DI4SHE: Deep Learning via Incremental Capacity Analysis for Sodium Battery State-of-Health Estimation

Abstract

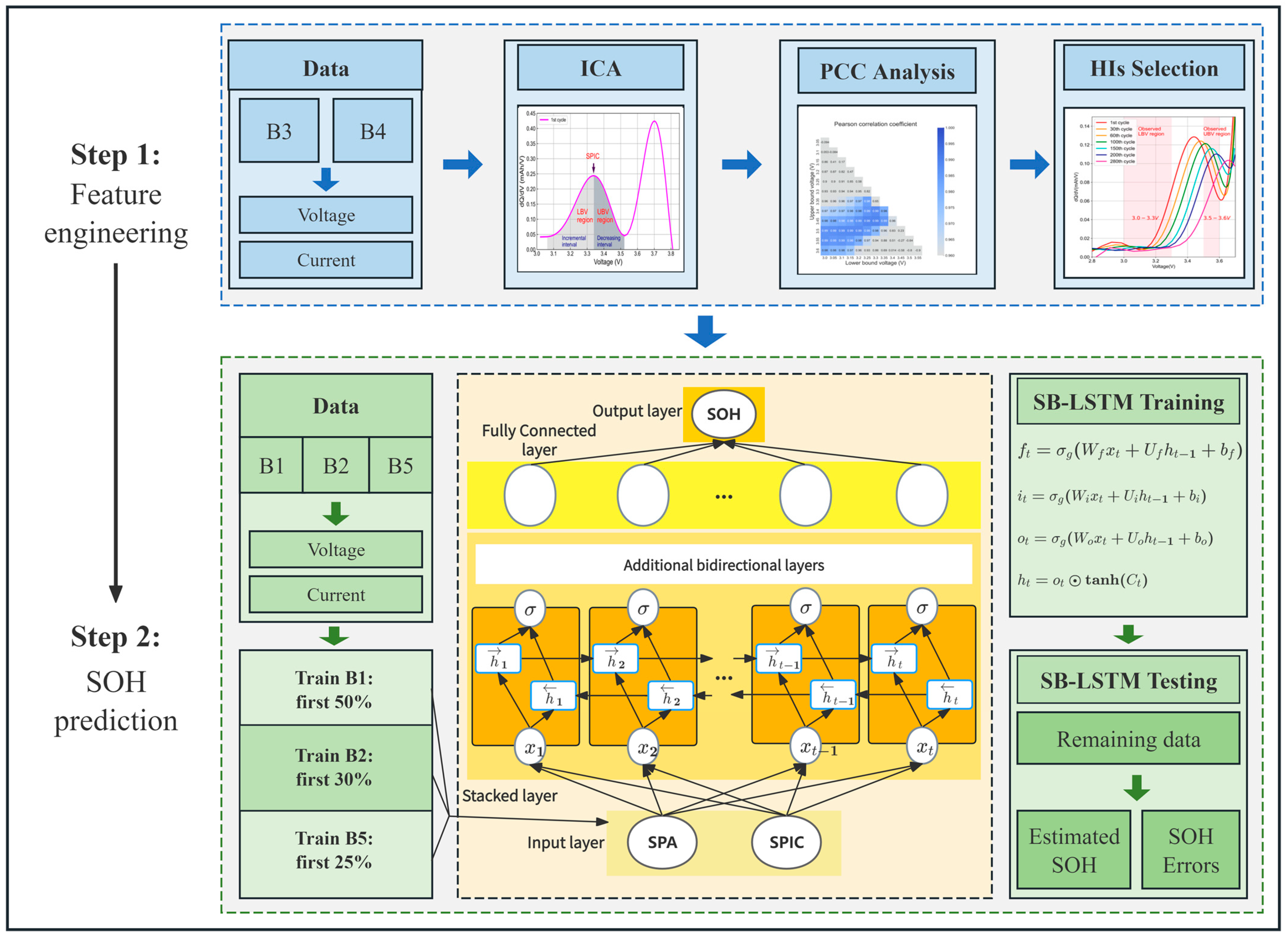

1. Introduction

1.1. Motivations and Literature Review

1.2. Gap Analysis and Article Contributions

2. Experimental Data and Feature Extraction

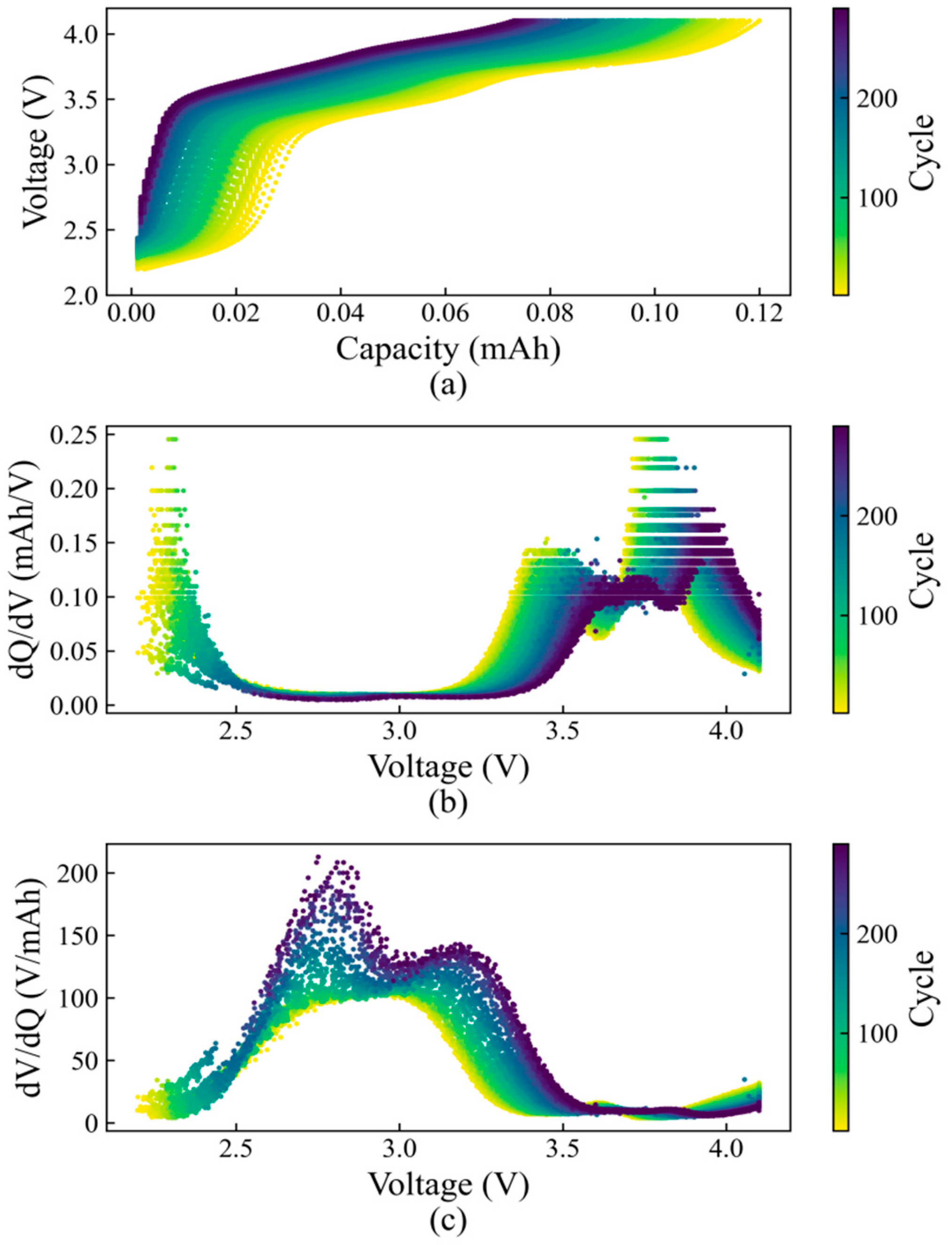

2.1. Data Description and Analysis

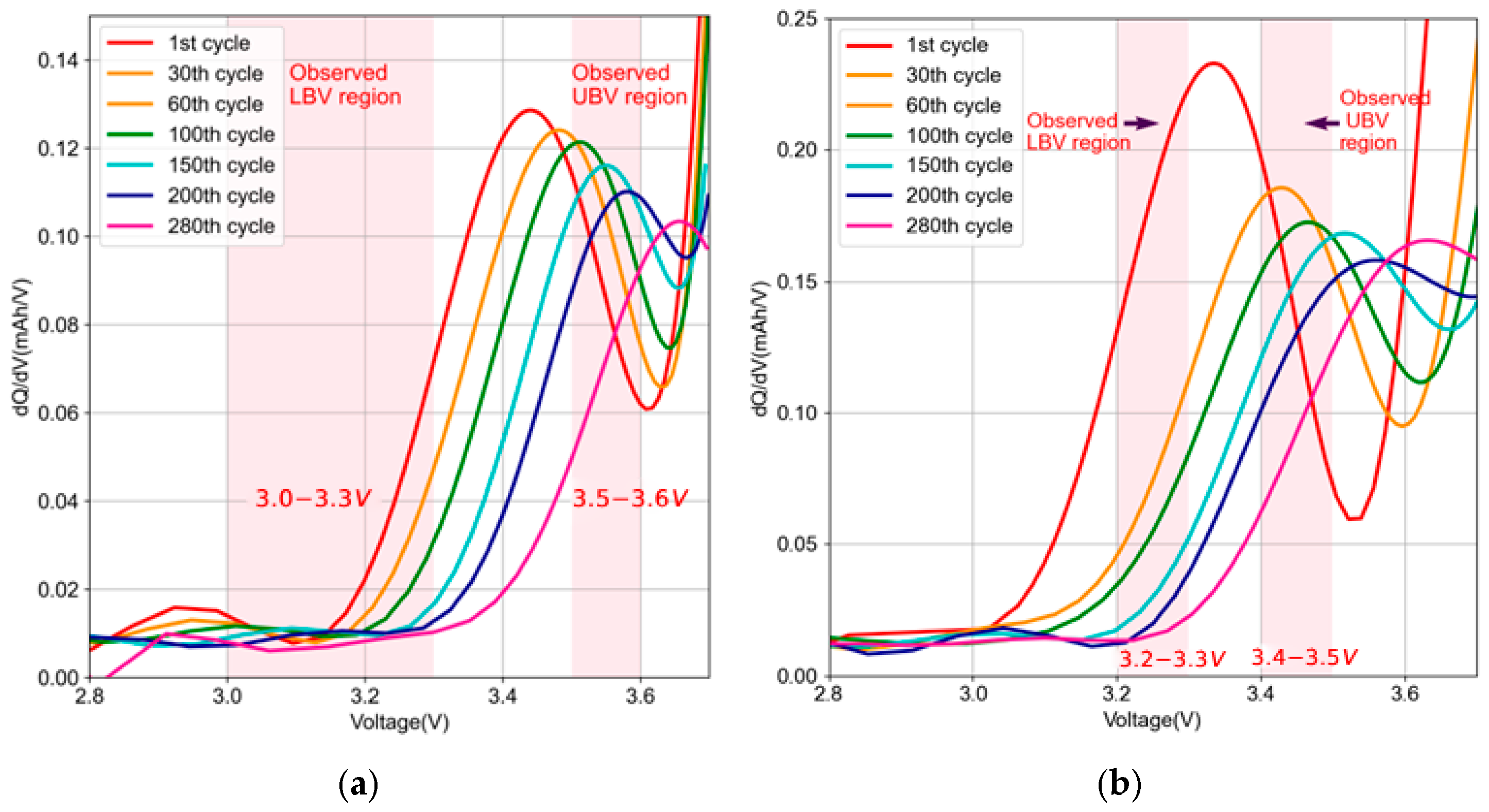

