Limitations of Upper Protective Layers as Pressure Relief Measures for Extra-Thick Coal Seam Mining: Insights from a Case Study

Abstract

1. Introduction

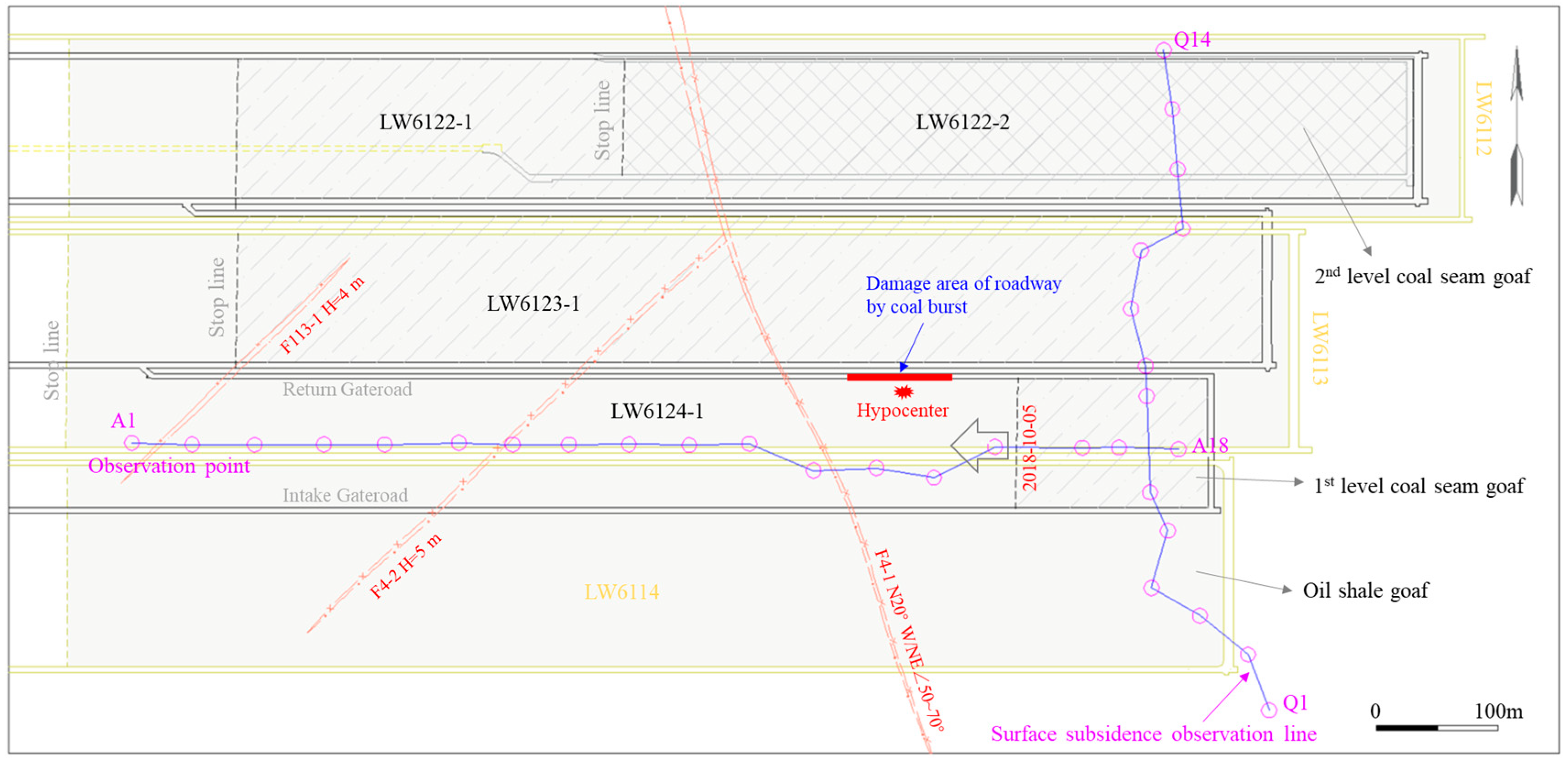

2. Engineering Background

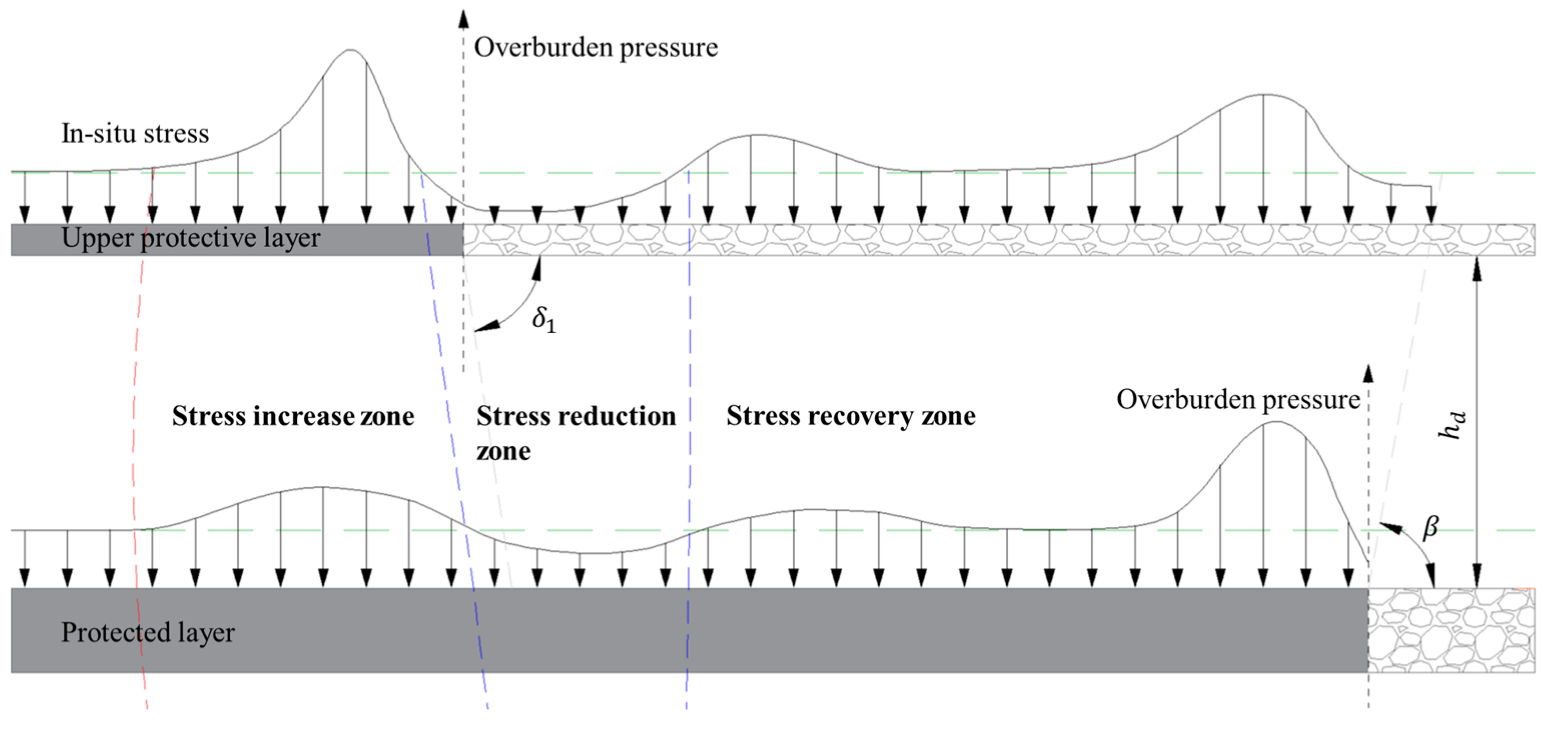

3. Coal Seam Excavation Height and Overburden Movement

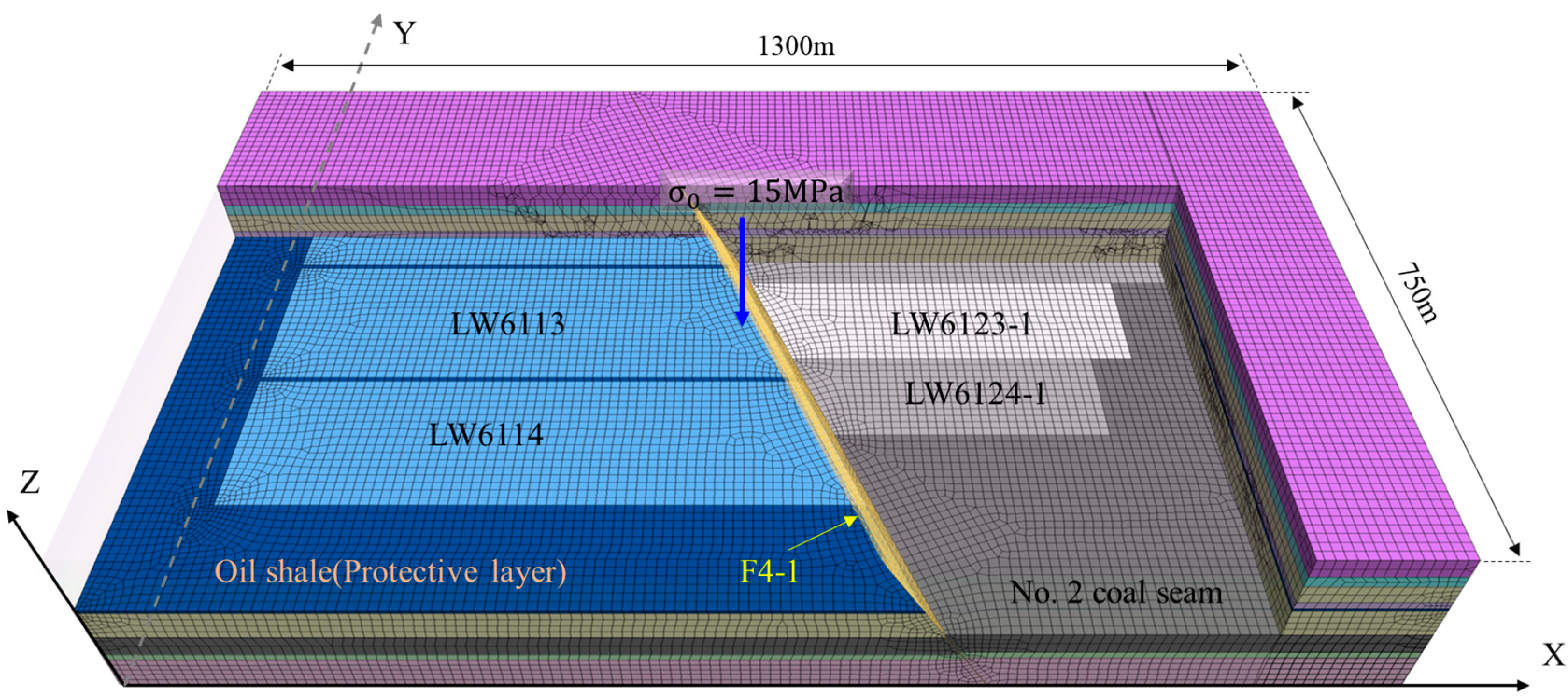

4. Numerical Simulation

4.1. Numerical Model

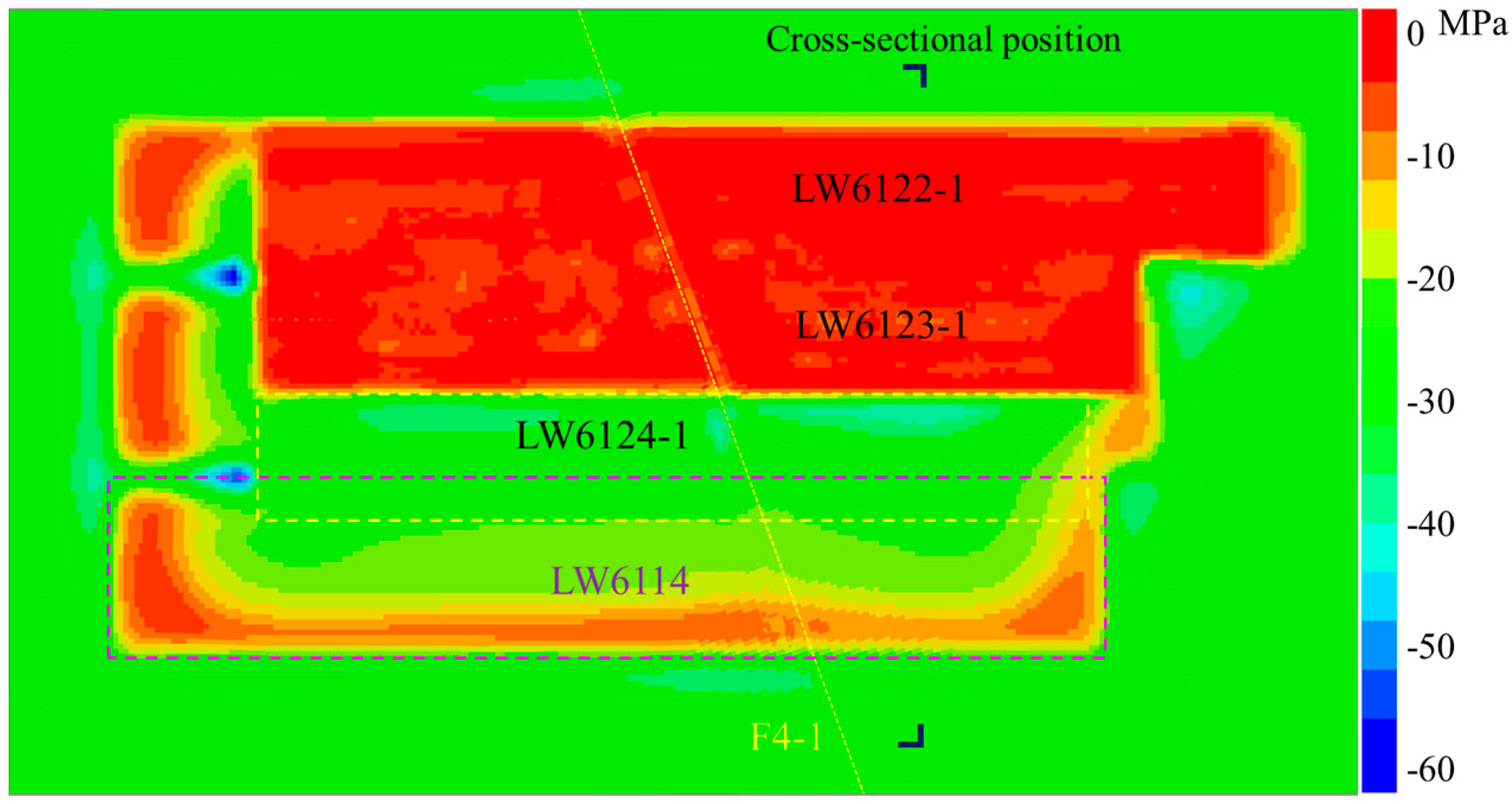

4.2. Results Analysis

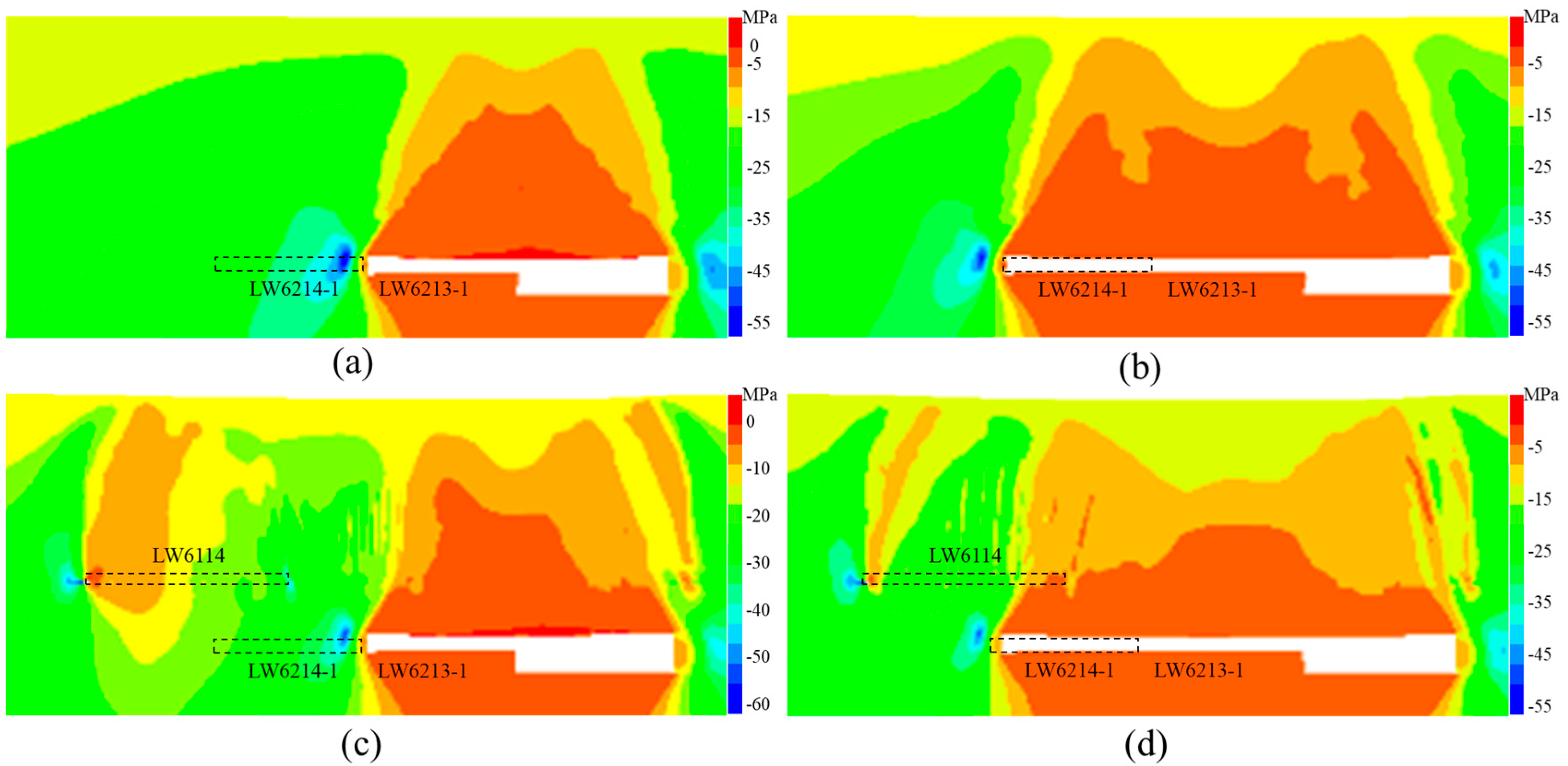

4.2.1. The Effect of Faults on Coal Seam Stress

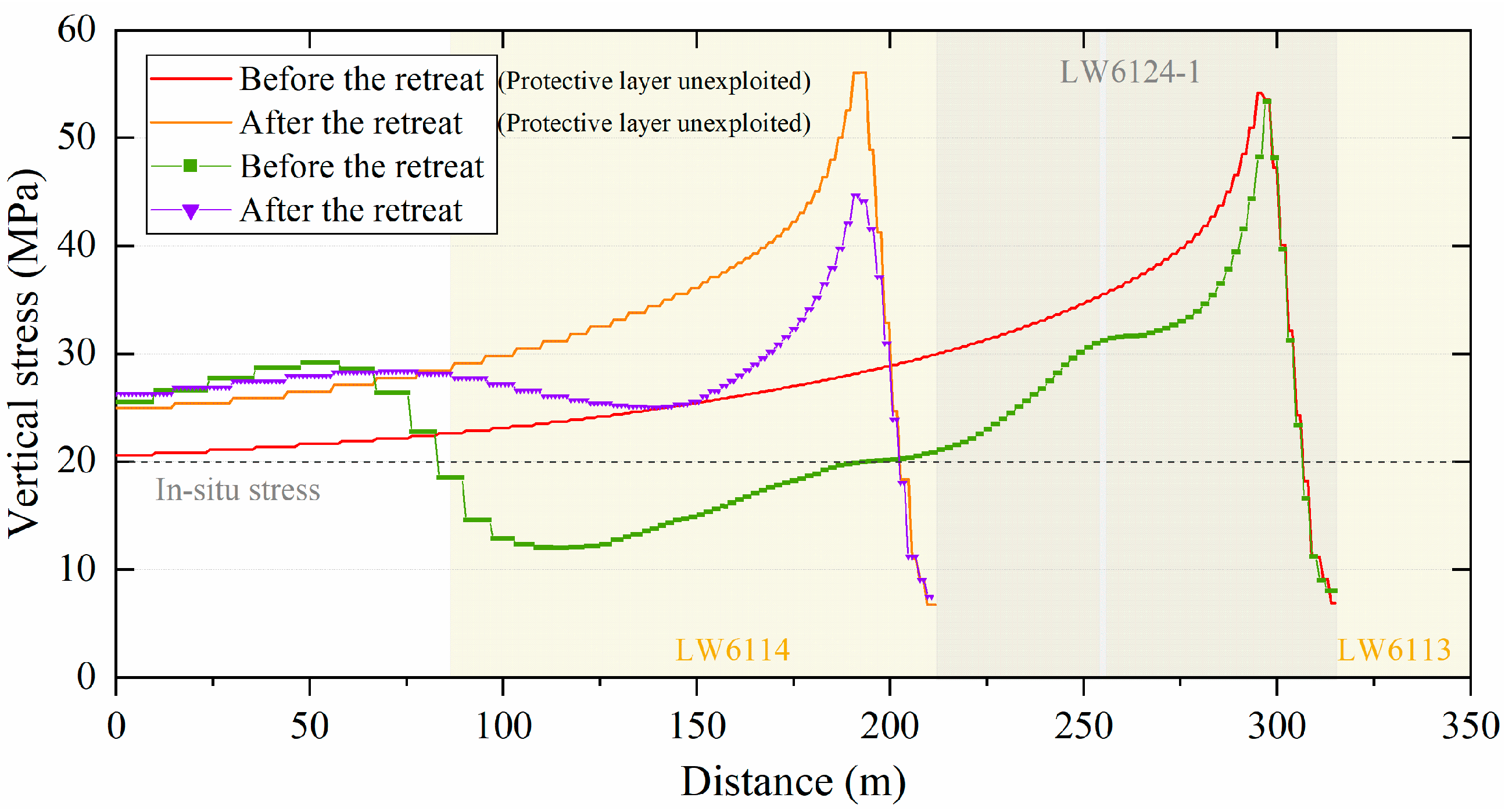

4.2.2. The Effect of Upper Protective Layer Mining

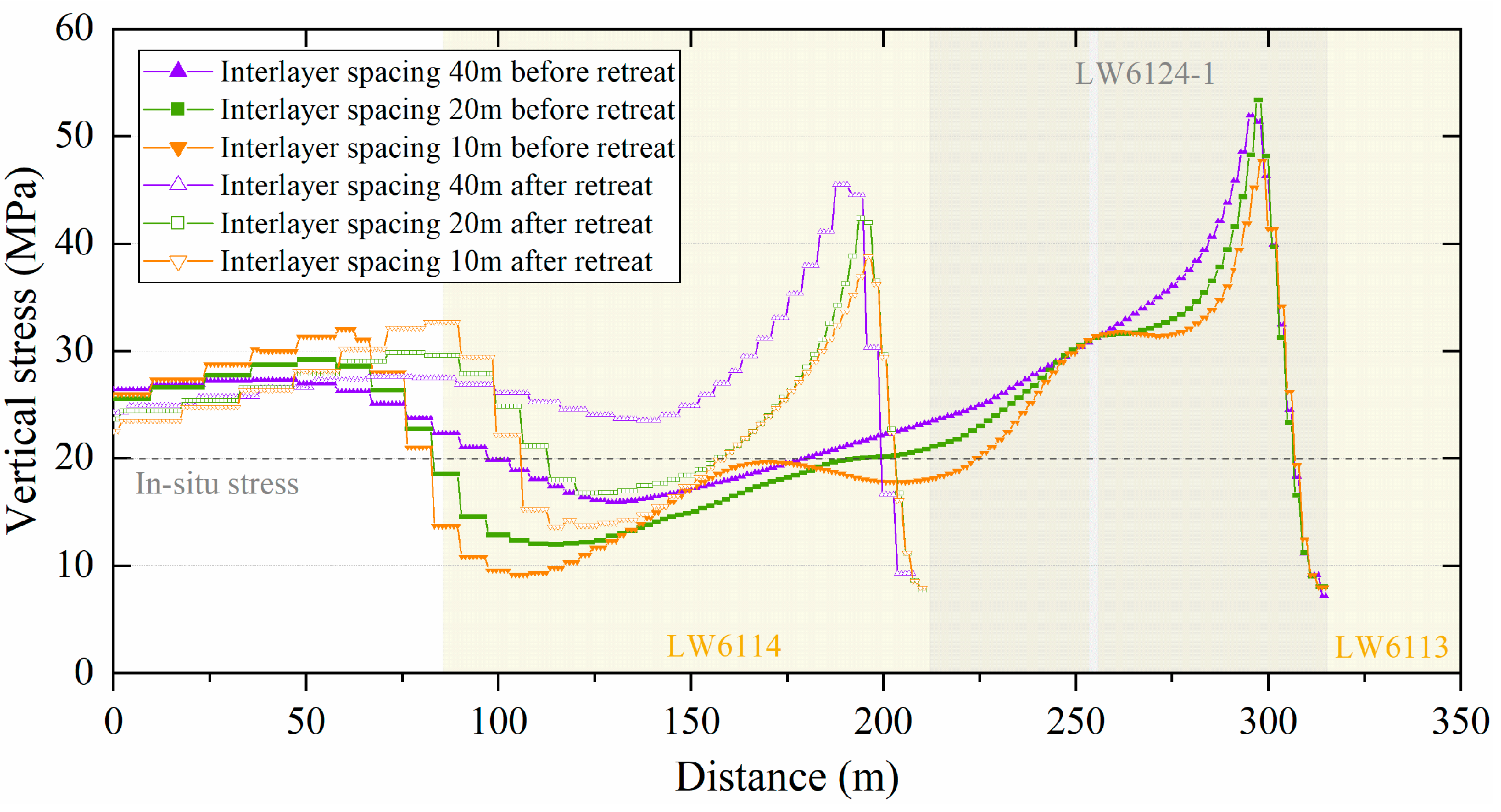

4.2.3. The Effect of Interlayer Spacing

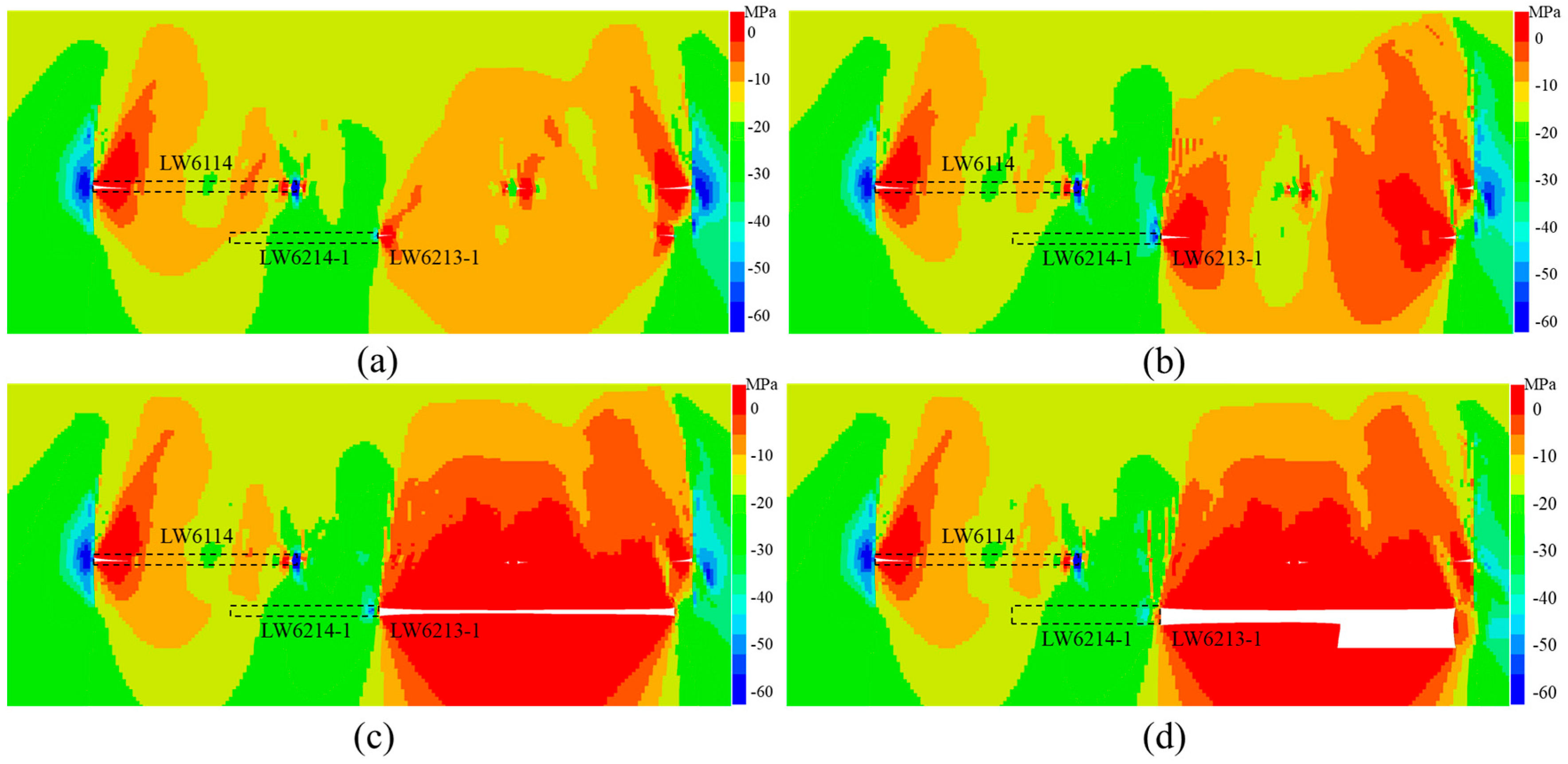

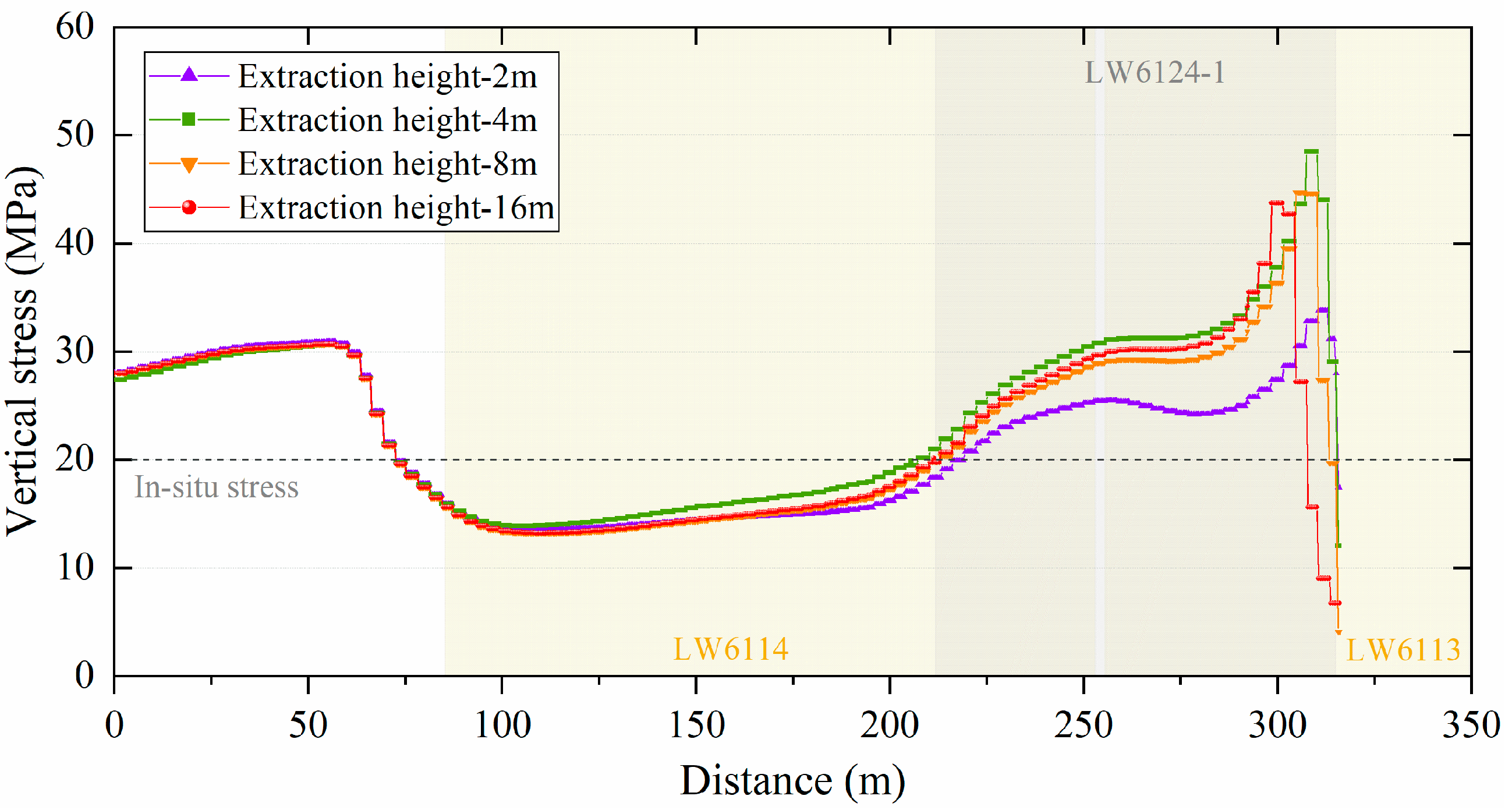

4.2.4. The Effect of Coal Seam Mining Height

5. Engineering Observation and Applications

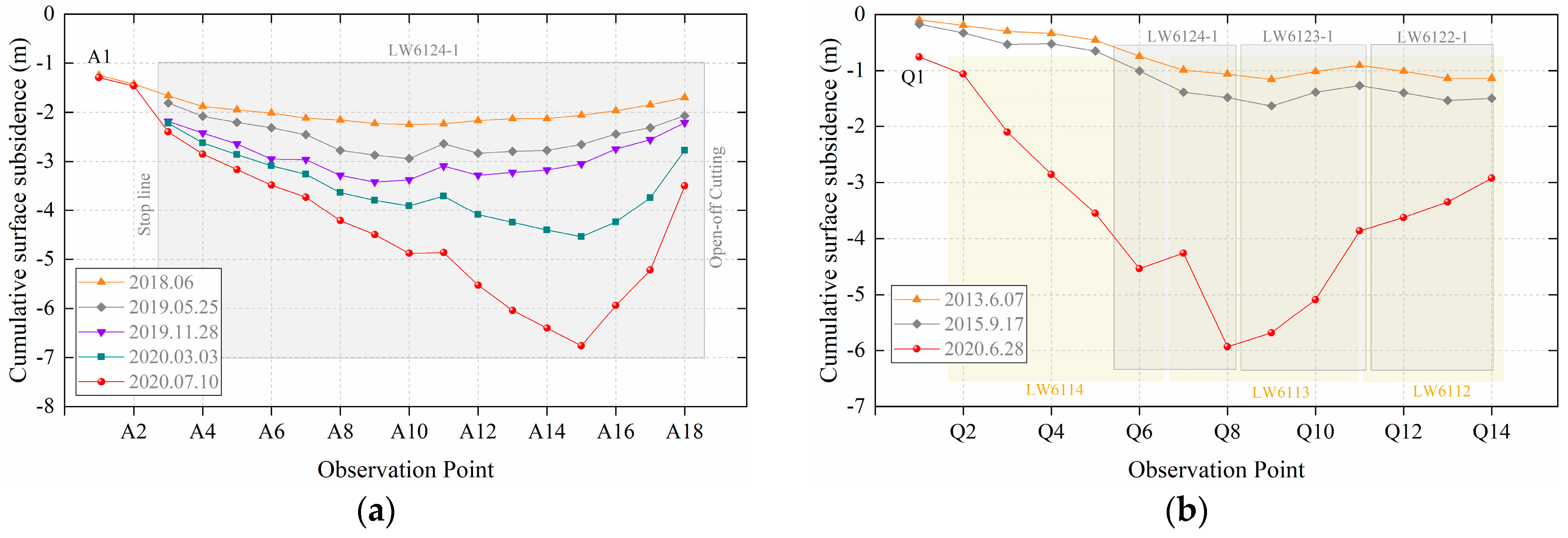

5.1. Surface Subsidence and Overburden Movement

