Analysis of the Application of Ammonia as a Fuel for a Compression-Ignition Engine

Abstract

1. Introduction

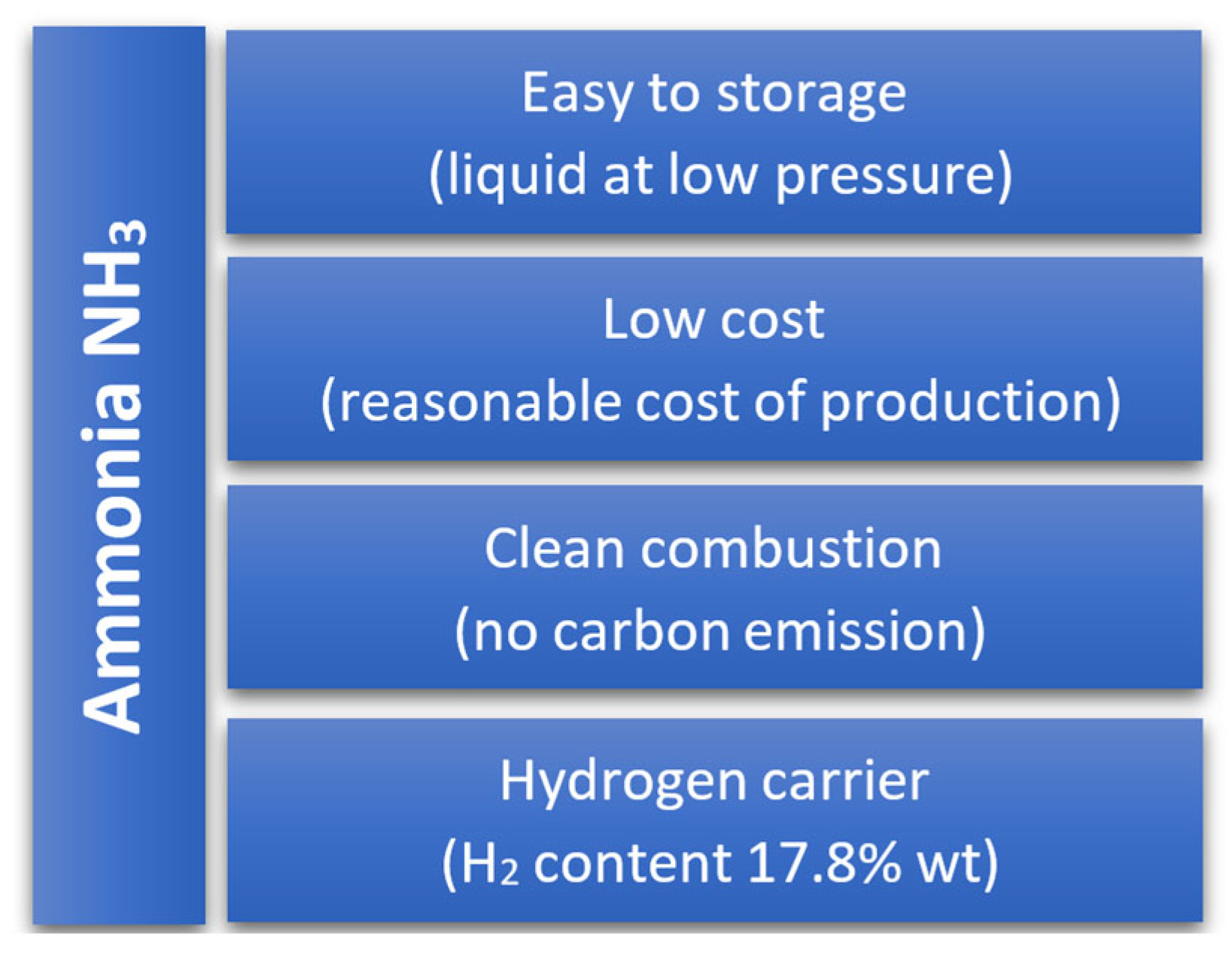

2. Ammonia as a Fuel for Piston Engines

3. Compression-Ignition Engine Powered by Ammonia

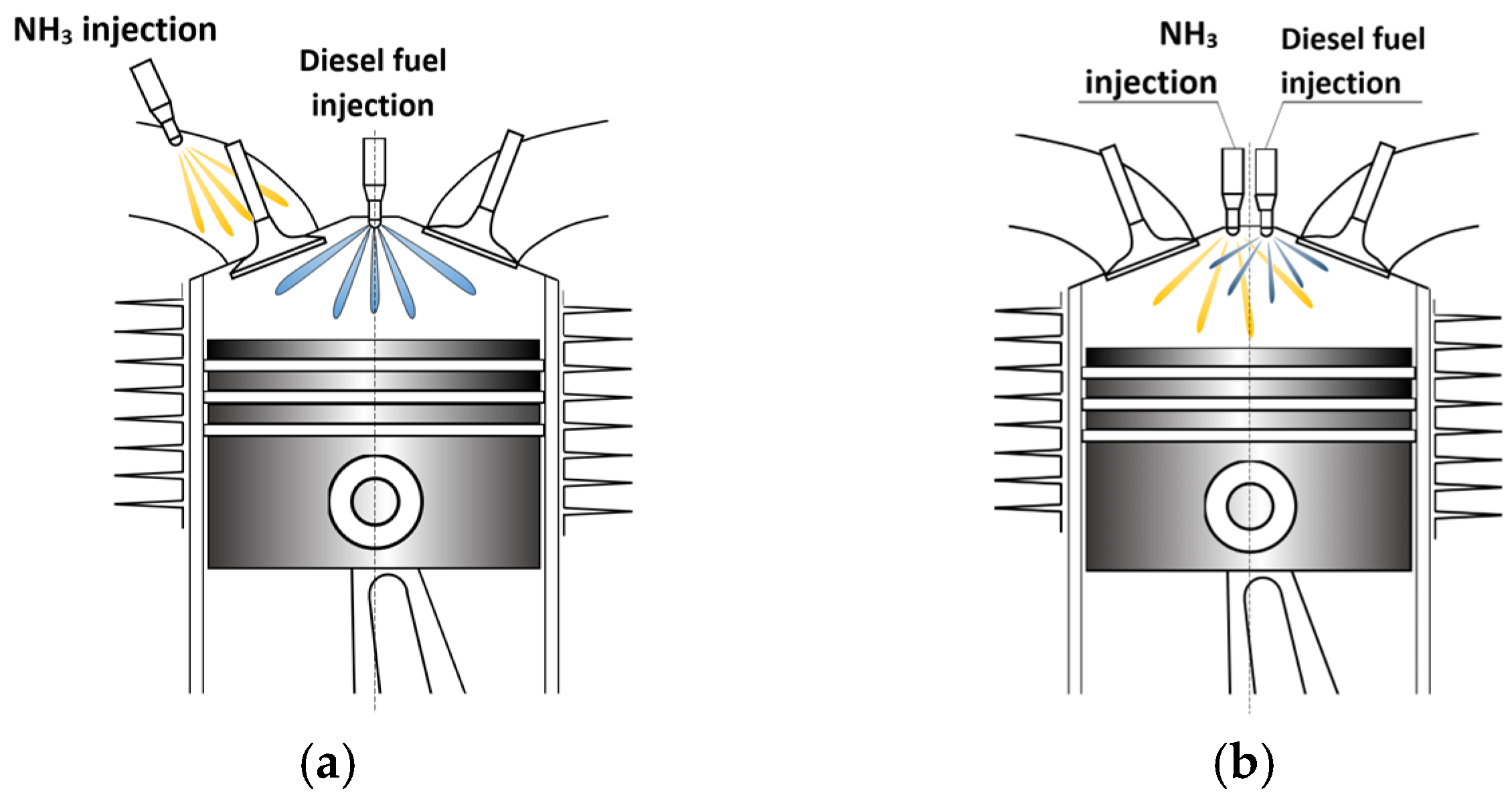

3.1. Ammonia in Dual-Fuel Engines

3.2. Engine Powered by Ammonia in Port Fuel Injection System

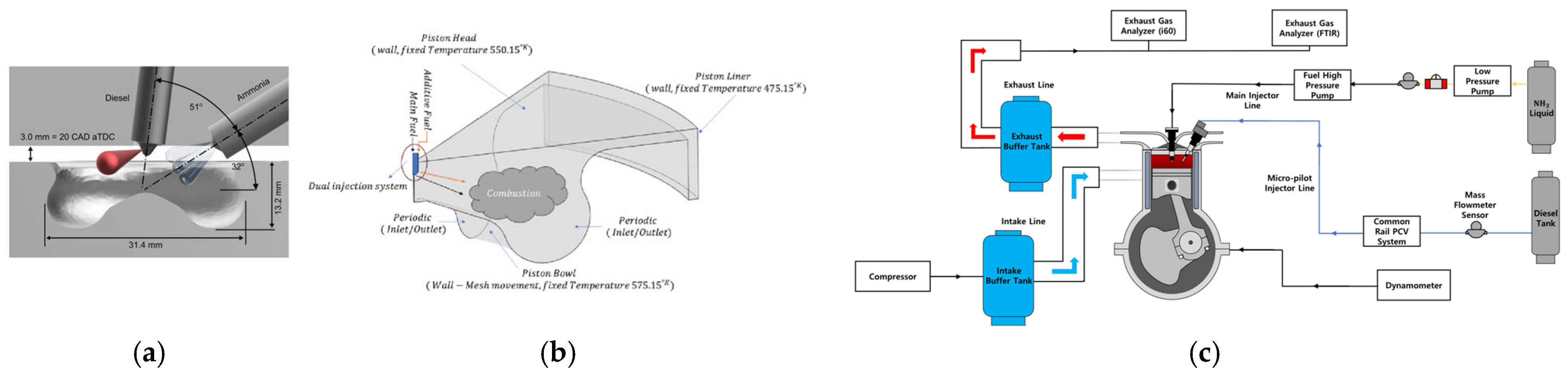

3.3. Engine Powered by Ammonia in the Direct Injection System

| Ref. | Engine Type | Fueling Type | Operating Parameters | Emissions |

|---|---|---|---|---|

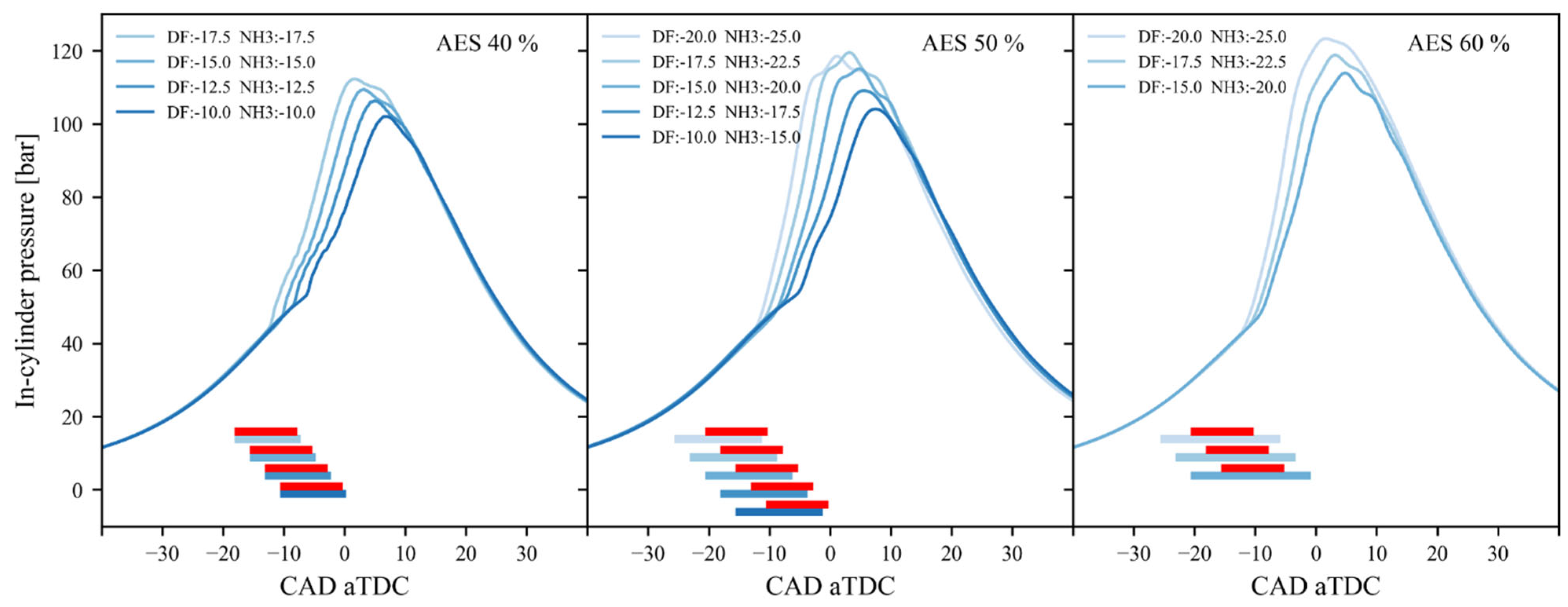

| Bjørgen et al. [96] (Exp.) | 1-cylinder, CR 17.5:1, 1500 rpm | DI, ammonia injection strategy, AEF 40, 50, and 60% | Early IT of NH3 cause premixed combustion, best when NH3 and diesel are injected at the same time | Higher NH3 emission, NOx and N2O emissions have opposite trends |

