1. Introduction

In a period characterized by growing worldwide apprehension regarding climate change and environmental conservation, it is imperative to prioritize the tackling of energy inefficiency and the emission of greenhouse gases (GHG). The construction and building industries have taken center stage in this endeavor due to their substantial consumption of resources and energy, which exerts immense pressure on natural ecosystems and limited resources [

1,

2,

3].

The scale of this challenge is staggering. The International Energy Agency (IEA) indicates that over 30% of worldwide energy is utilized in buildings [

4]. This significant energy consumption is not only a drain on resources but also a major contributor to global carbon emissions. The building sector’s impact on climate change is further exacerbated by inefficient design and outdated technologies, particularly in older structures that lack modern energy-saving features.

One of the most critical areas of concern is the management of solar radiation in buildings. Especially in summertime, solar radiation penetrating rooms via windows can notably elevate the energy usage of air-conditioning systems, especially in newly built high-rise structures with extensive window-to-wall ratios [

5]. This phenomenon is particularly problematic in urban areas where the proliferation of glass-facade skyscrapers has led to increased cooling demands and, consequently, higher energy consumption.

Thus, diminishing solar radiation infiltration through windows presents an effective strategy for curbing cooling demands and energy usage in air conditioning [

6]. This approach not only reduces energy consumption but also improves indoor comfort levels and can lead to significant cost savings for building operators and occupants. Innovative window technologies, such as smart glass and advanced shading systems, are being developed and implemented to address this issue.

The worldwide attention to combatting climate change and promoting environmental sustainability has resulted in the setting of ambitious goals for energy-efficient building practices. These goals reflect a growing recognition of the urgent need to transform the building sector to meet climate targets and ensure a sustainable future. In the United States, there was an expectation for all new commercial building projects to attain zero-energy status by 2030 [

7]. This ambitious target has spurred innovation in building design, materials, and technologies, pushing the industry towards more sustainable practices.

Similarly, the European Union (EU) has proposed transitioning from the existing Nearly Zero-Energy Building (NZEB) standard to Zero-Emission Buildings (ZEBs), ensuring that energy performance requirements for new buildings are in line with the EU’s broader climate neutrality goals [

8]. This shift represents a significant step forward, moving beyond energy efficiency to address the total environmental impact of buildings throughout their lifecycle.

These initiatives are part of a broader global movement towards sustainable architecture and urban planning. Countries around the world are implementing stricter building codes, offering incentives for green construction, and investing in research and development of new sustainable building technologies. The focus is not just on new construction but also on retrofitting existing buildings to improve their energy performance.

The challenge of creating energy-efficient buildings goes beyond just reducing energy consumption. It also involves consideration of material sustainability, waste reduction, water conservation, and the overall impact of buildings on human health and well-being. This holistic approach to sustainable building design is driving innovations in areas such as biophilic design, which incorporates natural elements into buildings to improve air quality and occupant well-being.

A crucial element in meeting ambitious energy-efficiency goals involves adopting advanced building envelopes, which encompass insulation, windows, roofing, solar chimneys, and exterior walls [

9,

10]. These components are instrumental in regulating energy flow within structures, highlighting the critical importance of enhancing their performance to effectively reduce overall primary energy consumption in buildings. The building envelope serves as a barrier between indoor and outdoor environments, playing a vital role in maintaining thermal comfort and minimizing energy usage. Studies have shown that passive architectural strategies, including solar chimneys and Trombe walls, can improve thermal comfort by up to 20% and reduce electricity consumption by as much as 46% [

9]. Furthermore, building-integrated photovoltaic (BIPV) systems, when applied to rooftops, windows, and facades, offer significant potential for energy generation and savings. However, challenges persist in the widespread adoption of these technologies, including economic feasibility, technical performance, and architectural considerations [

10]. The integration of smart control systems for heating, ventilation, and air conditioning (HVAC) has demonstrated energy savings of 10–28%, while advanced lighting control can achieve savings of 43–71% [

11]. These findings underscore the importance of a holistic approach to building design, incorporating not only envelope improvements but also occupant behavior and advanced technologies to achieve optimal energy efficiency [

12].

Among these components, windows have emerged as a critical focus area due to their significant impact on both energy performance and occupant comfort. Traditional windows, while providing natural light and views, can be a major source of heat gain in summer and heat loss in winter, contributing to increased energy demands for cooling and heating.

The influence of windows on building energy consumption is a complex issue. Traditional windows with a high solar heat gain coefficient (SHGC) and visible light transmittance (

τvis) can lead to excessive heat and glare, necessitating solar shading solutions [

13]. However, these shading devices may block useful daylight, increasing reliance on artificial lighting and energy consumption. Smart windows offer a dynamic solution to this challenge. For instance, polymer-dispersed liquid crystal (PDLC) glazing can switch between translucent and transparent states, providing low ultraviolet (UV) (8%) and near infrared (NIR) (44%) transmission in its translucent state, with SHGC values of 0.68 and 0.63 for transparent and translucent states, respectively [

13]. Electrochromic windows controlled by operative temperature have shown the highest potential for reducing energy demand across various climates [

14]. In tropical regions, semi-transparent photovoltaic (STPV) glazing can offer both solar control and on-site electricity generation, with SHGC reducing significantly at incident angles above 45° [

15]. For subtropical climates, an optimum overhang and fin height equal to half the window height can lead to significant energy savings, with one study reporting a 7.05% reduction in annual energy consumption [

16]. These advances create a complex balancing act between managing solar heat gain, maintaining adequate natural light, and minimizing energy use while potentially generating electricity.

The energy efficiency of buildings is influenced by multiple factors, including lighting performance, electrical generation, and thermal properties [

17,

18]. Window performance is evaluated through various metrics, each addressing specific aspects of energy efficiency. Electrical performance is typically assessed based on photovoltaic (PV) conversion efficiency and electricity generation per square meter, particularly relevant for BIPV components. Thermal performance is mainly evaluated using metrics such as SHGC and U-value (heat transfer coefficient) [

19]. Studies have shown that advanced window technologies can significantly impact energy consumption. For instance, switchable windows can reduce annual heating and cooling energy by up to 59.1% and 64.9%, respectively, in certain U.S. climates [

19]. BIPV components with optimized design parameters can also offer substantial benefits. Geometric transparency degree (GTD) has been found to most significantly affect optical properties, with SHGC and visible transmittance (VT) positively correlating with GTD [

20].

