Abstract

This article presents the verification of the hypothesis on using certain approximation curves in the evaluation of used lubricating oil. These curves are plotted for fresh lubricating oil to approximate the parameters of lubricating oil diluted with diesel oil. To confirm the hypothesis, an experiment is conducted to determine the flash point, initial boiling point, density at 15 °C, kinematic viscosity at 40 °C and 100 °C, and viscosity index. The analysis covers fresh oil and used SAE 30 grade Marinol CB-30 RG1230 oil taken from the circulating lubrication system of a supercharged, trunk-piston, 4-stroke ZUT Zgoda Sulzer 5 BAH 22 engine that is located in the Marine Power Plant Laboratory of the Maritime University of Szczecin. Undiluted lubricating oils (both fresh and used) and mixtures of lubricating oils with diesel oil are examined for diesel oil concentrations in the mixture equal to 1, 2, 5, 10, 15, and 20% m/m. Orlen Efecta Diesel Biodiesel is used to prepare the mixtures. The functions approximating the parameters for fresh oil are determined and adapted to describe the variation of the same parameters for the used lubricating oil. For each case, the coefficient of determination, the maximum relative error of the model fitting to the experimental results, and the root mean square error (RMSE) are determined. In the experiment, the variation in the parameters of the used lubricating oil remained the same as for fresh oil parameters. Thus, the research hypothesis is confirmed.

1. Introduction

There are many studies seeking to evaluate the efficiency and reliability of internal combustion engines with contaminated circulating lubricating oil, including lubricating oil diluted with fuel (both distillate and residual). Experience shows that dilution of lubricating oil with fuel is unfavorable to the engine, including deterioration of engine performance, shortening of oil life, and reduction of engine reliability and safety [1,2,3]. An excessive, progressive dilution of oil with fuel can lead to significant wear and tear and, ultimately, to serious engine failure.

Oil film is crucial for reducing the coefficient of friction for tribological pairs. The main problem with the dilution of lubricating oil with distillation fuel is the reduced viscosity of the lubricating oil since diesel oil has a much lower viscosity than lubricating oil. Therefore, the dilution of lubricating oil can cause a deterioration of the lubricating properties of the given oil and a reduction in the strength of the oil film that, in turn, contributes to the intensification of the wear of cylinder liners and bearings [3,4], as well as the possibility of causing premature ignition in the engine cylinder [5].

The existing literature also indicates that other possible issues can occur because of lower oil viscosity or oil degradation. These issues include a reduction in the effectiveness of oil additives, increased oil volatility, and an accelerated rate of oil aging and oxidation [1,6,7,8,9]. Deterioration of lubricating oil properties results in more frequent oil changes and increases the engine operating costs.

This problem becomes even more significant when lubricating oils are diluted with fuels containing biocomponents, such as fatty acid methyl esters (FAMEs) [10,11]. In such a case, the oil-and-fuel mixture may not only have deteriorated lubricity properties [12] but also significantly reduced thermal and oxidative stability [13,14], and such a mixture may intensify the corrosion processes in the engine [15].

It should be noted that the main cause of fuel leakage from the combustion chambers into the crankcase is blow-by. This involves the deterioration of piston rings, pistons and cylinder liners [3], and the fuel injection system, as well as the fuel leakage drainage system [16]. The fuel that penetrates through (along) the cylinder liner into the crankcase intensifies the wear and tear of the piston–ring–cylinder liner tribological system. Consequently, the piston can be galled, and the amount of heat generated during this process will be enough to initiate an explosion [4]. Galling between the two elements, e.g., piston and liner, always constitutes emergency wear and is generally caused by inadequate lubrication—this includes oil contamination, an absence of oil, or insufficient oil lubricity—or by loads that exceed the permissible limits, leading to deformation of the mating parts and excessive thrust.

By measuring the ignition temperature and viscosity of the lubricating oil, one can rapidly identify instances of fuel contamination. Of course, lubricating oil is tested in laboratories in compliance with established procedures (such as those developed by CEC [17,18,19]) cyclically at fixed intervals [20], usually for several months [21]. It, therefore, will not be a valuable measure in the situation of sudden and rapidly developing damage to piston rings, pistons, cylinder liners, and injectors.

However, when an engine deteriorates over a long time, it is imaginable that testing the lubricating oil for potential oil contamination with fuel may be crucial for improving the safety of engine operation [22]. For the same reason, the lubricating oil flash point has been adopted as a common indicator for evaluating engine performance as an operating standard for marine vessel operators. It is measured by all major laboratories that conduct petrochemical product testing.

Research conducted to date indicates that diesel fuel, when present as a contaminant in lubricating oil, heightens the risk of engine component galling and/or explosion within the crankcase of a trunk-piston internal combustion engine. This is attributed to the independent effects of several factors, such as [23]:

- the deterioration of the lubricating and lubricity properties of oil diluted with fuel, relative to pure oil,

- an increase in the volatility and improvement of the ignition properties of fuel-diluted oil, relative to pure oil,

- an increase in the proportion of droplets with the smallest diameters in the oil mist produced from diluted oil, relative to pure oil.

In the absence of universal and relatively inexpensive methods for assessing the level of diesel contamination of lubricating oil, the research presented in this article was conducted. The experimental results, showcased herein, may prove useful for utilizing periodic, routine assessments of the physical and chemical properties of lubricating oil—collected from the engine’s circulating lubrication system—to evaluate the contamination level of the lubricating oil with diesel fuel, based on established reference characteristics for fresh lubricating oil.

Detecting oil contamination with fuel helps reduce the risk of engine damage. For this reason, engine oils undergo routine periodic testing in laboratories. The first investigations of the characteristics of lubricating oils diluted with diesel oil were carried out in the 1950s by G. W. Ferguson, who provided a detailed study on mixtures with concentrations of diesel oil in lubricating oil up to 20% m/m [24]. The qualitative and quantitative evaluation of lubricating oil dilution with fuel relies on various diagnostic methods [5,6,7]. These methods may include:

- viscosity measurement (PN-EN ISO 3104:2021-3 [8] and ASTM D445 [9]),

- flash point measurement (PN-EN ISO 2719:2016 [10] and PN-EN ISO 2592 [11]),

- measurement of self-ignition temperature (DIN 51794:2003-05 [12])

- oil volatility analysis, initial boiling point measurement, and distillation curve determination (ASTM D322-97(2016) [13], ASTM D5800-21 [14], and CEC L-40-A-93 [15]),

- gas chromatography (GC) (ASTM D3524-14(2020) [16], ASTM D3525-20 [17], ASTM D7593-14 [18], CEC L-94-10 [19], JPI-5S-23-2017 [20], and JPI-5S-24-2017 [21]),

- FTIR spectrometry (ASTM E2412-10(2018) [22]),

- surface acoustic wave sensing (SAW) (ASTM D8004-15 [23], ASTM D8004-23 [24]),

- gas chromatography coupled with mass spectrometry (GC-MS) [6], ultraviolet (UV) spectrofluorimetry [7,25,26],

- nuclear magnetic resonance (NMR) spectroscopy [6,27],

- the analysis of the oil mist particle morphology [25],

- electron spin resonance (paramagnetic) spectroscopy (ESR) [28],

- NMR coupled with GC-MS [6].

The advantages and disadvantages of each method are described in previous scientific publications [29,30,31]. However, due to factors such as availability, cost, and measurement speed, the most commonly used method remains the measurement of viscosity and flash point of oil. Quantitative assessment of the degree of lubricating oil contamination by fuel can be aided by mathematical models [30].The viscosity of the oil changes with the amount of fuel contamination in the lubricating oil, and viscosity may decrease when the lubricating oil is diluted with distillate fuel (i.e., diesel, gasoline, etc.) or increase due to the dilution of the lubricating oil with residual fuel (i.e., heavy diesel) [32]. To draw conclusions regarding the dilution of oil with fuel, it is necessary to identify the type of fuel used to power the specific engine that is evaluated for the lubricating oil. With the above in mind, the use of oil viscosity as an indicator for lubricating oil dilution with fuel is insufficient. It should be used as a complementary indicator to be combined with the oil’s flash point.

