Conditions That Determine Changing the Function of Mine Shafts in a Gassy Coal Mine—A Case Study

Abstract

1. Introduction

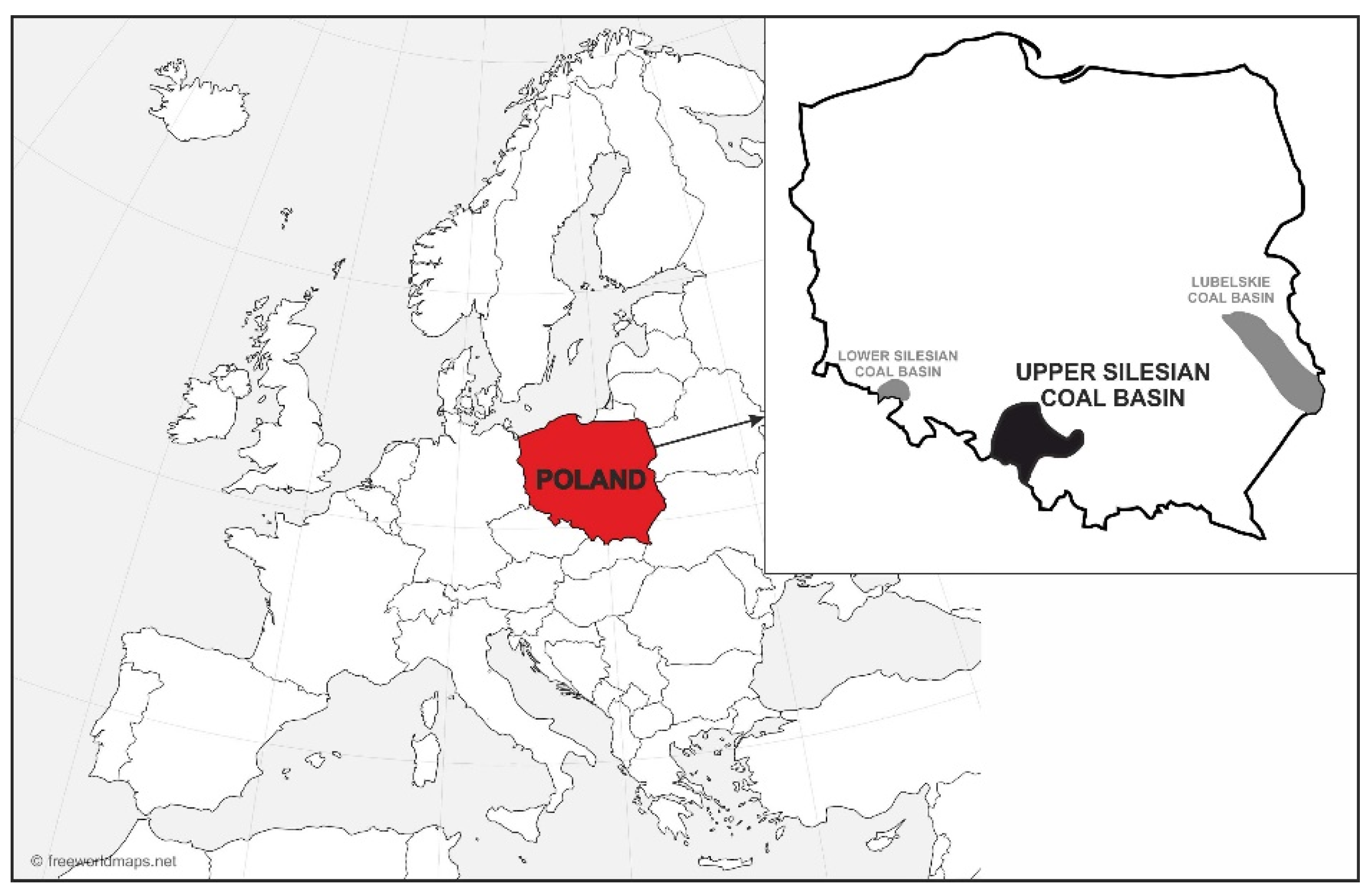

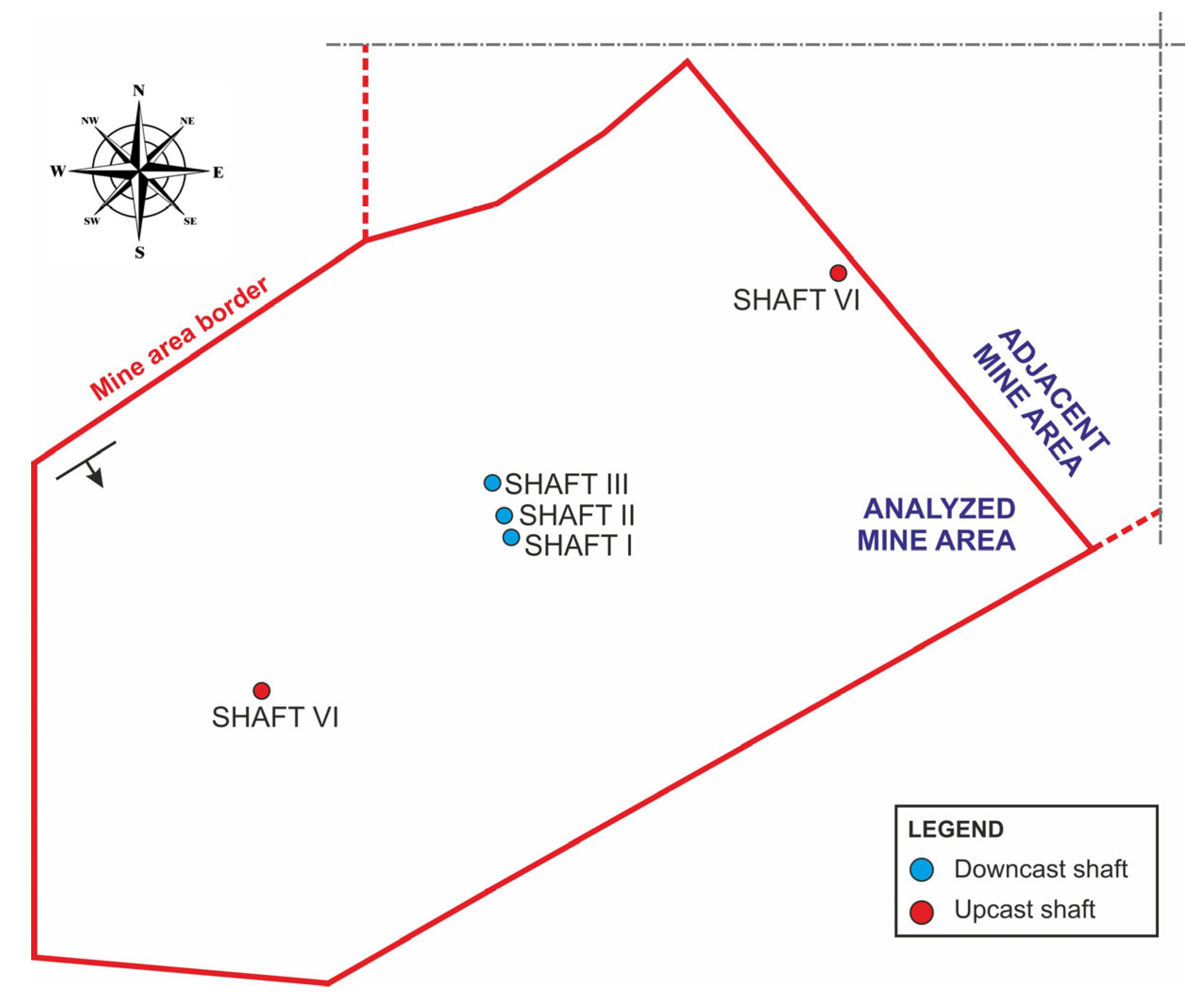

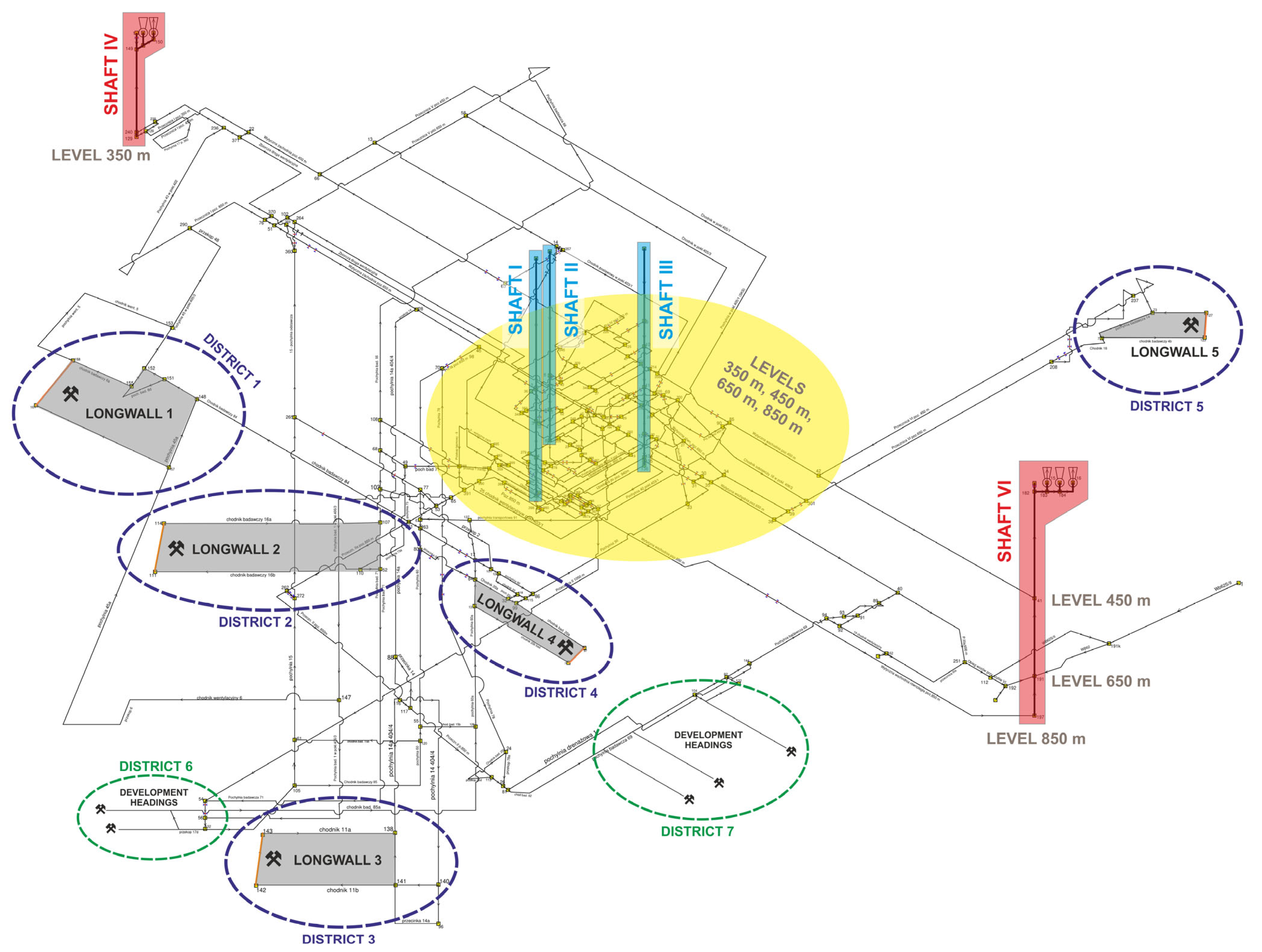

2. The Characteristics of the Mine

2.1. General Information

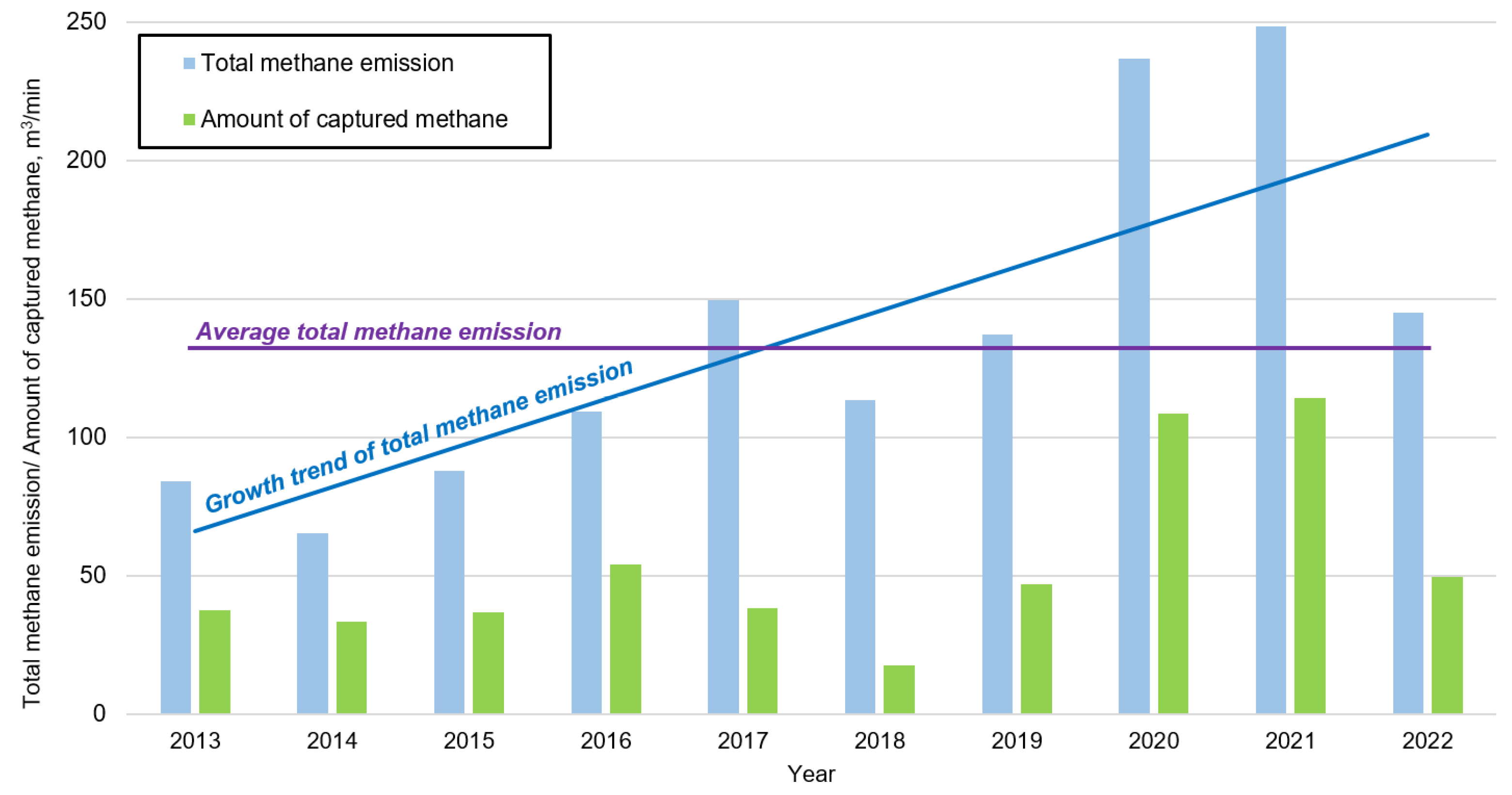

2.2. The Characteristics of Natural Hazards

- Outbursts of gas and rocks—categories II and III (there are three categories and III is the highest category);

- Dust coal explosion—class B (there are two classes and B is the highest class);

- Endogenous fire hazard—groups I and II of spontaneous combustion of coal (I and II are the lowest spontaneous combustion groups in the five-level classification);

- Climate hazard—the average virgin rock temperature is:

- ○

- Level 450 m—26.4 degrees of Celsius;

- ○

- Level 650 m—27.2 degrees of Celsius;

- ○

- Level 850 m—32.4 degrees of Celsius;

- ○

- Level 1050 m—39.7 degrees of Celsius;

- Water hazard—I and II degrees (there are three degrees and Idegree I is the lowest level—water inflow depends on the part of the deposit);

- Rockburst hazard—I and II degrees (there are two degrees—the level of rockburst hazard depends on mining depth and part of the deposit).

3. The Numerical Model of the Ventilation Network

3.1. Research Background

3.2. The Mapping of the Structure of the Mine Ventilation Network

- Atmospheric pressure at the nodes of the mine ventilation network;

- Dry bulb temperature and relative humidity of air;

- Air flow rate in the branches of the ventilation network.

