermocouple had a response frequency of 5 Hz and a measurement range of −200 to 1300 °C. We performed some calibration of the response time of the thermocouple by suddenly removing the thermocouple from the surrounding air and placing it in an ice mixture. The temperature change was then recorded by an NI temperature card and a PC. The response times obtained from the two tests were 1.75 s and 0.87 s. Therefore, the average value of 1.31 s can be used as a reference.

3. Results

3.1. Pressure Variation Rule

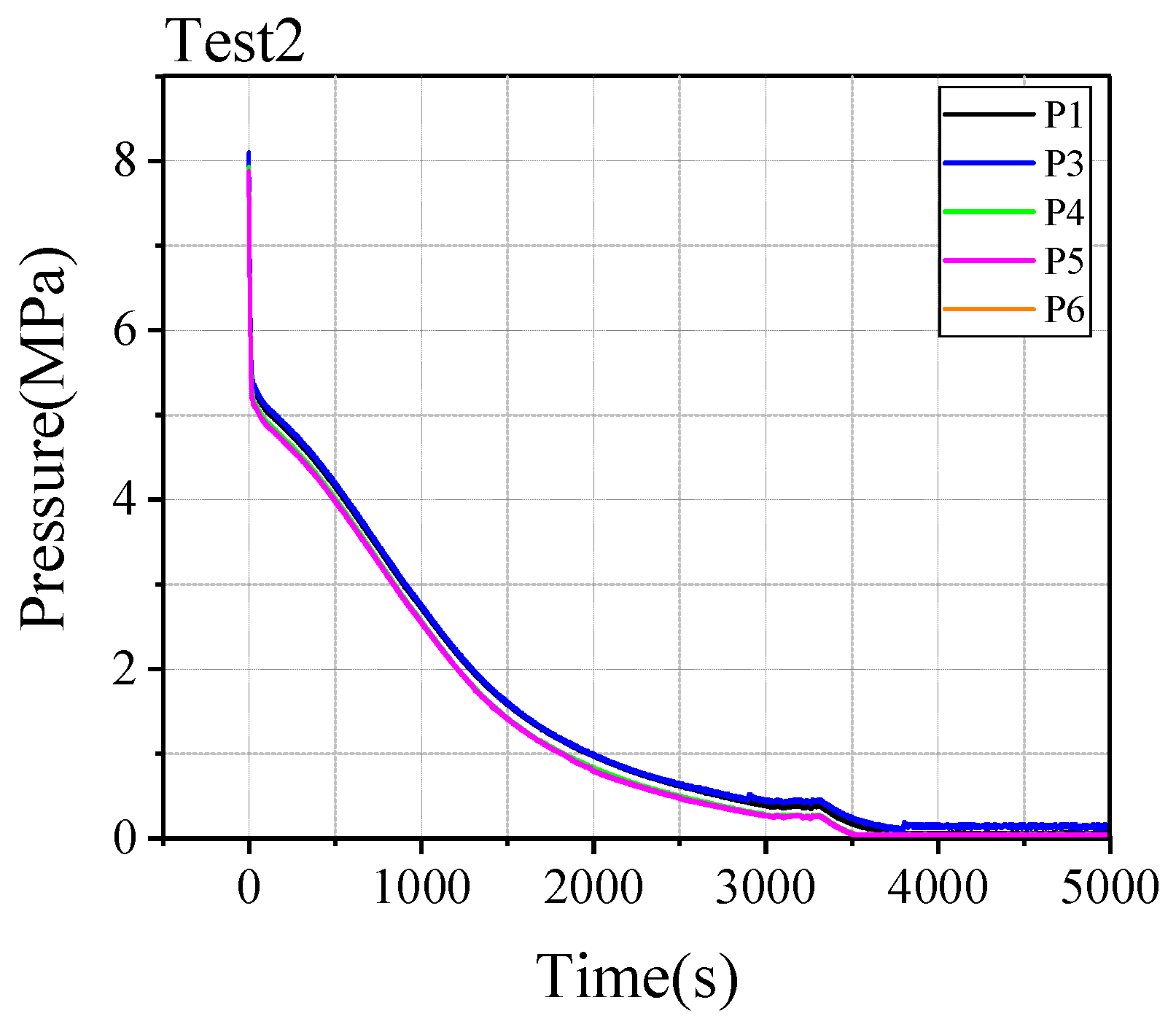

3.1.1. Result of Pressure Variation in the Main Pipeline

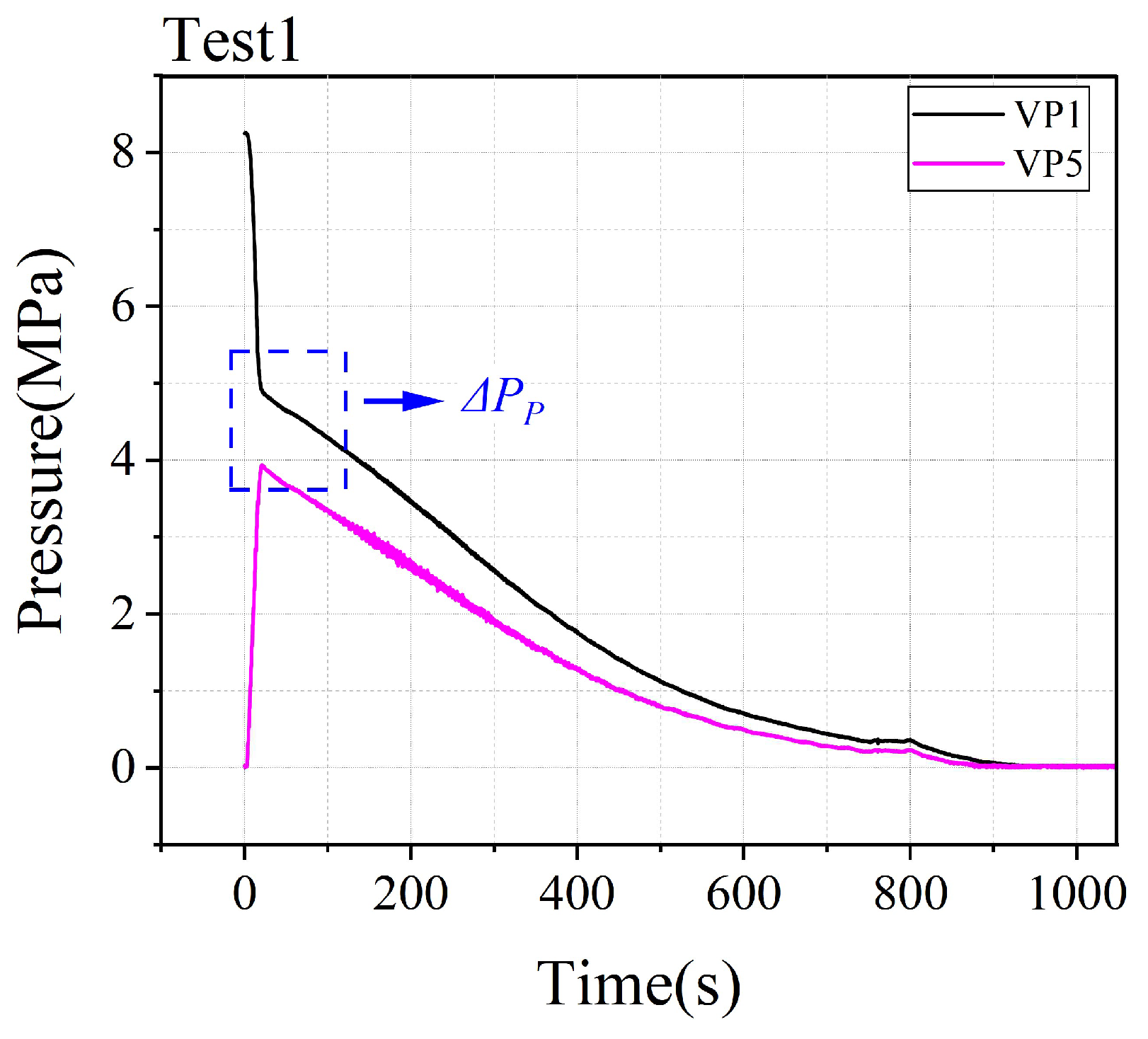

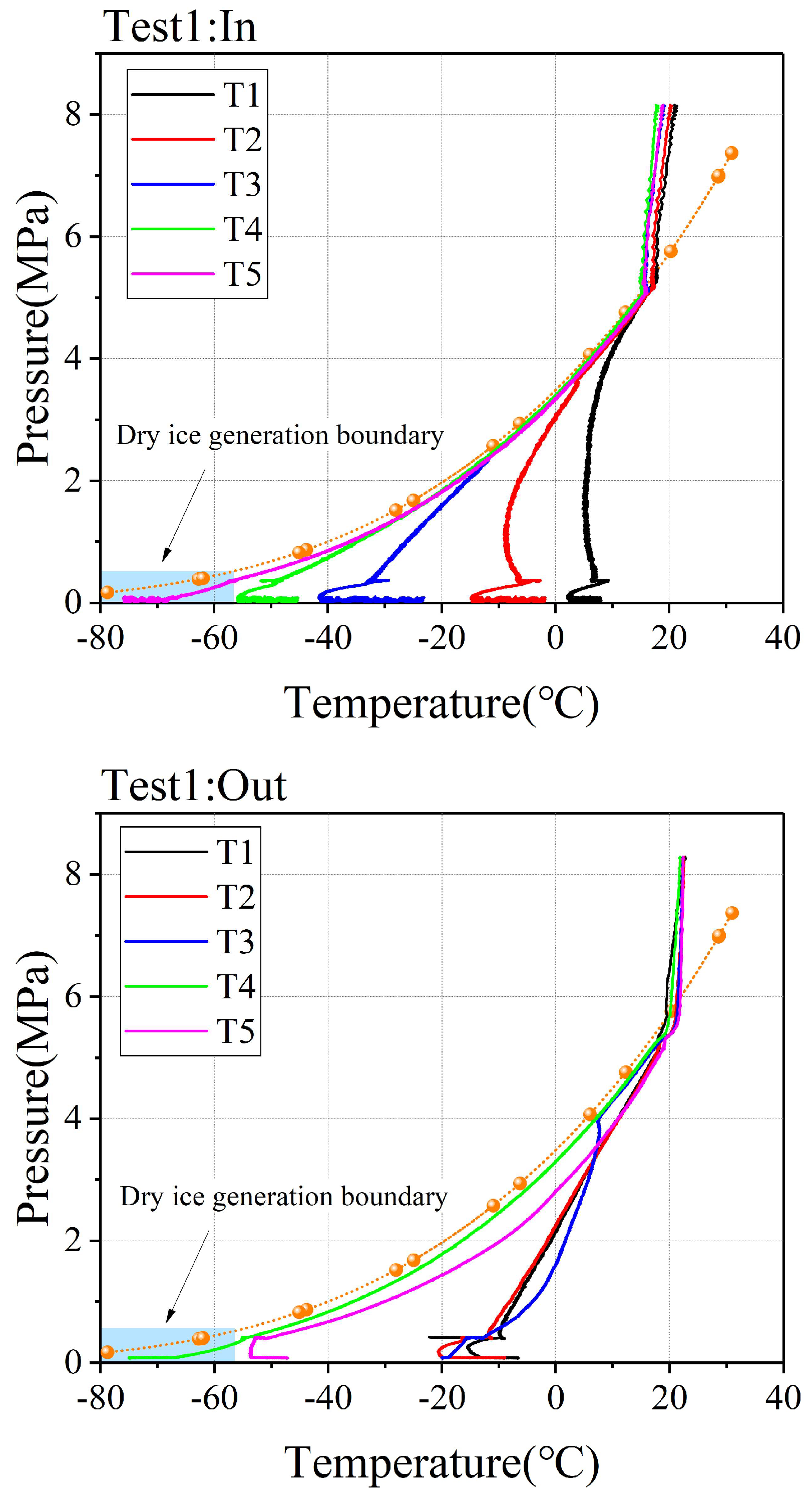

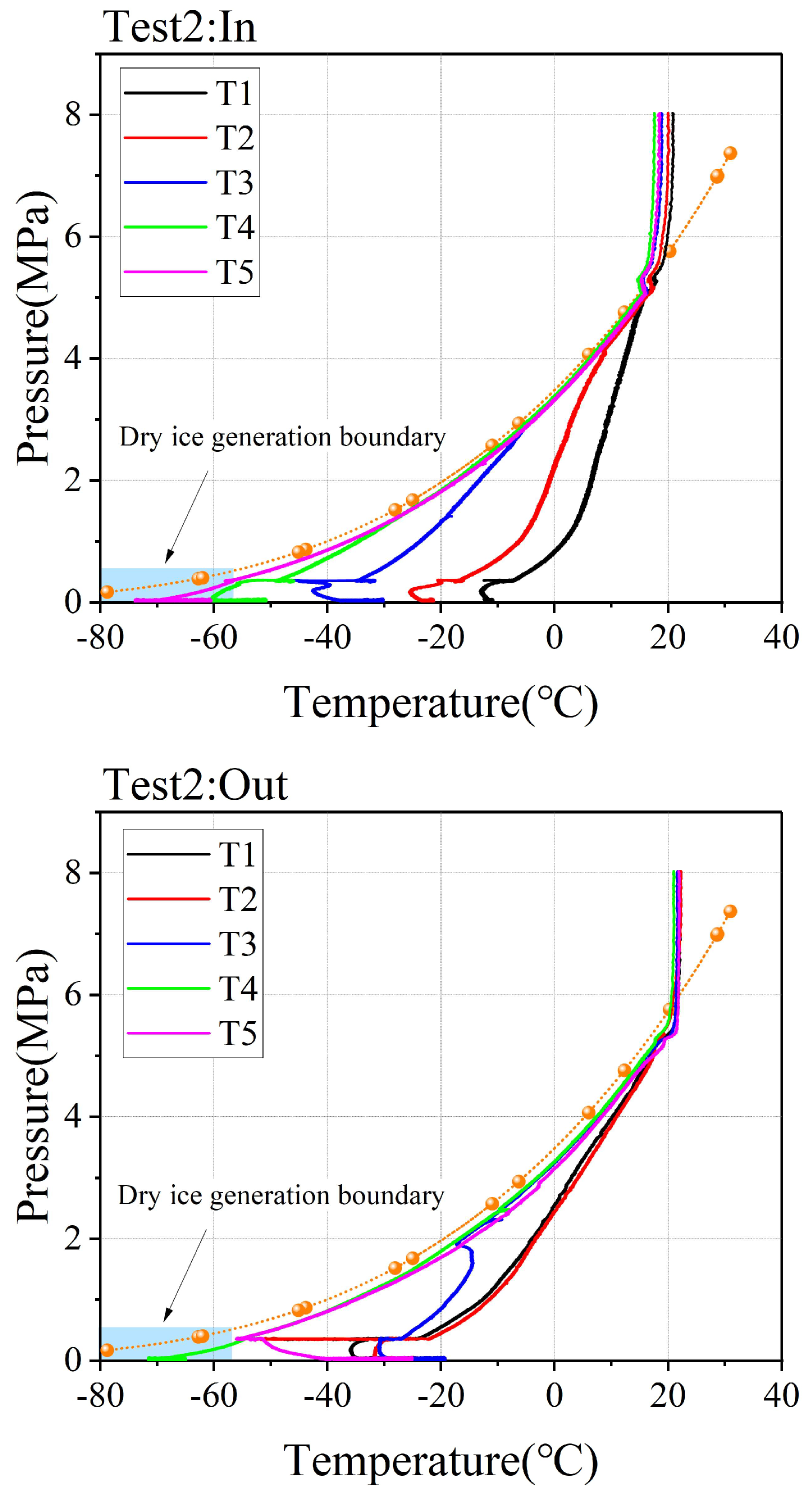

3.1.2. Results of Pressure Variation in the Vertical Pipe

