1. Introduction

Electrification or electronic mobility is a key strategy aimed at mitigating the negative impact of the transport sector on the environment and health [

1]. Electromobility is promoted as a future alternative to the means of transport that will bring noticeable environmental and economic benefits, thus encouraging actions towards sustainable urban transport [

2]. Therefore, in developing countries, it is important to increase the share of electricity. This is possible, for example, by promoting it in various types of vehicles [

1,

3]. This means that energy savings, including emission reduction, can be achieved by promoting electric vehicles, especially in the subsectors of passenger cars, light trucks, buses, and motorcycles [

4].

In addition, during the decarbonisation of the transport sector, it is important to implement low-emission alternative fuels. Various alternatives have been created, e.g., hydrogen or dimethyl ether/methanol, which is synthesised using carbon dioxide (CO

2), constituting a raw material for fuel production. Research in this area was conducted, for example, by the authors of the article [

5], who examined the relative economic and environmental efficiency of hydrogen and carbon dioxide. Hydrogen was produced during the reforming of steam methane and was produced by electrolysis using renewable energy. It was shown that a more favourable combination of costs and environmental efficiency is in the case of hydrogen, where it is recommended that CO

2 comes from fossil sources, to make it becomes profitable in the long term [

5].

Environmental and economic benefits were also sought for the use of an electric battery or a hybrid engine, comparing them to a combustion engine. This is due to the fact that electric vehicles are perceived as environmentally friendly and due to the fact that they do not emit emissions from the exhaust pipe. Despite this, battery production accounts for 50% of the total environmental impact of production [

6]. Therefore, this is a hotspot in the development activities carried out in the context of electric vehicles. An example of an analysis in this area was presented by the authors of the study [

7], who used a life cycle assessment “from the cradle to the grave”, including comparing these engines in various scenarios of solutions in the energy mix. In this analysis, the vehicle with an electric engine turned out to be the most advantageous. Similarly, in the work [

6], an assessment of the simulation of energy needed for battery cell production was made. A scenario analysis was carried out that ensured the identification of factors and circumstances that influence demand.

There were also studies on the development of diesel oil, gasoline, or electric batteries, for example [

8], which consisted of their analysis during real driving cycles. Another area of research was environmental indicators based on the life cycle assessment method, which were integrated with costs in various alternative vehicle production solutions, as in [

9]. It was pointed out that during extraction and production, there are increasing concerns about metal depletion, including toxicity to humans, which is mainly generated by technologies such as photovoltaic panels or electric vehicles. Actions were also taken to ensure a comprehensive assessment of the sustainable development of passenger vehicles, e.g., with an internal combustion engine, powered by synthetic biofuel, fossil petrol, and an electric battery, as in [

10], where these vehicles were assessed using environmental, economic, and social indicators. The assessments were supported by multi-criteria decision support methods.

A review of studies on the integration of LCA with other aspects, such as costs or product quality, was also conducted. For example, in [

11], as part of making design and development decisions, a combination of LCA with product cost analyses and scenario-based economic risk modelling was proposed. Decisions on environmental analyses of products were also supported by other tools, as reported in [

12], including environmental cost accounting, reporting, and the identification and analysis of environmental aspects. The aforementioned material flow cost accounting was also integrated with LCA in [

13], where techniques supporting product improvement were sought. In turn, the authors of [

14] proposed integrating LCA with quality aspects in the form of quality function deployment (QFD). This consisted of analysing customers’ quality requirements for products and, at the same time, environmental impact criteria. The cost aspect was also taken into account in the form of a model of production costs and environmental costs. The authors of [

15] also addressed the issue of designing new products or improving products currently available on the market. They proposed taking into account environmental and cost aspects through the integration of LCA and LCC (Life Cycle Costing). The use of LCC was aimed at taking into account hidden and potential external costs throughout the product life cycle. There were also studies, such as [

16], which were based on the development of a model for creating positive value for the customer in the form of integration of environmental and cost assessment and taking into account customer requirements. A similar model was presented by the authors of [

17], in which they included ecological costs in the entire product cost. Ecological costs are understood as the costs (direct and indirect) of environmental impact in the life cycle. The model creates product alternatives that become profitable in terms of environmental impact, but also total costs for so-called green products. This is a mathematical model that supports the analysis of the relationships between the aforementioned aspects.

The summary of the conducted review of the literature on the subject is presented in

Table 1.

