The Interaction between Short- and Long-Term Energy Storage in an nZEB Office Building

Abstract

1. Introduction

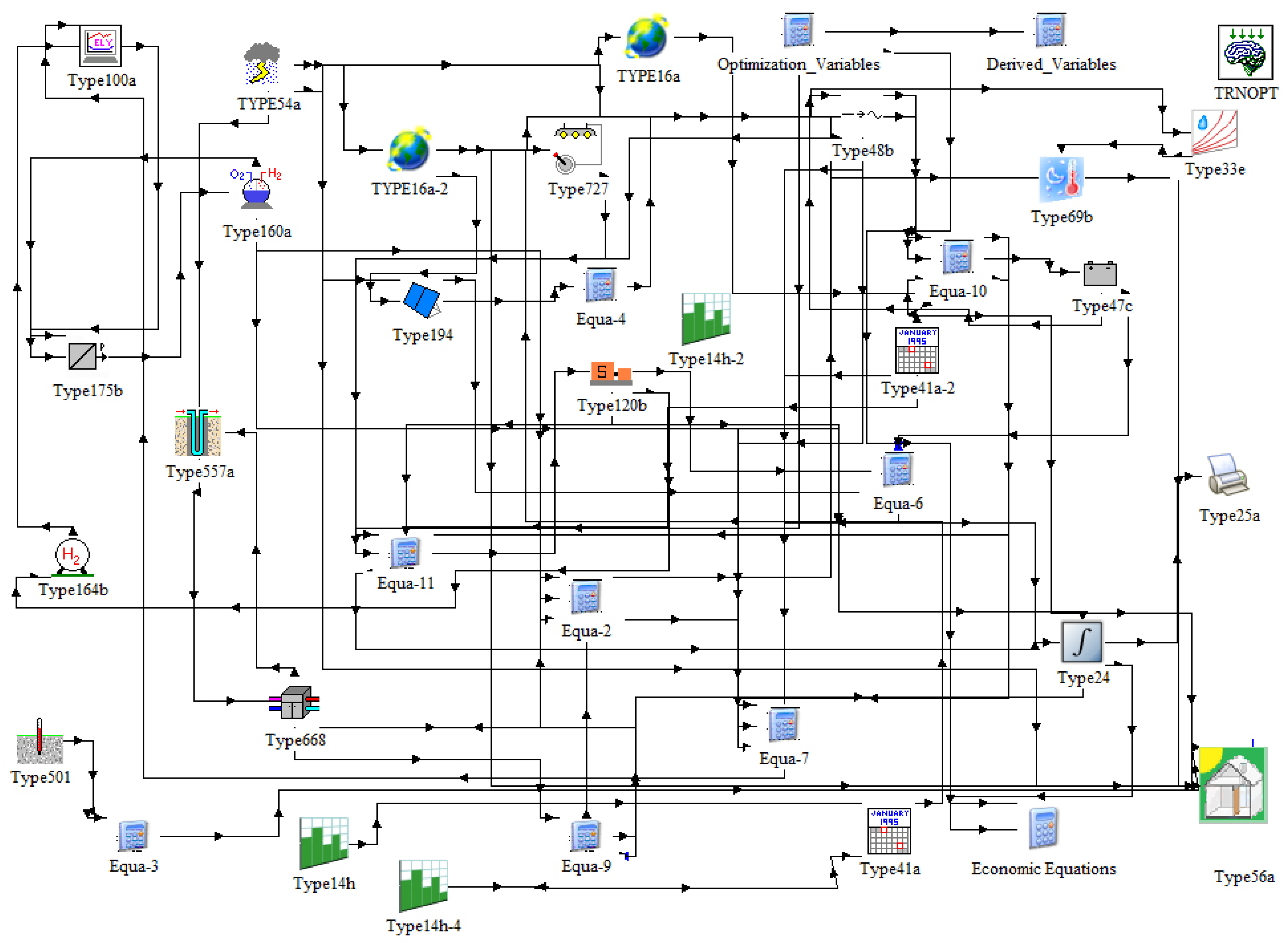

2. Materials and Methods

2.1. Building and HVAC System Description

2.2. Photovoltaic Installation

2.3. Electric Vehicles and Batteries

2.4. H2-Fueled SI Engine of Generator Set

2.5. Electrolyzer Unit

2.6. Pressurized Hydrogen Storage Tank

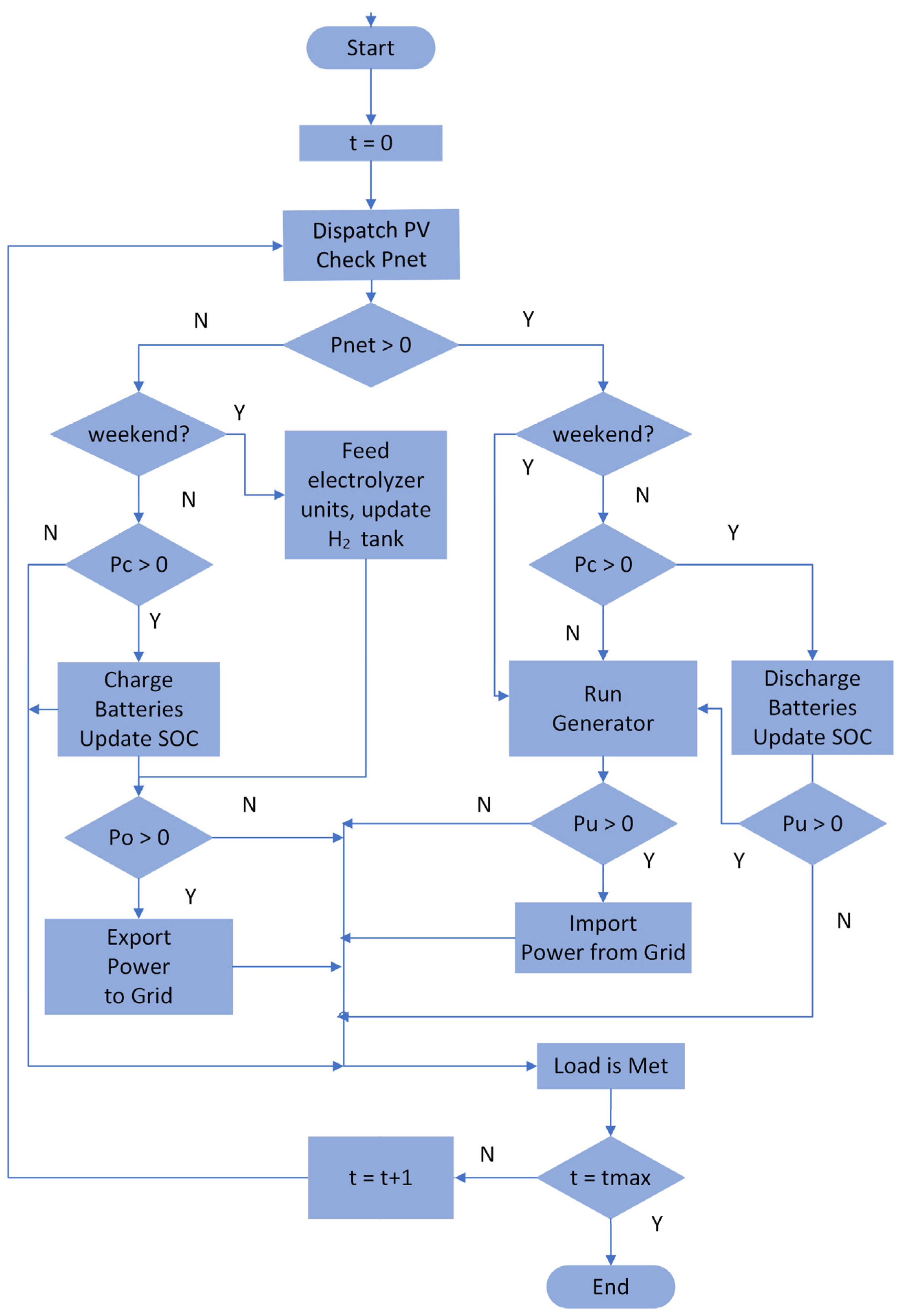

2.7. Dispatch Logic for Various Sources

2.8. Components’ Size Optimization

- The first parameter is the tilt angle of the rooftop photovoltaic panels. It is allowed to vary between 20 and 50 degrees for the system’s optimization. Usual values applied in PV installations in Greece are between 30 and 40 degrees. Higher tilt angles tend to increase electricity production during winter months.

- The second parameter is the maximum aggregate capacity of the electrolyzer units. It is allowed to vary between 2 and 5 stacks of 24 kW. The range was decided based on the available power levels for export during weekends.

- The third parameter is the rated power of hydrogen-fueled generator engine. This is allowed to vary between a minimum value of kW, required to cover basic backup electricity needs of the office building, and a maximum value of 80 kW that would cover the maximum computed levels of power imported from the grid. A rated power that is closer to the lowest value would be more energy efficient due to the higher engine efficiency values associated with the engine operating close to full load.

