Adhesion Characteristics of Crude Oil on Non-Metallic Pipelines During Low-Temperature Gathering and Transportation

Abstract

1. Introduction

2. Material and Methods

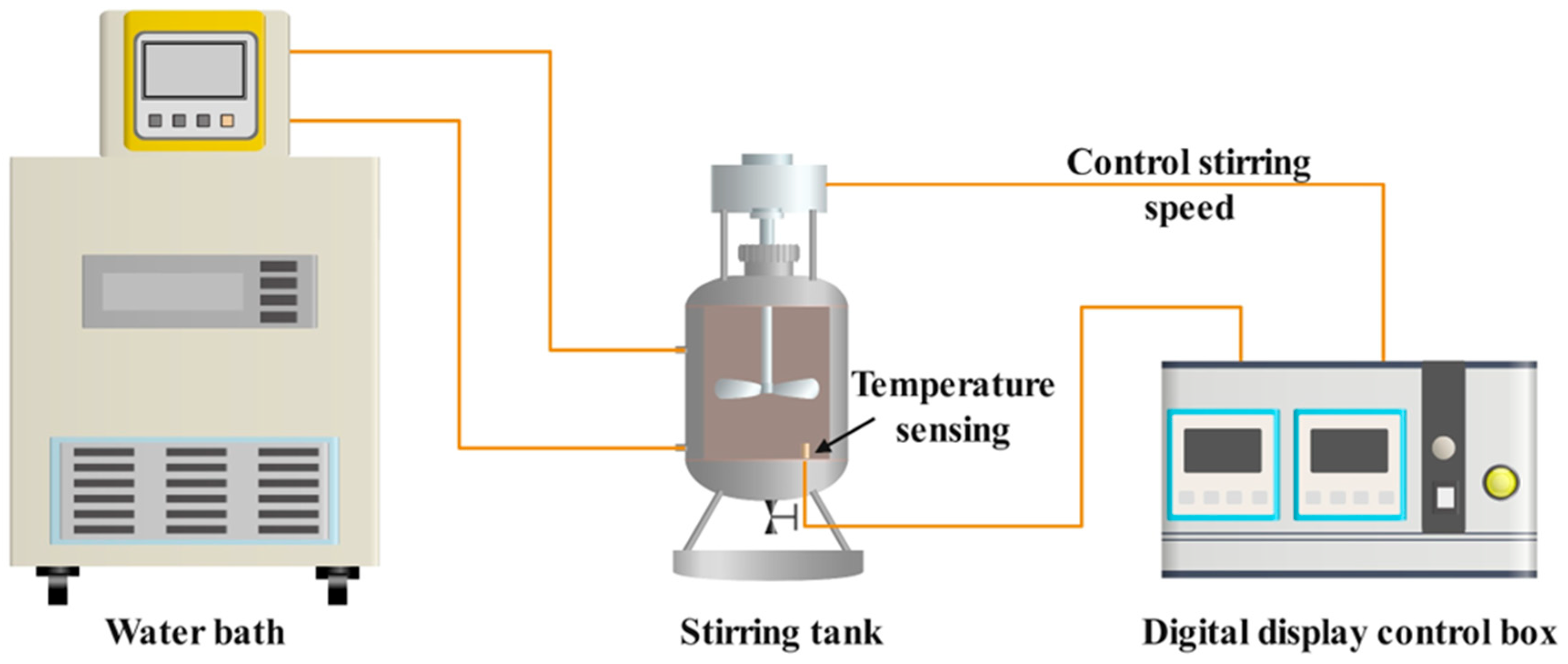

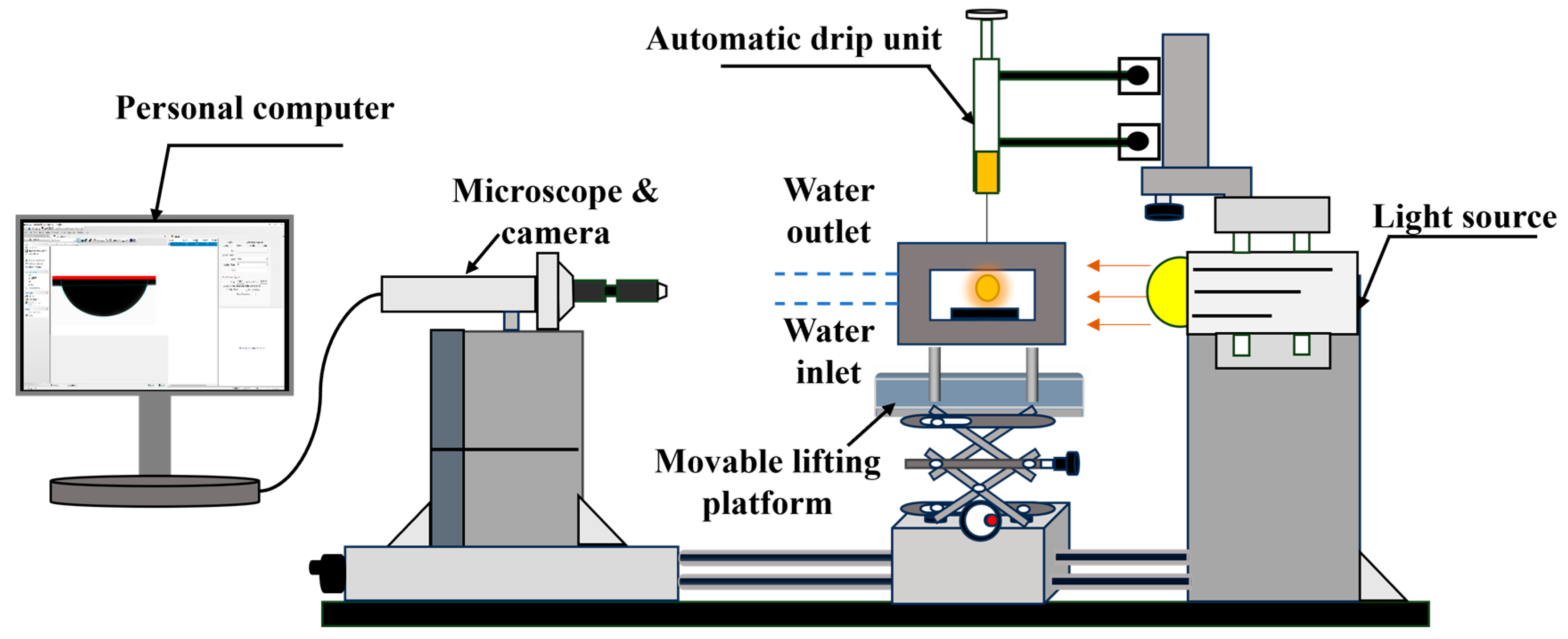

2.1. Experimental Device

2.2. Experimental Oil Sample

2.3. Experimental Method

- (1)

- Prepare oil–water emulsions with water cuts similar to those in field conditions. Mix crude oil and water at a temperature consistent with the wellhead temperature. Set the circulating water bath to 5 °C above the oil’s pour point. Preheat both the emulsion and the test setup in this bath for 1 h to ensure uniform temperature.

- (2)

- Introduce 200 mL of the prepared emulsion into the test tank. Start the stirring system and set the required rotational speed. The rotational speed is controlled by a frequency converter that regulates the motor speed. Gradually reduce the tank temperature at a rate of 0.5 °C/min. Once the target temperature is reached, continue stirring for 10 min to allow for stable adhesion behavior to occur. Open the tank outlet to drain the emulsion during stirring. Use a scraper to collect the adhered crude oil from the inner wall. Measure the mass of the collected oil.

- (3)

- Repeat the process at lower temperatures. When a significant increase in adhered oil mass is observed, stop the test. The corresponding temperature is defined as the temperature point where mn+1/mn > 50%; here, mn+1 and mn represent the adhered oil mass obtained from the (n + 1)th and nth test runs, respectively.

- (4)

- Set the minimum gathering and transportation temperature above the wall adhesion temperature to prevent oil deposition.