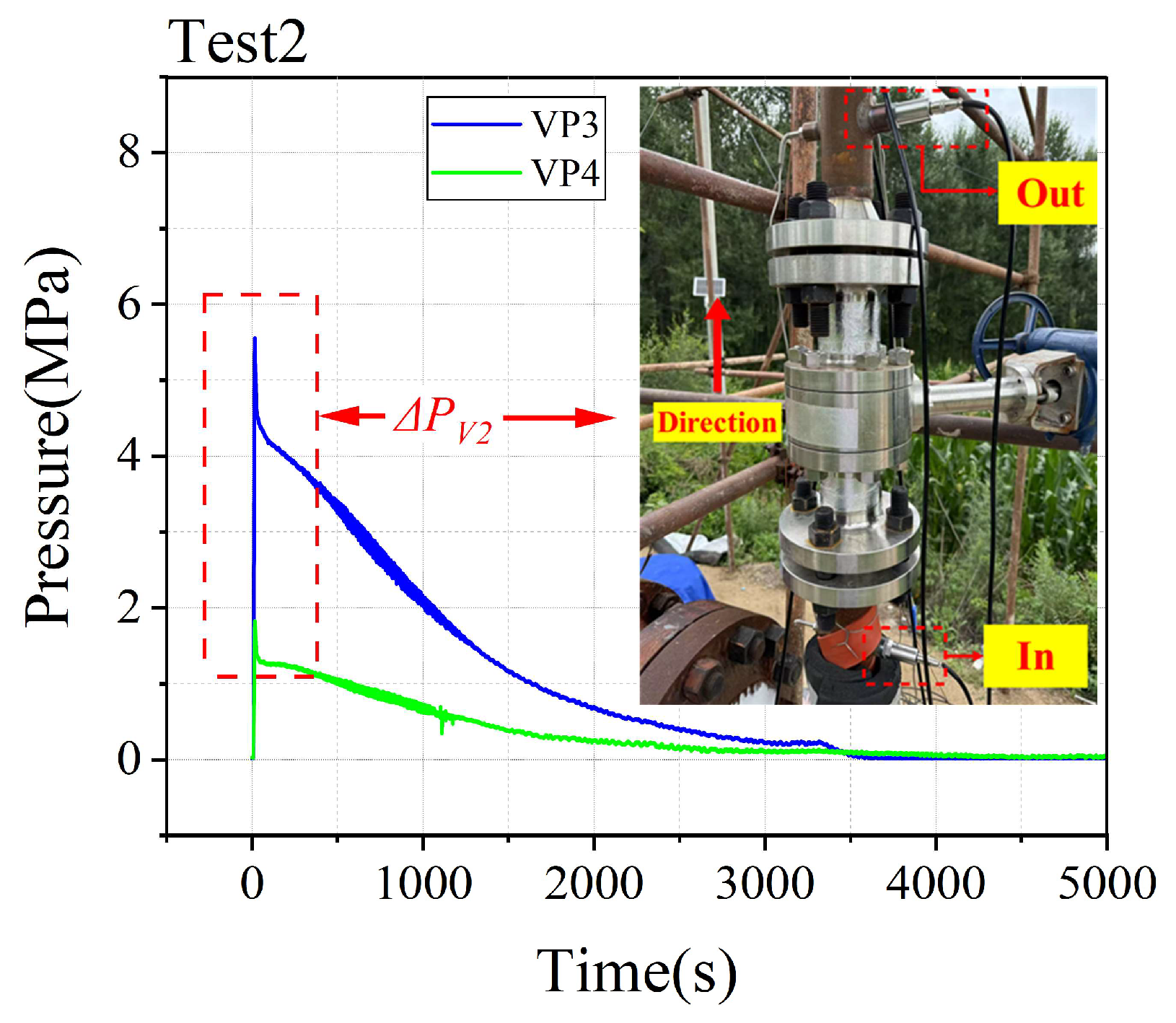

3.1.3. Results of Pressure Variation in the Venting Valve

3.2. Temperature Variation Rule

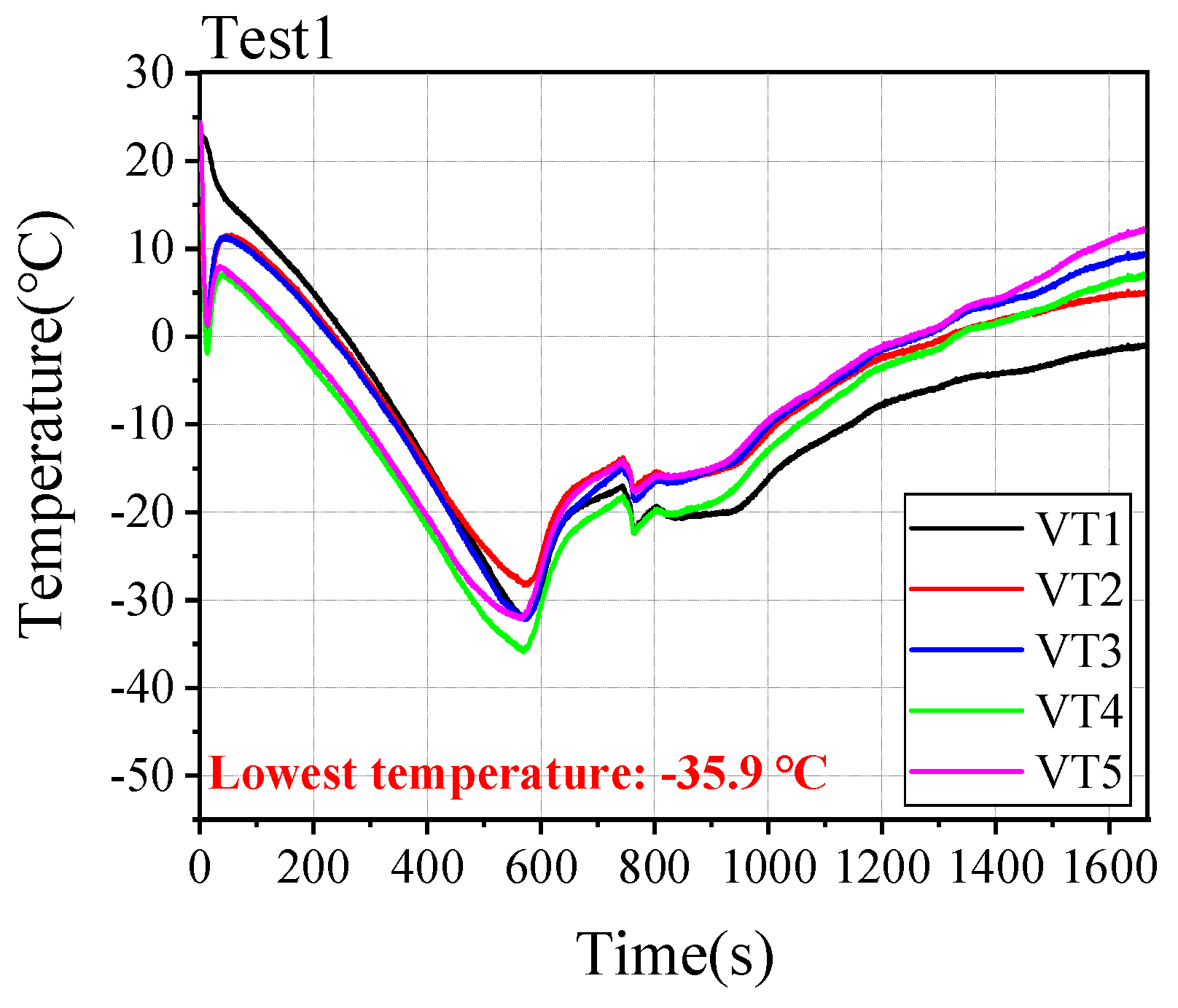

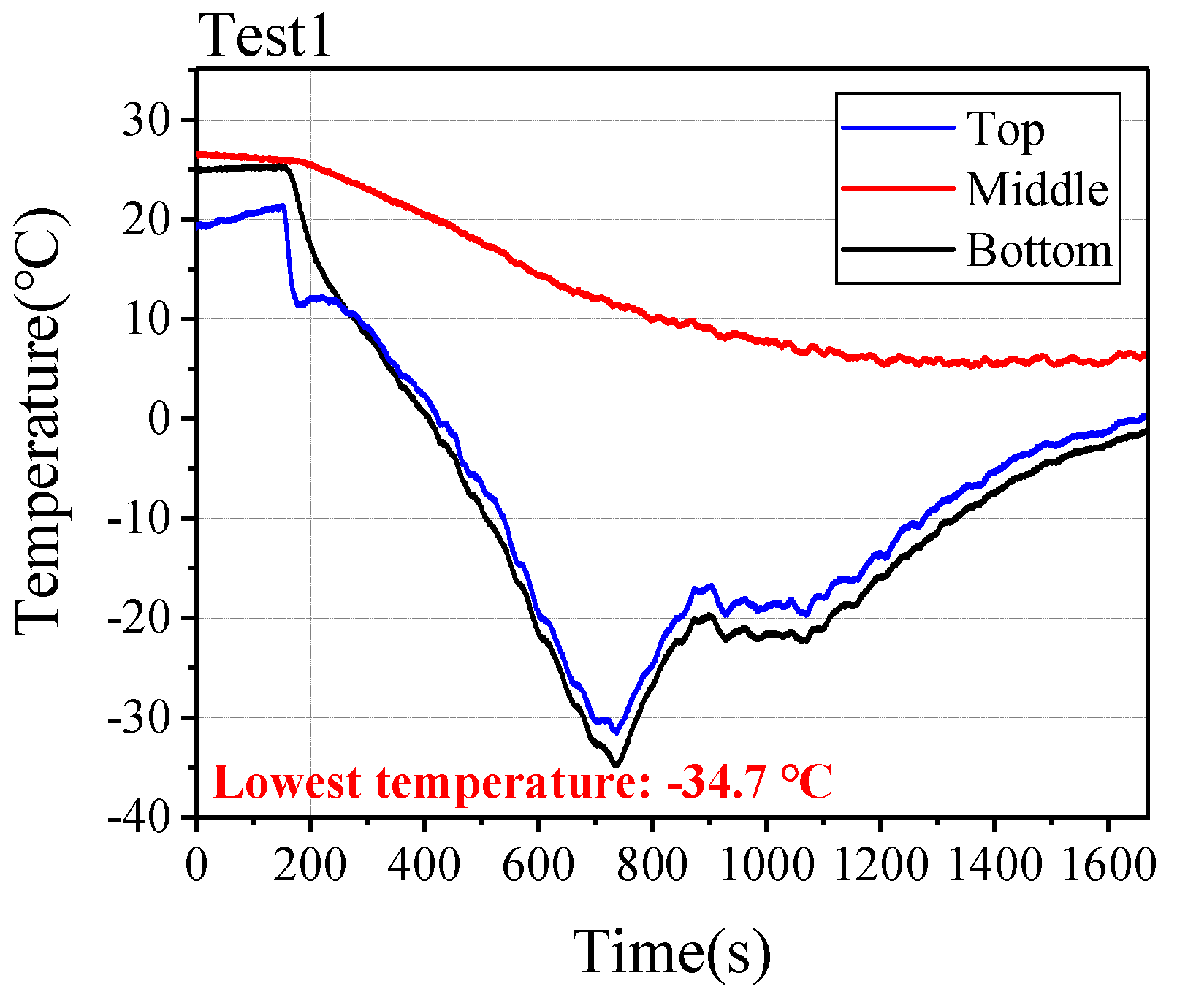

3.2.1. Temperature Variation Results of the Main Pipeline

3.2.2. Results of Temperature Variation in the Vertical Pipe

3.2.3. Results of Temperature Variation in the Venting Valve

4. Discussion

4.1. Unsteady-State Phase Transitions

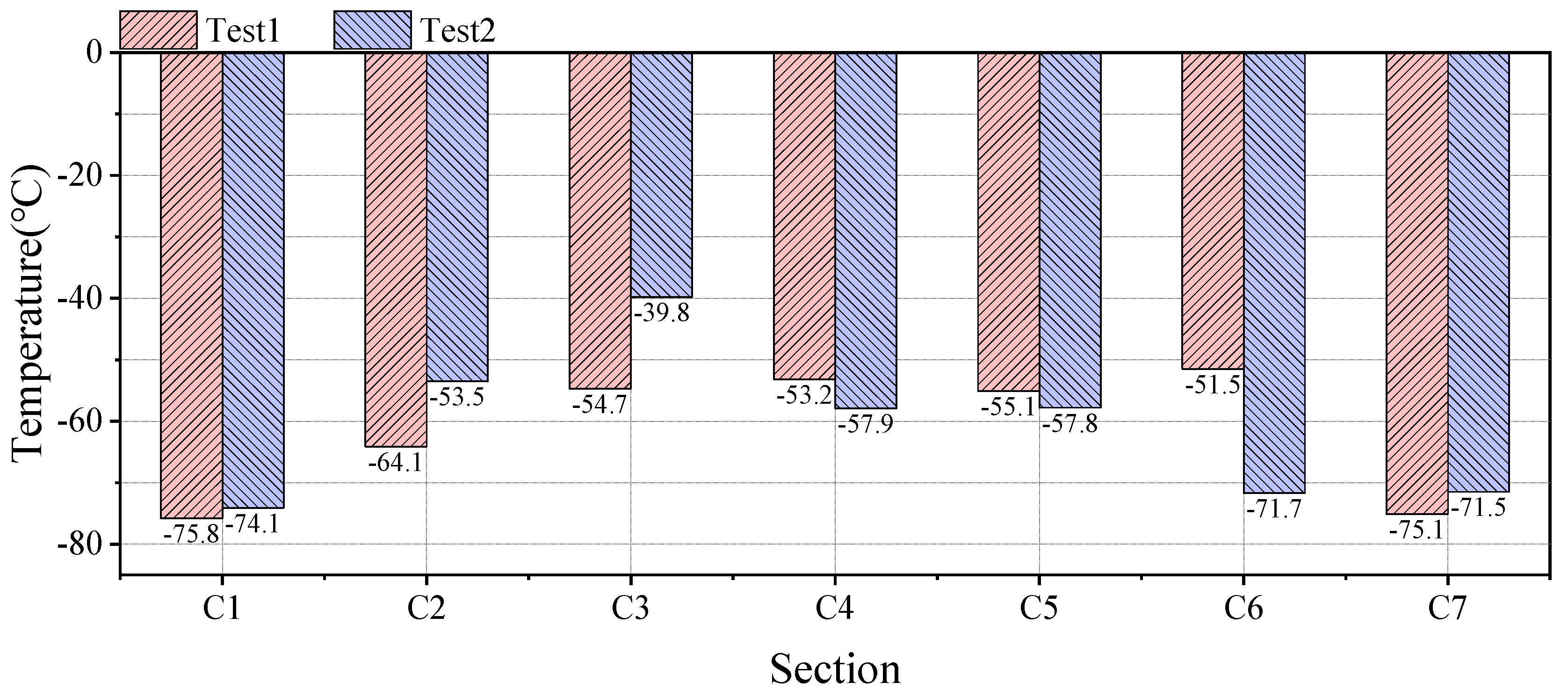

4.2. Temperature Drop Limit in the Main Pipeline

4.3. Risk of Freezing of Vertical Pipe and Valves

5. Conclusions

- (1)

- When using the double-stage throttling and pressure relief program, the increase in the length of the pressure relief process makes the pressure drop rate of the main pipeline decrease. Therefore, although