Abstract

To meet climate targets, a global shift away from fossil fuels is essential. For sectors where electrification is impractical, it is crucial to find sustainable energy carriers. Renewable methanol is widely considered a promising fuel for powering heavy-duty applications like shipping, freight transport, agriculture, and industrial machines due to its various sustainable production methods. While current technological efforts focus mainly on dual-fuel engines in shipping, future progress hinges on single-fuel solutions using renewable methanol to achieve net-zero goals in the heavy-duty sector. This review examines the research status of technologies enabling methanol as the sole fuel for heavy-duty applications. Three main categories emerged from the literature: spark-ignition, compression-ignition, and pre-chamber systems. Each concept’s operational principles and characteristics regarding efficiency, stability, and emissions were analyzed. Spark-ignition concepts are a proven and cost-effective solution with high maturity. However, they face limitations due to knock issues, restricting power output with larger bore sizes. Compression-ignition concepts inherently do not suffer from end-gas autoignition, but encounter challenges related to ignitability due to the low cetane number of methanol. Nonetheless, various methods for achieving autoignition of methanol exist. To obtain stable combustion at all load points, a combination of techniques will be required. Pre-chamber technology, despite its lower maturity, holds promise for extending the knock limit and enhancing efficiency by acting as a distributed ignition source. Furthermore, mixing-controlled pre-chamber concepts show potential for eliminating knock and the associated size and power limitations. The review concludes by comparing each technology and identifying research gaps for future work.

1. Introduction

For decades, fossil fuels have fulfilled around 80% of the total energy demand of the world [1]. Despite the rapid growth in electrification and renewables beginning to reduce this dominant share, the effect is not so obvious in the non-road transport sector, such as aviation, shipping, agriculture, and industrial machinery, since batteries simply cannot meet the required energy density for these heavy-duty (HD) applications. As promised by the COP28 consensus [2], the world should be transitioning away from fossil fuels, meaning the gap left behind for these HD applications needs to be filled by clean fuels that can be produced sustainably and in an environmentally friendly manner [3].

Methanol is one of the promising candidates for this role. First and foremost, it can be carbon-neutral via multiple sustainable production routes [4]. Currently, the industrial process for producing methanol utilizes synthesis gas (syngas), a mixture of hydrogen (H2), carbon monoxide (CO), and carbon dioxide (CO2), as feedstock, which is converted into methanol. The conversion process involves the following three reactions [5]:

- CO hydrogenation:

- CO2 hydrogenation:

- Water–gas shift reaction:

When the syngas is produced from biomass, such as by reforming biogas or by gasifying woody residue, the product is the so-called bio-methanol. When the syngas is composed of H2 from water electrolysis powered by renewable electricity and CO2 captured from the atmosphere, the product is the so-called e-methanol. Being able to be produced by these two sustainable pathways puts methanol in an interesting position. This is because there are concerns on whether renewable electricity could scale up quickly enough to meet the high energy demand of e-fuel production [6,7], and if it does, whether it should be prioritized to electrify other applications instead of fuel production [8]. Similarly, for biofuel, there is a concern that the valuable biomass resources should be prioritized to other sectors [9,10], and there is also a common belief that the limited biomass availability cannot meet much of the total fuel demand; hence, its contribution to carbon-neutrality is constrained [11]. Among these debates, relying on more than one sustainable resource obviously lowers the risk of mass-producing renewable methanol. It is also worth pointing out that a hybrid production pathway integrating both thermochemical biorefinery and renewable electrolytic hydrogen could be an attractive solution, as it boosts the fuel yield and carbon conversion per biomass input, which leads to a lower consumption of the scarce biomass resources [12,13]. While the above statement also applies to long-chain hydrocarbon fuels synthesized by the Fischer–Tropsch process [14], methanol synthesis usually has a 6 to 7 percentage point higher process efficiency due to its simpler molecular structure [15,16].

The oxygenated nature of methanol also means its combustion generates less pollutant emissions compared to hydrocarbon fuels like diesel and gasoline. Thanks to the facts that there is no carbon–carbon bond in a methanol molecule and its only carbon atom is bonded with an oxygen atom, methanol combustion tends to be more complete and generates lower unburned hydrocarbon (HC) and CO emissions. Combining with its higher ignition delay, which promotes better mixture formation, the soot emission is even negligible. Moreover, its strong evaporative cooling effect, low adiabatic flame temperature, and high heat capacity of its burned gas all contribute to reducing the cylinder temperature, which leads to much lower thermal nitrogen oxide (NOx) formation [17]. Table 1 summarizes the properties of methanol compared to other renewable fuel candidates and conventional fossil fuels.

Table 1.

Summary of properties of different fuels.

Fueling HD applications with methanol has already been proven in the shipping sector. Since methanol fuel contains no sulfur, it easily meets the requirement of the sulfur cap implemented by IMO in 2020. The adoption of methanol-fueled vessels has since increased steadily. As of today, there are 29 methanol-fueled vessels that are in operation and 228 on order [23]. With 138 of them ordered in 2023, methanol has overtaken liquefied natural gas (LNG) as the new favorite alternative marine fuel [24]. Another advantage of methanol that largely contributes to its popularity as a marine fuel is that it is a liquid under ambient conditions. The high cost and complexity of handling and storing other gaseous candidates such as LNG, liquefied H2, and ammonia (NH3) can thus be spared. Although its lower energy density compared to diesel may result in a reduced range, this can be compensated for by more frequent refueling or larger fuel tanks. The fact that methanol biodegrades easily and thus poses lower harm to aquatic ecosystems should spillage occur also enables more freedom in terms of methanol storage layout onboard a vessel.

The methanol-fueled vessels sailing on the water today are predominantly powered by internal combustion engines, but fuel cell is also an option [25]. These vessels come in various sizes, ranging from a smaller pilot boat powered by a four-stroke engine [26] to a much larger container ship powered by a two-stroke engine [27]. However, regardless of the number of strokes, the engines powering these vessels utilize predominantly dual-fuel (DF) technology. In DF engines, methanol combustion is initiated by a small quantity of diesel injection in the cylinder, as methanol is more difficult to autoignite compared to diesel. Retaining a diesel injector enables these engines a favorable redundancy to operate in diesel-only mode also. This operating flexibility is crucial at the moment as the supplies of carbon-neutral methanol at ports today are still highly volatile. Due to the fossil-based nature of diesel, it is obvious that the level of defossilization when operating DF engines depends on the fraction of (carbon-neutral) methanol used. This can usually be quantified by the methanol energy fraction (MEF), as defined in Equation (4),

where are the fuel flows and LHV are the lower heating values.

As the popularity of methanol fuel grows, more and more four-stroke DF engines appear on the market, and their development is in full swing [28,29,30,31]. While the maximum MEF achieved on these engines can exceed 90% [30,31,32], it is not a simple task to maintain a similar MEF level across the full load range. Methanol has a high heat of vaporization (HoV), which poses problems in achieving a high MEF when operating at low load, since the vaporization of methanol could reduce the cylinder temperature substantially and cause incomplete combustion [33,34]. As for high-load operation, depending on the homogeneity of the air–methanol mixture inside the combustion chamber, both excessive pressure rise rate and autoignition of unburned mixture could prevent achieving a high methanol fraction [35]. These constraints imply that the optimal window for high MEF operation in DF engines can be narrow and may not be suitable for applications where high- and low-load operations are emphasized. In addition, involving diesel in the operation offsets the low emission advantage of methanol, and expensive exhaust aftertreatment systems (EATS) are still required to handle the soot and NOx emissions from diesel combustion.

There is no denying that the DF approach is the best technology today to introduce renewable methanol into fleets and move them towards a net-zero future, but it should only be considered a bridging technology before the supply of renewable methanol gradually scales up and stabilizes. Moreover, other HD applications may not be able to afford the luxury of implementing a second fuel system on board as the marine industry does. Therefore, the research and development should move beyond DF technology, and it is envisioned that a dedicated single-fuel solution that does away with the need for two separate fuel systems will be desired in the future. Currently, multiple potential technologies that enable single-fuel methanol engines for HD applications are being explored. This review aims at reporting the status quo of their development progress and pinpointing their research gaps. These potential technologies can be categorized by how the air–methanol mixture is ignited in the combustion chamber, namely, either by a spark, by compression, or by jets created by a pre-chamber. These three different technologies are further introduced and discussed in the following sections. Appendix A, which lists the current European emissions standards regulating on-road and off-road HD applications, can be used as references to benchmark the emissions measurements reported below.

