Abstract

Cereal straw stands out as one of the most abundant and globally distributed agricultural residues. Traditional applications cope with a limited amount of production, leaving the remainder in the field for natural decomposition. Managing cereal straw through controlled biological transformation under anaerobic conditions holds the potential to generate added value in the form of bioenergy. However, the lignocellulosic composition of these substrates poses challenges for organic degradation, often requiring energy-intensive pretreatments. A detailed study with a comprehensive calculation of the overall energy balance of the integrated process is proposed, aiming to provide real added value and replicability. Three scenarios for wheat straw transformation were investigated, incorporating two preliminary pre-treatment stages—mechanical milling and physicochemical steam explosion. Three conditions of pretreatment were essayed, varying the time exposure of the steam explosion. The subsequent energy integration analysis revealed that the process was optimized by up to 15% in the final energy balance when the steam explosion was set to 10 min. The macromolecular composition determination revealed that the thermal pretreatment reduced the lag phase of the hydrolysis step through hemicellulose breakdown.

1. Introduction

There is a growing interest in the use of agricultural residues as an alternative to fossil fuels in energy production. Materials such as crop residues and manure are abundant and renewable, making them a sustainable source of energy [1]. In addition to reducing dependence on fossil fuels, transforming these materials into bioenergy avoids the release of diffuse greenhouse gas emissions [2]. Anaerobic digestion (AD) yields high-calorific-value biogas, primarily composed of biomethane, a substitute for traditional natural gas, thereby reducing the release of greenhouse gas emissions in the primary sector.

Among the agricultural wastes that can be used for biogas production, cereal waste is the most abundant and widely generated residue. However, straw is characterized by its substantial lignocellulosic content, which, owing to its limited degradability, presents a significant hurdle in the biogas production process [3]. These wastes primarily consist of three distinct polymers: cellulose, hemicellulose, and lignin. Cellulose, which presents a rigid crystalline structure, makes up a significant percentage. Hemicellulose, on the other hand, has a lower molecular weight and short side chains, making it a polymer that can be easily hydrolyzed. Lignin, a complex and amorphous heteropolymer, comprises three different phenylpropane units and is insoluble in water [4]. In the case of wheat straw the percentages of each polymer are: cellulose 30–45%, hemicellulose 20–35% and lignin 7–22% [5,6,7]. Both the cellulose and hemicellulose fractions can be broken down into monomeric sugars that are subsequently transformed into biogas, but the low biodegradability due to the rigid structure of the polymers reduces the amount of biomass transformed, compromising the viability of the process. Several pretreatments have been proposed to increase the rate of hydrolysis, with thermal pretreatment being the most commonly applied [8].

Thermal pretreatment is an effective strategy to improve the degradability of lignocellulosic wastes [9]. It consists of subjecting the waste to high temperatures, typically above 150 °C, for a given time [10]. This process breaks down the lignocellulose structure, increasing the accessibility of enzymes and facilitating the release of monomers. Thermal pretreatment can be performed by different methods, such as steam explosion, pyrolysis, and or in combination with chemical processes such as a thermal–acid treatment [11], which is the most widely employed pretreatment method for lignocellulosic biomass due to its cost-effectiveness and efficiency [12]. These methods modify the chemical composition and physical properties of the residues, making them more susceptible to enzyme action during the fermentation stage [13]. As a result, a higher conversion of waste to biogas is achieved, thus improving the efficiency and profitability of the process of producing renewable energy from lignocellulosic waste [14]. Steam explosion has been tested in the case of cereal straw and obtained a wide range of values in terms of an increase in biogas production. This process involves exposing the material to high temperatures by directly injecting saturated steam; subsequently, the material undergoes rapid depressurization, which generates shear forces capable of separating the fibers.

Table 1 presents a literature review of yields and conditions achieved by steam explosion pretreatment of wheat straw. The great variation in the methane enhancement (from 6.7 to 85.7%) can be seen. Beside this, it is important to note that while steam explosion treatment exhibits high performance compared to other pretreatment methods, it does have certain drawbacks when operated at high temperatures or for extended periods of time [15]. Along with the high energy consumption that reduces the net energy balance, the partial degradation of xylans in hemicelluloses and the incomplete breakdown of the lignin–carbohydrate has been related to the generation of inhibitors that can have a negative impact on the performance of anaerobic digestion, as reported by Bauer et al. (2014) [16].

Table 1.

Summary of the anaerobic digestion effect of steam explosion pretreatment on AD of lignocellulosic biomass.

On that path, the energy cost of thermal shock pretreatment must be weighed against the benefits obtained in form of biomethane produced. Therefore, a significant increase in biogas production should be achieved in a limited exposure time. The current study explores the biological transformation of wheat straw as a substrate for energy production via the anaerobic digestion process with a previous steam explosion pretreatment. Different conditions of time exposure were essayed and energy balances were calculated in order to maximize the energy recovery of the whole process. The production rate of biomethane was modelled for a better understanding of the pretreatment effect. In the same manner, the relative number of polymers (cellulose, hemicellulose, and lignine) was determined before and after pretreatment to evaluate the impact of thermal shock.