the double-stage throttling and pressure relief program will increase the time required to relieve the pressure in long-distance industrial pipelines, it will effectively improve the structural stability of the pressure relief process.

- (2)

- The double-stage throttling relief process reduces the risk of hypothermia in the upstream section of the main pipeline compared with the direct pressure relief process, but increases the temperature drop limit in the downstream section. Therefore, when the double-stage throttling scheme is used to relieve pressure, the downstream section of the main pipeline should be protected from low temperatures by artificial heating.

- (3)

- Even if no dry ice is generated at the inlet of the relief device, the relief valve is still exposed to the threat of dry ice carried in by the gas–solid multiphase flow of the main pipeline. Therefore, in order to prevent the risk of valve freeze-up in long-distance industrial pipelines, it is recommended that the valve be shut down in order to return it to the appropriate temperature and an intermittent pressure relief program be used during the long pressure relief process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pham, L.H.H.P.; Rusli, R. A review of experimental and modelling methods for accidental release behaviour of high-pressurised CO2 pipelines at atmospheric environment. Process Saf. Environ. Prot. 2016, 104, 48–84. [Google Scholar] [CrossRef]

- Al Baroudi, H.; Patchigolla, K.; Thanganadar, D.; Jonnalagadda, K. Experimental study of accidental leakage behaviour of liquid CO2 under shipping conditions. Process Saf. Environ. Prot. 2021, 153, 439–451. [Google Scholar] [CrossRef]

