Experimental Study on the Thermal Reduction of CO2 by Activated Solid Carbon-Based Fuels

Abstract

1. Introduction

2. Experimental

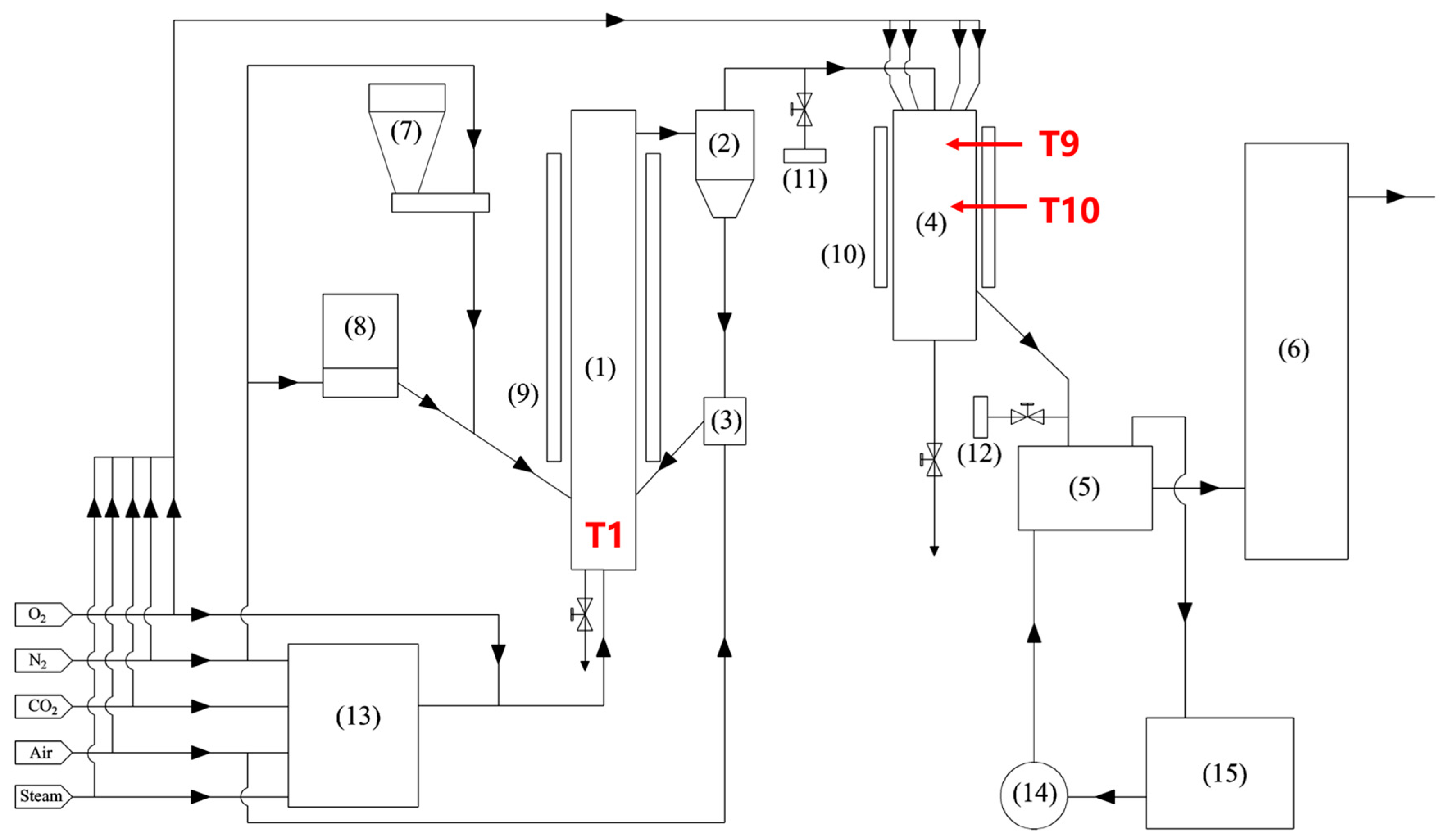

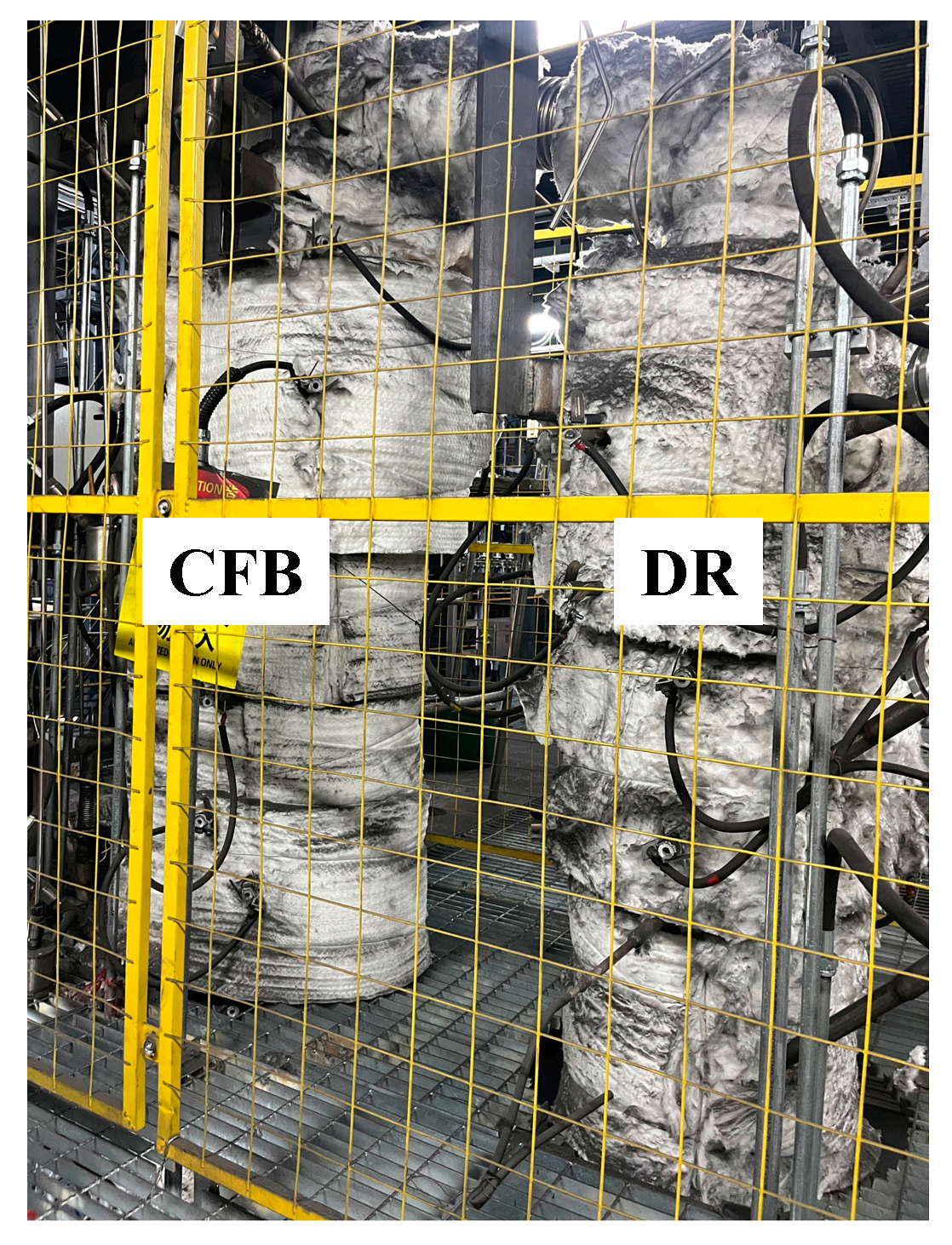

2.1. Test Rig and Experimental Process

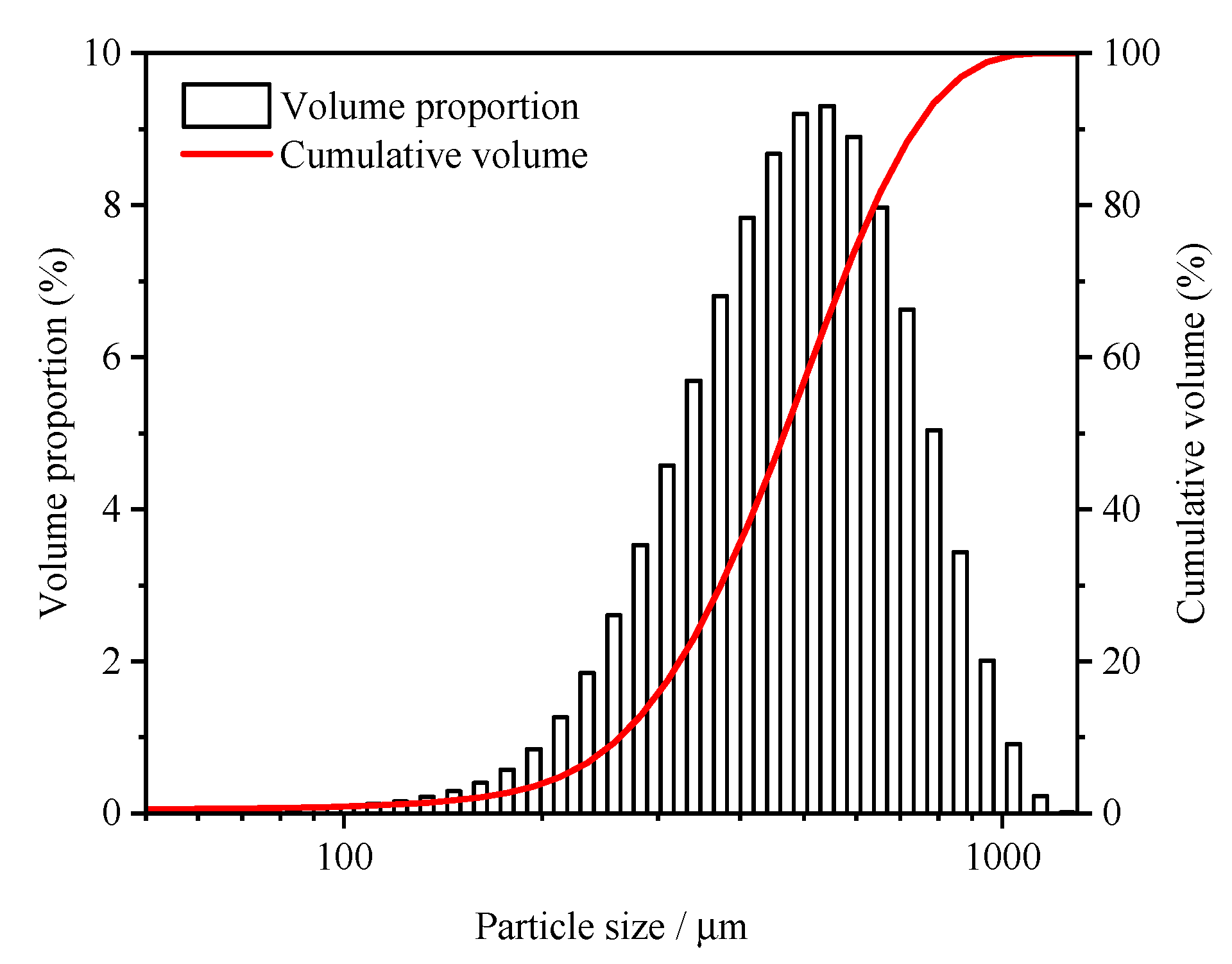

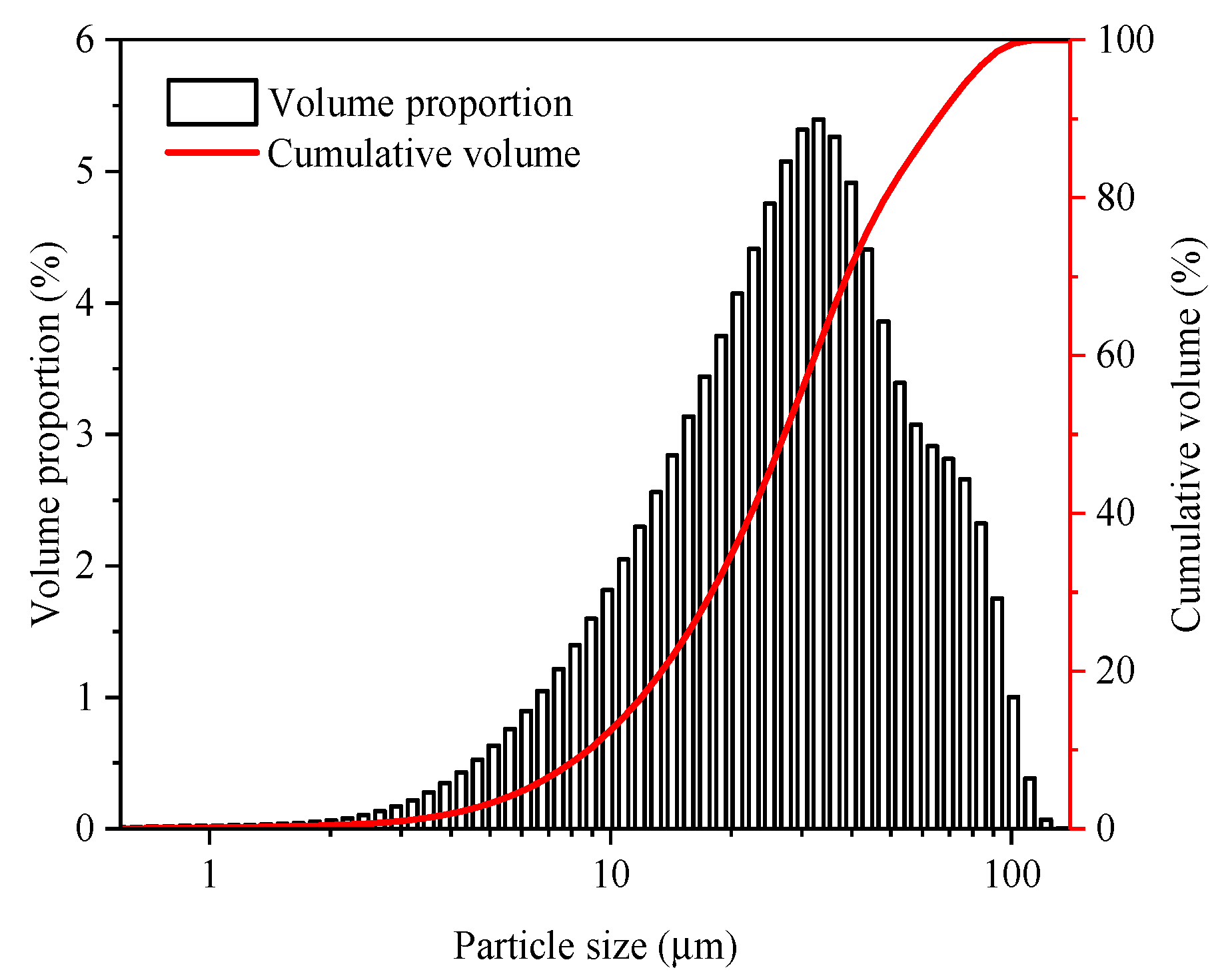

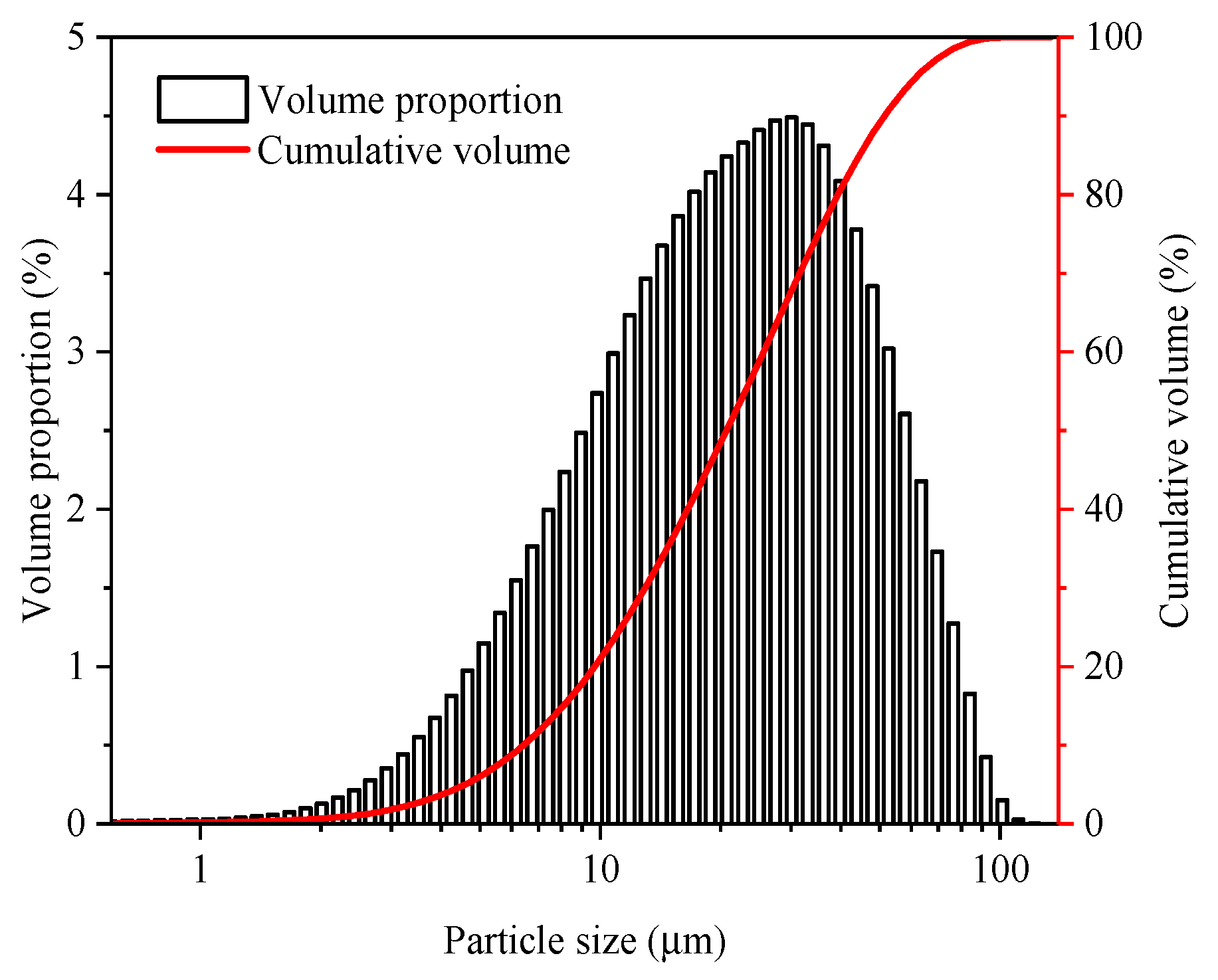

2.2. Material Conditions

2.3. Calculation and Analysis Methods

- (1)

- Load approximately 15 mg of sample into the TGA apparatus;

- (2)

- After loading the sample, purge with N2 for 30 min to remove other gases from the sample chamber;

- (3)

- Ramp the temperature to 1200 °C at a rate of 20 °C/min while maintaining N2 flow.

- (4)

- Upon reaching 1200 °C, hold for 10 min; then, introduce CO2;

- (5)

- When the sample weight stabilizes, indicating the completion of the gasification process, initiate the cooling procedure.