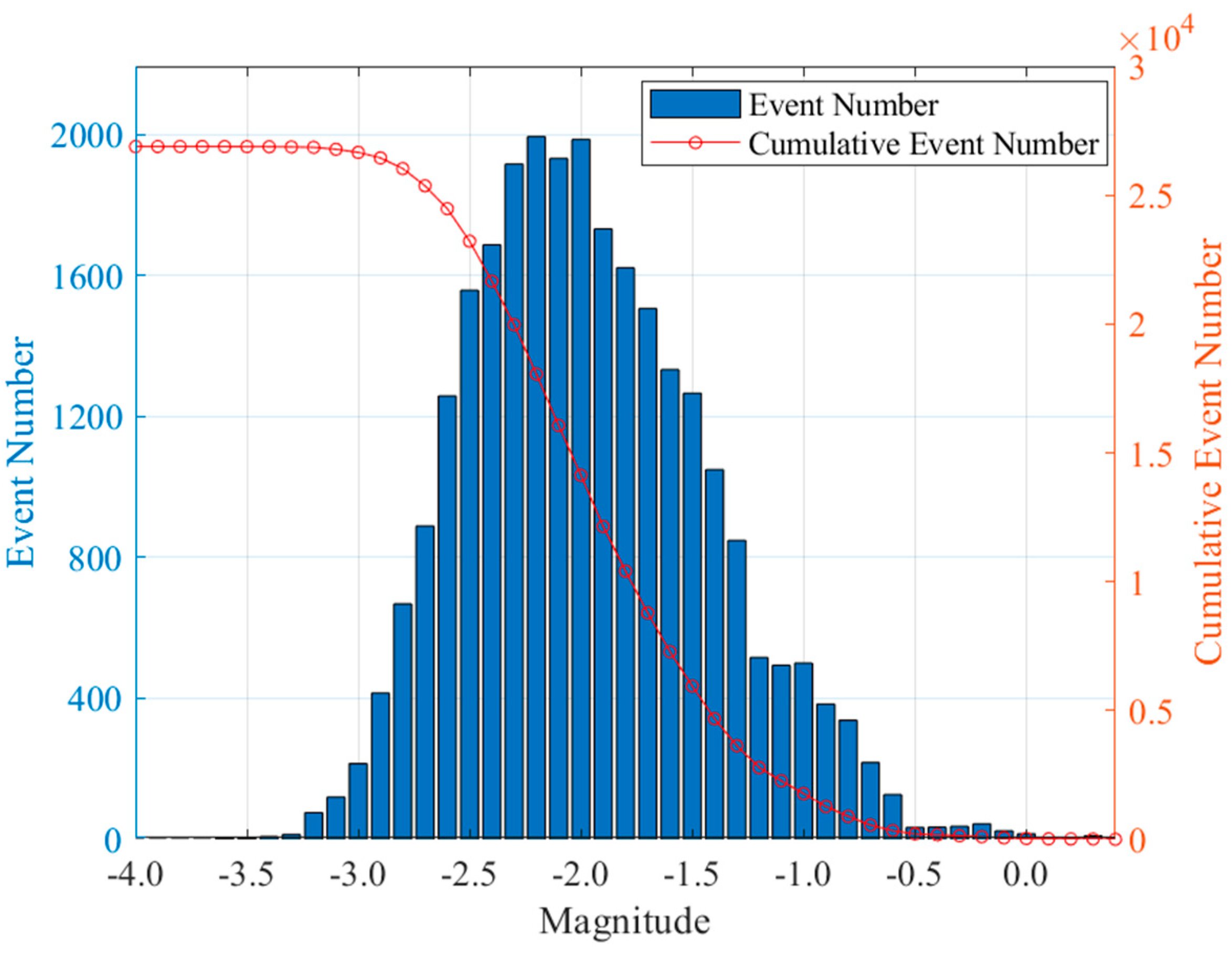

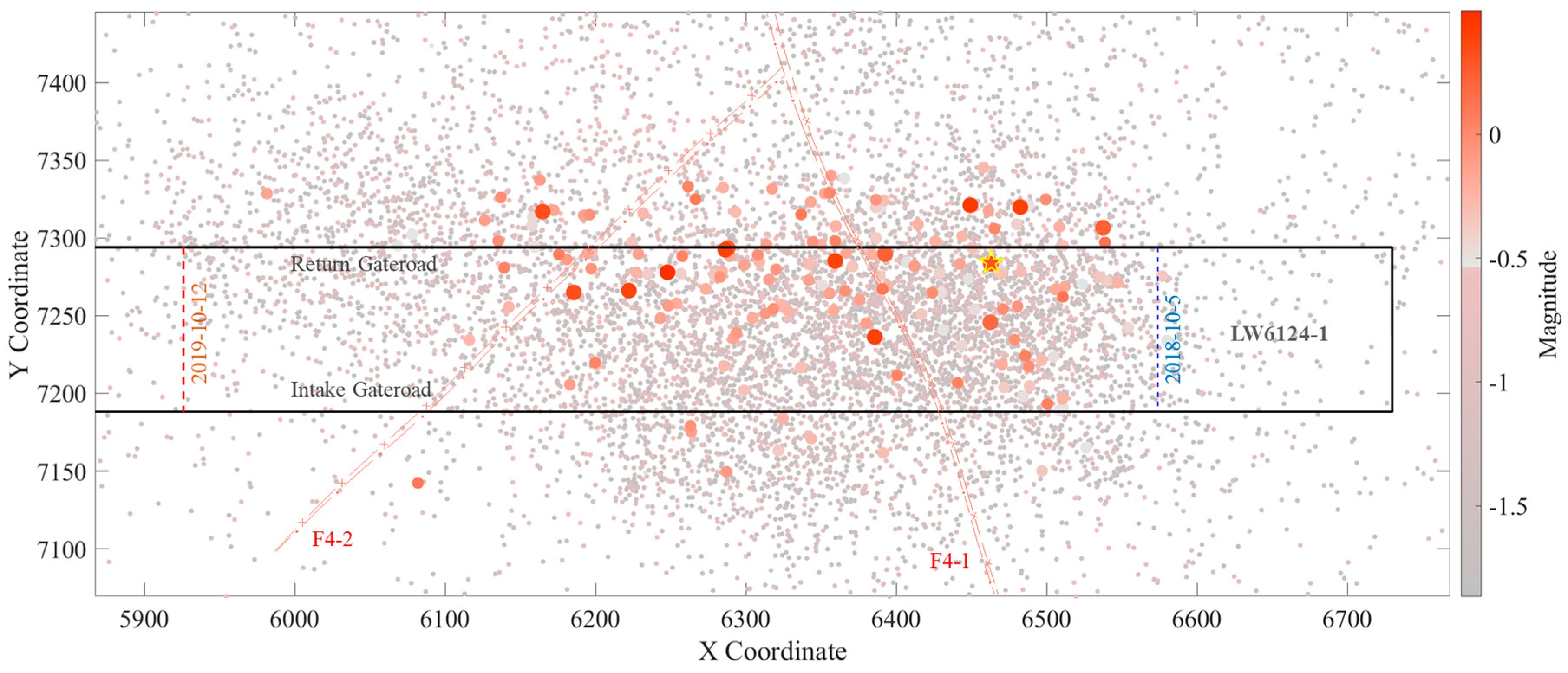

5.2. Mining-Induced Seismicity in Extra-Thick Coal Seam

5.3. Prevention and Control Measures

6. Discussion

7. Conclusions

- (1)

- The height of coal seam extraction will affect the development of the collapse zone in the goaf and determine the position where the key layer blocks of the overburden form a “masonry beam” structure. The effective support width of the structure at high-position is relatively large, leading to an increased load on the overburden that is supported by the coal rock mass on both sides of the structure. This will result in an increase in stress on the extra-thick coal seam near the goaf and eliminate the pressure relief effect of the protective layer;

- (2)

- The extraction of the UPL has a significant pressure relief effect, which gradually diminishes with the increase in interlayer spacing, especially when the spacing exceeds 40 m. Faults beneath the protective layer, by altering the continuity of the geological structure, will