1. Introduction

The halide perovskite (PVSK) family of materials proves to be the rising star in the next generation of solar devices, with lab-reported power conversion efficiencies (PCE) rivaling commercial silicon modules at 26.1% after just over ten years of research [

1]. Additionally, the compositionally tunable bandgap of PVSK films offers an attractive means of advancing silicon modules when used in tandem, making the push towards scalability increasingly urgent. While PVSK technologies show great promise, the U.S. Department of Energy continues to consider manufacturability, stability, and scalability as key challenges in the effort to reach commercialization [

2]. Furthermore, large-area perovskite modules prove even more challenging in their development, with efficiency gaps appearing between them and their small-scale counterparts under 200 cm

2 [

3].

In an effort to address these challenges and move from lab-to-fab, emphasis has shifted from processing via spin coating to innovating scalable techniques such as spray coating, electrochemical deposition, ink jet printing, slot-die coating, and doctor-blade coating [

4,

5,

6]. Specifically, meniscus-driven doctor-blade coating offers a promising lab-scale deposition method that easily translates to industrial manufacturing techniques such as slot-die coating and roll-to-roll manufacturing on flexible substrates. Interestingly, blade coating and slot-die coating are suggested to be among the most cost-affordable and promising solution processing technologies for industrialization [

7].

However, this transition from spin coating to meniscus-driven processing is often complicated by an incompatibility with inks optimized for use with traditional antisolvent quenching. Tuning parameters associated with alternative quenching methods, such as gas or vacuum-based techniques, further complicate process optimization, reproducibility, and the overall feasibility of commercialization. Entire studies have been dedicated to the reproducibility of these methods recently [

8].

Furthermore, transitioning from lab-style inert fabrication to industrial ambient manufacturing poses further complications. Open-air, antisolvent-free blade coating of unmodified PVSK inks previously optimized for spin coating in an inert environment with an antisolvent produces void-filled, uneven, and shunted films, demonstrating that the mild annealing step alone is not enough to control crystallization [

4,

9,

10]. In recent studies, solvent engineering and novel polymeric modifiers have been used to improve film uniformity, density, and stability while also improving manufacturability through an increase in ink viscosity, which offers improved fluid dynamics and crystallization while blade coating [

11,

12,

13]. Furthermore, biopolymers from the food industry, such as cornstarch, have been found to enhance mechanical integrity and the operational lifetime of devices in addition to inducing spherulitic domains that can be tuned in size by temperature and precursor concentration to increase PCEs, while a hypothesized organizational scaffolding increases resistance to humidity [

14,

15,

16].

The biopolymer chosen for this study, gellan gum—a non-toxic extracellular polysaccharide produced from bacteria known as

Sphingomonas elodea—forms firm, transparent gels in the presence of metallic ions and features heat resistance properties [

17,

18]. Gellan gum is thought to mediate the gelation process by undergoing a reversible transition from a disordered single chain to a self-assembled highly ordered double helix upon cooling through crosslinking structures, whereby various fibrous formations are possible depending on the temperature, cation attachment, and concentration introduced [

18]. Outside of being used as a suspension agent, binder, and coagulant in the food industry, gellan gum has been utilized in the biomedical community and conductive polymer field to create high-quality films without interrupting expected electrical properties [

19,

20]. More recently, gellan gum has been incorporated into solar devices featuring a polymer-mediated crystallization process to achieve single-junction methylammonium lead iodide, CH

3NH

3PbI

3 (MAPI), devices, and wide-bandgap mixed-halide perovskite solar cells for tandem applications with improved photostability compared to reference cells. For MAPI devices with gellan gum, Bisconi et al. reported an efficiency of 16.98% with an open-circuit voltage of 1.072, short circuit current density of 21.24 mA/cm

2 and fill factor of 74.6%. For MAPb(I

0.8Br

0.2)

3 devices manufactured with gellan gum, they reported an efficiency of 16.37% with an open-circuit voltage of 1.104, short-circuit current density of 20.36 mA/cm

2, and fill factor of 72.8% [

21]. The addition of gellan gum has also been shown to induce an intrinsic compressive stress within the perovskite film, a property correlated with improved mechanical and environmental stability [

22,

23].

