Multi-Energy Optimal Dispatching of Port Microgrids Taking into Account the Uncertainty of Photovoltaic Power

Abstract

1. Introduction

- (1)

- Modeling of port multi-energy complementary systems: A port microgrid energy structure is constructed, covering PV, thermal power, energy storage, EV clusters, demand response, and interactions with the distribution network. A refined operation model is established.

- (2)

- Virtual battery model for EV clusters: By introducing an electricity correction term and power-energy coupling constraints, the dynamic grid connection and disconnection behaviors of EVs are characterized to support flexible scheduling.

- (3)

- Multi-objective optimal scheduling model: With the minimization of total operation costs as the core, a two-stage stochastic programming model is constructed. In the first stage, typical scenarios are generated, and in the second stage, the multi-energy coordinated output is optimized. Through the power purchase–sale balance constraint and multi-energy complementarity strategies, both economic efficiency and the accommodation of clean energy are enhanced.

2. Introduction to System Energy Structure and Model Establishment

2.1. Energy Structure of Multi-Energy Complementary Systems

2.2. Port Load Characteristics

2.3. Generator Set Model

- (1)

- Fuel cost:

- (2)

- Start-stop cost:

2.4. Electrochemical Energy Storage Model

2.5. EV Model

- (1)

- Single EV Model

- (2)

- Cluster EV model

2.6. Demand Response Model

2.7. Power Purchase and Sale Model

3. Scenario Analysis of PV and Load Outputs

3.1. Scenario Generation Based on Latin Hypercube Sampling (LHS)

- (1)

- Data Pre-processing: Input the original data of the estimated PV power generation for the next day. Divide the day into 24 time periods.

- (2)

- LHS Sampling: Assume that the dimensionality of the sampling samples is N and the sample length is 24. Generate an N × 24 sample space through LHS. Each dimension of the sample contains 24 data points ranging from 0 to 1.

- (3)

- Scenario Generation: Utilize the data in step (1) to perform an inverse transformation operation on the 0–1 data of each sample point in the N-dimensional sample space. After the transformation, the corresponding PV output scenarios are obtained.

3.2. Scenario Clustering Based on Improved ISODATA

- (1)

- Input the random PV output scenario set C = {xi, i = 1, 2, …, N}, and randomly select a single scenario as the initial clustering center z1.

- (2)

- Calculate the distances from the remaining scenarios to the determined clustering center z1, record the shortest distance in each scenario and denote it as d(xi). Calculate the probability using Equation (28) and select the new round of initial clustering centers according to the probabilities.

- (3)

- Repeat step 2 until k initial clustering centers {z1, z2, z3, …. zk} are selected.

- (4)

- Calculate the Euclidean distances between each initial clustering center and the random scenarios and assign each scenario to the cluster where the nearest clustering center is located.

- (5)

- Determine whether the number of scenarios in each cluster meets the condition of Equation (29). If it does, delete this cluster, reallocate the scenarios in this cluster, and update the number of clusters to k = k − 1.

- (1)

- Update the clustering center {zj, j = 1, 2, …, k} by modifying the following formula:

- (7)

- Use Equation (31) to calculate the average distance Dj from scenarios within each cluster to their corresponding clustering centers and use Equation (32) to calculate the average distance D from all scenarios to the clustering centers.

- (8)

- Determine whether to split. Enter step 10 if the following conditions are met:

- (9)

- Determine whether to merge. Enter step 11 if the following conditions are met:

- (10)

- Start the splitting operation. Set the splitting parameter l. The clustering centers and of the two new clusters formed after splitting can be calculated by the following two formulas:

- (11)

- Start the merging operation. The clustering center of the new cluster after merging can be expressed by the following formula:

- (12)

- Iterate repeatedly until the clustering results no longer change or the iteration limit is reached.

3.3. PV Output Scenario Reduction Based on the Backward Elimination Method

- (1)

- Initialization: Set the scenario set S’ as an empty set.

