A Multi-Criteria Decision-Making Framework for Zero Emission Vehicle Fleet Renewal Considering Lifecycle and Scenario Uncertainty

Abstract

1. Introduction

2. Literature Review

- Phase 1 (from 2020 to 2024): birth of the hydrogen market and definition of an ad hoc legislative-regulatory framework.

- Phase 2 (from 2025 to 2030): development of the hydrogen market, creation of the first localized applications, and construction of the transport infrastructure.

- Phase 3 (from 2031 to 2050): large-scale diffusion of hydrogen with massive penetration of the vector into the energy mix of final consumption.

2.1. Transportation Technologies

2.2. Strategic Decision-Making Approaches

3. Methodology

3.1. Technology Alternatives

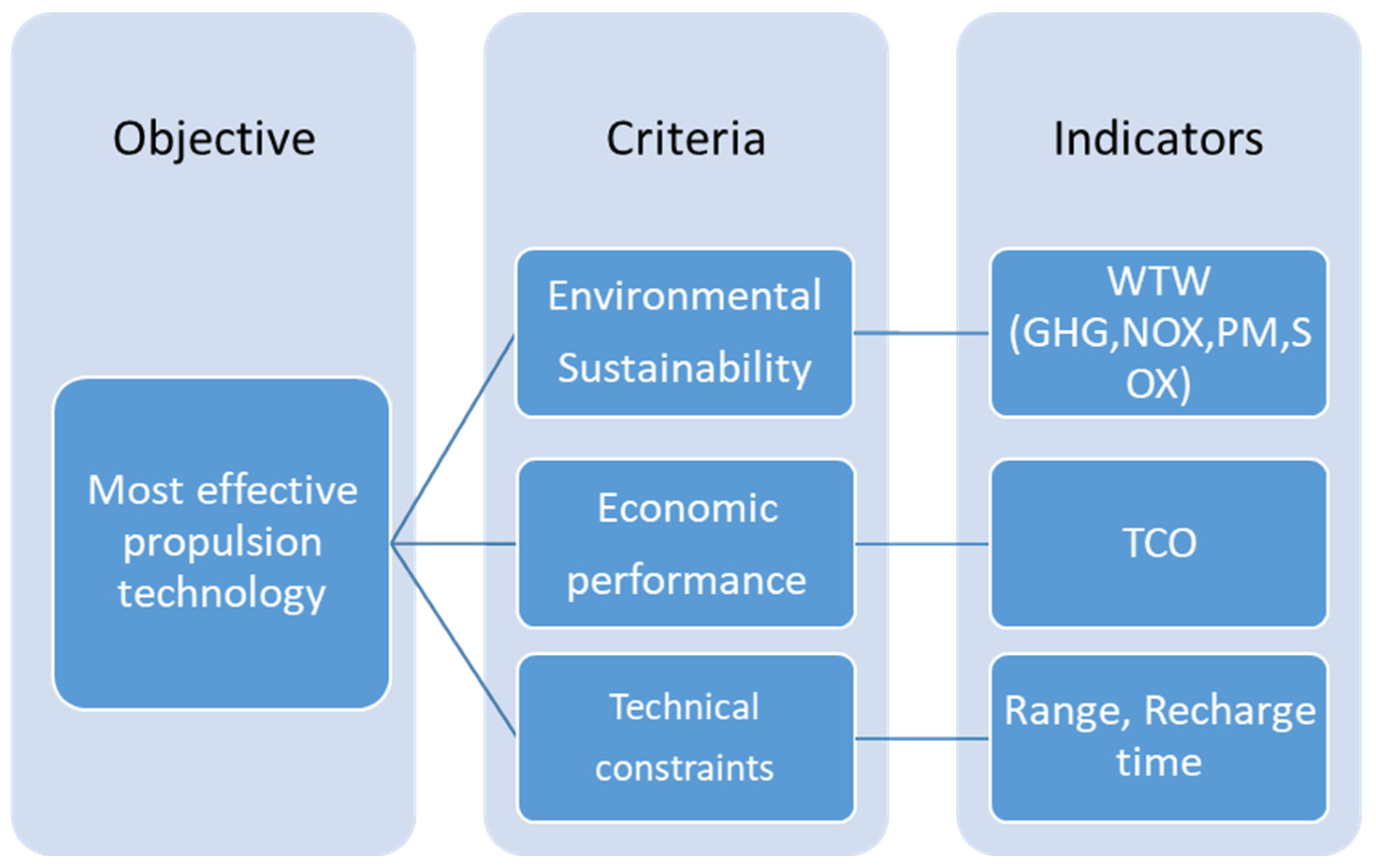

3.2. Decision Criteria

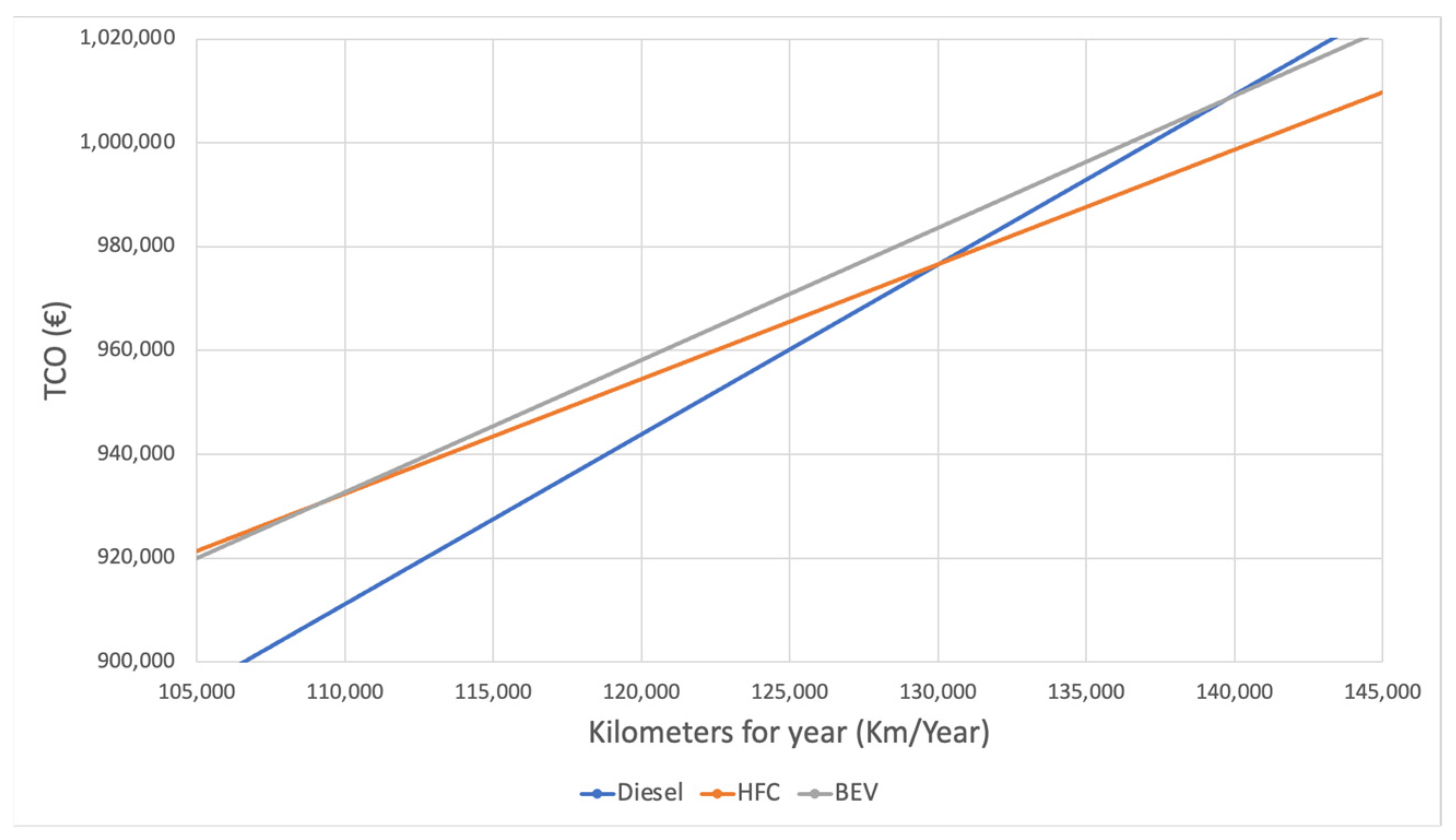

3.2.1. Economic Performance

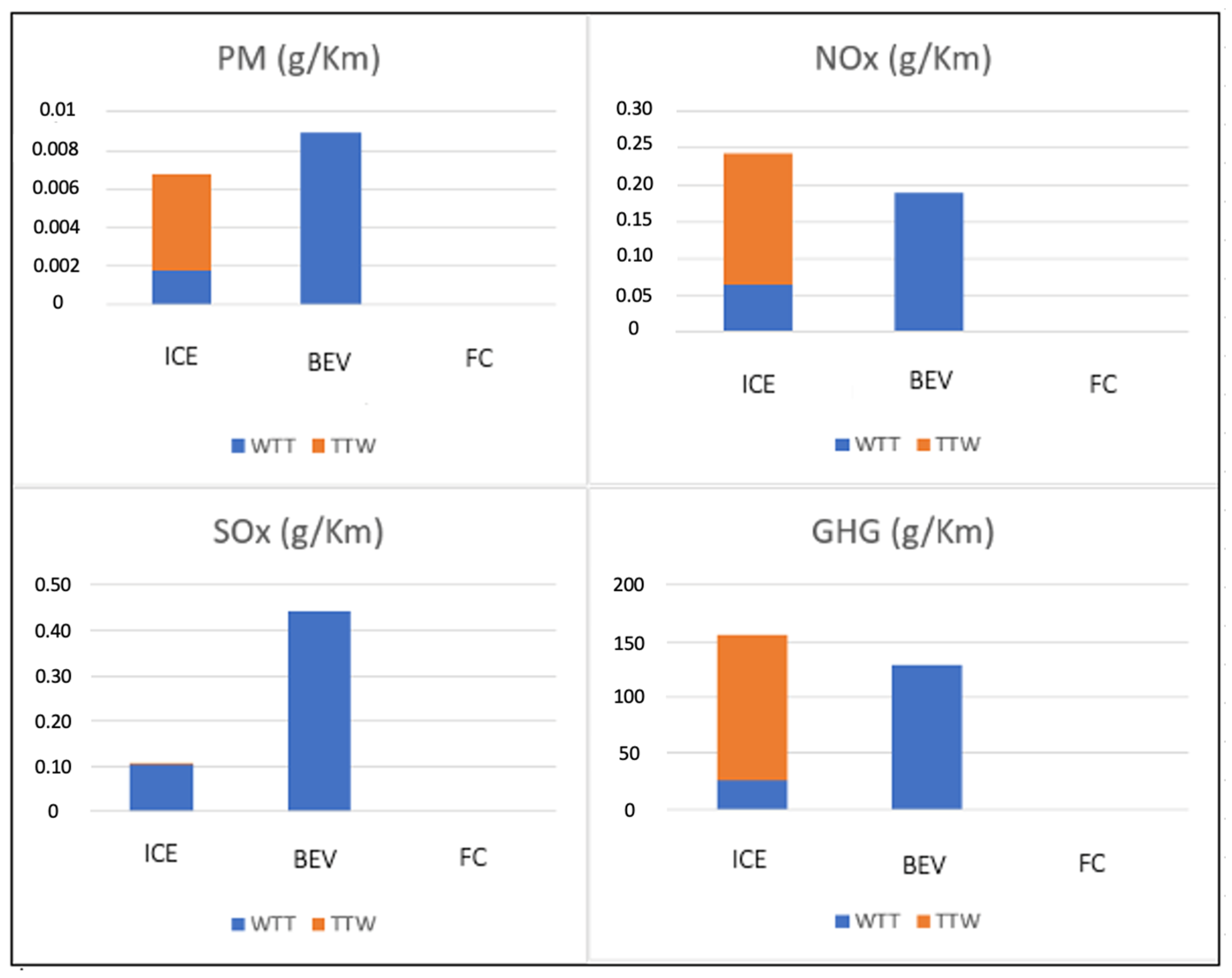

3.2.2. Environmental Performance

3.2.3. Technical Implications: Range Charging Time

3.3. Multi-Criteria Decision-Making Approach

4. Case Study

- Case 1: an increment of 10% has been considered for the weights related to the environmental sustainability criterion, the cost criterion has been maintained constant, while a suitable reduction has been considered for the weights related to the technical features ensuring the overall sum is equal to 1.

- Case 2: an increment of 10% has been considered for the weights related to the environmental sustainability criterion, the technical criterion has been maintained constant, while a corresponding reduction has been considered for the weights related to the cost features to ensure the overall sum is equal to 1.