Rather than directly controlling solvent evaporation with an antisolvent, air gun, or the use of heat, gellan gum alters fluid dynamics and free energy considerations within the ink to tune the crystallization process by acting as a barrier to excessive homogenous and early heterogeneous nucleation through intermediate interactions and a change in wetting angle thanks to rheological modification. These factors stimulate the radial, spherulitic growth of similarly oriented domains that grow in a space-filling nature that combats the presence of pinholes while possibly collecting defects and impurities, including the additive, along grain boundaries, which may assist in relieving detrimental thermal or intrinsic stresses typically associated with the thermal expansion mismatch between the PVSK layer and substrate without inhibiting optoelectronic properties [

12,

22].

In this work, we demonstrate a method of polymer-mediated crystallization enabling the production of high-quality blade-coated MAPI films in open air without quenching that feature improved mechanical, optoelectronic, and stability characteristics. With the introduction of less than one weight percent of gellan gum, we show that the crystallization process can be fully controlled, which allows for the tuning of the perovskite film morphology according to the additive concentration. This tunability is enabled by controlling supersaturation rates of the evaporating wet film, which thereby changes the balance between the nucleation and growth regimes involved in the overall crystallization process [

10,

20].

3. Results and Discussion

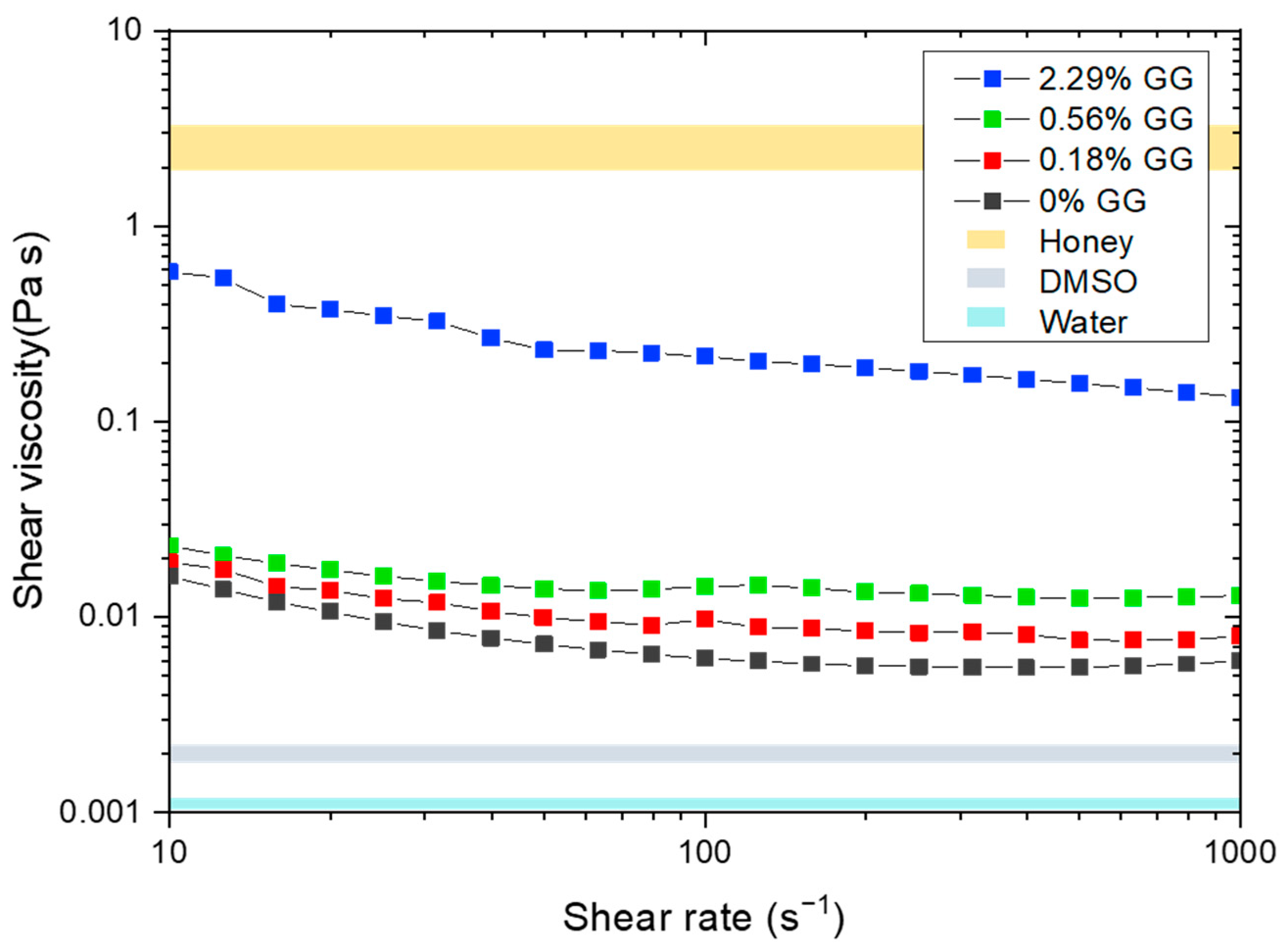

We tested several concentrations of MAPI-x% gellan gum (GG), where x% GG is the weight percent of gum to perovskite precursors. For example, 0.18% corresponds to 1.1 mg of GG in 1 mL of MAPI. Note that the ratio of perovskite precursor to dimethyl sulfoxide (DMSO) remained the same for all inks, 28 wt%. As seen in

