1. Introduction

The dual-stator single-rotor AFPMM holds significant potential for application in electric vehicles, flywheel energy storage systems, and aerospace due to its compact structure and high torque density [

1,

2,

3,

4,

5]. As power density requirements increase in these applications, the compact design of AFPMM poses challenges to the rotor heat dissipation, particularly when fractional slot centralized windings are employed, leading not only to excessive temperature rise in the PM but also potentially causing irreversible demagnetization under severe conditions [

6,

7,

8]. However, existing methods for calculating PM eddy-current losses in AFPMM predominantly rely on 3D-FEM, which is very time-consuming. Consequently, fast and accurate evaluation of the PM eddy-current loss is essential for AFPMM.

Currently, numerous studies have proposed analytical methods to evaluate PM eddy-current loss in radial flux machines. In [

9,

10], the subdomain method was used to calculate PM eddy-current loss under no-load and loaded conditions, respectively. In [

11], the subdomain method was further extended by deriving the PM eddy-current loss caused by each harmonic of the armature reaction field. In [

12], an analytical model based on image theory that accounts for the three-dimensional distribution of PM eddy currents was introduced. However, all of the studies mentioned above overlook the influence of eddy-current reaction field and stator saturation.

In radial flux machines, the 2D analytical model assumes that the length of the PM is significantly larger than its width, so the eddy-current loss in the circumferential direction is neglected. However, for AFPMMs, the radial length of the PM is comparable to its circumferential length, making the eddy currents in the circumferential direction non-negligible. Consequently, the conventional 2D method is not fully applicable to AFPMMs. To address this issue, a multilayer-2D coupled model for YASA machine is proposed in [

13], effectively transforming the 3D finite element model into a multilayer-2D finite element model. The total PM loss is obtained by summing the eddy-current losses in each layer, which significantly reduces computation time. However, this method requires substantial post-processing work. Studies [

14,

15] combined the conformal transformation method with the resistive network model, and the reaction field of eddy current was represented by inductance, thereby establishing an analytical model for PM eddy-current losses in yokeless and segmented armature (YASA) AFPMM. Similarly, [

16] simplified the 3D eddy-current path for a dual-stator, single-rotor AFPMM and calculated the PM eddy-current loss. Nevertheless, these studies neglected the effect of stator saturation on PM eddy-current loss.

This paper integrates a HAM with a PM resistance network model to accurately calculate the PM eddy-current losses in AFPMM. To account for stator saturation, the hybrid model adopts an MEC model for the stator in order to consider the effect of stator saturation. Meanwhile, an analytical model based on scalar magnetic potential is utilized in the air-gap and PM regions. By combining these two models, the magnetic field distribution in the AFPMM is obtained. A resistance network model of the PM is then established, which allows for analytical calculation of PM eddy-current loss under both no-load and load conditions. The accuracy of the proposed HAM is validated using 3D-FEM. Finally, the effects of slot opening width and air-gap length on the PM eddy-current loss in AFPMM are analyzed through the proposed HAM.