- Case 3: a decrease of 10% has been considered for the weights related to the environmental sustainability criterion, the cost criterion has been maintained constant, while a suitable increment has been considered for the weights related to the technical features ensuring the overall sum is equal to 1.

- Case 4: a decrease of 10% has been considered for the weights related to the environmental sustainability criterion, the technical criterion has been maintained constant, while a corresponding increment has been considered for the weights related to the cost features to ensure the overall sum is equal to 1.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Al-Alawi, B.M.; Bradley, T.H. Total cost of ownership, payback, and consumer preference modeling of plug-in hybrid electric vehicles. Appl. Energy 2013, 103, 488–506. [Google Scholar] [CrossRef]

- Offer, G.J.; Howey, D.; Contestabile, M.; Clague, R.; Brandon, N. Comparative analysis of battery electric, hydrogen fuel cell and hybrid vehicles in a future sustainable road transport system. Energy Policy 2010, 38, 24–29. [Google Scholar] [CrossRef]

- Zhao, Y.; Pohl, O.; Bhatt, A.I.; Collis, G.E.; Mahon, P.J.; Rüther, T.; Hollenkamp, A.F. A review on battery market trends, second-life reuse, and recycling. Sustain. Chem. 2021, 2, 167–205. [Google Scholar] [CrossRef]

- Rezvani, Z.; Jansson, J.; Bodin, J. Advances in consumer electric vehicle adoption research: A review and research agenda. Transp. Res. Part D Transp. Environ. 2015, 34, 122–136. [Google Scholar] [CrossRef]