impact the stress distribution in the coal seam, especially when the interlayer spacing is large. With the increase in coal seam extraction height, the depressurisation effect on the coal seam adjacent to the goaf under the protective layer vanishes, leading to stress concentration;

- (3)

- The accumulated subsidence on the surface before the retreat of the longwall panel 6124-1 is relatively small, depending on the width of inclination in the goaf and the overburden structure. During the retreat of the panel, mining-induced seismic events clustered around the faults, while large-magnitude seismic events were mainly distributed near the return gateroad, which is associated with the static stress in the coal seam. In response to the high static stress during the retreat of the panel, it is proposed to address the coal seam and roof rock separately with large-diameter drilling and deep-hole blasting.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fuksa, D. Opportunities and Threats for Polish Power Industry and for Polish Coal: A Case Study in Poland. Energies 2021, 14, 6638. [Google Scholar] [CrossRef]

- Hancox, P.J.; Götz, A.E. South Africa’s coalfields—A 2014 perspective. Int. J. Coal Geol. 2014, 132, 170–254. [Google Scholar] [CrossRef]

- Panaedova, G.; Borodin, A.; Zehir, C.; Laptev, S.; Kulikov, A. Overview of the Russian Coal Market in the Context of Geopolitical and Economic Turbulence: The European Embargo and New Markets. Energies 2023, 16, 6797. [Google Scholar] [CrossRef]

- Han, S.; Chen, H.; Long, R.; Cui, X. Peak coal in China: A literature review. Resour. Conserv. Recycl. 2018, 129, 293–306. [Google Scholar] [CrossRef]

- Mark, C. Coal bursts that occur during development: A rock mechanics enigma. Int. J. Min. Sci. Technol. 2018, 28, 35–42. [Google Scholar] [CrossRef]

- Li, X.; Chai, Y. Determination of pillar width to improve mining safety in a deep burst-prone coal mine. Saf. Sci. 2019, 113, 244–256. [Google Scholar] [CrossRef]