2. Spark-Ignition

In spark-ignition (SI) engines, air and fuel are premixed and then ignited by a spark plug in the cylinder. The premixing process can take place either upstream of the cylinder or inside the cylinder. The former configuration is termed port-fuel-injection (PFI) since fuel is injected close to the intake port, while the latter configuration is termed direct-injection (DI) since fuel is injected directly in the cylinder. Different injection locations result in different injection pressures. PFI fuel systems (including pumps and piping) usually employ an injection pressure below 50 bar, as they only need to cope with the boost pressure in the intake path. On the other hand, DI systems usually employ an injection pressure above 100 bar, as the injection sometimes occurs during the compression stroke when the cylinder pressure is considerably high. The schematic diagrams of both configurations are shown in Figure 1 with PFI on the left and DI on the right.

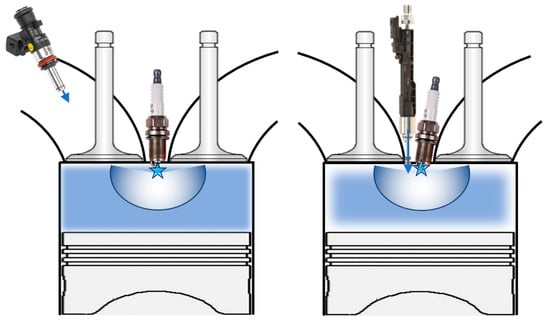

Figure 1.

Schematic diagrams of PFI configuration on the (left) and DI configuration on the (right). The star represents the spark and the arrows highlight the locations where fuel injection occurs.

SI operation is characterized by premixed combustion, where the homogeneous air–fuel mixture is combusted by a propagating flame front, as depicted in Figure 1. The flame front can propagate at a very high speed if there is strong turbulence present in the combustion chamber, which leads to a desirable shorter combustion duration compared to compression-ignition (CI) operation. The homogeneous air–fuel mixture also lowers the chance of soot formation in the combustion chamber of SI engines. Knock is the major constraint for SI operation, which occurs when one or more pockets of unburned mixture autoignite outside of the envelope of the propagating flame front. Uncontrolled autoignition may lead to detonation, and the associated shockwave may severely damage the engine. Knock typically happens when the unburned mixture is exposed to high temperature and pressure for a residence time longer than its ignition delay. Therefore, the boost level and compression ratio (CR) for SI engines need to be limited to avoid knock. It is also common to apply a retarded spark timing when operating SI engines close to their peak output.

DI-SI engines are usually more knock-resistant than PFI-SI engines thanks to the charge cooling effect resulting from fuel evaporation. In PFI-SI engines, this evaporative cooling effect takes place in the intake path and the heat is absorbed not only from the inlet air but also from metal components such as the port wall and valves. For DI-SI engines, the evaporative cooling effect takes place inside the cylinder and therefore, cools primarily the inlet air, which leads to a cooler unburned mixture. The temperature of the unburned mixture would further decrease if the residual gas fraction in the cylinder could be minimized through over-scavenging, which is enabled by an overlap of the inlet and exhaust valve open durations. This can only be implemented with a DI configuration, as with PFI, over-scavenging would lead to a loss of unburned fuel [36]. With the higher knock limit of DI-SI engines, a higher CR and boost level can be adopted; hence, a higher power output can be expected. A cooler air–fuel mixture also has a higher density, thus facilitating a higher volumetric efficiency in DI-SI engines.

As shown in Table 1, methanol has a number of physicochemical properties that make it particularly suitable for SI operation, including a higher burning velocity, a higher autoignition temperature, and a higher HoV compared to a typical SI fuel like gasoline. A higher flame speed implies that there is a higher chance that the propagating flame front can “capture” the pocket of hot unburned mixture before it reaches the autoignition temperature; a higher HoV helps cool down the unburned mixture in general; and a higher autoignition temperature means it takes longer for the unburned mixture to reach the autoignition temperature. With this superior knock-suppressing ability, SI engines on methanol can be operated at a higher CR or a more advanced spark timing compared to gasoline and thus achieve better performance and efficiency.

Koenig et al. [37] already verified the aforementioned benefits of introducing methanol in SI engines in 1976, right after the world was shocked by the oil crisis and was eagerly looking for an alternative to petroleum fuels. This prompted an on-road methanol-fueled fleet trial during the 1980s and 1990s in California [38,39]. The focus gradually shifted from energy security to air quality during the trial, where methanol also provides significant advantages over gasoline. Eventually, around 15,000 vehicles, ranging from passenger cars to buses and trucks, were involved in the trial. While this number was obviously not enough to demonstrate that methanol can replace gasoline, extensive and valuable experiences were gained, which greatly helped the later development of flex-fuel vehicles.

Methanol’s higher burning velocity and wider flammability limits also open up some alternative options for load control in SI engines [40]. Pannone et al. [41] reported a substantial thermal efficiency improvement and a CO emission reduction with lean turbocharging compared to stoichiometric operation, although at the expense of lower combustion efficiency. Brusstar et al. [42] achieved a peak brake thermal efficiency (BTE) of nearly 43% when operating a turbocharged engine unthrottled with stoichiometric fueling and the load being controlled via exhaust gas recirculation (EGR). The test engine was a diesel engine and features a compression ratio (CR) as high as 19.5. Vancoillie et al. [43,44] experimentally verified the two operating strategies mentioned above and confirmed that both the EGR dilution limit and lean burn limit of methanol are significantly higher than that of gasoline. They then compared the two operating strategies and concluded that unthrottled stoichiometric operation with load control via EGR is a more promising strategy since the relatively cheap three-way-catalyst (TWC) technology can be utilized for EATS.

Using methanol in SI engines also faces its challenges. One of the notorious enemies is cold-starting, which is a well-known problem for engines on alcohol fuels owing to their relatively low vapor pressures and relatively high HoV. In fact, one of the reasons that the fuel used during the California fleet trial evolved from neat methanol to 85% methanol mixed with 15% gasoline (so-called M85 fuel) was to boost the vapor pressure to an extent that cold-starting is possible again in most climates [38]. Over the years, many solutions have been developed that do not involve adding a more volatile fuel. One straightforward and widely adopted method is raising the fuel temperature before injection using heated injector tips [45,46,47]. Other methods include electrically heating the engine block, intake manifold, and even the lubricating oil and coolant water [48]. DI configurations can also mitigate this issue by creating charge stratification via late injection; consequently, a richer mixture at the proximity of the spark plug can be formed and the ignitability can be improved [17]. Next to cold-start, methanol SI engines also exhibit different oscillation behavior when they knock. As recently discussed by Suijs et al. [49] and Robeyn et al. [50], the pressure oscillation caused by knock in SI engines on methanol is very different from those on gasoline. This necessitates extra attention and calibration for knock detection algorithms in engine control software.

Nowadays, apart from some small model engines on radio-controlled vehicles and motorsports engines on drag racers, SI engines on methanol are mostly found on the road in China thanks to its nationwide policy to promote methanol usage. This policy is primarily driven by the scarcity of oil resources in China, although it has abundant coal reserves, which can be used to produce methanol [51]. As of April 2022, the fleet consists of close to 30,000 methanol-powered vehicles, which covered a total mileage of nearly 10 billion kilometers [52]. However, it is worth pointing out that the carbon footprint of producing methanol from coal is significantly higher than the sustainable production routes [53], which are discussed in Section 1.

Most of the benefits of operating SI engines on methanol mentioned above were verified on light-duty (LD) automotive engines. HD engines, on the other hand, are characterized by a larger bore size and lower revving speed compared to LD engines. A larger bore size implies a longer distance for the flame front to travel and the lower revving speed induces lower turbulence, hence, a slower flame speed. Both features render HD engines more susceptible to knock, which explains why SI operation is very rare for HD applications. However, this also highlights that methanol SI operation for HD applications is an interesting research topic, and promising results have been achieved with lab-scale demonstration. The following subsections go through more details of the demonstrators found in the literature, with Section 2.1 focusing on demonstrators with the PFI configuration and Section 2.2 focusing on demonstrators with the DI configuration.

2.1. Port-Fuel-Injection

It is relatively simple to convert an existing diesel engine to PFI-SI configuration, with additional methanol injectors installed on the intake manifold and the diesel injectors replaced by spark plugs. A Scania D12 diesel engine featuring a 127 mm bore and a 154 mm stroke went through such conversion and was tested by Mahendar et al. [54]. Its knock-limited performance was evaluated with increasing excess air ratios (λ) at a fixed engine speed of 1200 revolutions per minute (rpm). The geometric CR of the engine was reduced to 13 through a customized piston. The peak indicated mean effective pressure (IMEP) achieved was 26.8 bar at λ = 1.4 with an indicated thermal efficiency (ITE) of 46.8%. In fact, the engine was able to achieve a similar level of IMEP from stoichiometry up to λ = 1.6 with retarded spark timing for richer operation. Further diluted operation compromised the combustion stability and resulted in unacceptably high HC emission. However, there was also a clear trend showing that increased dilution led to improved ITE and substantially dropped NOx and CO emissions, hinting that lean burn operation with λ between 1.4 to 1.6 may be optimal among the trade-offs.