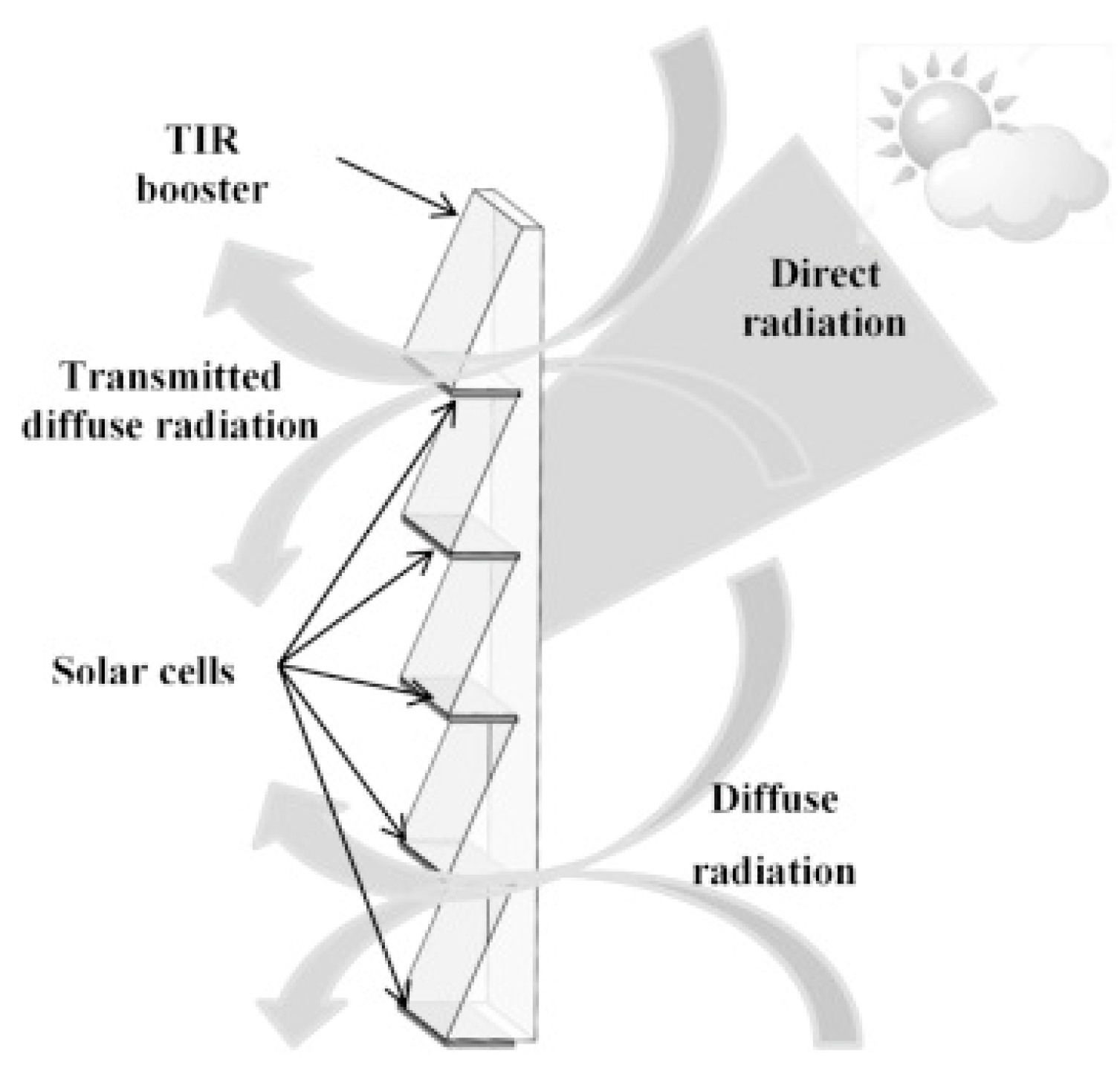

In response to these challenges, innovative solar window technologies have been developed to transform windows from passive elements into active energy-generating components of the building envelope. Integrating PV cells into windows or shading devices, known as BIPV, presents a promising solution to these challenges [

21]. BIPV windows can replace conventional windows entirely, generating electricity while reducing solar radiation entering the building, thus decreasing the power consumption of air-conditioning systems [

22].

BIPV windows come in various forms, each with unique characteristics and applications [

21,

22]:

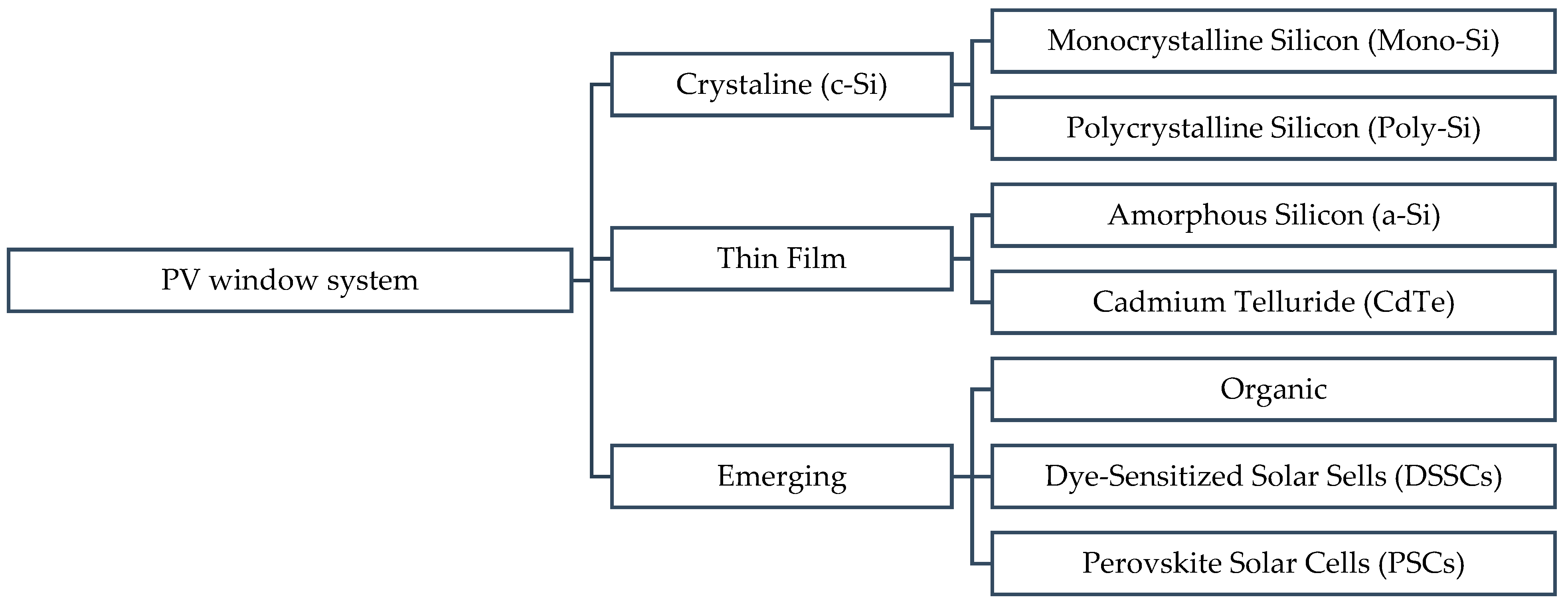

Crystalline Silicon Solar Cells: These are the most common type of PV cells used in BIPV windows. They offer high efficiency but can be opaque, making them suitable for spandrel areas or where transparency is not required.

Thin-Film Solar Cells: These cells can be made semi-transparent and are more flexible in application. While they typically have lower efficiency than crystalline silicon, they perform better in low-light conditions and at high temperatures.

Dye-Sensitized Solar Cells (DSSCs): These cells can be made in various colors and transparencies, offering aesthetic versatility. They are particularly effective in low-light conditions and can be integrated into windows without significantly compromising visibility.

Perovskite Solar Cells: A newer technology that has shown rapid improvements in efficiency. Perovskite cells can be made semi-transparent and have the potential to offer high efficiency at a lower cost than traditional silicon cells.