- Feng, X.T.; Liu, J.; Chen, B.; Xiao, Y.; Feng, G.; Zhang, F. Monitoring, Warning, and Control of Rockburst in Deep Metal Mines. Engineering 2017, 3, 538–545. [Google Scholar] [CrossRef]

- Chai, Y.; Dou, L.; Cai, W.; Małkowski, P.; Li, X.; Gong, S.; Bai, J.; Cao, J. Experimental investigation into damage and failure process of coal-rock composite structures with different roof lithologies under mining-induced stress loading. Int. J. Rock Mech. Min. Sci. 2023, 170, 105479. [Google Scholar] [CrossRef]

- Gao, R.; Yu, B.; Xia, H.; Duan, H. Reduction of Stress Acting on a Thick, Deep Coal Seam by Protective-Seam Mining. Energies 2017, 10, 1209. [Google Scholar] [CrossRef]

- Wang, H.; Cheng, Y.; Yuan, L. Gas outburst disasters and the mining technology of key protective seam in coal seam group in the Huainan coalfield. Nat. Hazards 2013, 67, 763–782. [Google Scholar] [CrossRef]

- Wang, L.; Lu, Z.; Chen, D.-P.; Liu, Q.Q.; Chu, P.; Shu, L.Y.; Ullah, B.; Wen, Z.J. Safe strategy for coal and gas outburst prevention in deep-and-thick coal seams using a soft rock protective layer mining. Saf. Sci. 2020, 129, 104800. [Google Scholar] [CrossRef]

- Li, W.; Cheng, Y.P.; Guo, P.-K.; An, F.H.; Chen, M.Y. The evolution of permeability and gas composition during remote protective longwall mining and stress-relief gas drainage: A case study of the underground Haishiwan Coal Mine. Geosci. J. 2014, 18, 427–437. [Google Scholar] [CrossRef]

- Kurlenya, M.V.; Seryakov, V.M.; Korotkikh, V.I. Geomechanical substantiation of pillar-and-room sequences of mining the protective layer. Rock Mech. Mine Press. 1991, 27, 269–275. [Google Scholar] [CrossRef]

- Korotkikh, V.I.; Tapsiev, A.P.; Red’kin, V.A.; Selyaev, I.S. Improvement of production schemes for constructing protective layers in mining gently sloping deposits. J. Min. Sci. 1990, 26, 277–281. [Google Scholar] [CrossRef]

- Yang, W.; Lin, B.Q.; Qu, Y.A.; Zhao, S.; Zhai, C.; Jia, L.L.; Zhao, W.Q. Mechanism of strata deformation under protective seam and its application for relieved methane control. Int. J. Coal Geol. 2011, 85, 300–306. [Google Scholar] [CrossRef]