A drop in the ignition temperature of the lubricating oil in the engine during operation very likely shows that fuel contamination of the lubricating oil has occurred. The method can, therefore, be used in the assessment of the dilution of lubricating oil with marine gas oil (MGO), distillate marine oil (DMO), and residual marine (RM) fuels.

The present authors have conducted a number of studies evaluating, among other things, the variation of viscosity, density, initial boiling point, and flash point of selected types of lubricating oils as a function of the dilution of these lubricating oils with fuel. To ensure objectivity, repeatability, and verifiability in the studies, individual experiments were carried out using mixtures of fresh lubricating oil and fuel oil. This prompted the question of whether used lubricating oil would have parameter variations similar to fresh oil and whether the mathematical models developed for fresh lubricating oils could be used to accurately evaluate the initial characteristics of used lubricating oil.

In the absence of universal and relatively inexpensive methods for assessing the level of diesel contamination of lubricating oil, the research presented in this article was conducted. The experimental results, showcased herein, may prove useful for utilizing periodic, routine assessments of the physical and chemical properties of lubricating oil—collected from the engine’s circulating lubrication system—to evaluate the contamination level of the lubricating oil with diesel fuel based on established reference characteristics for fresh lubricating oil.

The authors hypothesized that the characteristic fused(C) describing the variability of a specific parameter as a function of the percentage concentration of fuel oil in lubricating oil C (% m/m) can be described, for the purposes of rough analyses, as follows:

where fused(C) defines the value of the analyzed parameter determined for fresh lubricating oil contaminated with fuel oil at a concentration of C, and K is an indicator of the degradation of lubricating oil (characteristics shift). The mass percentage concentration is determined by the following relationship:

where mDO represents the mass of the diesel oil, and mLO is the mass of the lubricating oil.

In order to verify the above research hypothesis, an experiment was conducted, the results of which are presented in this article.

2. Materials and Methods

For the experiment used in this research, the employed lubricating oil was Marinol CB-30 RG1230, designed for trunk-piston powered marine engines of the SAE 30 viscosity class, and Orlen Efecta Diesel Biodiesel was used. The lubricating oil meets the requirements of engine manufacturers Pielstick (12PA6-280, 12PC2.5V), MAN-B&W (ALPHA6S28L), MAN Augsburg (16V40/45), New Sulzer Diesel, and Wartsila (VASA: 6R32; 16V32). The manufacturers’ specifications of the lubricating oil and fuel oil used in the experiment are shown in Appendix A in Table A1 and Table A2, respectively.

Tests were conducted on fresh oil samples and oil samples taken from the circulating lubrication system of the ZUT Zgoda Sulzer 5 BAH 22 four-stroke supercharged, trunk-piston marine engine, which is owned by the Marine Power Plant Laboratory of the Maritime University of Technology in Szczecin. The engine is shown in Figure 1, while the basic specifications of the engine and the permissible operating parameters of the lubrication system are shown in Table A3 and Table A4 in Appendix A, respectively. The operating time of the used lubricating oil when taking samples was 60 h. The number of operating hours (60 h) mentioned is relatively small. Due to its applications for teaching, the engine used realizes the mentioned number of hours in a fairly long calendar period of about two years. Keeping this in mind, we assumed that, while the products of engine wear in the oil are present in relatively small amounts, the products of oil aging will have a significant impact on the physical and chemical parameters of the oil. To standardize the changes in oil parameters, we have included a series of appendices in the article that detail the composition, impurities, and properties of the lubricating oil used. This step is crucial because each instance of measuring the properties of used oil is inherently unique. Therefore, to present the data objectively, it is necessary to fully characterize the lubricating oil under analysis. We have endeavored to do this through the information provided in the appendices, among other means.

Figure 1.

Sulzer 5 BAH 22 engine and associated circulating lubrication system.

Table A5 and Table A6 of Appendix A show the recorded parameters and elemental composition of the lubricating oils and fuel oil used in the experiment. Table A7 depicts the results of measuring the contaminants of the used lubricating oil tested, including determining the water content, diesel oil content, and solids content. Among the available methods for evaluating the level of solid contaminants, two methods can be employed—one for fuels and the other for hydraulic oils. However, due to the similar chemical composition of the lubricating oils, it was decided to apply both methods to each case. Lubricating oil contamination with diesel oil was measured at the Laboratory of Diagnostics of Tribological Systems (PDST) of the Air Force Institute of Technology. All other measurements presented here were made at the Center for Testing Fuels, Working Fluids, and Environmental Protection (CBPCRiOS) of the Maritime University of Szczecin.

To compare the results of the experiment with previous studies, mixtures with concentrations of diesel oil in lubricating oil in an analogous range were examined. Namely, fresh and used lubricating oil samples were diluted with diesel oil at concentrations of 0, 1, 2, 5, 10, 15, and 20% m/m. For each sample, their characteristic physical and chemical properties (presented in Table A6 of Appendix A) were tested.

A RADWAG WPs 510/C/2 (Radom, Poland) precision laboratory balance with a minimum graduation d of 0.001 g was used to prepare the samples. The maximum indication error of the scale δ from the calibration certificate is 0.002 g and applies to the measurement of a 400 g standard weight. In the experiment, samples with a nominal weight of 200 g were prepared each time.

To obtain a mixture of lubricating oil and diesel oil with a mass fraction of C, the sample was prepared according to the following procedure:

- A clean glass vessel was placed on the scale, and the balance tared.

- Using a precise laboratory pipette, the lubricating oil weighing mLO was measured into the vessel placed on the scale.

- The scale was tared, and fuel with a mass of mDO was measured using a precise laboratory pipette.

- The resulting mixture was agitated with a magnetic stirrer for 15 min.

Before each measurement, the repeatability of the measurement is tested with a reference weight. The calibration certificates of the scale and the 200 g standard weight are included in Appendix A. The type-B standard uncertainty of the mass fraction of diesel oil in the mixture with lubricating oil uw (% m/m) was measured using a laboratory scale with the uncertainty of the weight indicated as compliant with the recommendations of the Guide to the Expression of Uncertainty in Measurement (GUM) [26]. The type-B standard uncertainty of laboratory scale mass indications can be determined using the following formula:

where d denotes the scale resolution, δ is the error of the balance indications from the calibration certificate, u(δ) is the uncertainty of the balance indication error from the calibration certificate, and u(r) is the combined uncertainty of the repeatability scale indications.

The measured mass of fuel and oil is (each time) the difference between the mass of the liquid and the tare of the scale. The mixture mass uncertainty is determined using the following formula:

The uncertainty of the determined mass, um, is 0.0023 g. To determine the type-B standard uncertainty of the mass fraction, a partial differential equation of the following form is derived from Relationship (2):

where is the type-B standard uncertainty of the mass fraction C. After expanding Relationship (5), the final formula is obtained:

The calculated values of uB(C) for the mass fractions of diesel oil in the tested lubricating oils analyzed in this article are 0.026%, 0.010%, 0.002%, 0.001%, 0.001%, and 0.001% by weight for C = 1%, 2%, 5%, 10%, 15%, and 20% m/m, respectively.

