Numerical Simulation of a 330 MW Tangentially Fired Boiler by a Model Coupling CFD and Hydrodynamic Calculation

Abstract

1. Introduction

2. Materials and Methods

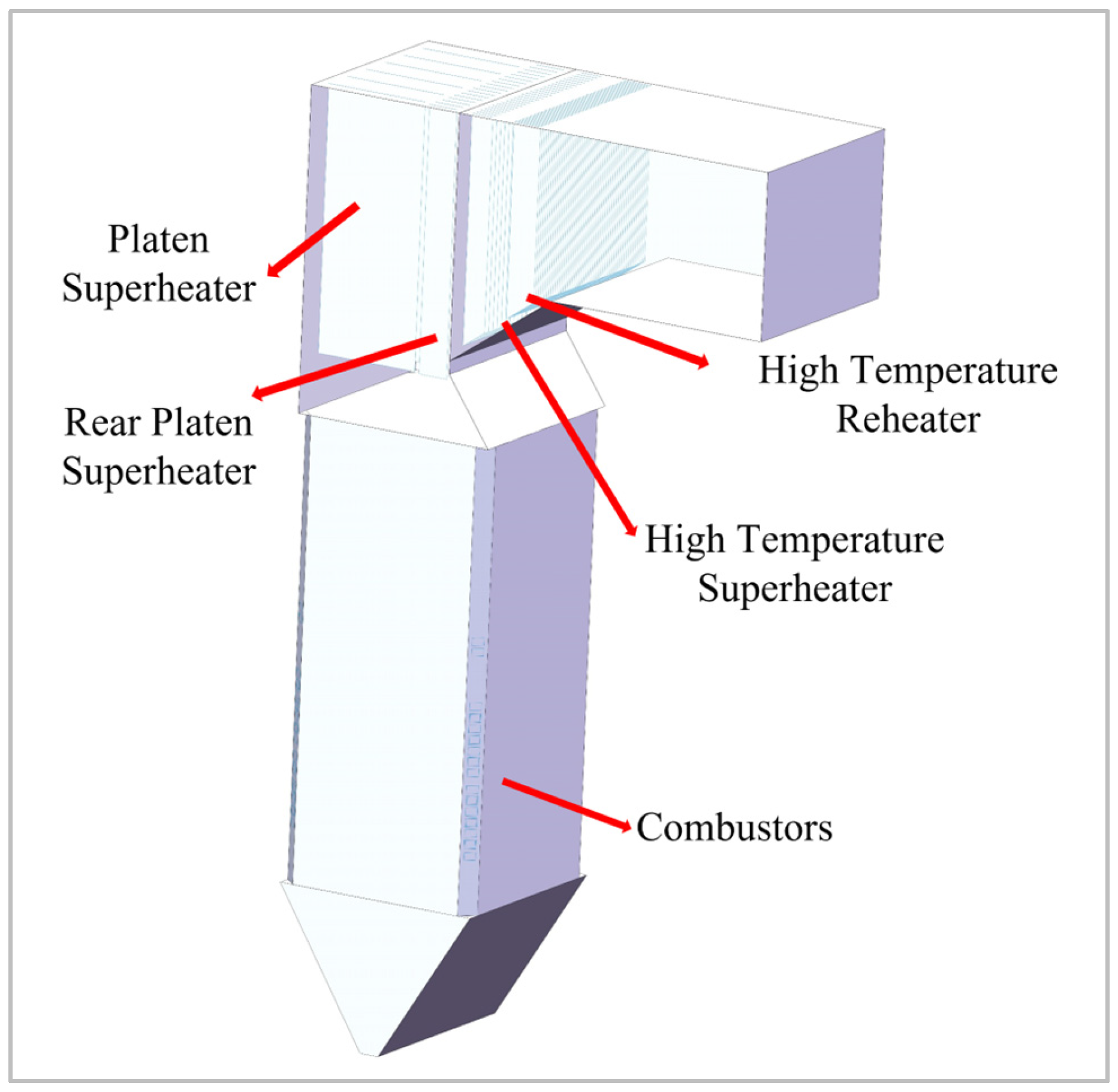

2.1. Research Object

2.2. CFD Numerical Simulation Method

2.2.1. Physical Modeling and Meshing

2.2.2. Numerical Modeling

2.2.3. Boundary Conditions

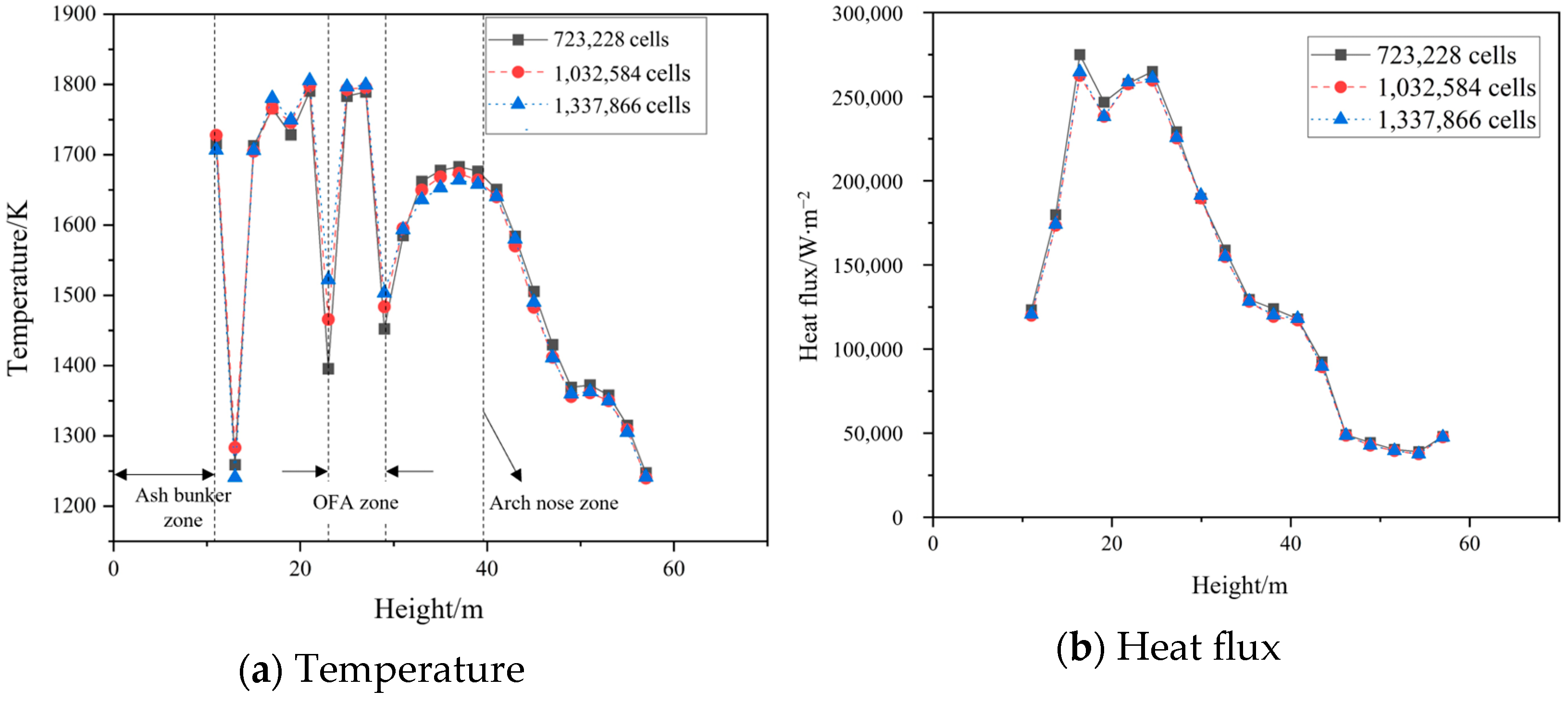

2.2.4. Mesh Independence Verification

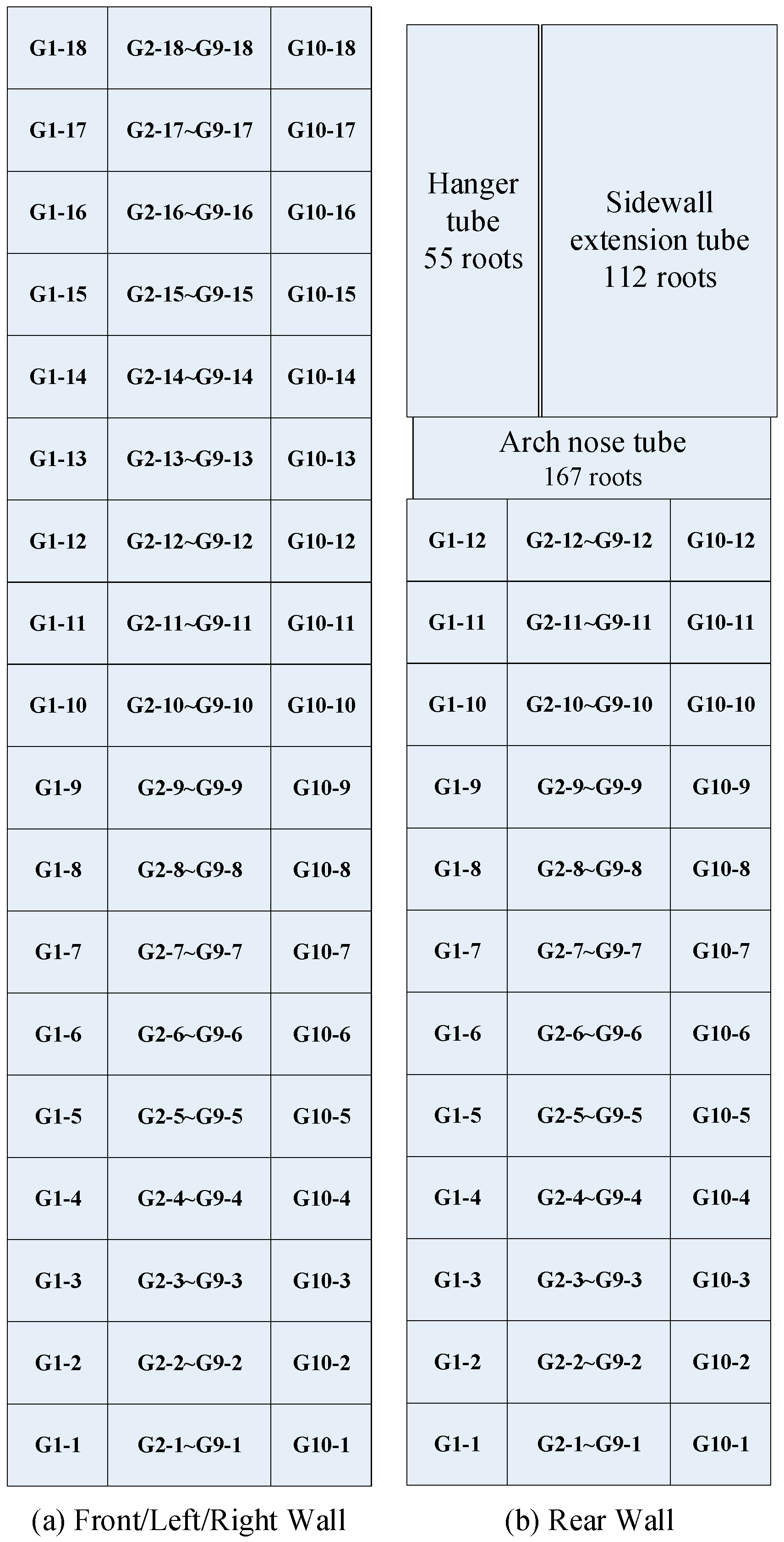

2.3. Hydrodynamic Calculation Model

2.4. Sulfide Formation Model

2.5. Coupled Model

2.6. Model Verification

3. Results and Discussion

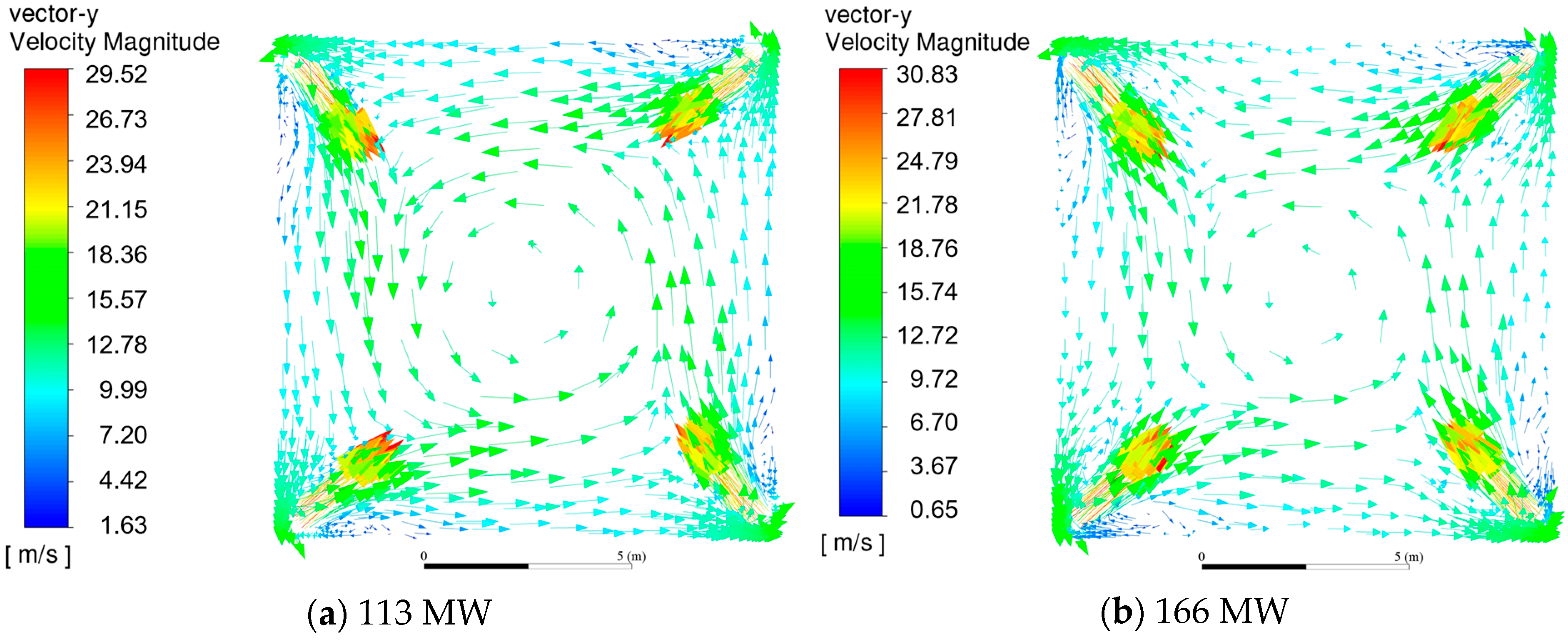

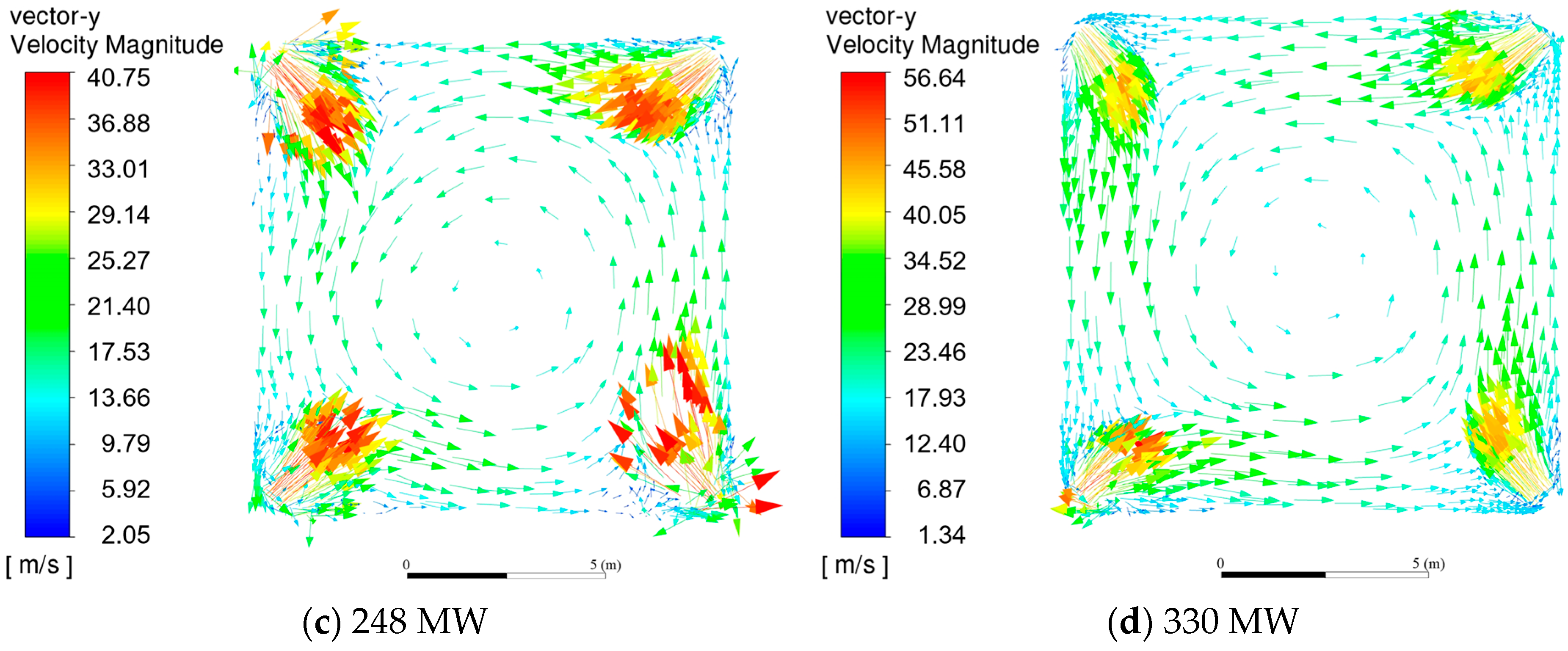

3.1. Flue Gas Field

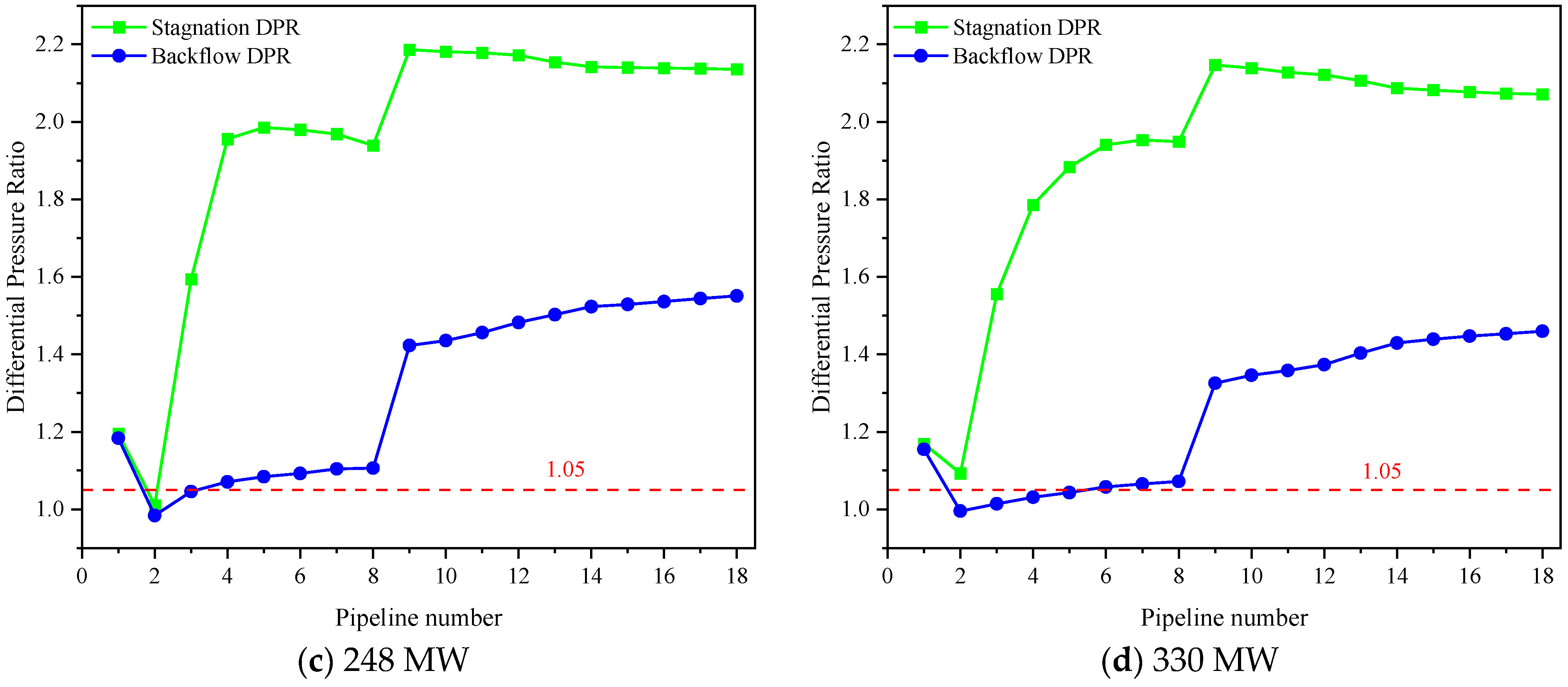

3.2. Hydrodynamic Safety Inspection

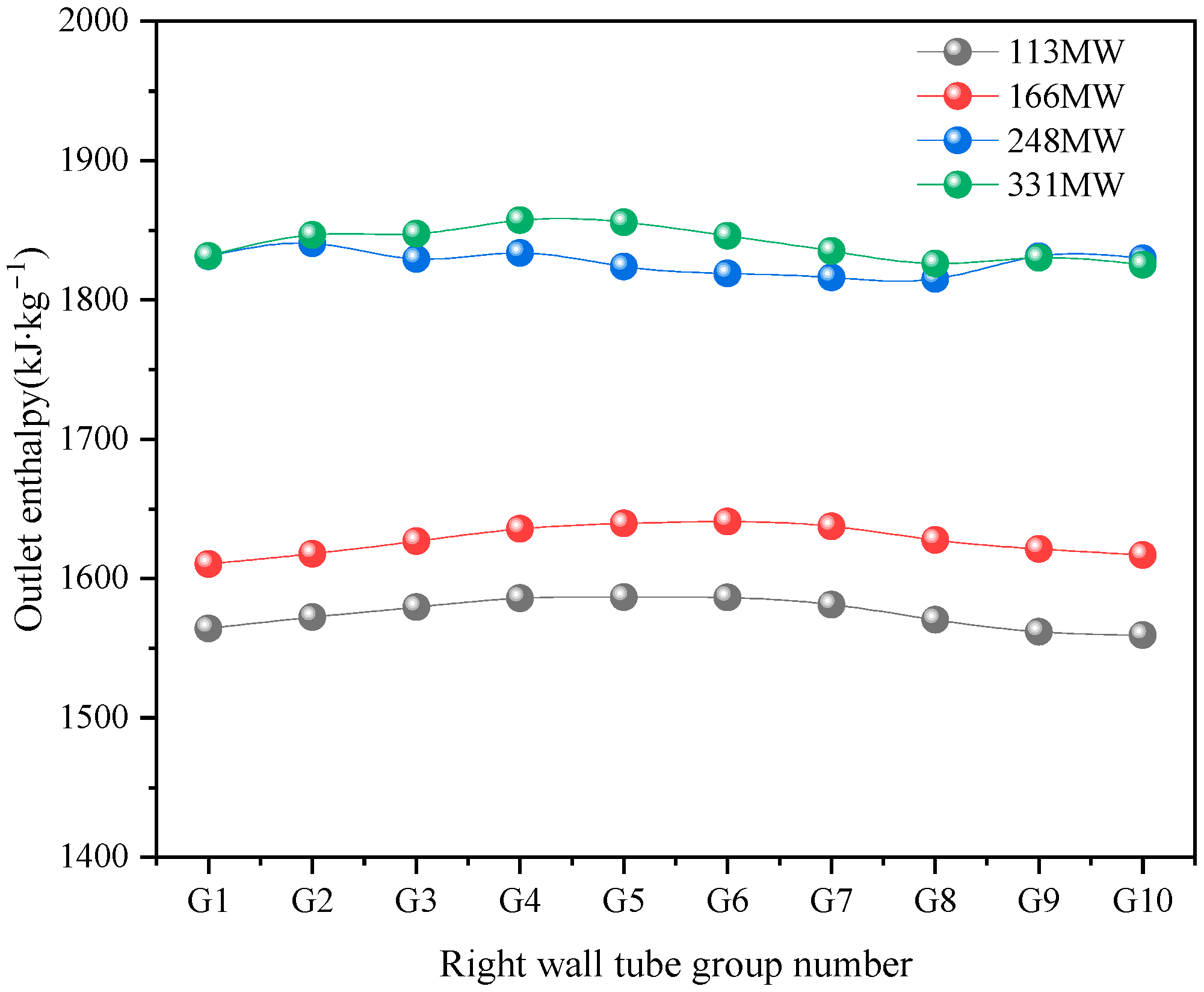

3.3. Hydrodynamic Analysis

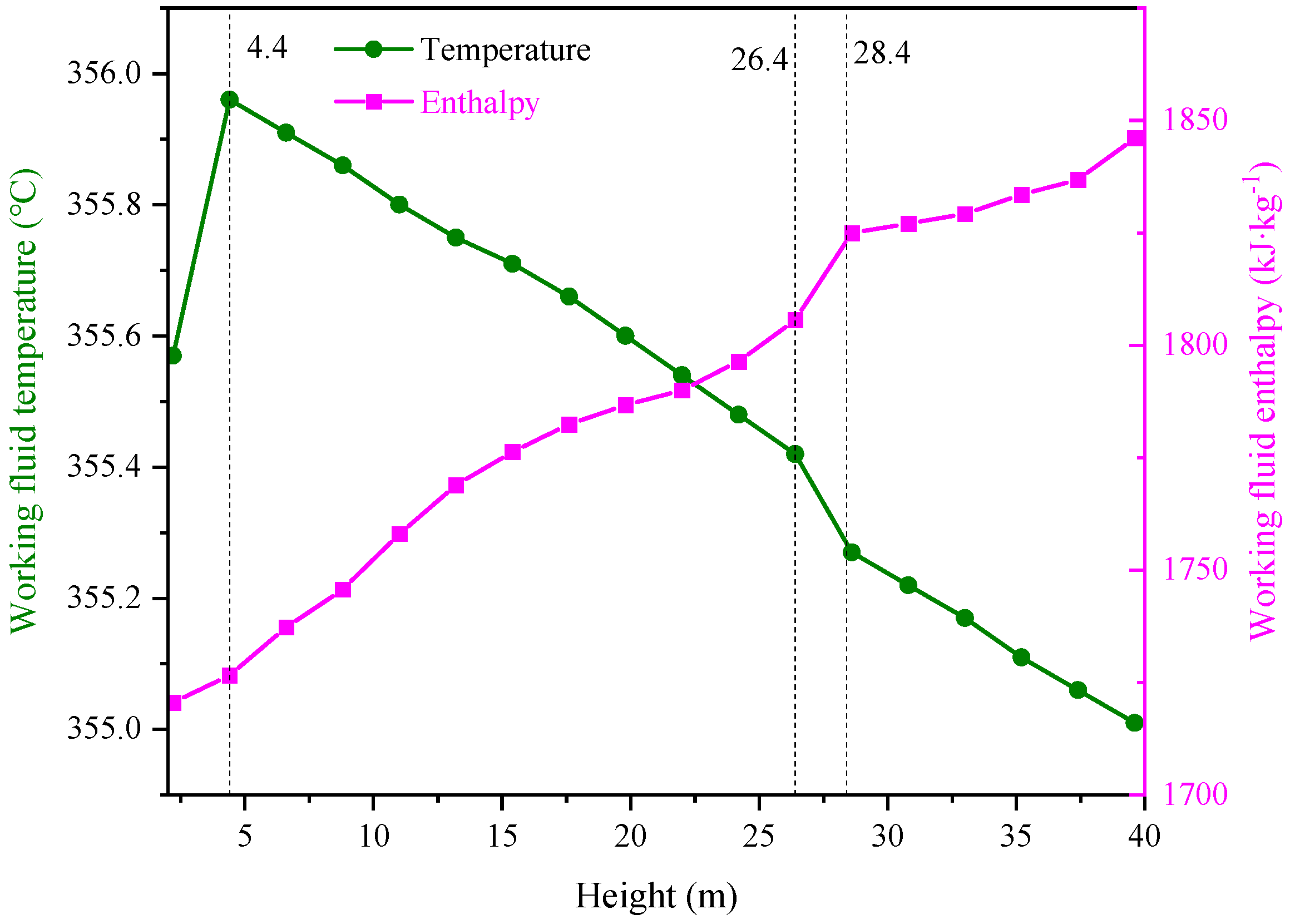

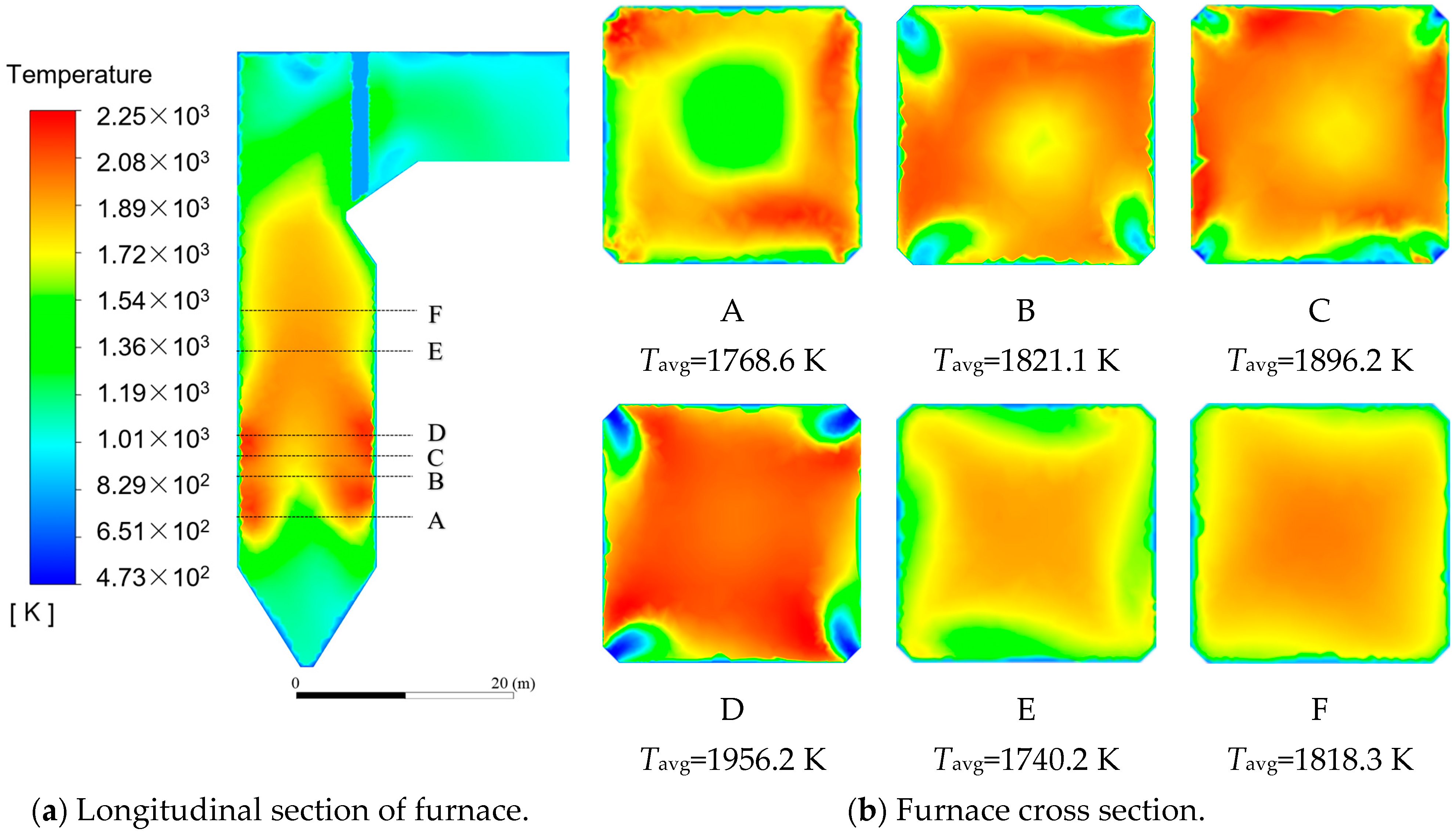

3.4. Temperature Distribution Inside the Furnace