| Lewandowski et al. [97] (CFD) | 1-cylinder, CR 21.5:1 | DI, ammonia injection up to 200 MPa, variable IT | Decrease in Tmax of 130K and pmax of 3 bar, best performance for injector coverage | N2O decreased, higher NOx emission |

| Drazdauskas et al. [98] (CFD) | Wartsila 6L46 diesel engine, 500 rpm | DI, AEF 95%, Liquid ammonia injection of 50 to 200 MPa | ITE increase of 5% | Injection 100 MPa causes decrease in CO2 of 24%, GHG emissions were also reduced by 45% |

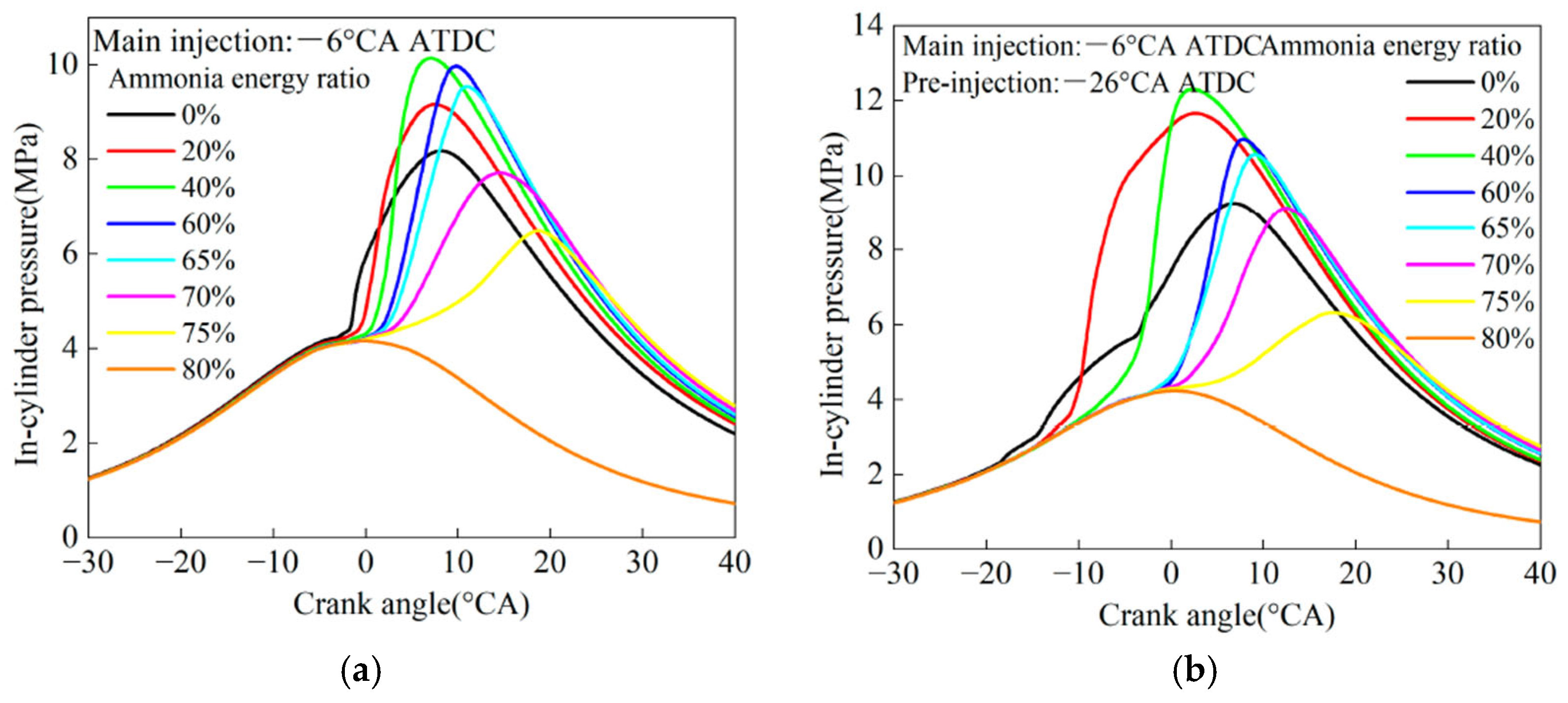

| Guo et al. [99] (CFD) | 1-cylinder, CR 19:1, 1200 rpm | DI, AEF up to 70%, NH3 injection 150 and 60 deg bTDC at 60 MPa, pre-injection | pmax increases and then decreases with AEF, ID increase | GHG decrease of 41%, 98.13% and 99.6% decrease in soot with single and pre-injection |