- Mocellin, P.; Vianello, C.; Maschio, G. Hazard investigation of dry–ice bank induced risks related to rapid depressurization of CCS pipelines: Analysis of different numerical modelling approaches. Int. J. Greenh. Gas Control 2016, 55, 82–96. [Google Scholar] [CrossRef]

- Khudhair Mohammed, R.; Farzaneh, H. Investigating the impact of the future carbon market on the profitability of carbon capture, utilization, and storage (CCUS) projects; the case of oil fields in southern Iraq. Energy Convers. Manag. X 2024, 22, 100562. [Google Scholar] [CrossRef]

- Liu, X.; Godbole, A.; Lu, C.; Michal, G.; Venton, P. Study of the consequences of CO2 released from high-pressure pipelines. Atmos. Environ. 2015, 116, 51–64. [Google Scholar] [CrossRef]

- Vitali, M.; Zuliani, C.; Corvaro, F.; Marchetti, B.; Tallone, F. Statistical analysis of incidents on onshore CO2 pipelines based on PHMSA database. J. Loss Prev. Process Ind. 2022, 74, 200–210. [Google Scholar] [CrossRef]

- Guo, X.; Yan, X.; Yu, J.; Yang, Y.; Zhang, Y.; Chen, S.; Mahgerefteh, H.; Martynov, S.; Collard, A. Pressure responses and phase transitions during the release of high pressure CO2 from a large-scale pipeline. Energy 2017, 118, 1066–1078. [Google Scholar] [CrossRef]

- Yan, X.; Guo, X.; Yu, J.; Chen, S.; Zhang, Y.; Mahgerefteh, H.; Martynov, S.; Brown, S. Flow characteristics and dispersion during the vertical anthropogenic venting of supercritical CO2 from an industrial scale pipeline. Energy Procedia 2018, 154, 66–72. [Google Scholar] [CrossRef]