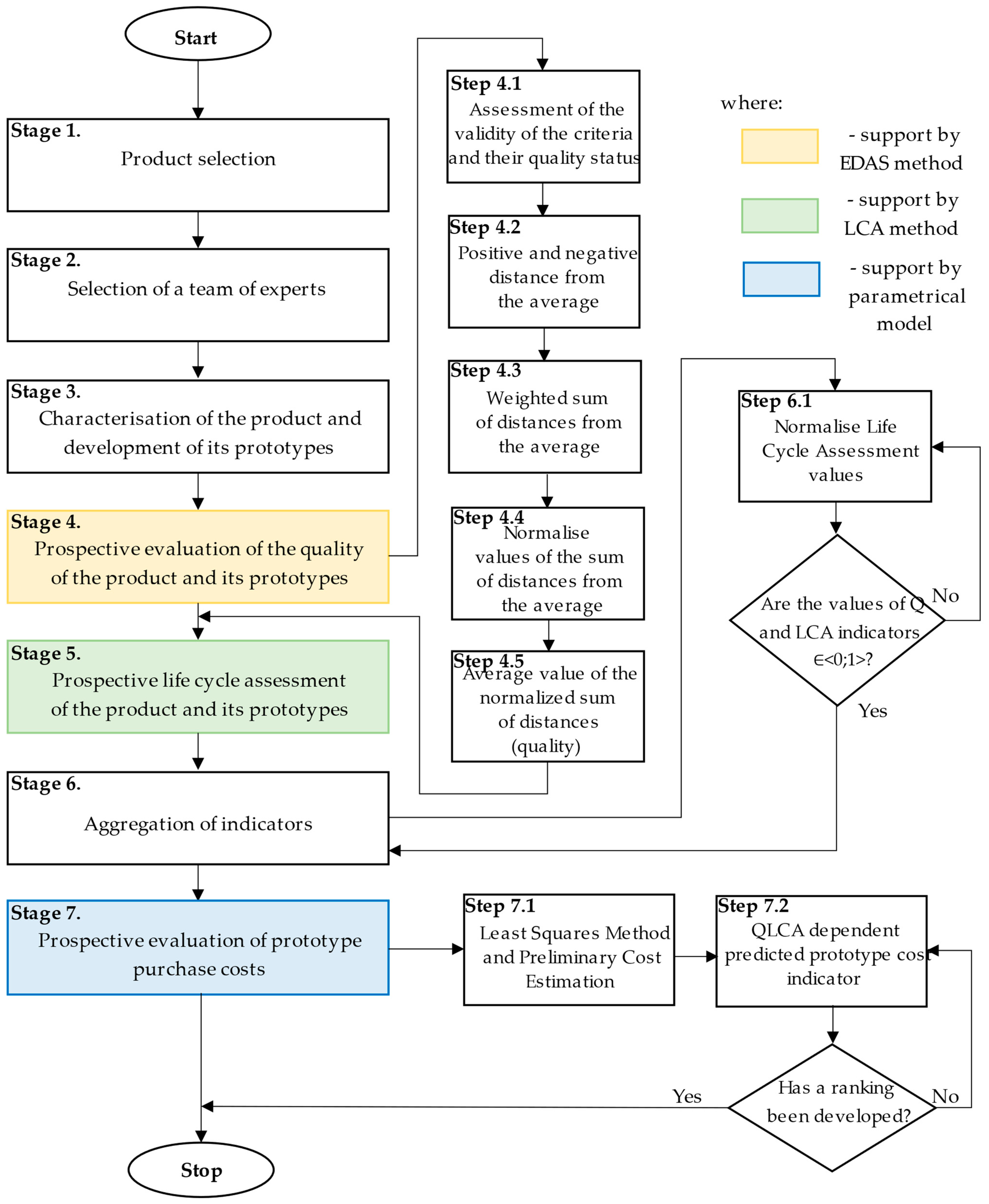

Research was shown to be undertaken within the framework of improving products from the transport sector, mainly in the direction of searching for more environmentally friendly solutions, e.g., electric vehicles. However, there was no research that would take into account other aspects, such as cost or quality. The integration of these aspects for other products has been found, but most of them focused on the environmental and cost aspects, mainly through extensive LCA and LCC analyses. In the case of the quality aspect, research was conducted on creating design solutions in QFD. Despite this, no solutions were developed to support the aggregation of alternative design solutions (prototypes) that would provide the modelling of product quality and environmental impact in the life cycle with an uncomplicated estimation of costs dependent on the quality and environmental solutions of the product. Therefore, the objective was to develop a CQ-LCA model that supports the creation of alternative product solutions and their assessment in terms of the following: (i) environmental impact in the life cycle, (ii) quality (customer satisfaction with use), and (iii) production and/or purchase costs. The novelty is the developed methodology, which provides a qualitative and quantitative interpretation of the results, including verbally on a relative state scale and indicatively (CQ-LCA). The originality lies in providing a multi-aspect morphological analysis, after which different scenarios of product solutions are determined depending on quality, LCA, and costs. The model was developed in a general way so it could be applied to various products.

Therefore,

Section 2 is a presentation and characterisation of the model, including the general approach and scheme of the procedure and assumptions. However, its test is shown in the example of electric motorcycles. In turn,

Section 3 is a test of the model on electric motorcycles.

3. Results

The test and illustrations of the model were carried out on the example of electric motorcycles. Their selection was determined by their growing popularity among customers, where according to data from BusinessWire, they are expected to reach USD 892.4 million by 2025. At the same time, they are a more environmentally friendly alternative to traditional combustion motorcycles. The electric motorcycles selected, for example, are motorcycles for general use, so they are considered a reference product (generalisation of electric motorcycles of this type). Following the authors of the work [

55], it is assumed that motorcycles are used for everyday use in normal conditions, for example, on city roads.