A similar conversion was performed on two diesel engines by Güdden et al. [55]. The smaller engine featured a cylinder displacement of roughly 2.1 L and the CR of the engine was reduced to 11.5 [56]. At 900 rpm with wide-open throttle (WOT) and stochiometric mixture, an EGR fraction of 16% was chosen for a realistic boost pressure demand. Under this operating condition, the engine attained a peak IMEP of 14 bar at an ITE of 41% with minimum spark advance for best torque (MBT) before reaching the knock limit. The maximum attainable IMEP could be extended to 20 bar when the spark timing was retarded, but the ITE also dropped to 39%. It is worth noting that the maximum IMEP was not limited by knock but an intolerably high exhaust gas temperature due to the retarded spark timing. The larger engine had a displacement of roughly 5 L per cylinder (L/cyl) [57]. The modified piston reduced the geometric CR to 14.5 and a Miller valve timing reduced the effective CR to around 13.8. The tests were performed with a fixed engine speed of 1800 rpm. The load sweep was carried out at λ = 1.7 and the highest IMEP achieved was around 17 bar with an ITE close to 47%. NOx emissions at this peak operating point were around 1 g/kWh, HC was around 2.5 g/kWh, and CO was around 4.5 g/kWh. Similar to what Mahendar et al. [54] reported, a retarded spark timing was required to achieve the peak IMEP and the combustion stability was severely compromised when λ approached 1.8.

As highlighted by Güdden et al. [57], large-bore SI engines on methanol exhibit great potential to outperform the most common large-bore SI engines on the market currently, i.e., natural gas (NG) engines. This was confirmed by Zhu et al. [58], who reported the test results of an HD NG engine that was modified to facilitate PFI-SI operation on methanol. The engine featured a bore of 123 mm, a stroke of 154 mm, and a CR of 11.5 and was operated stoichiometrically with EGR dilution. It managed to attain a brake mean effective pressure (BMEP) of 21.7 bar with a brake thermal efficiency (BTE) of over 40%, which was more than 2 percentage points higher than that of the original NG engine. This peak output could be sustained for engine speeds ranging from 1000 rpm to 1700 rpm, with corresponding EGR fractions from 19.4% to 23.2%. The reported NOx emissions within this speed range were between 0.3 and 0.8 g/kWh, HC emission between 1.0 and 2.1 g/kWh, and CO emission between 6.8 and 8.6 g/kWh. Further research indicated that the injection timing exhibited a significant effect on mixture formation, which could either be optimized for regulated emissions such as HC and CO [59] or unregulated emissions, such as unburned methanol and formaldehyde [60], but proved difficult for both. It was also found that unburned methanol emissions decreased with lower EGR fraction; the trend was not monotonic for formaldehyde emissions, though.

Laiminger et al. [61] tested a Jenbacher Type 6 gas engine from INNIO that was converted to operate on methanol by adding a methanol injector in the intake path. This engine has a displacement of roughly 6 L/cyl, which is by far the largest in the literature. Promising ITEs of 40% to 44% were attained at 1500 rpm across various engine loads. Nonetheless, due to unsuitable automotive injectors adopted, the amount of methanol that could be injected was limited; hence, the operating window was narrow. It was reported that the ignition delay time in this engine was much longer than its NG counterpart, and it decreased with a richer mixture or later spark timing, while the burn duration also decreased with a richer mixture but increased with later spark timing. In addition, a high cyclic variability was observed.

Despite the positive results from the demonstrators mentioned above, their displacement between 2 and 6 L/cyl only covers a fraction of HD engines. For even larger medium-speed engines, only simulation results are available in the literature. Based on the combustion profiles presented in the publications of both Mahendar et al. [54] and Güdden et al. [57], Pu et al. [62] extrapolated methanol PFI-SI operation to a medium-speed ABC DZ engine that featured a displacement close to 16 L/cyl and a CR of 12. The engine speed in the simulation was set to 1000 rpm, the rated speed of the engine, and a maximum boost of 2.5 bar (absolute) was applied. The knock limit was evaluated with a neural-network-based model developed by Suijs et al. [63]. It was found that, if the crank angle degree (CAD) where 50% of the fuel is burned (CA50) was kept at 15 CAD after top dead center (TDC) and the mixture temperature at the intake port was kept at well below 20 °C, knock-free operation was feasible with an IMEP of 22.5 bar, an ITE of 42.8%, and NOx emissions of 2.8 g/kWh.

2.2. Direct-Injection

The diesel engine with cylinder displacement of roughly 2.1 L that was converted to PFI operation on methanol by Güdden et al. [56] mentioned in Section 2.1 was also tested with DI operation. The CR of the engine was identical for both configurations, and the engine was also tested stoichiometrically with WOT at 900 rpm. With a similar boost level as the PFI operation, the EGR fraction reached 28% with the DI operation. The knock limit was reached at an IMEP of 24 bar using MBT spark timing, which is a substantial increase from 14 bar with PFI operation. Similar to PFI, the maximum attainable IMEP could be extended to 29 bar with retarded spark timing before reaching the exhaust gas temperature limit, and the peak ITE attained was above 43%. Compared to the peak IMEP of 20 bar achieved at 39% ITE with the PFI configuration, the DI configuration clearly exhibited its superiority in terms of power density and efficiency thanks to its elevated knock limit.

Instead of demonstrating the advantage of a DI configuration with demonstrators featuring a larger bore size, an engine with similar size but much higher CR was tested by Li et al. [64]. This single-cylinder research engine featured a CR of 17.3 and was converted to DI-SI operation on methanol from a Scania D13 diesel engine with a bore of 130 mm and a stroke of 160 mm. A high-pressure common rail injection system was installed on the engine. The tests were performed at a fixed IMEP of 8 bar and a fixed engine speed of 1200 rpm with different start-of-injection (SOI) timing. The engine operated with a λ of 1.5, and the spark timing was retarded to around TDC to avoid an excessively high pressure rise rate beyond the hardware tolerance. The peak ITE achieved was around 48% with an injection pressure of 2000 bar, a spark timing of 2 CAD before TDC (bTDC), and an SOI at 27 CAD bTDC. The reported NOx emissions were between 8 and 10 g/kWh with an injection pressure of 1000 bar and a spark timing of 4 CAD bTDC. These measurement results were then used to validate a multi-dimensional simulation model for an in-depth study with parameter sweeps. The study showed that advancing SOI can improve both ITE and NOx emissions, while advancing the spark timing benefits ITE at the expense of slightly worsened NOx emissions.

Compared to the PFI configuration, there are much fewer lab-scale DI demonstrators in the literature. This is likely due to the difficulty of retrofitting existing diesel engines to this configuration, as both the injector and spark plug need to be installed in the cylinder, so re-tooling is needed for the cylinder head. However, DI-SI HD engines on methanol have actually shown a proven record in the real world. Back in 1982, Ullman et al. [65] reported the test results from a naturally aspirated MAN D2566 diesel engine converted to facilitate DI-SI operation on methanol. This six-cylinder engine featured a bore of 125 mm, a stroke of 155 mm, and a CR of 18. It had a rated output of 147 kW at 2200 rpm with a methanol fuel flow of 77 kg per hour, which corresponds to a BMEP of 7 bar and a BTE of 34.3%. Regulated and unregulated emissions were measured on a testbed with a TWC coupled to the engine during both steady-state and transient operations following the Federal Test Procedure (FTP). The measured CO and HC emissions were well below 1 g/kWh, and NOx emissions were at the level of 9 g/kWh for both transient and steady-state cycles. The unburned alcohol almost doubled during the transient cycle and reached 0.91 g/kWh compared to steady-state, while aldehydes showed a completely different trend, reaching 0.06 g/kWh during steady-state and negligible during transient cycles. The same engine was later mounted on a bus for revenue transit service as part of the California fleet trial mentioned earlier and accumulated an extensive mileage of 45,500 km. The emissions from this methanol-powered bus were then evaluated again on the chassis dynamometer by Ullman et al. [66] for a comparison to diesel-powered buses. They concluded that the regulated emission levels from the methanol-powered bus were significantly lower than those obtained from the diesel ones, while aldehyde emission was on par with the diesel ones.