- (2)

- Start the iteration: Calculate the probability distance of each scenario according to Equation (36).

- (3)

- Scenario deletion: Select the scenario wi that minimizes Equation (36) as the discarded scenario and add it to S’. Update the number of scenarios in the original scenario set as n = n−1.

- (4)

- Scenario replacement: In the updated scenario set S, find the scenario wj that is closest to the scenario w, and use it to replace the discarded scenario wi. Update the probability of the scenario as pj’ = pj + pi.

- (5)

- Return to step 2 until the number of remaining scenarios in the set S reaches the given value and then stop the iteration.

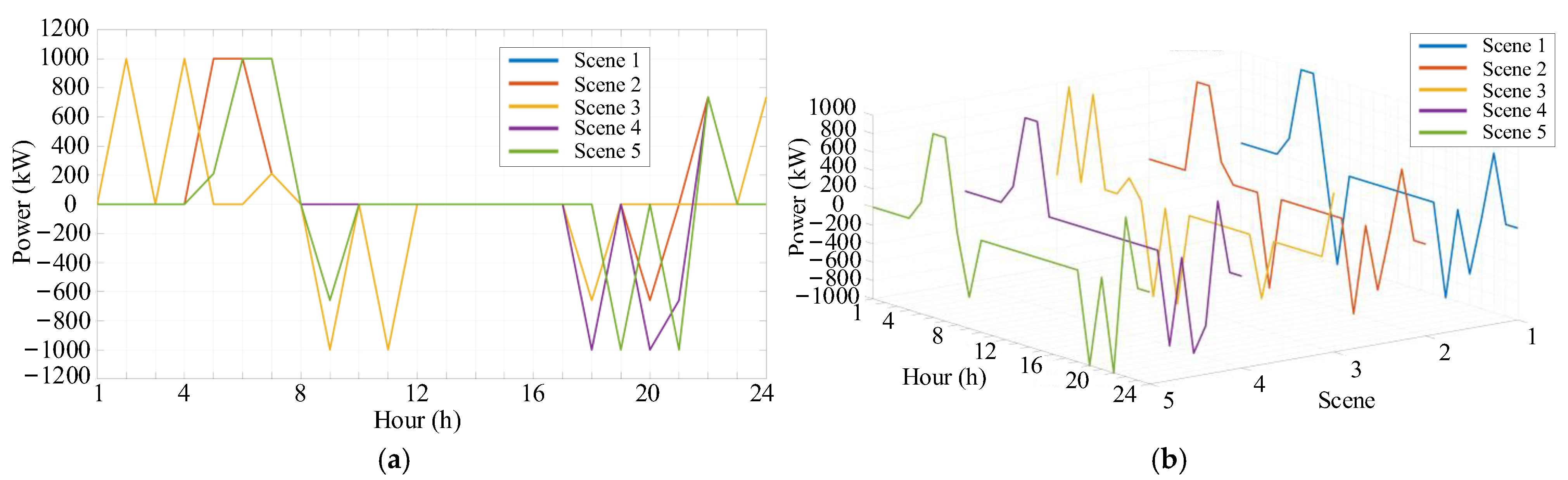

3.4. Scenario Generation Example Analysis

- (1)

- Scenario Generation Results

- (2)

- Scenario reduction results

4. Optimization Model of Multi-Energy Complementary System

4.1. Optimization Objectives

4.2. Constraints

- (1)

- PV accommodation rate constraint

- (2)

- Generator output constraint

- (3)

- Electrochemical energy storage charge-discharge constraint

- (4)

- Demand response constraint

- (5)