2. Hybrid Analytical Model

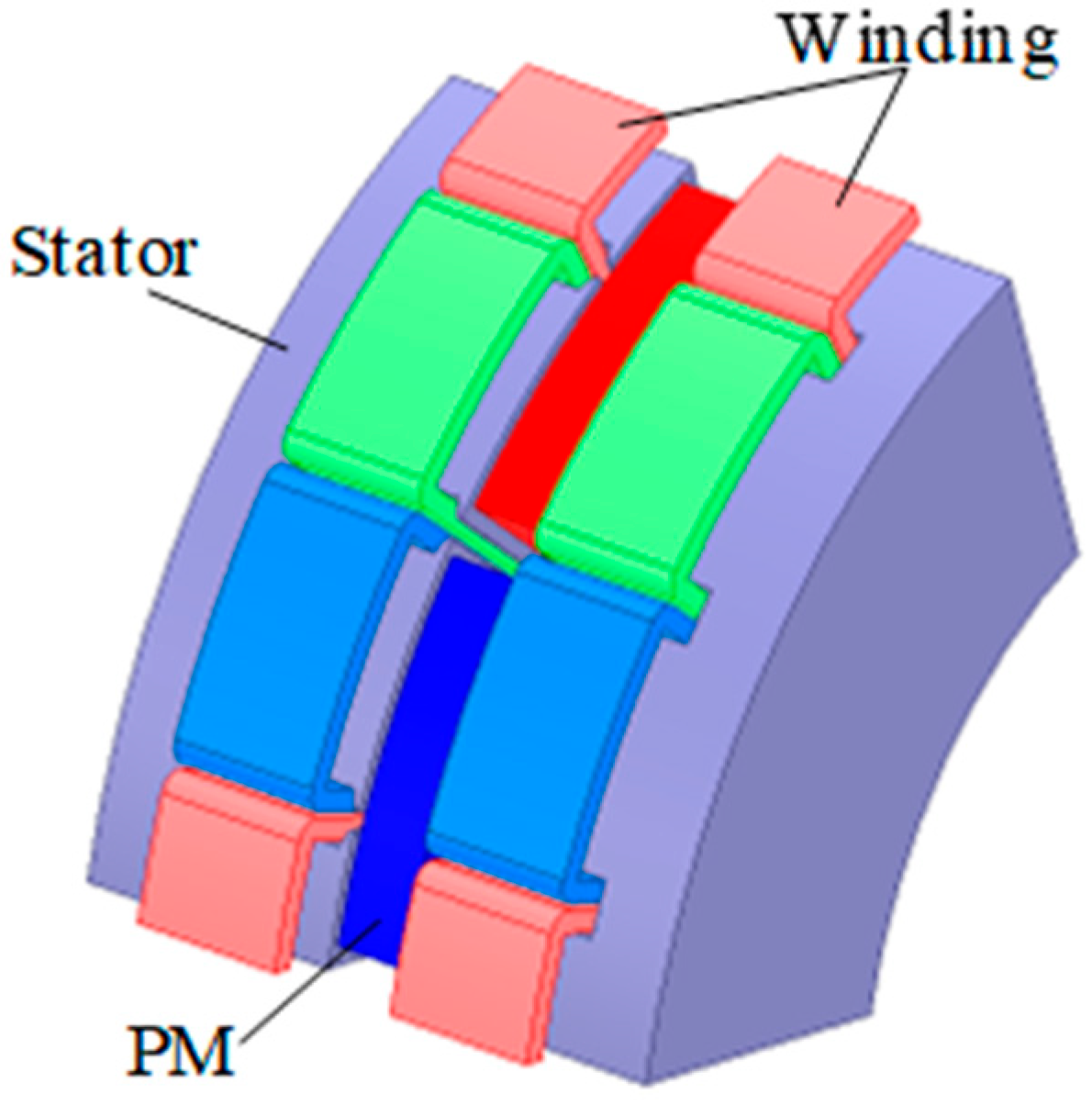

The saturation of the stator core is considered by using the MEC model. For the conventional magnetic network model, the air-gap region and the PM region in MEC needs to be reconstructed as the rotor position changes. To avoid this problem, these two regions are modeled by the analytical model. In this paper, an eighteen-slot, twelve-pole, dual-stator, single-rotor AFPMM is used as an example. Due to the symmetry and periodicity of the magnetic flux path, the one/sixth model of the machine with one stator is modeled, as shown in

Figure 1.

Since the magnetic field of the AFPMM is distributed in three dimensions, the quasi-3D method is used to convert the 3D-AFPMM into a combination of

ns 2D linear machines without end effects. The thickness of each 2D linear machine is

ls, which can be calculated as follows:

where

ns is the number of the 2D linear machine, and

Ro and

Ri are the outer and inner radius of the stator.

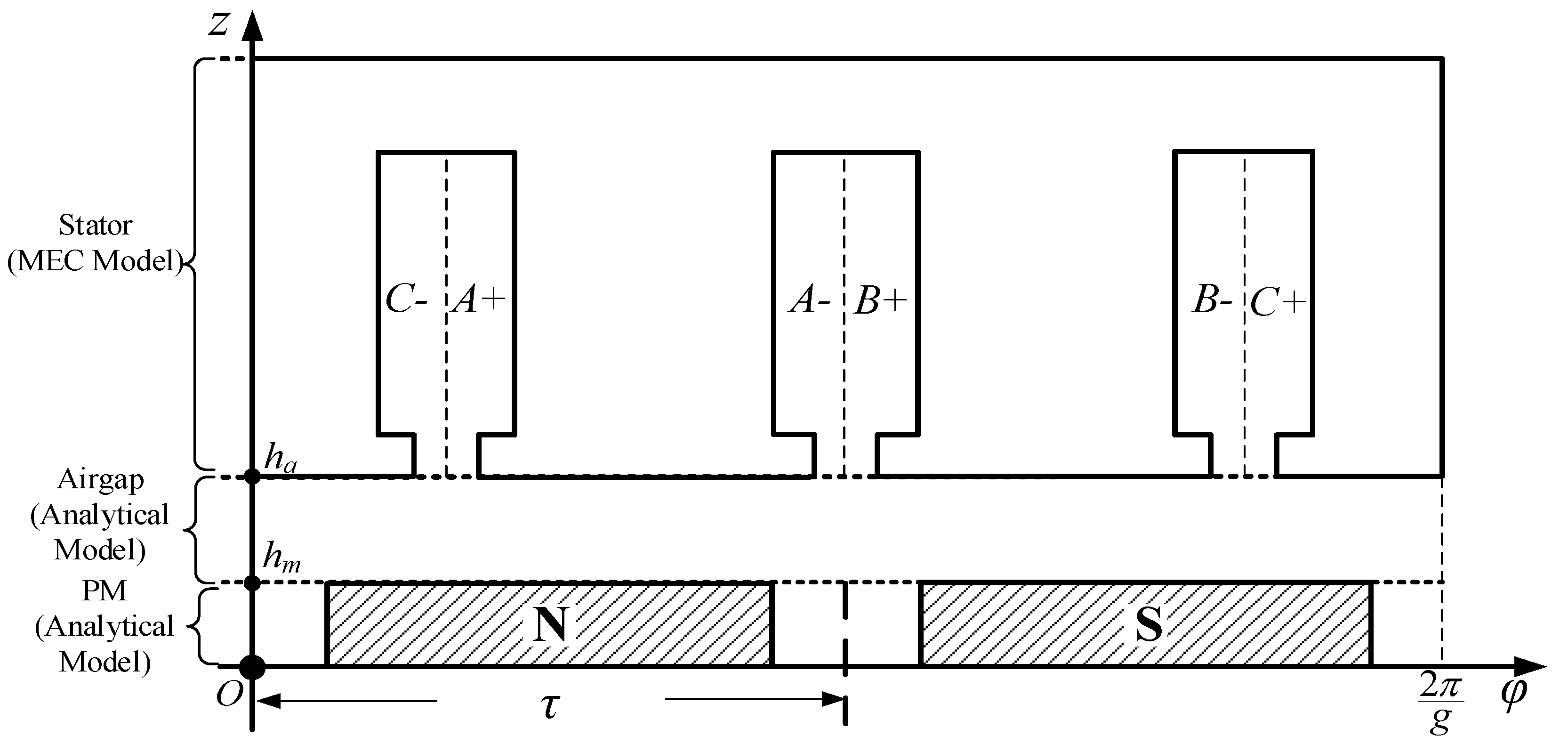

Due to the periodicity and symmetry of the magnetic flux in dual-stator single-rotor AFPMM, to avoid unnecessary computations, it is adequate to model only half of the 1/6 model of the AFPMM. The equivalent model for a 2D linear machine is shown in

Figure 2, where

hm is the thickness of PM,

τ is the pole pitch, and

g is the greatest common divisor of the number of slots and poles (In this case,

g = 6 since the pole number and slot number are 12 and 18, respectively). To simplify the solving process of HAM, the following assumptions are made:

- (1)

The permeability of the PM is same as vacuum, and the relative permeability for PM is taken as 1;

- (2)

The leakage magnetic flux at the inner and outer diameter is neglected.