| Nadimi et al. [102] (CFD) | 1-cylinder, CR 16.45:1, 1500 rpm | DI, AEF 50%, NH3 injection 10 MPa | ITE increases with 3 injector holes | Reduction in 3-injector holes causes 29.2% reduction in NH3 and CO |

| Shin et al. [103] (CFD) | 1-cylinder, CR 16.25:1, 910 rpm | DI, AEF 95, 97, and 99%, injection strategy | ITE increased by 8%, AEF lowering in-cylinder temperature | NO decreased by up to 13.5%, GHG reduced by 91% |

| Park et al. [101] (Exp.) | 1-cylinder, CR13-14, 900 rpm | DI, pilot injection | Lower CR causes unstable combustion, increase in CR causes increase ITE | decrease in unburned ammonia |

3.4. Ammonia Co-Burned with Other Fuels in a Dual-Fuel Engine

3.5. Ammonia Combustion in Alternative Combustion Systems

3.6. Challenges for Ammonia-Powered Engines

- Safety aspects: Ammonia is harmful to health and requires safety precautions during transport, storage, and usage. It forms an explosive mixture in air within a volume concentration range of 15 to 33.6%.

- Infrastructure: Currently, there is inadequate infrastructure for storing and distributing NH3 as a widely used fuel. This necessitates significant financial and technological investments. For ammonia to be considered a zero-emission fuel, it should be produced using renewable energy, which also encourages the development of this technology.

- Energy value: The LHV of ammonia is 18.8 MJ/kg, more than two times lower than that of hydrocarbon fuels. This requires a correspondingly higher mass flow of NH3 to achieve the same energy output compared to conventional fuels. It also necessitates the use of larger storage tanks, creating logistical challenges in transportation due to larger volumes.

- Combustion technologies: Efficient combustion of ammonia is not straightforward, as indicated by selected studies on this topic. Despite increasing scientific research on ammonia combustion in ICE, there are still many unresolved aspects. Challenges include the ignition difficulties of the NH3/air mixture and the emission of pollutants, particularly unburned NH3 and N2O.

- Corrosion and material degradation: Ammonia adversely affects engine construction materials and fuel system components, necessitating the use of materials such as nickel alloys or specialized protective coatings.

- Economic and social aspects: For NH3 to be widely adopted as a fuel, it must be economically viable. Currently, the cost of ammonia is higher than that of traditional fuels. Concerns regarding safety may influence the societal acceptance of ammonia-powered engines.

4. Conclusions

- −

- Easier to implement technically; simple control system.

- −

- High emissions of unburned NH3—crevice effect.

- −

- Require additional injectors in the engine head; advanced control system.

- −

- Potential for achieving low NH3 emissions.

- −

- The use of PFI technology contributes to an increase in unburned NH3 emissions in the exhaust gases, primarily due to the crevice effect, with ammonia emissions potentially exceeding 10,000 ppm. Direct injection of ammonia exhibits better characteristics in this regard.

- −

- As the NH3 share increases, ignition delay and combustion duration also increase; this effect can be mitigated by appropriate control of the injection of the highly reactive fuel.

- −

- The use of ammonia as a fuel can lead to excessive NOx emissions as well as the release of N2O, a highly harmful compound to the environment. Unburned NH3 can intensify deNOx reactions, thereby reducing nitrogen oxide emissions.

- −

- In CI engines fueled with ammonia, increasing the compression ratio improves combustion stability and engine efficiency.