2. Materials and Methods

2.1. Feedstocks and Anaerobic Inoculum

Wheat straw was collected in the Soria province of Spain following the harvest season and employed as a substrate. To prepare the substrate, a physical pretreatment process was performed using a Moulinex grinder, resulting in particle sizes of 1 mm [22]. Inoculum for the anaerobic reactor, operated under mesophilic conditions, was sourced from the anaerobic digester of sewage sludge of the wastewater treatment (WWT) plant in Soria, Spain. The inoculum used required an adaptation period of four weeks under continuous conditions feeding with wheat straw in a 1.2 L reactor at 35 ± 0.5 °C degrees and magnetic stirring. Table 2 offers detailed characteristics of both the substrates and the inoculum.

Table 2.

Substrate and inoculum characterization.

2.2. Thermal Hydrolysis Pretreatment

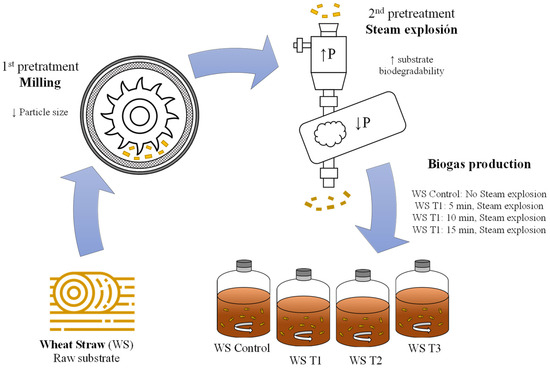

The laboratory-scale hydrolysis system consists of a 2 L reactor where substrate was introduced and is heated by the steam and a 5 L flash tank where the steam explosion takes place once the hydrolysis reaction time has passed (Figure 1). A detailed description of the thermal hydrolysis TH equipment was recently published by Diez et al. [23]. The temperature and pressure were maintained constant until depressurization at values of 170 °C and 7 ± 0.2 bar, respectively. These conditions were established following the approach by [24]. Therefore, the steam explosion exposure time was studied as the main variable with three levels: 5, 10, and 15 min. This approach was taken on the basis that the optimum temperature reported for this kind of pretreatment is 170 °C, but the adequate exposure time has not been documented.

Figure 1.

Schematic diagram of the wheat straw transformation from the field to the AD processing through mechanical and thermal pretreatment.

2.3. Biochemical Methanogenic Potential Tests

2.3.1. Anaerobic Digestion Tests

The anaerobic biodegradation of the pretreated substrates was assessed in batch mode over a 40-day period. The tests were initiated following the biochemical methanogenic potential (BMP) methodology, in accordance with the standard protocol outlined by Holliger et al. [25].

For these experiments, 120 mL serological glass bottles with a working volume of 70 mL and a headspace of 50 mL were prepared. The temperature was maintained at 35 ± 0.5 °C in an incubator (Hotcold-GL, Selecta, Barcelona, Spain), and mixing was achieved using an orbital stirring plate (Rotabit, Selecta). The inoculum to substrate ratio was set at 1.5:1 g VS, and 1.5 g of CaCO3 L−1 was added as a buffering agent to prevent pH fluctuations [26,27]. To establish anaerobic conditions, the bottles were purged with nitrogen to remove any residual air at the start of the experiment.

Three parallel tests were conducted for each pretreatment condition, namely, wheat straw standalone (WS Control), wheat straw with a 5 min period of steam explosion pretreatment (WS T1), with a 10 min pretreatment period (WS T2), and with a 15 min pretreatment period (WS T3). A blank test with only the inoculum was included to measure the endogenous production of biogas originating from the inoculum. The measurements were adjusted by subtracting the endogenous biogas production. Daily biogas production was quantified using a water displacement method, and the biogas volume was corrected for standard conditions, accounting for ambient pressure and operating temperature. Biogas composition was also measured by gas analysis equipment (Biogas 5000, GeoTech, Leamington Spa, UK).

2.3.2. Analytical Procedure

The American Public Health Association’s standard methods were employed for the analysis of total solids (TS), volatile solids (VS), and chemical oxygen demand (COD) [28]. The determination of carbon (C) and nitrogen (N) content was carried out using a Leco CNS-928 elemental analyzer (LECO corporation, St. Joseph, MI, USA). This analyzer employs a process that involves the total combustion of the sample, followed by the determination of the percentage of total weight for each element.

The lignocellulosic fractions (comprising hemicellulose, lignin, and cellulose) in both the pre- and post-pretreatment samples were analyzed using the lignocellulosic biomass analysis methods established by the National Renewable Energy Laboratory [29].

2.4. Modelling

Biogas Production

The experimental data acquired from the tests were applied to the modified Gompertz mathematical model to adjust the biomethane production for each test and applied to evaluate the AD performance following Equation (1) [30,31,32]. The Gompertz model offers several advantages in the context of biological processes, such as the degradation of organic substances. It effectively describes the biogas production and allows for the identification of three distinct stages: the lag phase, a subsequent exponential phase where biogas production increases linearly with time, and a final stationary phase where the biogas production rate returns to zero [33]. This information provides a rapid insight into the degradation process and possible effect of the pretreatments [34].