4. An Analysis of Airflow Distribution in the Network before Modifications

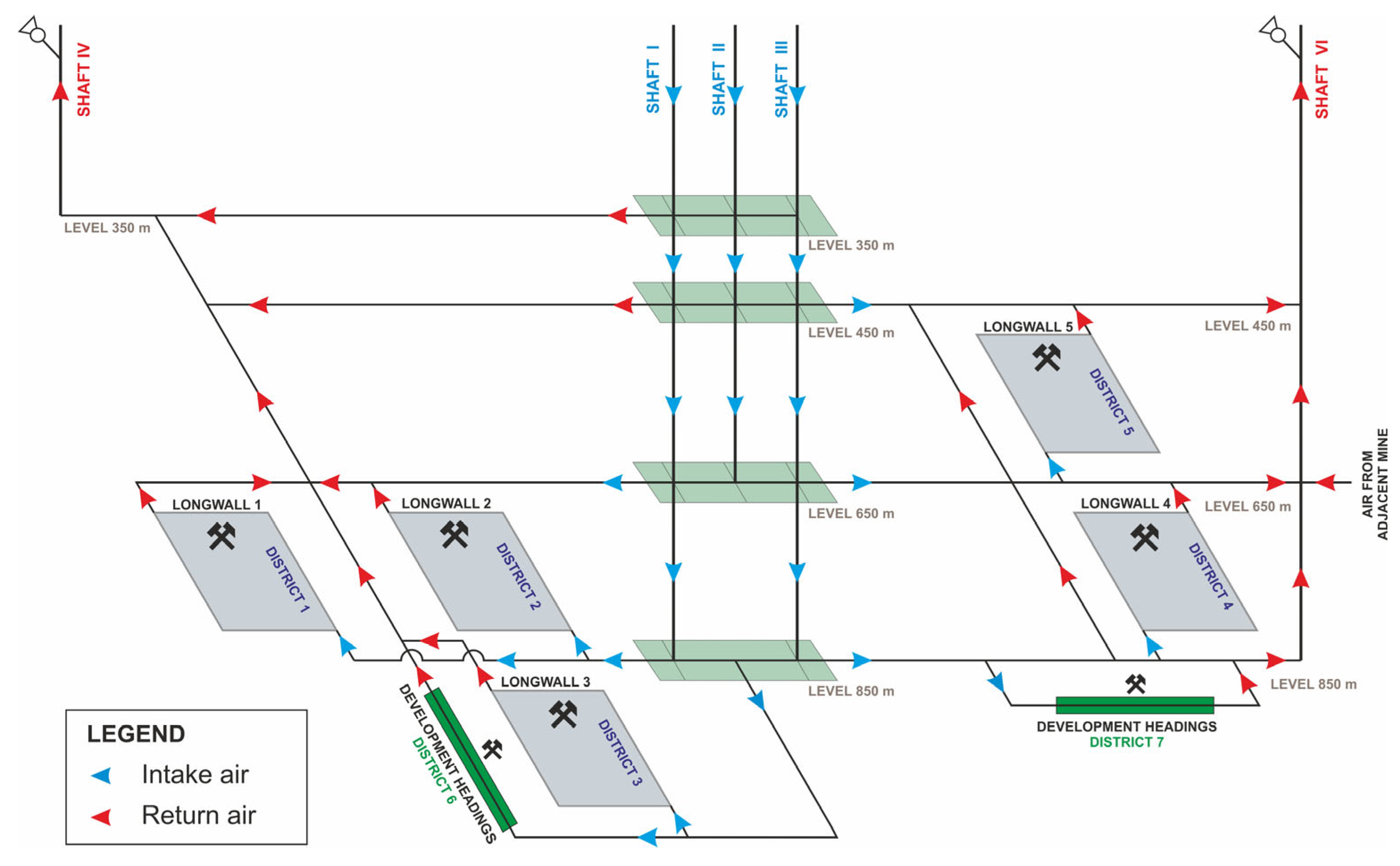

4.1. Air Flow Distribution

4.2. Conclusions Concerning the Present Situation

5. An Analysis of the Planned Modifications to the Ventilation Network

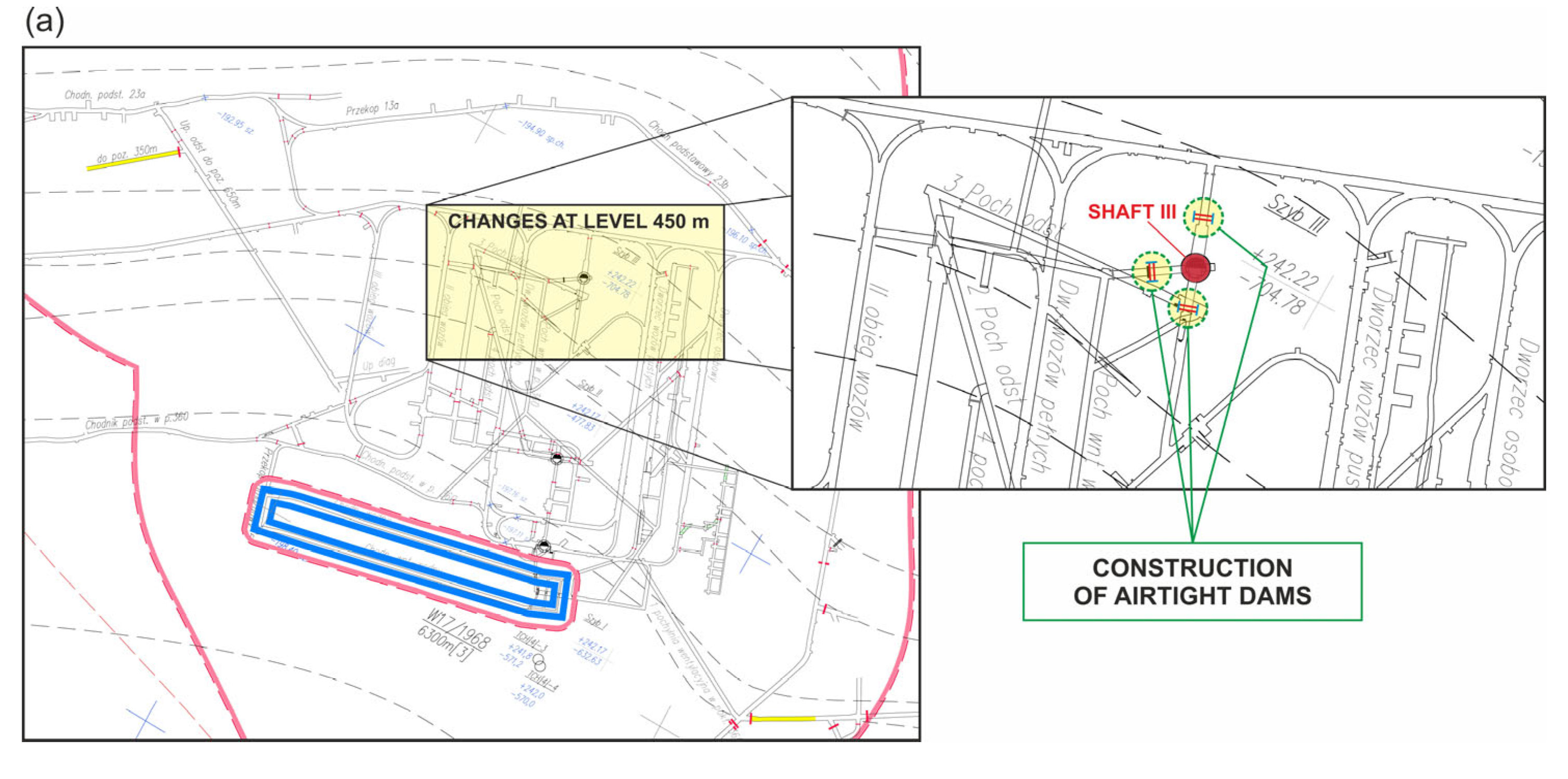

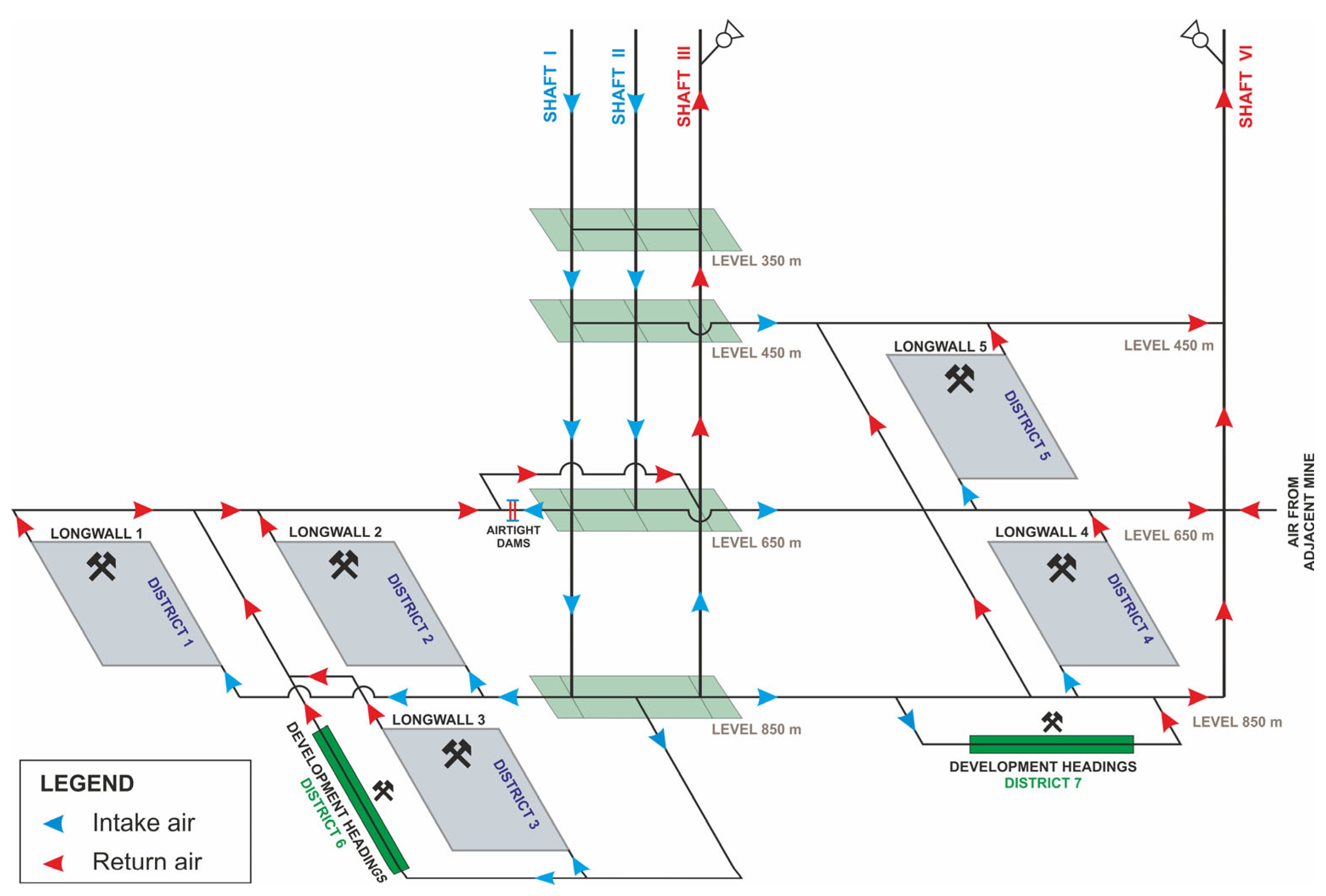

5.1. The Scope of the Planned Modifications

5.2. Possible Equipment of the Shaft after Conversion to an Upcast Shaft

- Solution 1—removing all shaft hoisting (only the ventilation function of Shaft III is retained);

- Solution 2—converting the shaft hoisting from skip hoisting to cage hoisting for transporting long elements, and the removal of skip hoisting from the second compartment;

- Solution 3—the removal of skip hoisting from one of the compartments and converting the shaft hoisting in the other compartment to the functions of transporting both the personnel and the output (cages combined with skips);

- Solution 4—leaving the skips in both compartments of the shaft.

5.3. An Analysis of the Calculated Values

6. Results Discussion

- Despite closing Shaft IV, it was possible to achieve a higher intake air flow rate (depending on the analyzed solution it could be about 9÷13% higher intake air flow) by creating additional connections to the converted shaft and selecting an adequate primary fan;

- Following modifications to the structure of air flow distribution, caused by the necessity to allocate ventilation routes for return air, in the area of Shaft III losses of air from the ventilation network increased (in solution 4, the least favorable solution, they reached almost 48%);

- Losses of air in the network depend to a large extent on the assumed technical function of Shaft III, which is connected with the airtightness of the dams installed there to separate the flows of the supply and the return air. The most favorable option is to use Shaft III solely for ventilation (without hoisting to transport materials and personnel or to deliver coal output to the surface);

- Finally, the analysis proved that closing one of the shafts might cause a small reduction in the air flow through districts with mining activity (solution 1). In the case discussed here, the supply air flow to the longwall mining districts decreased by less than 6%; if development mining districts are taken into account, the decrease in air flow is almost 12%. Such drops in the intensity of ventilation are acceptable in the analyzed mine, given the existing and forecasted methane hazard;

- Closing Shaft IV releases the deposit bound in the pillar of the shaft. The deposit has already been made accessible due to mining works, which is economically advantageous.