- −

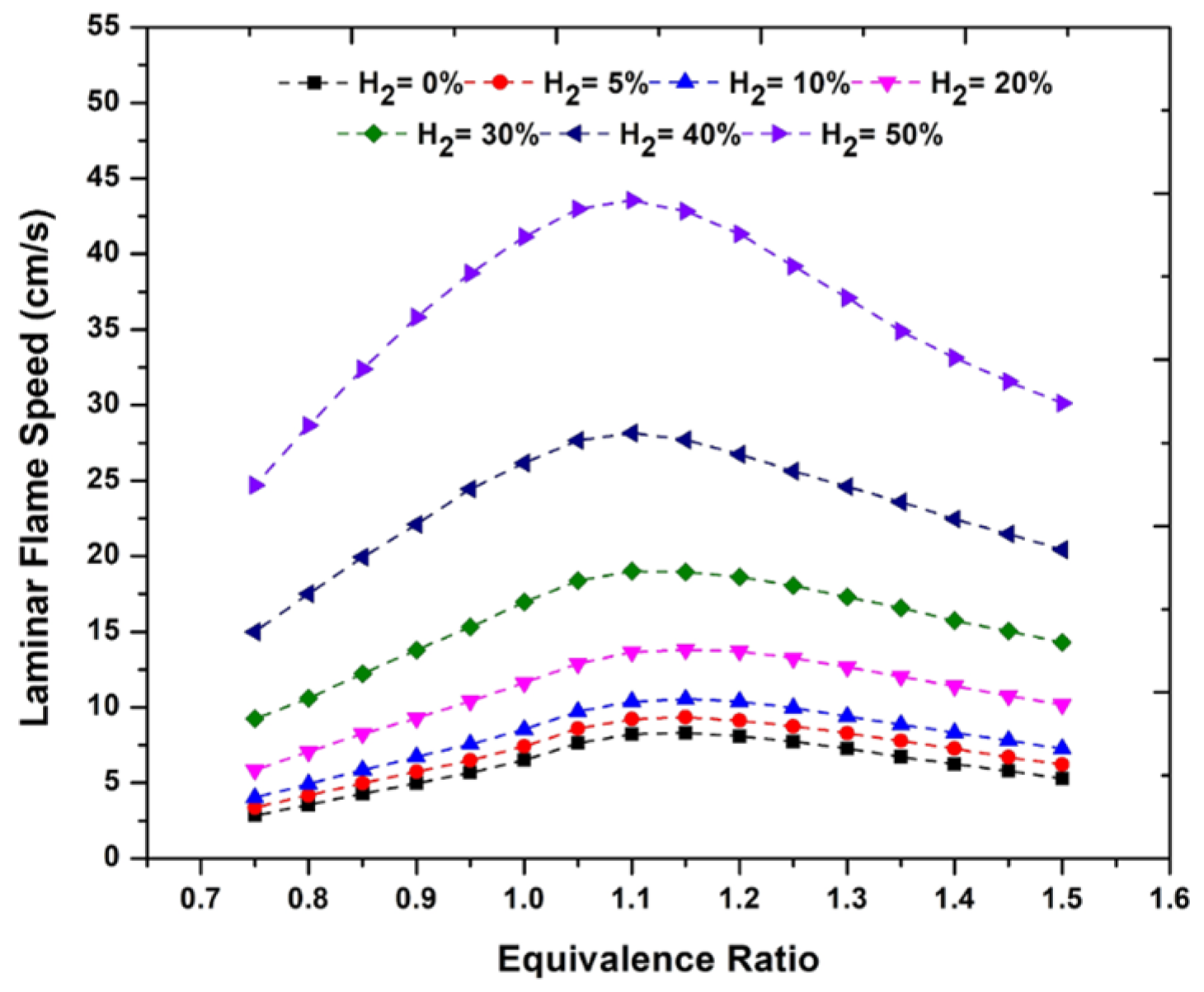

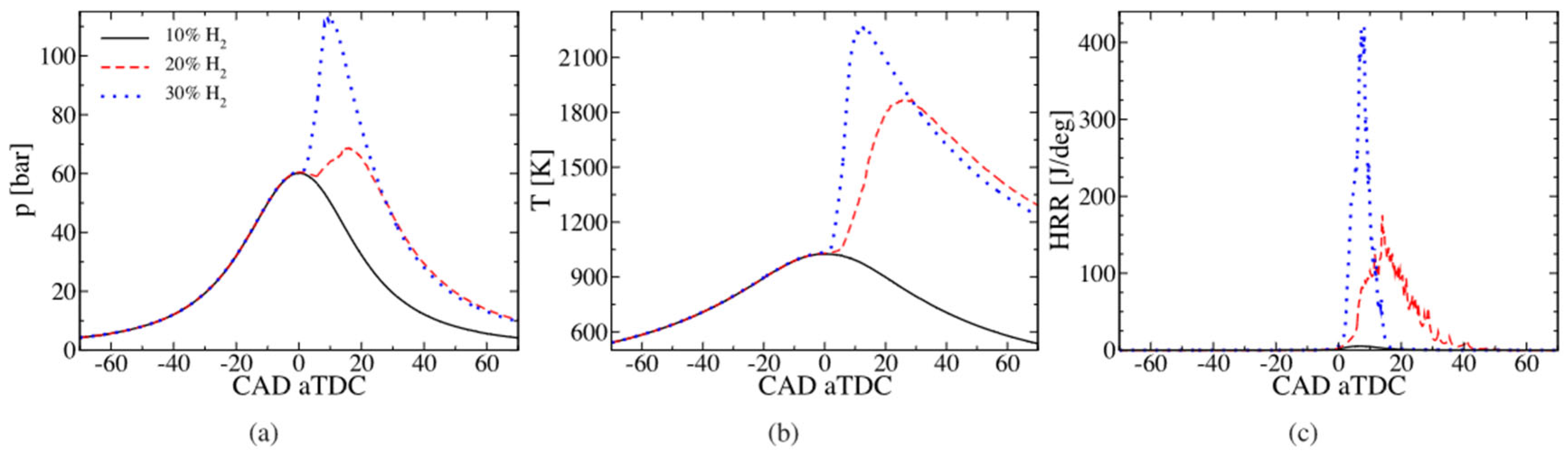

- To enhance the combustion properties of the NH3–air mixture, hydrogen can be used as a fuel additive that increases flame propagation speed; a 20% hydrogen share doubles the laminar flame speed (LFS).

- −

- Many researchers indicate that an optimal NH3 share in a dual-fuel engine is around 40% (AEF).

Funding

Conflicts of Interest

Nomenclature

| AEF | ammonia energetic fraction |

| aTDC | after top dead center |

| BTE | brake thermal efficiency |

| BSEC | brake specific energy consumption |

| CFD | computational fluid dynamics |

| CI | compression ignition |

| CN | cetane number |

| CR | compression ratio |

| DI | direct injection |

| GHG | greenhouse gas |

| HCCI | homogeneous charge compression ignition |

| IC | internal combustion |

| IMEP | indicated mean effective pressure |

| ITE | indicated thermal efficiency |

| IT | injection time |

| LFS | laminar flame speed |

| LHV | lower heating value |

| WC | water cooled |

| PFI | port fuel injection |

| RCCI | reactivity controlled compression ignition |

| rpm | rotation per minute |

| SoI | start of injection |

References

- Filonchyk, M.; Peterson, M.P.; Zhang, L.; Hurynovich, V.; He, Y. Greenhouse gases emissions and global climate change: Examining the influence of CO2, CH4, and N2O. Sci. Total Environ. 2024, 935, 173359. [Google Scholar] [CrossRef] [PubMed]

- Ovaere, M.; Proost, S. Cost-effective reduction of fossil energy use in the European transport sector: An assessment of the Fit for 55 Package. Energy Policy 2022, 168, 113085. [Google Scholar] [CrossRef]

- Venkata Sundar Rao, K.; Kurbet, S.N.; Kuppast, V.V. A Review on Performance of the IC Engine Using Alternative Fuels. Mater. Today Proc. 2018, 5, 1989–1996. [Google Scholar] [CrossRef]

- Ergen, G. Comprehensive analysis of the effects of alternative fuels on diesel engine performance combustion and exhaust emissions: Role of biodiesel, diethyl ether, and EGR. Therm. Sci. Eng. Prog. 2024, 47, 102307. [Google Scholar] [CrossRef]

- Geng, P.; Cao, E.; Tan, Q.; Wei, L. Effects of alternative fuels on the combustion characteristics and emission products from diesel engines: A review. Renew. Sustain. Energy Rev. 2017, 71, 523–534. [Google Scholar] [CrossRef]

- Othman, M.F.; Adam, A.; Najafi, G.; Mamat, R. Green fuel as alternative fuel for diesel engine: A review. Renew. Sustain. Energy Rev. 2017, 80, 694–709. [Google Scholar] [CrossRef]

- Zhang, Y.; Gao, S.; Zhang, Z.; Li, W.; Yuan, T.; Tan, D.; Duan, L.; Yang, G. A comprehensive review on combustion, performance and emission aspects of higher alcohols and its additive effect on the diesel engine. Fuel 2023, 335, 127011. [Google Scholar] [CrossRef]

- Jin, C.; Xiao, J.; Hou, J.; Wu, X.; Zhang, J.; Du, E. Flexibility improvement evaluation of hydrogen storage based on electricity–hydrogen coupled energy model. Glob. Energy Interconnect. 2012, 4, 371–383. [Google Scholar] [CrossRef]

- Maka, A.O.M.; Ghalut, T.; Elsaye, E. The pathway towards decarbonisation and net-zero emissions by 2050: The role of solar energy technology. Green Technol. Sustain. 2024, 2, 100107. [Google Scholar] [CrossRef]

- Muhammed, N.S.; Gbadamosi, A.O.; Epelle, E.I.; Abdulrasheed, A.A.; Haq, B.; Patil, S.; Al-Shehri, D.; Kamal, M.S. Hydrogen production, transportation, utilization, and storage: Recent advances towards sustainable energy. J. Energy Storage 2023, 73, 109207. [Google Scholar] [CrossRef]

- Ham, K.; Bae, S.; Lee, J. Classification and technical target of water electrolysis for hydrogen production. J. Energy Chem. 2024, 95, 554–576. [Google Scholar] [CrossRef]

- Zhang, Z.; Turap, Y.; Wang, Y.; Wang, Y.; Wang, Z.; Wang, W. Study on the impact of hydrogen storage temperature on iron-based thermochemical hydrogen storage technology. Chem. Eng. J. 2024, 490, 151536. [Google Scholar] [CrossRef]

- Gopinathan, R.L.; Ibrahim, M.M. Ammonia as a sustainable fuel for diesel engines: Exploring advanced combustion strategies for green transportation. J. Energy Inst. 2015, 121, 102159. [Google Scholar] [CrossRef]

- Jafar, U.; Nuhu, U.; Khan, W.U.; Hossain, M.M. A review on green ammonia as a potential CO2 free fuel. Int. J. Hydrogen Energy 2024, 71, 857–876. [Google Scholar] [CrossRef]

- Available online: https://www.statista.com/statistics/1065865/ammonia-production-capacity-globally/ (accessed on 20 May 2025).