In this equation, B(t) represents the cumulative methane production at standard temperature and pressure (mL CH4∙g VS−1). B stands for the potential methane production in (mL CH4∙g VS−1), R represents the maximum methane production rate (mL CH4∙g VS−1 d−1), P represents the maximum volume of methane achieved (mL CH4∙g VS−1), λ signifies the lag phase duration in days, and t denotes the elapsed time in days. The model was fitted to the experimental data using the least-squares methodology. The adjusted coefficient of determination (R2), which represents the correlation coefficient, was computed using Equation (2):

2.5. Energy Feasibility Study

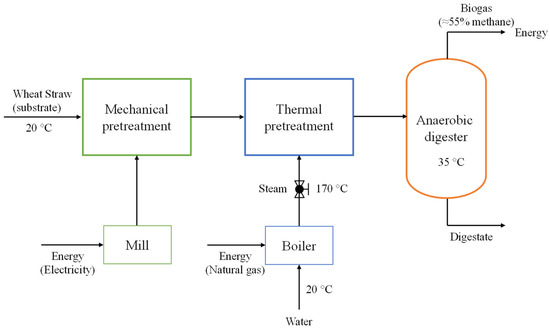

A scenario was created based on the configuration shown in Figure 2, which integrates two pretreatment methods: mechanical and thermal. The energy requirements for both pretreatment processes were determined using the electrical consumption for substrate grinding and the steam requirements based on Cano et al.’s (2014) prior research [19]. To achieve this, the scenario was applied in a full-scale plant, with a thorough analysis of energy inputs and outputs.

Figure 2.

Energy flow diagram configuration. Mechanical and thermal hydrolysis pretreatments.

The potential biomethane generated from the BMP tests was assessed using an energy content of 10 kWh∙Nm−3 [35,36]. Initially, all raw substrates and cold water were assumed to be 20 °C, with a consistent heat-capacity equivalent to that of water (4.18 kJ∙kg−1 °C−1) assigned to them to achieve hydrolysis conditions at 170 °C and anaerobic digestion at 35 °C. Furthermore, the process considered the grinding of straw in a 30 kW knife mill. This grinding operation had a specific flow rate per dry matter (DM) of 2.6 kg DM∙h−1∙kW−1 and consumed 140 kWh∙t DM−1 [22,37,38]. The net energy balance of the process was determined as the difference between the energy produced from renewable sources and the energy associated with natural gas, as can be observed in Equations (3)–(6).

where E(generation) is the energy produced in the anaerobic digestion process and E(consumption) is the energy consumed including the pretreatments.

where MP is the methane production per ton of substrate, vs. is the volatile solids of the substrate, and CV is the calorific value of the methane.

where E(miller) is the energy consumed in the mechanical pretreatment of cutting the substrate to 1 mm size with a value of 140 kWh∙t−1 and E(steam) is the energy consumed in the thermal pretreatment.

where Steam is the steam needed in the pretreatment per ton, ηbo is the boiler efficiency (90%), and CV the calorific value of the natural gas used.

In addition to improving this balance, there are energy savings in heating consumption achieved by increasing the temperature of the substrate as it enters in the anaerobic digester. This avoids losses within the digester since, following pretreatment, the substrate is already at a high temperature (≈100 °C), eliminating the need for additional heat during AD. Energy savings are defined in Equation (7):

where WS substrate is the biomass entering in the anaerobic digester, Sh is the specific heat of the substrate, and ΔT is the temperature difference between the outdoor conditions and the inside reactor conditions (15 °C).

3. Results and Discussion

3.1. Impact of Steam Explosion Pretreatment on Biogas Production

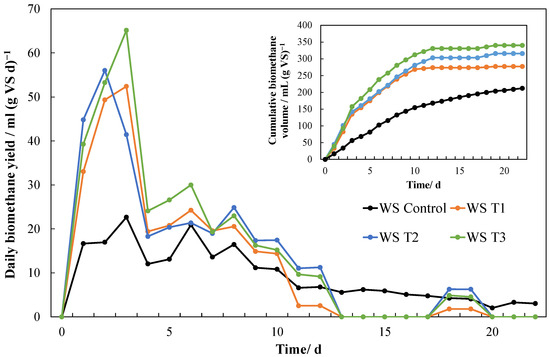

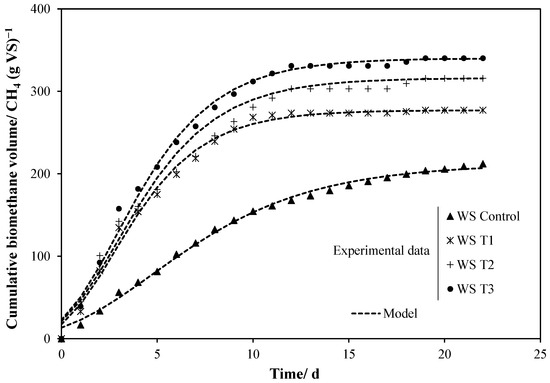

Figure 3 shows the daily and cumulative biomethane generation outcomes from a 25-day experimental regimen. Over this period, notable fluctuations in biomethane production were observed, corresponding with distinct growth phases.

Figure 3.

Daily and cumulative biomethane production from the anaerobic digestion of wheat straw with steam explosion pretreatment at different conditions throughout the experiment. WS Control stands for wheat straw standalone, and WS T1, WS T2, and WS T3 for wheat straw with a 5 min, 10 min and 15 min period of steam explosion pretreatment, respectively.