- Eel, exp is the total electricity exported annually to the grid (kWh);

- Eel, imp is the total electricity imported from the grid (kWh);

- VH2, cons is the net hydrogen annually consumed (Nm3);

- HHVH2 is the higher heating value of hydrogen (3.54 kWh/Nm3);

- is the total efficiency of the engine generator set (-).

3. Results

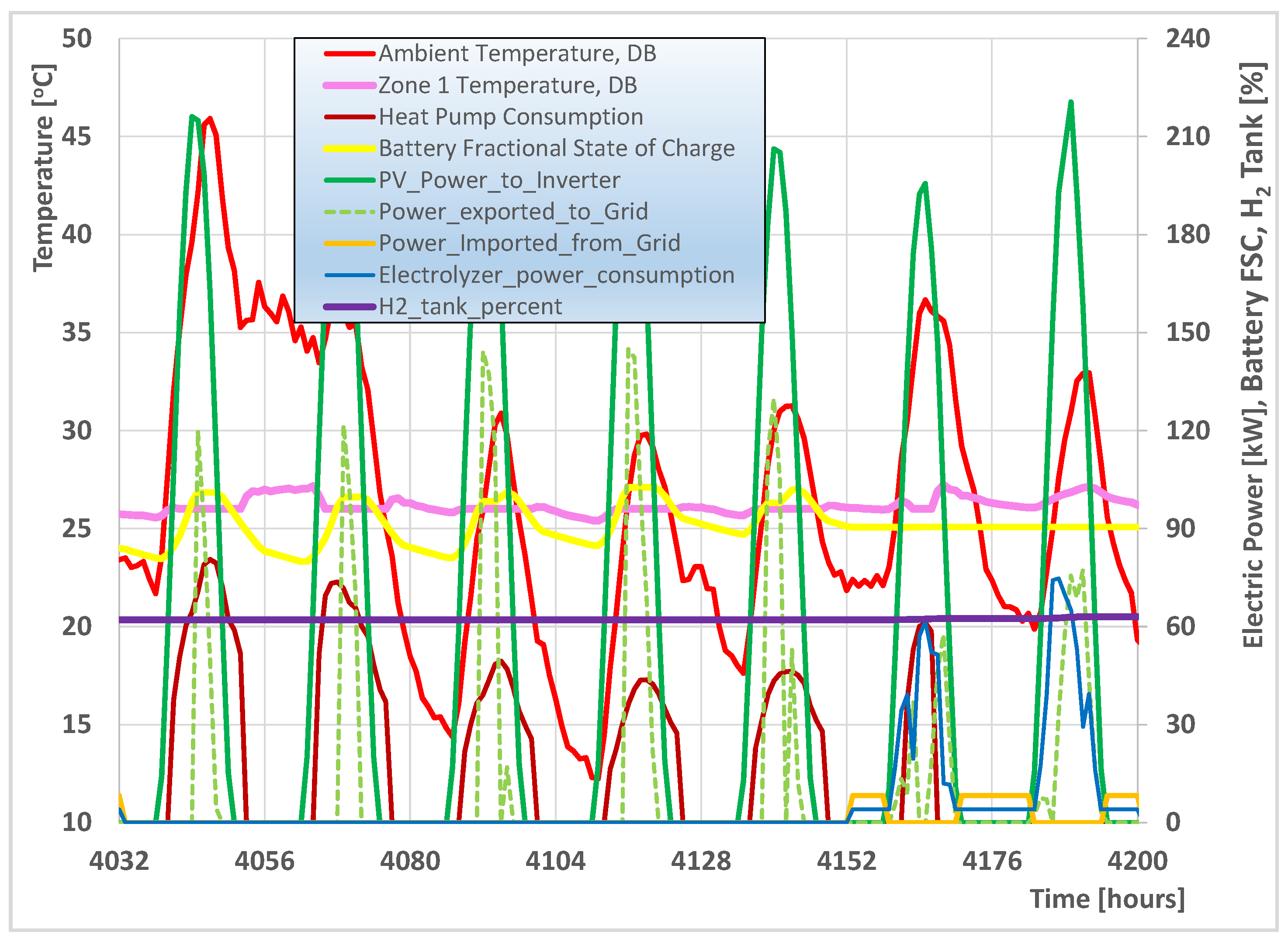

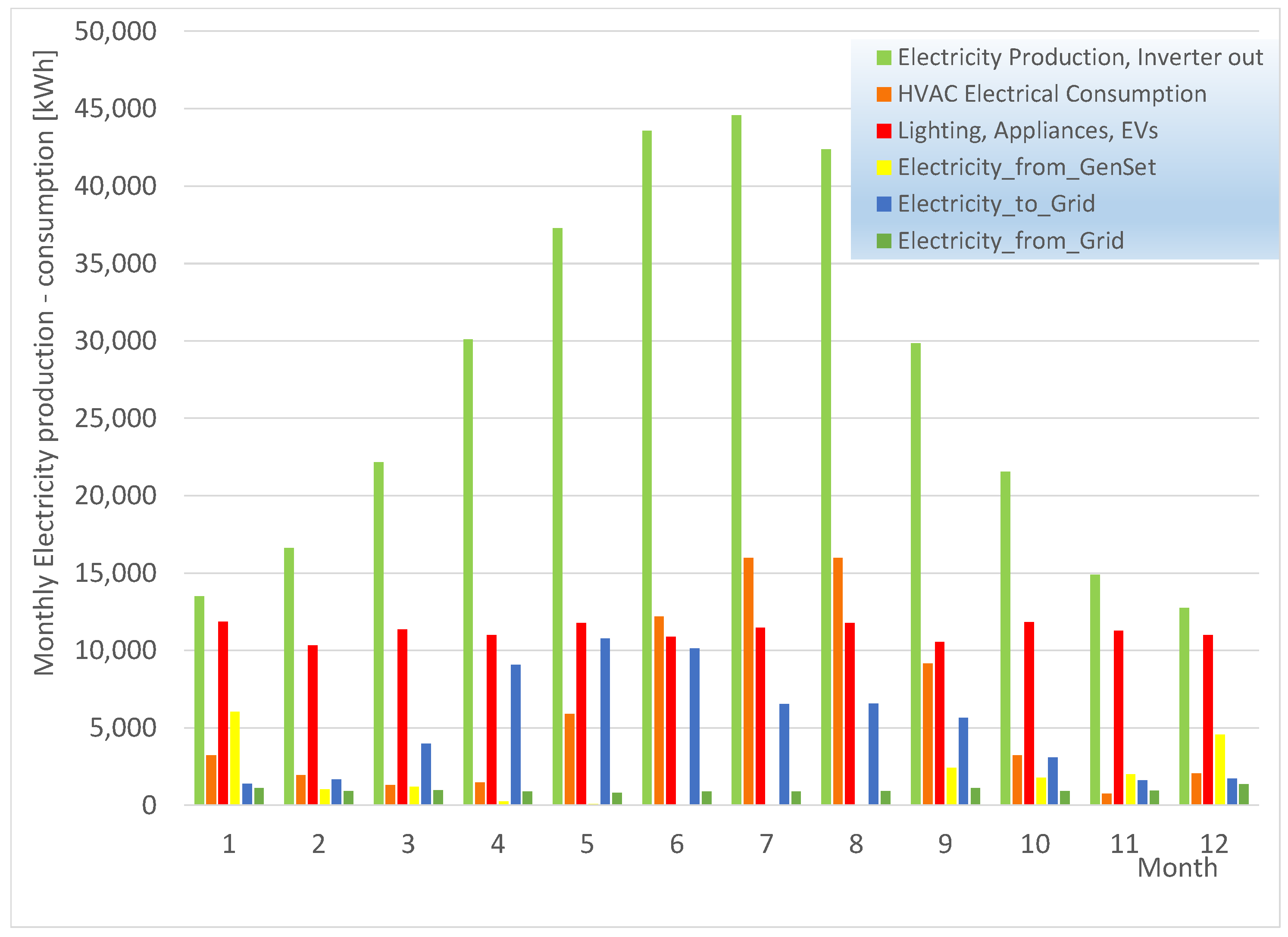

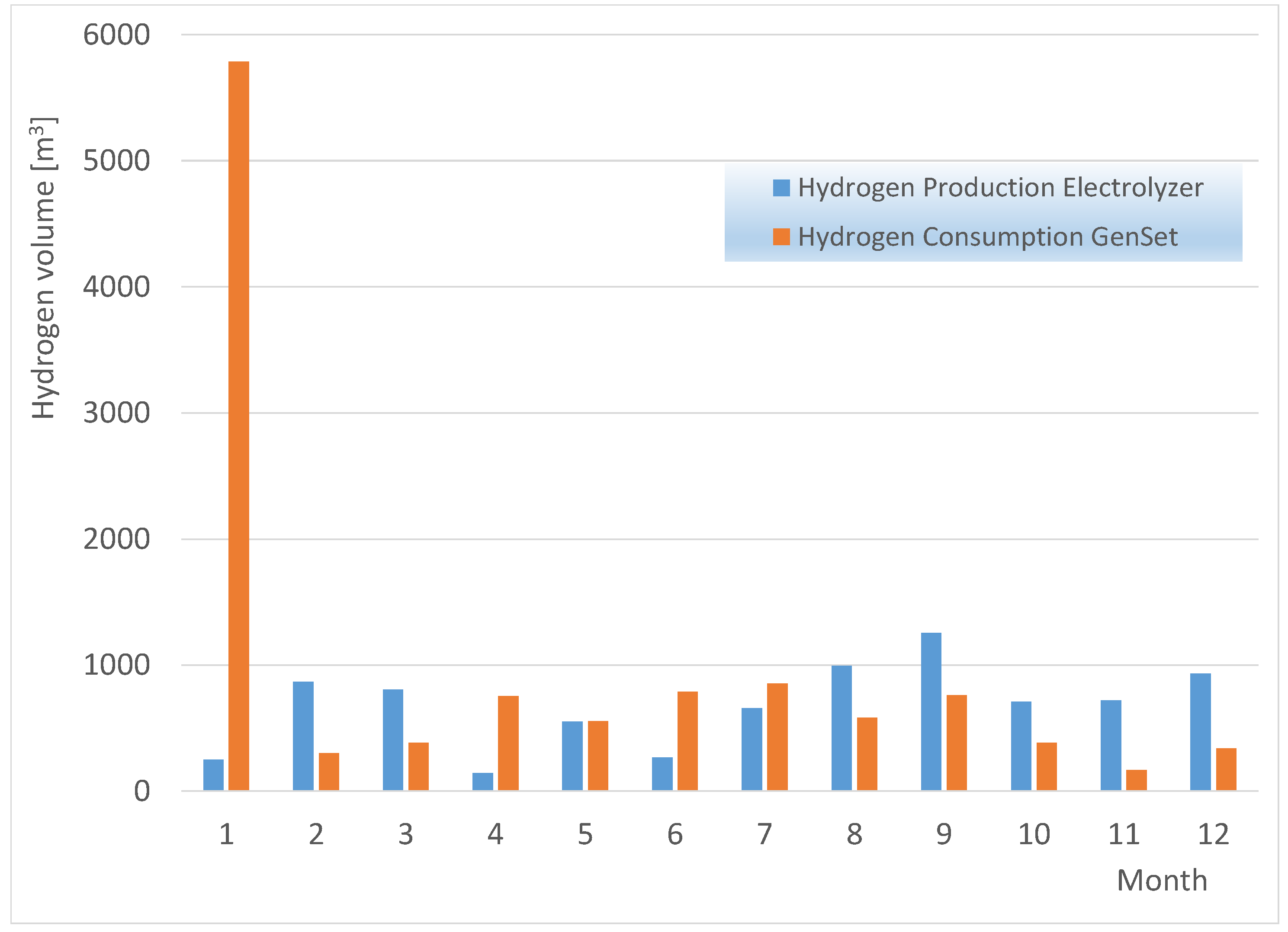

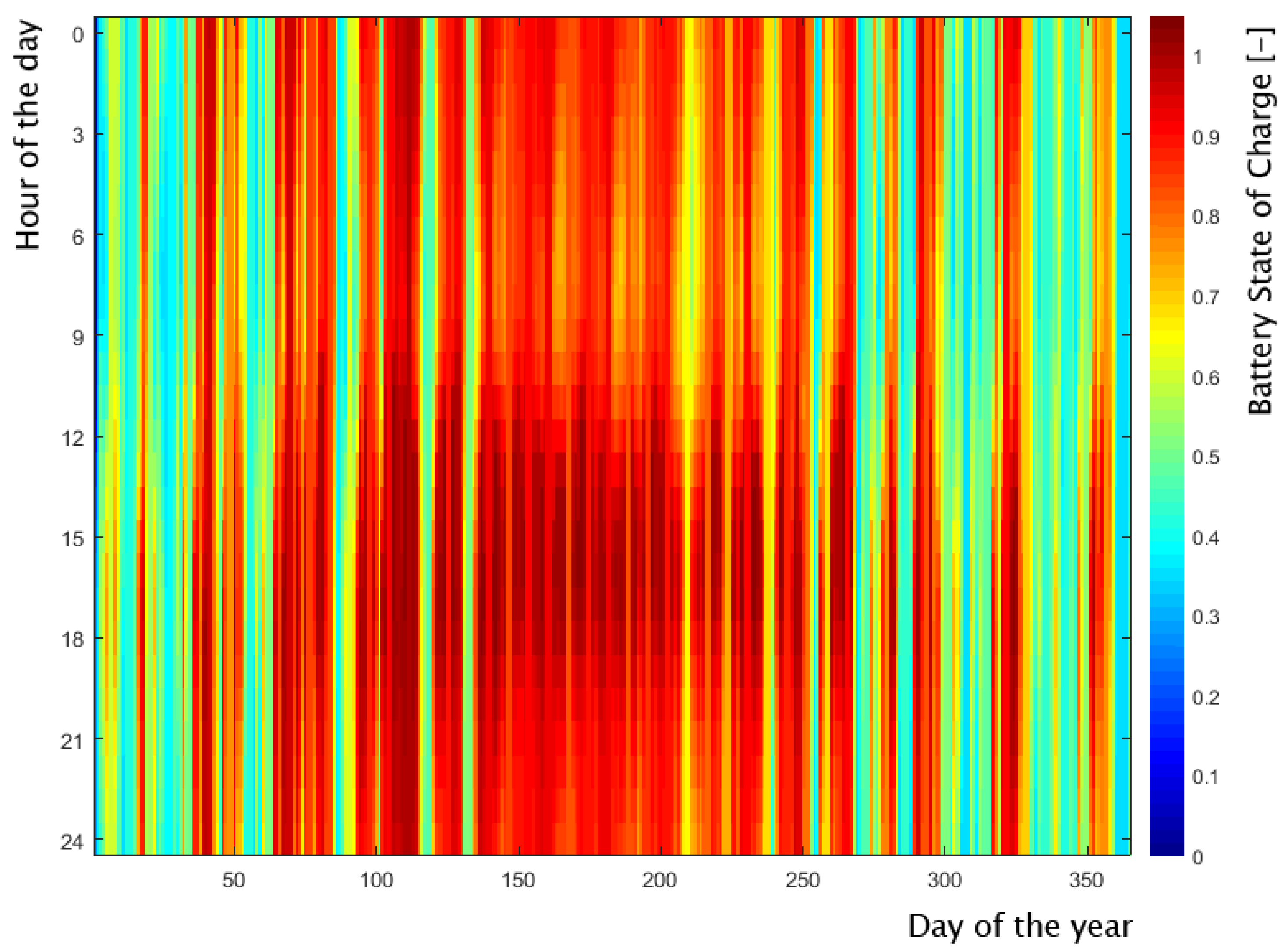

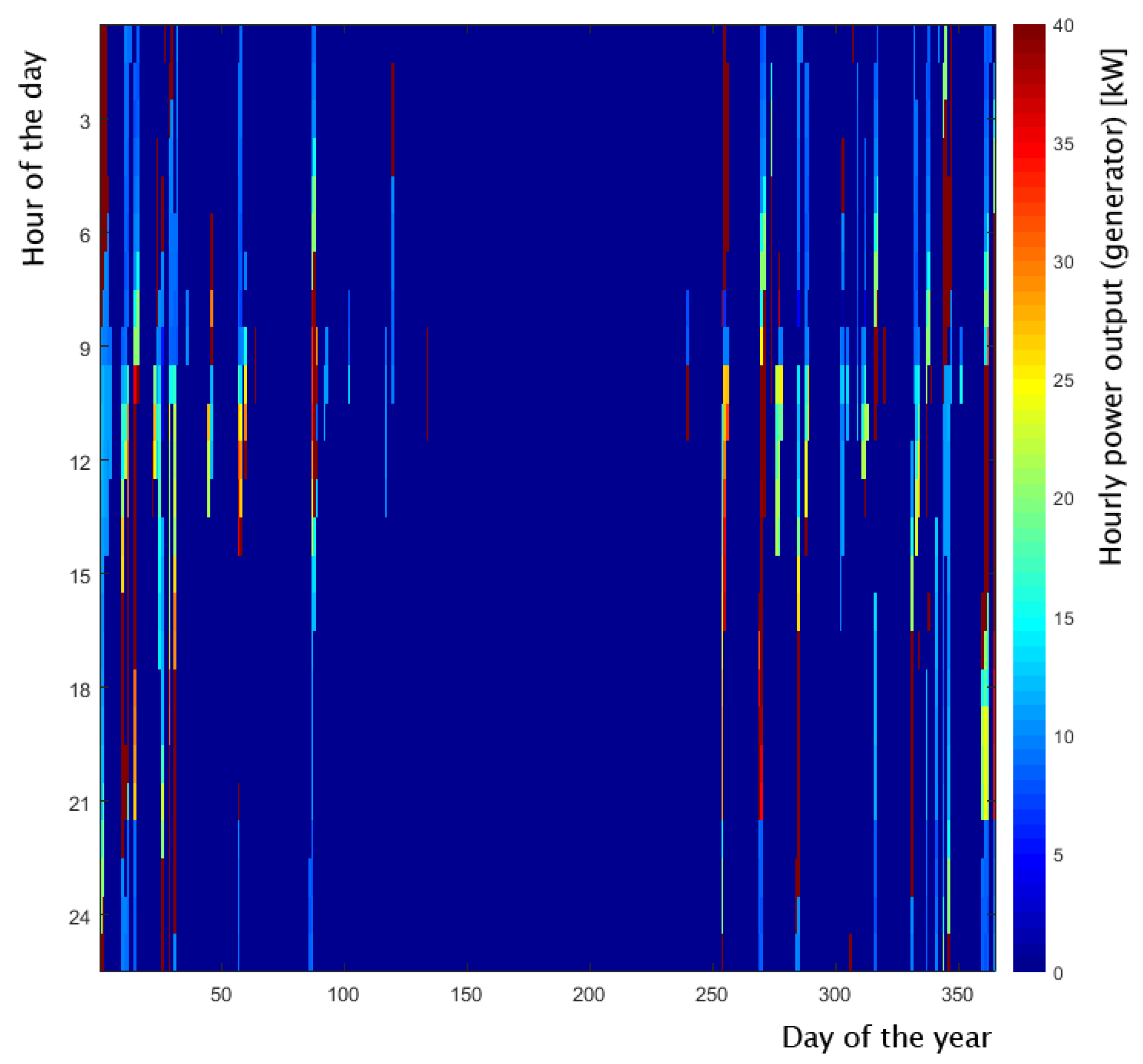

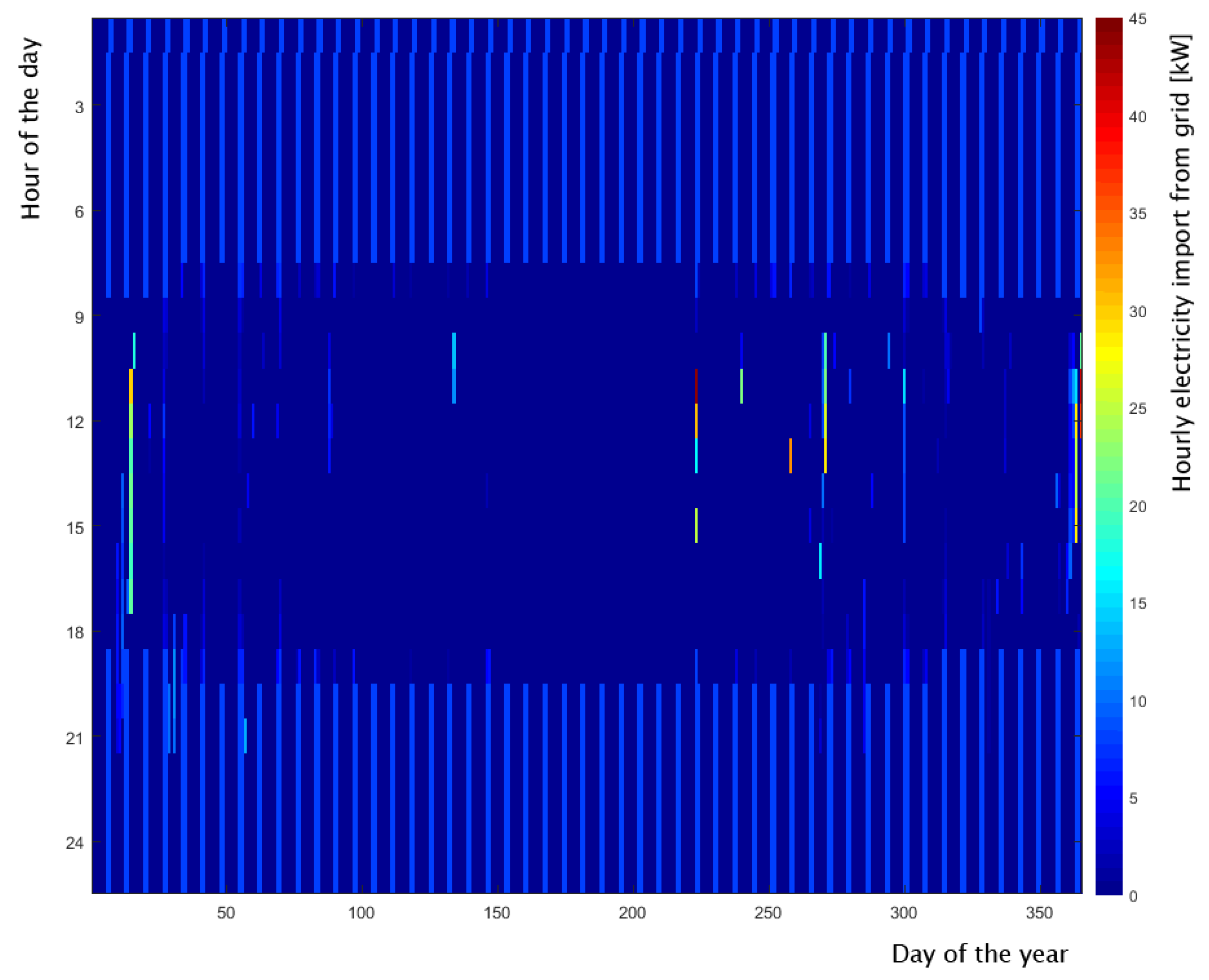

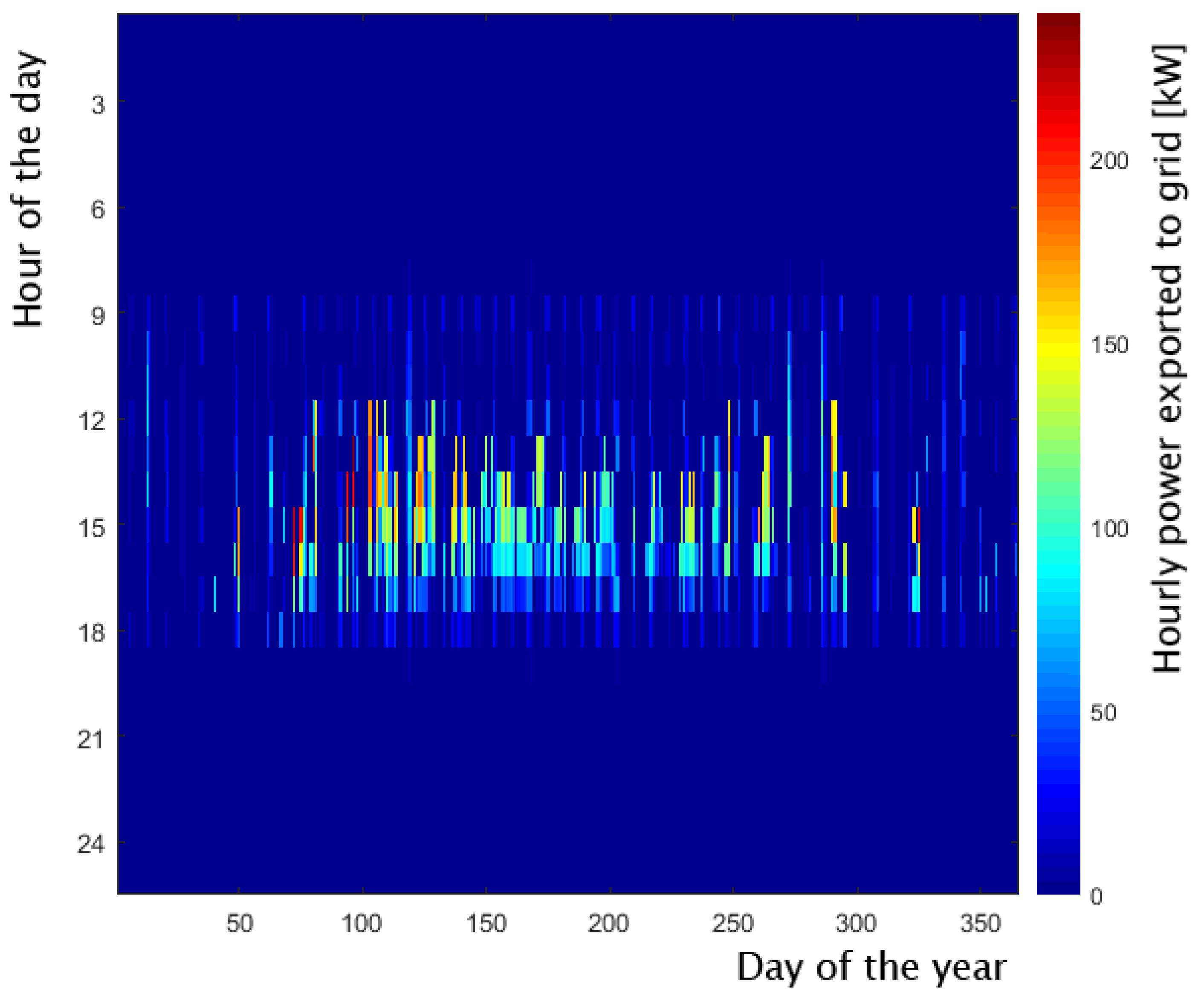

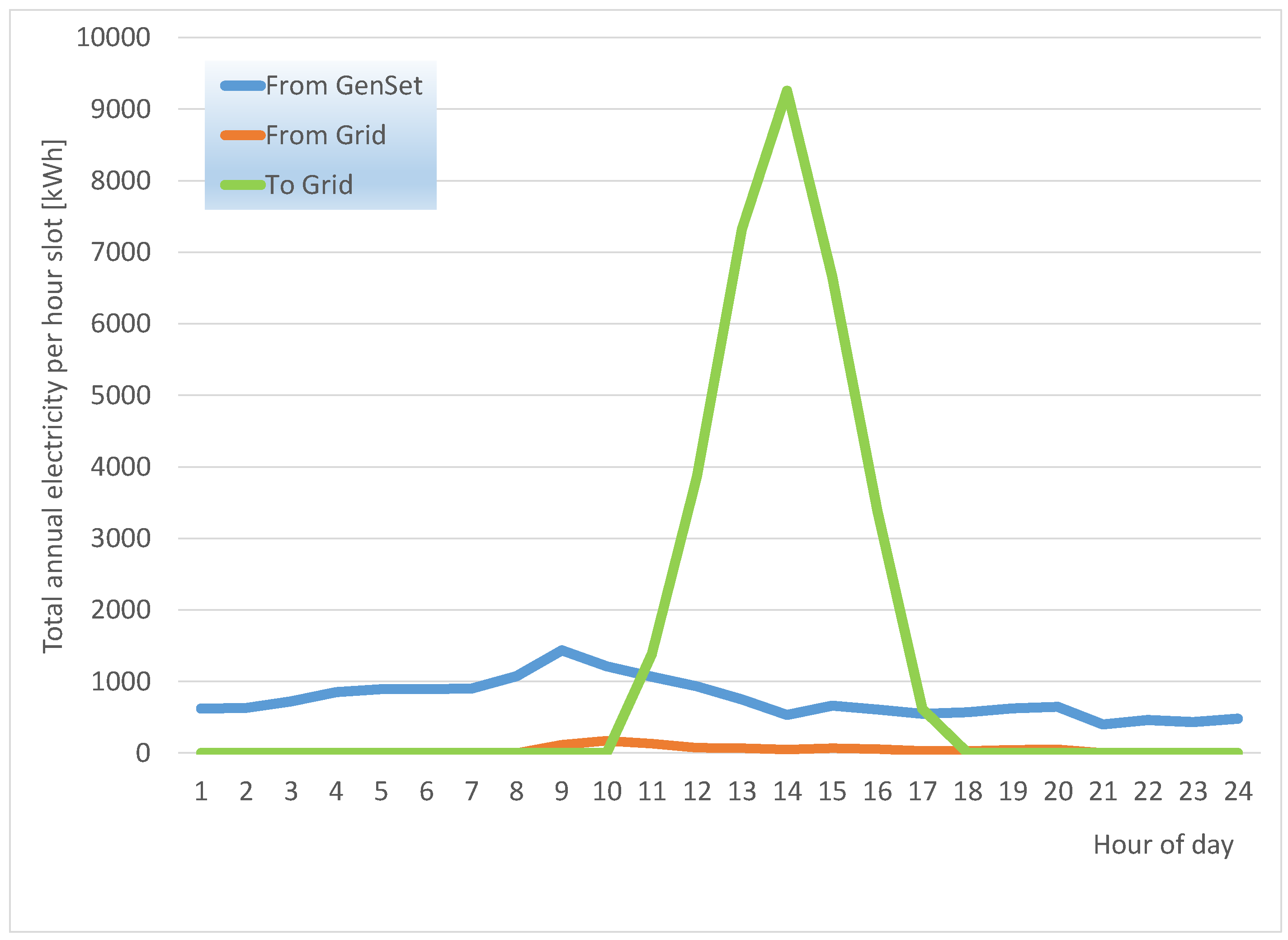

3.1. System’s Performance with Initial Sizing Parameters’ Values