- Zhou, H.; Chen, Z.; Meng, W.; Yang, S. Design, global energy integration, and sustainability analyses of a process coupling renewable energy water electrolysis for hydrogen production with ammonia synthesis. J. Environ. Chem. Eng. 2024, 12, 112892. [Google Scholar] [CrossRef]

- Kojima, Y. Safety of ammonia as a hydrogen energy carrier. Int. J. Hydrogen Energy 2024, 50, 732–739. [Google Scholar] [CrossRef]

- Dinesh, M.H.; Kumar, G.N. Effects of compression and mixing ratio on NH3/H2 fueled Si engine performance, combustion stability, and emission. Energy Convers. Manag. X 2022, 15, 100269. [Google Scholar] [CrossRef]

- Zhang, R.; Shu, G.; Zhao, H.; Chen, L.; Wei, H.; Pan, J. A comparative study on NH3/H2 and NH3/CH3OH combustion and emission in an optical SI engine. Fuel 2024, 369, 131731. [Google Scholar] [CrossRef]

- Tornatore, C.; Marchitto, L.; Sabia, P.; De Joannon, M. Ammonia as green fuel in internal combustion engines: State-of-the-art and future perspectives. Front. Mech. Eng. 2022, 8, 944201. [Google Scholar] [CrossRef]

- Hu, X.; Pan, J.; Zhang, R.; Li, J.; Li, W.; Wei, H. Effects of intake parameters and compression ratio on ammonia combustion and emissions in SI engines. Fuel 2023, 354, 129382. [Google Scholar] [CrossRef]

- Wen, H.; Li, J.; Li, J.; Xu, C. Effect of intake air conditions on combustion and emission performance of ammonia-diesel dual fuel engine. J. Energy Inst. 2025, 118, 101938. [Google Scholar] [CrossRef]

- Raza, H.; Woo, S.; Kim, H. Investigation of an ammonium carbamate–based SCR system for NOx reduction in diesel engines under transient conditions. Energy 2022, 251, 123918. [Google Scholar] [CrossRef]

- Nie, X.; Bi, Y.; Shen, L.; Lei, J.; Wan, M.; Xiao, Y.; Chen, G. Experimental study for optimizing EGR strategy in an ammonia-diesel dual-fuel engine under different altitudes. Energy 2024, 313, 133953. [Google Scholar] [CrossRef]

- Salcedo, A.; Caputo, S.; Loehlé, S.; Steinmann, S.N.; Michel, C. Molecular modeling of the diffusion of ammonia through corrosion inhibitor films on copper. Corros. Sci. 2024, 240, 112491. [Google Scholar] [CrossRef]

- Jespersen, M.C.; Rasmussen, T.Ø.H.; Ivarsson, A. Widening the operation limits of a SI engine running on neat ammonia. Fuel 2024, 358, 130159. [Google Scholar] [CrossRef]

- Zhu, T.; Fan, Y.; Zhu, L.; Huang, Z. Research on the spark-integrated auto ignition in ammonia/polyoxymethylene dimethyl ether engine. Fuel 2025, 387, 134376. [Google Scholar] [CrossRef]

- Uddeen, K.; Tang, Q.; Shi, H.; Turner, J.W.G. Ammonia-methanol and ammonia-ethanol dual-fuel combustion in an optical spark-ignition engine: A multiple flame generation approach. Appl. Therm. Eng. 2025, 265, 125544. [Google Scholar] [CrossRef]

- Sonthalia, A.; Varuvel, E.G.; Subramanian, T.; Femilda Josephin, J.S.; Alahmadi, T.A.; Pugazhendhi, A. Comparative analysis to reduce greenhouse gas (GHG) emission in CI engine fuelled with sweet almond oil using ammonia/after treatment system. Fuel 2024, 371, 131865. [Google Scholar] [CrossRef]

- Cheng, H.; Tang, Q.; Uddeen, K.; Huang, L.; Zheng, Z.; Turner, J.; Yao, M. The ignition mechanisms and chemical reaction kinetics of nitrogen oxides of ammonia/diesel dual-fuel engine combustion. Appl. Therm. Eng. 2025, 262, 125287. [Google Scholar] [CrossRef]

- Alvarez, L.F.; Ulishney, C.J.; Askari, O.; Dumitrescu, C.E. Dumitrescu, Neat ammonia use in a heavy-duty diesel engine converted to spark ignition focused on lean operation. Fuel 2025, 382, 133786. [Google Scholar] [CrossRef]

- Pyrc, M.; Gruca, M.; Tutak, W.; Jamrozik, A. Assessment of the co-combustion process of ammonia with hydrogen in a research VCR piston engine. Int. J. Hydrogen Energy 2023, 48, 2821–2834. [Google Scholar] [CrossRef]

- Fakhari, A.H.; Gharehghani, A.; Salahi, M.M.; Amin Andwari, M. Numerical investigation of the hydrogen-enriched ammonia-diesel RCCI combustion engine. Fuel 2024, 375, 132579. [Google Scholar] [CrossRef]

- Sarıtaş, M.; Kül, V.S.; Akansu, S.O.; Sinkala, H. Compression ignition engine performance and emissions: An experimental study on the impact of aqueous ammonia, hydrogen, and diesel fuel blends. Int. J. Hydrogen Energy 2025, 137, 679–688. [Google Scholar] [CrossRef]

- Scharl, V.; Sattelmayer, T. Ignition and combustion characteristics of diesel piloted ammonia injections. Fuel Commun. 2022, 11, 100068. [Google Scholar] [CrossRef]

- Sun, W.; Wang, X.; Guo, L.; Zhang, H.; Zeng, W.; Lin, S.; Zhu, G.; Jiang, M.; Ma, X. Study on effects of EGR and injection strategies on the combustion and emission characteristics of ammonia/diesel dual-fuel engine. Energy 2025, 315, 134391. [Google Scholar] [CrossRef]

- Wang, X.; Li, T.; Zhou, X.; Huang, S.; Chen, R.; Yi, P.; Lv, Y.; Wang, Y.; Rao, H.; Liu, Y.; et al. Reductions in GHG and unburned ammonia of the pilot diesel-ignited ammonia engines by diesel injection strategies. Appl. Therm. Eng. 2025, 260, 124967. [Google Scholar] [CrossRef]

- Szabados, G.; Bereczky, Á.; Ajtai, T.; Bozóki, Z. Evaluation analysis of particulate relevant emission of a diesel engine running on fossil diesel and different biofuels. Energy 2018, 161, 1139–1153. [Google Scholar] [CrossRef]

- Kuszewski, H.; Jakubowski, M.; Jaworski, A.; Lubas, J.; Krzysztof Balawender, K. Effect of temperature on tribological properties of 1-butanol–diesel fuel blends—Preliminary experimental study using the HFRR method. Fuel 2021, 296, 120700. [Google Scholar] [CrossRef]

- Kuszewski, H. Experimental investigation of the effect of ambient gas temperature on the autoignition properties of ethanol–diesel fuel blends. Fuel 2018, 214, 26–38. [Google Scholar] [CrossRef]

- Feroskhan, M.; Gobinath, N. Experimental study of butanol blending in biogas-biodiesel fueled CI engine under dual fuel, RCCI and HCCI combustion modes. Case Stud. Therm. Eng. 2024, 58, 104349. [Google Scholar] [CrossRef]

- Paykani, A.; Garcia, A.; Shahbakhti, M.; Rahnama, P.; Reitz, R.G. Reactivity controlled compression ignition engine: Pathways towards commercial viability. Applied Energy 2021, 282, 116174. [Google Scholar] [CrossRef]

- Splitter, D.A.; Reitz, R.D. Fuel reactivity effects on the efficiency and operational window of dual-fuel compression ignition engines. Fuel 2014, 118, 163–175. [Google Scholar] [CrossRef]

- Reitz, R.D.; Duraisamy, G. Review of high efficiency and clean reactivity controlled compression ignition (RCCI) combustion in internal combustion engines. Prog. Energy Combust. Sci. 2015, 46, 12–71. [Google Scholar] [CrossRef]

- Duan, X.; Lai, M.-C.; Jansons, M.; Guo, G.; Liu, J. A review of controlling strategies of the ignition timing and combustion phase in homogeneous charge compression ignition (HCCI) engine. Fuel 2021, 285, 119142. [Google Scholar] [CrossRef]

- Verma, S.K.; Gaur, S.; Akram, T.; Gautam, S.; Kumar, A. Emissions from homogeneous charge compression ignition (HCCI) engine using different fuels: A review. Environ. Sci. Pollut. Res. 2022, 29, 50960–50969. [Google Scholar] [CrossRef]

- Ali, K.; Kyritsis, D.C.; Ali, M.H. Computational investigation of combustion and emission characteristics of HCCI engine fueled with Carbon-Free NH3–H2O2 blend. Energy Convers. Manag. 2024, 322, 119105. [Google Scholar] [CrossRef]

- Krishnan, M.G.; Rajkumar, S.; Devarajan, Y.; Rajiv, A. A comprehensive review on advancement and challenges of renewable biofueled reactivity controlled compression ignition (RCCI) engine. J. Energy Inst. 2024, 113, 101540. [Google Scholar] [CrossRef]

- Saxena, S.; Bedoya, I.D. Fundamental phenomena affecting low temperature combustion and HCCI engines, high load limits and strategies for extending these limits. Prog. Energy Combust. Sci. 2013, 39, 457–488. [Google Scholar] [CrossRef]