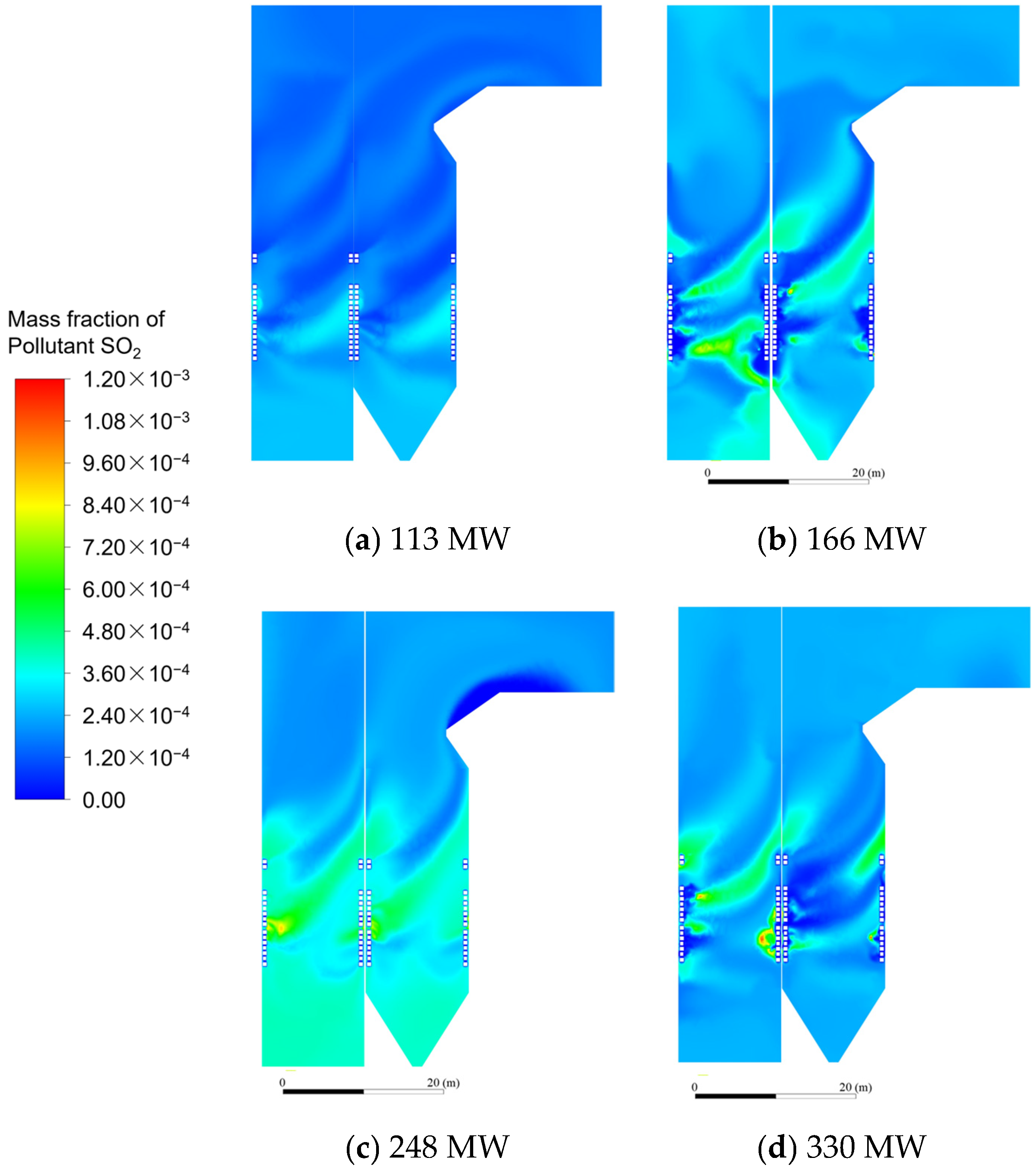

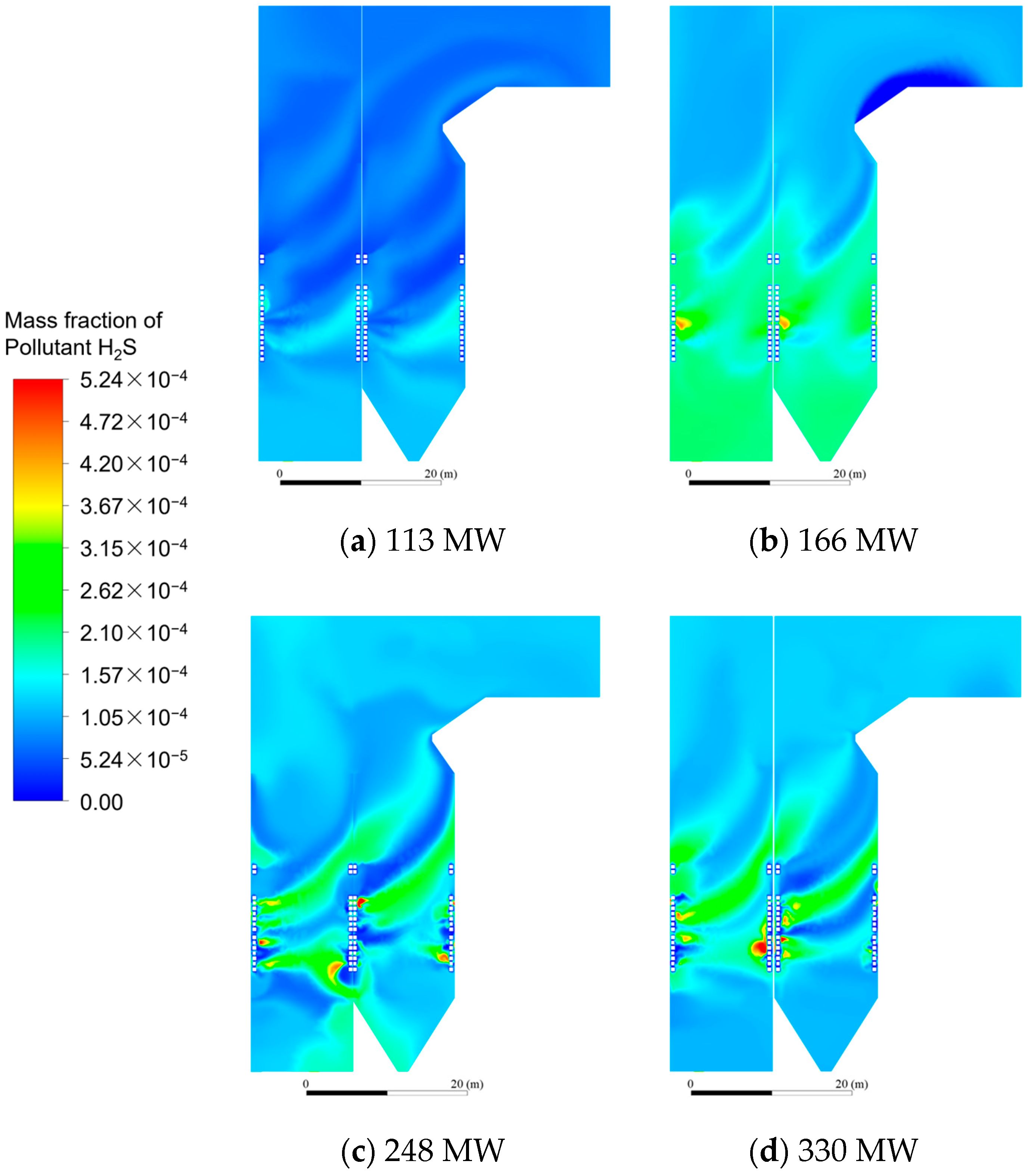

3.5. High Temperature Corrosion

4. Conclusions

- (1)

- The flue gas in the furnace can form a tangent circle under different loads, and the furnace is full. At low loads (113 MW, 166 MW), the swirl intensity of the airflow is low, and the jet deflection of the burner is not obvious. At high loads (248 MW, 330 MW), the trend of air flow rotation is enhanced. In particular, at 330 MW load, the risk of flame scouring the water wall is significantly increased. It is recommended to balance combustion stability and safety by optimizing the imaginary tangent circle diameter.

- (2)

- Due to the weakest heating of the right wall G1 tube group, the stagnation and reversal DPR of the local tubeline is close to the critical value of 1.0, but the overall DPR (stagnation DPR ≥ 1.85, reversal DPR ≥ 1.22) is higher than the safety threshold of 1.05, indicating that there is no flow anomaly in the water wall circuit