7. Conclusions

- In the decision to convert a downcast shaft into an upcast shaft, the following criteria need to be considered: the current functions of the shaft, the possibility of providing return air ventilation routes to the shaft, and the possibility of installing primary fans in the vicinity of the shaft;

- The benefits of closing a ventilation shaft may include releasing a deposit located in the shaft area. Decisive factors in selecting the shaft to be closed may be its technical condition or relative insignificance for future extraction;

- An analysis of hazards present in a given mine, especially methane hazards, should be conducted with respect to the forecasts of the required intensity of ventilation needed during future extraction. In the example analyzed here, despite the possibility of increasing the air flow rate in the ventilation network, the modifications caused a decrease in the amount of air flow supplied to the areas with mining activity.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| number of independent junctions | |

| number of all independent junctions | |

| number of independent ventilation branches | |

| number of all branches | |

| character-oriented constant of the junction-branch matrix of the network | |

| character-oriented constant of a mesh-branch matrix of a network | |

| number of the fundamental mesh of the network | |

| number of all fundamental meshes | |

| sum of frictional pressure drop and shock pressure losses in a branch , Pa | |

| sum of the increase in total pressure across the fan, Pa | |

| natural ventilation pressure gain in branch , Pa | |

| volumetric flow rate of air in branch , m3/s | |

| equivalent resistance of branch i, (N·s2)/m8 | |

| positive or negative value depending on the air flow direction within ith branch to the direction defined for the mesh | |

| mesh in which all air flows in branches are replaced by air flow of a basic branch | |

| character-oriented constant of a transpose of a mesh-branch matrix of the network, for replacing air flows in branches by air flows in basic branches | |

| iteration step |

References

- De Souza, E. Optimization of complex mine ventilation systems with computer network modelling. IFAC Proc. 2007, 40, 323–329. [Google Scholar] [CrossRef]

- Wei, G. Optimization of Mine Ventilation System Based on Bionics Algorithm. Procedia Eng. 2011, 26, 1614–1619. [Google Scholar] [CrossRef]

- Feng, W.; Zhu, F.; Lv, H. The Use of 3D Simulation System in Mine Ventilation Management. Procedia Eng. 2011, 26, 1370–1379. [Google Scholar] [CrossRef]

