Research on Insulation Configuration of 220 kV Bushing in High-Altitude Polluted Areas

Abstract

1. Introduction

2. Method of Obtaining Bushing Flashover Voltage

2.1. Test Sample

2.2. Test Equipment

2.3. Test Methods

- (1)

- Pre-treatment of the sample. Wipe the sample clean before the tests, remove the pollution accumulated on the surface of the sample, and place it in a ventilated place to keep it dry;

- (2)

- Sample polluting. The tests in this paper adopt the solid coating method to pollute the test bushing. The salt density of the selected filth is 0.05, 0.10, and 0.15 mg/cm2, respectively, and the fixed gray density is 0.5 mg/cm2. NaCl is used to simulate the soluble conductive substances, and diatomaceous earth simulates the non-soluble substances;

- (3)

- Barometric simulation. The altitude simulated in this paper is divided into 232, 1000, 2000, 3000, and 4000 m, corresponding to the atmospheric pressure of 98.6, 89.8, 79.4, 70.1, and 61.5 kPa, and the tests adopt a vacuum pump to adjust the atmospheric pressure in order to ensure the stability of the atmospheric pressure.

- (4)

- Sample wetting. The fogging system generates a uniformly distributed fog in the climatic chamber and controls the concentration of the fog to make sure that the surface of the test sample is saturated and moist.

- (5)

- Test sample voltage applied. The AC pollution flashover tests and impulse flashover tests in this paper adopt the constant voltage up and down method stipulated in the IEC 60507:2013 standard [15]. In the AC pollution flashover tests, the test sample is in the same degree of pollution and atmospheric pressure for many repeated tests to ensure that the impactive number of test voltages is more than 10 times. In the impulse flashover tests, the impactive number of test voltages is between 20 and 30 times, and the time interval between two voltages applied is 3 to 5 min. The U50 flashover voltage in tests can be obtained from the following equation [16].