under the current design. It is recommended to further improve safety by reducing the flow resistance of the loop or optimizing the design of the downcomer.

- (3)

- Under high load (330 MW), the working fluid of the G6 tube group undergoes heating, evaporation, and overheating stages along the furnace height, and the outlet dryness reaches 0.159. The temperature and pressure changes of the working fluid conform to the characteristics of the natural circulation boiler. The local temperature rises sharply after the secondary air is added, indicating that the combustion structure has a significant effect on the heat transfer characteristics of the water wall.

- (4)

- The temperature of the cross sections exhibits a typical tangential distribution, and the temperature gradient in the burner area is the largest (up to 1956.2 K). However, the cross-section D shows that there is a local high temperature zone (>1900 K) in the middle of the walls on both sides, which may cause coking and HTC. It is recommended to mitigate the risk by optimizing the secondary air ratio or strengthening the wall blowing.

- (5)

- The mass fractions of SO2 and H2S, as the primary sulfide species responsible for high-temperature corrosion, show a positive correlation with boiler load. At 330 MW operating conditions, maximum concentrations of SO2 (0.120%) and H2S (0.0524%) are observed near combustor nozzles and in the secondary air zones, respectively. Local reducing atmospheres are found to enhance H2S formation. Implementing auxiliary air injection in secondary air regions may effectively mitigate corrosive gas accumulation while maintaining combustion efficiency.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- The National Energy Administration Released the National Power Industry Statistics for 2024—National Energy Administration. Available online: https://www.nea.gov.cn/20250121/097bfd7c1cd3498897639857d86d5dac/c.html (accessed on 7 March 2025).