It can be observed that biogas production trends exhibited similarity in the three tests with thermal pretreatment. The highest production levels occurred during the initial five days, where the experiments surpassed the threshold of 50 mL biomethane g VS−1∙d−1. Subsequently, from the fifth day onwards, daily production displayed fluctuations, alternating between decline and ascent, within the range of 10 to 25 mL biomethane g VS−1∙d−1. However, an average biogas production level was sustained between days 10 and 25, marking the stationary phase of the process. Beyond the 13th day, biogas production gradually diminished due to reduced availability of convertible organic substrates. Ultimately, the cumulative production reached 277, 316, and 340 mL biomethane g VS−1 for pretreatment trials WS T1, WS T2, and WS T3, respectively. In contrast, the control trial, WS Control, exhibited a more gradual biogas production pattern, maintaining values within the range of 10–15 mL biomethane g VS−1∙d−1 for the first 10 days. Subsequently, it entered a stationary production phase, yielding between 5 and 10 mL biomethane mL∙g VS−1∙d−1 until the conclusion of the trial, with a cumulative production of 212 mL biomethane g VS−1. Different authors have reported values between 204 and 285 mL∙g VS−1 using raw wheat straw as substrate in the AD process [39,40,41].

Table 3 provides an overview of the increment in biomethane production observed throughout the trials involving the three pretreatments compared to the control. Remarkably, the most substantial disparity was discerned after the initial five days, owing to the effect of thermal pretreatment, which expedited the hydrolysis phase of the anaerobic digestion process. Over an extended period, the pretreatment effect remained prominent, ultimately finishing in a 35%, 53%, and 65% increase in biomethane production in comparison to the control test for pretreatments WS T1, WS T2, and WS T3. This rise has also been described by other authors, as shown in Table 1, using wheat straw as a substrate under various steam water pretreatment conditions in the AD process [12,16,17,20,21]. In the same manner, the direct correlation between methane increased, and the time of exposure to the steam was also previously documented.

Table 3.

Increase in cumulative methane production in comparison with the control experiment (%) from the anaerobic digestion of wheat straw with steam explosion pretreatment at different conditions.

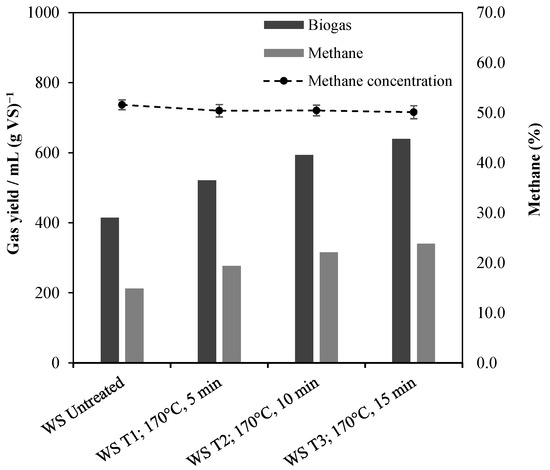

Regarding the biogas composition in each trial, it can be observed that it was quite similar across all four trials, with slightly over 50% methane content in Figure 4. This methane content was within the typical range for such substrates [16,42]. There was a slight trend of decreasing methane concentration observed from the control trial, with a recorded 52% for the trial with more pretreatment time, which showed a biogas content of 50%. This trend aligns with findings reported by Theuretzbacher et al. (2015) [17].

Figure 4.

Biogas composition (right axis) and biogas yield (left axis) from the anaerobic digestion of wheat straw with steam explosion pretreatment at different conditions.

3.2. Modelling

The modelling with the Gompertz equation is illustrated in Figure 5 and the corresponding parameter values are detailed in Table 4. Higher rates of biogas production, denoted as R in the model, signify a mitigation of the rate-limiting step within the hydrolysis phase, with maximum values in the more intense pretreatment. Specifically, WS T1 achieved a value of 38.89 mL biomethane g VS−1∙d−1, while WS T2 achieved 40.19 and WS T3 reached 43.68. Likewise, the reduction in the lag phase was evident, as indicated by values approaching zero in all trials, as a consequence of the reduction in fiber size and the subsequent increase in the hydrolysis step.

Figure 5.

Biomethane production per amount of volatile solid for wheat straw under three different pretreatment conditions. Gompertz modelling.

Table 4.

Kinetic parameters of methane production for the Gompertz modelling from the AD of wheat straw with steam explosion pretreatment at different conditions.

This substantial variation found in the biomethane production rates, ranging from 130% to 160% according to the Gompertz modelling for the three distinct pretreatment conditions with respect to the control experiment, suggests the potential operational benefits of integrating steam explosion systems into the AD. This integration could optimize, on the one hand, the biomethane production, and on the other hand, the potential reduction of the hydraulic residence time (HRT) by accelerating the organic decomposition of the substrate. Consequently, this acceleration could lead to a smaller digester size, lower HRT, decreased investment costs for the operator, and ultimately, a more sustainable process.

3.3. Lignocellulose Component Decomposition

Table 5 shows the alterations in the chemical composition of the samples, comparing those with and without thermal pretreatment. In the control test, the dry-matter content of the ground sample without thermal pretreatment stood at 92.3%. This percentage decreased to 58.5% as the intensity of the pretreatment increased due to the use of steam to maintain the pretreatment temperature, which partly condensed in the flash tank. The proportion of volatile solids within the dry matter remained consistent, ranging from 91.7% to 95.5%. To ensure comparability between the biomass before anaerobic digestion, it was necessary to calculate the relative proportion of the analyzed components, excluding the water-soluble fractions. It can be observed that as the pretreatment severity increased, there was a reduction in hemicellulose content. This outcome was anticipated since hemicellulose becomes soluble at 150 °C, and therefore, its decrease can be attributed to both temperature and pretreatment duration [43].

Table 5.

Chemical composition of untreated and steam-exploded wheat straw.