- Tutak, W.; Jamrozik, A.; Gnatowska, R. Combustion of different reactivity fuel mixture in a dual fuel engine. Therm. Sci. 2018, 22, 1285–1297. [Google Scholar] [CrossRef]

- Tutak, W. Bioethanol E85 as a fuel for dual fuel diesel engine. Energy Convers. Manag. 2014, 86, 39–48. [Google Scholar] [CrossRef]

- Shah, Z.A.; Marseglia, G.; De Giorgi, M.G. Predictive models of laminar flame speed in NH3/H2/O3/air mixtures using multi-gene genetic programming under varied fuelling conditions. Fuel 2024, 368, 131652. [Google Scholar] [CrossRef]

- Xu, L.; Xu, S.; Bai, X.-S.; Repo, J.A.; Hautala, S.; Hyvönen, J. Performance and emission characteristics of an ammonia/diesel dual-fuel marine engine. Renew. Sustain. Energy Rev. 2023, 185, 113631. [Google Scholar] [CrossRef]

- Han, L.; Gong, Y.; Qian, D.; Liu, M.; Ma, H.; Xie, F. Optical investigation of the influence of passive pre-chamber turbulent jet ignition on the combustion characteristics of carbon-free ammonia-hydrogen engines. Appl. Therm. Eng. 2025, 278 Pt A, 127200. [Google Scholar] [CrossRef]

- Hroch, E. Ammonia—A fuel for motor buses. J. Inst. Pet 1945, 31, 213–223. [Google Scholar]

- Sehili, Y.; Loubar, K.; Tarabet, L.; Cerdoun, M.; Lacroix, C. Computational Investigation of the Influence of Combustion Chamber Characteristics on a Heavy-Duty Ammonia Diesel Dual Fuel Engine. Energies 2024, 17, 1231. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, G.; Yang, L.; Chen, G.; He, S. Intelligent optimization of diesel engine Selective catalytic reduction urea injection based on multi-model state estimation to reduce NH3 slip and NOx emission. Fuel 2024, 365, 131188. [Google Scholar] [CrossRef]

- Kobayashi, H.; Hayakawa, A.; Somarathne, K.D.K.A.; Okafor, E.C. Science and technology of ammonia combustion. Proc. Combust. Inst. 2019, 37, 109–133. [Google Scholar] [CrossRef]

- Heywood, J.B. Internal Combustion Engine Fundamentals, 2nd ed.; McGraw-Hill Education: New York, NY, USA, 2018. [Google Scholar]

- Yu, J.; Hong, J.; Lee, Y. Parametric evaluation of the operating conditions for NO reduction in flameless combustion of an H2/NH3/N2 fuel mixture. Int. J. Hydrogen Energy 2025, 74, 404–413. [Google Scholar] [CrossRef]

- Lu, M.; Long, W.; Wei, F.; Dong, D.; Cong, L.; Dong, P.; Tian, H.; Chen, X.; Chen, S.; Wang, Y.; et al. Assessment of carbon-free fuel ammonia combustion with low methanol blends in reducing GHG emissions including N2O. J. Clean. Prod. 2024, 463, 142755. [Google Scholar] [CrossRef]

- Zheng, Z.; Xia, M.; Liu, H.; Shang, R.; Ma, G.; Yao, M. Experimental study on combustion and emissions of n-butanol/biodiesel under both blended fuel mode and dual fuel RCCI mode. Fuel 2018, 226, 240–251. [Google Scholar] [CrossRef]

- Yang, R.; Liu, J.; Liu, J. Investigation of the formation mechanisms of nitrogen-based pollutants in ammonia-diesel dual-fuel engines by decoupling dilution, thermal, and kinetic effects. J. Energy Inst. 2025, 120, 102125. [Google Scholar] [CrossRef]

- Imtenan, S.; Masjuki, H.H.; Varman, M.; Rizwanul Fattah, I.M.; Sajjad, H.; Arbab, M.I. Effect of n-butanol and diethyl ether as oxygenated additives on combustion–emission-performance characteristics of a multiple cylinder diesel engine fuelled with diesel–jatropha biodiesel blend. Energy Convers. Manag. 2015, 94, 84–94. [Google Scholar] [CrossRef]

- Börnhorst, M.; Deutschmann, O. Advances and challenges of ammonia delivery by urea-water sprays in SCR systems. Prog. Energy Combust. Sci. 2021, 87, 100949. [Google Scholar] [CrossRef]

- Xiao, H.; Guo, F.; Li, S.; Wang, R.; Yang, X. Combustion performance and emission characteristics of a diesel engine burning biodiesel blended with n-butanol. Fuel 2019, 258, 115887. [Google Scholar] [CrossRef]

- Farzam, R.; Liko, B.; Bebar, A.; Dev, S.; Stevenson, D.; Guo, H.; McTaggart-Cowan, G. Performance and emissions characteristics of hydrogen-diesel heavy-duty engines: The influence of engine control parameters. Int. J. Hydrogen Energy 2025, 109, 1325–1340. [Google Scholar] [CrossRef]

- Bartels, J.R. A Feasibility Study of Implementing an Ammonia Economy. Master’s Thesis, Iowa State University, Ames, IA, USA, 2008. [Google Scholar]

- Zhao, F.; Wang, Z.; Dong, B.; Li, M.; Ji, Y.; Han, F. Comprehensive life cycle cost analysis of ammonia-based hydrogen transportation scenarios for offshore wind energy utilization. J. Clean. Prod. 2023, 429, 139616. [Google Scholar] [CrossRef]

- Jang, H.; Mujeeb-Ahmed, M.P.; Wang, H.; Park, C.; Hwang, I.; Jeong, B.; Zhou, P.; Mickeviciene, R. Regulatory gap analysis for risk assessment of ammonia-fuelled ships. Ocean Eng. 2023, 287, 115751. [Google Scholar] [CrossRef]

- Chen, L.; Wang, C.; Wang, W. Effect of ammonia co-firing on heat transfer, safety, and economy of coal-fired boilers. Fuel 2023, 334, 126649. [Google Scholar] [CrossRef]

- Tutak, W.; Jamrozik, A.; Grab-Rogaliński, K. Co-Combustion of Hydrogen with Diesel and Biodiesel (RME) in a Dual-Fuel Compression-Ignition Engine. Energies 2023, 16, 4892. [Google Scholar] [CrossRef]

- Paykani, A.; Kakaee, A.H.; Rahnama, P.; Reitz, R.D. Effects of diesel injection strategy on natural gas/diesel reactivity controlled compression ignition combustion. Energy 2015, 90, 814–826. [Google Scholar] [CrossRef]

- Jamrozik, A.; Tutak, W.; Grab-Rogaliński, K. Effects of Propanol on the Performance and Emissions of a Dual-Fuel Industrial Diesel Engine. Appl. Sci. 2022, 12, 5674. [Google Scholar] [CrossRef]

- Yang, S.; Wan, M.; Shen, L.; Wang, Z.; Huang, F.; Ma, Y.; Xiao, Y. Investigation of the impacts of regeneration temperature and methanol substitution rate on the active regeneration of diesel particulate filter in a diesel-methanol dual-fuel engine. Energy 2024, 301, 131657. [Google Scholar] [CrossRef]

- Jamrozik, A.; Tutak, W.; Pyrc, M.; Grab-Rogaliński, K. Experimental study on ammonia-diesel co-combustion in a dual-fuel compression ignition engine. J. Energy Inst. 2024, 115, 101711. [Google Scholar] [CrossRef]

- Hosseini, S.H.; Tsolakis, A.; Alagumalai, A.; Mahian, O.; Lam, S.S.; Pan, J.; Peng, W.; Tabatabaei, M.; Aghbashlo, M. Use of hydrogen in dual-fuel diesel engines. Prog. Energy Combust. Sci. 2023, 98, 101100. [Google Scholar] [CrossRef]

- Tutak, W.; Lukács, K.; Szwaja, S.; Bereczky, Á. Alcohol–diesel fuel combustion in the compression ignition engine. Fuel 2015, 154, 196–206. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, Z.; Chen, H.; Ji, Z.; Ma, Y.; Sun, F. A review on performance, combustion and emission of diesel and alcohols in a dual fuel engine. J. Energy Inst. 2024, 116, 101760. [Google Scholar] [CrossRef]

- Li, Y.; Cai, Y.; Jia, M.; Wang, Y.; Su, X.; Li, L. A full-parameter computational optimization of both injection parameters and injector layouts for a methanol/diesel dual-fuel direct injection compression ignition engine. Fuel 2024, 369, 131733. [Google Scholar] [CrossRef]