3. Analysis of Flashover Characteristics of 220 kV Bushing in High-Altitude Polluted Areas

3.1. Analysis of AC Pollution Flashover Characteristics

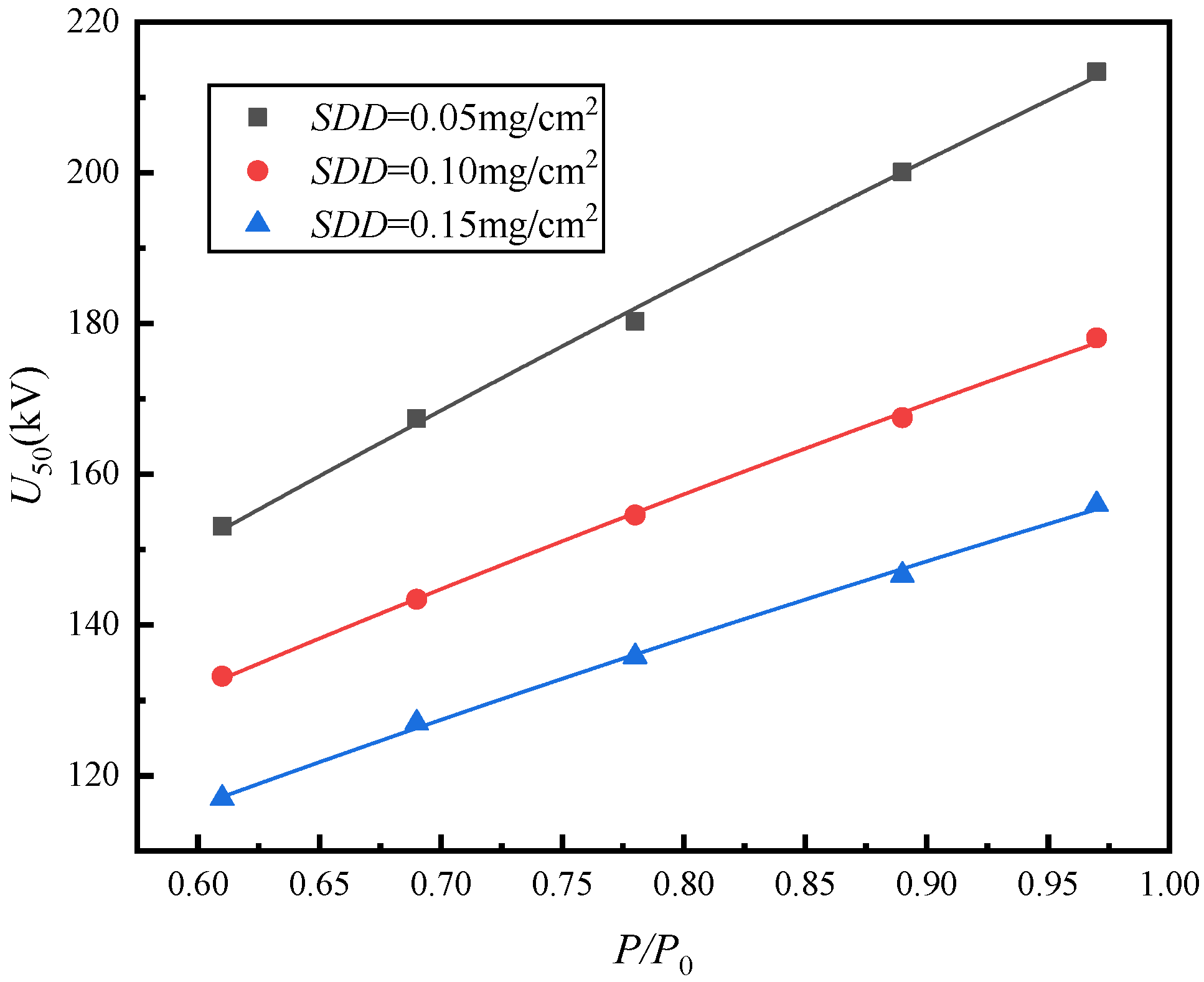

- The relative standard deviation values of AC pollution flashover voltages of the test bushing are all less than 7%, indicating that the test results have little dispersion and the test data are reasonable and impactive.

- Atmospheric pressure has an impact on the AC pollution flashover voltage of the bushing. Under the same salt density, the pollution flashover voltages of the bushing decrease with the decrease in atmospheric pressure. For example, when the salt density is 0.10 mg/cm2, and the atmospheric pressure is 98.6, 89.8, 79.4, 70.1, and 61.5 kPa, respectively, the AC pollution flashover voltage of the bushing is 178.1, 167.5, 154.6, 143.4, and 133.2 kV, respectively; that is, when the atmospheric pressure is reduced from 98.6 to 61.5 kPa, the AC pollution flashover voltage of the bushing is decreased by 25.2%.

- Salt density also has a significant impact on the AC pollution flashover voltages of the bushing. Under the same atmospheric pressure, the AC pollution flashover voltages of the bushing decrease with the increase in salt density. For example, when the atmospheric pressure is 79.4 kPa and the salt density is 0.05, 0.10, and 0.15 mg/cm2, respectively, the AC pollution flashover voltage of the bushing is 180.3, 154.6, and 135.8 kV, respectively; that is, when the salt density increases from 0.05 to 0.15 mg/cm2, the pollution flashover voltage of the bushing decreases by 24.7%.

- The fitted correlation coefficients, R2, are all greater than 0.99, indicating that the deviation of each data point from the fitted curve is not large and there is no abnormal data. At the same time, it also shows that under the same SDD, the AC pollution flashover voltage of the test bushing decreases with the decrease in P/P0.

- SDD has an impact on the value of n of the bushing. The value of n decreases with the increase in salt density.

- The value of n of the test bushing under each salt density condition does not differ much, ranging from 0.608 to 0.716, with an average value of 0.649, indicating that the atmospheric pressure under each salt density condition has a similar impact on the AC pollution flashover voltages of the bushing.

- The fitted correlation coefficients, R2, are all greater than 0.98, indicating that the test results are uniformly distributed around the fitted curves without abnormal data points. At the same time, it also shows that the AC pollution flashover voltages of the bushing decrease with the increase in salt density in a negative power exponential function.

- The atmospheric pressure has an impact on the value of a of the bushing. The value of a decreases with the decrease in atmospheric pressure.

- The value of a of the test bushing under each atmospheric pressure condition does not differ much, ranging from 0.236 to 0.280, with an average value of 0.258, indicating that the impact of salt density on the AC pollution flashover voltages of the bushing under each atmospheric pressure condition is similar.