Quantum Dot Solar Windows: These utilize quantum dots to absorb sunlight and re-emit it at infrared wavelengths that can be captured by PV cells at the edges of the window. This technology allows for highly transparent solar windows.

Beyond electricity generation, solar windows can also contribute to passive solar design strategies. Passive solar systems, like solar walls (SWs), are significant developments in enhancing the thermal storage ability of materials and improving heat transfer processes [

23]. SWs, also known as Trombe walls, consist of a dark-colored wall with a glass exterior and an air space in between. They work by absorbing solar radiation during the day, storing it as heat in the wall’s thermal mass, and then releasing it into the building at night or during cooler periods. This passive solar heating can significantly reduce the need for active heating systems, particularly in colder climates [

24]. The integration of passive solar systems such as SWs into building envelopes, coupled with advancements in energy storage materials, has the potential to boost solar energy as a sustainable alternative, thus raising energy efficiency standards [

25,

26].

The main objective of this research is to assess the notable impact of merging photovoltaics with thermal regulation, particularly through SW, in addressing challenges within the construction and building sector. This study will conduct an in-depth examination of relevant literature, concentrating on the operational principles of SW and past research in this field.

This investigation aims to elucidate how innovative building envelope solutions can play a crucial role in establishing a sustainable and energy-efficient built environment, making significant contributions to global efforts in combating climate change and alleviating the negative impacts of environmental deterioration [

27]. The building sector accounts for over one-third of global energy consumption and a significant share of carbon emissions, emphasizing the urgent need for improved energy efficiency, particularly in tropical regions where future development is concentrated. Building-integrated photovoltaic thermal (BIPV/T) systems within building façades can successfully produce both electrical and thermal energy, thus improving buildings’ energy performance. These systems can overcome space constraints in urban areas by utilizing building façades for energy production, potentially reducing up to 40% of global energy demand [

28].

Comprehensive reviews of building envelope design variables in tropical climates have shown that insulation, glazing properties, and window-to-wall ratio (WWR) are promising solutions for improving energy efficiency. Optimized designs in cooling-dominated climates can save 35% of annual energy and up to 60% in some cases [

29].

Phase change material (PCM) solar walls, as a low-carbon technology, have shown potential in both cold and warm seasons. Experimental investigations revealed that PCM solar walls could maintain comfortable indoor temperatures for extended periods—up to 7 h above 20 °C during the heating season and within the comfort range for about 17 h during the cooling season. By capturing solar radiation during the day and releasing stored energy at night, these systems optimize energy utilization, lessening reliance on conventional energy sources and resulting in substantial energy and carbon footprint reductions [

30].

This research provides an innovative and comprehensive exploration of integrating photovoltaics with thermal regulation in sustainable building design, specifically focusing on SW. The study uniquely synthesizes various cutting-edge technologies, including crystalline, thin-film, and emerging PV cells, with advanced thermal management strategies.

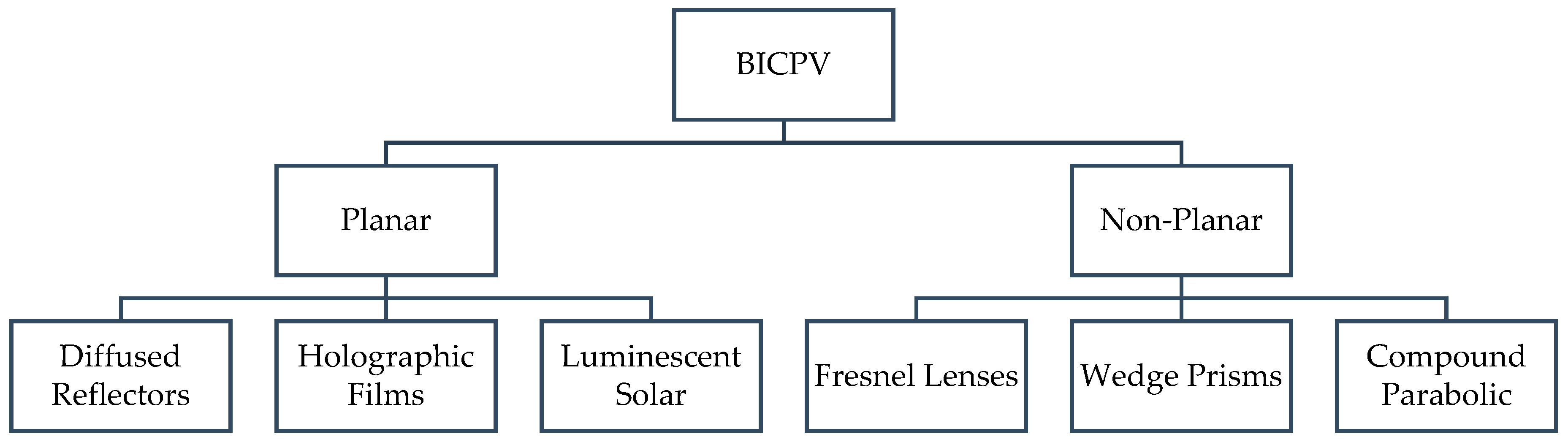

The work’s originality lies in its holistic approach, combining BICPV glazing systems with thermotropic smart glazing technologies. This integration addresses both energy generation and thermal regulation challenges in buildings, offering a novel solution to reduce energy waste and greenhouse gas emissions.