The degradation of hemicellulose in pretreated wheat straw showed an increase from 4.5% to 9.2% as the retention time increased, aligning with findings from previous studies [12,17]. In the same way, Theuretzbacher et al. (2015) found a 9.9% decrease in hemicellulose, resulting in a 71.2% increase in biogas production. Shang et al. (2019) observed a 26.6% increase in biogas production and a 6.5% decrease in hemicellulose content after thermal pretreatment [17,44]. Long exposure to steam accelerated the rate of hemicellulose hydrolysis, which ultimately had a positive impact on AD. Conversely, the degradation rate of lignin and cellulose exhibited the opposite effect, remaining at a similar concentration or even increasing as consequence of the hemicellulose decline. In the case of lignin, as previously reported by Brownell and Saddler in 1987, its resistance to hydrolysis was attributed to the formation of pseudolignin or the creation of cross-linked compounds resulting from the reactions of sugars released from the hemicellulose fraction [45,46]. More severe treatment, involving higher temperatures or longer exposure times, of lignocellulosic biomass can lead to lower methane yield due to the release of phenolic and heterocyclic compounds from the degradation of hemicellulose and cellulose, such as furfural and hydroxymethylfurfural [47,48]. These compounds can inhibit the activity of fermenting microorganisms in the process, as noted by Hendriks and Zeeman in 2009 [49].

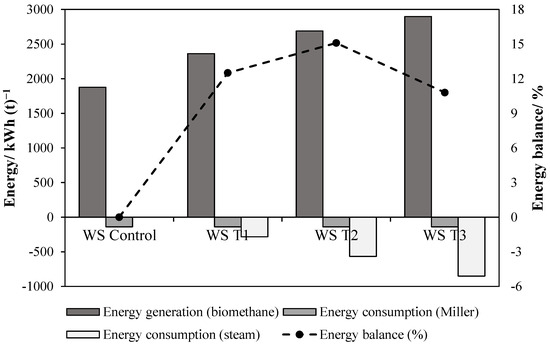

3.4. Energy Feasibility Study

The viability of employing thermal hydrolysis pretreatment in a continuous processing facility was assessed using the configuration outlined in Section 2.5 and the data obtained in the BMP tests. The energy consumption associated with both mechanical and thermal pretreatment was quantified using empirical data resulting from actual operational processes. These calculations were based on the processing of one metric ton of raw wheat straw within the facility.

Table 6 represents the primary outcomes of the study. Particle size reduction by a knife mill presented constant values of energy consumption across all four trials at 140 kWh∙t−1. Previous studies indicate that this pretreatment could account for the highest percentage of energy input [50,51]. Biogas requirements for steam generation increase with prolonged thermal pretreatment times. Energy production is related to biomethane generation under each operational condition. It is important to note that all trials involving thermal pretreatment exhibited a positive energy balance, resulting in a net benefit. However, after a 10 min period of thermal pretreatment, the enhancement of the energy balance declined due to the increased consumption associated with the pre-treatment. A limited percentage improvement in the energy balance was achieved for the 10 min pretreatment, accounting for a final value of 15.1% (Figure 6). In view of the narrow energy profit and the possible detrimental effects associated with the prolonged exposure times, steam explosion systems must be carefully designed based on previous essays complemented with energy balances.

Table 6.

Energy feasibility results expressed per ton of wheat straw fed.

Figure 6.

Energy generation and consumption per ton of wheat straw with steam explosion pretreatment at different conditions (left axis). Increase in the energy balance compared to the control tests (right axis).

Substrates with high vs. content like wheat straw, ideally above 110 g kg−1, have demonstrated positive outcomes when applying a steam water pretreatment [19]. Conversely, it is important to highlight that other waste materials, such as fatty wastes, may require no pretreatment and can yield exceptionally high energy consumption levels exceeding 3000 kWh∙t−1. This underscores the substantial potential for anaerobic digestion in this substrate category [19]. On the other hand, waste materials with greater availability but lower volatile solid content, such as livestock waste or sewage sludge, do necessitate pretreatment to achieve positive net energy balances in the process [52,53].

4. Conclusions

The high availability of lignocellulosic organic residues from the agricultural sector presents a novel opportunity in its management for energy valorization through anaerobic digestion. This potential that can be maximized by applying pretreatments such as a combination of mechanical grinding and physico-chemical steam explosion. Although the production of biomethane can be doubled with this configuration, the overall energy balance was limited to an increase of 15% in a real-scale process integration. The rates of biomethane generation were significantly increased after thermal shock with a total reduction in the lag phase, evidencing the increase in the hydrolytic phase. Prolonged exposure (15 min) to the thermal pretreatment reduced the energy recovery and viability. The macromolecular analysis revealed that the positive effect of the steam treatment impacted the breakdown of hemicellulose, while lignin and cellulose remained unaltered.

Author Contributions

A.G.Á.: conceptualization, methodology, research development, writing; C.R.P.: methodology and research development; I.D.V.: conceptualization, review and editing; D.H.: conceptualization, methodology, review, editing, supervision, funding acquisition; R.M.: conceptualization, supervision; I.d.G.: review and editing, supervision, project administration, funding acquisition. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Regional Government of Castilla y León and the EU-FEDER program (CL-EI-2021-07), grant PID 2020-114918RB-I00 funded by MCIN/AEI/10.13039/501100011033, and funded by the LIFE program through LIFE SMART AgroMobility (LIFE19 CCM/ES/001206).