- Chaczykowski, M.; Osiadacz, A.J. Dynamic simulation of pipelines containing dense phase/supercritical CO2-rich mixtures for carbon capture and storage. Int. J. Greenh. Gas Control 2012, 9, 446–456. [Google Scholar] [CrossRef]

- Yu, S.; Yan, X.; He, Y.; Hu, Y.; Qiao, F.; Yang, K.; Cao, Z.; Chen, L.; Liu, Z.; Yu, J.; et al. Study on the effect of valve openings and multi-stage throttling structures on the pressure and temperature during CO2 pipeline venting processes. Energy 2024, 308, 132967. [Google Scholar] [CrossRef]

- Guo, X.; Yan, X.; Zheng, Y.; Yu, J.; Zhang, Y.; Chen, S.; Chen, L.; Mahgerefteh, H.; Martynov, S.; Collard, A.; et al. Under-expanded jets and dispersion in high pressure CO2 releases from an industrial scale pipeline. Energy 2017, 119, 53–66. [Google Scholar] [CrossRef]

- Cao, Q.; Yan, X.; Yu, S.; Yu, J.; Chen, S.; Zhang, Y.; Guo, X. Experimental Investigation of the Characteristics of Supercritical CO2 during the Venting Process. Int. J. Greenh. Gas Control 2021, 110, 103424. [Google Scholar] [CrossRef]

- Woolley, R.M.; Fairweather, M.; Wareing, C.J.; Falle, S.A.; Mahgerefteh, H.; Martynov, S.; Brown, S.; Narasimhamurthy, V.D.; Storvik, I.E.; Sælen, L.; et al. CO2 PipeHaz: Quantitative Hazard Assessment for Next Generation CO2 Pipelines. Energy Procedia 2014, 63, 2510–2529. [Google Scholar] [CrossRef]

- Joshi, P.; Bikkina, P.; Wang, Q. Consequence analysis of accidental release of supercritical carbon dioxide from high pressure pipelines. Int. J. Greenh. Gas Control 2016, 55, 166–176. [Google Scholar] [CrossRef]

- Fan, X.; Wang, Y.; Zhou, Y.; Chen, J.; Huang, Y.; Wang, J. Experimental study of supercritical CO2 leakage behavior from pressurized vessels. Energy 2018, 150, 342–350. [Google Scholar] [CrossRef]

- Vitali, M.; Corvaro, F.; Marchetti, B.; Terenzi, A. Thermodynamic challenges for CO2 pipelines design: A critical review on the effects of impurities, water content, and low temperature. Int. J. Greenh. Gas Control 2022, 114, 103605. [Google Scholar] [CrossRef]

- Xie, Q.; Tu, R.; Jiang, X.; Li, K.; Zhou, X. The leakage behavior of supercritical CO2 flow in an experimental pipeline system. Appl. Energy 2014, 130, 574–580. [Google Scholar] [CrossRef]

- Wang, C.; Li, Y.; Teng, L.; Gu, S.; Hu, Q.; Zhang, D.; Ye, X.; Wang, J. Experimental study on dispersion behavior during the leakage of high pressure CO2 pipelines. Exp. Therm. Fluid Sci. 2019, 105, 77–84. [Google Scholar] [CrossRef]

- Gu, S.; Li, Y.; Teng, L.; Wang, C.; Hu, Q.; Zhang, D.; Ye, X.; Wang, J.; Iglauer, S. An experimental study on the flow characteristics during the leakage of high pressure CO2 pipelines. Process Saf. Environ. Prot. 2019, 125, 92–101. [Google Scholar] [CrossRef]

- Li, K.; Zhou, X.; Tu, R.; Tu, H.; Fang, Y.; Su, L. Investigation of flow characteristics in small-scale highly pressurized leaked CO2 jet plume from pipeline. Int. J. Therm. Sci. 2019, 141, 160–170. [Google Scholar] [CrossRef]

- Koeijer, G.; Borch, J.H.; Jakobsenb, J.; Drescher, M. Experiments and modeling of two-phase transient flow during CO2 pipeline depressurization. Energy Procedia 2009, 1, 1683–1689. [Google Scholar] [CrossRef]

- Wareing, C.J.; Fairweather, M.; Falle, S.A.; Woolley, R.M.; Ward, A.M. High pressure CO2 CCS pipelines: Comparing dispersion models with multiple experimental datasets. Int. J. Greenh. Gas Control 2016, 54, 716–726. [Google Scholar] [CrossRef]

- Lankadasu, A.; Tripathi, A.; Saysset, S.; Yackow, A.; De La Roussiere, B. Numerical Modeling of Supercritical CO2 Leaks and its Subsequent Dispersion in the Ambient Air. Procedia IUTAM 2015, 15, 49–56. [Google Scholar] [CrossRef]

- Liu, X.; Godbole, A.; Lu, C.; Michal, G.; Venton, P. Source strength and dispersion of CO2 releases from high-pressure pipelines: CFD model using real gas equation of state. Appl. Energy 2014, 126, 56–68. [Google Scholar] [CrossRef]

- Aursand, E.; Aursand, P.; Hammer, M.; Lund, H. The influence of CO2 mixture composition and equations of state on simulations of transient pipeline decompression. Int. J. Greenh. Gas Control 2016, 54, 599–609. [Google Scholar] [CrossRef]

- Karpenko, M.; Stosiak, M.; Šukevičius, Š.; Skačkauskas, P.; Urbanowicz, K.; Deptuła, A. Hydrodynamic Processes in Angular Fitting Connections of a Transport Machine’s Hydraulic Drive. Machines 2023, 11, 355. [Google Scholar] [CrossRef]

- Vitali, M.; Leporini, M.; Masi, O.; Speranza, A.; Corvaro, F.; Marchetti, B. Net zero Flow Assurance—Validation of various equations of state for the prediction of VLE and density of CO2-rich mixtures for CCUS applications. Int. J. Greenh. Gas Control 2023, 125, 103877. [Google Scholar] [CrossRef]