Figure 1, higher concentrations of GG, such as 2.29%, approach the viscosity of honey and feature stronger pseudo-plastic behavior, which requires significantly slower coating speeds (below 2.5 mm/s) to achieve the desired 500-nm-thick films compared to lower gum concentrations like 0.56% and 0.18%, which behave more like Newtonian fluids with a constant viscosity at a given temperature and can be coated at faster speeds (upwards of 25 mm/s) that are needed for commercial viability. In addition to altering processing parameters, an increased concentration of GG slows film conversion by altering the crystallization process and the resulting final film morphology due to the polymer’s interactions with the solvent and precursor materials. Additionally, GG acts as an especially efficient thickener compared to other polysaccharide additives such as cornstarch, which require more than 10 wt% to achieve similar shear viscosities to 0.56% GG [

14].

After identifying the rheological properties of GG, we then studied the effect of viscosity on PVSK crystallization. While the exact mechanisms of the PVSK crystallization process remain an active area of research, the LaMer theory, a qualitative analogy that builds upon classical nucleation theory to describe the removal of solvent from a simplified monodispersed crystalline nanoparticle system, is often presented as a link between theory and processing [

6,

16,

24,

25,

26,

27,

28,

29]. The LaMer curve is most often plotted with concentration versus time respective to the nucleation and growth regimes to illustrate their respective dominance and influence on morphology, yet this plot is not always intuitive from a processing point of view.