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Singh, R. Chapter 7—Toxic risk assessment of engineered nanoparticles used in ink formulations. In Smart Multifunctional Nano-Inks; Gupta, R.K., Nguyen, T.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2023; pp. 159–194. [Google Scholar] [CrossRef]

- Gołasa, P.; Wysokiński, M.; Bieńkowska-Gołasa, W.; Gradziuk, P.; Golonko, M.; Gradziuk, B.; Siedlecka, A.; Gromada, A. Sources of Greenhouse Gas Emissions in Agriculture, with Particular Emphasis on Emissions from Energy Used. Energies 2021, 14, 3784. [Google Scholar] [CrossRef]

- Dar, R.A.; Parmar, M.; Dar, E.A.; Sani, R.K.; Phutela, U.G. Biomethanation of agricultural residues: Potential, limitations and possible solutions. Renew. Sustain. Energy Rev. 2021, 135, 110217. [Google Scholar] [CrossRef]

- Jin, X.; Ai, W.; Dong, W. Lignocellulose degradation, biogas production and characteristics of the microbial community in solid-state anaerobic digestion of wheat straw waste. Life Sci. Space Res. 2022, 32, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Dale, B.E. Life cycle assessment of various cropping systems utilized for producing biofuels: Bioethanol and biodiesel. Biomass Bioenergy 2005, 29, 426–439. [Google Scholar] [CrossRef]

- Passoth, V.; Sandgren, M. Biofuel production from straw hydrolysates: Current achievements and perspectives. Appl. Microbiol. Biotechnol. 2019, 103, 5105–5116. [Google Scholar] [CrossRef]

- Xu, C.; Li, J.; Zhang, X.; Wang, P.; Deng, B.; Liu, N.; Yuan, Q. Effects of segmented aerobic and anaerobic fermentation assisted with chemical treatment on comprehensive properties and composition of wheat straw. Bioresour. Technol. 2022, 362, 127772. [Google Scholar] [CrossRef]

- Hashemi, B.; Sarker, S.; Lamb, J.J.; Lien, K.M. Yield improvements in anaerobic digestion of lignocellulosic feedstocks. J. Clean. Prod. 2021, 288, 125447. [Google Scholar] [CrossRef]

- Tsapekos, P.; Kougias, P.G.; Frison, A.; Raga, R.; Angelidaki, I. Improving methane production from digested manure biofibers by mechanical and thermal alkaline pretreatment. Bioresour. Technol. 2016, 216, 545–552. [Google Scholar] [CrossRef]

- Rajput, A.A.; Zeshan; Visvanathan, C. Effect of thermal pretreatment on chemical composition, physical structure and biogas production kinetics of wheat straw. J. Environ. Manag. 2018, 221, 45–52. [Google Scholar] [CrossRef]

- Camargo, F.P.; Rabelo, C.A.B.S.; Duarte, I.C.S.; Silva, E.L.; Varesche, M.B.A. Biogas from lignocellulosic feedstock: A review on the main pretreatments, inocula and operational variables involved in anaerobic reactor efficiency. Int. J. Hydrogen Energy 2023, 48, 20613–20632. [Google Scholar] [CrossRef]

- Yu, Y.; Wu, J.; Ren, X.; Lau, A.; Rezaei, H.; Takada, M.; Bi, X.; Sokhansanj, S. Steam explosion of lignocellulosic biomass for multiple advanced bioenergy processes: A review. Renew. Sustain. Energy Rev. 2022, 154, 111871. [Google Scholar] [CrossRef]

- Song, Z.; Yang, G.; Liu, X.; Yan, Z.; Yuan, Y.; Liao, Y. Comparison of seven chemical pretreatments of corn straw for improving methane yield by anaerobic digestion. PLoS ONE 2014, 9, e93801. [Google Scholar] [CrossRef] [PubMed]

- Naik, G.P.; Poonia, A.K.; Chaudhari, P.K. Pretreatment of lignocellulosic agricultural waste for delignification, rapid hydrolysis, and enhanced biogas production: A review. J. Indian Chem. Soc. 2021, 98, 100147. [Google Scholar] [CrossRef]

- Periyasamy, S.; Karthik, V.; Kumar, P.S.; Isabel, J.B.; Temesgen, T.; Hunegnaw, B.M.; Melese, B.B.; Mohamed, B.A.; Vo, D.-V.N. Chemical, physical and biological methods to convert lignocellulosic waste into value-added products. A review. Environ. Chem. Lett. 2022, 20, 1129–1152. [Google Scholar] [CrossRef]

- Bauer, A.; Bösch, P.; Friedl, A.; Amon, T. Analysis of methane potentials of steam-exploded wheat straw and estimation of energy yields of combined ethanol and methane production. J. Biotechnol. 2009, 142, 50–55. [Google Scholar] [CrossRef]

- Theuretzbacher, F.; Lizasoain, J.; Lefever, C.; Saylor, M.K.; Enguidanos, R.; Weran, N.; Gronauer, A.; Bauer, A. Steam explosion pretreatment of wheat straw to improve methane yields: Investigation of the degradation kinetics of structural compounds during anaerobic digestion. Bioresour. Technol. 2015, 179, 299–305. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, L.C.; Donoso-Bravo, A.; Nilsen, P.J.; Fdz-Polanco, F.; Pérez-Elvira, S.I. Influence of thermal pretreatment on the biochemical methane potential of wheat straw. Bioresour. Technol. 2013, 143, 251–257. [Google Scholar] [CrossRef]