3. Results and Discussion

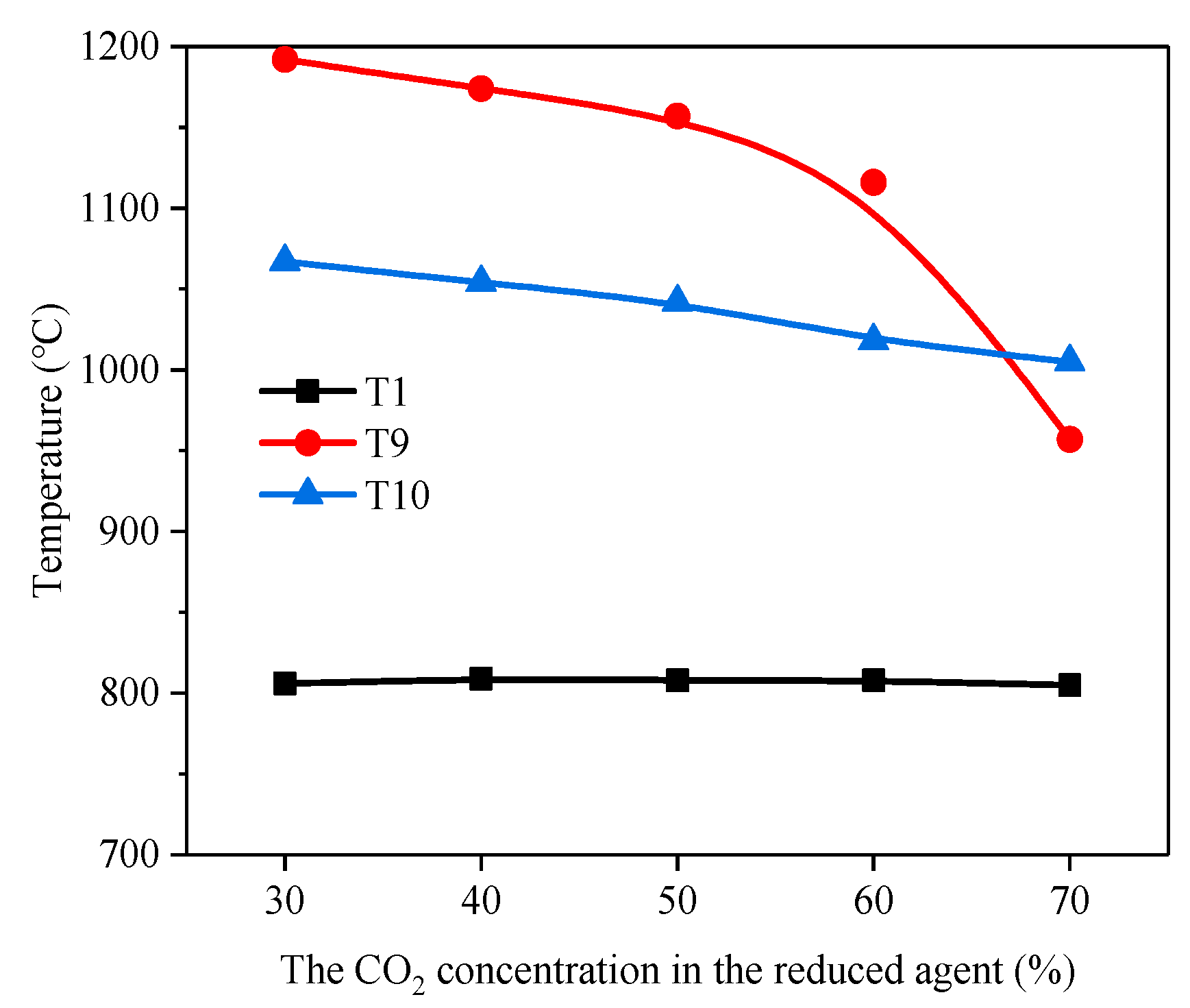

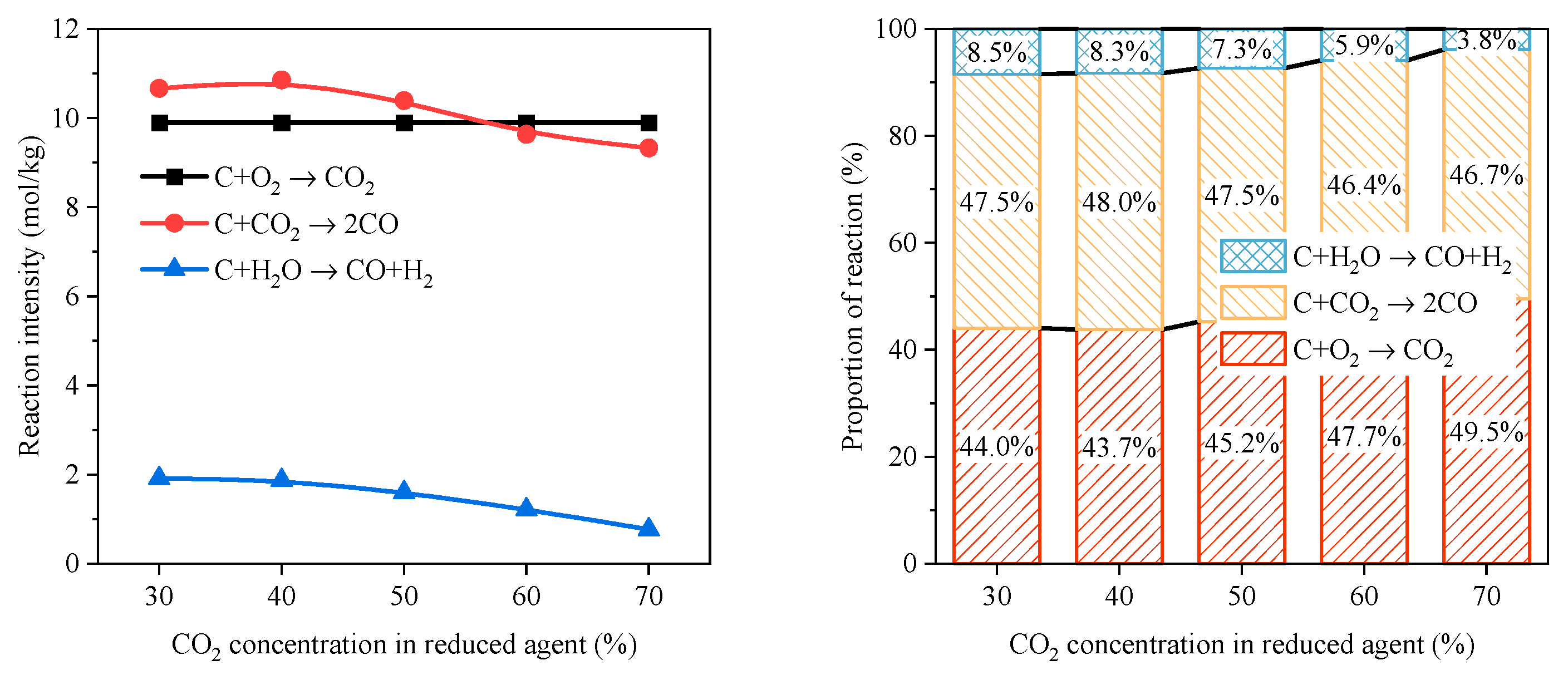

3.1. Effect of CO2 Concentration in the Reduced Agent

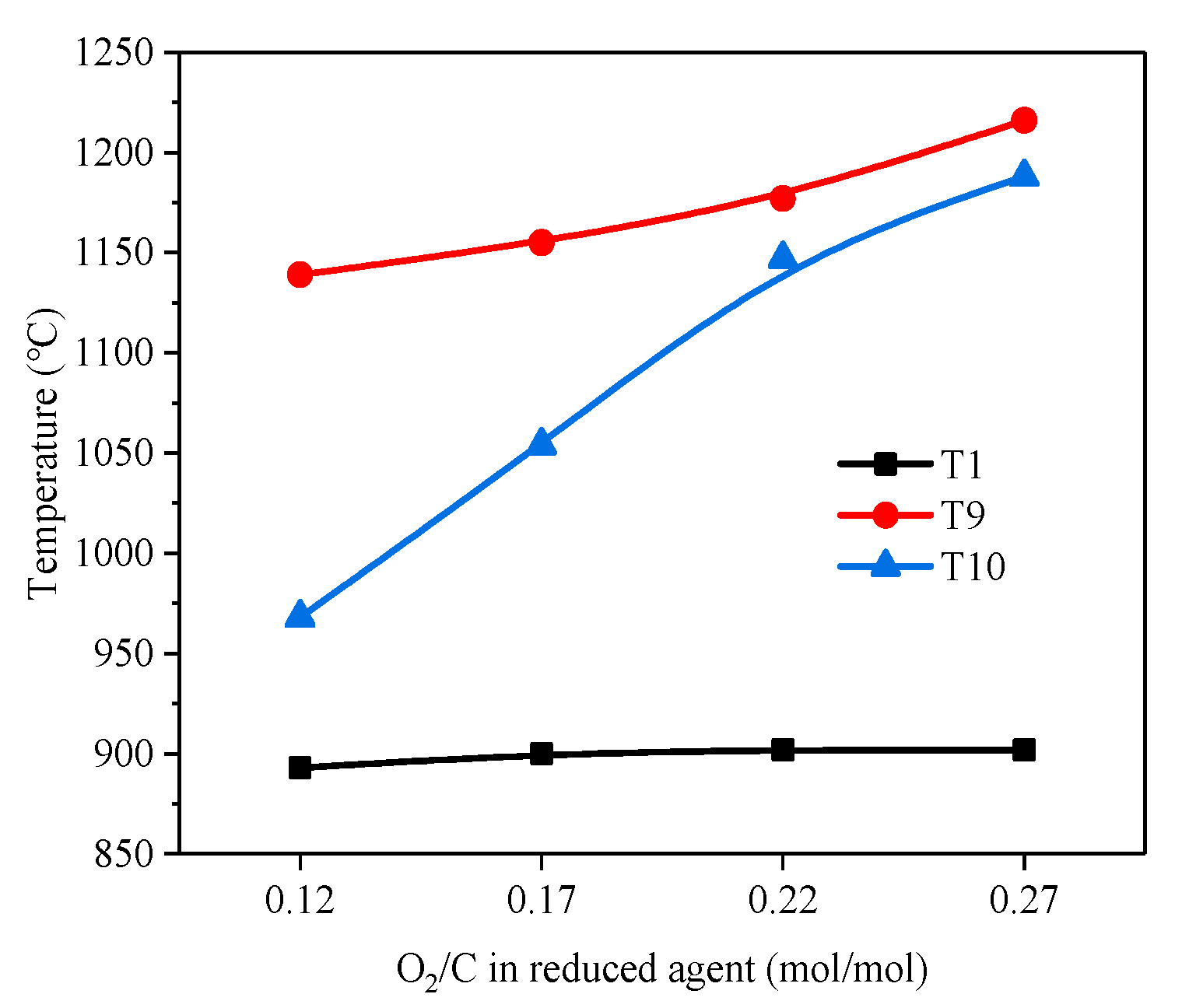

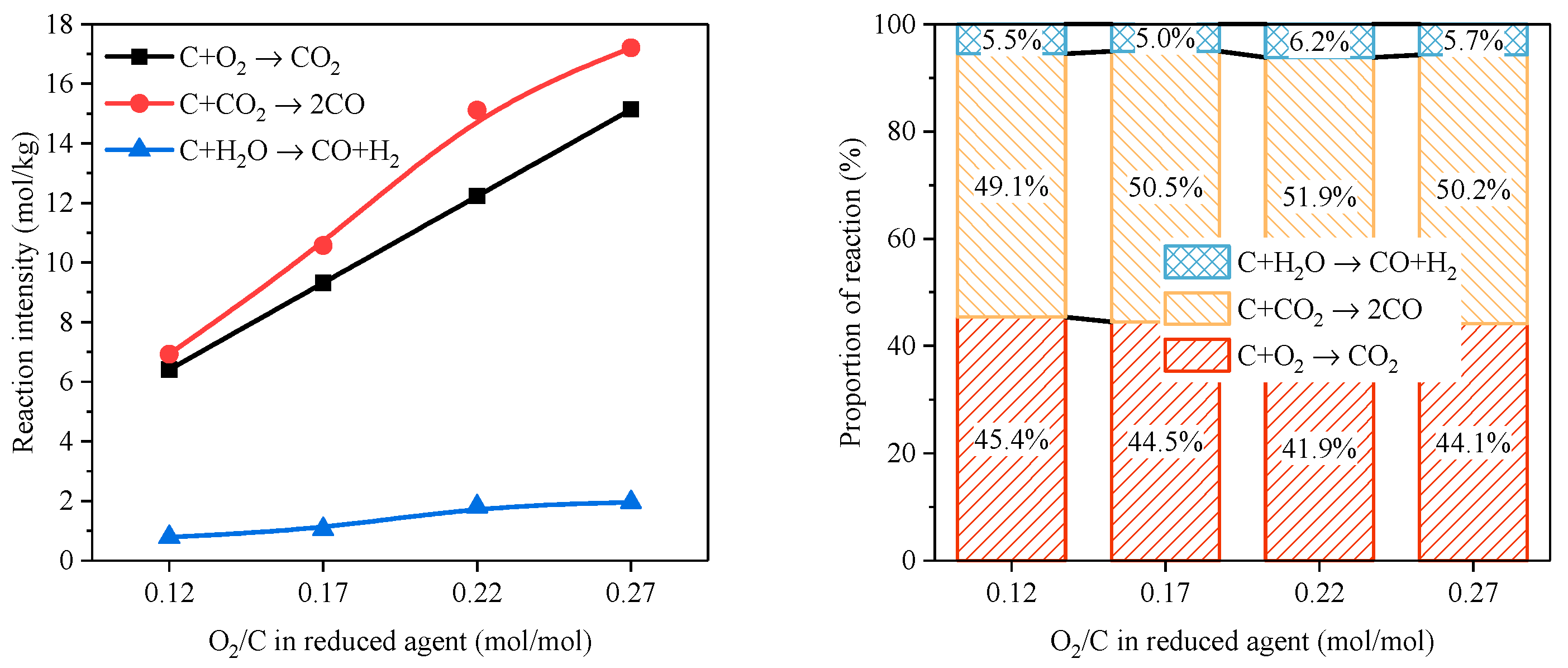

3.2. Effect of O2/C in the Reduced Agent

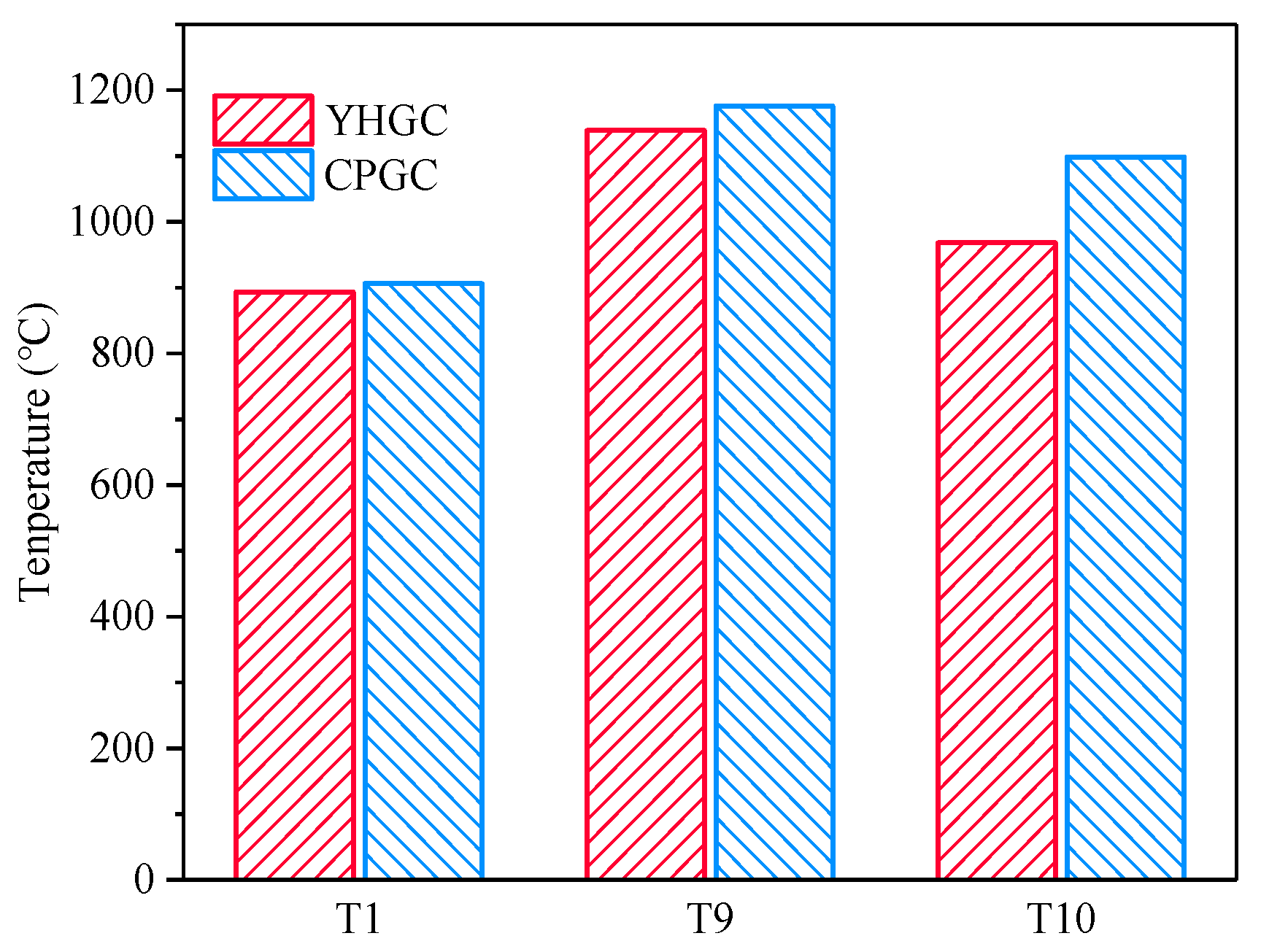

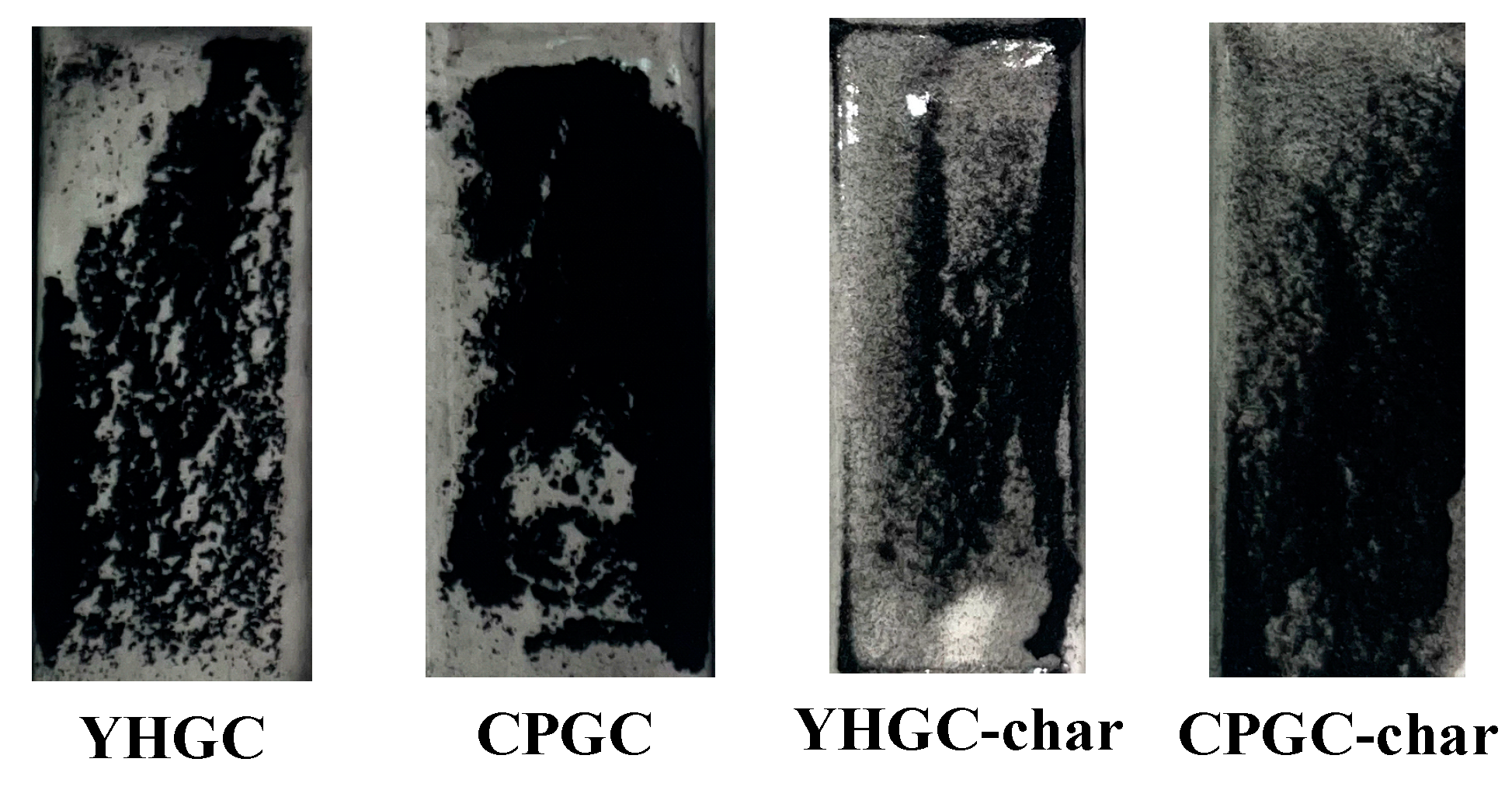

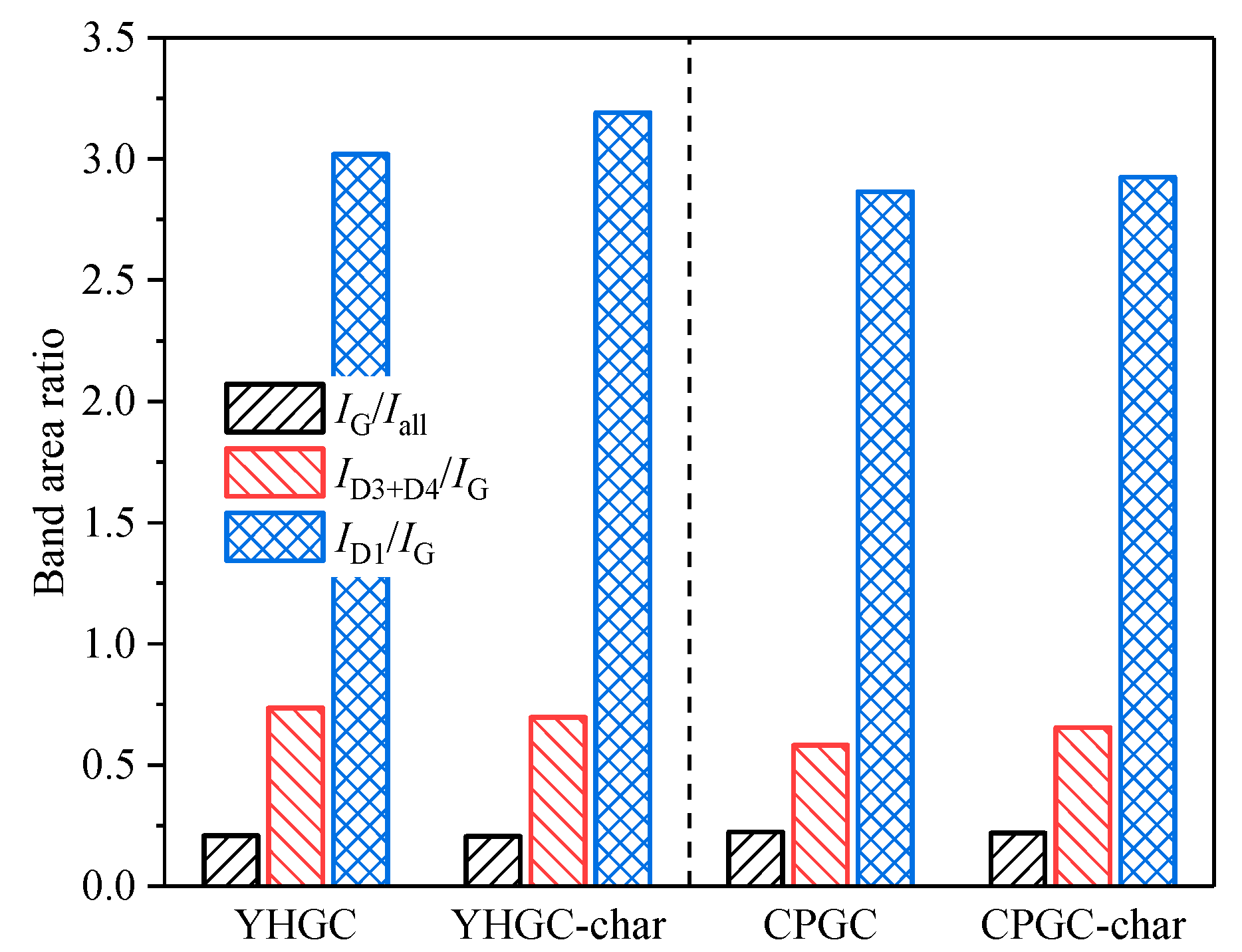

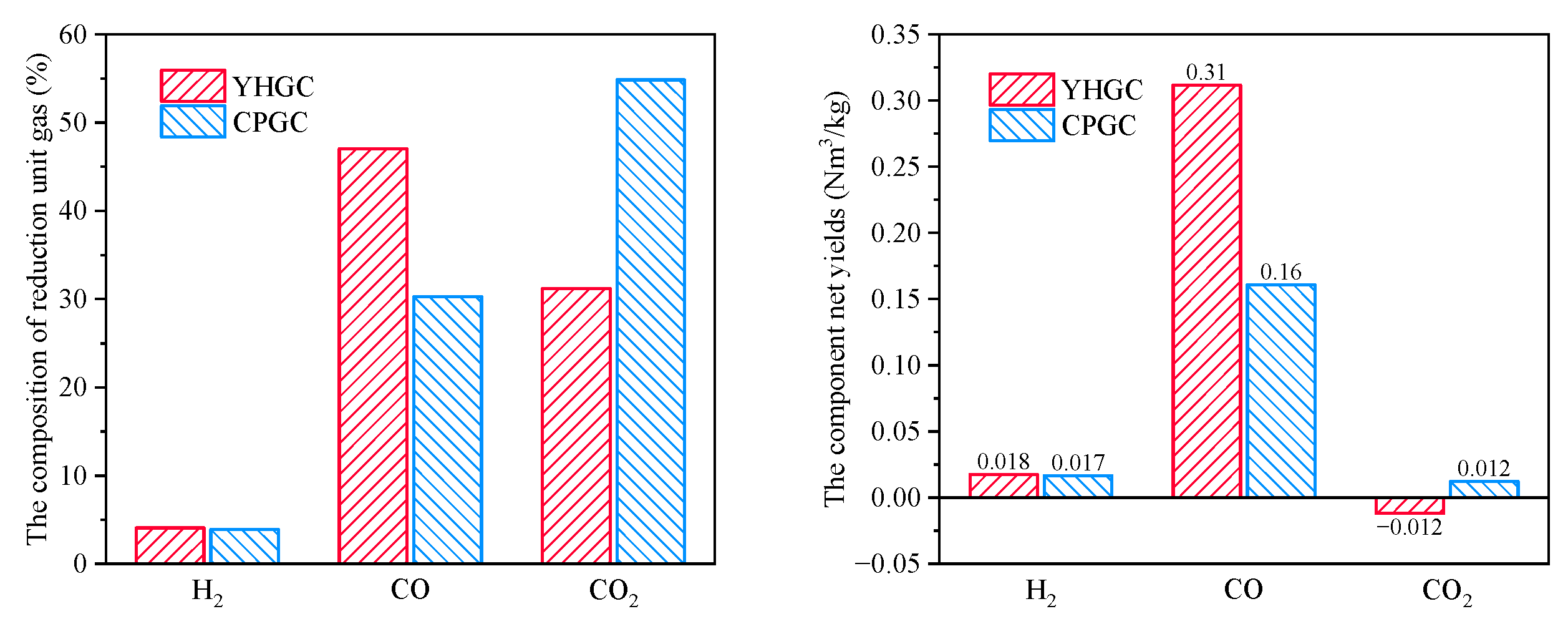