- Renewable Energy Grid-Connected Operation in 2024—National Energy Administration. Available online: https://www.nea.gov.cn/20250221/e10f363cabe3458aaf78ba4558970054/c.html (accessed on 7 March 2025).

- Zhu, M.X.; Lu, H.; Zhao, W.J.; Huang, S.W.; Chang, X.Q.; Dong, L.J.; Kong, D.; Jing, X.H. A Numerical Study of Ash Deposition Characteristics in a 660MW Supercritical Tangential Boiler. Adv. Theor. Simul. 2023, 6, 2300133. [Google Scholar] [CrossRef]

- Belosevic, S.; Tomanovic, I.; Crnomarkovic, N.; Milicevic, A. Full-scale CFD investigation of gas-particle flow, interactions and combustion in tangentially fired pulverized coal furnace. Energy 2019, 179, 1036–1053. [Google Scholar] [CrossRef]

- Wang, H.P.; Deng, S.S.; Ti, S.G.; Jin, H.Z.; Yang, Z.; Gao, K.; Wu, X.H.; Liu, S.Y.; An, J.X.; Sheng, R.R. Experimental combustion characteristics and NOx emissions for a 600-MWe utility boiler after the retrofitted: Effects of load variation. Asia-Pac. J. Chem. Eng. 2024, 19, e3092. [Google Scholar] [CrossRef]

- Liu, P.; Zhang, W.; Chu, W.; Zhou, M. Combustion modification of expanded coal adaptability in ultra-small section circle-fired boiler. Clean Coal Technol. 2024, 30, 111–122, (In Chinese with English Abstract). [Google Scholar]

- Liu, T.; Wang, Y.G.; Zou, L.; Bai, Y.Y.; Shen, T.; Wei, Y.W.; Li, F.X.; Zhao, Q.X. Numerical investigation of stable combustion at ultra-low load for a 350 MW wall tangentially fired pulverized-coal boiler: Effect of burner adjustments and methane co-firing. Appl. Therm. Eng. 2024, 246, 122980. [Google Scholar] [CrossRef]

- Ma, D.F.; Zhang, S.Y.; He, X.; Zhang, J.; Ding, X. Combustion stability and NOx emission characteristics of a 300 MWe tangentially fired boiler under ultra-low loads with deep-air staging. Energy 2023, 269, 126795. [Google Scholar] [CrossRef]

- Jiang, Y.; Lee, B.H.; Oh, D.H.; Jeon, C.H. Influence of various air-staging on combustion and NOx emission characteristics in a tangentially fired boiler under the 50% load condition. Energy 2022, 244, 123167. [Google Scholar] [CrossRef]

