Abstract

Buildings are responsible for over one-third of global energy use and greenhouse gas emissions, with heating and cooling being major contributors. Phase change materials (PCMs) offer a promising passive solution to improve thermal regulation and reduce heating and cooling loads. This review analyses different experimental and simulation-based studies on the integration of PCMs into building structures for enhancing building energy performance. The key variables examined include melting temperature, latent heat capacity, thermal conductivity (λ), PCM positioning (interior, exterior, or embedded), thickness, and climate zone. The results show that PCMs reduce heat transfer by up to 47.6%, stabilize indoor temperatures with up to a 46% reduction in fluctuations, and decrease heating and cooling demands by as much as 31%, depending on component placement and climate. The optimal melting range for moderate climates lies between 22 °C and 28 °C. This review identifies critical trade-offs between PCM quantity, placement, and climatic suitability and provides a matrix of design recommendations for various building types.

1. Introduction

Buildings and infrastructure play a significant role in energy consumption and the release of greenhouse gases into the atmosphere worldwide. With the growing emphasis on energy conservation to effectively address climate change, the construction sector is increasingly prioritizing methods to improve building efficiency. In particular, concrete structures, which are commonly used in public infrastructure, present both challenges and opportunities for reducing energy consumption, especially in heating and cooling systems. Globally, the buildings sector accounts for about 34% of the total energy demand, with space heating and cooling representing a significant share of this energy use [1,2]. Despite improvements in energy efficiency, overall energy consumption in buildings continues to rise, partly due to increasing floor space and population growth. Additionally, space heating and cooling are major contributors to greenhouse gas emissions, with the buildings sector responsible for around 37% of the global energy and process-related CO2 emissions in 2022 [3,4]. A substantial portion of these emissions comes from the direct use of fossil fuels in heating systems, such as natural gas and coal. These factors, combined with the expected rise in heating and cooling needs due to global warming, highlight the importance of improving energy efficiency and transitioning to cleaner energy sources in the building sector to reduce greenhouse gas emissions [5,6]. However, the increased adoption of renewable energy systems, particularly solar photovoltaic (PV) panels, also introduces new challenges to the energy supply grid. PV systems generate electricity most efficiently during midday, while residential demand typically peaks in the evening when electricity generation from PV is at its lowest. This mismatch between energy generation and consumption highlights the need for effective load management strategies, such as peak load shifting [7].

Incorporating PCMs into building structures offers a promising solution to this issue. PCMs store excess thermal energy during periods of high energy production and release it during times of high demand, helping to flatten peak energy loads and balance supply with consumption [8]. Additionally, PCMs enhance energy efficiency and improve thermal comfort by passively regulating indoor temperatures, reducing reliance on active heating and cooling systems. This leads to lower energy consumption and a reduced carbon footprint [9,10]. Thus, integrating PCMs into concrete structures enhances the thermal performance of buildings and aligns with the broader goals of energy efficiency and sustainable construction, ensuring that buildings can better manage fluctuating energy demands while maintaining comfortable indoor environments [11].

The thermal performance of buildings integrated with PCMs is influenced by several key variables. The melting temperature of PCMs must align with target indoor comfort ranges to store and release energy efficiently [12,13,14,15,16,17,18,19,20]. Critical thermal properties, like latent heat capacity and thermal conductivity (λ), determine storage efficiency and heat transfer rates [21,22,23,24,25,26,27,28]. The application of PCMs (walls, roofs, floors) [15,29,30,31,32,33] and their positioning (external vs. internal) [34,35,36,37,38,39] affect how they interact with the environment, while the quantity and thickness of the PCM layer balance energy storage capacity and practicality [40,41,42,43,44,45,46]. Additionally, climate conditions [15,16,36,47,48,49,50,51] and building orientation [17,52,53,54,55,56] influence PCM effectiveness, as variations in temperature and sunlight exposure impact energy absorption and release. Optimizing these factors is essential to maximize energy efficiency and thermal comfort in buildings.

Globally, residential, commercial, and other concrete buildings rank among the most energy-intensive because of their size, high occupancy, and reliance on heating, ventilation, and air conditioning (HVAC) systems [57]. Many of these structures feature thick walls made from thermally conductive materials, which can lead to significant heat loss in winter and heat gain in summer. In addition to building envelope applications, recent studies have increasingly explored the integration of PCMs into HVAC system components, such as ducts [58], evaporator coils [59], heat exchangers [60], and ventilation systems [61,62]. These applications aim to enhance thermal energy storage, improve part–load efficiency, and reduce peak electricity demand. By embedding PCMs in active systems, researchers are extending their functionality beyond passive regulation to direct interaction with heating and cooling cycles. The challenge lies in reducing heating and cooling demands without compromising structural integrity [63]. This highlights the critical role HVAC systems play in building energy efficiency and carbon footprints, making it essential to boost the thermal performance of building materials [22].

In this context, PCMs enhance the thermal energy storage capabilities of building materials, offering a cost-effective way to lower thermal conductivity and reduce the need for active heating and cooling by storing heat during warmer periods and releasing it [13,64]. The interplay between PCM properties (melting temperature, latent heat, thermal conductivity, specific heat), placement within building components (walls, roofs, floors), climate conditions, and practical constraints, such as thickness or quantity, remains insufficiently explored in a consolidated and application-oriented manner. There is a clear need for a comprehensive overview that brings together findings from experimental and simulation-based studies across diverse climate zones and building types.

Several comprehensive reviews have previously examined the application of PCMs in buildings. For example, Song et al. [65] provided a broad synthesis of PCM use in both building envelopes and HVAC systems, emphasizing general benefits without offering comparative analysis across design parameters. Da Cunha et al. [66] reviewed PCM incorporation in construction systems and its socio-economic impact, but their synthesis was primarily qualitative and lacked performance-based comparisons. Marani et al. [67] focused specifically on PCM incorporation techniques (microencapsulation, shape-stabilization, macroencapsulation), providing detailed materials science insights but without evaluating performance outcomes in full-scale building scenarios. Wang et al. [68] offered an extensive survey on PCM properties, numerical modelling, and hybrid materials but did not present comparative results across climate contexts or structural configurations. Finally, Al-Yasiri et al. [69] examined PCM use in building envelopes with a focus on simulation tools and envelope design but did not explore quantitative cross-study findings. In, contrast, the main contributions of this review are as follows: it reviews findings from over 100 experimental, numerical, and hybrid studies focused on PCM integration into building materials; it analyses key variables affecting PCM performance, including melting temperature, latent heat, thermal conductivity, layer thickness, and climate suitability; it compares PCM placement strategies (interior, middle, and exterior) across various building components, such as walls, roofs, floors, and ceilings; it evaluates the effectiveness of PCMs in diverse climate zones and under different building orientations; it compiles practical design recommendations based on quantitative results to support energy-efficient applications; and it identifies research gaps and future directions for optimizing PCM use in passive thermal regulation systems within buildings. By structuring the findings around critical variables, such as material properties, component placement, and climate conditions, this work contributes a valuable reference for both researchers and practitioners engaged in energy-efficient building design.

The structure of this review is organized to provide a logical and comprehensive synthesis of the literature. Section 2 introduces the review methodology, including the criteria for study selection, classification, and analysis. Section 3 explores the integration of PCMs into building components, such as walls, roofs, ceilings, and floors, while examining the influence of PCM thermal properties, placement strategies, and climate conditions. Section 3 also includes both qualitative assessments and quantitative comparisons across studies. Section 4 discusses overarching trends and cross-sectional insights, synthesizing the results in terms of energy performance and thermal regulation effectiveness. Section 5 focuses on practical implications for design and construction, outlining application-oriented recommendations and identifying research gaps. Finally, Section 6 concludes this paper by summarizing the key findings and proposing directions for future research and development.

2. Methodology

This review followed a structured approach to identify, screen, and analyse studies related to the integration of PCMs into concrete buildings. A four-step process was adopted: literature search, eligibility screening, study classification, and thematic analysis.

2.1. Literature Search Strategy

A comprehensive search was conducted in academic databases, including ScienceDirect and Google Scholar. The search covered publications from 2018 to 2024, using combinations of the following keywords:

“phase change material”, “PCM”, “PCM concrete”, “thermal energy storage”, “thermal performance”, “energy efficiency”, “latent heat”, “PCM placement”, “PCM in different climate zones”, and “PCM in building materials”.

Only peer-reviewed journal articles and conference papers in English were included.

2.2. Inclusion and Exclusion Criteria

- The included studies met the following criteria:

- ▪

- Investigated PCM integration into building envelopes (e.g., walls, roofs, slabs, ceilings);

- ▪

- Reported quantitative results (e.g., temperature reduction, energy savings, thermal conductivity);

- ▪

- Conducted experimental, simulation-based, or hybrid analysis.