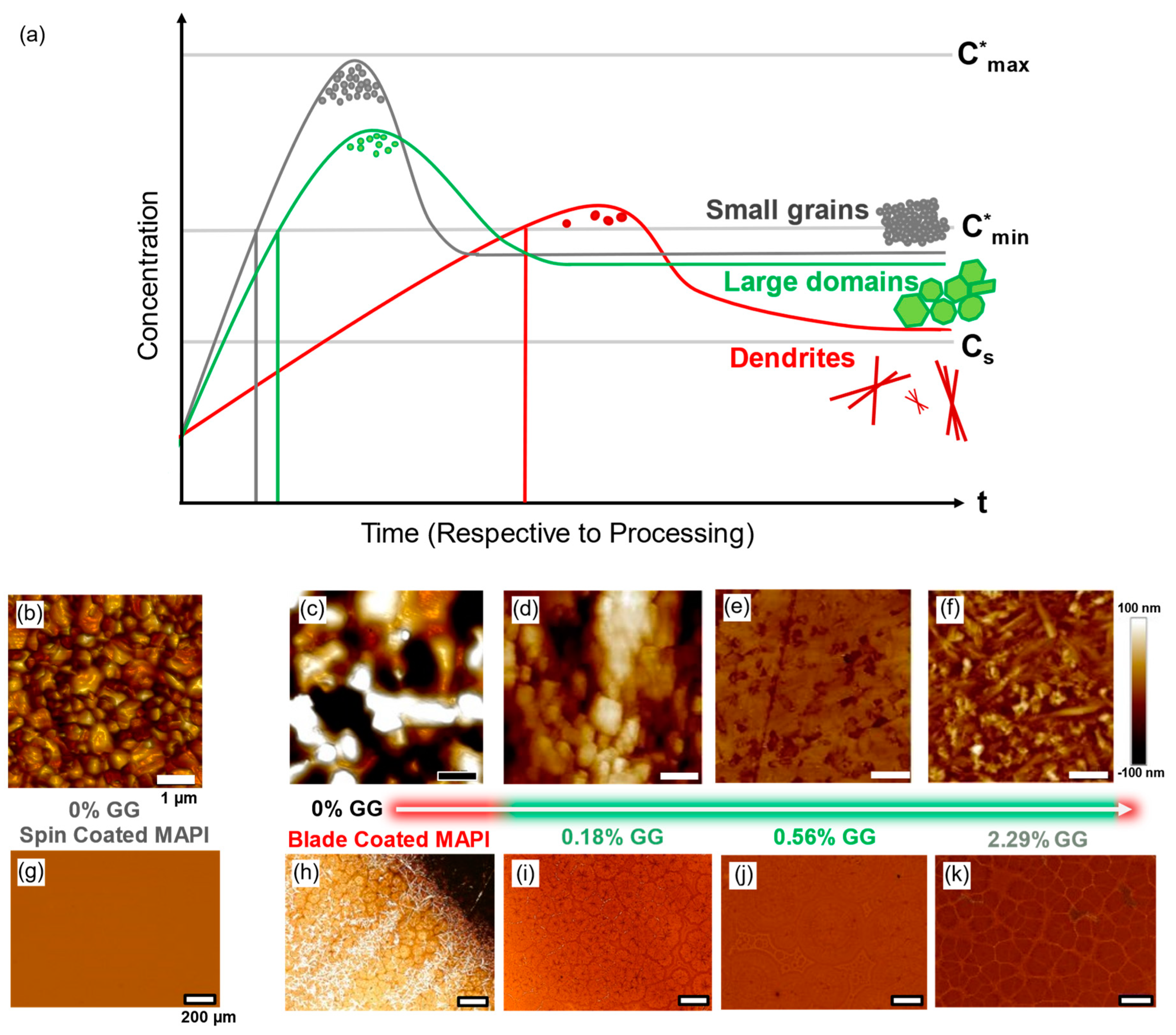

Figure 2a presents a modified visualization of the classic LaMer curve, where concentration is plotted against processing time for complete film conversion. The plot begins with the initial drying process, whereby the removal of solvent from the wet film increases the concentration of the remaining liquid to saturation, C

s, at a near-constant rate before reaching a critical supersaturation concentration, C

*, between C

*min and C

*max, whereby stable nucleates are likely to form. Once nucleation occurs, the available precursor concentration in solution will drop below C

*min into a regime dominated by crystal growth until all available liquid is removed. Because the final morphology of the PVSK is dependent on the balance of the nucleation and growth regimes, controlling the rate of supersaturation during processing is of utmost importance.

For example, the red curve in

Figure 2a corresponds to spin coating with an antisolvent, which induces a sudden film conversion due to the high rate and degree of supersaturation achieved, which results in instantaneous burst nucleation because of the targeted solvent removal. This fast, uniform, and dense burst nucleation scenario creates fine-grained morphologies such as the film in

Figure 2b,g, which were captured via tapping mode atomic force microscopy (AFM) and transmission optical microscopy, respectively. On the other extreme, as seen in grey in

Figure 2a, if the degree and rate of supersaturation are low, then the conversion of the film will be slow due to a lesser driving force in the creation of stable nucleates as prolonged growth will occur at these fewer existing sites. This slow process yields rough dendritic films with many voids, like the antisolvent-free blade-coated 0% GG film in

Figure 2c,h.

GG enables modulation between these two extremes. The green curve in

Figure 2a corresponds to the polymer-mediated process where sufficiently dense burst nucleation ensures complete coverage while reserving time and nutrients for domain growth. The AFM image in

Figure 2d and the corresponding transmission image in

Figure 2i show the increase in size of similarly oriented domains with 0.18% GG versus ultra-fast antisolvent quenching in

Figure 2b, as suggested by the LaMer curve. Likewise, at an optimized concentration of 0.56% GG, AFM images in

Figure 2e and the corresponding transmission image in

Figure 2j reveal that large, uniform spherulitic domains and a compact surface morphology are favored, which may create a better interface with transport layers deposited after the active layer in solar devices. Interestingly, AFM and transmission images in