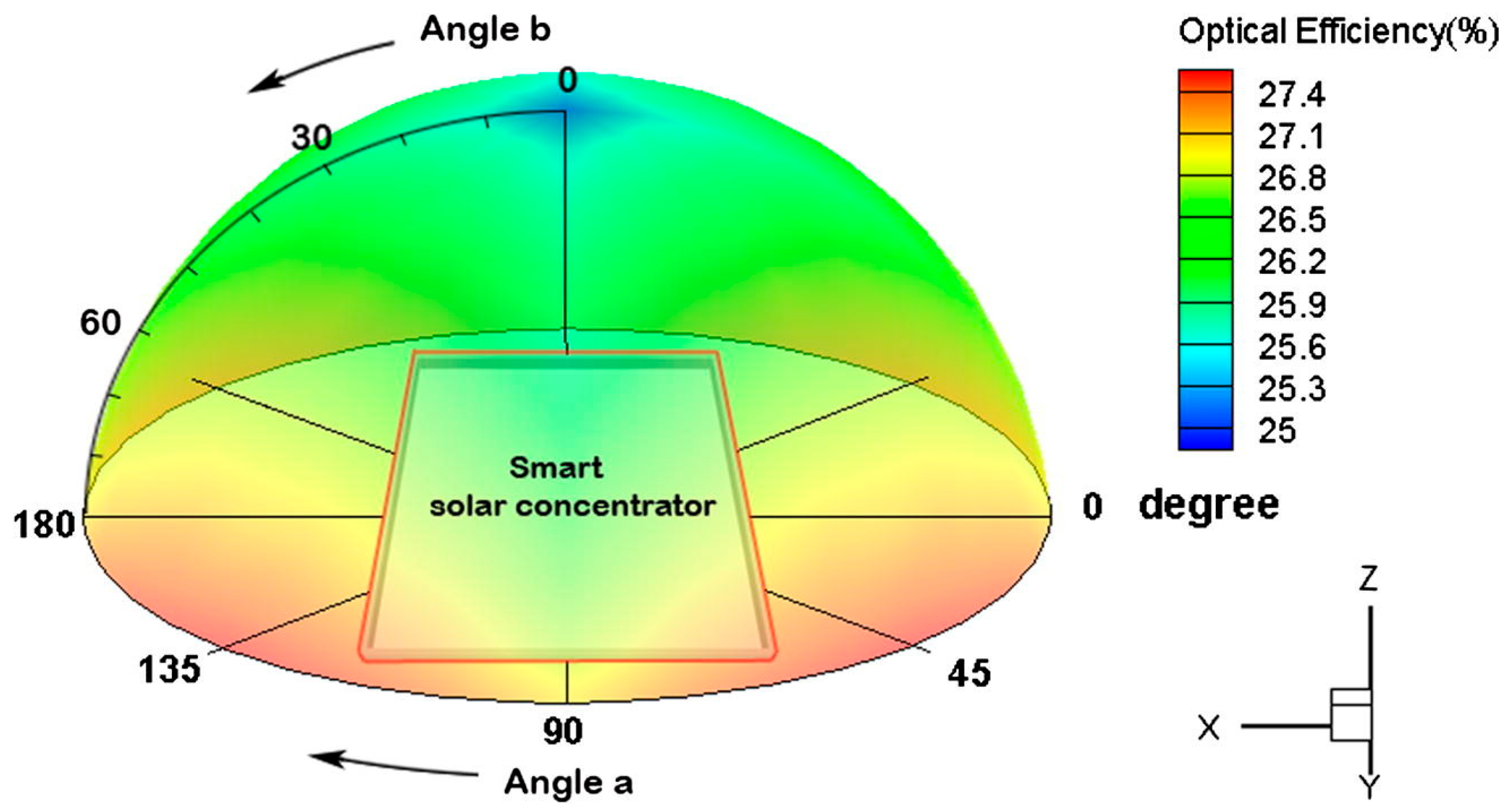

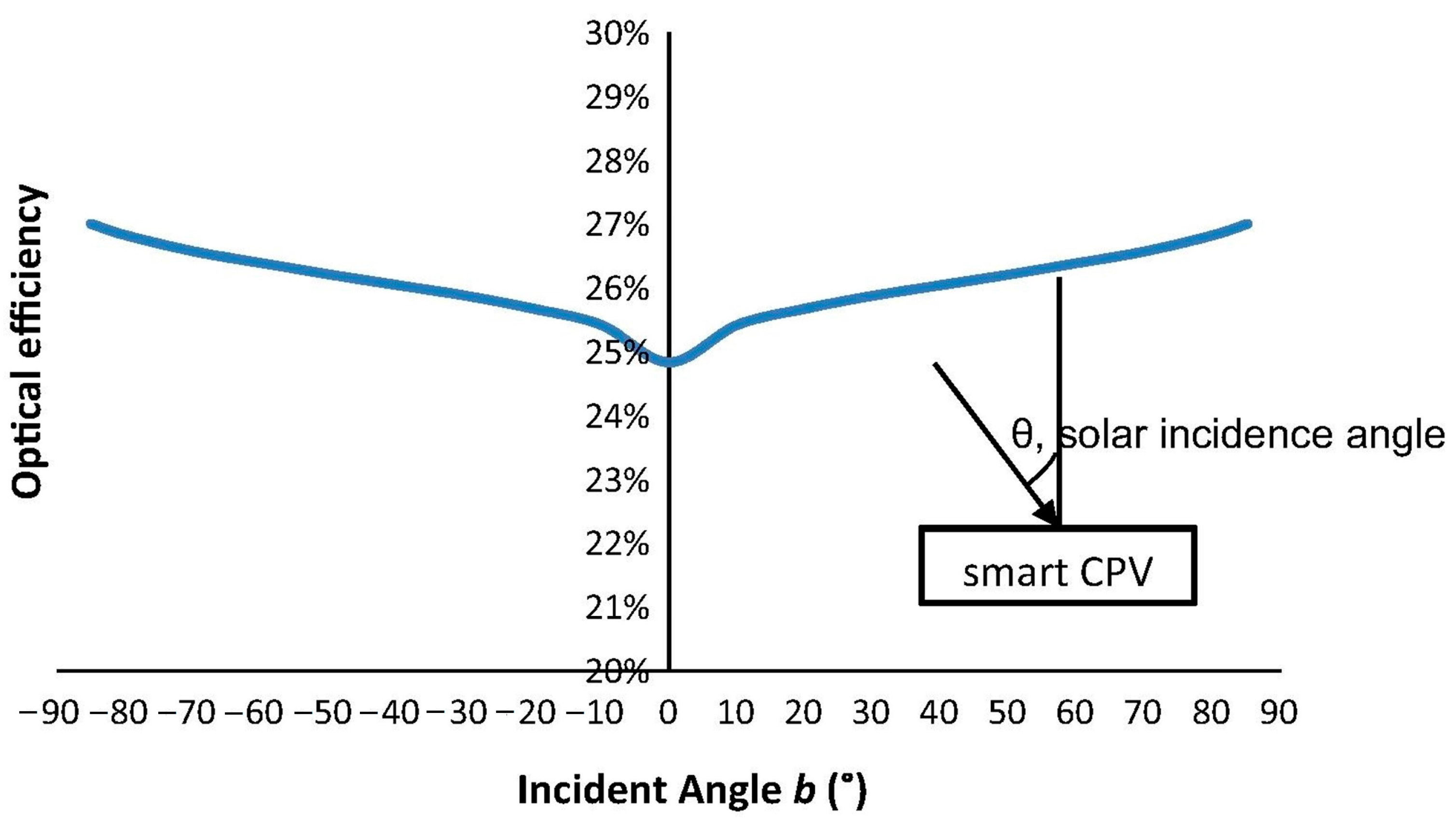

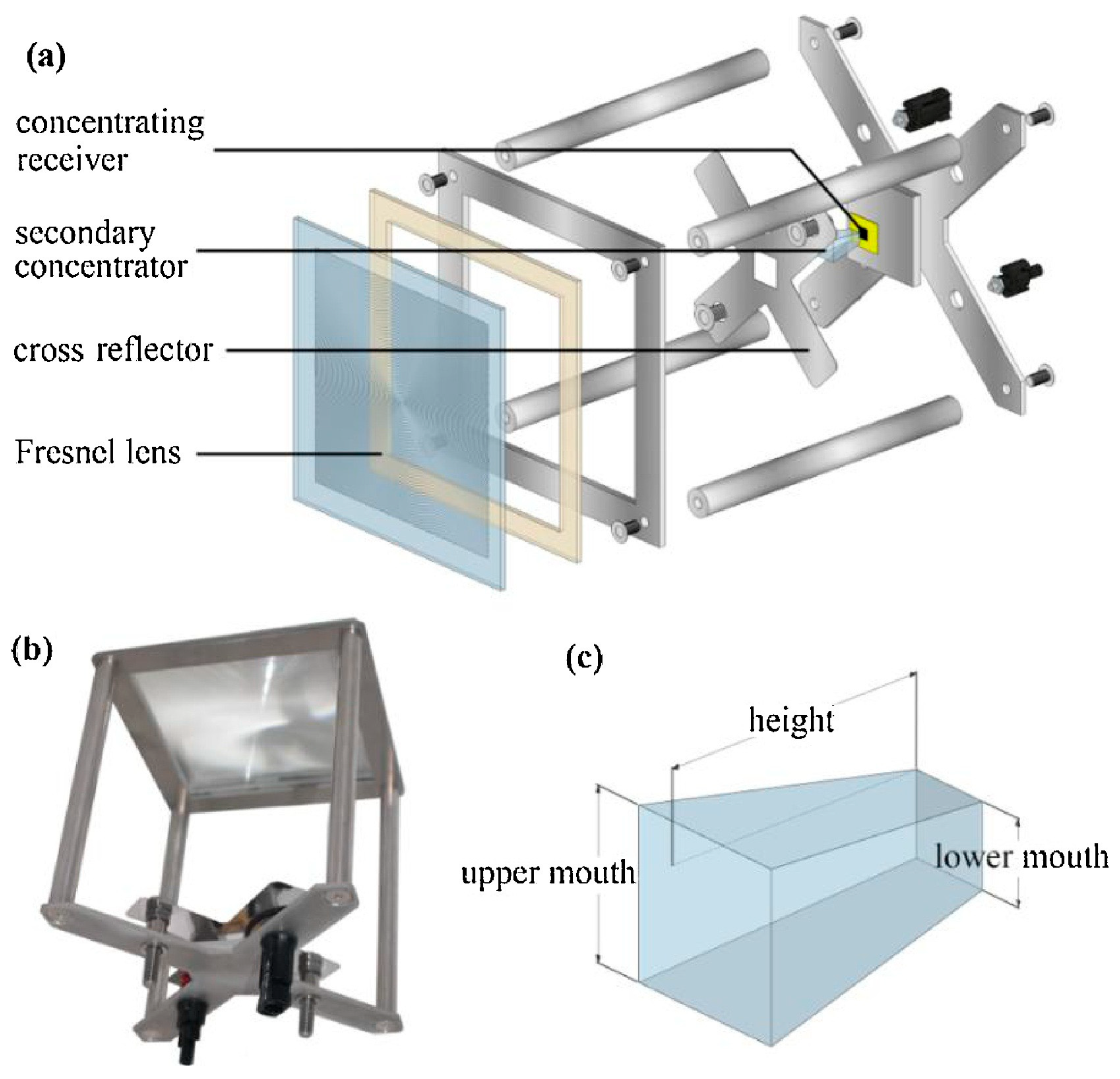

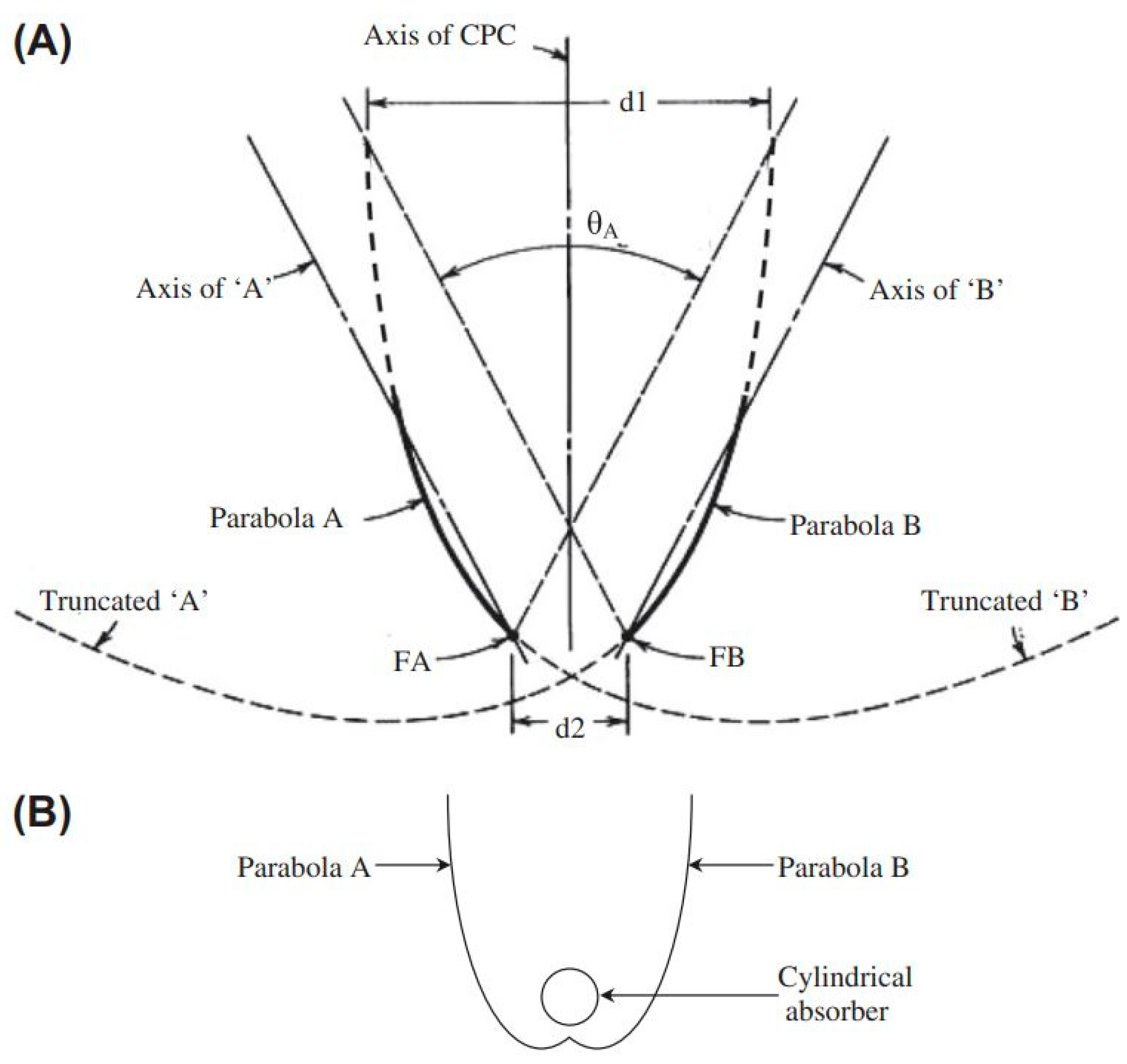

The research breaks new ground by analyzing the potential of various concentrating optics, such as diffused reflectors, holographic films, and luminescent solar concentrators (LSCs), in the context of building-integrated applications. It also explores innovative non-planar optics, like Fresnel lenses, prismatic lenses, and compound parabolic concentrators, for enhanced energy capture and daylighting control.

Furthermore, the study advances the field by examining the synergy between PV and electrochromic technologies in smart windows. This integration represents a forward-looking approach to creating energy-efficient and environmentally friendly buildings.

By comprehensively evaluating these diverse technologies and their potential combinations, this research contributes significantly to the development of next-generation sustainable building solutions. It provides valuable insights into optimizing energy performance, thermal comfort, and architectural aesthetics, paving the way for more efficient and visually appealing building exteriors that actively contribute to energy production and management.