Following the proposed model, a team of experts was selected to support the further stages of the analysis. Initially, the authors of the article selected two more experts, consisting of customers who own electric scooters or plan to buy them in the near future. Then, using Formulas (1) and (2), it was estimated that the minimum number of experts in the team should be at least four experts. Then, each of the experts in the team estimated their coefficient of competence according to Formulas (3) and (4). One of the experts estimated his skills in the analysis of the considered issue below the assumed threshold value of 0.6. Therefore, using Formula (5), the team of experts included five experts, who were the authors of the article and three customers.

The reference electric motorcycle was then characterised and its hypothetical prototypes were developed. As assumed in the third stage of the model, the electric motorcycle is characterised by the quality criteria that affect customer satisfaction with the motorcycle’s usability. The quality criteria were selected based on publicly available catalogues of these products and according to a review of the literature, e.g., [

56]. These criteria are as follows:

Finally, 11 main criteria of the electric motorcycle were chosen, based on the adopted assumptions about the number of criteria, as in [

57]. Subsequently, the criteria were described according to the current catalogue of these products, and then their possible modifications were proposed in the form of alternative design solutions. The result is presented in

Table 2.

Hence, one electric motorcycle as a reference product expressed by the criteria in its current state (P0) and nine prototypes in a modified state (P1–P9) were further analysed.

Following the adopted model, the team of experts assessed the quality of the electric motorcycle and its prototypes. The EDAS method was used for this purpose. Therefore, initially, the importance of quality criteria was given. In the case analysed, the most important criterion was the maximum engine power (0.15), then the maximum range (0.13) and then the battery capacity (0.11). The following criteria turned out to be less important: maximum speed, charging time, height (0.09), and then battery voltage, permissible load, and colour (0.07). The least important were length and width (0.06). Each of these criteria was additionally classified into advantage criteria (the more, the better) and disadvantage criteria (the more, the worse). Based on the real parameters of these criteria, including the use of Formula (6), the average solution for these criteria was calculated in relation to the analysed prototypes (AV). The results are presented in

Table 3.

Using Formulas (8) and (9), the positive distance from the mean (PDA) and the negative distance from the mean (NDA) were calculated. On their basis, the weighted sum of the positive distance from the mean (SP) and the sum of the negative distance from the mean (SN) (10–11) were calculated. Subsequently, according to Formulas (12) and (13), the normalised values of the sum of the positive and negative distances from the mean were calculated. Based on it, according to Formula (14), the value of the normalised sum of the positive and negative distance from the mean was estimated, i.e., the quality of the electric motorcycle prototypes (Q). The results are presented in

Table 4.

According to the Q indicator (as in

Table 4), a ranking of prototypes was created. The results are shown in

Figure 4.

It was observed that prototype 7 was the most advantageous in terms of quality. It ranked first in the ranking and was characterised by the highest quality indicator among those analysed. Prototype 5 turned out to be the least advantageous. However, within the proposed modelling process, the environmental aspect of these prototypes was taken into account.

Therefore, a prospective life cycle assessment of the electric motorcycle and its prototypes was carried out. It was based on the ISO 14040 standard in this “from cradle to grave” approach, which takes into account the acquisition and extraction of materials, production, use, and end of life. Hence, the system boundaries were the aforementioned LCA phases, including the assumption of conducting LCA with respect to one criterion of environmental burden, which is carbon dioxide (CO

2) emission kg equivalent. The choice of this criterion resulted from its direct connection with electric motorcycles, as reported, e.g., in [

26]. Furthermore, the system boundaries included the main components of the electric scooter, which were selected based on [

58], that is, accessories, battery, brakes and wheels, electrical and electronic components, frame, mechanical and mechatronic components, electric motor, steering system and gearbox, suspension, tyres and inner tubes, and packaging. Following the authors of other works, for example, [

55], the functional unit was defined as 80,000 km travelled by the motorcycle in the life cycle. This corresponds to the distances also given by [

26], and also meets the conditions of the assumptions about the BEV battery adopted by the authors of the work [

55].

To estimate carbon dioxide emissions in the extraction and processing of materials used for the production of electric motorcycles, following the authors of the work [

59], the following formula (20) was adopted:

where

—carbon dioxide emission from fuel consumption during material production;

—carbon dioxide emission from electricity consumption during material production; x—material; m—mass (kg); n—production process;

—energy consumption per unit of material in its production process (kJ/kg); k—fuel;

—share of fuel consumption in

;

—share of electricity consumption in

; and

—carbon emission factor in fuel

.

Therefore, it was necessary to estimate the materials used for the production of electric motorcycles. It was based on selected data from the GREET v1.3.0.13991 programme [

60], including a review of the literature, e.g., [

55,

58]. Additionally, following the authors of the works [

61,

62,

63,

64,

65,

66], the CO

2 emission factor was estimated in the production of materials (kg/kg) for selected materials, and the results obtained results are presented in

Table 5.

Then, based on the literature review, for example [

61], the energy consumption coefficient for material production and the carbon dioxide emission coefficient were estimated, excluding the motorcycle battery. This is presented in

Table 6.

Inventory data may differ, e.g., due to different processes of material extraction and processing. However, for the reference electric motorcycle, including the assumptions indicated, these data were sufficient for a preliminary estimate of CO

2 emissions for the acquisition and extraction of materials. Formula (20) was used for this purpose, and the results are presented in

Table 7.