Figure 2f,k demonstrate that a high concentration of GG can delay the onset of both homogeneous and heterogeneous nucleation much longer than 0.56% GG ink, with one such source of this delay resulting from the increased viscosity, which can slow species diffusion rates critical to the overall crystallization process, such that even a lower supersaturation rate stimulates a dense burst-like nucleation event accompanied by extra time for crystallite growth into textured dendritic microstructures while retaining the overall morphology and uniformity of spherulitic domains. While this surface texturing is accompanied by visually continuous films, 0.56% GG was selected as the upper threshold for our following experiments due to its decrease in root-mean-square roughness from 19.2 nm in the spin-coated control film to 11.2 nm, which offers a promising interface for the deposition of thin-charge transport layers that will be fabricated on top of the PVSK film. In summary, utilizing the lowest concentration of GG possible while maintaining sufficient morphological control over roughness, crystallinity, and uniformity during processing led to the selection of 0.56% GG and below for further investigation thanks to the increased processing speeds inherent to the fluid dynamics of the mildly viscous inks compared to higher concentrations such as 2.29%, as well as to avoid unintended electronic consequences as the insulator-like tendency of the polymeric GG could disrupt efficient charge flow above a critical concentration.

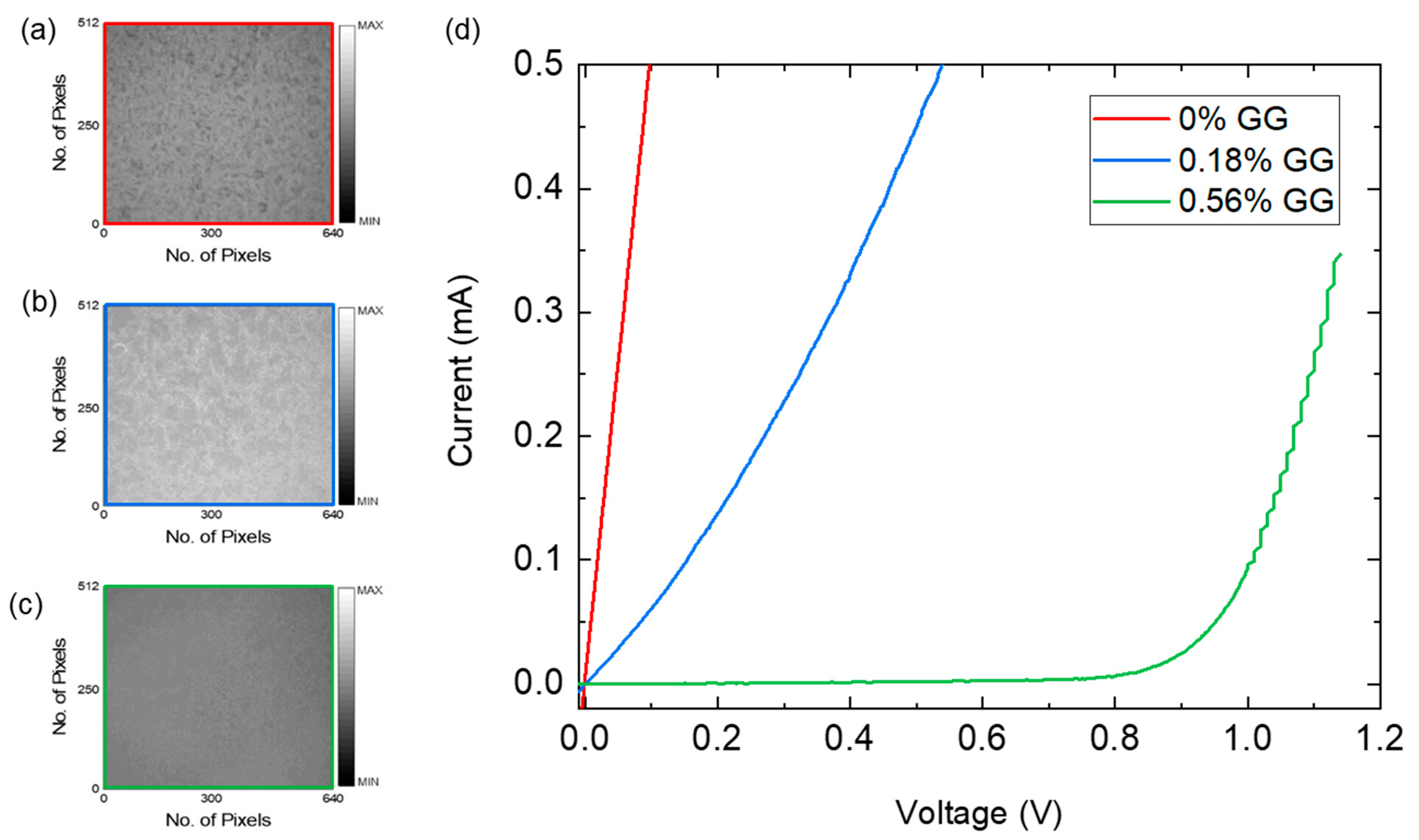

We then performed optoelectronic characterization of the MAPI films as a function of GG concentration. Illuminated lock-in thermography (ILIT) was thus performed on blade-coated samples with 0%, 0.18%, and 0.56% GG to observe the correlation between morphology changes in the film and thermographic response with the compositions. Thermal topography images from