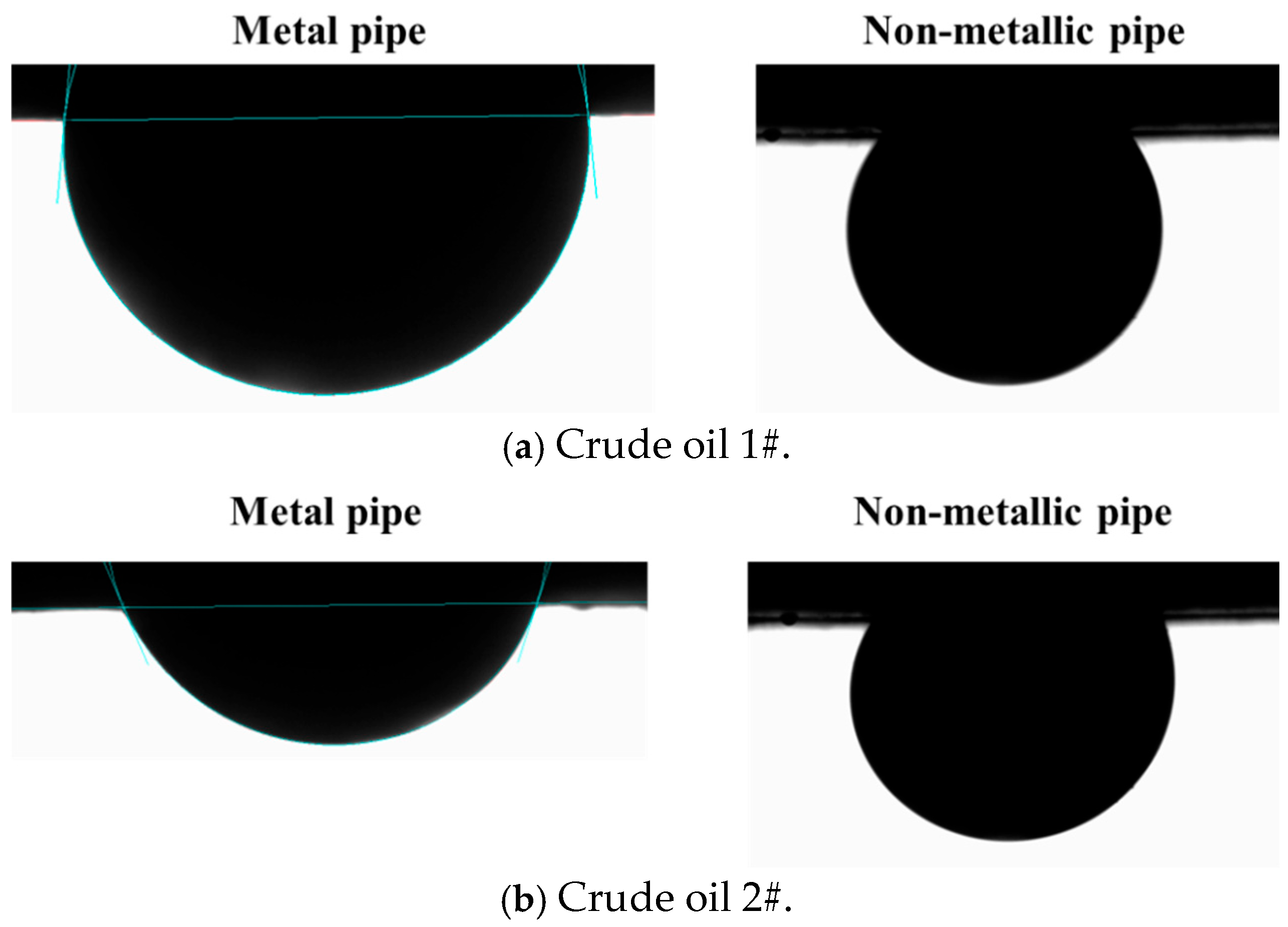

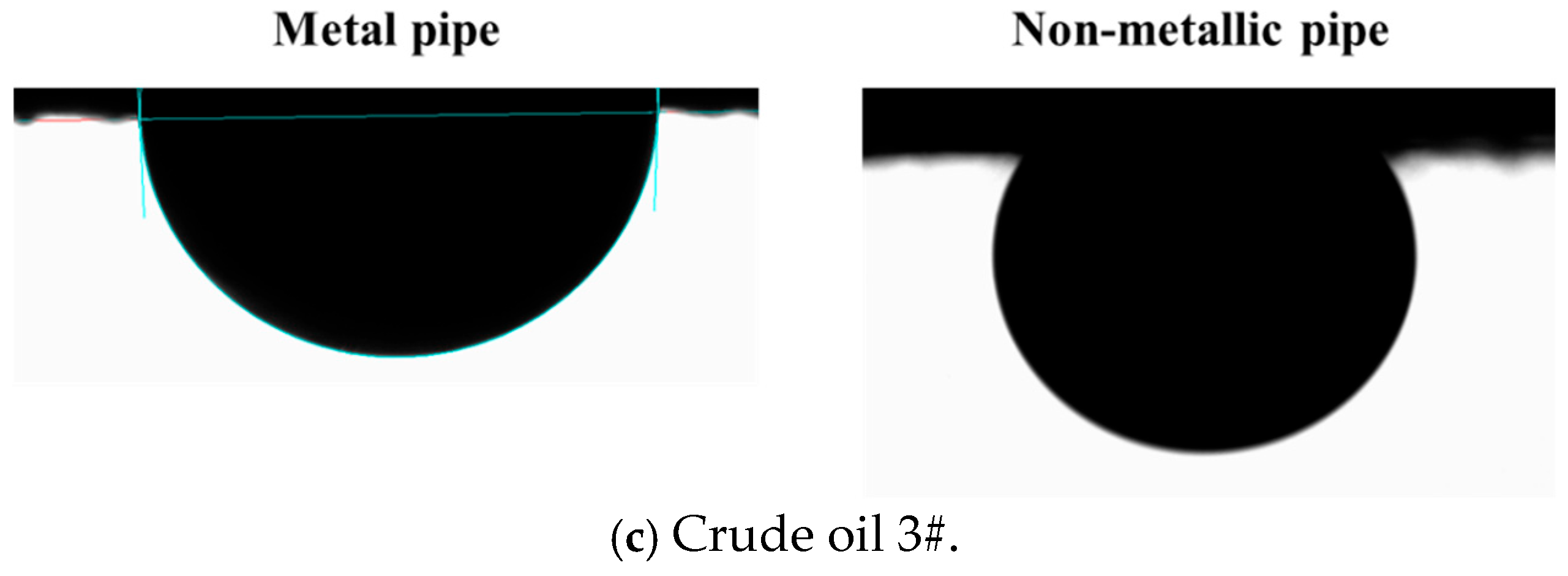

- (1)

- Sample Preparation: Cut rectangular plates (2 cm × 1.1 cm) from flexible composite pipe material and stainless steel sheets. Polish both the plates to achieve uniform surface roughness.

- (2)

- Setup and Preheating: Place the test plate on the sample stage in a solution tank filled with deionized water (water level above plate). Level the stage. Set the oil and water baths to the target test temperature for preheating the system and crude oil sample.

- (3)

- Contact Angle Measurement: Use a microsyringe (0.52 mm needle) to draw crude oil. Position the needle above the center of the test plate. Start the testing device and adjust brightness for clear visibility. Inject the oil droplet and start recording when it makes contact with the plate. Measure and record the contact angle after 5 min of equilibrium. Replace deionized water and repeat under different conditions as needed.

- (4)

- Interfacial Tension Measurement: Keep the temperature stable in the chamber. Remove the sample stage and inject a 10 μL oil droplet into the water phase using a microsyringe.

- (5)

- Measure and record the interfacial tension using the software.