In 2023, Duan et al. [67] reported the test results of a commercially available HD truck in China, also equipped with a methanol DI-SI engine and a TWC, on the world harmonized transient cycle (WHTC) on a chassis dynamometer. The engine featured a bore of 130 mm, a stroke of 160 mm, and a CR of 12.5. The weighted results combining the cold-start and hot-start tests are summarized in Table 2. It can be seen that they are all well within the limits of the China VI emission standards, which are aligned with the Euro VI emission standards. The transient emission measurement from Ullman is also included in Table 2 to showcase the technical advancement across more than four decades.

Table 2.

Exhaust emissions of heavy-duty vehicles powered by DI-SI engines on methanol under transient operation.

2.3. Discussion

From the demonstrators in the lab and on the road mentioned in the previous subsections, it can be concluded that SI engines on methanol for HD applications have already achieved a fairly high technology readiness level (TRL). Table 3 summarizes the pros and cons of the two different concepts presented along with their TRL. But still, how do they compare to the existing diesel engines or even DF engines on the market? The comprehensive emission and performance comparison conducted by Güdden et al. [55,56] between the two retrofitted SI engines reported in the previous subsections and the two retrofitted DF engines on methanol/diesel of similar sizes may provide some insights into this question. It was shown that for the size range around 2 L/cyl, the DF engine, which features a CR of 18, equal to the baseline diesel, still possesses a clear edge in terms of thermal efficiency. The SI engines, on the other hand, feature a CR of merely 11.5, so their inferiority in efficiency is unsurprising. If a higher CR could be utilized, a similar efficiency level as the baseline diesel engine is potentially obtainable. As for the size range around 5 L/cyl, the PFI-SI engine achieved slightly higher efficiency and considerably lower NOx emissions than its DF counterpart from medium load to high load, whereas its CO and HC emissions were higher and its maximum attainable IMEP was lower.

Table 3.

Summary table of the SI concepts presented in Section 2.

These test results nicely summarize the strengths and weaknesses of methanol SI engines compared to the current diesel and DF engines on the market. In general, on-par efficiency with diesel engines can be anticipated with further design optimization for methanol combustion, as most of the demonstrators are retrofitted from existing diesel or gas engines. Much lower NOx emissions can also be expected, which may spare the need for a costly selective catalytic reduction (SCR) unit in the EATS. However, the premixed nature of SI engines renders higher HC and CO emissions inevitable, which likely necessitates an oxidation catalyst. Torque delivery is another area that SI engines may struggle with due to their susceptibility to knock. At high engine speeds, this problem leads directly to a lower power density, while at lower engine speeds, this problem translates to inferior drivability (or time-to-torque). Despite that, no issues were reported when the two methanol-powered HD vehicles listed in Table 2 were tested with transient and dynamic maneuvers. Since they are both equipped with DI-SI engines, torque delivery may be less of an issue for them thanks to the higher knock resistance. As for PFI-SI engines, they are better suited to applications with less transient and dynamic demand, such as stationary gensets or marine auxiliary engines.

Given the excellent results achieved by the 5 L/cyl PFI-SI engine, DI-SI engines with similar bore size can potentially outperform the existing diesel engines in terms of both efficiency and power output. However, there is no demonstrator of this kind that can be found from either industry or the literature. This can possibly be attributed to the difficulty of retrofitting existing diesel engines to this configuration, as both the injector and spark plug need to be installed in-cylinder, so re-tooling is needed for the cylinder head. There is also a lack of development for appropriate methanol DI injectors that can deliver the required flow rate for this size range. Another unknown is whether methanol SI operation is feasible for medium-speed engines with cylinder sizes more than 10 L. The simulation shows positive results [62], but whether knock will be an issue is yet to be proven in the real world. As already pointed out by Suijs et al. [68], the threshold of the metrics that quantify the knock intensity can be very different for medium-speed engines.

3. Compression-Ignition

Methanol, with its distinct fuel characteristics, finds optimal use in SI engines; however, the majority of heavy transport vehicles use conventional CI diesel engines. As industries increasingly seek renewable and sustainable transport alternatives, retrofitting existing CI engines to run on methanol becomes an appealing option over engine replacements. This approach aims to reuse most current engine components in the retrofitting process. Nevertheless, the widespread adoption of methanol faces obstacles.

Challenges arise from methanol’s high heat of vaporization, coupled with a low cetane number and higher fuel injection volumes, which introduces a major cooling effect at injection particularly affecting low-load and cold-start compression-ignition [69]. Research has mainly focused on addressing these ignition difficulties, resulting in several proposed solutions. As mentioned earlier, one common approach involves the dual-fuel setup, injecting diesel fuel to create the heat/flame needed to start the combustion of methanol [28,35,70,71]. This serves as an intermediate technology during the transition; however, it does not eliminate fossil diesel fuel usage and requires the implementation of a dual-fuel system. The associated complexities and costs make retrofitting current single-fuel systems a challenging step in eliminating fossil diesel fuel from engine operations. Keeping the single-fuel solution is much more enticing, and when it comes to intermediate technology solutions with methanol, blending it with biodiesel fuel is an alternative. This capitalizes on their miscibility without the need for a co-solvent or emulsifier, unlike the non-miscible nature of methanol and fossil diesel fuel. This strategy addresses challenges such as high heat of vaporization and lubricity issues that come with methanol, although the MEFs that have been tested are on the lower side. The results have shown that an increasing proportion of methanol led to a reduction in NOx emissions while concurrently increasing CO and HC emissions [72]. This, although it is a single-fuel solution, still has issues, as it involves a blending process, it needs access to enough biodiesel fuel, and it does not utilize the full potential of methanol in CI engines. In the following sections, we review different single-fuel solutions utilizing CI of methanol fuel, see Figure 2, without a major blending process.

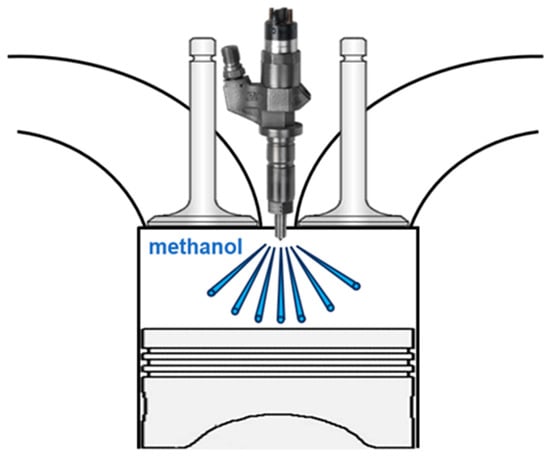

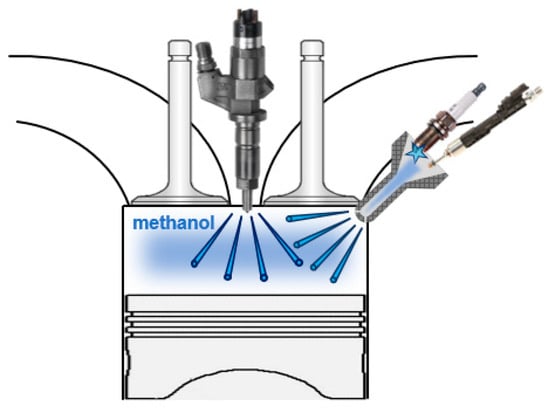

Figure 2.

Schematic diagrams of DICI configuration.

3.1. Ignition Improver

Instead of blending methanol with diesel, an alternative approach involves adding an ignition improver to the methanol fuel. The primary function of an ignition improver when mixed with methanol is to enhance the ignition properties, particularly by increasing the cetane number compared to pure methanol. This enhancement promotes ignition through compression alone, removing the need for an additional fuel source. However, it is essential to acknowledge that ignition improvers can be relatively costly compared to methanol. Hence, minimizing the ignition improver content is crucial to ensure it remains a viable and cost-effective option.

The use of ignition improver has been proven to work In real-world applications through the GreenPilot [73] and FASTWATER [74] projects. In the GreenPilot project, a blend comprising 95% methanol and 5% ignition improver was tested in a Scania ED95 engine, originally designed for a blend of 95% ethanol with 5% ignition improver. It showed stable combustion and even reliable start-up [73]. Subsequently, the European Horizon 2020 project FASTWATER further validated this approach by successfully converting a diesel-fueled CI engine to methanol operation, incorporating 3% ignition improver (MD97) [75]. This converted engine, based on the Scania ED95 engine with slight modifications such as an increased compression ratio and an in-house designed engine control unit (ECU), attained certification to the NOx Technical Code 2008 with IMO Tier III standards, all without requiring an EATS. Its installation and running on the Pilot 120 SE boat off the east coast of Sweden showcases the high TRL of methanol with ignition improvers [25].