In this experiment, the flash point, temperature at the beginning of evaporation, density at 15 °C, kinematic viscosity at 40 °C and 100 °C, and viscosity index were determined for the tested mixtures. The density and viscosity of the substance are parameters that depend on the measurement temperature. Both of these parameters decrease in value with increasing temperature of lubricating oils and diesel oil. To compare different measurements, their values are determined at standardized reference temperatures. In this experiment, measurements were made in accordance with the guidelines of the relevant standards. According to PN-EN ISO 12185:2002 [27], the density of petroleum products is usually measured at 15 °C, while PN-EN ISO 3104:2021-3 [28] specifies the reference temperatures for determining kinematic viscosity for base oils and refined oils at 40 °C and 100 °C, for petroleum paraffin and lubricating additives at 100 °C, while for diesel oils at 40 °C. The viscosity index was determined in accordance with ASTM D2270-10(2016) [29], which requires knowledge of the kinematic viscosity of the tested oil at reference temperatures of 40 °C and 100 °C for its calculation. Considering the above standards, as well as the substances tested and the scope of the experiment, the appropriate reference temperatures for determining the individual parameters of mixtures of fresh or used lubricating oil with diesel oil were adopted as 15 °C for density and 40 °C and 100 °C for kinematic viscosity.

The fundamental indicators that determine the ignition properties of liquid fuels are ignition/self-ignition temperature and ignition/self-ignition delay. According to EN IEC 60079-10-1:2021-09 [30], the flash point of a substance is the lowest temperature at which a liquid, under standard conditions, produces vapor in sufficient quantity to form a flammable mixture with air. This is the lowest temperature of the analytical sample, corrected for an atmospheric pressure of 101.3 kPa, at which the application of an ignition source will momentarily ignite the vapor above the surface of the liquid tested [31]. On the other hand, the autoignition temperature is the lowest temperature at which flammable substances spontaneously ignite in the presence of air (at this temperature, no external initiation is needed for ignition, such as a flame or spark) [32]. The autoignition temperature is always higher than the flash point. In this experiment, the ignition temperature of the lubricating oil/diesel mixtures tested was determined as the primary indicator of ignition properties.

There are several methods for determining the flash point. The method for determining the flash point is selected based on several factors. First, a method imposed by the product specification is chosen. In addition, the method may be selected as determined by law. If regulations or specifications allow the choice of a procedure from several ones, it is advisable to use the most easily available method. There are two classes of flash point test methods [33]: closed cup—using the Abel [34], Pensky–Martens device [35], or Tag [36,37]; and open cup—using the Tagliabue [38] or Cleveland [39] device. The flash point measurement results depend on the method used, so it is important to indicate what method a measurement was made with. Measurement in a closed cup usually gives results that are 20–40 °C lower than in an open cup [8]. The test method is selected depending on the type of substance to be tested and its physical and chemical properties. For example, highly volatile substances, such as some alcohols or some hydrocarbons, can be tested using both the Abel method and the equilibrium method [40] but not the Pensky–Martens and Cleveland methods. Petroleum substances such as diesel, fuel oil, or gasoline should be tested by non-equilibrium methods such as the Pensky–Martens, Abel, or Cleveland [31] methods.

Accordingly, bearing in mind the advantages and disadvantages of each method, the flash point in this experiment was determined in a closed crucible using the Pensky–Martens method. The flash point and initial boiling point were found using a Flashpoint Pensky–Martens Semi-Automatic apparatus (Walter Herzog GmbH, Lauda-Königshofen, Germany). The flash point was determined in accordance with EN ISO 2719:2016 [10].

Density was found using a DMA 4500 density analyzer (Anton Paar GmbH, Graz, Austria) with an oscillating U-tube according to PN-EN ISO 12185:2002 [35]. The accuracy of the measurement temperature setting is 0.02 °C. The accuracy of density measurement is 5 × 10−5 g/cm3.

Kinematic viscosity was measured using a Cannon-Fenske Opaque glass capillary viscometer (Paradise Scientific Company Ltd., Dhaka, Bangladesh) and a TV 2000 viscometric bath (Labovisco bv, Zoetermeer, the Netherlands) according to PN-EN ISO 3104:2004 [8]. The accuracy of the bath temperature setting is 0.01 °C. The accuracy of viscosity measurement is 0.1 mm2/s.

Using the measured kinematic viscosities of the individual mixtures at 40 °C and 100 °C, the viscosity index was calculated and determined as per ASTM D2270-10(2016) [36]. An Anton Paar calculator was used for this purpose [37].

3. Results and Discussion

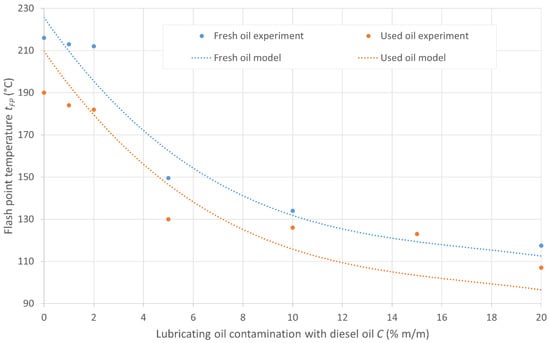

Figure 2 shows the measured ignition temperature values of the lubricating oil and oil fuel mixtures tested for fresh oil and used oil. In addition, curves approximating these relationships are plotted.

Figure 2.

Relationship between the flash point and lubricating oil contamination with diesel oil for tested lubricating oil and oil fuel mixtures.

The relationship between the flash point and concentration of diesel oil mixed in lubricating oil for the fresh oil that has been tested can be effectively fitted with the following polynomial:

where a1 = 0.0001 °C/(% m/m)4, a2 = –0.0219 °C/(% m/m)3, a3 = 0.9596 °C/(% m/m)2, a4 = 16.888 °C/(% m/m), and a4 = 225.62 °C.

Figure 2 shows this fitting model using the blue dotted line. The fit of the model described by Formula (7) has R2 > 0.97, while the maximum relative error over the measurement range studied is <8.70% and the root mean square error (RMSE) is <9.2 °C. The model is experimentally adapted to describe the flash point of the used lubricating oil diluted with fuel. For this purpose, Formula (7) is modified by shifting the approximating curve down by |K1| to obtain a model expressed by:

where K1 = −16 °C is the oil aging constant.

The adopted constant K1 ensures the lowest value of the relative error of fitting the model (8) to the recorded values of the flash point of mixtures of used lubricating oil with diesel oil for the tested concentrations. The relationship (8) is represented in Figure 2 by the orange dotted curve. The maximum relative error of the model fitting to measurements is <14.23%, and the fitting of a model (8) to experimental results is very good at R2 > 0.93. The model’s root mean square error (8) is <14.2 °C. In view of the above, it can be assumed that a modified model originally created for fresh oil can be used to evaluate the flash point of used lubricating oil. The modeling of the relationship between ignition temperature and lubricating oil contamination with diesel oil using a regression equation would have yielded an equation with a better fit to the measurements depicted in Figure 2 with orange points than the one presented. In addition, the orange line fitted in this way would approach the blue line with the increasing concentration of diesel oil in the mixture, as a reviewer rightly observed. To enhance the quality of the paper, we omitted the plotting of the characteristic in question from the aforementioned figure. Our objective was to demonstrate that the characteristics delineated by Relation (7)—represented as the blue line—adequately model the relationship between ignition temperature and the concentration of diesel oil in a mixture with used lubricating oil. This aligns with the research hypothesis we introduced in the opening section.