- Shen, Y.; Wang, H. Study and Application on Simulation and Optimization System for the Mine Ventilation Network. Procedia Eng. 2011, 26, 236–242. [Google Scholar] [CrossRef]

- Wallace, K.; Prosser, B.; Stinnette, J.D. The practice of mine ventilation engineering. Int. J. Min. Sci. Technol. 2015, 25, 165–169. [Google Scholar] [CrossRef]

- Wang, W.; Shao, W.; Wang, S.; Liu, J.; Shao, K.; Cao, Z.; Liu, Y.; Cui, Z. Operation Optimization of Thermal Management System of Deep Metal Mine Based on Heat Current Method and Prediction Model. Energies 2023, 16, 6626. [Google Scholar] [CrossRef]

- Zhong, D.; Wang, L.; Wang, J.; Jia, M. An Efficient Mine Ventilation Solution Method Based on Minimum Independent Closed Loops. Energies 2020, 13, 5862. [Google Scholar] [CrossRef]

- Szlązak, N.; Korzec, M. The Solution of the Main Fan Station for Underground Mines Being Decommissioned in Terms of Reducing Energy Consumption by Ventilation. Energies 2022, 15, 4612. [Google Scholar] [CrossRef]

- Liu, H.; Mao, S.; Li, M. A Case Study of an Optimized Intermittent Ventilation Strategy Based on CFD Modeling and the Concept of FCT. Energies 2019, 12, 721. [Google Scholar] [CrossRef]

- Pach, G.; Różański, Z.; Wrona, P.; Niewiadomski, A.; Zapletal, P.; Zubíček, V. Reversal Ventilation as a Method of Fire Hazard Mitigation in the Mines. Energies 2020, 13, 1755. [Google Scholar] [CrossRef]

- Tutak, M.; Brodny, J.; Szurgacz, D.; Sobik, L.; Zhironkin, S. The Impact of the Ventilation System on the Methane Release Hazard and Spontaneous Combustion of Coal in the Area of Exploitation—A Case Study. Energies 2020, 13, 4891. [Google Scholar] [CrossRef]

- Szlązak, N.; Swolkień, J.; Kamiński, P. Design of Coal Seam Exploitation in Methane Hazard Conditions: A Case Study. Energies 2023, 16, 365. [Google Scholar] [CrossRef]

- Regulation of the Minister of the Environment on Natural Hazards in Mining. 2021. Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20210001617/O/D20211617.pdf (accessed on 8 February 2024).

- McPherson, M.J. Subsurface Ventilation and Environmental Engineering; Chapman & Hall: London, UK, 1993. [Google Scholar]

- Pawiński, J.; Roszkowski, J.; Strzemiński, J. Przewietrzanie Kopalń; Ślaskie Wydawnictwo Techniczne: Katowice, Poland, 1995. [Google Scholar]

- Scott, D.R.; Hinsley, F.B. Ventilation Network Theory, Parts 1 to 4. Colliery Eng. 1951, 28, 67–71, 159–166, 229–235, 497–500. [Google Scholar]

- El-Nagdy, K.A. Stability of multiple fans in mine ventilation networks. Int. J. Min. Technol. 2013, 23, 569–571. [Google Scholar] [CrossRef]

- Luo, W.; Xie, X.; Xiao, H.; Cui, C.; Yin, X.; Su, M.; Wang, T.; Li, J.; Tan, X. Reliability calculation of mine ventilation network. Procedia Eng. 2014, 84, 752–757. [Google Scholar]

- Maleki, B.; Mozaffari, E. A comparative study of the iterative numerical methods used in mine ventilation networks. Int. J. Adv. Comput. Sci. Appl. 2016, 7, 356–362. [Google Scholar] [CrossRef][Green Version]

- Atkinson, J.J. On the Theory of the Ventilation of Mines. Trans. North Engl. Inst. Min. Engrs. 1854, 3, 118. [Google Scholar]

- Wang, Y.J. A Non-linear Programming Formulation for Mine Ventilation Networks with Natural Splitting. Int. J. Rock Mech. Min. Sci. Geomech. 1984, 21, 43–45. [Google Scholar] [CrossRef]

- Cross, H. Analysis of flow in networks of conduits or conductors. Univ. Illinois Bull. 1936, 286, 1–32. [Google Scholar]

- Acuna, E.I.; Lowndes, I.S. A Review of Primary Mine Ventilation System Optimization. Interfaces 2014, 44, 163–175. [Google Scholar] [CrossRef]

- Widzyk-Capehart, E.; Watson, B. Agnew Gold Mine Expansion, Mine Ventilation Expansion Evaluation Using Ventsim. In Proceedings of the 7th International Mine Ventilation Congress, Krakow, Poland, 17–22 June 2001; Available online: https://www.ventsim.com/wp-content/uploads/2019/04/Agnew_Gold_Mine_Expansion_using_Ventsim.pdf (accessed on 8 February 2024).

- Marx, W.; Belle, B.K. Simulating Air Flow Conditions in a South African Coal Mine, Using the VUMA-Network Simulation Software. 2002. Available online: https://www.vuma3d.com/wp-content/uploads/2021/04/Simulating-Airflow-conditions-in-a-South-African-coal-mine-using-the-VUMA-network-simulation-software.pdf (accessed on 8 February 2024).

- Hardcastle, S.G. 3D-canvent: An interactive mine ventilation simulator. In Proceedings of the 7th U.S. Mine Ventilation Sympos. (Society for Mining, Metallurgy & Exploration), Englewood, CO, USA, 5–7 June 1995; pp. 467–472. [Google Scholar]

- Wallace, K.G., Jr. General Operational Characteristics and Industry Practices of Mine Ventilation Systems. 2001. Available online: https://mineventilationservices.com/files/Publications/07th_INT-1.pdf (accessed on 8 February 2024).