In exploring ignition improver additives, various additives have undergone testing and investigation. Aakko-Saksa et al. [76] conducted a study of methanol blended with several types of ignition improver and lubricity additives tailored for diesel engine application. Their research demonstrated that MD95 fuel blends exhibited clean-burning characteristics, emitting fewer gaseous emissions than ED95, particularly when utilizing a glycerol ethoxylate additive as an ignition improver. Moreover, the PM and PN emissions originating from the additives in the tested fuels could be mitigated with the utilization of an oxidation catalyst. The study also explored the feasibility of reducing additive dosing in MD95 fuels, which was found to be feasible with the aid of fuel injection into the intake manifold. Overall, the authors concluded that their results showcased the MD95 concept as a promising solution for smaller vessels equipped with 800–1200 kW engines.

Similarly, Cordtz et al. [77] investigated methanol blended with a polyethylene glycol ignition improver in a significantly smaller engine with a swept volume of 0.96 L, employing a standard diesel setup with an CR of 18. Their findings revealed that utilizing a 5% ignition improver was sufficient to achieve stable premixed combustion with a 45 CAD bTDC injection timing, without the need for intake air heating. However, this setup was found to be sensitive to changes in λ and temperature. When employing a classic diesel injection timing of 10 CAD bTDC, the intake air temperature exceeded 100 °C before stable combustion was achieved. In contrast to the larger engines tested and developed, the experiment of Cordtz et al. featured a significantly lower CR of 18. This observation suggests that the installation of a higher compression ratio, if possible, can reduce the required amount of ignition improver needed for stable combustion.

Samson et al. [78] conducted experiments on a similar engine to Cordtz’s, employing a single-cylinder engine with a displacement of 0.499 L and a CR of 17.5. They investigated varying amounts of an enhancer containing alkyl nitrate (CEN), ranging from 0 to 5%. Similar to the findings of Cordtz et al., Samson et al. concluded that a 5% ignition improver is necessary to lower the required intake temperature and achieve stable combustion. Regarding emissions, higher concentrations of CEN resulted in reduced CO and HC emissions due to enhanced combustion completeness. However, there was an increase in NOx emissions, attributed to the presence of nitrate in CEN. These findings demonstrate that methanol with an ignition improver is viable for smaller engines as well. Furthermore, they observed that increasing concentrations of CEN altered the combustion process from solely premixed, characterized by a long ignition delay and short combustion duration, to a combination of premixed and diffusion combustion, characterized by a shorter ignition delay and longer combustion duration. Cheng et al. [79] observed the same phenomena on a larger five-cylinder 9.4 L engine when testing different amounts of ignition improver and varied ignition timing. Their results showed that when varying the injection timing with 5% ignition improver, the combustion characteristics were more similar to that of partially premixed combustion (PPC), and the use of 3.5% ignition improver gave a pronounced premixed combustion process. Cheng et al. [80] expanded on this investigation through experimental and multi-packet-mode simulation studies. Their findings revealed an ignition delay ranging from 14.1 to 22.8 CAD and an efficiency in the range of 35 to 43%. Furthermore, the simulation study demonstrated that the chemical ignition delays consistently exceeded the physical one, underscoring the importance of prioritizing the chemical ignition delay to enhance the ignition performance of methanol fuel.

Further simulation studies were performed by Chang et al. [81] using a detailed investigation into the influence of 2-ethylhexyl nitrate (EHN) cetane improver on methanol ignition through chemical kinetic analysis. For the simulation study, CHEMKIN PRO was utilized with a proposed and verified reduced mechanism of methanol and EHN, comprising 61 species and 479 reactions. Their study revealed a significant increase in efficiency upon the addition of EHN. Specifically, compared to pure methanol, the ignition delay of methanol with 3% EHN was reduced by 99.85% at 800 K and by 99.99% at 1400 K. However, as the EHN ratio increased, the effect of EHN on shortening the ignition delay did not exhibit a linear increase but instead demonstrated a slowing trend. The decomposition of EHN generated NO2, which actively participated in reactions at low temperatures, resulting in methanol combustion initiation at lower temperatures. This phenomenon partly explains how EHN enhances the combustibility of methanol upon its addition.

The studies discussed demonstrate the viability of methanol with ignition improver as a single-fuel solution for CI engines, with only some modifications to existing engines. However, there is room for further research to enhance combustion, expand the operating area of engine sizes, and reduce the amount of costly ignition improvers. What is missing from these studies is a comparison of methanol with ignition improver to other fuels. While Aakko-Saksa et al. [76] compared it to ethanol with ignition improver, the question remains how methanol with ignition improver fares in comparison to diesel, the fuel it seeks to replace, as well as to neat methanol.

Svensson et al. [82] addressed this gap by conducting a comprehensive evaluation of the MD97 fuel blend previously mentioned [75], and comparing it to diesel fuel and non-blended methanol (MD100). This investigation utilized a single-cylinder converted six-cylinder heavy-duty CI engine with a displacement of 2.124 L/cyl. along a propeller curve. Their results revealed that MD97 closely matches diesel fuel in gross ITE across most load conditions and even surpasses it at higher loads. Only at the lowest load did MD97 exhibit a slight decrease in efficiency, but it still maintained stable combustion. Furthermore, the study highlighted the significant enhancement in methanol’s combustibility with the addition of a 3% ignition improver, particularly evident at lower loads. Noteworthy findings also include the substantial reduction in NOx emissions with methanol usage, accompanied by minimal soot emissions, but with an increase in unburnt HC emissions.

A study by Liu et al. [83] explored various concentrations of ignition improver, 0.1%, 1%, and 3% of 2-ethylhexyl nitrate (EHN), and compared this against pure methanol and diesel. Their investigation focused on examining the effects on combustion and emissions under operating conditions of 2.2 bar BMEP and 1200 rpm engine speed, a lower-load case compared to Svensson et al. [82]. The results revealed that the lowest possible intake temperatures for stable operation with 0%, 0.1%, 1%, and 3% EHN were 100 °C, 100 °C, 80 °C, and 40 °C, respectively, highlighting the impact of ignition improver addition on low-load methanol combustion. Additionally, it was observed that at an intake temperature of 120 °C, 3% EHN exhibited a combustion phasing similar to diesel at 50 °C. Interestingly, the efficiency of pure methanol at 120 °C was relatively higher than that of diesel, with the efficiency decreasing initially upon the addition of EHN and then increasing with higher EHN concentrations. This was likely due to the longer ignition delay from neat methanol creating a more premixed in-cylinder condition resulting in faster combustion.

Utilizing ignition improver blended with methanol demonstrates significant promise as a single-fuel solution to replace diesel in compression-ignition engines. Research and development efforts have demonstrated the potential in both smaller car engine sizes and heavy-duty engines, highlighting its potential across various vehicle types. However, as highlighted earlier, ignition improver is costlier than methanol and necessitates an additional blending stage in the fuel production line. Therefore, it remains interesting to explore neat-methanol engine solutions as an alternative avenue, considering their potential advantages in addressing the cost and production complexities associated with ignition improver blends.

3.2. Glow Plug

One of the explored solutions involving neat methanol is the use of a glow plug to generate a hot spot in proximity to the fuel injection jet, facilitating ignition and subsequent combustion propagation throughout the combustion chamber. This approach gained significant interest during the 1970s, 1980s, and 1990s, driven by U.S. concerns regarding petroleum imports, leading to numerous research projects and developments focusing on neat methanol compression-ignition employing glow plugs. In 1983, Toepel et al. [84] converted a 9 L, six-cylinder Detroit Diesel Allison 6V-92TA two-stroke coach engine to operate on methanol. This conversion was achieved by controlling the scavenging process to attain the desired in-cylinder conditions during fuel injection, complemented by the use of a glow plug during start-up and light-load operation. The resulting engine, operating on methanol, exhibited a thermal efficiency equal to or better than its diesel counterpart, showcasing the feasibility of glow plugs in two-stroke engines.

In 1986, Kroeger et al. [85] at Caterpillar presented a study of a four-stroke diesel in-line six-cylinder 10.5 L engine converted to methanol use utilizing a glow plug, showing that four-stroke engines are also feasible. Their findings demonstrated that methanol with a glow plug performs at comparable efficiency to diesel. Additionally, their study revealed a 50% reduction in NOx emissions, negligible soot levels, and slightly higher HC emissions compared to when using diesel fuel.