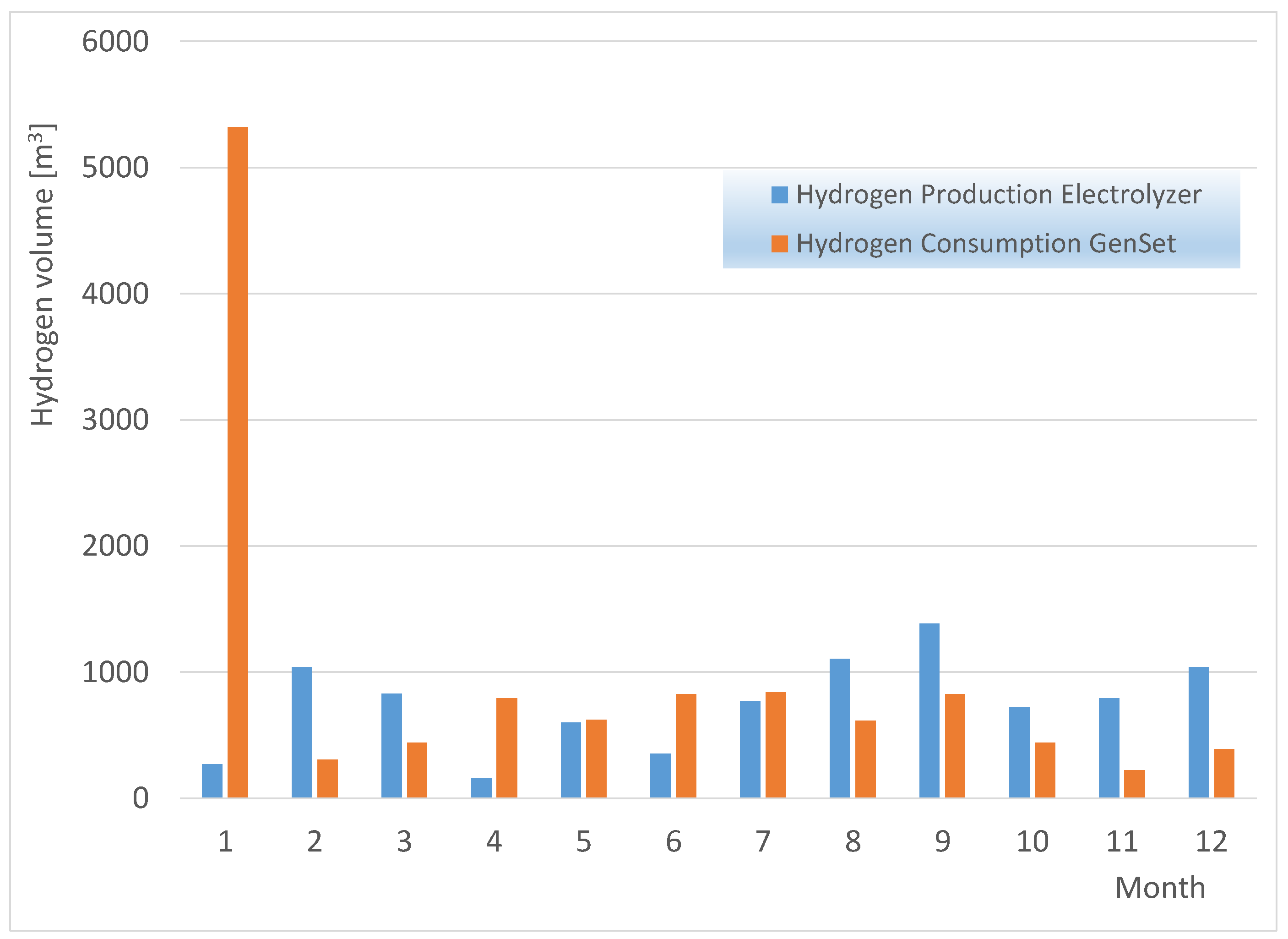

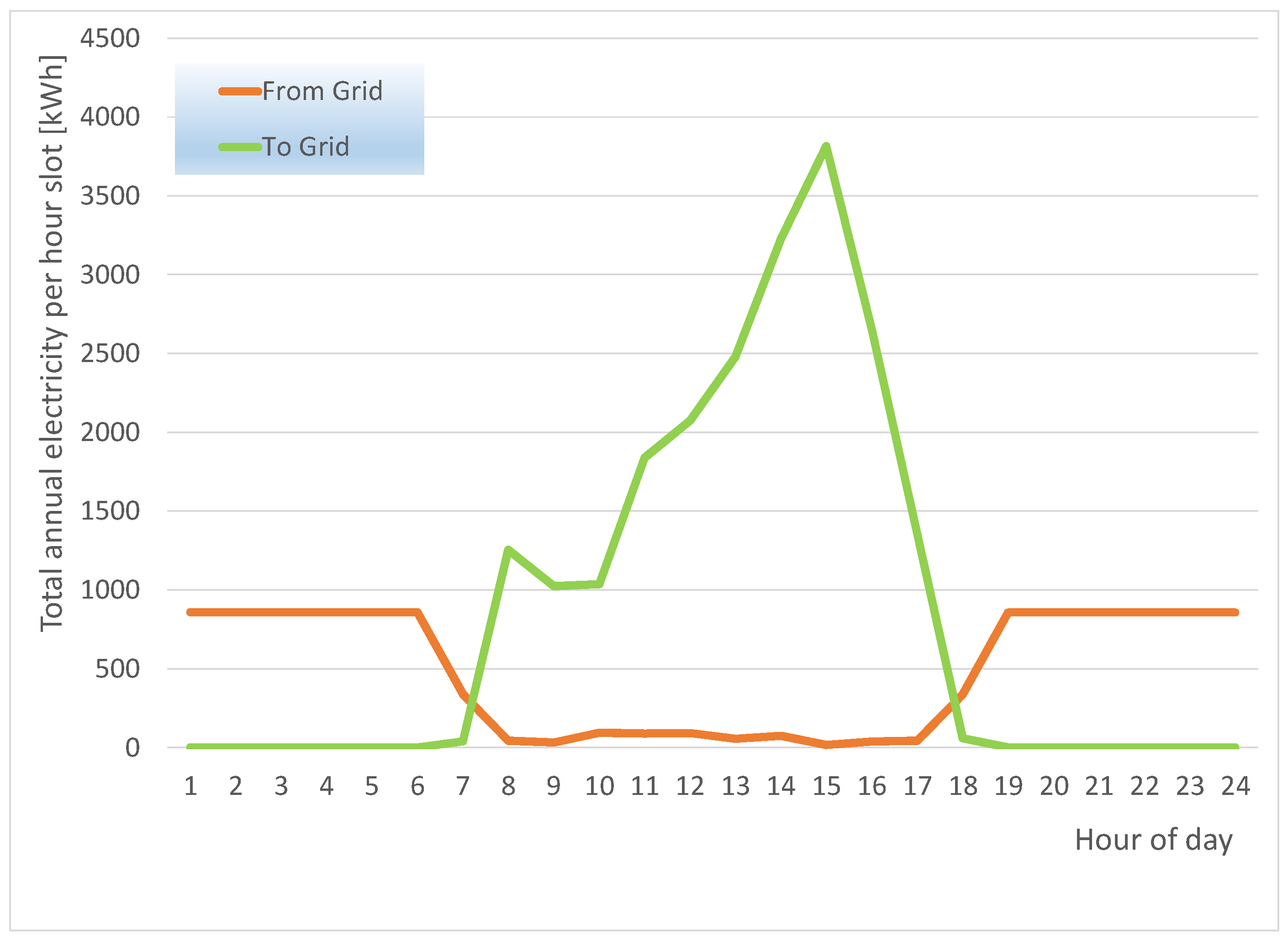

3.2. Component Sizing Parameters’ Optimization Results

- Tilt angle of rooftop photovoltaic panels: 39 degrees;

- Maximum capacity of electrolyzer units: three stacks, 72 kW total peak power;

- Rated power of hydrogen-fueled generator engine: 40 kW.

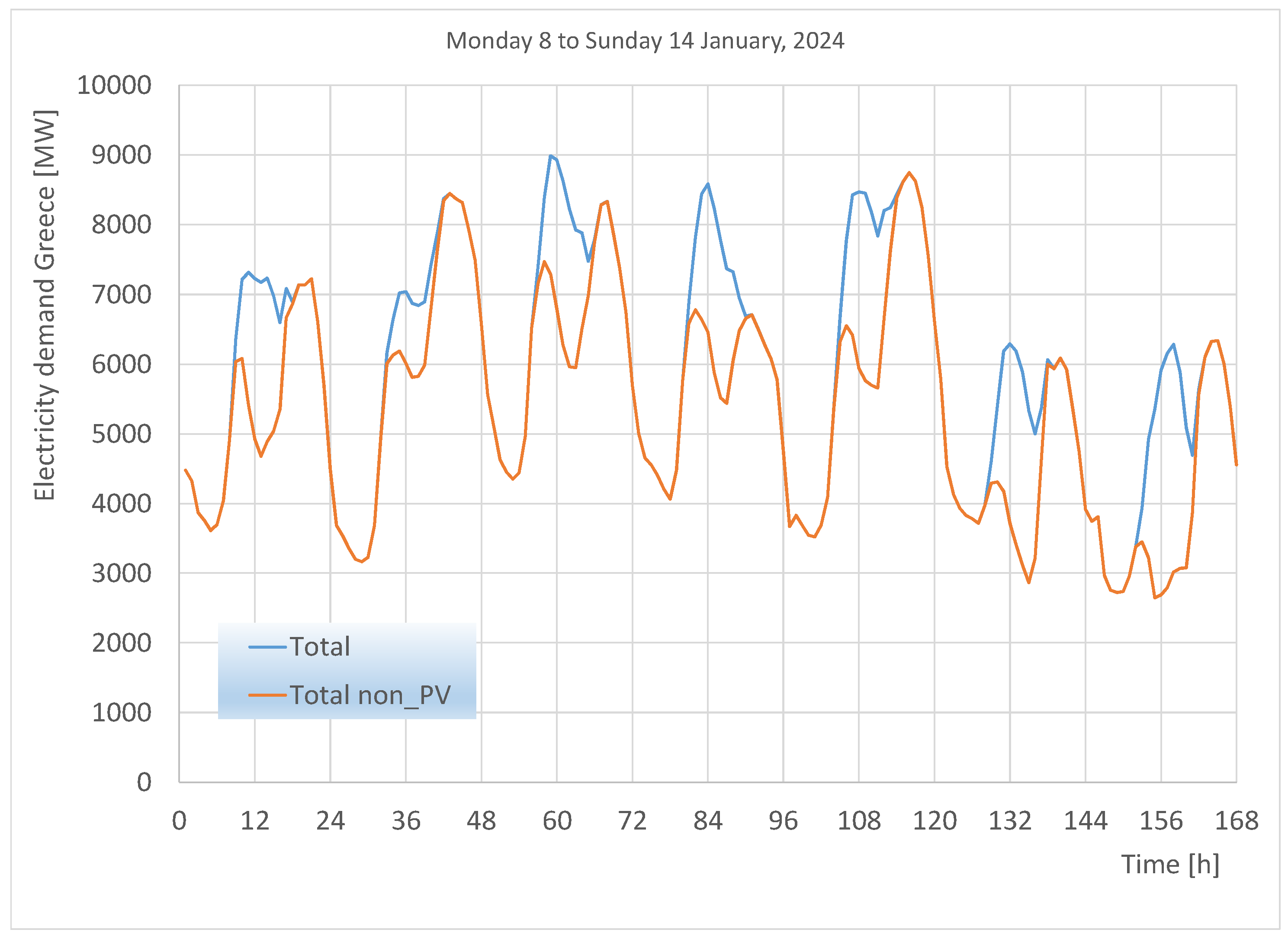

3.3. Cumulative Hourly Distributions of Grid Interaction

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Shell Type | Layers | U (W/m2K) |

|---|---|---|

| Roof insulation | Reinforced concrete slab, extruded polystyrene, lightweight concrete, ceramic tiles | 0.272 |

| Concrete column | Reinforced concrete, extruded polystyrene | 0.324 |