- Sharma, R.; Manzie, C.; Bessede, M.; Brear, M.; Crawford, R. Conventional, hybrid and electric vehicles for Australian driving conditions–Part 1: Technical and financial analysis. Transp. Res. Part C Emerg. Technol. 2012, 25, 238–249. [Google Scholar] [CrossRef]

- Jacobson, M.Z.; Colella, W.; Golden, D. Cleaning the air and improving health with hydrogen fuel-cell vehicles. Science 2005, 308, 1901–1905. [Google Scholar] [CrossRef]

- Thomas, C. Fuel cell and battery electric vehicles compared. Int. J. Hydrogen Energy 2009, 34, 6005–6020. [Google Scholar] [CrossRef]

- Cunanan, C.; Tran, M.K.; Lee, Y.; Kwok, S.; Leung, V.; Fowler, M. A review of heavy-duty vehicle powertrain technologies: Diesel engine vehicles, battery electric vehicles, and hydrogen fuel cell electric vehicles. Clean Technol. 2021, 3, 474–489. [Google Scholar] [CrossRef]

- Shin, J.; Hwang, W.S.; Choi, H. Can hydrogen fuel vehicles be a sustainable alternative on vehicle market?: Comparison of electric and hydrogen fuel cell vehicles. Technol. Forecast. Soc. Chang. 2019, 143, 239–248. [Google Scholar] [CrossRef]

- Ni, M.; Leung, M.K.; Leung, D.Y.; Sumathy, K. A review and recent developments in photocatalytic water-splitting using TiO2 for hydrogen production. Renew. Sustain. Energy Rev. 2007, 11, 401–425. [Google Scholar] [CrossRef]

- da Silva Veras, T.; Mozer, T.S.; da Silva César, A. Hydrogen: Trends, production and characterization of the main process worldwide. Int. J. Hydrogen Energy 2017, 42, 2018–2033. [Google Scholar] [CrossRef]