In 1980, Nagalingam et al. [86] showed that smaller engines can also be converted by converting a four-stroke single-cylinder 0.553 L diesel engine to operate on alcohols and gasoline, employing a heated and insulated surface ignition source. Their findings indicated that, at equivalent speeds, the engine exhibited optimal performance with the highest efficiency when running on methanol, followed by ethanol, with a performance comparable to diesel operation.

Later, in 1994, Goetz et al. [87] conducted an investigation into how the design of piston shape, injector design, combustion chamber swirl, and injection timing affect emissions from a CI engine on methanol with a glow plug to obtain a deeper understanding of methanol glow plug engine design. Their study utilized both a single-cylinder test engine and a heavy-duty six-cylinder engine. The results from the single-cylinder test highlighted a significant influence of the interaction between injector sprays with the piston bowl and the glow plug on engine emissions, emphasizing the importance of considering these factors in the design of a methanol glow plug engine. Specifically, swirl was found to reduce HC emissions while increasing NOx emissions, whereas fuel impingement on the piston resulted in lowered NOx emissions. In the case of the multi-cylinder engine, the need for a glow plug decreased as the engine heated up, and once fully warmed up, the engine could operate at all speeds and loads without the need for the glow plug. This shows that the real need for ignition assistants is at start-up and cold-engine conditions.

Green et al. [88] conducted a comparative study between glow plug ignition of methanol and the utilization of dimethyl ether (DME) in the intake for ignition of DI methanol. The use of DME is a dual-fuel concept that relies on the early combustion of DME, which heats the air in the cylinder prior to methanol injection, creating favorable conditions for methanol compression-ignition. This is intriguing because DME can be synthesized from methanol, making the refueling process only require one fuel. At the lowest tested load and speed, DME accounted for a substantial 59% of the injected fuel mass, but at higher loads and speeds, this proportion dropped to almost zero, indicating methanol’s ability to ignite under hotter engine conditions independently, but also its need for aid at colder conditions. The resulting emission measurements indicated reduced CO and NOx emissions when using glow plug ignition compared to DME, but HC emissions were significantly increased. This study suggested that glow plug ignition may not be the optimal ignition assistance method for methanol, but further research is needed.

In 2001, Mueller and Musculus [89] conducted optical studies on a heavy-duty DI diesel engine fueled with methanol and assisted by glow plug ignition operating at 1200 rpm under moderate-load conditions. Their investigation revealed a distinct three-step heat release pattern from the ignition of the glow plug. This phenomenon was attributed to the placement of the glow plug between two of the six injection jets emitted by the six-hole injector. As a result, combustion initiation occurred sequentially at the two nearest jets to the glow plug, followed by the next two, and finally the last two, shown as the observed three-step heat release. Later, Krishnan et al. [90], through computational fluid dynamics (CFD) simulations, confirmed this by demonstrating that the sprays ignite sequentially starting from the jet closest to the glow plug, which thereby extends the combustion duration. This prolonged combustion can lead to significantly lower peak heat release rates, resulting in a notably quieter engine operation.

After a period of limited research following extensive development of glow plug-assisted ignition in the 1970s, 1980s, and 1990s, recent interest in methanol has spurred new research and development efforts. Garcia et al. [91,92] conducted a comprehensive evaluation of methanol in a 1.6 L four-cylinder CI diesel engine, converting it to methanol operation through increased compression ratio, intake heating, and glow plug assistance for low-load ignition stability. Their experiments revealed that methanol performs similarly to diesel in terms of efficiency at medium to high loads when the engine is warm. However, methanol exhibits poorer combustion stability at low loads, attributed by the authors to the high ignition energy requirements and long ignition delay of methanol. The heating accessories used were insufficient for low-load operations, prompting the authors to recommend higher compression ratios and/or spark plug assistance, and although at high load they were not necessary, they were found to enhance stability when utilized.

3.3. Increased in-Cylinder Temperature

Numerous researchers have employed intake air heating as a method to assist in CI of neat methanol. However, this approach faces limitations in real-world applications due to the requirement for additional heaters and the electrical power needed to operate them. Instead, alternative engine parameters can be manipulated to raise the in-cylinder temperature effectively.

3.3.1. EGR

Using exhaust gas recirculation (EGR) with methanol CI combustion is an enticing concept, as it exploits the absence of significant soot levels in methanol emissions to circumvent the NOx–soot trade-off typically associated with conventional fuels, and it is also possible to use hot EGR to avoid using an intake heater to increase the in-cylinder temperature.

Garcia et al. [91,92] also investigated the use of EGR, observing a reduction in NOx emissions across all loads with more EGR, accompanied by increased CO emissions at all loads and elevated HC emissions at low loads but reduced at medium loads. Furthermore, their estimations based on the Worldwide Harmonized Light Vehicles Test Procedure (WLTP) cycles demonstrated an almost 50% decrease in NOx emissions with EGR utilization for the cycle.

Gainey et al. [93] conducted experiments with methanol CI utilizing EGR on a 0.423 L single-cylinder research engine at medium to high loads, employing a standard diesel CR of 16. Their findings indicated a decrease in engine-out NOx emissions with increasing EGR, accompanied by an elongation of the heat release and a slight reduction in efficiency. Notably, the dilution with EGR led to continued oxidation of CO late into the expansion stroke, resulting in a non-zero heat release that became longer with higher EGR levels. However, as the equivalence ratio approached stoichiometry, insufficient time for complete CO oxidation led to a significant increase in emissions with a corresponding decline in efficiency, although NOx emissions were reduced substantially. It is worth noting that the lower compression ratio necessitated significant intake heating, which may impact EGR limitations and equivalence ratio due to the reduced oxygen density in hotter air.

3.3.2. Compression Ratio

The concept of employing higher compression ratios in CI engines running on methanol has been explored by several researchers, as demonstrated in the previously described engines utilizing methanol with an ignition improver [82]. The objective behind this approach is to elevate the in-cylinder temperature to aid in facilitating the ignition of methanol. While such a practice is not typical for diesel engines due to concerns about emissions, particularly NOx formation at higher temperatures, this is less of an issue with methanol due to its cooling effect from injection, which mitigates NOx production.

Svensson et al. [94] demonstrated that elevating the CR from 17 to 40 in a heavy-duty engine can reduce the necessary intake temperature for stable combustion by over 100 °C. However, such a high CR is impractical for real-world applications, as it would lead to peak pressures exceeding the engine’s maximum allowable limits at high loads. Additionally, Svensson et al. illustrated that incorporating a small pilot injection prior to the main injection could also decrease the required intake temperature.

Shamun et al. [95] implemented a more practical yet still elevated CR of 27 in a Scania D13 engine modified to run on one cylinder. Their study investigated the impact of injection pressure, EGR, λ, and CA50 on efficiency and emissions during methanol CI combustion at 6 bar IMEPg and 1200 rpm. With this CR, methanol exhibited easy ignition at a 50 °C intake temperature, indicating promising prospects for methanol CI engine configurations. Among the tested parameters, higher fuel pressure was found to decrease efficiency due to more incomplete combustion, likely from higher levels of wall-wetting. A λ between 1.75 and 1.9 yielded the highest efficiency, while increasing EGR also enhanced efficiency. Moreover, elevated HC emissions were observed due to the higher compression ratio and a greater fraction of squish area.

3.4. Advanced Injection Strategies

3.4.1. Pilot Injection

The cooling effect of injecting methanol has a great negative effect on the combustibility of methanol, especially in cold and low-load conditions; therefore, concepts that can counteract this effect are of great interest. One possibility is employing a pilot injection alongside a larger main injection to spread out the cooling effect induced by methanol injection while utilizing the pilot as a means to preheat the combustion chamber, thereby facilitating the ignition of the main injection. Gainey et al. [93] demonstrated that advancing both the pilot and main injections could positively influence efficiency, provided that excessive fuel does not combust before TDC. Additionally, they highlighted the significance of pilot size, emphasizing that an insufficiently sized pilot might fail to adequately assist the main injection in ignition. Conversely, an excessively large pilot injection necessitated significant retardation of pilot timing to prevent engine damage resulting from premature heat release. Thus, optimizing the size and timing of the pilot injection emerged as crucial factors in achieving effective main injection ignition.