- The excluded studies met the following criteria:

- ▪

- Focused on non-building integration;

- ▪

- Did not report thermal performance metrics;

- ▪

- Lacked clarity in PCM type, thickness, or placement.

2.3. Study Selection and Classification

While not limited to a specific research method, this review emphasized works that employed experimental, numerical simulation, or hybrid approaches. Studies were compared and synthesized across several key variables, including the following:

- PCM thermal properties (melting point, latent heat, conductivity);

- Integration method (embedded vs. layered);

- Application component (walls, roofs, floors, ceilings);

- Placement position (interior, middle, exterior);

- Climate zone (hot, cold, temperate, mixed).

Most of the reviewed studies (approximately 75%) focused on residential buildings, such as single-family homes, multi-story dwellings, and apartments, reflecting their dominant role in energy consumption and occupant comfort. About 15% of the studies addressed commercial or institutional buildings, including offices and educational prototypes, while the remaining 10% used generalized or unspecified models applicable to multiple building types. Geographically, the selected literature spanned Asia (notably China, India, Iran, and Japan), Europe (including the UK, Spain, Germany, Turkey, and Italy), North America (particularly the United States), Oceania (New Zealand), and parts of South America. This diversity enabled a reasonably wide generalization of findings across climate zones (cold, hot, temperate, mixed) and building typologies.

2.4. Data Extraction and Analysis

Quantitative performance indicators, such as peak temperature reduction, time lag, energy savings (% or kWh), thermal comfort, and indoor temperature fluctuation, were extracted. A comparative analysis was conducted to assess the effect of individual parameters on overall thermal performance.

3. Thermal Behaviour in Buildings

Thermal behaviour in buildings refers to how effectively a structure regulates temperature to maintain comfort and energy efficiency. It involves the ability of a building to minimize heat loss in cold climates and heat gain in hot climates. The key factors influencing thermal behaviour include insulation quality, window and glazing properties, thermal mass, ventilation, and the building envelope design. It is critical for reducing energy consumption, lowering greenhouse gas emissions, and ensuring occupant comfort [70]. Thermal behaviour is often evaluated using metrics and energy modelling tools to design buildings that meet efficiency and sustainability standards. Energy modelling tools, such as Ansys Fluent, EnergyPlus, and DesignBuilder, help analyse and optimize building designs for improved efficiency, occupant thermal comfort, sustainability, and reduced energy consumption [71].

- Thermal comfort

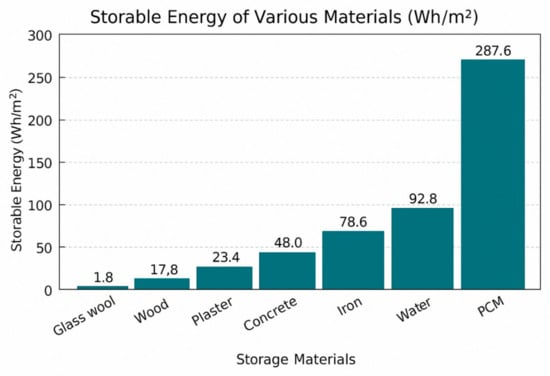

Thermal comfort is a crucial factor in building design, directly influencing the well-being of occupants, productivity, and energy consumption of buildings. Traditional methods of maintaining thermal comfort, such as heating, ventilation, and HVAC systems, can be energy-intensive and environmentally damaging [72]. Therefore, sustainable approaches to improve thermal performance in buildings are gaining prominence. One such strategy involves the integration of PCMs, which are chosen for their high energy storage capability, as represented in Figure 1, allowing them to absorb and release large amounts of thermal energy during phase transitions [11,13], thus enhancing thermal regulation and reducing reliance on conventional HVAC systems [10,16,73]. Especially for concrete structures, incorporating PCMs offers additional benefits, such as improving thermal inertia, which helps moderate indoor temperature fluctuations [9,63,74].

Figure 1.

Energy storage capacity of different materials under the same conditions and for the same quantity (Redrawn after [11]).

- Phase Change Materials (PCMs) for Building Applications

The type and integration methods of PCMs should be carefully selected to align with the desired properties for optimal effectiveness in a given application [75]. These properties can be grouped as follows: thermal properties (melting temperature, latent heat capacity, specific heat, and thermal conductivity). Table 1 presents the primary properties of PCMs used in various studies. This section analyses studies addressing each factor individually, examining how specific thermal properties, application location within the building (external wall, internal wall, roof, ceiling, floor), PCM position (outer or inner side), thickness and quantity, climate conditions, and building orientation influence the effectiveness of PCMs in building applications.

Table 1.

Thermal properties of different phase change materials (PCMs) used in building applications. Data include thermal conductivity, latent heat capacity, specific heat, and melting temperature. Values vary between solid and liquid phases when reported. Sources correspond to studies cited in the main text.

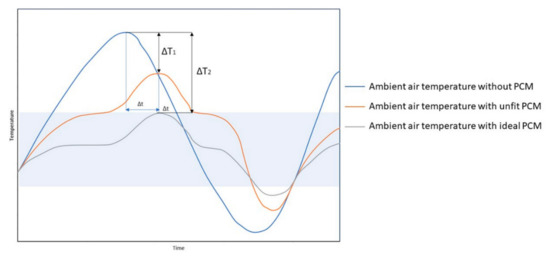

3.1. Melting Point

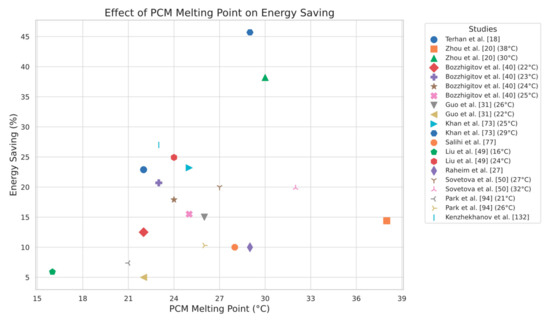

The melting point of a PCM is essential for effective temperature regulation, as it should align with the target temperature range for thermal control within a concrete structure. The phase change process, where a PCM absorbs or releases heat, must occur within the daily or seasonal temperature fluctuation range to ensure optimal performance and to reach the highest energy savings, as represented in Figure 2. Wang et al. [17] found that the inclusion of PCMs resulted in significant temperature reductions during hydration of about 4 °C with PCM18P and 5 °C with PCM25P incorporated. The PCM with the higher melting point (25 °C) delayed the peak temperature by about 60 min compared to the control, whereas the PCM18P mixture showed a 35 min delay. Moreover Wang et al. conducted a simulation study on a building in Shanghai under hot summer conditions. They showed that PCMs with different melting points (31 °C, 35 °C, 42 °C, 47 °C, 50 °C, and 55 °C) had varying effectiveness in reducing heat flow. The PCM with a melting temperature of 42 °C RT42 performed best, achieving the most complete melting– solidification cycle and resulting in the highest heat gain reduction ratio of 28.3% during office hours, compared to the other PCMs that either melted too early or did not solidify completely.

Figure 2.

Reported energy savings (%) as a function of PCM melting point (°C) across 20 different studies. The data show that optimal energy savings are generally achieved with PCM melting points between 24 °C and 26 °C, corresponding to typical indoor comfort temperatures. Each point represents a distinct experimental or simulation-based study, with symbols and colours identifying specific references. This trend highlights the importance of matching PCM thermal properties to ambient thermal loads for maximizing passive energy savings.

Terhan et al. [18] conducted a study on a residential building model located in Istanbul, Turkey, using energy simulation software to assess the impact of integrating PCMs into the exterior walls. The analysis considered various melting temperatures and evaluated the building’s heating and cooling energy demands throughout the year. The results showed that PCMs with melting temperatures between 21 °C and 23 °C resulted in the highest energy savings, achieving 21.32% heating and 24.45% cooling energy savings.

Zhou et al. [20] investigated the effects of PCM melting points on the thermal performance of Trombe walls in a mixed dry climate. Their simulations revealed that in summer, using a PCM layer with a melting point of 38 °C reduced the maximum peak load by 48.9%, decreased the temperature fluctuation by 76%, and reduced the cooling load by 14.4% while achieving time lags of 4.5 h for maximum and 6.1 h for minimum indoor temperatures. In winter, a PCM with a 30 °C melting point reduced the thermal load by 38.2%, decreased the fluctuations by 28.5%, and produced time lags of 4.0 and 1.7 h.

Berardi et al. [30] showed that the melting temperature of PCMs had a significant impact on the results of their study. Two PCMs with different melting points were used: BioPCM, which has a melting point of 25 °C and is suitable for summer months, and Energain, which has a lower melting point of 21 °C and is suitable for cooler conditions. During July and August, BioPCM was highly effective, reducing indoor temperature swings by 46% in July and 37% in August, as its higher melting point allowed it to absorb excess heat during the day and release it at night. In contrast, Energain, with its lower melting range, performed better during cooler months, like September and October, reducing temperature swings by 35% and achieving full solidification on 60% of the days in September. The combination of these two PCMs helped regulate indoor temperatures year-round by activating at different temperature ranges, effectively reducing both high peak temperatures and maintaining comfort during cooler nights.