3.2. Analysis of Lightning Impulse Flashover Characteristics

- The relative standard deviation values of the lightning impulse flashover voltages of the bushing are all within 3%, indicating that the dispersion of the test results is small and the test data are reasonable and valid.

- Atmospheric pressure has a significant impact on the lightning impulse flashover voltages of the bushing. When the atmospheric pressure decreases, the lightning impulse flashover voltage decreases. For example, when the atmospheric pressure is 98.6, 89.8, 79.4, 70.1, and 61.5 kPa, the lightning impulse flashover voltage in positive polarity is 1221.6, 1122.6, 1013.6, 903.7, and 813.9 kV. In addition, the voltage in negative polarity is 1646.9, 1504.5, 1349.0, 1190.4, and 1062.5 kV. That means when the atmospheric pressure is lowered from 98.6 to 61.5 kPa, the lightning impulse flashover voltages of the bushing under positive polarity decrease by 33.4%, and those of the bushing under negative polarity decrease by 35.5%.

- The lightning impulse flashover voltages of the test bushing have an obvious polarity effect. The voltages in negative polarity are obviously larger than the positive polarity under the same atmospheric pressure.

- The fitted correlation coefficients, R2, are all greater than 0.99, indicating that the deviation of each data point from the fitted curve is not large and there is no anomalous data. At the same time, it also shows that the lightning impulse flashover voltages of the bushing decrease exponentially with the decrease in atmospheric pressure.

- The atmospheric pressure impact characteristic index of the test bushing at positive and negative polarity conditions are 0.870 and 0.938. The larger the value of n is, the faster the flashover voltage decreases. This shows that the lightning impulse flashover characteristics of the bushing under negative polarity conditions are more affected by atmospheric pressure than those under positive polarity conditions.

- The value of n of the atmospheric pressure impact characteristic index is similar to that of air gap discharge. It shows that the lightning impulse flashover characteristics of the test bushing are similar to the air gap discharge characteristics, which is similar to the conclusion obtained from the literature [20].