3. Results and Discussion

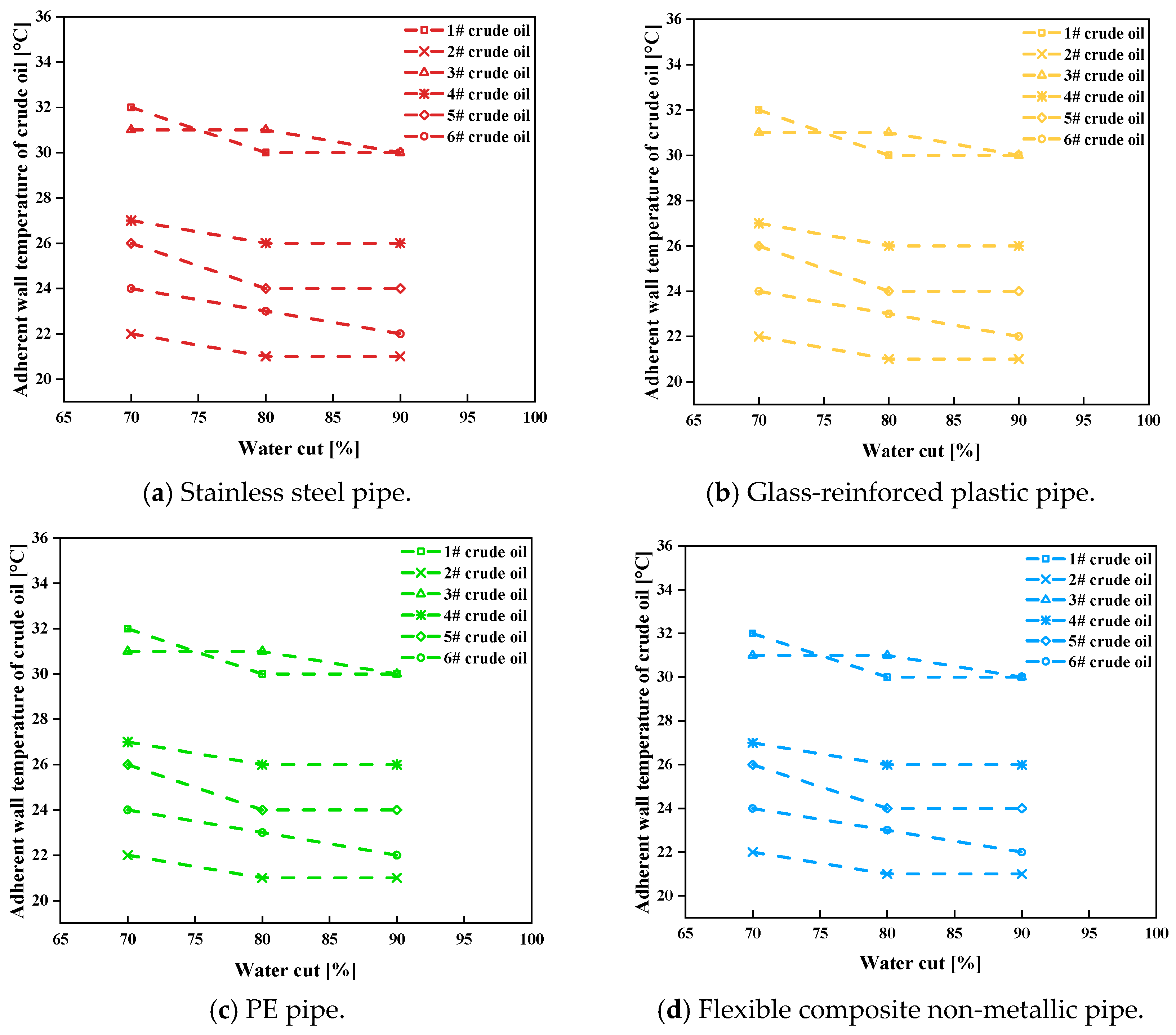

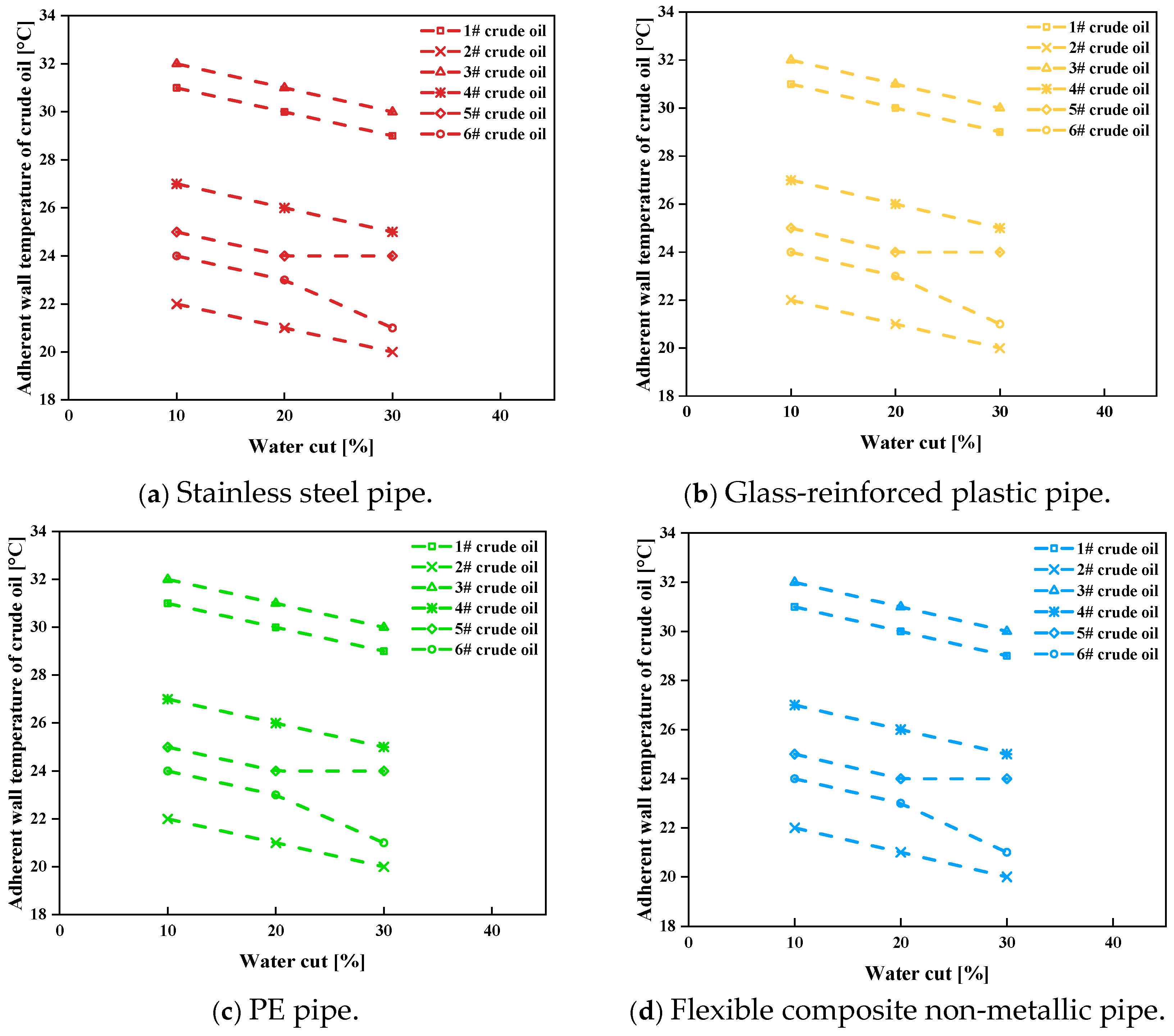

3.1. Effects of Different Water Cut Contents

3.2. Effects of Different Shear Intensities

3.3. Effects of Different Wax Contents in Crude Oil

3.4. The Quality Difference in Crude Oil Adhering to the Wall Between Non-Metallic and Metallic Pipelines

3.5. Modelling of Wall Adhesion Temperature of Crude Oil in Non-Metallic Pipelines

3.6. The Wall Adhesion Mechanism of Crude Oil in Non-Metallic and Metallic Pipelines

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Abubakar, A.; Al-Wahaibi, Y.; Al-Wahaibi, T.; Al-Hashmi, A.; Al-Ajmi, A.; Eshrati, M. Effect of low interfacial tension on flow patterns, pressure gradients and holdups of medium-viscosity oil/water flow in horizontal pipe. Exp. Therm. Fluid Sci. 2015, 68, 58–67. [Google Scholar] [CrossRef]

- Zhu, C.; Zhu, S.; Duan, P.; Li, L.; Gong, L. Study on leakage and diffusion characteristics of Hydrogen-blended natural gas in utility tunnels and ventilation strategies. Comput. Energy Sci. 2024, 1, 102–116. [Google Scholar] [CrossRef]

- Li, A.; Zhu, M.; Hao, P.; Wu, H.; Gong, J.; Wang, K.; Yu, W.; Feng, Y. Wall sticking inhibition of high water cut crude oil (below pour point) by underwater superoleophobic PA-FC modification. Colloids Surf. A Physicochem. Eng. Asp. 2020, 607, 125427. [Google Scholar] [CrossRef]

- Al-Ghouti, M.A.; Al-Kaabi, M.A.; Ashfaq, M.Y.; Da’na, D.A. Produced water characteristics, treatment and reuse: A review. J. Water Process Eng. 2019, 28, 222–239. [Google Scholar] [CrossRef]

- Esaklul, K.A.; Mason, J. Nonmetallics applications in oil and gas production (pipes, liners, rehabilitations). In Trends in Oil and Gas Corrosion Research and Technologies; Woodhead Publishing: Cambridge, UK, 2017; pp. 627–660. [Google Scholar]

- Bukhari, A.O.; Bashar, M.; Aladawy, A.S.; Goh, S.L.M.; Sarmah, P. Review of Non-Metallic Pipelines in Oil & Gas Applications—Challenges & Way Forward. In Proceedings of the International Petroleum Technology Conference, Riyadh, Saudi Arabia, 21–23 February 2022. [Google Scholar]