3. The Challenges Posed by Traditional Windows (e.g., Heat Gain, Glare, Energy Consumption)

Conventional windows present significant challenges in terms of heat transfer, glare, and energy use, all of which can significantly affect a building’s overall energy performance. According to statistical evidence, windows can contribute to as much as 40% of heat dissipation in winter and up to 87% of heat accumulation in summer [

38]. Overcoming these challenges is crucial for fostering sustainable building designs and reducing overall energy usage.

One major challenge with conventional windows is the excessive accumulation of heat. These windows are susceptible to heat transfer through conduction, convection, and radiation, leading to heightened cooling demands during warmer months [

39]. This increased heat gain in warm climates can elevate energy consumption for air conditioning systems [

40].

Figure 1 illustrates the factors influencing the performance and characteristics of windows. It presents two main mechanisms: heat conduction and solar heat gain. Heat conduction pertains to the transfer of heat across window materials such as glass, frames, air seals, and spacers between panels. This process is measured by the Uw value (thermal conductivity of the window), which represents its thermal conductivity. A lower Uw value indicates higher resistance to heat flow, indicating better insulation properties.

Conversely, solar heat gain denotes the solar radiation infiltration through windows, leading to internal heat buildup. This parameter is quantified by the SHGC, which varies from 0 to 1. A lower SHGC implies that the window allows less incident solar heat radiation to pass through, thereby diminishing the heat transmitted, absorbed, and emitted within the building, consequently reducing heat gain through windows.

Figure 2 visually represents how these two mechanisms, heat conduction and solar heat gain, interact to influence the thermal performance of windows. It stresses the significance of taking into account both the Uw value and SHGC when creating energy-efficient windows for buildings. These factors are critical in managing heat transfer and solar heat gain, which in turn affect energy usage for heating and cooling needs [

38].

Additionally, direct sunlight penetrating through windows can create glare, diminishing visual comfort and productivity and potentially escalating the use of artificial lighting, thereby adding to energy consumption [

41].

Another significant challenge stems from the limited insulating properties of traditional windows, resulting in considerable heat loss during winter. This heat loss drives up the energy needed for space heating, contributing to higher overall energy consumption [

42]. Integrating PV technology into windows provides additional benefits such as shading and glare control. Strategically positioning PV cells can block direct sunlight, lessening the need for external shading devices and enhancing visual comfort [

43].

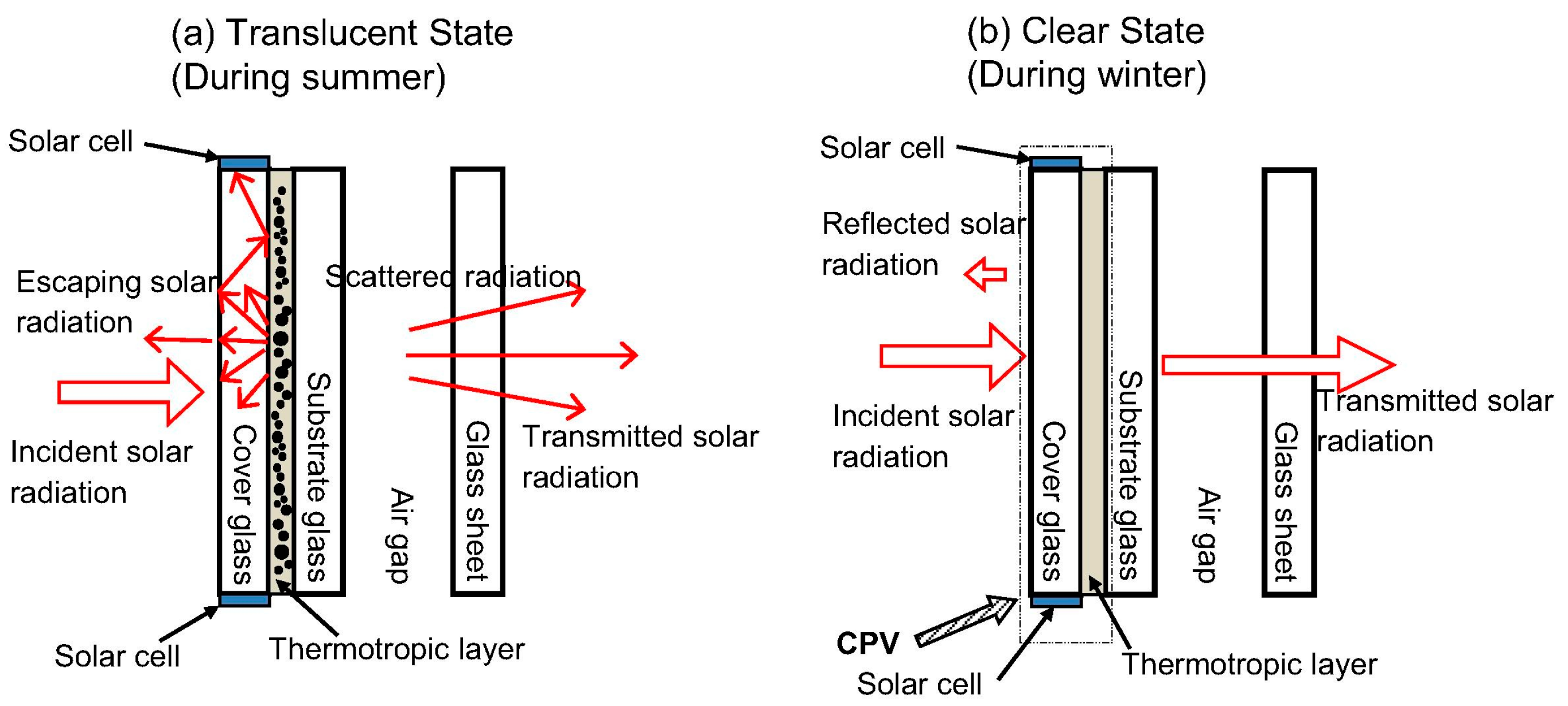

Another promising technology is the utilization of thermotropic materials for energy-efficient windows. Thermotropic materials are substances that change their properties in response to temperature variations. These materials typically undergo phase transitions or structural changes when exposed to different temperatures, altering their optical, mechanical, or electrical characteristics [

44]. These materials possess the capability to reversibly modulate their light transmission properties, delivering holistic performance in terms of indoor thermal conditions, energy efficiency, and daylight utilization. Thermotropic double-glazed windows notably improved indoor thermal comfort in west-facing rooms when compared to conventional options. They lowered the cooling electricity needs by 19% in west-facing rooms while providing suitable indoor illumination [

45].

Moreover, studies show that the energy efficiency of windows is affected not only by their thermal characteristics but also by climatic variations and the orientation of buildings. The angle at which solar radiation strikes the window surface has a substantial impact on heat transfer, with the highest transfer occurring when the sun is directly perpendicular to the glass surface [

46].

6. Thermotropic Smart Glazing Technologies

Thermotropic smart glazing technologies provide an innovative method for dynamically managing solar heat gain and daylighting within buildings. This is achieved by integrating thermotropic materials into window systems. These materials exhibit a reversible change in optical properties, particularly light transmittance, in response to temperature variations.