- Li, T.; Zhao, P.; He, H.; Wang, C.; Zhang, H.; Chen, Z.; Chen, H. Dual-fuel dual-direct injection: An efficient and clean combustion technology for diesel engines. J. Energy Inst. 2025, 119, 102006. [Google Scholar] [CrossRef]

- Chintala, V. Influence of flame quenching and crevice gas on hydrocarbon emission formation in an enriched biogas dual-fuel engine—An experimental and theoretical investigation. Fuel 2020, 277, 118084. [Google Scholar] [CrossRef]

- Tang, Q.; Liu, X.; Raman, V.; Shi, H.; Chang, J.; Im, H.G.; Johansson, B. Effects of fuel trapping in piston crevice on unburned hydrocarbon emissions in early-injection compression ignition engines. Combust. Flame 2021, 231, 111496. [Google Scholar] [CrossRef]

- Grimes, P. Energy Depot Fuel Production and Utilization. SAE Tech. Pap. 1965, 650051. [Google Scholar] [CrossRef]

- Pham, Q.; Park, S.; Agarwal, A.K.; Park, S. Review of dual-fuel combustion in the compression-ignition engine: Spray, combustion, and emission. Energy 2022, 250, 123778. [Google Scholar] [CrossRef]

- Nadimi, E.; Przybyła, G.; Lewandowski, M.T.; Adamczyk, W. Effects of ammonia on combustion, emissions, and performance of the ammonia/diesel dual-fuel compression ignition engine. J. Energy Inst. 2023, 107, 101158. [Google Scholar] [CrossRef]

- Cai, K.; Liu, Y.; Chen, Q.; Qi, Y.; Li, L.; Wang, Z. Combustion Behaviors and Unregular Emission Characteristics in an Ammonia–Diesel Engine. Energies 2023, 16, 7004. [Google Scholar] [CrossRef]

- Mi, S.; Shi, Z.; Wu, H.; Zheng, L.; Zhao, W.; Qian, Y.; Lu, X. Expanding high ammonia energy ratios in an ammonia-diesel dual-fuel engine across wide-range rotational speeds. Appl. Therm. Eng. 2024, 251, 123608. [Google Scholar] [CrossRef]

- Wang, X.; Liu, J.; Zhao, W.; Ji, Q.; Li, Z.; Xiang, P.; Wang, X. Experimental investigation on in-cylinder working process and thermal efficiency of ammonia/diesel low-carbon engine with pre-injection strategy. Appl. Therm. Eng. 2024, 248, 123272. [Google Scholar] [CrossRef]

- Elumalai, R.; Sumathy, S.; Ravi, K.; Akhtar, M.N.; Elumalai, P.V.; Khan, S.A.; Gupta, M.S.; Asif, M. Experimental investigation and gray relational optimization of engine parameters to improve the output characteristics of an ammonia biodiesel powered dual fuel combustion engine. Case Stud. Therm. Eng. 2024, 56, 104197. [Google Scholar] [CrossRef]

- Lasocki, J.; Bednarski, M.; Sikora, M. Simulation of ammonia combustion in dual-fuel compression-ignition engine. IOP Conf. Ser. Earth Environ. Sci. 2019, 214, 012081. [Google Scholar] [CrossRef]

- Cheng, C.; Cordtz, R.F.; Førby, N.L.; Schramm, J. Experimental and simulation investigation of n-heptane/ammonia dual fuel on a light-duty compression ignition engine. Int. J. Hydrogen Energy 2024, 57, 1339–1353. [Google Scholar] [CrossRef]

- Reiter, A.J.; Kong, S.C. Combustion and emissions characteristics of compression-ignition engine using dual ammonia-diesel fuel. Fuel 2011, 90, 87–97. [Google Scholar] [CrossRef]

- Lang, M.; Su, Y.; Wang, Y.; Zhang, Y.; Wang, B.; Chen, S. Experimental Study on the Effects of pilot injection Strategy on Combustion and Emission Characteristics of Ammonia/Diesel Dual Fuel Engine under low load. Energy 2024, 303, 131913. [Google Scholar] [CrossRef]

- Huang, Y.; Lyu, L.; Liang, J.; Yang, H.; Zhu, N.; Sang, H.; Zhang, X. Performance and emission characteristics of marine ammonia/diesel dual-fuel engines at different diesel substitution rates. Fuel 2025, 379, 132967. [Google Scholar] [CrossRef]

- Bjørgen, K.O.P.; Emberson, D.R.; Terese Løvås, T. Combustion of liquid ammonia and diesel in a compression ignition engine operated in high-pressure dual fuel mode. Fuel 2024, 360, 130269. [Google Scholar] [CrossRef]

- Lewandowski, M.T.; Pasternak, M.; Haugsvær, M.; Terese Løvås, T. Simulations of ammonia spray evaporation, cooling, mixture formation and combustion in a direct injection compression ignition engine. Int. J. Hydrogen Energy 2024, 52, 916–935. [Google Scholar] [CrossRef]

- Drazdauskas, M.; Lebedevas, S. Optimization of Combustion Cycle Energy Efficiency and Exhaust Gas Emissions of Marine Dual-Fuel Engine by Intensifying Ammonia Injection. J. Mar. Sci. Eng. 2024, 12, 309. [Google Scholar] [CrossRef]

- Guo, L.; Zhu, J.; Fu, L.; Li, Z.; Liu, F.; Wang, Z.; Liu, X.; Dong, Q. Effects of Pre-Injection Strategy on Combustion Characteristics of Ammonia/Diesel Dual-Fuel Compression Ignition Mode. Energies 2023, 16, 7687. [Google Scholar] [CrossRef]

- Ghadamkheira, K.; Safamanesha, F.; Moghimana, M.; Hatami, M. Numerical investigation of the effects of hydrogen/ammonia addition to n-heptane combustion and emissions for a dual injection compression-ignition engine. Heliyon 2025, 11, e42106. [Google Scholar] [CrossRef]

- Park, C.; Jang, I.; Kim, M.; Park, G.; Kim, Y. Effect of high compression ratio on thermal efficiency and unburned ammonia emissions of a dual-fuel high-pressure direct injection marine ammonia engine. Appl. Therm. Eng. 2025, 261, 125183. [Google Scholar] [CrossRef]

- Nadimi, E.; Przybyła, G.; Løvås, T.; Adamczyk, W. Effects of biodiesel injector configuration and its injection timing on performance, combustion and emissions characteristics of liquid ammonia dual direct injection engine. J. Energy Inst. 2024, 114, 101605. [Google Scholar] [CrossRef]

- Shin, J.; Park, S. Numerical analysis and optimization of combustion and emissions in an ammonia-diesel dual-fuel engine using an ammonia direct injection strategy. Energy 2024, 289, 130014. [Google Scholar] [CrossRef]

- Tutak, W.; Jamrozik, A.; Bereczky, Á.; Lukacs, K. Effects of injection timing of diesel fuel on performance and emission of dual fuel diesel engine powered by diesel/E85 fuels. Transport 2018, 33, 633–646. [Google Scholar] [CrossRef]

- El-Adawy, M.; Nemitallah, M.A.; Abdelhafez, A. Towards sustainable hydrogen and ammonia internal combustion engines: Challenges and opportunities. Fuel 2024, 364, 131090. [Google Scholar] [CrossRef]

- Tutak, W. Co-combustion of ammonia and hydrogen in spark ignition engines—State-of-the-art and challenges. Int. J. Hydrogen Energy 2024, 80, 188–205. [Google Scholar] [CrossRef]

- Zhang, Z.; Hu, J.; Yang, D.; Yin, Z.; Lu, K.; Tan, D. A comprehensive assessment over the environmental impact and combustion efficiency of using ammonia/ hydrogen/diesel blends in a diesel engine. Energy 2024, 303, 131955. [Google Scholar] [CrossRef]

- Paterson, G.; Tingas, E.A.; Hardalupas, Y.; Taylor, A.M.K.P. Engine performance and emissions from a fumigated hydrogen/ammonia compression ignition engine with a hydrogen peroxide pilot. Int. J. Hydrogen Energy 2024, 67, 334–350. [Google Scholar] [CrossRef]

- Wang, H.; Wang, B.; Yang, C.; Hu, D.; Duan, B.; Wang, Y. Study on dual injection strategy of diesel ignition ammonia/hydrogen mixture fuel engine. Fuel 2023, 348, 128526. [Google Scholar] [CrossRef]