Svensson et al. [96] delved deeper into the impact of the timing and duration of a single pilot injection, coupled with a diffusion-controlled main injection, on the combustion behavior of neat methanol in a heavy-duty compression-ignition engine with a 5 bar load. Their study revealed that incorporating a pilot injection significantly reduced the required intake temperature for stable combustion compared to relying solely on a single main injection, while also notably lowering NOx emissions. They observed distinct combustion characteristics, whereby a short injection length and dwell time between the pilot and main injections led to the pilot burn being integrated into the main heat release, resulting in a characteristic “hump” in the heat release profile. Conversely, longer injections and dwell times caused the pilot to burn independently, yielding a two-stage heat release pattern. Optimal results were achieved with a dwell time of 15 to 20 CAD and a pilot to main injection ratio ranging from 0.18 to 0.27, resulting in the lowest emissions and a 5-percentage-point increase in efficiency compared to a single injection. Notably, the study utilized a compression ratio of 26:1 and intake temperature of 61 °C, underscoring the significant impact of increased compression ratio coupled with advanced injection strategies in enhancing low-load CI combustion of methanol.

3.4.2. Homogenous Charge Compression-Ignition

Further investigation into advanced injection strategies with neat methanol combustion has been undertaken by several researchers. One approach, which stands in stark contrast to conventional diesel diffusion combustion, is homogeneous charge compression-ignition (HCCI). HCCI relies on the creation of a homogeneous air/fuel mixture by very early fuel injection ignited by compression, a concept that poses challenges in controlling ignition timing, as it depends on meeting autoignition conditions. To address this, various methods have been investigated, including adjusting the intake temperature, utilizing EGR, and varying the compression ratio and valve timing to influence the in-cylinder conditions and thus, control ignition timing. The reason for using HCCI combustion lies in its capacity to maintain flame temperatures below 1900 K, thereby minimizing or even eliminating NOx emissions.

Maurya and Agarwal [97] conducted a study of the performance, combustion, and emission characteristics of an HCCI engine fueled with ethanol and methanol, comparing them with gasoline fuel. Their experiments utilized a modified four-cylinder four-stroke engine equipped with a port fuel injection system to achieve the homogeneous mixture. The findings revealed significantly low levels of NOx emissions; however, they also indicated elevated CO and HC emissions. Moreover, gasoline and ethanol exhibited a higher maximum efficiency compared to methanol.

Gharehghani [98] investigated the load limitations of methanol, ethanol, and natural gas in HCCI operation using a comparable engine setup to that of Maurya and Agarwal. The results largely corroborated the previous findings. They also indicated that methanol and ethanol perform better at low loads, while natural gas is more effective at high loads. Additionally, it was observed that methanol exhibited the highest levels of NOx emissions among the tested fuels. These findings collectively suggest that the HCCI strategy may not be the most suitable option for methanol in CI engines.

3.4.3. PPC

Another advanced injection strategy that has been more extensively researched is partially premixed combustion (PPC), which can be viewed as an intermediary approach between HCCI and diffusion combustion. PPC involves an early injection, though not as early as HCCI, during the compression stroke, ensuring that fuel and air are adequately (partially) premixed before combustion to mitigate high temperatures and fuel concentrations, while not being “too mixed” to encounter the HCCI challenges mentioned above.

Kristersson [99] explored PPC with neat methanol and demonstrated its feasibility. Employing a heavy-duty Scania engine with a CR of 15, the study utilized an injection timing of 23 CAD bTDC to facilitate methanol combustion under PPC conditions. Notably, the intake temperature required for combustion initiation at low loads was set at 150 °C, a value impractical for production engines. To address this limitation, the author suggests an increased compression ratio as a potential solution. Building upon this research, Zincir et al. [100] delved deeper into the effects of intake air temperature on low-load methanol combustion under PPC conditions, utilizing a slightly elevated CR of 20. Despite this adjustment, intake temperatures of 100 °C or higher were still necessary, albeit enabling stable PPC operation under idle engine conditions, achieving a gross indicated efficiency of around 29%. At higher loads of 3 bar, the efficiency was 42–43%, which is in line with diesel CI. Interestingly, Zincir et al. found that splitting the injection into a pilot and main injection could lower the required intake temperature when running PPC, similar to earlier findings with diffusion-combustion-like injection timings. A similar outcome was observed by Lönn [101], who investigated the impact of single- and double-injection strategies on low-load methanol PPC using an optical engine. Notably, a configuration with a first injection at 20 CAD bTDC followed by a second one at 6 CAD bTDC could reduce the required inlet temperature by 58 °C compared to the worst-case single-injection strategy. Aziz et al. [102] delved further into the design of injection timing for methanol PPC and examined different multiple-injection strategies. The results demonstrated that among the tested double-injection strategies, a 50/50 split of the fuel in the pilot/main with a pilot injection timing of 40 CAD and main timing of 30 CAD bTDC exhibited the best merit function. This configuration yielded low NOx and HC emissions along with an indicated efficiency of 44.4%. Further benefits of using a double injection are the lowered maximum pressure rise rate, which, according to the simulation study by Pucilowski et al. [103], can be lowered by a factor of three.

Svensson et al. [104] conducted a comprehensive investigation into the potential emissions of PPC methanol. They utilized a 0-D approach with constant pressure, temperature, and equivalence ratio to construct T-Φ maps showing emission characteristics, complemented by a stochastic reactor model (SRM) for engine simulation with end-gas emission predictions. Analysis of the T-Φ maps revealed non-existent soot, avoidable formaldehyde emissions, low methane levels compared to diesel, and similar CO and NOx emission levels to diesel.

To further explore emissions, Shamun et al. [105] investigated PM emissions from a heavy-duty Scania engine utilizing PPC with methanol, ethanol, and naphtha gasoline. They examined particle number, soot mass emissions, and particle number size distributions. The results indicated that the alcohols did not emit particles larger than 30 nm, with ethanol generally yielding smaller sizes compared to methanol. Methanol also emitted a higher number of particles overall. None of the tested alcohols exceeded the Euro VI PM or PN emission standards, unlike gasoline. However, current regulations for PN do not consider solid particles with a diameter less than 23 nm.

Shamun et al. [106] extended this investigation by employing an electrostatic precipitator (ESP) sample PM on copper grids for transmission electron microscopy (TEM) and utilizing energy-dispersive X-ray analysis. They also analyzed new and used lubrication oil, along with methanol and diesel, to assess their sulfur and metal content. The findings revealed that particles emitted from methanol and ethanol combustion primarily originated from the lubrication oil, containing elements such as Ca, S, P, and Zn. In contrast, diesel combustion produced a higher abundance of particles, with PM/soot emissions measured to be three to ten times higher than those from the alcohols. Although fewer nucleation-mode particles were present in diesel emissions, they also comprised the same four elements. This underscores the advantages of utilizing alcohols in CI engines concerning PM and particle number emissions. However, efforts to mitigate nucleation-mode particles are crucial and might be possible using a diesel oxidation catalyst.

3.5. Discussion

Several different concepts utilizing CI methanol have been presented, summarized in Table 4, and to conclude, methanol is viable but requires some form of aid to combust through compression. Using ignition improvers, which improve the cetane number, has been shown to work in real-world operations with good efficiency and emission results. However, it requires the addition of ignition improvers, which can be costly and add complexity with a fuel blending stage in production or refueling. Another option is the use of a glow plug, which has also been proven to work, especially in the 1970s, 1980s, and 1990s with stable start-up. However, this requires cylinder head space to accommodate a glow plug and regular service to change the glow plug, and the combustion characteristics of a glow plug can lead to suboptimal prolonged heat release.

Table 4.

Summary table of the CI concepts presented in Section 3.

Many of the researchers cited here have instead opted to use an increased intake air temperature to create the conditions needed to compression-ignite neat methanol. This requires the addition of an electrical heater to the intake, which needs power and space and is therefore not very convenient to use. Instead, other methods can be used to raise the in-cylinder temperature. Hot EGR is one method, which can also lower NOx emissions. Additionally, because methanol has negligible soot emissions, there is no NOx–soot trade-off to consider, which can extend the range of use for EGR. But this method does not aid at start-up when no exhaust gases are available and is therefore limited in use. Another method is to increase the compression ratio, which increases the cylinder temperature in all cases. This can also enhance the thermal efficiency, particularly when coupled with methanol’s cooling effect during injection, which helps mitigate NOx emissions that would otherwise pose a challenge. However, a notable drawback of this concept is the elevation of peak pressure in all cases, potentially restricting the engine’s operating range due to pressure limitation.