3.3. Effect of Different Coal Gasification Chars

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Aad | The content of ash on the air-dry basis |

| CFB | Circulating fluidized bed |

| CPGC | Chiping gasification char |

| CPGC-char | Activated char of CPGC |

| DR | Downdraft reactor |

| FCad | The content of fixed carbon on the air-dry basis |

| Mad | The content of moisture on the air-dry basis |

| Qnet,ad | The net calorific value on the air-dry basis |

| TGA | Thermogravimetric analysis |

| Vad | The content of volatiles on the air-dry basis |

| WGSR | Water gas shift reaction |

| YHGC | Yihua gasification char |

| YHGC-char | Activated char of YHGC |

References

- Zhi, K.; Li, Z.; Wang, B.; Klemeš, J.J.; Guo, L. A review of CO2 utilization and emissions reduction: From the perspective of the chemical engineering. Process Saf. Environ. Prot. 2023, 172, 681–699. [Google Scholar] [CrossRef]

- Theofanidis, S.A.; Antzaras, A.N.; Lemonidou, A.A. CO2 as a building block: From capture to utilization. Curr. Opin. Chem. Eng. 2023, 39, 100902. [Google Scholar] [CrossRef]

- Chan, Y.H.; Syed Abdul Rahman, S.N.F.; Lahuri, H.M.; Khalid, A. Recent progress on CO-rich syngas production via CO2 gasification of various wastes: A critical review on efficiency, challenges and outlook. Environ. Pollut. 2021, 278, 116843. [Google Scholar] [CrossRef] [PubMed]