Bozzhigitov et al. [40] confirmed that the melting temperature of PCMs significantly impacts building thermal performance and energy savings. Their study optimized PCM melting temperatures between 18 °C and 30 °C in office buildings across eight cities in a marine climate zone with a temperature range between −3 °C and 18 °C. The optimal range, 22 °C to 25 °C, provided substantial savings. In Bilbao, the 22 °C PCM saved 12,460 kWh annually, while in Srinagar, it saved 20,468 kWh. At 23 °C, Bogota and Zonguldak saved 20,741 kWh and 12,497 kWh, respectively. For Paris, Mar del Plata, and Port Elizabeth, 24 °C was ideal, saving 14,543 kWh, 17,868 kWh, and 10,380 kWh. Melbourne saw the most savings with 25 °C PCM, achieving 15,541 kWh.

Moreover, Guo et al. [31] studied the effect of the melting temperature of the PCM layer on energy performance. The phase change material (PCM) used in the study had melting temperature ranges of 20 °C to 28 °C, with three types of PCM implemented: PCM I with a melting point of 20–24 °C, PCM II with 22–26 °C, and PCM III with 24–28 °C. The study was conducted in real-world conditions, with ambient temperatures fluctuating across seasons, from cold conditions that dropped below 20 °C to warmer climates where the temperature exceeded 28 °C. The PCMs with different melting temperatures demonstrated varying results depending on the season. For instance, in hot weather, the PCM with a higher melting point achieved up to a 15% reduction in cooling energy consumption, while in colder conditions, the energy savings were less pronounced, with reductions of around 5%.

A study conducted by Li et al. [34] examined the effects of different PCM melting temperatures, ranging from 18 °C to 26 °C, on the thermal performance of a retrofitted building in Ottawa, Canada, with outdoor summer temperatures fluctuating between 15.0 °C and 26.5 °C. It found that a PCM layer with a peak melting temperature of 20 °C provided the best results, reducing heat gain by 41% and heat loss by 96% compared to a non-PCM wall. Other PCM temperatures showed varied performance. For instance, a melting temperature of 18 °C reduced heat gain by 16% and heat loss by 33%, while a temperature of 24 °C reduced heat gain by 24% and heat loss by 69%. The results demonstrated that the PCM’s melting temperature played a crucial role in optimizing the building’s energy efficiency, with 20 °C being the most effective.

In their study, Khan et al. [82] demonstrated that the incorporation of PCMs significantly affects the thermal performance of buildings by reducing energy consumption. Specifically, PCM25, with a melting range of 24–26 °C, reduced summer electricity consumption by 13.7% and winter natural gas usage by 32.7%. Meanwhile, PCM29, which has a higher melting point of 28–30 °C, further decreased summer electricity consumption by 45.7% but showed a lower effect in winter, reducing energy consumption by only 6.8%. The combined use of both PCMs led to an overall reduction in electricity and natural gas usage by 25.3% and 16.5%, respectively.

Colarossi et al. [83] examined an experimental study of the thermal performance of solar ponds integrated with PCMs, focusing on two types of paraffin-based PCMs (RT35HC and RT44HC) under real atmospheric conditions. The building type studied consisted of salt gradient solar ponds, with PCMs embedded in the Lower Convective Zone to improve thermal energy storage. The pond with RT35HC showed higher night-time temperatures due to latent heat release, providing more constant temperatures, while RT44HC offered better insulation, with 5.77% lower daytime peaks. RT35HC (35 °C) suited applications needing constant night temperatures, and RT44HC (44 °C) stabilized daytime peaks at higher ambient temperatures.

A study conducted by Salihi et al. [85] evaluated the energetic performance of PCM-integrated walls in a typical lightweight building located in Benguerir City, Morocco. The PCMs were layered between a gypsum plasterboard and a brick layer on the interior surface of the walls. The research tested various paraffin-based PCMs (RT-18 HC, RT-21 HC, RT-25 HC, RT-28 HC, and RT-35 HC), finding that RT-28 HC, with a melting point of 28 °C, provided the best overall performance. This PCM significantly reduced daytime temperatures by 1.64 °C and increased night-time temperatures by 1.37 °C, improving thermal comfort. Additionally, it offered substantial energy savings, particularly in summer, with an annual cooling energy reduction of 295.90 kWh, making it the most effective PCM for the semi-arid climate of the region.

The results demonstrate that selecting a phase change material with an appropriate melting point is crucial for optimizing thermal regulation, as it effectively reduces peak temperatures and delays heat release, leading to more stable thermal conditions and minimizing risks associated with thermal expansion.

3.2. Thermal Properties of PCMs

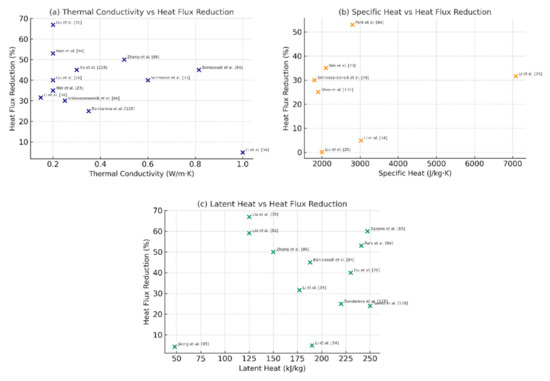

PCMs have gained significant attention in recent years for their potential to enhance the thermal performance of buildings. The key thermal properties of PCMs that influence their effectiveness in building applications include thermal conductivity, latent heat, and specific heat. Each of these properties plays a crucial role in determining how well a PCM can absorb, store, and release heat, which directly impacts the energy efficiency and thermal comfort of a building [68,86]. Thermal conductivity affects the rate of heat transfer; the low thermal conductivity of PCMs allows them to absorb and release heat slowly. This characteristic helps in maintaining a more stable temperature over time and improves thermal comfort with a reduction in energy consumption [21,87]. Latent heat, the energy absorbed or released during a phase change, is crucial for thermal energy storage, reducing indoor temperature fluctuations by storing heat during warmer periods and releasing it when cooler [88]. Specific heat (cp) influences how much heat a PCM can store as sensible heat, contributing to the building’s thermal mass before and after phase transitions [68]. Together, these properties allow PCMs to stabilize indoor temperatures, reduce heat flux, as represented in Figure 3, and improve overall energy efficiency when integrated into building materials.

Figure 3.

Influence of PCM thermal properties on heat flux reduction based on experimental and simulation studies. (a) Relationship between PCM thermal conductivity (W/m·K) and heat flux reduction (%). (b) Relationship between specific heat capacity (J/kg·K) and heat flux reduction. (c) Latent heat (kJ/kg) vs. heat flux reduction. These graphs highlight the critical role of thermal conductivity, specific heat, and latent heat in improving thermal buffering and passive energy performance.

A study by Li et al. [34] tested PCMs on a wall structure made of plaster, clay brick, and cement. The analysis focused on thermophysical properties: thermal conductivity, specific heat, and latent heat. The results showed that Enerciel 22, with a latent heat of 177 kJ/kg, cp of 7085 J/kg·K, and λ of 0.148 W/m·K, reduced heat transfer by 15.6–47.6%. In contrast, CaCl2·6H2O, with 190 kJ/kg, 3020 J/kg·K, and 1 W/m·K, only reduced heat transfer by 2–7.8%. This illustrates that a lower λ and a higher cp in PCMs significantly enhance heat transfer reduction.

Liu et al. [35] studied how λ and latent heat impact the thermal performance of PCMs integrated into building walls. They found that lower λ values improved thermal performance by reducing peak heat flux (q) by up to 66.92% and increasing the delay in heat transfer by 7.86 h. Similarly, higher latent heat values significantly reduced temperature fluctuations by 92.99–97.04%. However, the efficiency of latent heat beyond 125 kJ/kg diminished, indicating that there is an optimal value for maximizing thermal performance. Liu et al. [80] conducted an experimental study and revealed that the latent heat of a PCM significantly impacted the thermal regulation capacity of walls. Increasing the PCM’s latent heat improved the walls’ ability to attenuate temperature fluctuations and delay heat transfer. Specifically, as the latent heat increased from 25 kJ/kg to 225 kJ/kg, the ability to reduce heat flux improved substantially. For instance, with a latent heat of 125 kJ/kg, the peak heat flux reduction was up to 59.1%. This showed that the higher latent heat improved the PCM’s capacity to regulate indoor temperatures. However, beyond a certain latent heat value, the benefits plateaued.