- Dumortier, J.; Siddiki, S.; Carley, S.; Cisney, J.; Krause, R.M.; Lane, B.W.; Rupp, J.A.; Graham, J.D. Effects of providing total cost of ownership information on consumers’ intent to purchase a hybrid or plug-in electric vehicle. Transp. Res. Part A Policy Pract. 2015, 72, 71–86. [Google Scholar] [CrossRef]

- Contestabile, M.; Offer, G.; Slade, R.; Jaeger, F.; Thoennes, M. Battery electric vehicles, hydrogen fuel cells and biofuels. Which will be the winner? Energy Environ. Sci. 2011, 4, 3754–3772. [Google Scholar] [CrossRef]

- Wu, G.; Inderbitzin, A.; Bening, C. Total cost of ownership of electric vehicles compared to conventional vehicles: A probabilistic analysis and projection across market segments. Energy Policy 2015, 80, 196–214. [Google Scholar] [CrossRef]

- Davis, B.A.; Figliozzi, M.A. A methodology to evaluate the competitiveness of electric delivery trucks. Transp. Res. Part E Logist. Transp. Rev. 2013, 49, 8–23. [Google Scholar] [CrossRef]

- Dablanc, L.; Giuliano, G.; Holliday, K.; O’Brien, T. Best practices in urban freight management: Lessons from an international survey. Transp. Res. Rec. 2013, 2379, 29–38. [Google Scholar] [CrossRef]

- Gilmore, E.A.; Lave, L.B. Comparing resale prices and total cost of ownership for gasoline, hybrid and diesel passenger cars and trucks. Transp. Policy 2013, 27, 200–208. [Google Scholar] [CrossRef]

- Al-Alawi, B.M.; Bradley, T.H. Review of hybrid, plug-in hybrid, and electric vehicle marketmodeling studies. Renew. Sustain. Energy Rev. 2013, 21, 190–203. [Google Scholar] [CrossRef]

- Burke, A.; Sinha, A.K. Technology, Sustainability, and Marketing of Battery Electric and Hydrogen Fuel Cell Medium-Duty and Heavy-Duty Trucks and Buses in 2020–2040. UC Davis Res. Rep. 2020. [CrossRef]

- Abhyankar, N.; Gopinathan, N.; Khandekar, A.; Karali, N.; Phadke, A.; Rajagopal, D. Freight Trucks in India Are Primed for Electrification; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2022; Available online: https://escholarship.org/uc/item/7pc0818t (accessed on 30 January 2024).

- Satterfield, C.; Nigro, N.; Wood, E.; Jensen, J.; Smith, C.; Desai, R.; Ge, Y. Electrification Assessment of Public Vehicles in Washington: A Vehicle-by-Vehicle Assessment of the Electrification Potential for Publicly-Owned Vehicles; Atlas Public Policy: Washington, DC, USA, 2020. [Google Scholar]

- Wolff, S.; Brönner, M.; Held, M.; Lienkamp, M. Transforming automotive companies into sustainability leaders: A concept for managing current challenges. J. Clean. Prod. 2020, 276, 124179. [Google Scholar] [CrossRef]

- Liu, D.; Xu, L.; Sadia, U.H.; Wang, H. Evaluating the CO2 emission reduction effect of China’s battery electric vehicle promotion efforts. Atmos. Pollut. Res. 2021, 12, 101115. [Google Scholar] [CrossRef]

- Li, M.; Zhang, X.; Li, G. A comparative assessment of battery and fuel cell electric vehicles using a well-to-wheel analysis. Energy 2016, 94, 693–704. [Google Scholar] [CrossRef]

- Gupta, S.; Patil, V.; Himabindu, M.; Ravikrishna, R. Life-cycle analysis of energy and greenhouse gas emissions of automotive fuels in India: Part 1–Tank-to-Wheel analysis. Energy 2016, 96, 684–698. [Google Scholar] [CrossRef]

- Fishburn, P.C. Interdependence and additivity in multivariate, unidimensional expected utility theory. Int. Econ. Rev. 1967, 8, 335–342. [Google Scholar] [CrossRef]

- Keeney, R.L. Multiplicative utility functions. Oper. Res. 1974, 22, 22–34. [Google Scholar] [CrossRef]

- Tsoukiàs, A.; Vincke, P. A new axiomatic foundation of partial comparability. Theory Decis. 1995, 39, 79–114. [Google Scholar] [CrossRef]

- Haase, M.; Wulf, C.; Baumann, M.; Ersoy, H.; Koj, J.; Harzendorf, F.; Mesa Estrada, L.S. Multi-criteria decision analysis for prospective sustainability assessment of alternative technologies and fuels for individual motorized transport. Clean Technol. Environ. Policy 2022, 24, 3171–3197. [Google Scholar] [CrossRef]

- Hamurcu, M.; Eren, T. Electric bus selection with multicriteria decision analysis for green transportation. Sustainability 2020, 12, 2777. [Google Scholar] [CrossRef]

- Więckowski, J.; Sałabun, W.; Kizielewicz, B.; Bączkiewicz, A.; Shekhovtsov, A.; Paradowski, B.; Wątróbski, J. Recent advances in multi-criteria decision analysis: A comprehensive review of applications and trends. Int. J. Knowl.-Based Intell. Eng. Syst. 2023, 27, 367–393. [Google Scholar] [CrossRef]