- Dziurzyński, W.; Kruczkowski, J. Validation of the mathematical model used in the VENTGRAPH programme on the example of the introduction of new headings to the ventilation network of mine. Arch. Min. Sci. 2007, 52, 155–169. [Google Scholar]

- von Glehn, F.H.; Marx, W.M.; Bluhm, S.J. Verification and calibration of ventilation network models. In Proceedings of the 12th U.S. North American Mine Ventilation Symposium, Reno, Nevada, 9–12 June 2008; pp. 275–279. [Google Scholar]

- Bluhm, S.; Moreby, R.; Von Glehn, F.; Pascoe, C. Life-of-mine ventilation and refrigeration planning for Resolution Copper Mine. J. South. Afr. Inst. Min. Metall. 2014, 114, 497–503. [Google Scholar]

- Șuvar, M.C.; Lupu, C.; Arad, V.; Cioclea, D.; Păsculescu, V.M.; Mija, N. Computerized simulation of mine ventilation networks for sustainable decision making process. Environ. Eng. Manag. J. 2014, 13, 1445–1451. [Google Scholar] [CrossRef]

| Level | Volumetric Flow Rate, m3/min | Flow Rate on the Level, m3/min | Percentage of Total Flow Rate, % | ||

|---|---|---|---|---|---|

| Shaft I | Shaft II | Shaft III | |||

| 350 m | 300 | 50 | 50 | 400 | 1.5 |

| 450 m | 600 | 800 | 200 | 1600 | 6.1 |

| 650 m | 2550 | 2950 | 2550 | 8050 | 30.8 |

| 850 m | 6450 | - | 4600 | 11,050 | 42.3 |

| Total | 9900 | 3800 | 7400 | - | - |

| Intake air entering the mine through shafts | 21,100 | 80.8 | |||

| Intake air from the adjacent mine | 5000 | 19.2 | |||

| Total | 26,100 | 100.0 | |||

| Level | Volumetric Flow Rate, m3/min | Flow Rate on the Level, m3/min | Percentage of Total Flow Rate, % | |