3.3. Analysis of Switching Impulse Flashover Characteristics

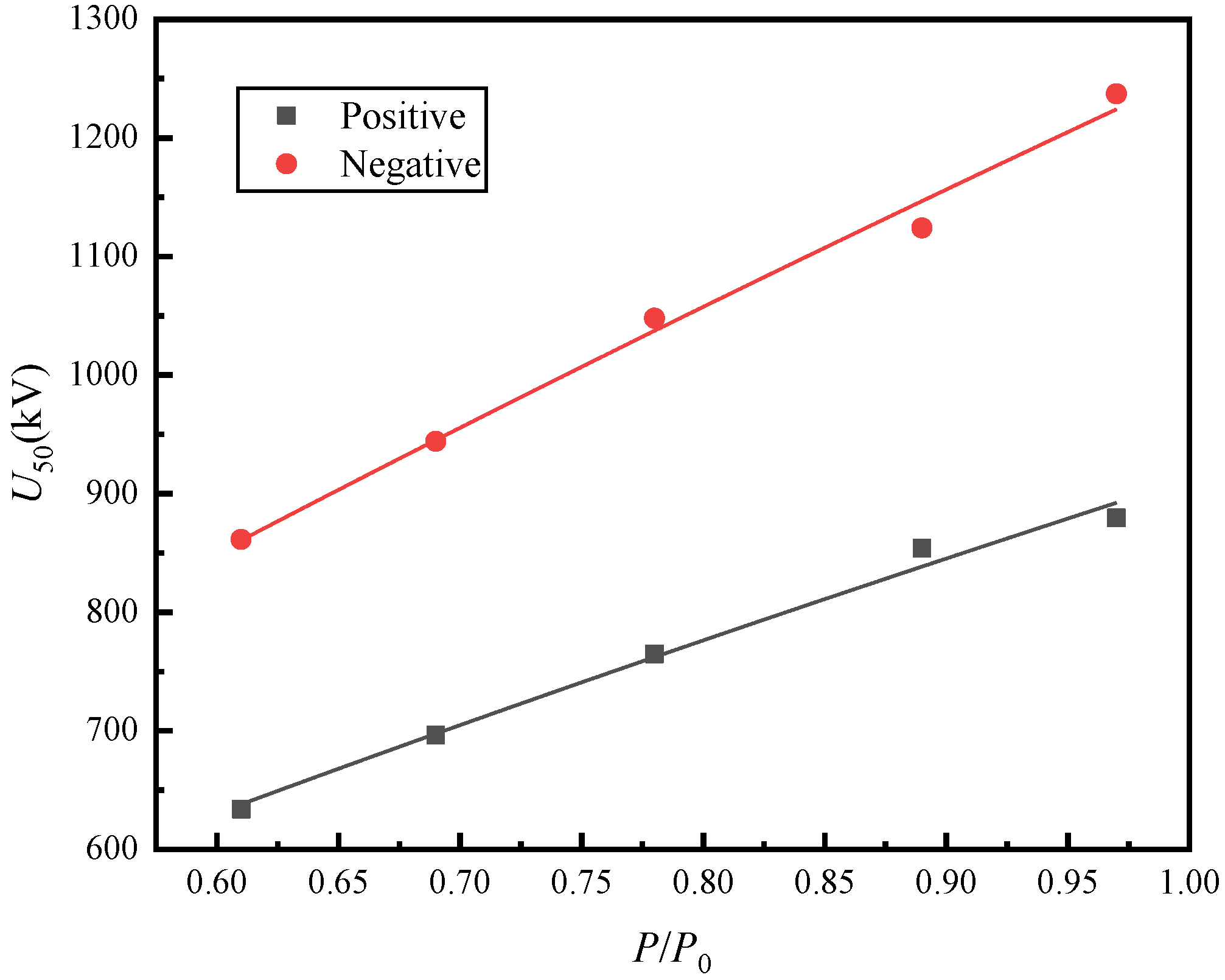

- The relative standard deviation values of the switching impulse flashover voltages of the bushing are all within 3%, indicating that the dispersion of the test results is small and the test data are reasonable and valid.

- Atmospheric pressure has a significant impact on the switching impulse flashover voltages of bushing. When the atmospheric pressure decreases, the switching impulse flashover voltage decreases. For example, when the atmospheric pressure is 98.6, 89.8, 79.4, 70.1, and 61.5 kPa, the switching impulse flashover voltage in positive polarity is 879.6, 854.0, 764.8, 696.3, and 633.8 kV. In addition, the voltage in negative polarity is 1237.1, 1124.0, 1047.9, 944.1, and 861.3 kV. That means when the atmospheric pressure is lowered from 98.6 to 61.5 kPa, the voltages in positive polarity of the bushing decrease by 27.9%, and in negative polarity decrease by 30.4%.

- The switching impulse flashover voltages of the test bushing have a significant polarity effect. That is, under the same pressure, the voltages in negative polarity are significantly larger than in positive polarity.

- Compared with the lightning impulse flashover voltages of the bushing, the switching impulse flashover voltages are lower under the same polarity and atmospheric pressure conditions, and the switching impulse flashover voltages are 24.3% lower than the lightning impulse flashover voltages on average under positive polarity and 22.4% lower than those under negative polarity.

- The fitting correlation coefficients R2 are all greater than 0.99, the test data points are evenly distributed on both sides of the fitting curve, and the fitting correlation is good. At the same time, it also shows that the switching impulse flashover voltages of the casing decrease with the decrease in the atmospheric pressure in a power exponential function.

- The atmospheric pressure impact characteristic index of the test bushing at positive and negative polarity conditions are 0.723 and 0.759. Both of them are smaller than the value n under lightning impulse flashover conditions. That means the switching impulse flashover characteristics of the bushing are less affected by atmospheric pressure. At the same time, it also indicates that the switching impulse flashover characteristics of the bushing under negative polarity are more affected by atmospheric pressure than by positive polarity.

- The value of n of the atmospheric pressure impact characteristic index is similar to that of air gap discharge. That means the switching impulse flashover characteristics are similar to the lightning impulse flashover characteristics, and both of them are similar to the air gap discharge characteristics.