- Fleet EV constraint

5. Case Analysis

5.1. Basic System Parameters

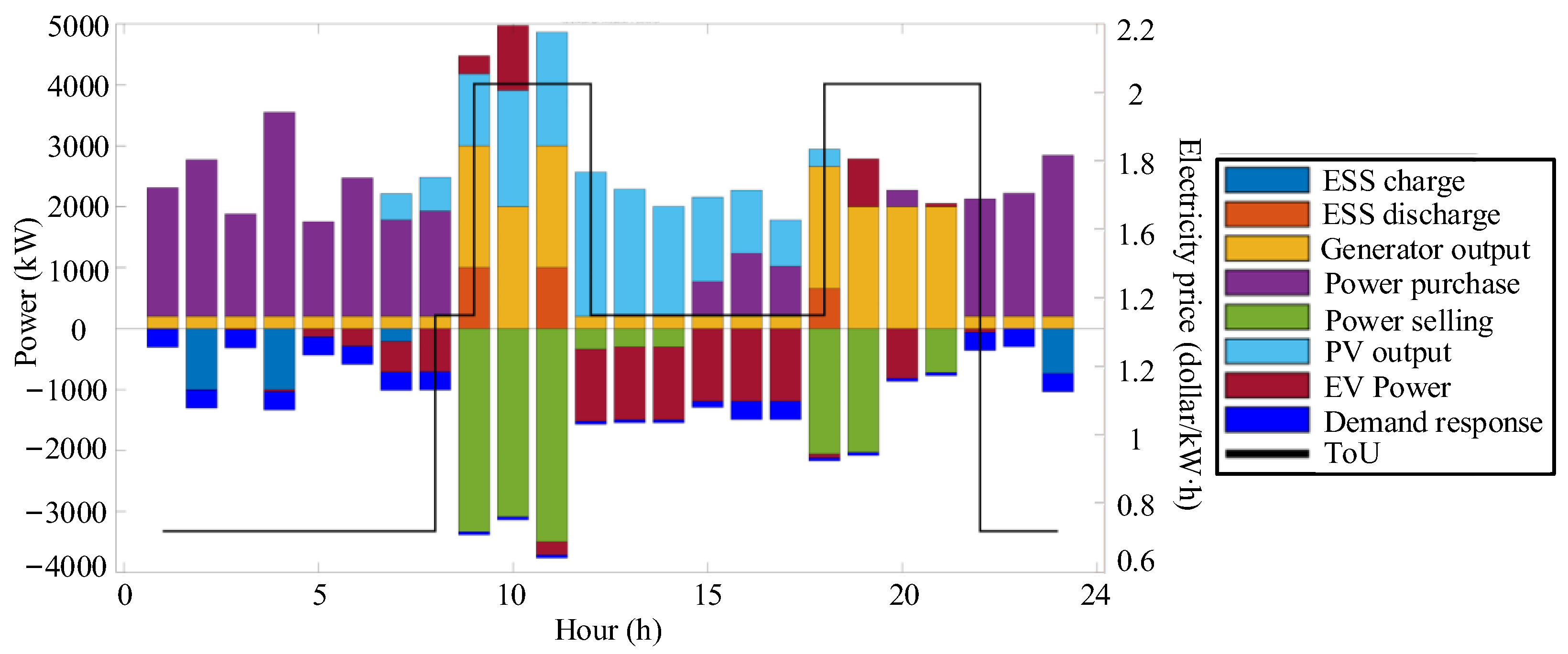

5.2. Energy Balance Results

- (1)

- Power Purchase during Off-peak Hours (0:00–8:00): As shown in the figure, from 0:00 to 8:00, solar energy resources are scarce, approaching zero. Meanwhile, this period coincides with the off-peak period of electricity prices. To meet the basic load requirements of the system and fulfill the demand-response needs, the system gives priority to purchasing electricity from the distribution network. Any surplus power resources are stored in the energy storage system in advance.

- (2)

- PV Accommodation and Energy Storage Charging (9:00–17:00): The period from 9:00 to 17:00 represents the peak output period of photovoltaics. During this time, the system prioritizes the accommodation of PV power. At the same time, the energy storage power station operates in charging mode to absorb the surplus PV power. The electric vehicle (EV) cluster flexibly adjusts its charging and discharging power according to the off-grid time constraints, with a maximum discharging power of 1000 kW. This strategy significantly reduces the output of thermal power units.