2.2. Feature Extraction from IC Curve

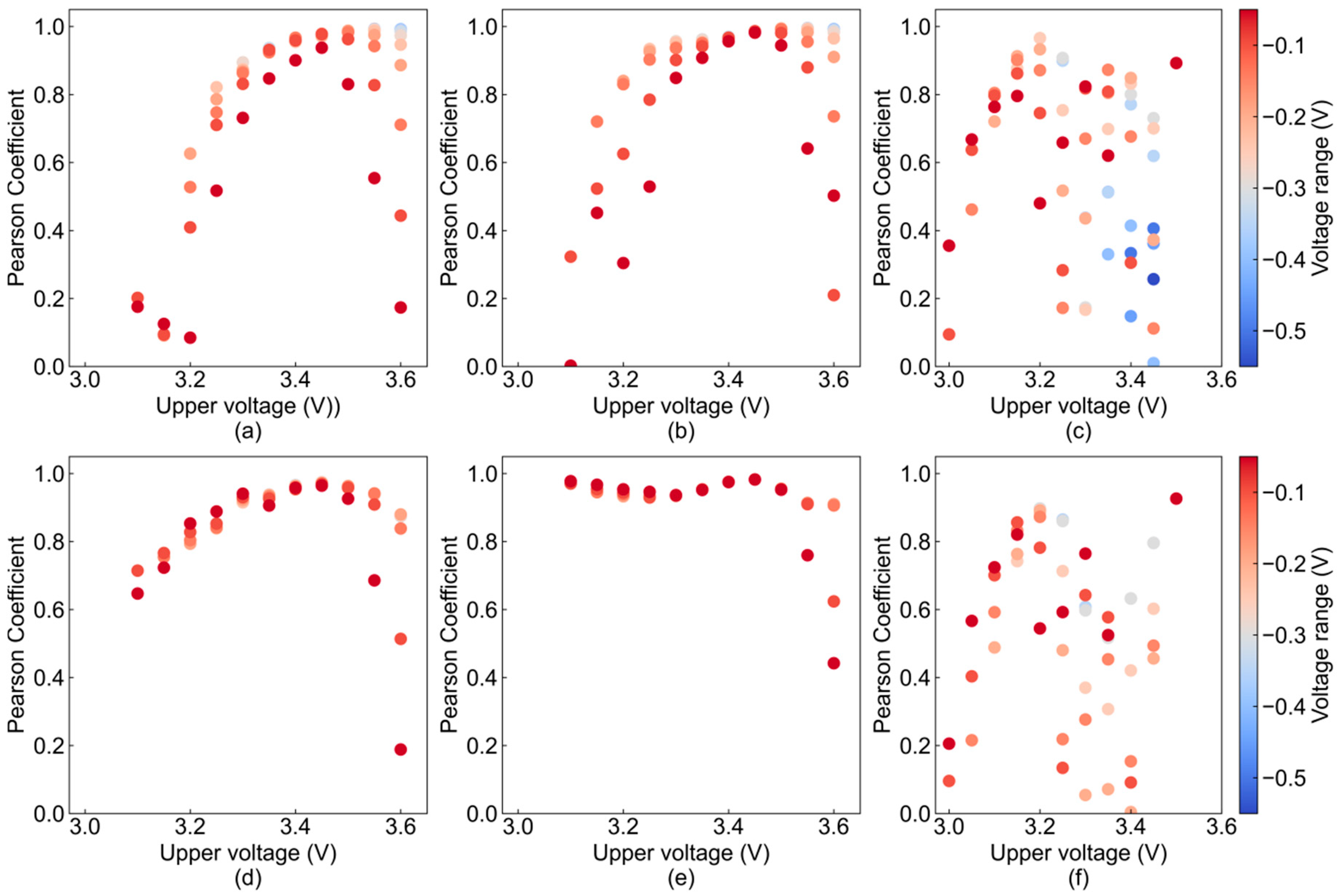

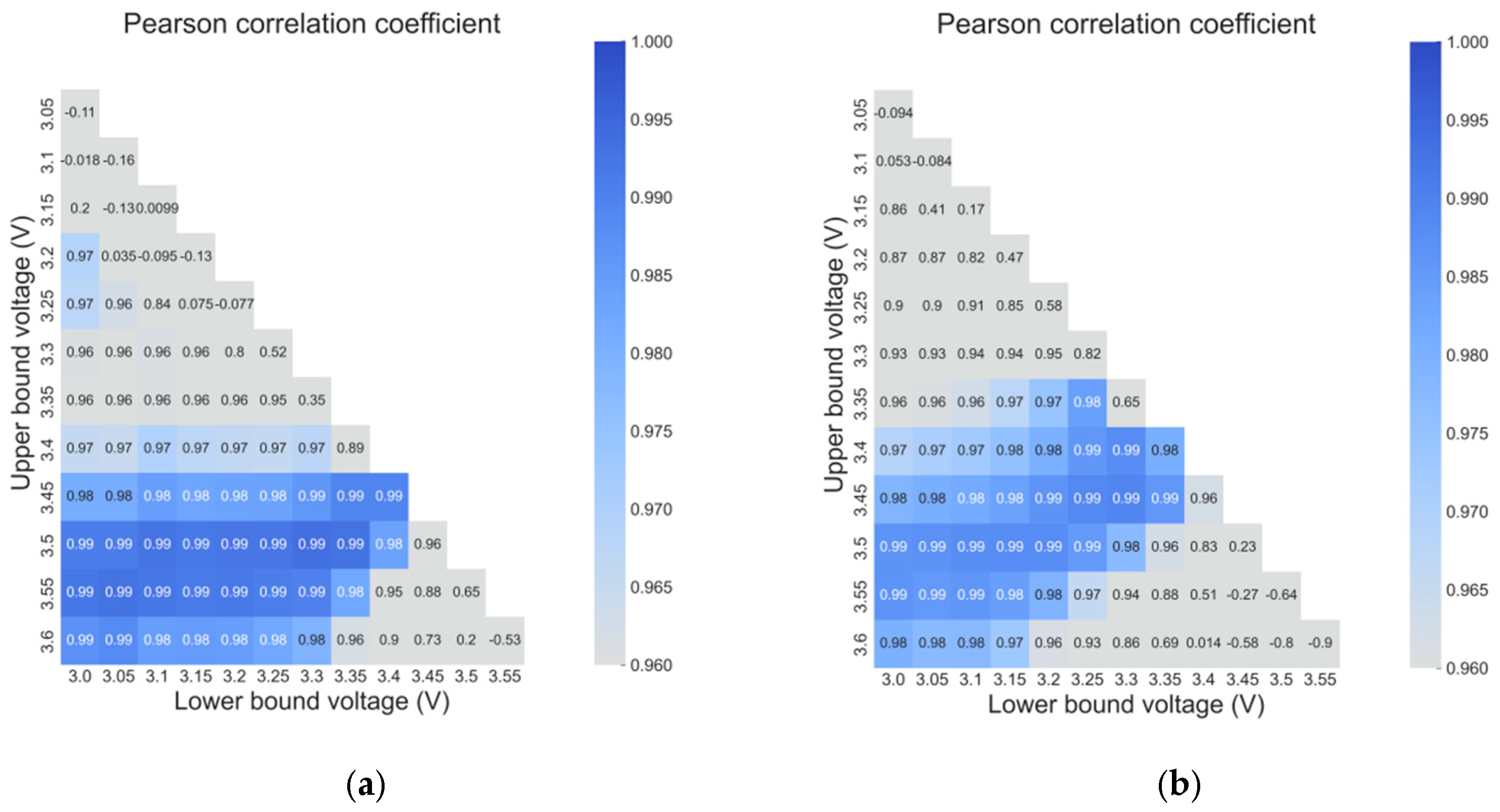

2.3. Voltage Range Determination

2.4. The Process of Establishing the SOH Estimation Model

2.5. Method and Evaluation

| Algorithm 1: The algorithm flow of DI4SHE | |

| Input: Battery charging data (voltage, current, capacity, time) | |

| Output: Estimated SOH | |

| ICA for HIs Extraction | |

| divide data into cycles(); first cycle = data [0]; IC_curve = diff(first_cycle.capacity) / diff(first_cycle.voltage); secondary_peak = find_secondary_peak(IC_curve); voltage_range = determine_voltage_range(secondary_peak); for each sub_range in voltage_range do SPA = calculate_area(sub_range); SPIC = find_max_IC(sub_range); correlation = calculate_PCC(SPA, SPIC, SOH); optimal_range = range_with_max_correlation; for each cycle in data do SPA[cycle] = calculate_area(optimal_range); SPIC[cycle] = find_max_IC(optimal_range); | |

| SB-LSTM for SOH Estimation | |

| model = creat SB-LSTM_model(); train_model(model, [SPA, SPIC], SOH_lable); data’ = data_online() for each cycle in data’ do SPA’ = calculate_area(optimal_range); SPIC’ = find_max_IC(optimal_range); estimated_SOH = model.predict([SPA’, SPIC’]); | |