- Xu, P.; He, L.; Yang, D.; Zhou, S.; Wang, J.; Yang, D. Blocking characteristics of high water-cut crude oil in low-temperature gathering and transportation pipeline. Chem. Eng. Res. Des. 2021, 173, 224–233. [Google Scholar] [CrossRef]

- Zhang, T.; Bai, H.; Sun, S. A self-adaptive deep learning algorithm for intelligent natural gas pipeline control. Energy Rep. 2021, 7, 3488–3496. [Google Scholar] [CrossRef]

- Wang, Y.; Huang, Q.; Qi, J. Migration of dense phase waxy particle oil flow in horizontal pipeline: Experiment and CFD simulation. Fuel 2025, 379, 133005. [Google Scholar] [CrossRef]

- Haj-Shafiei, S.; Ghosh, S.; Rousseau, D. Kinetic stability and rheology of wax-stabilized water-in-oil emulsions at different water cuts. J. Colloid Interface Sci. 2013, 410, 11–20. [Google Scholar] [CrossRef]

- Hu, X.-Y.; Zhao, X.-L.; Ma, C.-Y.; Wang, Z.-X.; Liu, Y.-C.; Liu, J.; Cao, J.; Zou, T.; Li, J. Experimental Study on Wall Sticking Occurrence Temperatures of High Water Cut Crude Oil Gathered and Transported at Normal Temperatures. In Proceedings of the International Petroleum and Petrochemical Technology Conference, Beijing, China, 27–29 March 2018; Shemwell, S.M., Lin, J., Eds.; Springer: Singapore, 2018; pp. 128–135. [Google Scholar]

- Shi, S.; Wang, Y.; Liu, Y.; Wang, L. A new method for calculating the viscosity of W/O and O/W emulsion. J. Pet. Sci. Eng. 2018, 171, 928–937. [Google Scholar] [CrossRef]

- Paolinelli, L.D.; Rashedi, A.; Yao, J.; Singer, M. Study of water wetting and water layer thickness in oil-water flow in horizontal pipes with different wettability. Chem. Eng. Sci. 2018, 183, 200–214. [Google Scholar] [CrossRef]

- Wang, X.; Ouyang, J.; Wang, Z.M. Exploring the dynamic mechanism of water wetting induced corrosion on differently pre-wetted surfaces in oil–water flows. J. Colloid Interface Sci. 2024, 664, 284–298. [Google Scholar] [CrossRef]

- Alhosani, M.; Asthagiri, D.; Puerto, M.; Chapman, W.G. Insights into the mechanisms affecting water/oil interfacial tension as a function of salt types and concentrations. Fluid Phase Equilibria 2020, 522, 112771. [Google Scholar] [CrossRef]

- Akstinat, M. Chemical and physicochemical properties of formation waters of the oil and gas industry. J. Hydrol. 2019, 578, 124011. [Google Scholar] [CrossRef]