- Wang, H.P.; Jin, H.Z.; Yang, Z.; Deng, S.S.; Wu, X.H.; An, J.X.; Sheng, R.R.; Ti, S.G. CFD modeling of flow, combustion and NOx emission in a wall-fired boiler at different low-load operating conditions. Appl. Therm. Eng. 2024, 236, 121824. [Google Scholar] [CrossRef]

- Wang, Y.; He, Y.; Weng, W.B.; Wang, Z.H. Numerical simulation of ammonia combustion with coal in a 135 MW tangentially fired boiler. Fuel 2024, 370, 131831. [Google Scholar] [CrossRef]

- Chen, X.; Liu, X.; Deng, C.B.; Fan, C.N. Numerical Simulation Study on Boiler Combustion Characteristics with Different Volume Fraction of Ventilation Air Methane. J. Energy Resour. Technol. 2022, 144, 112304. [Google Scholar] [CrossRef]

- Yuan, M.B.; Deng, L.; Liu, H.; Wu, Y.; Liang, Y.; Belosevic, S.; Tomanovic, I.; Che, D.F. Numerical investigation on H2S formation characteristics in air-staging combustion of a tangentially coal-fired boiler. Energy Sources Part A 2022, 44, 1854–1863. [Google Scholar] [CrossRef]

- Modlinski, N.; Janda, T. Mathematical procedure for predicting tube metal temperature in the radiant superheaters of a tangentially and front fired utility boilers. Therm. Sci. Eng. Prog. 2023, 40, 101763. [Google Scholar] [CrossRef]

- Liu, Y.C.; Fan, W.D.; Li, Y. Numerical investigation of air-staged combustion emphasizing char gasification and gas temperature deviation in a large-scale, tangentially fired pulverized-coal boiler. Appl. Energy 2016, 177, 323–334. [Google Scholar] [CrossRef]

- Guo, J.J.; Liu, Z.H.; Wang, P.; Huang, X.H.; Li, J.; Xu, P.; Zheng, C.G. Numerical investigation on oxy-combustion characteristics of a 200 MWe tangentially fired boiler. Fuel 2015, 140, 660–668. [Google Scholar] [CrossRef]

- Liu, H.; Wang, Y.K.; Zhang, W.; Wang, H.; Deng, L.; Che, D.F. Coupled modeling of combustion and hydrodynamics for a 1000MW double-reheat tower-type boiler. Fuel 2019, 255, 115722. [Google Scholar] [CrossRef]

- Wu, X.F.; Fan, W.D.; Liu, Y.C.; Bian, B. Numerical simulation research on the unique thermal deviation in a 1000 MW tower type boiler. Energy 2019, 173, 1006–1020. [Google Scholar] [CrossRef]

- Edge, P.J.; Heggs, P.J.; Pourkashanian, M.; Williams, A. An integrated computational fluid dynamics-process model of natural circulation steam generation in a coal-fired power plant. Comput. Chem. Eng. 2011, 35, 2618–2631. [Google Scholar] [CrossRef]

- Park, H.Y.; Faulkner, M.; Turrell, M.D.; Stopford, P.J.; Kang, D.S. Coupled fluid dynamics and whole plant simulation of coal combustion in a tangentially-fired boiler. Fuel 2010, 89, 2001–2010. [Google Scholar] [CrossRef]

- Yu, C.; Xiong, W.; Ma, H.; Zhou, J.; Si, F.; Jiang, X.; Fang, X. Numerical investigation of combustion optimization in a tangential firing boiler considering steam tube overheating. Appl. Therm. Eng. 2019, 154, 87–101. [Google Scholar] [CrossRef]

- Bhutta, M.; Hayat, N.; Bashir, M.H.; Khan, A.R.; Ahmad, K.N.; Khan, S. CFD applications in various heat exchangers design: A review. Appl. Therm. Eng. 2012, 32, 1–12. [Google Scholar] [CrossRef]

- Gromke, C.; Buccolieri, R.; Di Sabatino, S.; Ruck, B. Dispersion study in a street canyon with tree planting by means of wind tunnel and numerical investigations—Evaluation of CFD data with experimental data. Atmos. Environ. 2008, 42, 8640–8650. [Google Scholar] [CrossRef]

- Mahmoodi, B.; Hosseini, S.H.; Ahmadi, G.; Raj, A. CFD simulation of reactor furnace of sulfur recovery units by considering kinetics of acid gas (H2S and CO2) destruction. Appl. Therm. Eng. 2017, 123, 699–710. [Google Scholar] [CrossRef]

- Yin, C.E.; Johansen, L.; Rosendahl, L.A.; Kær, S.K. New Weighted Sum of Gray Gases Model Applicable to Computational Fluid Dynamics (CFD) Modeling of Oxy-Fuel Combustion: Derivation, Validation, and Implementation. Energy Fuels 2010, 24, 6275–6282. [Google Scholar] [CrossRef]

- Li, J.; Brzdekiewicz, A.; Yang, W.H.; Blasiak, W. Co-firing based on biomass torrefaction in a pulverized coal boiler with aim of 100% fuel switching. Appl. Energy 2012, 99, 344–354. [Google Scholar] [CrossRef]

- Eaton, A.M.; Smoot, L.D.; Hill, S.C.; Eatough, C.N. Components, formulations, solutions, evaluation, and application of comprehensive combustion models. Prog. Energy Combust. 1999, 25, 387–436. [Google Scholar] [CrossRef]

- Rodriguez, J.A.; Chaturvedi, S.; Kuhn, M.; VanEk, J.; Diebold, U.; Robbert, P.S.; Geisler, H.; Ventrice, C.A. H2S adsorption on chromium, chromia, and gold/chromia surfaces: Photoemission studies. J. Chem. Phys. 1997, 107, 9146–9156. [Google Scholar] [CrossRef]

- Madejski, P. Numerical study of a large-scale pulverized coal-fired boiler operation using CFD modeling based on the probability density function method. Appl. Therm. Eng. 2018, 145, 352–363. [Google Scholar] [CrossRef]

- Oka, Y.I.; Okamura, K.; Yoshida, T. Practical estimation of erosion damage caused by solid particle impact: Part 1: Effects of impact parameters on a predictive equation. Wear 2005, 259, 95–101. [Google Scholar] [CrossRef]

- Oka, Y.I.; Yoshida, T. Practical estimation of erosion damage caused by solid particle impact: Part 2: Mechanical properties of materials directly associated with erosion damage. Wear 2005, 259, 102–109. [Google Scholar] [CrossRef]

- Kung, S.C. Further Understanding of Furnace Wall Corrosion in Coal-Fired Boilers. Corrosion 2014, 70, 749–763. [Google Scholar] [CrossRef]

- Xin, S.W.; Wang, H.; Li, J.B.; Wang, G.; Wang, Q.H.; Cao, P.Q.; Zhang, P.; Lu, X.F. Discussion on the Feasibility of Deep Peak Regulation for Ultra-Supercritical Circulating Fluidized Bed Boiler. Energies 2022, 15, 7720. [Google Scholar] [CrossRef]

- Shao, H.S.; Liao, M.; Zhang, C.; Wang, Y.B.; Sun, J.; Zhao, Q.X. A New Method for Calculating Hydrodynamics of Corner-Tube Boiler Based on Differential Pressure Solution. Therm. Sci. 2024, 28, 2831–2843. [Google Scholar]

- Han, H.; He, Y.L.; Tao, W.Q.; Li, Y.S. A parameter study of tube bundle heat exchangers for fouling rate reduction. Int. J. Heat Mass Transf. 2014, 72, 210–221. [Google Scholar] [CrossRef]