Saxena et al. [89] conducted an experiment in New Delhi, India, which falls under a tropical composite climate, and evaluated the thermal performance of buildings using macroencapsulated PCMs embedded in hollow bricks. The PCM layer was embedded within the bricks and tested in a tropical composite climate. Two PCMs, OM35 and n-Eicosane, were used; OM35 has a latent heat capacity of 157 J/g, and n-Eicosane has a value of 247.3 J/g. Incorporating the PCMs reduced the peak inside surface temperature by 6–7 °C compared to conventional bricks, with n-Eicosane being more effective because of its higher latent heat capacity, reducing the peak temperature to 39.8 °C. The PCM-embedded bricks also decreased temperature fluctuations, with a sub-cooling effect of around 3 °C, improving the daily thermal regulation of the buildings. This approach significantly enhanced thermal mass, thus reducing cooling loads in tropical climates.

A numerical study followed by an experiment conducted by Baniassadi et al. [90] analysed the thermal performance of an inorganic eutectic PCM integrated into the rooftop of test rooms in Antofagasta, Chile. The PCM, with a λ of 1.09 W/mK (solid) and 0.54 W/mK (liquid), and a latent heat of fusion of 188 kJ/kg, smoothed diurnal indoor temperature fluctuations. The PCM room experienced a more stable temperature variation of 21.1 °C ± 10.6 °C, compared to 28.3 °C ± 18.5 °C in an air-cavity room. With a phase change temperature of 26–28 °C, the PCM absorbed heat during the day and released it at night, reducing maximum temperatures and improving thermal comfort. This significantly improved the building’s energy efficiency by moderating temperature extremes.

Jeong et al. [91] experimentally investigated two PCMs (n-octadecane and beeswax) embedded into gypsum–cement boards via vacuum impregnation to enhance building energy performance in a warm climate. Their results showed that n-octadecane increased λ by 129% and beeswax increased λ by 150%, with latent heat capacities of 48.03 J/g and 34.08 J/g, respectively. Energy savings were higher with n-octadecane, which reduced cooling energy by up to 4.3% because of its more suitable phase change temperature, making it the better-performing PCM in warm climates.

Zhang et al. [92] investigated the effect of PCM thermal conductivity and latent heat. They found that the λ of PCMs is critical in determining their effectiveness in thermal regulation. A higher λ allows a PCM to absorb and release heat more efficiently during the phase change process. While the study explored PCMs with latent heat ranging from 100 to 200 kJ/kg, it was noted that λ had a more pronounced effect on performance than latent heat within this range. An enhanced λ ensured that heat could be rapidly transferred through the PCM, enabling quicker responses to temperature changes and resulting in a more efficient thermal energy storage system. This underscored the importance of choosing PCMs with higher λ to optimize energy savings and maintain comfort in building applications.

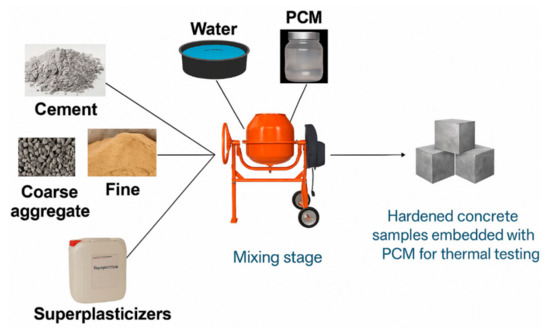

3.3. Application in Building Components

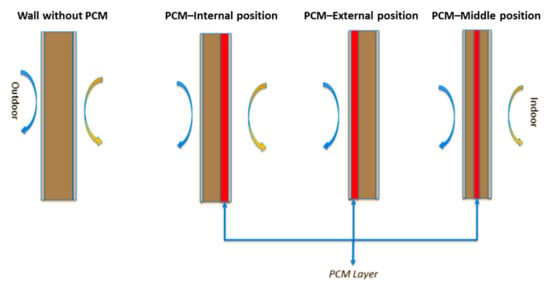

PCMs can be embedded into the concrete matrix [32,84,93,94,95], as represented in Figure 4, or applied as a separate layer [30,37,81,94], as shown in Figure 5, to enhance thermal storage capacity, helping to regulate indoor temperatures by absorbing and releasing heat. This integration improves energy efficiency, reduces reliance on heating and cooling systems, and contributes to a more stable and comfortable indoor environment.

Figure 4.

Schematic figure representing the process of embedding phase change material (PCM) into concrete for the production of thermally enhanced specimens.

Figure 5.

Schematic representation of a wall section showing different possible positions of a phase change material (PCM) layer within the wall assembly. Configurations include a reference wall without PCM and walls with PCM placed at the internal, external, and middle positions relative to the wall cross-section. The diagram illustrates how PCM placement affects thermal flow from the outdoor to the indoor environment in passive building systems.

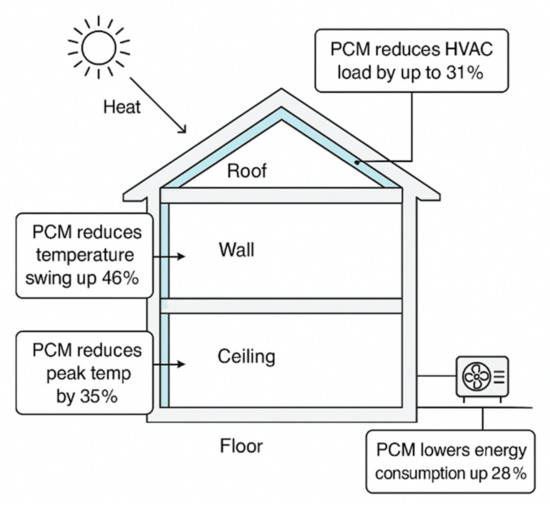

Regarding PCM integration into different building components [9,75,96,97], PCMs can be integrated into wall [29,30,31,37], roof [29,33,49,76,77,98,99,100], floor [16,33,76,101], and ceiling [12,16,24,29,41,102,103,104] systems in two main ways: as a distinct layered application or as embedded systems some studies are represented in Figure 6. In layered applications, PCM panels are placed within the wall structure, often sandwiched between insulation materials or applied to the surface of wallboards, allowing for ease of installation and retrofitting. Recent research has also explored the use of inter-floor void formers as innovative cavities for integrating PCMs in multi-story buildings. Mokhberi et al. [105] performed advanced CFD simulation, which showed that inserting bio-based PCMs into semi-ellipsoid void formers could reduce the 48 h average heat flux by up to 36.7% and extend the thermal endurance time to nearly 90 h. The study also emphasized the impact of void former geometry, PCM type, and placement location, concluding that placing PCMs near a thermally active floor enhances energy performance more effectively than traditional insulation. This represents a promising avenue for latent heat storage in modern concrete slab systems.

Figure 6.

Conceptual illustration of a building envelope incorporating phase change materials (PCMs) for thermal regulation. PCMs are embedded in walls, ceilings, and roofs to passively absorb and release heat, reducing indoor temperature fluctuations, peak temperatures, and overall heating and cooling energy demand. This schematic demonstrates the potential of PCMs to enhance thermal comfort and reduce energy consumption in building applications.

This approach is flexible and effective in regulating indoor temperatures by absorbing excess heat during the day and releasing it during cooler periods [81]. Research on PCM-embedded wall materials highlights their potential to enhance thermal regulation and energy efficiency by stabilizing indoor temperatures and reducing heating and cooling loads. A study conducted by Dardouri et al. [29] evaluated the energy-saving effects of integrating PCMs into the roof and walls of buildings. Integrating PCMs into the roof was found to provide significant energy savings, with reductions of up to 31.42% in heating and cooling. When PCMs were incorporated into the walls, the energy savings could still reach up to 9% for heating and cooling.

Berardi et al. [30] conducted a study that involved constructing two test cells in a residential building, one enhanced with a composite PCM system applied to the walls and ceiling and another without PCMs. The addition of PCMs in the walls and ceiling resulted in a reduction in indoor temperature swings by 46% in July, 37% in August, and 35% in September. The peak temperature reductions were 6% in July, 4% in August, and 6% in September. The integration of PCMs, especially in the ceiling, demonstrated better performance in absorbing and storing excess heat, leading to a smoother and more stable indoor environment throughout the day.