Finally, it was shown that the total CO2 emission during the extraction and processing phase of the materials used in the electric motorcycle is 0.27 MJ.

Then, an analysis of CO

2 emissions was carried out in the production of the components of this vehicle. Emissions are often taken into account during the processing of the main components, including their assembly, welding, or painting [

67]. Formula (21) is used to estimate CO

2 emissions during the production of the vehicle and its components [

59]:

where

—carbon dioxide emission from fuel consumption during component production;

—carbon dioxide emission from electricity consumption during component production; y—vehicle component (part);

—electricity consumption during vehicle assembly; q—production process;

—energy consumption by the component in the production process (kJ);

—share of fuel consumption in

;

—share of electricity in

; and

—carbon emission factor in fuel

.

The reference electric motorcycle was assumed to weigh 230 kg. Therefore, CO

2 emissions and electricity consumption in the production phase were estimated based on data from the GREET model and data from a review of the literature [

59,

68,

69,

70,

71]. The results are presented in

Table 8.

In the production phase of the electric motorcycle life cycle, it is also necessary to determine the type of battery. According to the authors of the works [

72,

73,

74], it was assumed that a lithium-ion battery was installed in the analysed electric motorcycle. Since the CQ-LCA model is based on an in-depth analysis of the quality of the criteria, their impact on the environment in the life cycle, and costs, the analysis was not extended to the criteria for the lithium-ion battery. As part of the model test, available data from the literature were used. Its detailed analysis in light vehicles is presented, for example, in [

75,

76]. Following the authors of the article [

59], the energy consumption used to install the battery in a light passenger vehicle (e.g., an electric motorcycle) is 2.67 MJ/kg. Then, according to Formula (21), the total value of carbon dioxide consumption of the reference electric motorcycle in the production phase is about 7505 MJ.

The phase of use of the reference electric motorcycle was then analysed [

67]. For an electric vehicle, Formula (22) is used [

59]:

where P

E—electricity consumption per 100 km by the electric vehicle (kWh/km); C

E—charging efficiency; and d—total driving distance of the vehicle (km).

Therefore, considering the reference electric motorcycle, it was assumed that the average electric energy consumption of an electric motorcycle is 0.126 MJ/h [

56]. In turn, the charging efficiency is approximately 94% (for lithium-ion batteries) [

75,

76,

77]. According to the functional unit, the electric motorcycle will cover a distance of 80,000 km in its lifetime [

55]. Using Formula (22), it was estimated that the carbon dioxide emissions during the use of this vehicle are 10,723 MJ.

The carbon dioxide emissions during recycling from selected components of electric motorcycles were then analysed. In the recycling phase, for example, materials are separated, cleaned, and others. It is often possible to observe the division of the recycling phase into components, omitting the battery and then including the battery. It is also possible to consider recycling and reuse in this phase [

67]. Carbon dioxide emissions in light vehicle recycling are estimated using Formula (23) [

59]:

where

—carbon dioxide emission from fuel consumption in vehicle recycling;

—carbon dioxide emission from electricity consumption in vehicle recycling;

—energy consumption per unit of material x in the recycling phase (kJ/kg); x—recycled material;

—share of fuel consumption in

;

—share of electricity consumption in

; m—mass (kg); and

—energy consumption during vehicle dismantling.

According to previous assumptions, using Formula (23), CO

2 emissions that occur in the recycling process of selected components of an electric motorcycle (taking into account battery recycling using hydrometallurgical technology) were estimated. Data were based on the GREET model and a review of the literature and reports [

78,

79,

80,

81], including previous studies, e.g., [

76]. Finally, CO

2 emissions (taking into account battery recycling) were estimated at about

= 1760 MJ. As confirmed by the authors of other works, e.g., [

78,

81,

82], it was shown to emit a significant amount of CO

2 in the last phase of LCA.

Finally, calculations were possible to determine the carbon dioxide emission factor throughout the entire life cycle of electric motorcycles (24) [

59]:

where LCA—total life cycle carbon dioxide emissions of the vehicle;

—carbon dioxide emissions from material extraction and processing; C

VA—carbon dioxide emissions from vehicle and component production; C

VU—carbon dioxide emissions from vehicle use; and C

RE—carbon dioxide emissions from vehicle recycling, i-ith vehicle alternative, reference vehicle.

Ultimately, the total environmental impact of CO2 emissions from the electric motorcycle under consideration was estimated at 19,988 MJ throughout the life cycle “from cradle to grave”. The highest CO2 emissions were observed during the use phase.

Due to the fact that the proposed approach performs a prospective life cycle assessment of product prototypes, it was assumed that it would be carried out by means of conventional modelling of the change in the environmental impact indicator of the reference product in the life cycle (calculated for the reference product). This modelling included making the value of environmental impact in the life cycle dependent on the main quality criteria, which are directly related to the potential environmental burden of the product. The quality criteria, which were made dependent on the modelling of LCA results, were battery capacity, charging time, length, width, and height. Significant changes in the parameters of these criteria may have a significant impact on the environment. Therefore, the average value of the parameters of these criteria was estimated for the current reference motorcycle and its prototypes. Then, the change in the value of the environmental impact of CO

2 emissions for the electric motorcycle was estimated. For this purpose, the value of the environmental impact of the current electric motorcycle was modelled in terms of the average value of the parameters of the important quality criteria (

Table 9).