The magnetic field for an electric machine is considered as a quasi-static field, and therefore, the magnetic field strength

H can be expressed as follows:

where

U is the scalar magnetic potential.

For magnetic materials such as PM, the magnetic density can be stated as follows:

For non-magnetic materials such as air, the magnetic density can be given by the following:

where

μ0 is the permeability of vacuum,

μr is the relative permeability of the medium, and

M is the magnet magnetization vector. From Equations (2)–(4), it can be known that as long as the scalar magnetic potential equation within the corresponding region is obtained, the magnetic flux density distribution can be calculated.

2.1. General Scalar Magnetic Potential Solution of Analytical Model

2.1.1. PM Region

The Laplace equation for the scalar magnetic potential in the PM region can be expressed as follows:

where

UI is the scalar magnetic potential in PM region, and

r stands for radius. The internal boundary conditions can be denoted as follows:

By means of the separated variable method, the general solution of

UI can be expressed as follows:

where

n is the harmonics number considered in the PM region, and

A1 and

B1 are the undetermined constants.

Based on the principle of the electromagnetic field, the circumferential and axial magnetic field components

HI,φ and

HI,z can be expressed as the negative gradient of the scalar magnetic potential

UI:

According to Equation (8), the circumferential and axial magnetic flux density of the PM region can be expressed as

where

Mz is the magnetization vector in the axial direction.

Mz,

Mcn, and

Msn are given by the following:

where

Br is the remanence of PM, ω

r is the rotor rotational speed,

φ0 is the rotor initial position, and α

p is the pole arc coefficient.

2.1.2. Air-Gap Region

In air-gap region, the Laplace’s equation is as follows:

where

UII is the scalar magnetic potential in air-gap region. The internal boundary conditions are satisfied as follows

:The general solution of

UII is as follows:

where

A2,

B2,

C2, and

D2 are the undetermined constants.

At the interface (

z =

hm) between the air-gap region and the PM region, since the permeability of the two regions are the same, according to the boundary conditions of the electromagnetic field, the circumferential and axial magnetic field strengths are equal at the boundary

z =

hm. The boundary conditions can be denoted as follows:

Substituting Equation (15) into Equations (14) and (7), the undetermined constants in

UII can be represented as follows:

Thus, the scalar magnetic potential

UII can be rewritten as

The circumferential and axial component of magnetic flux density in the air gap can be given by the following:

2.2. Stator MEC Model

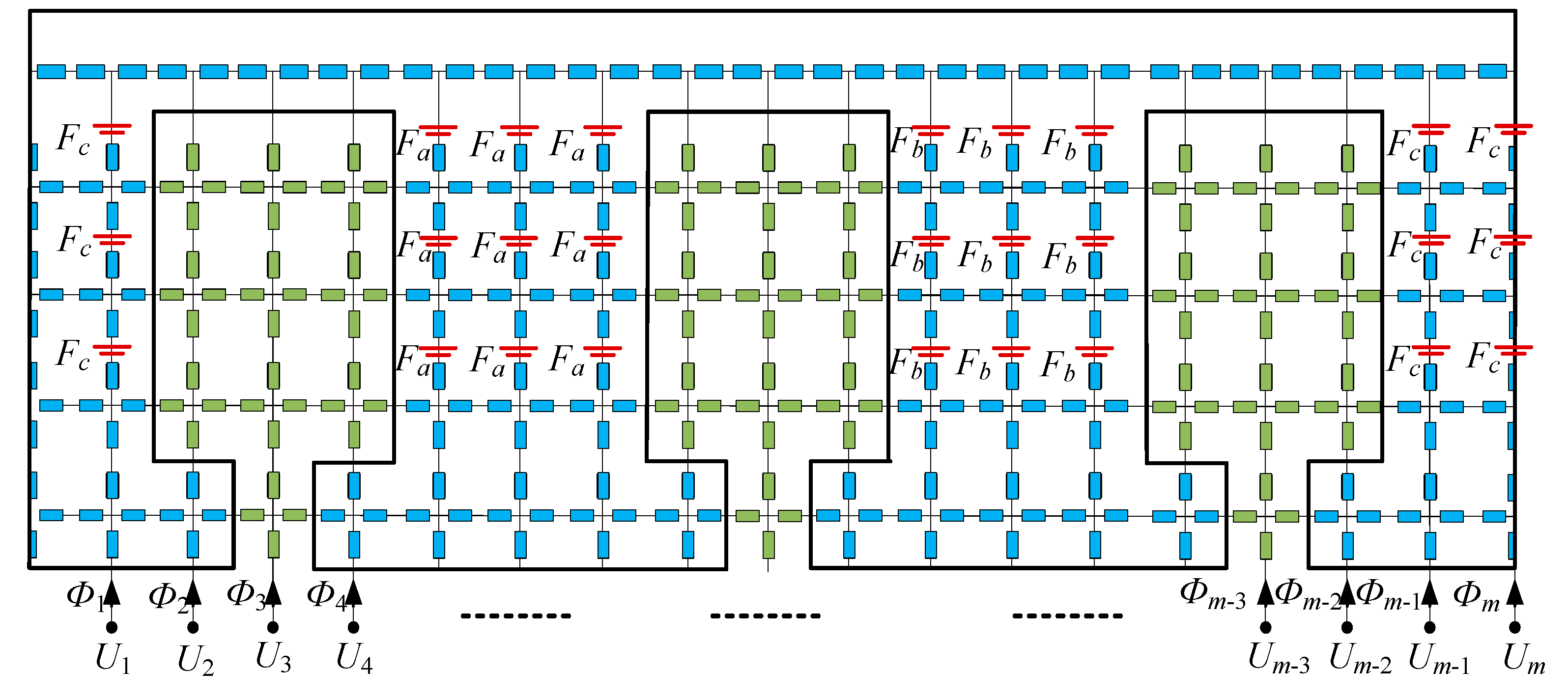

The stator MEC model is shown in

Figure 3. Along the axial direction, the stator is divided into

m columns, which means that the surface of stator (interface between air-gap region and stator) has a total of

m magnetic potential nodes, represented as

U1,

U2, …,

Um. The magnetic flux that flows into each node of the stator surface is denoted by

Φ1,

Φ2, …,

Φm, and the magnetic potential of armature winding is given by

Fa,

Fb, and

Fc.