Guo et al. [31] conducted a study under realistic seasonal weather conditions, considering variations in solar radiation, wind speed, and ambient temperature, to evaluate the performance of a PCM layer in reducing energy consumption across different environmental scenarios. The addition of a PCM layer to the building wall significantly improved thermal performance by reducing energy consumption for heating and cooling. The results showed that the PCM-integrated wall achieved a reduction in energy usage by up to 11% in cold weather and up to a 38% reduction in cooling loads during hot weather. This led to an overall smoothing of the energy consumption pattern, helping to reduce peak demand and maintain a more consistent energy load throughout the year, improving both the comfort level and the building’s energy efficiency. Schmerse et al. [33] found that applying PCMs on different building components significantly reduced energy consumption. Roof placement was the most effective, reducing energy use by up to 31.1% and achieving 11.42 kWh/m2 annually (713.75 kWh for the entire building). The floors showed a reduction of 28.2%, saving 4.92 kWh/m2, especially when combined with natural ventilation. The external walls reduced energy consumption by up to 16.2%, while the interior partitions contributed a 25.4% reduction, aiding thermal comfort between zones. Applying PCMs across all components together led to the highest reduction, cutting energy use by up to 56.1% overall.

Refahi et al. [81] investigated the integration of double-layer PCM wallboards into the exterior walls of a four-story residential building in Tehran, focusing on optimizing energy efficiency. Using different configurations of PCMs (RT18 and RT28) alongside thermal insulation, the study examined the effects of varying placements of these materials within the interior side of the walls. The results showed that strategic layering of PCMs with insulation significantly reduced energy consumption, with the RT18/insulation/RT28 configuration proving most effective for heating efficiency across the lower floors, while RT28/RT18/insulation was best on the uppermost floor. Overall, employing double-layer PCMs in the walls led to a 6.6% reduction in heating energy and a 2.8% reduction in cooling energy, highlighting the potential of PCM integration for enhanced thermal management.

A study conducted by Kuczyński et al. [84] evaluated the thermal performance of a PCM (melting range 22–26 °C) compared to traditional heavyweight materials in experimental rooms during summer in Poland. The PCM was applied to two longitudinal walls inside aluminium cassettes covered with plasterboard. It reduced indoor temperatures by 1.4 °C on days when temperatures stayed within the PCM’s melting range. However, during hotter days (above 30 °C), the PCM became ineffective, reducing temperatures by only 0.3–0.4 °C. Despite using 200 kg of the PCM (11 kg/m2), traditional heavyweight materials, such as reinforced concrete, provided better results, lowering temperatures by up to 3.5 °C. The PCM’s cooling effect was most effective on only half of the 34 test days, with reductions of 0.6–1.5 °C.

Moshtaghi et al. [95] investigated the effects of PCMs on lightweight building walls, showing significant improvements in thermal regulation. The PCM layer reduced indoor temperature fluctuations by about 25 °C compared to conventional walls, enhancing thermal comfort. It also increased the time lag by 3.33 to 4.17 h and improved the heat flow attenuation by 142.81–159.09%. These results demonstrated that incorporating PCMs into wall systems can effectively stabilize indoor temperatures, reduce heat flow, and improve energy efficiency, particularly in buildings exposed to significant temperature variations.

Ji et al. [98] used a numerical model via EnergyPlus to evaluate the energy performance of building envelopes integrated with phase PCMs in the subtropical climate of Guangzhou, China. The PCM was layered on both the exterior and interior surfaces of the walls and roof, with various parameters, such as transition temperature, thermal conductivity, and thickness, examined. The results showed that PCM integration can reduce annual energy consumption by up to 20.9%. Notably, PCM placement on the roof resulted in the highest energy savings (5.79%), as it received the most solar radiation, while placement on the walls showed lower but still significant energy savings, with the wall achieving a reduction of 5.39%. Thus, the roof outperformed the walls in terms of energy reduction because of its greater solar exposure.

D’Alessandro et al. [106] investigated the integration of PCMs embedded into a concrete mixture, prepared under controlled laboratory conditions with varying PCM contents (1%, 3%, and 5%). The addition of PCMs enhanced the thermal properties of the concrete by increasing its thermal inertia, acting as a thermal buffer, and stabilizing internal temperatures during phase transitions. This effect allowed the concrete to absorb and release heat, providing prolonged thermal regulation.

3.4. Internal, External, and Middle Positioning

Previous research illustrates that the PCM location within the building envelope, as shown in Figure 5, has a significant effect on the thermal performance of the building envelope. Liu et al. [35] analysed the thermal performance of a PCM in lightweight residential building walls under various positions using a numerical model. The study found that placing the PCM in the middle of the wall was the optimal location, as it reduced peak heat flux by 53.02–63.47% and average heat flux by 22.50–26.01% and increased delay time by 3.71–4.86 h, outperforming outside or inside locations. Nizovtsev et al. [41] studied the effect of the PCM layer location in a wall. They found that the optimal location for the PCM layer was in the central zone of the wall, where it reduced heat flux fluctuations by 13 times and delayed the heat transfer by 6.2 h, providing the best thermal performance. Placing the PCM on the inner surface was less effective, with higher heat flux fluctuations and a shorter delay, though it still significantly improved thermal inertia, with the heat flux density reaching 35–40 W/m2. Positioning the PCM near the outer surface yielded the least benefit, with a minimal reduction in heat flux.

Li et al. [36] studied the effect of PCM layer placement in walls on building thermal performance. They found that placing a PCM closer to the interior surface improved thermal regulation, maintaining indoor temperature within the comfort zone for a longer period. In contrast, placing it near the exterior led to an 84% reduction in efficiency compared to interior placement because of an increased exposure to outdoor conditions. Hence, positioning the PCM near the interior maximized thermal performance and energy savings. This was primarily because the interior placement allowed the insulation to act as a barrier against external heat, preventing the PCM from being exposed directly to outdoor conditions, which could cause premature melting and saturation of its thermal storage capacity.

Another study conducted by Fateh et al. [51] examined the thermal performance of buildings using PCMs placed at three different wall locations: interior, exterior, and middle. The findings revealed that positioning PCMs at the interior edge of the wall provided superior thermal performance for about 99% of the interior temperature in the comfort zone, which was increased by 20% and 53% during summer and by 23% and 43% during winter compared to the middle and exterior placements, respectively. This configuration aligned better with indoor temperature fluctuations, optimizing energy storage and release. Li et al. [34] concluded that the placement of a PCM in walls has a significant impact on heat transfer. When positioned closer to the exterior surface, the PCM more effectively reduced heat transfer, achieving a reduction of approximately 47.6%, while placing the PCM closer to the interior resulted in a slightly lower reduction of about 46.8%. These findings highlighted the importance of PCM positioning and material selection in enhancing energy efficiency.

Asghari et al. [78] conducted a numerical study by adding a PCM to the external walls of a building in a mixed-humid climate (Kansas City) and found that the placement of the PCM in different wall layers significantly impacted energy savings. Placing the PCM in the inner layer provided the highest heating energy savings of up to 33% but had moderate cooling savings up to 16.7%. Placing the PCM in the middle layer balanced both heating and cooling performance, achieving 30% heating and 17.8% cooling energy savings. The outer layer placement resulted in the best cooling energy savings of 20% but lower heating savings of 16%. Thus, the inner placement was more effective for heating, while the outer placement was better for cooling.

The study conducted by Liu et al. [107] investigated the thermal performance of lightweight building walls with integrated PCMs, analysing how the position of PCMs within a wall impacts thermal regulation. The results showed that placing PCMs in the middle of the wall improved thermal performance by reducing peak heat flux by up to 66.4% and average heat flux by 29.5%, significantly enhancing indoor temperature stability. Inside or outside placements of PCMs also showed notable improvements, depending on external conditions, with reductions in peak heat flux of up to 62.8% and average heat flux by 28.2%. These findings highlighted the importance of PCM positioning in optimizing building thermal performance.

An experimental and numerical study by Khan et al. [108] studied the effect of PCMs in different positions. The experimental setup included two water baths, one hot, at 100 °C, representing outdoor conditions, and one cold, at room temperature, simulating indoor conditions. The used PCM had a melting point range of 42 °C to 72 °C, suitable for hot climates. The position of the PCM layer inside the wall was varied to determine the optimal location for minimizing heat transfer. Regarding the results, the position of the PCM layer significantly impacted the heat transfer. When the PCM was placed 0.076 m from the heat source, the indoor temperature rise was reduced to 0.6 °C, compared to 1.2 °C when the PCM was placed 0.381 m from the heat source. This configuration led to a 37.2% reduction in peak heat flux. The study showed that the closer the PCM was to the heat source, the better it was at regulating the indoor temperature and reducing temperature.

Alshuraiaan et al. [109] investigated the effect of the location of a 3 cm PCM layer in a multilayer wall system in a hot environment. The PCM layer was introduced into two configurations: one near the exterior surface (case 1) and another near the interior surface (case 2). In case 1, the PCM layer melted after 55.6 h, leading to ineffective long-term thermal performance. The PCM remained fully melted, providing no discharge effect, eventually resulting in a higher heat flow into the room. In contrast, in case 2, the PCM did not reach the melting point, making it less efficient than the reference wall. Hamidi et al. [110] conducted a study that investigated the thermal performance of hollow brick walls with PCMs in a warm climate using numerical analysis. The focus was on PCM placement within double hollow brick walls. The results showed that PCM placement on the internal side could reduce energy consumption by 97%, while placement on the outer side only offered up to 8% savings. In some cases, placing PCM on the outer side increased the cooling load.