- (3)

- Load Support and Thermal Power Adjustment (18:00–24:00): When 18:00–24:00 arrives, the PV output approaches zero. The energy storage power station switches to discharging mode to provide power support. The EV cluster also participates in power supply through discharge scheduling. The output of thermal power units is increased to 2 MW, accounting for a certain proportion of the total load. Additionally, electricity is purchased from the distribution network to ensure a stable supply of load demand.

- (4)

- Cost-effective Electricity Trading: As shown in Section 5.6, the interactive power of electricity purchase and sale throughout the day is influenced by time-of-use electricity prices. During the off-peak period, electricity is mainly sold, while during the peak period, electricity is mainly purchased.

- (5)

- Validation of the Model: The multi-energy complementary scheduling strategy effectively coordinates the volatility of PV, the randomness of load, and the operating constraints of equipment, verifying the practical application value of the model.

5.3. Optimization Results of Power-Generating Units

5.4. Optimization Results of Energy Storage Power Station

- (1)

- Charging during Off-peak and Discharging during Peak: As shown in Figure 16, the energy storage station charges at maximum power from 0:00 to 7:00, with the electricity storage increasing from 1500 kWh to 3200 kWh. Then, it discharges from 8:00 to 21:00. Compared with the scenario without energy storage, the “low-charge and high-discharge” strategy reduces the electricity purchase cost on a single day. It compensates for the power gap and reduces the demand for thermal power units.

- (2)

- Strict Compliance with Electricity Quantity Constraints: The electricity quantity of the energy storage remains within the safe range at all times. There are no over-charging or over-discharging phenomena. Moreover, the electricity quantity at the end of the scheduling period returns to the initial required value, meeting the cyclic scheduling constraints and effectively ensuring the service life of the energy storage.

- (3)

- Significant Synergistic Effect of Multi-energy Complementarity: During the peak load period, the discharging power of the energy storage and the discharging of the EV cluster work in coordination to provide flexible power, replacing the output of thermal power units.

5.5. Optimization Results of EV Fleet

- (1)

- High Coordination of Charging and Discharging with Electricity Prices and Load Demand: The charging and discharging behavior of EVs is highly coordinated with electricity prices and load demand. Specifically, EVs charge during the off-peak period (from 0:00 to 6:00) to increase SOC to 85%, and discharge during the peak period (from 18:00 to 21:00) to support the load demand.

- (2)

- Photovoltaic Energy Accommodation: During the peak output period of photovoltaics, EVs charge to absorb the surplus photovoltaic power. The SOC increases from 40% to 75%, thereby reducing the loss of curtailed photovoltaic energy.

- (3)

- Strict Compliance with SOC Constraints: The SOC of all EVs is greater than the user’s expected value when they are disconnected from the grid. This not only meets the port operation plan but also maximizes the flexibility of charging and discharging.

- (4)

- Significant Benefits of Multi-energy Complementarity: During the peak load period, the discharge of EVs in coordination with energy storage reduces the output of thermal power units, thus lowering fuel costs.

- (5)

- Advantage of Model Calculation Efficiency: Compared with the traditional single-EV scheduling model, the VB model reduces the dimensionality of decision variables to 1, shortening the solution time by 30%.

5.6. Optimization Results of Electricity Purchase and Sale

- (1)

- Remarkable Economic Efficiency: As shown in the figure, the microgrid purchases electricity from 0:00 to 7:00 and sells electricity during the peak photovoltaic output period.

- (2)

- Reduced Electricity Purchase Demand during Peak Price Periods: During high-electricity-price periods, the electricity purchase power approaches zero. The load demand is mainly met by the discharging of energy storage and EVs, which helps reduce expenditure.