3. Verification and Discussion

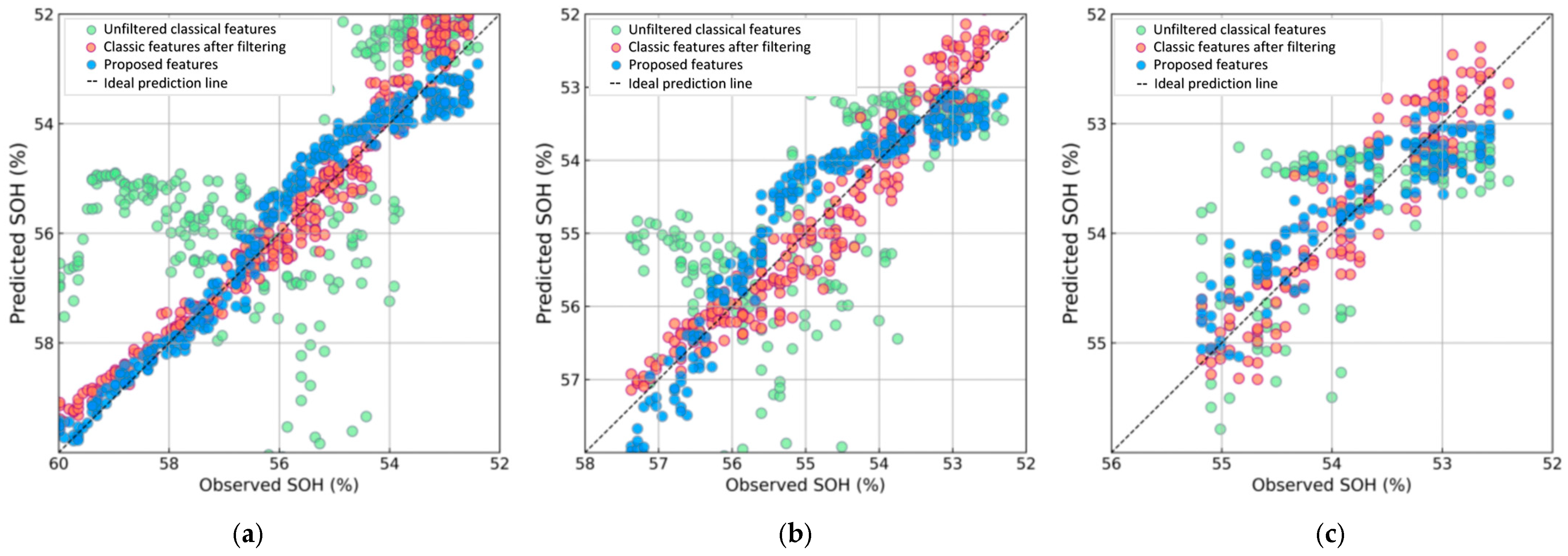

3.1. Feature Comparison Verification

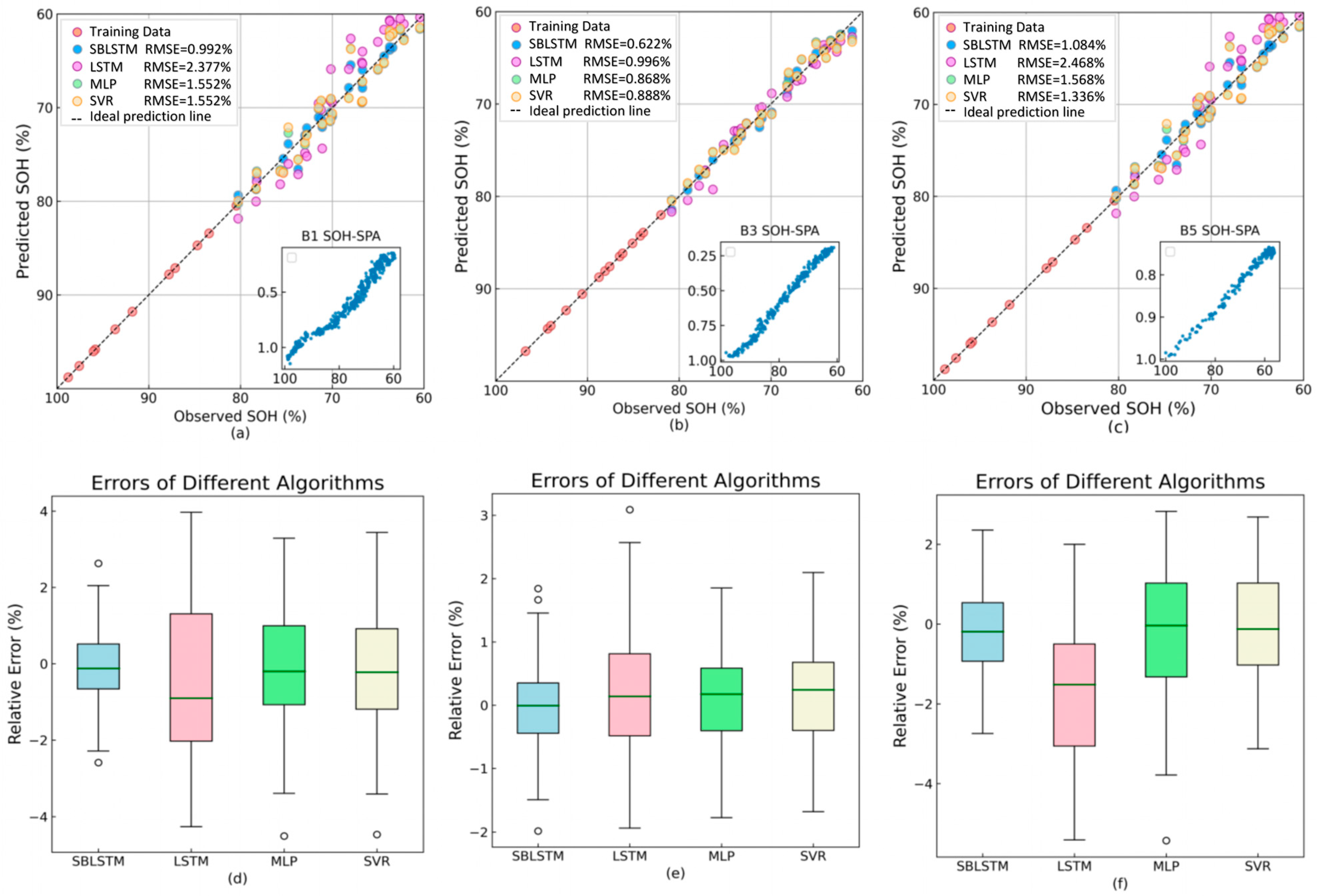

3.2. Figures, Tables and Schemes

3.3. Discussions and Future Work

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Acronyms | |

| BMS | battery management system |

| BP | back propagation |

| CT | constant current |

| DVA | differential voltage analysis |

| EIS | electrochemical impedance spectroscopy |

| EV | electric vehicle |

| HI | health indicator |

| ICA | incremental capacity analysis |

| LBV | lower bound voltage |

| LIBs | lithium-ion batteries |

| LLI | loss of lithium inventory |

| LSTM | long short-term memory |

| MAE | mean absolute error |

| ML | machine learning |

| MLP | multi-layer perceptron |

| OCV | open-circuit voltage |

| PCC | Pearson correlation coefficient |

| PSF | position of the secondary peak in the first cycle |

| RNN | recurrent neural network |

| SB | stacked bidirectional |

| SIBs | sodium-ion batteries |

| SOC | state of charge |

| SOH | state of health |

| SPIC | secondary peak of the incremental capacity curve |

| SPA | secondary peak area |

| SVR | support vector regression |

| UBV | upper bound voltage |

| RMSE | root mean square error |

References

- Song, T.; Yao, W.; Kiadkhunthod, P.; Zheng, Y.; Wu, N.; Zhou, X.; Tunmee, S.; Sattayaporn, S.; Tang, T. A low-cost and environmentally friendly mixed polyanionic cathode for sodium-ion storage. Angew. Chem. 2020, 132, 750–755. [Google Scholar] [CrossRef]

- Lan, Y.; Yao, W.; He, X.; Song, T.; Tang, Y. Mixed polyanionic compounds as positive electrodes for low-cost electrochemical energy storage. Angew. Chem. Int. Ed. Engl. 2020, 59, 9255–9262. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Gao, Y.; Liu, X.; Yang, Z.; He, X.; Li, L.; Qiao, Y.; Chen, W.; Zeng, R.; Wang, Y.; et al. Organic cathode materials for sodium-ion batteries: From fundamental research to potential commercial application. Adv. Funct. Mater. 2022, 32, 2107718. [Google Scholar] [CrossRef]

- Wu, Y.; Shuang, W.; Wang, Y.; Chen, F.; Tang, S.; Wu, X.-L.; Bai, Z.; Yang, L.; Zhang, J. Recent Progress in Sodium-Ion Batteries: Advanced Materials, Reaction Mechanisms and Energy Applications. Electrochem. Energy Rev. 2024, 7, 1–50. [Google Scholar] [CrossRef]

- Nekahi, A.; Reddy, A.K.M.R.; Li, X.; Deng, S.; Zaghib, K. Rechargeable Batteries for the Electrification of Society: Past, Present, and Future. Electrochem. Energy Rev. 2024, 8, 1–30. [Google Scholar] [CrossRef]