For optimal thermal performance, PCM placement varies by climate: closer to the interior, it stabilizes indoor temperatures by absorbing heat during the day and releasing it at night, which is ideal in cooler or mixed climates. Near the exterior, PCM acts as a thermal buffer, reducing overheating in warmer climates. And in some cases, middle placement offers balanced regulation. Table 2 presents and summarizes several representative studies that investigated the impact of incorporating PCM into buildings.

Table 2.

Representative research that studied the impact of adding PCM to buildings.

3.5. PCM Behaviour in Different Climate Zones

The effectiveness of PCM in buildings varies significantly across different climate zones because of their ability to absorb and release heat [9,96,97], as shown in Table 3. In hot climates, PCMs can help mitigate indoor temperatures by absorbing excess heat during the day and releasing it at night, thus reducing cooling demands [9]. In cold climates, PCMs can store solar heat during the day and release it during colder periods, thus maintaining indoor warmth and reducing heating needs [119]. For temperate climates, PCMs can moderate indoor temperatures throughout the year by balancing daily temperature fluctuations, leading to improved comfort and energy savings [84]. The success of PCM integration depends on selecting the appropriate melting point to match the specific temperature patterns of each climate zone [12,97,120].

Table 3.

Matrix summarizing optimal PCM melting temperatures and material types in relation to major climate zones, synthesized from the reviewed studies.

Li et al. [34] conducted a study in the hot, dry climate of Isfahan, Iran, focusing on the effects of weather conditions on thermal performance in buildings. It was found that weather conditions significantly influenced the results. In hot weather, where external temperatures were higher, a larger portion of the PCM melted, leading to greater heat storage and a higher heat transfer reduction of up to 47.6%.

Li et al. [36] conducted a simulation study carried out on North American residential building walls subjected to one-dimensional heat transfer for 7 days. The PCM application was varied in different locations for different categories (hot, moderate, and cold) in summer. The boundary conditions were based on weather data from various U.S. cities. The hot cities were Miami and Las Vegas, the moderate cities were Chicago and Fargo, and Seattle represented cold conditions. PCMs were chosen based on each category. In Las Vegas and Miami, a PCM with a higher melting point (26–30 °C) was more effective at reducing peak indoor temperatures, lowering indoor maximum temperatures by 6–8%. However, in Fargo and Chicago, PCMs with lower melting points (20–24 °C) provide the best results, with indoor thermal comfort duration extending up to 34.5% longer in Fargo compared to Miami and 75% longer than Las Vegas. In Seattle, a PCM’s melting point should be lower, as higher melting points failed to store sufficient heat during the day because of lower temperatures.

A numerical study by Xu et al. [47] evaluated the impact of a phase change material (PCM) across eight cities with varying climate conditions. These included Guangzhou and Shanghai (subtropical monsoon climates with hot summers and, in Shanghai, cold winters), Kunming (mild subtropical monsoon climate), Beijing (temperate monsoon with hot summers and cold winters), Harbin (temperate continental monsoon with severe cold winters), and three European cities: Rome (Mediterranean climate with hot summers and mild winters), London (temperate marine climate with cool summers and warm winters), and Berlin (temperate continental climate with warm summers and cold winters). The PCM was most effective in colder cities like Harbin and Berlin, reducing heating energy consumption by up to 44.74%, with the optimal PCM thickness ranging from 10 to 40 mm depending on climate severity. The PCM significantly reduced peak heating loads in these regions by up to 100 W/m2. In warmer and milder climates, such as Guangzhou and Kunming, the PCM contributed to moderate energy savings, but the reduction in cooling or heating loads was less pronounced.

Qiao et al. [48] experimentally studied the effect of a PCM as a layer within wallboards under controlled conditions. The PCM was added as macroencapsulated panels combined with extruded polystyrene panels and tested in a climate chamber that simulated conditions in various cities in Northern and Western China. The results showed that the PCM wallboards were most effective in regions with moderate climate conditions, such as Xi’an and Kashi, where temperature attenuation ratios exceeded 88%, demonstrating excellent thermal performance. In Turpan, where outdoor temperatures were excessively high, the PCM could not complete its melting–solidification cycle, reducing the attenuation ratio to 60.2%. In Xining, with a colder climate, the PCM’s thermal storage was significantly limited, leading to a low attenuation ratio of 36.8%. This highlighted that PCM wallboards perform best in climates with moderate temperature fluctuations.

Lagou et al. [51] investigated the use of a PCM in vernacular and historic buildings, particularly focusing on buildings under three various climatic conditions with appropriate melting temperatures. They found that in southern Europe, 94% of the temperature data in summer and 92% in winter fell within the comfort temperature range, while in northern Europe, 83% of the summer data and 91% of the winter data also supported this position. In central Europe, it was found that 97% of the temperature data in summer and 99% in winter were within the thermal comfort temperature.

Jia et al. [77] used numerical simulation to investigate the effect of adding a PCM layered into the walls and roofs of buildings in different climate zones. In severe cold areas (Anda), the PCM reduced energy consumption by 17.7% for walls and 14.5% for roofs, though temperature improvement was minimal. In cold areas (Lanzhou), the PCM achieved a 15.1% energy-saving rate, with better performance when applied to interior walls. The highest savings were seen in mild climates (Kunming), with 77.1% for walls and 67.47% for roofs. In hot summer and cold winter regions (Wuhan), the PCM reduced energy consumption by 37.1% and 31.2% for walls and roofs, respectively, while in hot summer and warm winter climates (Xiamen), the PCM reduced energy consumption by 32.53%, primarily benefiting cooling efficiency. The PCM proved more effective in warmer regions for stabilizing indoor temperatures and reducing energy use.

Baniassadi et al. [90] studied single-family detached homes across U.S. climates with a PCM embedded between insulation and drywall. Using EnergyPlus simulations, they analysed thermal performance during both normal and heat disaster conditions (AC off during extreme heat). The PCM’s effectiveness varied by climate. In Phoenix, extreme heat reduced its efficiency, as the PCM already melted before peak temperatures. In Albuquerque, cooler conditions allowed the PCM to stay solid longer, significantly lowering indoor temperatures. In some climates, the PCM reduced peak temperatures by over 5 °C. A numerical study conducted by Pirasaci [102] examined the effectiveness of PCM–composite aggregates embedded in the walls of residential buildings across different climate zones in Turkey. The results showed that the impact of the PCMs on energy savings depended heavily on the local climate. In warmer areas like Izmir, the energy savings reached 0.42%, while in colder regions like Erzurum, the savings were much lower, at 0.16%. The PCMs performed best when they could store and release heat efficiently, achieving over 95% effectiveness in optimal conditions. However, in colder climates, the energy-saving benefits were minimal, suggesting that PCM integration might not be as practical or efficient in these regions.

Li et al. [115] conducted a study of three single-story buildings with PCM foamed cement walls in five climate zones in China: Harbin (severe cold), Beijing (cold), Shanghai (hot summer, cold winter), Kunming (mild), and Shenzhen (hot summer, warm winter). Climate conditions significantly impacted thermal performance and energy savings. In Harbin, the inner surface temperature of a south wall increased by 0.378 °C in January, while in Shenzhen, it only rose by 0.113 °C in July. The highest energy savings were achieved in Kunming, about 37.02%, and Shanghai, 22.83%, while the lowest were in Harbin, 19.82%, and Shenzhen, 15.99%.

Venegas et al. [121] analysed a PCM-modified thermal envelope of a residential building in Chile, focusing on the effects of the PCM and insulation thickness. The building type was a dwelling with a layered PCM incorporated into the exterior walls. The study considered two different thermal zones: Santiago (warm climate) and Puerto Montt (cooler climate). The effect of PCM variables on thermal performance was significant. The inclusion of the PCM in the envelope reduced the cooling demand by 8% in Santiago and 29% in Puerto Montt. However, it increased the heating demand by 64.9% and 43.7% in Santiago and Puerto Montt, respectively. The cooling demand increased by 47.8% in Santiago and by 107.3% in Puerto Montt, while the heating demand was reduced by 83.5% and 59% in Santiago and Puerto Montt, respectively.

Xu et al. [122] conducted a study using a numerical simulation tool to analyse PCMs layered into the interior side of ceilings in buildings located in Shanghai and Guangzhou. Their results showed that the optimal λ for PCMs was around 0.3 in both climates, with Shanghai (hot summers, cold winters) and Guangzhou (hot summers, warm winters) displaying similar performance trends.