- (3)

- Export of Surplus Photovoltaic Electricity: From 8:00 to 12:00, when the photovoltaic output exceeds the port load demand, the microgrid sells the surplus electricity to the distribution network.

- (4)

- Support of Sale Revenue for Economic Efficiency: The sale revenue partially offsets the fuel cost of thermal power units.

5.7. Comparative Metrics with Existing Studies

6. Conclusions

- (1)

- Effectiveness of the Multi-energy Complementary Coordinated Scheduling Model: By integrating thermal power, PV, energy storage, EV clusters, and demand-response resources, a coordinated optimization framework for the port micro-grid is constructed. Under the premise of ensuring the stable operation of the system, the model significantly reduces the operating cost, improves the PV accommodation capacity, and reduces the dependence on traditional thermal power, providing a feasible path for the low-carbon transformation of the port energy system.

- (2)

- Uncertainty Scenario Characterization: The improved clustering algorithm and scenario reduction method effectively characterize the randomness of PV output and load, extracting representative typical scenarios and significantly reducing the complexity of the optimization model.

- (3)

- Flexible Scheduling Potential of EV Clusters: The proposed VB accurately quantifies the impact of the dynamic connection and disconnection behavior of EVs on the system, achieving a balance between user demand and scheduling flexibility. Through the coordinated charging and discharging strategy, the EV cluster shows power regulation ability comparable to that of energy storage, becoming a key resource to support the economy and reliability of the system.

- (4)

- Economic Benefits of Electricity Purchase and Sale Strategies and Multi-energy Complementarity: The electricity purchase and sale strategy driven by time-of-use electricity prices and the coordinated optimization of multi-energy resources significantly reduce the dependence on the external grid and improve energy utilization efficiency. The joint scheduling of energy storage, EVs, and demand response effectively smooths the peak-valley difference of the load, reduces the electricity purchase demand during high-price periods, and verifies the comprehensive benefits of multi-energy complementarity.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- International Energy Agency (IEA). Energy Technology Perspectives 2024; International Energy Agency (IEA): Paris, France, 2024; Available online: https://www.iea.org/reports/energy-technology-perspectives-2024 (accessed on 18 December 2024).

- Wang, Y.; Zhang, H.; Zhang, W.; Han, S.; Yang, Y. Energy Optimal Configuration Strategy of Distributed Photovoltaic Power System for Multi-Level Distribution Network. Appl. Sci. 2025, 15, 234. [Google Scholar] [CrossRef]

- Fresia, M.; Robbiano, T.; Caliano, M.; Delfino, F.; Bracco, S. Optimal Operation of an Industrial Microgrid within a Renewable Energy Community: A Case Study A Greentech Company. Energies 2024, 17, 3567. [Google Scholar] [CrossRef]

- Hu, W.; Dong, Y.; Zhang, L.; Wang, Y.; Sun, Y.; Qian, K.; Qi, Y. Research on complementarity of multi-energy power systems: A review. iEnergy 2023, 2, 275–283. [Google Scholar] [CrossRef]

- Xiao, H.; Pu, X.; Pei, W.; Ma, L.; Ma, T. A Novel Energy Management Method for Networked Multi-Energy Microgrids Based on Improved DQN. IEEE Trans. Smart Grid 2023, 14, 4912–4926. [Google Scholar] [CrossRef]

- Liu, J.; Wang, A.; Song, C.; Tao, R.; Wang, X. Cooperative Operation for Integrated Multi-Energy System Considering Transmission Losses. IEEE Access 2020, 8, 96934–96945. [Google Scholar] [CrossRef]

- Zhao, S.; Suo, X.; Ma, Y.; Dong, L. Multi-Point Layout Planning for Multi-Energy Power System Based on Complex Adaptive System Theory. CSEE J. Power Energy Syst. 2024, 10, 2138–2146. [Google Scholar]