- Fan, E.; Li, L.; Wang, Z.; Lin, J.; Huang, Y.; Yao, Y.; Chen, R.; Wu, F. Sustainable recycling technology for Li-ion batteries and beyond: Challenges and future prospects. Chem. Rev. 2020, 120, 7020–7063. [Google Scholar] [CrossRef]

- Lu, L.; Han, X.; Li, J.; Hua, J.; Ouyang, M. A review on the key issues for lithium-ion battery management in electric vehicles. J. Power Sources 2013, 226, 272–288. [Google Scholar] [CrossRef]

- Hansen, T.; Wang, C.-J. Support vector based battery state of charge estimator. J. Power Sources 2005, 141, 351–358. [Google Scholar] [CrossRef]

- Tran, M.-K.; Cunanan, C.; Panchal, S.; Fraser, R.; Fowler, M. Investigation of individual cells replacement concept in lithium-ion battery packs with analysis on economic feasibility and pack design requirements. Processes 2021, 9, 2263. [Google Scholar] [CrossRef]

- Stroe, D.-I.; Świerczyński, M.; Stan, A.-I.; Teodorescu, R.; Andreasen, S.J. Accelerated lifetime testing methodology for lifetime estimation of lithium-ion batteries used in augmented wind power plants. IEEE Trans. Ind. Appl. 2014, 50, 4006–4017. [Google Scholar] [CrossRef]

- He, X.; Yan, Q.; He, H.; Shang, J.; Zhou, X.; Chanlek, N.; Tunmee, S.; Kidkhunthod, P.; Yao, W.; Tang, Y. A Vanadium-Based Fluoroxide Cathode Material for Lithium-Ion Storage with High Energy Density. Adv. Sustain. Syst. 2022, 6, 2200122. [Google Scholar] [CrossRef]

- Broussely, M.; Biensan, P.; Bonhomme, F.; Blanchard, P.; Herreyre, S.; Nechev, K.; Staniewicz, R. Main aging mechanisms in Li ion batteries. J. Power Sources 2005, 146, 90–96. [Google Scholar] [CrossRef]

- R-Smith, N.A.-Z.; Leitner, M.; Alic, I.; Toth, D.; Kasper, M.; Romio, M.; Surace, Y.; Jahn, M.; Kienberger, F.; Ebner, A.; et al. Assessment of lithium ion battery ageing by combined impedance spectroscopy, functional microscopy and finite element modelling. J. Power Sources 2021, 512, 230459. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, K.; Zhu, C.; Zhang, X.; Zhang, D. Co-Estimation of State-of-Charge and State-of- Health for Lithium-Ion Batteries Using an Enhanced Electrochemical Model. IEEE Trans. Ind. Electron. 2022, 69, 2684–2696. [Google Scholar] [CrossRef]

- Zheng, L.; Zhu, J.; Lu, D.D.-C.; Wang, G.; He, T. Incremental capacity analysis and differential voltage analysis based state of charge and capacity estimation for lithium-ion batteries. Energy 2018, 150, 759–769. [Google Scholar] [CrossRef]

- Dubarry, M.; Svoboda, V.; Hwu, R.; Liaw, B.Y. Incremental capacity analysis and close-to-equilibrium OCV measurements to quantify capacity fade in commercial rechargeable lithium batteries. Electrochem. Solid-State Lett. 2006, 9, A454–A457. [Google Scholar] [CrossRef]