3.6. PCM Quantity and Thickness

The thermal behaviour of buildings is mainly affected by the quantity or thickness of the PCM used in building envelopes. This factor influences the thermal capacity, heat storage efficiency, and overall energy performance of a building [34,35,111].

The total quantity of PCMs incorporated into a structure directly affects its thermal energy storage capacity, which is determined by the material’s density, volume, and latent heat. A larger PCM mass absorbs and releases more heat, improving thermal regulation. However, excessive PCMs can lead to saturation, reducing phase change efficiency.

Wei et al. [23] examined energy storage enhanced with a microencapsulated PCM embedded within concrete at concentrations ranging from 1% to 4%. They found that increasing the PCM concentration significantly improved thermal performance, with latent heat increasing by 460%. However, higher PCM concentrations reduced λ because of increased porosity. The phase change delay also rose by 60%, with faster temperature change rates (from 0.2 °C/min to 0.5 °C/min) impacting heat transfer efficiency. Additionally, the cp increased with higher PCM content, improving the material’s ability to regulate temperatures during heating and cooling.

A study conducted by Srinivasaraonaik et al. [46] explored the thermal performance of a microencapsulated PCM embedded in gypsum composite boards used for building applications. The PCM used in the study had a melting point of 36.1 °C. The PCM was embedded within the gypsum composite material rather than applied as a separate layer. The results showed that increasing the PCM concentration from 5% to 10% led to a decrease in λ by 20% and 28%, respectively, improving the insulation properties of the building material. The higher the PCM content, the greater the temperature difference and delay in heat transfer, which enhanced the thermal comfort within the building.

The thickness of a PCM layer influences its ability to regulate indoor temperatures by delaying heat transfer and stabilizing temperature fluctuations. Thicker layers provide a larger thermal mass, leading to greater heat storage capacity. However, an optimal thickness must be determined to balance energy efficiency with cost and practicality [34].

For instance, Norouziasas et al. [43] found that the thickness of a PCM layer significantly affected the thermal performance of building walls. Thicker PCM layers resulted in higher energy savings, with up to 21.32% heating energy savings and 24.45% cooling energy savings. This was because thicker layers could store and release more thermal energy, providing better temperature regulation. In contrast, thinner layers offered lower energy savings due to their reduced capacity to absorb and release heat. Therefore, increasing PCM thickness improved energy efficiency, particularly in both heating and cooling seasons.

Li et al. [36] found that the thickness of a PCM layer in a wall had a notable impact on its thermal performance. A thicker PCM layer, ranging from 2.5 mm to 15 mm, enhanced the wall’s heat storage capacity and thermal inertia, which led to more significant reductions in peak indoor temperatures and an increase in trough temperatures. For instance, a 15 mm PCM layer could reduce peak temperatures by up to 8.8% and increase trough temperatures by 16.7%, compared to a 2.5 mm layer. This improvement occurred because thicker layers allow the PCM to store and release more thermal energy, resulting in better regulation of indoor temperatures and a reduction in temperature swings.

Another study conducted by Li et al. [34] explored three different PCM thicknesses: 1 cm, 2 cm, and 4 cm. The results showed that the heat transfer reduction was 15.6%, 26.7%, and 47.6%, respectively, for these thicknesses. This demonstrated that increasing the thickness did improve the heat transfer. Bozzhigitov et al. [40] studied the optimization of PCM layer thickness to improve the energy-saving potential of office buildings located in eight different cities within the marine climate zone. The results revealed that a PCM layer with a thickness of 2 cm achieved the highest energy savings per unit thickness. This layer was considered optimal because of its cost-effectiveness. Increasing the thickness beyond 2 cm led to diminishing returns, with energy savings decreasing from 10,142 kWh/cm for the 2 cm thickness to 2061 kWh/cm for the 20 cm thickness. This demonstrated the substantial effect of PCM thickness on the thermal performance of the building.

Guo et al. [31] observed that the thickness of a PCM layer in a wall significantly influenced a building’s thermal performance. Their study revealed that increasing the PCM layer thickness from 20 mm to 120 mm resulted in improved energy savings. In cold seasons, energy savings rose by about 5–10% with thicker layers, while in hot seasons, savings increased by up to 15%. However, the improvement rate slowed as thickness continued to increase, suggesting that beyond a certain point, additional thickness offered diminishing returns in terms of energy efficiency. Imafidon et al. [42] examined the effect of PCM layer thickness on a building’s thermal performance by testing thicknesses from 0.25 cm to 3 cm. It was found that increasing the thickness from 0.25 cm to 1 cm significantly improved thermal performance, with heat gain reduction increasing from 24% at 0.25 cm to 41% at 1 cm and heat loss reduction improving from 42% to 96%. However, increasing the thickness beyond 1 cm provided diminishing returns, with little to no further improvement in heat flux reduction. Therefore, the optimal PCM thickness for energy efficiency was 1 cm, beyond which the benefits plateaued, making further increases in thickness unnecessary.

Moreles et al. [44] used a numerical simulation method to study the effects of PCM walls in climates that experience both hot and cold thermal discomfort. Specifically, the climate for the simulation was based on Nogales, Sonora, Mexico, in April. The climate conditions used for the simulation reflected a typical day in Nogales, characterized by large variations in temperature during the day, which include hot afternoons and cool nights. Their results showed that increasing the thickness of PCM walls significantly improved thermal performance by reducing cooling loads in air-conditioned environments and decreasing discomfort in non-air-conditioned settings. For example, cooling load reductions ranged from 4% at 6 mm thickness to 29% at 18 mm, while hot discomfort degree hours saw improvements from 4% to 30% over the same range. However, the rate of improvement diminished as thickness increases, with larger thicknesses beyond 18 mm showing reduced benefits due to challenges in achieving complete melting–freezing cycles. Thus, while thicker PCM layers enhanced performance, the gains tapered off beyond a certain point.

Liu et al. [35] investigated the addition of a PCM layer in a wall and found that increasing PCM thickness up to 10 mm improves thermal performance, reducing peak heat flux by 79.56%. However, beyond 10 mm, the benefits diminished, with minimal reductions in heat flux, making 10 mm the optimal thickness. Nizovtsev et al. [41] investigated the effect of a PCM layer on the thermal inertia of a lightweight building’s outer wall. It was found that doubling the PCM content from 4 vol% to 8 vol% reduced heat flux fluctuations by a factor of 1.9.

Hasan et al. [45] conducted an experimental study on residential buildings in Iraq (Kut city), where two identical rooms were constructed with and without a PCM. The PCM used was paraffin wax, with a melting point of 44 °C. The PCM was incorporated into the walls and ceiling and placed inside aluminium frames attached to the internal surfaces of the walls and ceiling. The study found that increasing the thickness of the PCM significantly improved thermal performance. With a 1 cm thick PCM layer, the indoor temperature was reduced by 2.18 °C, and the cooling load decreased by 20.9% during peak hours. When the PCM thickness was increased to 2 cm, the temperature reduction improved to 3.32 °C, and the cooling load reduction reached 19.95%.

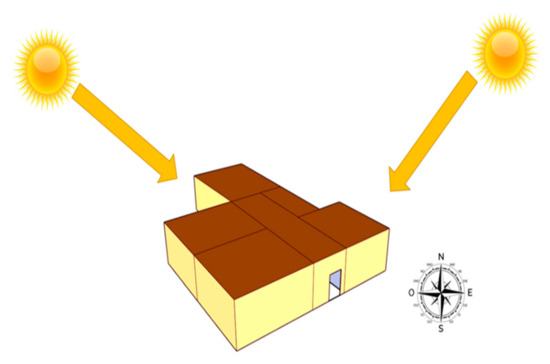

3.7. Effect of PCM Application in Different Orientations

This section reviews findings from the existing literature on how building orientation affects PCM performance in regulating indoor temperatures and improving energy efficiency. Various studies have examined the impact of solar exposure, facade orientation, and shading on the effectiveness of PCM integration. The literature indicates that optimal PCM placement depends on a building’s orientation relative to solar radiation and climate conditions. The orientation of a building greatly influences its thermal performance by affecting how it absorbs sunlight, utilizes natural ventilation, and interacts with the local climate, as reported in previous studies and illustrated in Figure 7. Proper orientation can take advantage of prevailing winds to enhance natural ventilation, reducing reliance on air conditioning [76,97,123].

Figure 7.

The figure illustrates the building orientation factor that impacts the performance of phase change materials (PCMs).

A numerical study conducted by Park et al. [79] analysed high-rise apartment buildings in South Korea, specifically flat-type and tower-type apartments, where PCMs were layered into interior walls. The results showed that building orientation played a crucial role in energy performance. For flat-type apartments, southward-facing units achieved the highest energy savings, with a PCM melting temperature of 20 °C, while westward-facing units performed best, with a PCM of 26 °C, reducing cooling loads from intense afternoon solar radiation. In tower-type apartments, eastward and southward orientations saw the most energy savings, with PCM at 24 °C, while westward and northward orientations benefited from a lower melting temperature of 23 °C due to reduced solar exposure. This highlighted the importance of selecting PCMs based on the building’s orientation for optimal energy savings.