- Li, F.B.; Bai, B.F. Flow and heat transfer of supercritical water in the vertical helically-coiled tube under half-side heating condition. Appl. Therm. Eng. 2018, 133, 512–519. [Google Scholar] [CrossRef]

- Chong, P.A.; Zhu, X.L.; Li, J.N.; Li, X.; Deng, L. Investigation on Hydrodynamic Performance and Wall Temperature of Water-Cooled Wall in 1000 MW Boiler Under Low-Load Conditions. Energies 2024, 17, 5751. [Google Scholar] [CrossRef]

- Zhu, X.J.; Wang, W.S.; Xu, W.H. A study of the hydrodynamic characteristics of a vertical water wall in a 2953t/h ultra-supercritical pressure boiler. Int. J. Heat Mass Transf. 2015, 86, 404–414. [Google Scholar] [CrossRef]

- Yuan, M.B.; Deng, L.; Zhang, J.K.; Jiang, J.H.; Liang, Y.; Liu, H.; Che, D.F. Prediction of H2S corrosion depth for water-cooled wall in lower furnace of utility boiler. Fuel 2022, 329, 125466. [Google Scholar] [CrossRef]

- Meng, F.B.; Gao, S. Study on generation characteristics of H2S in tangentially fired boiler. Heilongjiang Electr. Power 2019, 41, 87–90. [Google Scholar]

- Liu, J.; Feng, L.L.; Wu, Y.X.; Feng, R.H.; Chen, S.K.; Zhao, D.Q. Numerical investigation on H2S formation in a pulverized coal-fired boiler using recycled flue gas as near-wall air. Energy 2024, 313, 134134. [Google Scholar] [CrossRef]

- Liu, H.; Hu, S.J.; Zhang, L.; Li, Q.Q.; Deng, L.; Che, D.F. Influence of near-wall air position on the high-temperature corrosion and combustion in a 1000 MWth opposed wall-fired boiler. Fuel 2019, 257, 115983. [Google Scholar] [CrossRef]

- Yang, W.J.; You, R.Z.; Wang, Z.H.; Zhang, H.T.; Zhou, Z.J.; Zhou, J.H.; Guan, J.; Qiu, L.C. Effects of Near-Wall Air Application in a Pulverized-Coal 300 MWe Utility Boiler on Combustion and Corrosive Gases. Energy Fuels 2017, 31, 10075–10081. [Google Scholar] [CrossRef]

- Huo, H.; Su, F.; Meng, P.; Zhang, B.; Bi, Y.; Luo, H.; Sun, J.; Zhao, P.; Wang, X.; Wang, Q.; et al. Retrofit of near-wall air system of a 600 MW opposed firing boiler. Clean. Coal Technol. 2024, 30, 461–468, (In Chinese with English Abstract). [Google Scholar]

| Parameters | BMCR | ECR |

|---|---|---|

| Superheated steam flow rate (t∙h−1) | 1164.00 | 1129.00 |

| Superheater outlet steam pressure (MPa) | 17.50 | 17.45 |

| Superheater outlet steam temperature (°C) | 541.0 | 541.0 |

| Reheat steam flow rate (t∙h−1) | 959.74 | 928.19 |

| Reheater inlet/outlet steam pressure (MPa) | 4.00/3.82 | 3.87/3.70 |

| Reheater inlet/outlet steam temperature (°C) | 335.5/541.0 | 331.9/541.0 |

| Economizer outlet feedwater temperature (°C) | 358.2 | 355.8 |

| Boiler efficiency (%) | 92.42 | 92.42 |

| Ultimate Analysis (%) | Proximate Analysis (%) | Qnet,ar (kJ∙kg−1) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Var | Aar | Mar | FCar | Car | Har | Oar * | Nar | Sar | |

| 8.88 | 25.69 | 6.00 | 59.43 | 52.00 | 3.40 | 3.20 | 1.30 | 1.10 | 22,190 |

| Load | Coal Feed Amount (t∙h−1) | Primary Air Volume (km3∙h−1) | Primary Air Temperature (K) | Secondary Air Volume (km3∙h−1) | Secondary Air Temperature (K) |

|---|---|---|---|---|---|

| 100% BMCR | 168 | 240 | 359.3 | 887 | 588.8 |

| 75% BMCR | 144 | 207 | 356.8 | 706 | 578.3 |

| 50% BMCR | 118 | 176 | 350.7 | 524 | 567.3 |

| 35% BMCR | 75 | 115 | 348.0 | 437 | 549.2 |

| Parameters | Value |

|---|---|

| Coal feed amount (kg∙s−1) | 46.67 |

| Excess air ratio | 1.25 |

| Primary air flow (m3∙s−1) | 66.67 |

| Primary air temperature (K) | 359.3 |

| Primary air density (kg∙m−3) | 0.59 |

| Secondary air flow (m3∙s−1) | 246.39 |

| Secondary air temperature (K) | 588.8 |

| Secondary air density (kg∙m−3) | 0.58 |

| Over-fire air flow (m3∙s−1) | 78.05 |

| Nozzle area of primary air (m2) | 0.26 |

| Nozzle area of secondary air (m2) | 0.32 |

| Nozzle area of over-fire air (m2) | 0.32 |

| Hydraulic diameter of primary air (mm) | 502 |

| Hydraulic diameter of secondary air (mm) | 556 |

| Hydraulic diameter of over-fire air (mm) | 551 |

| Primary air nozzle flow rate (m∙s−1) | 10.81 |

| Secondary air nozzle flow rate (m∙s−1) | 23.84 |

| Over-fire air nozzle flow rate (m∙s−1) | 30.93 |

| Name | CFD Simulation | Actual | Deviation (%) |

|---|---|---|---|

| Furnace Outlet Temperature (K) | 1281 | 1288 | 0.54 |

| Lower Furnace Outlet Temperature (K) | 1686 | 1698 | 0.71 |

| Total Pressure Drop of Water Wall (MPa) | 0.2213 | 0.2200 | 0.59 |

| Working Fluid Temperature of Separator (°C) | 358.05 | 358.38 | 0.09 |

| Oxygen Content of the Flue Gas at Economizer Outlet (%) | 2.83 | 2.81 | 0.71 |

| CO Content of the Flue Gas at Economizer Outlet (%) | 0.86 | 0.82 | 4.87 |

| NOx Content of the Flue Gas at Economizer Outlet (mg∙m−3) | 325.2 | 320.3 | 1.53 |

| Name | 113 WM | 166 WM | 248 WM | 330 WM |

|---|---|---|---|---|

| 1.89 | 2.07 | 1.88 | 1.85 | |

| 1.22 | 1.28 | 1.30 | 1.23 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, L.; Wang, M.; Chong, P.; Shao, Y.; Deng, L. Numerical Simulation of a 330 MW Tangentially Fired Boiler by a Model Coupling CFD and Hydrodynamic Calculation. Energies 2025, 18, 2585. https://doi.org/10.3390/en18102585

Sun L, Wang M, Chong P, Shao Y, Deng L. Numerical Simulation of a 330 MW Tangentially Fired Boiler by a Model Coupling CFD and Hydrodynamic Calculation. Energies. 2025; 18(10):2585. https://doi.org/10.3390/en18102585

Chicago/Turabian StyleSun, Lijun, Miao Wang, Peian Chong, Yunhao Shao, and Lei Deng. 2025. "Numerical Simulation of a 330 MW Tangentially Fired Boiler by a Model Coupling CFD and Hydrodynamic Calculation" Energies 18, no. 10: 2585. https://doi.org/10.3390/en18102585

APA StyleSun, L., Wang, M., Chong, P., Shao, Y., & Deng, L. (2025). Numerical Simulation of a 330 MW Tangentially Fired Boiler by a Model Coupling CFD and Hydrodynamic Calculation. Energies, 18(10), 2585. https://doi.org/10.3390/en18102585