- Kizielewicz, B.; Więckowski, J.; Shekhovtsov, A.; Wątróbski, J.; Depczyński, R.; Sałabun, W. Study towards the time-based mcda ranking analysis–a supplier selection case study. Facta Univ. Ser. Mech. Eng. 2021, 19, 381–399. [Google Scholar] [CrossRef]

- Shekhovtsov, A.; Więckowski, J.; Kizielewicz, B.; Sałabun, W. Towards Reliable Decision-Making in the green urban transport domain. Facta Univ. Ser. Mech. Eng. 2022, 20, 381–398. [Google Scholar] [CrossRef]

- Geldermann, J.; Rentz, O. Multi-criteria Analysis for Technique Assessment: Case Study from Industrial Coating. J. Ind. Ecol. 2005, 9, 127–142. [Google Scholar] [CrossRef]

- Hermann, B.G.; Kroeze, C.; Jawjit, W. Assessing environmental performance by combining life cycle assessment, multi-criteria analysis and environmental performance indicators. J. Clean. Prod. 2007, 15, 1787–1796. [Google Scholar] [CrossRef]

- Myllyviita, T.; Holma, A.; Antikainen, R.; Lähtinen, K.; Leskinen, P. Assessing environmental impacts of biomass production chains–application of life cycle assessment (LCA) and multi-criteria decision analysis (MCDA). J. Clean. Prod. 2012, 29, 238–245. [Google Scholar] [CrossRef]

- Seppälä, J.; Koskela, S.; Melanen, M.; Palperi, M. The Finnish metals industry and the environment. Resour. Conserv. Recycl. 2002, 35, 61–76. [Google Scholar] [CrossRef]

- Bouwman, M.E.; Moll, H.C. Environmental analyses of land transportation systems in The Netherlands. Transp. Res. Part D Transp. Environ. 2002, 7, 331–345. [Google Scholar] [CrossRef]

- Elghali, L.; Clift, R.; Sinclair, P.; Panoutsou, C.; Bauen, A. Developing a sustainability framework for the assessment of bioenergy systems. Energy Policy 2007, 35, 6075–6083. [Google Scholar] [CrossRef]

- Zhou, X.; Schoenung, J.M. An integrated impact assessment and weighting methodology: Evaluation of the environmental consequences of computer display technology substitution. J. Environ. Manag. 2007, 83, 1–24. [Google Scholar] [CrossRef]

- Narayanan, D.; Zhang, Y.; Mannan, M.S. Engineering for sustainable development (ESD) in bio-diesel production. Process Saf. Environ. Prot. 2007, 85, 349–359. [Google Scholar] [CrossRef]

- Mohamadabadi, H.S.; Tichkowsky, G.; Kumar, A. Development of a multi-criteria assessment model for ranking of renewable and non-renewable transportation fuel vehicles. Energy 2009, 34, 112–125. [Google Scholar] [CrossRef]

- Prado-Lopez, V.; Seager, T.P.; Chester, M.; Laurin, L.; Bernardo, M.; Tylock, S. Stochastic multi-attribute analysis (SMAA) as an interpretation method for comparative life-cycle assessment (LCA). Int. J. Life Cycle Assess. 2014, 19, 405–416. [Google Scholar] [CrossRef]

- Rogers, K.; Seager, T.P. Environmental decision-making using life cycle impact assessment and stochastic multiattribute decision analysis: A case study on alternative transportation fuels. Environ. Sci. Technol. 2009, 43, 1718–1723. [Google Scholar] [CrossRef]

- Tan, R.R.; Culaba, A.B.; Purvis, M.R. POLCAGE 1.0—A possibilistic life-cycle assessment 660 model for evaluating alternative transportation fuels. Environ. Model. Softw. 2004, 661, 907–918. [Google Scholar] [CrossRef]

- Kolak, O.İ.; Akın, D.; Birbil, Ş.İ.; Feyzioğlu, O.; Noyan, N. Multicriteria sustainability evaluation of transport networks for selected European countries. Lect. Notes Eng. Comput. Sci. 2011, 2190, 117–122. [Google Scholar]

- Awasthi, A.; Chauhan, S.S. Using AHP and Dempster–Shafer theory for evaluating sustainable transport solutions. Environ. Model. Softw. 2011, 26, 787–796. [Google Scholar] [CrossRef]

- Haghshenas, H.; Vaziri, M. Urban sustainable transportation indicators for global comparison. Ecol. Indic. 2012, 15, 115–121. [Google Scholar] [CrossRef]

- Linkov, I.; Burmistrov, D. Model uncertainty and choices made by modelers: Lessons learned from the international atomic energy agency model intercomparisons. Risk Anal. Int. J. 2003, 23, 1297–1308. [Google Scholar] [CrossRef] [PubMed]

- Leach, M.; Scoones, I.; Stirling, A. Governing epidemics in an age of complexity: Narratives, politics and pathways to sustainability. Glob. Environ. Chang. 2010, 20, 369–377. [Google Scholar] [CrossRef]

- Lempert, R.J. Shaping the Next One Hundred Years: New Methods for Quantitative, Long-Term Policy Analysis; RAND: Santa Monica, CA, USA, 2003. [Google Scholar]

- Wang, Z.; Hao, H.; Gao, F.; Zhang, Q.; Zhang, J.; Zhou, Y. Multi-attribute decision making on reverse logistics based on DEA-TOPSIS: A study of the Shanghai End-of-life vehicles industry. J. Clean. Prod. 2019, 214, 730–737. [Google Scholar] [CrossRef]