- Mahgerefteh, H.; Zhang, P.; Brown, S. Modelling brittle fracture propagation in gas and dense-phase CO2 transportation pipelines. Int. J. Greenh. Gas Control 2016, 46, 39–47. [Google Scholar] [CrossRef]

| Section Sequence | C1 | C2 | C3 | C4 | C5 | C6 | C7 |

|---|---|---|---|---|---|---|---|

| Length/m | 20.6 | 96.0 | 149.2 | 203.8 | 247.6 | 250.6 | 257.3 |

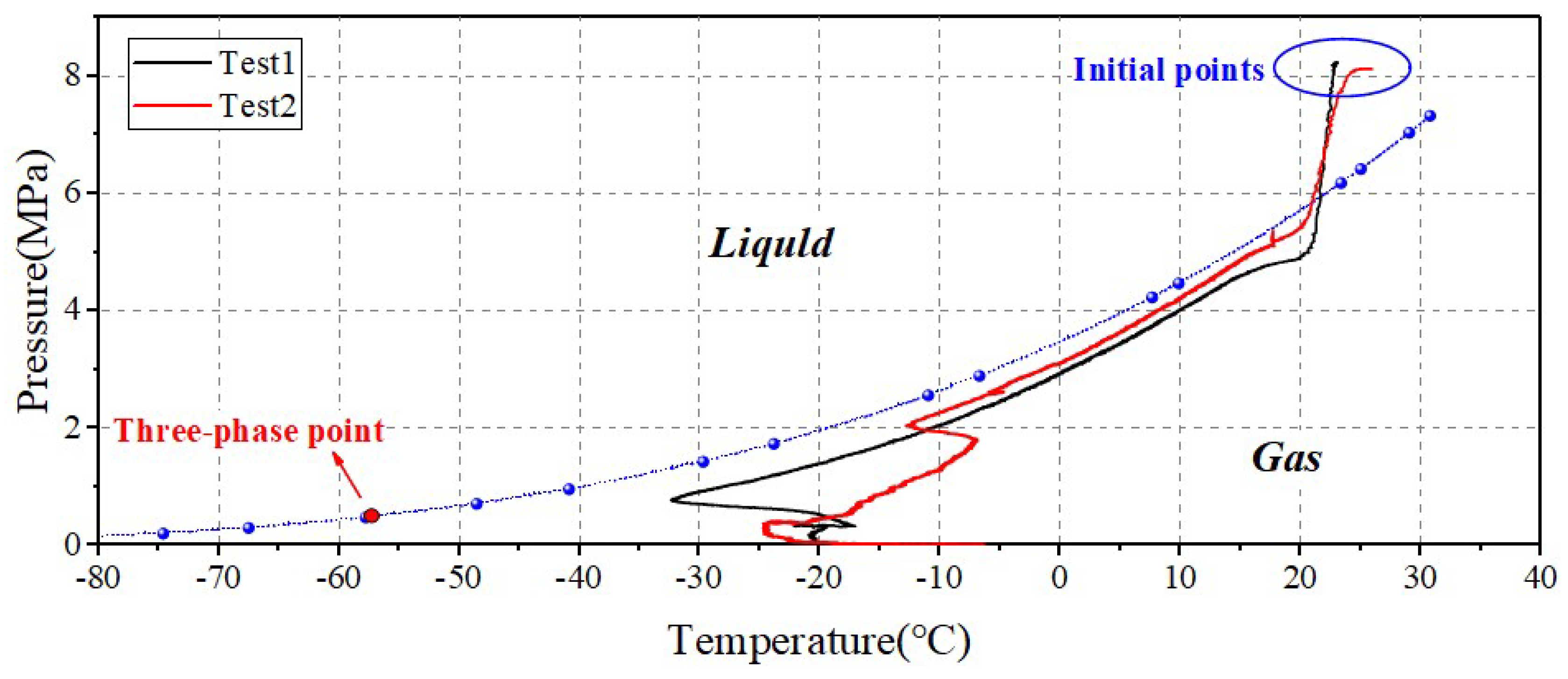

| Experimental Group | Initial Temperature/°C | Initial Pressure/MPa | Throttle Valve Opening | Emptying Program |

|---|---|---|---|---|

| Test1 | 20.2 | 8.3 | 100% | Direct venting |

| Test2 | 19.8 | 8.1 | 50% | Double-stage throttle |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, H.; Wang, T.; Qi, J.; Jin, K.; Liu, J.; Li, F.; Qiao, F.; Zhao, K.; Yin, B.; Yu, J. Experimental Study of the Effect by Double-Stage Throttling on the Pressure Relief Characteristics of a Large-Scale CO2 Transportation Pipeline. Energies 2025, 18, 3244. https://doi.org/10.3390/en18133244

Song H, Wang T, Qi J, Jin K, Liu J, Li F, Qiao F, Zhao K, Yin B, Yu J. Experimental Study of the Effect by Double-Stage Throttling on the Pressure Relief Characteristics of a Large-Scale CO2 Transportation Pipeline. Energies. 2025; 18(13):3244. https://doi.org/10.3390/en18133244

Chicago/Turabian StyleSong, Huifang, Tingyi Wang, Jingjing Qi, Kai Jin, Jia Liu, Feng Li, Fanfan Qiao, Kun Zhao, Baoying Yin, and Jianliang Yu. 2025. "Experimental Study of the Effect by Double-Stage Throttling on the Pressure Relief Characteristics of a Large-Scale CO2 Transportation Pipeline" Energies 18, no. 13: 3244. https://doi.org/10.3390/en18133244

APA StyleSong, H., Wang, T., Qi, J., Jin, K., Liu, J., Li, F., Qiao, F., Zhao, K., Yin, B., & Yu, J. (2025). Experimental Study of the Effect by Double-Stage Throttling on the Pressure Relief Characteristics of a Large-Scale CO2 Transportation Pipeline. Energies, 18(13), 3244. https://doi.org/10.3390/en18133244