The core working mechanism lies in thermotropic hydrogels, which are water-based polymer networks containing both hydrophilic and hydrophobic groups. When the temperature is below the lower critical solution temperature (LCST), which is generally in the range of 25–35 °C, the hydrophilic polymer chains are soluble in water, leading to a transparent hydrogel state. As the temperature exceeds the LCST, the polymer chains undergo a phase change, gathering together and pushing out water molecules. This phase transition induces light scattering at the boundaries between the polymer-rich and water-rich areas, resulting in the hydrogel appearing translucent or opaque [

139,

140].

Extensive research has been conducted on both synthetic polymers, like poly(N-isopropylacrylamide) PNIPAm, (N-isopropylacrylamide)-2-aminoethylmethacrylate hydrochloride) PNIPAm-AEMA, and biopolymers, such as HPC, for developing thermotropic hydrogels with desirable optical properties and transition temperatures. Various strategies, including copolymerization, addition of co-solvents, and salt inclusion, have been employed to tune the LCST and optical performance [

141,

142].

Table 5 provides an overview of the optical characteristics of specific thermotropic hydrogels, outlining their capacity for modulating visible transmittance (ΔTlum), near-infrared transmittance (ΔTIR), and solar transmittance (ΔTsol).

Diverse approaches have been investigated to adjust the optical qualities and transition temperatures of thermotropic hydrogels, encompassing copolymerization, incorporation of co-solvents, and salt integration. For instance, PNIPAm hydrogels can be customized to display lower critical solution temperature (LCST) values varying between 25 °C and 40 °C through copolymerization with either hydrophobic or hydrophilic monomers [

145]. The LCST of PNIPAm hydrogels could be decreased from 32.2 °C to 20.4 °C by increasing the glycerol concentration from 0 wt.% to 35 wt.% in the water-glycerol solvent blend [

141]. Moreover, the inclusion of glycerol co-solvent not only improved the freezing resilience of PNIPAm hydrogels but also reduced water evaporation.

Regarding biopolymer-based hydrogels, HPC-based thermotropic hydrogels with varying polymer and gelling agent concentrations are shown in

Table 6. Higher HPC concentrations resulted in lower transmittance and higher reflectance in the translucent state above the transition point (~42 °C), demonstrating the ability to control the light-scattering performance [

142].

Moreover, the addition of salts has been shown to shift the cloudy point (phase separation temperature) of HPC aqueous solutions. Heightening the sodium chloride (NaCl) concentration from 0 to 1.4 mol/L, for instance, triggered a decrease in the clouding point of HPC solutions from 42 °C to 20 °C [

146].

Incorporating thermotropic hydrogels into window systems shows significant promise in enhancing building energy efficiency and indoor environmental conditions. HPC-based thermotropic windows, for example, delivered up to 22% annual energy savings in a Mediterranean climate due to decreased cooling demands. Additionally, a smart window system covering a large area (1 m

2) and utilizing a PNIPAm-based thermotropic hydrogel achieved a 45% decrease in HVAC energy usage compared to standard double glazing in Singapore’s climate [

147].

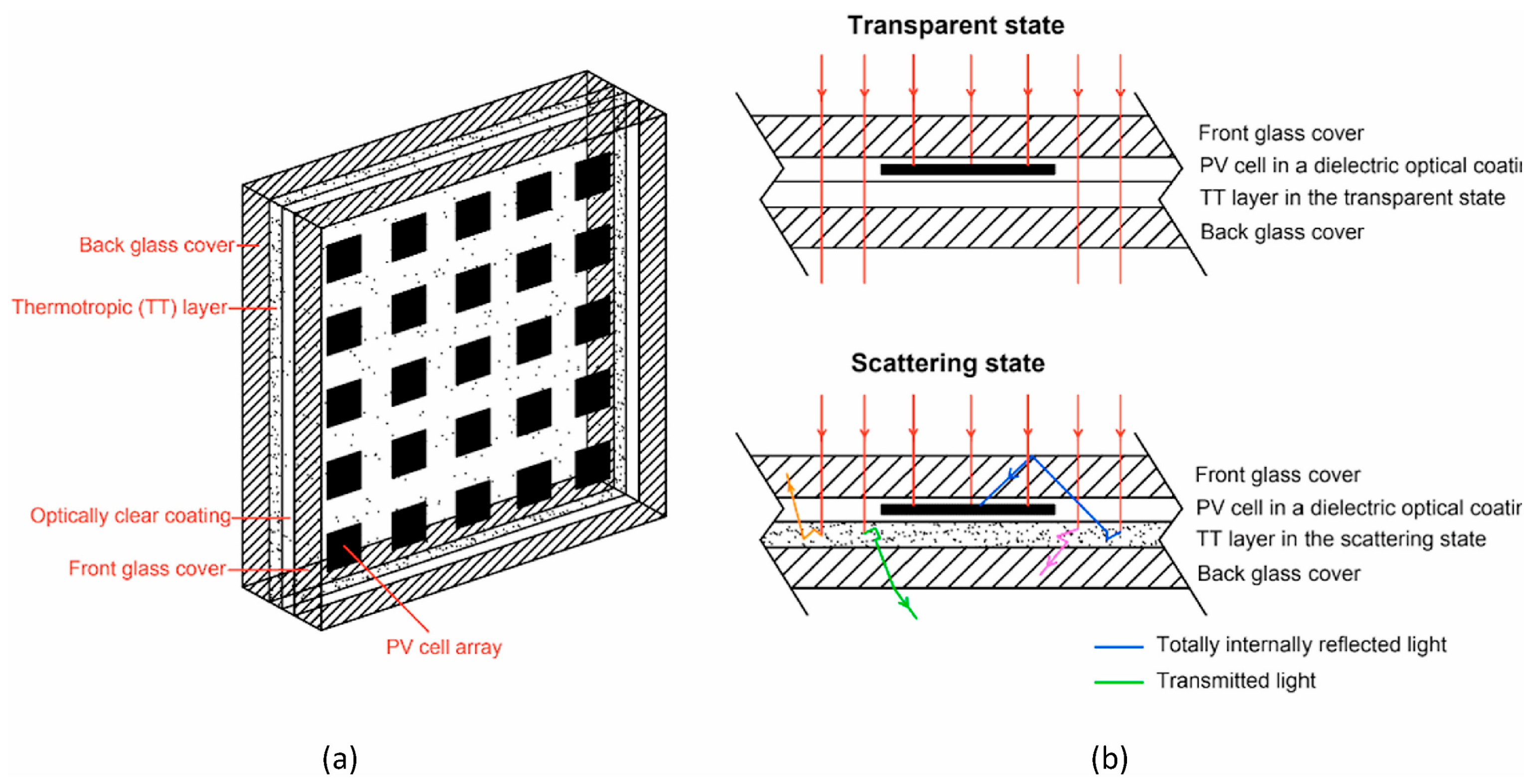

To enhance the efficiency of thermotropic windows, a window structure known as thermotropic parallel slat-transparent insulation material (TT PS-TIM) has been developed, as depicted in

Figure 13. This system merges thermotropic substances with insulating slats to provide dynamic control over solar heat gain and daylight infiltration while boosting thermal insulation. Simulations carried out for various climates (London, Stockholm, Rome, and Singapore) indicated that the TT PS-TIM system could yield energy savings of up to 21.5% compared to standard double glazing, alongside improved access to daylight [

148,

149].