|---|---|---|---|---|

| Shaft IV | Shaft VI | |||

| 350 m | 8000 | - | 8000 | 30.7 |

| 450 m | - | 4450 | 4450 | 17.0 |

| 650 m | - | 13,150 | 13,150 | 50.4 |

| 850 m | - | 500 | 500 | 1.9 |

| Total | 8000 | 18,100 | 26,100 | 100 |

| Mining District | Volumetric Flow Rate, m3/min | |

|---|---|---|

| To the Mining District | To the Longwall Face | |

| District 1—Longwall 1 in seam 405/3 | 1100 | 650 |

| District 2—Longwall 2 in seam 407/3 | 1350 | 950 |

| District 3—Longwall 3 in seam 404/4 | 1550 | 1200 |

| District 4—Longwall 4 in seam 405/1 | 2650 | 1200 |

| District 5—Longwall 5 in seam 408/3 | 1500 | 900 |

| Total (longwall mining districts) | 8150 | 4900 |

| Development headings—districts 6 and 7 | 4800 | - |

| Total (longwall mining and development heading districts) | 12,950 | - |

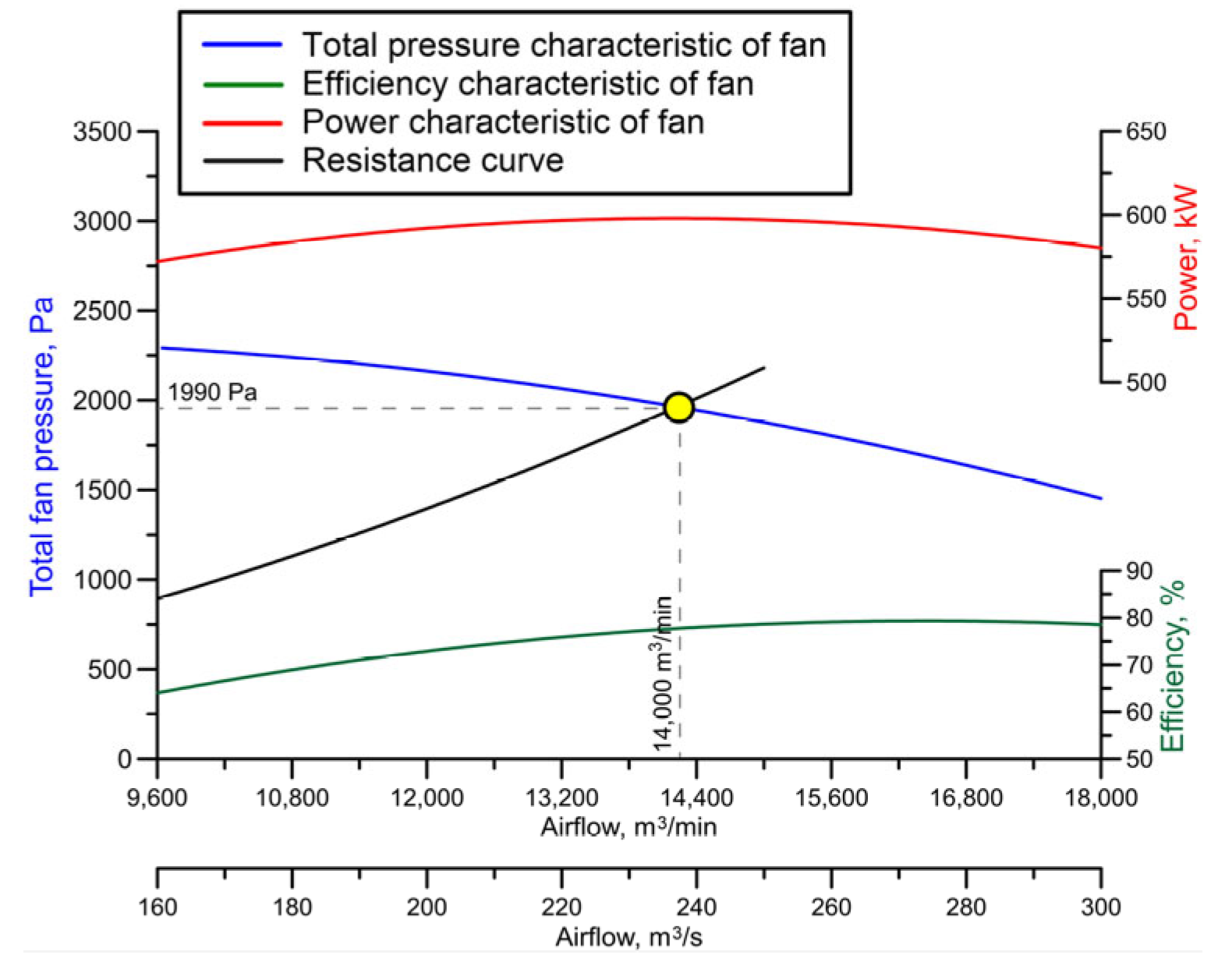

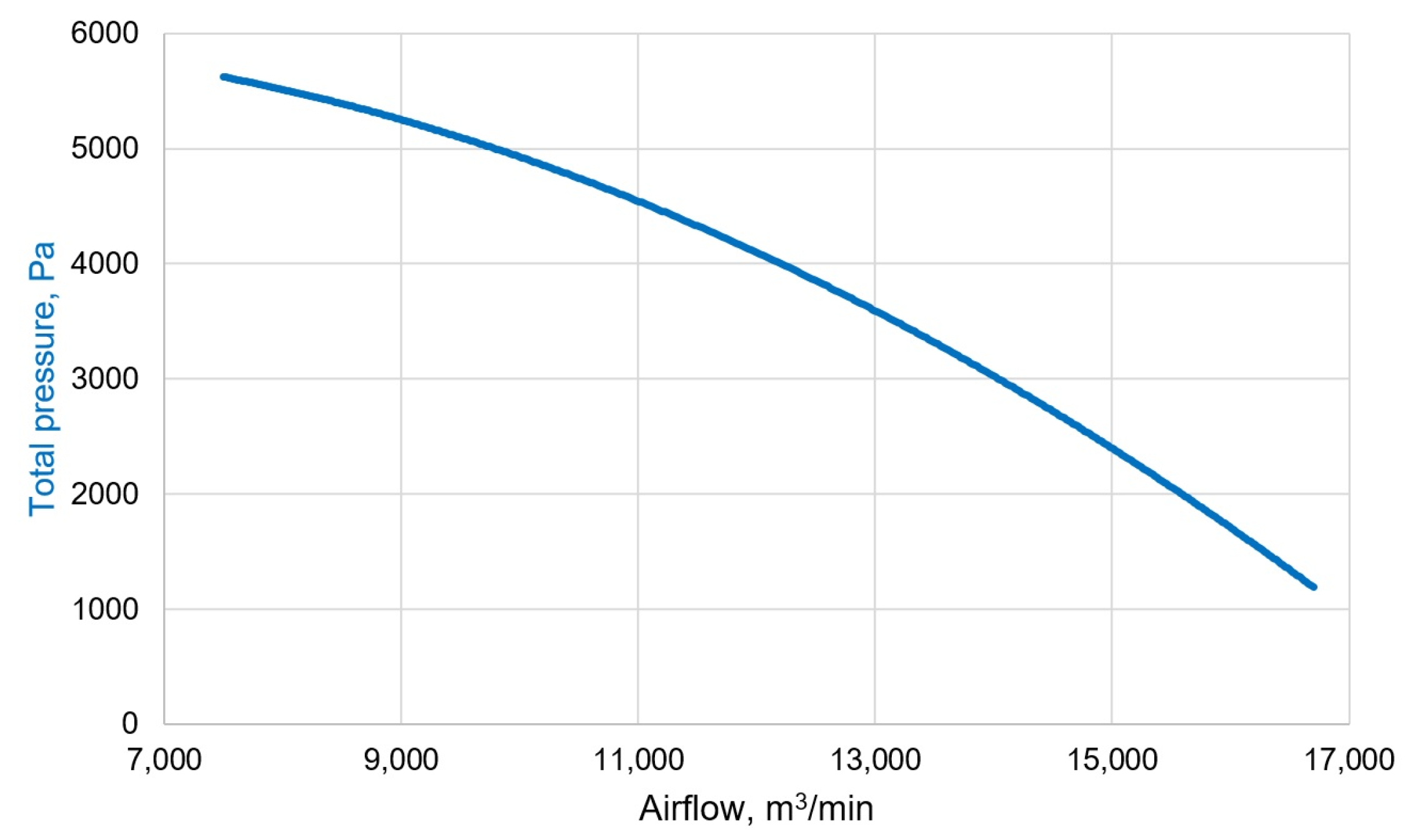

| Shaft | Number of Working Fans | Volumetric Air Flow, m3/min | Total Pressure, Pa | Equivalent Orifice, m2 | |||

|---|---|---|---|---|---|---|---|

| In the Shaft | External Losses | Fan Air Flow | Shaft | Fan | |||

| IV | 1 | 8000 | 6000 | 14,000 | 1990 | 3.81 | 6.23 |

| V | 2 | 18,100 | 1850 | 19,950 | 2980 | 7.00 | 7.26 |

| Total | 26,100 | 7850 | 33,950 | ||||

| Description | Unit | Current State | Solution 1 | Solution 2 | Solution 3 | Solution 4 | ||

|---|---|---|---|---|---|---|---|---|

| Without New Excavation | After Performing an Additional Excavation to Shaft III | |||||||

| Total intake air supplied to the mine through the shafts | m3/min | 21,100 | 19,140 | 23,440 | 23,100 | 24,030 | 23,750 | |

| Total intake air supplied to the mine | 26,100 | 24,390 | 28,890 | 28,540 | 29,500 | 29,200 | ||