- Cai, J.; Zhang, S.; Liu, S.; Li, X.; Wan, Z.; Noskov, B.A.; Yang, X. pH-responsive microgels constructed from soy protein coacervates: Structure and rheology at the oil-water interface. Food Hydrocoll. 2025, 167, 111433. [Google Scholar] [CrossRef]

- Shi, L.; LaCour, R.A.; Qian, N.; Heindel, J.P.; Lang, X.; Zhao, R.; Head-Gordon, T.; Min, W. Water structure and electric fields at the interface of oil droplets. Nature 2025, 640, 87–93. [Google Scholar] [CrossRef]

- Alabtah, F.G.; Mahdi, E.; Eliyan, F.F. The use of fiber reinforced polymeric composites in pipelines: A review. Compos. Struct. 2021, 276, 114595. [Google Scholar] [CrossRef]

- Paolinelli, L.D.; Yao, J.; Rashedi, A. Phase wetting detection and water layer thickness characterization in two-phase oil-water flow using high frequency impedance measurements. J. Pet. Sci. Eng. 2017, 157, 671–679. [Google Scholar] [CrossRef]

- Zhu, B.; Yang, M.; Yan, Y.; Zhong, J.; Li, J.; Li, Z.; Zhang, J. Insights into the effect of water content on asphaltene aggregation behavior and crude oil rheology: A molecular dynamics simulation study. J. Mol. Liq. 2024, 396, 124042. [Google Scholar] [CrossRef]

- Adewunmi, A.A.; Hussain, S.M.S.; Patil, S.; Kamal, M.S. Influence of Varying Oil–Water Contents on the Formation of Crude Oil Emulsion and Its Demulsification by a Lab-Grown Nonionic Demulsifier. ACS Omega 2024, 9, 19620–19626. [Google Scholar] [CrossRef] [PubMed]

- L’Estimé, M.; Schindler, M.; Shahidzadeh, N.; Bonn, D. Droplet Size Distribution in Emulsions. Langmuir 2023, 40, 275–281. [Google Scholar] [CrossRef] [PubMed]

- Dalmazzone, D.; Hamed, N.; Dalmazzone, C. DSC measurements and modelling of the kinetics of methane hydrate formation in water-in-oil emulsion. Chem. Eng. Sci. 2009, 64, 2020–2026. [Google Scholar] [CrossRef]

- Zhu, Y.; Shi, B.; Liao, Q.; Song, S.; Li, Y.; Sui, J.; Liu, L.; Liao, N.; Yao, H.; Gong, J. Molecular dynamics simulation of wax micro-structure characteristics in the oil-water emulsion. Fuel 2024, 374, 132456. [Google Scholar] [CrossRef]

- Brahmbhatt, J.; Chaudhuri, S. Insight into material behavior via surface free energy calculations for common energetic materials. Propellants Explos. Pyrotech. 2024, 49, e202300230. [Google Scholar] [CrossRef]

- Si, Y.; Yu, C.; Dong, Z.; Jiang, L. Wetting and spreading: Fundamental theories to cutting-edge applications. Curr. Opin. Colloid Interface Sci. 2018, 36, 10–19. [Google Scholar] [CrossRef]

- Zhang, J.; Peng, K.; Xu, Z.-K.; Xiong, Y.; Liu, J.; Cai, C.; Huang, X. A comprehensive review on the behavior and evolution of oil droplets during oil/water separation by membranes. Adv. Colloid Interface Sci. 2023, 319, 102971. [Google Scholar] [CrossRef]

| Oil Sample | Gel Point (°C) | Density (20 °C), kg/m3 | Density (50 °C), kg/m3 | Wax Appearance Temperature, °C | Peak Temperature Point for Wax Appearance, °C | Wax Content, wt% |

|---|---|---|---|---|---|---|

| #1 | 38 | 841 | 821 | 54.62 | 25.88 | 27.71 |

| #2 | 30 | 852 | 830 | 51.90 | 19.89 | 17.52 |

| #3 | 37 | 862 | 842 | 54.32 | 28.71 | 26.17 |

| #4 | 34 | 853 | 873 | 43.89 | 16.21 | 15.91 |

| #5 | 33 | 810 | 788 | 49.68 | 18.49 | 24.57 |

| #6 | 30 | 843 | 822 | 59.37 | 24.30 | 13.91 |

| Oil Sample | Wax Content, wt% | The Adhesion Temperature of Non-Metallic Pipes to the Wall, °C | The Adhesion Temperature of Metallic Pipes to the Wall, °C |

|---|---|---|---|

| #1 | 27.71 | 30 | 30 |

| #2 | 17.52 | 21 | 21 |

| #3 | 26.17 | 31 | 31 |

| #4 | 15.91 | 26 | 26 |

| #5 | 24.57 | 24 | 24 |

| #6 | 13.91 | 23 | 23 |

| Parameter | a | b | h | k | m | n |

|---|---|---|---|---|---|---|

| Value | 2.945 | 37.925 | 0.854 | 0.211 | 0.166 | 0.060 |

| Water Content, % | Average Shear Rate, s−1 | Predicted Values, °C | Experimental Values, °C | Error, °C |

|---|---|---|---|---|

| 70 | 10 | 30.18 | 29 | 1.18 |

| 20 | 28.92 | 27 | 1.92 | |

| 30 | 28.16 | 26 | 2.16 | |

| 80 | 10 | 29.34 | 27 | 2.34 |

| 20 | 28.04 | 26 | 2.04 | |

| 30 | 27.25 | 25 | 2.25 | |

| 90 | 10 | 28.57 | 27 | 1.57 |

| 20 | 27.24 | 26 | 1.24 | |

| 30 | 26.43 | 24 | 2.43 |

| Water Content, % | Average Shear Rate, s−1 | Predicted Values, °C | Experimental Values, °C | Error, °C |