- Suo, X.; Zhao, S.; Ma, Y.; Dong, L. New Energy Wide Area Complementary Planning Method for Multi-Energy Power System. IEEE Access 2021, 9, 157295–157305. [Google Scholar] [CrossRef]

- Zhu, S.; Ding, T.; Chen, C.; Chow, M.Y.; Guan, X. DEED-ADMM: A Scalable Distributed Algorithm for Economic Dispatch in Multi-Energy Systems with Energy Storage. IEEE Trans. Autom. Sci. Eng. 2025, 22, 11431–11443. [Google Scholar] [CrossRef]

- Xie, S.; Wu, Q.; Zhang, M.; Guo, Y. Coordinated Energy Pricing for Multi-Energy Networks Considering Hybrid Hydrogen-Electric Vehicle Mobility. IEEE Trans. Power Syst. 2024, 39, 7304–7317. [Google Scholar] [CrossRef]

- Wang, D.; Huang, D.; Hu, Q.; Jia, H.; Liu, B.; Lei, Y. Electricity-Heat-Based Integrated Demand Response Considering Double Auction Energy Market with Multi-Energy Storage for Interconnected Areas. CSEE J. Power Energy Syst. 2024, 10, 1688–1700. [Google Scholar]

- Sun, L.; Bao, J.; Pan, N.; Jia, R.; Yang, J. Optimal Scheduling of Wind-Photovoltaic- Pumped Storage Joint Complementary Power Generation System Based on Improved Firefly Algorithm. IEEE Access 2024, 12, 70759–70772. [Google Scholar] [CrossRef]

- Wang, T.; Huang, Z.; Ying, R.; Valencia-Cabrera, L. A Low-Carbon Operation Optimization Method of ETG-RIES Based on Adaptive Optimization Spiking Neural P Systems. Prot. Control Mod. Power Syst. 2024, 9, 162–177. [Google Scholar] [CrossRef]

- Yang, H.; Li, M.; Jiang, Z.; Zhang, P. Multi-Time Scale Optimal Scheduling of Regional Integrated Energy Systems Considering Integrated Demand Response. IEEE Access 2020, 8, 5080–5090. [Google Scholar] [CrossRef]

- Zhong, W.; Yang, C.; Xie, K.; Xie, S.; Zhang, Y. ADMM-Based Distributed Auction Mechanism for Energy Hub Scheduling in Smart Buildings. IEEE Access 2018, 6, 45635–45645. [Google Scholar] [CrossRef]

- Zhang, W.; Sun, C.; Alharbi, M.; Hasanien, H.M.; Song, K. A voltage-power self-coordinated control system on the load-side of storage and distributed generation inverters in distribution grid. Ain Shams Eng. J. 2025, 16, 103480. [Google Scholar] [CrossRef]

- Lyu, J.; Cheng, K. Two-Stage Stochastic Coordinated Scheduling of Integrated Gas-Electric Distribution Systems Considering Network Reconfiguration. IEEE Access 2023, 11, 51084–51093. [Google Scholar] [CrossRef]

- Zhu, S.; Wang, E.; Han, S.; Ji, H. Optimal Scheduling of Combined Heat and Power Systems Integrating Hydropower-Wind-Photovoltaic-Thermal-Battery Considering Carbon Trading. IEEE Access 2024, 12, 98393–98406. [Google Scholar] [CrossRef]

- Aggarwal, S.; Kumar, N.; Tanwar, S.; Alazab, M. A Survey on Energy Trading in the Smart Grid: Taxonomy, Research Challenges and Solutions. IEEE Access 2021, 9, 116231–116253. [Google Scholar] [CrossRef]

- Chen, Z.; Qi, J.; Chen, X.; Xu, J. Stability Margin Evaluation of Black-Box Power Distribution Systems in a Wide Load Range. CPSS Trans. Power Electron. Appl. 2023, 8, 325–335. [Google Scholar] [CrossRef]