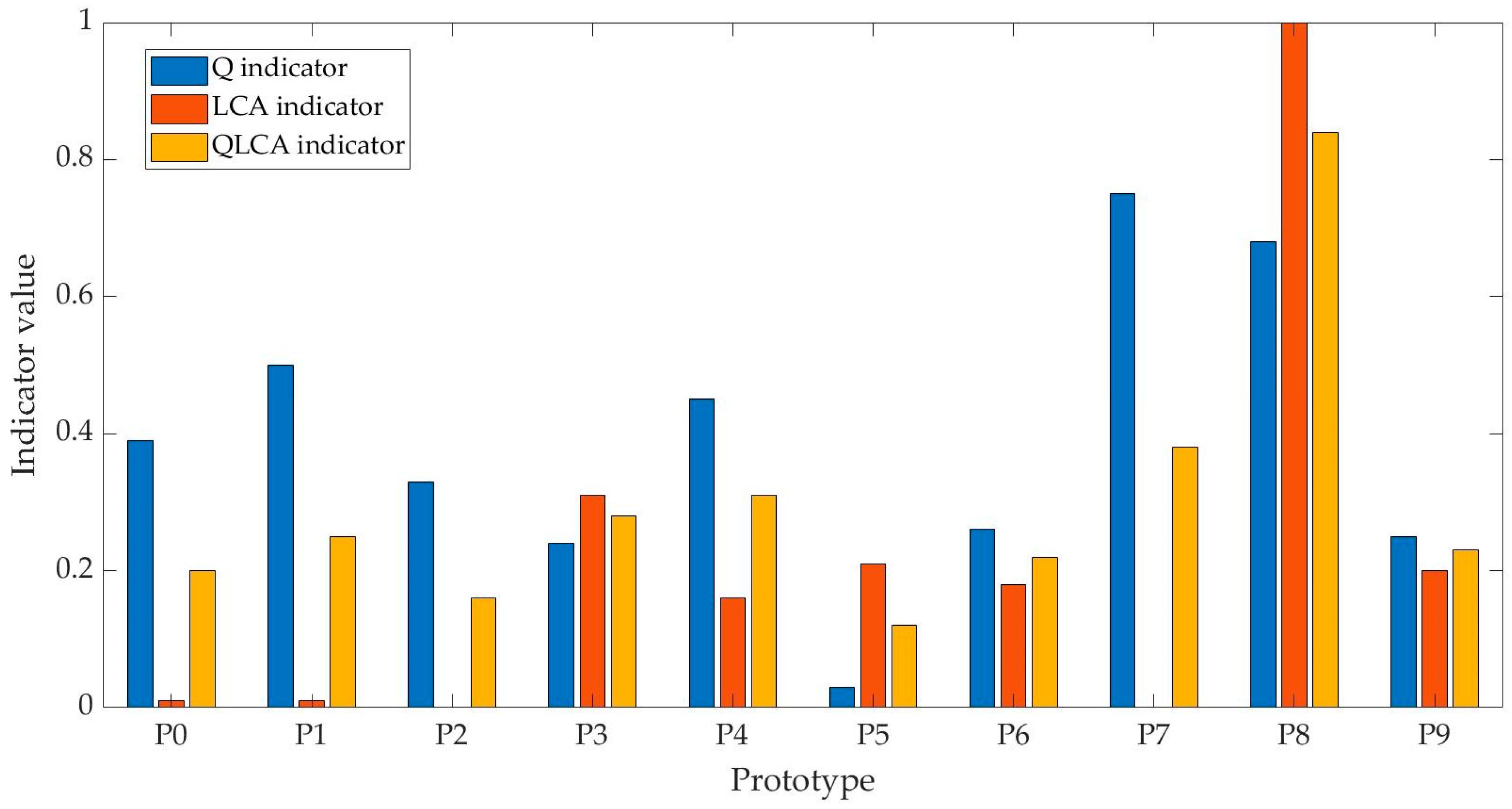

As a result, the environmental impact index (EI) of the electric motorcycle and its prototypes in the life cycle was modelled. Using Formula (14), the EI values were normalised, which was called the LCA indicator, as shown in

Figure 5.

It was shown that the most advantageous is prototype 8, which took the first position in the ranking and had the lowest environmental burden index in the life cycle in the case of carbon dioxide emissions. As part of the standardised analysis of the model results, it was necessary to aggregate (integrate) them. According to Formula (15), an aggregated quality and environmental index (QLCA) was created, according to which a ranking of electric motorcycle prototypes was developed. The result is presented in

Figure 6.

As shown in

Figure 6, taking into account both quality and environmental aspects, prototype 8 was shown to be the most advantageous. In this case, it has the second position for the quality aspect and the first position for the environmental aspect. The next one is prototype 7, which has the first position for the quality aspect and the last position for the environmental aspect. In the case under consideration, this indicates the advantage of the share of the quality aspect in relation to the environmental aspect in the overall QLCA indicator.