- Yazami, R.; Touzain, P. A reversible graphite-lithium negative electrode for electrochemical generators. J. Power Sources 1983, 9, 365–371. [Google Scholar] [CrossRef]

- Dahn, J. Phase diagram of Li x C 6. Phys. Rev. B 1991, 44, 9170. [Google Scholar] [CrossRef]

- Yazami, R.; Reynier, Y. Thermodynamics and crystal structure anomalies in lithium-intercalated graphite. J. Power Sources 2006, 153, 312–318. [Google Scholar] [CrossRef]

- Dubarry, M.; Svoboda, V.; Hwu, R.; Liaw, B.Y. A roadmap to understand battery performance in electric and hybrid vehicle operation. J. Power Sources 2007, 174, 366–372. [Google Scholar] [CrossRef]

- Dubarry, M.; Liaw, B.Y. Identify capacity fading mechanism in a commercial LiFePO4 cell. J. Power Sources 2009, 194, 541–549. [Google Scholar] [CrossRef]

- Weng, C.; Cui, Y.; Sun, J.; Peng, H. On-board state of health monitoring of lithium-ion batteries using incremental capacity analysis with support vector regression. J. Power Sources 2013, 235, 36–44. [Google Scholar] [CrossRef]

- Stroe, D.-I.; Schaltz, E. Lithium-ion battery state-of-health estimation using the incremental capacity analysis technique. IEEE Trans. Ind. Appl. 2019, 56, 678–685. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Y.; Wang, J.; Zhang, T. State-of-health estimation for lithium-ion batteries by combining model-based incremental capacity analysis with support vector regression. Energy 2022, 239, 121986. [Google Scholar] [CrossRef]

- Dubarry, M.; Liaw, B.Y.; Chen, M.-S.; Chyan, S.-S.; Han, K.-C.; Sie, W.-T.; Wu, S.-H. Identifying battery aging mechanisms in large format Li ion cells. J. Power Sources 2011, 196, 3420–3425. [Google Scholar] [CrossRef]

- Bian, X.; Liu, L.; Yan, J. A model for state-of-health estimation of lithium ion batteries based on charging profiles. Energy 2019, 177, 57–65. [Google Scholar] [CrossRef]

- Lin, C.; Xu, J.; Shi, M.; Mei, X. Constant current charging time based fast state-of-health estimation for lithium-ion batteries. Energy 2022, 247, 123556. [Google Scholar] [CrossRef]

- Bian, C.; He, H.; Yang, S. Stacked bidirectional long short-term memory networks for state-of-charge estimation of lithium-ion batteries. Energy 2020, 191, 116538. [Google Scholar] [CrossRef]

- Hewamalage, H.; Bergmeir, C.; Bandara, K. Recurrent neural networks for time series forecasting: Current status and future directions. Int. J. Forecast. 2021, 37, 388–427. [Google Scholar] [CrossRef]

- Xiong, R.; Sun, Y.; Wang, C.; Tian, J.; Chen, X.; Li, H.; Zhang, Q. A data-driven method for extracting aging features to accurately predict the battery health. Energy Storage Mater. 2023, 57, 460–470. [Google Scholar] [CrossRef]

- Wang, Y.; Hou, B.; Guo, J.; Ning, Q.; Pang, W.; Wang, J.; Lü, C.; Wu, X. An ultralong lifespan and low-temperature workable sodium-ion full battery for stationary energy storage. Adv. Energy Mater. 2018, 8, 1703252. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, W.; Wang, W.; Wang, S.; Li, B. Comprehensive review of P2-type Na2/3Ni1/3Mn2/3O2, a potential cathode for practical application of Na-ion batteries. ACS Appl. Mater. Interfaces 2019, 11, 22051–22066. [Google Scholar] [CrossRef] [PubMed]

- Xiang, H.; Wang, Y.; Li, K.; Zhang, X.; Chen, Z. A comprehensive study on state-of-charge and state-of-health estimation of sodium-ion batteries. J. Energy Storage 2023, 72, 108314. [Google Scholar] [CrossRef]

- You, G.-W.; Park, S.; Oh, D. Real-time state-of-health estimation for electric vehicle batteries: A data-driven approach. Appl. Energy 2016, 176, 92–103. [Google Scholar] [CrossRef]

- Bai, G.; Su, Y.; Rahman, M.M.; Wang, Z. Prognostics of Lithium-Ion batteries using knowledge-constrained machine learning and Kalman filtering. Reliab. Eng. Syst. Saf. 2023, 231, 108944. [Google Scholar] [CrossRef]

- Wen, J.; Chen, X.; Li, X.; Li, Y. SOH prediction of lithium battery based on IC curve feature and BP neural network. Energy 2022, 261, 125234. [Google Scholar] [CrossRef]

- Lin, M.; Wu, D.; Meng, J.; Wu, J.; Wu, H. A multi-feature-based multi-model fusion method for state of health estimation of lithium-ion batteries. J. Power Sources 2022, 518, 230774. [Google Scholar] [CrossRef]

- Driscoll, L.; de la Torre, S.; Gomez-Ruiz, J.A. Feature-based lithium-ion battery state of health estimation with artificial neural networks. J. Energy Storage 2022, 50, 104584. [Google Scholar] [CrossRef]