Adjusting the optical properties and transition temperature of the thermotropic material layer is crucial to achieve a balance between energy efficiency and daylight provision. They noted that reducing absorptance in the translucent state could decrease energy usage while aiming for a lower transition temperature, approximately 21 °C for the London climate, which could enhance daylight performance. Furthermore, they proposed varying optimized designs tailored to different climatic conditions [

149].

Table 7 summarizes the energy-conserving abilities and daylight performance of distinct TT PS-TIM window prototypes tailored for London’s climate. The table outlines different prototypes along with their corresponding transition temperatures (°C), energy-saving potential, and average UDI 500–2000 lx values. The prototypes are labeled as CS-TSt followed by their transition temperature and optical characteristics, with “r” indicating reflectance and “T” representing transmittance in the visible spectrum. For example, the CS-TSt40r35 prototype, featuring a transition temperature of 35 °C, demonstrates an energy-saving potential of 21.7% and an average UDI 500–2000 lx value of 67.1%. Similarly, other prototypes such as CS-TSt20r35, CS-TSt10r35, and CS-TSt10r19 exhibit varying energy-saving potentials and average UDI values, providing insights into the performance variations based on different design parameters [

149].

9. Discussion and Conclusions

This comprehensive review has unveiled a myriad of innovative BIPV glazing solutions that seamlessly integrate with smart window technologies, enabling remarkable strides toward energy efficiency and daylighting control in buildings. These state-of-the-art technologies fall into three main categories depending on their primary functions: concentrating PV glazing, thermotropic smart glazing, and dynamic glazing systems that integrate BIPV with smart window features.

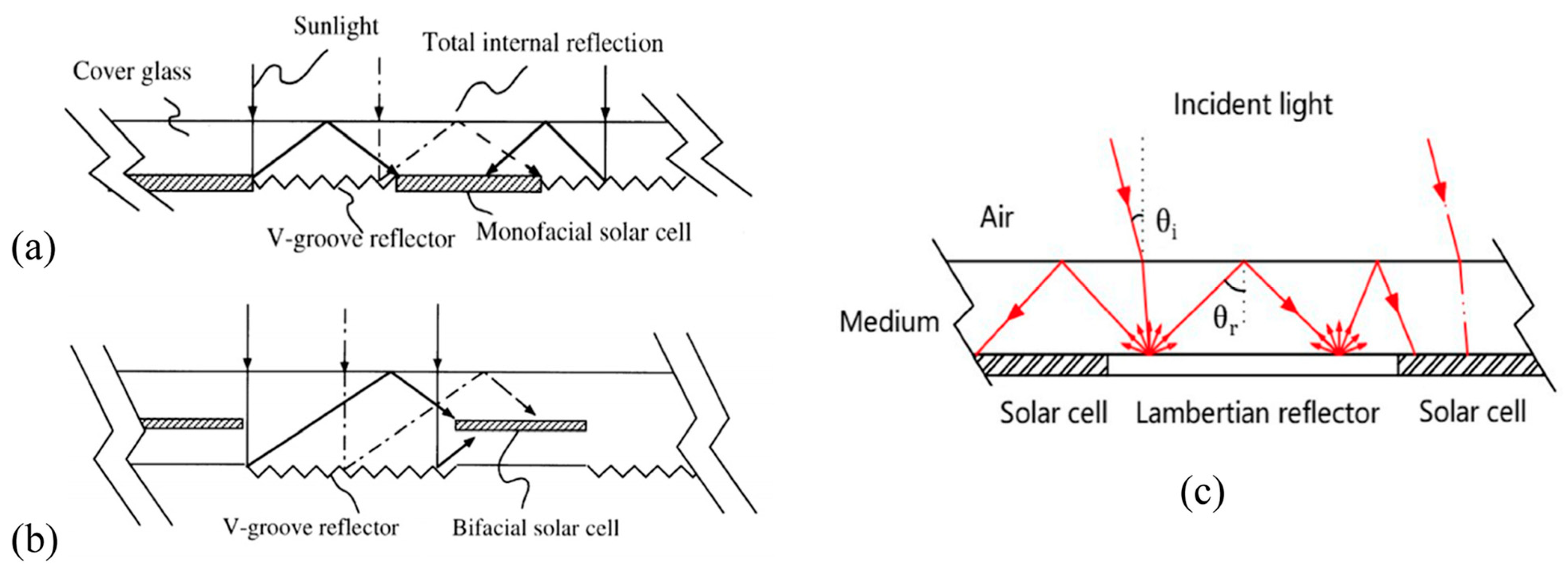

BICPV glazing systems have demonstrated exceptional performance by leveraging various concentrating optics to boost the efficiency of integrated PV cells while facilitating controlled daylighting transmission. Significant breakthroughs have been achieved in planar concentrating optics, such as diffused reflectors, holographic films, and LSCs, as well as non-planar optics like Fresnel lenses, prisms, and CPCs. Notably, a BICPV system incorporating a Fresnel lens concentrator achieved an optical efficiency of up to 86.5% and an impressive geometric concentration ratio of 1000 suns. Holographic concentrating systems employing transmission holographic lenses and GaAs/2.1-eV bandgap tandem solar cells attained a remarkable 31.0% system efficiency under one-sun illumination. LSCs employing optimal quantum dot luminophores demonstrated ambitious yet attainable target efficiencies of 11.0% and 5.5% for laboratory-scale devices with opaque and semi-transparent (50% visible transmission) configurations, respectively.

Thermotropic smart glazing systems utilizing the distinctive characteristics of thermochromic hydrogels have demonstrated impressive energy-saving abilities by dynamically controlling solar heat gain and daylight transmission based on temperature fluctuations. An exemplary instance is a PNIPAm-based thermotropic window system covering a significant area (1 m2), which managed to reduce HVAC energy consumption by 45% when contrasted with standard double glazing in Singapore’s tropical climate. Additionally, the TT PS-TIM window system exhibited energy savings of up to 21.5% compared to double-glazing in various climates like London, Stockholm, Rome, and Singapore, all while improving the availability of daylight.

Emerging dynamic glazing technologies have successfully integrated BIPV functionality with smart window capabilities, resolving the trade-off between high visible light transmission and efficient power conversion. These systems offer the unique advantage of simultaneous electricity generation and daylight regulation within a single glazing unit. A photothermally controlled methylammonium lead iodide PV window exhibited an outstanding 68% visible light transmission, coupled with an impressive 11.3% power conversion efficiency and a rapid switching time of less than 3 min. PDLC smart windows achieved visible light transmittance ranging from 41% in the OFF state to 68% in the ON state, with self-powered operation enabled by integrated PV cells.

Furthermore, switchable PV-EC glazing technologies, such as SBS, TST, and TLT configurations, have demonstrated promising thermal and visual comfort, energy efficiency, and aesthetic potential. The TLT technology, in particular, exhibited higher and faster phase transition compared to TST, making it more suitable for solar control glazing in various climatic conditions.

These innovative BIPV glazing and smart window technologies hold transformative potential for establishing sustainable and energy-efficient built environments, significantly contributing to global initiatives aimed at mitigating climate change and promoting environmental sustainability. By seamlessly integrating PV energy generation with dynamic thermal regulation and daylighting control, these glazing systems offer a game-changing solution for reducing energy consumption and carbon footprint in buildings.