Another concept that also has a mostly positive impact is the use of advanced injection strategies. It has been shown to lower the required intake heating, achieve good emission levels, and potentially lower the peak pressure. Among the different injection strategies of pilot injection, PPC, and HCCI, HCCI does not seem to be a good option for methanol. It is hard to control, has elevated HC and CO emissions from more fuel in crevices, and is shown to be more suited for gasoline and ethanol. Instead, PPC or classical diffusion combustion with a pilot injection are more suitable alternatives for methanol CI. Both of these concepts have been tested, demonstrating good efficiencies and low emissions levels, while also reducing the requirement for high in-cylinder temperatures. However, it is important to note that both PPC and diffusion combustion with pilot injection require careful optimization to avoid the risk of excessive combustion before TDC, which could lead to engine damage. Additionally, opening of the injector multiple times per cycle may accelerate injector wear, causing additional cost and service time.

As a final point, the further development of methanol should focus on combining different concepts, as this could potentially make neat methanol work for a large variety of engine sizes under most conditions and loads. A good combination could potentially include increased CR, a glow plug (for cold-start and, if needed, the lowest loads), a multi-injection strategy (to spread out the cooling effect, add heat for the main injection, and lower peak pressures), and EGR (to lower NOx and use hot EGR for extra in-cylinder temperature).

4. Pre-Chamber

Historically, the concept of auxiliary combustion chambers or pre-chambers (PC) originates from the early 20th century, when Sir Harry Ricardo patented his Ricardo Dolphin engine in the 1910s [107] using the Comet pre-chamber to enable fast air–fuel mixing in small, high-speed diesel engines. In these engines, a separate combustion chamber, the pre-chamber, was connected to the main combustion chamber (MC) via a nozzle, passageway, or one or more orifices [108]. In the early days of PC research, the focus was on systems featuring large volumes and large-diameter throats connecting the PC and MC. This enables continuous flame front propagation across the two chambers. The downside is that the increased PC wall surface leads to increased heat transfer losses and higher hydrocarbon emissions. Hence, these large PCs gradually disappeared in the past decades [107]. The remaining parts of this chapter will thus focus mainly on the smaller (2–5% of clearance volume) PC concepts.

The concept of using an auxiliary chamber was later adopted by gasoline spark ignition engines when reducing fuel consumption became a high priority [109]. Here, the PC is typically a smaller volume that is connected to the MC through a series of smaller orifices. During the compression stroke, the air–fuel mixture from the MC is forced into the PC, where it is ignited by a spark plug. This causes the mixture in the PC to burn, resulting in a higher pressure. The pressure buildup expels the burning mixture through the orifices into the MC. The flames are quenched when passing through the narrow openings, which results in the formation of highly turbulent and reactive jets rather than continuous flame propagation. The partially combusted reactants and products, a turbulent mixture of highly reactive chemical species with a high thermal energy, penetrate the main air–fuel mixture and ignite it, acting as a distributed ignition source [110]. This results in a substantial increase in the combustion velocity, establishing a more concentrated heat release closer to the optimum, leading to a highly efficient combustion of the MC fuel while at the same time suppressing knock.

This jet ignition concept, depicted in Figure 3, was first introduced in the late 1950s by Nikolai Semenov [109]. The intention was to use PC technology to establish stable combustion while running very lean mixtures with a λ of 2 or above [107], as lean operation can increase efficiency and lower emissions. NOx emissions have been reported to be reduced to single-digit ppm values while reducing specific fuel consumption [110]. This can be attributed to lowered in-cylinder temperatures, resulting in less heat loss. Additionally, there are lower pumping losses due to a lesser need for throttling. Finally, a higher oxygen content leads to a more complete combustion. PC combustion systems are commonly used in large gas engines [111] and have been used since 2015 by Formula-1 racing teams [112], highlighting the possibilities of this technology as an enabler of methanol as a fuel in HD engines.

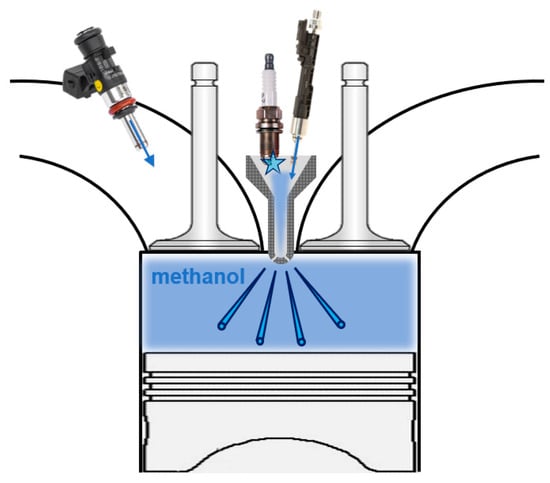

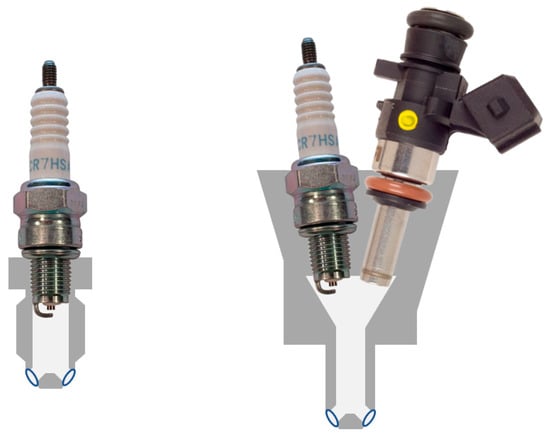

Figure 3.

Schematic of the jet ignition concept with an actively fueled pre-chamber. The star represents the spark and the arrows highlight the locations where fuel injections occur.

Research on the use of PCs in combustion engines was reviewed and summarized by Toulson et al. [109], Alvarez et al. [112], and Zhu et al. [107]. A major contribution to the foundation of small-volume PC research focusing on design parameters was made by Gussak et al. [113,114,115], who were among the early researchers investigating PCs starting in the 1970s. They concluded that a PC with a size of 2–3% of the clearance volume combined with an orifice total area of 0.03 to 0.04 cm² per cm³ of PC volume is optimal for combustion stability, efficiency, and power. More recent work on the matter by Shah et al. [116], which studies the effect of PC volume and nozzle diameter in a single-cylinder engine, lies in line with Gussak’s findings on geometrical parameters.

When delving into PCs used in premixed combustion, two different layouts can typically be discerned. The distinction is whether or not an auxiliary fuel system is used in the PC [107], which results in an active- or passive-fueled PC. In an active PC, a second injection enriches the PC mixture to have a richer mixture near the spark plug. With a passive PC, typically a cap with orifices on the spark plug, fuel in the PC originates from the scavenged gases that enter the PC during the compression stroke. A schematic of both systems is given in Figure 4. The use of an additional injection system in the PC has proven to be beneficial [112], as will be discussed later, yet increases complexity and, thus, the cost of the system.

Figure 4.

Schematic of the pre-chamber configurations, passive on the (left) and active on the (right).

In recent years, pre-chamber technology has gained interest as a means to facilitate the use of renewable fuels in ICEs, next to improving combustion with classic fossil fuels. Research has explored the feasibility of employing pre-chambers with a variety of renewable fuels [110,117,118,119,120,121]. Many of these possess high octane numbers, rendering them challenging to ignite in CI engines. While SI engines are better-suited for these high-octane renewable fuels, their size and achievable power output are often constrained by knock, as explained earlier. This is where pre-chamber systems emerge as a solution to reduce knock and enhance combustion stability. A comprehensive review of the use of different renewable fuels in conjunction with pre-chamber technology was conducted by Trombley et al. [122]. This review encompassed pre-chamber systems aimed at optimizing combustion in both SI and CI engines, providing insights into various fuels such as biodiesel, jet fuel, methanol, ethanol, ammonia, syngas, LPG/propane, natural gas/methane, and hydrogen, with gasoline and diesel as reference fuels.

An in-depth analysis of the effects of fuel properties on PC combustion was conducted by Hlaing et al. [110]. Their study examined parameters such as the flammability limits, combustion stability, emissions, and attainable efficiencies of different renewable fuels. The findings underscored the significance of fuel properties, particularly flame speed, in shaping the MC heat release characteristics. It could be concluded that PCs facilitate stable, efficient, and low-emission combustion while utilizing alternative fuels [122].

A final distinction between PC concepts can be made by categorizing them based on premixed or non-premixed combustion in the MC. Premixed air–fuel mixtures are inherently susceptible to knock, limiting the size and power output of such engines to a certain extent. Non-premixed concepts [123] offer a potential solution to this issue while providing additional benefits compared to premixed PC combustion. This concept was introduced by Kammel et al. [124], who used a PC to enable the mixing-controlled combustion of methane in a large-bore gas engine. This concept was later adopted by Dempsey et. al. [125] for liquid high-octane fuels as well. Nonetheless, it is essential to note that each technology has its own set of benefits and drawbacks, which will be included in the comparison later in this review.