- Wang, B.; Wang, H.; Hu, D.; Yang, C.; Duan, B.; Wang, Y. Study on the performance of premixed natural gas/ammonia engine with diesel ignition. Energy 2023, 271, 127056. [Google Scholar] [CrossRef]

- Bayramoğlu, K.; Bahlekeh, A.; Masera, K. Numerical investigation of the hydrogen, ammonia and methane fuel blends on the combustion emissions and performance. Int. J. Hydrogen Energy 2023, 48, 39586–39598. [Google Scholar] [CrossRef]

- Fakhari, A.H.; Gharehghani, A.; Salahi, M.M.; Amin Andwari, M. RCCI combustion of ammonia in dual fuel engine with early injection of diesel fuel. Fuel 2024, 365, 131182. [Google Scholar] [CrossRef]

- Elumalai, R.; Ravi, K. Strategy to reduce carbon emissions by adopting ammonia–Algal biodiesel in RCCI engine and optimize the fuel concoction using RSM methodology. Int. J. Hydrogen Energy 2022, 47, 39701–39718. [Google Scholar] [CrossRef]

- Elumalai, R.; Ravi, K.; Elumalai, P.V.; Chanduveetil Ahamed, S.; Saboor, S. Investigation on Ammonia–Biodiesel Fueled RCCI Combustion Engine Using a Split Injection Strategy. ACS Omega 2023, 8, 30990–31001. [Google Scholar] [CrossRef]

- Xu, W.; Zhang, M.; Zhang, Y.; Wang, J.; Huang, Z. Effects of temperature and composition inhomogeneity on the ignition characteristics of NH3/H2 co-firing fuels under HCCI operating conditions. Appl. Energy Combust. Sci. 2023, 15, 100194. [Google Scholar] [CrossRef]

- Pfahl, U.J.; Ross, M.C.; Shepherd, J.E.; Pasamehmetoglu, K.O.; Unal, C. Flammability limits, ignition energy, and flame speeds in H2–CH4–NH3–N2O–O2–N2 mixtures. Combust. Flame 2000, 123, 140–158. [Google Scholar] [CrossRef]

- Wang, C.; Deng, J.; Ding, W.; Huang, Y.; Tang, Y.; Li, L. Thermodynamic analysis of employing argon as the diluent and adding hydrogen in an HCCI ammonia engine: Ignition characteristics and performances of combustion and NO emissions. Int. J. Hydrogen Energy 2024, 49, 293–300. [Google Scholar] [CrossRef]

- Pochet, M.; Truedsson, I.; Foucher, F.; Jeanmart, H.; Contino, F. Ammonia-Hydrogen Blends in Homogeneous-Charge Compression-Ignition Engine. SAE Tech. Pap. 2017. [Google Scholar] [CrossRef]

- Shafiq, O.; Tingas, E.-A. Computational investigation of ammonia-hydrogen peroxide blends in HCCI engine mode. Int. J. Engine Res. 2023, 24, 2279–2294. [Google Scholar] [CrossRef]

- Jamrozik, A.; Tutak, W.; Kociszewski, A.; Sosnowski, M. Numerical simulation of two-stage combustion in SI engine with prechamber. Appl. Math. Model. 2013, 37, 2961–2982. [Google Scholar] [CrossRef]

- Liu, X.; Tang, Q.; Im, H.G. Enhancing ammonia engine efficiency through pre-chamber combustion and dual-fuel compression ignition techniques. J. Clean. Prod. 2024, 436, 140622. [Google Scholar] [CrossRef]

- Ezzat, M.F.; Dincer, I. Comparative assessments of two integrated systems with/without fuel cells utilizing liquefied ammonia as a fuel for vehicular applications. Int. J. Hydrogen Energy 2018, 43, 4597–4608. [Google Scholar] [CrossRef]

| Diesel | Ammonia | Hydrogen | |

|---|---|---|---|

| Molecular formula | C14H30 | NH3 | H2 |

| Cetane number | 51 | 0 | (5–10) |

| Molecular weight (kg/kmol) | 198.4 | 17.03 | 2.02 |

| Density at 15 °C and 1 bar (kg/m3) | 626 | 0.73 | 0.08 |

| Lower heating value (MJ/kg) | 42.5 | 18.8 | 120 |

| Volumetric energy density (MJ/m3) | - | 13.72 | 9.6 |

| Autoignition temperature (°C) | 230 | 651 | 520 |

| Stoichiometric air–fuel ratio (kg/kg) | 14.6 | 6.04 | 34.3 |

| Flammability limits in air (vol%) | - | 15–28 | 4.7–75 |

| Laminar flame speed (m/s) | - | 0.07 | 3.51 |

| Heat of evaporation (kJ/kg) | 243 | 1370 | 461 |

| Hydrogen content (wt%) | 15 | 17.6 | 100 |

| Carbon content (wt%) | 85 | 0 | 0 |

| Nitrogen (wt%) | 0 | 82.4 | 0 |

| Ref. | Engine Type | Fueling Type | Operating Parameters | Emissions |

|---|---|---|---|---|

| Xu et al. [53] | 6-cylinder, CR 16:1, 750 rpm | RCCI engine, PFI (1.29 bar), AEF 57–68.7% | Low combustion efficiency due to LFS | Unburnt NH3 increased, GHG decreased by 70%, 89% decrease in CO2 |

| Nadimi et al. [86] | 1-cylinder, CR 16.5:1, 1200 rpm | PFI (2 bar), AEF up to 84%, λ 1.35–1.47 | ITE increased by 5.6%, EGT decreased by 132 °C, SFC decreased by 43%, ID increased, CD decreased | CO2 decreased, unburnt NH3 increased, specific GHG decreased by 36% |

| Elumalai et al. [90] | 1-cylinder, WC, CR 18:1, 1500 rpm, SoI 26 deg bTDC | AEF 40% | BTE increase, BSEC decrease by 13% | HC decrease by 16.7%, CO decrease by 15%, soot decrease by 26.8%; |

| Cai et al. [87] | 1-cylinder, CR 18:1, 800 rpm | PFI, AEF 20% | Early pilot injection timing improved comb. eff. of 15% | Ammonia increased 5-times HCN emission |

| Lasocki et al. [91] | 4-cylinder, CR 18.23:1, 1400 rpm | PFI, varied AEF of NH3, 10–100% load | BSFC increased for all loads, max power obtained for various AER | NO increased with ammonia, CO decreased for partial loads |

| Cheng et al. [92]; | 2-cylinder, CR 18:1, 1200 rpm | PFI, AEF 80–98%, N-heptane pilot fuel, λ 1.1, IT 20 deg bTDC | Chemical ignition delay of n- heptane was much longer than the physical ignition delay | - |

| Reiter et al. [93] | 4-cylinder, turbocharged | PFI, AEF 40–60% | Ignition delay increased with increasing of ammonia, decrease in pmax | NOx increased, Soot decreased, high emission of unburned NH3 |

| Maochun et al. [94] | 1-cylinder, 1200 rpm, 30% load | PFI, AEF up tom 50%, impact of pilot dose | IMEP increased, COVIMEP reduced | CO decreased by 23%, NOx decreased by 20% |

| Huang et al. [95] | 1-cylinder, CR17.5, 1500 rpm, 25–75% of load | PFI (mixer) | NH3 causes increase ID and decrease CD | NH3 fraction causes its emission |

| Wen et al. [22] | 1-cylinder | AEF 30–80%, impact of intake temp | Higher intake temp. increase ITE | Higher intake temp. increase NOx |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tutak, W.; Jamrozik, A. Analysis of the Application of Ammonia as a Fuel for a Compression-Ignition Engine. Energies 2025, 18, 3217. https://doi.org/10.3390/en18123217

Tutak W, Jamrozik A. Analysis of the Application of Ammonia as a Fuel for a Compression-Ignition Engine. Energies. 2025; 18(12):3217. https://doi.org/10.3390/en18123217

Chicago/Turabian StyleTutak, Wojciech, and Arkadiusz Jamrozik. 2025. "Analysis of the Application of Ammonia as a Fuel for a Compression-Ignition Engine" Energies 18, no. 12: 3217. https://doi.org/10.3390/en18123217

APA StyleTutak, W., & Jamrozik, A. (2025). Analysis of the Application of Ammonia as a Fuel for a Compression-Ignition Engine. Energies, 18(12), 3217. https://doi.org/10.3390/en18123217