- Ulkhaq, M.M.; Wijayanti, W.R.; Zain, M.S.; Baskara, E.; Leonita, W. Combining the AHP and TOPSIS to evaluate car selection. In Proceedings of the 2nd International Conference on High Performance Compilation, Computing and Communications, Hong Kong, China, 15–17 March 2018; pp. 112–117. [Google Scholar]

- Moreno, N.G.; Molina, M.C.; Gervasio, D.; Robles, J.F.P. Approaches to polymer electrolyte membrane fuel cells (PEMFCs) and their cost. Renew. Sustain. Energy Rev. 2015, 52, 897–906. [Google Scholar] [CrossRef]

- Shanian, A.; Savadogo, O. TOPSIS multiple-criteria decision support analysis for material selection of metallic bipolar plates for polymer electrolyte fuel cell. J. Power Sources 2006, 159, 1095–1104. [Google Scholar] [CrossRef]

- He, G.; Mallapragada, D.S.; Bose, A.; Heuberger-Austin, C.F.; Gençer, E. Sector coupling via hydrogen to lower the cost of energy system decarbonization. Energy Environ. Sci. 2021, 14, 4635–4646. [Google Scholar] [CrossRef]

- Torchio, M.F.; Santarelli, M.G. Energy, environmental and economic comparison of different powertrain/fuel options using well-to-wheels assessment, energy and external costs–European market analysis. Energy 2010, 35, 4156–4171. [Google Scholar] [CrossRef]

- O’Donovan, A.; Frith, J.; Mckerracher, C. Electric Buses in Cities: Driving towards Cleaner Air and Lower CO2; Bloomberg New Energy Finance: London, UK, 2018; Volume 148. [Google Scholar]

- Antwi, S.; Grytli, S.O. Assessing the Drivers of Green Road Transport Electrification: A Case of Europe. Master’s Thesis, Høgskolen i Molde-Vitenskapelig Høgskole i Logistikk, Molde, Norway, 2022. [Google Scholar]