- Cano, R.; Nielfa, A.; Fdz-Polanco, M. Thermal hydrolysis integration in the anaerobic digestion process of different solid wastes: Energy and economic feasibility study. Bioresour. Technol. 2014, 168, 14–22. [Google Scholar] [CrossRef] [PubMed]

- Lizasoain, J.; Trulea, A.; Gittinger, J.; Kral, I.; Piringer, G.; Schedl, A.; Nilsen, P.J.; Potthast, A.; Gronauer, A.; Bauer, A. Corn stover for biogas production: Effect of steam explosion pretreatment on the gas yields and on the biodegradation kinetics of the primary structural compounds. Bioresour. Technol. 2017, 244, 949–956. [Google Scholar] [CrossRef]

- Steinbach, D.; Wüst, D.; Zielonka, S.; Krümpel, J.; Munder, S.; Pagel, M.; Kruse, A. Steam Explosion Conditions Highly Influence the Biogas Yield of Rice Straw. Molecules 2019, 24, 3492. [Google Scholar] [CrossRef]

- Dell’Omo, P.P.; Spena, V.A. Mechanical pretreatment of lignocellulosic biomass to improve biogas production: Comparison of results for giant reed and wheat straw. Energy 2020, 203, 117798. [Google Scholar] [CrossRef]

- Díaz, I.; Díaz-Curbelo, A.; Pérez-Lemus, N.; Fdz-Polanco, F.; Pérez-Elvira, S.I. Traceability of organic contaminants in the sludge line of wastewater treatment plants: A comparison study among schemes incorporating thermal hydrolysis treatment and the conventional anaerobic digestion. Bioresour. Technol. 2020, 305, 123028. [Google Scholar] [CrossRef] [PubMed]

- Fdz-Polanco, F.; Velazquez, R.; Perez-Elvira, S.I.; Casas, C.; del Barrio, D.; Cantero, F.J.; Fdz-Polanco, M.; Rodriguez, P.; Panizo, L.; Serrat, J.; et al. Continuous thermal hydrolysis and energy integration in sludge anaerobic digestion plants. Water Sci. Technol. 2008, 57, 1221–1226. [Google Scholar] [CrossRef] [PubMed]

- Holliger, C.; Alves, M.; Andrade, D.; Angelidaki, I.; Astals, S.; Baier, U.; Bougrier, C.; Buffière, P.; Carballa, M.; de Wilde, V.; et al. Towards a standardization of biomethane potential tests. Water Sci. Technol. 2016, 74, 2515–2522. [Google Scholar] [CrossRef]

- Romagnoli, F.; Pastare, L.; Sabūnas, A.; Bāliņa, K.; Blumberga, D. Effects of pre-treatment on Biochemical Methane Potential (BMP) testing using Baltic Sea Fucus vesiculosus feedstock. Biomass Bioenergy 2017, 105, 23–31. [Google Scholar] [CrossRef]

- Rouches, E.; Escudié, R.; Latrille, E.; Carrère, H. Solid-state anaerobic digestion of wheat straw: Impact of S/I ratio and pilot-scale fungal pretreatment. Waste Manag. 2019, 85, 464–476. [Google Scholar] [CrossRef]

- Eaton, A.D.; Clesceri, L.S.; Greenberg, A.E.; Franson, M.A.H. Standard Methods for the Examination of Water & Wastewater, 22nd ed.; APHA: Washington, DC, USA, 2012. [Google Scholar]

- National Renewable Energy Laboratory. Determination of Structural Carbohydrates and Lignin in Biomass. Biomass Compositional Analysis Laboratory Procedures. 2012. Available online: https://www.nrel.gov/docs/gen/fy13/42618.pdf (accessed on 25 March 2024).

- Li, W.; Khalid, H.; Zhu, Z.; Zhang, R.; Liu, G.; Chen, C.; Thorin, E. Methane production through anaerobic digestion: Participation and digestion characteristics of cellulose, hemicellulose and lignin. Appl. Energy 2018, 226, 1219–1228. [Google Scholar] [CrossRef]

- Meneses Quelal, O.; Pilamunga Hurtado, D. Anaerobic Fermentation of Slaughterhouse Waste—Codigestion with Wheat Straw to Determine Methane Biochemical Potential and Kinetic Analysis. Fermentation 2023, 9, 726. [Google Scholar] [CrossRef]

- Zhao, Y.; Sun, F.; Yu, J.; Cai, Y.; Luo, X.; Cui, Z.; Hu, Y.; Wang, X. Co-digestion of oat straw and cow manure during anaerobic digestion: Stimulative and inhibitory effects on fermentation. Bioresour. Technol. 2018, 269, 143–152. [Google Scholar] [CrossRef]

- Chen, Y.R.; Hashimoto, A.G. Substrate utilization kinetic model for biological treatment process. Biotechnol. Bioeng. 1980, 22, 2081–2095. [Google Scholar] [CrossRef]

- Krishania, M.; Vijay, V.K.; Chandra, R. Methane fermentation and kinetics of wheat straw pretreated substrates co-digested with cattle manure in batch assay. Energy 2013, 57, 359–367. [Google Scholar] [CrossRef]

- Deublein, D.; Steinhauser, A. Biogas from Waste and Renewable Resources. Focus Catal. 2011, 2011, 8. [Google Scholar] [CrossRef]