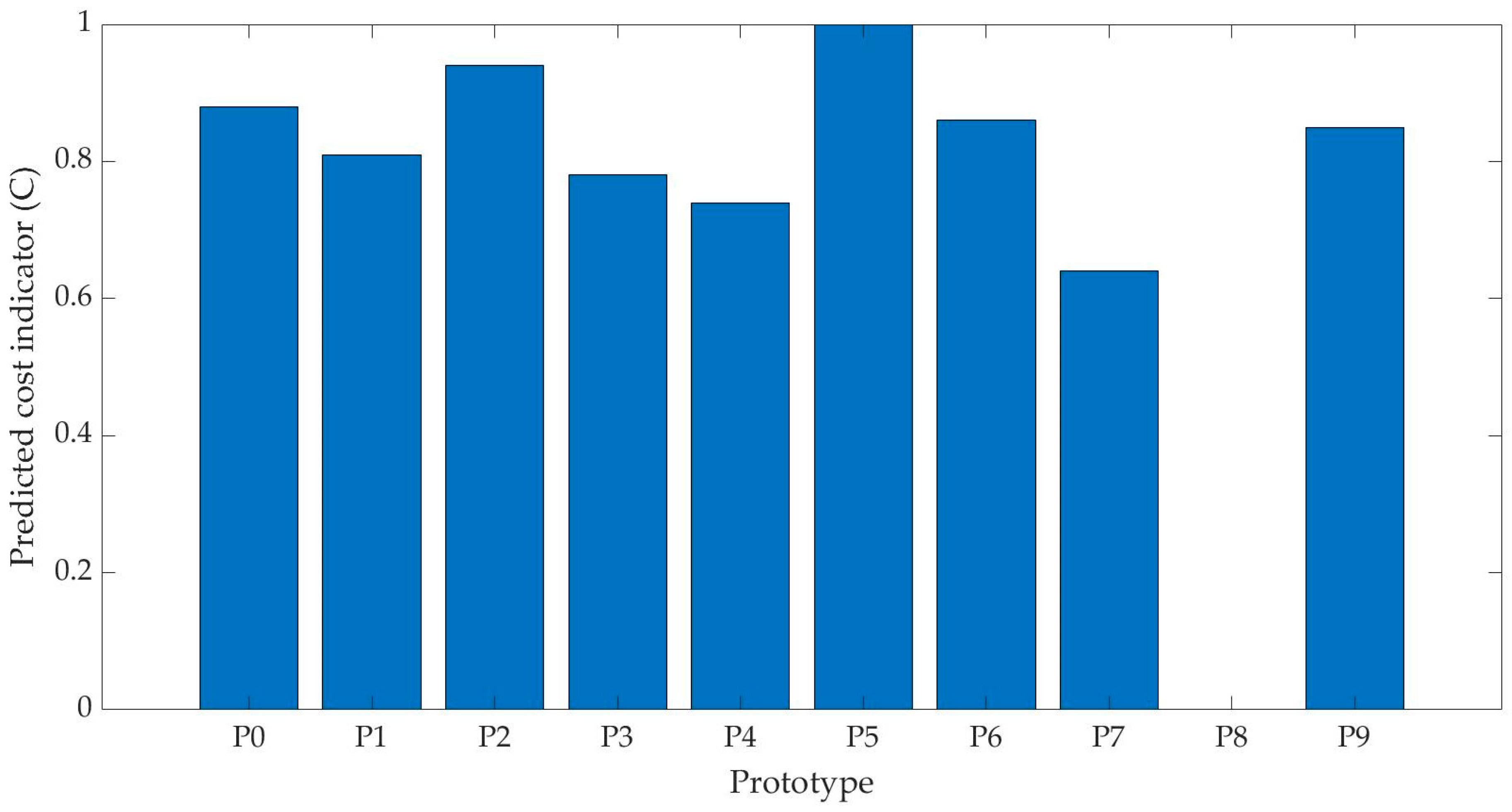

Due to the fact that sustainable product development and product development decision-making often depend on the cost aspect, an analysis was carried out using a parametric model. As assumed, the method of the least normal squares was used, as in Formula (17), which consists of identifying the parameter value. In the case analysed, the costs were estimated depending on the quality–environmental indicator (QLCA). Then, it was possible to determine partial derivatives with respect to constants a and b and then equate them to zero. Later, using Formula (18), the constants with values a and b were estimated. The average value of the prototype QLCA index for the analysis was 0.30. In the case of estimated prototype costs, it was PLN 5684.90. Subsequently, according to Formula (18), constants with values a = 3296.48 and b = 5684.60 were estimated. According to them, a structural model was developed, as in Formula (16), where in this case it is

. The results of the calculations for the analysed prototypes and their ranking are presented in

Table 10.

Based on the analysis results, the predicted cost values were normalised using Formula (14). Finally, a comparison of electric motorcycle prototypes was developed in relation to the normalised cost index (C) dependent on the quality–environmental index (QLCA), as shown in

Figure 7.