- Zhang, Y. Distribution law of floor stress during mining of the upper protective coal seam. Sci. Prog. 2020, 103. [Google Scholar] [CrossRef]

- Yin, W.; Miao, X.; Zhang, J.; Zhong, S. Mechanical analysis of effective pressure relief protection range of upper protective seam mining. Int. J. Min. Sci. Technol. 2017, 27, 537–543. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, D.; Qi, D.; Hu, W.; He, Z.; Zhang, W. Floor failure depth of upper coal seam during close coal seams mining and its novel detection method. Energy Explor. Exploit. 2018, 36, 1265–1278. [Google Scholar] [CrossRef]

- Yang, W.; Lin, B.Q.; Qu, Y.A.; Li, Z.W.; Zhai, C.; Jia, L.L.; Zhao, W.Q. Stress evolution with time and space during mining of a coal seam. Int. J. Rock Mech. Min. Sci. 2011, 48, 1145–1152. [Google Scholar] [CrossRef]

- Zhang, C.; Yu, L.; Feng, R.; Zhang, Y.; Zhang, G. A Numerical Study of Stress Distribution and Fracture Development above a Protective Coal Seam in Longwall Mining. Processes 2018, 6, 146. [Google Scholar] [CrossRef]

- Liu, Z.; Yang, H.; Cheng, W.; Xin, L.; Ni, G. Stress distribution characteristic analysis and control of coal and gas outburst disaster in a pressure-relief boundary area in protective layer mining. Arab. J. Geosci. 2017, 10, 358. [Google Scholar] [CrossRef]

- Fang, S.; Zhu, H.; Huo, Y.; Zhang, Y.; Wang, H.; Li, F.; Wang, X. The pressure relief protection effect of different strip widths, dip angles and pillar widths of an underside protective seam. PLoS ONE 2021, 16, e246199. [Google Scholar] [CrossRef]

- Cheng, X.; Zhao, G.; Li, Y.; Meng, X.; Tu, Q. Key technologies and engineering practices for soft-rock protective seam mining. Int. J. Min. Sci. Technol. 2020, 30, 889–899. [Google Scholar] [CrossRef]

- Feng, Y.; Wang, W.; Zhang, Z.; Yang, W. Pattern of Influence of the Mining Direction of the Protective Seam on the Stress of the Surrounding Rock. Sustainability 2023, 15, 13623. [Google Scholar] [CrossRef]

- Jin, K.; Cheng, Y.; Wang, W.; Liu, H.; Liu, Z.; Zhang, H. Evaluation of the remote lower protective seam mining for coal mine gas control: A typical case study from the Zhuxianzhuang Coal Mine, Huaibei Coalfield, China. J. Nat. Gas Sci. Eng. 2016, 33, 44–55. [Google Scholar] [CrossRef]

- Cheng, Z.; Pan, H.; Zou, Q.; Li, Z.; Chen, L.; Cao, J.; Zhang, K.; Cui, Y. Gas Flow Characteristics and Optimization of Gas Drainage Borehole Layout in Protective Coal Seam Mining: A Case Study from the Shaqu Coal Mine, Shanxi Province, China. Nat. Resour. Res. 2021, 30, 1481–1493. [Google Scholar] [CrossRef]

- Chen, H.; Cheng, Y.; Ren, T.; Zhou, H.; Liu, Q. Permeability distribution characteristics of protected coal seams during unloading of the coal body. Int. J. Rock Mech. Min. Sci. 2014, 71, 105–116. [Google Scholar] [CrossRef]

- Yang, M.; Wang, M.; Wang, Y.; Zhang, J.; Zhang, L.; Wang, Z. Coal pore structure changes in upper protective seam after mining: Pingdingshan Shenma Group, Henan Province, China. J. Pet. Sci. Eng. 2022, 218, 111045. [Google Scholar] [CrossRef]

- Wang, F.; Zhangm, C.; Liang, N. Gas Permeability Evolution Mechanism and Comprehensive Gas Drainage Technology for Thin Coal Seam Mining. Energies 2017, 10, 1382. [Google Scholar] [CrossRef]

- Sun, Q.; Zhang, J.; Zhang, Q.; Yin, W.; Germain, D. A protective seam with nearly whole rock mining technology for controlling coal and gas outburst hazards: A case study. Nat. Hazards 2016, 84, 1793–1806. [Google Scholar] [CrossRef]

- Ding, K.; Wang, L.; Wang, W.; Li, Z.; Jiang, C.; Ren, B.; Wang, S. Experimental Study on Gas Seepage Characteristics of Axially Unloaded Coal under Different Confining Pressures and Gas Pressures. Processes 2022, 10, 1055. [Google Scholar] [CrossRef]

- Cheng, X.; Zhao, G.; Li, Y.; Meng, X.; Dong, C.; Liu, Z. Researches of fracture evolution induced by soft rock protective seam mining and an omni-directional stereo pressure-relief gas extraction technical system: A case study. Arab. J. Geosci. 2018, 11, 326. [Google Scholar] [CrossRef]

- Dou, L.M.; He, X.Q.; Hu, H.E.; Jiang, H.E.; Jun, F.A.N. Spatial structure evolution of overlying strata and inducing mechanism of rockburst in coal mine. Trans. Nonferrous Met. Soc. China 2014, 24, 1255–1261. [Google Scholar] [CrossRef]

- Mu, Z.; Dou, L.; He, H.; Fan, J. F-structure model of overlying strata for dynamic disaster prevention in coal mine. Int. J. Min. Sci. Technol. 2013, 23, 513–519. [Google Scholar] [CrossRef]

- Cheng, G.; Xu, W.; Shi, B.; Wu, J.; Sun, B.; Zhu, H. Experimental study on the deformation and failure mechanism of overburden rock during coal mining using a comprehensive intelligent sensing method. J. Rock Mech. Geotech. Eng. 2022, 14, 1626–1641. [Google Scholar] [CrossRef]

- Ju, J.; Xu, J. Surface stepped subsidence related to top-coal caving longwall mining of extremely thick coal seam under shallow cover. Int. J. Rock Mech. Min. Sci. 2015, 78, 27–35. [Google Scholar] [CrossRef]

- Ju, J.; Xu, J. Structural characteristics of key strata and strata behaviour of a fully mechanized longwall face with 7.0 m height chocks. Int. J. Rock Mech. Min. Sci. 2013, 58, 46–54. [Google Scholar] [CrossRef]

- Yang, B.; Yuan, S.; Liang, Y.; Liu, J. Investigation of overburden failure characteristics due to combined mining: Case study, Henan Province, China. Environ. Earth Sci. 2021, 80, 143. [Google Scholar] [CrossRef]

- Wang, X.; Qin, D.; Zhang, D.; Guan, W.; Xu, M.; Wang, X.; Zhang, C. Evolution Characteristics of Overburden Strata Structure for Ultra-Thick Coal Seam Multi-Layer Mining in Xinjiang East Junggar Basin. Energies 2019, 12, 332. [Google Scholar] [CrossRef]

- Jiang, N.; Lv, K.; Gao, Z.; Di, H.; Ma, J.; Pan, T. Study on Characteristics of Overburden Strata Structure Above Abandoned Gob of Shallow Seams—A Case Study. Energies 2022, 15, 9359. [Google Scholar] [CrossRef]

- Cai, W.; Dou, L.; Si, G.; Hu, Y. Fault-Induced Coal Burst Mechanism under Mining-Induced Static and Dynamic Stresses. Engineering 2021, 7, 687–700. [Google Scholar] [CrossRef]

- Li, Z.; Dou, L.; Cai, W.; Wang, G.; He, J.; Gong, S.; Ding, Y. Investigation and analysis of the rock burst mechanism induced within fault–pillars. Int. J. Rock Mech. Min. Sci. 2014, 70, 192–200. [Google Scholar] [CrossRef]

- Cai, W.; Dou, L.; Li, Z.; He, J.; He, H.; Ding, Y. Mechanical Initiation and Propagation Mechanism of a Thrust Fault: A Case Study of the Yima Section of the Xiashi-Yima Thrust (North Side of the Eastern Qinling Orogen, China). Rock Mech. Rock Eng. 2015, 48, 1927–1945. [Google Scholar] [CrossRef]