4. Analysis of Bushing Insulation Level in High-Altitude Polluted Areas

4.1. Calculation of Creepage Distance

4.2. Calibration of Impulse Flashover Voltage

4.2.1. Calibration of Lightning Impulse Flashover Voltage

4.2.2. Calibration of Switching Impulse Flashover Voltage

4.3. Recommended Values for Creepage Distances of Bushing in High-Altitude Polluted Areas

5. Conclusions

- The AC pollution flashover voltages of the bushing are significantly impacted by atmospheric pressure and salt density and decrease as a power exponential function with the decrease in atmospheric pressure and the increase in salt density.

- Under the application of lightning impulse and switching impulse voltage, the flashover voltages of the bushing are also impacted by the atmospheric pressure. With the decrease in atmospheric pressure, a power exponential function decreases. In addition, the flashover voltages have an obvious polarity effect.

- According to the AC pollution flashover test results, the value of n of the atmospheric pressure impact characteristic index of the test bushing ranges from 0.608 to 0.716, and the value of a of the pollution impact characteristic index ranges from 0.236 to 0.280. According to the lightning impulse flashover test results, the values of n of the atmospheric pressure impact characteristic index of the test bushing in positive and negative polarity are 0.870 and 0.938. According to the results of the switching impulse flashover tests, the values of n of the atmospheric pressure impact characteristic index of the test bushing in positive and negative polarity are 0.723 and 0.759.

- When the test bushing works in high-altitude polluted areas, its external insulation level does not meet the requirements of insulation configuration. This paper proposes a new external insulation configuration scheme for the test bushing under high-altitude polluted areas according to the results of AC pollution flashover tests and the calibration results of lightning and switching impulse flashover voltage of the test bushing.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, C.; Wang, L.; Guan, Z.; Zhang, F. Pollution flashover performance of full-scale ±800 kV converter station post insulators at high altitude area. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 717–726. [Google Scholar] [CrossRef]

- Yang, L.; Hao, Y.; Li, L.; Zhao, Y. Comparison of pollution flashover performance of porcelain long rod, disc type, and composite UHVDC insulators at high altitudes. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1053–1059. [Google Scholar] [CrossRef]

- Yang, L.; Hao, Y.; Li, L.; Zhang, F. Artificial pollution flashover performance of porcelain long rod UHVDC insulators at high altitudes. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 1965–1971. [Google Scholar] [CrossRef]

- Huang, D.; Ruan, J.; Cai, W.; Li, T.; Wei, Y.; Liu, J. Flashover prevention on high-altitude HVAC transmission line insulator strings. IEEE Trans. Dielectr. Electr. Insul. 2009, 16, 88–98. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, X.; Wang, L.; Guan, Z.; Wen, H.; Li, R.; Ma, Y. Effect of arcing on DC flashover performance of contaminated porcelain insulators for various suspension patterns at high altitudes. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 783–791. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, L.; Guan, Z.; Macalpine, M. Influence of composite insulator shed design on contamination flashover per-formance at high altitudes. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 739–744. [Google Scholar] [CrossRef]

- Li, J.; Wang, Z.; Meng, X.; Wang, L. Influence of Shed Shape on Direct-Current Pollution Flashover Voltage and Pressure Decrease Exponent. IEEE Access 2022, 10, 51804–51813. [Google Scholar] [CrossRef]

- Lu, M.; Li, Y.; Hu, J. Influence of Sheds Damage on the AC Pollution Flashover Performance of Different Voltage Class Composite Insulators. IEEE Access 2020, 8, 84713–84719. [Google Scholar]

- Hussain, M.M.; Farokhi, S.; McMeekin, S.G.; Farzaneh, M. Mechanism of saline deposition and surface flashover on outdoor insulators near coastal areas part II: Impact of various environment stresses. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1068–1076. [Google Scholar] [CrossRef]

- Qiu, Z.; Sun, Y.; Cui, Y.; Zhang, Z.; Liu, Y.; Chen, X.; Wu, Y.; Li, C.; Wang, L.; Lei, Z. Optimized Design of Shed Parameters for Polluted Hollow Porcelain Insulators at High Altitude. IEEE Access 2023, 11, 63451–63462. [Google Scholar] [CrossRef]

- Li, L.; Gu, Y.; Hao, Y.; Xue, Y.; Xiong, G.; Yang, L.; Zhang, F. Shed parameters optimization of composite post insulators for UHV DC flashover voltages at high altitudes. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 169–176. [Google Scholar] [CrossRef]