According to Kirchhoff’s voltage law, the magnetic potential of each node (

Unode) and the flux of each branch (

Φbranch) in the MEC model can be obtained by the node voltage method:

where

Us is the matrix of magnetic potential sources combined with

Fa,

Fb, Fc, and

U1,

U2, …,

Um,

A is the relation matrix of MEC model, and

G is the permeance matrix. More details about the construction of the MEC model and the solution process can be found in the studies [

17,

18].

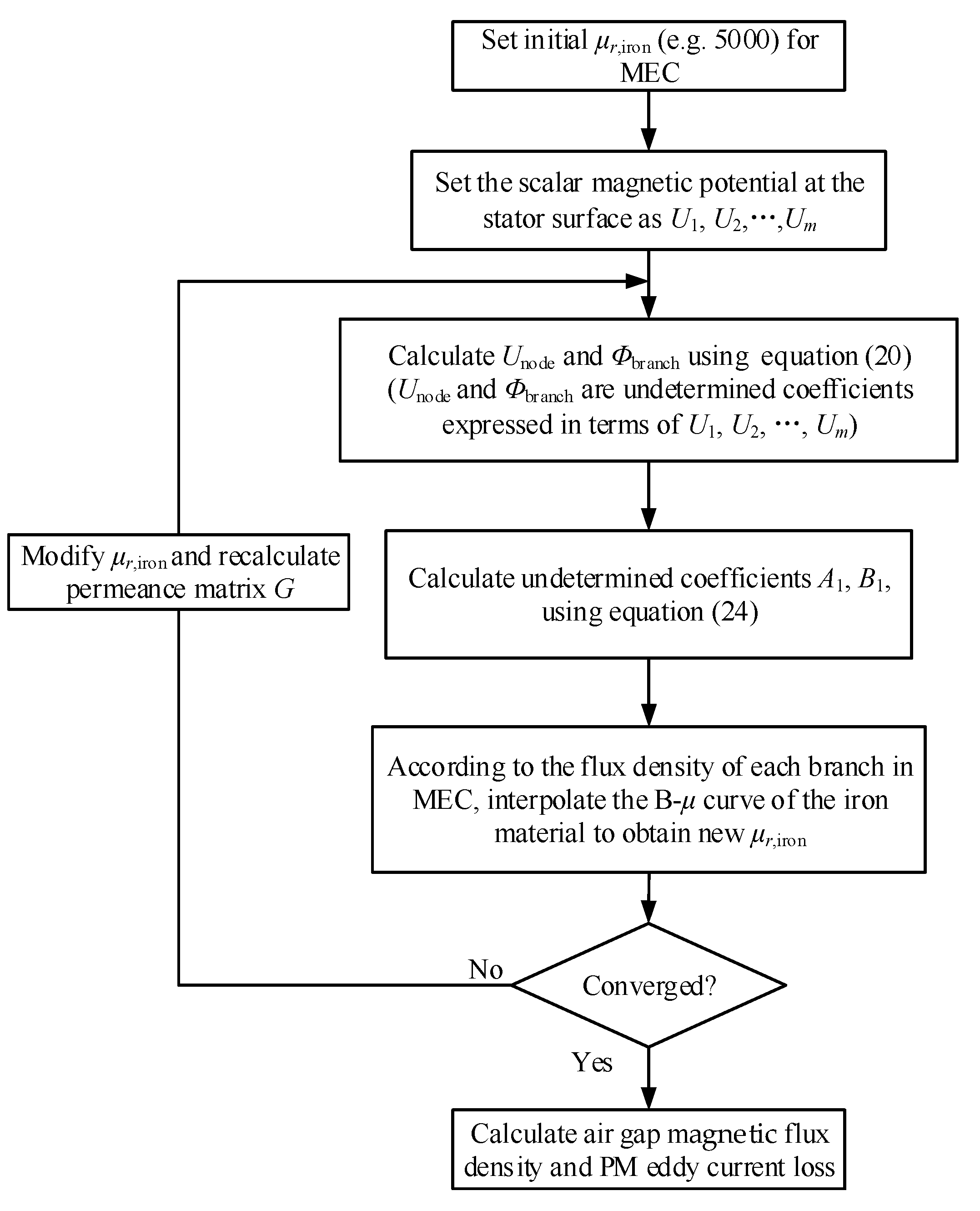

2.3. Solving Process of Hybrid Analytical Model

Because the stator MEC model is divided into

m columns, the scalar magnetic potential of each node at the stator surface

U1,

U2, …,

Um can be given by the following:

To facilitate the association of the magnetic scalar potential at the stator surface in the MEC model with air-gap scalar magnetic potential

UII,

UMEC(

φ) can be rewritten in Fourier series form:

where

a0,

an, and

bn are given by

In accordance with the continuity boundary condition of the electromagnetic field, the magnetic scalar potentials of the MEC model and analytical model at the interface (

z =

ha) are equal, and the magnetic flux that flows into the MEC model is exactly equal to the magnetic flux that flows out of the analytical model, which can be denoted as follows:

where

Φk is the magnetic flux flowing into the

kth nodes (

Uk) at the stator surface. It is obtained by Equation (20). Solving the above equation, the undetermined constants

A1 and

B1 can be determined, and so can the circumferential and axial component of magnetic flux density in both the air-gap region and PM region. It should be noted that in order to take into account the saturation effect of the iron core, the permeance of each branch in MEC needs to be calculated by an iteration process searching the B-

μ curve of iron material. The calculation flowchart is shown in

Figure 4.