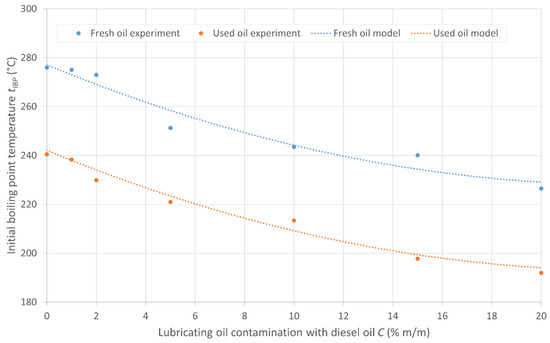

Figure 3 shows the measured initial boiling temperatures of the lubricating oil and oil fuel mixtures tested for fresh oil and used oil. In addition, curves approximating these relationships are depicted with dotted plots.

Figure 3.

Relationship between the initial boiling point temperature and lubricating oil contamination with diesel oil for tested lubricating oil and oil fuel mixtures.

The relationship between the initial boiling temperature and concentration of diesel oil mixed in lubricating oil for the fresh oil being tested can be effectively fitted with the following polynomial:

where b 1 = 0.0892 °C/(% m/m)2, b2 = −4.1848 °C/(% m/m), and b3 = 277.12 °C.

Figure 3 shows this fitting model using the blue dotted line. The fit of the model described by Formula (9) has R2 > 0.95, while the maximum relative error over the measurement range studied is <2.84% and the RMSE is <4.0 °C. This model is experimentally adapted to describe the initial boiling point of the used lubricating oil diluted with fuel. For this purpose, Formula (9) is modified by shifting the approximating curve down by |K2| to obtain a model expressed by:

where K2 = −35 °C is the oil aging constant.

The adopted constant K2 ensures the lowest value of the relative error in fitting the model (10) to the recorded values of the initial boiling point temperature of mixtures of used lubricating oil with diesel oil for the tested concentrations. The relationship (10) is represented in Figure 3 by the orange dotted curve. The maximum relative error of the model fit to measurements is <1.98%, and the fit of the model (10) to experimental results is very good at R2 > 0.98. The model’s root mean square error (10) is <2.7 °C. In view of the above, it can be assumed that a modified model originally created for fresh oil can be used to evaluate the initial boiling point of used lubricating oil.

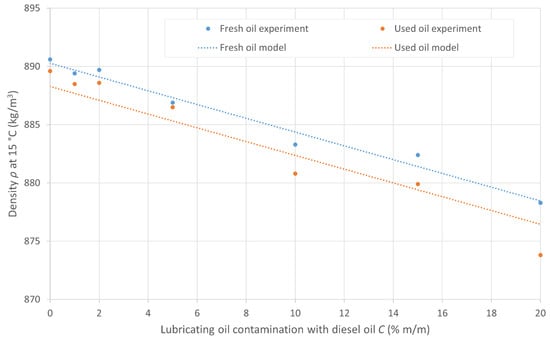

Figure 4 shows the measured density at 15 °C of the lubricating oil and diesel oil mixtures tested for fresh oil and used oil. In addition, curves approximating these relationships are depicted with dotted plots.

Figure 4.

Relationship between the lubricating oil density at 15 °C and lubricating oil contamination with diesel oil for tested lubricating oil and oil fuel mixtures.

The relationship between the lubricating oil density and the concentration of diesel oil in the lubricating oil for the fresh oil under study can be highly effectively described with a linear relationship model. For the density determined at 15 °C, this is given by the following formula:

where c1 = −0.5912 kg/[m3(% m/m)2] and c2 = 890.28 kg/m3.

Figure 4 shows this fitting model using the blue dotted line. The fit of the model described by Formula (11) has R2 > 0.97, while the maximum relative error over the measurement range studied is <0.13% and the RMSE is <0.7 kg/m3. The model is experimentally adapted to describe the density of the used lubricating oil diluted with fuel. For this purpose, Formula (11) is modified by shifting the approximating curve down by |K3| to obtain a model expressed by:

where K3 = −2 °C is the oil aging constant.

The adopted constant K3 ensures the lowest value of the relative error in fitting the model (12) to the recorded values of density of mixtures of used lubricating oil with diesel oil at 15 °C. The relationship (12) is represented in Figure 4 by the orange dotted curve. The maximum relative error of the model fit to measurements is <0.18%, and the fit of the model (12) to experimental results is very good at R2 > 0.97. The RMSE of model (12) is <1.6 kg/m3. In view of the above, it can be assumed that a modified model originally created for fresh oil can be used to evaluate the density of used lubricating oil at 25 °C.

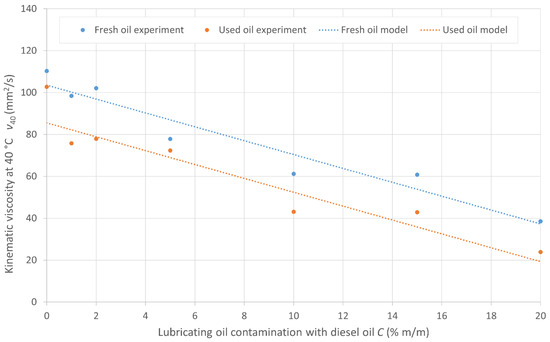

Figure 5 shows the measured kinematic viscosity at 40 °C of the lubricating oil and oil fuel mixtures tested for fresh oil and used oil. In addition, curves approximating these relationships are depicted with dotted plots.

Figure 5.

Relationship between the lubricating oil’s kinematic viscosity at 40 °C and lubricating oil contamination with diesel oil for tested lubricating oil and oil fuel mixtures.

The relationship between the lubricating oil kinematic viscosity and the concentration of diesel oil in the lubricating oil for the fresh oil tested can be highly effectively described with a linear relationship model. For the kinematic viscosity determined at 40 °C, this is given by the formula:

where d1 = −3.3119 mm2/[s(% m/m)2] and d2 = 101.53 mm2/s.

Figure 5 shows this fitting model using the blue dotted line. The fit of the model described by Formula (13) has R2 > 0.92, while the maximum relative error over the measurement range studied is <16.0%, and the RMSE is <6.5 mm2/s. The model is experimentally adapted to describe the kinematic viscosity of the used lubricating oil diluted with fuel. For this purpose, Formula (13) is modified by shifting the approximating curve down by |K4| to obtain a model expressed by:

where K4 = −18 mm2/s is the oil aging constant.

The adopted constant K4 ensures the lowest value of the relative error in fitting the model (14) to the recorded values of kinematic viscosity of mixtures of used lubricating oil with diesel oil at 40 °C. The relationship (14) is represented in Figure 5 by the orange dotted curve. The maximum relative error of the model fit to measurements is <21.66%, and the fit of the model (14) to experimental results is very good at R2 > 0.89. The RMSE of the model (14) is <8.6 mm2/s. In view of the above, it can be assumed that a modified model originally created for fresh oil can be used to evaluate the kinematic viscosity of used lubricating oil at 40 °C.

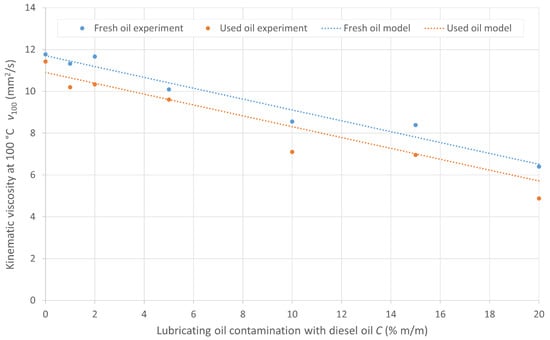

Figure 6 shows the measured kinematic viscosity at 100 °C of the lubricating oil and oil fuel mixtures tested for fresh oil and used oil. In addition, curves approximating these relationships are depicted with dotted plots.

Figure 6.

Relationship between the lubricating oil’s kinematic viscosity at 100 °C and lubricating oil contamination with diesel oil for tested lubricating oil and oil fuel mixtures.