Figure 3a–c validate the improvement in the uniformity of the deposited film with the addition of the optimum amount of the additive (0.56% GG) to the ink, which is observed as a lesser variation of temperature across the sample as shown in

Figure 3c. Variations in temperature or the presence of dark and bright regions in

Figure 3a,b imply the presence of gaps or morphological variations across the samples observed in the samples with 0% GG and 0.18% GG. Illumination amplitude images from

Figure S1a–c in correlation with illumination phase images from

Figure S1d–f validate the presence of these gaps and the improvement of film uniformity. The presence of extremely bright spots on the illuminated amplitude images corresponds to either recombination centers or defects. The phase variations on the illuminated phase images show the changes in the depth at those particular points. Based on the above correlations, the reduction in the bright spots on the amplitude image and the reduction in the phase changes on the phase image for the 0.56% GG composition show the improvement in uniformity and optoelectronic response across the sample. These improvements were further validated by electronic characterization when I-V response, series, and shunt resistances of these samples were measured (ITO/MAPI/Carbon), where 0% and 0.18% GG did not show any response to the applied voltage and 0.56% GG showed uniform I-V response (

Figure 3d). The 0.56% GG condition also showed an improvement with the values of resistance being in the required range for a good IV response, with very low series resistance and very high shunt resistance (

Table S2).