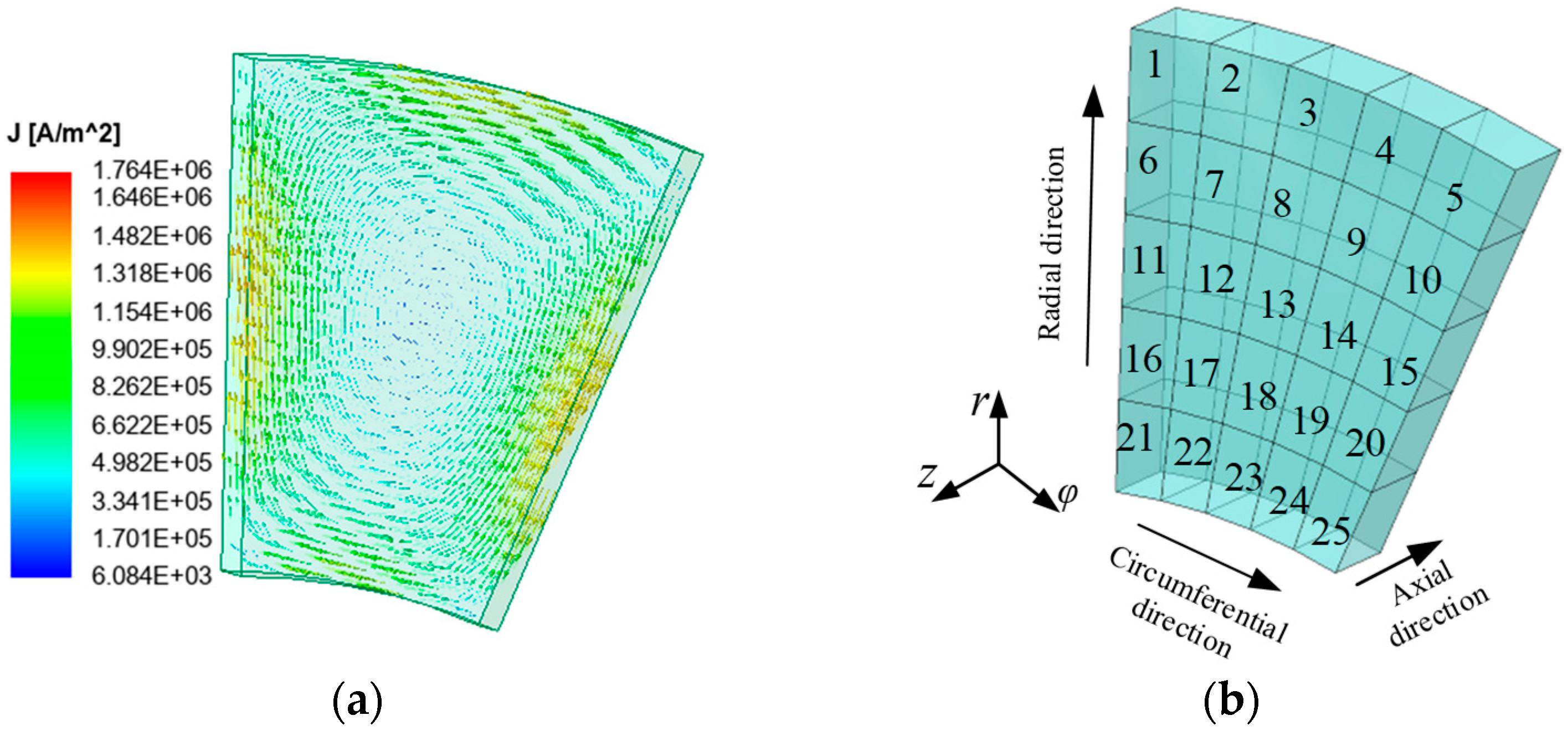

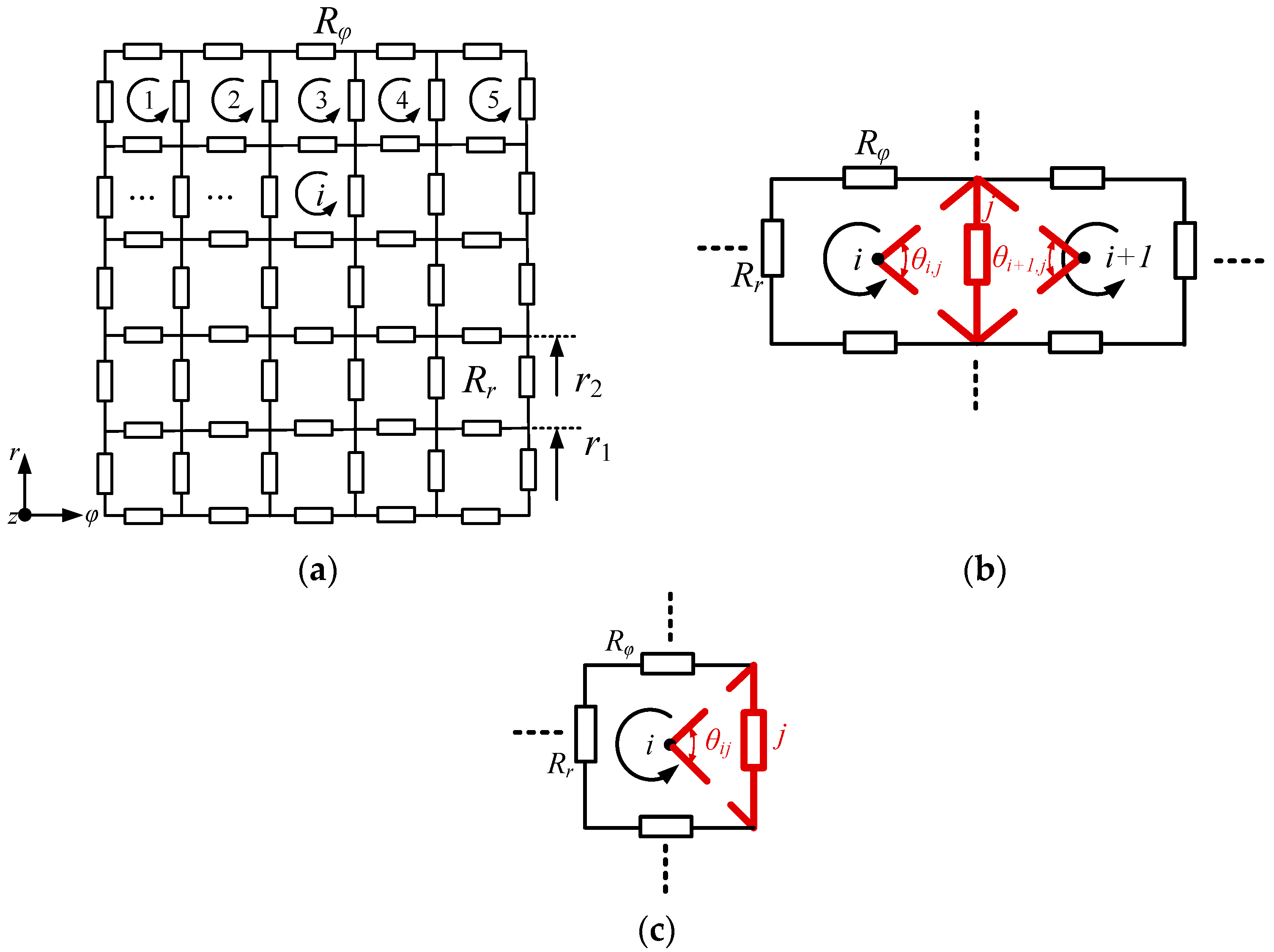

3. Resistance Equivalent Network Model of PM

In the 2D PM loss analytical model in conventional radial flux motors, the axial length is assumed to be much larger than the circumferential length, such that only eddy currents along the axial direction within the PM are considered. However, for AFPMM, the circumferential length of the permanent magnet is comparable to its radial length. Consequently, the eddy current within the PM includes both circumferential and radial components, which are indispensable, as shown in

Figure 5a. To account for this effect, the PM is divided into segments along both the radial and circumferential directions to form a resistance network, as shown in

Figure 5b. These segments are equivalent to interconnected resistance; thus, a resistance network consisting of multiple resistance branches, as shown in

Figure 6, is constructed. The voltage source in the circuit is the induced voltage caused by the stator slotting and armature winding harmonics; by solving the resistance loss of each branch in the resistance network, the eddy-current loss of the whole piece of the PM can be obtained.

In

Figure 6a,

Rr and

Rφ are equivalent resistances in the radial and circumferential directions, respectively:

where σ

pm is the conductivity of PM, and

Nr and

Nφ are both 5 and represent the number of layers divided in radial and circumferential directions, respectively.

The induced voltage

Ei,n induced by

nth magnetic flux harmonic in

ith resistance sub-circuit can be expressed as follows:

where

Φpm,in is the

nth magnetic flux harmonic in

ith sub-circuit,

Bz,

n represents the

nth axial flux density harmonic on the surface of PM, and

Si is the area of

ith sub-circuit.

The induced voltage

Eb,

j in branch

j can be divided into two cases. One is when branch

j is located between two sub-circuits, in which case

Eb,

j is contributed by both sub- circuits, as shown in

Figure 6b. The other case is when branch

j is at the edge of the resistance network, in which case

Eb,

j is only related to one sub-circuit, as shown in

Figure 6c. The

Eb,

j can be denoted as follows [

15]:

where

θi,j is the angle between the center of

ith resistance sub-circuit and branch

j.

Since the induced voltage and resistance for branch

j is determined, the current in branch

j is also determined:

where

Rj is the resistance for branch

j.

After the induced voltage

Eb,j and current

Ib,j for branch

j are both derived, the eddy-current loss in PM can be calculated according to Joule’s Law:

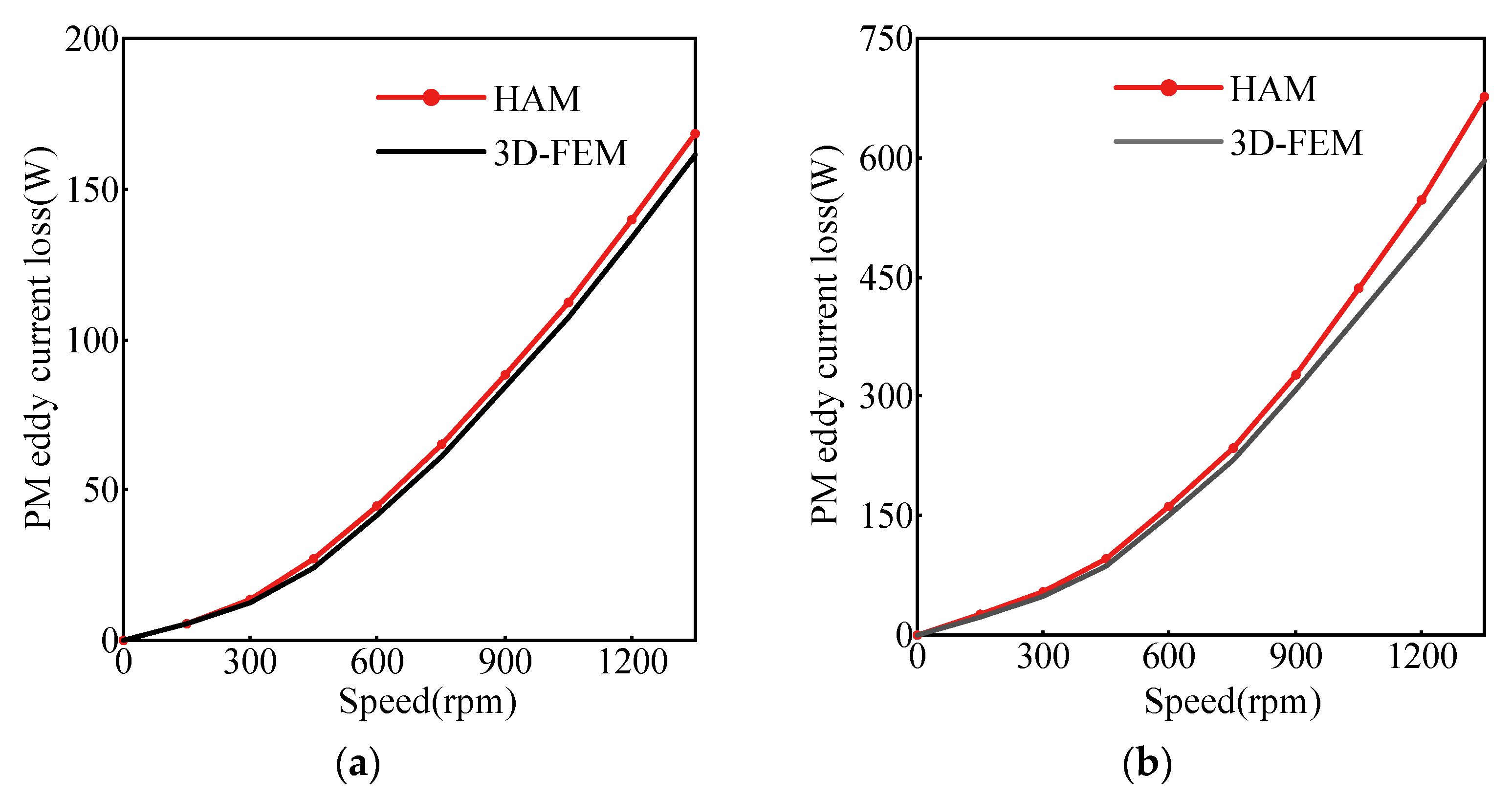

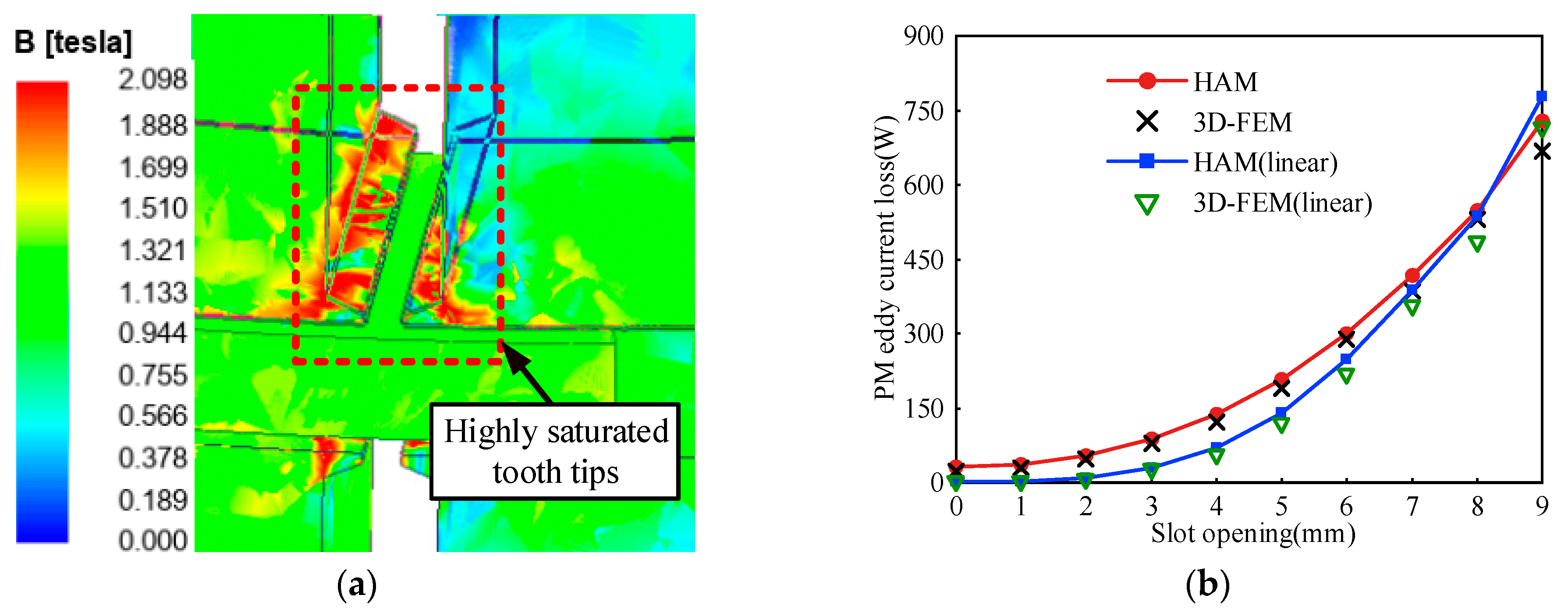

5. Influence of Structural Parameters on PM Eddy-Current Loss

The air-gap permeability harmonics caused by stator slots are a primary source of no-load PM eddy-current losses. Due to the small size of the slot tips, they tend to saturate frequently, as shown in

Figure 9a. Ignoring this saturation during calculations can significantly impact the accuracy of the PM eddy-current loss estimation under no-load condition.

Figure 9b illustrates the comparison of PM eddy-current loss calculated both with and without considering slot tip saturation across various slot widths. The figure clearly demonstrates a significant difference between the two scenarios, and the HAM can reflect the effect of slot tip saturation.

Under load conditions, armature reaction field harmonics is the main contributor to PM eddy-current loss.