- Suzuki, H.; Hayase, Y.; Yamashiro, K. Study on Creepage Dielectric Insulation under Combined Salt Pollution, High Humidity and Transient Air Pressure. In Proceedings of the 2020 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), East Rutherford, NJ, USA, 18–30 October 2020; pp. 51–54. [Google Scholar]

- Abbasi, A.; Shayegani, A.; Niayesh, K. Pollution performance of HVDC SiR insulators at extra heavy pollution conditions. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 721–728. [Google Scholar] [CrossRef]

- Zhang, Z.; Shi, H.; Sun, Y.; Yue, S.; Zhu, X.; Jiang, X. Flashover characteristics and altitude correction of railway insulators at high altitude and polluted areas. Electr. Power Syst. Res. 2023, 224, 109724. [Google Scholar] [CrossRef]

- IEC 60507:2013; Artificial Pollution Tests on High-Voltage Ceramic and Glass Insulators to Be Used on a.c. Systems. International Electrotechnical Commission: Worcester, MA, USA, 2013.

- IEC 60060-1:2010; High-Voltage Test Techniques-Part 1: General Definitions and Test Requirements. International Electrotechnical Commission: Geneva, Switzerland, 2010.

- Li, J.; Zhou, J.; Guan, Z.; Wang, L. Effects of low pressure on DC pollution performance under different insulator profiles. In Proceedings of the 2012 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Montreal, QC, Canada, 14–17 October 2012; pp. 733–736. [Google Scholar]

- Dong, Q.; Sau, A. Breakup of a leaky dielectric drop in a uniform electric field. Phys. Rev. E 2019, 99, 043106. [Google Scholar] [CrossRef] [PubMed]

- IEC 60071-2:2018; Insulation Co-Ordination—Part 2: Application Guidelines. International Electrotechnical Commission: Geneva, Switzerland, 2018.

- Shu, L.; Yuan, Q.; Jiang, X.; Hu, Q.; Yang, Z. Insulator Pollution Flashover Characteristic Under Low Air Pressure Caused by Lightning Surge. High Volt. Technol. 2010, 36, 1347–1352. (In Chinese) [Google Scholar]

- Jiang, X.; Shu, L.; Sun, C. Pollution and Icing Insulation in Power System, 1st ed.; China Electric Power Press: Beijing, China, 2009; pp. 256–262. [Google Scholar]

- IEC 60071-1:2019; Insulation Co-Ordination—Part 1: Definitions, Principles and Rules. International Electrotechnical Commission: Geneva, Switzerland, 2019.