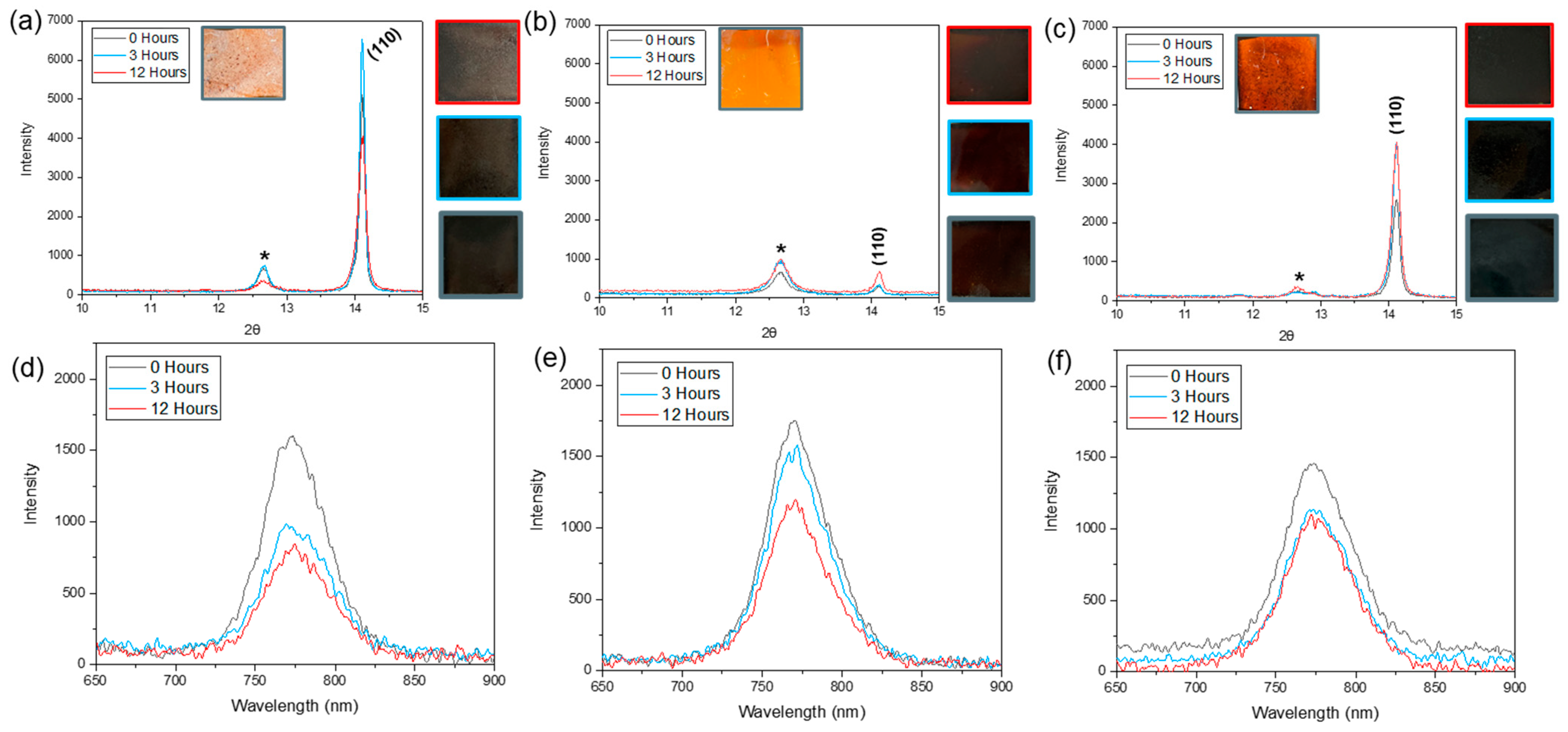

Next, we tested the effects of GG inclusion on the operational stability of MAPI films. X-ray diffraction spectrums and photoluminescent data were collected for unencapsulated MAPI blade-coated samples after humidity (25C, 85% RH in an environmental test chamber) or heat aging (85C in a vacuum oven as to avoid humidity-based degradation) initially and after three hours and 12 h, as shown in

Figure 4 and

Figure 5, in which grey correlates to as-coated films before testing, blue to samples after 3 h of testing, and red for samples after 12 h of cumulative testing.

Figure 4a–c indicates the effects of aging in humid air for 12 cumulative hours with both 0% GG (

Figure 4a) and 0.18% GG (

Figure 4b) featuring a near-complete elimination of characteristic perovskite peaks coupled with an increase in peaks associated with lead iodide. This crystallographic evidence suggests the volatilization of the methylammonium cation, possibly as a means of stress relaxation, and PL data in

Figure 4d,e confirms the near-complete loss of the black photoreactive phase after 12 h, as seen in the optical images alongside

Figure 4a,b. In contrast, at an optimized concentration of the polymeric additive, 0.56% GG, the film retains its characteristic perovskite peaks and black phase (

Figure 4c) while suppressing excessive lead iodide formation with notably improved retention of the photoreactive phase after 12 h of moisture exposure (

Figure 4f). This improvement against humidity can likely be attributed to the improved film uniformity and morphology made possible by the alterations in film crystallization induced by the addition of the GG, and this evidence further points towards an induced beneficial compressive stress inherent to the film.

XRD and PL data were then collected for ambient MAPI blade-coated samples after aging under vacuum at 85 °C initially and after three hours and 12 h, as shown in

Figure 5. While the XRD evidence of the degradation of the perovskite into lead iodide is not as dramatic as under humid conditions in

Figure 4, which is plotted across a wide 2θ axis,

Figure 5c indicates that 0.56% GG can markedly suppress lead iodide formation compared to 0% GG and 0.18% GG (

Figure 5a,b). It is important to also note the dramatic difference in final film quality between 0% GG and the GG samples as seen in inset transmission camera images in

Figure 5a–c, clearly indicating the improved coverage enabled by GG. The PL data (

Figure 5d–f) enables a more nuanced evaluation of the optoelectronic degradation across the samples with aging, with both 0% and 0.18% GG films featuring a continuous drop in PL intensity while 0.56% GG retains a higher PL reading with no noticeable loss in intensity between 3 and 12 h of aging.