|---|---|---|---|---|

| 70 | 10 | 26.44 | 27 | −0.56 |

| 20 | 25.09 | 26 | −0.91 | |

| 30 | 24.27 | 24 | 0.27 | |

| 80 | 10 | 25.53 | 25 | 0.53 |

| 20 | 24.14 | 24 | 0.14 | |

| 30 | 23.29 | 24 | −0.71 | |

| 90 | 10 | 24.70 | 25 | −0.30 |

| 20 | 23.27 | 24 | −0.73 | |

| 30 | 22.41 | 23 | −0.59 |

| Water Content, % | Average Shear Rate, s−1 | Predicted Values, °C | Experimental Values, °C | Error, °C |

|---|---|---|---|---|

| 70 | 10 | 24.76 | 25 | −0.24 |

| 20 | 23.53 | 24 | −0.47 | |

| 30 | 22.78 | 23 | −0.22 | |

| 80 | 10 | 23.93 | 24 | −0.07 |

| 20 | 22.66 | 23 | −0.34 | |

| 30 | 21.90 | 21 | 0.90 | |

| 90 | 10 | 23.18 | 24 | −0.82 |

| 20 | 21.88 | 22 | −0.12 | |

| 30 | 21.09 | 21 | 0.09 |

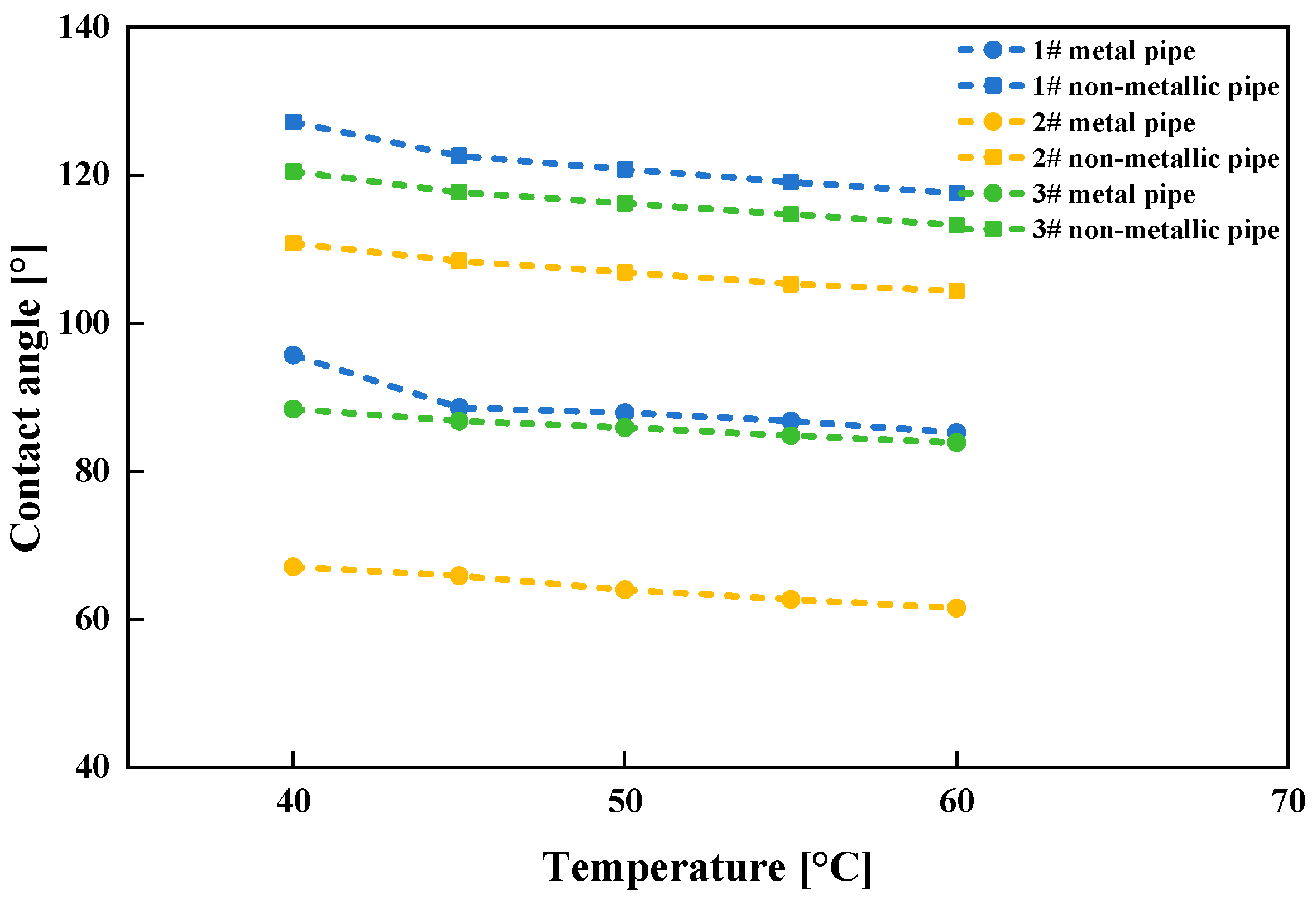

| Oil Sample | Test Temperature, °C | Metal Surface Adhesion, mJ/m2 | Non-Metallic Surface Adhesion Work, mJ/m2 |