- Schley, P.; Beck, M.; Uhrig, M.; Sarge, S.M.; Rauch, J.; Haloua, F.; Filtz, J.-R.; Hay, B.; Yakoubi, M.; Escande, J.; et al. Measurements of the Calorific Value of Methane with the New GERG Reference Calorimeter. Int. J. Thermophys. 2010, 31, 665–679. [Google Scholar] [CrossRef]

- Ji, G.; Xiao, W.; Gao, C.; Cao, Y.; Zhang, Y.; Han, L. Mechanical fragmentation of wheat and rice straw at different scales: Energy requirement in relation to microstructure properties and enzymatic hydrolysis. Energy Convers. Manag. 2018, 171, 38–47. [Google Scholar] [CrossRef]

- Jiradechakorn, T.; Chuetor, S.; Kirdponpattara, S.; Narasingha, M.; Sriariyanun, M. Performance of combined hydrochemo-mechanical pretreatment of rice straw for bioethanol production. Energy Rep. 2023, 9, 180–185. [Google Scholar] [CrossRef]

- Eskicioglu, C.; Monlau, F.; Barakat, A.; Ferrer, I.; Kaparaju, P.; Trably, E.; Carrère, H. Assessment of hydrothermal pretreatment of various lignocellulosic biomass with CO2 catalyst for enhanced methane and hydrogen production. Water Res. 2017, 120, 32–42. [Google Scholar] [CrossRef] [PubMed]

- Menardo, S.; Balsari, P. An Analysis of the Energy Potential of Anaerobic Digestion of Agricultural By-Products and Organic Waste. Bioenergy Res. 2012, 5, 759–767. [Google Scholar] [CrossRef]

- Sambusiti, C.; Monlau, F.; Ficara, E.; Carrère, H.; Malpei, F. A comparison of different pre-treatments to increase methane production from two agricultural substrates. Appl. Energy 2013, 104, 62–70. [Google Scholar] [CrossRef]

- Kang, Y.-R.; Su, Y.; Wang, J.; Chu, Y.-X.; Tian, G.; He, R. Effects of different pretreatment methods on biogas production and microbial community in anaerobic digestion of wheat straw. Environ. Sci. Pollut. Res. 2021, 28, 51772–51785. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, Y.; Wang, S.; Wu, G.; Zhan, X. A critical review on dry anaerobic digestion of organic waste: Characteristics, operational conditions, and improvement strategies. Renew. Sustain. Energy Rev. 2023, 176, 113208. [Google Scholar] [CrossRef]

- Shang, G.; Zhang, C.; Wang, F.; Qiu, L.; Guo, X.; Xu, F. Liquid hot water pretreatment to enhance the anaerobic digestion of wheat straw—Effects of temperature and retention time. Environ. Sci. Pollut. Res. 2019, 26, 29424–29434. [Google Scholar] [CrossRef] [PubMed]

- Nelson, M.C.; Morrison, M.; Yu, Z. A meta-analysis of the microbial diversity observed in anaerobic digesters. Bioresour. Technol. 2011, 102, 3730–3739. [Google Scholar] [CrossRef] [PubMed]

- Yadav, M.; Vivekanand, V. Combined fungal and bacterial pretreatment of wheat and pearl millet straw for biogas production—A study from batch to continuous stirred tank reactors. Bioresour. Technol. 2021, 321, 124523. [Google Scholar] [CrossRef] [PubMed]

- Akizuki, S.; Suzuki, H.; Fujiwara, M.; Toda, T. Impacts of steam explosion pretreatment on semi-continuous anaerobic digestion of lignin-rich submerged macrophyte. J. Clean. Prod. 2023, 385, 135377. [Google Scholar] [CrossRef]

- Li, P.; Wei, X.; Wang, M.; Liu, D.; Liu, J.; Pei, Z.; Shi, F.; Wang, S.; Zuo, X.; Li, D.; et al. Simulation of anaerobic co-digestion of steam explosion pulping wastewater with cattle manure: Focusing on degradation and inhibition of furfural. Bioresour. Technol. 2023, 380, 129086. [Google Scholar] [CrossRef] [PubMed]

- Hendriks, A.T.W.M.; Zeeman, G. Pretreatments to enhance the digestibility of lignocellulosic biomass. Bioresour. Technol. 2009, 100, 10–18. [Google Scholar] [CrossRef] [PubMed]

- Alvaro, A.G.; Palomar, C.R.; Redondo, D.H.; Torre, R.M.; de Godos Crespo, I. Simultaneous production of biogas and volatile fatty acids through anaerobic digestion using cereal straw as substrate. Environ. Technol. Innov. 2023, 31, 103215. [Google Scholar] [CrossRef]

- Garuti, M.; Sinisgalli, E.; Soldano, M.; Fermoso, F.G.; Rodriguez, A.J.; Carnevale, M.; Gallucci, F. Mechanical pretreatments of different agri-based feedstock in full-scale biogas plants under real operational conditions. Biomass Bioenergy 2022, 158, 106352. [Google Scholar] [CrossRef]

- Kakar, F.L.; Aqeel, H.; Liss, S.N.; Elbeshbishy, E. Impact of Hydrothermal Pretreatment Parameters on Mesophilic and Thermophilic Fermentation and Anaerobic Digestion of Municipal Sludge. Fermentation 2023, 9, 508. [Google Scholar] [CrossRef]

- Vanegas, M.; Romani, F.; Jiménez, M. Pilot-Scale Anaerobic Digestion of Pig Manure with Thermal Pretreatment: Stability Monitoring to Improve the Potential for Obtaining Methane. Processes 2022, 10, 1602. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).