From the analysed results presented in

Figure 7, it was observed that the most advantageous prototype turned out to be the P5 prototype. It is characterised by a relatively low cost, good quality, and at the same time does not have a very negative impact on the natural environment in the life cycle compared to the other prototypes. Therefore, it is proposed to consider this prototype as the most advantageous with the assumptions adopted. However, the final decision depends on the entity using the model. In the case of, for example, a lack of resources or difficult access to technology, it is possible to decide on the next prototype, e.g., P2. The least advantageous in the simultaneous qualitative-environmental-cost approach is the prototype P8.

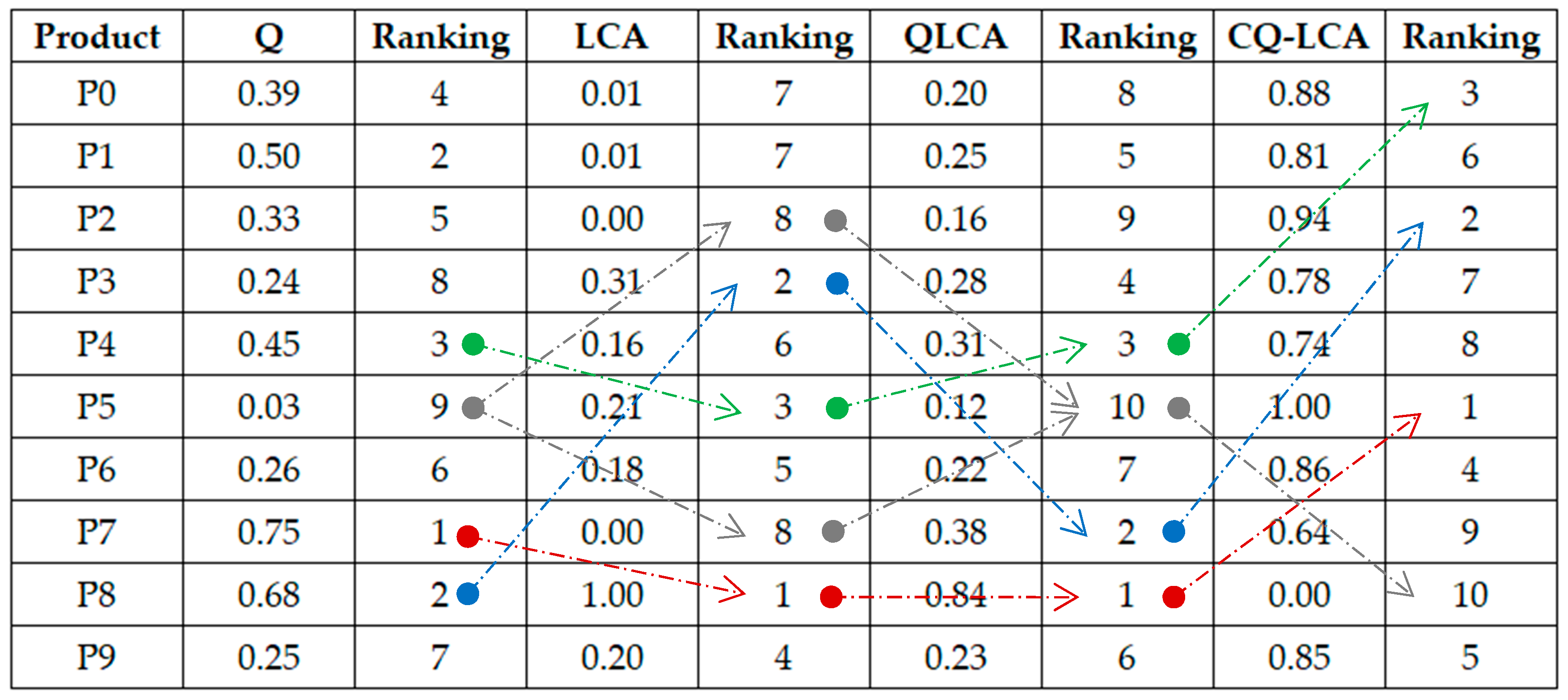

To supplement the research, the main results of the model were subjected to a morphological analysis, as shown in

Figure 8.

Based on morphological analysis, it was shown that considering the positioning of prototypes in the rankings, e.g., for position 1, P7 (Q), P8 (LCA), P8 (QLCA), and P5 (CQ-LCA) are observed, respectively. In the case of position 2, P8 (Q), P3 (LCA), P7 (QLCA), and P2 (CQ-LCA) are observed, respectively. Therefore, it is concluded that the model is sensitive to changes in indicators and their aggregation, which can be observed through changes in the prototypes in the rankings. Another example is the prototype analysis, where the P7 is assumed to be the first in the ranking in the case of the qualitative aspect. This prototype took the eighth position in terms of the impact on the environment in the life cycle. In turn, by aggregating quality aspects with the environment, it reached the second position in the ranking. It was shown that in this analysis, the share of the qualitative indicator exceeded the environmental indicator. However, considering the prospective cost of the prototypes taking into account the quality–environmental indicator, it was observed that the P7 prototype finally achieved the ninth (penultimate) position in the ranking. This may be due to the fact that the higher the quality, the higher the cost.