- Sabri, M.A.; Al Jitan, S.; Bahamon, D.; Vega, L.F.; Palmisano, G. Current and future perspectives on catalytic-based integrated carbon capture and utilization. Sci. Total Environ. 2021, 790, 148081. [Google Scholar] [CrossRef] [PubMed]

- Lu, W.; Cao, Q.; Xu, B.; Adidharma, H.; Gasem, K.; Argyle, M.; Zhang, F.; Zhang, Y.; Fan, M. A new approach of reduction of carbon dioxide emission and optimal use of carbon and hydrogen content for the desired syngas production from coal. J. Clean. Prod. 2020, 265, 121786. [Google Scholar] [CrossRef]

- Antolini, D.; Ail, S.S.; Patuzzi, F.; Grigiante, M.; Baratieri, M. Experimental investigations of air-CO2 biomass gasification in reversed downdraft gasifier. Fuel 2019, 253, 1473–1481. [Google Scholar] [CrossRef]

- Lahijani, P.; Zainal, Z.A.; Mohammadi, M.; Mohamed, A.R. Conversion of the greenhouse gas CO2 to the fuel gas CO via the Boudouard reaction: A review. Renew. Sustain. Energy Rev. 2015, 41, 615–632. [Google Scholar] [CrossRef]

- Qinggang, L.; Zhen, C. Highly efficient and clean utilizaiton of fossil energy under carbon peak and neutrality targets. Bull. Chin. Acad. Sci. 2022, 37, 541–548. [Google Scholar]

- Hunt, J.; Ferrari, A.; Lita, A.; Crosswhite, M.; Ashley, B.; Stiegman, A.E. Microwave-Specific Enhancement of the Carbon–Carbon Dioxide (Boudouard) Reaction. J. Phys. Chem. C 2013, 117, 26871–26880. [Google Scholar] [CrossRef]

- Shurtz, R.C.; Fletcher, T.H. Coal Char-CO2 Gasification Measurements and Modeling in a Pressurized Flat-Flame Burner. Energy Fuels 2013, 27, 3022–3038. [Google Scholar] [CrossRef]

- Vamvuka, D.; Karouki, E.; Sfakiotakis, S. Gasification of waste biomass chars by carbon dioxide via thermogravimetry. Part I: Effect of mineral matter. Fuel 2011, 90, 1120–1127. [Google Scholar] [CrossRef]

- Duman, G.; Uddin, M.A.; Yanik, J. The effect of char properties on gasification reactivity. Fuel Process. Technol. 2014, 118, 75–81. [Google Scholar] [CrossRef]

- Tong, W.; Liu, Q.; Yang, C.; Cai, Z.; Wu, H.; Ren, S. Effect of pore structure on CO2 gasification reactivity of biomass chars under high-temperature pyrolysis. J. Energy Inst. 2020, 93, 962–976. [Google Scholar] [CrossRef]

- Zhang, X.; Zhu, S.; Zhu, J.; Liu, Y.; Zhang, J.; Hui, J.; Ding, H.; Cao, X.; Lyu, Q. Preheating and combustion characteristics of anthracite under O2/N2, O2/CO2 and O2/CO2/H2O atmospheres. Energy 2023, 274, 127419. [Google Scholar] [CrossRef]

- Su, K.; Ouyang, Z.; Ding, H.; Wang, W.; Zhang, J.; Wang, H.; Zhu, S. Experimental investigation on effect of external circulation system on preheating characteristics of pulverized coal. Energy 2023, 278, 127781. [Google Scholar] [CrossRef]

- Jiang, D.; Song, W.; Wang, X.; Zhu, Z. Physicochemical properties of bottom ash obtained from an industrial CFB gasifier. J. Energy Inst. 2021, 95, 1–7. [Google Scholar] [CrossRef]

- Guizani, C.; Jeguirim, M.; Valin, S.; Limousy, L.; Salvador, S. Biomass Chars: The Effects of Pyrolysis Conditions on Their Morphology, Structure, Chemical Properties and Reactivity. Energies 2017, 10, 796. [Google Scholar] [CrossRef]

- Zhang, X.-s.; Song, X.-d.; Su, W.-g.; Wei, J.-t.; Bai, Y.-h.; Yu, G.-s. In-situ study on gasification reaction characteristics of Ningdong coal chars with CO2. J. Fuel Chem. Technol. 2019, 47, 385–392. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, J.; Lyu, Q.; Zhu, J.; Pan, F. Microstructure analysis of fluidized preheating pulverized coal under O2/CO2 atmospheres. Fuel 2021, 292, 120386. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, J.; Lyu, Q.; Liu, J.; Pan, F. Coke generation and conversion behavior of pulverized coal combustion. J. Energy Inst. 2020, 93, 2096–2107. [Google Scholar] [CrossRef]

- Liang, C.; Lyu, Q.; Na, Y.; Wang, X. Gasification of preheated coal: Experiment and thermodynamic equilibrium calculation. J. Energy Inst. 2019, 92, 1005–1013. [Google Scholar] [CrossRef]

- Ding, H.; Ouyang, Z.; Shi, Y.; Chen, R.; Zhang, Z.; Zhu, S.; Lyu, Q. Effects of the T-abrupt exit configuration of riser on fuel properties, combustion characteristics and NOx emissions with coal self-preheating technology. Fuel 2023, 337, 126860. [Google Scholar] [CrossRef]

- Mahinpey, N.; Gomez, A. Review of gasification fundamentals and new findings: Reactors, feedstock, and kinetic studies. Chem. Eng. Sci. 2016, 148, 14–31. [Google Scholar] [CrossRef]

- Wang, Z.; Burra, K.G.; Li, X.; Zhang, M.; He, X.; Lei, T.; Gupta, A.K. CO2-assisted gasification of polyethylene terephthalate with focus on syngas evolution and solid yield. Appl. Energy 2020, 276, 115508. [Google Scholar] [CrossRef]

- Singh, P.; Déparrois, N.; Burra, K.G.; Bhattacharya, S.; Gupta, A.K. Energy recovery from cross-linked polyethylene wastes using pyrolysis and CO2 assisted gasification. Appl. Energy 2019, 254, 113722. [Google Scholar] [CrossRef]

- Wang, B.; Xu, F.; Wang, X.; Li, J.; Song, Y.; Qiao, Y.; Tian, Y. Comparative study on pyrolysis and gasification within CO2 atmosphere of typical forestry biomass in Northeast Asia: Thermal behavior and kinetic analysis. Fuel 2022, 324, 124540. [Google Scholar] [CrossRef]

- Liu, T.-f.; Fang, Y.-t.; Wang, Y. An experimental investigation into the gasification reactivity of chars prepared at high temperatures. Fuel 2008, 87, 460–466. [Google Scholar] [CrossRef]

- Jing, X.; Wang, Z.; Yu, Z.; Zhang, Q.; Li, C.; Fang, Y. Experimental and Kinetic Investigations of CO2 Gasification of Fine Chars Separated from a Pilot-Scale Fluidized-Bed Gasifier. Energy Fuels 2013, 27, 2422–2430. [Google Scholar] [CrossRef]

- Xie, Y.; Yang, H.; Zeng, K.; Zhu, Y.; Hu, J.; Mao, Q.; Liu, Q.; Chen, H. Study on CO2 gasification of biochar in molten salts: Reactivity and structure evolution. Fuel 2019, 254, 115614. [Google Scholar] [CrossRef]

- Liang, C.; Zhang, H.; Zhu, Z.; Na, Y.; Lu, Q. CO2-O2 gasification of a bituminous coal in circulating fluidized bed. Fuel 2017, 200, 81–88. [Google Scholar] [CrossRef]

- Fermoso, J.; Stevanov, C.; Moghtaderi, B.; Arias, B.; Pevida, C.; Plaza, M.G.; Rubiera, F.; Pis, J.J. High-pressure gasification reactivity of biomass chars produced at different temperatures. J. Anal. Appl. Pyrolysis 2009, 85, 287–293. [Google Scholar] [CrossRef]

- Malekshahian, M.; Hill, J.M. Kinetic Analysis of CO2 Gasification of Petroleum Coke at High Pressures. Energy Fuels 2011, 25, 4043–4048. [Google Scholar] [CrossRef]

- Wall, T.F.; Liu, G.-s.; Wu, H.-w.; Roberts, D.G.; Benfell, K.E.; Gupta, S.; Lucas, J.A.; Harris, D.J. The effects of pressure on coal reactions during pulverised coal combustion and gasification. Prog. Energy Combust. Sci. 2002, 28, 405–433. [Google Scholar] [CrossRef]