| Outside wall | Ceramic brick, extruded polystyrene, ceramic brick | 0.319 |

| Floor insulation | Reinforced concrete slab, extruded polystyrene | 0.443 |

| Heating Mode: Ground Loop Water Temperature [°C] | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 18.0 | 15.0 | 13.0 | 10.0 | 8.5 | 7.0 | 4.5 | 2.0 | 0.0 | ||||

| kW thermal | 271.4 | 255.4 | 241.9 | 228.8 | 216.0 | 209.7 | 193.2 | 183.0 | 173.0 | |||

| KW | 46.8 | 45.6 | 44.8 | 44 | 43.2 | 42.8 | 42 | 41.6 | 41.2 | |||

| COP | 5.8 | 5.6 | 5.4 | 5.2 | 5 | 4.9 | 4.6 | 4.4 | 4.2 | |||

| Cooling Mode: Ground Loop Water Temperature [°C] | ||||||||||||

| 20 | 25 | 30 | 35 | 40 | 45 | |||||||

| kW thermal | 201.6 | 198.9 | 196.1 | 194.2 | 185.6 | 177.8 | ||||||

| kW | 48 | 51 | 53 | 55.5 | 58 | 63.5 | ||||||

| COP | 4.2 | 3.9 | 3.7 | 3.5 | 3.2 | 2.8 | ||||||

| PV Module Parameter | Value | Comments |

|---|---|---|

| ISC at STC | 13.87 A | Short circuit current |

| VOC at STC | 38.08 V | Open circuit voltage |

| IMPP at STC | 13.18 A | Current at max power point |

| VMPP at STC | 31.49 V | Voltage at max power point |

| Temperature coefficient of ISC (STC) | 0.054%/K | αISC |

| Temperature coefficient of VOC (STC) | −0.262%/K | βVOC |

| Number of cells wired in series | 2 strings × 60 mod. | |

| Module temperature at NOCT | 315.5 K | |

| Ambient temperature at NOCT | 293 K | |

| Module area | 1.95 m2 | |

| Module efficiency | 21.25% |

References

- Zheng, Z.; Shafique, M.; Luo, X.; Wang, S. A systematic review towards integrative energy management of smart grids and urban energy systems. Renew. Sustain. Energy Rev. 2024, 189, 114023. [Google Scholar] [CrossRef]

- Liu, J.; Wu, H.; Huang, H.; Yang, H. Renewable energy design and optimization for a net-zero energy building integrating electric vehicles and battery storage considering grid flexibility. Energy Convers. Manag. 2023, 298, 117768. [Google Scholar] [CrossRef]

- European_Commission. Nearly Zero-Energy Buildings. 2022. Available online: https://energy.ec.europa.eu/topics/energy-efficiency/energy-efficient-buildings/nearly-zero-energy-buildings_en (accessed on 10 March 2024).