- Piotr, M.; Łukasz, O.; Piotr, B. Modelling the Small Throw Fault Effect on the Stability of a Mining Roadway and Its Verification by In Situ Investigation. Energies 2017, 10, 2082. [Google Scholar] [CrossRef]

- Skrzypkowski, K.; Zagórski, K.; Zagórska, A.; Apel, D.B.; Wang, J.; Xu, H.; Guo, L. Choice of the Arch Yielding Support for the Preparatory Roadway Located near the Fault. Energies 2022, 15, 3774. [Google Scholar] [CrossRef]

- Cao, J.; Huang, Q.; Guo, L. Subsidence prediction of overburden strata and ground surface in shallow coal seam mining. Sci. Rep. 2021, 11, 18972. [Google Scholar] [CrossRef] [PubMed]

- Cui, X.; Wang, J.; Liu, Y. Prediction of progressive surface subsidence above longwall coal mining using a time function. Int. J. Rock Mech. Min. Sci. 2001, 38, 1057–1063. [Google Scholar] [CrossRef]

- Gutenberg, B.; Richter, C.F. Magnitude and Energy of Earthquakes. Nature 1955, 176, 795. [Google Scholar] [CrossRef]

- Si, G.; Cai, W.; Wang, S.; Li, X. Prediction of Relatively High-Energy Seismic Events Using Spatial–Temporal Parametrisation of Mining-Induced Seismicity. Rock Mech. Rock Eng. 2020, 53, 5111–5132. [Google Scholar] [CrossRef]

- Fujii, Y.; Ishijima, Y. Numerical simulation of microseismicity induced by deep longwall coal mining. Min. Sci. Technol. 1991, 12, 265–285. [Google Scholar] [CrossRef]

- Kan, J.; Dou, L.; Li, X.; Li, J.; Bai, J.; Cao, J.; Liu, M. Effect of initiation pattern on rock damage and blasting seismic under multi-hole blasting. Geomat. Nat. Hazards Risk 2023, 14, 2192334. [Google Scholar] [CrossRef]

- Yang, J.; Fu, Q.; Gao, Y.; Wu, X.; Chang, X.; Li, C. A Novel Method of Combined Deep Hole Blasting for Gob-Side Roadway Protection. Rock Mech. Rock Eng. 2023, 56, 3551–3571. [Google Scholar] [CrossRef]

- Skrzypkowski, K. 3D Numerical Modelling of the Application of Cemented Paste Backfill on Displacements around Strip Excavations. Energies 2021, 14, 7750. [Google Scholar] [CrossRef]

- Yang, W.; Zhang, W.; Lin, B.; Si, G.; Zhang, J.; Wang, J. Integration of protective mining and underground backfilling for coal and gas outburst control: A case study. Process Saf. Environ. Prot. 2022, 157, 273–283. [Google Scholar] [CrossRef]

- Wu, B.; Wang, X.; Bai, J.; Wu, W.; Zhu, X.; Li, G. Study on Crack Evolution Mechanism of Roadside Backfill Body in Gob-Side Entry Retaining Based on UDEC Trigon Model. Rock Mech. Rock Eng. 2019, 52, 3385–3399. [Google Scholar] [CrossRef]

- Li, Z.L.; Dou, L.M.; Cai, W.; Wang, G.F.; Ding, Y.L.; Kong, Y. Roadway Stagger Layout for Effective Control of Gob-Side Rock Bursts in the Longwall Mining of a Thick Coal Seam. Rock Mech. Rock Eng. 2016, 49, 621–629. [Google Scholar] [CrossRef]

- Jingli, Z.; Qiang, F. New scheme of roadway layout in longwall top-coal caving system. J. China Univ. Min. Technol. 1998, 8, 162–165. [Google Scholar]

| Key Strata | Lithology | Thickness (m) | Distance from Coal Seam (m) | Breakage Distance (m) |

|---|---|---|---|---|

| Sub-key layer I | Siltstone | 32.2 | 0 | 58.28 |

| Sub-key layer II | Silty-fine sandstone | 34.97 | 51.67 | 67.88 |

| Sub-key layer III | Siltstone | 30.19 | 384.61 | 70.67 |

| Sub-key layer IV | Fine sandstone | 34.32 | 416.30 | 77.30 |

| Sub-key layer V | Fine sandstone | 31.86 | 552.01 | 105.34 |

| Main key layer | Fine sandstone | 61.43 | 602.04 | 256.80 |

| Lithology | Thickness (m) | Density (kg·m−3) | Shear Modulus (GPa) | Bulk Modulus (GPa) | Cohesion (MPa) | Friction Angle (°) |

|---|---|---|---|---|---|---|

| Oil shale | 30 | 2100 | 2.75 | 10.42 | 1.9 | 33 |

| Fine sandstone | 15 | 2800 | 4 | 7.07 | 4 | 33 |

| Siltstone | 25 | 2450 | 2 | 9.39 | 2.5 | 36 |

| Mud limestone | 10 | 2570 | 2.4 | 3.8 | 2.5 | 35 |

| Oil shale | 4 | 2100 | 2.75 | 10.42 | 1.9 | 33 |

| Siltstone | 40 | 2450 | 2 | 9.39 | 2.5 | 36 |

| No. 2 coal seam | 32 | 1328 | 1.49 | 1.67 | 2.8 | 30 |

| Conglomerate | 10 | 2550 | 2.7 | 9.39 | 2.5 | 36 |

| Gravelly sandstone | 45 | 2700 | 3.2 | 12.40 | 4.8 | 35 |

| Energy (J) | Number of Events | Proportion (%) |

|---|---|---|

| <1.0 × 102 | 15,350 | 57.10 |

| 1.0 × 102~1.0 × 103 | 8750 | 32.54 |

| 1.0 × 103~1.0 × 104 | 2561 | 9.53 |

| 1.0 × 104~1.0 × 102 | 209 | 0.78 |

| >1.0 × 105 | 13 | 0.05 |

| Blast Hole Number | Dip Angle (°) | Azimuth Angle (°) | Diameter (mm) | Length in Roof Rock (m) | Charging Length (m) | Charge Density (kg/m) | Total Charge (kg) |

|---|---|---|---|---|---|---|---|

| 1 | 60 | 180 | 75 | 25 | 22 | 3.6 | 79.2 |

| 2 | 45 | 180 | 75 | 25 | 22 | 3.6 | 79.2 |

| 3 | 30 | 180 | 75 | 30 | 25 | 3.6 | 90 |

| 4 | 45 | 0 | 75 | 30 | 25 | 3.6 | 90 |

| 5 | 60 | 0 | 75 | 25 | 22 | 3.6 | 79.2 |

| 6 | 75 | 0 | 75 | 25 | 22 | 3.6 | 79.2 |

| Blast Hole Number | Dip Angle (°) | Azimuth Angle (°) | Diameter (mm) | Length in Roof Rock (m) | Charging Length (m) | Charge Density (kg/m) | Total Charge (kg) |

|---|---|---|---|---|---|---|---|

| B1 | 70 | 90 | 75 | 25 | 22 | 3.6 | 79.2 |

| B2 | 70 | 180 | 75 | 25 | 22 | 3.6 | 79.2 |

| B3 | 75 | 0 | 75 | 25 | 22 | 3.6 | 79.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chai, Y.; Dou, L.; He, J.; Ma, X.; Lu, F.; He, H. Limitations of Upper Protective Layers as Pressure Relief Measures for Extra-Thick Coal Seam Mining: Insights from a Case Study. Energies 2024, 17, 1446. https://doi.org/10.3390/en17061446

Chai Y, Dou L, He J, Ma X, Lu F, He H. Limitations of Upper Protective Layers as Pressure Relief Measures for Extra-Thick Coal Seam Mining: Insights from a Case Study. Energies. 2024; 17(6):1446. https://doi.org/10.3390/en17061446

Chicago/Turabian StyleChai, Yanjiang, Linming Dou, Jiang He, Xiaotao Ma, Fangzhou Lu, and Hu He. 2024. "Limitations of Upper Protective Layers as Pressure Relief Measures for Extra-Thick Coal Seam Mining: Insights from a Case Study" Energies 17, no. 6: 1446. https://doi.org/10.3390/en17061446

APA StyleChai, Y., Dou, L., He, J., Ma, X., Lu, F., & He, H. (2024). Limitations of Upper Protective Layers as Pressure Relief Measures for Extra-Thick Coal Seam Mining: Insights from a Case Study. Energies, 17(6), 1446. https://doi.org/10.3390/en17061446