As seen in

Figure 4a–c and

Figure S2, an increasing dominance of the (112) plane located at 2θ of approximately 20° as well as the corresponding (224) plane at approximately 40° over the traditionally dominant (110) MAPI plane in spin-coated samples at approximately 14° indicates that blade-coated GG films have a preferential orientation of the polycrystalline grains that likely arises at least in part to the uniaxial direction of coating. This change in orientation of the PVSK grains is consistent between the surface and bulk as supported by grazing incident wide-angle X-ray scattering (GIWAXS) data collected at various penetration depths, and the data confirms that an increase in GG leads to partially to highly oriented 3D bulk crystal texturing (

Figure S3). This change in crystal orientation likely plays a role in degradation that is thought to correspond to stress relaxation in the perovskite film, and we hypothesize that defects present and diffusion along grain boundaries likely play a critical role in film degradation and its rate of occurrence. However, some defects may have beneficial effects, with previous evidence of the presence of self-passivated lead iodide between adjacent spherulites at the grain boundaries in blade-coated samples being reported, and this might explain the improved stability of GG films over 0% GG samples due to the intensity of lead iodide peaks present relative to PVSK peaks in the GG films at 0 h in

Figure 4b,c and

Figure 5b,c [

12].

In addition to the improved resistance to aging, we hypothesized that the mechanical properties of the GG films would be improved as well. Our previous work validated this in spin-coated PVSK with starch additives, where a significant increase in fracture energy was observed with the addition of 10 wt% of starch and above [

15]. Double cantilever beam testing was performed on spin-coated control and blade-coated samples with varying compositions of GG to observe the changes in the fracture energy, G

c, of the MAPI films.

Figure 6a indicates that the addition of GG can increase the average G

c of the perovskite layer from 1.5 ± 0.2 J/m

2 for a spin-coated control to 6.6 ± 2.5 J/m

2 with the addition of 0.18% GG and 10.9 ± 2.3 J/m

2 for 0.56% GG, which is among the highest values obtained for perovskites and is comparable with crystalline silicon modules that have a G

c of ~10 J/m

2 [

30]. A G

c of over 5 J/m

2 has been identified as a critical metric for ensuring durability during handling, a value which is exceeded by both 0.18% and 0.56% GG films [

15,

30]. Note that a spin-coated 0% GG sample was chosen over a blade-coated one due to the many voids present in the latter (see

Figure 2c,h), which results in fracture outside of the PVSK yielding unrepresentative fracture energies similar to that of the epoxy layer. Mitigating delamination and fracture of the active layer is critical to increasing the overall durability and stability of PVSK solar cells, especially with respect to suppressing pathways to accelerated environmental degradation.

4. Conclusions

Our findings suggest that the addition of an optimized concentration of GG, 0.56 wt%, allows the fabrication of uniquely stable and durable quench-free perovskite films in ambient conditions. This is enabled through an increase in viscosity while maintaining Newtonian characteristics, thus balancing the crystal nucleation and growth regimes for efficient deposition, upwards of 25 mm/s. This also induces a smooth compact surface with over a 40% reduction in root-mean-square roughness compared to spin-coated control films, as shown through optical images and AFM measurements. These morphological benefits are accompanied by a proper I-V response in 0.56% GG films as validated through lock-in thermography, as well as enhanced optoelectronic and chemical stability under humidity and heat conditions for 12 h at 85% RH or 85 °C validated through XRD and PL measurements, all the while boasting one of the highest fracture energies reported for perovskite materials, making these films scalable, stable, and durable.

With the help of the biopolymer additive and efficient meniscus-driven blade coating, the crystallization process can be effectively altered. Supersaturation rates can be tuned to produce a unique range of morphologies with variable domain sizes and degrees of surface texturing according to additive concentration and without the use of excessive heat. The result is a reduction in detrimental tensile thermal stresses, which can advance degradation in the film. By altering the rheology and free energy considerations of the PVSK ink, the radial, spherulitic growth of similarly oriented domains occurs in a space-filling nature while concentrating defects, impurities, and possibly the additive to domain boundaries. This serves as one possible mechanism of self-passivation behind the improved resilience to heat and humidity aging.

Most notably, this work shows a systematic means of investigating key stability characteristics derived from a tunable morphology for the scalable, quench-free production of mechanically and environmentally robust PVSK films. For the first time, less than one weight percent addition of a polysaccharide biopolymer has been able to convert an ink optimized for use with antisolvent spin coating in an inert environment into a quench-free ink capable of being processed in open-air via a scalable deposition method. A key implication of this work is to hopefully accelerate the commercialization of PVSK solar cells through the usage of a single, common PVSK solvent in ambient conditions without a quenching step. In doing so, we hope to enable a scalable manufacturing process of robust perovskite solar cells by having shown how crystallization theory can be leveraged to improve morphology, stability, and durability.