- European Commission. COMMISSION RECOMMENDATION (EU) 2016/1318 of 29 July 2016 on Guidelines for the Promotion of Nearly Zero-Energy Buildings and Best Practices to Ensure that, by 2020, All New Buildings Are Nearly Zero-Energy Buildings; Commission of the European Communities, Ed.; Official Journal of the European Union: Brussels, Belgium, 2016. [Google Scholar]

- Sun, C.; Negro, E.; Vezzù, K.; Pagot, G.; Cavinato, G.; Nale, A.; Bang, Y.H.; Di Noto, V. Hybrid inorganic-organic proton-conducting membranes based on SPEEK doped with WO3 nanoparticles for application in vanadium redox flow batteries. Electrochim. Acta 2019, 309, 311–325. [Google Scholar] [CrossRef]

- European Commission. Directive 2010/31/EU of the European Parliament and of the Council of 19 May 2010 on the Energy Performance of Buildings; Official Journal of the European Union: Brussels, Belgium, 2010. [Google Scholar]

- European_Commission. Proposal for a DIRECTIVE OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL on the Energy Performance of Buildings (Recast) COM/2021/802 Final; Office for Official Publications of the European Communities: Luxembourg, 2021. [Google Scholar]

- Stamatellos, G.; Zogou, O.; Stamatelos, A. Energy Analysis of a NZEB Office Building with Rooftop PV Installation: Exploitation of the Employees’ Electric Vehicles Battery Storage. Energies 2022, 15, 6206. Available online: https://www.mdpi.com/1996-1073/15/17/6206 (accessed on 10 March 2024). [CrossRef]

- Nafeh, A.E.S.A.; Omran, A.E.F.A.; Elkholy, A.; Yousef, H.M. Optimal economical sizing of a PV-battery grid-connected system for fast charging station of electric vehicles using modified snake optimization algorithm. Results Eng. 2024, 21, 101965. [Google Scholar] [CrossRef]

- Yan, H.; Zhang, W.; Kang, J.; Yuan, T. The Necessity and Feasibility of Hydrogen Storage for Large-Scale, Long-Term Energy Storage in the New Power System in China. Energies 2023, 16, 4837. [Google Scholar] [CrossRef]

- Jung, J.; Baek, K.; Lee, E.; Ko, W.; Kim, J. Economic Analysis of Special Rate for Renewable Energy Based on the Design of an Optimized Model for Distributed Energy Resource Capacities in Buildings. Energies 2021, 14, 645. [Google Scholar] [CrossRef]

- Shorbila, S.E.A.; Hebala, O.M.; Ashour, H.A. Decarbonization of Net Zero Energy Buildings by an Intelligent Energy Management System for Smart Grids. In Proceedings of the 2022 11th International Conference on Power Science and Engineering (ICPSE), Eskisehir, Turkey, 23–25 September 2022. [Google Scholar]

- Ju, Y.; Jokisalo, J.; Kosonen, R. Peak Shaving of a District Heated Office Building with Short-Term Thermal Energy Storage in Finland. Buildings 2023, 13, 573. [Google Scholar] [CrossRef]

- Seboldt, D.; Mansbart, M.; Grabner, P.; Eichlseder, H. Wasserstoffmotoren für zukünftige Pkw und leichte Nutzfahrzeuge. Mot. Z. 2021, 82, 47–51. [Google Scholar] [CrossRef]

- Chen, Q.; Kuang, Z.; Liu, X.; Zhang, T. Optimal sizing and techno-economic analysis of the hybrid PV-battery-cooling storage system for commercial buildings in China. Appl. Energy 2024, 355, 122231. [Google Scholar] [CrossRef]

- Oussama, H.; Amine, H.M.; Amine, S.M.; Aissa, B.; Abdeselem, C.; Othmane, A. Intelligent Energy Management Strategy For Multi-Sources Isolated DC-Microgrid. In Proceedings of the 2023 Second International Conference on Energy Transition and Security (ICETS), Adrar, Algeria, 12–14 December 2023. [Google Scholar]

- Lee, H.; Kang, J.-W.; Choi, B.-Y.; Kang, K.-M.; Kim, M.-N.; An, C.-G.; Yi, J.; Won, C.-Y. Energy Management System of DC Microgrid in Grid-Connected and Stand-Alone Modes: Control, Operation and Experimental Validation. Energies 2021, 14, 581. [Google Scholar] [CrossRef]

- Bosisio, A.; Morotti, A.; Penati, S.; Berizzi, A.; Pasetti, C.; Iannarelli, G. A feasibility study of using renewable-based hydrogen in off-grid domestic energy systems: A case study in Italy. In Proceedings of the 2022 Second International Conference on Sustainable Mobility Applications, Renewables and Technology (SMART), Virtual, 23–25 November 2022. [Google Scholar]

- Sharshir, S.W.; Joseph, A.; Elsayad, M.M.; Tareemi, A.A.; Kandeal, A.; Elkadeem, M.R. A review of recent advances in alkaline electrolyzer for green hydrogen production: Performance improvement and applications. Int. J. Hydrogen Energy 2024, 49, 458–488. [Google Scholar] [CrossRef]

- Abdolmaleki, L.; Berardi, U. Dynamic simulation of a hydrogen-fueled system for zero-energy buildings using TRNSYS software. In Proceedings of the IAQVEC2023 E3S Web of Conferences, Tokyo, Japan, 20–23 May 2023. [Google Scholar]

- Siebel, T. Druck im Wasserstofftank. Mot. Z. 2021, 82, 8–12. [Google Scholar]

- Razmara, M.; Bharati, G.R.; Shahbakhti, M.; Paudyal, S.; Robinett, R.D. Bilevel Optimization Framework for Smart Building-to-Grid Systems. IEEE Trans. Smart Grid 2018, 9, 582–593. [Google Scholar] [CrossRef]

- Zhang, J.; Jiang, Q.; Pan, A.; Li, T.; Liu, Z.; Zhang, Y.; Jiang, L.; Zhan, X. An Optimal Dispatching Strategy for Charging and Discharging of Electric Vehicles Based on Cloud-Edge Collaboration. In Proceedings of the 2021 3rd Asia Energy and Electrical Engineering Symposium (AEEES), Chengdu, China, 26–29 March 2021. [Google Scholar]

- Song, K.; Lan, Y.; Zhang, X.; Jiang, J.; Sun, C.; Yang, G.; Yang, F.; Lan, H. A Review on Interoperability of Wireless Charging Systems for Electric Vehicles. Energies 2023, 16, 1653. [Google Scholar] [CrossRef]

- Dreisbusch, M.; Mang, S.; Ried, S.; Kellerer, F.; Pfab, X. Regulation of Grid-efficient Charging from the User’s Perspective. MTZ Worldw. 2020, 81, 66–70. [Google Scholar] [CrossRef]

- Engel, H.; Hensley, R.; Knupfer, S.; Sahdev, S. The Potential Impact of Electric Vehicles on Global Energy Systems; McKinsey Center for Future Mobility: Milpitas, CA, USA, 2018. [Google Scholar]

- Thomas, D.; Deblecker, O.; Ioakimidis, C.S. Optimal operation of an energy management system for a grid-connected smart building considering photovoltaics’ uncertainty and stochastic electric vehicles’ driving schedule. Appl. Energy 2018, 210, 1188–1206. [Google Scholar] [CrossRef]

- Fachrizal, R.; Shepero, M.; Åberg, M.; Munkhammar, J. Optimal PV-EV sizing at solar powered workplace charging stations with smart charging schemes considering self-consumption and self-sufficiency balance. Appl. Energy 2021, 307, 118139. [Google Scholar] [CrossRef]

- Pyloudi, E.; Papantoniou, S.; Kolokotsa, D. Retrofitting an office building towards a net zero energy building. Adv. Build. Energy Res. 2015, 9, 20–33. [Google Scholar] [CrossRef]

- Karlessi, T.; Kampelis, N.; Kolokotsa, D.; Santamouris, M.; Standardi, L.; Isidori, D.; Cristalli, C. The Concept of Smart and NZEB Buildings and the Integrated Design Approach. Procedia Eng. 2017, 180, 1316–1325. [Google Scholar] [CrossRef]

- Wang, B.; Yu, X.; Xu, H.; Wu, Q.; Wang, L.; Huang, R.; Li, Z.; Zhou, Q. Scenario analysis, management, and optimization of a new Vehicle-to-Micro-Grid (V2μG) network based on off-grid renewable building energy systems. Appl. Energy 2022, 325, 119873. [Google Scholar] [CrossRef]