The relationship between the lubricating oil kinematic viscosity and the concentration of diesel oil in the lubricating oil for the fresh oil tested can be highly effectively described with a linear relationship model. For the kinematic viscosity determined at 100 °C, this is given by the following formula:

where e1 = −0.2596 mm2/[s(% m/m)2] and e2 = 11.705 mm2/s.

Figure 6 shows this fitting model using the blue dotted line. The fit of the model described by Formula (15) has R2 ≈ 1.00, while the maximum relative error over the given measurement range is <6.83%, and the RMSE is <0.38 mm2/s. The model is experimentally adapted to describe the kinematic viscosity of the used lubricating oil diluted with fuel. For this purpose, Formula (15) is modified by shifting the approximating curve down by |K5| to obtain a model expressed by:

where K5 = −0.8 mm2/s is the oil aging constant.

The adopted constant K5 ensures the lowest value of the relative error in fitting the model (16) to the recorded values of kinematic viscosity of mixtures of used lubricating oil with diesel oil at 100 °C. The relationship (16) is represented in Figure 6 by the orange dotted curve. The maximum relative error of the model fit to measurements is <17.15%, and the fit of the model (16) to experimental results is very good at R2 ≈ 1.00. The model’s RMSE (16) is <0.62 mm2/s. In view of the above, it can be assumed that a modified model originally created for fresh oil can be used to evaluate the kinematic viscosity of used lubricating oil at 100 °C.

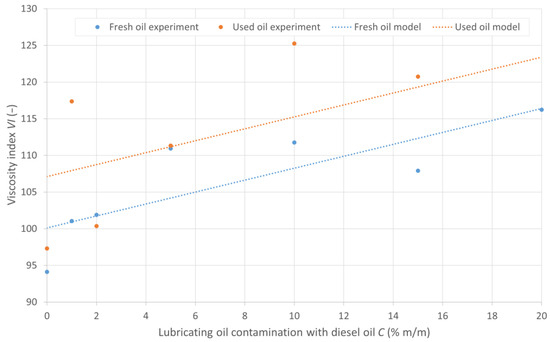

Figure 7 shows the viscosity index values calculated from the measured kinematic viscosity values at 40 °C and 100 °C for the lubricating oil/fuel mixtures tested for fresh oil and used oil. In addition, curves approximating these relationships are depicted with dotted plots.

Figure 7.

Relationship between lubricating oil viscosity and lubricating oil contamination with diesel oil for tested lubricating oil and diesel oil mixtures.

The relationship between the viscosity index of lubricating oil and the concentration of diesel oil mixed in for the fresh oil under study can be highly effectively described with a linear relationship model. This is given by the following formula:

where f1 = 0.8138 (% m/m) and f1 = 10.12.

Figure 7 shows this fitting model as the blue dotted line. The fit of the model described by Formula (17) has R2 > 0.67, while the maximum relative error over the measurement range studied is <6.37%, and the RMSE is <4.03 mm2/s. The model is experimentally adapted to describe the viscosity index of the used lubricating oil diluted with fuel. For this purpose, Formula (17) is modified by shifting the approximating curve up by |K6| to obtain a model expressed by:

where K6 = 7 is the oil aging constant.

The adopted constant K6 ensures the lowest value of the relative error in fitting the model (18) to the calculated values of viscosity of mixtures of used lubricating oil with diesel oil. The relationship (18) is represented in Figure 7 by the orange dotted curve. The maximum relative error of the model fit to measurements is <10.08%, and the fit of the model (18) to experimental results is good at R2 > 0.66. The model’s RMSE (18) is <7.59 mm2/s. In view of the above, it can be assumed that a modified model originally created for fresh oil can be used to evaluate the viscosity indicator of used lubricating oil.

4. Conclusions

For all the parameters analyzed, the models showed satisfactory accuracy in approximating these parameters as a function of the dilution of the test lubricating oil with diesel oil. The experiment confirmed the feasibility of using models for fresh oils, i.e., models prepared for reference conditions for used lubricating oils. In the presented case study, the variation in the parameters of used lubricating oil remained the same as for fresh oil parameters. The hypothesis stated in the Introduction was, therefore, confirmed.

The application of these models faced a major challenge: the need to establish constant K values that account for the degradation of used lubricating oil compared to fresh oil. The value of constant K always depends on the type of engine, technical condition of the engine, operating time of the oil, and operating conditions. Nevertheless, the proposed approach may be applied in the comparative assessment of the lubricating oil dilution with diesel oil for engine oils taken for analysis in power plants, where several engines of the same type operate under the same operating conditions and maintenance schedule.

Author Contributions

Conceptualization, L.C. and M.S.; methodology, L.C. and M.S.; software, L.C. and M.S.; validation, L.C., M.S., R.S. and P.B.; formal analysis, L.C., M.S., R.S. and P.B.; investigation, L.C., M.S., R.S. and P.B.; resources, L.C., M.S., R.S. and P.B.; data curation, L.C.; writing—original draft preparation, L.C. and M.S.; writing—review and editing, L.C., M.S., R.S. and P.B.; visualization, L.C. and M.S.; supervision, L.C.; project administration, L.C.; funding acquisition, L.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was partly funded by the Ministry of Science and Higher Education (MEiN) of Poland, grant number 1/S/KPBMiM/24.

Data Availability Statement

All data are available in this paper.

Acknowledgments

The authors would like to thank the following people for the technical support in conducting the research presented in this article: Janusz Hordyjewicz (provision of lubricating oil), Przemysław Kowalak (consultation regarding measurement uncertainty), Przemysław Jóźwiak, Magdalena Szmukała, and Barbara Żurańska (commissioned laboratory measurements).

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the study’s design, collection, analysis, interpretation of data, writing the manuscript, or deciding to publish the results.

Abbreviations

| a1, a2, a3, a4, a5 | coefficients of the model approximating the flash point |

| ASTM | American Society for Testing and Materials |

| b1, b2, b3 | coefficients of the model approximating the initial boiling point |

| C | exact (expected) mass concentration of diesel oil in the lubricating oil |

| c1, c2 | coefficients of the model approximating density at 15 °C |

| CDO | contamination of used lubricating oil with diesel oil |

| CH2O | contamination of used lubricating oil with water |

| CV | elemental composition of the tested oil |

| d | measurement scale resolution |

| d1, d2 | coefficients of the model approximating kinematic viscosity at 40 °C |

| DCN | derived cetane number |

| DIN | German Institute for Standardization (ger. Deutsches Institut für Normung) |

| e1, e2 | coefficients of the kinematic viscosity model at 100 °C |

| ESR | electron spin resonance |

| f1, f2 | coefficients of the model approximating the viscosity index |

| FDM | fuel dilution meter |

| FILM | oil film resistance drop |

| ffresh(C) | general designation of the fresh lubricating oil parameter depending on the value of C |

| fused(C) | general designation of the used lubricating oil parameter depending on the value of C |

| FTIR | Fourier-transform infrared spectroscopy |

| GC | gas chromatography |

| GC-MS | gas chromatography and mass spectrometry |

| GUM | Guide to the Expression of Uncertainty in Measurement |

| ISO | International Organization for Standardization |

| JPI | Japan Petroleum Institute |

| K, K1, K2, K3, K4, K5, K6 | coefficients for the oil degradation process |

| mDO | mass of diesel oil |

| mLO | mass of lubricating oil |

| MDO | marine diesel oil |

| MGO | marine gas oil |

| NMR | nuclear magnetic resonance |

| MP | content of contaminant particulates |

| MR | marine residua (residual fuel) |

| R2 | coefficient of determination |

| RMSE | root mean square error |

| SAE | Society of Automotive Engineers |

| SAE 30 | viscosity grade of lubricating oils according to the SAE J300-2021 standard [41] |