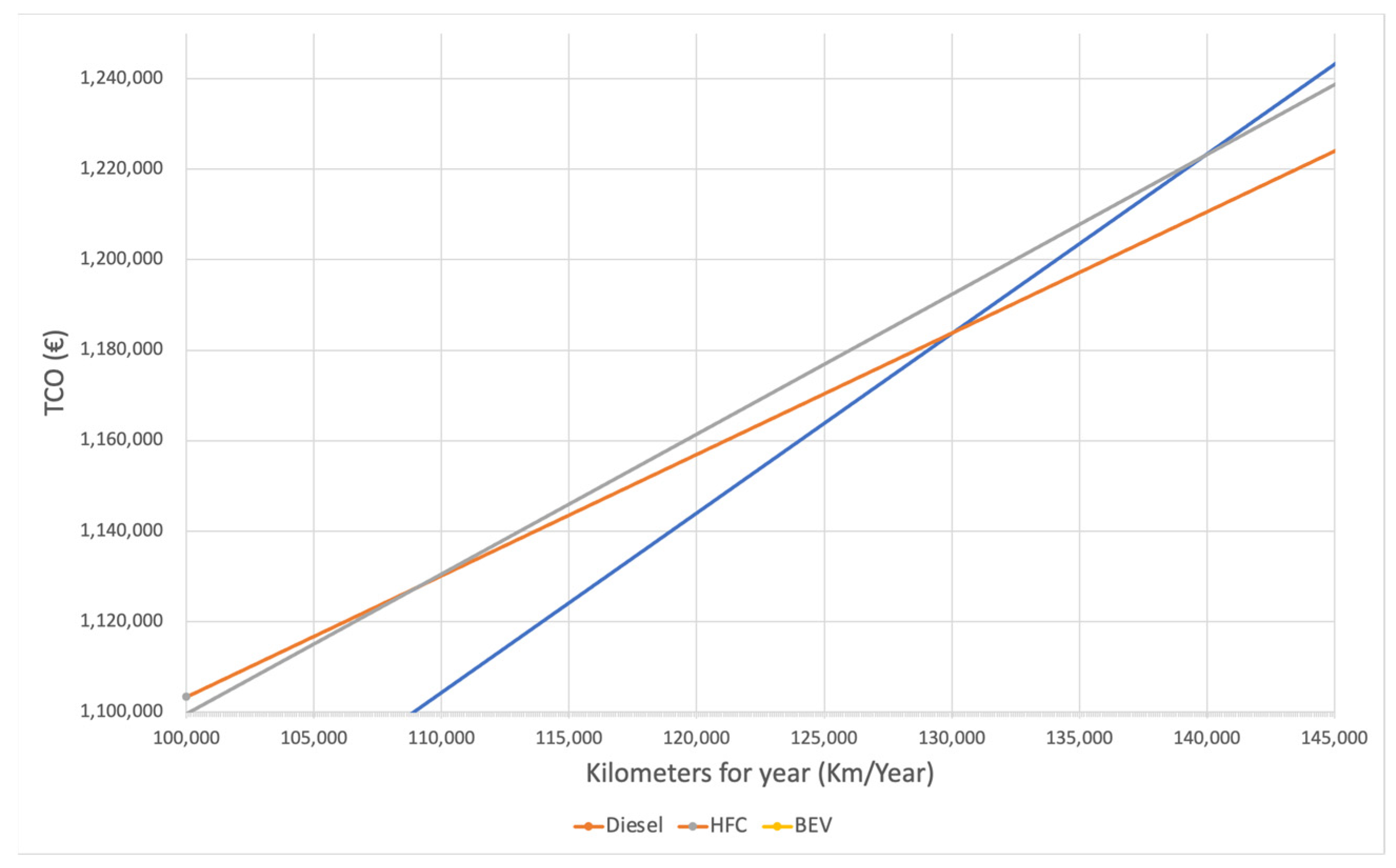

| Diesel | HFC | BEV | |

|---|---|---|---|

| Truck purchase Cost (€) | 135,000 | 330,000 | 385,000 |

| Energy cons. (kwh/km) | 1.25 | ||

| Fuel cons. (lt/100 km) | 33 | 8 | |

| Diesel fuel cost (€/liter) | 1.5 | ||

| Energy fuel cost (€/kwh) | 4.65 | ||

| H2 fuel cost (€/kg) | 4.65 | ||

| Distance traveled (Km) | 350,000 | 350,000 | 350,000 |

| Driver cost (€/Year) | 60,000 | 60,000 | 60,000 |

| Adblue (€/100 km) | 0.5 | ||

| Tires (€) | 2784 | 2784 | 2784 |

| Diesel | HFC | BEV | |

|---|---|---|---|

| Turck Cost | 150,000.00 | 330,000.00 | 385,000.00 |

| fuel cost (€/year) | 1,865,500.00 | 1,260,000.00 | 1,452,500.00 |

| driver cost (€/Year) | 600,000.00 | 600,000.00 | 600,000.00 |

| tires | 27,840.00 | 27,840.00 | 27,840.00 |

| service | 120,000.00 | 165,000.00 | 50,000.00 |

| Total Cost | 2,763,340.00 | 2,382,840.00 | 2,515,340.00 |

| Alternatives | Scores | ||||||

|---|---|---|---|---|---|---|---|

| Sustainability | TCO (€) | Technical | |||||

| NOx (g/kg) | PM (g/kg) | Sox (g/kg) | CO2 (g/kg) | Range (km) | Refueling Time (min) | ||