- Hossain, J.; Shareef, H.; Hossain, A.; Kalam, A.; Kadir, A.F.A. Hybrid PV and Battery System Sizing for Commercial Buildings in Malaysia: A Case Study of FKE-2 Building in UTeM. IEEE Trans. Ind. Appl. 2024, 1–14. [Google Scholar] [CrossRef]

- Go, J.; Byun, J.; Orehounig, K.; Heo, Y. Battery-H2 storage system for self-sufficiency in residential buildings under different electric heating system scenarios. Appl. Energy 2023, 337, 120742. [Google Scholar] [CrossRef]

- Hai, T.; Ali, M.A.; Dhahad, H.A.; Alizadeh, A.; Sharma, A.; Almojil, S.F.; Almohana, A.I.; Alali, A.F.; Wang, D. Optimal design and transient simulation next to environmental consideration of net-zero energy buildings with green hydrogen production and energy storage system. Fuel 2023, 336, 127126. [Google Scholar] [CrossRef]

- Mohammadi, Z.; Ahmadi, P.; Ashjaee, M. Comparative transient assessment and optimization of battery and hydrogen energy storage systems for near-zero energy buildings. Renew. Energy 2024, 220, 119680. [Google Scholar] [CrossRef]

- Hassan, Q.; Azzawi, I.D.J.; Sameen, A.Z.; Salman, H.M. Hydrogen Fuel Cell Vehicles: Opportunities and Challenges. Sustainability 2023, 15, 11501. [Google Scholar] [CrossRef]

- Ascione, F.; Festa, V.; Manniti, G.; Ruggiero, S.; Tariello, F.; Vanoli, G.P. H2 micro-cogeneration in buildings: From nZEBs to HZEBs. State of Art, with a novel experimental set-up. In Proceedings of the 2023 8th International Conference on Smart and Sustainable Technologies (SpliTech), Split/Bol, Croatia, 20–23 June 2023. [Google Scholar]

- Yang, Z.; Wang, B.; Jiao, K. Life cycle assessment of fuel cell, electric and internal combustion engine vehicles under different fuel scenarios and driving mileages in China. Energy 2020, 198, 117365. [Google Scholar] [CrossRef]

- Sinigaglia, T.; Martins, M.E.S.; Siluk, J.C.M. Technological forecasting for fuel cell electric vehicle: A comparison with electric vehicles and internal combustion engine vehicles. World Pat. Inf. 2022, 71, 102152. [Google Scholar] [CrossRef]

- Stamatellos, G.; Stamatelos, T. Study of an nZEB Office Building with Storage in Electric Vehicle Batteries and Dispatch of a Natural Gas-Fuelled Generator. Energies 2023, 16, 3195. [Google Scholar] [CrossRef]

- SEL. TRNSYS 16 Manual; Solar Energy Laboratory, University of Wisconsin-Madison: Madison, WI, USA, 2005. [Google Scholar]

- Neymark, J.; Judkoff, R.; Knabe, G.; Le, H.-T.; Dürig, M.; Glass, A.; Zweifel, G. Applying the building energy simulation test (BESTEST) diagnostic method to verification of space conditioning equipment models used in whole-building energy simulation programs. Energy Build. 2002, 34, 917–931. [Google Scholar] [CrossRef]

- IEEE. IEEE Standard for Technical Specifications of a DC Quick and Bidirectional Charger for Use with Electric Vehicles-Redline; IEEE Std 2030.1.1-2021 (Revision of IEEE Std 2030.1.1-2015)-Redline; IEEE: Piscataway, NJ, USA, 2022; pp. 1–263. [Google Scholar]

- Thermal Energy Systems Specialists. T.E.S.S. Component Libraries for TRNSYS, Version 2.0. User’s Manual; T.E.S.S.: Madison, WI, USA, 2004; Available online: http://www.tess-inc.com/services/software (accessed on 10 March 2024).

- Sharp. 415Wp/Mono NUJC415 Data Sheet; Sharp, Japan 2023. Available online: https://docs.aws.sharp.eu/Marketing/Datasheet/2208_NUJC_415_HC-Mono_Datasheet_EN.pdf (accessed on 10 March 2024).

- De Soto, W.; Klein, S.A.; Beckman, W.A. Improvement and validation of a model for photovoltaic array performance. Sol. Energy 2006, 80, 78–88. [Google Scholar] [CrossRef]

- Stamatellos, G.; Zogou, O.; Stamatelos, A. Interaction of a House’s Rooftop PV System with an Electric Vehicle’s Battery Storage and Air Source Heat Pump. Solar 2022, 2, 186–214. [Google Scholar] [CrossRef]

- Hussein, A.A.; Batarseh, I. An overview of generic battery models. In Proceedings of the 2011 IEEE Power and Energy Society General Meeting, Detroit, MI, USA, 24–29 July 2011. [Google Scholar]

- Ulleberg, Ø. Stand-Alone Power Systems for the Future: Optimal Design, Operation and Control of Solar-Hydrogen Energy Systems. Ph.D. Thesis, Norges Teknisk-Naturvitenskapelige Universitet, Trondheim, Norway, 1998. [Google Scholar]

- Ulleberg, Ø. Modeling of advanced alkaline electrolyzers: A system simulation approach. Int. J. Hydrogen Energy 2003, 28, 21–33. [Google Scholar] [CrossRef]

- Sundén, B. Chapter 6-Thermal management of batteries. In Hydrogen, Batteries and Fuel Cells; Sundén, B., Ed.; Academic Press: Cambridge, MA, USA, 2019; pp. 93–110. [Google Scholar]

- Zhang, H.; Sun, C. Cost-effective iron-based aqueous redox flow batteries for large-scale energy storage application: A review. J. Power Sources 2021, 493, 229445. [Google Scholar] [CrossRef]

- Dudkina, E.; Villar, J.; Bessa, R.J.; Crisostomi, E. The Role of Batteries in Maximizing Green Hydrogen Production with Power Flow Tracing. In Proceedings of the 2024 4th International Conference on Smart Grid and Renewable Energy (SGRE), Doha, Qatar, 8–10 January 2024. [Google Scholar]

- Kojima, H.; Nagasawa, K.; Todoroki, N.; Ito, Y.; Matsui, T.; Nakajima, R. Influence of renewable energy power fluctuations on water electrolysis for green hydrogen production. Int. J. Hydrog. Energy 2023, 48, 4572–4593. [Google Scholar] [CrossRef]

- EN 16798-1:2019; Energy Performance of Buildings-Ventilation for Buildings-Part 1: Indoor Environmental Input Parameters for Design and Assessment of Energy Performance of Buildings Addressing Indoor Air Quality, Thermal Environment, Lighting and Acoustics. European Committee for Standardization CEN: Brussels, Belgium, 2019.

| Engine Type | In Line, 4 Cylinder, 4-Stroke SI, Turbocharged |

|---|---|

| Engine displacement | 2.0 dm3 |

| Compression ratio | 9.8 |

| Injection system | H2 direct injection |

| Ignition system | Series production ignition coils, cold spark plugs |

| Cam phasing | Hydraulic cam phasers for inlet/exhaust valves |

| Rated torque | 382 Nm @3000 rpm (bmep = 24 bar@3000 rpm) |

| Rate power | 140 kW@6000 rpm |

| Rated power for genset operation | 120 kW@3000 rpm |

| Optimization Variable | MIN | MAX | STEP | Units |

|---|---|---|---|---|

| PV panels’ tilt angle | 20 | 50 | 1 | deg |

| Number of electrolyzer stacks | 2 | 5 | 1 | [-] |

| Rated power of genset | 20 | 80 | 5 | kW |

| Optimization Variable | Initial Value | Optimized | Units |

|---|---|---|---|

| Annual electricity consumption | 117,000 | 116,000 | kWh |

| Annual net hydrogen consumption | 3490 | 2580 | Nm3 |

| Annual primary energy consumption | 61.7 | 60.6 | kWh/m2y |

| Annual PV electricity production | 329,000 | 322,000 | kWh |

| Annual electricity production, genset | 19,400 | 17,900 | kWh |

| Annual electricity imported from grid | 11,800 | 12,400 | kWh |

| Annual electricity exported to grid | 62,200 | 53,300 | kWh |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stamatellos, G.; Stamatellou, A.-M. The Interaction between Short- and Long-Term Energy Storage in an nZEB Office Building. Energies 2024, 17, 1441. https://doi.org/10.3390/en17061441

Stamatellos G, Stamatellou A-M. The Interaction between Short- and Long-Term Energy Storage in an nZEB Office Building. Energies. 2024; 17(6):1441. https://doi.org/10.3390/en17061441

Chicago/Turabian StyleStamatellos, George, and Antiopi-Malvina Stamatellou. 2024. "The Interaction between Short- and Long-Term Energy Storage in an nZEB Office Building" Energies 17, no. 6: 1441. https://doi.org/10.3390/en17061441

APA StyleStamatellos, G., & Stamatellou, A.-M. (2024). The Interaction between Short- and Long-Term Energy Storage in an nZEB Office Building. Energies, 17(6), 1441. https://doi.org/10.3390/en17061441