| Increase in total intake air supplied to the mine according to the current state | m3/min | - | −1710 | 2790 | 2440 | 3400 | 3100 | |

| % | - | −6.55 | 10.69 | 9.35 | 13.03 | 11.88 | ||

| Intake air supplied to the mining districts | m3/min | 12,950 | 9450 | 11,410 | 11,250 | 10,420 | 10,420 | |

| Longwall mining districts | 8150 | 5630 | 7680 | 7600 | 6780 | 6750 | ||

| Development headings district | 4800 | 3820 | 3730 | 3650 | 3640 | 3670 | ||

| Decrease in mining districts ventilation intensity | % | - | −27.0 | −11.9 | −13.1 | −19.5 | −19.5 | |

| Longwall mining districts | - | −30.9 | −5.8 | −6.7 | −16.8 | −17.2 | ||

| Development headings district | - | −20.4 | −22.3 | −24.0 | −24.2 | −23.5 | ||

| Returned air removed from the mine by Shaft III | m3/min | - | 6630 | 11,920 | 11,510 | 12,560 | 12,210 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szlązak, N.; Korzec, M. Conditions That Determine Changing the Function of Mine Shafts in a Gassy Coal Mine—A Case Study. Energies 2024, 17, 1379. https://doi.org/10.3390/en17061379

Szlązak N, Korzec M. Conditions That Determine Changing the Function of Mine Shafts in a Gassy Coal Mine—A Case Study. Energies. 2024; 17(6):1379. https://doi.org/10.3390/en17061379

Chicago/Turabian StyleSzlązak, Nikodem, and Marek Korzec. 2024. "Conditions That Determine Changing the Function of Mine Shafts in a Gassy Coal Mine—A Case Study" Energies 17, no. 6: 1379. https://doi.org/10.3390/en17061379

APA StyleSzlązak, N., & Korzec, M. (2024). Conditions That Determine Changing the Function of Mine Shafts in a Gassy Coal Mine—A Case Study. Energies, 17(6), 1379. https://doi.org/10.3390/en17061379