|---|---|---|---|

| 1# | 40 | 26.25 | 11.52 |

| 45 | 27.14 | 12.22 | |

| 50 | 23.93 | 11.26 | |

| 55 | 22.08 | 10.74 | |

| 60 | 18.99 | 9.40 | |

| 2# | 40 | 50.97 | 23.66 |

| 45 | 45.60 | 22.16 | |

| 50 | 41.22 | 20.33 | |

| 55 | 37.84 | 19.10 | |

| 60 | 32.75 | 16.66 | |

| 3# | 40 | 34.40 | 16.48 |

| 45 | 32.99 | 16.72 | |

| 50 | 29.82 | 15.54 | |

| 55 | 26.24 | 14.01 | |

| 60 | 23.87 | 13.04 |

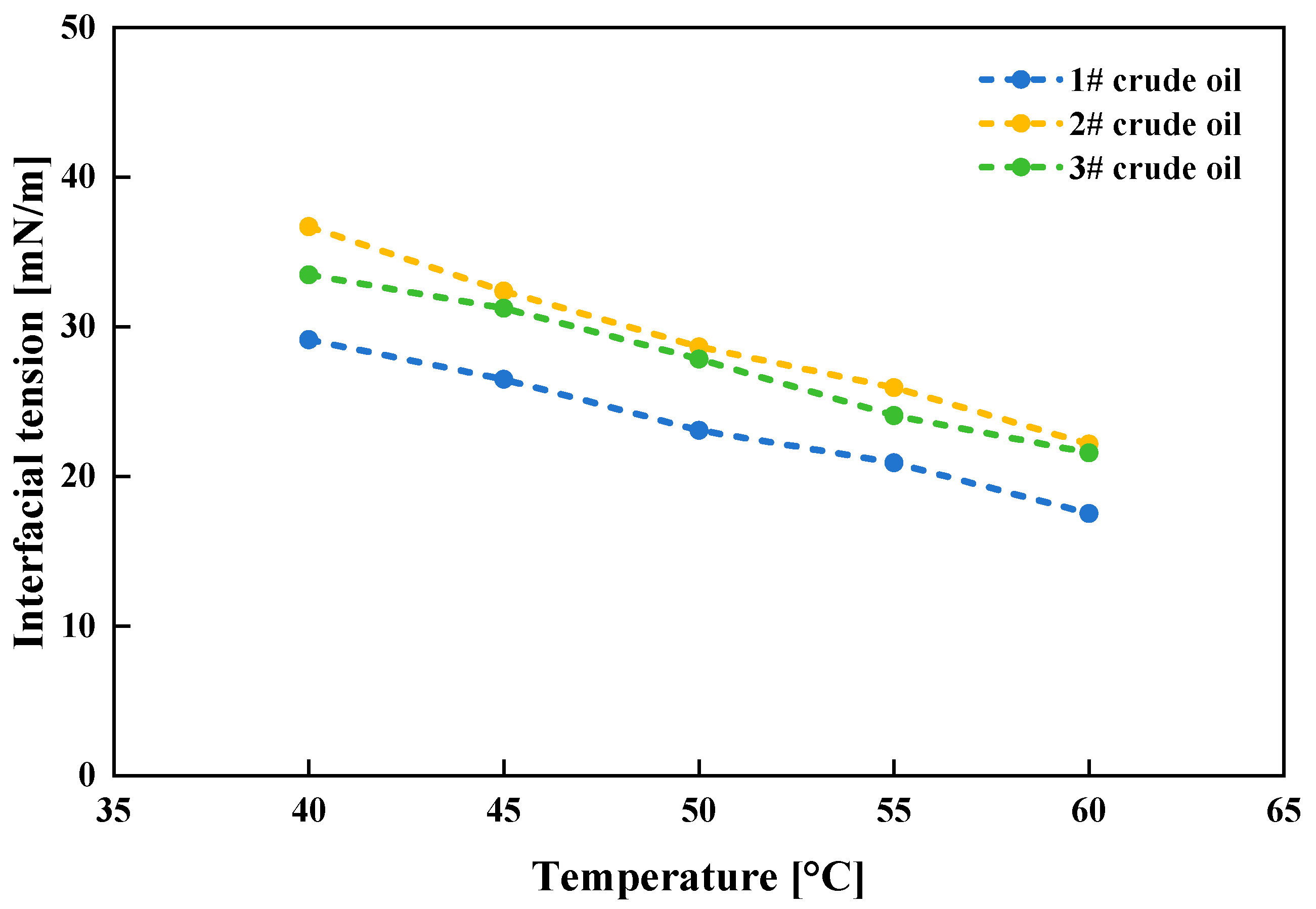

| Test Temperature/°C | #1, mJ/m2 | #2, mJ/m2 | #3, mJ/m2 |

|---|---|---|---|

| 40 | 58.28 | 73.38 | 66.94 |

| 45 | 52.98 | 64.76 | 62.5 |

| 50 | 46.16 | 57.32 | 55.66 |

| 55 | 41.82 | 51.88 | 48.12 |

| 60 | 35.04 | 44.34 | 43.16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, R.; Wang, Y.; Zheng, H.; Liu, W.; Huang, Q.; Huo, F.; Cao, Q.; Lin, G. Adhesion Characteristics of Crude Oil on Non-Metallic Pipelines During Low-Temperature Gathering and Transportation. Energies 2025, 18, 2828. https://doi.org/10.3390/en18112828

Yin R, Wang Y, Zheng H, Liu W, Huang Q, Huo F, Cao Q, Lin G. Adhesion Characteristics of Crude Oil on Non-Metallic Pipelines During Low-Temperature Gathering and Transportation. Energies. 2025; 18(11):2828. https://doi.org/10.3390/en18112828

Chicago/Turabian StyleYin, Ran, Yijie Wang, Hanpeng Zheng, Wenchen Liu, Qiyu Huang, Fuyong Huo, Qinliang Cao, and Ganggui Lin. 2025. "Adhesion Characteristics of Crude Oil on Non-Metallic Pipelines During Low-Temperature Gathering and Transportation" Energies 18, no. 11: 2828. https://doi.org/10.3390/en18112828

APA StyleYin, R., Wang, Y., Zheng, H., Liu, W., Huang, Q., Huo, F., Cao, Q., & Lin, G. (2025). Adhesion Characteristics of Crude Oil on Non-Metallic Pipelines During Low-Temperature Gathering and Transportation. Energies, 18(11), 2828. https://doi.org/10.3390/en18112828