| SAW | surface acoustic wave |

| Sm | total sediment contents |

| tFP | flash point temperature |

| flash point of fresh lubricating oil | |

| flash point of used lubricating oil | |

| u(δ) | initial boiling point temperature |

| initial boiling point of fresh lubricating oil | |

| initial boiling point of used lubricating oil | |

| u(δ) | uncertainty of the balance indication error from the calibration certificate |

| u(r) | combined uncertainty of repeatability of scale indications |

| uB | type-B standard uncertainty of measurement |

| type-B standard uncertainty of the mass fraction C measurement | |

| um | uncertainty of the determined mass of fuel or lubricating oil |

| us | type-B standard uncertainty of mass indication with a laboratory scale |

| UV | ultraviolet |

| VI | viscosity index |

| viscosity index of fresh lubricating oil | |

| viscosity index of used lubricating oil | |

| WD1.4 | normalized HFFR wear scar diameter |

| δ | error of the balance indications from the calibration certificate |

| μ | friction coefficient |

| ν100 | kinematic viscosity at 100 °C |

| kinematic viscosity of fresh lubricating oil at 100 °C | |

| kinematic viscosity of used lubricating oil at 100 °C | |

| ν40 | kinematic viscosity at 40 °C |

| kinematic viscosity of fresh lubricating oil at 40 °C | |

| kinematic viscosity of used lubricating oil at 40 °C | |

| ρ15 | density at 15 °C |

| density of fresh lubricating oil at 15 °C | |

| density of used lubricating oil at 15 °C |

Appendix A. Data Tables

Table A1.

Specification of the Marinol RG 1230 declared by the manufacturer [38,39].

Table A1.

Specification of the Marinol RG 1230 declared by the manufacturer [38,39].

| Parameter | Value |

|---|---|

| Kinematic viscosity at 100 °C (ASTM D445 [42]) | 11.5 mm2/s |

| Pour point (ASTM D5950 [43]) | –24 °C |

| Flash point in open cup (EN ISO 2592 [39]) | 220–255 °C |

| Total base number (PN-ISO 3771 [44]) | 12 mg KOH/g |

| Viscosity index (ASTM D2270 [29]) | 99.00 |

| Corrosiveness to copper (EN ISO 2160 [45]) | Corrosion copper strip (24 h/100 °C), Class 1 |

Table A2.

Specification of the Orlen Efecta Diesel Biodiesel oil declared by the manufacturer [8].

Table A2.

Specification of the Orlen Efecta Diesel Biodiesel oil declared by the manufacturer [8].

| Parameter | Value |

|---|---|

| Cetane index | ≤51 |

| Initial boiling point | 75–180 °C |

| Boiling temperature range | 95% vol. distils at 360 °C |

| Flashpoint (determined in a closed cup) | >56 °C |

| Autoignition temperature (according to DIN 51794:2003-05 [46]) | approx. 240 °C |

| Kinematic viscosity (according to EN ISO 3104 [28]) | 1.5–4.5 mm2/s (average 2.549 mm2/s) at 40 °C ~2.151 mm2/s at 50 °C |

| Density | 820–845 kg/m3 at 15 °C |

| Relative vapor density | approx. 6 (air = 1) |

| Cloud point | −7 °C |

| Cold filter plugging point | −28 °C |

Table A3.

Basic technical and operational parameters of a Sulzer 5 BAH 22 Engine.

Table A3.

Basic technical and operational parameters of a Sulzer 5 BAH 22 Engine.

| Parameter | Value/Description |

|---|---|

| Number of cylinders | 5 |

| Cylinder bore | 0.22 m |

| Piston stroke | 0.32 m |

| Nominal effective power | 220 kW |

| Nominal speed | 500 rpm |

| Mean piston speed | 5.33 m/s |

| Nominal specific diesel oil consumption | 232 g/kWh |

Table A4.

Limit operating parameters of the lubricating oil’s installation from which oil samples were taken.

Table A4.

Limit operating parameters of the lubricating oil’s installation from which oil samples were taken.

| Parameter | Value |

|---|---|

| Lubricating oil temperature at cooler outlet | 45–55 °C |

| Lubricating oil temperature at cooler inlet | 48–62 °C |

| Maximum lubricating oil temperature difference between inlet and outlet of the cooler | 7 °C |

| Lubricating oil pressure at filter and cooler inlet | 0.30–0.35 MPa |

| Lubricating oil pressure at filter and cooler outlet | 0.25–0.27 MPa |

| Alarm of low lubricating oil pressure at engine inlet | 0.20 MPa |

Table A5.

Properties of the tested Marinol RG 1230 lubricating oils (fresh and used) and Orlen Efecta Diesel Biodiesel oil.

Table A5.

Properties of the tested Marinol RG 1230 lubricating oils (fresh and used) and Orlen Efecta Diesel Biodiesel oil.

| Parameter | Method | Apparatus | Symbol | Unit | Value | ||

|---|---|---|---|---|---|---|---|

| Fresh Lubricating Oil | Used Lubricating Oil at 60 h of Working Time | Fresh Diesel Oil | |||||

| Density at 15 °C | Apparatus with oscillating U-tube performing measurements (PN-EN ISO 12185:2002 [27]) | DMA 4500 density analyzer (from Anton Paar GmbH, Graz, Austria) | ρ15 | kg/m3 | 890.6 | 889.6 | 828.3 |

| Kinematic viscosity at 40 °C | Glass capillary viscometer measurements (PN-EN ISO 3104:2021-3 [28]) | Cannon-Fenske Opaque viscometer (from Paradise Scientific Company Ltd., Dhaka, Bangladesh) and a TV 2000 viscometric bath (from Labovisco bv, Zoetermeer, The Netherlands) | ν40 | mm2/s | 110.310 | 102.740 | 2.480 |

| Kinematic viscosity at 100 °C | ν100 | mm2/s | 11.770 | 11.420 | 1.067 | ||

| Viscosity index | Calculated parameter (ASTM D2270-10(2016) [29]) | Anton Paar calculator [47] (from GmbH, Graz, Austria) | VI | – | 94.13 | 94.13 | 274.35 |

| Initial boiling point | Flashpoint Pensky–Martens method (PN-EN ISO 2719:2016 [35]) | Semi-automatic apparatus (from Walter Herzog GmbH, Lauda-Königshofen, Germany) | tIBP | °C | 276.0 | 240.5 | 175 |

| Flash point in closed cup | tFP | °C | 216.0 | 190.0 | 56.0 | ||

| Derived cetane number | Ignition delay and combustion delay using a constant volume combustion chamber method (ASTM D7668(2017) [48]) | Herzog Cetane ID 510 instrument [49] (PAC L.P., Houston, TX, USA) | DCN | – | N/A | N/A | 52 |

| Lubricity—HFFR wear scar diameter (normalized [50]) | High-frequency reciprocating rig—HFFR (PN-EN ISO 12156-1:2018 [51] and HFFR V.1.0.3 procedure [52]) | PCS HFFR V1.0.3 tribometer (from PCS Instruments, London, UK) and optical microscope with vertical illumination HFR2 (from PCS Instruments, London, UK) | WD1.4 | μm | 212 | 149 | 331 |

| HFFR friction coefficient | μ | – | 0.123 | 0.121 | 0.191 | ||

| Oil film resistance drop | FILM | % | 100 | 100 | 76 | ||

Table A6.

Chemical composition of the tested Marinol RG 1230 lubricating oils (fresh and used) and Orlen Efecta Diesel Biodiesel.

Table A6.