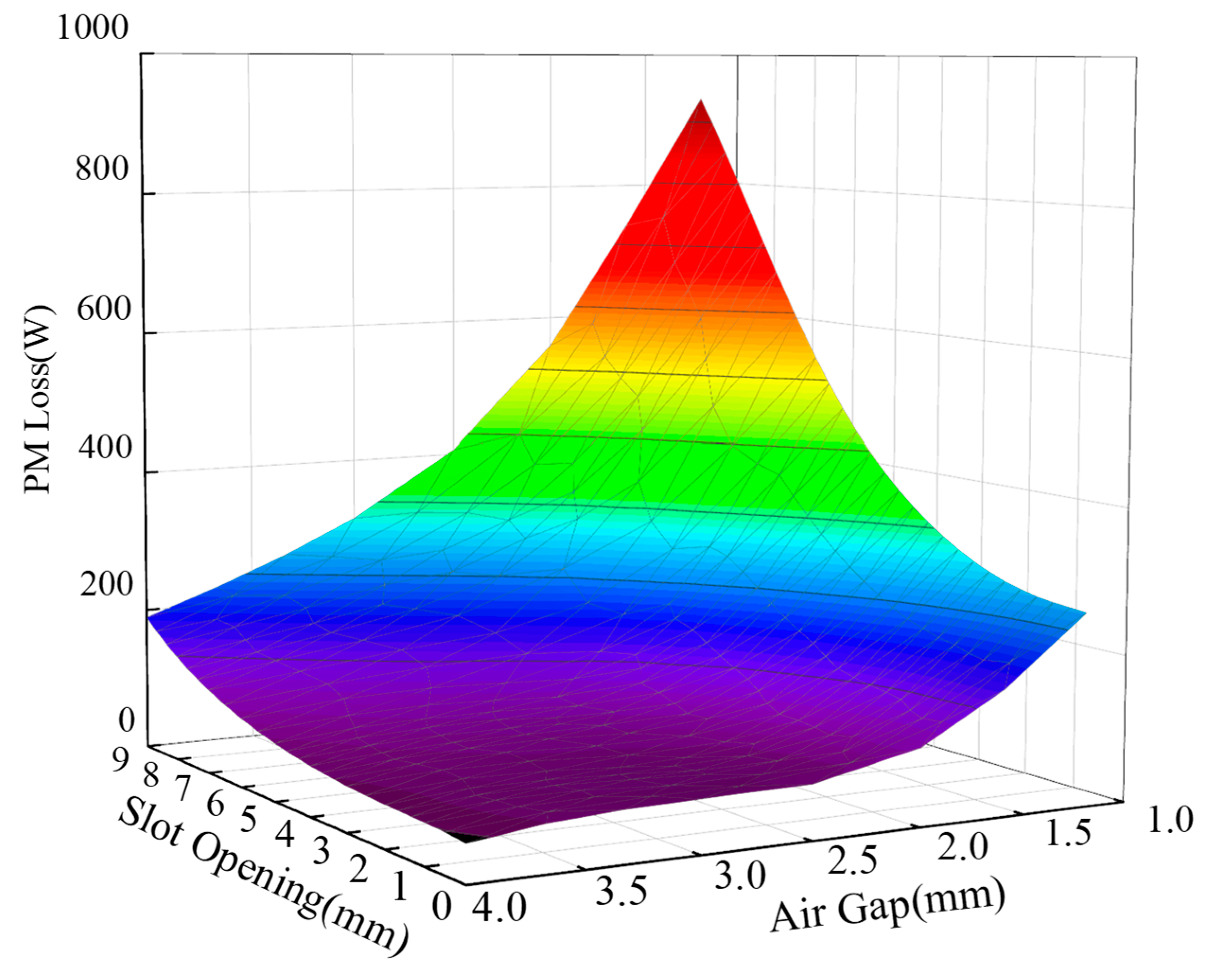

Figure 9 presents the PM eddy-current loss at different slot opening width and air-gap lengths under rated operating conditions. It is evident that increasing the air-gap length and decreasing the slot width can significantly reduce the PM eddy-current loss. For the AFPMM in

Table 1, when the slot width is 3 mm and the air-gap length increases from 1 mm to 4 mm, the eddy-current loss decreases from 321.6 W to 61.7 W, representing an 80.8% reduction. Additionally, reducing the slot width from 9 mm to 0 mm at air-gap length of 1 mm, the PM eddy-current loss decreases from 945.4 W to 267.7 W, a reduction of 71.68%.

From

Figure 10, it is evident that reducing the air-gap length and narrowing the slot opening width can effectively decrease the PM eddy-current loss. However, an excessively large air-gap length significantly diminishes the AFPMM’s output torque, which is detrimental to the efficient utilization of both PM and armature winding. In contrast, reducing the slot opening width has minimal impact on the AFPMM’s torque output performance while effectively mitigating the PM eddy-current loss. Therefore, to minimize the PM magnet eddy-current loss, a smaller slot opening width is advisable when designing the AFPMM.

6. Conclusions

In this paper, a HAM for evaluating the PM eddy-current loss in AFPMM is proposed. This model incorporates the saturation effect of the stator core, thereby enhancing the accuracy of calculations. Specifically, it can calculate the air-gap field distribution and evaluate the eddy-current loss under both no-load and load conditions. Compared to traditional methods that do not account for iron saturation, this HAM provides more accurate results for no-load conditions. The validity of the proposed method was confirmed through 3D FEM. Additionally, the impact of air-gap length and slot opening width on PM eddy-current loss was investigated using this HAM. The results indicate that reducing slot width effectively decreases PM eddy-current loss. Moreover, compared to the 3D FEM, the HAM significantly reduces computation time, which facilitates a shorter design period for AFPMM. Importantly, by considering the influence of stator core saturation, the model is also suitable for assessing the electromagnetic performance and PM eddy-current loss under highly saturated conditions such as when the armature current is way above the rated value or operating under overload condition.