Fateh et al. [52] used a numerical model to evaluate the thermal performance of PCM-integrated insulation layers in lightweight building walls, with the PCM layered at various positions (internal, external, and in the middle of the wall). The results showed that orientation significantly affected energy efficiency. In south-facing walls, the PCM reduced energy consumption by up to 60%, particularly when placed in the middle of the wall, because of effective solar heat load reduction. East- and west-facing walls saw even greater reductions, with the PCM being most effective in outer and middle positions. However, north-facing walls did not benefit from PCM integration, as the lack of solar radiation led to minimal heat load savings, sometimes increasing heat transfer instead.

Ji et al. [98] employed a numerical model using EnergyPlus software to assess the energy performance of building envelopes with a phase change material (PCM) integrated into them in the hot, subtropical climate of Guangzhou, China. The PCM was layered within walls. The study explored various orientations to determine their impact on building energy consumption. The orientation of the PCM installation on the walls significantly affected energy consumption. The south-facing wall achieved the highest energy savings, with a 5.39% reduction, followed by the west-facing wall, with a 5.13% reduction. The east-facing wall saw a slightly lower reduction, at 4.28%, while the north-facing wall achieved the least energy savings, at 3.68%, because of its limited solar radiation exposure. Thus, sun-exposed walls, particularly those facing south and west, provided the most significant energy savings when the PCM was installed.

Liu et al. [80] investigated the thermal performance of lightweight building walls integrated with a PCM numerically and experimentally in various orientations. The PCM was layered in different positions, and the results showed significant improvement, particularly in east- and west-facing walls, where peak heat flux was reduced by 62.8% to 66.4% and average heat flux was reduced by 28.2% to 29.5%, with a delay time increase of up to 5.34 h.

Mahmoud et al. [53] conducted a numerical study to analyse the thermal performance of lightweight building walls integrated with two PCMs under different orientations (horizontal, south, north, east, and west) in Sharjah, UAE. Four wall configurations were tested: a reference wall without a PCM, a wall with insulation, and walls using PCM-31 and RT-41. Their results showed that PCM-31 consistently provided the best thermal regulation, particularly in horizontal, south, and east orientations, where it reduced peak temperatures by over 2 °C and delayed heat peaks, thus lowering cooling loads. RT-41 also offered improvements but was less effective. The PCMs were most beneficial in orientations with high solar exposure, like east-facing walls in the mornings and west-facing walls in the afternoons, demonstrating their potential to enhance energy efficiency and indoor thermal comfort.

Liu et al. [49] evaluated the integration of PCMs into lightweight building walls across different climates in China and Japan, using EnergyPlus software to test various orientation effects on the thermal performance of buildings. Their results showed that east-facing walls provided the best cooling efficiency, cutting cooling loads by up to 3.67% through morning sunlight absorption, followed by west-facing walls for afternoon heat, by up to 3.25%. North-facing walls were the least effective, offering minimal energy savings due to lower solar exposure.

Wang et al. [124] investigated the use of PCM wallboards in high-rise lightweight buildings in Shanghai, focusing on energy savings across different wall orientations. Their simulations showed that east-facing walls had the highest cooling efficiency, with a 27.78% reduction due to the effective absorption of morning sunlight, followed by west-facing walls at 26.29% from afternoon sun. South-facing walls excelled in winter heating, saving up to 96.2% of energy thanks to prolonged sun exposure, while north-facing walls were the least effective because of limited solar radiation.

Hamadi et al. [54] conducted a study under Saharan climate conditions, focusing on a two-story building in Ghardaïa, Algeria, with simulations run using software to evaluate the thermal performance of different PCM integration approaches. The effect of wall orientation showed that south-facing walls provided better cooling performance due to higher solar exposure, leading to moderate energy savings. However, the performance was less effective during winter when the solar gain was lower. East- and west-facing walls achieved moderate benefits, with energy savings ranging between 7.09% and 7.82%, primarily due to morning and afternoon sunlight. In contrast, north-facing walls showed minimal improvement due to limited direct solar exposure. The combined integration of PCMs on all walls resulted in an annual energy savings of 29.83%.

A numerical study was conducted by Al-Absi et al. [55] under real-weather conditions to evaluate PCM-incorporated foamed concrete panels on building walls. The panels were tested for thermal performance across four cardinal orientations (north, south, east, and west). The results showed that wall orientation significantly influenced the effectiveness of PCM panels. The maximum reduction in internal wall surface temperature was 6.75 °C for west-oriented walls, followed by 6.50 °C for south-oriented walls, 5.00 °C for east-oriented walls, and 2.45 °C for north-oriented walls. The variations were due to differences in the intensity and duration of solar radiation exposure based on orientation.

Sharma et al. [56] conducted a numerical study on residential buildings in Delhi, India, to analyse the thermal performance of PCM-enhanced building envelopes under summer conditions. The effect of wall orientation showed that integrating PCMs in different wall orientations had varying impacts on heat gain reduction. PCM-enhanced walls reduced heat gain by 10.4% to 26.6%, with west-facing walls achieving the highest reduction due to prolonged afternoon solar exposure. East-facing walls showed moderate effectiveness, while north-facing walls had the least impact, highlighting the significance of wall orientation in optimizing PCM performance.

Overall, the findings from these studies highlight that PCM performance is highly dependent on building orientation and climate-specific factors. The proper selection and placement of PCMs in walls can maximize energy savings, improve indoor thermal comfort, and enhance the efficiency of passive cooling and heating strategies.

4. Comparison Table of Findings

To provide a clear synthesis of the diverse findings reported in the literature, a summary is presented in Table 4. This table consolidates the results from experimental and simulation-based studies that investigated the thermal performance of buildings integrated with PCMs under varying conditions. Key parameters, such as PCM melting temperature, integration method, climate zone, building component, and energy savings, are listed. The objective is to highlight trends, identify effective design strategies, and reveal how different PCM properties and placements influence thermal regulation and energy efficiency. This structured comparison offers practical insights for researchers and designers aiming to optimize PCM use in concrete-based construction across different climatic contexts.

Table 4.

Overview of selected studies that investigate the influence of various PCM thermal properties, such as thermal conductivity, specific heat capacity, and latent heat, on thermal performance and energy consumption. The table presents comparative findings under different experimental and numerical conditions, offering insight into how specific material characteristics and boundary configurations affect the thermal performance of PCM-enhanced building elements. The symbol “✓” indicates that the specific PCM parameter or integration condition was explicitly considered or analysed in the corresponding study.

5. Discussion

The integration of PCMs into building structures has been shown to significantly enhance thermal performance, but their effectiveness is influenced by various critical factors.

The melting temperature of PCMs is pivotal for optimal thermal performance. It must align with the target indoor temperature range to ensure effective heat absorption and release during daily and seasonal temperature fluctuations. Studies indicate that selecting PCMs with melting points suitable for local climate conditions can significantly improve energy savings by up to 50% by stabilizing indoor temperatures during peak heating or cooling periods. Moreover, if the melting temperature is designed for only one load/season (heating or cooling), PCMs may not have sufficient benefits for the entire year or, even worse, they may generate undesired thermal effects.

The thermal properties of PCMs, such as thermal conductivity, latent heat, and specific heat, are essential for their performance. High latent heat allows for greater energy storage capacity, while adequate λ ensures efficient heat transfer during phase transitions. Specific heat influences a material’s ability to store sensible heat, making the selection of PCMs with optimized thermal properties crucial for effective thermal management in buildings.

The thickness of PCM layers directly affects their ability to store and release heat. Thicker PCM layers provide more thermal mass, leading to enhanced energy storage and prolonged thermal regulation. However, there are diminishing returns beyond a certain thickness, suggesting the need for an optimal balance between thermal performance and practical considerations, like cost and installation.

The effectiveness of PCMs varies across different climate zones. In warmer climates, PCMs can reduce cooling loads by absorbing excess heat during the day and releasing it at night. In colder climates, they help maintain warmth by storing heat during the day and minimizing heat loss at night. Therefore, climate-specific customization of PCM properties is necessary for maximizing energy savings and thermal comfort.

The placement of PCMs within building components, such as walls, roofs, and floors, plays a significant role in their performance. For instance, in temperate climates, PCM integration into walls and roofs achieved energy savings of up to 31%, while in hot climates, peak indoor temperatures were reduced by up to 5 °C, enhancing thermal comfort. Roofs often receive the highest solar exposure, making them ideal for PCM integration to reduce cooling demands, while walls can be optimized to enhance thermal insulation and maintain stable indoor temperatures.