Chemical composition of the tested Marinol RG 1230 lubricating oils (fresh and used) and Orlen Efecta Diesel Biodiesel.

| Chemical Element | Content (ppm) | ||

|---|---|---|---|

| Fresh Lubricating Oil | Used Lubricating Oil @ 60 h | Fresh Diesel Oil | |

| Fe | 0.0 | 0.0 | 0.0 |

| Cr | 1.0 | 5.0 | 0.0 |

| Pb | 7.4 | 16.6 | 3.7 |

| Cu | 0.0 | 0.0 | 0.0 |

| Sn | 7.1 | 18.0 | 11.4 |

| Al | 5.8 | 12.2 | 5.3 |

| Ni | 7.5 | 17.4 | 4.6 |

| Ag | 0.7 | 4.0 | 0.3 |

| Si | 4.1 | 17.3 | 2.1 |

| B | 0.8 | 3.0 | 0.1 |

| Na | 4.9 | 7.7 | 4.6 |

| Mg | 0.1 | 1.0 | 0.2 |

| Ca | 4.8 | 5.4 | 3.1 |

| Ba | 0.0 | 0.0 | 0.0 |

| P | 0.0 | 0.0 | 0.0 |

| Zn | 1.1 | 10.2 | 0.0 |

| Mo | 2.1 | 2.6 | 1.0 |

| Ti | 0.0 | 0.0 | 0.0 |

| V | 0.0 | 0.0 | 0.0 |

Table A7.

Content and contaminations of used Marinol RG 1230 lubricating oil at 60 h of working time.

Table A7.

Content and contaminations of used Marinol RG 1230 lubricating oil at 60 h of working time.

| Parameter | Method | Apparatus | Symbol | Unit | Value |

|---|---|---|---|---|---|

| Content of diesel oil | Surface acoustic wave sensing (ASTM D8004-15 (2023) [53]) | Spectro FDM 6001 [54] (from Spectro Scientific, Chelmsford, MA, USA) | CDO | % m/m | 0.01 |

| Content of water | Coulometric titration by the Karl Fischer method (PN -EN ISO 12937:2005+AP1:2021-11P [55]) | Metrohm coulometer 831 KF (from Metrohm, Herisau, Switzerland) | CH2O | % m/m | 0.05 |

| Determination of total sediment | Filtration, by weight method (PN-ISO 10307-1:2001 [56]) | Setaclean—Total Sediment Tester (from Stanhope-Seta, Chertsey, UK) | Sm | mg/g | 0.35 |

| Determination of the contaminant particulates content | Filtration, by weight method (PN-ISO 4405:1994 [57]) | Millipore vacuum filtration kit (from Merck Millipore, Burlington, MA, USA), PL 2/4 vacuum pump (from AgaLabor, Warsaw, Poland), POL-EKO dryer (from POL-EKO, Wodzisław Śląski, Poland) | MP | mg/100 mL | 77.1 |

| Content of chemical elements | Rotating disc electrode atomic emission spectrometry (ASTM D6595-17 (2022) [58]) | SPECTROIL M spark spectrometer with rotating electrode (from AMETEK, Berwyn, PA, USA) | CV | ppm | See: Table A6 |

References

- Total Energies Fuel Dilution of Engine Oil: Causes and Effects. Available online: https://lubricants.totalenergies.com/fuel-dilution-engine-oil-causes-and-effects (accessed on 14 June 2022).

- Technomics International Case Study—Fuel Dilution of Engine Oil in Locomotives. Available online: https://www.techenomics.net/case-studies/fuel-dilution-engine-oil/ (accessed on 8 June 2022).

- Critchley, L. Fuel Dilution in Engine Oil—How It Happens and What It Leads to. Available online: https://www.azom.com/article.aspx?ArticleID=16891 (accessed on 16 June 2022).

- Dieselhub Fuel Dilution in Diesel Engines. Fuel Dilution Causes, How to Protect Your Engine. Available online: https://www.dieselhub.com/maintenance/fuel-dilution.html (accessed on 14 June 2022).

- Taylor, R.I. Fuel-Lubricant Interactions: Critical Review of Recent Work. Lubricants 2021, 9, 92. [Google Scholar] [CrossRef]

- Bowen, P.J. Current Understanding of Oil-Mist Explosions. In Crankcase Explosions; IMAREST: London, UK, 2002; pp. 149–164. [Google Scholar]

- Krupowies, J. Badania Pierwiastków Śladowych w Oleju Obiegowym Jako Element Diagnostyki Silnika; Wyższa Szkoła Morska w Szczecinie: Szczecin, Poland, 2001. [Google Scholar]

- Krupowies, J. Badania i Ocena Zmian Właściwości Użytkowych Olejów Urządzeń Okrętowych; Maritime University of Szczecin: Szczecin, Poland, 2009. [Google Scholar]

- Sejkorová, M.; Hurtová, I.; Jilek, P.; Novák, M.; Voltr, O. Study of the Effect of Physicochemical Degradation and Contamination of Motor Oils on Their Lubricity. Coatings 2021, 11, 60. [Google Scholar] [CrossRef]

- Baczewski, K.; Kałdoński, T. Paliwa do Silników o Zapłonie Samoczynnym; WKiŁ: Warszawa, Poland, 2018. [Google Scholar]

- Baczewski, K.; Szczawiński, P. Badanie właściwości reologicznych estrów metylowych oleju rzepakowego i ich mieszanin z olejami napędowymi. J. KONES Powertrain Transp. 2007, 14, 29–38. [Google Scholar]

- Abdullah, M.; Abdollach, M.; Mat-Nuri, N.; Amiruddin, H.; Tamaldin, N. Comparison of the frictional properties of nano-oil and SAE 15W40 oil diluted with biodiesel fuel. In Proceedings of the Malaysian International Tribology Conference, Penang, Malaysia, 16–17 November 2015; pp. 190–191. [Google Scholar]

- Mori, K.; Sugimoto, N.; Yamane, K.; Kawasaki, K. Influence of Biodiesel Fuel on Lubricant Oil Oxidative Degradation. In Proceedings of the JSAE/SAE 2015 International Powertrains, Fuels & Lubricants Meeting, Kyoto, Japan, 1–4 September 2015; SSAE Technical Paper Series, JSAE 20159. pp. 1–7. [Google Scholar] [CrossRef]

- Urzędowska, W.; Stępień, Z. Olej silnikowy a biopaliwa—Współdziałanie w eksploatacji. In Nafta-Gaz, Październi; Instytut Nafty i Gazu: Kraków, Poland, 2010; pp. 914–921. [Google Scholar]

- Watson, S.A.G.; Wong, V.W. The Effects of Fuel Dilution with Biodiesel on Lubricant Acidity, Oxidation and Corrosion—A Study with CJ-4 and CI-4 PLUS Lubricants. In Proceedings of the 2008 Diesel Engine-Efficiency and Emissions Research (DEER) Conference, Cambridge, MA, USA, 7 August 2008. [Google Scholar]

- Chybowski, L.; Kowalak, P.; Dąbrowski, P. Assessment of the Impact of Lubricating Oil Contamination by Biodiesel on Trunk Piston Engine Reliability. Energies 2023, 16, 5056. [Google Scholar] [CrossRef]

- CEC M-12-T-91; Representative Sampling In-Service of Marine Crankcase Lubricants. CEC: London, UK, 1991.

- CEC M-13-T-92; Recommended Standard Methods for Used Engine Oil Analyses. CEC: London, UK, 1992.

- CEC L-47-M-97; Recommended Standard Methods for Analysis of Used Oil from Large Diesel Engines. CEC: London, UK, 1997.