4. Discussion

Supporting the conceptualisation and prototyping of products is an essential activity for developing companies [

83]. More and more often, it is required to consider in detail not only the possibilities of improving the usability of the product but also the impact on the environment in the life cycle. In addition, it is important for the company to consider what costs the offered product generates as well as what costs the customer will have to bear when purchasing it. The three indicated aspects should be considered in an integrated manner, which is in line with the idea of their sustainable development. In this approach, techniques are sought to support the process of creating new products or improving existing ones. Therefore, the aim of the research was to develop a CQ-LCA model supporting the creation of alternative product solutions and their assessment in terms of: (i) the impact on the LCA environment, (ii) quality, and (iii) production and/or purchase costs. The model was developed in seven main stages and then tested for electric motorcycles.

The proposed approach is a new solution compared to other works, where the subject of the research is an electric motorcycle. For example, the authors of the article [

84] compared the results of the life cycle assessment of popular combustion motorcycles with electric motorcycles. They showed that the electric motorcycle achieves a lower global warming index, including shortages of fossil resources. The situation is different in the case of the eutrophication of main waters and the shortages of mineral resources, where the combustion motorcycle turned out to be more beneficial in terms of the environment. In turn, in the study [

1] the impact on the environment, the demand for primary energy, and the costs of owning an electric motorcycle in the life cycle were analysed. They showed, among other things, that the greatest demand for primary energy occurs in the use phase, while this phase is characterised by lower operating and maintenance costs. Another example is [

85], which compared motorcycles and minibuses in terms of their impact on the environment in the life cycle or costs in the life cycle. It has been shown, among other things, that vehicles with a smaller capacity in the informal transport system are characterised by better environmental efficiency. Similarly, in the case of the cost of living, where it was shown that motorcycles are more profitable. Similar analyses were conducted, for example, by [

86], in which they compared motorcycles with passenger cars, also in the case of combustion and electric engines. Another example is the article in which life cycle assessment and life cycle cost assessment were modelled in the form of hybrid modelling. The tests were carried out for electric motorcycles and gasoline-powered motorcycles. Similarly to the previously indicated authors, the largest amount of energy in the life cycle was consumed at the stage of use. Other examples of analyses of this type are presented, for example, in [

87,

88].

In the context of modelling taking into account selected aspects (quality, environment, and costs), it was observed that the proposed CQ-LCA model stands out from other decision models. Compared to the model offered in [

11], we extend the approach to product design and improvement based on LCA and cost analysis [

12] by creating alternative design solutions additionally taking into account the quality aspect. Similarly, in the research presented in [

13], only the costs of materials were considered, integrating them with LCA. In CQ-LCA, it is a comprehensive analysis of the costs not only of materials but also of final products, where these costs are combined with the quality of these products and their impact on the environment. In turn, considering the integrated aspects of CQ-LCA in relation to the proposal in [

14], it is performed within the framework of QFD, which is modified for the needs of analysing customer expectations and environmental impact. However, this study does not provide a prediction of different prototypes while taking into account the actual cost of the product, its impact on the environment in the life cycle and product quality. Other examples of studies are, e.g., [

15,

16,

17], which are based on LCA, LCC methods or extensive cost analyses. However, they do not provide coherent models that aggregate quality, cost and environmental aspects in a simple methodology adapted to the search for alternative product solutions. In contrast, the developed CQ-LCA model fills this gap and fits into the scope of research carried out by other authors.

Furthermore, when considering the efficiency of the model, it was compared to the traditional conceptualisation and prototyping, as shown in

Table 11.

Therefore, the main benefits of adopting the QC-LCA model to the process of conceptualisation and prototyping of products include the following:

The ability to create product prototypes in a hypothetical (model) manner, which helps reduce resource waste by focussing only on the most beneficial product solutions;

Supporting the process of assessing quality aspects (satisfaction with use), environmental aspects (LCA), and cost aspects (production and/or purchase) of the current product and its prototypes;

Improving the method for predicting various design solutions by modelling data according to the principles of sustainable product development;

Supporting the decision-making process (e.g., designers) through quantitative indicators regarding quality, environmental, and cost aspects, enabling the creation of prototype rankings and the selection of the most beneficial one;

Providing multi-aspect and multi-criteria analysis, the results of which can be used to select the most beneficial prototype in relation to selected aspects, while also taking into account all of them (quality, environment, and costs).

However, some limitations of the QC-LCA model include the limitation of the hypothetical creation of prototypes, the sample forms of which are not produced. This means that the production stage of selected prototypes is not considered in this model, which does not concern its further improvement. Additionally, a limitation is the need to engage an interdisciplinary team of experts who will have knowledge of the analysed product, as well as the aspects under consideration. This team should have basic skills that allow for reliable use of the QC-LCA model in practice, e.g., knowledge of product LCA, or the method of modelling data in accordance with the mathematical models offered. Access to current data necessary for modelling the level of quality and also the environmental impact in the life cycle, or the relationship between these data and the costs of prototypes may prove to be a problem.

Therefore, future research will involve conducting further tests of the model on other products. It is planned to generalise the model assumptions, including testing other combinations of techniques supporting it. It seems important to build a database dedicated to quality, environmental, and cost analyses, which will be useful for specific products. In addition, it is important to take into account other aspects of sustainable development, such as society.