| Parameters (mm) | |||

|---|---|---|---|

| H | h | L | P1/P2 |

| 2180 | 1963 | 7692 | 71/51 |

| No. | P/kPa | P/P0 | SDD/(mg/cm2) | |||||

|---|---|---|---|---|---|---|---|---|

| 0.05 | 0.10 | 0.15 | ||||||

| U50 | σ/% | U50 | σ/% | U50 | σ/% | |||

| 1 | 98.6 | 0.97 | 213.4 | 2.3 | 178.1 | 0.9 | 156.0 | 0.6 |

| 2 | 89.8 | 0.89 | 200.1 | 3.8 | 167.5 | 2.1 | 146.6 | 5.3 |

| 3 | 79.4 | 0.78 | 180.3 | 1.2 | 154.6 | 0.6 | 135.8 | 2.4 |

| 4 | 70.1 | 0.69 | 167.4 | 2.8 | 143.4 | 1.9 | 127.0 | 6.4 |

| 5 | 61.5 | 0.61 | 153.1 | 1.0 | 133.2 | 2.1 | 117.0 | 3.8 |

| Fitting Values | SDD (mg/cm2) | ||

|---|---|---|---|

| 0.05 | 0.10 | 0.15 | |

| U0 | 217.5 | 180.9 | 158.3 |

| n | 0.716 | 0.624 | 0.608 |

| R2 | 0.998 | 0.999 | 0.998 |

| Fitting Values | P(kPa) | ||||

|---|---|---|---|---|---|

| 98.6 | 89.8 | 79.4 | 70.1 | 61.5 | |

| A | 92.5 | 87.4 | 85.5 | 80.5 | 75.9 |

| a | 0.280 | 0.277 | 0.251 | 0.247 | 0.236 |

| R2 | 0.997 | 0.996 | 0.991 | 0.995 | 0.985 |

| No. | P/kPa | P/P0 | Positive | Negative | ||

|---|---|---|---|---|---|---|

| U50 | σ/% | U50 | σ/% | |||

| 1 | 98.6 | 0.97 | 1221.6 | 0.5 | 1646.9 | 0.5 |

| 2 | 89.8 | 0.89 | 1122.6 | 0.6 | 1504.5 | 0.4 |

| 3 | 79.4 | 0.78 | 1013.6 | 1.6 | 1349.0 | 1.0 |

| 4 | 70.1 | 0.69 | 903.7 | 1.1 | 1190.4 | 2.3 |

| 5 | 61.5 | 0.61 | 813.9 | 0.9 | 1062.5 | 0.7 |

| Fitting Values | Polarity | |

|---|---|---|

| Positive | Negative | |

| U0 | 1250.7 | 1690.2 |

| n | 0.870 | 0.938 |

| R2 | 0.999 | 0.999 |

| No. | P/kPa | P/P0 | Positive | Negative | ||

|---|---|---|---|---|---|---|

| U50 | σ/% | U50 | σ/% | |||

| 1 | 98.6 | 0.97 | 879.6 | 1.0 | 1237.1 | 0.7 |

| 2 | 89.8 | 0.89 | 854.0 | 0.4 | 1124.0 | 0.9 |

| 3 | 79.4 | 0.78 | 764.8 | 1.1 | 1047.9 | 3.0 |

| 4 | 70.1 | 0.69 | 696.3 | 2.9 | 944.1 | 1.2 |

| 5 | 61.5 | 0.61 | 633.8 | 0.9 | 861.3 | 0.6 |

| Fitting Values | Polarity | |

|---|---|---|

| Positive | Negative | |

| U0 | 912.2 | 1252.9 |

| n | 0.723 | 0.759 |

| R2 | 0.990 | 0.991 |

| Creepage | SDD (mg/cm2) | Altitude (m) | |||

|---|---|---|---|---|---|

| 1000 | 2000 | 3000 | 4000 | ||

| L (mm) | 0.05 | 4905 | 5443 | 5863 | 6410 |

| 0.10 | 5859 | 6348 | 6844 | 7368 | |

| 0.15 | 6694 | 7227 | 7727 | 8388 | |

| Creepage | Altitude (m) | |||

|---|---|---|---|---|

| 1000 | 2000 | 3000 | 4000 | |

| L (mm) | 5825 | 6451 | 7235 | 8034 |

| Creepage | Altitude (m) | |||

|---|---|---|---|---|

| 1000 | 2000 | 3000 | 4000 | |

| L (mm) | 4783 | 5341 | 5866 | 6445 |

| Creepage | SDD (mg/cm2) | Altitude (m) | |||

|---|---|---|---|---|---|

| 1000 | 2000 | 3000 | 4000 | ||

| L (mm) | 0.05 | \ | \ | \ | 8034 |

| 0.10 | \ | \ | \ | 8034 | |

| 0.15 | \ | \ | 7727 | 8388 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Zhang, Y.; Xiao, W.; Sun, Y.; Jiang, X. Research on Insulation Configuration of 220 kV Bushing in High-Altitude Polluted Areas. Energies 2024, 17, 1645. https://doi.org/10.3390/en17071645

Zhang Z, Zhang Y, Xiao W, Sun Y, Jiang X. Research on Insulation Configuration of 220 kV Bushing in High-Altitude Polluted Areas. Energies. 2024; 17(7):1645. https://doi.org/10.3390/en17071645

Chicago/Turabian StyleZhang, Zhijin, Yuanpeng Zhang, Wei Xiao, Yong Sun, and Xingliang Jiang. 2024. "Research on Insulation Configuration of 220 kV Bushing in High-Altitude Polluted Areas" Energies 17, no. 7: 1645. https://doi.org/10.3390/en17071645

APA StyleZhang, Z., Zhang, Y., Xiao, W., Sun, Y., & Jiang, X. (2024). Research on Insulation Configuration of 220 kV Bushing in High-Altitude Polluted Areas. Energies, 17(7), 1645. https://doi.org/10.3390/en17071645