- Carter, B.H.; Green, D. Marine Lubricants. In Chemistry and Technology of Lubricants; Springer: Dordrecht, The Netherlands, 2009; pp. 389–409. [Google Scholar]

- Krupowies, J. Badania Zmian Właściwości Oleju Obiegowego Okrętowych Silników Pomocniczych; Wyższa Szkoła Morska w Szczecinie: Szczecin, Poland, 2002. [Google Scholar]

- Ehsan, M.; Rahman, M.M.; Hasan, M.S. Effect of Fuel Adulteration on Engine Crankcase Dilution. J. Mech. Eng. 2010, 41, 114–120. [Google Scholar] [CrossRef]

- Chybowski, L. Rozcieńczenie Oleju Paliwem Jako Czynnik Ryzyka Eksplozji w Skrzyniach Korbowych Okrętowych Bezwodzikowych Silników Spalinowych; Maritime University of Szczecin Press: Szczecin, Poland, 2023; ISBN 978-83-64434-56-3. [Google Scholar]

- Ferguson, G.W. Diesel Engine Crankcase Explosion Investigation. SAE Tech. Pap. 1951, 510104, 1–28. [Google Scholar] [CrossRef]

- Chybowski, L.; Szczepanek, M.; Gawdzińska, K.; Klyus, O. Particles Morphology of Mechanically Generated Oil Mist Mixtures of SAE 40 Grade Lubricating Oil with Diesel Oil in the Context of Explosion Risk in the Crankcase of a Marine Engine. Energies 2023, 16, 3915. [Google Scholar] [CrossRef]

- JCGM. Evaluation of Measurement Data—Guide to the Expression of Uncertainty in Measurement. Int. Organ. Stand. 2008, 50, 134. [Google Scholar]

- PN-EN ISO 12185:2002; Ropa Naftowa i Przetwory Naftowe—Oznaczanie Gęstości—Metoda Oscylacyjna z U-Rurką. PKN: Warszawa, Poland, 2002.

- PN-EN ISO 3104:2021-03; Petroleum Products—Transparent and Opaque Liquids—Determination of Kinematic Viscosity and Calculation of Dynamic Viscosity. PKN: Warszawa, Poland, 2021.

- ASTM D 2270-10(2016); Standard Practice for Calculating Viscosity Index from Kinematic Viscosity at 40 °C and 100 °C. ASTM: West Conshohocken, PA, USA, 2016.

- PN-EN IEC 60079-10-1:2021-09; Explosive Atmospheres—Part 10-1: Classification of Areas—Explosive Gas Atmospheres. PKN: Warszawa, Poland, 2021.

- CNBOP-PIB-BW03P:2016; Metody Badania Temperatury Zapłonu Substancji Ciekłych Niebezpiecznych Pożarowo—Wytyczne. CNBOP-PIB Standard: Józefów, Poland, 2016.

- Świerżewski, M. Uwaga Wybuch; Instytut Wydawniczy CRZZ: Warszawa, Poland, 1972. [Google Scholar]

- Babrauskas, V. Ignition Handbook; Society of Fire Protection Engineers: Gaithersburg, MD, USA, 2003. [Google Scholar]

- ISO 13736:2021; Determination of Flash Point—Abel Closed-Cup Method, 4th ed. ISO: Geneva, Switzerland, 2021.

- ISO 2719:2016; Determination of Flash Point—Pensky-Martens Closed Cup Method, 4th ed. ISO: Geneva, Switzerland, 2016.

- ISO 1516:2002; Determination of Flash/No Flash—Closed Cup Equilibrium Method, 3rd ed. ISO: Geneva, Switzerland, 2002.

- ISO 1523:2002; Determination of Flash Point—Closed Cup Equilibrium Method, 3rd ed. ISO: Geneva, Switzerland, 2002.

- TSE-TS 1080; Method of Test for Flash Point with Tagliabue Open Cup. TSE: Ankara, Turkey, 1993.

- ISO 2592:2017; Petroleum and Related Products—Determination of Flash and Fire Points—Cleveland Open Cup Method, 3rd ed. ISO: Geneva, Switzerland, 2017.

- ISO 3679:2015; Determination of Flash No-Flash and Flash Point—Rapid Equilibrium Closed Cup Method, 5th ed. ISO: Geneva, Switzerland, 2015.

- SAE J300-2021; Engine Oil Viscosity Classification. Society of Automotive Engineers International: Warrendale, PA, USA, 2021.

- ASTM D445-21e1; Standard Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (and Calculation of Dynamic Viscosity). ASTM: West Conshohocken, PA, USA, 2022.

- ASTM D5950-14(2020); Standard Test Method for Pour Point of Petroleum Products (Automatic Tilt Method). ASTM: West Conshohocken, PA, USA, 2020.

- PN-ISO 3771:2012; Przetwory Naftowe—Oznaczanie Liczby Zasadowej—Metoda Potencjometrycznego Miareczkowania Kwasem Nadchlorowym. PKN: Warszawa, Poland, 2012.

- PN-EN ISO 2160:2004; Przetwory Naftowe—Korodujące Działanie na Miedź—Badanie na Płytce Miedzianej. PKN: Warszawa, Poland, 2004.

- DIN 51794:2003-05; Testing of Mineral Oil Hydrocarbons—Determination of Ignition Temperature. German Institute for Standardisation (Deutsches Institut für Normung): Berlin/Heidelberg, Germany, 2003.

- Anton Paar ASTM D 2270—Viscosity Index (VI) from 40 °C and 100 °C. Available online: https://wiki.anton-paar.com/pl-pl/wskaznik-lepkosci-vi-od-40c-i-100c-astm-d2270/ (accessed on 7 September 2022).

- ASTM D 7668-17; Standard Test Method for Determination of Derived Cetane Number (DCN) of Diesel Fuel OilsIgnition Delay and Combustion Delay Using a Constant Volume Combustion Chamber Method. ASTM: West Conshohocken, PA, USA, 2017.

- PAC L.P. Herzog Cetane ID 510; PAC L.P.: Houston, TX, USA, 2019. [Google Scholar]

- PN-EN ISO 12156-1:2008; Oleje Napędowe—Ocena Smarności z Zastosowaniem Aparatu O Ruchu Posuwisto-Zwrotnym Wysokiej Częstotliwości (HFFR)—Część 1: Metoda Badania. PKN: Warszawa, Poland, 2006.

- EN ISO 12156-1:2018; Diesel Fuel—Assesment of Lubricity Using the High-Frequency Reciporating Rig (HFFR)—Part 1: Test Method. ISO: Geneva, Switzerland, 2018.

- PCS Instruments. Aparat do Badania Paliw i Środków Smarnych. Instrukcja Obsługi Systemu HFFR V1.0.3; Inkom Instruments Co.: Warszawa, Poland.

- ASTM D8004-15; Standard Test Method for Fuel Dilution of In-Service Lubricants Using Surface Acoustic Wave Sensing. ASTM: West Conshohocken, PA, USA, 2023.

- Spectro Scientific FDM 6000 Series—Portable Fuel Dilution Meter. Available online: https://www.spectro.cz/store/datasheet-fdm-6000.pdf (accessed on 21 July 2023).

- PN-EN 12937: 2005; Przetwory Naftowe—Oznaczanie Wody—Miareczkowanie Kulometryczne Metodą Karla Fischera. PKN: Warszawa, Poland, 2005.

- ISO 10307-1:2009; Petroleum Products—Total Sediment in Residual Fuel Oils—Part 1: Determination by Hot Filtration. ISO: Geneva, Switzerland, 2009.

- PN-ISO 4405:1994; Zawartość Zanieczyszczeń Nierozpuszczalnych. PKN: Warszawa, Poland, 1994.

- ASTM D 6595-17; Standard Test Method for Determination of Wear Metals and Contaminants in Used Lubricating Oils or Used Hydraulic Fluids by Rotating Disc Electrode Atomic Emission Spectrometry. ASTM: West Conshohocken, PA, USA, 2022.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).