- Hüttinger, K.J.; Nill, J.S. A method for the determination of active sites and true activation energies in carbon gasification: (II) Experimental results. Carbon 1990, 28, 457–465. [Google Scholar] [CrossRef]

- Ahmed, I.I.; Gupta, A.K. Kinetics of woodchips char gasification with steam and carbon dioxide. Appl. Energy 2011, 88, 1613–1619. [Google Scholar] [CrossRef]

- Irfan, M.F.; Usman, M.R.; Kusakabe, K. Coal gasification in CO2 atmosphere and its kinetics since 1948: A brief review. Energy 2011, 36, 12–40. [Google Scholar] [CrossRef]

- Kajitani, S.; Hara, S.; Matsuda, H. Gasification rate analysis of coal char with a pressurized drop tube furnace. Fuel 2002, 81, 539–546. [Google Scholar] [CrossRef]

- Zhu, L.; Wang, Y.; Zhang, Z.; Li, J.; Yu, G. Effects of H2 and CO on Char-Gasification Reactivity at High Temperatures. Energy Fuels 2020, 34, 720–727. [Google Scholar] [CrossRef]

- Zhang, S.; Liang, C.; Wang, X.; Zhu, Z. Experimental study and equilibrium analysis on thermal reduction of CO2 by CFB gasification. J. Energy Inst. 2024, 101623. [Google Scholar] [CrossRef]

- Yang, Q.; Qi, X.; Lyu, Q.; Zhu, Z. Physicochemical Properties of Coal Gasification Fly Ash from Circulating Fluidized Bed Gasifier. J. Therm. Sci. 2023, 32, 1710–1720. [Google Scholar] [CrossRef]

- Liu, D.; Wang, W.; Tu, Y.; Ren, G.; Yan, S.; Liu, H.; He, H. Flotation specificity of coal gasification fine slag based on release analysis. J. Clean. Prod. 2022, 363, 132426. [Google Scholar] [CrossRef]

- Kou, M.; Zuo, H.; Ning, X.; Wang, G.; Hong, Z.; Xu, H.; Wu, S. Thermogravimetric study on gasification kinetics of hydropyrolysis char derived from low rank coal. Energy 2019, 188, 116030. [Google Scholar] [CrossRef]

- Chen, C.; Tang, Y.; Guo, X. Comparison of structural characteristics of high-organic-sulfur and low-organic-sulfur coal of various ranks based on FTIR and Raman spectroscopy. Fuel 2022, 310, 122362. [Google Scholar] [CrossRef]

- Dresselhaus, M.S.; Dresselhaus, G. Intercalation compounds of graphite. Adv. Phys. 1981, 30, 139–326. [Google Scholar] [CrossRef]

- Su, K.; Ding, H.; Ouyang, Z.; Zhang, J.; Zhu, S. Experimental study on effects of multistage reactant and air jet velocities on self-preheating characteristics and NOx emission of burning pulverized coal. Fuel 2022, 325, 124879. [Google Scholar] [CrossRef]

- Guedes, A.; Valentim, B.; Prieto, A.C.; Noronha, F. Raman spectroscopy of coal macerals and fluidized bed char morphotypes. Fuel 2012, 97, 443–449. [Google Scholar] [CrossRef]

- Jayaraman, K.; Gokalp, I. Effect of char generation method on steam, CO2 and blended mixture gasification of high ash Turkish coals. Fuel 2015, 153, 320–327. [Google Scholar] [CrossRef]

- Ma, C.; Zhao, Y.; Lang, T.; Zou, C.; Zhao, J.; Miao, Z. Pyrolysis characteristics of low-rank coal in a low-nitrogen pyrolysis atmosphere and properties of the prepared chars. Energy 2023, 277, 127524. [Google Scholar] [CrossRef]

- Frederick, W.J.; Wag, K.J.; Hupa, M.M. Rate and mechanism of black liquor char gasification with carbon dioxide at elevated pressures. Ind. Eng. Chem. Res. 1993, 32, 1747–1753. [Google Scholar] [CrossRef]

- Mitsuoka, K.; Hayashi, S.; Amano, H.; Kayahara, K.; Sasaoaka, E.; Uddin, M.A. Gasification of woody biomass char with CO2: The catalytic effects of K and Ca species on char gasification reactivity. Fuel Process. Technol. 2011, 92, 26–31. [Google Scholar] [CrossRef]

| Material | Proximate Analyze/wt% | Ultimate Analyze/wt% | Qnet,ad MJ/kg | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mad | FCad | Vad | Aad | Cad | Had | Oad | Nad | Sad | ||

| YHGC | 1.08 | 64.05 | 7.08 | 27.79 | 66.83 | 0.56 | 3.32 | 0.24 | 0.18 | 22.94 |

| CPGC | 6.12 | 77.18 | 2.04 | 14.65 | 74.86 | 0.73 | 2.57 | 0.62 | 0.34 | 28.85 |

| Peak Name | Functional Groups | Position | Type |

|---|---|---|---|

| D4 | Hybrid bonds of sp2 and sp3 | 1150 cm−1 | Lorentzian peak |

| D1 | In-plane defects; Edge effects | 1350 cm−1 | Lorentzian peak |

| D3 | Amorphous sp2 hybrid bonds | 1530 cm−1 | Gaussian peak |

| G | Graphite structure | 1580 cm−1 | Lorentzian peak |

| D2 | Intercalate concentration | 1620 cm−1 | Lorentzian peak |

| No. | Material | Feed Rate (kg/h) | Active Agent | Reduced Agent | ||

|---|---|---|---|---|---|---|

| Composition | O2/C (Mol/Mol) | Composition | O2/C (Mol/Mol) | |||

| 1 | YHGC | 23 | O2/CO2 (40%/60%) | 0.073 | O2/CO2 (70%/30%) | 0.18 |

| 2 | O2/CO2 (60%/40%) | |||||

| 3 | O2/CO2 (50%/50%) | |||||

| 4 | O2/CO2 (40%/60%) | |||||

| 5 | O2/CO2 (30%/70%) | |||||

| No. | Material | Feed Rate (kg/h) | The Active Agent | The Reduced Agent | ||

|---|---|---|---|---|---|---|

| Composition | O2/C (Mol/Mol) | Composition | O2/C (Mol/Mol) | |||

| 6 | YHGC | 23 | O2/CO2 (50%/50%) | 0.11 | O2/CO2 (50%/50%) | 0.12 |

| 7 | 0.17 | |||||

| 8 | 0.22 | |||||

| 9 | 0.27 | |||||

| No. | Material | Feed Rate (kg/h) | The Active Agent | The Reduced Agent | ||

|---|---|---|---|---|---|---|

| Composition | O2/C (Mol/Mol) | Composition | O2/C (Mol/Mol) | |||

| 6 | YHGC | 23 | O2/CO2 (50%/50%) | 0.11 | O2/CO2 (50%/50%) | 0.12 |

| 10 | CPGC | 32 | O2/CO2 (31%/69%) | 0.15 | O2/CO2 (60%/40%) | 0.10 |

| Specific Surface Area (m2/g) | Pore Volume (cm3/g) | Average Pore Diameter (Å) | |

|---|---|---|---|

| YHGC | 561.2566 | 0.659410 | 52.9117 |

| YHGC-char | 555.6712 | 0.530141 | 50.5930 |

| CPGC | 180.9190 | 0.251470 | 55.5980 |

| CPGC-char | 238.3206 | 0.144802 | 38.2710 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Liang, C.; Zhu, Z.; Cui, R. Experimental Study on the Thermal Reduction of CO2 by Activated Solid Carbon-Based Fuels. Energies 2024, 17, 2164. https://doi.org/10.3390/en17092164

Zhang S, Liang C, Zhu Z, Cui R. Experimental Study on the Thermal Reduction of CO2 by Activated Solid Carbon-Based Fuels. Energies. 2024; 17(9):2164. https://doi.org/10.3390/en17092164

Chicago/Turabian StyleZhang, Siyuan, Chen Liang, Zhiping Zhu, and Ruifang Cui. 2024. "Experimental Study on the Thermal Reduction of CO2 by Activated Solid Carbon-Based Fuels" Energies 17, no. 9: 2164. https://doi.org/10.3390/en17092164

APA StyleZhang, S., Liang, C., Zhu, Z., & Cui, R. (2024). Experimental Study on the Thermal Reduction of CO2 by Activated Solid Carbon-Based Fuels. Energies, 17(9), 2164. https://doi.org/10.3390/en17092164