| Diesel | 0.244 | 0.005 | 0.105 | 156.234 | 2,763,340.00 | 1250 | 15 |

| Electric | 0.190 | 0.009 | 0.445 | 128.871 | 2,515,340.00 | 200 | 45 |

| Hydrogen | 0.000 | 0.000 | 0.000 | 0.000 | 2,382,840.00 | 500 | 15 |

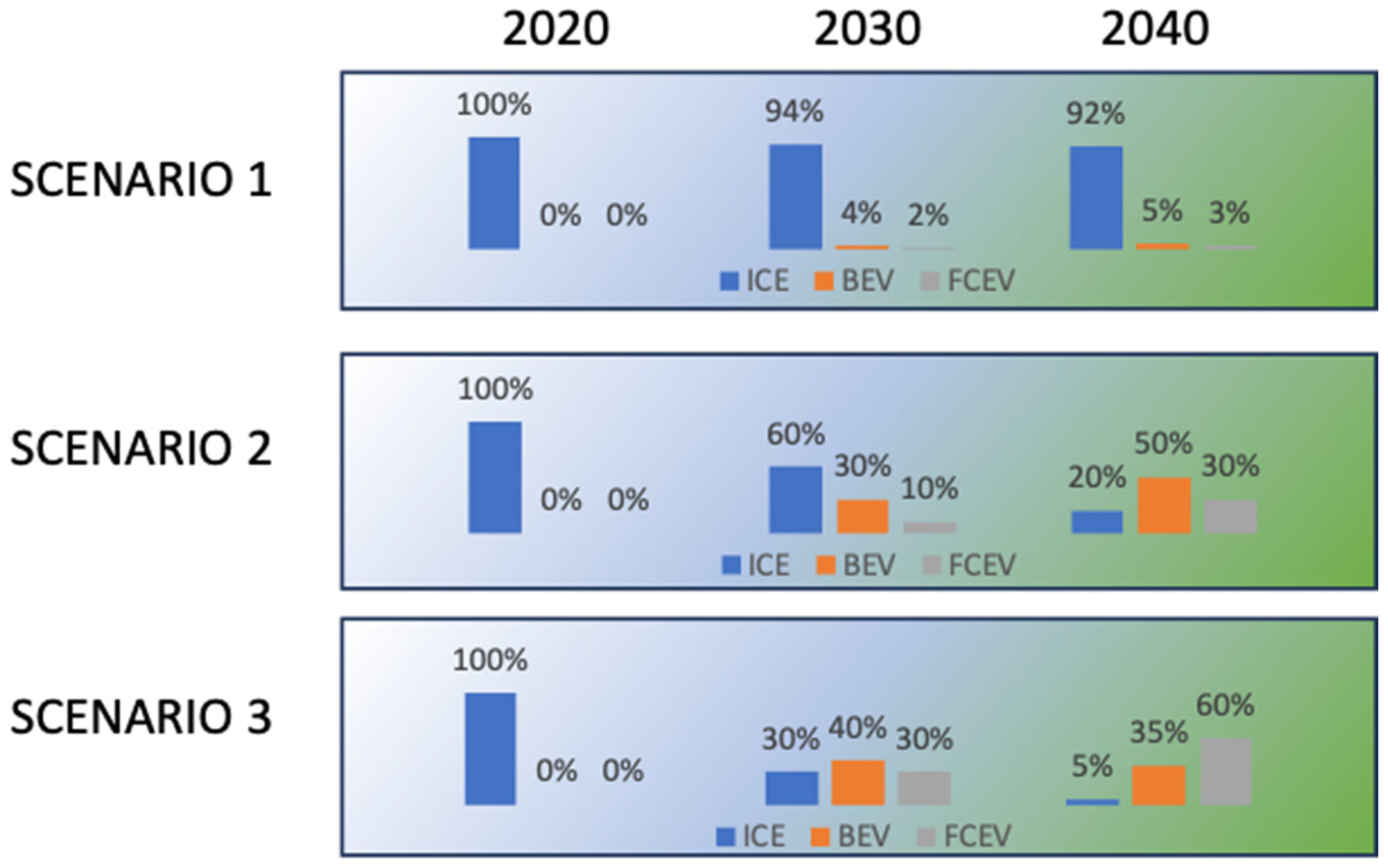

| Cost | Sustainability | Technical | |

|---|---|---|---|

| Scenario 1 | 0.50 | 0.20 | 0.30 |

| Scenario 2 | 0.40 | 0.40 | 0.20 |

| Scenario 3 | 0.40 | 0.50 | 0.10 |

| Sustainability | Cost | Technical | |||||

|---|---|---|---|---|---|---|---|

| Nox | PM | SOx | CO2 | TCO | Range | Refueling Time | |

| Scenario 1 | 0.050 | 0.050 | 0.050 | 0.050 | 0.500 | 0.150 | 0.150 |

| Scenario 2 | 0.100 | 0.100 | 0.100 | 0.100 | 0.400 | 0.100 | 0.100 |

| Scenario 3 | 0.125 | 0.125 | 0.125 | 0.125 | 0.400 | 0.050 | 0.050 |

| Scenario 1 | Scenario 2 | Scenario 3 | ||||

|---|---|---|---|---|---|---|

| Alternative | C* | Ranking | C* | Ranking | C* | Ranking |

| Diesel | 0.511 | 1 | 0.446 | 2 | 0.410 | 2 |

| Battery | 0.404 | 3 | 0.279 | 3 | 0.188 | 3 |

| Hydrogen Fuel Cell | 0.452 | 2 | 0.683 | 1 | 0.841 | 1 |

| Sustainability | Cost | Technical | Best Alterantive | |||||

|---|---|---|---|---|---|---|---|---|

| WNox | WPM | WSOx | WCO2 | WTCO | WRange | WRefuelingTime | 1 | Scenario 1 |

| 0.050 | 0.050 | 0.050 | 0.050 | 0.500 | 0.150 | 0.150 | 1 | |

| 0.055 | 0.055 | 0.055 | 0.055 | 0.500 | 0.140 | 0.140 | 1 | |

| 0.055 | 0.055 | 0.055 | 0.055 | 0.480 | 0.150 | 0.150 | 1 | |

| 0.045 | 0.045 | 0.045 | 0.045 | 0.500 | 0.160 | 0.160 | 1 | |

| 0.045 | 0.045 | 0.045 | 0.045 | 0.520 | 0.150 | 0.150 | 1 | |

| 0.100 | 0.100 | 0.100 | 0.100 | 0.400 | 0.100 | 0.100 | 3 | Scenario 2 |

| 0.110 | 0.110 | 0.110 | 0.110 | 0.400 | 0.080 | 0.080 | 3 | |

| 0.110 | 0.110 | 0.110 | 0.110 | 0.360 | 0.100 | 0.100 | 3 | |

| 0.090 | 0.090 | 0.090 | 0.090 | 0.400 | 0.120 | 0.120 | 3 | |

| 0.090 | 0.090 | 0.090 | 0.090 | 0.440 | 0.100 | 0.100 | 3 | |

| 0.125 | 0.125 | 0.125 | 0.125 | 0.400 | 0.050 | 0.050 | 3 | Scenario 3 |

| 0.138 | 0.138 | 0.138 | 0.138 | 0.400 | 0.012 | 0.012 | 3 | |

| 0.138 | 0.138 | 0.138 | 0.138 | 0.348 | 0.050 | 0.050 | 3 | |

| 0.113 | 0.113 | 0.113 | 0.113 | 0.400 | 0.074 | 0.074 | 3 | |

| 0.113 | 0.113 | 0.113 | 0.113 | 0.448 | 0.050 | 0.050 | 3 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aiello, G.; Quaranta, S.; Inguanta, R.; Certa, A.; Venticinque, M. A Multi-Criteria Decision-Making Framework for Zero Emission Vehicle Fleet Renewal Considering Lifecycle and Scenario Uncertainty. Energies 2024, 17, 1371. https://doi.org/10.3390/en17061371

Aiello G, Quaranta S, Inguanta R, Certa A, Venticinque M. A Multi-Criteria Decision-Making Framework for Zero Emission Vehicle Fleet Renewal Considering Lifecycle and Scenario Uncertainty. Energies. 2024; 17(6):1371. https://doi.org/10.3390/en17061371

Chicago/Turabian StyleAiello, Giuseppe, Salvatore Quaranta, Rosalinda Inguanta, Antonella Certa, and Mario Venticinque. 2024. "A Multi-Criteria Decision-Making Framework for Zero Emission Vehicle Fleet Renewal Considering Lifecycle and Scenario Uncertainty" Energies 17, no. 6: 1371. https://doi.org/10.3390/en17061371

APA StyleAiello, G., Quaranta, S., Inguanta, R., Certa, A., & Venticinque, M. (2024). A Multi-Criteria Decision-Making Framework for Zero Emission Vehicle Fleet Renewal Considering Lifecycle and Scenario Uncertainty. Energies, 17(6), 1371. https://doi.org/10.3390/en17061371