- Zhou, P.; Zhang, J.; Che, Z.; Quan, Z.; Duan, J.; Wu, X.; Weng, J.; Zhao, J.; Zhou, J. Insights into the enhanced structure stability and electrochemical performance of Ti4+/F− co-doped P2-Na0.67Ni0.33Mn0.67O2 cathodes for sodium ion batteries at high voltage. J. Energy Chem. 2022, 67, 655–662. [Google Scholar] [CrossRef]

| Cell Type | Coin-Type Half-Cell (B1) | Coin-Type Half-Cell (B2) | Coin-Type Half-Cell (B3) | ||

| Cathode | Na2/3Ni1/3Mn15/30Ti5/30O2 | Na2/3Ni1/3Mn15/30Ti5/30O2 | Na2/3Ni1/3Mn2/3O1.95F0.05 | ||

| Anode | sodium–metal | sodium–metal | sodium–metal | ||

| Electrolyte | 1 M NaClO4 in PC and FEC (V/V = 95:5) | 1 M NaClO4 in PC and FEC (V/V = 95:5) | 1 M NaClO4 in PC and FEC (V/V = 95:5) | ||

| Separator | Glassfiber | Glassfiber | Glassfiber | ||

| Standard specific capacity | 1 C = 173 mA g−1 | 1 C = 173 mA g−1 | 1 C = 173 mA g−1 | ||

| Voltage window | 1.5–4.1 V | 1.5–4.1 V | 1.5–4.1 V | ||

| Charge–discharge method | Galvanostatic charge–discharge | Galvanostatic charge–discharge | Galvanostatic charge–discharge | ||

| Current density | 2C | 1C | 1C | ||

| Test temperature | 25 °C | 25 °C | 25 °C | ||

| Cell type | Coin-Type Full-Cell (B4) | Coin-Type Full-Cell (B5) | |||

| Cathode | Na2/3Ni1/3Mn2/3O2 | Na2/3Ni1/3Mn17/30Ti3/30O1.95F0.05 | |||

| Anode | Hard carbon | Hard carbon | |||

| Electrolyte | 1 M NaClO4 in PC and FEC (V/V = 95:5) | 1 M NaClO4 in PC and FEC (V/V = 95:5) | |||

| Separator | Glassfiber | Glassfiber | |||

| Standard specific capacity | 1 C = 173 mA g−1 | 1 C = 173 mA g−1 | |||

| Voltage window | 1.5–3.6 V | 1.5–3.6 V | |||

| Charge–discharge method | Galvanostatic charge–discharge | Galvanostatic charge–discharge | |||

| Current density | 5 C | 5 C | |||

| Test temperature | 25 °C | 25 °C | |||

| Training Using Proposed Features | Training Using Filtered Classic Features | |||||

| 30% Data | 50% Data | 70% Data | 30% Data | 50% Data | 70% Data | |

| MAE | 1.095% | 0.826% | 0.626% | 2.629% | 2.695% | 2.009% |

| RMSE | 1.361% | 1.068% | 0.780% | 3.396% | 3.478% | 2.682% |

| 0.914 | 0.866 | 0.824 | 0.467 | −0.420 | −1.088 | |

| Trained with Proposed Features | Trained with Filtered Classic Features | Trained with Unfiltered Features | |||||||

| 30% Data | 50% Data | 70% Data | 30% Data | 50% Data | 70% Data | 30% Data | 50% Data | 70% Data | |

| MAE | 0.381% | 0.446% | 0.312% | 0.402% | 0.287% | 0.254% | 1.833% | 0.944% | 0.573% |

| RMSE | 0.460% | 0.523% | 0.367% | 0.517% | 0.360% | 0.313% | 2.794% | 1.325% | 0.753% |

| 0.956 | 0.858 | 0.784 | 0.944 | 0.933 | 0.843 | −0.623 | 0.088 | 0.091 | |

| SB-LSTM | LSTM | MLP | SVR | ||

| B1 | MAE (%) RMSE (%) | 0.693 0.861 0.976 | 1.825 2.053 0.866 | 1.139 1.374 0.940 | 1.171 1.405 0.937 |

| B2 | MAE (%) RMSE (%) | 0.801 1.013 0.931 | 1.174 1.454 0.865 | 1.087 1.330 0.882 | 0.945 1.191 0.905 |

| B3 | MAE (%) RMSE (%) | 0.496 0.635 0.986 | 0.758 0.922 0.971 | 0.623 0.761 0.980 | 0.649 0.799 0.978 |

| B5 | MAE (%) RMSE (%) | 0.849 1.054 0.962 | 1.971 2.457 0.796 | 1.324 1.653 0.907 | 1.098 1.302 0.942 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Zhou, B.; Xu, H.; Xu, S.; Wan, T.; Sun, W.; Guo, Y.; Ying, Z.; Yao, W.; Yang, Z. DI4SHE: Deep Learning via Incremental Capacity Analysis for Sodium Battery State-of-Health Estimation. Energies 2025, 18, 2792. https://doi.org/10.3390/en18112792

Wang X, Zhou B, Xu H, Xu S, Wan T, Sun W, Guo Y, Ying Z, Yao W, Yang Z. DI4SHE: Deep Learning via Incremental Capacity Analysis for Sodium Battery State-of-Health Estimation. Energies. 2025; 18(11):2792. https://doi.org/10.3390/en18112792

Chicago/Turabian StyleWang, Xikang, Bangyu Zhou, Huan Xu, Song Xu, Tao Wan, Wenjie Sun, Yuanjun Guo, Zuobin Ying, Wenjiao Yao, and Zhile Yang. 2025. "DI4SHE: Deep Learning via Incremental Capacity Analysis for Sodium Battery State-of-Health Estimation" Energies 18, no. 11: 2792. https://doi.org/10.3390/en18112792

APA StyleWang, X., Zhou, B., Xu, H., Xu, S., Wan, T., Sun, W., Guo, Y., Ying, Z., Yao, W., & Yang, Z. (2025). DI4SHE: Deep Learning via Incremental Capacity Analysis for Sodium Battery State-of-Health Estimation. Energies, 18(11), 2792. https://doi.org/10.3390/en18112792