- Wang, W.; Huo, Q.; Liu, Q.; Ni, J.; Zhu, J.; Wei, T. Energy Optimal Dispatching of Ports Multi-Energy Integrated System Considering Optimal Carbon Flow. IEEE Trans. Intell. Transp. Syst. 2024, 25, 4181–4191. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, Y.; Zeeshan, M.; Han, F.; Song, K. Super-twisting sliding mode control of grid-side inverters for wind power generation systems with parameter perturbation. Int. J. Electr. Power Energy Syst. 2025, 165, 110501. [Google Scholar] [CrossRef]

- Li, D.; Saad, W.; Guvenc, I.; Mehbodniya, A.; Adachi, F. Decentralized Energy Allocation for Wireless Networks with Renewable Energy Powered Base Stations. IEEE Trans. Commun. 2015, 63, 2126–2142. [Google Scholar] [CrossRef]

- Huang, Y.; Lin, Z.; Liu, X.; Yang, L. Bi-level Coordinated Planning of Active Distribution Network Considering Demand Response Resources and Severely Restricted Scenarios. J. Mod. Power Syst. Clean. Energy 2021, 9, 1088–1100. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, H.; Zhang, W.; Wang, X.; Wang, J. Optimization Method for Topology Identification of Port Microgrid Based on Line Disconnection. Energies 2025, 18, 706. [Google Scholar] [CrossRef]

- Huang, Y.; Sun, Q.; Chen, Z.; Gao, D.W.; Pedersen, T.B.; Larsen, K.G.; Li, Y. Dynamic Modeling and Analysis for Electricity-Gas Systems with Electric-Driven Compressors. IEEE Trans. Smart Grid 2025, 16, 2144–2155. [Google Scholar] [CrossRef]

| Scenario Number | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| probability | 0.132 | 0.255 | 0.197 | 0.145 | 0.217 |

| Unit | Cost-Characteristic Parameters | SG,i | |||

|---|---|---|---|---|---|

| /(Dollar/MW2) | /(Dollar/MW2) | /(Dollar/MW2) | |||

| 1 | 500/40 | 0.152 | 147.21 | 3400 | 35,000 |

| 2 | 500/40 | 0.152 | 147.21 | 3700 | 31,500 |

| 3 | 500/40 | 0.152 | 147.21 | 3450 | 31,500 |

| 4 | 600/40 | 0.183 | 167.44 | 4660 | 21,000 |

| Parameters | Value |

|---|---|

| /kW | 1000 |

| η | 0.95/0.95 |

| Ks/(dollar/MW2) | 0.38 |

| /kw·h | 3600 |

| /kw·h | 800 |

| ES(0)/kw·h | 1500 |

| Parameters | /kW | KDR | |

|---|---|---|---|

| Value | 400 | 50 | 0.22 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Wei, X.; Zhang, H.; Liu, B.; Wang, Y. Multi-Energy Optimal Dispatching of Port Microgrids Taking into Account the Uncertainty of Photovoltaic Power. Energies 2025, 18, 3216. https://doi.org/10.3390/en18123216

Wang X, Wei X, Zhang H, Liu B, Wang Y. Multi-Energy Optimal Dispatching of Port Microgrids Taking into Account the Uncertainty of Photovoltaic Power. Energies. 2025; 18(12):3216. https://doi.org/10.3390/en18123216

Chicago/Turabian StyleWang, Xiaoyong, Xing Wei, Hanqing Zhang, Bailiang Liu, and Yanmin Wang. 2025. "Multi-Energy Optimal Dispatching of Port Microgrids Taking into Account the Uncertainty of Photovoltaic Power" Energies 18, no. 12: 3216. https://doi.org/10.3390/en18123216

APA StyleWang, X., Wei, X., Zhang, H., Liu, B., & Wang, Y. (2025). Multi-Energy Optimal Dispatching of Port Microgrids Taking into Account the Uncertainty of Photovoltaic Power. Energies, 18(12), 3216. https://doi.org/10.3390/en18123216